Craftsman 315212900 Owner’s Manual

Operator's Manual

Ip..,,ss.°...I

356 mm (14 in.) ABRASIVE CUT-OFF MACHINE

Model No.

315.212900

Save this manual for

future reference.

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before first use of

this product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., 3333 Beverly Rd., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

983000-037

4-02

• Safety

• Features

• Adjustments

• Operation

• Maintenance

• Parts List

i Table of Contents ................................................................................................................................................. 2

• Warranty and Introduction ................................................................................................................................... 2

• Rules for Safe Operation ................................................................................................................................. 3-5

• Electricel ............................................................................................................................................................. 6

• Unpacking, Loose Parts, and Product Specifications .......................................................................................... 7

• Features ........................................................................................................................................................... 8-9

• Adjustments ................................................................................................................................................. 10-13

• Operation ..................................................................................................................................................... 13-16

• Maintenance ................................................................................................................................................ 16-17

• Troubleshooting ........................................................................................................................................... 17-18

• Exploded Views and Repair Parts Lists ....................................................................................................... 20-25

• Parts Ordering / Service .................................................................................................................................... 26

FULL ONE YEAR WARRANTY

If this product fails due to a defect in material or workmanship within one year from the date of purchase,

Sears will repair it free of charge-

Contact a Sears SerVice Center for repair.

It this product is used for commercial or rental purposes, this warranty applies only for g0 days from the date

of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state,

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

Your saw has many features for makingcutting

operationsmore pZeasantand enjoyable, Safety,

pedormance and dependability have been given top

priorityin 'thedesign ofthis saw making iteasy to

maintainand operate.

_, CAUTION: Carefully read through this entire

operator's manua[ before using your new saw.

Pay close attention to the Rules For Safe

Operation, and all Safety Alert Symbols including

Danger, Warning and Caution. if you use your

saw prot0erly and only for what it is intended, you

will enjoy years of safe, reliable service.

Look for this symbol to point out important safety precautions. It

means attention!!! Your safety is involved.

j_ WARNING:

The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning tool operation, always wear safety

goggles or safety glasses with side shields and a full face shield when needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses

with side shields_ A[ways wear eye protection which is marked to comply with ANSI Z87,1.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them. deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

SYMBOL

A

MEANING

SAFETY ALERT SYMBOL:

Indicates danger, warning or caution. May be used in conjunctionwith other symbols or picto-

graphs.

DANGER: Failure to obey a safetywarningwill result inseriousinjury to yourselforto others.

Always follow the safety precautionsto reducethe riskoffire, electric shockand personal injury.

A

A

WARNING; Failure to obey a safety warning can resuR in serious injuw to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and persona] injury.

CAUTION: Failure to obey a safety warning may result in propertydamage or personalinjuryto

yourself or to others.Alwaysfollow the safety precautionsto reducethe riskof fire,electricshook

and personal injury.

Note: Advisesyou of information orinstructionsvitalto the operationormaintenanceof the equipment.

_k WARNING: Do not attempf to operate this tool

until you have read thoroughly and understand

completely all instructions, safety rules, etc.

contained in this manual. Failure to comply can

result in accidents involving tire, electrical shock,

or serious personal injury. Save operator's

manual and review frequently for continuing safe

operation, and instructing others who may use

this tool.

IMPORTANT

Servicingrequires extreme care and knowledgeof the

system and shouldbe performedonly bya qualified

servicetechnician.Forservicewe suggest you return

thetool toyour nearestSears storeor repair centerfor

repair,Alwaysuse originalfactory replacement parts

when servicing.

READ ALL INSTRUCTIONS

• KNOW YOUR POWER TOOL. Read the

operator'smanual carefully. Learnthe saw's

applicationsand limitationsas well as the specific

poten'_ialhazards related to thistool.

• GUARD AGAINST ELECTRICAL SHOCK by

preventing bodycontact withgroundedsurfaces

such as pipes, radiators,ranges, refrigerator

enclosures,

• KEEP GUARDS IN PLACE and In good working

order.

• REMOVE WRENCHES AND ADJUSTING KEYS.

