Page 1

Professional Shop Manual

Electric Module

28906,28980, 28981,28984

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperi-

enced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product's Oper-

ators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accurate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2010 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

,FORM NUMBER-769-06468

09/2010

Page 2

Table of Contents

Introduction ....................................................................................................... 1

Professional Shop manual intent ...................................................................... 1

Fasteners ......................................................................................................... 1

Assembly .......................................................................................................... 1

Description of the GT series ............................................................................. 2

Model and Serial Numbers ............................................................................... 2

Precautions ...................................................................................................... 2

RMC Module .................................................................................................... 3

Key switch ........................................................................................................ 3

RMC module .................................................................................................... 5

RMC module plug test (electric PTO) ............................................................... 7

RMC module plug test (manual PTO) .............................................................. 9

Electric PTO switch ......................................................................................... 11

PTO relay ........................................................................................................ 11

PTO switch (manual PTO) .............................................................................. 12

Brake switch (manual PTO) ............................................................................ 12

Brake switch (electric PTO) ............................................................................. 13

Park brake switch ............................................................................................ 14

Reverse Safety Switch .................................................................................... 14

Seat Safety Switch .......................................................................................... 15

Starter solenoid ............................................................................................... 16

Fuse ................................................................................................................ 17

Electrical diagnosis .......................................................................................... 17

Electrical environment: AC Vs. DC .................................................................. 19

Types of circuits .............................................................................................. 21

Series ........................................................................................................... 21

Parallel ......................................................................................................... 21

Series/parallel .................................................................................................. 22

Shorts ........................................................................................................... 22

Opens ........................................................................................................... 22

Increased resistance ....................................................................................... 22

The Tools ........................................................................................................ 22

Equipment that may be useful: ........................................................................ 22

Digital Multi-meter ........................................................................................... 23

Wiring diagram or schematic ........................................................................... 24

Fused jumper wires ......................................................................................... 24

Test lights (high impedance) ........................................................................... 24

Ammeters and specialized charging system testers

Batteries .......................................................................................................... 27

Battery Testers: ............................................................................................... 29

Testing the battery: .......................................................................................... 29

Voltage Drop Test ........................................................................................... 33

Testing switches .............................................................................................. 35

Relay ............................................................................................................... 36

Diodes ............................................................................................................. 37

Schematics ...................................................................................................... 39

Page 3

CRAFTSMAN

Page 4

INTRODUCTION

ELECTRICALSYSTEM

INTRODUCTION

This module is divided into four sections:

Section 1: About this module and precautions

Section 2: Components

This section will describe the location and opera-

tion of the electrical components on the tractor.

Where appropriate, some disassembly or com-

ponent removal instructions will be included.

Section 3: Diagnostic Techniques

This section will cover basic tools, techniques,

and methodology for diagnosing electrical issues

on the tractor. A lot of the information in this sec-

tion can be applied to other equipment.

Section 4: Schematics

Professional Shop manual intent

This Manual is intended to provide service dealers with

an introduction to the mechanical aspects of the new

900 series tractor.

Detailed service information about the engine

will be provided by the engine manufacturer, in

most cases.

Disclaimer: This manual was written using first gener-

ation tractors. The information contained in this shop

manual is correct at the time of writing. Both the prod-

uct and the information about the product are subject to

change without notice.

About the text format:

• Bullet points: indicate sub-steps or points.

Disclaimer: This Professional Shop Manual is

intended for use by trained, professional technicians.

• Common sense in operation and safety is

assumed.

In no event shall MTD be liable for poor text

interpretation, or poor execution of the proce-

dures described in the text.

If the person using this manual is uncomfortable

with any procedures they encounter, they should

seek the help of a qualified technician.

Fasteners

Most of the fasteners used on the tractor are

sized in fractional inches. Some are metric. For

this reason, wrench sizes are frequently identi-

fied in the text, and measurements are given in

U.S. and metric scales.

If a fastener has a locking feature that has worn,

replace the fastener or apply a small amount of

releasable threadlocking compound such as

Loctite® 242 (blue).

Some fasteners like cotter pins are single-use

items that are not to be reused. Other fasteners

such as lock washers, retaining rings, and inter-

nal cotter pins (hairpin clips) may be reused if

they do not show signs of wear or damage. This

manual leaves that decision to the judgement of

the technician.

Assembly

NOTE: is used to point-out information that is

relevant to the procedure, but does not fit as a

step in the procedure.

CAUTION: Indicates a potentially hazardous sit-

uation that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

DANGER: Indicates an imminently hazardous

situation that, if not avoided, will result in death

or serious injury. This signal word is to be lim-

ited to the most extreme situations.

WARNING: Indicates a potentially hazardous

situation that, if not avoided, could result in

death of serious injury.

Torque specifications may be noted in the part of the

text that covers assembly, they may also be summa-

rized in tables along with special instructions regarding

locking or lubrication. Whichever method is more

appropriate will be used. In many cases, both will be

used so that the manual is handy as a quick-reference

guide as well as a step-by-step procedure guide that

does not require the user to hunt for information.

The level of assembly instructions provided will be

determined by the complexity and of reassembly, and

by the potential for unsafe conditions to arise from mis-

takes made in assembly.

Some instructions may refer to other parts of the man-

ual for subsidiary procedures. This avoids repeating

the same procedure two or three times in the manual.

Page 5

CRAFTSMAN

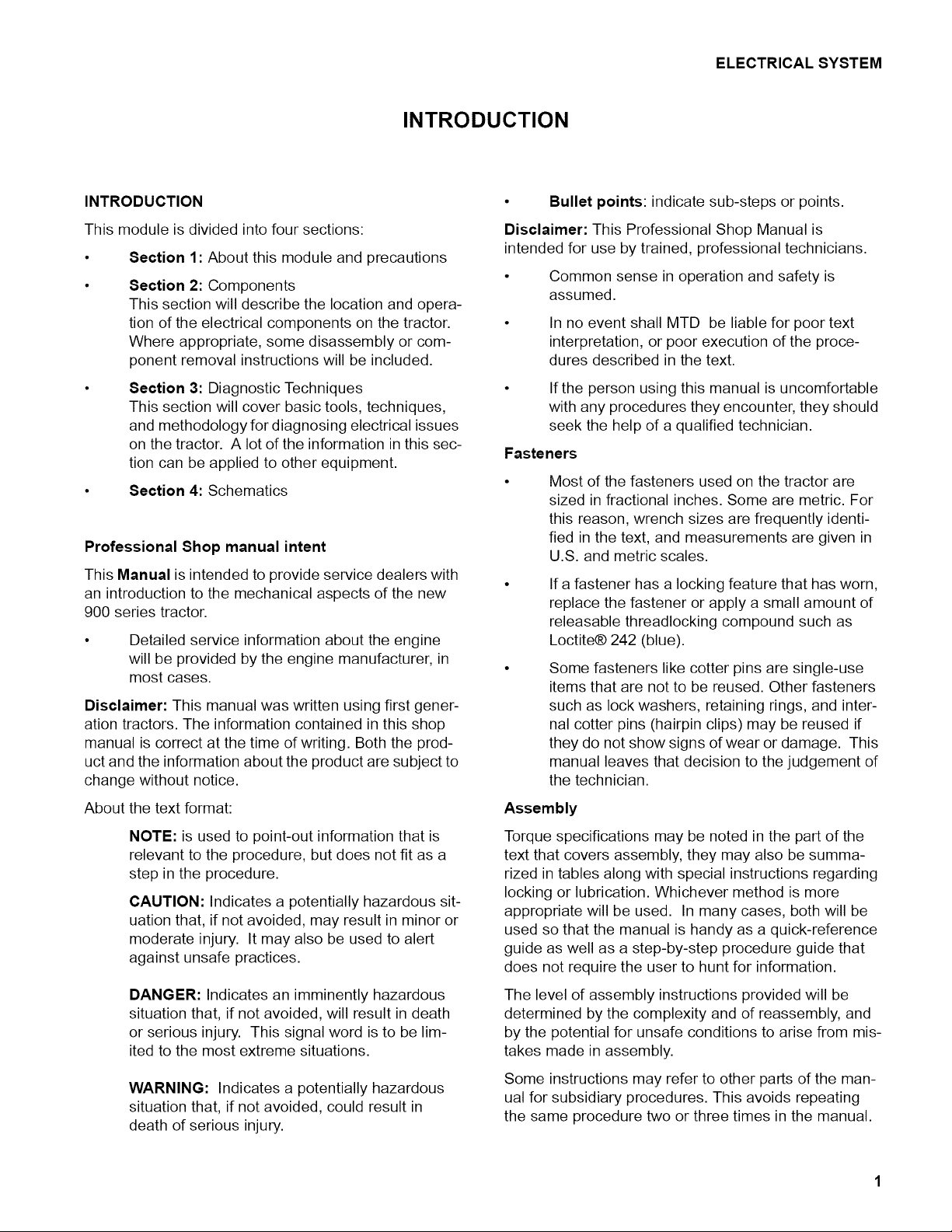

Description of the GT series

This tractor platform introduced in the 2010 season..

See Figure 1.1.

Figure 1.1

• New stronger frame

• New hood and grill designs

• Bumper

• A new 2 blade 46" deck

• Tighter turning radius

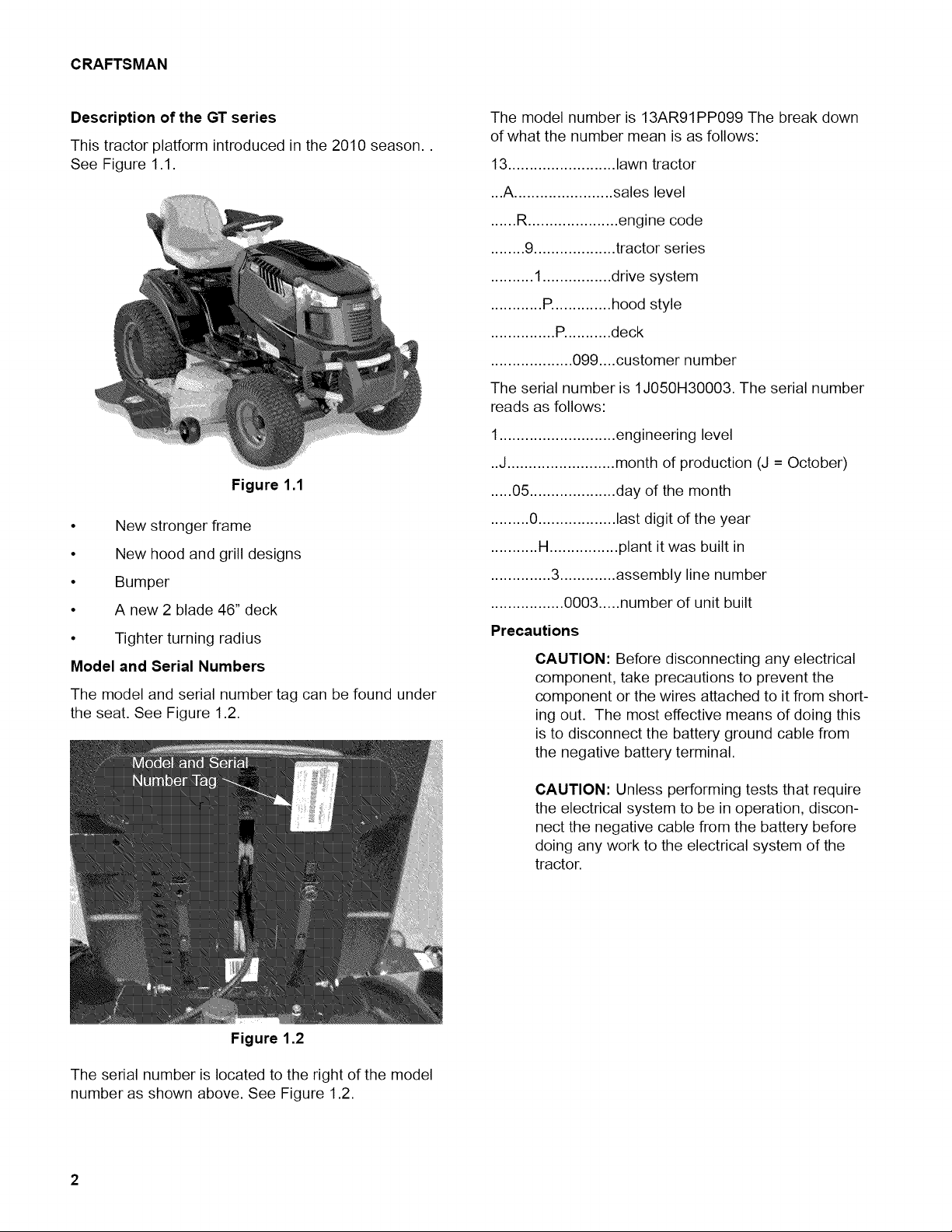

Model and Serial Numbers

The model and serial number tag can be found under

the seat. See Figure 1.2.

The model number is 13AR91PP099 The break down

of what the number mean is as follows:

13......................... lawn tractor

...A....................... sales level

......R..................... engine code

........9................... tractor series

.......... 1................ drive system

............ R............. hood style

............... P........... deck

................... 099 ....customer number

The serial number is 1J050H30003. The serial number

reads as follows:

1........................... engineering level

..J......................... month of production (J = October)

.....05 .................... day of the month

.........0.................. last digit of the year

........... H................ plant it was built in

.............. 3............. assembly line number

................. 0003 ..... number of unit built

Precautions

CAUTION: Before disconnecting any electrical

component, take precautions to prevent the

component or the wires attached to it from short-

ing out. The most effective means of doing this

is to disconnect the battery ground cable from

the negative battery terminal.

Figure 1.2

The serial number is located to the right of the model

number as shown above. See Figure 1.2.

2

CAUTION: Unless performing tests that require

the electrical system to be in operation, discon-

nect the negative cable from the battery before

doing any work to the electrical system of the

tractor.

Page 6

ELECTRICAL SYSTEM

ELECTRICALSYSTEM

COMPONENTS

RMC Module

The RMC module contains electronic logic circuits.

When diagnosing anything that is connected to the

RMC module, a high impedance test light or a high

impedance digital multi-meter (DMM) must be used.

The amperage draw of a standard incandescent test

light may over-burden some internal electronic circuits,

burning-out the module.

It is typical when industries shift from electro-

mechanical to electronic controls that diagnosis

shifts from tracing through a number of indepen-

dent circuits to checking the in-puts to and out-

puts from a central processor. This is similar to,

but much less complex than the transition that

the auto industry made with the conversion to

fuel injection in the 1980s.

NOTE: The starter safety circuit has no connec-

tion to the RMC module.

The only one switch in the safety circuit that is

capable of turning-off the engine works through

the RMC module.

It is still important to be familiar with the workings

of the individual components of the electrical

system, but some of them can now be checked

from a central point on the tractor. This makes

life easier on the technician, frequently making it

unnecessary to connect to difficult to reach

switches in the preliminary stages of trouble-

shooting.

The function of individual safety switches can be

seen as providing information "inputs" to the

RMC module.

The next part of this section gives a detailed

description of the electrical components on this

tractor, their function in the system, and their

physical location on the tractor. Armed with this

information and the proper tools, a technician

should be able to efficiently diagnose most elec-

trical problems.

