Page 1

Owner's Manual

CRAFTSMAN'

I.P B FESSIOHAL

1

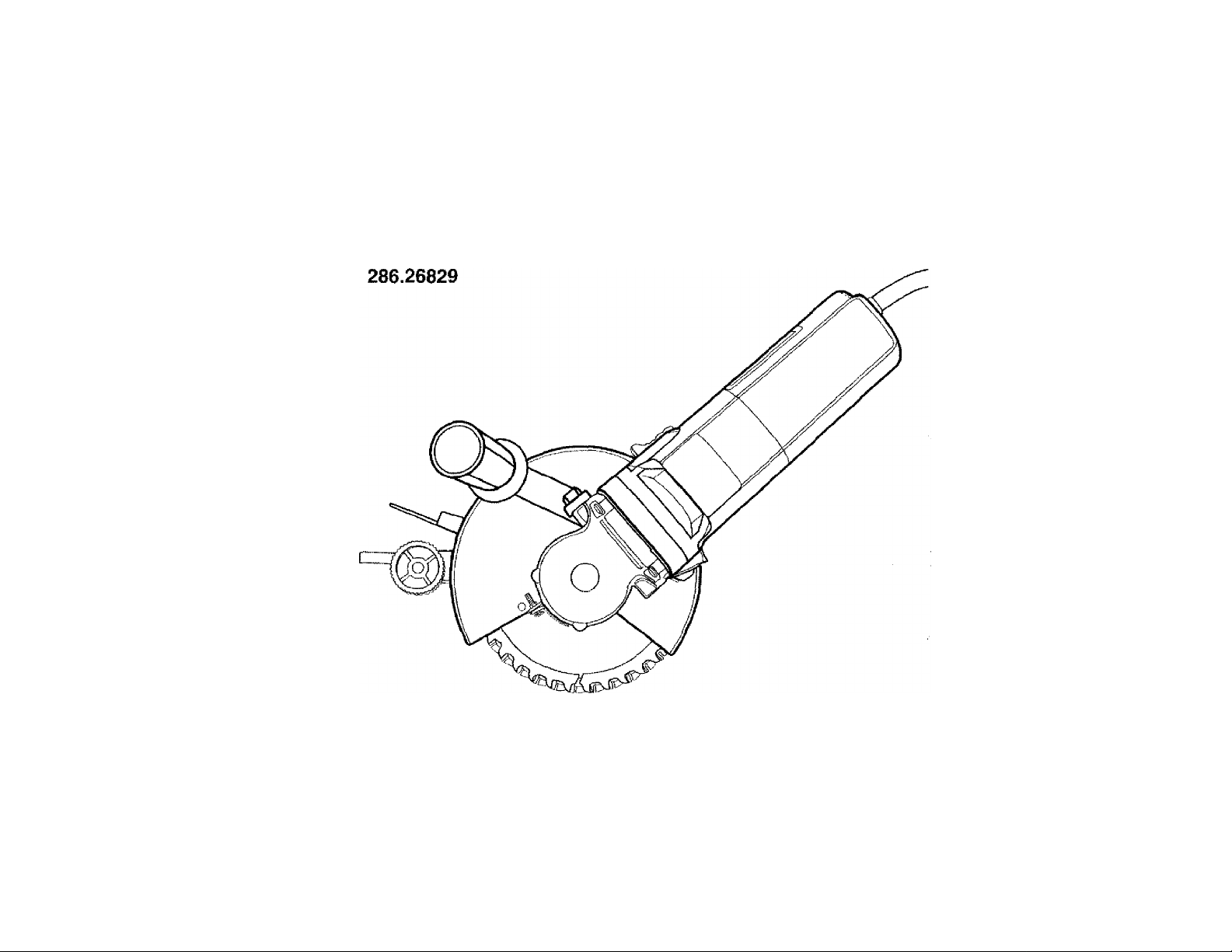

61/8-in.TWIN CUTTER SAW

Model No.

• SAFETY

CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions

in this manual before using this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

• OPERATION

> MAINTENANCE

• ESPAÑOL, PAGE 25

Page 2

TABLE OF CONTENTS

Warranty..........................................................................Page 2

Safety Instructions

Safety Symbols

Description................................................................... Page 9

Operation.....................................................................Pages 10-19

Removing and installing Blades..

Maintenance............................................................... ..Pages 19-20

Troubleshooting

Accessories.....................................................................Page 21

Repair Parts

..................................................................

Service Numbers....

ONE FULL YEAR WARRANTY ON CRAFTSMAN

PROFESSIONAL TWIN CUTTER SAW

If this product fails due to a defect in material or workmanship within one

year from the date of purchase, RETURN IT TO THE NEAREST SEARS

PARTS AND REPAIR CENTER IN THE UNITED STATES, and it will be

repaired, free of charge.

This warranty gives you specific legal rights, and you may also have other

rights which vary from stale to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

........................................................

.............................................................

..................................

....................................................

.......Page 21

......................................................

Pages 3-8

Page 8

Pages 17-19

Pages 22-23

Back Cover

SAVE THESE INSTRUCTIONS! READ ALL INSTRUCTIONS!

Page 3

SAFETY INSTRUCTIONS

/tX WARNING: BE SURE to read and understand all instructions. Failure to

follow at! instructions listed below may result in electric shock, fire and/or

serious personal injury.

WORK AREA SAFETY

1. ALWAYS keep your work area clean and well lit. Cluttered benches and dark

areas invite accidents.

2. DO NOT operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Power tools create sparks wfiich

may ignite the dust or fumes.

3. ALWAYS keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control

ELECTRICAL SAFETY

1. Double insulated tools are equipped with a polarized plug (one blade is

wider than the other.)This plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If H still does not

fit, contact a qualified electrician to install a polarized outlet. Do not change

the plug In any viray.

2. Double insulation ^eliminates the need for the three-wire grounded power cord

and grounded power supply system. Applicable only to Class II (double insulated)

tools.

3. Before plugging in the tool, BE SURE that the outlet voltage supplied is within the

voltage marked on the tool's data plate. DO NOT usé "AC only” rated tools with a

DC power supply.

4. ALWAYS avoid body contact with grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk ot electric shock

if your body is grounded.

5. If operating the power tool in damp locations is unavoidable, ALWAYS use a

Ground Fault Circuit Interrupter to supply power to your tool. ALWAYS wear

electrician's rubber gloves and footwear in damp conditions.

6. DO NOT expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

7. DO NOT abuse the cord. NEVER use the cord to carry the tools or pull the

plug from the outlet. Keep cord away from heat, oil, sharp edges or moving

parts. Replace damaged cords immediately. Damaged cords increase the risk

of electric shock.

8. When operating a power tool outside, ALWAYS use an outdoor extension cord

marked “W-A” or “W". These cords are rated for outdoor use and reduce the risk

of electric shock.

NOTE: The extension cord must have adequate wire size AWG (American Wire

Gauge) for safe, efficient use. Smaller gauge wires, have greater capacity (16 gauge

wire has more capacity than 18 gauge wire).

____________________________________

_

Page 4

SAFETY INSTRUCTIONS cont.

PERSONAL SAFETY

1. ALWAYS Stay alert, watch what you are doing and use common sense when

operating a power tool. DO NOT use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention white operating power

fools may result in serious personal injury.

2. ALWAYS dress properly. DO NOT wear loose clothing or jeweiry, Puil back

long hair. Keep your hair, clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught in moving parts.

3. ALWAYS avoid accidental starting. BE SURE switch is in the “Off ” position

before plugging in. DO NOT carry tools with your finger on the switch. Carrying

tools with your finger on the switch or plugging in tools that have the switch in the

“On” position invites accidents.

4. ALWAYS remove adjusting keys or wrenches before turning the tool “On”.

A wrench or a key that is left attached to a rotating part of the tool may result in

personal injury.

5. DO NOT overreach. ALWAYS keep proper footing and balance at ail times.

Proper footing and balance enables better control of the tool in unexpected

situations,

6. ALWAYS use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be used for appropriate

conditions.

TOOL USE AND CARE SAFETY

1. ALWAYS use clamps or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body

is unstable and may lead to loss of control.

2. DO NOT force the tool. Use the correct tool for your application. The correct

toot will do the job better and safer at the rate for which it is designed.

3. DO NOT use the tool if the switch does not turn it “On” or “Off”. Any tool that

cannot be controlled with the switch is dangerous and must be repaired.

4. ALWAYS disconnect the plug from the power source before making any

adjustments, changing accessories or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

5. ALWAYS Store idle tools out of the reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

6. ALWAYS maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edges are less likely to bind and are

easier to control,

7. ALWAYS check for misalignment or binding of moving parts, breakage of

parts, and any other condition that may affect the tool’s operation. If

damaged, have the tool serviced before using. Many accidents are caused by

poorly maintained tools.

A WARNING: US EOF ACCESSORIES THAT ARE NOT RECOMMENDED

for use with this tool may CREATE A HAZARDOUS CONDITION

8. ALWAYS use only accessories that are recommended for this tool.

Accessories that may be suitable for one tool can become hazardous when used

on another tool.

4

Page 5

SAFETY INSTRUCTIONS cont.

SERVICE SAFETY

1. If any part of this saw is missing or should break, bend, or fail in any way; or

should any electrical component fail to perform properly: ALWAYS shut off ihe

power switch and remove the saw plug from the power source and have the missing,

damaged or failed parts replaced BEFORE resuming operation.

2. Tool service must be performed only at a Sears Parts and Repair Center.

Service or maintenance performed by unqualified personnel could result in a risk of

injury.

SAFETY RULES FOR SAWS

DANGER! Keep hands away from cutting area and blades. Keep your

second hand on the auxiliary handle or motor housing. If both hands are

holding the saw, they cannot be cut by the blades.

1. ALWAYS keep your body positioned to either side of the saw blades, but not

in line with the saw blades.

2. DO NOT reach underneath the work. The guard cannot protect you from the

blades beneath the work.

3. ALWAYS check guard for proper closing BEFORE each use. DO NOT operate

the saw if the guard does not move freely and close instantly. Never clamp or

tie the blade guard in the open position. If the saw Is accidentatly dropped, the

guard may be bent. Raise the guard and make sure that it moves freely and does

not touch the blades or any other part,

4. ALWAYS check the operation and condition of the guard spring. If the guard

and the spring are not operating properly, they MUST be serviced before use.

The blade guard may operate sluggishly, due to damaged parts, gummy deposits,

or a buildup of debris.

5. The guard should be retracted manually ONLY for making special cuts, such

as pocket or compound cuts. ALWAYS raise the guard by retracting the

handle. As soon as the blade enters the material, the guard MUST be

released. For all other sawing, the guard should operate automatically.

6. ALWAYS make sure that the guard is covering the blades BEFORE placing the

saw down on a work bench or floor. An unprotected moving blades will cause the

saw to walk backwards, cutting whatever is in its path. Make note of the time it takes

for the blades to stop spinning after the switch is released.

7. NEVER hold the piece being cut in your hands or across your legs. It is

important to support the work properly in order to minimize body exposure, blade

binding, or loss of control.

