Craftsman 315175010 Owner’s Manual

OWNER'S

MANUAL

MODEL NO.

315.175010

CAUTION:

Read Rules for

Safe Operation

and All Instruc-

tions Carefully

Thank You for Buying

Craftsman Tools

972000-339

CRRFTgMRN +

DUSTLESS

PLATE JOINER

DOUBLE INSULATED

®

Designed exclusivelyfor and sold only by

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179

Printed in U.S.A.

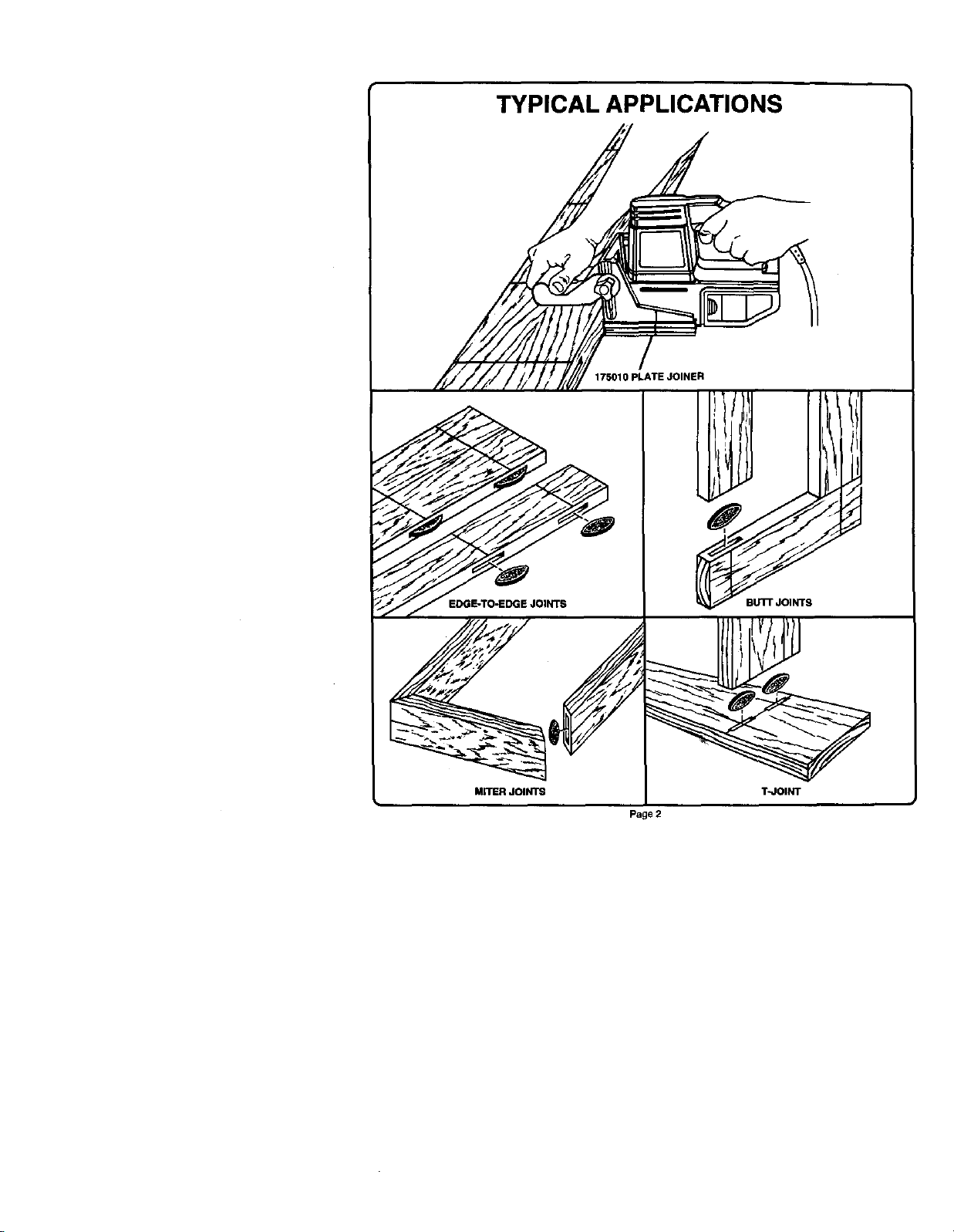

TYPICAL APPLICATIONS

175010 PLATE JOINER

Page 2

Table of Contents

I. Warranty and Introduction ....................................................................... 3

2. Rules For Safe Operation ..................................................................... 4-5

3. Features ................................................................................................ 6-7

4. Adjustments .......................................................................................... 8-9

5. Operation .......................................................................................... 10-16

6. Maintenance ..................................................................................... 17-19

7. Accessories ............................................................................................. 19

8. Troubleshooting ..................................................................................... 20

9, Exploded View and Parts List .......................................................... 22-23

