Page 1

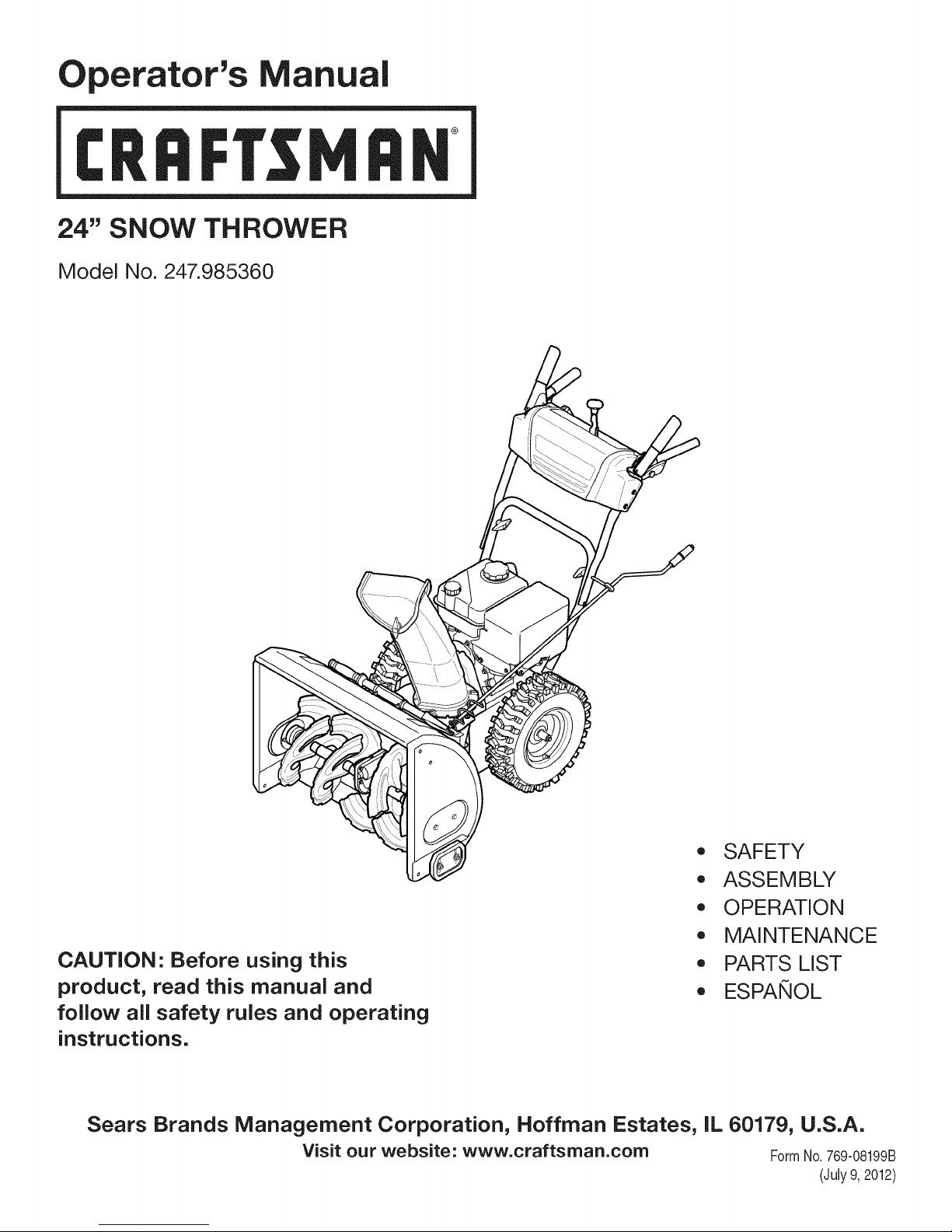

Operator's Manual

CRRFr MRN

24" SNOW THROWER

Model No. 247.985360

CAUTION" Before using this

product, read this manual and

follow all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FormNo.769-08199B

,, SAFETY

o ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

(July9,2012)

Page 2

WarrantyStatement.................... Page2

SafeOperationPractices.............. Pages3-6

Assembly......................... Pages8-11

Operation........................ Pages12-15

Service&Maintenance.............. Pages16-23

Off-SeasonStorage................... Page24

Troubleshooting...................... Page25

PartsList......................... Pages26-43

RepairProtectionAgreement............ Page47

Espadol............................. Page48

CRAFTSMANTWOYEARFULLWARRANTY

FORTWOYEARSfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.Defectiveproductwill

receivefreerepairorfreereplacementifrepairisunavailable.

