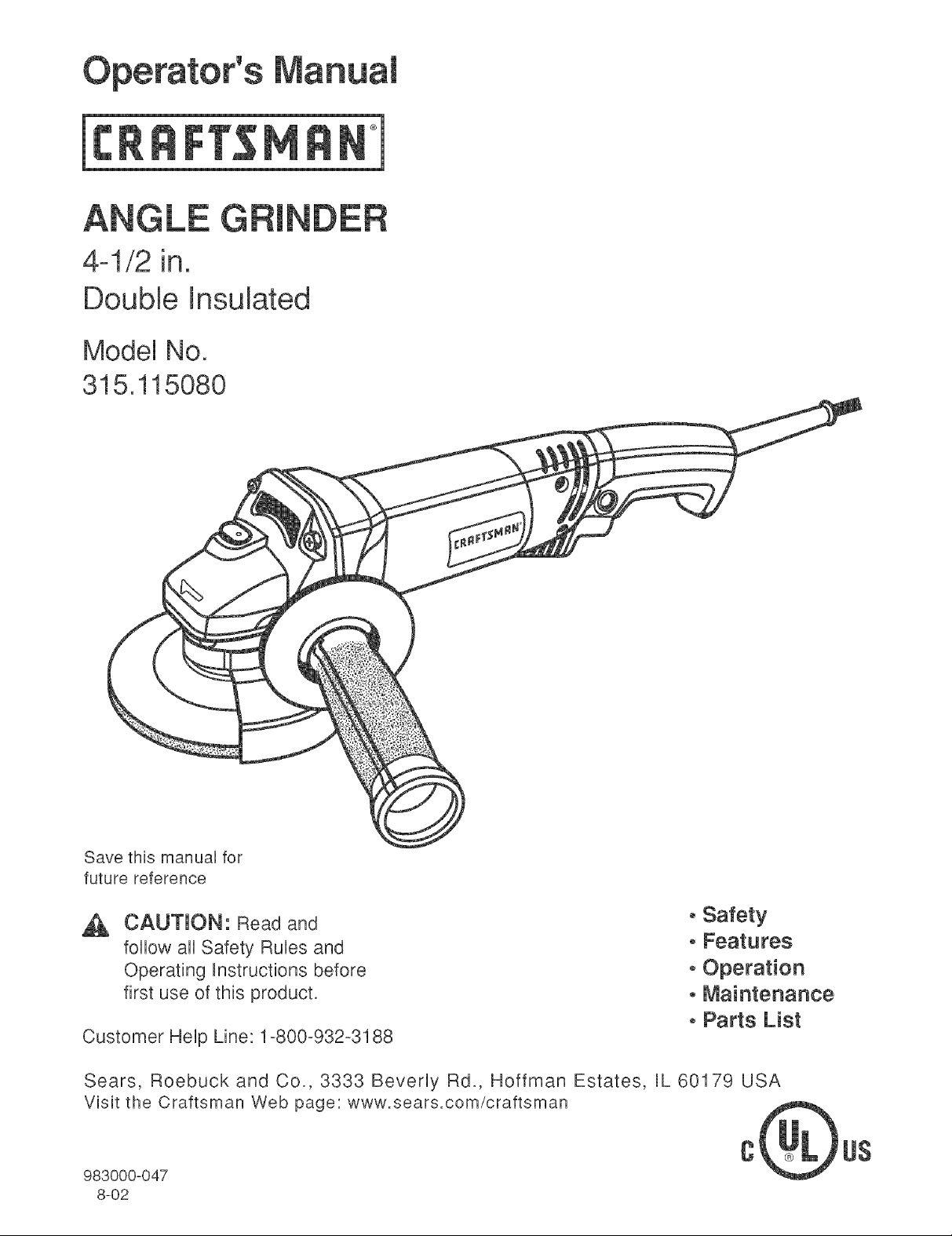

Craftsman 315115080 Owner’s Manual

i

T

G

4-1/2 in.

