Page 1

I R;IF TSMaN°

17

25968

4)

Instruction manual

Please read these instructions

carefully and make sure you

understand them before using this

machine.

Anleltungshandbuch

Bitte lesen Sie diesa Anleitungen

sorgf_ltig durch und vergewissem

Sie sich, dab Sie diese verstehen,

bevor Sie die Maschtne in Betdeb

nebmen.

Manuel d'instructlons

Merci de lira tr6s a_lentivement le

manuel d'instructions. Assurez-vous

d'avior- tout compds avant d'utiliser ce

tracteur.

Manual de las instrucclones

Per favor lea cuidedosamente y

comprenda estas Intrucciones antes

de ucar esta maquina.

Manualedi istruzlonl

Pdma di utUizzare la macchina

leggete queste istruzioni con

attenzione ed eccertatevi di averle

comprese bane.

Instructieboekje

Lees daze Inst_ucties aandachtig en

zorg dat u ze begdjpt voordat u daze

machine gebruikt.

Page 2

1

2

3

4

5

6

7

8

Safety specifications.

Assembly.

Functional description.

Procedure before start.

Driving.

Maintenance, adjustment.

Fault tracing.

Sto_mge.

We reserve the right to changes without prior notice.

2

Page 3

1. Safety Rules &

Safe Operation Practices for Ride-On Mowers

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS.'

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH,

@ I. Training

Read the instructionscarefully. Be familiar with the controls •

and the proper use of the equipment.

Never allow children or people unfamiliar with the instruc-

lions to use the lawnmower. Local regulations may restrict •

the age of the operator.

• Never mow while people, especially children, or pets are

nearby.

Keep in mind that the operator or user is responsible for

accidents or hazards occurdng to other people or their

property.

• All drivers should seek and obtain professional and practical

instruction. Such instruction should emphasize:

- the need for care and concentration when working with

ride-on machines;

- control of a dde*on machine sliding Ona slope will not be

regained by the application of the brake. .

The main reasons for loss of control are:

a) insufficient wheel grip;

b) being ddven too fast;

c) inadequate braking;

d) the type of machine is unsuitable for its task;

e) lack of awareness of the effect of ground

conditions,especially slopes;

f) incorrect hitching and load distribution.

II. Preparation

• While mowing, always wear substantial footwear and long

trousers. Do not operate the equipment when barefoot or

weadng open sandals.

• Thoroughly inspect the area where the equipment is to be

used and remove all objects which may be thrown by the

machine.

• WARNING - Petrol is highly flammable.

- Store fuel in containers specifically designed for this

purpose.

- Refuel outdoors only and do not smoke while refueling.

- Add fuel before starting the engine. Never remove the cap

of the fuel tank or addpetrol while the engine is running

or when the engine is hot.

- If petrol is soilled, do not attempt to start the engine but

move the r :chine away from the area of spillage and

avoid croat,r=g any source of ignition until petrol vapors

have dissipated.

- Replace all fuel tanks and container caps securely.

• Replace faulty silencers.

• Before using, always visually inspect to see that the blades,

blade bolts and cutter assembly are notworn or damaged.

Replace worn or damaged blades and belts in sets to

preserve balance.

- -. On multi-bladed machines, take care as rotating one blade

can cause other blades to rotate.

IlL Operation

Do not operate the engine in a confinedspace where

dangerouscarbon monoxidefumescan collect.

Mow only in daylight or in good artificial light.

Before attempting to start the engine, disengage all blade

attachment clutches and shift into neutral.

Do not use on slopes of more than 10°,

Remember there is no such thing as a =safe" slope. Treve

on grass.slopes requires parUcu|ar care. To guard against

overtummg;

- do not stop or start suddenly when going up or downhill;

- engage clutch slowly, always keep machine in gear,

especially when traveling downhill;

- machine speeds should be kept low on s opes and during

tight turns;

- stay alert for humps and hollows and other hidden haz-

ards;

- never mow across the face of the slope, unless the

lawnmower is designed for this purpose.

Use care when pulling loads or using heavy equipment.

- Use only approved drawbar hitch points.

- Limit loads to those you can safely control.

- Do not turn sharply. Use care when reversing.

- Use counterweight(s) or wheel weights when suggested

in the instruction handbook. •

Watch out for traffic when crossing or near roadways,

Stopthe blades from rotating before crossing surfaces other

than grass.

When using any attachments never direct discharge of

mateda toward bystanders nor allow anyone near the

machine while in operation.

Never operate the lawnmower with defective guards, shields

or without safety protective devices in place,

Do not change the engine governor settings or overspeed

the engine. Operating the engine at excessive speed may

increase the hazard of personal injmy.

Before leaving the operator's position:

- disengage the power take-off and lower the attachments;

- change into neutral and set the parking brake;

- stop the engine and remove the key.

Disengage drive to attachments, stop the engine, and

disconnect the spark plug wire(s) or remove the ignition key

- before cleaning blockages or unclogging chute;

• before checking, clear _g or working on the lawnmower;

- after striking a foreign object. Inspect the lawnmower for

damage and make repairs before restarting and operat-

ing the equipment;

- if the machine starts to vibrate abnormally (check imme-

diately).

Disengage drive to attachments when transporting or not

in use.

Stop the engine and disengage drive to attachment

- before refueling;

- before removing the grass catcher;

- before making height adjustment unless adjustment can

be made from the operator's position.

Reduce the throttle setting dudngengine run-out and, if the

engine is provided with a shut-off valve, turn the fuel off at

the conclusion of mowing•

3

Page 4

• IV. Maintenance and Storage

Keep a, nuts,boltsandscrewstighHobesurethe equip.

ment is in safe working condition.

• Never store the equipment with petrol inthe tank inside a

building where fumes may reach an open flame or spark.

Allow the engine to cool before storing in any enclosure.

• To reduce the fire hazard, keep the engine, silencer, battew

compartment and petrol storage araafrae of grass, leaves,

or excessive grease,

Check the grass catcher frequently for wear or deteriora-

tion.

• Replace wom or damaged parts for safety.

• If the fuel tank has to be drained, this should be done

outdoors.

• On multi-bladed machines, take care as rotating one blade

can cause other blades to rotate.

• When machine is to be parked, stored or left unattended,

lower the cutting means unless a positivemechanical lock

is used.

CAUTION: Always disconnect spark plug wire and place

wire where it cannot contact spark plug In order to prevent

accidental starting when setting up, transporting, adjusting

or making repairs.

4

Page 5

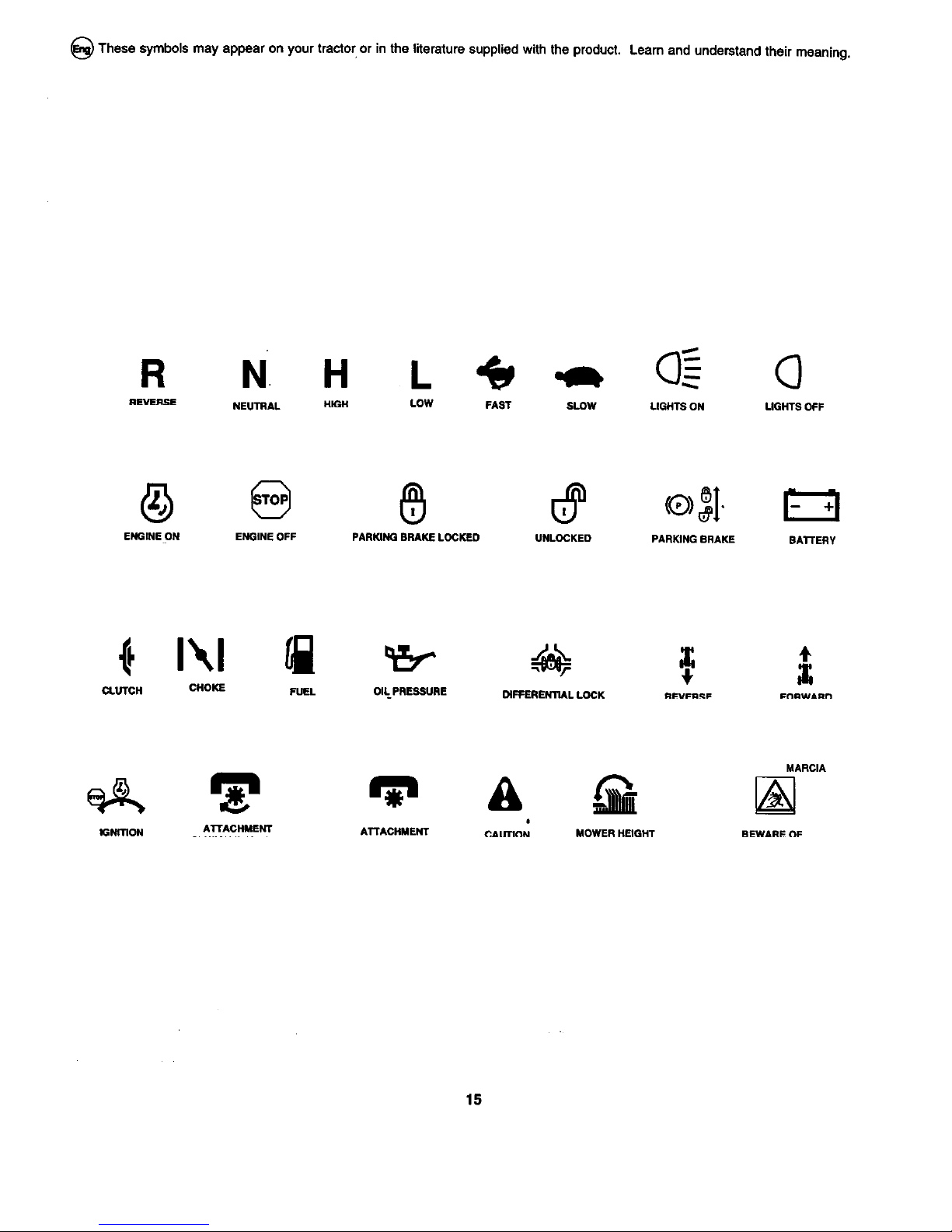

_) These symbols may appear on your tractor or in the literature supplied with the product. Learn and understand their moaning.