Get in the habit of checking - before turning on tool

- that hex keys and adjusting wrenches are re-

moved from tool.

• KEEP THE WORK AREA CLEAN. Clutteredwork

areas and work benches Invite accidents. DO NOT

leave tools or piecesof woodon the saw while it is

in operation.

• DO NOT USE IN DANGEROUS ENVIRON-

MENTS. Do not use power tools near gasoline or

other flammable IJcluids,in damp or wet locations,

or expose them to rain. Keep the work area well lit.

• KEEP CHILDREN AND VISITORS AWAY. All

visitors should wear satety gIasses and be kept a

safe distance from work area. Do not let visitors

contact tool or extension cord while operating.

• MAKE WORKSHOP CHILDPROOF with padlocks

and master switches or by removing starter keys.

• DO NOT FORCE THE TOOL it will do the job

better and more safely at the rate for which it was

designed.

• USE THE RIGHT TOOL FOR THE JOB. Do not

force the tool or attachment to do a job itwas not

designed for, Use it only the way itwas intended.

• USE THE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. Use

only a cord heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating. A wire gage size (A.W.G.) of at least

14 is recommended for an extension cord 25 feet

3

or less in length, tf in doubt, use the next heavier

gage. The smatler the gage number, the heavier

the cord,

• INSPECT EXTENSION CORDS PERIODICALLY

and replace if damaged.

• CRESS PROPERLY- DO not wear loose clothing,

neckties, dngs, bracelets, or other jewelry. They

can get caught and draw you into moving parts.

Rubber gloves and nonslip footwear are

recommended when working outdoors. Also wear

protective hair covering to contain long hair.

• ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-

resistant lenses; they are NOT safety glasses.

• PROTECT YOUR LUNGS. Wear a face or dust

mask if the cutting operation is dusty.

• PROTECT YOUR HEARING. Wear hearing

protection during extended periods of operation,

• SECURE WORK. Use clamps or a vise to hold

work when practical. It's eefer than using your hand

and it frees both hands to operate tool.

• DO NOT ABUSE CORD. Never yank cord to

disconnect it from receptacle, Keep cord _'om heat,

oil, and sharp edges.

• DO NOT OVERREACH. Keep proper tooting and

balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance, Follow

instructions for lubricating and changing

accessories-

• DISCONNECT ALL TOOLS. When net in use,

before servicing, or when changing attachments,

wheels, bits, cutters, etc., all tools should be

disconnected.

• AVOID ACCIDENTAL STARTING. Be sure switch

is off when plugging in.

• USE RECOMMENDED ACCESSORIES. The use

of improper accessories may cause risk of injury.

Consult operator's manual for recommended

accessories.

• NEVER STAND ON TOOL. Serious injury could

occur it the tool is tipped or if the wheel is

unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of

the tool, a guard or other par that is damaged

should be carefully checked to determine that it will

operate properly and perform its Intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A

guard or other part that is damaged must be

properly repaired or replaced by an authorized

service center to avoid risk of personal injury.

• NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF. Do not leave tool until it

comes to a complete step,

• USE ONLY CORRECT WHEELS. Do not use

wheels with incorrect size holes. Never use wheel

washers or wheel screws that are defective or

Incorrect, The maximum wheel capacity of your cut-

off machine is 14 in. (356 ram).

'= DO NOT REMOVE THE MACHINE'S WHEEL

GUARDS. Never operate the machine with any

guard or cover removed. Make sure all guards are

operating properly before each us_'.

m KEEP HANDS AWAY FROM CUTTING AREA.

Keep hands away from wheel. Do not reach

underneath work or around or under the wheel

whi(e the wheel is rotating. Do not attempt to

remove cut material whiSe wheel is moving.

• WHEEL COASTS AFTER TURN OFF.

• NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of the motor or sparking from

cutting metal could ignite fumes.

• INSPECTTOOL CORDS PERIODICALLY and if

damaged, have repaired at your nearest Sears

Authorized Service Center. Stay constantly aware

of cord location and keep it well away from the

rotating wheel.