8. ALWAYS hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or Its own cord.

Contact with a ‘live” wire will make the exposed metal parts of the tool “live” and

shock the operator.

9. DO NOT leave the saw running when carrying it in your hand.The lower blade

guard may be opened by contact with your clothing. Accidental contact with the

spinning saw blades could result in serious personal injury.

10. DO NOT use the tool If the switch does not turn “On” or “Off”. Any tool that

cannot be controlled with the switch is dangerous and must be repaired.

Page 6

SAFETY INSTRUCTIONS cont.

SAFETY RULES FOR SAW cont.

11. When removing the blades from the tool, ALWAYS wear protective gloves when

grasping the blades or accessory. Accessories may be hot after prolonged use,

KICKBACK...WHAT CAUSES IT AND WAYS TO PREVENT IT

The Causes of Kickback

1, Kickback is a sudden reaction to a pinched, bound or misaligned saw blades,

which cause the uncontrolled saw to lift up and out of the workpiece and towards

the operator.

2. When the blades are pinched or bound tightly by the kerf dosing down, the blades

stall and the motor reaction drives the unit rapidly back towards the operator.

3, If the blades become twisted or misaligned in the cut, the teeth at the back edges

of the blades can dig into the top surface of the wood. This causes the blades to

climb out of the kerf and Jump back towards the operator,

4. Kickback is a result of tool misuse and/or Incorrect operating procedures or

conditions. It can be avoided by taking the proper precautions, as listed below.

Ways to Prevent Kickback

1. ALWAYS maintain a firm grip with both hands on the saw and position your

body and arms to allow you to resist KICKBACK forces. KICKBACK forces can

be controlled by the operator, if the proper precautions are taken,

2. If the blades are binding, or when you are interrupting a cut for any reason,

ALWAYS turn off the saw and hold the saw motionless in the material until

the blades come to a complete stop. NEVER attempt to remove the saw from

the work or pull the saw backward while the blades are in motion or

KICKBACK may occur. ALWAYS check and be ready to take corrective action to

eliminate the cause of blade binding,

3. When restarting the saw in the workpiece, ALWAYS center the blades In the

kerf and check to be sure that the saw teeth are not engaged into the

material. If the saw blades are binding, they may walk up or KICKBACK from the

workpiece wherr the saw is restarted.

4. ALWAYS support large panels to minimize the risk of blades pinching and

KICKBACK. Large panels tend to sag under their own weight. Supports MUST be

placed i,inder the panel on both sides, near Ihe line of cut and near the edge of the

panel.

5. DO NOT use a dull or damaged blades. Unsharpened or improperly set blades

produce narrow kerf whicti causes excessive friction, blade binding and

KICKBACK.

6. ALWAYS use extra caution when making a “Pocket Cut" into existing wails or

other blind areas. The protruding blades may cut objects that can cause

KICKBACK,

7. ALWAYS have the saw blades at full speed before contacting workpiece

8. ALWAYS keep your body positioned to either side of the saw blades, but not in line

with the saw blades. KICKBACK could cause the saw to jump backwards towards

the operator. KICKBACK forces can be controlled by the operator, if proper

precautions are taken,

ALWAYS hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or its own cord.

Contact with a "live” wire will make the exposed metal parts of the tool "live” and

shock the operator. g

Page 7

SAFETY INSTRUCTIONS cont.

ADDITIONAL RULES FOR SAFE OPERATION

A WARNING: BE SURE to read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire and/or serious

personal injury.

1. Know your power tool. Read operator's manual carefully. Learn the

applications and limitations, as well as the specific potential hazards related

to this tool. Following this ruis will reduce the risk of electric shock, fire or serious

injury.

2. ALWAYS wear safety glasses or eye shields when using this saw. Everyday

eyeglasses have only impact-resistant lenses; they are NOT safety glasses.

Following this rule will reduce the risk of serious personal injury.

3. ALWAYS protect your lungs. Wear a face mask or dust mask if the operation

is dusty. Following this rule will reduce the risk of serious personal injury.

4. ALWAYS protect your hearing. Wear hearing protection during extended

periods of operation. Following this rule will reduce the risk of serious personal

injury.

5. ALWAYS inspect the tool cords periodically and if damaged have them

repaired at your nearest Sears Service Center or other Authorized Service

Facility. ALWAYS be aware of the cord location.

Following this rule will reduce

the risk of electric shock or fire.

6. ALWAYS check for damaged parts. Before further use of the tool, a guard or

other part that is damaged should be carefully checked to determine if it will

operate properly and perform its intended function. Check for misalignment

or binding of moving parts, breakage of parts, and any other condition that

may affect the tool's operation. A guard or other part that is damaged, should

be properly repaired or replaced at a Sears Service Center. Following this rule

will reduce the risk of electric shock, fire or serious injury.

7. DO NOT abuse the cord. NEVER use the cord to carry the tool or pull the

plug from the outlet. Keep cord away from heat, oil, sharp edges or moving

parts. Replace damaged cords Immediately.

Damaged cords increase the risk

of electric shock. Following this rule will reduce the risk of electric .shock or fire.

8. ALWAYS make sure that your extension cord is in good condition. When

using an extension cord be sure to use one that is heavy enough to carry the

current that your tool will draw. A wire gauge size (A.W.G.) of at feast 16 is

recommended for an extension 100 feet or less in length. Using an extension

cord that is over 100 feet in length is not recommended. If in doubt, use the

next heavier gauge. Smaller gauge wires, have greater capacity (16 gauge

wire has more capacity than 18 gauge wire). An undersized cord will cause a

drop in line voltage, resulting in loss of power and overheating.

9. DO NOT use the tool while tired or under the influence of drugs, alcohol or

any medication. Following this rule will reduce the risk of electric shock, fire or

serious personal injury.

10. SAVE THESE INSTRUCTIONS, Refer to them frequently and use them to

instruct others who may use this tool, if someone borrows this tool, make

sure they have these instructions also.

________________

Page 8

SAFETY INSTRUCTIONS cont.

ADDITIONAL RULES FOR SAFE OPERATION cont.

/K WARNING: Some dust particles created by power sanding, sawing,

grinding, drilling and other construction Jobs contains chemicals known

to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending upon how often you do this

type of work. To reduce your exposure to these chemicals:

• Work in a well-ventilated area.

• Work with approved safety equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

A WARNING: The operation of any saw can result in

foreign objects being thrown into your eyes, which can result in

severe eye damage. Before beginning power tool operation,

ALWAYS wear safety goggles or safety glasses with side shield

and a full face shield when needed. We recommend A Wide

Vision Safety Mask for use over eyeglasses or standard safety

glasses with side shield, available at Sears Retail Stores.

SAFETY SYMBOLS

The label on your tool may include the following symbols.

V.............................................................Vote

A

.............................................................

Hz......................

W............................................................

min

...........................................................Minutes

............................................................Alternating current

—.—

.......................................................

Ho

..........-................................................

B.............................................................Class II construction

■■■/min....................................................Revolutions or Strokes per minute

/1^...........................................................Indicates danger, warning or caution.

.....................................

IMPORTANT! READ ALL INSTRUCTIONS

Amperes

Hertz

Watts

Direct current

No-load speed

It means attention! Your safety is involved.

Page 9

DESCRIPTION

Betöre attempting to ose any tooi, be sure to tamiliarize with all the operating

features and safety instructions.

_________________

A WARNING: DO NOT let familiarity with your saw make you careless.

Remember that a careless fraction of a second is sufficient to cause severe injury.

KNOW YOUR SAW (SEE Fig. 1)

Your Twin Cutter saw has many built-in convenience features for fast, efficient cutting.

These features include a innovative 2-blade system with special blades that spin in

opposite directions to provide smooth, clean cuts. It also includes a pre-installed

blade lubricating system for use when cutting aluminum, copper, stainless steel and

cast iron. The auxiliary handle mounts on the top of the saw to provide maximum

support and ease of handling.

For your convenience, there is no assembly required for your Twin Cutter Saw. The

special 2-blade cutting system and the wax lubricating system are already installed.

Assist Handle

Lower Blade

Guard Handle -

Wax

Lubricating

Stick

Wax Lubricating

System Knob L\

Blades

Upper Blade Guard

Lower Blade Guard

PRODUCT SPECIFICATIONS "

Input

Output

Blade Diameter

Rating

No-load Speed 460Ö RPM

7.8 Amps

1.25-Peak HP

6 1/8 in. |155mm)

120 volts, 60 Hz AC

ASSEMBLY

UNPACKING

Your Twin Cutter Saw has been shipped completely assembled. Inspect the saw

carefully to make sure that no breakage or damage has occurred during shipping,

if any parts are damaged or missing return the saw to your nearest Sears Store to

have it replaced.

Motor

Housing

________

Fig. 1

A WARNING: if any parts are missing, DO NOT operate this saw until the

missing parts are replaced. Failure to do so could result in possible serious

personal injury ________

Page 10

OPERATION

SAW BLADES

Even the best saw blades wil! not cut efficiently if they are not kept clean, sharp and

properly set. Using dull blades will place a heavy load on your saw and increase the

danger of kickback. Keep extra blades on hand, so sharp blades are always available.

Gum and wood pitch hardened on your blades will slow your saw down. Use gum

and pitch remover, hot water or kerosene to remove these accumulations.

DO NOT use gasoline.

A WARNING: This Twin Cutter saw uses specially designed 6 Vann, blades

and no olher types or sizes of blades should ever be used. Other types and sizes of

blades will not operate safely in this saw and could result in serious personal injury.

To order extra blades or to replace the blades that came with the saw, see page 21

of this manual for ordering instructions. To install new blades onto to your saw see

the special instructions on pages 17 to 19 of this manual for proper removal and

inslallalion of blades.

BLADE GUARD SYSTEM

The lower blade guard, attached to your saw, is there for your protection and

safety. It should NEVER be altered for any reason. If it becomes damaged or

begins to return slowly or sluggishly. DO NOT operate your saw until the

problem has been corrected or the damaged part has been replaced. ALWAYS

leave the guard in its correct operating position when using the saw.