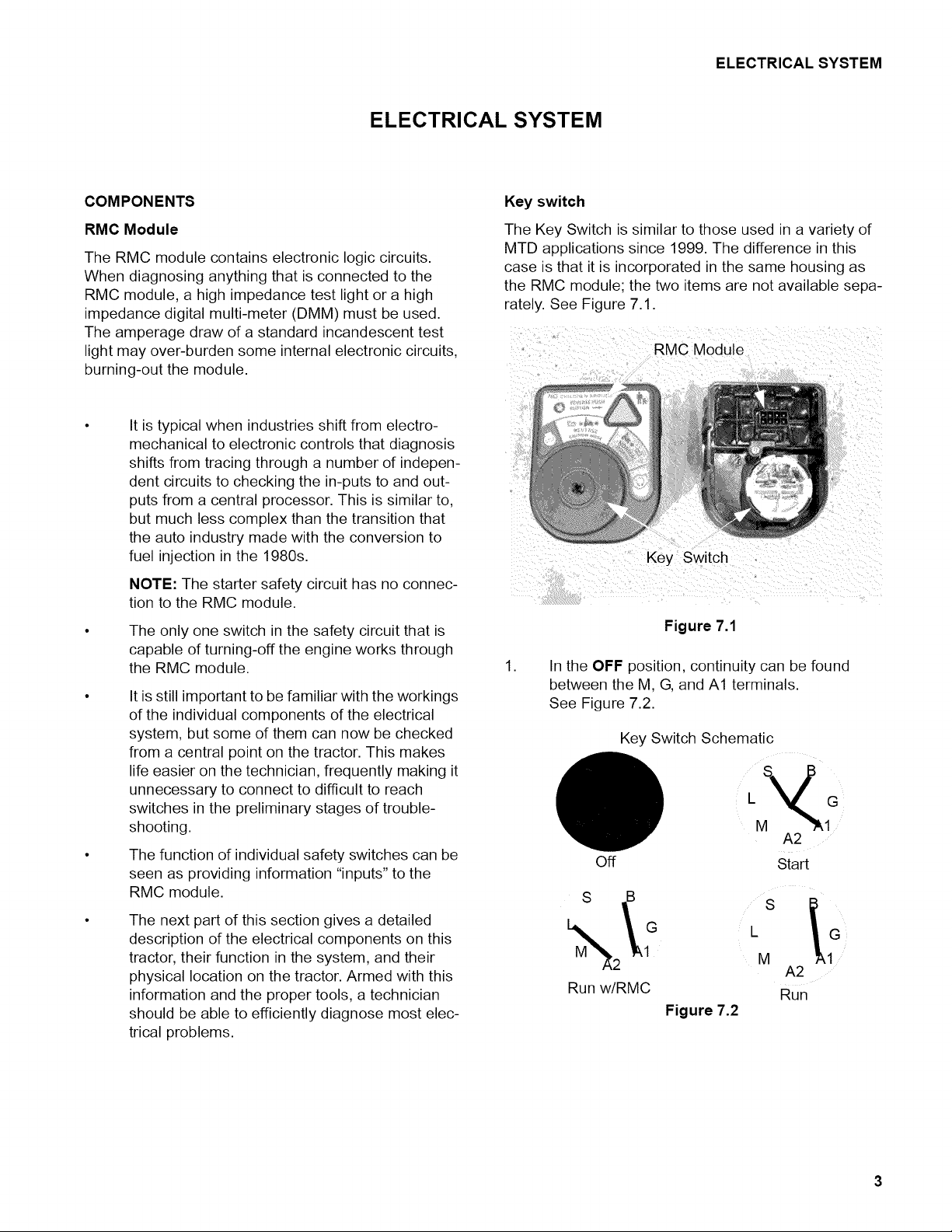

Key switch

The Key Switch is similar to those used in a variety of

MTD applications since 1999. The difference in this

case is that it is incorporated in the same housing as

the RMC module; the two items are not available sepa-

rately. See Figure 7.1.

RMC Module

Key Switch

Figure 7.1

,

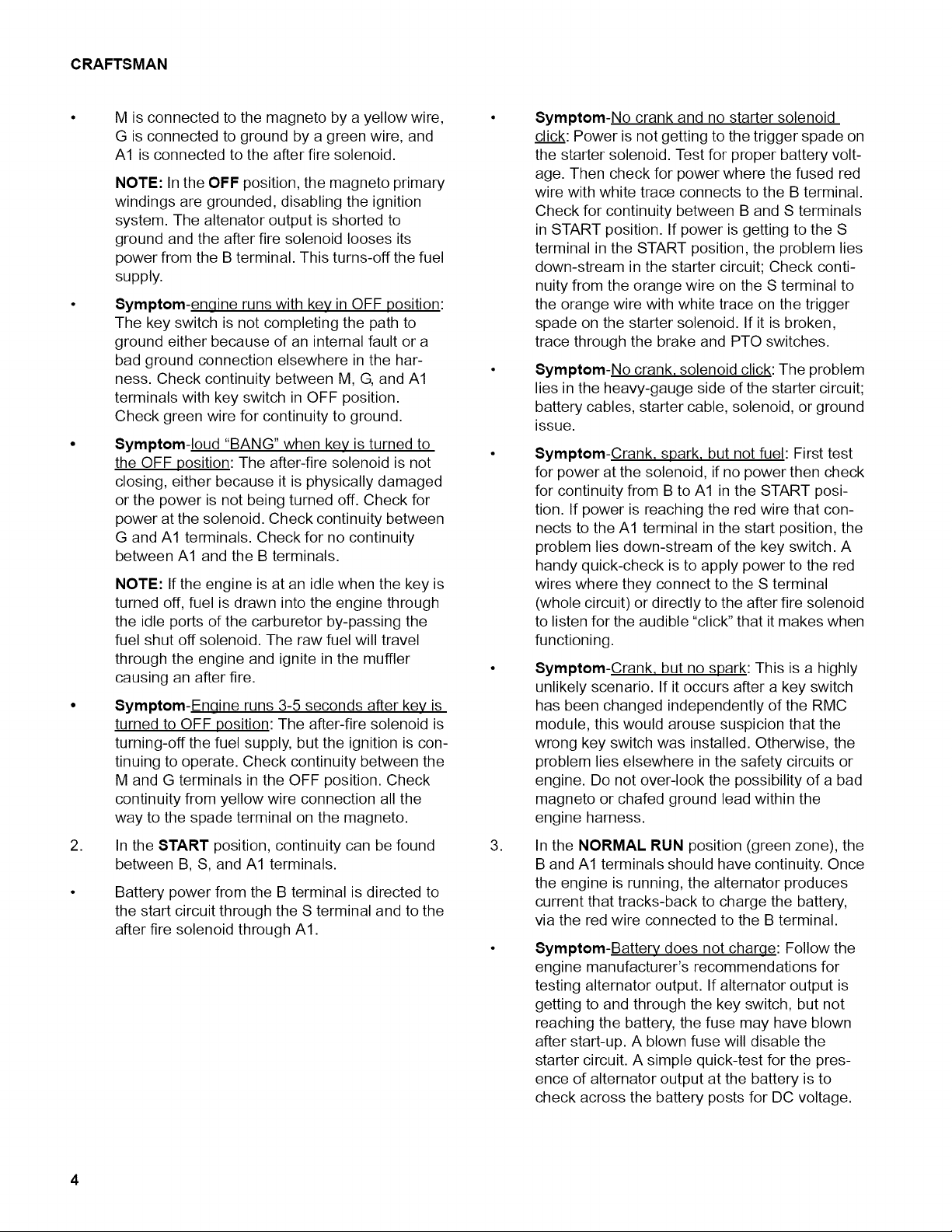

In the OFF position, continuity can be found

between the M, G, and A1 terminals.

See Figure 7.2.

Key Switch Schematic

A2

Off

S B

1

2

Run w/RMC

Figure 7.2

Start

S

L

M

A2

Run

3

Page 7

CRAFTSMAN

M is connected to the magneto by a yellow wire,

G is connected to ground by a green wire, and

A1 is connected to the after fire solenoid.

NOTE: In the OFF position, the magneto primary

windings are grounded, disabling the ignition

system. The altenator output is shorted to

ground and the after fire solenoid looses its

power from the B terminal. This turns-off the fuel

supply.

Symptom-enqine runs with key in OFF position:

The key switch is not completing the path to

ground either because of an internal fault or a

bad ground connection elsewhere in the har-

ness. Check continuity between M, G, and A1

terminals with key switch in OFF position.

Check green wire for continuity to ground.

Symptom-loud "BANG" when key is turned to

the OFF position: The after-fire solenoid is not

closing, either because it is physically damaged

or the power is not being turned off. Check for

power at the solenoid. Check continuity between

G and A1 terminals. Check for no continuity

between A1 and the B terminals.

NOTE: If the engine is at an idle when the key is

turned off, fuel is drawn into the engine through

the idle ports of the carburetor by-passing the

fuel shut off solenoid. The raw fuel will travel

through the engine and ignite in the muffler

causing an after fire.

Symptom-Enqine runs 3-5 seconds after key is

turned to OFF position: The after-fire solenoid is

turning-off the fuel supply, but the ignition is con-

tinuing to operate. Check continuity between the

M and G terminals in the OFF position. Check

continuity from yellow wire connection all the

way to the spade terminal on the magneto.

,

In the START position, continuity can be found

between B, S, and A1 terminals.

Battery power from the B terminal is directed to

the start circuit through the S terminal and to the

after fire solenoid through A1.

Symptom-No crank and no starter solenoid

click: Power is not getting to the trigger spade on

the starter solenoid. Test for proper battery volt-

age. Then check for power where the fused red

wire with white trace connects to the B terminal.

Check for continuity between B and S terminals

in START position. If power is getting to the S

terminal in the START position, the problem lies

down-stream in the starter circuit; Check conti-

nuity from the orange wire on the S terminal to

the orange wire with white trace on the trigger

spade on the starter solenoid. If it is broken,

trace through the brake and PTO switches.

Symptom-No crank, solenoid click: The problem

lies in the heavy-gauge side of the starter circuit;

battery cables, starter cable, solenoid, or ground

issue.

Symptom-Crank, spark, but not fuel: First test

for power at the solenoid, if no power then check

for continuity from B to A1 in the START posi-

tion. If power is reaching the red wire that con-

nects to the A1 terminal in the start position, the

problem lies down-stream of the key switch. A

handy quick-check is to apply power to the red

wires where they connect to the S terminal

(whole circuit) or directly to the after fire solenoid

to listen for the audible "click" that it makes when

functioning.

Symptom-Crank, but no spark: This is a highly

unlikely scenario. If it occurs after a key switch

has been changed independently of the RMC

module, this would arouse suspicion that the

wrong key switch was installed. Otherwise, the

problem lies elsewhere in the safety circuits or

engine. Do not over-look the possibility of a bad

magneto or chafed ground lead within the

engine harness.

,

In the NORMAL RUN position (green zone), the

B and A1 terminals should have continuity. Once

the engine is running, the alternator produces

current that tracks-back to charge the battery,

via the red wire connected to the B terminal.

Symptom-Battery does not charqe: Follow the

engine manufacturer's recommendations for

testing alternator output. If alternator output is

getting to and through the key switch, but not

reaching the battery, the fuse may have blown

after start-up. A blown fuse will disable the

starter circuit. A simple quick-test for the pres-

ence of alternator output at the battery is to

check across the battery posts for DC voltage.

4

Page 8

ELECTRICAL SYSTEM

Symptom-After fire solenoid does not work:

enqine starts and dies: The after fire solenoid is

powered directly by the red wire from the B ter-

minal of the key switch, and should operate

independently of anything else on the tractor

once the engine is running. If the alternator fails

and battery power is not reaching the after fire

solenoid through the key switch, it will not work.

This is an unusual set of circumstances.

,

In the REVERSE CAUTION MODE (yellow

zone), the same characteristics are true as for

the normal run position, but in addition the L ter-

minal will have continuity with the A2 terminal.

The A2 terminal is connected to the RMC mod-

ule by a purple wire (electric PTO) or a white

wire (manual PTO). The L terminal (formerly

used for the lighting circuit) connects directly to

the ground circuit of green wires. When the key

is in the REVERSE CAUTION MODE position,

the purple wire carries a ground signal to the

RMC module. When the parking brake is not set,

this ground signal arms (enables), but does not

tum-on the RMC module.

Symptom-RMC module will not turn-on: Check

for continuity between A2 and L terminals on the

key switch when it is in the REVERSE CAUTION

MODE position. Confirm that the green wire has

continuity to ground. If the switch is capable of

establishing a ground signal to the RMC module,

the problem is likely to lie elsewhere in the sys-

tem.

Symptom-RMC module will not turn-on: confirm

that the ground path (continuity to ground) to the

purple or white wire is broken when the key

switch is in any position other than REVERSE

CAUTION MODE. The RMC module is disarmed

(disabled) when the parking brake is set. To re-

arm the module, the key is moved to another

position, breaking the ground signal, then

returned to the REVERSE CAUTION MODE, re-

establishing the ground signal. It works some-

thing like a latched relay. If it is not possible to

break the ground-path, it is not possible to

freshly establish it either, and the RMC module

will not be armable. Causes for such a condition

might include a shorted or incorrect key switch,

or a chafed purple wire shorting to ground

between the key switch and the RMC module.

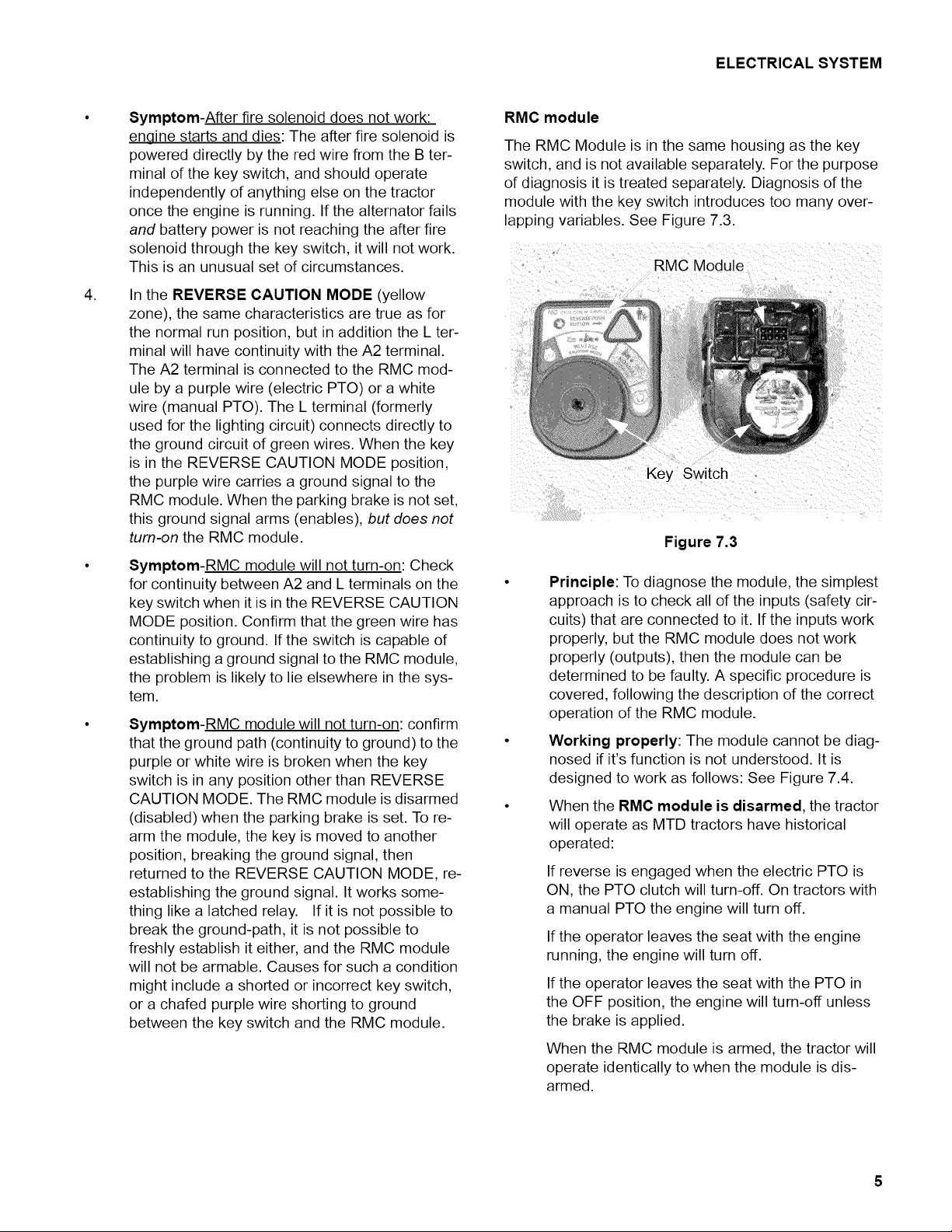

RMC module

The RMC Module is in the same housing as the key

switch, and is not available separately. For the purpose

of diagnosis it is treated separately. Diagnosis of the

module with the key switch introduces too many over-

lapping variables. See Figure 7.3.