Forwarrantycoveragedetails to obtain repairor replacement,visit the website: www.craftsman.com

This warranty covers ONLYdefects in materialandworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedto augers,augerpaddles,drift

cutters,skidshoes,shaveplate,shearpins,sparkplug,air cleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tire replacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbyover-speedingthe engine,orfromimpacting

objectsthatbendthe frame,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountofengineoil,or failureto maintaintheequipmentaccordingto theinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfuel determinedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

Normaldeteriorationandwearof theexteriorfinishes,or productlabelreplacement.

Thiswarrantyisvoidif thisproductiseverusedwhileprovidingcommercialservicesorif rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstateto state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineOilType: 5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2 Quarts

SparkPlug: F6RTC(951-10292)

SparkPlugGap: .020"to .030"

©SearsBrands,LLC

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase .............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Page 3

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartofthe operatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionsonthe machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodo socan resultinseriousinjurytothe operatorand/

orbystanders.Keepthismanualin a safeplaceforfutureand

regularreferenceandfororderingreplacementparts.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofagetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitis in operation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseof thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandonthemachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

• Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledin movingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordandreceptacleforall

machineswithelectricstartengines.

Disengageall controlleversbeforestartingthe engine.

Adjustcollectorhousingheighttocleargravelorcrushedrock

surfaces.

• Neverattemptto makeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

Page 4

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite. Washyour skinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuelwhiletheengineishotor

running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto providespaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

machinetoanotherarea.Wait5 minutesbeforestartingthe

engine.

• Neverstorethe machineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlight(e.g.furnace,waterheater,space

heater,clothesdryeretc.).

• Allowmachinetocoolat least5 minutesbeforestoring.

• Neverfill containersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthegroundaway

fromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthe truckor

trailerandrefuelitonthe ground.Ifthisisnot possible,thenrefuel

suchequipmenton a trailerwitha portablecontainer,ratherthan

froma gasolinedispensernozzle.

• Keepthe nozzlein contactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingis complete.Donotuse

a nozzlelock-opendevice.

OPERATION

• Do notputhandsorfeetnear rotatingparts,in the auger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleveris a safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothe disengagedpositionwhenreleased.

• Neveroperatewithamissingordamagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.Do notoperateon steepslopes.

Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

Neverdirectdischargeat children,bystandersand petsorallow

anyoneinfrontof themachine.

Donot overloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingandkeepafirmholdon thehandles.Walk,

neverrun.

Disengagepowerto theauger/impellerwhentransportingor not

in use.

Neveroperatemachineathightransportspeedson slippery

surfaces.Lookdownand behindand usecarewhenbackingup.

Ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgroundit againsttheengine.

Inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperating.

Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

Neverputyourhandinthe dischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineis running.Shutoff

engineand remainbehindhandlesuntilallmovingpartshave

stoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.). Forinformation

concerningtheseitems,call1-800-469-4663.

Whenstartingengine,pullcord slowlyuntilresistanceis felt,then

pull rapidly.Rapidretractionof startercord(kickback)willpull

handandarmtowardenginefasterthanyoucanlet go.Broken

bones,fractures,bruisesorsprainscouldresult.

Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.

Toorderpartsor scheduleserviceforthisproduct,call 1-800-

469-4663.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is themostcommoncauseof injuryassociatedwithsnowthrowers.

Neveruseyourhandto cleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe surethe impellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,not yourhands.

4

Page 5

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonlyaslistedinthe Partspagesof thisoperator's

manual.Useofpartswhichdonot meettheoriginalequipment

specificationsmayleadto improperperformanceandcompro-

misesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertotheadjustment

sectioninthisoperator'smanualfor instructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsand regulationsforgas,oil,etc. to

protecttheenvironment.

Priorto storing,runmachineafew minutestoclearsnowfrom

machineand preventfreezeupof auger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.Attheendof theAverageUsefulLifehavethemachine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodo socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinany way.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonornearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlessthe engine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,itshouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorfor the mufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

. +

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

"JIp

WARNING--THROWN OBJECTS

This machine may pick up and throw objects which can cause serious personal injury.

WARNING--GASOLINE ISFLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas+

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

Page 7

Thispageleftintentionallyblank.