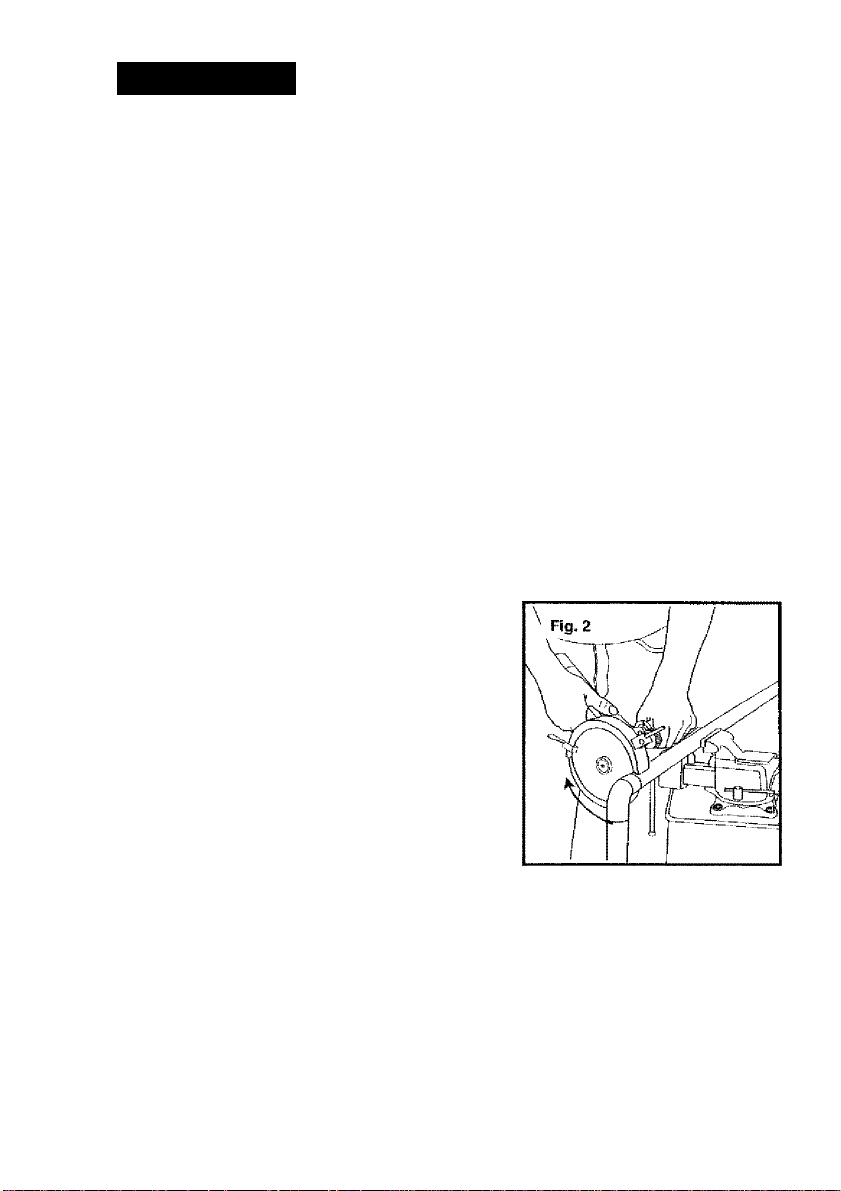

A DANGER: When sawing through a

workpiece, the lower blade guard does not

cover the blade on the underside of the

workpiece. Since the blade is exposed on the

underside of the workpiece, ALWAYS keep

your hands and fingers away from the cutting

area (see Fig. 2). Any part of your body

coming in contact with the moving blade will

result in serious injury.

l ower Blade Guard is in UP position when

making a cut. Blades are exposed on underside

of workpiece.

A WARNING: NEVER use the saw when the guard is not operating properly.

The guard should be checked for correct operation before each use. If you drop your

saw, check the lower blade guard for damage before using.

NOTE: The guard is operating properly when it moves freely and then readily

returns to the closed position. If, for any reason, your lower blade guard does not

close freely, take it to your nearest Sears Repair Center for sen/ice before using it.

10

Page 11

OPERATION cont.

KICKBACK

Kickback occurs when the blades stall rapidly and the saw Is driven back towards

you. Blade stalling Is caused by any action which pinches the blade in the material

being cut.

IMPORTANT: The best guard against kickback is to avoid dangerous practices.

A DANGER: ALWAYS turn OFF power to saw immediately if the blades bind

or the saw stalls. Kickback could cause you to lose control of the saw. Loss of

control can lead to serious injury.

ALWAYS provide proper support for the workpiece and hold the saw with

both hands

Kickback Is Caused By:

1. Twisting the blades while making a cut.

2. Making a cut with a dull, gummed up, or

improperly set blades.

3. Not providing proper support for workpiece.

ALWAYS provide proper support as shown

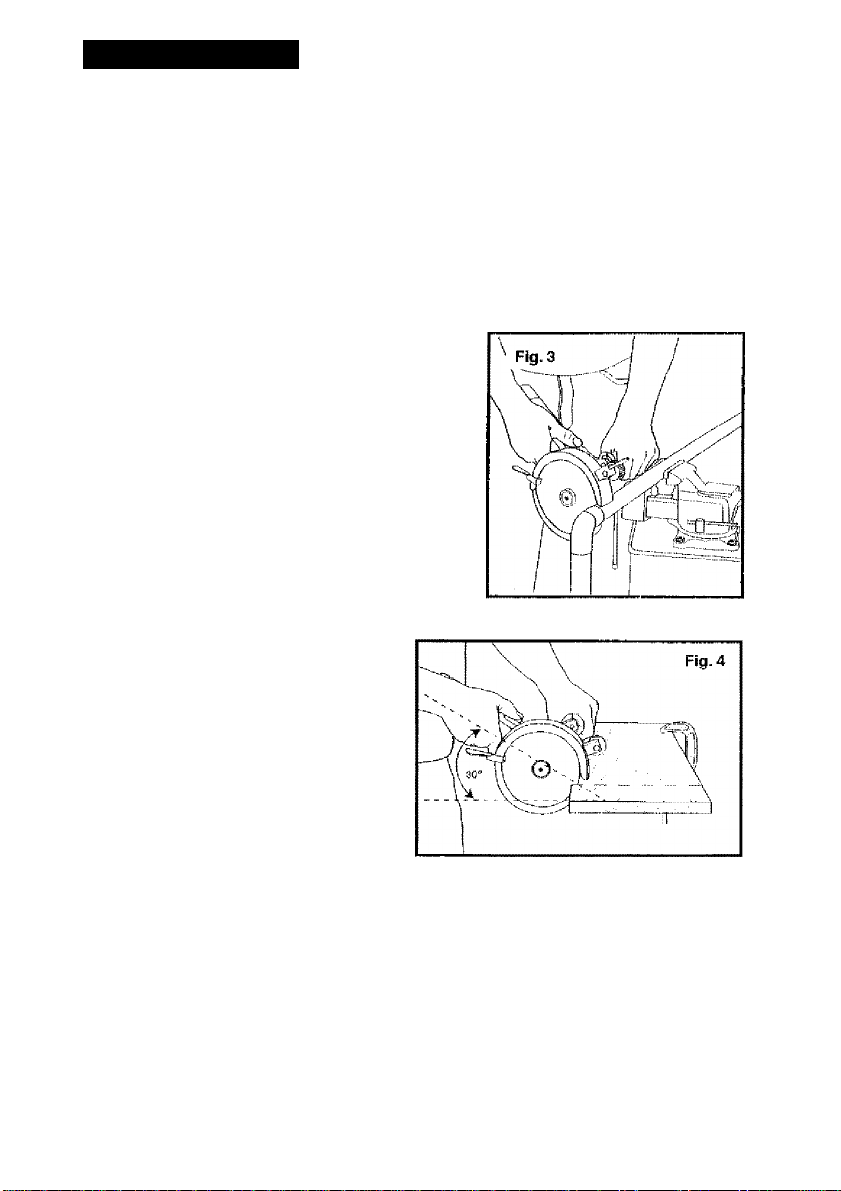

in Fig. 3.

4. Forcing a cut,

5. Cutting warped or wet lumber.

6 Tool misuse or incorrect operating procedures.

7. Contacting the workpiece with blades at less

than full speed.

To Lessen the Chance of Kickback

1. ALWAYS approach the workpiece with

the saw at an angle of approximately

30° to the workpiece, (see Fig, 4.)

2. ALWAYS make straight cuts.

This will help prevent twisting the

blade in the cut.

3. ALWAYS use clean, sharp and

properly set blades. NEVER make

cuts with dull blades.

4. ALWAYS properly support the

workpiece before beginning a cut. This will help you avoid pinching the blades

(see Fig. 3).

5. ALWAYS use steady, even pressure when making a cut. NEVER force the cut.

6. DO NOT cut wet or warped lumber.

7. ALWAYS hold the saw firmly with both hands and keep your body In a balanced

position. ALWAYS keep your body positioned to either side of the saw blades, but

not in line with the saw blades. This will help you resist the forces of kickback,

should it occur.

IMPORTANT: When using your saw, ALWAYS stay alert and exercise control.

DO NOT remove your saw from the workpiece, while the blade is moving.

11

Page 12

OPERAtíON coiit.

STARTING A CUT IMPORTANT;

BEFORE using the Twin Cutter Saw for the first time, ALWAYS familiarize yourself

with tire saw by making practice cuts in scrap rnateriais.

The weight of this saw helps to make the cuts smoother. Learn how to safely handle

and control the weight of the saw.

ALWAYS be sure that you position the blades perpendicular to the plane of the

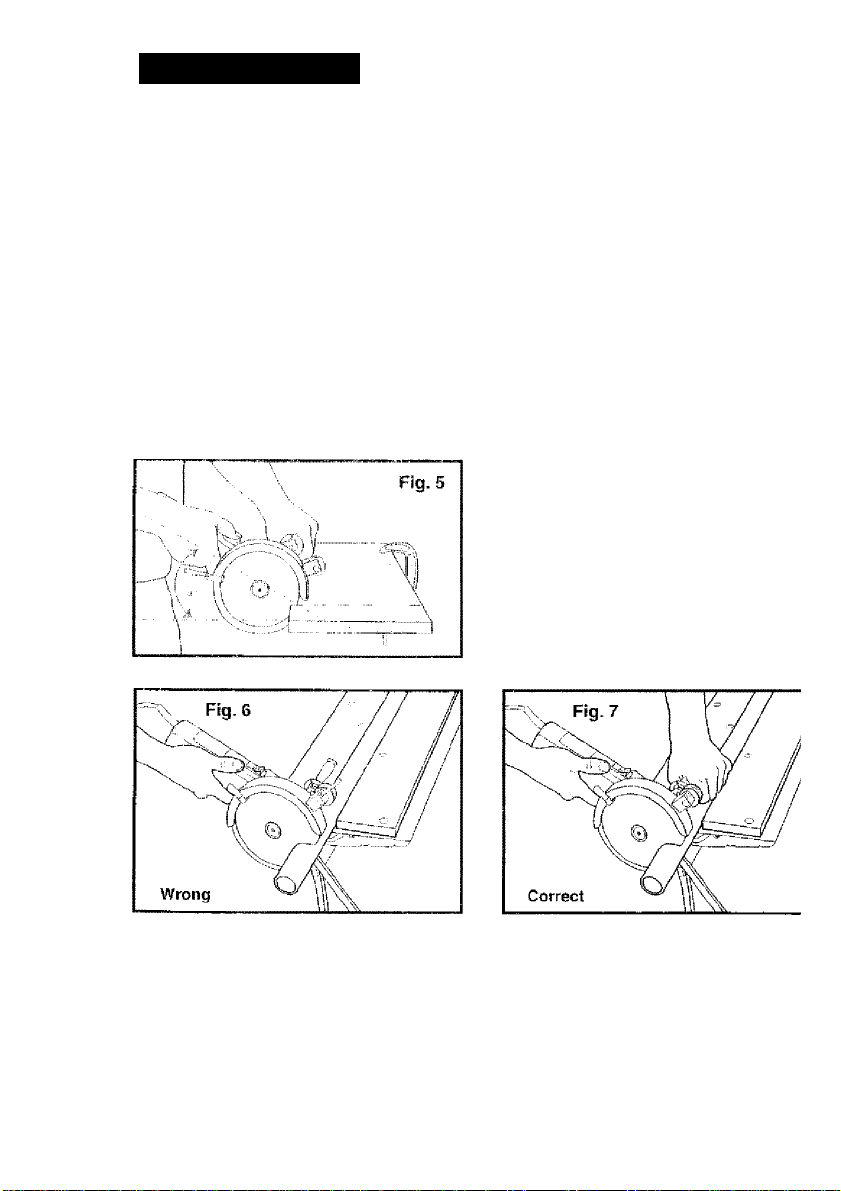

workpiece. Make the cut at an approximate 30" angle to the workpiece surface.

