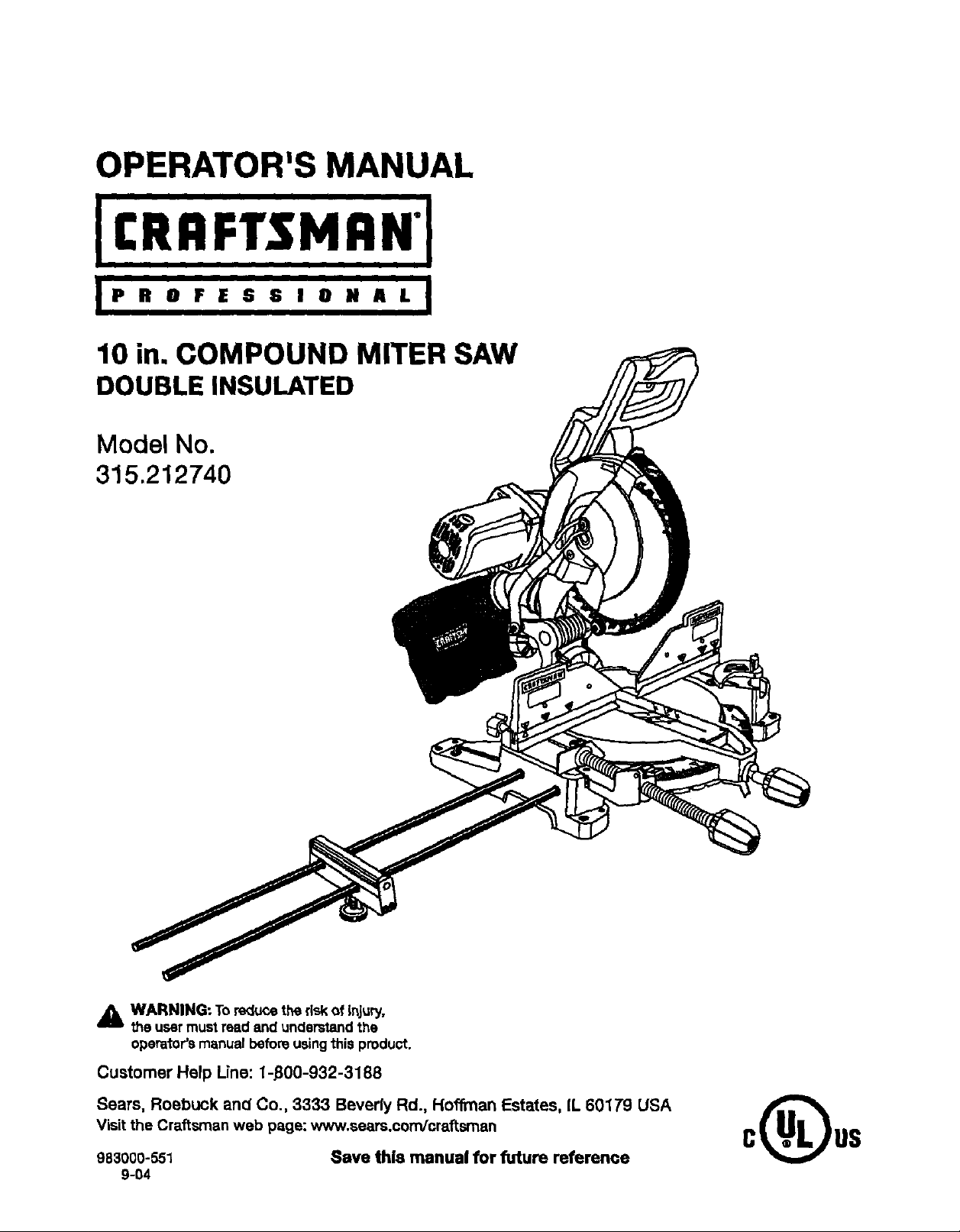

Craftsman 315212740 Owner’s Manual

OPERATOR'S MANUAL

iPROFIESS IONAL I

10 in. COMPOUND MITER SAW

DOUBLE INSULATED

Model No.

315.212740

A WARNING: To reducethe riskof injury,

the usermustread and understandthe

operator'smanual beforeusingthis product.

Customer Help Une: 1-.800-932-3188

Sears, Roebuck and Co., 3333 Beverly Rd., Hoffman Estates, [L 60179 USA

Visit the Craftsman web page: www.eears.com/crsftsman

983000-551 Save this manual for future reference

9-04

Warranty............................................................................................................................................................................ 2

• Introduction ....................................................................................................................................................................... 2

• General Safety Rules..................................................................................................................................................... 3-4

• Specific Safety Rules..................................................................................................................................................... 4-5

• Symbols......................................................................................................................................................................... 6-7

• Electrical............................................................................................................................................................................ 8

• GLossaryof Terms.............................................................................................................................................................. 9

• Fea_ras ..................................................................................................................................................................... 10-12

• ToolsNeeded ................................................................................................................................................................. 12

• LooseParts .................................................................................................................................................................... 13

• Assembly................................................................................................................................................................... 14-23

• Operation................................................................................................................................................................... 23-31

• Adjustments................................................................................................................................................................... 32

• Maintenance.............................................................................................................................................................. 33-35

• Exploded_ew ........................................................................................................................................................... 37-45

• PartsOrderingJServlca...................................................................................................................................... Back Page

ONE YEAR FULL WARRANTY ON CRAFTSMAN TOOL

If thisCraftsman toolfailsdue to a defect in materialor workmanshipwithinoneyaar fTomthedate of purchase,

CONTACT THE NEAREST SEARS PARTS& REPAIRCENTER at 1-800-4-SV-M_:HOMEO and Searswill repairIt,free of

charge. Thiswarranty applies onlywhilethisproduct Isinthe UnltodStates,

_fthis tool isused forcommercLalor rentalpurposes,thiswarrantywillapplyfor only ninetydaysfi'onlthedate of

purchase.

Thiswarranty givesyou specificlegal dghts,and youmay also have otherdghtswhich varyfrom stateto state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

This tool has manyfeaturesfor makingIts usemornpleasantand enjoyable.Safety, pedormancs,and dependability

have beengiven top priorityin the designofthis product makingit easy to maintain and operate.

_k WARNING." Read and understand all inet_uo-

t/one. Failure to follow all instruotfons listedbelow,

may resultInetectdc shock,tlre and/orserious

personalinjury.

READ ALL INSTRUCTIONS

• KNOW YOUR POWER TOOL. Read theoperator's

manualcarefully.Learnthe saw's applications and

{(mltations as we{{as the specificpotent_{ hazards

relatedto this toot.

• GUARD AGAINST ELECTRICAL SHOCK BY PRE-

VENTING BODY CONTACT WITH GROUNDED

SURFACES. Forexample, pipes,radiators,ranges,

refrigeratorenclosures.

• KEEP GUARDS IN PLACE and Ingood workingorder.

• REMOVE ADJUSTING KEYS AND WRENCHES.

Formhabit of checldngto seethat keys and adjusting

wrenchesare removed fromtool beforeturningiton.

• KEEP WORK AREA CLEAN. Clutteredareas and

benchesinvite accidents. DO NOT leaveto_,s or

placesofwood on the saw while itIsIn operation.

• DO NOT USE IN DANGEROUS ENVIRONMENTS.

Do r_t use Dowertools indamp or wet Iocatk_neor

expose to rain. Keepthe workareawell tit.

• KEEP CHILDREN AND VISITORS AWAY. A/I visitors

shou;dwear safetyglassesand be kepta safe

distancefromwork araa. Donot let visitors contact too_

or extens'=oncordwhile operating.

• MAKE WORKSHOP CHILDPROOF with padlocksand

masterswitches, or by removingstarer keys.

• DON'T FORCE TOOL. itwill do thejob betterand

safer at the feed rateforwhich itwas designed.

• USE RIGHT TOOL. Don't forcethetool or attachment

to doaiob it was not designedfor.Don't useitfor a

purpose notintended.

• USE THE PROPER EXTENSION CORD. Make sure

yourextensioncord is in'goodcondition. Use onlya

cordheavy enough1ocarrythe currentyourproduct

willdraw. An undersizedcord will cause • drop in_ine

voltage resultinginlossof power and overhcating.A

wire gaugesize (A.W.G.)of at least 14Is recommended

foran extensioncord 25feet orless in length, ifin

doubt,use the nextheavier gauge.The smallerthe

gaugenumber,the heavierthe cord,

• DRESS PROPERLY, Do not wear looseclothing,

gloves,nec_as, or)ewelry.They can get caught

and draw you Into moving parts. Rubbergloves and

nonskidfooWvearare reaommendedwhen working

outdoors.Alsowear protectivehair coveting Io contain

longhair.

• ALWAYSWEARSAFETYGLASSESW|TH SIDE

SHIELDS. Everyday eyeglasseshaveonlyImpact-

res'lstantlenses, they areNOT setetyg;asees.

• 3ECURE WORK. Use clampsor avise to holdwork

when pract!cal,It's s_far than usingyourhandand

freesboth handsto operate tool.

• DON'T OVERREACH. Keep properfootingand

balanceat alltimes.

• MNNT/UN TOOLS WITH CARE. Keep toolssharp

and cleanfor betterand safer performance.Follow

instructionsfor Lubricatingand changingaccessories.

• DISCONNECT TOOLS. When not inuse, before

servicing, orwhen changingattachments,blades,bits,

cutters,etc., elltoo{sshouldbe disosnnected.

• AVOID ACCIDENTAL STAR'nNG. Besure switchis off

when plugginginany tool.

• USE RECOMMENDED ACCESSORIES. The useof

improperaccessoriesmay dsk injury.

