Page 1

CRAFr.3

_xeRouter Table

:CAUTION!_ReadAllInstructionsCarefully

(RouterNotIncluded)

i

i

Pa_No.49LCN:59

Solday:

SEARS,ROEBUCKAndCO.

3333 BeverlyRoad,

HoffmanEstates,IL60179

Made In U,S.A.

Printed h7U,S.A.

Page 2

FAILURETOHEEDALLSAFETYAND OPERATINGINSTRUCTIONS

ANDWARNINGSREGARDINGUSEOFTHIS PRODUCTCANRESULT

IN SERIOUS80DILYINJURY.

GENERALSAFETYINSTRUCTIONSFORPOWERTOOLS

1. KNOWYOURPOWERTOOL

Readthe owner'smanualcarefully.Learnits applicationand

limitationsaswell asthe specificpotentialhazardspeculiarto this

toot.

2. GROUNDALLTOOLS(UNLESSDOUBLEINSULATED)

Iftool isequippedwith anapproved3-conductor cord and a3-

prong groundingtype plug,it should bepluggedintoathreehole

electricalreceptacle,Ifadapteris usedto accommodatea two-

prong receptacle,theadapterwire must be attachedto known

ground,(usuaflythescrewsecuring receptaclecover plate).Never

removethird prong.Neverconnectgreen ground wire to a

terminal.

3. KEEPGUARDSIN PLACE

Inworking order,andin properadjustmentand alignment,

4. REMOVEADJUSTINGKEYSANDWRENCHES

Formahabitof checkingto seethat keysandadjusting wrenches

areremovedfrom too! beforeturning it on.

5. KEEPWORKAREACLEAN

Clutteredareasandbenchesinviteaccidents,Floor mustnot be

slipperyduetowax or sawdust.

6. AVOIDDANGEROUSENVIRONMENT

Don't usepowertools in dampor wet locationsor exposetllem to

rain.Keepwork areawel!lighted: Provideadequatesurrounding

work space.

7. KEEPCHILDRENAWAY

All visitors shouldbe kepta safedistancefrom work area.

8. MAKEWORKSHOPKID-PROOF

Usepadlocks,masterswitches, or removestarterkeys.

9, DON'TFORCETOOLS

It wilt do the job betterand saferatthe rate for which it was

designed,

10. USERIGHTTOOL

Don'tforcetoot or attachmentto do a job it was not designedfor.

11. WEARRIGHTAPPAREL

Do notwearlooseclothing,gloves,necktiesor jewelry (rings,

wrist watches)to getcaugt]tin moving parts, Nonslipfootwearis

recommended,Wearprotectivehair coveringto contain long flair.

Rolllong sleevesabovethe elbow.

12. USESAFETYGOGGLES(HeadProtection)

WearSafetygoggles(mustcomplywith ANSI'Z87,1)atalltimes.

Also, usefaceor dust mask,if cutting operationisdusty,andear

protectors (plugsor muffs) during extendedperiodsofoperation.

13. SECUREWORK

Useclamps or a viseto hold work whenpractical, It's saferthan

using your hands,andit frees both handsto operatetool,

14. DON'TOVERREACH

Keepproperfooting and balanceatatftimes.

i5. MAINTAINTOOLSWITHCARE

Keeptoolssharpand cleanfor bestand safestperformance.

Follow instructionsfor lubricatingand changingaccessories.

16. DISCONNECTTOOLS

Beforeservicing,whenchangingaccessoriessuchas blades,bits,

cutters,etc.

17. AVOIDACCIDENTALSTARTING

Make sureswitch is in "OFF"positionbeforepluggingin.

18. USERECOMMEND_EDACCESSORIES

Consulttheowner's manualfor recommendedaccessoriesand

follow the instructions,Theuseof improper accessoriesmay

causehazards.

19. NEVERSTANDONTOOL

Serious injurycould occur if the tool is tippedor if the cutting tool

is accidenta!lycontacted.Do notstore materialsaboveornearthe

tool makingit necessaryto stand onthe tool to reachthem.

20. CHECKDAMAGEDPARTS

Beforefurther useof thetool, any guardor other partthat is

damagedshould becarefullycheckedto ensurethat it will operate

properlyand perform its intendedfunction.Checkforalignmentof

moving parts,binding of moving parts,breakageof parts,

mounting,andany otherconditions that may affect its operation.A

guard or anyother part that is damagedshould be properly

repairedor replaced.

21. DIRECTIONOF FEED

Feedwork intoa bladeor cutteragainstthedirection of rotation of

the bladeor cutter only.

22. NEVERLEAVETOOLRUNNINGUNATTENDED

Turn poweroff. Don't leavetool untilit comestoa completestop,

Page 3

ENERALSAFETYI UCTI THE

LEWITHUNITIZEDFENCE.

1. ALWAYSUSEEYEPROTECTION

Theoperationof any powertoo!can result inforeign objectsbeing

thrownintotheeyes,which canresult in severeeyedamage.

Alwayswear safetygogglesbeforecommencingpowertool

operation,Safetygogglesareavailableat Searsretailor catalog

stores,

2. KEEPHANDSCLEAROFBITSANDWORKINGAREA

3. MAKEANOUSEAPUSHSTICKTOMOVESMALL

WORKPIECESACROSSTHECUTTINGAREA.

4, KEEPROUTERCLEANAFTEREVERYUSE,CLEANSAWDUST

OFFTHEROUTER.

5. YOURROUTERTABLEiS PROVIDEDWITHADUST

COLLECTINGATTACHMENTALWAYSUSESHOPVACFORALL

ROUTINGOPERATIONSREQUIRINGUSEOFFRONTSIDEOF

UNITIZEDFENCE.(FRONTSiDEtS THESIDEWITHTHE

CRAFTSMANLABEL).

NOTE:Motors usedon wood-working tools areparticularly

susceptibleto theaccumulationof sawdustandwood chips and

should be"vacuumed"frequentlyto preventinterferencewith

normal motor ventilation.