(See Fig. 5).

Practice the proper feed speed rate for 1!ie materials being cut. The blades spin at a

consistent 4600 RPM {no-load speed).

Engage the on/off switch to start the saw, ALWAYS let the blades reach full speed

before you begin the cut into the workpiece.

IMPORTANT: When using your saw, ALWAYS stay alert and exercise control.

DO NOT remove your saw from the workpiece, while the blade is moving.

Blades perpendicular to workpiece Approximately 30"

WARNING; always

maintain proper control of the saw

to make sawing safer and easier.

Loss of control of the saw could

cause an accident resulting in

possible serious injury.

NEVER hold the saw with just

one hand (see Fig. 6).

always hold saw by motor body anc

assist handle (see Fig, 7).

12

Page 13

OPEft/n-ION coni.

TO HELP MAINTAIN CONTROL

1. ALWAYS support the workpiece near the cut,

2. ALWAYS support the workpiece so the cut will be on your right.

3. ALWAYS clamp the workpiece so it will not move during the cut.

Place the workpiece with the good side down. NOTE; The good aide is the side

where appearance is important.

Before starting a cut, draw a guideline along the desired line of cut. Then place the

front edge of the saw blades on the part of the workpiece that is solidly .supported.

4. NEVER place the saw on the part of the workpiece that will fall off when the cut is

made.

5. ALWAYS keep the cord away from the cutting area. ALWAYS place the cord so it

does not hang up on the workpiece when making a cut.

DANGER: if the cord hangs up on the workpiece during a cut, release the

on/off switch immediately. Unplug the saw and move the cord to prevent it from

hanging up again.

DANGER: Using the saw with a damaged cord could result in serious

injury or death. If the cord has been damaged, have it replaced before using the

saw again.

WARNtNG: if the blades come in contact with the workpiece before they

reach full speed, it could cause the saw to kickback towards you, resultincj in

serious injury.

When making a cut, ALWAYS use steady, even pressure. Forcing the saw causes

rough cuts and could shorten the life of the saw or cause kickback.

DANGER; When sawing through the workpiece, the lower blade guard

does not cover the blades. The blades are exposed on the under side of the

workpiece. ALWAYS keep your hands and fingers away from the cutting area.

Any part of your body coming in contact with the moving blades will result

in serious Injury.

After completing your cut, release the on/off switch and allow the blades to come to a

complete stop. DO NOT remove the saw from the workpiece while the blades

are moving.

CAUTION: Whenever you lift your saw from the workpiece, the blades are

exposed on the under side of the saw until the lower blade guard closes. ALWAYS

MAKE SURE that the lower blade guard is closed before setting the saw down on

work surface.

13

Page 14

OPÉRATION cont.

CUTTING INSTRUCTIONS

NOTE: The life span of the blades on your Twin Cutter saw and the quality of the

cuffing edges is dependent on keeping vibrations to a minimum.

ALWAYS securely clamp the workpiece

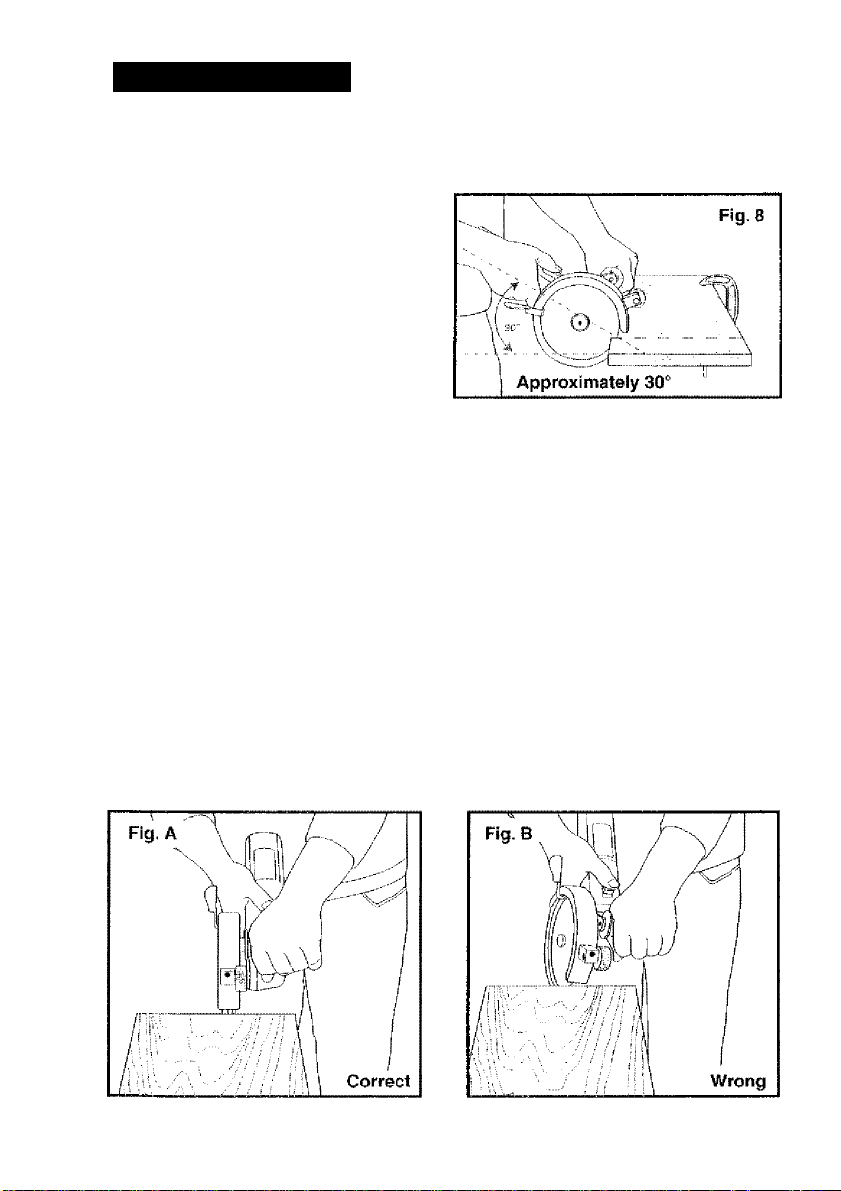

BEFORE beginning a cut. Then feed the

blade through the material at an angle

of approximately 30” (see Fig. 8).

This saw produces hot chips, not

sparks, when cutting metal.

It is recommended that you wear a

face shield over safety glasses to

protect your face.

FEED SPEED

Feed speed is how quickly you push the saw blades through Ihe material being cut.

The correct feed speed is totally determined by the hardness and the thickness of

the rnaterial being cut.

IMPORTANT: Feeding must ALWAYS be done with the blades perpendicular to the

plane of the workpiece (See Fig. A). Feeding at an angle can burn the blade and

damage the blade teetli (See Fig. B).

Selecting the correct feed speed is important.

If the feed speed is too slow:

1. The blades will only press down on the materia! rather than cutting it.

2- The blade edges glide and wear down the material.

3. A poor cut will result and cause excessive wear on the blades

If the feed speed is too fast:

1. There is a definite risk that the cut might split and the splintered opening of the cut

will nof be sufficient to divert the wood shavings.

2. A poor cut will result with a significant discharge of wood shavings on the lower

side of the cut.

14

Page 15

OPERATION com.

CUTTING INSTRUCTIONS cont.

CUTTING ALL MATERIALS

1. ALWAYS have the saw blades at full speed before contacting workpiece.

2. ALWAYS hold the saw so the blades feed perpendicularly into the workpiece. Hold

the saw at an approximate 30'’ angle.

3. ALWAYS keep your body positioned to either side of the saw blades, but not in line

with the saw blades.

4. Feed the blades into the workpiece until the desired cut is made.

5. The kerf (width of the cut) of the twin blades is approximately 1/8th of an inch.

Always be sure to allow for this kerf width.

This Twin Cutter Saw with It's special blades and cutting action Is a highly

versatile tool that quickly and efficiently provides smooth, efficient cuts a wide

variety of materials;

m

Rectangular Pipe

Thin Plate

Cutting other materials may require even more special handling. These include cutting aluminum, copper, stainless steel and cast iron or shaped plates

Cutting Aluminum, Copper, Stainless

Steel and Cast Iron up to 1/8-in. thick.

(See Fig. 9).

1. ALWAYS use the wax lubricating device

Shaped Plate

(included) when cutting these materials

because they have a tendency to soften

and adhere to the blades.

15

Page 16

OPÉR^ION cbnti

LUBRICATING INSTRUCTIONS

(See Figure C)

The blades of your Twin Cutter saw are

equipped with “dry cut teeth that under

normal cutting conditions do not need to

be lubricated. However, in extreme cutting

conditions, such as when you are sawing

into aluminum, copper, stainless steel and

cast iron, ttie wax lubricating device should

be used.

1. Insert wax lubricating stick into wax

lubricating device.

2. Turn feeder wheel to apply lubricant to

blade, A 1/4 turn should provide adequate

CUTTING INSTRUCTIONS cont.

Cutting Shaped Plates

up to 1/8-in, thick (See Fig. 10)

1. When cutting shaped metal plate

ALWAYS support the plate evenly orr

both sides and in the middle with

support blocks. This will keep it from

flexing when cutting. This should be

done, whether you're using a clamping

iable, or using adjustable clamps on a

flat work table.

lubrication.

PLUNGE CUTTING (See Figure 11)

1. Raise the retractable guard into the

open position with your left hand.

2. Use (he thumb of your left hand to hold

the guard in the open position while

gripping the saw's assist handle.

3. Turn on the saw and plunge the blades

into the material to be cut.

4. Push the saw forward to complete

the cut.

5. Turn off saw, allow blades to stop

completely, then remove saw from

workpiece.

6. Clean out the corners of the cut with a hand saw or sabre saw, depending

on project.

NOTE; When cutting roofing materials, blades must be kept clean with a tar and pitch

blade cleaning solvent

16

Page 17

OPERATION cont.