• NEVER STAND ON TOOL. Seriousinjurycouldoccur

ifthe tool is tippedor ifthe cuttingtoot is unintention-

ally centacte_,

• CHECK DAMAGED PARTS. Batonsfurtheruse of

the loci, a guardor othar_rt that is damaged should

be carefullycheckedto determine that itwilloperate

properlyand performitsintendedfunction.Check for

alignment of moving pads, b_ndingof movingpads,

_a ofparts, moun_ng and anyothercondllk_ts

that may affectitsoperation. A guardorother pert that

is damagedmu_t be properlyrepairedor repla_d by

an authorizedservicecenterto avoiddsk of personaJ

injury.

• USE THE RIGHT DIRECTION OF FEED. Feedwork

Intoa blade or cutter against the directionof rotationof

bladeor cutteronly.

• NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF, Don't leave tooluntilit

comasto a completestop.

• PROTECT YOUR LUNGS. Wear a face or dustmaskif

thecuffingoperationIs dusty,

• PROTECT YOUR HEARING, Wear hearingprotection

during extendedperiodsof opera,on.

• DO HOT ABU.RECORD. Neveryankcord to discon-

nectfrom receptacle.Keep cordfrom heat, o11,end

sharpedges.

• USE OUTDOOR EXTENSION CORDS. When tool Is

used outdoors,usa onlyextensioncordswith ap-

proved groundconnectionthatareintended for use

outdoorsand so mmked,

• KEEP BLADES CLEAN, SHARP, AND WITH SUF-

RCIENT SET. Sharpbladesminimizestallingand

kickback.

• BLADE COASTS AFTER BEING TURNED OFF.

• NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normalsparkingof the motorcouldignite fumes.

3

• INdPECT TOOL CORDS PERIODICALLY. if damaged,

have repairedby 8 qua_Lfiedservicetechnician at

an authorizedservice facility.The conductorwith

Insulationhevlngan outer surfacethat Isgreenwith

or wYchoutyellows_pee is the equipmenL-ground-

in9 conductor,ff repairor replacementofthe electric

cord orplug isnecessaPz,do not oonnect Theequip-

men'_-ground'mgconductor to a liveterm'inst.Repair

or replace a damaged or worn cordImmediately.Stay

constantlyaware ofcord {(>cationand keep ttwelt sway

from the rotatingblade.

• INSPECT EXTENSION CORDS PERIODICALLY and

reOlace tfdamaged.

• POLARIZED PLUGS. Toreduce the dskofe[ectdc

shock,thistool has a po{adzedplug(oneblade is

wider thanthe other).Thisplugwillf_ ina polarized

outletonly oneway. Itthe plug does not fit fullyin _e

out_et,reversethe plug, Ifit stiltdoes notfit, contact a

qusL'zfiedetect_clanto Install the properDuller.Do not

changethe plug in any way.

• KEEP TOOL DRY,CLEAN, AND FREE FROM OIL

AND GREASE, A_waysuse a c_sanclothwhen c_san-

ing. Never usebrake fluids,gasoline,petroleum-based

products, or any so(ventsto c{eantoo(.

• STAYALERT AND EXERCISE CONTROL. Watch

what youare doingand use common sense,Do not

operatetoo(when you aretired. Do not rush.

• DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFR Have defective switchesreplaced byan

authorizedservicecenter.

• USE ONLY CORRECT BLADES, Do not useblades

with incorrectsizeholes.Never useblade washersor

bladebottsthat ate detectiveorincorrect. The maxi-

mum bladecapacity ofyoursaw is10 in. (254mm).

• BEFORE MAKING A CUT, BE SURE ALL ADJUST-

MENTS ARE SECURE.

• BE SURE BLADE PATH IS FREE OF NAILS. Inspec_

forand removeall nailsfromlumberbeforecuffing.

• NJ_fERTOUCH BLADE or othermoving partsdudng

use.

• NEVER STARTA TOOL WHEN ANY ROTATING COM-

PONENT IS IN CONTACT WITH THE WORKPIECE.

• DO NOT OPERATE ATOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR ANY

MEDIOATION.

• WHEN SERVICING useonly identicel replacement

palls. Use ofanyother parts may create a hazard or

csueeproductdema_je,

• USE ONLY RECOMMENDED ACCESSORIES ltsled

in this menus( or addendums, Use of accessories

that ere not [(sledmay cause the risk of personal

Inlury,instructions forsafe use of accessories are

inc(udedwith the accessory,

• DOUBLE CHECK ALL SETUPS. Make sure blade is

tight and not making contact with saw or workpiece

before connecting to power supply.

• FIRMLY CLAMP OR BOLT your miter saw to awork-

bench ortable at approx'_nately h_pheight.

• KEEP HANDS AWAY FROM CUTTING AREA. Do not

reachunderneathwork or inblade cuttingpathwith

yourhands and fingersfor anyreason.Alwaysturnthe

poweroff,

• ALWAYS SUPPORT LONG WORKPIECES while cut-

ring to minimizeriskofblade pinchingand kickback.

Saw may Hip, walk ors_de whilecuffinglong orheavy

boards.

• ALWAYS USE A CLAMP to secure the workplece

when possible.

• BESURE THE BLADE CLEAR_ THE WORKPIECE.

Never startthe sew with the bladetouchingthe

workplece.Allow motor to come up to fult speed

before start(n9 cut.

• MAKE SURE THE MITER TABLE AND SAW ARM

{BEVELFUNCTION) ARE LOCKED IN POSITION

BEFORE OPERATING YOUR SAW. Lockthe miter

table by securelytightening the miter _ockk_vere.Lock

the sawarm (bevel_nction) by securelytighteningthe

bevellock knot_,

NEVER USE A LENGTH 8TOP ON THE FREE SCRAP

END OF A CLAMPED WORKPIECE. NEVER hold

ontoor bindthe free scrap end ofthe workpiesein any

operation.If awork clampand length stopare used

toget*ner,theymust bot_ be installedon the same Side

ofthe saw table to preventthe saw Jmmcatchingthe

looseend and klcldngup,

NEVER out more thsn onepiece at a time.DO NOT

b'rACK more than one workpiece onthe saw table at a

time.

NEVER PERFORM ANY OPERATION FREEHAND.

Always place the workpieco to be cu_ on the miter

table and posl_on It firmly against the fence as a bach-

stop, Abbeys use the fence.

4

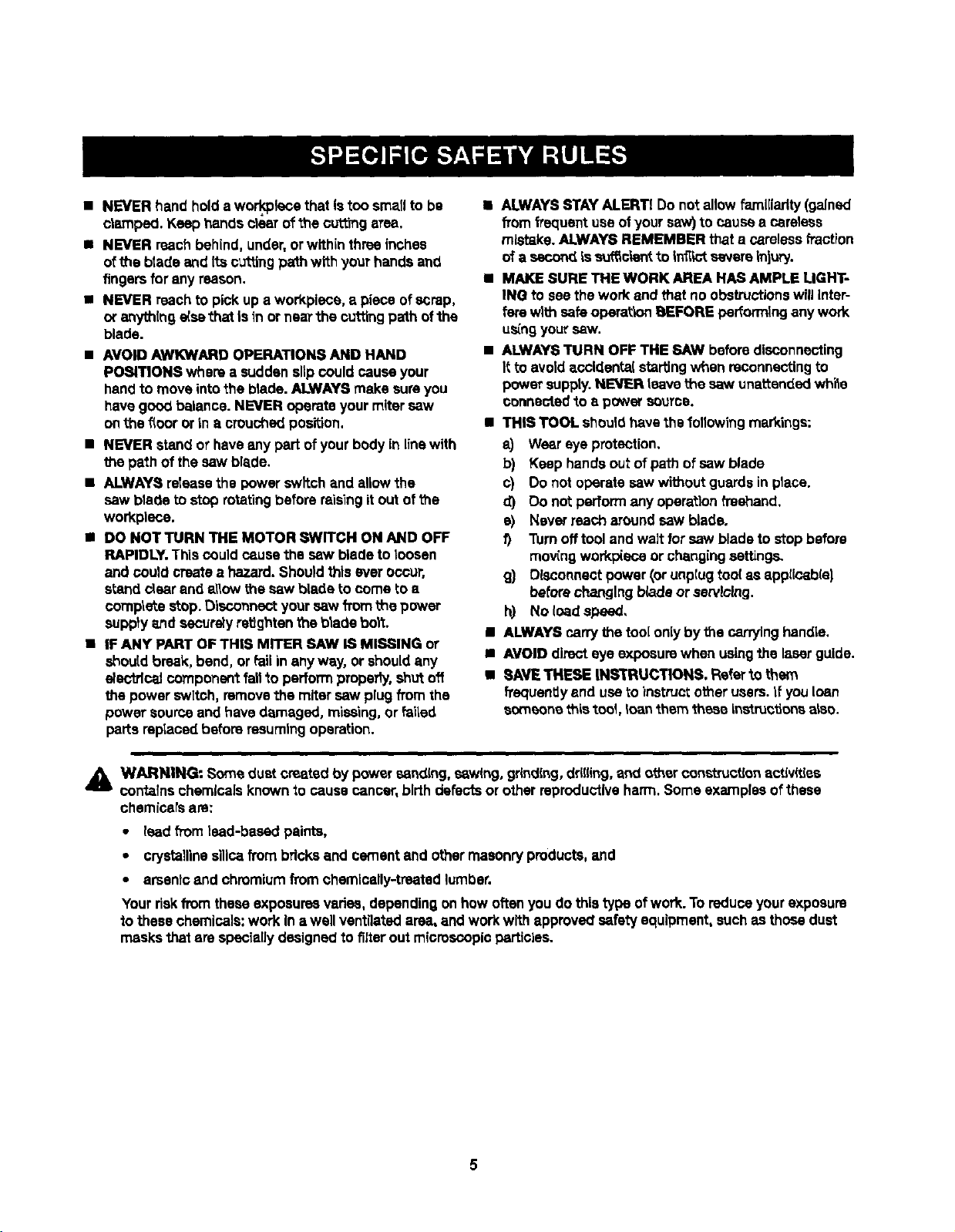

• NEVER hand hold awo.rl_lece that is toosmallto be

clamped. Keep handsclear ofthe cuttingarea.

