Page 1

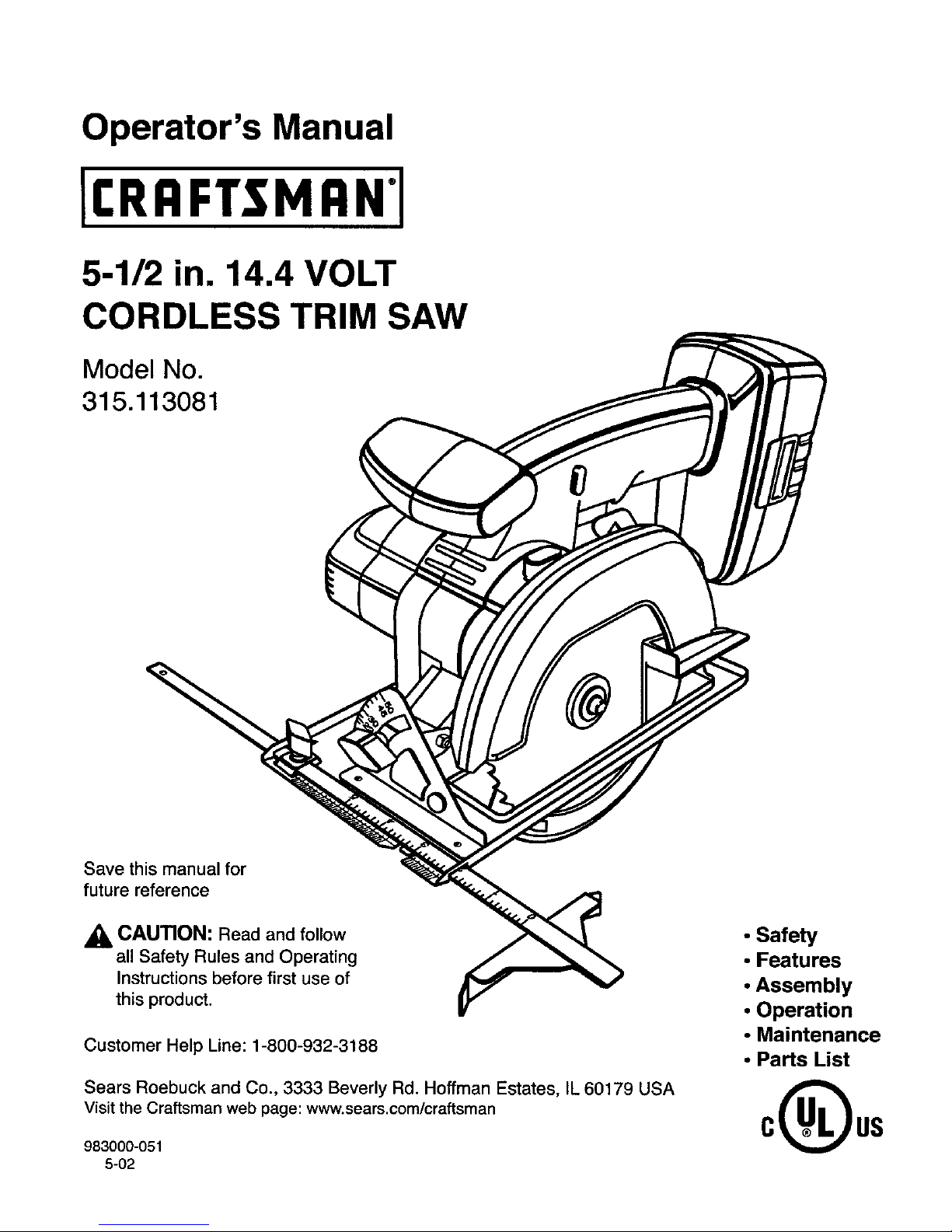

Operator's Manual

5-1/2 in. 14.4 VOLT

CORDLESS TRIM SAW

Model No.

315.113081

Save this manual for

future reference

,_L CAUTION: Read and follow

all Safety Rules and Operating

Instructions before first use of

this product.

Customer Help Line: 1-800-932-3188

Sears Roebuck and Co., 3333 Beverly Rd. Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

983000-051

5-02

• Safety

• Features

• Assembly

• Operation

• Maintenance

• Parts List

0( 0s

Page 2

• Table Of Contents and Warranty ................................................................................................................................ 2

• Introduction and General Safety Rules .................................................................................................................... 3-4

• Specific Safety Rules and Symbols ......................................................................................................................... 4-7

• Product Specifications, Unpacking, and Accessories ................................................................................................. 8

• Features ................................................................................................................................................................ 8-10

• Assembly .............................................................................................................................................................. 11-12

• Operation ............................................................................................................................................................. 12-18

• Maintenance ............................................................................................................................................................. 19

• Exploded View And Repair Parts List .................................................................................................................. 20-21

• Parts Ordering / Service ........................................................................................................................................... 22

FULL ONE YEAR WARRANTY ON CRAFTSMAN CORDLESS TRIM SAW

If thisI:RRI:TSMRNCordless Trim Saw fails to give completesatisfactionwithinone year fromthe date of purchase,

RETURN IT TO THE NEAREST SEARS STORE OR SEARS SERVICE CENTER IN THE UNITED STATES, and Sears

willrepairit,free of charge.

If this rRRFTSMAN Cordless Trim Saw is used for commercial or rental purposes, this warranty applies for only 90 days

from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

_1= Look for this symbol to point out important safety precautions It means attention!.! Your safety is

involved.

,_ WARNING:

The operation of any power tool can result in foreign objects being thrown into your eyes, which can

result in severe eye damage. Before beginning power tool operation, always wear safety goggles or

safety glasses with side shields and a full face shield when needed. We recommend Wide Vision

Safety Mask for use over eyeglasses or standard safety glasses with side shields, available at Sears

Retail Stores. Always wear eye protection which is marked to comply with ANSI Z87.t.

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and internationalsymbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating and maintenance, and repair information.

MEANING

Do notexpose to rainor use in damplocations.

Page 3

Your trimsaw has many featuresfor making your cutting

operations more pleasant and enjoyable. Safety,

performance and dependability have been given top

pdodty in the design of this trim saw making it easy to

maintain and operate.

,_ CAUTION: Carefully read throughthis entire

operator'smanual before usingyournew trim saw.

Pay close attention to the General Safety Rules,

Specific Safety Rules, Symbols, Warnings, and

Cautions. If you use your trim saw properly and only

for it's intended use, you will enjoy years of safe,

reliable service.

,_ WARNING: Reed and follow all instructions.

Failure tofollow all instructionslistedbelow, may

resultinelectric shock,fire and/orseriouspersonal

injury.

SAVE THESE INSTRUCTIONS

Work Area

• Keep your work area clean and well lit. Cluttered

benches and dark areas inviteaccident.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power toolscreatesparks

which may ignitethe dust orfumes.

• Keep bystanders, children, and visitors away while

operating a power tool. Distractionscan cause you

tolosecontrol.

Electrical Safety

Do not abuse the cord. Never use the cord to carry

the charger. Keep cord away from heat, oil, sharp

edges, or moving parts. Replace damaged cords

immediately. Damaged cordsmay create afire.