• USE OUTDOOR EXTENSION CORDS. When tool

is used outdoors, use only extension cords with

approved ground connection that are intended for

use outdoors and so marked.

• DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

rep(aced by an authorized serv[ce center.

• KEEP TOOL DRY, CLEAN, AND FREE FROM

OIL AND GREASE. Always use a clean cloth

when cleaning. Never use brake fluids, gasoline,

petroleum-based products, or any solvents to clean

tool.

m ALWAYS SUPPORT LONG WORKPIECES. To

minimize risk of tipping machine, always support

long workpieces.

• BEFORE MAKING A CUT, BE SURE ALL

ADJUSTMENTS ARE SECURE.

m ALWAYS USE THE VISE CLAMP to secure the

workpiece.

• NEVER TOUCH WHEEL or other moving parts

during use.

• NEVER START THE CUT-OFF MACHINE WHEN

THE WHEEL IS IN CONTACT WITH THE

WORKPIECE.

m NEVER cut more than one workpieca at a time,

DO NOT STACK more than one work.piece on the

machine base at a time.

• NEVER PERFORM ANY OPERATION "FREE-

HAND". Always secure the workpiece to be cut in

the vise.

• NEVERhand hold a workplace. Workpiece will

become very hot while being cut.

• NEVER reach behind, under, or within three inches

of the wheel and its cutting path with your hands

and fingers for any reason.

• NEVER reach to pick up a workplace, a piece of

scrap, or anything else that is in or near the cutting

path of the wheel.

• AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause your

band to move into the wheel. ALWAYS make sure

you have good balance.

• NEVER stand or have any part of your body in line

with the path of the wheel.

• ALWAYS release the power switch and aJlow the

wheel to stop relating before raising it out of the

workpiece.

• DO NOT TURN THE MOTOR SWITCH ON AND

OFF RAPIDLY. This could cause the wheel to

loosen and could create a hazard. Should this ever

occur, stand clear and allow the wheel to come to

a complete stop. Disconnect your cut-off machine

from the power supply and securely retighten the

wheel arbor bolt.

• REPLACEMENT PARTS. All repairs, whether

electrical or mechanical, should be made at a

Sears Authorized Service Center.

• WHEN SERVICING use only identical Sears

replacement parts. Use of any other parts may

create a hazard or cause product damage.

• NEVER leave the cut-off machine unattended

while connected to a power source.

• IF ANY PART OF THIS CUT-OFF MACHINE IS

MISSING or should break, bend, or fail in any way,

or should any electrical component fail to perform

properly, shut off the power switch, remove the

machine plug from the power source and have

damaged, missing, or failed parts replaced before

resuming operation.

• MAKE SURE THE CUT-OFF WHEEL IS SE-

CURELY MOUNTED as described in the operating

instructions before connecting the tool to a power

supply. Do not tighten wheel excessively, since this

can cause cracks.

• CHECKTHE WHEEL FOR FISSURES AND

CRACKS, and test for normal operation prior tO

use.

• ALWAYS EASE THE ABRASIVE WHEEL

AGAINST THE WORK PIECE when starting to cut.

A harsh impact can break the wheel.

• ONLY USE A CUT-OFF WHEEL RATED FOR

3300 RPM OR GREATER and manufactured in

compliance with ANSi B 7.1. Always store wheels

in a dry place with tittle temperature variation.

• BEFORE cUTrlNG, press the trigger switch and

allow the cut-off wheel to reach full speed before

cutting.

• MAKE SURE THE WORK ARF.A I:_S AMPLE

LIGHTING to see the work and tf'l_t no obstruc,

tlons will interfere with safe operation BEFORE

performing any work using your cut-off machine.

• DO NOT OPERATE THIS TOOL WHILE UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

ANY MEDICATION,

• ALWAYS STAY ALERT! DO not allow familiarity

(gained from frequent use of your cut-off machine)

to cause a careless mistake. ALWAYS REMEM-

BER that a careless fraction of a second is suffi-

cient to inflict severe injury

• STAY ALERT AND EXERCISE CONTROL. Watch

what you are doing and use common sense, DO

not operate toot when you are tired. DO not

rush.

