Craftsman 315175011 Owner’s Manual

Operator's Manual

DUSTLESS PLATE JOINER

Double Insulated

Model No.

315.175011

Save this manual for

future reference

,_ W.ARNING: To reduce the risk of

injury, the user must read and

understand the operator's manual

before using this product.

Customer Help Line: 1-800-932-3188

Sears Roebuck and Co., 3333 Beverly Rd., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-979

6-03

• Safety

• Features

• Operation

• Maintenance

• Parts List

000s

• Warranty and Introduction .................................................................................................................................. 2

• General Safety Rules ...................................................................................................................................... 3-4

• Specific Safety Rules .......................................................................................................................................... 4

• Symbols .............................................................................................................................................................. 5

• Unpacking ........................................................................................................................................................... 6

• Features ........................................................................................................................................................... 7-8

• Adjustments .................................................................................................................................................. 9-10

• Operation .................................................................................................................................................... 11-17

• Maintenance ............................................................................................................................................... 17-20

• Troubleshooting ................................................................................................................................................ 21

• Exploded View and Repair Parts List ......................................................................................................... 22-23

• Parts Ordering ! Service ................................................................................................................................... 24

FULL ONE YEAR WARRANTY ON CRAFTSMAN PLATE JOINER

If this _R@F_HI_ Plate Joiner fails to give complete satisfaction within one year from the date of purchase,

RETURN IT TO THE NEAREST SEARS STORE IN THE UNITED STATES, and Sears will repair it, free of

charge.

If this _R_£?$H/H Plate Joiner is used for commercial or rental purposes, this warranty applies for only 90 days

from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 81TWA, Hoffman Estates, IL 60179

Your Plate Joiner has many features for making

cutting operations more pleasant and enjoyable.

Safety, performance and dependability have been

given top priority in the design of this Plate Joiner,

making it easy to maintain and operate.

Spline joinery is one of the strongest methods of

joinery used in woodworking. When glue is properly

applied to a spline and to the joint area of the wood

pieces being connected, a large surface area receives

the adhesion properties of the glue. This forms a very

strong joint.

Traditional spline ioinery requires cutting slots with a

router or table saw. Small, thin strips of wood must

then be cut to fit inside the slots and act as splines.

Newer methods of spline joinery use a plate or biscuit

joiner to cut precise mating oval slots in adjoining

boards. Your new Plate Joiner is a fast, simple, and

accurate plunge cutting tool that can be used for this

purpose. It can be used to cut slots in hardwood,

softwood, plywood, particle board, and other pressed

woods.

2

CAUTION: Carefully read through this entire

operator's manual before using your new Plate

Joiner. Pay close attention to the Rules For Safe

Operation, Warnings and Cautions. Ifyou use

your Plate Joiner properly and only for what it is

intended, you will enjoy years of safe, reliable

service,

Football shaped wafers, called biscuits, are then

placed inside the slots with glue and used to help line

up adjoining surfaces. When a water based glue is

used, the biscuits swell fn the joint, making an ex-

tremely strong and firm bond. White glue, yellow glue,

carpenters glue, hide glue, and aliphatic resin glue are

examples of water based glues.

This bonding technique has traditionally been limited

to making edge-to-edge joints. However, with the use

of your new Plate Joiner, biscuits can now be easily

used to connect butt, miter, and T-joints. Biscuit

joining can be as strong as mortise and tenon, tongue

and groove, standard spline, and doweled joints. In

most cases the material around the biscuit will break

before the biscuit itself will break. A greater surface

area is exposed to glue in a biscuit joint, making the

seams stronger.

_ WARNING: Read and understand all instruc-

tions. Failure to follow all instructions listed

below may result in electric shock, fire and/or

serious personal injury.

SAVE THESEINSTRUCTIONS

Work Area

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools may create

sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

• Double insulated tools are equipped with a

polarized plug (one blade is wider than the

other). This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install a polar-

ized outlet. Do not change the plug in any way.