A battery operated tool with integral batteries or a

separate battery pack must be recharged only with

the specified charger for the battery. A chargerthat

may be suitablefor onetype of batterymay create a

riskof firewhenusedwith anotherbattery.Use battery

onlywithchargerlisted.

MODEL BATTERY PACK CHARGER

315.113081

Item No. _ 11007 Item No. 9 11006

(1310714) (1425005)

Use battery operated tool only with specifically

designated battery pack. Use of anyother batteries

may create a riskof fire.Use onlywithbattery pack

listed.

Personal Safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication. Amomentof inatten-

tionwhile operatingpowertoolsmay resultinserious

personalinjury.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Looseclothes,

jewelry, or long hair can be caught in movingparts.

• Avoid accidental starting. Be sure switch is in the

locked or off position before inserting battery

pack. Carryingtoolswithyour fingeron the switchor

insertingthe battery pack intoa toolwiththe switchon

invitesaccidents.

• Remove adjusting keys or wrenches before turn-

ing the tool on. Awrench or a keythat is leftattached

to a rotatingpartof the toolmay resultinpersonal

injury.

• Do not overreach. Keep proper footing and bal-

ance at all times. Properfootingand balanceenable

bettercontrolofthe toolin unexpectedsituations.

• Use safety equipment. Always wear eye protection.

Dustmask, nonskidsafety shoes,hard hat, or hearing

protectionmustbe usedfor appropriate conditions.

Tool Use and Care

• Use clamps or other practical way to secure and

support the workpiece to a stable platform. Holding

theworkbyhand oragainstyour bodyisunstableand

may lead to lossof control.

• Do not force tool. Use the correct tool for your

application. The correcttoolwilldo thejob betterand

saferat the rate for whichitis designed.

3

Page 4

• Donotusetoolif switch does not turn it on or off.

A toolthat cannot becontrolledwiththe switchis

dangerous and mustbe repaired.

• Disconnect battery pack from tool or place the

switch in the locked or off position before making

any adjustments, changing accessories, or storing

tool. Such preventive safety measures reduce the risk

ofstartingthe tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Toolsaredangerous in the

handsof untrainedusers.

• When battery pack is not in use, keep it away from

other metal objects like: paper clips, coins, keys,

nails, screws, or other small metal objects that can

make a connection from one terminal to another.

Shorting the battery terminalstogether may cause

sparks, burns, or a fire.

• Maintain tools with care. Keep cutting tools sharp

and clean. Properlymaintainedtools with sharp

cuttingedges are lesslikelyto bindand are easier to

control.

• Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool's operation. If damaged,

have the tool serviced before using. Many accidents

are caused by poorlymaintainedtools.

• Use only accessories that are recommended by

the manufacturer for your model. Accessoriesthat

may be suitablefor one tool, may create a riskof injury

when used on anothertool.

Service

Tool service must be performed by qualified repair

personnel. Service or maintenance performedby

unqualifiedpersonnelmay result in a riskof injury.

When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

section of this manual. Use of unauthorizedpartsor

failure tofollowMaintenance Instructionsmay create a

risk of shock or injury.

Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden

wiring. Contact with a "live" wire willmake exposed metal partsof the tool"live" and shock the operator.

Additional Rules For Safe Operation

• Know your power tool. Read operator's manual

carefully. Learn its applications and limitations, as

well as the specific potential hazards related to

this tool. Followingthis rulewillreduce the riskof

electricshock,fire, or serious injury.

• Make sure your extension cord is in good condi-

tion. When using an extension cord, be sure to use

one heavy enough to carry the current your prod-

uct will draw. A wire gage size (A.W.G.) of at least

16 is recommended for an extension cord 100 feet

or less in length. A cord exceeding 100 feet is not

recommended. If in doubt, use the next heavier

gage. The smaller the gage number, the heavier

the cord. An undersizedcord willcause a drop in line

voltageresultinginlossof power and overheating.

Important Rules For Battery Tools

• Battery tools do not have to be plugged into an

electrical outlet; therefore, they are always in

operating condition. Be aware of possible hazards

when not using your battery tool or when chang-

ing accessories.

• Do not place battery tools or their batteries near

fire or heat. This will reduce the riskof explosionand

possibleinjury.

_ WARNING: Batteriesvent hydrogen gas and can

explode in the presence of a source of ignition,such

as a pilotlight.To reducethe risk of serious personal

injury, never use anycordlessproductinthe pres-

ence of open flame. An explodedbatterycan propel

debris and chemicals. If exposed, flush withwater

immediately.

• Do not charge battery tool in a damp or wet loca-

tion. Followingthisrulewillreduce the riskofelectric

shock,fire,or seriouspersonal injury.

• Your battery tool should be charged in a location

where the temperature is more than 50°F but less

than 100°F. Followingthis rule willreducethe riskof

electricshock,fire, or seriouspersonal injury.

• Under extreme usage or temperature conditions,

battery leakage may occur. If liquid comes in

contact with your skin, wash immediately with

soap and water, then neutralize with lemon juice or

vinegar. If liquid gets into your eyes, flush them

with clean water for at least 10 minutes, then seek

immediate medical attention. Followingthis rule will

reducethe riskofseriouspersonalinjury.

4

Page 5

AdditionalSpecificSafetyRules

• DANGER!Keephandsawayfromcuttingaresand

blade.Keepyoursecondhandonauxiliaryhandle

ormotorhousing.Ifbothhandsare holdingthe saw,

they cannot be cut bythe blade.

• Keep your body positioned to either side of the

saw blade, but not in line with the saw blade.

KICKBACK couldcause the saw to jumpbackwards.

See Pages 13 and 14.

• Do not reach underneath the work. The guard

cannotprotectyou from the blade belowthework.

• Check the lower guard for proper closing before

each use. Do not operate saw if lower guard does

not move freely and close instantly. Never clamp

or tie the lower guard into the open position. If

saw is accidentallydropped, lowerguardmay be bent.

Raise the lowerguardwiththe retractinghandle and

make sure it movesfreely and does not touchthe

blade or anyother part,in all angles and depths ofcut.

• Check the operation and condition of the lower

guard spring. If the guard and the spring are not

operating properly, they must be serviced before

use. Lowerguardmay operate sluggishlydueto

damaged parts, gummy deposits, or a buildupof

debris.

• Lower guard should be retracted manually only for

special cuts such as "Pocket Cuts" and "Com-

pound Cuts". Raise lower guard by Retracting

Handle. As soon as blade enters the material,

lower guard must be released. Forall other sawing,

the lowerguard should operate automatically.

• Always observe that the lower guard is covering

the blade before placing saw down on bench or

floor. An unprotected,coastingblade willcause the

saw to walk backwards,cuttingwhatever isin itspath.

Beaware of the time ittakes for the blade to stopafter

switch isreleased.

NEVER hold piece being cut in your hands or

across your leg. It isimportantto supportthe work

properlyto minimizebody exposure, blade binding,or

lossofcontrol.

• Hold tool by insulating gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring. Contact with a "live" wire

willalso make exposed metal parts of the tool "live"

and shock the operator.

• When ripping always use a rip fence for a straight

edge guide. This improvesthe accuracyof cut and

reduces the chance of blade binding.

• Always use blades with correct size and shape

(diamond vs. round) arbor holes. Blades thatdonot

match the mounting hardware of the saw wiltrun

eccentrically, causing loss of control.