RMC Module

Key Switch

Figure 7.3

Principle: To diagnose the module, the simplest

approach is to check all of the inputs (safety cir-

cuits) that are connected to it. If the inputs work

properly, but the RMC module does not work

properly (outputs), then the module can be

determined to be faulty. A specific procedure is

covered, following the description of the correct

operation of the RMC module.

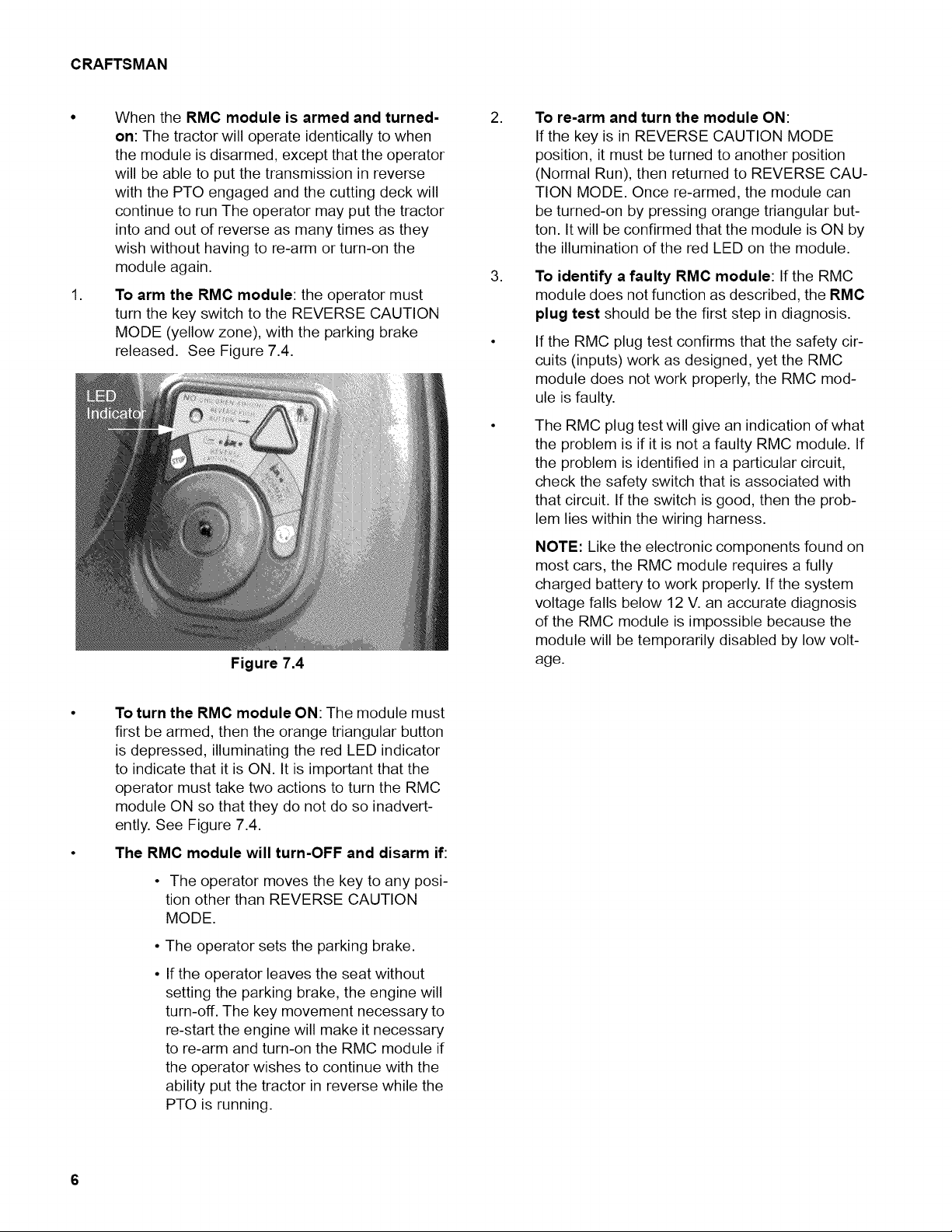

Working properly: The module cannot be diag-

nosed if it's function is not understood. It is

designed to work as follows: See Figure 7.4.

When the RMC module is disarmed, the tractor

will operate as MTD tractors have historical

operated:

If reverse is engaged when the electric PTO is

ON, the PTO clutch will turn-off. On tractors with

a manual PTO the engine will turn off.

If the operator leaves the seat with the engine

running, the engine will turn off.

If the operator leaves the seat with the PTO in

the OFF position, the engine will turn-off unless

the brake is applied.

When the RMC module is armed, the tractor will

operate identically to when the module is dis-

armed.

5

Page 9

CRAFTSMAN

When the RMC module is armed and turned-

on: The tractor will operate identically to when

the module is disarmed, except that the operator

will be able to put the transmission in reverse

with the PTO engaged and the cutting deck will

continue to run The operator may put the tractor

into and out of reverse as many times as they

wish without having to re-arm or turn-on the

module again.

,

To arm the RMC module: the operator must

turn the key switch to the REVERSE CAUTION

MODE (yellow zone), with the parking brake

released. See Figure 7.4.

Figure 7.4

,

To re-arm and turn the module ON:

If the key is in REVERSE CAUTION MODE

position, it must be turned to another position

(Normal Run), then returned to REVERSE CAU-

TION MODE. Once re-armed, the module can

be turned-on by pressing orange triangular but-

ton. It will be confirmed that the module is ON by

the illumination of the red LED on the module.

,

To identify a faulty RMC module: If the RMC

module does not function as described, the RMC

plug test should be the first step in diagnosis.

If the RMC plug test confirms that the safety cir-

cuits (inputs) work as designed, yet the RMC

module does not work properly, the RMC mod-

ule is faulty.

The RMC plug test will give an indication of what

the problem is if it is not a faulty RMC module. If

the problem is identified in a particular circuit,

check the safety switch that is associated with

that circuit. If the switch is good, then the prob-

lem lies within the wiring harness.

NOTE: Like the electronic components found on

most cars, the RMC module requires a fully

charged battery to work properly. If the system

voltage falls below 12 V. an accurate diagnosis

of the RMC module is impossible because the

module will be temporarily disabled by low volt-

age.

To turn the RMC module ON: The module must

first be armed, then the orange triangular button

is depressed, illuminating the red LED indicator

to indicate that it is ON. It is important that the

operator must take two actions to turn the RMC

module ON so that they do not do so inadvert-

ently. See Figure 7.4.

The RMC module will turn-OFF and disarm if:

• The operator moves the key to any posi-

tion other than REVERSE CAUTION

MODE.

The operator sets the parking brake.

If the operator leaves the seat without

setting the parking brake, the engine will

turn-off. The key movement necessary to

re-start the engine will make it necessary

to re-arm and turn-on the RMC module if

the operator wishes to continue with the

ability put the tractor in reverse while the

PTO is running.

6

Page 10

ELECTRICAL SYSTEM

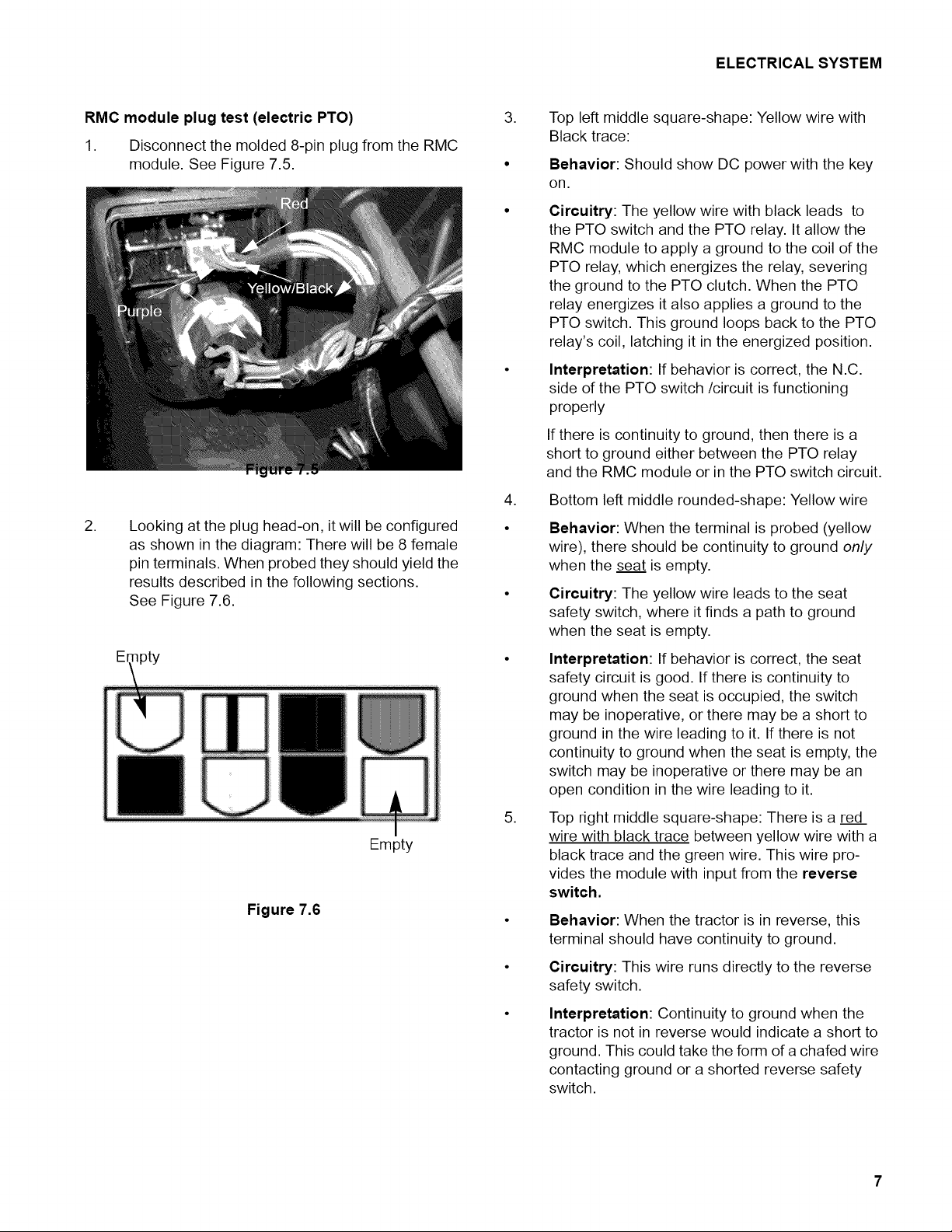

RMC module plug test (electric PTO)

1. Disconnect the molded 8-pin plug from the RMC

module. See Figure 7.5.

,

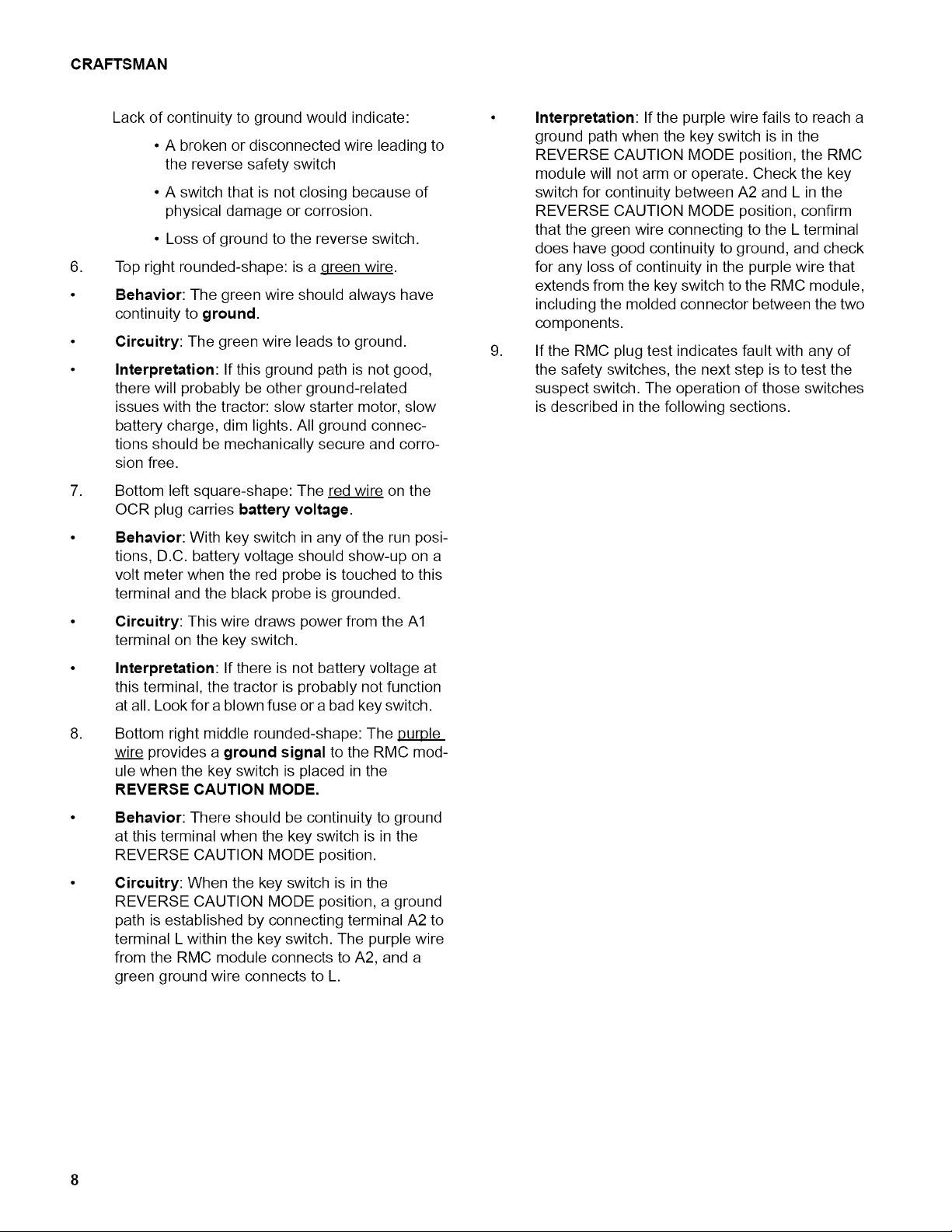

Looking at the plug head-on, it will be configured

as shown in the diagram: There will be 8 female

pin terminals. When probed they should yield the

results described in the following sections.

See Figure 7.6.

Empty

Empty

Figure 7.6

,

Top left middle square-shape: Yellow wire with

Black trace:

Behavior: Should show DC power with the key

on.

Circuitry: The yellow wire with black leads to

the PTO switch and the PTO relay. It allow the

RMC module to apply a ground to the coil of the

PTO relay, which energizes the relay, severing

the ground to the PTO clutch. When the PTO

relay energizes it also applies a ground to the

PTO switch. This ground loops back to the PTO

relay's coil, latching it in the energized position.