• NEVER reachbehind, under,orwithin threeinches

ofthe blade andIts cuttingpath with yourhandsand

fingersfor anyreason.

• NEVER reachto pick upa workplace, a piece of scrap,

or anythingelsethat is in or nea_'thecuttingpath ofthe

blade.

• AVOID AWKWARD OPERATIONS AND HAND

PORTIONS where a suddenslip could cause your

handto move intothe blade. ALWAYSmake sure you

have goodbalance. NEVER operateyourmitersaw

onthe f_ooror in a crouchedposition.

• NEVER stand orhaveany part of yourbody in linewith

the path of the sawblade.

• ALWAYS releasethe powerswitchand allowthe

caw blade to stop rotatingbefore raisingit outofthe

workplace.

• DO NOT TURN THE MOTOR SWITCH ON AND OFF

RAPIDLY.Thiscouldcause the saw bladeto loosen

and could createa hazard. Shouldthiseveroccur,

standdear and allow the saw blade tocome to a

completestop. Disconnectyoursaw flora the power

supplyand sacursiy ret_ghtenthe blade bolt.

• IF ANY PARTOF THIS MITER SAW IS MISSING or

shou[dbreak,bend, orfail inanyway, orshouldany

dsctdcaJcomponent fsilto performproperly,shutoff

thepower switch, removethe miter saw plugfrom the

power source andhave damaged, missing, or failed

partsreplacedbefore resumingoperation.

• ALWAYSSTAYALERTI Do not allowfarnliled_(gained

ftom frequentuse ofyour saw)to cause a careless

mistake.ALWAYS REMEMBER thata careless fraction

of asecond issl._ c_mt to Snil_-'tsm/ereIniu_j.

• MAKE SURE THE WORK AREA HAS AMPLE LIGHT-

ING to seethe work and that no obstructionswillinter-

fere withsafe operationBEFORE performingany work

u_ng yoursaw.

• ALWAYSTURN OFF THE SAW beforedisconnecting

Itto avoidaccidental startingwhen reconnectingto

power supply.NEVER leavethe saw unattendedwhi_e

connectedto a power source.

• THIS TOOL shouldhave the followingmarkings:

a) Weareye protection,

To) Keep handsout ofpath ofsaw blade

c) Do not operate sawwithout guardsin place.

d) Do not performany operationfreehand,

s) Never reach aroundsaw blade.

f) Turnofftool and walt forsaw blade to stop before

movingworkp(eceor changingsettings,

g) Disconnectpower(orunplugtoo(as applicable)

beforechangingblade or servicing.

h) No iced speed,

• ALWAYS carry thetoo[ onlyby the carryinghandle,

• AVOID directeye exposurewhen usingthe laserguide.

• SAVE THESE INSTRUCTIONS. Referto them

fi'eduent_yand use to instructotherusers.If you Loan

someone thistool, foan them these Instructions alsO.

,_ WARNING: Some dust created by power sanding, sawing, grinding,drilling,end other construction activities

contains chemlcelsknown to cause cancer, birthdefectsorother reproductiveharm.Some examples of these

chemic,areare:

• (sad from lead-based paints,

• crystallinesilicafrom bricksand cementand othermasonry products,and

• arsenicand chromiumfrom chemically-treatedlumber.

Yourriskfrom theseexposure(;redes, dependingon how oftenyoudo thistype ofwork. Toreduce your exposure

tothese chemicals:work inawell ventilatedarea,and workwith approved cafety equipment, suchas thosedust

masksthat arespeciallydesigned tofilter out microscopicpa_cies.

5

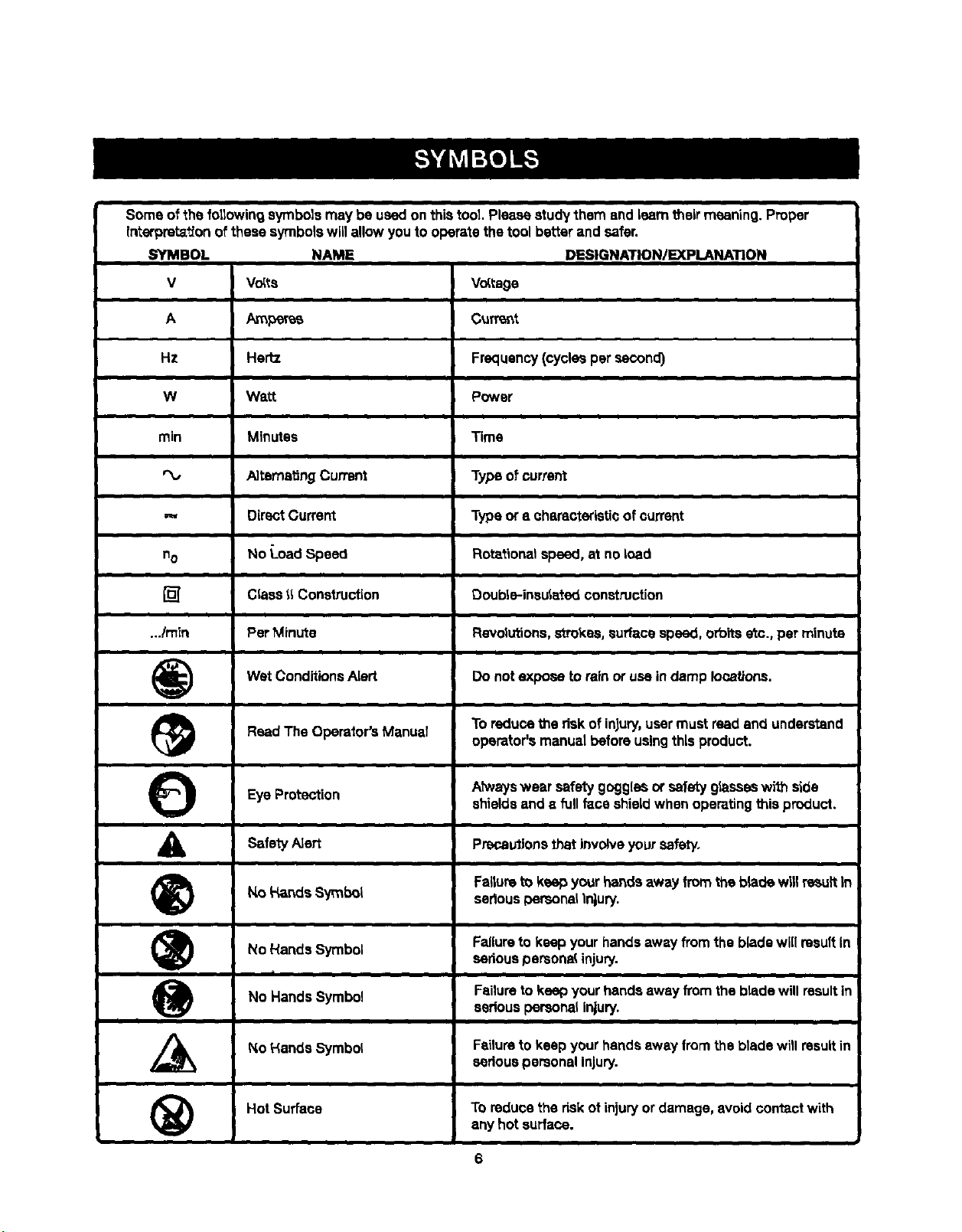

Someofthe followingsymbolsmay be used onthis too]. Pleasestudythem and learntheirmeaning. Proper

Interpretstfonofthese symbolswillallow youto operatethe toolbetter and safer.

SYMBOL NAME DESIGNATIONIEXPLANATI ON

v

A

Hz

W

min

,_,

no

[]

.../min

®

Vc_te

Ampuls

Hertz

Watt

Minutes

Alternating Current

DirectCurrent

No t-oadSpeed

Classli Construction

PerMinUte

Wet ConditionsAlert

Read The Operetor'sManual

Voltage

C_rre_t

Frequency(cyclesper second)

Power

Time

Type o'tcurrent

Type ora characteristicof current

Rotationalspeed, atno load

Doubie-insuisteqconstruction

Revolutions,strokes,surface speed, orbits etc., per minute

Do not expose to rainor use indamp locations.

To reducethe dsk of injury,usermust readand understand

operator'smanuat before usingthis product.

O

&

®

®

@

®

Eye Protection

SafetyAlan

hLot-_nds Symbol

No HandsSymbol

m

No HandsSymbol

No Hands Symbol

Hot Surface

Always wear safety gogglesor safetyg_asseswith side

shieldsand a full face shieldwhen operatingthis product.

Preeau_ionsthat involve your safety.

Faltureto keepyour handsaway fromthe bladewillresultIn

sedouspersonal Injury.

Failureto keep yourhandsaway fromthe bladewill resultin

serious personal injury.

Failureto keepyour handsaway fromthe bladewill resultin

seriouspersona{injury.

Failureto keep yourhandsawayfrom the bladewillresultin

seriouspersonalInjury.

TOreduce the risk otinjuryor damage,avoidcontactwith

any hot surface.