• Never use damaged or incorrect blade washers or

bolts. The blade washers and bolt were specially

designedforyoursaw, for optimumperformanceand

safety of operation.

• Causes and Operator Prevention of Kickback:

Kickbackis a sudden reaction to a pinched,bound, or

misalignedsaw blade, causingan uncontrolledsaw to

liftup and out oftheworkpiecetowardthe operator.

When the bladeis pinchedor boundtightlybythe kerf

closingdown,the blade stallsand the motorreaction

drivesthe unitrapidlyback towardthe operator.

Ifthe blade becomes twistedor misaligned inthe cut,

the teeth at the back edge of the blade can dig intothe

top surface ofthe wood causingthe bladeto climbout

ofthe kerrand jump back towardthe operator.

Kickback is a resultoftool misuse and/orincorrect

operatingproceduresor conditionsand can be

avoided bytakingproperprecautionsas given below:

• Maintain a firm grip on the saw and position your

body and arm in a way that allows you to resist

KICKBACK forces. KICKBACK forcescan be con-

trolledby theoperator,ifproperprecautionsare taken.

• When blade is binding, or when interrupting a cut

for any reason, release the trigger and hold the

saw motionless in the material until the blade

comes to a complete stop. Never attempt to

remove the saw from the work or pull the saw

backward while the blade is in motion or KICK-

BACK may occur. Investigateand take corrective

actions to eliminatethe cause of blade binding.

• When restarting a saw in the workpiece, center the

saw blade in the kerf and check that teeth are not

engaged into the material. If saw blade isbinding, it

may walk up or KICKBACKfrom the workpieceasthe

saw is restarted.

• Support large panels to minimize the risk of blade

pinching and KICKBACK. Large panelstendto sag

undertheirown weight. Supportsmust be placed

underthe panel on bothsides,near the line of cutand

near the edge of the panel.

• Do not use dull or damaged blade. Unsharpenedor

improperlyset blades producenarrow kerrcausing

excessivefriction, blade binding,and KICKBACK.

• Blade depth and bevel adjusting locking levers

must be tight and secure before making cut. If

bladeadjustmentshiftswhilecutting,itwillcause

bindingand KICKBACK.

• Use extra caution when making a "Pocket Cut"

into existing walls or other blind areas. The protrud-

ingblade may cut objectsthat can cause KICKBACK.

5

Page 6

,_ WARNING: Never use a battery that has been

dropped or received a sharp blow. A damaged

battery is subject to explosion. Properly dispose of a

dropped battery immediately. Failure to heed this

warning can result in serious personal injury.

• Save these instructions. This manual contains

important safety and operating instructions for

charger. Following this rule will reduce the risk of

electric shock, fire, or serious personal injury.

• Before using battery charger, read all instructions

and cautionary markings in this manual, on battery

charger, and product using battery charger. Follow-

ing this rule will reduce the risk of electric shock, fire,

or serious personal injury.

_1, CAUTION: To reduce risk of injury, charge only

nickel-cadmium and nickel metal hydride type

rechargeable batteries. Other types of batteries

may burst causing personal injury and damage.

Following this rule will reduce the risk of electric

shock, fire, or serious personal injury.

• Do not expose charger to rain or snow. Following

this rule will reduce the risk of electric shock, fire, or

serious personal injury.

• Use of an attachment not recommended or sold by

the battery charger manufacturer may result in a

risk of fire, electric shock, or injury to persons.

Following this rule will reduce the risk of electric shock,

fire, or serious personal injury.

• To reduce the risk of damage to charger body and

cord, pull by charger plug rather than cord when

disconnecting charger. Following this rule will reduce

the risk of serious personal injury.

• Make sure cord is located to that itwill not be

stepped on, tripped over, or otherwise subjected to

damage or stress. Followingthis rulewillreduce the

risk of serious personal injury.

• An extension cord should not be used unless

absolutely necessary. Use of improper extension

cordcouldresult ina riskoffire and electric shock, If

extension cord must be used, make sure:

a. That pins on plug of extension cord are the same

number, size and shape as those of plug on

charger.

b. That extension cord is properly wired and in good

electrical condition; and

c. That wire size is large enough for AC ampere rating

of charger as specified below:

Cord Length (Feet) 25" 50" 100"

Cord Size (AWG) 16 16 16

Note: AWG = American Wire Gage

• Do not operate charger with a damaged cord or

plug. If damaged, have replaced immediately by a

qualified serviceman. Followingthisrule will reduce the

riskofelectric shock, fire, orserious personal injury.

• Do not operate charger if it has received a sharp

blow, been dropped, or otherwise damaged in any

way; take it to a qualified serviceman. Followingthis

rulewillreduce the riskofelectric shock, fire,or

serious personalinjury.

• Do not disassemble charger; take it to a qualified

serviceman when service or repair is required.

Incorrect reassembly may result in a risk of elec-

tric shock or fire. Followingthis rulewill reduce the

riskof electricshock, fire, or serious personal injury.

• To reduce the risk of electric shock, unplug

charger from outlet before attempting any mainte-

nance or cleaning. Turning off controls will not

reduce this risk. Followingthis rulewillreduce the

risk of electricshock, fire, or serious personal injury.

• Do not use charger outdoors. Followingthisrule will

reducethe risk of electricshock, fire, or serious

personalinjury.

• Disconnect charger from power supply when not

in use. Followingthisrulewill reduce the riskof

electricshock, fire, or seriouspersonal injury.

_k DANGER: RISK OF ELECTRIC SHOCK. DO NOT

TOUCH UNINSULATED PORTION OF OUTPUT

CONNECTOR OR UNINSULATED BA'I-rERY

TERMINAL.

• Save these instructions. Refer to them frequently

and use them to instruct others who may use this

tool. If you loan someone this tool, loan them

these instructions also. Followingthis rule will

reduce the risk of electric shock,fire, or serious

personalinjury.

_. WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

SAVE THESEINSTRUCTIONS

Page 7

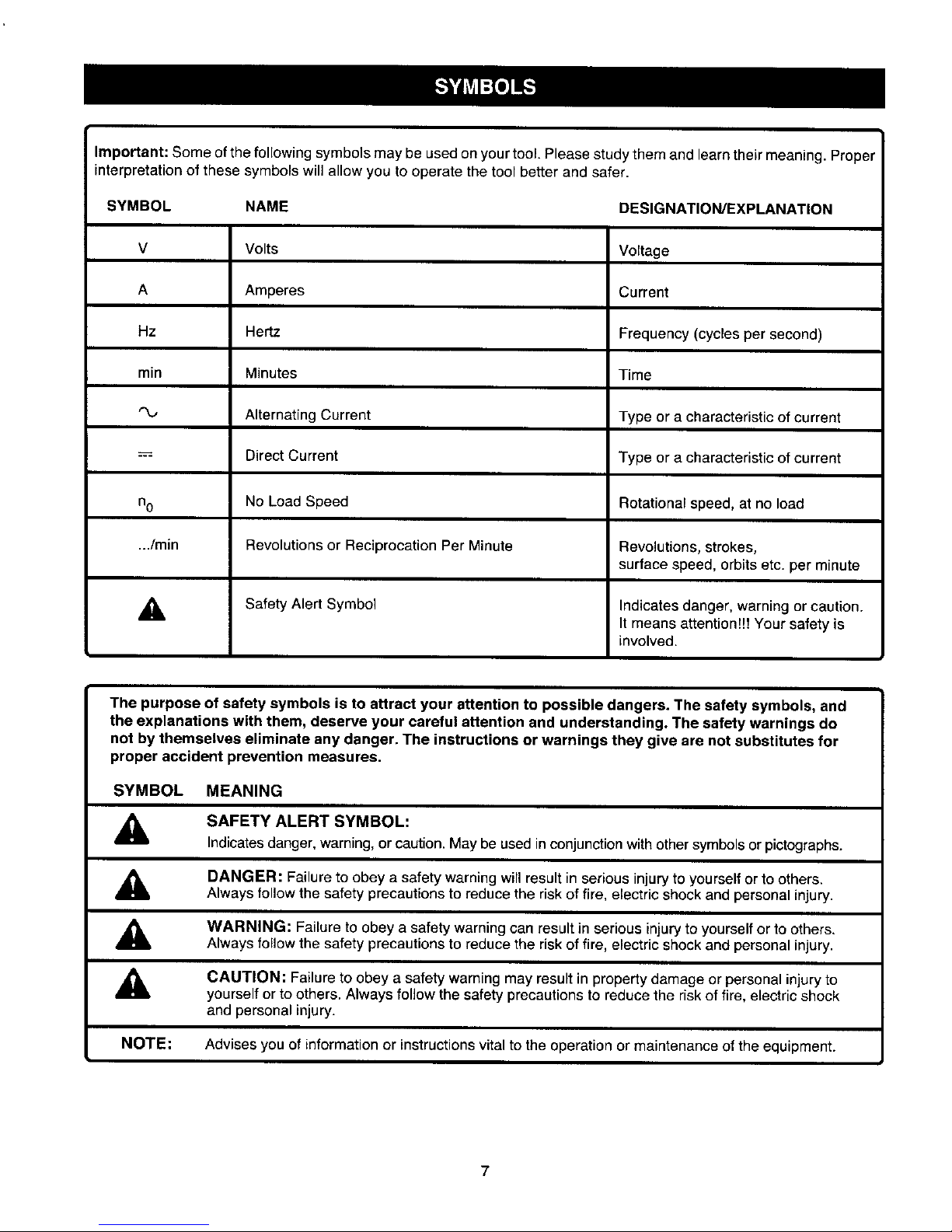

Important: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the tool better and safer.

SYMBOL NAME DESIGNATION/EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

min Minutes Time

"_ Alternating Current Type or a characteristic of current

---=- Direct Current Type or a characteristic of current

no No Load Speed Rotational speed, at no load

.../min Revolutions or Reciprocation Per Minute Revolutions, strokes,

surface speed, orbits etc. per minute

_k Safety Alert Symbol Indicates danger, warning or caution.

It means attentiont!T Your safety is

involved.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

the explanations with them, deserve your careful attention and understanding. The safety warnings do

not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for

proper accident prevention measures.

SYMBOL MEANING

A

A

A

A

SAFETY ALERT SYMBOL:

Indicates danger, warning,or caution. May be used in conjunction with other symbols or pictographs.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to

yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock

and personal injury.

NOTE: Advises you of information or instructionsvital to the operation or maintenance of the equipment.

Page 8

TRIM SAW 318.113081

Blade Diameter 5-1/2 in.

Blade Arbor 3/8 in.

Cutting Depth at 90° 1-9/16 in.

Cutting Depth at 45° 1-1/8 in.

No load Speed 3,800 RPM

Motor 14.4 Volt DC

CHARGER

Input

Charging Voltage

Charge Rate

BATTERY PACK

ITEM NO. 9 11006

(1425005)

120 v, 60 Hz, AC only

14.4 Volt

3-6 Hours

ITEM NO. 9 11007

(1310714)

Your trim saw has been shipped completely assembled

except for the blade. Inspect it carefully to make sure no

breakage or damage has occurred during shipping. If any

parts are damaged or missing, contact your nearest Sears

Retail Store to obtain replacement parts before attempting

to operate saw. A blade, blade wrench (5 mm hex key), rip

guide (edge guide) and this operator's manual are also

included.

_, WARNING: If parts are missing, do not operate

any

your saw until the missing parts are replaced. Failure to

do so could result in possible serious personal injury.

The following recommended accessories are currently available at Sears Retail Stores.

• 5-1/2 in. Thin Kerr Blade

,_ WARNING: The use of attachments or accessories not listed might be hazardous.

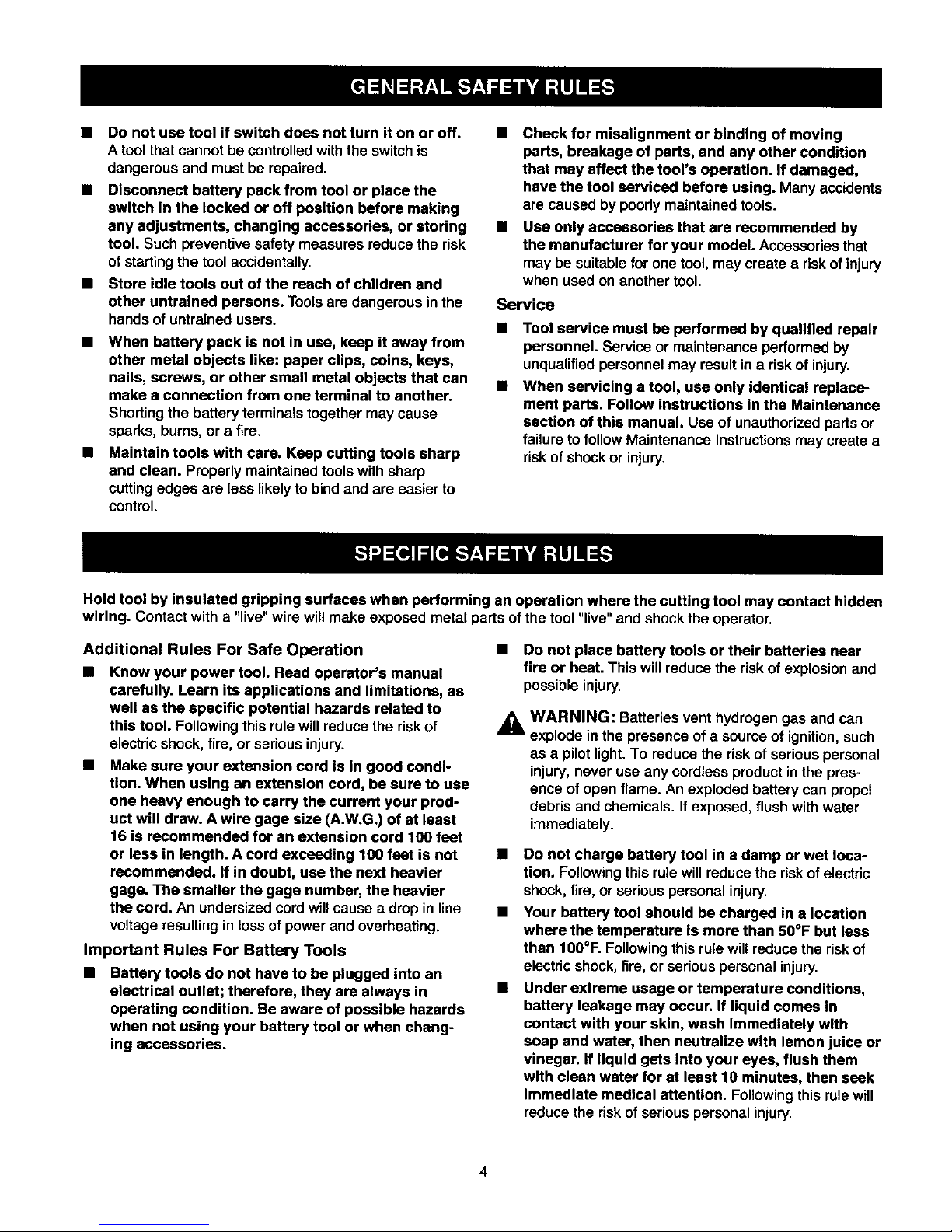

KNOW YOUR TRIM SAW

See Figure 1.

