Craftsman 31511782 Owner’s Manual

OWNERS

MANUAL

MODEL NO.

315.11782

CAUTION:

Read Rules for

Safe Operation

and instructions

Carefully

,@

4 INCH ELTSANDER

WRTH DUST PICK-UP

DOUBLE INSULATED

Introduction

Operation

Maintenance

Repair Parts

SEARS, ROEBUCK AND CO_, Chica.qo, IL 60684 U.S.A. and SIMPSONS-SEARS LIMITED, Toronto, Canada

2-620263-965

7-78 PRIt.IT[,D IN L__,_,

Designed exclusively for and sold onfy by

FULL ONE YEAR WARRANTY ON CRAFTSMAN BELT SANDER

If this Craftsman Belt Sander fails to give complete satisfaction within one year from the date of

purchase, RETURN IT TO THE NEAREST SEARS STORE THROUGHOUT THE UNITED STATES and

Sears will replace it, free of charge.

If this belt sander is used for commercial or rental purposes this warranty applies for only 90 days

from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

SEARS, ROEBUCK AND CO.

BSC 41 _ 3

SEARS TOWER

CHICAGO, 1L 60684

gNTRODUCTION

DOUBLE INSULATION is a concept in safety, in

etectric power tools, which eliminates the need for

the usual three wire grounded power cord and

grounded supply system. Wherever there is electric

current in the tool there are two complete sets of

insulation to protect the user_ All exposed metal

parts are isolated from the internal metal motor

components with protecting insulation..

IMPORl'ANT_Servicing of a tool with double in-

sulation requires extreme care and knowledge of the

system and should be performed only by a qualified

service technician.. For service we suggest you

return the tool to your nearest Sears Store for repair.

Always use original factory replacement parts when

servicing.

RULES FOR SAFE OPERATION

1. KNOW YOUR POWER TOOL _ Read owner's manual carefulty,_ Learn its applications and limitations

as well as the specific potential hazards peculiar to this tool.

2, GROUND ALL TOOLS -- UNLESS DOUBLE-INSULATED. If tool is equipped with three-prong

plug, it should be plugged into a three-hole electrical receptacle, tf adapter is used to accommodate

two-prong receptacle, the adapter wire must be attached to a known ground. (Usually the screw

securing receptacle cover plate)_ Never remove third prong.

3. KEEP GUARDS IN PLACE and in working order.

4 KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5. AVOID DANGEROUS ENVIRONMENT° Don't use power toot in damp or wet locations or expose to

r&in. Keep work area well tit.

6 KEEP CHILDREN AWAY. Al! visitors should be kept safe distance from work area.

7. STORE IDLE TOOLS. When not in use, tools should be stored ;n dry, high or-locked-up place_out of

reach of children_

8_ DON'T FORCE TOOL. it will do the job better and safer at the rate for which it was designed.

9. USE RIGHT TOOL. Don't force small tool or attachment to do the job of a heavy duty toot..

10 WEAR PROPER APPAREL. No loose clothing or jewetry to get caught in moving parts_ Rubber gloves

and footwear are recommended when working outdoors,

11 USE SAFETY GLASSES with most tools. Also face or dust mask if cutting operation is dusty_

12 DON'T ABUSE CORD. Never carry toot by cord or yank it to disconnect from receptacle. Keep cord

from heat, oil and sharp edges°

!3. SECURE WORK. Use clamps or a vise to hold work it's safer than using your hand and it frees both

hands to operate tool

14 DON'T OVERREACH. 'Keep proper footing and balance at all times..

15 MAINTAIN TOOLS WITH CARE. Keep tools sharp at all times, and clean for best and safest per-

formance. Follow instructions for lubricating and changing accessories.

16 DISCONNECT TOOLS. When not in use, before servicing; when changing attachments, blades, bits,

cutters, etc.

