Craftsman 31517500 Owner’s Manual

ISears I

OWNERS

MANUAL

MODEL NO

315.17500

CAUTION:

Read Rules for

Safe Operation

and Instructions

Careft_lly

SAVE THIS

MANUAL FOR

FUTURE REFERENCE

CRAFTSMAN

ELECTRONIC

ROUTER

DOUBLE INSULATED

Introduction

Operation

Maintenance

Repair Parts

Designed exclusively for and sold only by

SEARS, ROEBUCK AND CO., Dept. 698/731A, Sears Tower, Chicago, IL 60684

612547-213 PRfNTEtj (N U.S.A.

4.64

®

FULL ONE YEAR WARRANTY ON CRAFTSMAN ELECTRONIC ROUTER

If this Craftsman Electronic Router fails to give complete satisfaction within one year from the date

of purchase, RETURN IT TO THE NEAREST SEARS STORE THROUGHOUT THE UNITED STATES

and Sears will repair it, free of charge.

If this router is used for commercial or rental purposes this warranty applies for only 90 days from the

date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

SEARS, ROEBUCK AND CO.

DEPT. 698/731A

SEARS TOWER

CHICAGO, IL 60684

INTRODUCTION

DOUBLE INSULATION Is a concept in safety, In elec-

trlc power tools, which eliminates the need for the

usual three wire grounded power cord and grounded

sup_)ly system. Wherever there is electric current in

the tool there are two complete sets of insulation to

protect the user. All exposed metal parts are isolated

from the internal metal motor components with pro-

tecting Insulation.

GENERAL

Your electronic router is a versatile woodworking

tool which will give you years of trouble-free perfor-

mance. It is engineered with the professional in

mind, but its ease of operation allows the amateur to

produce work which is beautiful and precise. Your

new router has advanced electronic features which

are designed to assist you In getting the maximum

use from your router. By making "the proper selec-

tions on the front panel, your router can be adjusted

to your specific routing needs. This eliminates much

of the guess work previously needed to perform a

glven job. Both the experienced and inexperienced

router users benefit, obtaining professional like

results with fewer job errors.

The electronic feature of your router introduces the

flexibility of adjusting the motor speed to the re-

quired job Conditions. The front panel can be set ac-

cording to the approximate cutter diameter you will

be using and to the hardness of the material being

cut. Your router will then run smoothly up to the

RULES FOR SAFE OPERATION

WARNING -- DO NOT ATrEMPT TO OPERATE UNTIL YOU HAVE READ THOROUGHLY AND UNDERSTAND

COMPLETELY ALL INSTRUCTIONS, RULES, ETC. CONTAINED IN THIS MANUAL. FAILURE TO COMPLY CAN

RESULT IN ACCIDENTS INVOLVING FIRE, ELECTRIC SHOCK, OR SERIOUS PERSONAL INJURY. SAVE

OWNERS MANUAL AND REVIEW FREQUENTLY FOR CONTINUING SAFE OPERATION, AND INSTRUCTING

POSSIBLE THIRD.PARTY USER.

IMPORTANT -- Servicing of a tool with double in-

sulatlon requires extreme care and knowledge of the

system and should be performed only by a qualified

service technician. For service we suggest you

return the tool to your nearest Sears Store for repair.

Always use original factory replacement parts when

servicing.

desired speed and continue to maintain this speed

while under various loads.

Also, the best cuts are made when the cutter is fed

through the material at the proper rate. Your elec-

tronic router has "too slow" and "too fast" In-

dicators that will flash if the cutter is being fed too

slow or too fast. When possible, you should make

practice cuts on a scrap piece of wood to get a

"feel" of how fast to "feed" your router.

If your router should become overloaded or jammed,

then both the "too stow'" and "too fast" indicator

lights will begin flashing. If the overload condition Is

not corrected, your router will shut off. This helps

prevent the possibility of damage to the router. To

restart, release the trigger switch to its full "off"

position, wait until the indicator lights stop flashing,

then turn your router on. WARNING: DO NOT

OVERLOAD YOUR ROUTER REPEATEDLY. ABUSE

OF THIS NATURE WILL GREATLY REDUCE THE

LIFE OF YOUR ROUTER.

READ ALL INSTRUCTIONS

1. KNOW YOUR POWER TOOL -- Read owner's manual carefully, Learn its ap-

pllcatlons and limitations as well as the specific potential hazards peculiar to

this tool.

2. GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING BODY CONTACT

WITH GROUNDED SURFACES. For example: Pipes, radiators, ranges, refrig-

erator enclosures.