Before attempting to use your trim saw, familiarize yourself

with all operating features and safety requirements.

Features include easily operated bevel cut and depth of

cut adjustment mechanisms; positive 0° bevel stop;

spindle lock; and blade wrench storage.

_k WARNING: Do not allow familiarity with saw

your

to make you careless. Remember that a careless

fraction of a second is sufficient to inflict severe

injury.

SWITCH

Your saw is equipped with a tock-offbutton which reduces

the possibility of accidental starting. The lock-off button is

located on the handle above the switch trigger. You must

depress the lock-off button in order to pull the switch

trigger. The lockresets each time the trigger is released.

Note: You can depress the lock-off button from either the

left or right side.

APPLICATIONS

(Use only for the purposes listed below)

• Cutting all typesofwood products(lumber,plywood,

paneling).

Page 9

LOCK-OFF

SPINDLE BU'I-FON

LOCKBuTroN

BATTERY

TRIGGER

RIP

GUIDE SCREW

(WINGSCREW)

UPPER

BLADEGUARD

LOWERBLADE

GUARD HANDLE

BEVELCUTADJUSTMENT

(BEVELADJUSTMENT KNOB)

BASE

ASSEMBLY

BLADE

LOWER

BLADEGUARD

RIPGUIDE

BLADEWRENCH CUTADJUSTMENT

(5 mm HEXKEY) (DEPTH ADJUSTMENTKNOB)

Fig. 1

Page 10

BA'n'ERY PACK

The battery pack for your tool has been shipped in a low

charge condition to prevent possible problems. Therefore,

you should charge it overnight prior to use.

Note: Batteries will not reach full charge the first time they

are charged. Allow several cycles (drilling followed by

recharging) for them to become fully charged.

CHARGING BATTERY PACK

See Figure 2.

• Charge battery pack only with the charging assembly

provided.

• Make sure power supply is normal household

voltage, 120 volts, 60 Hz, AC only.

• Connect charger to power supply.

• Place battery pack in charging stand. Align raised rib

on battery packwith groove in charging stand.

See Figure 2.

BATTERYPACKSHOWN

INCHARGINGSTAND

CHARGER

RED LIGHT

(LED)

\

• Press down on battery pack tobe sure contacts on

battery pack engage properlywith contacts in charging

stand.

• The charge indicator light (LED), located on the

charging stand, will light up red and glow when the

charger is properly connected to power supply. This

light indicates the charger is operating properly. It will

remain on until battery pack is removed from charging

stand or charger is disconnected from power supply.

The light only glows while battery pack is charging.

• Note: If charger does not charge battery pack, return

battery pack and charging assembly to your nearest

Sears Repair Center for electrical check.

• After normal usage, 3 hours or less of charging time is

required to fully recharge battery pack. Note: Ifbattery

pack is completely discharged, 6 hours or longer of

charging time is required to fully recharge battery

pack.

• The battery pack willbecome slightly warm to the

touch while charging. This is normal and does not

indicate a problem.

• Do not place charger in an area of extreme heat or

cold. It will work best at normal room temperature,

• When batteries become fully charged, unplug charger

from power supply and remove the battery pack.

IMPORTANT INFORMATION FOR RECHARGING

HOT BA'n'ERIES

When using your trim saw continuously, the batteries in

your battery pack will become hot. You should let a hot

battery pack cool down for approximately 30 minutes

before attempting to recharge.

Note: This situation only occurs when continuous use of

your saw causes the batteries to become hot. It does not

occur under normal circumstances. Refer to "CHARGING

BATI'ERY PACK" for normal recharging of batteries. If the

charger does not charge your battery pack under normal

circumstances, return both the battery pack and charger to

your nearest Sears repair center for electrical check,

CHARGING

STAND Fig. 2

10

Page 11

,_ WARNING: Always remove battery pack from your

saw when you are assembling parts, making

adjustments,assemblingor removing blades,

cleaning, or when not in use. Removing battery pack

willpreventaccidental starting that could cause

serious personal injury.

Note: Your saw is assembled with the battery pack

attached.

TO REMOVE BATTERY PACK

See Figure 3.

i Locate latches on side of battery pack and depress to

release batterypack from your saw. See Figure 3.

• Remove battery pack from your saw.

TO

REMOVE

DEPRESSLATCHESTO

RELEASEBATTERYPACK

TO

INSTALL LATCHES

BATrERY PACK

Fig. 3

TO ASSEMBLE OR REMOVE BLADE

TO ASSEMBLE BLADE:

See Figure 4.

,_ WARNING: A 5-1/2 in. blade isthe maximum blade

capacity of your saw. Never use a blade that is too

thickto allowouter blade washer to engage with the

flats on the spindle. Larger blades will come in

contactwith the blade guard, whilethickerblades will

prevent blade screw from securing blade on spindle.

Eitherofthese situations could resultina serious

accident.

M Remove battery pack from saw.

_ WARNING: Failure to remove battery pack from

saw could result in accidental startingcausing

possibleserious personal injury.

• Locatelatchesonside of battery pack anddepressto

releasebattery packfrom yoursaw. See Figure 3.

SPINDLE

LOCKBUTTON

LOWERBLADE

, GUARD HANDLE

BLADE

;LADEWASHER OUTER

BLADEWASHER

SCREW Fig. 4

M Remove blade wrench (5 mm hex key) from storage

area. See Figure 1.

• Depress spindle lock button and remove blade screw

and outer blade washer. See Figure 4.

Note: Turn blade screw clockwise to remove.

• Wipe a dropof oil onto inner blade washer and outer

blade washer where they contact blade.

,_ WARNING: If inner blade washer has been re-

moved, replace itbefore placing blade on spindle.

Failureto do so couldcause an accidentsinceblade

wil! nottightenproperly.

• Fit saw blade inside lower blade guard and onto

spindle.

Note; The saw teeth point upward at the front of saw

as shown in figure 4.

• Replace outer blade washer.

n Depress spindle lock button, then replace blade screw.

Tighten blade screw securely.

Note: Turn blade screw counterclockwise to tighten.

• Return blade wrench to storage area.

REMEMBER: Never use a blade that is too thick to

aflow the outer blade washer to engage with the flats

on the spindle.

11

Page 12

TO REMOVE BLADE

See Figure 5.

• Remove battery pack from saw.

WARNING: Failure to remove battery pack from

sew could result in accidental starting causing

possible serious personal injury.