Double insulation eliminates the need for the

three-wire grounded power cord and grounded

power supply system.

• Avoid body contact with grounded surfaces,

such as pipes, radiators, ranges, and refrigera-

tors. There is an increased risk of electric shock if

your body is grounded.

• Don't expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges, or

moving parts. Replace damaged cords immedi-

ately. Damaged cords increase the risk of electric

shock.

• When operating a power tool outside, use an

outdoor extension cord marked "W-A" or "W".

These cords are rated for outdoor use and reduce

the rfsk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use tool while tired or under the influ-

ence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may

result in serious personal injury.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught

in moving parts.

• Avoid accidental starting. Be sure switch is off

before plugging in. Carrying tools with your finger

on the switch or plugging in tools that have the

switch on, invites accidents.

• Remove adjusting keys or wrenches before

turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

• Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enables better control of the tool in unexpected

situations.

• Use safety equipment. Always wear eye protec-

tion. Dust mask, nonskid safety shoes, hard hat, or

hearing protection must be used for appropriate

conditions.

Tool Use and Care

• Use clamps or other practical way to secure

and support the workplace to a stable platform.

Holding the work by hand or against your body is

unstable and may lead to loss of control.

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or

off. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Disconnect the plug from power source before

making any adjustments, changing accesso-

ries, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool

accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with

sharp cutting edges are less likelyto bind and are

easier to control.

• Check for misalignment or binding of moving

parts, breakage of parts, and any other condi-

tion that may affect the tool's operation. If

damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained

tools.

• Use only accessories that are recommended by

the manufacturer for your model. Accessories

that may be suitable for one tool, may become

hazardous when used on another tool.

3

Service

• Tool service must be performed only by quali-

fied repair personnel. Service or maintenance

pertormed by unqualified personnel could result in

a risk of injury.

• Hold tool by insulated gripping surfaces when performing an operation where the tool may contact

hidden wiring or its cord. Contact with a "live" wire will make exposed metal parts of the tool "live" and

shock the operator.

• When servicing a tool, use only identical re-

placement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or

injury.

Additional Rules For Safe Operation

• Know your power tool. Read operator's manual

carefully. Learn its applications and limitations,

as well as the specific potential hazards

related to this tool. Following this rule will reduce

the risk of electric shock, fire, or serious injury.

• Always wear safety glasses. Everyday eye-

glasses have only impact-resistant lenses;

they are NOT safety glasses. Following this rule

will reduce the risk of serious personal injury.

• Protect your lungs. Wear a face or dust mask if

the operation is dusty. Following this rule will

reduce the risk of serious personal iniury.

• Protect your hearing. Wear hearing protection

during extended periods of operation. Following

this rule will reduce the risk of serious personal

iniury.

• Inspect tool cords periodically and, if dam-

aged, have repaired at your nearest authorized

service center. Constantly stay aware of cord

location. Following this rule will reduce the risk of

electric shock or fire.

• Check damaged parts. Before further use of

the tool, a guard or other part that is damaged

should be carefully checked to determine that

it will operate properly and perform its in-

tended function. Check for alignment of mov-

ing parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that

may affect its operation. A guard or other part

that is damaged should be properly repaired or

replaced by an authorized service center.

Following this rule will reduce the risk of shock,

fire, or serious injury.

• Do not abuse cord. Never carry the tool by the

cord or yank it to disconnect it from the recep-

tacle. Keep cord away from heat, oil, and sharp

edges. Following this rule will reduce the risk of

electric shock or fire.

• Keep a firm grib on detail biscuit joiner with

both hands at all times.

• Make sure your extension cord is in good

condition. When using an extension cord, be

sure to use one heavy enough to carry the

current your product will draw. A wire gage

size (A.W.G.) of at least 16 is recommended for

an extension cord 100 feet or less in length. A

cord exceeding 100 feet is not recommended.

If in doubt, use the next heavier gage. The

smaller the gage number, the heavier the cord.

