Craftsman 31510411 Owner’s Manual

612547-207

OWNERS

MANUAL

MODEL NOr

315,1041-1

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

3/8 INCH

ELECTRIC DRILL

SAVE THIS

MANUAL FOR

FUTURE REFERENCE

el_$17,2gY

SEARS, ROEBUCK AND CO, Dept 698/73tA, Sears Tower. Chicago, IL 60884

t,4_e

DOUBLE INSULATED

VARIABLE SPEED

ADJUSTABLE - REVERSIBLE

Warranty

Introduction

Operation

Maintenance

Repair Parts

®

Dest ned exclusively for and sold only by

FULL ONE YEAR WARRANTY ON CRAFTSMAN ELECTRIC DRILL

If this Etectdc Drill fat_s to give complete satisfaction w_thtn one year from the date of purchase

RETURN tTTO THE NEAREST SEARS SERVtCE CENTER/DEPARTMENT THROUGHOUT THE UNITED

STATES and Sears will repair It, free of charge,

If this electric drill Is used for commercial or rental purposes this warJ:antyapptlas for only 90 days from

the date of purchase.

This warranty gives you specific tegat rights, end you may atso have other rights which vary from state

to state_

SEARS, ROEBUCK AND CO,

DEPT. 731CR,W

SEARS TOWER

CHICAGO. IL 60684

INTRODUCTION

DOUBLE INSULATION is a concept In safety, In elec,

trio power tools, which eliminates the need for the

usual three wire grounded power cord and grounded

supply system. Wherever there is electric current In

the tool there are two complete sets of insulation to

protect the user. Alt exposed metai parts are lsotated

Item the Internal metal motor components with pro..

tectlng InsuIatlon

RULES FOR SAFE OPERATION

READ ALL INSTRUCTIONS

1_ KNOW YOUR POWER T'OOL -- Read owner's manual carefully. Learn its ap-

plications and limitations as weft as the specific potential hazards related to

this tool.,

2, GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING BODY CONTACT

WITH GROUNDED SURFACES_ For example: Pipes, radiators, ranges, refrig-

erator enclosures.

3, KEEP GUARDS IN PLACE and in working order.

4 KEEP WORK AREA CLEAN, Cluttered areas and benches Invite accidents.

5, AVOID DANGEROUS ENVIRONMENT. Don't use power tool in damp or wet

locations or expose to rain_ Keep work area well lit.

6_ KEEP CHILDREN AWAY. Atl visitors should wear safety glasses and be kept

a safe distance from work area. Do not let visitors contact tool or extension

cord.

7_ STORE IDLE TOOLS. When not in use, tools should be stored In a dry, high or

locked-up place -- out of the reach of children,

8 DON'T FORCE TOOL It will do the Job better and safer at the rate for which it

was designed.

9 USE RiGRT TOOL. Don't force small tool or attachment to do the job of a heavy

duty tool Don't use toot for purpose not intended - for example - Don t use

a clrcutar saw for cutting tree limbs or logs=

10 WEAR PROPER APPAREL. No loose clothing or Jeweiry to get caught In moving

parts. Rubber gloves and non.skid footwear are recommended when working

outdoors, AJso, wear protective hair covering to contain long hair

11, USE SAFETY GLASSES with all toots. Also face or dust mask if operation Is

dusty_

IMPORTANT -- Servicing of a tool with double fn-

su_ation requires extreme care and knowledge of the

system and should be performed cnty by e qualified

service technician. For service we suggest you

return the tool to your nearest Sears Store for repair,

Always use original factory replacement parts whoa

servicing.

Page 2

RULES FOR SAFE OPERATION (Continued)

12 DON'T ABUSE CORD, Never carry tool by cord or yank it to disconnect from

receptacle. Keep cord from heat, oi!, and sharp edges.

13. SECURE WORK+ Use clamps or a vise to hold work, Both hands are needed to

operate the tool

!4, DON'T OVERREACH. Keep proper footing and balance at all times+ Do not use

on a ladder or unstable support, •

t5, MAINTAIN TOOLS WITH CARE,, Keep tools sharp at all ttmes, and clean for best

and safest performance Fotlow instructions for lubricating and chang+rig ac-

cessories,

16 DISCONNECT TOOLS. When not in use, before servicing, or when changing at-

tachments, blades, bits, cutters, etc, all tools should be disconnected from

ower supply.