Interpretation: If behavior is correct, the N.C.

side of the PTO switch/circuit is functioning

properly

If there is continuity to ground, then there is a

short to ground either between the PTO relay

and the RMC module or in the PTO switch circuit.

,

Bottom left middle rounded-shape: Yellow wire

Behavior: When the terminal is probed (yellow

wire), there should be continuity to ground only

when the seat is empty.

Circuitry: The yellow wire leads to the seat

safety switch, where it finds a path to ground

when the seat is empty.

Interpretation: If behavior is correct, the seat

safety circuit is good. If there is continuity to

ground when the seat is occupied, the switch

may be inoperative, or there may be a short to

ground in the wire leading to it. If there is not

continuity to ground when the seat is empty, the

switch may be inoperative or there may be an

open condition in the wire leading to it.

,

Top right middle square-shape: There is a red

wire with black trace between yellow wire with a

black trace and the green wire. This wire pro-

vides the module with input from the reverse

switch.

Behavior: When the tractor is in reverse, this

terminal should have continuity to ground.

Circuitry: This wire runs directly to the reverse

safety switch.

Interpretation: Continuity to ground when the

tractor is not in reverse would indicate a short to

ground. This could take the form of a chafed wire

contacting ground or a shorted reverse safety

switch.

7

Page 11

CRAFTSMAN

Lack of continuity to ground would indicate:

• A broken or disconnected wire leading to

the reverse safety switch

• A switch that is not closing because of

physical damage or corrosion.

• Loss of ground to the reverse switch.

,

Top right rounded-shape: is a qreen wire.

Behavior: The green wire should always have

continuity to ground.

Circuitry: The green wire leads to ground.

Interpretation: If this ground path is not good,

there will probably be other ground-related

issues with the tractor: slow starter motor, slow

battery charge, dim lights. All ground connec-

tions should be mechanically secure and corro-

sion free.

,

Bottom left square-shape: The red wire on the

OCR plug carries battery voltage.

Behavior: With key switch in any of the run posi-

tions, D.C. battery voltage should show-up on a

volt meter when the red probe is touched to this

terminal and the black probe is grounded.

Interpretation: If the purple wire fails to reach a

ground path when the key switch is in the

REVERSE CAUTION MODE position, the RMC

module will not arm or operate. Check the key

switch for continuity between A2 and L in the

REVERSE CAUTION MODE position, confirm

that the green wire connecting to the L terminal

does have good continuity to ground, and check

for any loss of continuity in the purple wire that

extends from the key switch to the RMC module,

including the molded connector between the two

components.

,

If the RMC plug test indicates fault with any of

the safety switches, the next step is to test the

suspect switch. The operation of those switches

is described in the following sections.

Circuitry: This wire draws power from the A1

terminal on the key switch.

Interpretation: If there is not battery voltage at

this terminal, the tractor is probably not function

at all. Look for a blown fuse or a bad key switch.

,

Bottom right middle rounded-shape: The DurDle

wire provides a ground signal to the RMC mod-

ule when the key switch is placed in the

REVERSE CAUTION MODE.

Behavior: There should be continuity to ground

at this terminal when the key switch is in the

REVERSE CAUTION MODE position.

Circuitry: When the key switch is in the

REVERSE CAUTION MODE position, a ground

path is established by connecting terminal A2 to

terminal L within the key switch. The purple wire

from the RMC module connects to A2, and a

green ground wire connects to L.

8

Page 12

ELECTRICALSYSTEM

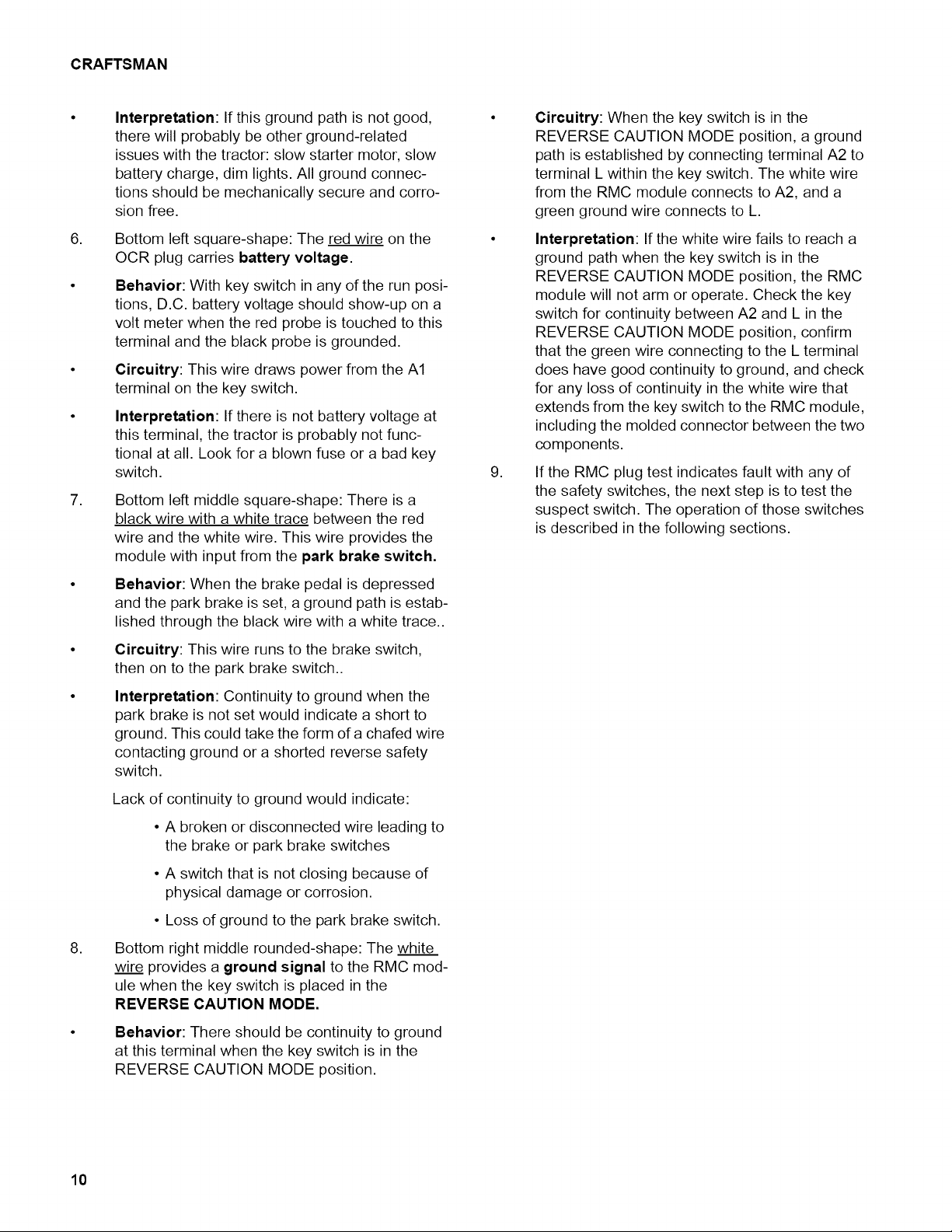

RMCmoduleplugtest(manualPTO)

1. Disconnect the molded 8-pin plug from the RMC

module. See Figure 7.7.

,

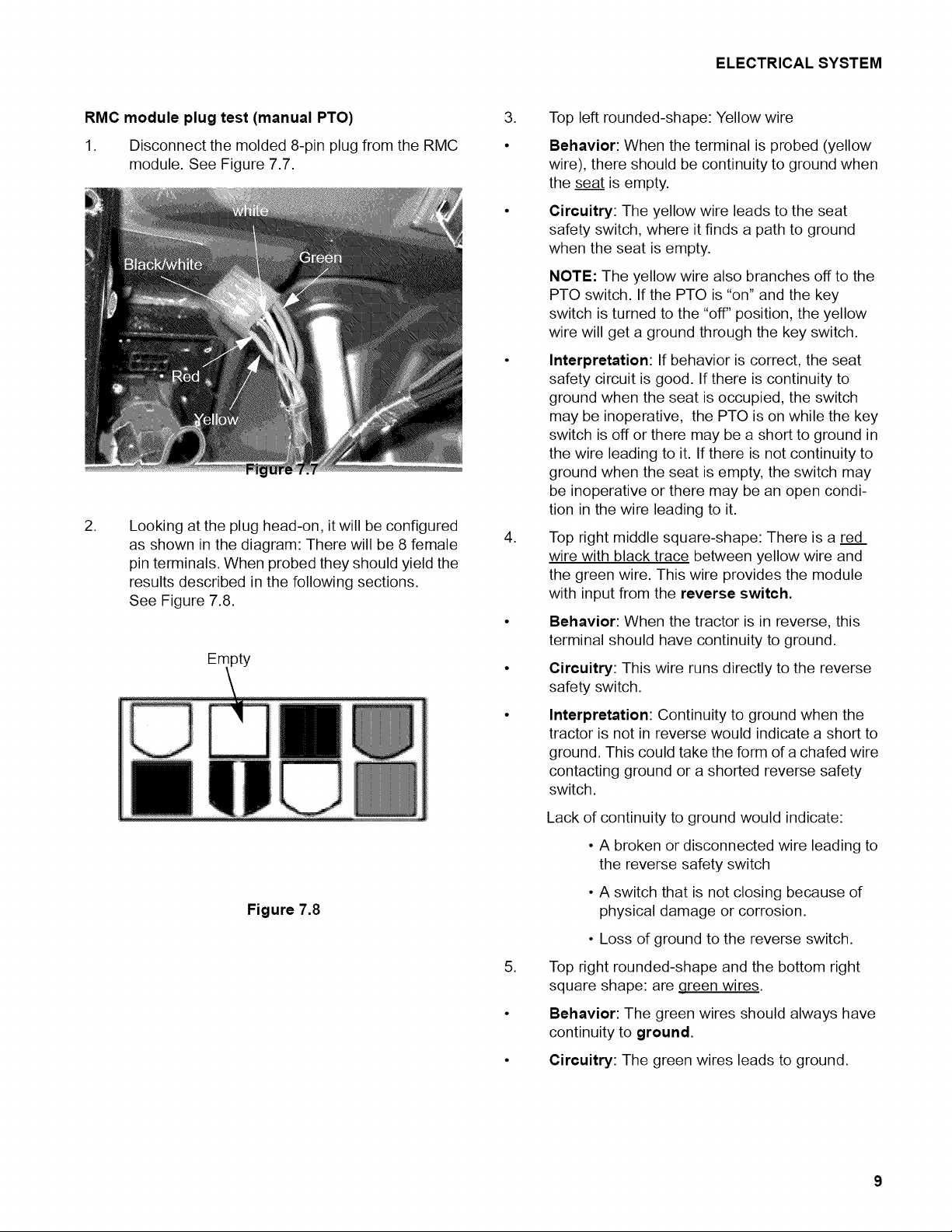

Looking at the plug head-on, itwill be configured

as shown in the diagram: There will be 8 female

pin terminals. When probed they should yield the

results described in the following sections.

See Figure 7.8.

Empty

,

Top left rounded-shape: Yellow wire

Behavior: When the terminal is probed (yellow

wire), there should be continuity to ground when

the seat is empty.

Circuitry: The yellow wire leads to the seat

safety switch, where it finds a path to ground

when the seat is empty.

NOTE: The yellow wire also branches off to the

PTO switch. If the PTO is "on" and the key

switch is turned to the "off" position, the yellow

wire will get a ground through the key switch.

Interpretation: If behavior is correct, the seat

safety circuit is good. If there is continuity to

ground when the seat is occupied, the switch

may be inoperative, the PTO is on while the key

switch is off or there may be a short to ground in

the wire leading to it. If there is not continuity to

ground when the seat is empty, the switch may

be inoperative or there may be an open condi-

tion in the wire leading to it.

,

Top right middle square-shape: There is a red

wire with black trace between yellow wire and

the green wire. This wire provides the module

with input from the reverse switch.

Behavior: When the tractor is in reverse, this

terminal should have continuity to ground.

Circuitry: This wire runs directly to the reverse

safety switch.

Figure 7.8

Interpretation: Continuity to ground when the

tractor is not in reverse would indicate a short to

ground. This could take the form of a chafed wire

contacting ground or a shorted reverse safety

switch.

Lack of continuity to ground would indicate:

• A broken or disconnected wire leading to

the reverse safety switch

• A switch that is not closing because of

physical damage or corrosion.

• Loss of ground to the reverse switch.

,

Top right rounded-shape and the bottom right

square shape: are qreen wires.

Behavior: The green wires should always have

continuity to ground.

Circuitry: The green wires leads to ground.

9

Page 13

CRAFTSMAN

Interpretation: If this ground path is not good,

there will probably be other ground-related

issues with the tractor: slow starter motor, slow

battery charge, dim lights. All ground connec-

tions should be mechanically secure and corro-

sion free.

,

Bottom left square-shape: The red wire on the

OCR plug carries battery voltage.

Behavior: With key switch in any of the run posi-

tions, D.C. battery voltage should show-up on a

volt meter when the red probe is touched to this

terminal and the black probe is grounded.

Circuitry: This wire draws power from the A1

terminal on the key switch.

Interpretation: If there is not battery voltage at

this terminal, the tractor is probably not func-

tional at all. Look for a blown fuse or a bad key

switch.

,

Bottom left middle square-shape: There is a

black wire with a white trace between the red

wire and the white wire. This wire provides the

module with input from the park brake switch.

Circuitry: When the key switch is in the

REVERSE CAUTION MODE position, a ground

path is established by connecting terminal A2 to

terminal L within the key switch. The white wire

from the RMC module connects to A2, and a

green ground wire connects to L.

Interpretation: If the white wire fails to reach a

ground path when the key switch is in the

REVERSE CAUTION MODE position, the RMC

module will not arm or operate. Check the key

switch for continuity between A2 and L in the

REVERSE CAUTION MODE position, confirm

that the green wire connecting to the L terminal

does have good continuity to ground, and check

for any loss of continuity in the white wire that

extends from the key switch to the RMC module,

including the molded connector between the two

components.

,

If the RMC plug test indicates fault with any of

the safety switches, the next step is to test the

suspect switch. The operation of those switches

is described in the following sections.

Behavior: When the brake pedal is depressed

and the park brake is set, a ground path is estab-

lished through the black wire with a white trace..

Circuitry: This wire runs to the brake switch,

then on to the park brake switch..

Interpretation: Continuity to ground when the

park brake is not set would indicate a short to

ground. This could take the form of a chafed wire

contacting ground or a shorted reverse safety

switch.

Lack of continuity to ground would indicate:

• A broken or disconnected wire leading to

the brake or park brake switches

• A switch that is not closing because of

physical damage or corrosion.

• Loss of ground to the park brake switch.

,

Bottom right middle rounded-shape: The white

wire provides a ground signal to the RMC mod-

ule when the key switch is placed in the

REVERSE CAUTION MODE.

Behavior: There should be continuity to ground

at this terminal when the key switch is in the

REVERSE CAUTION MODE position.

10

Page 14

ELECTRICAL SYSTEM

Electric PTO switch

Understanding the electric PTO switch

In A-Com, power is supplied to the PTO switch

from the A1 terminal of the ignition switch

through a red wire. when the PTO switch is

turned on this completes the circuit to allow

power to go to the PTO clutch. It is a normally

opened (NO) set of contacts.

B-COM is in the safety shut-down circuit. It is a

normally opened (NO) set of contacts. A circuit is

completed from the NO terminal on the PTO

relay through the white wire with black trace to

the E-PTO terminal on the RMC module and the

PTO relay coil through the yellow wire with black

trace when the contacts are closed. This gives

the RMC module the ability to turn-off the PTO

clutch.