6. CHECKFUNCTIONOFGUARDBEFOREEACHUSE.REMOVE

ALLDUSTANDCHIPSFROMGUARDAREAASNEEDEDTO

MAINTAINGUARDFUNCTION.

7. NEVERPUTYOURFINGERSUNDERTHEGUARDWHENTHE

ROUTERISPLUGGEDIN.

8, ALWAYSUSETHEROUTERTABLEFENCETO GUIDETHE

WORK.DONOTWORKFREEHAND.

Whenusingpilottype bits,keepthe fencesas closeto the pilotas

possibleto provideadditionalbackupand additionalguidanceand

to avoidchancesof an accidentandpossiLllepersonalinjury, ,

9. ALWAYSFEEDAGAINSTTHEROTATIONOFTHECUTTER

WHENROUTINGON THEROUTERTABLE.FEEDWORKPIECESIN

THEDIRECTIONOFTHEARROWASSHOWNONTHELABELON

THESIDEOFTHEFENCEBEINGUSED(WHENFACINGTHE

TABLEFRONT).

10. FORALLEDGECUTTINGANDENDCUTrlNGOPERATIONS,

USEFRONTSIDEOFUNITIZEDFENCE.USEBACKSIDEOF

FENCEONLYFORROUTINGOPERATIONSAWAYFROMEDGEON

THEUNDERSIDEOFWORKPtECESUCHASGROOVING,

FLUTING,VEINING,CROWNMOLDING,ETC.

11. WHENENDCUTTINGONWORKPIECES'4"WIDEOR LESS,

CLAMPANDHOLDAND FEEDTHEWORKPIECEWITHTHEPUSH

BLOCKUSINGBOTHHANDS,AS SHOWNiNFIG. #23. KEEP

FINGERSCLEAROF BITWHENMOVINGWORKPIECEACROSS

THECUTTINGAREA.NEVERPLACEYOURHANDSLOWERTHAN

THETOPOFRETRACTABLEGUARD.

12. ROUTERBITSARE_:_rREMELYSHARP.

Beextracarefulwhenworking around them.

13, SOMEROUTERS,WHENUSEDINAN UPSIDEDOWN

POSITION(SUCHASONAROUTERTABLE),WILLFALL(OR

DROP)OUTOFTHEROUTERBASEWHENTHEBASECLAMPIS

LOOSENED+IT IS THEREFOREABSOLUTELYNECESSARYTO

SUPPORTTHEROUTERMOTORFROMBELOWWHENTHEBASE

CLAMPIS LOOSENEDTO MAKEADJUSTMENTS,ORFORANY

OTHERREASON.

t4. ALWAYSLOOKUNDERTHETABLEATTHESWITCHWHEN

TURNINGTHEROUTERON!OFFANDTOUCHNOTHINGBUTTHE

SWITCH,NEVERREACHUNDERTHETABLEWHENROUTERtS

RUNNINGFORANYOTHERREASON.

NOTE:It isfar more safeand convenientto usea"Craftsman

+25183RouterTableSwitchpackage".Thisswitch providesa key

o 1

peratedON/OFFbutton-whichallowsfast andeasyaccesswhen

and if it becomesnecessaryto turn the router"OFF"quickly,The

keycan beremovedto renderthe switch inoperableto

unauthorizedpeople.

15. MOUNTROUTERTABLEFIRMLYANDSECURELYTOA

WORKSURFACEBEFOREUSE.FAILURETO DOSOCOULD

CAUSETABLETOTiP OVERORSLIDEDURINGOPERATION

RESULTINGIN PROPERTYDAMAGEAND/ORSERIOUSBOOILY

INJURY.

16. BEFOREMAKINGANYCUT,UNPLUG

ROUTERANDRETRACTGUARDTO

MAKEABSOLUTELYSURETHATRETRACTABLEGUARDCLEARS

THEROUTERBIT,ANDTHEGUARDIS FUNCTIONING

NORMALLY.SEEFIG.#16.

17. WARNING:ROUTERVIBRATIONS

SOMETIMESCANCAUSEFASTENERS

FORTHETABLE,THEROUTERANDTHEUNITIZEDFENCETO

GETLOOSErPERIODICALLYCHECKFASTENERSTOMAKESURE

THEYARETIGHTAND SECURE,

Page 4

INTRODUCTION

Howoftenhaveyou neededalargeguiding surfaceon a router table?YourCraftsmanRouterTablewith UnitizedFencecomeswith ttle

following:

• A unique4" highunitizedfencedesignedtoassist end grain

routingfor makingtenons,slidingdovetailsandtongue and

groovejoints along with most edgeand facecutting operations.

• A speciallydesignedpushblockwith quick clamp for back up

and clampingboardsup to 4"width for endgrain routing.

• An accurateandquick adjustingjointing fenceadjustableto

properjointing depth of cut.

• Reversingfeatureof unitizedfencedesignedto enablerouting

operationslikegrooving,fluting, veiningandcrown moldingetc.

up to 2_" awayfrom theedgetowards themid,die of the board.

• Twoguardsfor operationon either sideof ihe unitizedfence.

• Dustco!lectingattachmentfor most sllop vacuumhook ups,

• Extensionsthat providea largework surface.

If orderto facilitatehandlingand minimizeany damagethat might occur during shipment,your newroutertable is packaged

unassembled.We knowyouare anxiousto seewhatyOurnew too! wil! do, but a few minutesspent nowcarefullyreadingthefollowing

instructionswill resultin lessfrustration and more enjoyableoperationlater,

Startbycheckingandaccountingfor all the looseparts, If anypartsare missing,contact your local Craftsmanretailor hardwarestore

outletfor replacement.

OPTIONALROUTERTABLEACCESSORIES

#25326CRAFTSMANUNIVERSALADAPTERPLATE,for mounting non-Craftsman1/4"shank routersto Craftsmanrouter accessories.