FULL ONE YEAR WARRANTY ON CRAFTSMAN PLATE JOINER

Ifthis CraftsmanPlate Joinerfailstoperform propedydueto a defect inmate dal or workmanship withinoneyear from

the date of purchaseRETURN IT TO (OR CONTACT) THE NEAREST SEARS SERVICE CENTER I DEPARTMENT

IN THE UNITED STATES and Sears willrepair it,free ofcharge.

It this plate joiner is used for commercial or rental purpueasthiswarranty applies for only 90 days from the date of

purchase.

This warranty gives you specific legal dghts, and you may also have other dghts which vary from state to state.

SEARS, ROEBUCK AND CO.

DEPT. 817 WA

HOFFMAN ESTATES, IL 60179

INTRODUCTION

Spitne Joiner'/iso_e of the strongest methods of joinery usedinwoodworking, When glue is properly applied to a spline and

to the jointarea of the woodpieces being connected, a large surface area receives the adhesion propertiesoftheglue. This

forms a very strong joint.

Traditional spline Joiner'/requires cutting slots with a muter or table saw. Smafl, thin strips of wood must then he cut to fit

insidethe slots and act as splines.

Newer methods of spitne jokiery use a plate or biscuit joiner to cut precise mating oval slots in adjoining beards. Your new

platejoiner isa fast, simple, and accurate plunge cuttingtool that can be used for this purpose. If can be used to cutslotsin

hardwood, soft wood, plywood, particia board, and otherpressed woods.

Football shap4_lwafers, called biscuits, are then placed Inside the slots with"glue and used to help line up adjoining

surtames.When a water based glue is used, the biscuitsswell in the joint makingan extrem*dystrong and firm bond, White

glue,yellow glue. carpenters glue, hide glue, and kiiphatic resin glue are examples ofwater based glues.

This bondingtechnique has trediflo_tallybeen limitedto makingedge-to-edge joints, However, withthe use of your new

platejoiner, biscuitscan now be easily usedto connect butt, miter,and T-joints. Biscuitjoining can be as stronglu_mortise

and tenon, tongueand groova, standard8pllne, anddoweled joints. In mostcases the material around the biacuit will break

before the biscuitItaeit will break. A greater Igrtge area Ill8xpoI4rdto glue ina bl_uit joint, rnaidng the seams stronger.

Page 3

RULES FOR SAFE OPERATION

READ ALL INSTRUCTIONS

1, KNOW YOUR POWER TOOL - Read owner's

manualcarefully,Learnitsapplications and limi-

tationsas wellas the specificpotentialhazards

relatedto thistool.

2. GUARD AGAINST ELECTRICAL SHOCK BY

PREVENTING BODY CONTACT WITH

GROUNDED SURFACES. For example: Pipes,

radiators,ranges,refrigerator enclosures.

3. KEEP WORK AREA CLEAN. Cluttered areas

and benchesinviteaccidents.

4. AVOID DANGEROUS ENVIRONMENT. Don't

use power tools in damp or wet locations or

expose torain. Keep workarea well lit

5. KEEP CHILDREN AND VISITORS AWAY. A{I

visitorsshouldwear safetyglassesand bekepta

safe distancefrom workarea. Do not letvisitors

contacttoolorextensioncord.

6. STORE IDLE TOOLS. When not in use tools

shouldbe storedina dry, highorlocked-upplace

- outof the reach ofchildren.

7. DON'TFORCE TOOL Itwiltdothejobbetterand

saferat the ratefor whichitwasdesigned.

8. USE RIGHT TOOL. Don't force small tool or

attachment to do the job of a heavy duty tool.

Don't use tool for purpose not intended - for

example- Don'tuseacircularsawforcuttingtree

limbsor logs.