3. KEEP GUARDS IN PLACE and in working order.

4. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5. AVOID DANGEROUS ENVIRONMENT. Don't useiP°werIt, tool in clamp or wet

locations or expose to rain. Keep work area well .

Page 2

RULES FOR SAFE OPERATION (Continued)

6. KEEP CHILDREN AWAY. All visitors should be kept safe distance from work

area. Do not let visitors contact tool or extension cord.

7. STORE IDLE TOOLS. When not In use, tools should be stored in dry, high or

locked-up place -- out of reach of children.

8. DON'T FORCE TOOL. It will do the job better and safer at the rate for which it

was designed.

9. USE RIGHT TOOL. Don't force small tool or attachment to do the job of a heavy

duty tool. Don't use tool for purpose not intended - for example - Don't usa

a circular saw for cutting tree limbs or logs.

10. WEAR PROPER APPAREL. No loose clothing or jewelry to get caught in moving

parts. Rubber gloves and footwear are recommended when working outdoors.

Also, wear protective hair covering to contain long hair.

11. USE SAFETY GLASSES with all tools. Also face or dust mask if' cutting

operation Is dusty.

12. DON'T ABUSE CORD. Never carry tool by cord or yank it to disconnect from

receptacle. Keep cord from heat, oil and sharp edges.

13. SECURE WORK. Use clamps or a vise to hold work. It's safer than using your

hand and it frees both hands to operate tool.

14. DON'T OVERREACH. Keep proper footing and balance at all times.

15. MAINTAIN TOOLS WITH CARE. Keep tools sharp at all times, and clean for best

and safest performance. Follow instructions for lubricating and changing ac-

cessories.

16. DISCONNECT TOOLS. Whennot in use, before servicing_ or when changing at-

tachments, blades, bits, cutters, etc., all tools should be disconnected.

17, REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are removed from tool before turning it on.

18. AVOID ACCIDENTAL STARTING. Don't carry piugged-m tools with finger on

switch. Be sure switch is off whenplugging in.

19. OUTDOOR USE EXTENSION CORDS.When tool is used outdoors, use only

extension cords suitable for use outdoors, Outdoor approved cords are marked

with the suffix W-A, for example -- SJTW-A or SJOW-A.

20. KEEP CUTTERS CLEAN AND SHARP. Sharp cutters minimize stalling and kick-

back.

21. KEEP HANDS AWAY FROM CUTTING AREA. Keep hands away from cutters. Do

not reach underneath Work while cutter is rotating. Do not attempt to remove

material while cutter is rotating,

22. NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal sparking of the motor

could ignite fumes.

23. INSPECT TOOL CORDS PERIODICALLY and if damaged, have repaired at your

nearest Sears Repair Center.

24. INSPECT EXTENSION CORDS PERIODICALLY and replace if damaged.

25. KEEP HANDLES DRY, CLEAN, AND FREE FROM OIL AND GREASE. Always

use aclean cloth when cleaning. Never use brake fluid, gasoline, or any Strong

solvents to clean your tool.

26. STAY ALERT. Watch what you are doing and use common sense. Do not op-

erate tool whenyou are tired,

27. CHECK DAMAGED PARTS. Before further use of the tool, a guard or

other part that is damaged should be carefully checked to determine that it will

operate properly and perform its intended function. Check for alignment of mov-

ing parts, binding of moving parts, breakage of parts, mounting, and any other

conditions that may affect its operahon. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service center unless

indicated elsewhere In this instruction manual.

28. DO NOT USE TOOL I1=SWITCH DOES NOT TURN IT ON AND OFF. Have defect-

ire switches replaced by authorized 'service center.

29. Inspect for and remove all hails _from lumber before routitig

30. DRUGS, ALCOHOL, MEDICATION. Do not operate tool while under- the influ-

ence of drugs, alcohol, or any medication.

Page 3

-- - + ] , .u+ i1+1

nuL,-u PUR SAFE OPERATION (C0ntinu_l)

31. DO,NO, T USE TOOL UNDER ':BROWN:.0_T?_ORi_OTH_OW_vQLTAGE CON:

ul/Iu.P_. _lSO, oo not use wsth any deviC_!t'_÷('-_,l;_!_:i_-i_01wer supply

voltage to change. " ........... .......... _ "

32. SAVE THESE INSTRUCTIONS.

.... ,., ,,, - ,.. _: _: _. . . . ...