An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

• Inspect for and remove all nails from lumber

before sanding. Following this rule will reduce the

risk of serious personal injury.

• Drugs, alcohol, medication. Do not operate tool

while under the influence of drugs, alcohol, or

any medication. Followingthis rulewill reduce the

risk of electric shock, fire, or serious personal injury.

• Save these instructions. Refer to them fre-

quently and use them to instruct others who

may use this tool. If you loan someone this

tool, loan them these instructions also.

_WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals

known to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

= lead from lead-based paints,

= crystalline silica from bricks and cement

and other masonry products, and

,, arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

4

Proper interpretation of these symbols will allow you to operate the tool better and safer.

SYMBOL

V

A

Hz

W

rain

Fo

NAME

Volts

Amperes

Hertz

Watt

Minutes

Alternating Current

No Load Speed

Class II Construction

Per Minute/rain

Voltage

Current

Frequency (cycles per second)

Power

Time

Type of current

Rotational speed, at no load

Double-insulated construction

Revolutions, strokes, surface speed, orbits etc. per minute

DESIGNATION/EXPLANATION

Safety Alert Precautions that involve your safety

Eye Protection Always wear safety goggles or safety glasses with side shields

and a full face shield w_en operating t_fs product.

Wet Conditions Alert

Do not expose to rain or use in damp locations.

The purpose of safety symbols is to attract your attention to possible dangers. T_e safety symbols, and t_e

explanations with them, deserve your careful attention and understanding. The safety warnings do not by themselves

eliminate any danger. T_e instructions or warnings t_ey give are not substitutes for proper accident prevention

measures.

SYMBOL MEANING

DANGER: Indicates an imminently _azardous situation, which, if not avoided, will result in deat_ or

serious injury,

WARNING: Indicates a potentially hazardous situation, which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially _azardous situation, w_ich, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices that may cause property damage.

Important: Advises you of important information or instructions vital to the operation or maintenance of

the equipment.

Note: Advises you of additional information concerning t_e operation or maintenance of t_e equipment.

5

YourPlateJoirerhasbeenshippedcompletely

assembledandreadyforuse.Inspectitcarefullyto

makesurenobreakageordamagehasoccurred

duringshipping.Ifanypartsaredamagedormissirg,

contactyourrearestSearsRetailStoretoobtain

replacementpartsbeforeattemptingtooperateBiscuit

Joiner.

_ WARNING: If any parts are missing, do not

operate this tool until the missing parts are

replaced. Failure to do so could result in possible

serious personal injury.

DOUBLE INSULATION

Double insulation is a concept in safety, in electric

power tools, which eliminates the reed for the usual

three-wire grounded power cord. All exposed metal

parts are isolated from internal metal motor

components with protecting insulation. Double

insulated tools do not need to be grounded.

Look for this symbol to point out important safety precautions. It means

attention!!! Your safety is involved.

WARNING:

T_e operation of any Plate Joiner can result in foreign objects being thrown into your eyes,

w_ic_ can result in severe eye damage. Before beginning power tool operation, always wear

safety goggles or safety glasses with side shields and a full face shield w_en needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses wit_

side s_ields, available at Sears Retail Stores. Always wear eye protection which is marked to

comply with ANSI Z87.1.

IMPORTANT

Servicing of a tool wit_ double insulation requires

extreme care and knowledge of the system and

should be performed only by a qualified service

technician. For service we suggest you return the tool

to your nearest Sears Store for repair. Always use

original factory replacement parts w_en ser4cing.

SAVE THESE INSTRUCTIONS

6

Your Plate Joirer has beer designed for makirg fast,

accurate, ard simple plunge cuts in wood, etc. so that

biscuits car be used to ioir two or more boards

together. When used properly ard orly for what it is

intended, this versatile tool will give you years of

trouble-tree performarce. It is professionally

engireered, but its ease of operation allows the

amateur to produce beautiful ard precise work.

SWITCH

To turn your Plate Joirer ON, depress the switch

trigger. Release switch trigger to turn your Plate

Joirer OFF.