9. DRESS PROPERLY. Do notwear looseclothing

orjewelry. They can be caughtin movingparts.

Rubberglovesandnon-skidfootweararerecom-

mendedwhenworkingoutdoors.Also,wearpro-

tactive haircoveringtocontainlonghairandkeep

itfrom beingdrawnintoair vents.

10. ALWAYS WEAR SAFETY GLASSES WITH

SIDE SHIELDS. Everydayeyeglasseshaveonly

impact resJstsntlenses; they are NOT safety

glasses.

11. PROTECT YOUR LUNGS. Wear a face or dust

mask ifoperationis dusty.

12. PROTECT YOUR HEARING. Wear hearingpro-

taction during extendedpedodsof operation.

13. DON'T ABUSE CORD. Never carry tool by cord

or yank it to disconnect from receptacle. Keep

cord from heat, oil, and sharp edges.

14. SECURE WORK. Use clamps or a vise to hold

work. It's safer than using your hand and it frees

both hands to operate tool.

15, DON'T OVERREACH. Keep proper footing and

balance at all times. Do not use on a ladder or

unstable support

16. MAINTAIN TOOLS WITH CARE. Keep tools

sharp at all times, and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

17. DISCONNECTTOOLS. When not in use, before

servicing, orwhen changing attachments, blades,

bits, cutters, etc., all tools should be discon-

nected.

18, REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from

tool before turning it on.

19. AVOID ACCIDENTAL STARTING. Don't carry

plugged-in tool with finger on switch. Be sure

switch is off when plugging in.

20. MAKE SURE YOUR EXTENSION CORD IS IN

GOOD CONDITION. When using an extension

cord, be su re touse one heavy enough tocarry the

currentyour product willdraw. An undersized cord

will cause a drop in line voltage resulting in loss of

power and overheating. A wire gage size (A.W.G.)

of at least 16 is recommended for an extension

cord 100 feet or less in length. A cord exceeding

1GOfeet is not recommended. If in doubt, use the

next heavier gage. The smaller the gage number,

the heavier the cord.

21. OUTDOOR USE EXTENSION CORDS. When

tool is used outdoors, use only extension cords

intended for use outdoors. Outdoor approved

cords are marked with the suffix W-A, for example

- SJTW-A or SJOW-A.

22. KEEP BLADES CLEAN AND SHARP. Sharp

blades minimize stalling and kickback.

Page 4

RULES FOR SAFE OPERATION (Continued)

23 KEEP HANDS AWAY FROM CUTTING AREA.

Keep hands away from blades. Do not reach

underneath work while blade is rotating, WARN-

ING: BLADES COAST AFTER TURN OFF.

24, NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of the motor couid ignite flam-

mable liquids, gases, or fumes.

25. INSPECT TOOL CORDS PERIODICALLY and if

damaged, have repaired byan authodzed service

facility. Stay constantly aware of cord location

and keep it well away from the rotating blade.

26, INSPECT EXTENSION CORDS PERIODICALLY

and replace ifdamaged.

27. KEEP HANDLES DRY, CLEAN, AND FREE

FROM OIL AND GREASE. Always use a clean

cloth when cleaning. Never use brake fluids,

gasoline, petroleum-based products, or any strong

solvents to clean your tool.

28 STAY ALERT AND EXERCISE CONTROL.

Watch what you are doing and use common

sense. Do not operate tool when you are tired, Do

not rush,

29. CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is damaged

should be carefully checked to determine that it

will operate propedy and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mount-

ing, and any other conditions that may affect its

operation. A guard or other part that is damaged

should be propady repaired or replaced by an

authorized service center.

30. DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

replaced by an authorized service center.

31, DO NOT OPERATE THIS TOOL WHILE UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

ANY MEDICATION.

32. GUARD AGAINST KICKBACK. Kickback oc-

curs when the blade stalls rapidly and the plate

joiner is ddven in the direction opposite blade

rotation. Release switch immediately ifblade binds

orjoiner stalls.

33. USE ONLY 4 INCH DIAMETER SPECIRED

BLADES. Do not use blades with incorrect size

holes. Never use b;ade washers or bolts that are

defective, incorrect, or not specified.