• Remove blade wrench from storage area. See Figure 1.

• Position saw as shown in figure 5, depress spindle lock

button, and remove blade screw.

Note: Turn blade screw clockwise to remove.

• Remove outer blade washer. See Figure 4.

Note: Blade can be removed at this point.

TO

LOOSEN

\

\

DEPRESSSPINDLE

LOCKBUTFON

BLADE

WRENCH

TO

TIGHTEN

SCREW

Fig. 5

TO INSTALL BATFERY PACK

See Figure 6.

Note: Battery pack is shipped in a low charge condition.

Therefore, it must be charged priorto use. Refer to page

10, "CHARGING BATTERY PACK" for charging

instructions.

• Race battery pack in your saw. Align raised rib on

battery pack with groove inside saw, then slide battery

peck in saw as shown in figure 6.

• Make sure the latches on each side of your battery

pack snap into place and battery pack is secured in

saw before beginning operation.

A CAUTION: When placing battery pack in your saw,

be sure raised rib on battery pack aligns with groove

inside saw and latches snap into place properly.

Improper assembly can cause damage to saw and

battery pack.

LATCHES

BATrERYPACK Fig. 6

BLADE GUARD SYSTEM

The lower blade guard attached to your trim saw is

there for your protection and safety. It should never be

altered for any reason. If it becomes damaged or

begins te return slow or sluggish, do not operate your

saw until the damage has been repaired or replaced.

Always leave guard in operating position when using

saw'.

,_ DANGER: When sawing through workpiece, lower

blade guard does not cover blade on the underside of

workptece. Since blade is exposed on underside of

workpiece, keep hands and fingers away from cutting

area. Any part of your body coming in contact with

moving blade will result in serious injury.

See Figure 7.

LOWERBLADE GUARD

IS IN UP POSI'nON

WHEN MAKINGA CUT

BLADEEXPOSED ON

b'NDERSlOEOFWORKPIECE

Fig. 7

Never use saw when guard is not operating correctly.

Guard should be checked for correct operation before

each use. If you drop your saw, check the lower blade

guard a=-tdI_umper for damage at all depth settings

before reuse. Note: The guard is operating correctly

when it moves freely and readily returns to the closed

position. If for any reason your lower blade guard

does not dose freely, take it to the nearest Sears Parts

and Repair Center for service before using.

12

Page 13

KICKBACK

See Figure 8.

II_ II1_ ilni_llHi_ KICKBACK

TO LESSEN THE CHANCE OF KICKBACK:

• Always keep the correct blade depth setting - the

correct blade depth setting for all cuts should not

exceed 1/4 in. below the material to be cut.

See Figure 10. One blade tooth below the material to

be cut works best for most efficient cutting action.

BLADESETTOO DEEP

Fig. 8

The best guard against kickba_ is to avoid dangerous

practices.

Kickback occurs when the I:dade stalls rapidly and the sew

is driven back towards you. Blade s_ is caused by any

action which pinches the blade in _ wood,

,_ DANGER: Release switch immediately if blade

binds or saw stalls. Kickback could cause you to lose

control of your saw. Loss of control can lead to

serious injury,

KICKBACK IS CAUSED BY:

• Incorrect blade depth setting. See Figure 8.

• Sawing into knots or nails in workpiece.

• Twisting blade while making a cut.

• Making a cut with a dull, gummed up, or improperly set

blade.

• Incorrectly supporting workpieee. See Figure 9.

• Forcinga cut,

• Cutting warped or wet k_r.

• Tool misuseor incorrectaperatmg procedures.

Fqg. 9

CORRECTBLADEDEPTHSETT'_ =

BLADqEEXPOSEDONE BLADETOOTH

BELOWTHE MATERIALTO BE CUT

Fig. t0

• Inspect the workpiece for knots or nails before

beginning a cut. Never sew into a knotor nail.

• Make straightcuts.Always use a straightedge guide

when rip cutting.This helps preventtwistingthe blade

in the cut.

• Always use clean, sharp and properly set blades.

Never make cuts with dull blades.

• To avoid pinching the blade, support the workpiece

properly before beginning a cut. The right and wrong

ways to support large pieces of work are shown in

figures 9 and 11.

Fig. 11

13

Page 14

• When making a cut use steady, even pressure.

Never force cuts.

• Do not cut warped or wet lumber.

• Always hold your sow firmly with bothhands and keep

your body in a balanced position so as to resist the

forces of kickbackshould itoccur.

using your saw, always stay alert and exercise

cor_rol. Do not r_ your saw from workpiece

while the blade is moving.

DEPTH OF CUT ADJUSTMENT

Always keep correct blade depth setting. The correct

blade depth setting for all cuts should not exceed 1/4 inch

below the material to be cut. More blade depth will

increase the chance of kickback and cause the cut to be

rough. One blade tooth below the material to be cut wo_s

best for most efficient cutting action.

"rid ADJUST BLADE DEPTH

• Remove battery pack from saw.

WARNING: Failure to remove battery pack from

saw could result in accidental starting causing

possible serious personal injury.

• Loosen depth adjustment knob. See Figure 12.

STARTING A CUT

Know the right way to use yOUrsaw.

See F_gure 13.

Never use your saw as shown in figure 14.

Fig. 13

TORAISE

SAW"

TO

TIGHTEN BASE

TO ASSEMBLY

LOOSEN DEPTH

TO ADJUSTMENT

LO_ SAW KNOB Fig. 12

• Hold base flat against the workpiece and raise or lo_er

saw until the required depth is reached.

• Tighten depth adjustment knob securely,

Fig. 14

Never place your hand on the m:wkpiece behind your

sa_ mr,bile maldng a ced.

A WARNING: To rna_ sewing easier and safer,

always maintain proper controlof your saw. Lossof

controlof your saw couldcause an accident resultir'_g

in possibloseriousinjury.

14

Page 15

TO HELP kI_NTAIN CONTROL:

• Always supportyourworkplecenearthe cut.

• Support your_orkpieco sothe cut willbe on your left.

• Clamp ymJrimdq_ieea soit willnot move duringthe cut.

Place your _mckpiece with itsgood side down.

[_k_'e:The good _ isthe side on which appearance is

important.

Before begirming a cut, draw a guideline along the desired

line of cut. Then place front edge of base on that part of

your workpiecethat is sor_ supported. See Figure 13.

Never place your saw on that part of the workpiece

that will fall off _ Ihe cut is made. See Figure 15.

Hold your saw firmly with both hands.

See Figure 16+

Fig. 15

FLIGHT Fig. 16

Depress the lock-off button and squeeze the switch trigger

to start your saw. Always let the blade reach full speed,

then guide your saw into the workpiese.

_k WARNING: The blade coming in contact with the

workpiece before it reaches full speed could cause

your saw to "kickback" towards you resulting in

serious injury.

When making a cut use steady, even pressure. Forcing

causes rough cuts, could shorten the life of your saw and

could cause "kickback."

REMEMBER:

When sawing _ work, the lower blade guard

does not cover the blade, e_posing it on the

underside of _ Keep your hands and fingers away

from cutting area. Any part of your body coming in

contact with the mo_ blade will resuR in serious

injury.

Afteryou complete your cutrelease the trigger and allow

the blade to come to a complete stop.De not

your saw from wodlq_e_e _ the blade is moving.