R N H L "_ (]._ (]

REVER_F NEU'I1RAL HmH LOW FAST SLOW LIGHTS ON LIGHTS OFF

ENGINE ON ENGINE OFF PARKING BRAKE LOCKED UNLOCKEO PARKING BRAKE BATrERY

CLUTCH CHOKE FUEL DIL PflESSURE DIFFERENTIAL LOCK _l:vFn_ FnnwA=m

MARCIA

I

IGNITION ATTACHMENT ATTACHMENT _AIm_ MOWER HEIGHT RFWARI= _F

15

Page 6

_ These symbols may appear on your tractor or in the literature supplied with the product. Learn and understand their meaning.

NICHT AUF ABH_NGEN MIT TENIR LEe PASSANTE _ DISTANCE

MEHR ALS lr STEIGUNG BETREIBEN OMSTANDERS UIT DE

NE PAS UTILISER SUR DEe BUURT HOUDEN

PENTES OE PLUS DE 10 ° GUJ_RDESE LEJOS DE GENTE

NIET OP HELUNGEN VAN MEER OAN TENERE LONTANI I PASSANTI

10 ° GEBRUIKEN

NO OPERE SOBRE PENDIENTES

DE MAS DE 10 o

NON USARE SU PENOII CON

UN'INCLINAZIONE DI OLTRE 10°

NO OPERATION KEEP BYSTANOERS AWAY READ OWNERS MANUAL

ON SLOPES MORE THAN 10° . ZUSCHAUER FERNHALTEN BETRIEBSANLEITUNG LESEN •

LIRE LE MANUEL

OINSTRUCTIONS

GEBRUIKERSHANOLEIOtNG

LEZEN

LEA EL MANUAL DE

INSTRUCCIONES

LEGGERE IL MANUALE

DELL'OPERATORE

MOWER UFT

I_HWERKHUB

RELEVt_',E DE L'UNITI_ DE COUPE

|."._M=ItOOGTER EGE UNG

LEVANTAMIENTO DE LA SEGADORA

SOLLEVAMENTO APPARATO FALCIANTE

OANGER, KEEP HANDS AND FEET AWAY

GEFAHR, HJ_IDE UND FOSSE FERNHALTEN

DANGER, GARDEZ LEe MAINS ET LES PIEDE AU LOIN

GEYAAR, HANDEN EN VOETEN un" DE BUURT HOUDEN

PELIGRO, MANTENGA LAS MANOS y LOS PIES LEJOS

PERICOLO. TENERE LONTANI MANI PIED4

EUROPEAN MACHINERY WARNING

DIRECTIVE FOR SAFETY WARNUNG

EUROPAISCHE VERORDNUNG DANGER

FOR MASCHINEN-SICNERNErr WAARSCHUWING •

CONFORME AUX NORMES DE ATENCI(_N

S_CURITI_ EDROPI_ENNES AVVERTENZA

VEILIGHEIDSRICHTLMN VOOR

EUROPESE MACNINES

DIRECTIVO DE MAQUINARIA

EUROPEO PARA LA SEGURIOAO

NORMATIVE ANTINFORTUNISTICRE

EUROPEE PER MACCHINARI

FREE WHEEL

FREILAUF

RODE UBRE

FREEWHEEL

RUEDA LIBRE

COMANDO OISINNESTO

DO NOT OPERATE WITHOUT BAGGER OR DEFLECTOR

NICHT IN BETRIEB NEHMEN OHNE G _ "SFANGBOX ODER DEFLEKTOR

NE JAMAIS UTIUSER SANS _ OU DI!_PLECTEUR.

NONAZlONARE LA MACCHINA SEI@.A IL CES , O SENZO IL DEFLETTONE DI SCARICO

NO PONGA EN MARCNA SIN :,ECOGEDOR O OEFLECTOR

ZONDER STORTGOOT OF AFWMKENDE SPAll)OEK NIET OPEREREN

16

Page 7

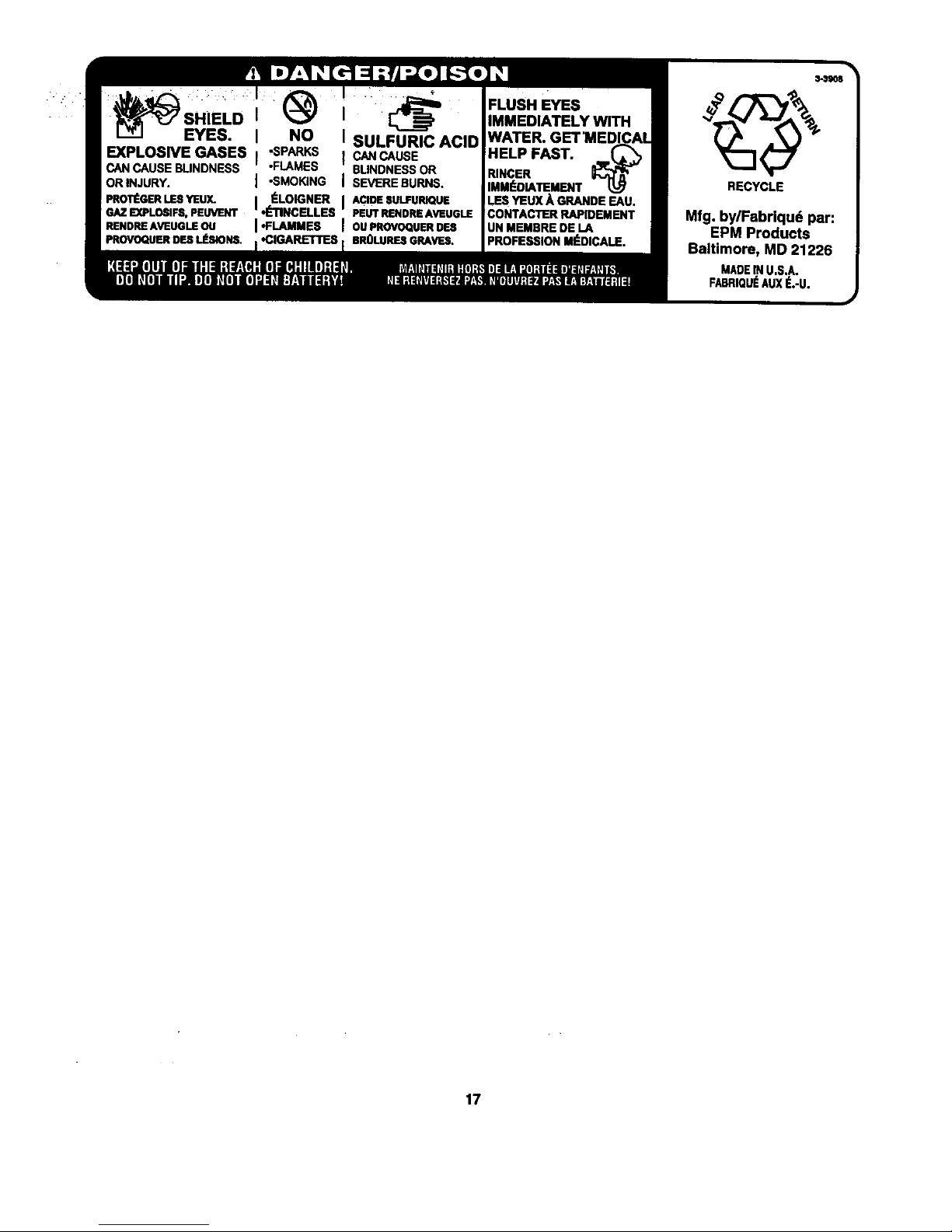

EYES.

i .FLAMMES

SULFURIC ACID WATER. (

FLUSHEYES ___/.

IMMEDIATELY WITH

RECYCLE

"CIGARETTES

17

Page 8

2• Assembly•

_ Beforethetraqtorcanbe usedcertainpartsmustbeassembled,

whichfor transportationreasonsare enclosedin the packing.

The pictureshowswhichpartsmustbe assembled.