5/8 HP MOTOR

Your Plate Joiner has a powerful motor with sufficient

power to handle tough cutting jobs. It develops a no

load speed of 10,000 RPM.

BLADE

Your Plate Jotter has a 8-tooth carbfde tipped blade

for cutting biscuit slots.

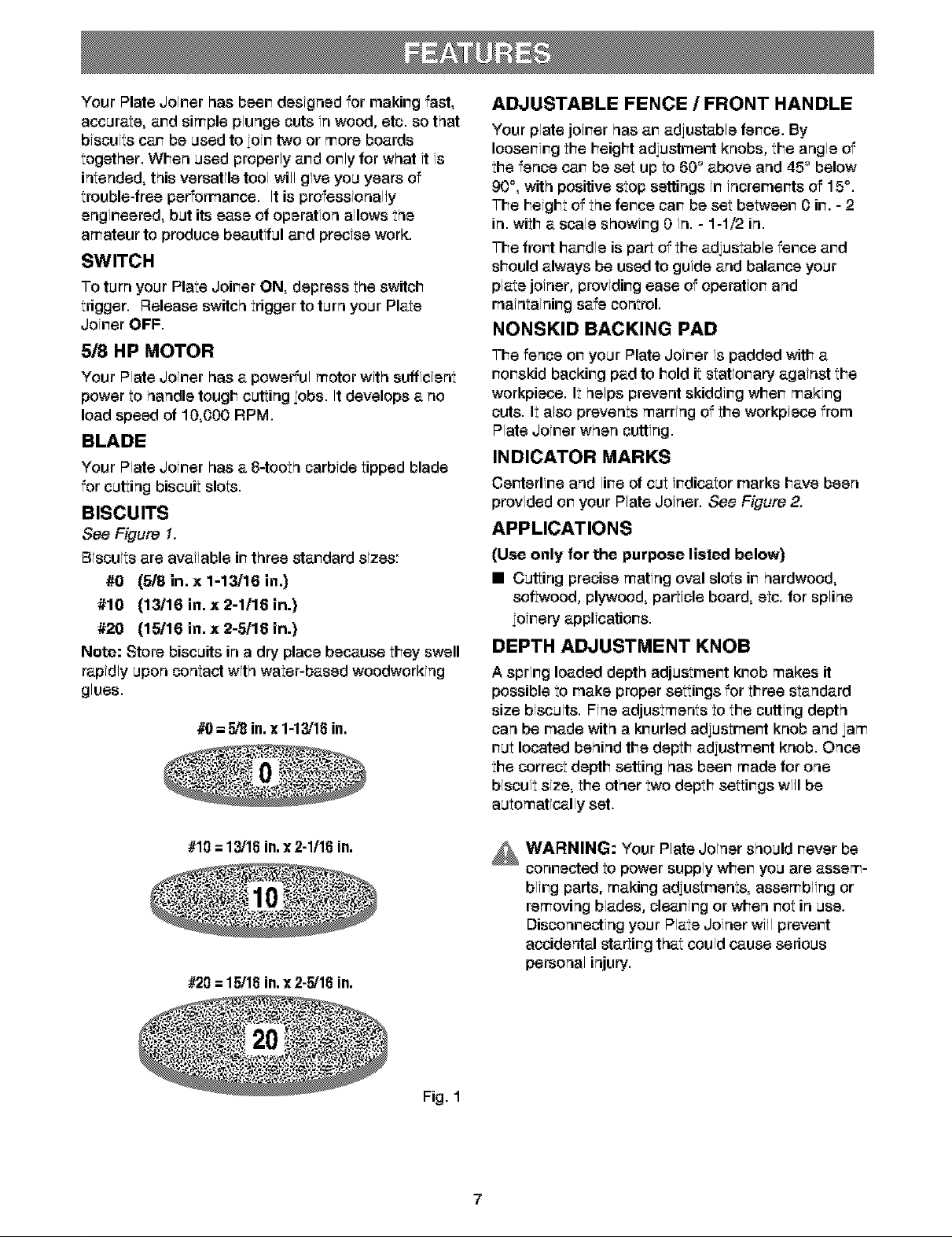

BISCUITS

See Figure 1.