C-COM is in the starter inhibit circuit. It is a nor-

mally closed (NC) set of contacts. When the

PTO is OFF, and the contacts are closed, power

coming from the brake switch (key switch in

START, brakes ON) through the oranqe wire

with black trace is passed on to the trigger termi-

nal on the starter solenoid through the orang_g_

wire with white trace.

..........................

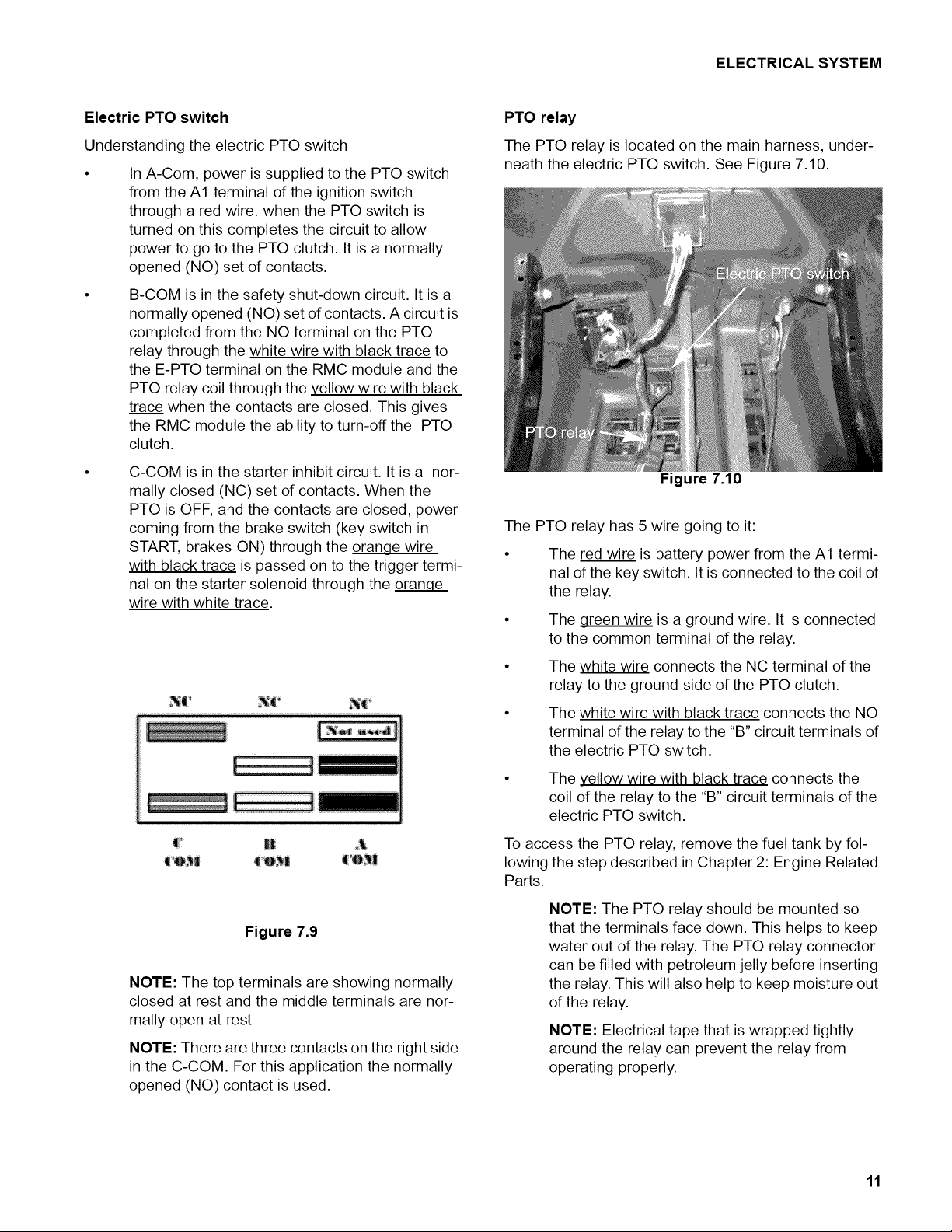

PTO relay

The PTO relay is located on the main harness, under-

neath the electric PTO switch. See Figure 7.10.

Figure 7.10

The PTO relay has 5 wire going to it:

• The red wire is battery power from the A1 termi-

nal of the key switch. It is connected to the coil of

the relay.

• The qreen wire is a ground wire. It is connected

to the common terminal of the relay.

• The white wire connects the NC terminal of the

relay to the ground side of the PTO clutch.

• The white wire with black trace connects the NO

terminal of the relay to the "B" circuit terminals of

the electric PTO switch.

_ IL A

Figure 7.9

NOTE: The top terminals are showing normally

closed at rest and the middle terminals are nor-

mally open at rest

NOTE: There are three contacts on the right side

in the C-COM. For this application the normally

opened (NO) contact is used.

The yellow wire with black trace connects the

coil of the relay to the "B" circuit terminals of the

electric PTO switch.

To access the PTO relay, remove the fuel tank by fol-

lowing the step described in Chapter 2: Engine Related

Parts.

NOTE: The PTO relay should be mounted so

that the terminals face down. This helps to keep

water out of the relay. The PTO relay connector

can be filled with petroleum jelly before inserting

the relay. This will also help to keep moisture out

of the relay.

NOTE: Electrical tape that is wrapped tightly

around the relay can prevent the relay from

operating properly.

11

Page 15

CRAFTSMAN

PTO switch (manual PTO)

• The manual PTO switch is mounted on the right

side of the seat box section of the frame.

See Figure 7.11.

Figure 7.11

The PTO switch plunger is depressed when the

PTO lever is moved to the "off" position.

The switch has two pair of contacts: one NO and

one NC.

The Oranqe wire with black trace connects to

one of the NO terminals of the PTO switch.

When the PTO is turned "off' the NO contacts

close, completing a circuit from the brake switch

to the starter solenoid through the oranqe wire

with white trace.

There are three yellow wires connected to the

NC terminals.

,

The yellow wire from the seat switch and

the yellow wire from the RMC module are

connected to the same terminal.

,

The other yellow wire goes to the ignition

module.

,

If the seat is empty or an unsafe condition

is sensed by the RMC module, a ground

signal is sent to the PTO switch. If the PTO

is "on" the ground signal will pass through

the switch and go to the ignition module

turning the engine off.

Brake switch (manual PTO)

• The brake switch is mounted on the top side of

the frame, on the left side behind the dash.

The brake switch used on manual PTO tractors

is a triple pole single throw switch. It has one set

of contacts that are normally closed (NC) and

the other two sets are normally open (NO).

See Figure 7.12.

A- NC

PoleB- NO PoleC- NO

Figure 7.12

The plunger on the switch is depressed when

the clutch / brake pedal is pressed-down, de-

clutching the drive belt and applying the brakes.

The switch contains two sets of contacts.

The normally closed (NC) set of contacts is in

the safety shut-down circuit. If the seat is vacant

the seat switch contacts will close connecting

the yellow wire with white trace to ground. When

the brake pedal is up, the contacts close con-

necting the ground signal in the yellow wire with

white trace to the module through the yellow

wire.

A normally open (NO) set of contacts is in the

starter inhibit circuit. When the clutch / brake

pedal is depressed, the contacts are closed,

power coming from the key switch (key switch in

START) through the oranqe wire is passed on to

the PTO switch through the oranqe wire with

black trace.

The other set of NO contacts receives the signal

from the parking brake switch through the pur-

ple wire. When the brake pedal is down, the con-

tacts close, sending that signal to the RMC

module through the black wire with white trace.

12

Page 16

ELECTRICAL SYSTEM

To access the brake switch:

,

Remove the deck by following the steps

described in Chapter 8: Cutting Decks and Lift

Shaft.

,

Squeeze the tab on the underside of the brake

switch with a pair of pliers, while pushing up on

the brake switch. See Figure 7.13.

Figure 7.13

,

Reach in between the left side of the engine and

the dash. Pull the switch and harness pigtail out

as one piece. See Figure 7.14.

Brake switch (electric PTO)

The brake switch is mounted on the top side of the

frame, on the left side behind the dash.

See Figure 7.15.

The plunger on the switch is depressed when

the clutch / brake pedal is pressed-down, de-

clutching the drive belt and applying the brakes.

The switch contains two sets of contacts.

The brake switch is accessed by removing the

fender and dash. The fender and dash can be

removed by following the steps described in

Chapter 4: Body/Chassis.

Figure 7.14

,

Install the brake switch by following the previous

steps in reverse order.

A normally open (NO) set of contacts is in the

starter inhibit circuit. When the clutch / brake

pedal is depressed, the contacts are closed,

power coming from the key switch (key switch in

START) through the oranqe wire is passed on to

the PTO switch through the oranqe wire with

black trace.

A normally closed (NC) set of contacts is in the

safety shut-down circuit. A circuit is completed

from the ignition module's primary windings to

ground. The ground comes from the seat switch

(if the seat is empty) through the yellow wire with

black trace. If the brake pedal is up, that ground

signal will pass through the brake switch to the

ignition through the yellow wire.

13

Page 17

CRAFTSMAN

Park brake switch

The park brake switch is only used on tractors that are

equipped with a manual PTO. The park brake switch is

a simple NO single pole single throw (SPST) switch.

The park brake switch is located on the frame, behind

the dash on the right hand side. See Figure 7.16.

Figure 7.16

Reverse Safety Switch

The Reverse Safety Switch is a simple metal contact

tang switch.

CVT transmissions

Tractors that have the CVT transmissions have the

reverse switch mounted on the left side of the frame, by

the rear wheel. When the tractor is placed in reverse,

the shift linkage will contact the switch providing a

ground, See Figure 7.17. This switch has a red wire

with black trace that goes directly to the RMC module.

See Figure 7.17.

The .qreen wire is attached to ground.

The purple wire is connected to the brake

switch.

If the brake pedal is depressed and the parking

brake is set, a ground signal will pass from the

park brake switch, through the brake switch to

the RMC module.

7.17

14

Page 18

ELECTRICAL SYSTEM

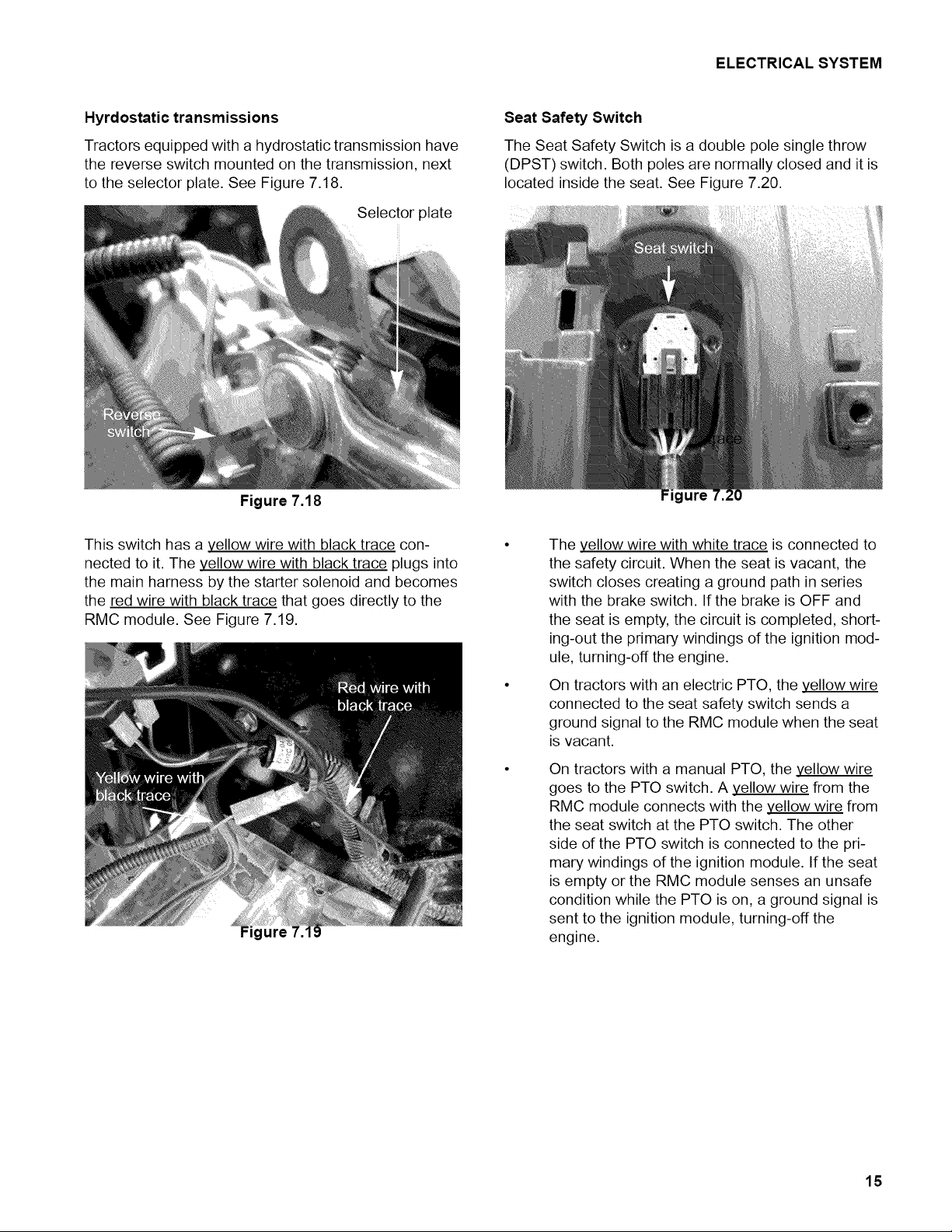

Hyrdostatic transmissions

Tractors equipped with a hydrostatic transmission have

the reverse switch mounted on the transmission, next

to the selector plate. See Figure 7.18.

Selector

Figure 7.18

This switch has a yellow wire with black trace con-

nected to it. The yellow wire with black trace plugs into

the main harness by the starter solenoid and becomes

the red wire with black trace that goes directly to the

RMC module. See Figure 7.19.

Seat Safety Switch

The Seat Safety Switch is a double pole single throw

(DPST) switch. Both poles are normally closed and it is

located inside the seat. See Figure 7.20.

The yellow wire with white trace is connected to

the safety circuit. When the seat is vacant, the

switch closes creating a ground path in series

with the brake switch. If the brake is OFF and

the seat is empty, the circuit is completed, short-

ing-out the primary windings of the ignition mod-

ule, turning-off the engine.

On tractors with an electric PTO, the yellow wire

connected to the seat safety switch sends a

ground signal to the RMC module when the seat

is vacant.

On tractors with a manual PTO, the yellow wire

goes to the PTO switch. A yellow wire from the

RMC module connects with the yellow wire from

the seat switch at the PTO switch. The other

side of the PTO switch is connected to the pri-

mary windings of the ignition module. If the seat

is empty or the RMC module senses an unsafe

condition while the PTO is on, a ground signal is

sent to the ignition module, turning-off the

engine.

15

Page 19

CRAFTSMAN

Starter solenoid

The starter solenoid is mounted inside the seat box

section of the frame. See Figure 7.21.

Figure 7.21

The starter solenoid can be accessed by removing the

battery box and reaching through the opening.

See Figure 7.22.

Lighting circuit

The lighting circuit is hot whenever the engine is run-

ning. It receives it's power from the A1 terminal of the

key switch. See Figure 7.23.

Figure 7.23

The red wire carries battery power, the green

wire is a ground.

Figure 7.22

When the proper safety conditions are met, (brake

applied, PTO OFF) the oran,qe wire with white trace

energizes the windings that magnetize an iron core,

pulling the contacts closed between the two heavy

posts, connecting battery power to the starter motor.

The ,qreen wire provide a ground for the coil inside the

starter relay.