@

STEERING WHEEL

• Mountextensionshaft(I) todesiredholes and installhex

boltend locknut. Tightensecurely.

• Mountthemainshaftcover. Make surethattheguidetabs

inthe coverfit thecoverin respectiveholes.

• Checkthatfrontwheelsarealignedforward. Slideadapter

onto shaft extensionand place steedng wheel onto the

adaptor.

• Assemblelargeflatwashers,leckwasherand3/8 hexbolt.

Tightensecurely.

Snapinsert into centerofsteeringwhee|.

1. EXTENSIONSHAFT

rill _ * I

_,,_ _. _ _ It •

18

Page 9

2

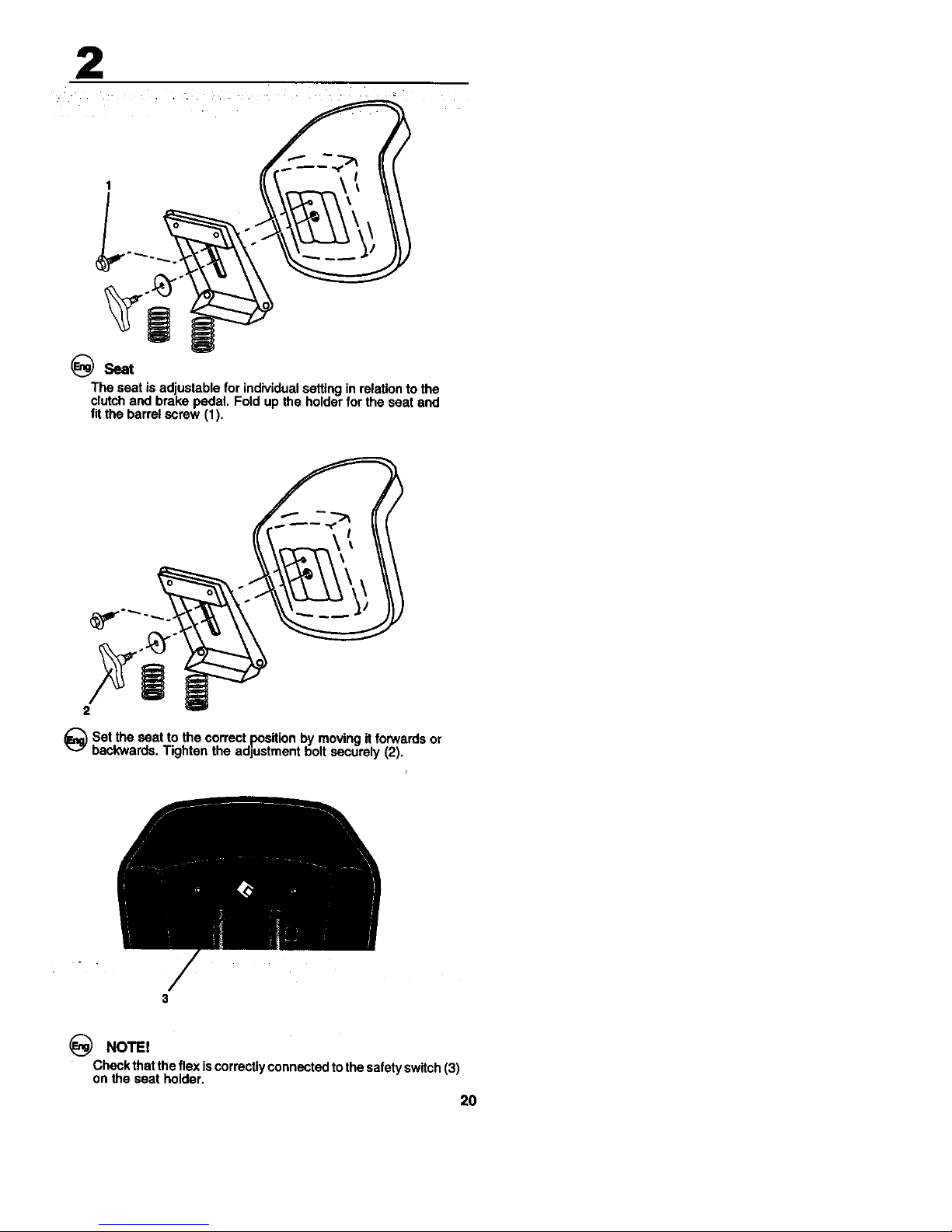

_Seat

The seat isadjustableforindividualsettingin relationtothe

clutchandbrake pedal. Foldup the holderfor theseat and

fitthe barrelscrew (1).

_Set the seat to the correct position by moving it forwards or

backwards, Tighten the adjustment bolt securely (2).

/

3

NOTE!

Checkthatthe flexiscorrectlyconnectedtothesafetyswitch(3)

onthe seat holder.

20

Page 10

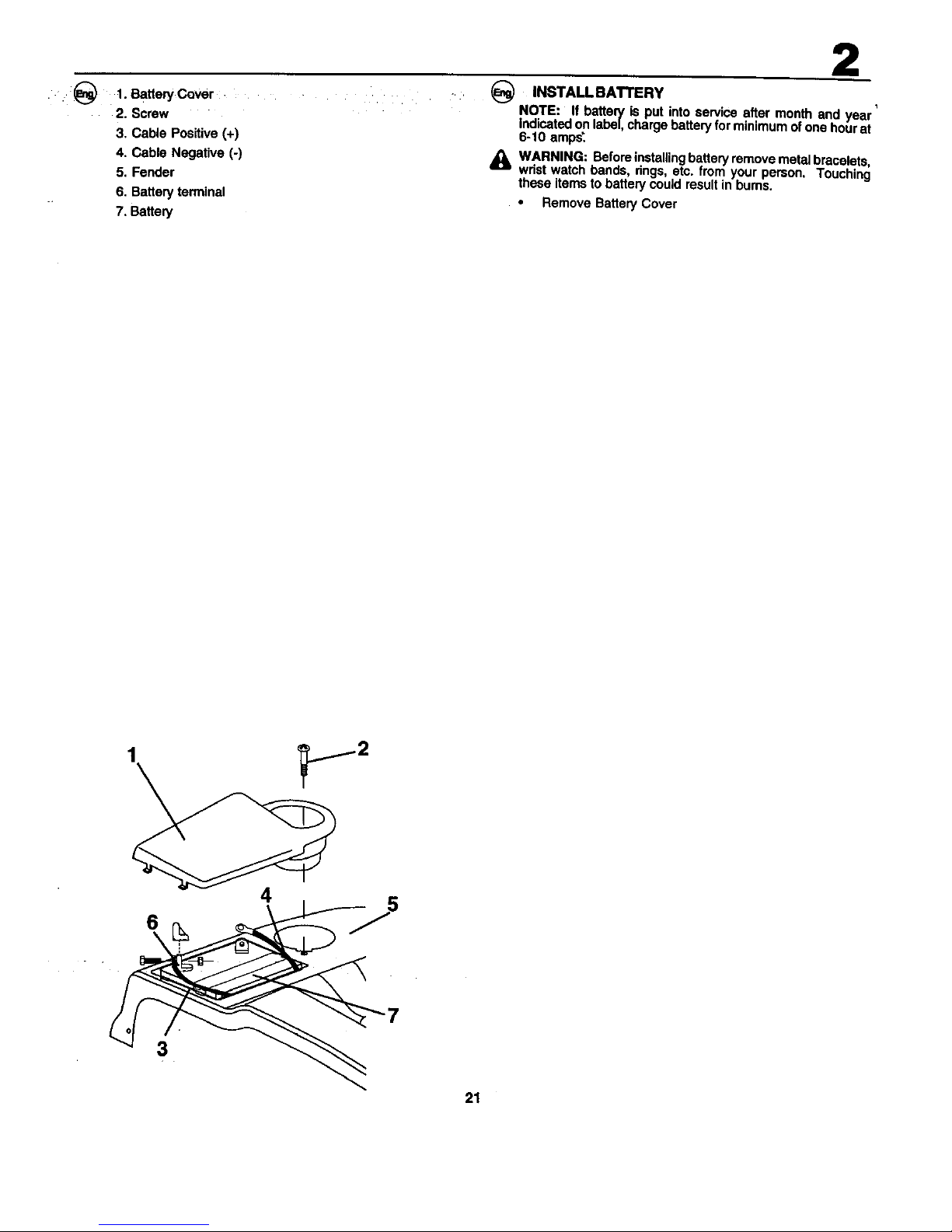

• .:_) .t. BattenjCover

2. Screw

3, Cable Positive (+)

4. Cable Negative (-)

5. Fender

6. Battery terminal

7. Battery

2

INSTALL BATTERY

NOTE: If battery is put into service after month and veAr'

indicated on label, charge battery for minimum of one hour at

6-10 amps'.

,_ WARNING: Before installing battery remove metal bracelets,

wrist watch bands, rings, etc. from your person Touching

those terns to battery could result in bums.