• SAVE THESE INSTRUCTIONS. Refer to them

frequently and use them to instruct other users. If

you loan someone this tool, loan them these

instructions also

_1 WARNING: some dustcreated by power

sanding, sawing, grinding,drilling,and other

constructionactivities containschemic_.lsknown

tocause cancer, birth defectsorother reproduc-

tive harm. Some examples ofthese chemicals

are:

lead from lead-based paints,

crystalline silica from bricks and cement

and other masonry products, and

arsenic and chromium from chemically-

treated lumber.

Your riskfrom these exposuresvaries,depending

on how oftenyoudo thistypeofwork, To reduce

yourexposureto these chemicals,work in a well

ventilatedarea and workwithapgroved safety

equipment,suchas those dust masksthatare

speciallydesignedto filter out microscopic

particles.

SAVE THESE INSTRUCTIONS

5

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug. When using a power tool at a consid-

erable distance from the power source, use an

extension cord heavy enough to carry the current that

the tool will draw. An undersized extension cord wiJl

cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the

chart provided below to determine the minimum wire

size required in an extension cord. Only round jack-

eted cords listed by UndeP,vriter's Laboratories (UL)

should be used.

Length of Extension Cord Wire Size (A.W.G.)

Up to 25 feet 14

26-50 feet 12

When working with the tool outdoors, use an exten-

sion cord that is designed for outside use. This is

indicated by the letters WA on the cord's jacket.

Before using an extension cord, inspect it for loose or

exposed w_rss and cut or worn insulation.

CAUTION: Keep the cord away fromthe

cu'_ingarea and position the cord so that it will

notbe caught on material, tools, or otherobjects

duringcutting.

ELECTRICAL CONNECTION

Your Sears Abrasive Wheel Cut-off Machine is

powered by a precision built electric motor. It should

be connected to a power supply that is 120 volts,

60.Hz. If the machine does not operate when plugged

into art outlet, double check the power supply.

GROUNDING INSTRUCTIONS

In the event of a malfunction or bre_:ciown, grounding

provides a path of least resistance for electric current

to reduce the risk of electric shock. This tool is

equipped with an electric cord having an equipment-

grounding conductor and a grounding plug. The plug

must be plugged into a matching outlet that is prop-

erly installed and grounded in accordance with all

local cedes and ordinances.

Do not modifythe plugprovided.If itwill not fit the

outlet, have the proper outletinstalledby • qual{fied

electdcfan.Improper connectionof the equipment-

groundingconductorcan resultin a riskof electric

shock.The conductorwithinsulationhaving an outer

sudaco that is green withor withoutyellowstripesis

the equipment-groundingconductor.If reps.iror

replacement ofthe electriccord orplugis necessary,

do not connectthe equipment-groundingconductorto

a liveten'ninal,

Check with a qualified electrician or service personnel

it the grounding instructions _,re not completely

understood, or if in doubt as to whether the tool is

properly grounded.

"Repair or repl_ee a damaged or worn cord immedi-

ately.