#25183CRAFTSMANROUTERTABLEPOWERSWITCH,for turning routerand other accessories"on" and"off" from the front of the

routertable, i

#25468CRAFTSMANGUIDEMASTERRouterTablePush Shoe,aids in push shoeand hold down operations,accuratemeasurementand

routertablesetup,transforms into a miter gauge,and givesquick set up for 1/2"slidingdovetailjoints.

#25489CRAFTSMANROUTERTABLEFLOORSTAND,placesrouter tablesat convenientworking height,hasadjustablefloor levelers,

andtwo steelshelvesfor storage,

UNPACKINGANDCHECKINGCONTENTS

Referto PartsList on Page16

YOUMUST READANDUNDERSTANDALLTHEINSTRUCTIONSCOMPLETELYBEFOREATTEMPTINGTO

ASSEMBLEANDOPERATEYOURROUTER/ROUTERTABLE,

TOOLSREQUIRED

, A smalland medium sizescrewdriver.

• A small or medium sizeadjustablewrench,

• An electricalor hand drill with 1/8"drill bit,

• Hammer

Page 5

ASSEMBLYOFEXTENSIONSANDLEGS

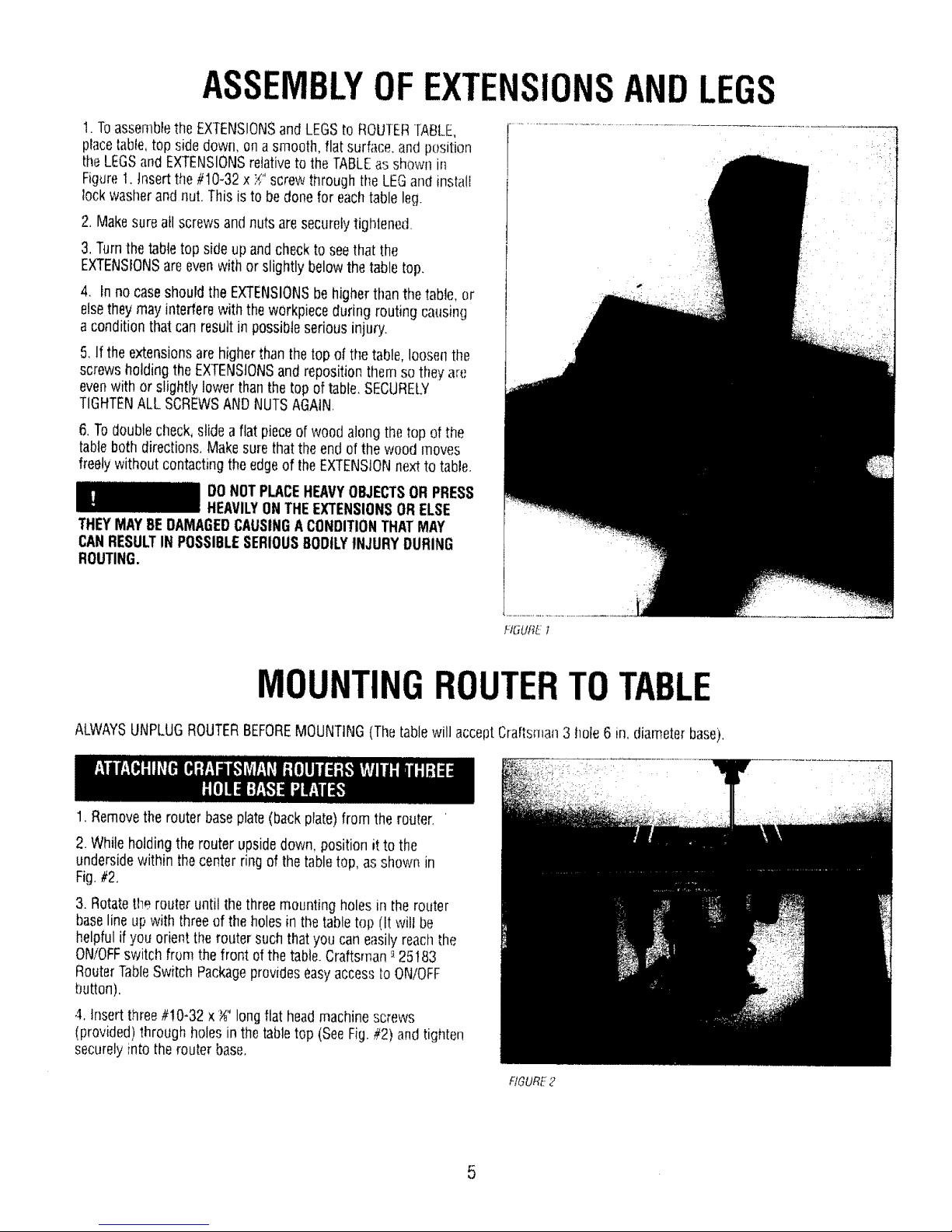

t. ToassembletheEXTENSIONSand LEGSto ROUTERTABLE,

placetable,top side down, on a smooth, flat surfi_ce,andposition

theLEGSandEXTENSIONSrelativeto the TABLEasshown in

Figure1. htsertthe #10-32 x Yi'screwthrough the LEGand install

lock washerandnut. This is to bedone for eachtableleg.

2, Makesureall screws andnuts aresecurelytightened,

3.Turnthe tabletop sideup andcheckto see that tfm

EXTENSIONSare evenwithor slightly belowthe tabletop.

4, In no caseshouldthe EXTENSIONSbehigher thanthe table, or

elsetheymay interferewith the workpieceduring routing causing

a conditionthat can resultin possibleserious injury.