• Remove Battery Cover

4

o J

3

21

Page 11

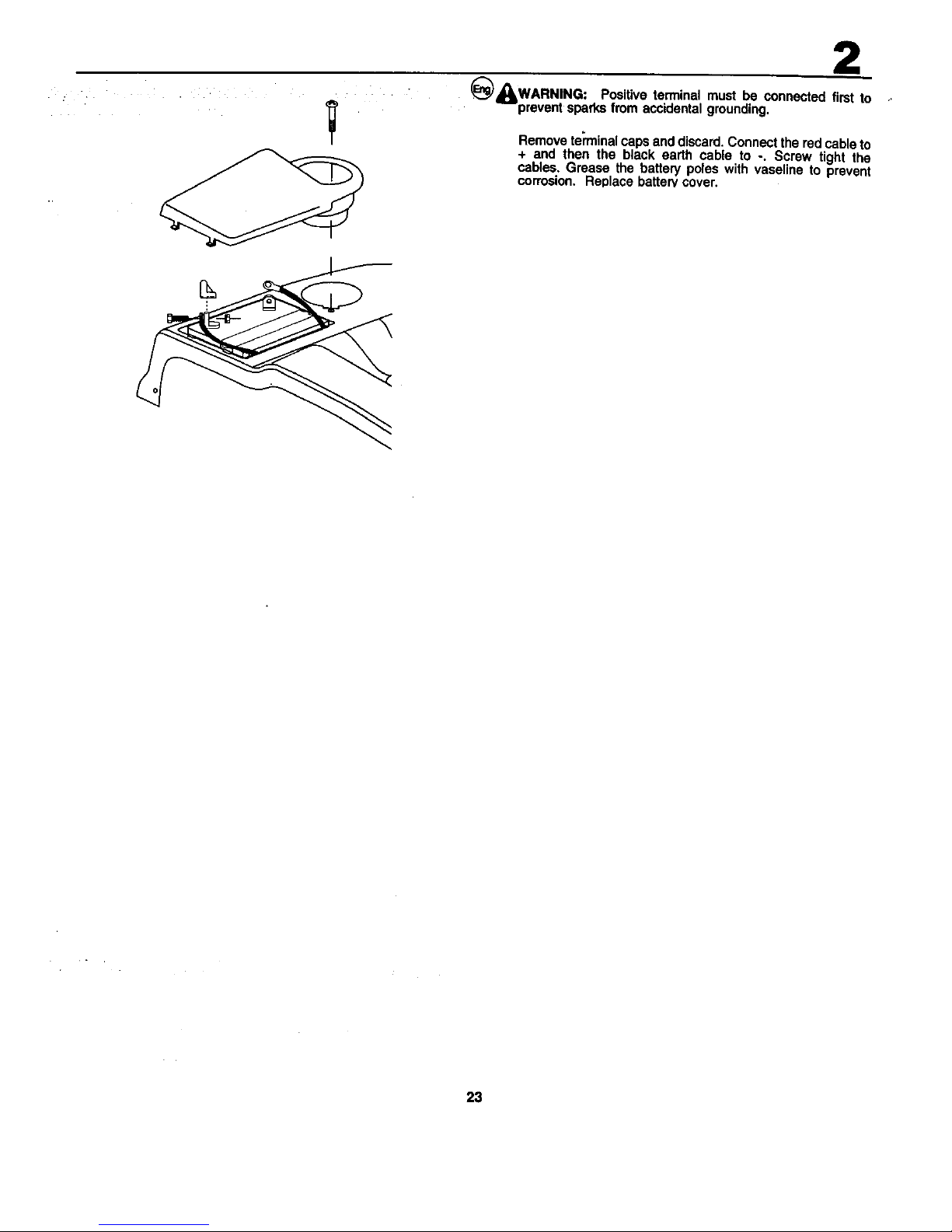

2

_)_WARNING: Positiveterminal must be connected first to

preventsparksfrom accidentalgrounding.

Removeterminalcapsanddiscard.Connecttheredcableto

+ and then the black earth cable to -. Screw tight the

cables.Grease the batted/poleswith vaseline to prevent

corrosion. Replacebatten/cover.

23

Page 12

2

To install bagger oomponents to tractor

1. Discharge Chute

2. 3/8Nut "%# 2..,.,.,_. -. -.

3. FlatWasher - / ,_'_

3"

Removedischargechutefromrearoftractor. Unhook the

two(2) strapsand pullchuteoutandawayfrom tractor.

Removethetwo(2)3/8 nutsandflat washersfromthebolts

at thetractorbackplate.

1. 3/8 Locknut

2. FlatWasher

3. SupportTube

2_

1-_--.

Using the nuts and flat washers removed from tractor back

plate, install the bagger support tube to the back plate as

shown. Tighten securely.

1. Rear Door

4

4

2. Support Bracket

3. 3/8 Carriage Bolt

4. 3/8 Lock Nut

2

5. 3/8 x 63,5mm Hex Bolt

6. 10,3mm (13/32") flat 6

was'her

• While holding the rear door open, install the two upper

support I_rackets through the back plate and to the chas-

sis, using the 3/8 x 19mm carriage bolts and Iocknuts

supplied. Tighten securely.

• Assemble both support brackets to the outside of the

baggger support tube using two each 3/8 x 63 5mm hex

bolts13/32" I.D. flat washers and 3/8 Iocknuts from parts

bag. Tighten securely.

1.

2.

3.

Hook

Discharge

Back plate slot

3

• Replace discharge chute into rear opening of tractor.

, Secure the chute with the two hook straps.

NOTE: The strap hook must go through the discharge chute

only. Do notallow the hook toenter the slotin the tractor back

plate. This will allow the discharge chute to float with the

mower deck when moving on uneven terrain.

24

Page 13

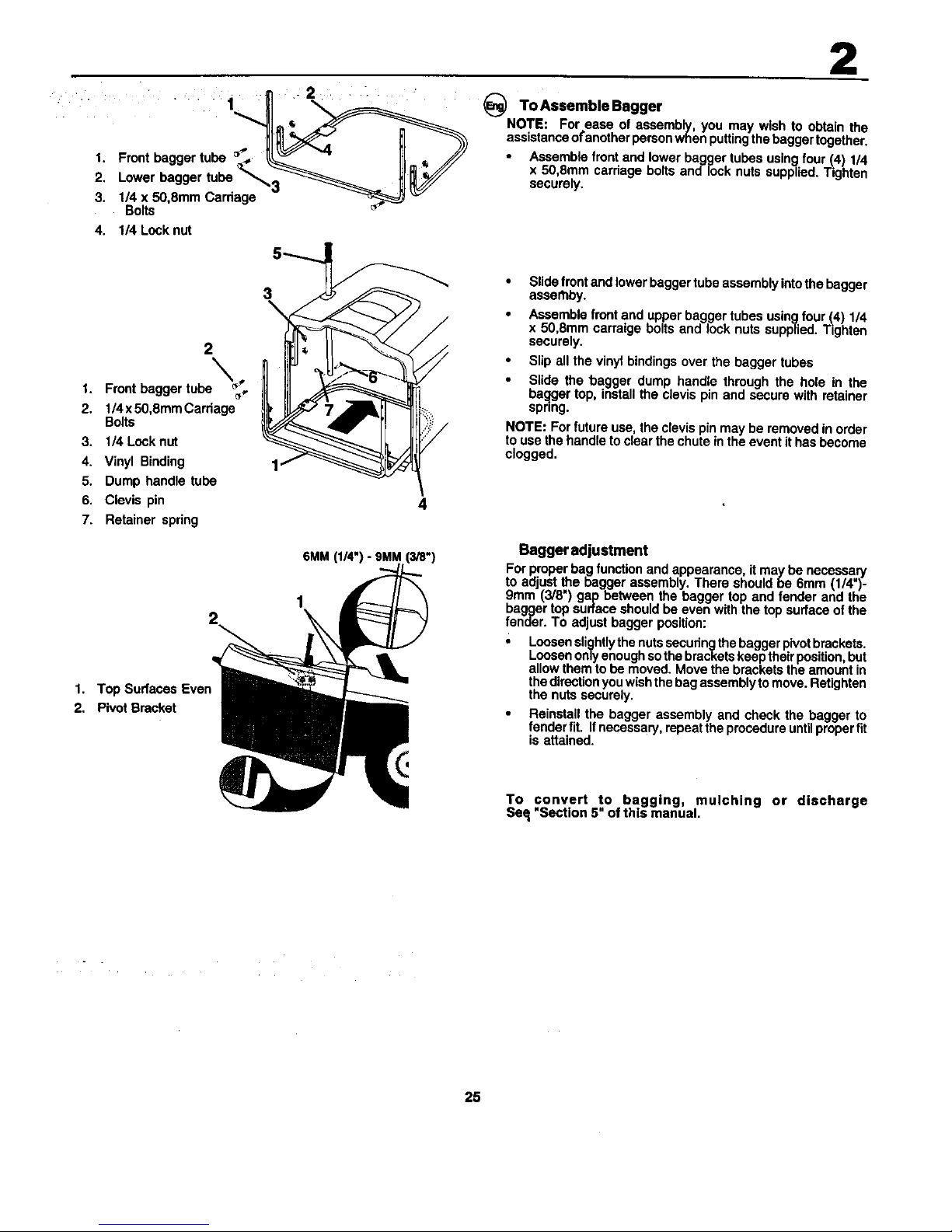

: L 1 ¸-2¸¸ ....