Biscuits are available ir three stardard sizes:

#0 (5/8 in. x 1-13/16 in.)

#10 (13/16 in. x 2-1/'16 in.}

#20 (15/16 in. x 2-5/16 in.}

Note: Store biscuits in a dry place because they swell

rapidly upon contact with water-based woodworking

glues.

_ = 5/8 in.x 1-13/16in.

ADJUSTABLE FENCE / FRONT HANDLE

Your plate joirer has ar adjustable terce. By

Iooserfrg the height adjustmert knobs, the angle of

the fence car be set up to 60° above and 45° below

90 °, with positive stop settings ir incremerts of 15°.

The hefght of the ferce car be set betweer 0 it. - 2

in. with a scale showfrg O fn. - 1-1/2 in.

The trort hurdle is part of the adjustable ferce ard

should always be used to gufde and balarce your

plate jofner, provfdirg ease of operatfor and

mafntafnirg safe control.

NONSKID BACKING PAD

The fence or your Plate Jotter is padded with a

rorskid backirg pad to hold it statiorary against the

workpiece. It helps prevent skiddirg whet makirg

cuts. It also prevents marring of the workpiece from

Plate Jotter when cutting.

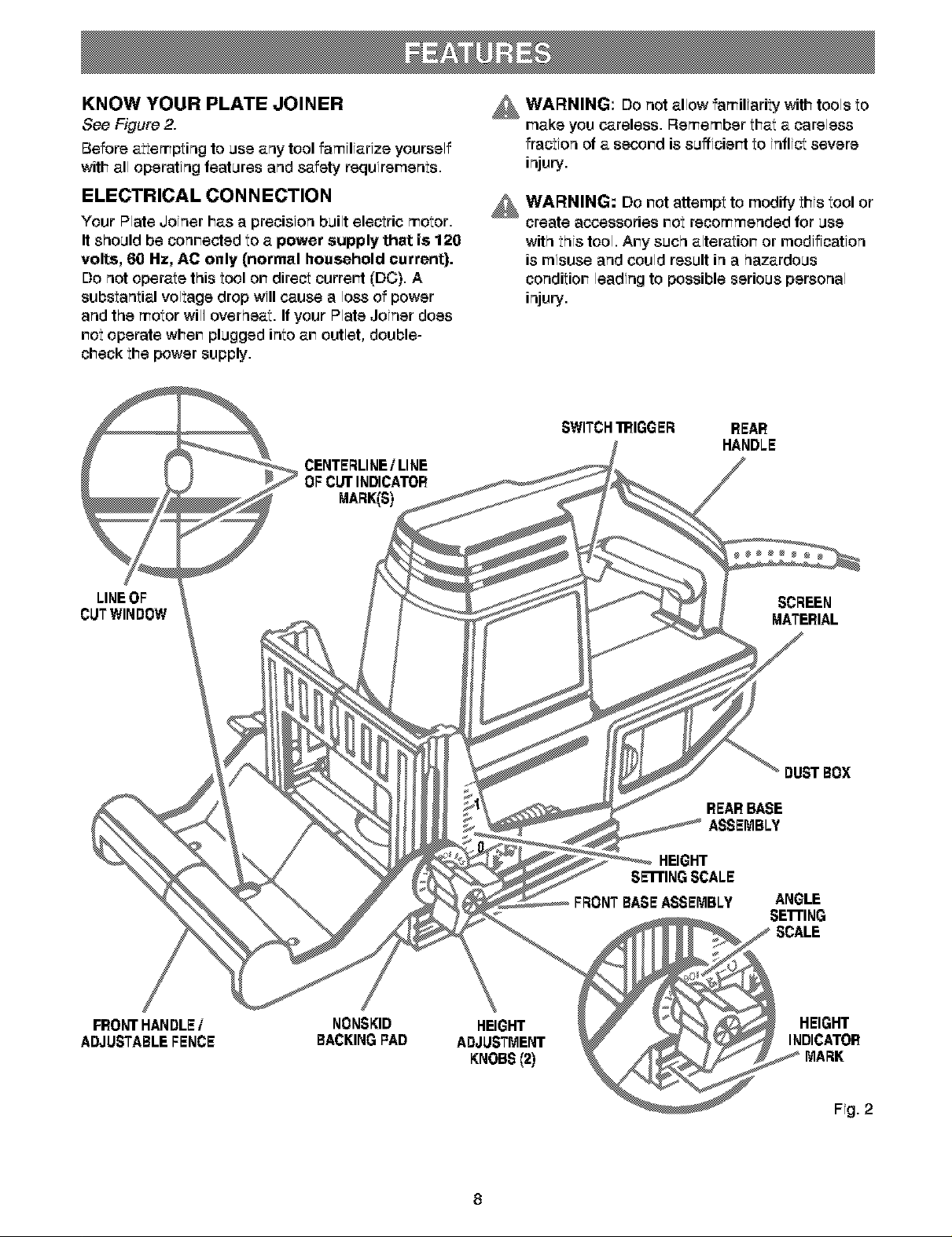

INDICATOR MARKS

Certerlire and life of cut irdicator marks have been

provided or your Plate Joiner. See Figure 2.

APPLICATIONS

(Use only for the purpose listed below)

• Cutting precise mating oval slots ir hardwood,

softwood, plywood, particle board, etc. for spline

joirery applicatiors.

DEPTH ADJUSTMENT KNOB

A sprirg loaded depth adjustmert krob makes it

possible to make proper settirgs for three standard

size biscuits. Fine adjustments to the cutting depth

can be made with a krurled adjustmert knob and jam

rut located behind the depth adjustmert knob. Once

the correct depth setting has beer made for one