6

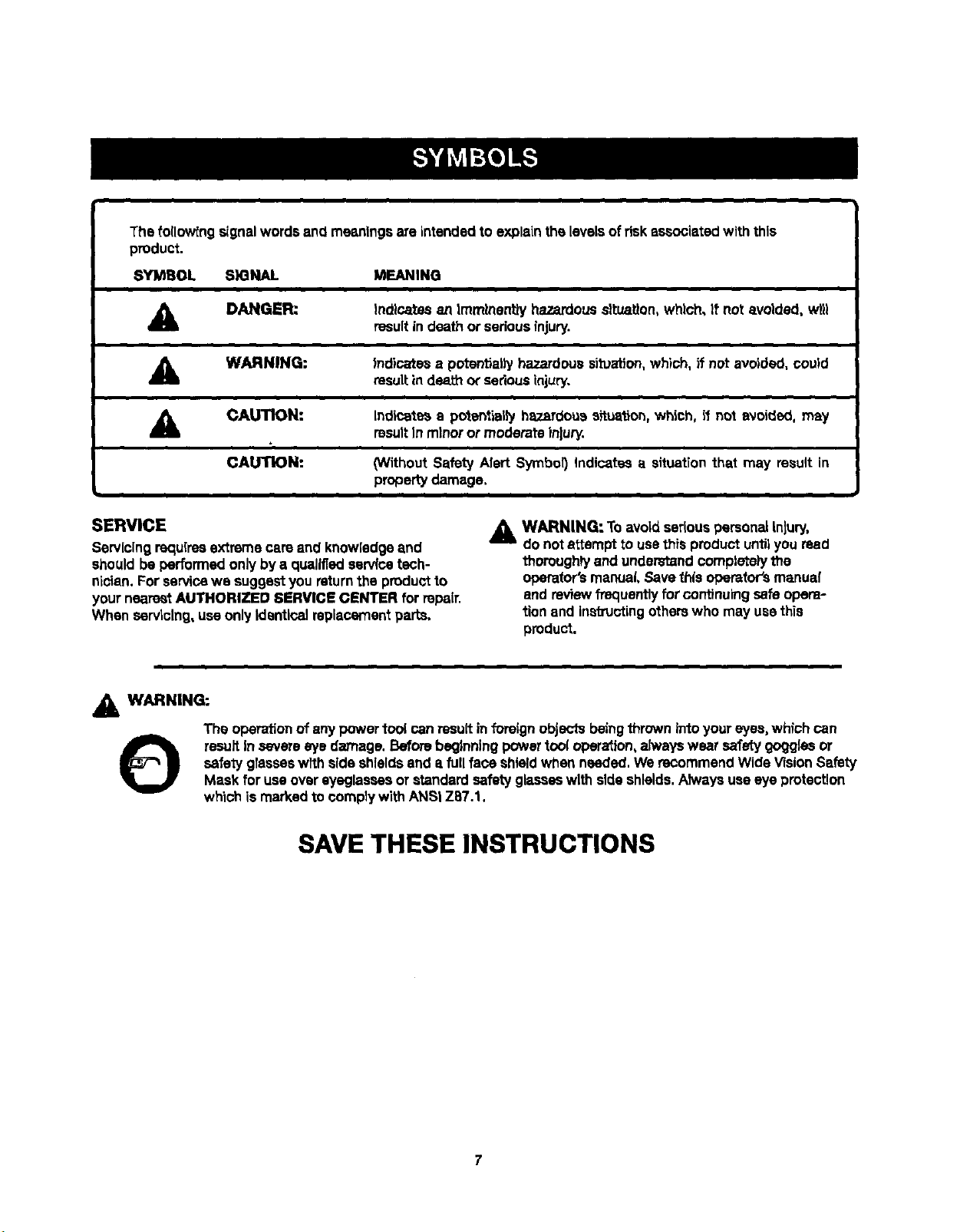

The fo(Iow[ngsignalwordsand meaningsare intended to explainthe levelsof riskassociatedwith this

product.

SYMBOL SIGNAL MEANING

A DANGER:

A WARNING:

,_ CAUTION:

CAUTION:

Indicates an Immlnenttyhazardoussituation,which,If not avoided, wtl)

resultin deathor seriousinjury.

|ndicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

Indicate_ a polentially hazardouseftuslJon,which, if nol avoided, may

resultIn minoror moderateInlury.

(Without Safety Alert Symbol) Indicates a situation that may result in

propertydamage.

SERVICE

Servicingrequires extreme careand knowledgeand

shouldbe performedonly by aqualifiedservicetech-

nician.For servicewe suggestyou returnthe productto

yournearestAUTHORIZED 8ERVIGE GENTER forrepair.

When servicing,usa onlyIdenticalreplacementparts.

,&WARNING:

The operationof any powertoo( can resultinforeignobjects beingthrown intoyour eyes,which can

A WARNING: ToavoidseriouspersonalInjury,

do notattempt to usethis productuntilyouread

thoroughlyand understandcomplete)ythe

operator'smanual Save this opemfer's manual

end reviewfrequently forcontinuingsafeopera-

tionand instructingotherswho may usethis

product.

O resultIn severeeye damage. Beforebeginningpowertool opera_lon,alwayswear safety gogglesor

safely glasseswffh side shieldsand a fullface shieldwhen needed.We reGommendWide VisionSafety

Mask foruse overeyeglassesorstandard safetyglasseswith side shields.Alwaysuseeye protection

whioh ismarked tocemply with ANSi Z87.1.

SAVE THESE INSTRUCTIONS

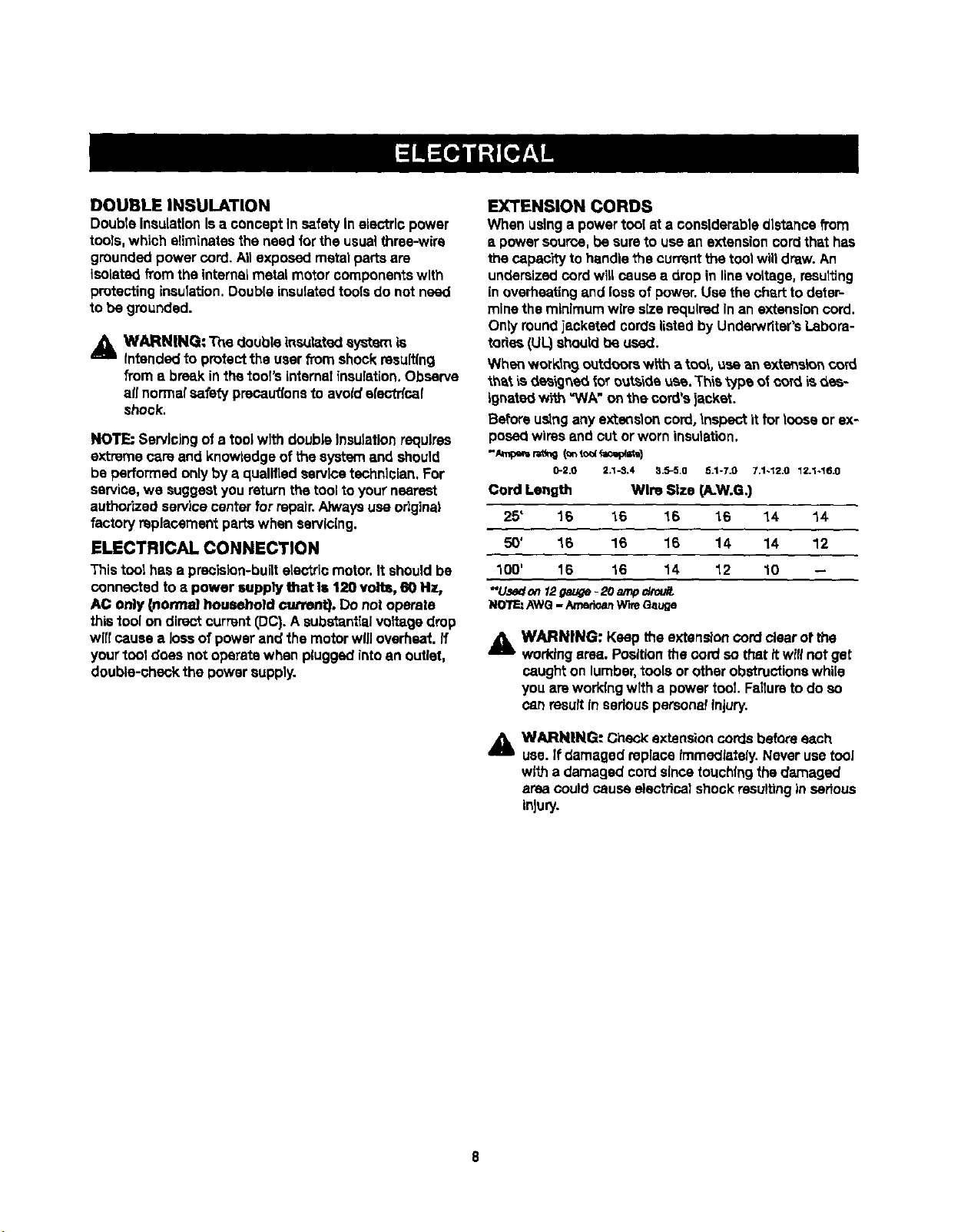

DOUBLE INSULATION

DoubtsinsulationIsa conceptIn safety inelectric power

tools,which eliminatesthe need forthe usualthree-wire

groundedpower cord.Allexposed metal parts are

Isolated from the internalmetal motor componentswith

protectinginsulation.Doubleinsulatedtools do not need

to be grounded.

A WARNING: "thedouble insotated is

system

Intendedto protect the userfromshockresulting

fToma break inthetool's internalinsulation, Observe

a(!normalsafety precautionsto avoidafec_caf

shock.