5. If the extensionsarehigherthanthetop ofthe table, loosenthe

screwsholdingtheEXTENSIONSandrepositionthem so they art;

evenwith or slightly lower thanthe top oftable, SECURELY

TIGHTENALL SCREWSANDNUTSAGAIN,

6.Todoublecheck,slidea flat pieceof woodalong the top of the

tableboth directions,Makesurethatthe end of the wood moves

freelywithout contactingthe edgeof the EXTENSIONnextto table,

DONOTPLACEHEAVYOBJECTSOR PRESS

HEAVILYONTHEEXTENSIONSORELSE

THEYMAYBEDAMAGEDCAUSINGACONDITIONTHATMAY

CANRESULTIN POSSIBLESERIOUS80DtLYINJURYDURING

ROUTING.

FIGURE 1

MOUNTINGROUTERTO TABLE

ALWAYSUNPLUGROUTERBEFOREMOUNTING(Thetablewill acceptCraftsman3 hole 6 in. diameterbase).

, i:f •

1. Removethe routerbaseplate(back plate)from the router. '

2. Whileholding the router upsidedown,position it to the

undersidewithin thecenterring of the tabletop, as shown in

Fig.#2,

3. Rotatethe router until thethree mountingholesin the router

baselineup with threeof the holes in thetabletop (It will be

helpfulif you orient therouter suchthat you caneasilyreachthe

ON/OFFswitch from the front of thetable.Craftsman_-25183

RouterTableSwitchPackageprovideseasyaccessto ON/OFF

button).

4. Insertthree#!0-32 x _" longflat headmachinescrews

(provided)throughholesin the tabletop (SeeFig,#2)and tighten

securelyinto the routerbase.

FIGURE2

5

Page 6

SELECTINGANDINSTALLING[ABLEINSERTS

1.With thedesiredbit in the router,selectatable insertwhich hasa

centerholeslightly largerthanthe diameterof therouter [)it.Note:

Forbits largerthanapproximately!_;" diameter,do not usean

insert,

2, Thetable insertsaredesignedto besnappedinto the routertable.

Stidethe largetangunder the edgeof the largehole in the router

tableas shownin Fig.#3.Usingyour thumb, pressdown on the

insertuntilthe smalltangsnaps into position

3,Toremovetheinsert,placethebladeof asmall screwdriverinto

theslot (with the smalltang)and prythe insert out of [herouter

table.

BEFOREASSEMBLINGANDATTACHING

UNITIZEDFENCETOTABLE,MAKESURE

THATROUTERIS UNPLUGGEDANDTHEBITIS BELOWTHETOP

SURFACEOFTHETABLE.

HGURE3

ASSEMBLYOFUNITIZEDFENCE

1, Slidejointing fencethrough rectangularopeninginthe cavity

providedon the unitizedfence(ribs on the unitizedfencewill slide

in thegrooveson the undersideof jointing fence).SeeFig.#4a &

#4b.

2, Insert;./.-20x t" tong hexheadbolt through thehole in the

unitizedfence (from theunderside)and theslot in the jointing

fence,

3.Whileholdingthe headof the bolt in thehex recesson the

undersideof unitized[ence,placea flat washeroverthebolt and

screwsmall _-20 knob on bolt.

Whenknob is loosened,thejointing fencecanslide backand forth

in thecavityfor proper iointing adjustment.

FIGURe."4a

FIGURE4b

6

Page 7

1. Placethe unitizedfenceupsidedown on a flat surface asshown

in Fig.#5a & #Sb.

2.Orienttheretractableguardasshown in Fig,#5a & #5b.

Positionand hold the springoverits hub such that formed end of

spring wrapsovertheguard asshown in Fig.#So& #5b.

3. Whileholdingthe springoverthe hub, and formed end overthe

guard,positionand pressthestraight legof springagainstsurface

'X' to align holein hubover bosson unitizedfence(seeFig.#5a &

#5b). Slipthe guardover theboss, Spring wil! now betrapped

betweenthe guardand thefence.(Springdiameteris biggerthan

thehub diameter.Youwill needto use both handsto hold spring

in proper position,).

4,Tightlysecureretractableguardin placeusingset!threading #8-

10 x_" longpanheadptasformscrew anda flat washer asshown

in Fig.#5a & #5b,

5, Swingguarda few timesin the direction of arrowto see that it

retractsout freelyby itself and returnsto itsnormal positionover

the routertable hole.SeeFig.#5a & #5b.

NOTE:Ifthe guarddoesnot retractout freely,loosenscrewjust

enoughuntil it does retractout freelyand snapsback to normal

forward position by itself,

6.Turnthe unitizedfencerightside up.

f.'K._URE5a

FIGURE5b

ATTACHMENTOFUNITIZEDFENCEASSEMBLY

TOTABLE

FROMTABLE.

ALWAYSUNPLUGROUTERBEFORE

ATTACHINGFENCETOANDREMOVING

1.Assembleunitizedfenceassemblyto table as shown in Fig.#6.

2. Insertoneof the_-20 x 1_" long hexheadbolts through the

holein thetabletop (from theunderside)and theslot in the fence.

3.Whileholding theheadof the bolt in the hex recesson the

undersideof the tabletop,placea flat washeroverthe bolt and

installalarge'_-20knobonto the bolt to looselysecurethefen_:e.

4, Repeatfor tile other slot,

NOTE:Theunitizedfenceassemblycanbe attachedtobible with

eithersidefacingthe front, Touseotherside,justremovethe

knobsandturn the fencearound.

RGURE6

7

Page 8

!, Screwthesmall endof clamp rod into threadedhole mclamp

ptateuntilthe platebottomson its shoulder(makesureclamp

plateisorientedsuch that letter "C" is facing outwardsas shown

in Fig,//7).

2. Tightlysecureclamp plateto clamp rod using_" helicallock

washerand a hexnut.

3, Inserttheoppositethreadedendof clamp rod through hole in

pushblock, and installa flat washeranda wing nut on to it.

ROUTERVIBRATIONSSOMETIMESCAN

CAUSE1/4-28 HEXNUTANOCLAMP

PLATETOGETLOOSEtPERIODICALLYCHECKFASTENERSAND

CLAMPPLATETOMAKESURETHEYARETIGHTANDSECURE.