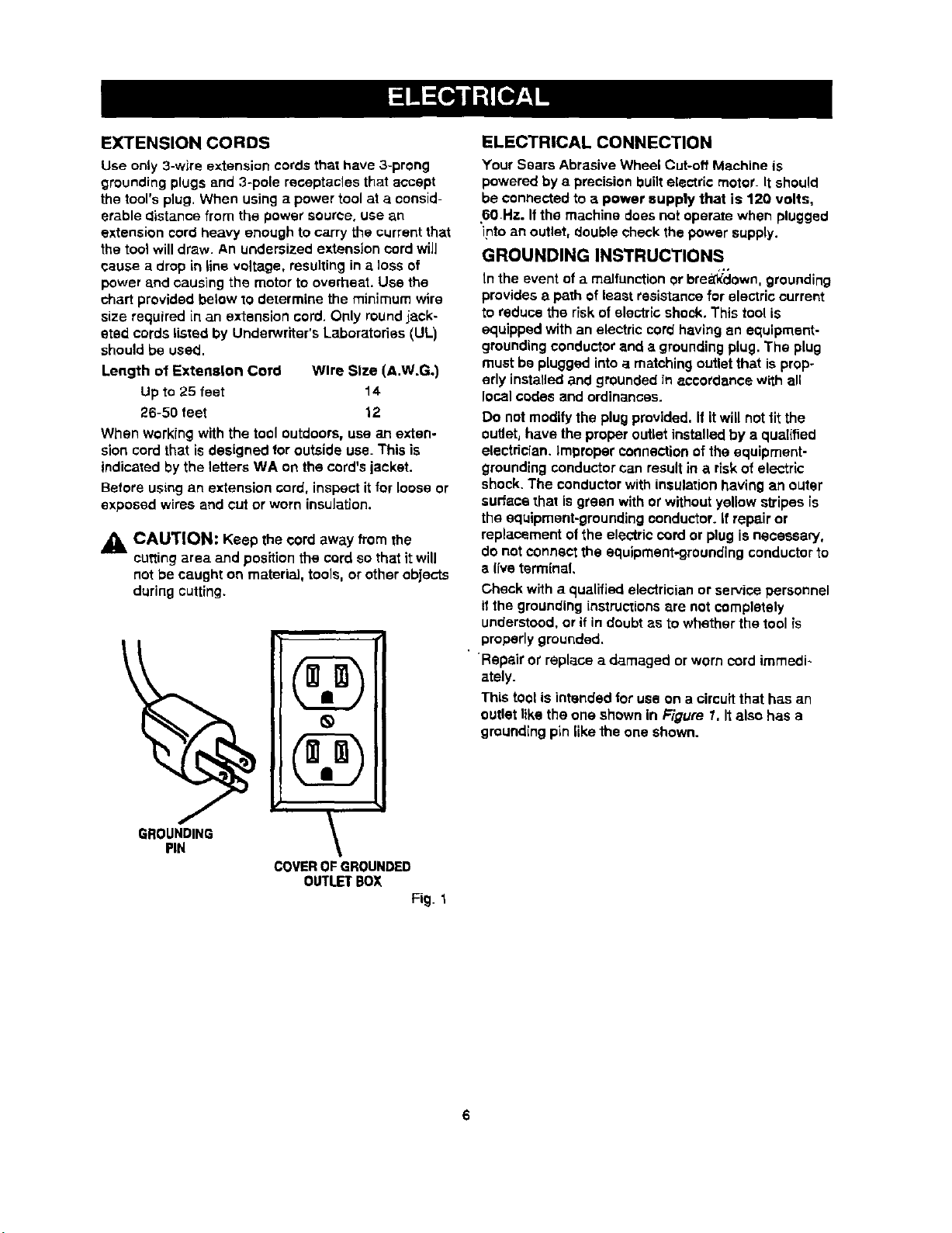

This tool is intended for use on a circuit that has an

outlet like the one shown in Figure 1. It also has a

grounding pin like the one shown.

COVEROF GROUNDED

OUTLET BOX

Fig. 1

6

Your abrasive cut-off machine has been shipped

completely assembled.

• Remove all loose parts from the carton.

• Remove the packing materials from around your

machine

• Carefully Ii_the cut-off machine from the carton

and place it on a level work surface. This is a

heavy Ioo1. To avoid back injury, get help when

needed,

• Do not discard the packing materials until you have

carefully inspected the machine, identified all loose

parts, and satisfactorily operated your new abra-

sive cut-off machine.

• Your cut-off machine has been shipped with the

machine a.rm looked in the down position. To

release the arm. push clown on top of the machine

arm and pull the arm lock lever. See Figure 3.

• Hand pressure should remain on the machine arm

to prevent sudden rise upon release of the arm

lock lever.

• Examine allpartsto make sure no breakage or

damage has occurred duringshipping.

If any partsare damaged or missing, do not attempt to

plug in thepower cordand turnthe switchon untilthe

damagedor missing parts areobtained and are

installedcorrectly.

._ WARNING: If anypartsare missingdo not

operateyour cut-offmachineuntilthe missing

partsare replaced. F_tura to do so couldresult

inpossibleserious injury.