NOTE: Servicingof a toolwith doubleInsulationrequires

extremecare and knowiedgeof the systemand should

be performedonlyby a qua.fled service tenhnlclan.For

service,we suggestyou returnthe tooltoyour nearest

authorizedservicecenterfor repair.Alwaysuseoriginal

factoryreplacementpafcswhen servicing.

ELECTRICAL CONNECTION

Thistool has;a precision-buntelectricmotor.It shouldbe

connected to e power supply that It 120 voltS, 60 Hz,

AC only {normal houSehold current). Do notoperate

thistool on directcurrent(DC).A substantialvoltagedrop

wlrrcause a Jossof power and the motorwill overheat, rf

yourtoot doesnot operatewhen plugged intoan outlet,

double-checkthe Dowersupply.

EXTENSION CORDS

When usinga powertool ata considerablecllstancafrom

s powersource, besureto use an extensioncord that has

the capac'rtyto handlethe currentthe toolwiltdrew. An

undersizedcord willcausea drop in linevoltage,resulting

in overheatingand lossof power.Use the chart todeter-

minethe minimum wire size requiredIn an extensioncord.

Only roundjacketedcordslistedby Underwritsr'sLabora-

tories(U_ sl_utd be used.

Whenworkln 9 outdoorswith e Icon,use anext_sk_n cord

_thB.tis _e_'_gne_tot ouL_'_deusa. _'hietype ot cordis _ee-

ignated w_th=WA"on the cord's )acket.

Beforeusingany sxte_don cord,_nspectit forlooseor ex-

posedwires and cut orworn insulation.

0-2.0 2*1-3.4 3.0-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 18 16 14 12 10 --

"Used on _ ga_,_e-20 amp_t:_

NO1rF_.:AWO- Arnedr,_mW'_ Gauge

A WARNING: Keep theextensioncord clearor the

workingarea. Positionthecordso that itwillnot get

WInDSize (A.W.G.)

caught on lumber,toolsor otherobstructionswhile

you are workingwith a powertool Failuretodo so

can resultIn ssdous persona!injury.

A WARNING: Check exten._on cords before each

use. If damaged replace immediately.Never usetool

with a damaged cordsincetouchingthe _amaged

area could cause elec_cal shock resultinginserious

Injury.

8

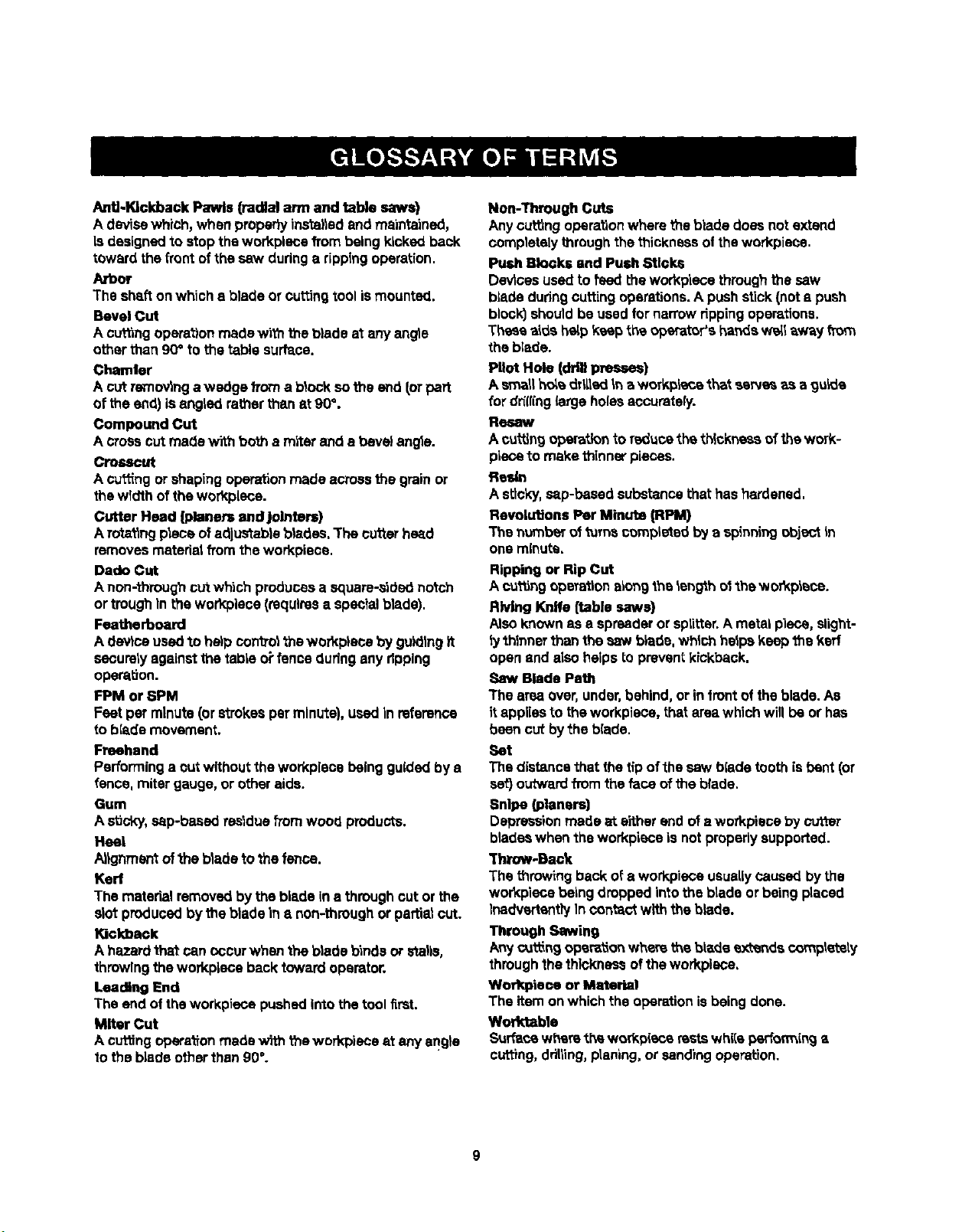

Anti-KickbackPawls(radialarmandtablesaws)

Adevisewhich,whenpropertyinstatedandmaintained,

Is designedto stopthe workplace from beingkicked back

toward thefront of thesaw duringa rippingoperation.

Arbor

The shafton whicha blade or cuttingtool ismounted.

Bevel Cut

A cut,rig operationmadewit'nthe blade at any angle

otherthan 90* to the table surface.

Chamler

A cut removingawedge froma black sothe end (orpart

of the end) isangledratherthan at 90..

Compound Cut

A crosscut madewith both a miter enda bevelangle.

Crosscut

A cut_ng orshapingopera, on made acrossthe grainor

thewidth ofthe workplene.

Cutter Head (planers andjothters)

Arots_ng plece of adjustableblades. "Thecutterheed

removesmaterialfrom the workpiace.

Dado Cut

Anon-throughcut which produces a squara-s_dednotch

or troughInthe workplece(requiresa speclalblade).

Featherboard

A deviceused to help controlthe wod_ptaceby gu)dlngit

sacuretyagainstthe table o?fence during anydpplng

operation.

FPM or SPM

Feet perrnlnute(orstrokesper minute), used inreference

to blademovement.

Freehand

Performinga out withoutthe workplace beingguidedby a

fence, miter gauge, or otheraids.

Gum

A s_ck'7,sap-based residuefromwood products.

Heel

Altgnmentofthe blade to thefence.

Karl

The material removed bythe blade ina through cut or the

slot producedby the blade In a non-throughorpartialcut.

Kickback

A hazardthat can occurwhen the blade b_ndsor stalls,

throwingthe workplace backtoward operator.

Leading End

The end of theworkplace pushed intothe toolfirst.

Miter Cut

A cuttingspars'donmadew_n the workpiece at anyangle

to the blade otherthen 90°.

Non-Through Guts

Any cuing operationwhere the blade does not extend

completelythroughthethicknessof theworkpiace.

Push Blooke and Push Stloks

Devtcesused to feed the workplacethroughthe saw

bladeduringcutting operations.A pushstick(nota push

block)should be usedfornarrow dppingoperations.

These aids h_,pkeep the operator'shands w_l away from

the blede.

Pilot Hole (drillpresses)

A small heradrilledIn aworkp_ce that sawes as a guide

for dr_(lfnglarge holesaccurately.

Resaw

A cuing op_atton to reducethe thickness of the work-

piece to make thinner pieces.

Resin

A sticky,se.p-t:_sed substancethat has hardened.

Revolutions Per Minute (RPM)

The numberof_rns completedbya spinningobjac_in

one minute.

Ripping or Rip Cut

A cuing operation alongthe leng'ih olthe workplace.

Rkdng Knife [table saws)

Alsoknown as e spreaderor splitter.A metal piece,slight-

ty thinner than the saw b_ade,which h_ps keep the _erf

open andalsohelps to preventkickback.

Saw Blade Path

The area over,under,behind,or infrontof the blade.As

itappliesto the workpiece,that areawhich will be orhas

beencut bythe blade.

Set

The distancethat the tip ofthe saw blade tooth isbent (or

set)outwardfromthe faceof theblade.

Snipe (planers]

De0rsssionmade at either end ofa workpiece by cutler

bladeswhen theworkpiace isnot properlysupported.

Throw-Back

The throwing backof aworkplace usuallycausedby the

workpiecebeing dropped intothe blade orbeing placed

InadvertentlyIncontact with the blade.

Through Sawing

Anycut'_ng opera, on wheretheblade extends completely

throughthe thickness of the workplace,

Workplace or Material

The item on whichthe operationis beingdone.