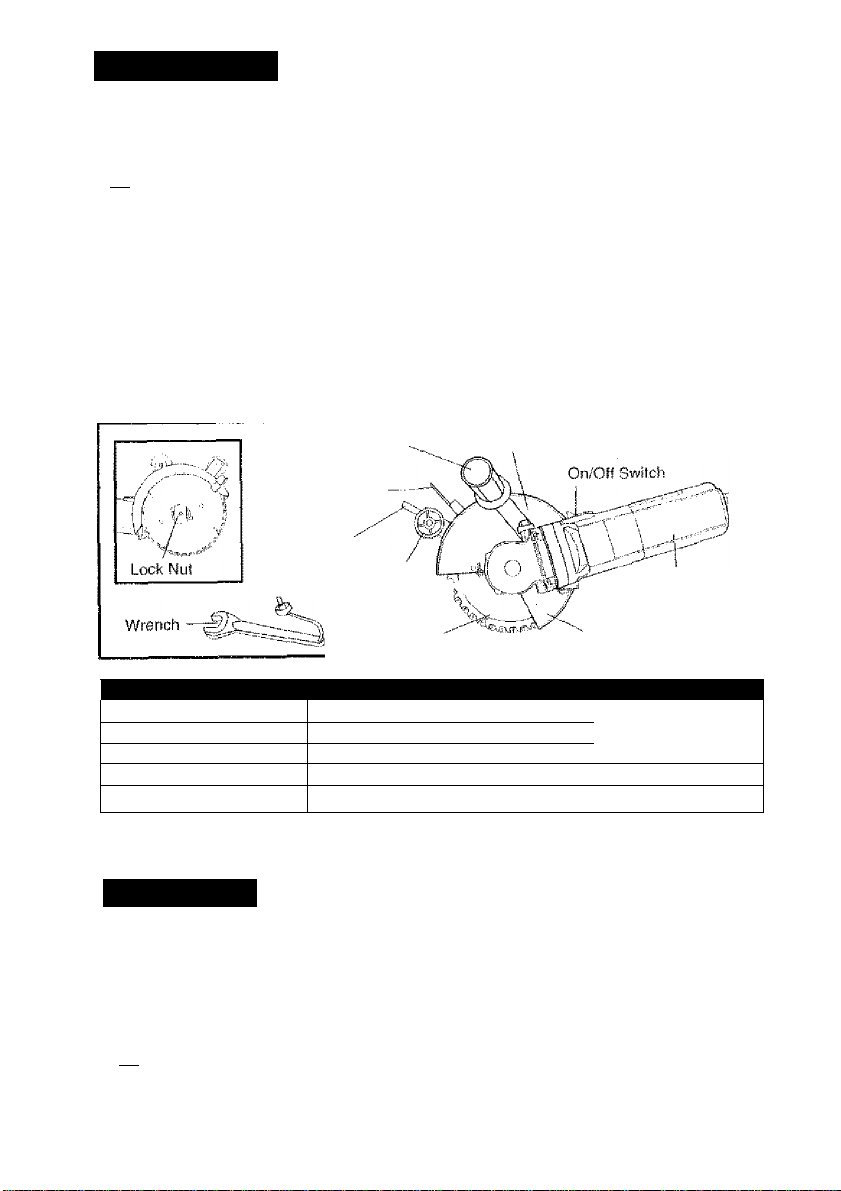

REMOVING BLADES FROM SAW (See Figs. 12 -16)

1. Unplug the saw and allow blades to cool.

A WARNING: Failure to unplug the saw could result in accidental starting

causing possible serious personal injury.

2. Rotate the blades until the holes in both blades are aligned. Then place pin

attached to the wrench through holes In blades. Unscrew Lock Nut

counterclockwise and remove (see Fig. 12).

3. Open the retractable guard (see Fig. 13).

4. Lift up and remove Blade "B” (see Fig. 14),

5. Remove the arbor adapter (see Fig. 15).

6. Lift up and remove Blade "A” (see Fig. 16),

Fig. 13

...

/S'!

B '<ff

T

................

T

Blade Guard »

Retracted

K

Fig. 16

17

Fig, 15

a;.,

'' Adapter

Arbor

Page 18

OPERATION cont.

ATTACHING REPLACEMENT BLADES TO THE SAW (See Figs. 17 - 20)

A WARNING: This Twin Cutter saw uses specially designed eVs-in, blades

and no other types or sizes of blades should ever be used. Other types and sizes

of blades will not operate safely in this saw and could result in serious personal

injury.

See the accessories section of this manual for the proper replacement blades

that are needed for this saw.

1. Unplug the saw.

A WARNING: Failure to unplug the saw could result in accidental starting

causing possible serious personal injury.

2. Lay the saw down with the blade arbor pointing upward,

3. Place blade “A" onto ttie blade flange with the "A” clearly visible (see Fig. 17).

4. Align the holes on the blade with the pins on the flange and securely fit the blade

on the flange (see Fig. 18).

5. Take the arbor adapter “1” and push it down onto the flange with the "1" clearly

visible. Make sure that the adapter is properly seated over the flat sides of the

flange.(see Fig. 18}.

6. Place blade “B” onto the adapter with the “B" easily visible, then thread lock nut

onto shaft, DO NOT tighten, (see Fig. 19).

7. Turn the blades so that the holes in both blades are lined up.

Fig. 17

..__W /

i

I I

I... - u

■

/

■ f ■ A

it

\

\

Flange

A '

;

18

Page 19

OPERATION cont.

ATTACHING REPLACEMENT BLADES TO THE SAW cont. (See Figs. 17

8. Place the pin (included with the

wrench) into the lined up holes,

9. Tighten the lock nut clockwise with

the wrench and then remove the pin

from the blades (see Fig. 20). This wi

allow the blades to turn freely.

10. Carefully turn blades with your hand

to be sure they easily turn in

opposite directions.

20)

MAINTENANCE

GENERAL

A WARNING: To avoid accidents, ALWAYS disconnect the tool from tlie

power source BEFORE cleaning or performing any maintenance.

All parts represent an important part of the double insulation system and should be

serviced only at a Sears Service Center.

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to

damage from various types of commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, carbon du si, etc.

A WARNING: DO NOT at any time let brake fluids, gasoline, petroleum-based

products, penetrating oils, etc. to come in contact with plastic parts. They contain

chemicals that can damage, weaken or destroy plastic.

It is a known fact that electric tools are subject to accelerated wear and possible

premature failure when they are used to work on fiber glass boats and sports cars,

wallboard, speckling compounds or plaster. The chips and grindings from these

materials are highly abrasive to electrical tool parts, such as bearings, brushes,

commutators, etc. Consequently, it is not recommended that this too! be used for

extended work on any fiber glass material, wallboard, spackling compound, or plaster.

During any use on these materials, it is extremely important that the tool is cleaned

frequently by blowing with an air jet.

A WARNING: ALWAYS wear safety goggles or safety glasses with side shields

orfece shield when blowing dust from tool when cleaning it. If operation is dusty, also

wear a dust mask.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient amount of high-grade

lubricant for the life of the tool under normal operating conditions. Therefore, no

further lubrication is required.

19

Page 20

MAINTENANCE cont.

DOUBLE INSULATION

Double insulation is a concept in safety in eiectric power toois, which eiiminates the

need for the standard 3-wire grounded power cord. All exposed metal parts are

isolated from the internal motor components with protectve insulation. Double

insulated tools do not need to be grounded.

IMPORTANT

The servicing of a tool with double insulation requires extreme care and knowledge

of the system and should be performed only by a qualified service technician. For

service, we recommend that you return the tool to your nearest Sears Service Center

for repair. ALWAYS use original factory replacement parts when servicing.

EXTENSION CORDS

The use of any extension cord will cause some loss of power. To keep the loss at a

minimum and to prevent overheating, use an extension cord that is heavy enough to

carry the current that the tool will draw.

A wire gauge (AWG) of at least 16 is recommended for an extension cord 100 feet or

Iges in length. When working outdoors ALWAYS use an extension cord that is

suitable for outdoor use. The cord's jacket will be marked WA.

A CAUTION: Keep extension cords away from the cutting area, and position

ihe cord so It will not get caught on lumber, tools, etc. during the cutting operation

A DANGER; Check extension cords before each use. If damaged, replace

it immediately. NEVER use a tool with a damaged cord because touching the

damaged area could cause electrical shock, resulting in serious injury.

Extension cords that are suitable for use with your saw are available at your nearest

Sears Store.

MAXIMUM STOCK SIZE & FEED RATES

C/R TYPE MATEmAL

Galvanizecj Iran ! )/?•' t/ñ" 360 cuts 20 Sec

Square channel j

Channel jj

Sheet Metal

Stud

Pipe Flastio (PVC) 1 1/2'

Ps. Averiige biRdR IIIr inrIicRteR reisullis nf performance iKRt in parliculai type ot lesl t^iaierial as per the above table However the

rnsuHs mey very if Ihe earvie blacle Is nser! on combinolion of ilnted rnalerinlr;.

..................

----------------------

...................

j

1

M s

AlLrntinnm

M.S.

M.S.

Aliiminnm

Wood (Pine)

MAX. SIZE

iCnOBS SECTION)

1 1/2*' 1/B- 140 culs 30 Sec

1 1/2'’

1 1/2' 1/8' 120culs 30 Sec

2*' X 4*'

MAX

THICKNESS

1/0" 8000 cuts 5 Sec

1/8" 70 Feet

1/8" 112 Feet 102 Incli/mln

1 1/2"

3/16" 12000 cuts 6 Sec

AVERAGE

BLADE UFE

10000 cuts

AVERAGE

TIME cm FEED

4.3 Incfi/rtiin

11 Sec

ao

Page 21

TROUBLESHOOTING

PROBLEM

An unusuaily

large amount

of sparks

A lot of wear

in sections

Blades are

breaking

Possible causes

of broken teeth

ACCESSORIES

CAUSE

1. Damaged teeth

2. Feed speed is too slow

3. Blunt teeth

1. Feed speed is too tast

2. Damaged teeth

3. Blunt teeth

4. Not cutting perpendicular

to work surface

1. Damaged teeth

2. Feed speed is too fast

3. Blunt teeth

4. Blades have buckled

5. Blades have burned out

1. Feed speed is loo fast

2. The surface being

cut is too hard

3. The teeth have been

damaged by Impact

4. Blades were not

installed properly

5. Blades are burned out

6. Not cutting perpendicular

to work surface

SOLUTION

1. Replace blades

2. Increase feed speed

3. Replace blades

1 Reduce teed speed

2. Replace blades

3. Replace blades

4. Hold saw perpendicular

to work surface

1. Replace blades

2. Reduce feed speed

3. Replace blades

4. Replace blades

5. Replace blades

1. Reduce feed speed

2. Replace Wades

3. Replace blades

4. Replace blades and follow

the proper blade inslallatfon

instmetions

5. Replace blades

6. Replace blades and always

hold saw perpendicular to

work surface when cutting

WARNING: This Twin Cutter saw uses specially designed 6 Ve-in. blades

and no other types of blades should ever be used. Other blades will not operate

safely in this saw and could result in serious personal injury.