LOOSE PARTS LIST

The following itemsare includedwith your Abrasive

Cut-offMachine;

[] 14 in. (356 ram) - AbrasiveWheel- installed on

Machine

• Wheel Wrench - 8 mm Hax Kay - Storedon

Machine

• Operator'sManual

Wheel Type

Wheel Diameter

Wheel Thickness

Wheel Arbor Hole

Overall Wheel Size

ReinforcedAbrasive Wheels FenceAngle

14 in. (356 ram) Right

1/8 in. (3,2 ram) - • Left

1.0 in. (25,4 ram)

14in. x1/ain, xtin.

356 mm x 3,2 mm x 25.4 mm

No Load Speed

Rating

Input

Net Weight

3300 RPM

120 Volts,AC/DC

15 Amp

65 Ibs. (30 kg.)

,_ WARNING: This cut-offmachine has been

designed for cuffingmetals, usingreinforced

abrasive cut-off wheels only, Do notremovethe

wheel, install a steel blade, and attemptto cut

other types ofmaterials such as wood, masonry.

etc. Attemptingto cut these othertYpes of

materialscouldcause an accident resultingin

possibleserious personalinjury.

45U

Vise Clamp Angle

Rightor Left

45°

MaximumCuttingCapacities:

RoundPipe

AngleStock

Flat Metal Stock

5 in. (127 mm) OUtside diameter

6-t/2 in. wide x 3-5/16 in. tall

165 mm wide x 84 mm tall

8-1/16 in. wide x 2-5/16 in. tall

205 mm wide x 59 mm tall

_, WARNING: Do notattempt to modify this tool

or create accessories not recommendedfor use

withthistool. Any suchalterationor modification

is misuseand could resultin a hazardous

conditionleading to possiblesedouspersonal

injury.