17 REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are removed from toot before turning it on

18, AVOID ACCIDENTAL STARTING,, Don't carry plugged+in toots with f_nger on

switch. Be sure switch is off when plugging in+

19, OUTDOOR USE EXTENSION CORDS, When tool is used outdoors, use only

extension cords suitable for use outdoors Outdoor approved cords are marked

wtth the suffix W.A for example -- SJTW-A or SJOW+A+

20_ KEEP BITS CLEAN AND SHARP+ Sharp bits minimize stalling and klckbac_

21+ KEEP HANDS AWAY FROM DRILLING AREA,, Keep hands away from bits Do

not reach underneath work white b_t is rotating- Do not attempt to remove

material while bit is rotating,

22_ NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal sparking of the motor

could tgnlte fumes.

23+ INSPECT TOOL CORDS PERIODICALLY and if damaged, have repaired at your

nearest Sears Repair Center.

24 INSPECT EXTENSION CORDS PERIODICALLY and replace tf damaged,

25+ KEEP HANDLES DRY, CLEAN, AND FREE FROM OIL AND GREASE. Always

use a clean cloth when cleaning. Never use brake fluids, gasoline, petroleum-

based products or any strong solvents to clean your toot,

26 STAY ALERT. Watch what you are doing and use common sense Do not op,

erate tool when you are tired,, Do not rush

27, CHECK DAMAGED PARTS,, Before further use of the toot, a guard or other part

that ts damaged should be carefully checked to determine that It witl operate

properly and perform its intended function, Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other

conditions that may affect its operation A guard or other part that is damaged

should beproperly repaired or replaced by an authorized service center,

28+ DO NOT USE TOOL IF SWITCH DOES NOTTURN IT ON AND OFF,, Have defect,

ire switches replaced by an authorized service center.

29 DRILLING INTO ELECTRICAL WIRING IN WALLS CAN CAUSE DRILL BIT AND

CHUCK TO BECOME ELECTRICALLY LIVE. Do not touch the chuck or metal

houslng when drilling into a wail; grasp only the Insulated handle(s) provided on

the tool.,

30. Inspect for and remove al! naits from lumber before drilling.

3t DRUGS, ALCOHOL, MEDICATION, Do not operate tool while under the influ-

ence of drugs atcohol, or any medication

32 WEAR HEARING PROTECT ON DUR NG EXTENDED PERIODS OF OPERA.

TION.