A CAUTION: _ _ your saw fromthe

workpiece, the blade isexposed on the underside of

your saw untilthe lower blade guard closes. Make

sure lower blade _ is closed before setting your

saw down on _ surface+

15

Page 16

TO CROSS CUT OR RIP CUT

When making a cross cut or rip cut, alig_ your line of cut

with the outer blade guide notch on the saw base as

shown in figure 17.

T0P VIEW0F SAW

_ NOTCH

6UIOELINE

ALIGNOUTIB] BLADE GU_ NOTCHON SAWBASE'_ LINE

OF CUTAS_ WHEN MAKING CROSSCUTS OR _ CUTS

Fig. 17

Since blade thicknesses vary, always make a trial cut in

scrap material along a guideline to determine how much,

if any, the guideline must be offset to produce an accurate

cut.

Note: The distance from the line of cut to the guideline is

the amount you should offset the guideline.

WIDTH OF CUT SCALE

See Figure 18.

A width of cut scale has been provided on the base of

your saw. When making straight cross cuts or rip cuts, the

scale can be used to measure up to four inches to the

right side of the blade. It can be used to rneasere up to

one inch to the left side of the blade.

RIP GUIDE (EDGE

Use the rip guide provided with your saw whet}

wide rip cuts. A five inch scale has been provided on the

rip guide. When using the width of cut scale on the base

in combination with the rip guide, cuts can be made up to

6 id. to the left of the rip guide or 8-7/8 in. to the right of

the rip guide.

The rip guide helps prevent the blade from twL_ng in a

cut. The blade twisting in a cut can cause kickback.

TO ASSEMBLE RIP GUIDE

IN Remove battery pack from saw.

A W,.,!I_il_NG: Failure to remove battery pack from

saw could result in accidental starting caz_ing

possible serious personal injury.

RIP

GUIDESCREW

(WINGSCREW}

F_g_18

PLACERIP

GUg)£THI_ I'IOLES

• Place rip guide _h holes in saw base a=s_hovm in

figure !9.

• Ad_us_rip guide to _ widthneeded.

• lighten rip guide screw (wing screw) securely_

When using a rip guide, position the face of the rip £K_de

firmly against _ edge of workpiece. This makes for a

true cut without pinching the blade. The guiding ectge of

werkplece must be stTaight for your cut to be sa_gtfL Use

caution to peswenttt_e biade from binding in the cut.

16

Page 17

ALTERNATIVE RIP METHOD

,__seFigure 20.

Using C-clamps, firmlyclamp a straight edge to the

wodq_eleeand grade the saw along the straightedgeto

achieve a straightrip cut. Do not bind the blade inthe cut.

MJ:l_lt_ IE'THODFORRIPCUI"I"I_G

Align your line of oat with the inner blade guide notch on

the saw _ when making 45 ° bevel cuts.

Since blade thicknesses vary and different angles

requite erzHer_( settings, always make a trial cut in

scrap mallei along a guideline to determine how

muds _ should offset _ guideline on the board to

be ,-_

When making a bevel cut hold your saw firmly with both

hands as shown in figure 22.

\

NOTE:C-CLAM_

BOTHE]NOSOFSTRAIGHT

EDGEBEFOREMAKINGCUT

Fig. 20

TO BEVEL CUT

The angle of cutof your saw may be adjusted to any

desired settingbetween zero and 50°. Note: When

makingcutsat 50°, blade should be set at full depth of

cut.

When making 45 ° bevel cute, there is a notch in the saw

base to help you line up the blade with the line of cut. See

Figure 21.

SCALE

LOWER

Bt.ABEGUARD Fig. 22

Rest the front edge of the base on the workpiece. Depress

the Iod( offbutton and squeeze the switch trigger to start

your saw. Xltrays let the blade reach full speed, then

guide your saw into the workpiece.

_kW_: The blade coming incontact with the

workpiece before it reaches full speed could cause

saw to "kickback" toward you resulting in serious

injury.

After you _ your cutrelease the tTk:jgerand allow

the blade to come to a complete stop. _ the btade has

stopped, _ your saw from the workpiece.

TO ADJUST BEVEL SETTING

• Rm'go_m battory pack from sew.

,& WAIBIgI_IIG: Fa#L,re to remove b,sttery pack fTOm

saw could r_sult in acoidental starting causing

serous personal injury.

• Loosenbeve_adjusbnentknob. SeeF_jure21.

• Raisemolagrhousingendo_sawunfityou_ desired

ang_ set_j onbe_ sc_. See F_se 21.

• T_jWaen_ adjustment knob securely.

_i= W_NIm_ A_mptmg bevel cz,'twid_c_ut_nob

secu_y tigfd_ed can result in serm._ injury.

17

Page 18

POSITIVE 0 ° BEVEL STOP • "rum screw and adjust base Lmtilsquare with_w

See Figure 23. blade.

POS_'tYEO°

BEVELSTO_

BLADE

• Tighten hex nut and bevel ad_stment knob securely.

&WA_: Attemptingto make cutswithoutbevel

adjustmentknob securely t_JY_enedcan restaitin

seriousir_y.

TO POCKET CUrT

See Figure24.

A WARI_: AhNaysadju_ {m_vEd_ to zero

beforemakinga pocketcut. _ a pocketoutat

any other _g can result in loss of ountmt of your

saw possibly causingserious k,lj_y.

Adjust the bevel setting to zero, set b_ade to correct blade

depth setting, and swing the lower blade _ up using

the lower blade guard handle.

Ai_ I'ai_e the tower blade gltld mih 1_ halzdlle to

serious irdury.

While holding lower blade guard bythe handle, firmly rest

the front of the base flat against the wodq_leos with the

rear of the handle raised so the blade does not to_ch the

workplece. See Figure 24.

Fig. 23

Your saw has a positive 0° bevel stop, that has been

factoryadjusted to assure 0° angle of your saw blade

when making 90° cuts. However, misalignment can occur

during shipping.

TO CHECK

• Remove battery pack from saw.

A W_: Failure to remove _ pack from

saw could result in acciderdal sta_ causing

possible serious personal injury.

• Place your saw in an upside down positio, on

workbench. See Figure 23.

• LIs=nga caq)enter's square, check _ of saw

blade to the base of your saw.

TO_

• Remove battery pack from saw_

A W_lMmlG: Failure to r_ batterypa_Yfrom

s_w could result in accidental _ _g

possibleserious personal inj_'y.

• Loosen bevel adjustment knolb.

• Loosen .he',(nut securing adjustment sc_v.

LOWERBLADE

GUARD HANDLE

POCKET CUT LOIER _ GIJIABD

Fig. 24

Depressthe Ioc_-offbutton and squee_ ttm S_Nik_Wigger

to slart your saw. Always let the bible readlfsl s4m_d

1hen _ Iomer blade into tl_ =mdqdm:_ u_BI base

isfla_ agm_ Im_rkpiece.

_ yco _rnplete your cut release It_el_gger and ,m_lowthe

blade to come to a complete stop. Af_zrthe bladeI'=_ls

st_oped, _ it from the workl:_ez_e.Comms mmj then be

cleared cot witha hend saw or sabeasa_w.

A WIII4_INIIIIG: Never tie the Imuer btad_ _a_l in a

raised position. Leaving the _ exposed could

lead to seriousinjury.