0o

7

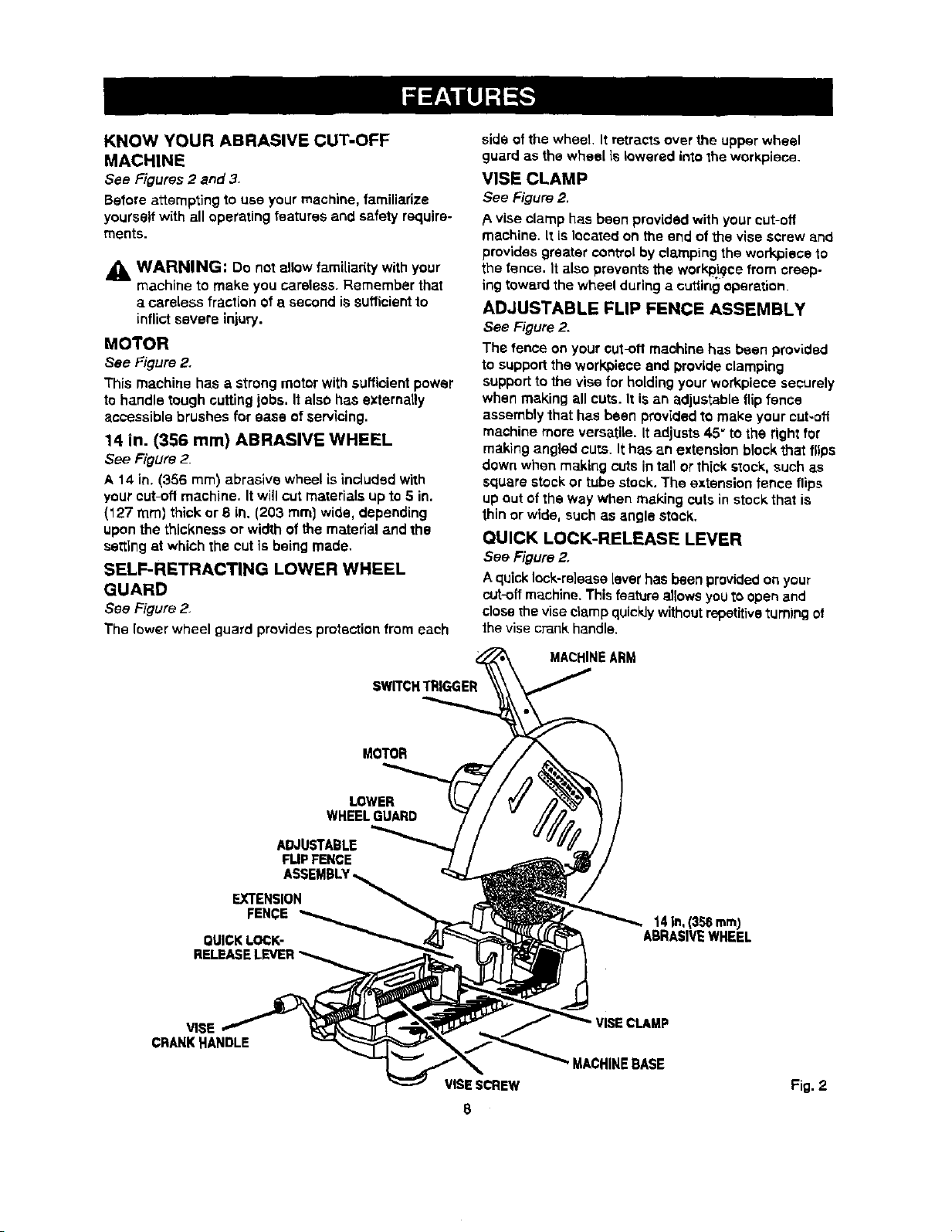

KNOWYOURABRASIVECUT-OFF

MACHINE

See Figures2 and 3.

Beforeattempting to use your machine,familiarize

yourselfwith all operatingfeatures and safety require-

ments.

WARNING: Do not e,ow familiarity with your

machine to make you careless.Remember that

a careless fraction of a secondis sufficientto

inflictsevere injury.

MOTOR

See Figure2.

This machine has a strongmotorwithsufficientpower

to handletough cuffingjobs. It also has externatly

accessible brushes for ease of servicing,

14 in. (356 mm) ABRASIVE WHEEL

See Figure2.

A 14 in. (356 ram) abrasive wheel is included with

yourcut-offmachine. It willcut materials up to S in.

(127 ram) thickor 8 in. (203 ram) wide, depending

uponthe thickness or widthofthe material and the

setting at which the cut is being made.

SELF-RETRACTING LOWER WHEEL

GUARD

See Figure 2.

The lewer wheel guard provides protection from each

sideof the wheel It retractsover the upperwheel

guard as the wheel is lowered intothe workplace.

VISE CLAMP

See Figure 2.

F,viseclamp has been providedwithyourcut-off

machine. It is located on the end of the visescrew and

providesgreater contTolbyclampingthe workpieceto

thefence. It also prevents theworkp:_cefrom creep.

ingtoward the wheel duringa cutting operation.

ADJUSTABLE FLIP FENCE ASSEMBLY

see Figure 2.

The fence on yourcut-offmachine has been provided

tosupportthe workplaceand provide clamping

support tothe vise for holdingyourworkpiecesecurely

when making all cuts.It is an adjustable flipfence

assemblythat has been providedto make your cut-off

machine more versatile. It adjusts45" to the rightfor

making angled cuts. It has an extensionblockthat flips

downwhen making cuts intall or thickstock, such as

square stock or tube stock. The extensionfence flips

up out ofthe way whenmaking cutsin stock that is

thin or wide, such as angle stock.

QUICK LOCK-RELEASE LEVER

see Figure2.

A quick lock-re]easeleverhasbeen providedon your

cut-offmachine.Thisfeature allowsyou to openand

c]osethe viseclampquickJywithoutrepetitiveturningof

the vise crank handle.

MACHINEARM

EXTENSION

GUICKLOCK-

RELEASELEVER

VISE

CRANKHANDLE

ADJUSTABLE

FUPFENCE

FENCE

SWITCHTRIGGER

MOTOR

LOWER

WHEELGUARD

14 In, (356 ram)

ABRASIVEWHEEL

V_ECLAMP

VISESCREW Fig. 2

B

Loading...

Loading...