33 SAVE THESE INSTRUCTIONS, Refer to them frequently and use them to

instruct third party users ff you loan someone this toot, loan them these

Instructions also,

PagB 3

OPERATION

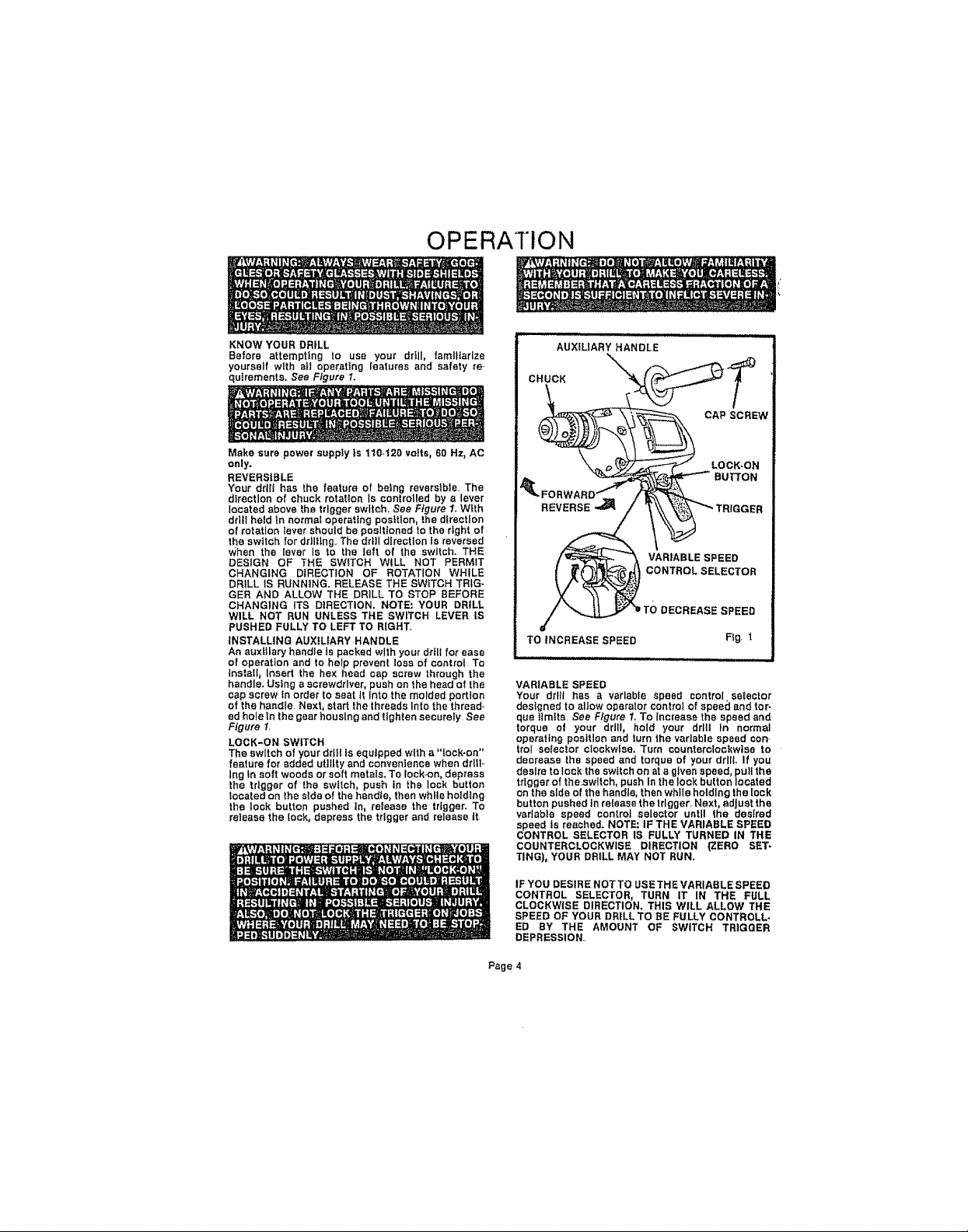

KNOW YOUR DRILL

Before attempting to use your drill, familiarize

yourself with all operat ng leatures and safety re

quirements. See Figure 1.

Make sure power supply is t10o120 veils, 60 Hz, AC

only.

REVERSIBLE

Your ddit has the feature of being reversible, The

direction of chuck rotafion Is controlled by a lever

located above the trigger sw_loh, See Figure 1. With

drill held In normal operating position, the direction

of rotatton lever should be positioned to the right of

the switch for drilling The dd}l direction fe reversed

When the iever ts to the left of the switch, THE

DESIGN OF THE SWITCH WILL NOT PERMIT

CHANGING DIRECTION OF ROTATION WHILE

DRILL IS RUNNING. RELEASE THE SWITCH TRIG-

GER AND ALLOW THE DRILL TO STOP BEFORE

CHANGING iTS DIRECTION, NOTE: YOUR DRILL

WILL NOT RUN UNLESS THE SWITCH LEVER IS

PUSHED FULLY TO LEFT TO RIGHT.

INSTALLING AUXIUARY HANDLE

An auxtUary handle is packed with your drill for ease

of operation and to help prevent loss of control To

Instal_, Insert the hex head cap screw through the

handle, Using a screwdriver, push on the head of the

cap screw in order to seat tt Into the molded portion

of the handie. Next, start the threads Into the thread..

ed hole In the gear housing and tighten securely See

Figure I,

LOCK-ON SWITCH

The switch of your drUl is equipped w_th a "lock.on"

feature for added ut]ltty and convenience when drill,,

lng In soft woods or soft metaSs, To lock-on, depress

the trigger of the switch, push in the lock button

located on the side of the hendte, then while h01dlng

the look button pushed in, release the trigger. To

release the took, depress the tdgger and release tt

AUXILIARY HANDLE

CHUCK "XX"x4

CAP SCREW

LOCK-ON

VARIABLE SPEED

CONTROL SELECTOR

DECREASE SPEED

TO INCREASE SPEED

VARIABLE SPEED

Your drill has a variable speed control, selector

deslgned to allow operator central of speed and tor-

que tlmits See Figure 1, To Increase the speed and

torque of your drift, hold your dill! tn normal

operating position and turn the variable speed conh

trol seteotor clockwfee. Turn counterclockwise to

decrease the speed and torque of your drill If you

desire to lock the switch on at a given speed, pull the

trigger of the.switch, push In the lock button located

on the side of the handle, then while holding the Iock

button pushed In release the Irlgger, Next, adjust the

varlabte speed control selector until the desired

speed is reached. NOTE: IF THE VARIABLE SPEED

CONTROL SELECTOR IS FULLY TURNED IN THE

COUNTERCLOCKWISE DIRECTION {ZERO SET.

TTNG), YOUR DRILL MAY NOT RUN.

Fig. 1

IF YOU DESIRE NOT TO USE THE VARIABLE SPEED

CONTROL SELECTOR, TURN IT IN THE FULL

CLOCKWISE DIRECTION, THIS WILL ALLOW THE

SPEED OF YOUR DRtLL TO BE FULLY CONTROLL.

ED BY THE AMOUNT OF SWITCH TRIGGER

DEPRESSION=

Page 4

Loading...

Loading...