16

Page 20

ELECTRICAL SYSTEM

Fuse

The 20A fuse is located inside the seat box section of

the frame, on the left side near the deck lift shaft.

See Figure 7.24.

Figure 7.24

The solid red wire feeds the fuse with power

picked-up from the battery cable connection to

the "hot" post of the starter solenoid.

The red wire with white trace carries fused

power to the B terminal on the key switch.

A failed fuse will disable most of the tractor's

electrical system.

Remember that a failed fuse has done it's job of

protecting the rest of the circuit from an over-

load. If a fuse blows, figure-out why and correct

the core problem before returning the tractor to

service.

ELECTRICAL DIAGNOSIS

NOTE: Electrical diagnostic procedures and

tools are the same for all Cub Cadet and MTD

tractors. This section is written in a way to pro-

vide basic trouble shooting skills that can be

used on any tractor.

With a basic understanding of the behavior of electricity

and the tools used to measure that behavior, a techni-

cian can be about 80% effective at finding electrical

problems. 80% effective is not bad, but the remaining

20% of the diagnoses are the really difficult ones that

can devour the same amount of time as the easy

80%. Experience plays a big part in successfully diag-

nosing the really difficult electrical problems. Experi-

ence leads to greater understanding.

Two German Physicists, working independently during

the late 18th and early 19th centuries summarized

what they had figured-out about electricity into some

basic laws that can help a technician understand how a

system works or why it does not work. Their names

were Gustav Kirchhoff and Georg Ohm, and their laws

are named for them.

There are basically three things that a technician is

likely to test in trying to identify an electrical problem:

Volts, Resistance, and Current. To help technicians

understand the behavior of electricity, this section

begins with an explanation of:

• Basic electrical values.

• Ohm'slaw.

• Kirchhoff's current law.

• Kirchhoff's voltage law.

• How the system is wired together.

NOTE: A graphic explanation of Kirchhoff's laws

can be found atthe following web site:

http :llonline.cctt.orglphysicslablcontentlphyapbl

lessonnotes/DCcircuits/lessonKirchoff.asp

The section then continues by explaining handy tools

and techniques for diagnosing electrical problems on

outdoor power equipment.

17

Page 21

CRAFTSMAN

Electronics

The outdoor power equipment has historically had rela-

tively simple electro-mechanical controls. Customer

expectations and regulatory demands continue to drive

change in the industry, while electronic controls have

become relatively inexpensive.

In many cases, electronic controls can simplify a sys-

tem that would otherwise be very complex. Instead of

creating a huge mass of switches and relays that are

tied together by spaghetti-like wiring harness, sensors

(switches) in an electronic system send signals to a

processor. These input signals are processed by a

control module that produces outputs.

Outputs can include power to run an electric PTO

clutch, a trigger signal to a starter solenoid, or the

grounding of a magneto to turn-off an engine if an

unsafe condition exists.

Most electronic devices are quite dependable, but they

are vulnerable to things that simple electrical devices

are not bothered by. Examples include:

EMh Electro-Magnetic Interference is created by

electronic "noise". This noise is created by igni-

tion systems in general with non-resistor spark

plugs being especially "noisy". Alternators, and

even power passing through wires can also gen-

erate EMI. Countermeasures against EMI

include metal shielding (take a look at the igni-

tion system on a fiberglass-bodied Corvette),

and filtering devices built into vulnerable compo-

nents. Something as simple as putting non-

resistor spark plugs in a machine with electronic

controls can disable the controls.

Heat and Vibration: Heat and vibration are

hard on most mechanical devices. The same is

true of electronics.

Moisture: Moisture causes a nasty combination

of corrosion and shorts. Corroded connections

and wires create resistance that results in low

voltage and ground issue. Many electronic com-

ponents are "potted" or encased in a sealant that

protects them from moisture. They are still vul-

nerable to bad inputs caused by corroded exter-

nal connections and damaged switches.

Improper Tools: Some test lights can over-

load electronic circuits.

Voltage Spikes: A dramatic increase in voltage

will damage many electronic devices. Such

spikes may be caused when jumper cables are

disconnected or a voltage regulator fails. Some

early automotive systems could even be dam-

aged by personal discharge of static electricity.

Most are better protected now.

Low Voltage: Many electronic devices simply

stop working if system voltage falls below a

given threshold. If a 12 volt system is run at 11

volts with a failing alternator, electronic controls

may stop working.

Bad Grounds: Bad grounds can reduce the

effective system voltage, create resistance and

heat, and send false signals. This is the single

most common breeding ground of electronic

gremlins.

18

Page 22

ELECTRICAL SYSTEM

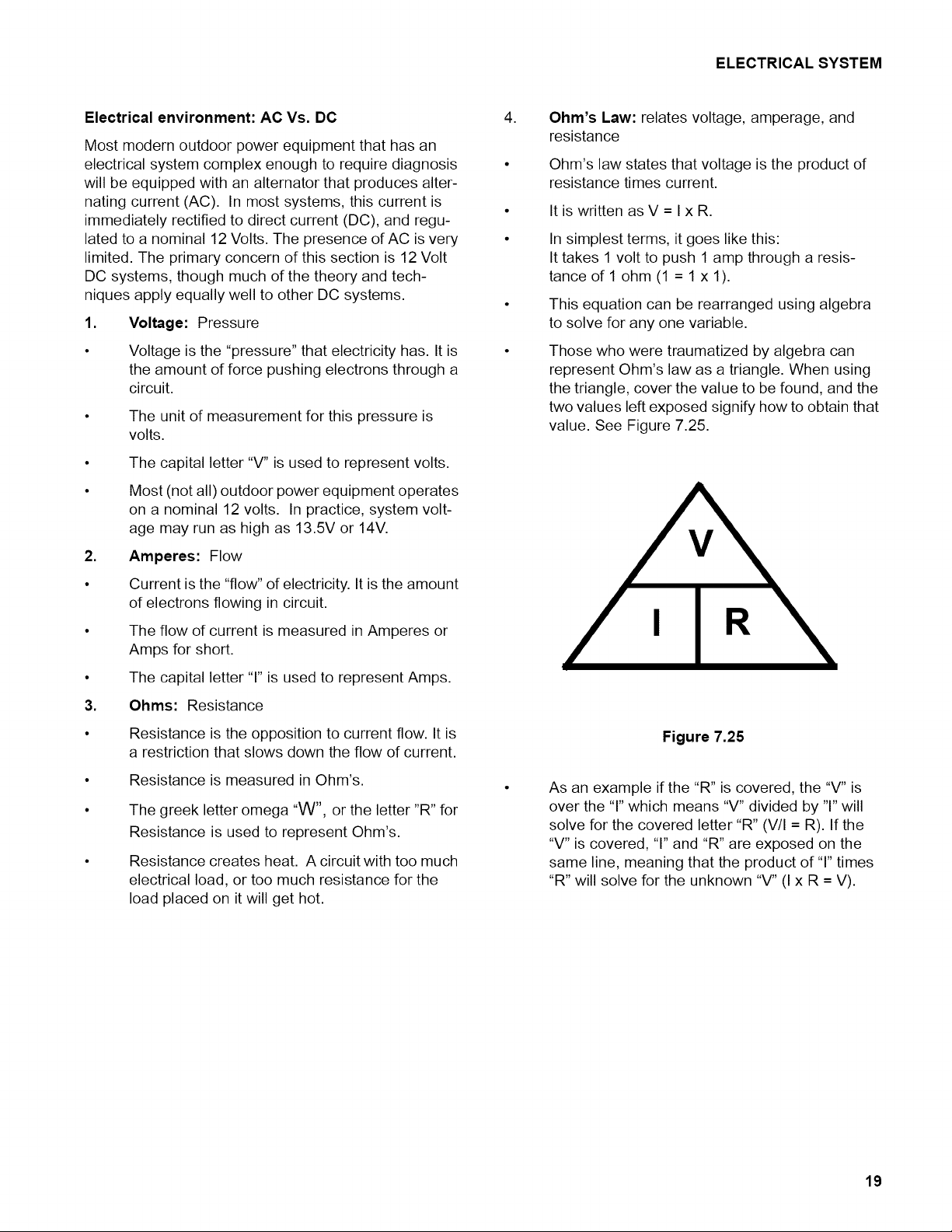

Electrical environment: AC Vs. DC

Most modern outdoor power equipment that has an

electrical system complex enough to require diagnosis

will be equipped with an alternator that produces alter-

nating current (AC). In most systems, this current is

immediately rectified to direct current (DC), and regu-

lated to a nominal 12 Volts. The presence of AC is very

limited. The primary concern of this section is 12 Volt

DC systems, though much of the theory and tech-

niques apply equally well to other DC systems.

1. Voltage: Pressure

Voltage is the "pressure" that electricity has. It is

the amount of force pushing electrons through a

circuit.

The unit of measurement for this pressure is

volts.

The capital letter "V" is used to represent volts.

Most (not all) outdoor power equipment operates

on a nominal 12volts. In practice, system volt-

age may run as high as 13.5V or 14V.

.

Amperes: Flow

,

Ohm's Law: relates voltage, amperage, and

resistance

Ohm's law states that voltage is the product of

resistance times current.

It is written as V = I x R.

In simplest terms, it goes like this:

It takes 1 volt to push 1 amp through a resis-

tance of 1 ohm (1 = 1x 1).

This equation can be rearranged using algebra

to solve for any one variable.

Those who were traumatized by algebra can

represent Ohm's law as a triangle. When using

the triangle, cover the value to be found, and the

two values left exposed signify how to obtain that

value. See Figure 7.25.

Current is the "flow" of electricity. It is the amount

of electrons flowing in circuit.

The flow of current is measured in Amperes or

Amps for short.

The capital letter 'T' is used to represent Amps.

3.

Ohms: Resistance

Resistance is the opposition to current flow. It is

a restriction that slows down the flow of current.

• Resistance is measured in Ohm's.

The greek letter omega "W", or the letter "R" for

Resistance is used to represent Ohm's.

Resistance creates heat. A circuit with too much

electrical load, or too much resistance for the

load placed on it will get hot.

I R

Figure 7.25

As an example if the "R" is covered, the "V" is

over the 'T' which means "V" divided by 'T' will

solve for the covered letter "R" (VII = R). If the

"V" is covered, "1"and "R" are exposed on the

same line, meaning that the product of 'T' times

"R" will solve for the unknown "V" (I x R = V).

19

Page 23

CRAFTSMAN

. Kirchhoff's current law:

Kirchhoff's current law deals with nodes. Nodes

are the junction of two or more wires or the junc-

tion of a wire to a component.

Kirchhoff's current law states that what ever cur-

rent goes into a node must come out.

As an example: Three wires are connected with

a wire nut. One wire has 5 amps going into the

connection.

The sum of the currents coming out of the other

two wires must equal 5 amps. That could be 3

amps in one wire and 2 amps in the other or it

could be 2.5 amps in each wire, but the total

coming out must be the same as the current

going in. See Figure 7.26.

Node

5 Amps

___,_ _ 3 Amps

.

Kirchhoff's voltage law:

Kirchhoff's voltage law deals with voltage drops.

A voltage drop is the amount of voltage used up

or "dropped" by resistance in a circuit. Ohm's law

states that V = IxR, every component in a circuit

has resistance, even the wires. To push current

through resistance, it takes voltage. Kirchhoff's

voltage law states that the sum of all the voltage

drops equals the source voltage.

As an example, imagine a circuit that has a 12V

battery that produces 4 amps of current power-

ing a light bulb that creates 3 W of resistance.

The wires are assumed to have 0 W resis-

tance*. The light bulb uses 12 volts (4 amps x 3

ohms = 12 volts). The battery produces 12 volts

that equals the 12 volts used by the light bulb.

See Figure 7.27.

2 Amps

Figure 7.26

4 Amps flow

X

3 _) resistance

12 Volts

Figure 7.27

NOTE: * If the proper size wire is used and

there is no corrosion in the wire, the resistance

will be too small to worry about.

20

Page 24

ELECTRICALSYSTEM

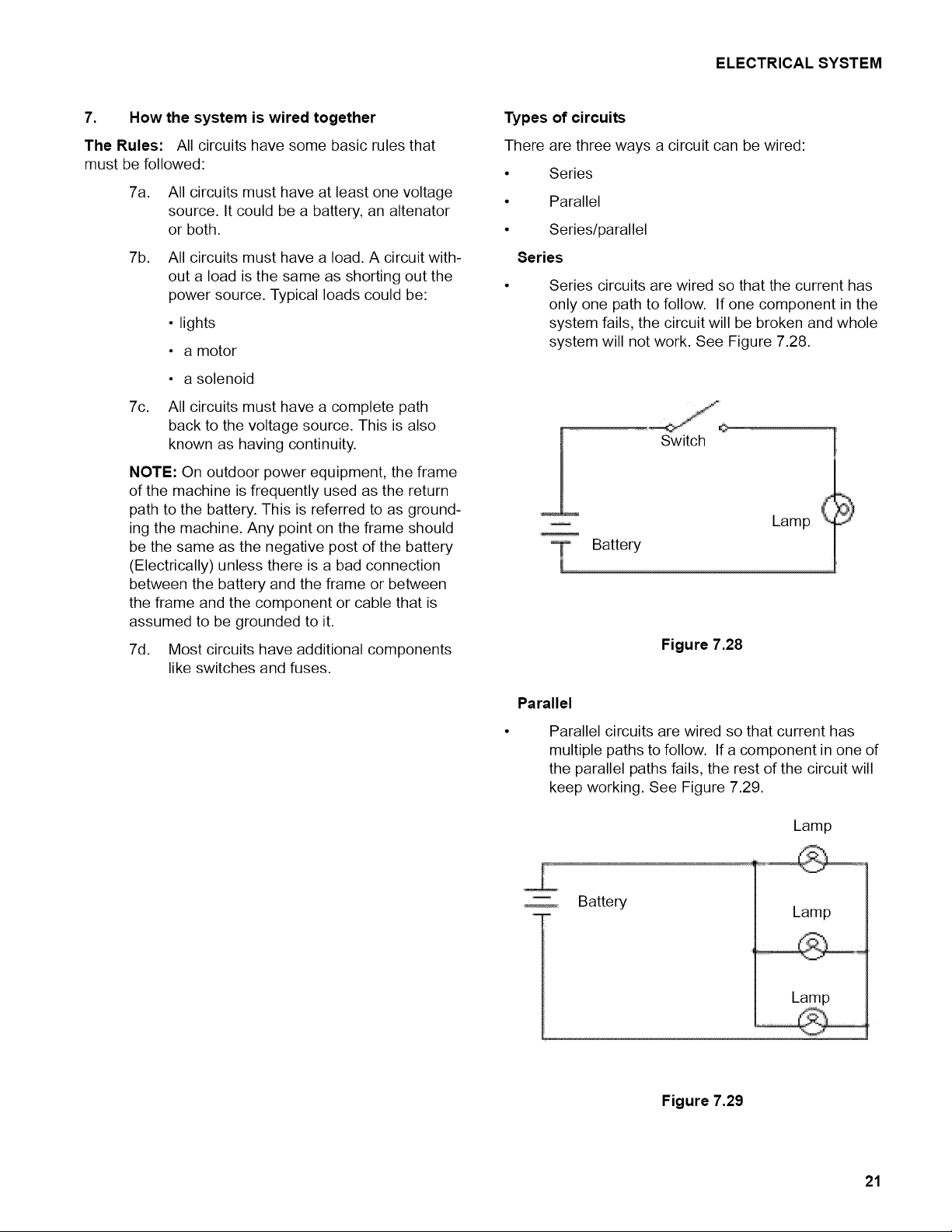

7. How the system is wired together

The Rules: All circuits have some basic rules that

must be followed:

7a. All circuits must have at least one voltage

source. It could be a battery, an altenator

or both.