, NUT

i[ CLAMPPLATE-

RGURE F

i

'FLAT WASHER

" PUSH BLOCK

ASSEMBLYOF BLOCK& GUARDTO

UNITIZED

Clampplate,whenfree,tries to swing in the directionof arrow

(SeeFig.#8)due to its weight.

t. Mount pushblockassemblyontheunitizedfenceby supporting

clampplateagainsttheface ofthe fenceand aligning retaining rib

on pushblockwith thegroovein the faceof unitizedfence,

2.Slide push blockassemblybackand forth alongentirelength of

unitizedfenceto seethat it slidesfreely.

NOTE:a,Removedustandchips from slidingsurfacesof push

blockandunitizedfenceas neededto maintaingood

slidingmotion.

b,Occasionalapplicationof furniturespray wax on sliding

surfacesof PUSHBLOCKONLYwilt greatly in]provethe

sliding motion,

FORROUTINGONENDS(TENONS,SLIDINGDOVETAILS,ETC,)

WORKPIECEISHELDAGAINSTFACEOFUNITIZEDFENCEAND

CLAMPEDBETWEENCLAMPPLATEANDSURFACE'S'OFPUSH

BLOCK.SEEFIG.#8.

FIGURE8

1.Assembleguardto unitizedfenceasshown in Fig,#9,

2.Whileholdingthe guardat a slight angle,asshown, inserttab

on onesideof guardinto the holeinsidethe slot on the fence.

3,Holdtheguard againstthis slot,straighten it into avertical

position,and insert theoppositetab into the matingslot.

SeeFig,#9.

4, Pivotguardbackandforth a fewtimes to makesurethat it

movesfreely.

NOTE:Oncetheguard hasbeeninstalled,donol removeit for any

reason,

FIGURE9

8

Page 9

THEROUTERTABLEMUSTALWAYSBEFIRMLYANDSECURELY

MOUNTEDTOAWORKSURFACEBEFOREUSE.FAILURETODO

SOCOULDCAUSETABLETOTIPOVERORSLIDE,RESUL.TINGIN

PROPERTYDAMAGEANDIORSERIOUSPERSONA[.INJURY,

Eachleghas(4} lloles at the bottomfor mounting. Firmlysecure

routertabletowork surfaceusingappropriate fasteneis(not

provided)as shownin Fig,#10.

Attach1"x 6"or 2" x 6"skidsto bottom of legs asshown in Fig.

#10.thensecuretablefirmly to work surface.

FIGUREI0

Unitizedfenceis providedwitha hookupfor most Craftsman2_"

and 1¼"hosediameterwet!drj vats.

FORALL OPERATIONSREQUIRINGUSEOFFRONT-SIDEOF

UNITIZEDFENCE,connectwet/dry vacasfollows:

1. Raiseguardandleanit againstthe fence,

2. Attach2_" hosediameternozzleas shown in Fig.#'! 1.

3.Attach 17" hosediameternozzleas shown in Fig. #12,

4. Lowerguard andlet it rest on thevac hose.

NOTE'.Formaximum suctionefficiency,stick a pieceof tapeor use

a pieceOfscrapwoodto cover upthe openingin the rear of the

fenceas shownin Figures1! and 12. Uncoveropeningafter use,

FOROPERATIONSREQUIRINGUSEOFBACKSIDEOF

UNITIZEDFENCE,DONOTCONNECTWET/DRYVACAS IT

WILL HINDEROPERATION,THEBACKSIDEOFFENCE1SONLY

FORCUTTINGOPERATIONSONTHEUNDERSIDEOF

WORKPIECETHEWORKPIECEDURINGSUCHOPERATIONS

COMPLETELYCOVERSTHEROUTERBITAND THEDUST

CANNOTBEVACUUMED.

OPERATINGROUTERTABLEWITHOUTUSE

OFWET/DRYVACMAYRESULTtN

EXCESSIVECOLLECTIONOFSAWDUSTANDCHIPSUNDERTHE

FENCEANDTHERETRACTABLEGUARDAREA,

FORYOUROWNSAFETY,ALWAYSUNPLUGTHE ROUTERAND

CHECKFUNCTIONOFGUARDBEFOREEACHUSE REMOVE

DUSTANDCHIPSFROMGUARDAREAASNEEDEDTO

MAINTAINGUARDFUNCTION,KEEPWORKAREACLEAN.

REMOVEUNITIZEDFENCEFROMTABLE(MAKESUREROUFEr_

tSUNPLUGGED)TOCLEAROUSTANDCHIPSTRAPPED

BElWEENFENCEANDTABLETOE

FIGURE11

FIGURE 12

9

Page 10

Assembleprotractor headtOmiter barasshown in Fig.#13.

1.Measuredistancefromeach endof unitizedfenceto edge'E'of

miter barslot on thetable as shownin Fig.#t4. If both distances

arethe same,thefenceis parallelto miter barsfot. !t not, loosen

largeknobs andadjust fenceaccordingly,Tightenboth knobs.

2.Position miter gaugeon tableas shown in Fig #14.

.._4-417X 3/4 LG

,_" PANHEAD

MACHINESCREW

__"t¢"*......._ -_-- POtNTER

HEX

/

3,'t6'f'ALNUT............... \,

PALNU_TOBE PU,S'HEOONTOSTUDUNTIL #t0-32 x 3,;4"LG.

tT BOTTOMSOUTAGAINSTMtTERBAR CARRtAGEBOLT

FIGURE13

ALWAYSUNPLUGTHEROUTERBEFOREMAKINGANYSETTING,

ADJUSTMENTSORCHANGINGBITS,

WHENROUTING,ALWAYSFEEDAGAINSTTHEROTATIONOF

THECUFrERFEEDWORKPIECEIN THEDIRECTIONOFARROW

AS SHOWNONTHELABELONTHESIDEOFTHEFENCEBEING

USED(when facingthetable front).

Theunitizedfenceon your table is providedasa guide,against

whichthe workpieceshouldbe heldfor accuracyin routing. Free

handrouting (not holding work againstthe fence)is hazardous

andshouldbestrictly avoided.