1. Front bagger tuba

2,oworbaggertuba' ',.

3. 114 x 50,8mm Carriage - _ "_

Bolts

4. 1/4 Lock nut

2

1. Frontbaggertuba _.

2. 1/4x50,8mmCarriage

Bolts

3. l_Leckn_

4. Vinyl Binding

5. Dumphandle tuba

6. Clevispin

7. Retainer spdng

2

To Assemble Bagger

NOTE: For ease of assembly you may wish to obtan the

assstanceofanotherpersonwhenputtingthebaggertogether,

Assemblefrontand lowerbaggertubasusingfour(4)1/4

x 50,8ram carriageboltsand locknutssupplied.Tighten

securely,

/

• Slidefrontandlowerbaggertubeassemblyintothebagger

asse_by.

• Assemblefrontand upperbaggertubesusingfour ._4)1/4

x 50,Smmcarraigebolts and lock nutssupplied.Tighten

securely.

• Slipall the vinylbindingsover the baggertubes

• Slide the bagger dump handle throughthe hole in the

baqgertop,installtheclevispinand securewith retainer

spring.

NOTE: Forfutureuse,theclevispin maybe removedinorder

tousethehandletoclearthechuteintheevent ithas become

clogged.

4

1. Top Sudaces Even

2. Pivot Bracket

6MM

1

2

Bagger adjustment

For proper bag function and appearance, it may be necessary

to adjust the bagger assembly. There should be 6mm (1/4")-

9mm (3/8") gap between the bagger top and fender and the

bagger top surface should be even with the top surface of the

fender. To adjust bagger position:

• Loosen slightlythe nuts secudngthe bagger pivot brackets.

Loosen only enough so the brackets keep theirposition, but

allow them to be moved. Move the brackets the amount in

the directionyou wish the bag assembly to move. Retighten

the nuts securely.

Reinstall the bagger assembly and check the bagger to

fender fit. IfnecessarY, repeat the procedure until proper fit

is attained.

To convert to bagging, mulching or discharge

Seq"Section 5" of this manual.

25

Page 14

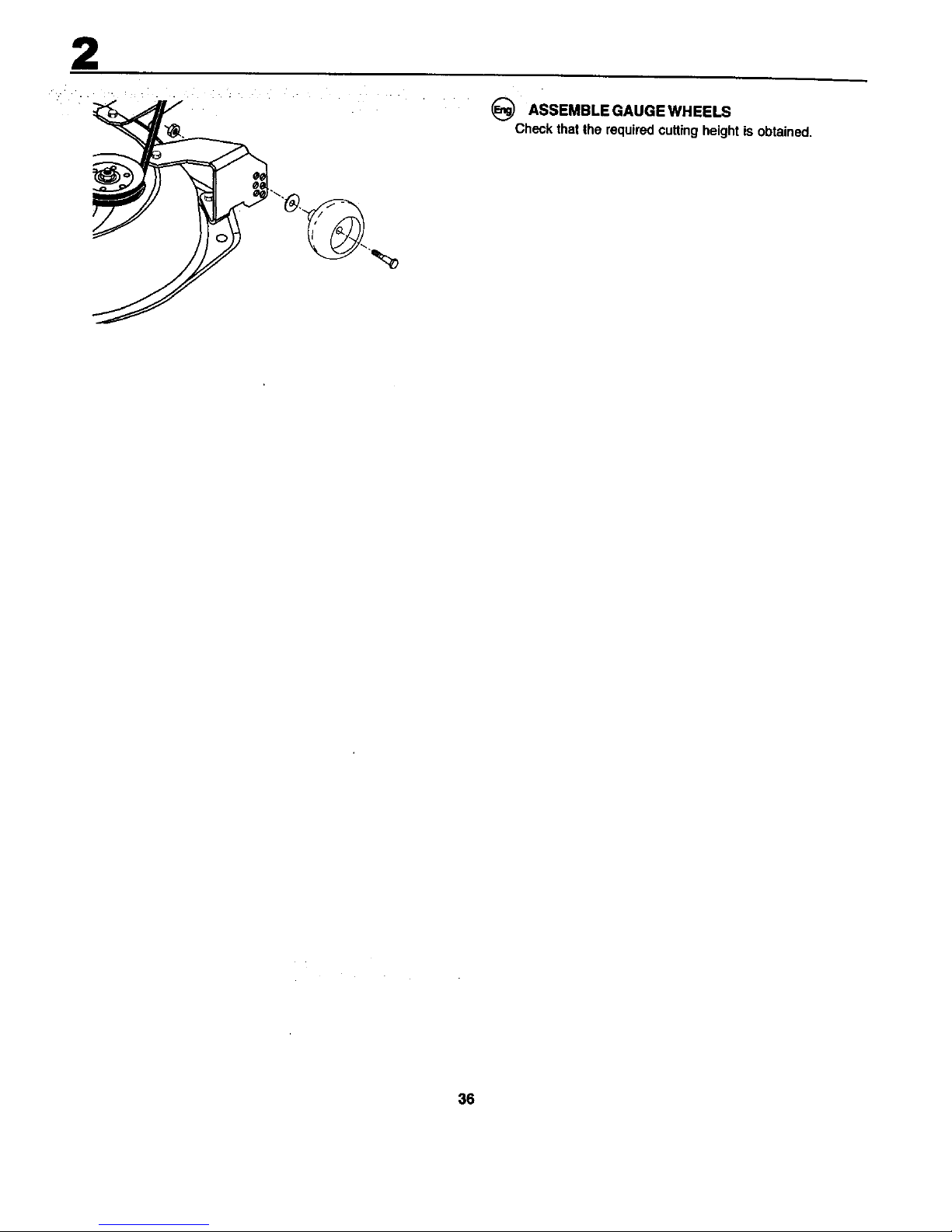

2

ASSEMBLE GAUGE WHEELS

Checkthatthe requiredcuttingheightis obtained.

36

Page 15

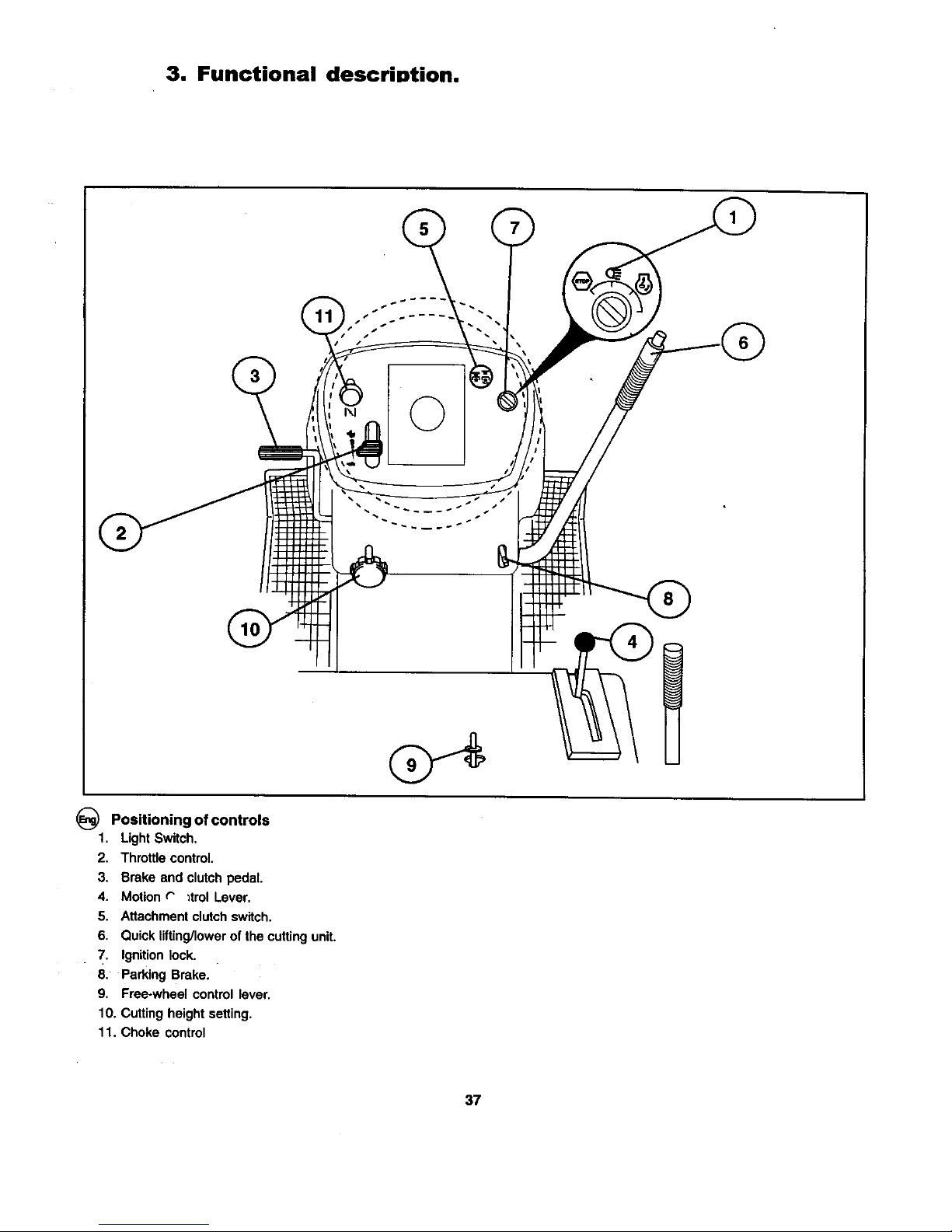

3. Functional descrintion.

©

_) Positioning of controls

1. Light Switch.

2. Throttle control.

3, Brake and clutch pedal.