The following accessories for your Twin Cutter saw are avaitabie at your local

Sears store.

9-26677 — A packaged set of 2 Universal Twin Cutter Saw Blades 9 26678 — 6 Packaged Wax Lubricating Sticks

ZK WARNING: The use of attachments or accessories that are not

recommended might be dangerous.

21

Page 22

ro

ro

N

W

TWIN-CUTTER SAW - MODEL NUMBER 286.26829

The Model Number will be found on the Nameplate. Always mention the Model Number in ail correspondence regarding your tool.

Item No.

Parts No. Part Description Qty.

1

PW001 Biade 1 Set

2 PW002

3 PW003

4

PW004

5 PWOOS

6 PW006

7 PW007

8

PWOOS Guard 1

9

10 PW010

11

12 PW012

13 PW013

14

15 PW015

16 PW016

IS PW018

19

20 PW020

21

22 PW022

23 PW023 Tapping Screw ST 4.2 x 12 1

24 PW024

25 PW025

26 PW026 Spring Washer 1

27 PW027

28

29 PW029 Switch Button 1

PW009

PW011 Gear Box SA 1

PW014

PW019 Bearing 607 VV 1

PW021 Cord Armor 1

PW028

Guard Plate 1

Active Guard 1

Guard Washer 1

Screw M4 X 14

Rubber Pin

Screw SA M4 X 12

Guard Cork

Tapping Screw ST 4,2 x 35

Side Handle 1

Cover 1

Pinion 1

Bearing 6000 W

Armature 1

Rubber Ring 1

Labie

Cord Platen

Lead iV 2

Spring ’

Switch lever 1

Tapping Screw ST 4.2 x 20

Item No.

1

1

1

1

4

1

1

1

Parts No. Part Description Qty.

30

31 PW031

33 PW033

34

35

36 PW036

38 PW038 Switch 1

40

41 PWQ41

42

43

47

48

49

50

51 PW051

52

53 PW053

54

55

56

57

PW030

PW034

PW035 Tapping Screw ST 4,2 x 16

PW040 Housing 1

PW042

PWQ43

PWQ47

PW048 Tapping Screw ST 2.2 x 8.5 4

PW049

PW050

PW052

PWQ54

PW055 Wax Tube 1

PWQ56 Lubrication Unit 1

PW057 Tapping Screw ST 4.3 x 10 1

Tapping Screw ST 4,2 x 65 2

Cover 1

Spring 1

Small table 1

Back Cover 1

Name Plate 1

Stator 1

Cord and Plug 1

Lead VII

Washer

Brush 2

Brush Holder 2

Outer Clip 1

Clip 1

Wrench 1

2

1

4

1

2

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

Page 23

Page 24

Manual del Usuario

C1^^ fli R NI

|pROFESSIOWflL~|

SIERRA TWIN CUTTER

de 6 1/8 pulg.

ATENCION: Lea, comprenda y siga todas

las Reglas de Seguridad y las Instrucciones

de Funcionamiento incluidas en este manual

antes de usar esta herramienta.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

SEGURIDAD

FUNCIONAMIENTO

' MANTENIMIENTO

Page 25

TABLA DE MATERIAS

Garantía.......................................................................

Instrucciones de Seguridad

Símbolos de Seguridad

.........................................

...............................................

Página 26

Páginas 27-32

Página 32

Descripción..................................................................Página 33

Funcionamiento...........................................................Páginas 34-43

Desmontaje e Instalación de las Hojas

.......................

Páginas 41-43

Mantenimiento.............................................................Páginas 43-44

Localización y Solución de Averías

Accesorios

Repuestos

Números de Servicio

...................................................................

...................................................................

...................................................

.............................

Página 45

Página 45

Páginas 46-47

Contraportada

UN AÑO COMPLETO DE GARANTIA PARA LA SIERRA

TWIN CUTTER PROFESIONAL CRAFTSMAN

Si esta sierra faiia debido a un defecto de materiai o de fabricación dentro

de un año de la fecha de compra, DEVUELVALA AL CENTRO DE

REPUESTOS Y REPARACION SEARS MAS CERCANO EN LOS

ESTADOS UNIOOS y será reparada gratuitamente.

Esta garantía le otorga derechos legales específicos y usted además puede

lener'otros derechos que varían de un estado a otro.

Sears, Roebuck and Co,, Depl. 817 WA, Hoffman Estates, IL 60179

¡CONSERVE ESTAS INSTRUCCIONES! ¡LEATODAS LAS INSTRUCCIONES!

26

Page 26

INSTRUCCIONES DE SEGURIDAD

A ADVERTENCIA: ASEGURESE de leer y comprender todas las

instrucciones. El Incumplimiento de todas las instmcciones indicadas a continuación

puede ocasionar un choque eléctrico, incendio y/o lesión personal grave.

SEGURIDAD EN EL LUGAR DETRABAJO

1. SIEMPRE mantenga e! lugar de trabajo limpio y bien iluminado. Los bancos de

trabajo desordenados y mal iluminados favorecen los accidentes.

2. NO utilice las herramientas eléctricas en una atmósfera explosiva, tal como en

presencia de líquidos inflamables, gases o polvo. Las herramientas eléctricas

crean chispas que pueden inflamar el polvo o los vapores,

3 SIEMPRE mantenga a los espectadores, niños y visitantes a una distancia

prudente cuando esté utilizando una herramienta eléctrica. Las distracciones

pueden hacerle perder ei control.

SEGURIDAD ELECTRICA

1. Las herramientas con aislamiento doWe están equipadas con un enchufe

polarizado (una hoja de contacto es más ancha que la otra.) Este enchufe

puede colocarse en un tomacorriente polarizado en una sola dirección. Si el

enchufe no calza bien en el tomacorriente, Invierta el enchufe. Si todavía no

calza, póngase en contacto con un electricista calificado para que instale un

tomacorriente polarizado. NO modifique e! enchufe de ninguna manera.

2. ElQde aislamiento doble elimina la necesidad del cordón eléctrico trifilar puesto a

tierra y del sistema de alimentación de energía puesto a tierra. Aplicable solamente

a las herramientas de la Clase II (con aislamiento doble).

3. Antes de enchufar la herramienta, ASEGURESE de que el voltaje del tomacorriente

esté dentro del voltaje marcado en la placa de datos de la herramienta NO use

herramientas clasificadas "CA solamente" con una fuente de energía CC.

4. SIEMPRE evite contacto del cuerpo con las superficies puestas a tierra tales

como tuberías, radiadores, estufas y refrigeradores. Existe mayor riesgo de

suirir choque eléctrico si su cuerpo está a tierra.

5 Si es inevitable el uso de la herramienta en lugares húmedos, SIEMPRE use

' un interruptor de pérdida a tierra que le suministre energía a su herrarnienta.

SIEMPRE use guantes y calzado de goma de electricista cuando trabaje en

ambientes húmedos.

6. No exponga las herramientas eléctricas a la lluvia ni a ambientes húmedos.

Cuando entra agua a una herramienta eléctrica, se aumenta el riesgo de sufrir un

choque eléctrico.

7. NO abuse dei cordón eléctrico. NUNCA use el cordón para transport^ las

herramientas ni tire del cordón para desenchufarlas. Mantenga el cordon

alejado dei calor, del aceite, bordes afilados o piezas móviles. Reernplace

inmediatamente los cordones que estén dañados. Los cordones dañados

aumentan el riesgo de sufrir un choque eléctrico,

8. Cuando utilice una herramienta elecirica al aire libre, SIEMPRE use un cordón de

extensión marcado "W-A" o "W". Estos cordones están aprobados para uso al aire

libre y reducen el riesgo de choque eléctrico,

NOTA- El cordón de extensión debe ser de calibre adecuado (AWG -American Wire

Gauge) para uso eficiente y seguro. Los alambres de calibre más pequeño tienen

mayor capacidad (alambre de calibre 16 tiene más capacidad que el alambre de lo).

27

__

Page 27

INSTRUCCIONES DE SEGURIDAD coni.

SEGURIDAD PERSONAL

1. SIEMPRE manténgase alerta, observe lo que está haciendo y use sentido común

cuando esté usando una herramienta. NO use la herramienta cuando esté

cansada o bajo la influencia de drogas, alcohol o medicamentos. Un momento de

distracción cuando está trabajando con ias herramientas eléctricas, puede ocasionar

una levSión personal grave.

2. SIEMPRE vístase adecuadamente. NO use ropas sueltas o joyas. Atese el cabello

largo. Mantenga su cabello, ropas y guantes alejados de las piezas móviles. Las

ropas sueltas, las joyas o el cabello largo pueden quedar atrapados en ias piezas

móviles.

3. SIEMPRE evite la puesta en marcha accidental. ASEGÚRESE de que el Interruptor

esté en la posición "Off " (apagado) antes de enchufar la herramienta. NO

transporte las herramientas con su dedo en el interruptor. Se puede producir un

accidente si transporta la herramienta con su dedo en eí interruptor o si enchufa la

herramienta cuando el interruptor está en la posición "On" (encendido).

4. SIEMPRE saque las llaves de ajuste o llaves inglesas antes de poner en marcha

la herramienta. Si se deja una llave inglesa o una llave de ajusto en una pieza móvil

de ia herramienta, se puede producir una lesión personal.

5. NO use la herramienta a una distancia demasiado alejada. Mantenga SIEMPRE

un buen equilibrio y una posición firme. El buen equilibrio y la posición firme

permiten un mejor control de la herramienta en situaciones imprevistas.

6. SIEMPRE use equipo de seguridad. Use siempre lentes protectores. Se debe usar

máscaras contra el polvo, zapatos de seguridad antirresbaladizos, casco de seguridad

o protección auditiva de acuerdo con las circunstancias.

USO Y CUIDADO DE LAS HERRAMIENTAS DE SEGURIDAD

1 mordazas u otro método práctico para asegurar y apoyar la pieza

de trabajo en una plataforma estable. Si sujeta ei trabajo con la mano o contra su

cuerpo queda inestable y puede conducir a la pérdida de control.

2. NO fuerce la herramienta. Use la herramienta apropiada para el trabajo. La

herramienta correcta hará el trabajo mejor y de manera más segura, a la velocidad

para la cual fue disotáada,

3. NO use la herramienta si et interruptor no funciona debidamente. Es peligroso si la

herramienta no puede ser controlada con el interruptor y por lo tanto debe ser reparada.

4. SIEMPRE desenchufe la herramienta antes de hacer algún ajusfe, cambiar

accesorios o guardarla. Estas medida.? preventivas de seguridad reducen el riesgo

de que la herramienta se ponga en marcha accidentalmente.

5. SIEMPRE guarde las herramientas lejos del alcance de los niños y de otras

personas inexpertas. Las herramientas son peligrosas en manos de personas

inexpertas.

6. SIEMPRE mantenga bien cuidadas las herramientas. Las herramientas cortantes

deben mantenerse afiladas y limpias. Las herramientas que se mantienen bien

cuidadas y bien afiladas tienen menos probabilidad de atascarse y se pueden controlar

más fácilmente.