Wet/dryvacwith eitller2S"diameteror 1/" diameterhosenozzle

shouldbe connectedtothe dust collectionattachmentwhen using

theroutertable,

FIGUREt4

tn orderto retractthe guardand haveful!accessto the router bit

for makingadjustments,selecta boardthat is smooth with edges

and endstrueto eachotherand its surfaces,Keepin mind the

foi!owingaswel!:

1.Mark lines 'A and 'B' on theendof this board.Line'A' for

desireddepth of cut (amount of materialyou want Io remove)and

line'B' for desiredcutting heighLSeeFig.#I 5,

2. Positionthis boardagainsttheface of tile fencewithedge

restingontabletop and endmarkedwith lines'A' and 'B' dose to

the bit. SeeFig,#t5. (Thiswill retractguardinsidetenceand

provideaccessto the bit for makingadjustments,MAKESURE

ROUTERtSUNPLUGGEDWHENMAKINGADJUSTMENTS.)

3,Loosenbothlargeknobs thatallow movementoffence and

movefenceforwardandbackwarduntil outermostcutting edgeef

routerbit is alignedwith line 'A'. Tightenboth knobs. FfGUREt5

t0

Page 11

4. Raiseor lower the _outeruntil top cutting edg(_cf bd _,.__f!:(m,}d

with line 'B. (Referto your router ownel's!rla,llual hji' adjusliq_ I

your routerproper}y).AFTERMAKINGTHISAOJUS:rMENT,i-3E:

SURETHATROUTERISSECURELYTIGHTENEDtN ]HE ROUTER

BASE,BITtS SECURELYTIGHTENEDIN THEROUTEF_CHUCK,

ANDROUTERBASEIS 1tGHTLYSECUREDTO TABLETOK

5, Removethe boardflora the fence,

WHENADJUSTINGHEIGHTOFROUTER

BITFORANYDESIREDCUT,MAKE

ABSOLUTELYCERTAINTHATTOPOFBITIS BELOWTHEINSIDE

SURFACEOFRETRACTABLEGUARD,ASSHOWNIN FIG.#16,

CHECKTO SEETHATGUARDRETRACTSFREELYIN ANDOUTOF

FENCETOITSNORMALPOSITIONOVERTHEROUTERTABLE

HOLE, DONOTOPERATEROUTERIF ANYPARTOFTHEBIT

CONTACTSTHEGUARD.

NOTE:Theproceduredescribedaboveis intendedto provide a

wayof retractingandholdingthe guard to havefull accessto the

_outerbit for makingadjustment&Workpieceto be routed could

besubstitutedfor thescrap boardfor makingadjustmertts.

Formaximumstrengthand accuracy,boardsto be joinedtogether

shouldbe smooth andtrue. Theedgesshould be trueto the (90°)

workpiecesurface,You cantrue the edgesof workpieceonyour

routertableusinga straight bit.

!, Checktoseeif faceofjointingfence is flush with thefaceof

unitizedfence,If not, loosensmallknobon jointing fenceand

pushjointingfenceinsidethecavity in unitizedfence.Tightenknob

on jointiagfence.

NOTE:Thejointingfenceprovidesa continuoussupport for the

workpiece,asit is fed beyondthe router bit, tt compensatesfor

theamount of materialremovedby the routerbit,

2. Adjustdepthof cut (materialyouwant to remove)and routerbit

l]eightas describedbeforefor Fig,#!5, Tightly securethefence

andthe router asdescribedbefore.(MAKESUREROUTERIS

UNPLUGGEDWHENMAKINGADJUSTMENTS.)

3. Checkyour adjustmentsbyturningthe router 'ON'and feeding

a pieceof scrapwood a few inchesbeyondrouterb_t.Thenstop

andturn router 'OFF',

NOTE:Feedwork in the directionof arrowshown on labelonthe

frontsideof unitizedfence(whenfacingtable front).

4, Loosenknob on jointing fenceandmove it out flush againsti:l]e

finishededgeof scrapwood, Retightentheknob SeeFig _17.

5. Repealthetest cut on the scrapwood.

6. Therouter tableis now readyfor use,

NOTE:Forbestjointing results,takevery shallowcuts_--/;:,"or

less.

1.Positionthe jointingfence suchthat its faceis flush with the

faceof unitizedfence.Tightensmallknob on jointing fence.See

Fig,#! 8,

fIGUREt6

FIGURE17

RGURE t8

11

Page 12

2_Adjusldepthof(;ut(materialyouwanttoremove)and routerbit

Ileight asd_,scribedbefore.Tightenboth largeknobs to lock fence

on table.Tightlysecurethe router,(MAKE SUREROUTERtS

UNPLUGGEDWHENMAKINGADJUSTMENTS,)

3.Testcuta pieceof scrap wood to makesureyour adjuslments

aresatisfactory.

NOTE:Feedwork in thedirection ofarrow shown on labelon

frontsideof unitizedfence(whenfacing tablefront),

4,Theroutertable is now readyfor use,

Rememberthefollowingwhenbits with pilots are usedto control

thecutting depth:

1. Positionthejointingfencein thesamemanneraswith non-

pilotedbits.

2, Movetheunitizedfencebackonlyenoughto permit thepilot to

controlthe cutting depth.Positioningthe unitizedfenceasclose to

thepilot aspossiblewill serveasa back-upand will help in

avoidingan accidentand possiblepersonalinjury, SeeFig.#!9.

NOTE:if you havepurchasedRAILANDSTILECUTFERS

(Craftsman-_21257 or _21259) for makingcabinetdoorframeson

your routertable,MAKESURETHATFRAMETHICKNESSis not

morethan_". II frame thicknessis morethan _",thetop of i[f_ebit,

asshown in Fig.20, will interferewith retractableguardonyour

unitizedfence,SeeFig.#20 and Fig.#16,

Whenroutingon endsof workpiecefor making tenons,sliding

dovetailsandtongueandgroovejoints, theworkpiecemust be

madesmooth with bothedgesandends madetrue to eachother

and its surfaces.(90°)

NOTE:Thepush blockand clampplateassemblywilt not

accommodateworkpiecewiderthan4".