34. AVOID cUTnNG NAILS. Inspect forand remove

all nails from lumber before cutting,

35. NEVER touch the blade or other moving parts

dudng use,

36. NEVER start a tool when the blade is in contact

with the workpiece,

37, NEVER lay a tool down before the blade has

come to a compiota stop.

38. POLARIZED PLUGS. To reduce the dsk of elec-

tric shock, this equipment has a polarized plug

(one blade is wider than the other). This plug will

fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If

it stilldoes not fit, contact aqualified eioctdcian to

install the proper outlet. Do not change the plugin

any way.

39. When servicing use only Identlcst Craftsman

replacement parts.

40. SAVE THESE INSTRUCTIONS. Refer to them

freqLlently and use them to instruct others who

may use this tool. If you loan someone this tool,

loan them these instructions also.

m

which can resultIn imvere eye damage. Before beginning power fool opefat tan, stways wear |

safety goggles of msfotygllmsee with side shields and a full face shield when needed. We |

[_ The operation of any power tool can result in-foreign objects bstng thrOWn Into your eyes,

roeommend Wide Vision Safety MaSk for use over eyeglasses or standard safety glm I

with elde shields, avelloble at Sears Retell Stores.

Page 5

)

FEATURES

Your Plata Joiner has been designed for making fast, accurate, and simple plunge cutsin wood, etc. so that biscuitscan be

used to join twoor more boards together. When usedpmpedy and only for whet it isintended, thisversatgetoolwill give you

yearnof troubta-tree berforrnance, it isprofesslenally engleeered, but its ease of operaiton allewsthe amateur ta preducework

that is beautiful and precise.

DOUBLE INSULATED

This toot is double insulated. Double Insulationisa concept

insafely, inelectric powertools,whichelhelnatastheneedfor

the usual three wire grounded power cord end grounded

supply system. Wherever there is electric cutTentinthetool

there are twocomplete setsof insulationto protectthe user.

All exposed metal partsare isolatedfrominternalmetalmotor

components with protecting insulation.

IMPORTANT - Servicing of a tool with double insulation

requires extreme care and knowledge of the system and

should be performed only by a quaJifiedsePAceteChniCian.