7. SIEMPRE verifique si hay piezas desafineadas o atascadas, si hay piezas

quebradas o si existe cualquier otra situación que pueda afectar el

funcionamiento de la herramienta. SI la herramienta está dañada, debe repararse

antes de usarla. Muchos accidentes son causados debido al mal estado de las

herramientas.

A

ADVERTENCIA: EL USO DE ACCESORIOS NO RECOMENDADOS PARA SER

USADOS CON ESTA HERRAMIENTA PUEDEN CREAR UNA SITUACION PELIGROSA

8. SIEMPRE use solamente los accesorios recomendados por el fabricante para esta

herramienta. Los accesorios adecuados para una herramienta, pueden ser peligrosos

si so utilizan en otra herramienta.

28

Page 28

INSTRUCCIONES DE SEGURIDAD cont.

SEGURIDAD SOBRE LAS REPARACIONES

1. Sf falta cualquier pieza de esta sierra o se rompe, dobla o falla de cualquier

manera; o si alguno de los componentes eléctricos no funciona en forma debida,

SIEMPRE

las piezas dañadas, faltantes o falladas ANTES de volver a ponerla en íunclonamiento.

2. La reparación de las herramientas debe ser efectuada solamente en un Centro de

Repuestos y Reparación Sears. La reparación o mantenimiento efectuado por

personal no especializado puede causar una lesión.

REGLAS DE SEGURIDAD PARA LAS SIERRAS

/К PELIGRO! Mantenga las manos aleladas del área de corte y de las hojas.

Mantenga la otra mano en la manija auxiliar o en la caja del motor. Si sujeta la

sierra con ambas manos, evitará el peligro de que la sierra se las lesione.______________

1. SIEMPRE mantenga su cuerpo colocado a cualquier lado de las hojas de la

sierra, pero no en línea con las hojas de la sierra.

2. NO trate de alcanzar nada por debajo del trabajo. El protector no puede protegerlo

contra contacto con las hojas por el lado inferior del trabajo.

3. SIEMPRE verifique si el protector está bien cerrado ANTES de cada uso. NO use

la sierra si el protector no se mueve libremente y se cierra instantáneamente.

Nunca sujete con mordazas ni ate el protector de la hoja en posición abierta. Si !a

sierra S0 deja caer accidentalmente, el protector puede doblarse. Levante el protector y

asegúrese de que se mueve libremente y que no toca las hojas ni ninguna otra pieza,

4. SIEMPRE verifique el funcionamiento y el estado del resorte del protector. Si el

protector y el resorte no están funcionando de manera apropiada, DEBE hacerlos

reparar antes del uso. El protector de la hoja puede funcionar en forma lenta debido a

piezas dañadas, depósitos gomosos o acumulación de suciedad.

5. El protector de la hoja debe manipularse manualmente SOLAMENTE cuando se

hacen cortes especiales, tal como cortes de cavidades o cortes compuestos.

SIEMPRE levante el protector mediante la manija. Tan pronto como la hoja penetra

el material, se DEBE soltar el protector. Para todos los otros cortes, el protector

funcionará automáticamente.

6. SIEMPRE asegúrese de que el protcrctor esté cubriendo las hojas ANTES de

depositar la sierra en un banco de trabajo o en el piso. Si las hojas en movimiento

no están protegidas la sierra se moverá hacia atrás, cortando lo que encuentre a su

paso. Observe cuanto demoran ¡as hojas en dejar de girar después de que se suelta el

interruptor.

7. NUNCA sujete la pieza que está siendo corlada en sus manos o a través de sus

piernas. Es importante apoyar la pieza de trabajo en forma debida para reducir a un

mínimo la exposición del cuerpo, atascamiento de las hojas o la pérdida de controi.

8. SIEMPRE sostenga la herramienta por las superficies de sujeción aisladas

cuando realice operaciones en que la sierra puede tocar alambrado oculto o su

propio cordón eléctrico. Sí se produce contacto con un alambre "bajo tensión" las

piezas de metal expuestas de ia herramienta quedarán bajo tensión y el operador

puede recibir un choque eléctrico,

9. NO deje la sierra funcionando cuando la transporte en la mano. El protector de

la hoja inferior puede abrirse ai tocar su ropa. Ei contacto accidental con las hojas

rotatorias de ia sierra puede causar una lesión personal grave.

10. NO use la herramienta si el interruptor no funciona debidamente. Cualquier

herramienta que no puede ser controlada con el interruptor es peligrosa y debe ser

reparada.

apague el interruptor de puesta en marcha, desenchufe la sierra y reemplace

_____________________________

29

Page 29

INSTRUCCIONES DE SEGURIDAD cont.

REGLAS DE SEGURtDAD PARA LAS SIERRAS cont.

11. Cuando retire las hojas de la herramienta, SIEMPRE use guantes protectores para

sujelar las hojas o accesorios. Los accesorios pueden estar callentes después de uso

prolongado.

RETROCESO.„SUS CAUSAS Y COMO SE PUEDE EVITAR

Causas del Retroceso

1. El retroceso es una reacción repentina que se produce cuando las hojas de las sierras

se aprietan, atascan o desalinean, causando que la sierra sin control se levante y se

salga de la pieza de trabajo retrocediendo hacía el operador.

2. Cuando la entalla aprieta o atasca firmemente las hojas, éstas se detienen y el motor

reacciona Impulsando rápidamente la sierra hacia atrás, hacia el operador.

3. Si las hojas se tuercen o desalinean en el corle, los dientes en los bordes traseros de

las hojas pueden enterrarse en la superficie superior de la madera. Esto causa que las

hojas se salgan de la entalla y salten hacia atrás, hacía el operador.

4. El retroceso se produce a causa del mal uso y/o procedimientos o condiciones de

operación incorrectas. Puede evitarse tomando las precauciones apropiadas, como se

indica a continuación.

Como Evitar el Retroceso

1. SIEMPRE sujete la sierra firmemente con ambas manos y coloque su cuerpo y

brazos de manera que puedan resistir fas fuerzas del retroceso. El operador

puede controlar las fuerzas del retroceso si se toman las precauciones apropiadas.

2. Si las hojas se están atascando o si por cualquier razón usted interrumpe un

corte, SIEMPRE apague la sierra y manténgala inmóvil en el materia! hasta que

las hojas se detengan completamente. NUNCA intente sacar la sierra del trabajo

o tirar de la sierra hacia atrás cuando las hojas estén en movimiento pues puede

ocurrir RETROCESO. SIEMPRE verifique y esté preparado para tomar medidas

correctivas que elimínen la causa del atascamiento de las hojas.

3. Cuando ponga en marcha nuevamente la sierra en la pieza de trabajo, SIEMPRE

centre las hojas en la entalla y compruebe que los dientes de la sierra no estén

enganchados en el material. Si la.s hojas de la sierra se atascan, pueden salirse

hacia arriba o RETROCEDER de la pieza de trabajo cuando la sierra es puesta en

marcha nuevamente.

4. SIEMPRE apoye los paneles grandes a fin de reducir el riesgo de que las hojas

se aprieten y retrocedan. Los paneles grandes tienden a combarse bajo se propio

peso. Los apoyos DEBEN colocarse en ambos lados, cerca de la línea de corte y cerca

del borde del panel.

5. NO use hojas desafiladas o dañadas. Las hojas desafiladas o incorrectamente

triscadas producen una entalla angosta que causa demasiada fricción, atascamiento

de la hoja y RETROCESO.

6. SIEMPRE tenga sumo cuidado cuando haga "Cortes de Cavidades" en paredes

existentes u otras áreas ciegas. Las hojas safionles pueden cortar objetos que

causen RETROCESO.

7- SIEMPRE espere hasta que las hojas hayan alcanzado la velocidad plena antes de

que toquen la pieza de trabajo.

8, SIEMPRE mantenga su cuerpo en cualquier lado de las hojas de la sierra, pero no en

línea con las hojas. El RETROCESO puede lanzar la sierra hacia atrás hacia el

operador. Las fuerzas del RETROCESO pueden ser controladas por e! operador, si se

toman las debidas precauciones.

SIEMPRE sostenga la herramienta por las superficies de sujeción aisladas cuando

realice operaciones en que la sierra puede tocar alambrado oculto o su propio

cordón eléctrico. Si se produce contacto con un alambre "bajo tensión" las piezas de

metal expuestas de la herramienta quedarán bajo tensión y el operador puede recibir un

choque eléctrico. 30

Page 30

INSTRUCCIONES DE SEGURIDAD cont.

REGLAS ADICIONALES PARA FUNCIONAMIENTO SEGURO

A ADVERTENCIA: ASEGURESE de leer y comprender todas las

instrucciones. El incumplimiento de todas las instrucciones indicadas a continuación

puede resultar en un choque eléctrico, incendio y/o lesión personal grave.

1. Conozca su herramienta eléctrica. Lea cuidadosamente el manual del usuario.

Aprenda sus aplicaciones y limitaciones asi como también los riesgos

potenciales específicos relacionados con esta herramienta. Si se cumple esta

regla se reducirá el riesgo de un choque eléctrico, incendio o lesión grave.

2. Cuando use esta sierra SIEMPRE use lentes protectores o gafas de seguridad.

Los anteojos regulares tienen solamente lentes resistentes al impacto; ellos NO

son lentes protectores. Si se cumple esta regla se reducirá el riesgo de sufrir una

lesión personal grave.

3 gii^iyippg proteja sus pulmones. Use una máscara contra el polvo si la operación

va a despedir mucho polvo. Si se cumple esta regla se reducirá el riesgo de sufrir

una lesión personal grave,

4. SIEMPRE proteja su audición. Use protección para ios oídos durante períodos

prolongados de funcionamiento. Si se cumple esta regia se reducirá el riesgo de

sufrir una lesión personal grave.

5. SIEMPRE Inspeccione periódicamente los cordones eléctricos de la herramienta

y si están dañados hágalos reparar en su Centro de Servicio Sears más cercano

o en otro Centro de Servicio Autorizado. SIEMPRE esté atento de la ubicación del

cordón. Si se cumple esta regla se reducirá el riesgo de un choque eléctrico o incendio.

6. SIEMPRE verifique si hay piezas dañadas. Antes de seguir utilizando la

herramienta, inspeccione para determinar si algún protector o cualquier piera

que esté dañada funcionará debidamente. Verifique el alineamiento de las piezas

móviles, si están atascadas o si hay piezas rotas y cualquier otro estado que

pueda afectar el funcionamiento de ia herramienta. Si se daña un protector o

cualquier otra pieza debe ser reparada o reemplazada por un Centro de Servicio

Autorizado. Si se cumple esta regla se reducirá e! riesgo de un choque eléctrico,

incendio o lesión grave.

7. NO abuse dei cordón eléctrico. NUNCA transporte la herramienta por el cordón ni

tire del cordón para deséhchufarla. Mantenga el cordón alejado del calor, del

aceite, bordes afilados o piezas móviles. Reemplace inmediatamente los

cordones eléctricos que estén dañados. Los cordones dañados aumentan el riesgo

de sufrir un choque eléctrico. Si se cumple esta regla se reducirá el riesgo de un

choque eléctrico o incendio.