7b. All circuits must have a load. A circuit with-

out a load is the same as shorting out the

power source. Typical loads could be:

• lights

• a motor

• a solenoid

7c. All circuits must have a complete path

back to the voltage source. This is also

known as having continuity.

NOTE: On outdoor power equipment, the frame

of the machine is frequently used as the return

path to the battery. This is referred to as ground-

ing the machine. Any point on the frame should

be the same as the negative post of the battery

(Electrically) unless there is a bad connection

between the battery and the frame or between

the frame and the component or cable that is

assumed to be grounded to it.

7d. Most circuits have additional components

like switches and fuses.

Types of circuits

There are three ways a circuit can be wired:

• Series

• Parallel

• Series/parallel

Series

• Series circuits are wired so that the current has

only one path to follow. If one component in the

system fails, the circuit will be broken and whole

system will not work. See Figure 7.28.

L--

Lamp (

T Battery

Figure 7.28

Parallel

Parallel circuits are wired so that current has

multiple paths to follow. If a component in one of

the parallel paths fails, the rest of the circuit will

keep working. See Figure 7.29.

Lamp

m

Battery

Figure 7.29

Lamp

Lamp

21

Page 25

CRAFTSMAN

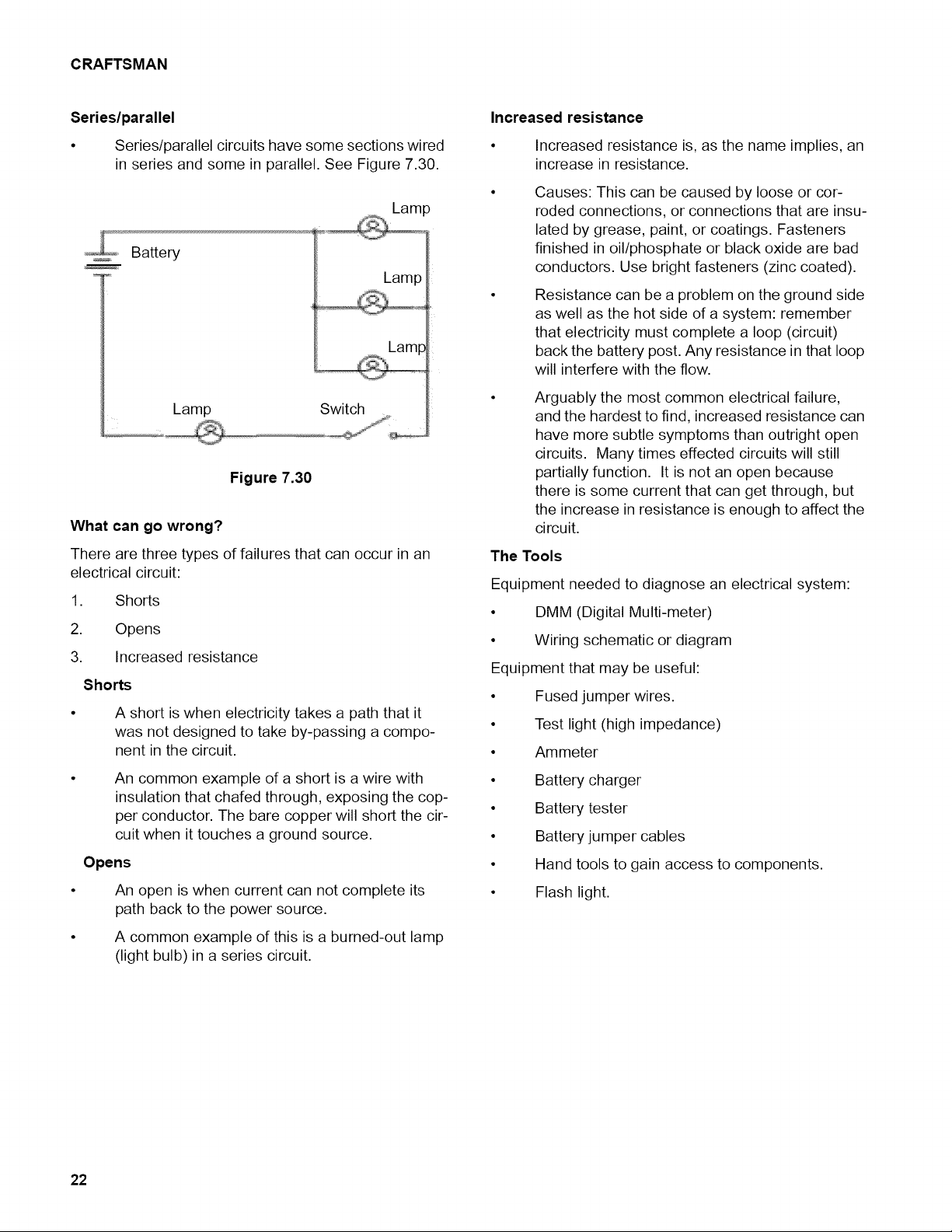

Series/parallel

• Series/parallel circuits have some sections wired

in series and some in parallel. See Figure 7.30.

Battery

Lamp

Earn

Lamp Switch

Figure 7.30

What can go wrong?

There are three types of failures that can occur in an

electrical circuit:

1. Shorts

2. Opens

3. Increased resistance

Shorts

A short is when electricity takes a path that it

was not designed to take by-passing a compo-

nent in the circuit.

Increased resistance

Increased resistance is, as the name implies, an

increase in resistance.

Causes: This can be caused by loose or cor-

roded connections, or connections that are insu-

lated by grease, paint, or coatings. Fasteners

finished in oil/phosphate or black oxide are bad

conductors. Use bright fasteners (zinc coated).

Resistance can be a problem on the ground side

as well as the hot side of a system: remember

that electricity must complete a loop (circuit)

back the battery post. Any resistance in that loop

will interfere with the flow.

Arguably the most common electrical failure,

and the hardest to find, increased resistance can

have more subtle symptoms than outright open

circuits. Many times effected circuits will still

partially function. It is not an open because

there is some current that can get through, but

the increase in resistance is enough to affect the

circuit.

The Tools

Equipment needed to diagnose an electrical system:

• DMM (Digital Multi-meter)

• Wiring schematic or diagram

Equipment that may be useful:

• Fused jumper wires.

• Test light (high impedance)

• Ammeter

An common example of a short is a wire with

insulation that chafed through, exposing the cop-

per conductor. The bare copper will short the cir-

cuit when it touches a ground source.

Opens

An open is when current can not complete its

path back to the power source.

A common example of this is a burned-out lamp

(light bulb)in a series circuit.

22

Battery charger

Battery tester

Battery jumper cables

Hand tools to gain access to components.

• Flash light.

Page 26

ELECTRICALSYSTEM

DigitalMulti-meter

A DMM is the most useful tool to trouble-shoot

any electrical system. There is an amazing vari-

ety of DMMs on the market. Some are very

basic, others are tailored to specific industries,

and some high-end graphing meters function

like oscilloscopes. Even the most basic ones are

quite versatile. See Figure 7.31.

Amperage: Most DMMs have a very limited capacity

to test amperage (2-3 Amperes). When measuring cur-

rent flow, the meter must be connected in series with

the component to be measured. That means opening

the circuit and having the circuit go through the meter.

Some meters have an inductive "Amp clamp"

accessory that can be used without breaking the

circuit.

Testing amperage beyond the capacity of the

meter can burn-out an internal fuse in some

meters. The fuses can be expensive.

Resistance: Set the meter for the "W" scale.

Isolate the part of the circuit to be tested (discon-

nect it from the source of power).

Ohms are read on a scale of 0 to 1, with "0" indi-

cating no resistance and "1" indicating infinite

resistance.

Most auto-ranging meters will provide readings

on several scales. For outdoor power equip-

ment, the straight Ohm scale is most appropri-

ate. If a letter appears next to the W on the

screen of the DMM, it indicates different scales

of sensitivity.

Uses:

Voltage: Set meter to read "Volts DC ( _ __ )" if using

an auto-ranging meter or to an appropriate scale (typi-

cally 20 Volts DC) if using a more basic model.

Connect the meter in parallel to the circuit

being measured, between the test point and a

known-good ground. Turn-on the circuit to be

tested, and read the meter. For most tests the

engine need not be running, but the key will be

turned-on.

If there is question about which end of the circuit

the electricity is coming from, the circuit may be

disconnected near the test point.

If the meter is connected with the polarity

reversed, a "-" will appear in front of the voltage

reading. It has no ill effects on the meter nor on

accuracy.

If the meter is set to Volts AC (~) the reading will

be much lower that expected, but no physical

harm will be done to the meter nor the equip-

ment being diagnosed. It may waste some time

though.

"m" is micro-Ohms (.001 W), a more sensitive

scale that effectively moves the decimal point

three places to the left of its location for plain W

"K" is Kilo-Ohms (1,000 W), a less sensitive

scale that effectively moves the decimal point

three places to the right of its location for plain W

"M" is Meg-Ohms (1,000,000 W), is the least

sensitive scale that effectively moves the decimal

point six places to the right of its location for plain

W

A reading of "0" may be called "Continuity".

A reading of "OL" may be referred to as "No

Continuity".

Mistaken Ohm readings most frequently come

from bad technique. Poor connections between

the probes and the point to be read can throw-off

readings. False readings can be generated if the

technician touches both probes with their fingers

while taking the reading.

The meter has it's own power source to measure

resistance. Connecting the meter to a compo-

nent that has current going through it will dam-

age the meter (usually beyond repair).

23

Page 27

CRAFTSMAN

Wiringdiagramorschematic

A wiring or a schematic diagram, and the ability

to read it are very important in troubleshooting a

circuit. The diagram shows how the circuit was

designed and what paths the electricity is sup-

pose to flow.

Fused jumper wires

Fused jumper wires are handy to help find bad

grounds or to jump across switches for testing

purposes.

CAUTION: Only use fused jumper wires. If there

is a short in the circuit, using an unfused jump

could damage components in the circuit.

Test lights (high impedance)

Test lights are used as a quick way to verify volt-

age at a point in a circuit. Like DMMs, they come

in a wide variety from many manufacturers.

The most basic test lights simply use the current

being checked to light an incandescent lamp.

These should not be used on any equipment

that has or may have solid-state circuitry.

The power necessary to light the bulb is more

than many solid-state circuits were designed to

handle. Components will be destroyed in the

process of testing them. See Figure 7.32.

Some high impedance test lights are capable of

indicating whether the current being sampled is

AC or DC.

Battery Jumper Cables

The obvious use: jumper cables can be used to

jump-start equipment to get it into the shop. This

is not recommended for any fuel injected Kohler-

powered equipment.

The clever use: If the technician suspects that

there is resistance on the ground side of the sys-

tem, a quick-and-dirty test can be made using

jumper cables.

Connect one cable clamp to the negative post of

the battery, and connect the clamp at the other

end of the same cable to the engine block.

If there is an immediate difference in starter

motor performance, use the voltage drop tech-

nique discussed later in this section to identify

the source of the resistance.

Ammeters and specialized charging system testers

Inductive ammeters are available in many forms.

Some are as simple as a gauge to be held

against the circuit in question when it is ener-

gized. See Figure 7.33.

NOTE: Do not use a test light on a 900 series

tractor. It can damage the RMC module.

Figure 7.32

If a test light is used at all, it should have "high-

impedance", indicating that it only takes a sam-

ple of the electricity being tested, and illuminates

an LED to indicate the presence of power.

24

Page 28

ELECTRICALSYSTEM

There are two primary reasons to measure

amperage:

,

To check the out-put of a charging system

or battery.

,

To check the performance of a component

that draws a substantial flow of power, typ-

ically a motor or clutch.

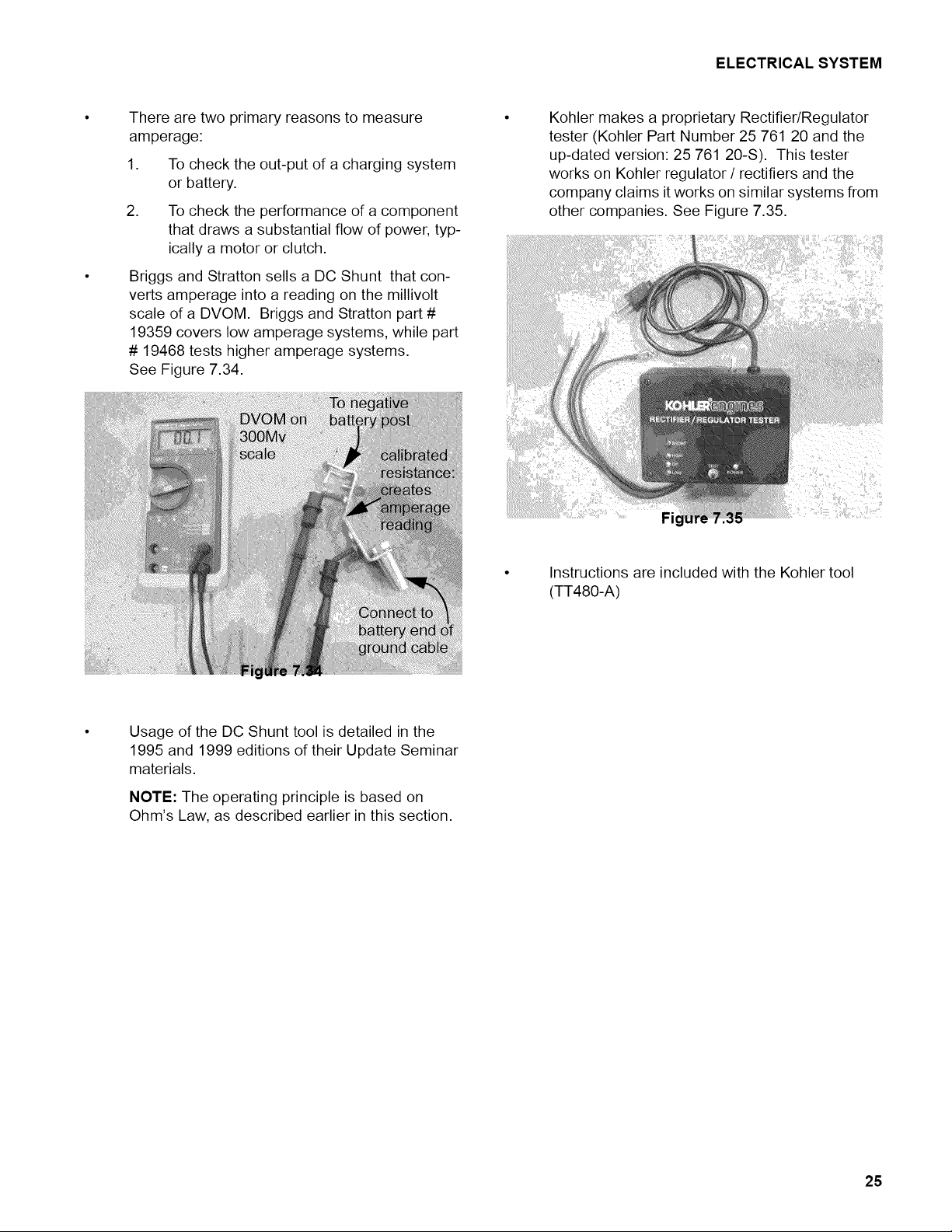

Briggs and Stratton sells a DC Shunt that con-

verts amperage into a reading on the millivolt

scale of a DVOM. Briggs and Stratton part #

19359 covers low amperage systems, while part

# 19468 tests higher amperage systems.

See Figure 7.34.