Double Insulated

Model No.

315.115080

Save this manuaU for

future reference

CALJ'[ION: Read and

follow aH Safety RuUesand

Operating hstructions before

first use of this product.

Customer HeUp Line: 1-800-932-3188

Sears, Roebuck and Co., 3333 Bevedy Rd., Hoffman Estates, RL60179 USA

Visit the Craftsman Web page: www.sears.com/craftsman

983000-047

8-02

oSafety

oFeatures

oOperation

oMaintenance

oParts List

US

FULL ONE YEAR WARRANTY ON CRAFT=_MRN ANGLE GRINDER

Ufthis I:RRF'[$MRN Angb Grinder falls to give compbte satisfaction within one year from the date of purchase,

RETURN IT TO THE NEAREST SEARS STORE IN THE UNITED STATES, and Sears will replace it, free of

charge.

Ufthis _:RAFTSMRN Angle Grinder is used for commercial or rental purposes, this warranty applies for only 90

days from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

Your angle grinder has many features for making

grinding operations more pleasant and enjoyable.

Safety, performance and dependability have been

given top priority in the design of this angle grinder

making it easy to maintain and operate.

Look for this symbol to point out important safety precautions, it means attention!!!

Your safety is involved.

WARNING: The operation of any angle grinder can result in foreign objects being thrown

into your eyes, which can result in severe eye damage. Before beginning power tool

operation, always wear safety goggles or safety glasses with side shields and a full face

shield when needed. We recommend Wide Vision Safety Mask for use over eyeglasses or

standard safety glasses with side shields, available at Sears Retail Stores. Always wear eye

protection which is marked to comply with ANSI Z87.1.

_ CAUTmON: Carefully read through this entire

operator's manual before using your new angle

grinder. Pay close attention to the Rubs for Safe

Operation, Warnings and Cautions. If you use

your angle grinder properly and only for what it is

intended, you will enjoy years of safe, reliable

service.

WARNING:ReadandunderstandaH

instructions.FailuretofollowaHinstructions

Hstedbebw,mayresuUtineUectricshock,fire

and/orseriouspersonaUinjury.

WORKAREA

[] Keepyourworkareacleanandwet1tit.CUuttered

benchesanddarkareasinviteaccidents.

[] Donotoperatepowertoolsinexplosiveatmo-

spheres,suchasinthepresenceofflammable

liquids,gases,or dust.PowertooBmaycreate

sparkswhichmayignitethedustorfumes.

[] Keepbystanders,children,andvisitorsaway

whileoperatinga powertool.Distractionscan

causeyoutolosecontrol.

ELECTRICALSAFETY

[] Doubteinsulatedtoolsareequipped with a

poJadzed plug (one blade is wider than the

other). This plug will fit in a poJarized outlet onty

one way. if the ptug does not fit fully in the

outJet, reverse the pJug. If it still does not fit,

contact a qualified electrician to install a polar-

ized outtet. Do not change the plug in any way.

Double insulation _'_ eliminates the need for the

three-wire grounded power cord and grounded

power supply system.

[] Avoid body contact with grounded surfaces, such

as pipes, radiators, ranges, and refrigerators.

There is an increased risk of electric shock if your

body is grounded.

[] Don't expose power tools to rain or wet condio

tions. Water entering a power tool will increase the

risk of electric shock.

[] Do not abuse the cord. Never use the cord to carry

the tooJs or pull the ptug from an outlet. Keep cord

away from heat, oH, sharp edges, or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electric shock.

[] When operating a power tooJ outside, use an out-

door extension cord marked "W-A" or "W'. These

cords are rated for outdoor use and reduce the risk of

electric shock.

PERSONAL SAFETY

[] Stay abrt, watch what you are doing and use

common sense when operating a power tool

Do not use tooJ while tired or under the influo

ence of drugs, alcohoJ, or medication. A moment

of inattention while operating power tools may

result in serious personal injury.