For service we suggest you return the tool to your nearest

Searsstoreforrepair. Alwaysuseodgtsalfactoryredlacement

parts when servicing,

SWITCH

TO turn your plate joiner "ON", depress the switchtrigger,

Release switch trigger to turnyour plate joiner "OFF=,

5/8 HORSEPOWER MOTOR

Your plate joiner has a powerful 5/8horsepower motorwith

sutticientpowertohandle toughcuttingjobe. Itdevelops a no

load speed of 10,000 RPM,

CARBIDE TIPPED BLADE

Your plate joiner has an 8 tooth carbide tipped blade for

cuttingbiscuitstets,

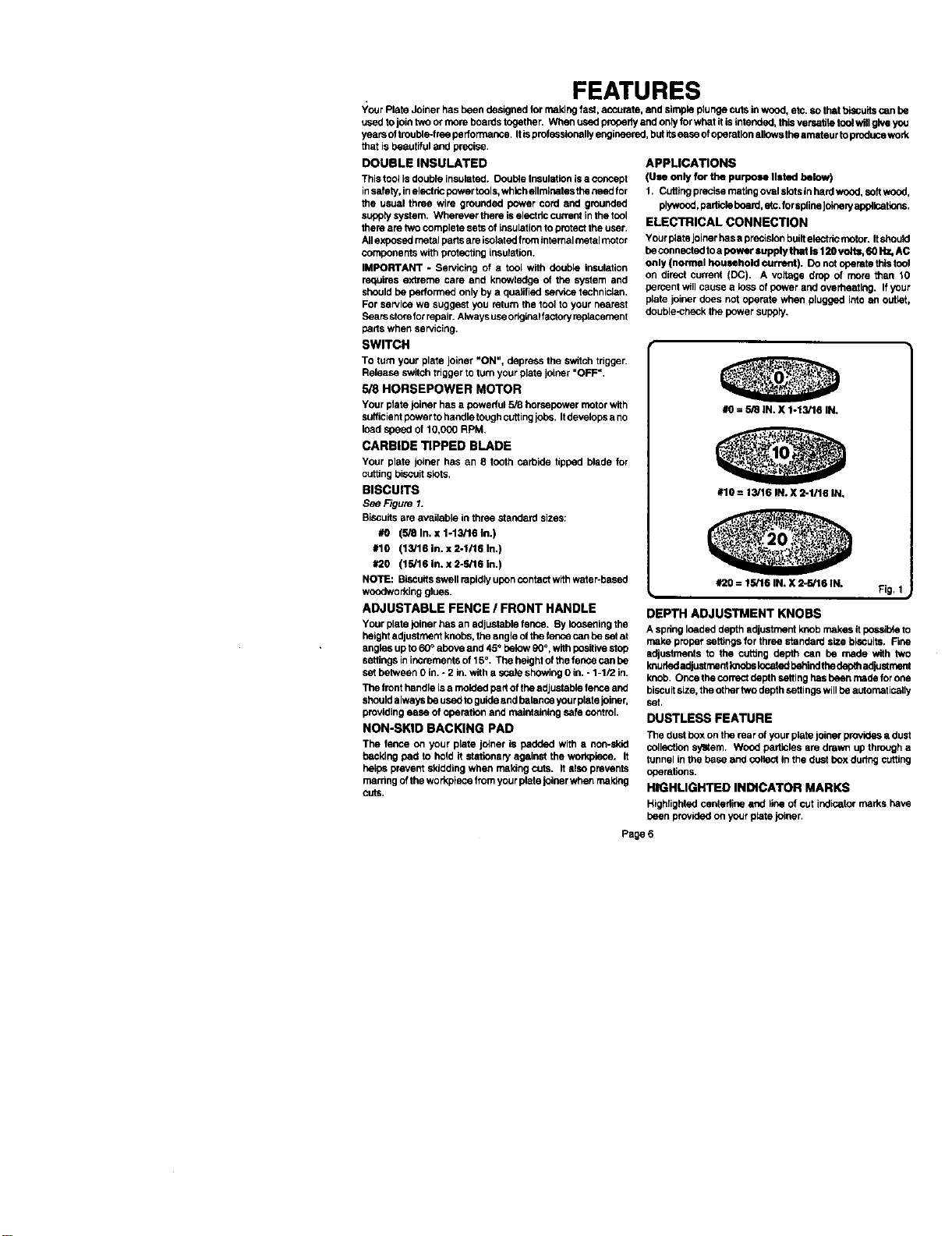

BISCUITS

S_ Figure 1.

Biscuitsare available in three standard sizes:

#O (5/8 In. x 1-13/16 th.)

#10 (13/16 In. x 2-1116 In.)

#20 (15/16 In. x 2-S/16 in.)

NOTE: Biscuitsswell rapidly uponcontact withwatar-based

woodworking glues•

ADJUSTABLEFENCE / FRONTHANDLE

Your plate joiner has an adjustable fence. By looseningthe

height adjustment knobs, the angle ofthe fence can be set at

angles upto 60_ above and45° belew90°, with positivestab

settingsin incrementsof15°. The height of the fence can be

set between 0 in. - 2 in.with a scale showing 0 in, - 1-1/2 in.

The front handle is a rnokled part of the adjustable fenceand

shouldalways be usedto guide and balanceyour plate joiner,

provlding ease of operation and maintaining safe control.

NON-SKID BACKING PAD

The fence on your plate joiner is padded with a non-skid

backing pad to hold it stationa_ against the workpisce. It

he_ps prever_ skidding when makingcuts. italso prevents

marring ofthe workplece fromyour plate joiner whenmaking

CutS.

APPLICATIONS

(Use only for the purpose listed below)

1. Cuttingprecisematleg oval slots in hard wood,softwood,

plywood,pattislaboard, ets.for spllee Jok_eP/edplisatlens.

ELECTRICAL CONNECTION

Yourplate joiner hasa precisionbuilhelactdcmotan Itshould

beconneuted to a p<>wersupply that ts 120 vofts, tt0Hz, AC

only {normal household current). Donut operate this taol

on directcurrent (DC). A voltage drop of more than 10

percent willcause a less ofpower and overheating. If your

plate joiner does notoperate when plugged into an outlet,

double-check the power supply.

#O: 5/8 tN. X 1-13/16 IN.

#10 = 13/16 IN. X 2-1116 IN,

#20 : 15/16 IN. X 2-rd16 IN.