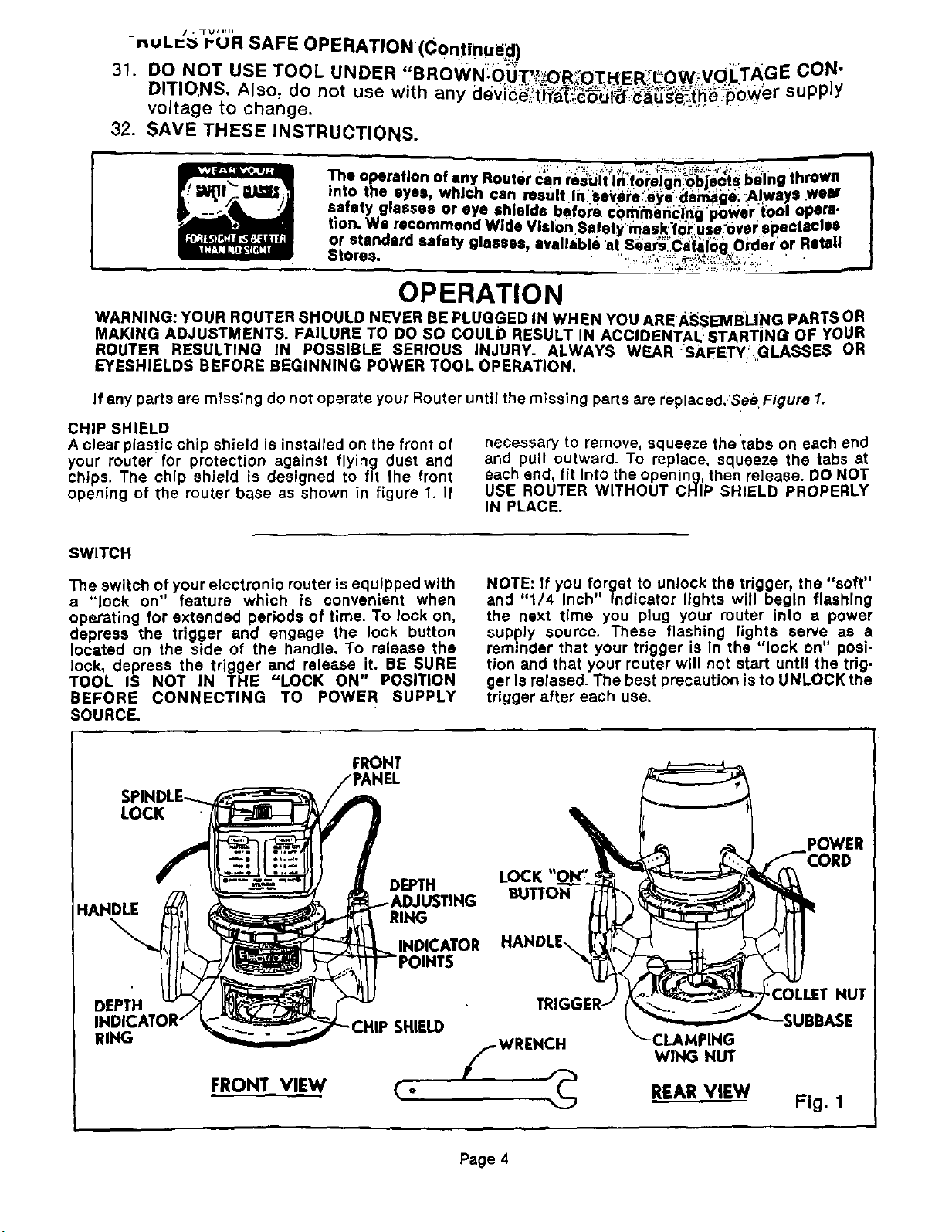

.Theoperation of any Router can result In forelg'n::Ob[eots being thrown

rote the.eyes, which can result Ih _eve_e:_;e:_ja_ge!:Alway$ wear

safety glasses or eye shields before €omh_encl_g _wer tool opera.

lion. we. recommend Wide Vlsl0n Safety maskforluse:_Vai; spectacles

or stanaara safety glasses, available at Si_al;_€_._l_g_O_derOr Retail

_tOres. ..• • "..,.,:_i.-.::_:.:_._i_i_+_!_%_!_,:y_,:... ' .

OPERATION

WARNING: YOUR ROUTER SHOULD NEVER BE PLUGGED IN WHEN YOU ARE._P_SEMBLING PARTS OR

MAKING ADJUSTMENTS. FAILURE TO DO SO COULD RESULT IN ACCIDENTAL STARTING OF YOUR

ROUTER RESULTING IN POSSIBLE SERIOUS INJURY. ALWAYS WEAR SAFF_TY :GLASSES OR

EYESHIELDS BEFORE BEGINNING POWER TOOL OPERATION.