4. Motion r _trol Lover.

5. Attachment clutch switch.

6, Quick lifting/lower of the cutting unit.

7. Ignition lock.

8. Parking Brake.

9, Free-wheel control lever,

10. Cutting height setting.

11. Choke control

37

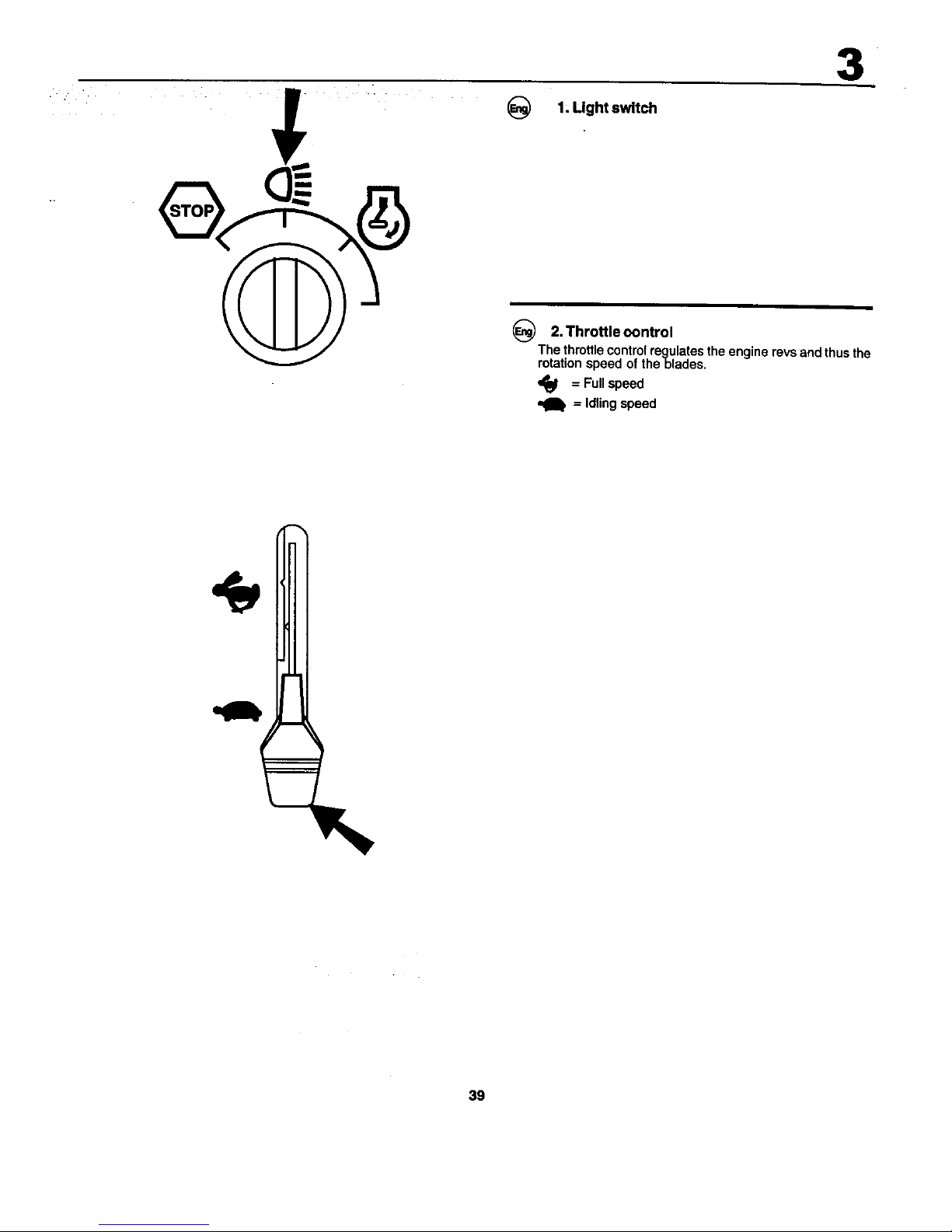

Page 16

1, Light switch

3

_) 2. ThrotUe oontrol

The throttle control regulates the engine revs and thus the

rotation speed of theblades,

,_ = Full speed

= Idling speed

39

Page 17

3

3. Brake and clutch pedal

When the pedal is pushed down the brake is applied and the

motor is d_sengaged.

40

Page 18

3

S

N

4. Motion control lever

Thereare fourdifferentpositionsforthislever:

N = Neutral(no drive)

S = Slow

F= Fast

R = Reverse

The levercanbe movedsteplesslybetweenSandFtoensure

the requiredspeed.

41

Page 19

3

5. Attachment clutch switch

of the cutting unit

6. Quick

lifting/lowering

Pullthe lever backwardstoquicklyliftthe cuttingunitwhen

passingoverirregularitiesinthe lawn.etc.Durin_transporta-

tionthe cuttingunit shallbe in the highestposihon,Pullthe

lever back until it locks.To lower the unit:Pull the lever

backwards(1), Pushinthebutton(2)andthenmovethelever

forwards(3).

42

Page 20

OFF ON START

3

7. Ignition Lock

There are three different positions for the ignition key:

OFF All electdc current broken,

ON Electdc current connected,

START Start motor connected.

WARNING!

Never leave the key in the ignition rock when leaving the

machine on its own.

8. Parking brake

Connect the parking brake in the following way:

1. Press down the rake peda! to bottom position.

2. Move the parking brake lever upwards and hold in this

position.

3. Release the brake pedal,

To release the parking brake all that is necessary is to push

down the brake pedal.

43

Page 21

3

_) 9, Free-wheel Control Lever

Totowormovethetractorwithouttheaidoftheenginethefree-

wheelcontrolknobmustbepu ed outand lockedinposition.

44

Page 22

3

10. Cutting height setting

The requiredcuttingheightissetwiththe aidofthe wheel,

The cuttingheight is increasedwhen itisturnedclockwise.

The whee/is easierto turnifthe leverfor lifUng/Iowedngof

thecuffingunitispulledbackwardsat thesame time,

11. Choke control

When the engine is cold the choke should be pulled out

before starting. When the engine has started and is running

smoothly push the choke in.

45

Page 23

4. Before starting.

Filling up

The engineshouldbe runof pure (not oil mixed) unleaded

petrol.Do notfillbeyondthe loweredgeofthefilling hole. Do

notfill over max level.

WARNING!

Petrolishighlyinflammable.Proceedwithcareandfill upwith

petroloutdoors.Do not smokewhenfilling withpetrolorfill up

whenthe engine is warm. Do notoverfillthetank sincethe

pertrolcanexpandandoverflow.Make surethatthepetrolcap

securelytightenedafterfilling. Storepetrolin a cool place

inan appropriatecontainerfor enginefuel. Checkthe petrol

tankand pipes.

46

Page 24

4

_) OII level

The combined oil refilling cap and the oil stick is accessible

when the bonnet is lifted forwards. The oil level in the engine

should be checked before each run. Make sure that the tractor

is horizontal. Unscrew the oil stick and wipe clean. Replace

the oilstickand screw tiQht.Remove again andcheck thelevel.

_)The oillevelshouldlie betweenthetwo markingsonthe o

stick.If moreoilis needed add SAE 30 oiltothe FULL"

marking.SAE 5W-30 oil shouldbe usedduringthe winter

(belowfreezing point).

ADD "-=

*--FULLCAUTION - DO

47

Page 25

4

Tire air _)ressure

Checkthetyre pressureregularly.The pressureinthefront

tyresshouldbe1bar(14PSI) and0.8 bar(12 PSI) intheback

tyres.

48

Page 26

• • • • .

5. Driving.

Starting of motor

Makesurethatthe cuttingunitisinthetransportposition(top

position)and thatthe lever for connection/disconnectionof

the cuttingunit is inthe disconnectionposition.

_) Press down the clutch/brakepedal completelyanO hold

down,Set the motioncontrollever in neutral"N*.

_Pull out the choke control (if engine is co d)

49

Page 27

5

_Warm motor: Pushthe gas controlhalf-wayto fullgas$

po_lfion",,_".

_)Tum the ignition key to "START position',

NOTE!

Do n_ mnthe mad motormomMan 5seconds = once.If

the enginewillnotstart, waitaboutl0secondsbefom the

ne_tw.