EXAMPLE:CUTTINGTENONS

1.Makecertainthatjointing fenceis lockedin position with its

faceflushwith that of unitizedfence.

2.Mount push blockassemblyon unitizedfence asshown before

in Fig.#8.

3. Installpropertableinsert intothe tabletop hole,

4, Marklines'A' and'B' on the edgeof theworkpiece closest to

the endto becut. Line'A' for FULLDEPTHOFCUT(totalamount

of materialyou want to remove)andline 'B' for FULLOEStRED

HEIGHTOFTENON.SeeFig.#2t.

FIGURE_19

THAN3/4"

FIGURE20

[

FfGURE21

12

Page 13

DONOTSETDEPTHOFCUTMORETHAN

_" (FIG. #23). IF DEPTHOFCUTIS MORE

THAN %",THEEDGE'E' OFWORKPIECEWHENSLIOtNG

ACROSSWILL INTERFEREWITHPORTION'P' OFGUARD.THE

GUARDTHENWILLNOTRETRACTINSIDEFENCE,ANDYOU

WILLNOTBEABLETOSLIDEWORKPIECEACROSSTHEBIT TO

MAKETHECUT,SEEFIG.#24.

5. POsitionworkpiecebetweenclampplateandpush block such

that its sideis held flushagainstfaceof the unitizedfence,el_(ito

becut is restingon the edgeof thetable top hole andedge

markedwithlines'A' and 'B' is facingthe router bit. Clamp

workpiecein this position by snuglytightening the wing nut on

clamp rod whilemakingsurethat clamp platestays orientedon

workpieceas shownin Fig.#21. (This will retractguard insidethe

fenceandprovideaccessto the bit for making adjustments.MAKE

SUREROUTERISUNPLUGGEDWHENPOSITIONINGAND

CLAMPINGWORKPIECEAND MAKINGADJUSTMENTS)

NOTE:Tightenwing nut just enoughto clamp workpiece in

position.OVERTIGHTENINGwingnut couldcausebinding in tim

slidingmotion of pushblock,which in turn may resultin variations

andlor stepsin thefinishedtenon surfacewhen cut. SeeFig, #25.

6. Slideworkpiececloseto the bit andadjust unitizedfenceand

therouterasdescribedbefore,sothat outer-most cuttingedgeof

bit is alignedwith line'A' and top cutting edgeof bit is alignedwith

line 'B'. SeeFig,#21.Tightlysecurethefenceandtherouter, as

describedbeforein ADJUSTINGDEPTHANDHEIGHTOFCUT.

7. Slidepushblockandworkpiecebackto let guard swing out to

its normal positionasshown in Fig. #14.

8.Turnrouterand wet/dryvac 'ON'.While holding push biock

GUIDEWORKPIECEAGAINSTFENCEWITHBOTHHANDS(Fig.

#23 & #24) and FINGERSATSAFEDISTANCEABOVEGUARD

ANDSPINNINGBIT.Feedworkpieceacrossthe bit to makeFULL

DEPTHOFCUTtN ONEPASS(DONOTSTOPFEEDUNTIL

WORKPIECEISFARENOUGHBEYONDSPINNINGBITTOALLOW

GUARDTORETRACTOUTFULLYTOITSNORMALPOSITION).

NOTE:Clampand testcut a pieceof scrapwood Io ci:leckyour

adjustmentsbeforemakingyour finishedcut.

9. Turnrouter and wet/dry vac 'OFF'.Unclampworkpieceandslide

pushblockback,

10.Positionand clamptheoppositeskJeofworkpiecein tile same

manneras describedin Step#5 (makesurethe wing nut is tight

just enoughto clamp workpiecein position and end to becut is

restingontheedgeoftabletop hole.} Repeatslops#7. #8,and

#9.

11,Tocut endsof thetenon, positionand clamp workpiecein the

samemanrmrasin step#5 above,exceptedgeof workpiece

shouldbe hetdflush againstfaceof fenceandend to becut

shouldbe restingon edgeof tabletop hole, SeeFig.#24, Repeat

steps#7, #8, #9, and#10.

• " ' " , 3,"8'MAX.DEPTH

f

3,'8"&'lAX.DEPTH

o_-CUr

FIGURE22

HGURE23

EDGE"E"

_ i ¸ i :' ¸¸ ?

#IGURE24

13

Page 14

NOTE:Whencutting tenons,alwaysclamp work[)ic(:_,_,_.Ati,(:ndto

becutrestingon edgeof tabletop hote,1his will inmnuizeste_s m

finishedtenor]surface(Fig.#25) dueto w.triationsin lhe tabletop

flatness,

ALWAYSCUTFULLDEPTHONALL4 SIDES

OFTENONIN ONEPASSACROSSTHE6IT,

ONCETHESIDESARECUTANDIF STEPSOROTHER

IMPERFECTIONSARENOTICEDONFINISHEDTENONSURFACE,

CLEANTHEMWITHWOO0CHISEL,SANDPAPERORFILE,ETC.

DONOTTRYTO CLEANTHEMBY RE-SETTINGWORKPIECEON

ROUTERTABLEAND FENCE,WORKPIECEMAYINTERFERE

WITHGUARD(SEEFIG.#21) WHICHiN TURNWILLPREVENTIT

FROMSLIDINGACROSSTHEBIT.

STEPStNFINISHED

TENONSURFACE

FIGURE25

OPERATION

ROUTINGUSINGBACKSIDEOF

UNITIZEDFENCE

USEBACKSIDEOFFENCEONLYFORROUTINGOPERATIONS

AWAYFROMEDGEONTHEUNDERSIDEOFWORKPIECE,SUCH

AS GROOVING,FLUTING,VEINING,CROWNMOLDING,ETC,

ALWAYSUNPLUGTHEROUTERBEFOREMAKINGANYSETTING,

ADJUSTMENTS,ORCHANGINGBITS.