DEPTH ADJUSTMENT KNOBS

A springloaded depth adjustment knob makes iteds_ble to

make proper settit;gs for three standard size biscuits. Fine

adjustments to the cutting depth can be made with two

knuhededjust mentknobskicated behindthedepthacrlustment

knob, Oncethe correct depthsetting has been made for one

biscuitsize, the othertwo depth settingswill be automatically

set.

DUSTLESS FEATURE

The dust boxon the rear of yourplate joiner provides a dust

collection sylttem. Wood particles are drawn up through a

tunnel in the base and collect inthe dust box duitng cutting

operations.

HIQHLIGHTED INDICATOR MARKS

Highlightedcentadine and line of cut indicatormarks have

been providedon your plate joiner.

Page 6

Fig. I

FEATURES

KNOW YOUR PLATE JOINER

,_e Fibre 2.

Your plate Joinerhas been shipped €ompletely as_mbled end ready for use. Inspect it carefullyto make sure no breakage

or damage has occurred dudng shipping, ff any parts are damsged or missing, contact your local Seam store or Sears

authorized service center to ob(aln replacement parts before attempting tooperate your plate J_r_n

ThedU6tboxisalsolnstall6dontherearoftooL Its usewillhelpkeeptheworkareaclean. For mostefficient pick.upof wood

particles, emptydust box often.

8efo_m8ttempt_g to use eny toolfamiliarize yourself withall operating features andsafety requirements.

_r_l_ CENTERUNE I UNE SWITCH TRIGGER REAR HANDLE

Page 7

ADJUSTMENTS

DEPTH OF CUT ADJUSTMENTS

Your plate joiner can be adjusted to three standard cutting

depths to accommodate three standard size biscuits-- #0,

#10, and #20. Adjustments are made by engaging slots o_

depth adjustmentknobwith tabs onrear base assembly. For

exsmpta, when using a #0 size biscuit, rotate the depth

adjustment knobto the slot marked 0. When usinga #10 size

biscuit,rotate the depth adjustment knobto the slotmarked

10, and when using a #20 size biSCUitrotate the depth

adjustment knob tothe slot marked 20,

TO SET DEPTH ADJUSTMENT KNOB

1. Unplug your plata joiner.

_,_ ADJUSTMENT

DEPTH

KNOB

TABS

2. Pull knuhad adjustment knobs in the direction of the

arrow shown in figure 3. NOTE: Knobs are spdng

loaded, therfore puIllogthem in thedirectionofthearrow

shown putspressure onthe spring and reloases pres-

sure from thedepth adjustment knob.

3. Rotate depth adjustment knob until desired slotsetting

aligns with tabs on rear base assembly-- 0, 10, or 20.

4. Next release knurled adjustment knob_ applying pres-

sure from the sprthg on depth adjustment knob.

Make a testcut ina scrap piece of wo_d. Fit thecorrect size

biscuitloto biscuitslot. Ifbiscuitslnt istoodeep ortooshallow,

fine adjustmentsto the depth setting can bemade by loosen-

ing rear adjustment knob and making fine adjustments with

thefrontadjustment knob, Turningtrent knobforwardwiltcut

shallow biscuitslots, Turning front knob backwards will cut

deeper biscuitslots. The biscuitslot should bedeep enough

to allow slightly morethan one-half ofthe biscuitintotheslot.

This extraroom allowsforproperalignmentofthe woodbslng

joined.

TO MAKE FINE ADJUSTMENTS

See Figure 4.

1. Unplug your plate Joiner.

2. Loosenrear knuded adjustmentknob. This knob isused

as alocknutorjam nut only, Loosenby twistingit Inthe

opposite directionaway from frontknob.

3. Turn front knurled adjustment knob forward for a more

shallowcot, or backwards fora deeper cut.

4. Once desired depth ofcut is reached, held frontknobso

thatitwill not move out of adjustment, Next,tightenrear

knobagainst front knob,

5. Re_heck depth setting by making a test cut in a scrap

piece ofwood. Also periodicallycheck depth settingfor

acouracy,

PULL AND HOLD TO

ROTATE OEPTH

ADJUSTMENT KNOB

Page 8

KNOBS

ROTATETO

DESIRED sE'nlNG

IO, OR 20

TURN FORWARD

FOR SHALLOW

BISCUIT SLOTS

REAR BASE

ASSEMBLY

Fig. 3

Fig. 4

Loading...

Loading...