If any parts are missing do not operate your Router until the missing parts are replaced,See Figure 1.

CHIP SHIELD

A clear plastic chip shield is installed on the front of

your router for protection against flying dust and

chips. The chip shield is designed to fit the front

opening of the router base as shown in figure 1. If

necessary to remove, squeeze the tabs on each end

and pull outward. To replace, squeeze the tabs at

each end, fit Into the opening, then release. DO NOT

USE ROUTER WITHOUT CHIP SHIELD PROPERLY

IN PLACE.

SWITCH

The switch of your electronic router is equipped with

a "lock on" feature which is convenient when

operating for extended periods of time. To lock on,

depress the trigger and engage the lock button

located on the side of the handle. To release the

lock, depress the trigger and release it. BE SURE

TOOL IS NOT IN THE "LOCK ON" POBITION

BEFORE CONNECTING TO POWER SUPPLY

SOURCE.

FRONT

LOCK

DEPTH LOCK

HAHDLE

DEPTH

lUSTING BUTTON

RING

NOTE: If you forget to unlock the tdgger, the "soft"

and "1/4 Inch" Indicator lights will begin flashing

the next time you plug your router into a power

supply source. These flashing lights serve as a

reminder that your trigger is In the "lock on" posi-

tion and that your router will not start until the trig-

ger is relased. The best precaution is to UNLOCK the

trigger after each use.

POWER

_.COLLET NUT

RING

FRONT_VIEW

-CLAMPING

WING NUT

REAR VIEW

Fig. 1

Page 4

OPERATION

KNOW YOUR ELECTRONIC ROUTER

Before attempting to usa your router, familiarize

yourself with all operating features, electronic

features, and safety requirements. See Figure

/.WARNING: DO NOT ALLOW FAMILIARITY WITH

YOUR ROUTER TO MAKE YOU CARELESS.

REMEMBER THAT A CARELESS FRACTION OF A

SECOND IS SUFFICIENT TO INFLICT SEVERE IN.

JURY.

We suggest that you practice with the electronic

features of your router before installing a cutter and

making cuts in wood. CHECK THE FOLLOWING

BEFORE CONNECTING YOUR ROUTER TO POWER

SUPPLY:

1. Make sure the spindle lock is in the unlocked

position.

2. Make sure the trigger is not In the "lock on" posi-

tion.

3. Make sure there Is not a cutter In the collet.

4, Make sure the coIlet is inside the subbase.