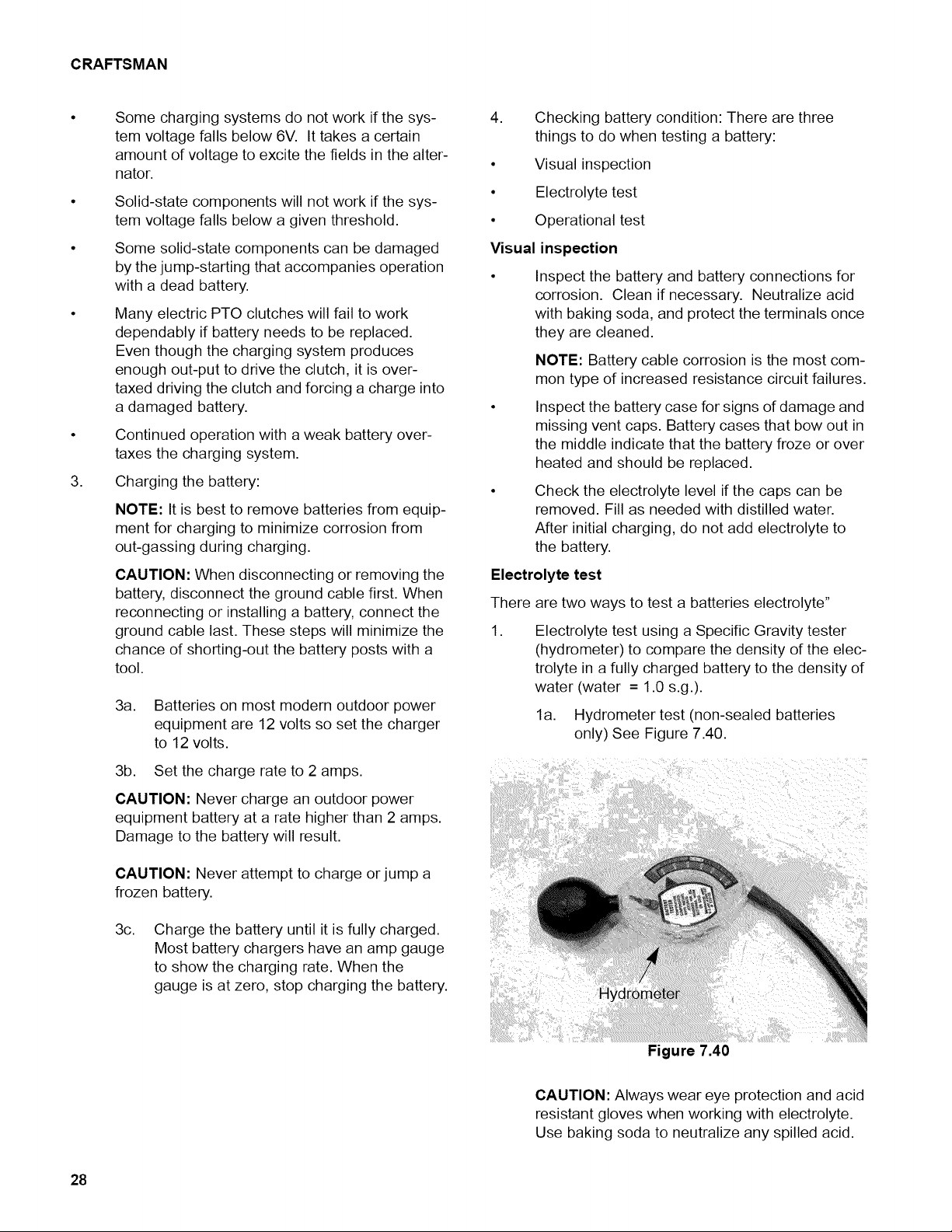

Kohler makes a proprietary Rectifier/Regulator

tester (Kohler Part Number 25 761 20 and the

up-dated version: 25 761 20-S). This tester

works on Kohler regulator / rectifiers and the

company claims it works on similar systems from

other companies. See Figure 7.35.

Usage of the DC Shunt tool is detailed in the

1995 and 1999 editions of their Update Seminar

materials.

NOTE: The operating principle is based on

Ohm's Law, as described earlier in this section.

Instructions are included with the Kohler tool

(TT480-A)

25

Page 29

CRAFTSMAN

Testingthechargingsystem

Quick and dirty test: check voltage across the battery

posts using a DMM set to read D.C. voltage with the

engine turned-off. It will read battery voltage, typically

around 12 V. Start the engine and repeat the voltage

measurement. The system voltage should rise, reflect-

ing the out-put of the charging system, typically in the

range of 13.0 - 14.5 V. Ifthe voltage does not rise, or

rises significantly above this threshold, there is a prob-

lem with the charging system that needs to be identi-

fied using more in-depth techniques.

NOTE: If system voltage is beyond roughly 15.7

volts, it is over-charging and there is a problem

with the voltage regulator/rectifier.

To identify a specific charging system problem, isolate

the components of the system and check their perfor-

mance individually.

,

First check the raw AC. Voltage out-put from the

stator. It will be necessary to compare it to the

engine manufacturer's specified out-put. This

varies from model to model.

la. With a DMM set to read AC Voltage, con-

nect the probes between ground and one

of the AC wires of the stator.

lb. Leave the regulator-rectifier connected to

the harness.

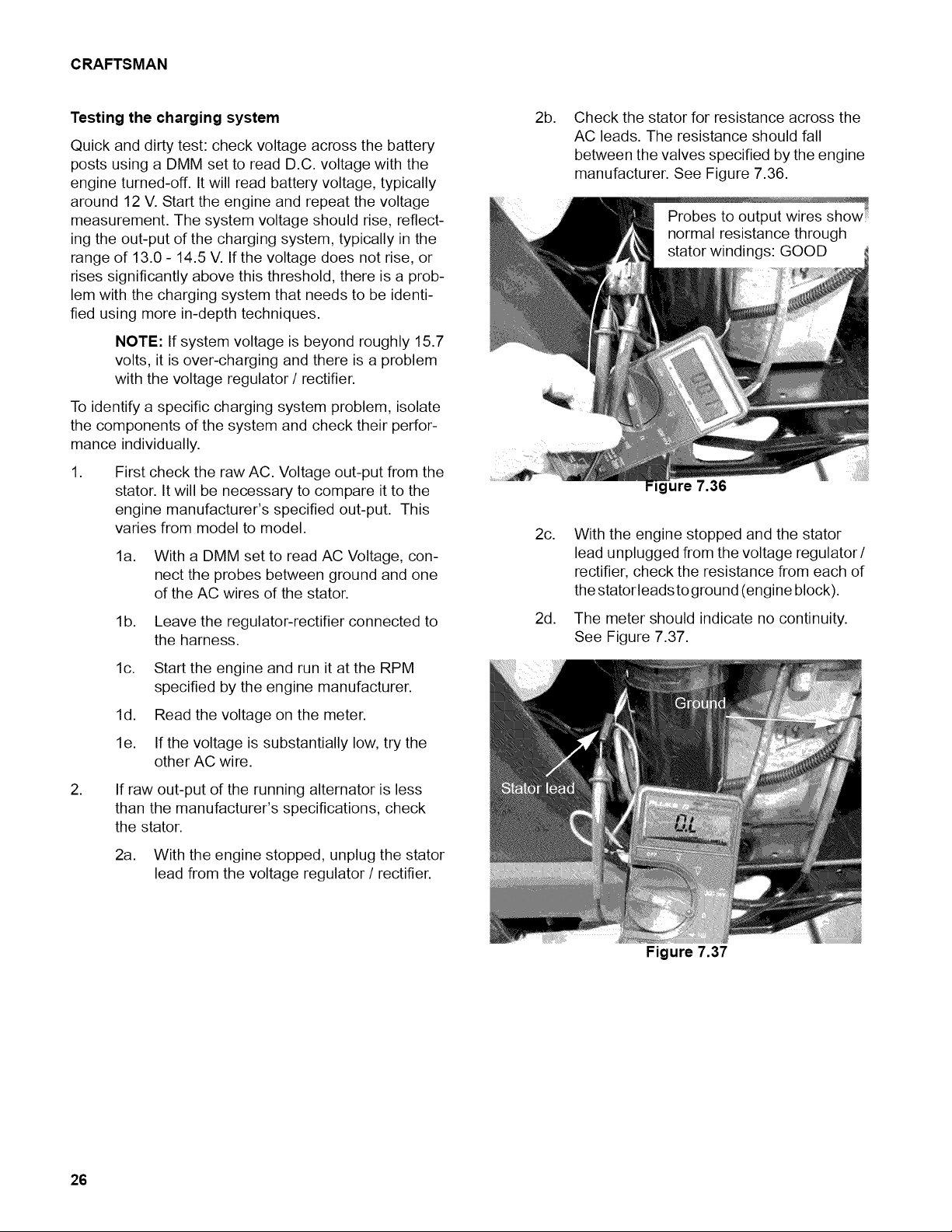

2b.

Check the stator for resistance across the

AC leads. The resistance should fall

between the valves specified by the engine

manufacturer. See Figure 7.36.

normal resistance through

Jre 7.36

20.

With the engine stopped and the stator

lead unplugged from the voltage regulator/

rectifier, check the resistance from each of

the statorleads toground (engine block).

2d.

The meter should indicate no continuity.

See Figure 7.37.

lc. Start the engine and run it at the RPM

specified by the engine manufacturer.

ld. Read the voltage on the meter.

le. If the voltage is substantially low, try the

other AC wire.

,

If raw out-put of the running alternator is less

than the manufacturer's specifications, check

the stator.

2a. With the engine stopped, unplug the stator

lead from the voltage regulator / rectifier.

Figure 7.37

26

Page 30

ELECTRICALSYSTEM

2e.

Interpretation: If the ohm meter indicates

no continuity between the two stator leads,

there is a fault in the stator windings. If the

ohm meter indicates continuity between

either stator lead and ground, the stator

windings are shorted to ground.

NOTE: If there is an intermittent charging sys-

tem problem, perform these tests when the

engine is cold, and again when the engine is hot.

NOTE: Low voltage readings may also result

from poor test connections or low engine RPM.

,

If the stator is good, test the amperage out-put

from the regulator / rectifier.

3a.

Attach a DC shunt with DVOM or an

ammeter capable of reading up to 25

amperes of DC current. The most accu-

rate point to take a reading will be at the

battery ground cable.

3b.

The altenator should produce the rated

current at the rated RPM under an electri-

cal load.

3c. Connect a load tester between the battery

terminals.

Batteries

1. Precautions: See Figure 7.39.

CAUTION: Batteries produce flammable and

explosive gases, particularly during charging:

Figure 7.39

Do not smoke or allow an open flame or heat

source near the battery.

3d.

With the engine running at the rated RPM,

energize the load tester to draw amperage

from the system.

3e.

Read the amperage on the meter.

See Figure 7.38.

NOTE: Output varies with load. A fixed-load

battery tester can be used to apply enough load

to test the charging system out-put.

Charge batteries in an open area

Wear eye protection and acid resistant gloves

when handling batteries.

Do not allow direct metal contact across the

posts. This will produce extreme heat that may

cause direct burns or ignite flammable gas.

CAUTION: California Proposition 65 warning:

Battery posts, terminals, and related accessories

contain lead and lead compounds. These chem-

icals are known in the State of California to

cause cancer and reproductive harm. Wash

hands after handling.

NOTE: Some batteries used in Current Cub

Cadet equipment are sealed. It is not possible to

check, test or add fluid.

CAUTION: Batteries contain electrolyte, which is

highly corrosive. If a battery is ruptured, neutral-

ize the electrolyte with baking soda, then care-

fully rinse the effected area with water.

,

Importance of battery charge level and condi-

tion: A fully charged battery that is in good condi-

tion is an important factor when trying to

diagnose other parts of an electrical system:

27

Page 31

CRAFTSMAN

Some charging systems do not work if the sys-

tem voltage falls below 6V. It takes a certain

amount of voltage to excite the fields in the alter-

nator.

Solid-state components will not work if the sys-

tem voltage falls below a given threshold.

Some solid-state components can be damaged

by the jump-starting that accompanies operation

with a dead battery.

Many electric PTO clutches will fail to work

dependably if battery needs to be replaced.

Even though the charging system produces

enough out-put to drive the clutch, it is over-

taxed driving the clutch and forcing a charge into

a damaged battery.

Continued operation with a weak battery over-

taxes the charging system.

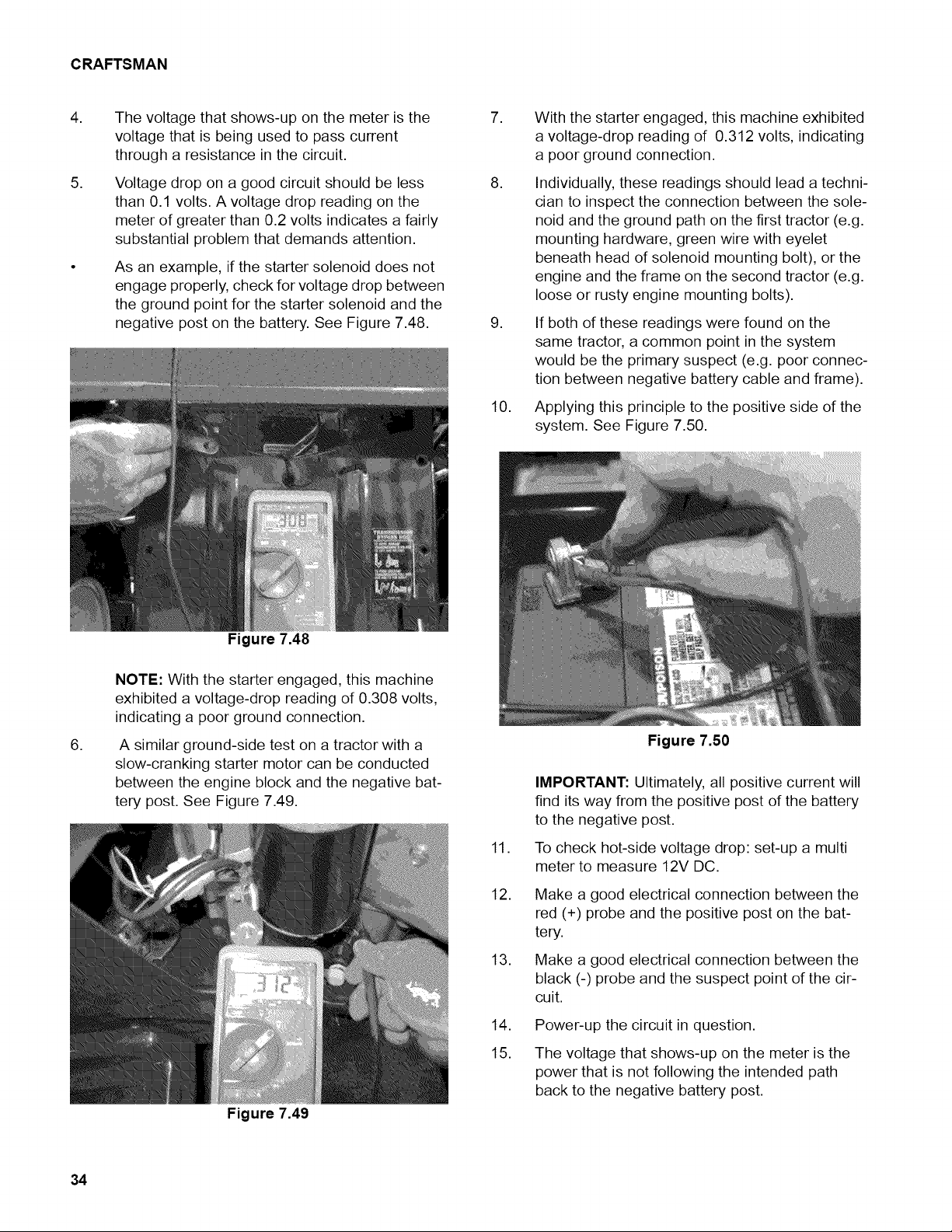

,