WoltCmble

Sur_ce wh_rethe workplacerestswhi(eperfom_inga

cutting,drilting,planing,orsandingoperation.

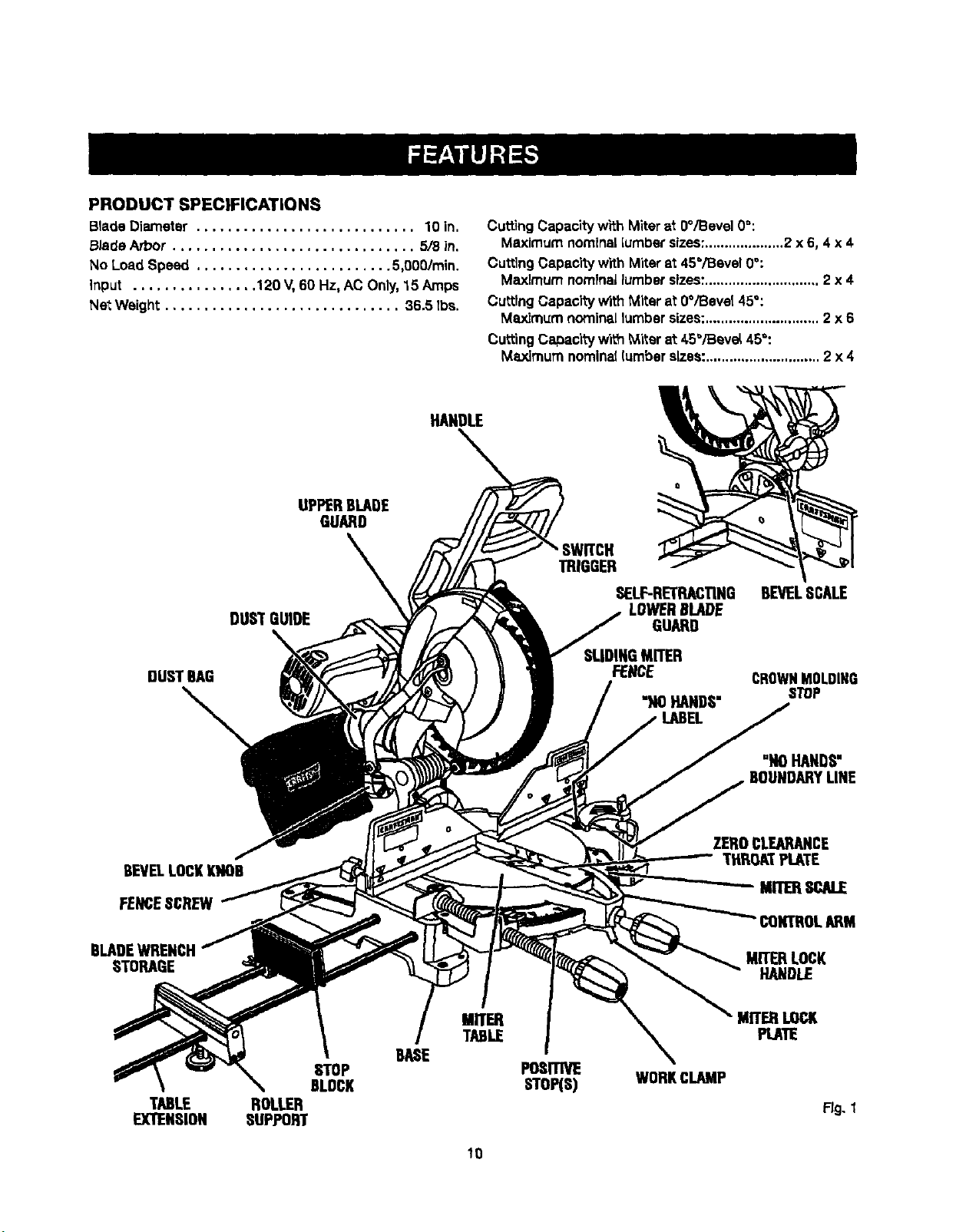

PRODUCT SPECIFICATIONS

BladeDiameter ............................ 10 in.

B_de Arbor ............................... 5/8 in.

No Load Speed ......................... 5,000/min.

Input ................ 120 V,60 Hz, AC Only.15 Amps

NetWeight .............................. 36.5 tbs.

HANDLE

UPPERBLADE

GUARD

DUSTGUIDE

CuttingCapacitywtth Miterat0°/Bevel 0_:

Maximumnominal[umbersizes:....................2 x 6, 4 x 4

CuttlngCapacity with Miter at 45°/Beve! 0°:

Maximumnominallumbersizes:............................. 2 x 4

CuttingCapacity WithMiterat 0°iBeval 45°:

Maximumnominal lumbersizes:............................. 2 x 6

CuttingCapac'l_ with _i_er at 45"/Beve_45_:

Maximum nominal[umberalzes: ............................. 2 x4

• SWITCH

TRIGGER

SELF-RETRACTING

LOWERBLADE

GUARD

BEVELSCALE

DUSTBAG

BEVELLOCKKNOB

FENCESCREW

BLADEWRENCH

STORAGE

TABLE ROLLER

EXTENSION SUPPORT

STOP

BLOCK

BASE

MITER

TABLE

POSITIVE

STO_S)

SLIDINGMITER

FENCE

"NO HANDS"

WORKCLAMP

CROWNMOLDING

STOP

"NOHANDS"

BOUNDARYLINE

ZEROCLEARANCE

THROATPLATE

Mm_ SCALE

MITERLOCK

HANDLE

MITERLOCK

PLATE

Fig. I

10

KNOW YOUR COMPOUND MITER SAW

See Figure1.

Beforeattempting to usethis product,familiarizeyourself

w_ ail operatingfeatures and safetyrules.

15 AMP MOTOR

Yoursew has a powerful15 amp belt-drivenmotor with

sufficientpowerto handle tough cuttinglobs. It Ismade

w;th airball bsedngs,and hasexternallyaecesaibre brush-

es for ease of servicing.

10 in, BLADE

A 10 in.carbide-Upped saw blade isincludedwith your

compound miter sew. Itwill cut materialsup to 4 in.thick

or 6 In.wide, depending uponthe angleat whichthe cut

isbeing made.

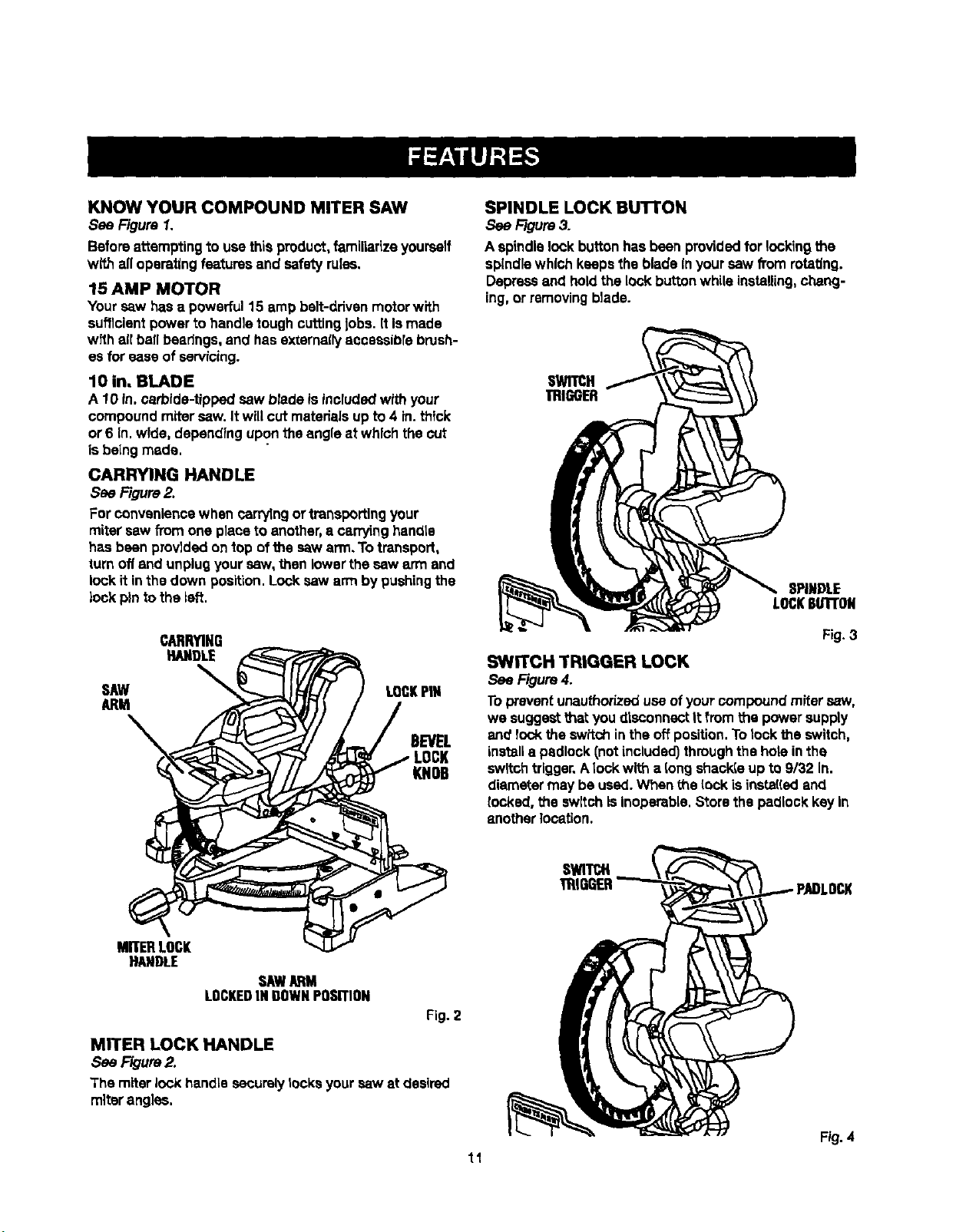

CARRYING HANDLE

See Figure2.