WHENROUTING,ALWAYSFEEDAGAINSTTHEROTATIONOF

THECUTi'ER.FEEDWORKPtECEINTHE DIRECTIONOFARROW

ASSHOWNONLABELONTHESIDEOFFENCEBEINGUSED

(whenfacingthetable front),

DONOTCONNECTWET/DRYVACWHENUSINGBACKSIDEOF

FENCE,THEHOSEWILL HINDEROPERATION.

t. Removebothlargeknobsandk._-20x 1_" lg. hex headbotts,

turn theunitizedfence aroundandattachit backto table with

backsideof fencefacingthetablefront. SeeFig.#26. (MAKE

SUREROUTERISUNPLUGGEDWHENREMOVINGAND

ATTACHINGFENCETOTABLE).

2. Raiseguardandlet it leanagainst,thefence.

3. Positionthefencebehindthe routerbit for the desiredcutting.

depth(thedistanceof the cut from theedgeof the workpiece,as

shown in Fig.#27).

FIGURE26

FIGURE27

14

Page 15

4. S(;cureivllgh!(!nbr}thkn(}b::_andi i)WER ll-fi} f_lJ_&iq_:_,_');.;_:t:_

THEBIT

5. Make,die cut fly sli(lmg,shai[,hi _,,_I!j-;_'o! wo_kpiecea:lamStt!]e

fence.(For eachsucc_ssve cut, thefencewould needto bc

readjtJsted.)

NOTE:Testcol a pieceof scrapwood before makingyotir finish(!d

cut. Feedworkpiecein the directiond arrow shownon _er_c__,label

(Fig.//28).

NOTE:Whenrouting deepcuts(conboiled byrouter bit) in a

workpie(,e,removematerialin incrementsto preventyour router

from overloading.Repeatoperationwith severalpassesuntil the

desireddepth isachieved.

F!GLIR_28

PROTRACTOR

Yourprotractorwillserveasa !landyaidwhenextrasupportis

neededfor routingsmallworkpiecesorendsoi'largeworkpiec:e,s.

SeeFig.#29.

NOTE:FORALL ROUTINGOPERATIONSREQUIRINGUSI!:OF

MITERGAUGEALONGWITHTHEFENCE.BESURETOALIGN

FENCEwrrH MITERBARSLOTBEFOREMAKINGANYCU]S

SEEFIG.#14,

FIGURE29

NOTES

15

Page 16

PARTSLISTFORCRAFTSMANROUTERTABLE

! -_ 4t _'_.._ ..... 36

Key

No. PartNO,

! 31L-431

2 29LCN-985

3 F29A*306-41

4 F29A-489-10

5 F29A-242-2

6 2gLeN-967

7 29L-183

8 29LCN-966

9 F29A-310-20

tO F29L-469-21

I1 F29L-242-15

t2 29L-293

13 31L-560

14 29L-202

15 29LDo841-4

16 29A-509-1

17 29A-306-37

18 29L-645

19 29L-650

20 29L-647

2_ ...... 2__:6_9._....... AAdjustableFence

t

,/

J

14 39

/

/

/

29

Description Quan,

CastRouterTableTop 1

TableLeg_ 4

Y_"O.D.x ?d'!O, x/,_" FiatWasher 3

Hex.Hd, Bolt ¼-2(Yx I:Y,' 2

#10-32Hex.Hd,MachineScrewNut 16

Miter Pointer 1

GroovedPinY¢ dia,x _"_LL_

Miter Bar 1

#!0-24 X ¾"Lg_CarnageBolt t

#4-40x ¾"Lfl, PanHd.MachineScrew !

#4-40Hex.Hd.MachineScrewNut 1

ProtractorHead ' 1

Knob 1

PlasticInsert 5

#!0-32 x _" FlatC'SunkHd. Machine 3

Screwwith Phil. Recess

#10LockWasher 16

_" O,D.x _" I.O.FlatWasher 1

UnitizedFence I

Guard(Red) 1

Guard(Small) 1

Key

No,

22

23

24

25

26

27

28

29

MODELNO.25481

5.I .3_ 3,t7.28.31 lb

'_,_-h ' {t[Lt&WaIIIiMB

25,4 29

27 40

t6

-';'i;'_ 30

J [ " :__

Parl No. Oescrtlltlon Quan.

29L-648 PushBlock 1

29L-65t Ct_m£Rod 1

29L-652 C]am_Plate t

F29A-246-20 Hex.Hd.CaPScrew¼- 20 x 1" Lg, 1

29L-654 Spring 1

F29A-252-16 Wing.Nut _" - ! 8 ....... 1

F29A-306-40 W' FlatWasher 1

F29A-970-5 #10-32x 1/2" Lg.TrussHd. Machine t6

Screwwith Phi!.Recess

30 F29A-327-5 _"-LockWasher(He!ica!) 1

31 F29A-306-26 #8 FlatWasher¾_"IO. x _" 0.0. 1

32 F29A-653 #8-10x _" Lg. PlasformScrew 1

33 29L-660 Knob£Lar__ 2

34 29L-659 Knob 1

35 45A-382 Label(Fence) 1

36 29L-655 VacuumHoseReducer 1

37 F29A-242-16 _4-28HexNut 1

38 29L-610 TableExtensions 2

39 45A-383 Label(Table_]. 1

40 29A-491*2 Y,"Palnut !

41 45A-292 Label6___.uard__ 1

49LCN-59 instructionManual 1

Printed in U.S.A,

11/96

I]1111!11 ........

Whencorresponding,alwaysgivethefollowing informalionasshowninthelist.

1. The PARTNUMBER

2. The PARTDESCRIPTION

3. The MODEL 25481

4. The ITEM NAME-DELUXE ROUTER TABLE

16

Loading...

Loading...