[] Dress properly. Do not wear Joose clothing or

jeweJry. Contain Jong hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught in

moving parts.

[] Avoid accidental starting. Be sure switch is off

before pJugging in. Carrying tools with your finger

on the switch or plugging in tools that have the

switch on, invites accidents.

[] Remove adjusting keys or wrenches before

turning the tooJ on. A wrench or a key that is left

attached to a rotating part of the tool may result in

[] Do not overreach. Keep proper footing and

baJance at aH times. Proper footing and balance

enabbs better control of the tool in unexpected

situations. Do not use on a ladder or unstabb

supporL

[] Use safety equipment. AJways wear eye protec-

tion. Dust mask, nonskid safety shoes, hard hat, or

hearing protection must be used for appropriate

conditions.

TOOL USE AND CARE

[] Use clamps or other practicaJ way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your body is

unstabb and may lead to loss of control.

[] Do not force toot. Use the correct toot for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

[] Do not use tool if switch does not turn it on or

off. Any tool that cannot be controlbd with the

switch is dangerous and must be repaired.

[] Disconnect the plug from power source before

making any adjustments, changing accesso-

ries, or storing the tool Such preventive safety

measures reduce the risk of starting the tool

accidentally.

[] Store idle tooJs out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

[] Maintain tooJs with care. Keep cutting tools

sharp and clean. Properly maintained tools with

sharp cutting edges are less likely to bind and are

easier to control.

[] Check for misaJignment or binding of moving

parts, breakage of parts, and any other condio

tion that may affect the tooFs operation, if

damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained

tools.

[] Use only accessories that are recommended by

the manufacturer for your model. Accessories

that may be suitable for one tool, may become

hazardous when used on another tool.

SERVICE

[] TooJservicemustbeperformed only by qualio

fled repair personnel. Service or maintenance

performed by unqualified personnel could result in

a risk of injury.

[] When servicing a tooJ, use only identicaJ reo

pJacement parts. Follow instructions in the

Maintenance section of this manual Use of

unauthorized parts or failure to follow Maintenance

hstrucfions may create a risk of eUectricshock or

injury.

[] AJways use proper guard with grinding wheet. A

guard protects operator from broken wheel frag-

ments.

[] Accessories must be rated for at Jeast the

speed recommended on the tool warning JabeL

Wheels and other accessories running over rated

speed carl fly apart and cause injury.

[] HoJd tool by insuJated gripping surfaces when

performing an operation where the cutting toot

may contact hidden wiring or its own cord.

Contact with a "live" wire wiii make exposed metal

parts of the tool "live" and shock the operator.

[] Grinding wheet and guard must be securely

attached as described in this operating manual

before connecting the grinder to a power source.

[] Grinding wheets must be stored in a dry pJace.

[] Before attaching the grinding wheel, inspect it

for visible defects. If cracked, chipped, or warped,

do not install it.

[] Do not overtighten the clamp nut on the grinding

wheek Excessive tightening carl cause the wheel

to crack during operation.

[] l_ake sure that the guard is in good condition

and securely installed before operating grinder.

[] Do not cJamp the grinder in a vise or use as a

fixed grinder.

[] Never turn on the grinder with the grinding wheel

or any rotating parts touching the workpiece.

[] Use only grinding wheets in compliance with

ANSI standard B7.1 and rated greater than 11,000

RPM.

[] Do not use the grinder if the disc flange or

clamp nut is missing or if the spindle is bent.

[] AJways hotd the grinder securely with two

hands while working and at all times when it is

[] Dust and waste materials should not be

allowed to build up in the workshop. Hot metal

sparks could start a fire.

[] Do not enJarge or alter the center hote of the

grinding wheel as this could result in breaking it.

[] Use onty the normaJ grinder surface. Never use

the side or upper surfaces for cutting.

[] Keep the toot and its handte dry, cJean, and

free from oit and grease. Always use a clean

cloth when cleaning. Never use brake fluids,

gasoline, petrobum-based products, or any strong

solvents to clean your tool.