17 REMOVE ADJUSTING KEYS AND WRENCHES, Form habit of checking to see that keys and ad-

justing wrenches are removecf from tool before turning it on

!8 AVOID ACCIDENTAL STARTING. Don't carry plugged-in tools with finger on switch Be sure switch

is off when plugging in.

19 OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension cords suitable

for use outdoors and so marked

Your Craftsman 4-inch Dustless Belt Sander is suitable

for coarse, medium and fine sanding of wood, metals,

plastics and other materials. It is ideal when used for

smoothing rough boards, chamfering, rounding edges

and many other general sanding applications. It is ideal

for refinishing large pieces of furniture, stairs and

other large surfaces. Its balanced design makes it easy

to use.

The built-in dust collection system will remove most of

the sanding dust from the work and eliminate the dust

in the air -- usually associated with power sanding°

SWITCH

A trigger switch controls operation of the Sander',

The trigger switch can be locked on for continuous

operatiom To lock, pull trigger, press lock button

inward, and release trigger, Pull trigger and release

to stop°

Page 2

OPERATION

PREPARING FOR OPERATION

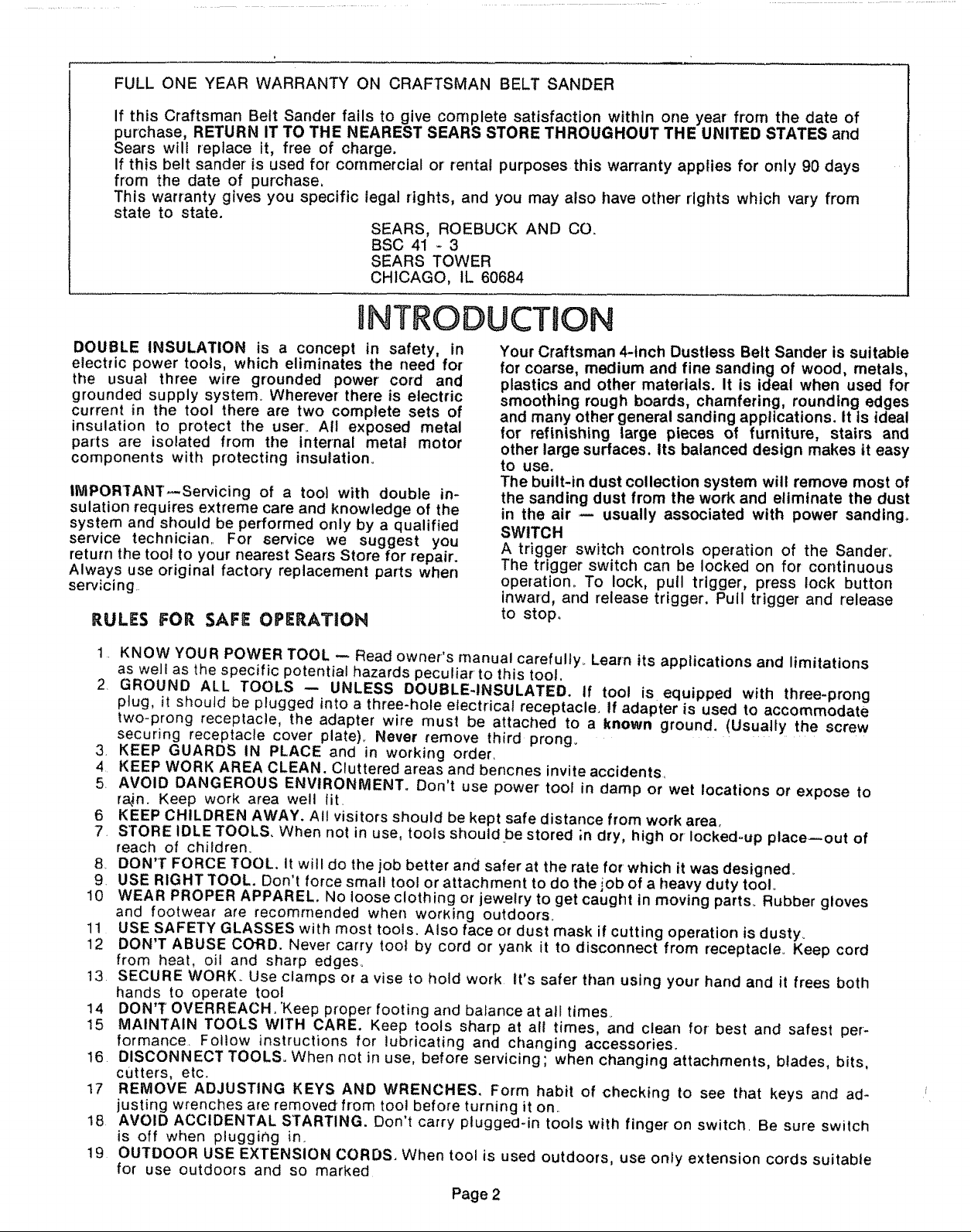

Your Sander is equipped with its own built-in auxiliary handle

located at the front of the unit, This handle allows for two-

hand use which wilt aid in maintaining complete control and

keeping sanding area level with work piece (See Fig, 1),

Selecting the correct size and type sanding belt is an extremely

important step in achieving a high quality sanded finish,.

Aluminum oxide silicone carbide and other synthetic abrasives

are best for power sanding.