Q When the engine has started let the ignitionkeygo back to

the "ON posttion_. Push the gas control to the required

speed, For cutting: full gas.

50

Page 28

5

• • _) [MPORTANTI COLDSTARTING FOR HYDRO i

IMPORTANT: cOLD STARTING FOR HYDRO (BELOW

4O°F[4°C]) - AFTER STARTING ENGINE AND BEFORE

DRIVING, LET TRANSMISSION WARM UP FOR ONE(1)

MINUTEBY PLACING MOTION CONTROL LEVER INNEU

TRAL (N) POSITION AND RELEASING CLUTCH/BRAKE

PEDAL,

• Disengagetransmissionbyplacingfreewheelcontrolin

freewheelingposition.

• StadengineandmovethrotUecontroltoslowposition.Be

sure parkingbrakeis not engaged.

• Move motioncontrolleverto full forward positionand

hold for five (5) seconds. Move lever to full reverse

positionand hold for five (5) seconds. Repeat this

procedurethree(3) times•

• Move motioncontrolleverto neutral(N) position.

• Stoptractorbytumingignitionkeyto"OFF"position.

• Engage transmissionby placing freewheel controlin

drivingposition.

• Startengineand movethrottlecontrolto slowposition.

• Drive tractorforward for approximatelyfive feet then

backwardsfor,five feet• Repeat thisdrivingprocedure

threetimes.

Your tractor is now ready for normal operation.

_) PURGETRANSMISSION

To ensure proper operation and performance, it is recom

mended that the transmission be purged before operating

tractor for the first time. Th s procedure will remove any

• trapped air inside the transmission which may have devel-

oped during shipping of your tractor.

IMPORTANT: SHOULD YOUR TRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, ITSHOULD

BE PURGED AFTER REIN STALLATION BEFORE OPER-

ATING THE TRACTOR.

Park tractor on level surface so it will not roll in any

direction. Parking brake must be disengaged for the

following procedure.

51

Page 29

5

• "t'----_: NOTEI .....

= The machine is equipped with a safety Switch which

immediately breaks the current to the engine if the driver

leaves the seat with engine running and with the connec-

tion/disconnection lever in position "connection".Your

machine is also equiped with a system that will not allow

mower to operate if the bagger or optional rear discharge

deflector is not installed properly.

Driving

Warm up the engine for a few minutes with the throttle

athalf-speed. Lower the cutting unit by moving the lever

forwards, Release the brake/clutch pedal slowly. Connect

the cutting unit and move the motion control lever to the

requireposition.

53

Page 30

5

_Move the t_orottlecontrolto fullspeed (_). Choose a driving

speed which suits the terrain and requ=radcutting results.

Cuttingtips

• Clearthelawnfromstonesand otherobjectswhichcan

be thrownaway by the blades.

• Localizeand mark stones and other fixed objectsto

avoid collision,

• Begin with a high cuttingheight and reduce untilthe

requiredcuttingresultis obtained.

• The cuttingrosultisbestwithhighenginespeed(blades

rotatequickly)and Iowgear(machinegoesslowly).Ifthe

grass is too long and thick the drive speed can be

fncreasedby selectinga highergear or reducingthe

motorspeed,withoutaffectingthe cuttingresult.

• The bestlawnisachievedifthegrassiscutoften.Cutting

becomesmore even and the cutgrass is more evenly

distributedover the surface. Total time taken is not

greater since higher drive speed can be selected

withoutaffectingthe cuttingresuis.

• Avoidcuttingwet grass.The cuttingresultswillbeworse

sincethe wheels willsinkintothe softlawn.

• Spraythecuttingunitwithwater underneathafteruse.

54

Page 31

5

Dump Bagger

To

Yourtractorisequippedwitha Dump BagAlarm.Totum off

the alarm disengagethe attachmentclutchswitch.

• Positiontractorin locationyouwishto dump bagger.

Place motioncontrol lever in Neutral positionand set

parking brake.

• Raise dump handleto its highestposition.Pull handle

forward to raisebagger and dumpclippings.

• To continuemowing, be sure bagger is down and in

proper operatiz_:_positionwhich will allow mower tv

operate.

56

Page 32

5

' :(_-_ Toconvert mower

Convertingto mulchingorreardischargingwillrequirethe

purchaseofthese accessories.)

To mulching

• Placedeck into thehighcut position.

• Remove baggeror optionalrear dischargedeflector.

Unhookthe two(2) strapsandremovedischargechute

Insert plug and hartdteassemblythroughback plate

and ontothe mowerdeckchute adaptor,

• Retaintheplugassemblybyconnectingthetwo straps

overthe handleand hook intothe holes provided.

• Replacebaggeroroptionalreardischargedeflectorto

allowmowerto operate.

You are now ready to begin mulching.

To rear discharging

• Placedeck Into the highoutposition.

• Remove baggerand mulchingplug (if installed).

• Installdischargechutethroughopeningin backplate

and slide over deck adaptor•

• Attachthe chute by hookingthe two straps into the

holesin the flange ofthechute.

• Installthe discharge deflectorto the backplate by

screwing thefour (4) wing screws intothe threaded

insertslocatedin the backplate.

• Tightenthe wing screwssecurely.

To bagging

• Placedeck intothe highcut position.

• Removethereardischargedeflectorormulchingplug,

Insert the dischargechute into the opening in the

backplate and ontothe mowerdeck adaptor.

Attachthechutetothetractorby hooldngthetwostraps

tothe flange of thechute.

• Installbaggerintotractor.

57

Page 33

5

=

WARNING!

• Do notdriveinterrainatan angleofmorethanmax.10°.

The riskfor spark-overbackwardsislarge.

• In steepterrainthe riskfor tippingis considerable.

• Avoidstoppingand startingin slopingterrain.

• Onlychangegear whenthe machineisstandingstillto

avoiddamaging thegear box.

59

Page 34

5

_Use the left side ofthe machine to cut close to trees, bushes

and paths, etc. The blade cuts about 15 mm inside the edge

of the cover.

Switching off the engine

Movethegascontrolto=NIb".

Disconnectthecuttingunitby movingthe connect/discon-

nectlever downwards.

Liftup the cuttingunit and turn the ignitionkey to =OFF"

position.

Allowthe engineto idlefor 1-2 minutestocooldownbefore

switchingoffafter a hardwork.

60

Page 35

6. Maintenance, adjustment•

WARNING!

Beforeservicingthe engineor cuttingunitthe following

shallbe carriedout:

• Switchoffengine.

• Putgear leverin neutral,

• Moveconnection/disconnectionlevertodisengaged

position.

• Pressdown the clutch/brakepedal and engagethe

parkingbrake lever.

• Removethe ignitioncable from the plug.

(1) Hood

(2) Headlight wire connector

@

Engine hood

• Raise hood.

• = U _snap head!ight wire connector.

S and infront ,)'.tractor. Grasp hood at sides, tiltforward

an., lift offof b _ctor.

• To reinstall, sl ce hood pivotbrackets into slots in frame.

• Reconnect h_dlight wire connector and close hood.

62

Page 36

Malntenance_

NOTE: Periodic maintenance should be performed on a

regular basis in order to keep your tractor in good running

condition.

_ WARNING: Disconnectsparkplugwiretopreventacciden-

tal startingbefore attemptingany repair, inspection, or

maintenance.

Before each use:

• Check oil, lubricate pivot points as necessary.

• Check to see all bolts, nuts, and cotter pins are in place

and secure.

• Check the battery, terminals and vents.

• Recharge slowly at 6 amperes if needed.

• Clean air screen.

• Keep tractor free of dirt'and chaff to prevent engine

damage or overheating.

• Check brake operation.

64

Page 37

Service Record

Fill in dates as you complete regular service

Change engine oil

Lubricatepivot points

Check brake operation

Clean air screen

Clean air filterand pre-cleaner

Replaceair cleaner paper cartridge

Clean enginecoolingfins

Replace spark plug

Check tire pressure

Replace fuelfilter

Clean batteryand terminals

Check muffler

Lubricateball joints

Tce-in adjustment

Carburetoradjustment

JnA'_eeded

Every 8

hours

Every

25 hours

Every

50 hours

Every

100hours

Every

200hours

6

66

Page 38

6

!/_) Blades

The blades should be sharp to achieve best cutting results,

Sharpening can be carded out with a file or gdnding disc.

NOTE!

It isvery important that both blades are sharpened equally to

avoid imbalance.

VIEW FROM BOTTEM OF MOWER DECK

@

BladeCare

Important: The blades on your mower are not the same and

must be installedon the correct side. It issuggested that you

work on one blade at a time to ensure proper assembly of

components,

I

1.

5-Star patternbladew/right

hand threadedbolt

2,

_ 6-Star pattem blade w/left

hand threaded bolt

69

Page 39

6

8

_) 5 Star pattern blade

Thecenterofthisbladehasafive(5)starpattern.Theboltthat

attachestkis blade has normal Right Hand threads that

loosensby tumin_](u) counter-clockwiseand tightensby

turning(z) clockwMse.

6

\

_) I. Hext_righthandthmaded.