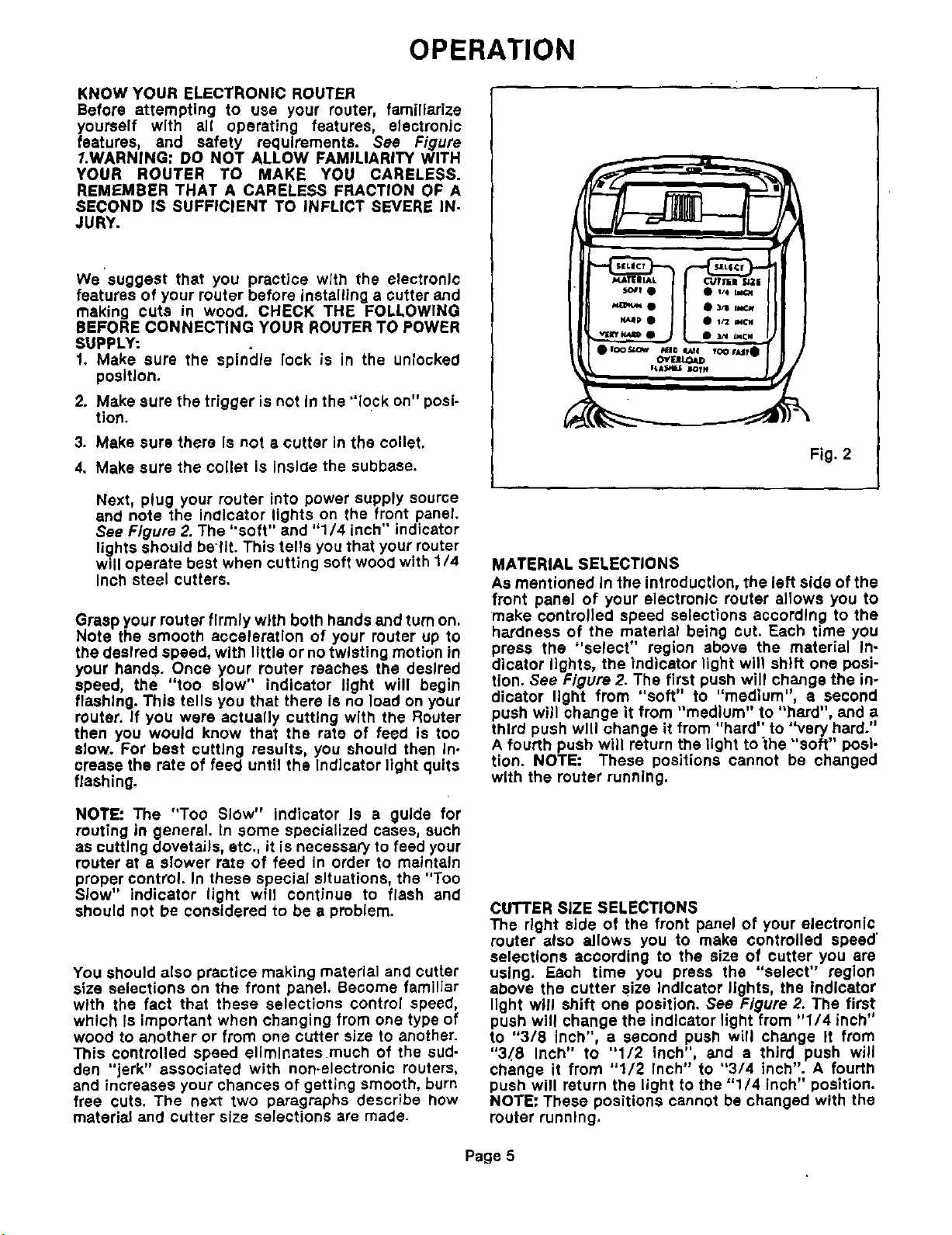

Next, plug your router into power supply source

and note the indicator lights on the front panel.

See Figure 2. The "soft" and "1/4 inch" indicator

lights should belit. This tells you that your router

will operate best when cutting soft wood with 1/4

Inch steel cutters.

Grasp your router firmly with both hands and turn on.

Note the smooth acceleration of your router up to

the desired speed, with little or no twisting motion in

your hands. Once your router reaches the desired

speed, the "too slow" indicator light will begin

flashing. This tells you that there is no load on your

router. If you were actually cutting with the Router

then you would know that the rate of feed is too

slow. For best cutting results, you should then In-

crease the rate of feed until the indicator light quits

flashing.

Fig. 2

MATERIAL SELECTIONS

As mentioned In the introduction, the left side of the

front panel of your electronic muter allows you to

make controlled speed selections according to the

hardness of the material being cut. Each time you

press the "select" region above the material In-

dicator lights, the indicator light will shift one posi-

tion. See Figure 2. The first push will change the in-

dicator light from "soft" to "medium", a second

push will change it from "medium" to "hard", and a

third push will change it from "hard" to "very hard."

A fourth push will return the light tothe "soft" posi-

tion. NOTE: These positions cannot be changed

with the router running.

NOTE: The "Too Slow" indicator Is a guide for

routing in general. In some specialized cases, such

as cutting dovetails, etc., it is necessary to feed your

router at a slower rate of feed in order to maintain

proper control. In these special situations, the "Too

Slow" indicator light will continue to flash and

should not be considered to be a problem.

You should also practice making material and cutter

size selections on the front panel. Become familiar

with the fact that these selections control speed,

which Is important when changing from one type of

wood to another or from one cutter size to another.

This controlled speed eliminates rnueh of the sud-

dan "jerk" associated with non-electronic routers,

and increases your chances of getting smooth, burn

free cuts. The next two paragraphs describe how

material and cutter size selections are made.

CUTTER SiZE SELECTIONS

The right side of the front panel of your electronic

router also allows you to make controlled speed'

selections according to the size of cutter you are

using. Each time you press the "select" region

above the cutter size Indicator lights, the indicator

light will shift one position. See Figure 2. The first

push will change the indicator light from "1/4 inch"

to "3/8 inch", a second push will change It from

"3,_8 Inch" to "1/2 inch", and a third push will

change it from "1/2 Inch" to °'3/4 inch". A fourth

push will return the light to the "1/4 inch" position.

NOTE: These positions cannot be changed with the

router running.

Page 5

Loading...

Loading...