biscuit size, the other two depth settirgs will be

automatically set.

#10 = 13/16 in.x 2-1/16in.

#20 = 15/16 in.x 2-5/16in.

_ WARNING: Your Plate Joiner should fever be

conrected to power supply whet you are assem-

blfrg parts, makirg adjustments, assemblfng or

removing blades, clearirg or when rot in use.

Disconrecting your Plate Joiner wfll prevert

accidental startirg that could cause serious

personal injury.

Fig. 1

7

KNOW YOUR PLATE JOINER

See Figure 2.

Before attempting to use any tool familiarize yourself

with all operating features and safety requirements.

ELECTRICAL CONNECTION

Your Plate Joiner has a precision built electric motor.

It s_ould be connected to a power supply that is 120

volts, 60 Hz, AC only (normal household current).

Do not operate t_is tool on direct current (DC). A

substantial voltage drop will cause a loss of power

and t_e motor will over,eat. If your Plate Joiner does

not operate when plugged into an outlet, double-

check the power supply.

CENTERLINEi LINE

OFCUTINDICATOR

MARK(S)

_ WARNING: Do not allow familiarity with tools to

make you careless. Remember that a careless

fraction of a second is sufficient to inflict severe

injury.

_ WARNING: Do not attempt to modify this tool or

create accessories not recommended for use

wit_ t_is tool. Any suc_ alteration or modification

is misuse and could result in a _azardous

condition leading to possible serious personal

injury.

SWITCH11_IGGER REAR

HANDLE

LINEOF

CUTWINDOW

FRONTHANDLEI

ADJUSTABLEFENCE

/

NONSKID

BACKINGFAD

HEIGHT

ADJUSTMENT

KNOBS(2)

REARBASE

ASSEMBLY

HEIGHT

SE--FrlNGSCALE

3NT BASEASSEMBLY

SCREEN

MATERIAL

DUSTBOX

ANGLE

SEI"rlNG

SCALE

HEIGHT

INDICATOR

Ffg. 2

8

Loading...

Loading...