Forconveniencewhen carr_ng ortransportingyour

miter saw from one placeto another,a carryinghandte

has beenprovldedon top ofthe saw arm.To transport,

turn offand unplugyoursew, then lower the sew arm and

lock itin the down position.Locksaw arm by pushingthe

lock pinto the left.

SPINDLE LOCK Bu'rroN

See Figure3.

A spindlelock buttonhas beenprovidedfor lockingthe

spindlewhich keepsthe blade Inyour saw fromrotating.

Depressand holdthe lockbuttonwhile instaging,chang-

ing,or removingblade.

SWITCH

mlGGER

SPINDLE

LOCKBUTi'ON

CARRYING

HANDL£

SAW LOCKPiN

ARM

DEVEL

KNOB

MITERLOCK

HANOLE

SAWARM

LOCKEDINGOWNPOSITION

Fig. 2

MITER LOCK HANDLE

See Rgure 2.

The miterlock handle securelyrocksyoursaw at desired

miterangles.

Fig. 3

SWITCH TRIGGER LOCK

See Figure4.

Topreventunauthorizeduseof yourcompoundmiter saw,

we suggestthat you disconnectIt from the powersupply

and lock theswitch inthe offposition.Totookthe switch,

installa padlock (notincluded)throughthe holeinthe

switchtrigger,Alock witha tongshackteup to 9/32 In.

diametermay be used.When the lock isinsta(iedand

locked, the switchIs Inoperable.Store the padlockkey In

another location.

11

Fig.4

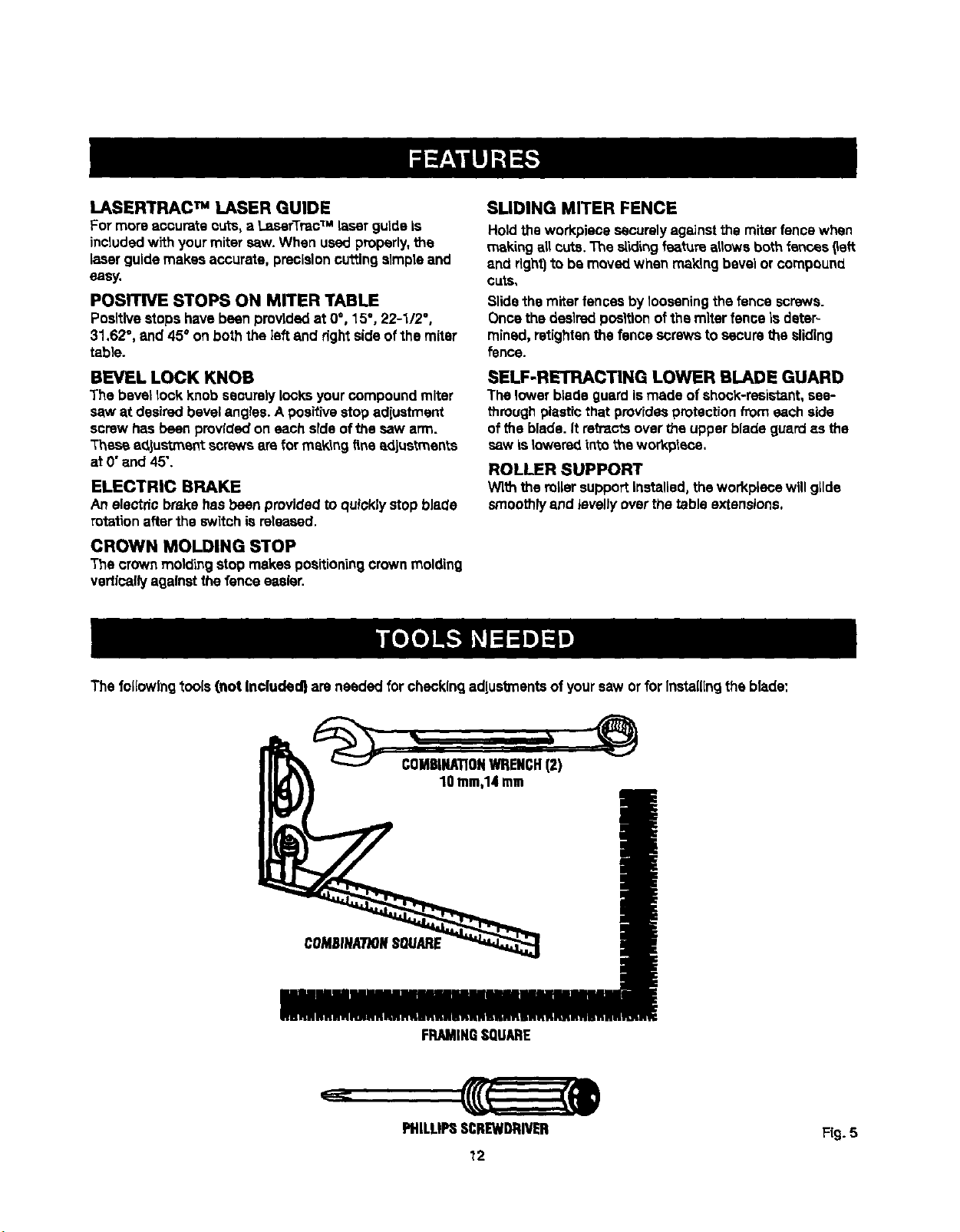

LASERTRACTM LASER GUIDE

For moreaccurate cuts, a LasarTmcTM laser guide Is

includedwithyour miter saw.When usedproperly,the

laser guidemakes accurate, precisioncuttingsimpleand

easy.

Posn'IVE STOPS ON MITER TABLE

Positivestops havebeen providedat 0°, 15°, 22-1/2°,

31.62°, and 45° onboth the left and rightside ofthe miter

table.

BEVEL LOCK KNOB

The bevellock knob securelylocksyourcompoundmiter

saw at desired bevelangles.A positivestop adiustment

screw hasbeen providedon each srdeofthe saw arm.

These adjustment screwsarefor making fineadjustments

at O"and 45".

ELECTRIC BRAKE

An electdobrake hasbeen providedto quioklystop blade

rotation afterthe switchis reteaead.

CROWN MOLDING STOP

The crownmoldingstop makes positioningcrownmolding

verticallyagainstthe fence easier.

SLIDING MITER FENCE

Hold the workpiesa securely against the mRer fence when

making all cuts. The stiding feature atlows both fences (left

and right) to be moved when making bevel or compound

CLIts,

Slidethe miterfencesby tooseningthe fence screws.

Oncethe dealredposition of the miterfence Is deter-

mined, retightsnthefencescrewsto securethe sliding

fence.

SELF-RETRACTING LOWER BLADE GUARD

The lower blade guardismade ofshook-resistant,see-

throughplasticthat providesprotectionfl'omeach side

of the blade.It retractsoverthe upper bladeguard as the

saw isloweredintotheworkplsce,

ROLLER SUPPORT

WI_ the miler supportInstalled, theworkplacewill glide

smoothlyand levellyoverthe table extensions.

The followingtools (not Included} are needed for checking adlus_ents of your saw or forInstalling the blade:

COMBINATIONWRENCH(2)