In general, coarse grit will remove the most material and finer

grit will produce best finish in all sanding operations, The

condition of the surface to be sanded will determine which grit

belt will do the job, If the surface is rough, start with a coarse

grit belt sanding until surface is uniform., Medium grit belt may

then be used to remove scratches left by the coarser belt and

,\

finer grit belt used for finishing of the surface. Always con-

tinue sanding with each grit belt until surface is uniform°

Fig, I

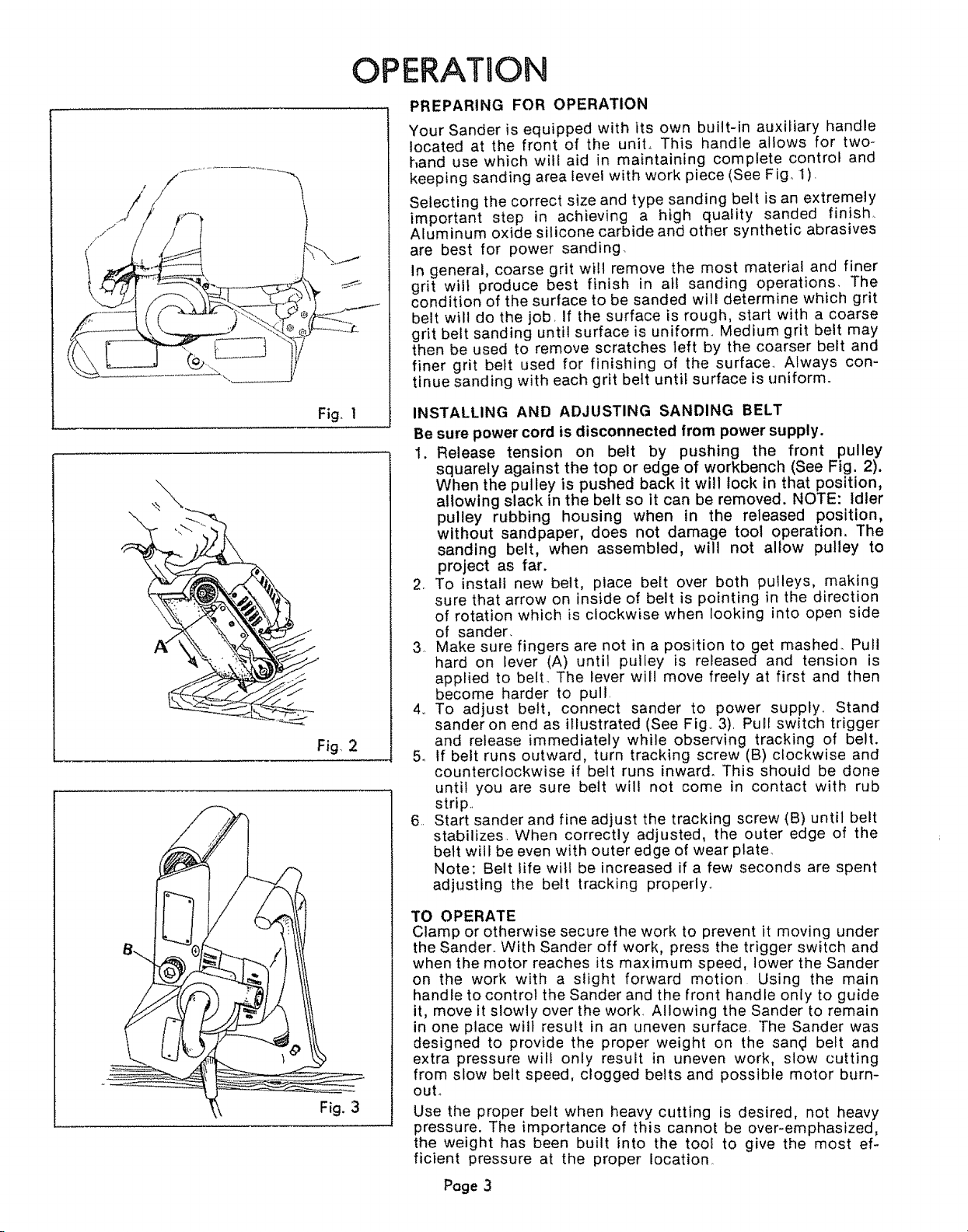

Fig, 2

INSTALLING AND ADJUSTING SANDING BELT

Be sure power cord is disconnected from power supply.

1. Release tension on belt by pushing the front pulley

squarely against the top or edge of workbench (See Fig. 2).

When the pulley is pushed back it will lock in that position,

allowing slack in the belt so it can be removed. NOTE: Idler

pulley rubbing housing when in the released position,

without sandpaper, does not damage toot operation. The

sanding belt, when assembled, will not allow pulley to

project as far.

2, To install new belt, place belt over both pulleys, making

sure that arrow on inside of belt is pointing in the direction

of rotation which is clockwise when looking into open side

of sander.

3,. Make sure fingers are not in a position to get mashed. Pull

hard on lever (A) until pulley is released and tension is

applied to bett. The lever will move freely at first and then

become harder to pull