[] Never cover the air vents in the motor housing

with your hands while operating the grinder.

[] Notd the tooJ away from your body while it is

running. Keep your hands away from the abrasive

attachments.

[] Knowyourpower tool Read operator's manuaJ

carefully. Learn its applications and Hmitations,

as well as the specific potential hazards retated

to this tool Following this rub wHUreduce the risk

of eUectricshock, fire, or serious injury.

[] AJways wear safety gJasses. Everyday eye°

glasses have onJy impact-resistant tenses; they

are NOT safety gJasses. Following this rule will

reduce the risk of serious personal injury.

[] Protect your tungs. Wear a face or dust mask if

the operation is dusty. Following this rule will

reduce the risk of serious personal injury.

[] Protect your hearing. Wear hearing protection

during extended periods of operation. Following

this rule will reduce the risk of serious personal

injury.

[] mnspect tool cords periodically and, if damaged,

have repaired at your nearest authorized sero

vice center. Constantly stay aware of cord

location. Following this rule will reduce the risk of

electric shock or fire.

[] Check damaged parts. Before further use of the

too!, a guard or other part that is damaged

shouJd be carefully checked to determine that it

wilt operate property and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that may

affect its operation. A guard or other part that is

damaged should be property repaired or reo

placed by an authorized service center. Follow-

ing this rule will reduce the risk of shock, fire, or

serious injury.

[] Do not abuse cord. Never carry the tooJ by the

cord or yank it to disconnect it from the recepo

tacJe. Keep cord away from heat, oiJ, and sharp

edges. Following this rule will reduce the risk of

electric shock or fire.

[] Make sure your extension cord is in good

condition. When using an extension cord, be

sure to use one heavy enough to carry the

current your product will draw. A wire gage size

(A.W.G.) of at Jeast 1{} is recommended for an

extension cord 100 feet or Jess in Jength. A cord

exceeding 100 feet is not recommended. If in

doubt, use the next heavier gage. The smaller

the gage number, the heavier the cord. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.

[] inspect for and remove aH naris from tumber

before grinding. Following this rule will reduce the

risk of serious personal injury.

[] Drugs, alcohol, medication. Do not operate tool

while under the influence of drugs, alcohol, or

any medication. Following this rule will reduce the

risk of electric shock, fire, or serious personal injury.

[] Keep hands away from grinding area. Following

this rule will reduce the risk of serious personal

injury.

[] Save these instructions. Refer to them freo

quently and use them to instruct others who

may use this tool. If you loan someone this toot,

toan them these instructions also.

WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known

to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

" lead from lead-based paints

" crystalline silica from bricks and cement and

other masonry products, and

" arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of work.

To reduce your exposure to these chemicals:

work in a well ventilated area, and work with

approved safety equipment, such as those dust

masks that are specially designed to filter out

microscopic particles.