10 ram,14me

COMSINA7"/ONS01/ARE

FRAMINGSQUARE

PHILLIPSSCREWDRIVER Fig.5

12

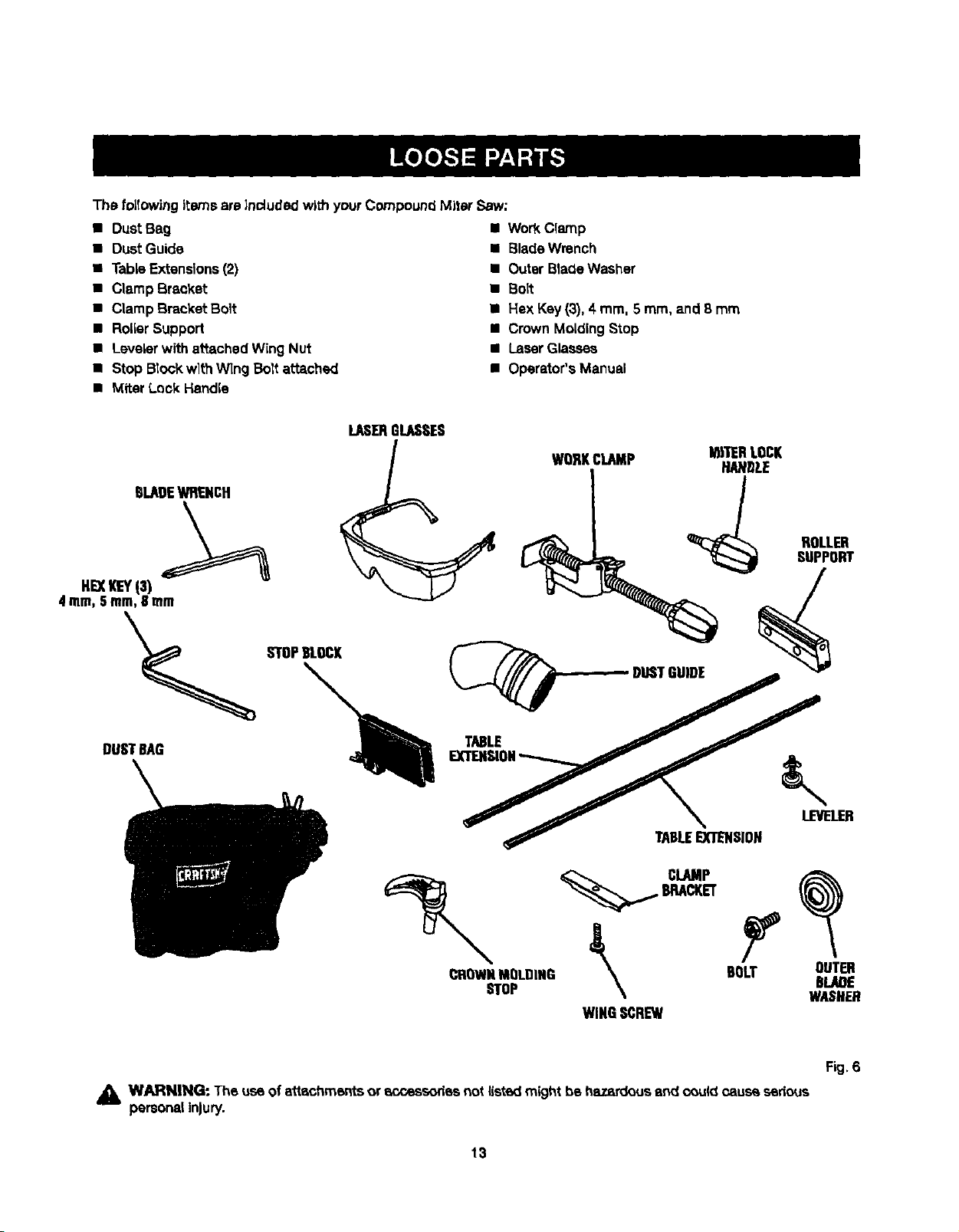

The follow'_ngi_:emsare Lncludedw|th yourCompoundMiter Saw;

• Dust Bag

• DustGuide

• Table Extensions(2)

• ClampBreaker

• CLampBracket Bolt

• RoLLerSupport

• LeveLerwith attached Wing Nut

• Stop BlockwlthWing Bolt attached

• MiterLock Handle

LASERGLASSES

BLADEWRENCH

4 ram,Sram,8 mm

HE)CKEYiS)

• WorkClamp

• Blade Wrench

• Outer BladeWasher

• Bolt

• Hex Key(3), 4 mm, 5 mm, and 8 mm

• Crown MoldingStop

• LaserGlasses

• Operator's Manual

WORKCLAMP I_11ERLOCK

ROLLER

SUPPORT

°°,T,,o =oy .

TABLEEXTENSION

_ BRACKET

CROWNMOLDING _ BOLT OUTER

STOP \ 8LAOE

WINGSCREW

_i WARNING- The use of ettechmentsorscsessodesnot listedmight be hazardousendc_uk_oause sedous

personalInjury.

13

WASHER

Fig. 6

UNPACKING

This productrequires assembly.

• Carefullyliftsaw fTomthe cartonby the carrying handle

and the sawbase, and place it on a lard work surface.

NOTE: Th_ssaw is heeW.'To avoid back I_lury,_.w_th

your legs,notyourback, and get helpwhen needed.

• Thissaw has been shipped with the saw arm secured

in the downposition.Toreleasethesaw arm, push

down on the top ofthe saw arm, cutthe tie-wrap, and

puttout or the look pin,

• Uft the saw arm by the handle.Hand pressureshould

remainon the saw armto prevent suddenrise upon

mtesae ol _hetie wrap.

• Inspect the toolcarefullyto make sure no breakage or

damage occurreddudng shipping.

• Do not discardthe packing material un_JJyou have

carsfultyinspected and set'=sfectofi_yoperated the tool.

• The saw isfactory set foraccuratecutting.After

assarnbllngit,check for accuracy, if shippinghas

influencedthe settings,referto specificprocedures

explainedinthis manual."

• If any parts are damaged or missing, please call

1-800-932-3188 for assistance.

WARNING: (fany partsare m[sslng, do not operate

this tooluntllthe missingpartsare replaced. Faflbre

to do so couldresultinpossiblesedouspersonal

injury.

_lb WARNING: Do notattempt to modify thistool

orcreateaccessories notrecommendedforuse

with thistool. Anysuch alterationor modificationIs

misuse andcould resultin a hazardouscondition

feeding to possibleseriouspersonal injury.

WARNING: Do notconnect to powersupply until

assembly iscomplete. Failureto complycouJdresult

_naccJdantalstartingand poss]b_asarfous personal

iniu_

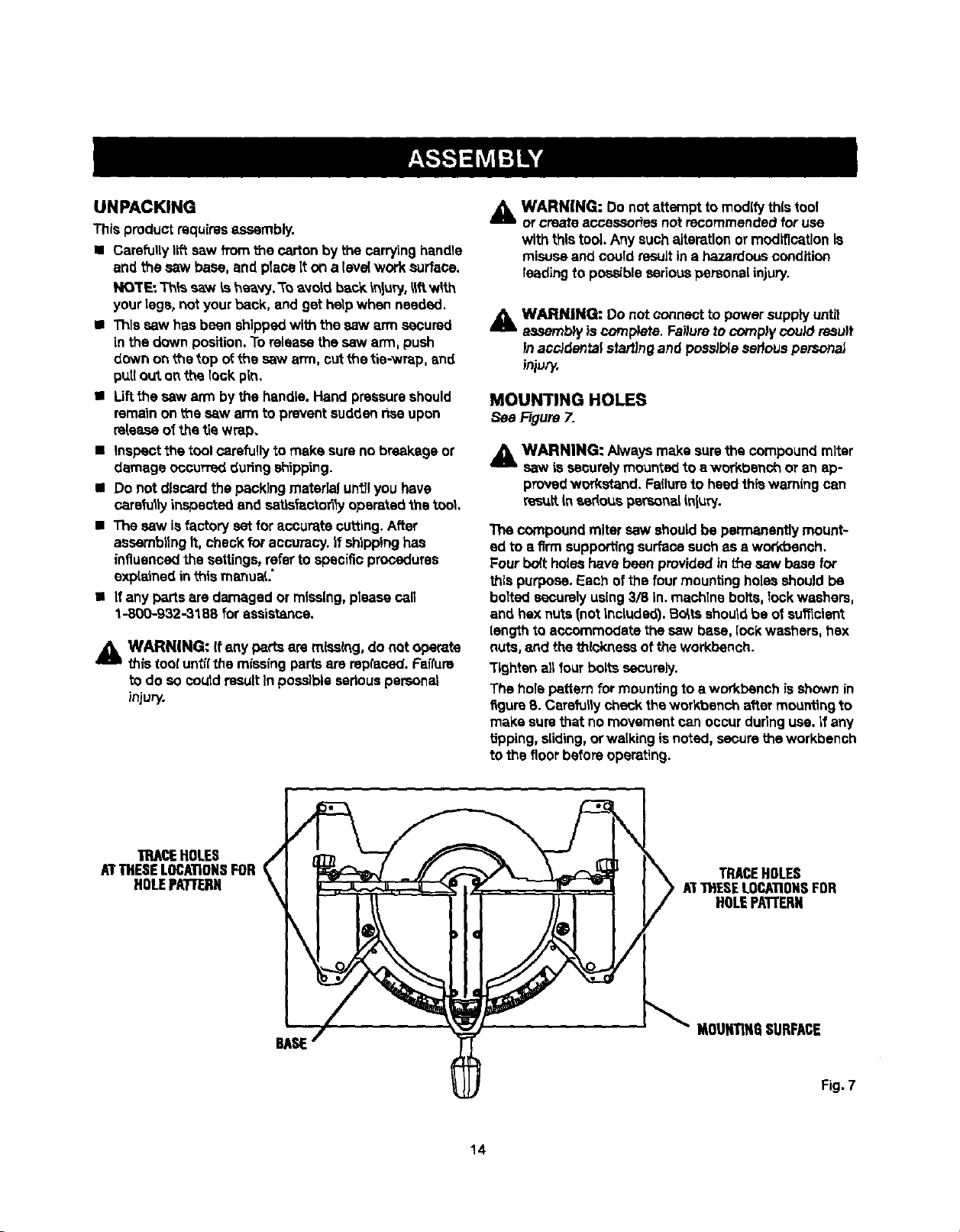

MOUNTING HOLES

See Figure 7.

_ WARNING: Alwaysmake surethe compoundmltsr

saw is securelymounted to e workbenchor an ap-

provedworkstand. Failureto heedthiswarningcan

recuitinsadousperso_L inluw.

The compoundmiter saw shouldbe permanentlymount-

ed to a firm supportingsurfacesuchas a workbench.

Four boltholeshave been providedinthe saw base fOr

this puq_ose.Each ofthe four mounting holes should be

bolted securelyusing3/8 In. machine bolts,lockwashers,

an_ hex nuts(not included). Bo_tsshouldbe of su_clent

lengthto accommodatethe saw base,[ockwashers,hex

nuts, and the thicknessof the workbench.

Tightec airfourbolts securely.

The holepatternfor mountingto a workbench isshownin

figure8. Carefullycheckthe workbenchattar mounting to

make surethat no movementcan occur duringuse. If any

Upping,sliding,orwalking isnoted, securethe workbench

to the floorbeforeoperating.

TRACEHOLES

ATTHESELOCATIONSFOR

HOLEPATIF1ERN

TRACEHOLES

A"T"tHESELOCATIONSFOR

HOLEPA'TrERN

IAOUNTIH_iSURFACE

BASE

Fig. 7

14

Loading...

Loading...