2, Lock Washer

3. Flat Washer

4. Blade

5. 5 StarCe_er Hole

6, 5 StarPattern

7. TrailingEdge

8. MandrelAssembly

_1. Hex bolt leRhand

threa_ed.

2. LockWSsher

3. FiatWasher

4. Blade

_'7 8

5. 6 StarCenterHole

6. 6 Star Pagem

7. TrailingEdge

8. MandrelAssembly

6 Star pattern blade

Thecenterofthisbladehasa6starpattem.Theboltattaching

thisbtadehasLeftHand threadsthat loosens by turning(z_

clockwiseand tightenby turning(u) counterclockwise.

70

Page 40

_) For best results mower blades must be kept sharp. Re-

"_" place bent or damaged blades.

BLADE REMOVAL

• Raise mower to highest position to allow access to

blades.

Remove hex bolt, lock washer and flat washer secur-

ing blade.

Instan new or msharpened blade with trailing edge up

towards deck as shown.

Important: To ensure proper assembly, center hole in

blade must align with star on mandrel assembly.

• Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

• Tighten bolt securely (27-35 Ft. Lbs. torque).

6

72

Page 41

Brakes

The brakesarelocatedinsidethe rightrearwheel.Thewheel

shouldbe dismantledfor best access.

1. Press down the clutch/brakepedal and engage the

parkingbrake.

1. Measure the distance between the brake lever and the

adjuster nut.

2. The distance should be 40 mm (1.56").

3. Ad ust the distance if necessary by first loosening the

nck nut (2) and then adjusting with the nut (1).

WARNING!

Do not forget to tighten the lock nut after complet-

ingadjustment.

73

Page 42

6

¸

I• ¸

Dismantling of the cutting unit

Work from the right side of the machine.

1, Take off the belt from the engine pulley (1).

2. Rar_ove the two rear retainer springs (2) and knock off

the axle taps with a hammer,

74

Page 43

6

_)3. Removethe retainersprings(3), (4), (5) and axles.

4. Pull the lever for lifting/loweringthe cuttingunit back-

wards.

5. Pulloutthecuttingunitfrom the machine.

_) Assembly of the unit

cutting

Assemble in the reverse order to dismantling,

• Push in the cutting unit under the machine. The ejector

opening should be to the right.

75

Page 44

6

Replacement of drive belt for cutting unit

1. Dismantle the cutting unit as described pmviousley.

2. Work offthe belt from the unit's left pulley and then from

the other wheels.

3, Pull the belt away from the cutting unit.

4. The new belt is mounted in the reverse order. Check that

the belt lies inside all the belt guides,

76

Page 45

6

_) Adjustment of the cutting unit

A. In the direction of travel

1. Checkthat theair pressureis correctinallfourlyres.

2. Makesure thatthe machineis on a hodzontalsurface.

3, Liftupthe cuttingunitto its highestposition.

4. Measurethe distancesA and B.

_)To achievebestcuttingresultsthecuttingunit'sfrontedge(B)

shouldbe about 10 mm (0.375) lowerthanthe backedge

(A). Adjustin the followingway to raisethe backedge:

1. Loosenthe nut(1) on boththe left and rightlevers.

2, Screw the nut (2) the same numberof turn s on both

levers.

3. Whenthecorrectdistance(A) is obtainedthissettingis

lockedwiththe nut (1).

77

Page 46

_(1) Bottom edge of mower

(2) Lift link adjustment nut

6

_ SIDE-TO-SIDE ADJUSTMENT

• Raise mowerto highestposition.

• Atthe midpoint of bothsidesof mower,measureheight

from bottom edge of mowerto ground. Distance A

shouldbe the sameor within6ram(1/4") ofeach other.

• Ifadjustmentis necessary,makeadjustment ononeside

of moweronly.

• To raiseonesideofmower,tightenliftlinkadjustmentnut

onthatside.

• To Iowerone side of mower, loosen liftlinkadjustment nut

on that side.

NOTE: Three funtums of adjustment nut willchange mower

height about 1/8".

• Recheck measurements after adjusting.

7!

Page 47

6

Replacement of drive belt

1. Dismantle the cutting unit as described previously.

2. Pull apad the contactfor the cable to the electrical connec

tion (1).

3. Dismantle the motion restrainer for the clutch (2).

4. Engage the parking brake and work off the belt upwards

from the pulley (3), the clutch pulley (4).

5. Push the belt up between two fan blades and rotatethe

fan clockwise until the belt comes loose (5).

6. Take off the be_tfrom the engine pulley.

_ Assembleinthereverseordertodismantling.Checkthatthe

beltliesinsideallthebeltguides.Useodgina]beltsonlywhen

repiacingt

79

Page 48

6

_1. Motion Control Lever

2. Neutral Lock Gate

3, Adjustment Bolt

_) TRANSAXLE MOTION CONTROL LEVER NEU-

TRAL ADJUSTMENT

The motioncontrollever has been presetat thefactory and

adjustmentshouldnot be necessary.

• Loosenadjustmentboltin frontofthe rightrear wheel,

and lightly tighten.

• Startengineand movemotioncontrolleveruntiltractor

does notmoveforward or backward.

Holdmotioncontrolleverinthatpositionand tumengine

off.

• Wi "- holding motioncontrollever in place,loosenthe

aOlustmentbolt.

• Movemotioncontrollevertothe neutral(N) (lockgate)

position.

• Tightenadjustmentbolt securely.

NOTE: Ifadditional•clearanceisneededtogetto adjustment

bolt movemowerdeck heightto the lowestposition.After

aboveadustment is made, t!thetractorstillcreepsforward

orbackwardwh e motioncontrol leverisinneutral position.

followthese steps:

• Loosenthe adjustF,_entbolt.

Move the motionconLrellever 114to 1/2 inch in the

directionitistryingto creep.

• Tightenadjustmentbolt securely.

• Startengineand test.

Iftractorstillcreeps, repeatabovestepsuntilsatisfied.

8O

Page 49

The fan and cooling fins oftransmission shouldbe kept clean

to assure proper cooling.

Do not attempt to clean fan or transmission while engine is

running or while the transmission is hot.

Inspect cooling fan to be sure fan blades are intact and

clean.

• inspect cooling fins for dirt, grass clippings and other

materials,

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factoryand fluid mainte

nance is not required. Shouldthe transaxleever leak or

requireservicing,contact your nearestauthorizedservice

center/department.

6

82

Page 50

7. TROUBLESHOOTING.

_J Engine will not start

1. Nofuelin fueltank.

2, Plug defecUve.

3. Plug connectiondefective.

4. Dirtincarburettoror fuel pipe.

Start motor will not turn engine

1. Batteryfiat.

2. Poor contact between cable and battery pole.

3. Connection/disconnection level in wrong po6ition.

4. Main fuse defective.

5. |gnition took defective.

6. Safety contact for clutch/brake pedal defective.

7, Clutch/brake pedal not pushed down,

Engine runs unevenly

1. Gear too high.

2. Plug defective.

3, Carburettor incorrectly set,

4. Air filter blocked.

5, Fuel tank ventilation blocked,

6. Ignition setting defective,

7. Dirt in fuel pipe.

Engine feels weak

1. Air filter blocked.

2. Plug defective.

3. Dirt in carburettor or fuel pipe,

4, Carburettor incorrectly set.

Engine overheats

1. Engine ovedoaded.

2. Air inlet or cooling fins blocked.

3. Fan damaged.

4. Too little or no oil in engine.

5. ignition setting defective.

6. Plug defective.

Battery does not charge

1. Fuse defective,

2. One or several cells defective.

3. Poor contact between battery poles and cables,

Lighting does not function

1. Bulbsdr: ,'ctive.

2. Switchdefective.

3, Short-circuitin cable.

The machine vibrates

1. Blades loose.

2. Engine loose.

3. Unbalance in one or both blades resulting from damage

or poor balancing after sharpening.

Uneven cutting results

1. Blades blunt.

2, Cutting unit skew,

3. Long or wet grass.

4. Grass stuck under cover.

5. Different air pressures in lyres on left and right side.

6. Gear too high.

7. Drive belt slipping.

83

Page 51

8. STORAGE.

_)The following steps should be taken when mowing season

is over:.

Clean the entire machine, especially undemeath the

cutting unit cover.

• Touch.up all chipped paint surfaces in order to avoid

corrosion.

• Change engine oil.

• Drain the fuel tank. Start the engine andallowit to rununtil

it is out of fuel.

• Remove the spark plug and pour one table spoon of

engine oil into the cylinder. Pull the engine over in order

to distribute the oil. Retum the spark plug.

• Remove the battery. Recharge and store itina cool dry

place. Protect the batter_ from low temperatures.

• The machine should be stored indoors in a dry, dust-free

place.

WARNING!

Never use gasoline when cleaning.Use degreasingdeter

gentand warm water instead.

Service

When ordering, we need the following information:

Date ofpurchase, model, type and serial number of the

mower. Always use original spare parts. Contact your local

dealer of distributor for warranty service and repairs.

86

Page 52

CRAFTSMAN"

168732 flev. 2 4.21.99 VB/RDIflH Printed in U.S.A.

Loading...

Loading...