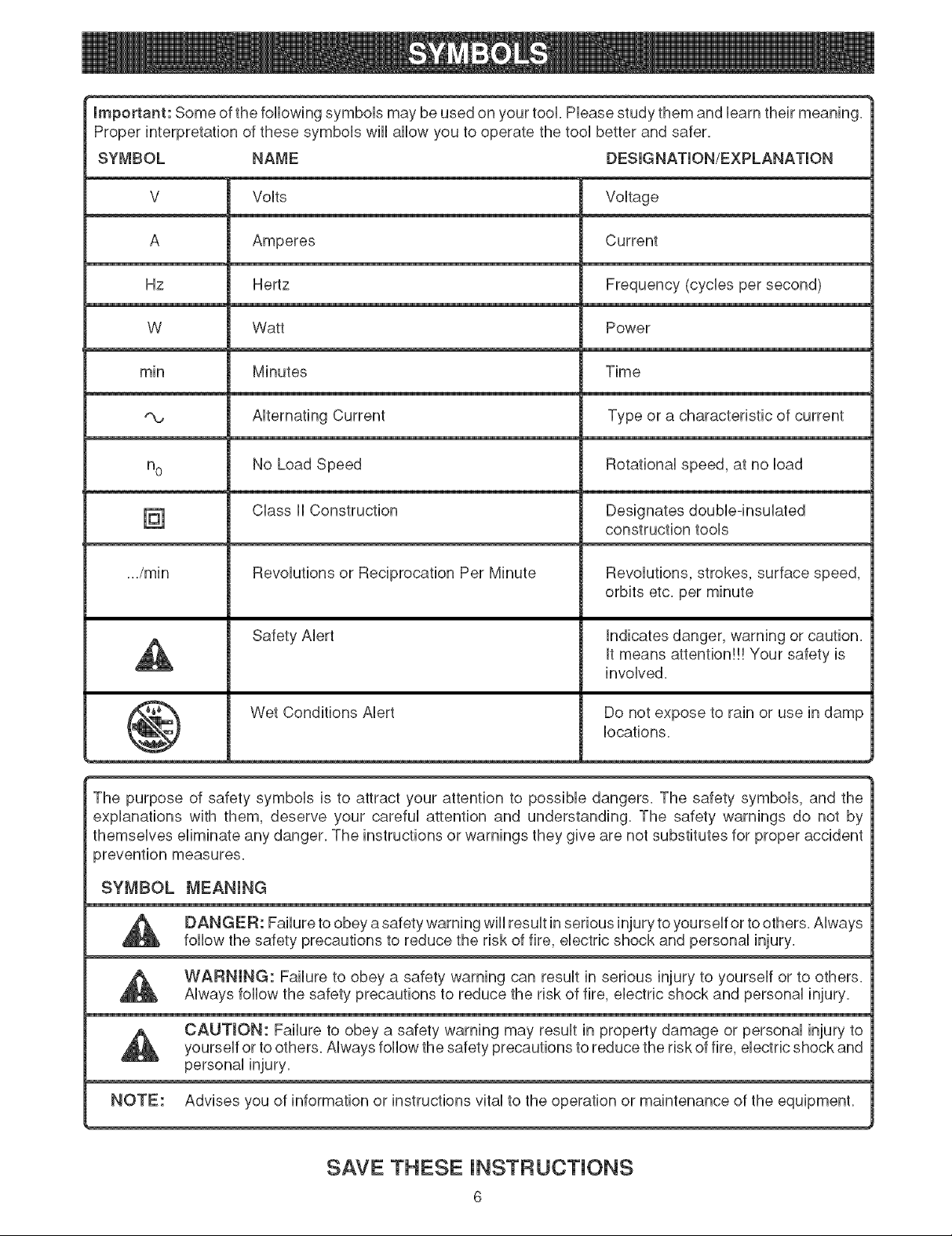

important: Some of the following symbols may be used on your tool. Please study them and barn their meaning.

Proper interpretation of these symbols wiii allow you to operate the tool better and safer.

SYMBOL NAME DESmGNATmON/EXPLANATmON

V

A

Hz

W

min

n o

._/min Revolutions or Reciprocation Per Minute Revolutions, strokes, surface speed,

Volts

Amperes

Hertz

Watt

Minutes

Alternating Current

No Load Speed

Class HConstruction

Safety Alert

Voltage

Current

Frequency (cycles per second)

Power

Time

Type or a characteristic of current

Rotational speed, at no load

Designates double-insulated

construction tools

orbits etc. per minute

Undicates danger, warning or caution.

Utmeans attention!!! Your safety is

involved.

Wet Conditions Alert

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them, deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

SYMBOL MEANmNG

DANGER: Failure to obey a safety warning will result inserious injury to yourself or to others. Always

follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNmNG: Failure to obey a safety warning can result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAU'NON: Failure to obey a safety warning may result in property damage or personal injury to

yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and

personal injury.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

Do not expose to rain or use in damp

locations.

SAVE THESE iNSTRUCTiONS

Loading...

Loading...