18

Page 19

A W/_JSMING: servicing, use only

When identical

Craftsman replacement parts. Use of any other part

may create a hazard or cause product damage.

Avoid usmg solvents when cleaning plast_ parts. Most

plasticsare susceptible to damage from varleus types of

commerci_ solvents and may be damaged by their use.

Use clean clothsto remove dirt, dust, oil, grease, etc.

A W_JRINING: Do not at any tittle let brake fluids,

gasoline, petroleum-based products, penetrating oils,

etc. come in contact with plastic parts. They contain

chemicals that can damage, weaken or destroy

plastic.

Do not abuse power tools. Abusive practices can damage

as well as workpiece.

Only the parts shown on parts list, page 21, are intended

fe be repaired or replaced by the customer. All other parts

should be replaced at a Sears Service Center.

A W_4ff4G: Do not attempt to modify this tool or

create accessories not recommended for use with

this tool. Any such alteration or modification is

misuse and could result in a hazardous condition

feading to possible serious personal injury.

BKnEI_ES

Your saws battery pack is eq_ with nickel-cadmium

batteries. _ of service from each

charging will depend on the type of work you are doing.

batteries in this tool have been designed to provide

maximum trouble free life. However, like all batteries, they

eventually wear out. Do not disassemble battery pack

attempt to replace the batteries. Handling of these

batteries, aspecially when wearing rings and jewelry,

could result in a serious burn.

To obtain the longest possible battery life, we suggest the

_ng:

I S_ and charge your batteries in a cool area.

T_res above or below norm_ room

temperature will shorten battery life.

• Never store batteries in a discharged condition.

Recharge them immediately after they are discharged.

• All batteries gradually lose their charge. The higher the

temperature the quicker they lose their charge. If you

store your tool for long periods of time without using it,

recharge the batteries every month or two. This

practice will prolong battery life.

To preserve natural resources, please

recycle or dispose of batteries properly.

Thisproduct contains nickel-cadmium

battery. Local, st;ate,or federal laws may

prohibit d_posat of nickel-cadmium

batteries in ordinary _asJn.

(_sl_, _ur local waste a_tt_rity for information

available recyclingand/or d_uosal options.

BATIFERY PACK REMOVAL AND PREPARATION

FOR RECYCUNG

A W._lmNG: Upon removal,cover the battery pack's

tem_nals with heavy dutyadhesive tape. Do not

attempt to destroy or disassemble battery pack or

remove any of its components.Nickel-cadmium

I_tfe,ges mustbe recycledordisposedof properly.

Also, r_m/ertouch both terminals with metal objects

and/orbody parts as short circuit may result. Keep

,_way$Tomchildren. Failure to cor_ with these

couldresult in fire andic__m_ousinjury.

19

Page 20

CRAFTSMAN 14.4 VOLT CORDLESS TRIM SAW - MODEL NUMBER 315.113081 , i

5

27

12

3

10 _ 19 20 W 23

6

_..9 16 21 22

I

24

2

25

I I [ I J III I _ I _ I

2O

Page 21

_ CRAFTSMAN 14.4 VOLT CORDLESS TRIM SAW - MODEL NUMmER 316.113081

i i lJl I J IJ[IJllJ II _ I I I II III I J I I II _

{ The medal number wilD bs f°und °n a Plata etta(_hed l° the meter h°uslf*Ig' Always menti°rl the m°del number in eli c°rresp°ndanca re9_rdlng y°urI(_ORDLEB B 'TRIM SAW or when orderin 9 repalr parts.

i

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

i ii iiiii, iii i

PARTS LIST

Kay Part

No. Number

1 975546-000

2 975547-000

3 975544-000

4 5224502

5 975552-000

6 975581-000

7 975549-000

8 975559-000

9 975558-000

10 975850-000

11 983396-001

12 975557-000

13 975545-000

14 975543-000

15 5217802

Description Quan.

Carriage Bolt (M6 x 102 mm) ..................... 1

Base Assembly .......................................... 1

Lock Nut ..................................................... 2

Knob ........................................................... 2

Spring ......................................................... 1

Wing Screw ................................................ 1

Base Screw ................................................ 1

Hsx Nut ...................................................... 1

Borew......................................................... 1

Carriage Bolt(M6 x 13 ram) ....................... 1

Data Plate .................................................. 1

Warning Label ............................................ 1

Upper Blade Guard .................................... 1

Upper Blade Guard Screw ......................... 3

Bumper ....................................................... 1

I

i i ]

Key Part

No. Number

16 6619302

17 6867201

18 5599402

19 6807001

20 6850303

21 6600506

22 6112004

23 "982296-001

24 975533-000

25 975532-000

26 **Item No. 9 11006

27 **Item No._ 11007

28 975554-000

29 975553-000

30 982113-001

983000-051

I I i i i

* Available At Your Nearest Bears Catalog Order Or Retail Store

** Can Be Purohasad Thru RSOS (Retail Special Order System)

i i i i i i

Description Quart.

Bumper Screw........................................... I

Torsion Spring............................................ 1

Lower Blade Guard .................................... 1

BallBearing (NTN #6000ZZ) ..................... 1

BearingRetainer ........................................ 1

BearingRotnlner Borew............................. 4

Inner Blade Washer ................................... 1

Baw Blade .................................................. 1

Outer Blade Washer .................................. 1

Blade Screw ............................................... 1

Charger (1425005) ..................................... 1

Battery Pack (1310714) ............................. 1

Rip Guide ................................................... 1

Blade Wrench (5 mm Hex Key) ................. 1

Tool Bag - Not Shown ............................... 1

Operator's Manual

II I II i ! II i • J•rl I

J I i i iiii

21

Page 22

Yom'Home •

ii!i;ili

For repair - in your home- of all major brand appliances ....

and garden equipment, or heating and cooling systems,

no mal_e_rwho made it, no matterWbo sold

For the replacement parts, accessories and

owner's manuals that you need to de-it-yeu_elf

For Sears N_mat installation of _ _N_mces

and items like garage door openers and _ healers.

1-800-4-MY-HOME _ (1-8_

Ca, anytime day or night (U SA andCaRada)

1_1_111..._-_._ O1_ _. sear$._a

i!i!iiliii

Our Home

)

For repair of carry-in items like vacuums, lawn equipment, ......

,, and electronics, call or go on-line for the location of your nearest .......

Sears Parts & Repair Center ........

71

.

:)5

1-800-488 1222

Call anytime day or night (U S A only)

m.sears.com

r

To purchase protecik_ agreement by Sears

a on a product sen4ced :

11-8_-827-6655 (u s_) 1-800-381-6665 (Canada)

Para pedir servicio de _ Au Canada peer sen4ce en _:

a _, y para ordenar pkP.zas: 1

(1.-_8-533-68_7)

.... (_78€-642_

_8 ......

® R_emd Tra_l_ / _ T_ertak t _ Sen,_e Ma_ af S_'s, Roebuck and Co.

® Ma_a _'_Em_0_l_ / T_ &_n:a de F_bn_ / s_ Wa'_a de Sen,',c_ de Sears, _ an_ Co.

_c Mlan_e de _ / _ Marque d_Pe_e de Sears, P,ee_mx_ and Co, © S_rs, Roeb_ ano C4_.

Loading...

Loading...