8. SIEMPRE asegúrese de que su cordón de extensión esté en buen estado.

Cuando use un cordón de extensión, asegúrese de que sea de calibre suficiente

para portar ia corriente que necesita su herramienta. Se recomienda un cordón

de por lo menos calibre 16 (A.W.G.) para un cordón de extensión de 100 pies o

menos de largo. No se recomienda el uso de un cordón de extensión de más de

100 pies de largo. Si tiene duda, use el calibre siguiente de mayor capacidad. Los

alambres de calibre más pequeño tienen mayor capacidad (el alambre de calibre

16 tiene más capacidad que el alambre de calibre 18). Un cordón de calibre inferior

causará una pérdida en el voltaje de linea resultando en pérdida de potencia y

sobrecalentamiento,

9. SIEMPRE inspeccione y saque todos tos clavos de la madera antes de cortarla.

Si se cumple esta regla se reducirá el riesgo de sufrir una lesión personal grave.

10. NO haga funcionar esta herramienta cuando esté cansado o bajo la influencia de

drogas, alcohol o haya tomado alguna medicina. Si se cumple esta regla se

reducirá el riesgo de un choque eléctrico, incendio o lesión grave,

31

________________

Page 31

INStRUCCÍONES DE SEGURIDAD cont.

REGLAS ADICIONALES PARA FUNCIONAMIENTO SEGURO cont.

IX ADVERTENCIA: Algunas partículas de polvo creadas por el lijado

A

mecánico, aserrado, rectificado, taladrado y otros trabajos de construcción

contienen productos químicos que se sabe causan cáncer, defectos congénitos

u otros daños al sistema reproductor. Algunos de estos productos químicos son:

• Plomo proveniente de pinturas a base de plomo

• Sílice cristalizada de ladrillos y cemento y otros productos de albañifería.

• Arsénico y cromo de madera tratada químicamente.

Su riesgo de exposición a estos productos v^aría dependiendo de cuan a menudo

usted hace este tipo de trabajo. Para reducir su exposición a estos productos químicos:

•Trabaje en lugares bien ventilados

• Utilice equipo de seguridad aprobado, tal como máscaras contra ei polvo

especialmente diseñadas para filtrar partículas microscópicas.

A ADVERTENCIA: La utilización do cualquier cepiíladora

puede causar la proyección de objetos extraños a sus ojos, lo cual

puede ocasionar daños oculares severos. Antes de comenzar a

usar ia herramienta mecánica, SIEMPRE use sus lentes

protectores o gafas de seguridad con protección iateral y una

máscara completa cuando sea necesario. Recomendamos una

Máscara de Visión Amplia para usar sobre sus lentes protectores

o sus lentes de seguridad estándar, con protección lateral,

disponible en los Almacenes Sears.

SIMBOLOS DE seguridad

REGLAS ADICIONALES PARA FUNCIONAMIENTO SEGURO cont.

La etiqueta ele su herramienta puede incluir los siguientes símbolos.

V

...............................................................

A...............................................................Amperios

Hz.............................................................Hertz

W.

.............................................................

min...........................................................Minutos

'Xv

.............................................................

.......................................................Corriente Continua

no

.............................................................

0...............................................................Construcción Clase II

.../min

......................................................

..........................................................Indica peligro, advertencia o atención.

¡IMPORTANTE! LEA TODAS LAS INSTRUCCIONES

Voltios

Watts

Corriente Alterna

Velocidad sin Carga

Revoluciones o Carreras por minuto

[Significa atención! Existe riesgo para su seguridad

32

Page 32

Antes de intentar usar cualquier herramienta, es necesario familiarizarse con todas las

características de funcionamiento y las instrucciones de seguridad.

A ADVERTENCIA! NO permiía que su familiaridad con la sierra lo haga

descuidado. Recuerde que un descuido de una fracción de segundo es suficiente para

ocasionar una lesión grave. ________________________

CONOZCA SU SÍERRA (ver Fig. 1)

La sierra Twin Cutter tiene incorporadas muchas características prácticas para cortes

eficientes y rápidos. Entre ellas cabe mencionar un sistema innovador de 2 hojas

especiales que giran en dirección opuesta para lograr cortes suaves y exactos con menos

vibración y retroceso. También está equipada con un sistema de lubricación de la hoja

preinstalado para usar cuando corte aluminio, cobre, acero inoxidable y hierro forjado, La

manija auxiliar se instala en la parte superior de la sierra ofreciendo apoyo adicional y

facilidad de manipulación,

Para mayor conveniencia, la sierra Twin Cutter no necesita ser armada. Las hojas

especiales y el sistema de lubricación ya está instalado.

Protector Superior de la Hoja Fig. 1

interruptor "On/Off"

(Encendido/Apagado)

Protector inferior

de ta Hoja

Llave

Manija Auxiliar

Manija del Protector

Interior de la Hoja

Varilla de

Lubricación

a la Cera

Perilla dei

Sistema de

Lubricación

a ia Cera

Hojas

_

Caja del

Motoi’

ESPECIFÍCACIONES DEL PRODUCTO

Alimentación

Potencia Máxima

Diámetro de la Hoja

Corriente Nominal

Velocidad sin Carga

1 7,8 Amps. 1

i 1,25 HP

6 1/8 pulq. (155mm)

120 voltios, 60 Hz CA

4600 RPM

MONTAJE

DESEMPAQUE

Su sierra Twin Cutter fue embarcada completamente armada. Inspeccione atentamente ta

sierra para asegurarse de que no ocurrió daño ni quebradura durante ei embarque. Si

alguna pieza está dañada o falta, devuelva la sierra a su Almacén Sears más cercano

para que se la cambien.

A ADVERTENCIA: Si hay piezas faltantes, NO haga funcionar esta sierra

hasta que se reemplacen las piezas faltantes. El incumplimiento de esta advertencia

puede ocasionar una lesión persona! grave.

33

Page 33

FUNCIONAMIENTO

HOJAS DE LA SIERRA

Aún las mejores hojas de sierras no cortarán de manera eficiente si no se mantienen

limpias, afiladas y debidamente colocadas, Las hojas desatiladas ejercen mayor

esfuerzo en la sierras y aumentan el peligro de retroceso, Mantenga hojas

adicionales de modo que siempre tenga hojas afiladas disponibles.

La goma y resina de la madera que se endurece en las hojas reducirán la velocidad

de la sierra. Use un disolvente de goma y resina, agua caliente o kerosén para quitar

estas acumulaciones. NO use gasolina.

A ADVERTENCIA: Esta sierra Twin Cutter usa hojas especialmente

diseñadas de 6 1/8 pulg. y nunca so debe usar níngiün otro tipo ni tamaño de

hojas. Las hojas de otro tipo y tamaño no funcionarán en forma segura en esta

sierra y pueden provocar una lesión personal grave.

Para hacer pedidos ds hojas adicionales o para reemplazar las hojas que venían

con la sierra, vea en la página 45 de este manual las instrucciones para hacer

pedidos. Para instalar las hojas nuevas en la sierra, vea las instrucciones especiales

en las páginas 41 a 43 de este manual para el desmontaje e instalación apropiada

de las hojas.

SISTEMA DE PROTECCION DE LAS HOJAS

El protector inferior de la hoja, instalado en su sierra, tiene por objeto velar por

su protección y seguridad. NUNCA debe ser modificado, por ningún motivo. SI

se daña o comienza a funcionar más lentamente, NO haga funcionar su sierra

hasta que el problema no haya sido corregido o se haya reemplazado la pieza

dañada, SIEMPRE mantenga el protector en su posición correcta de

funcionamiento cuando use la sierra.

PELIGRO: Cuando corta a través de

una pieza de trabajo, el protector inferior de la

hoja no cubre la hoja por e! lado inferior de ta

pieza de trabajo. Debido a que ia hoja está

expuesta por el lado inferior dei trabajo,

SIEMPRE mantenga las manos y los dedos

alejados del área de corte (ver Fig. 2),

Cualquier parte de su cuerpo que toque la

hoja en movimiento puede sufrir una lesión

personal grave.

El protector Inferior de la hoja está en posición

HACIA ARRIBA cuando se hace un corte.

Las hojas están expuestas por el lado inferior de

A ADVERTENCIA: NUNCA use la sierra si el protector no está funcionando

en forma debida. Se debe verificar el funcionamiento correcto del protector antes de

cada uso. Si !a sierra se deja caer, antes de usarla verifique si se ha dañado el

protector inferior de la hoja. NOTA: El protector está funcionando en forma debida

cuando se mueve libremente y retorna oportunamente a la posición cerrada. Si por

cualquier motivo ei protector Inferior de la hoja no se cierra libremente, antes de usar

la sierra llévela a su Centro de Reparación Sears más cercano para su reparación.

34

Page 34

FUNCIONAMIENTO cont.

RETROCESO

El retroceso ocurre cuando tas hojas se detienen rápidamente y la sierra es lanzada

hacia atrás, hacia usted, Las hojas pueden detenerse si la hoja queda apretada en el

material que está siendo cortado,

IMPORTANTE: La mejor protección contra el retroceso es evitar las prácticas

peligrosas.

A PELIGRO: SIEMPRE apague inmediatamente la sierra si las hojas se

atascan o la sierra se detiene. El retroceso le puede hacer perder el control de la

sierra. La pérdida de control puede ocasionar una lesión grave.

SIEMPRE apoye en forma apropiada la pieza de trabajo y sujete la sierra con

ambas manos

Causas que provocan el retroceso:

1. Torcedura de las hojas cuando está haciendo

un corte.

2. Hacer un corte con hojas desafiladas,

engomadas o incorrectamente triscadas.

3. Sin apoyo apropiado para la pieza de trabajo.

SIEMPRE proporcione apoyo apropiado como

se muestra en la Fig. 3.

4. Forzar un corte,

5. Cortar madera combada o húmeda,

6. Mal uso de la herramienta o procedimientos de

funcionamiento incorrectos.

7. Colocar las hojas en la pieza de trabajo antes de que alcancen la velocidad plena.

__________________________

Para reducir la posibilidad de retroceso

1. SIEMPRE diríjase hacia la pieza de

trabajo con la sierra en un ángulo de

aproximadamente 30° en relación con

la pieza de trabajo, (ver Fig. 4),

2. SIEMPRE haga cortes derechos. Así

evitará que la hoja se tuerza en el corte.

3. SIEMPRE use hojas limpias, afiladas y

debidamente triscadas. NUNCA haga

cortes con hojas desafiladas.

4. SIEMPRE apoye en forma apropiada la

pieza de trabajo antes de comenzar un corte. Esto le ayudará a evitar que las

hojas queden apretadas en el corte (ver Fig. 3).

5. SIEMPRE use una presión uniforme y constante cuando haga un corte. NUNCA

tuerce el corte.

6. NO corte madera combada o húmeda.