4,, To adjust belt, connect sander to power supply,, Stand

sander on end as illustrated (See Fig,, 3), Pull switch trigger

and release immediately while observing tracking of belt.

5o tf belt runs outward, turn tracking screw (B) clockwise and

counterclockwise if belt runs inward. This should be done

until you are sure belt will not come in contact with rub

strip,

6 Start sander and fine adjust the tracking screw (B) until belt

stabilizes. When correctly adjusted, the outer edge of the

belt will be even with outer edge of wear plate,

Note: Belt life will be increased if a few seconds are spent

adjusting the belt tracking properly°

TO OPERATE

Clamp or otherwise secure the work to prevent it moving under

the Sander., With Sander off work, press the trigger switch and

when the motor reaches its maximum speed, lower the Sander

on the work with a slight forward motion Using the main

handle to control the Sander and the front handle only to guide

it, move it slowly over the work, Allowing the Sander to remain

in one place will result in an uneven surface, The Sander was

designed to provide the proper weight on the sand belt and

extra pressure wil! only result in uneven work, stow cutting

from slow belt speed, clogged belts and possible motor burn-

ouL

Use the proper belt when heavy cutting is desired, not heavy

pressure. The importance of this cannot be over-emphasized,

the weight has been built into the tool to give the most ef-

ficient pressure at the proper location.

Poge 3

Loading...

Loading...