7

Page 8

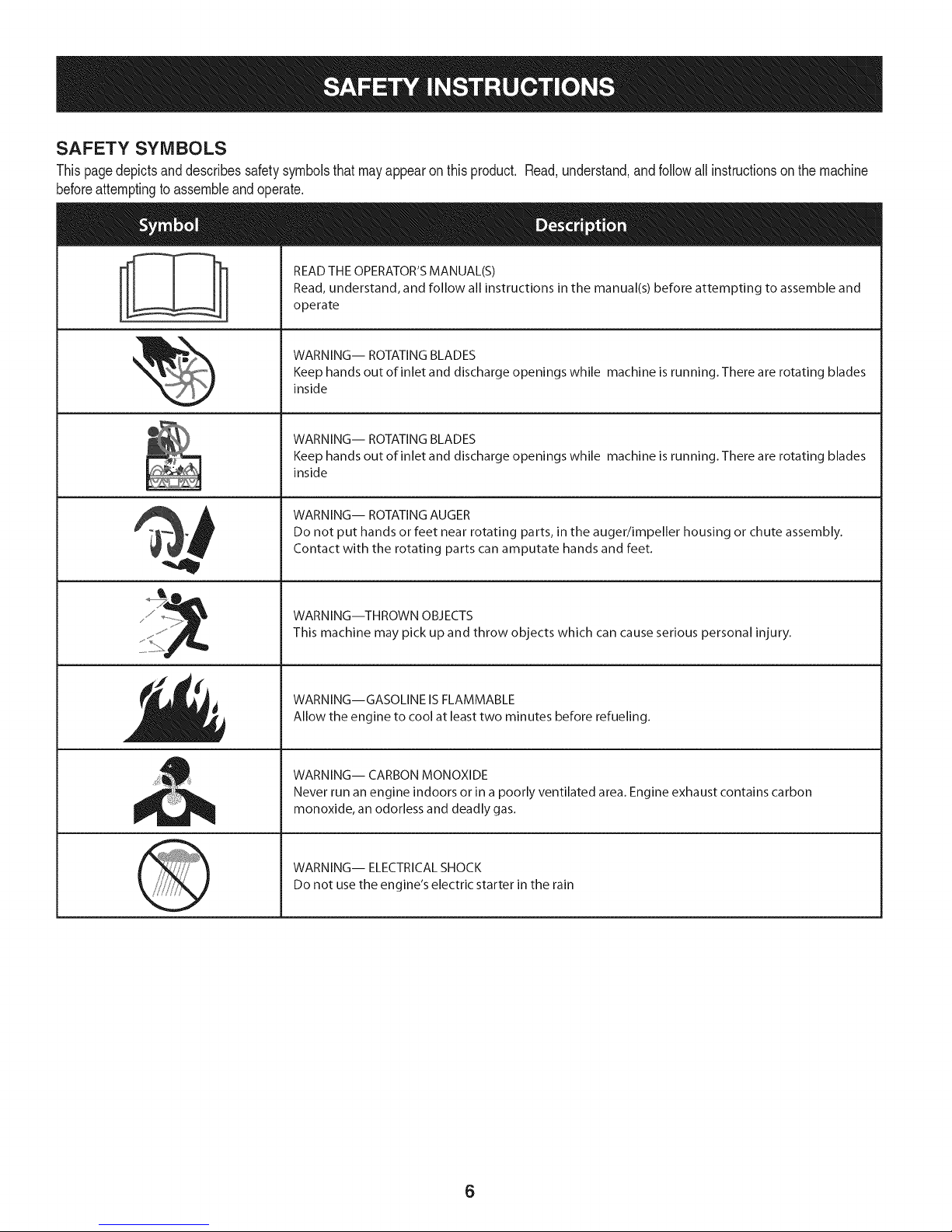

NOTE:Referencesto rightorleft sideofthesnowthrowerare

determinedfrombehindtheunit intheoperatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CARTON

1. Cutthecornersof thecartonandlaythe sidesflaton the ground.

Removeanddiscardallpackinginserts.

2. Movethesnowthrowerout of thecarton.

3. Makecertainthecartonhas beencompletelyemptiedbefore

discardingit.

ASSEMBLY

1. Placethe shiftleverin theForward-6position.

2. Observethe lowerrearareaofthe snowthrowertobesureboth

cablesarealignedwith rollerguidesbeforepivotingthe handle

upward.See Figure1.

NOTE:Makecertainthe upperendsofeachcableare seatedproperly

in itsbracket.

.

Securethehandlebytighteningtheplasticwingknoblocatedon

boththe leftand rightsidesofthe handle.SeeFigure2.Remove

anddiscardanyrubberbands,if present.Theyareforpackaging

purposesonly.

\

Figure1

f

Figure2

8

Page 9

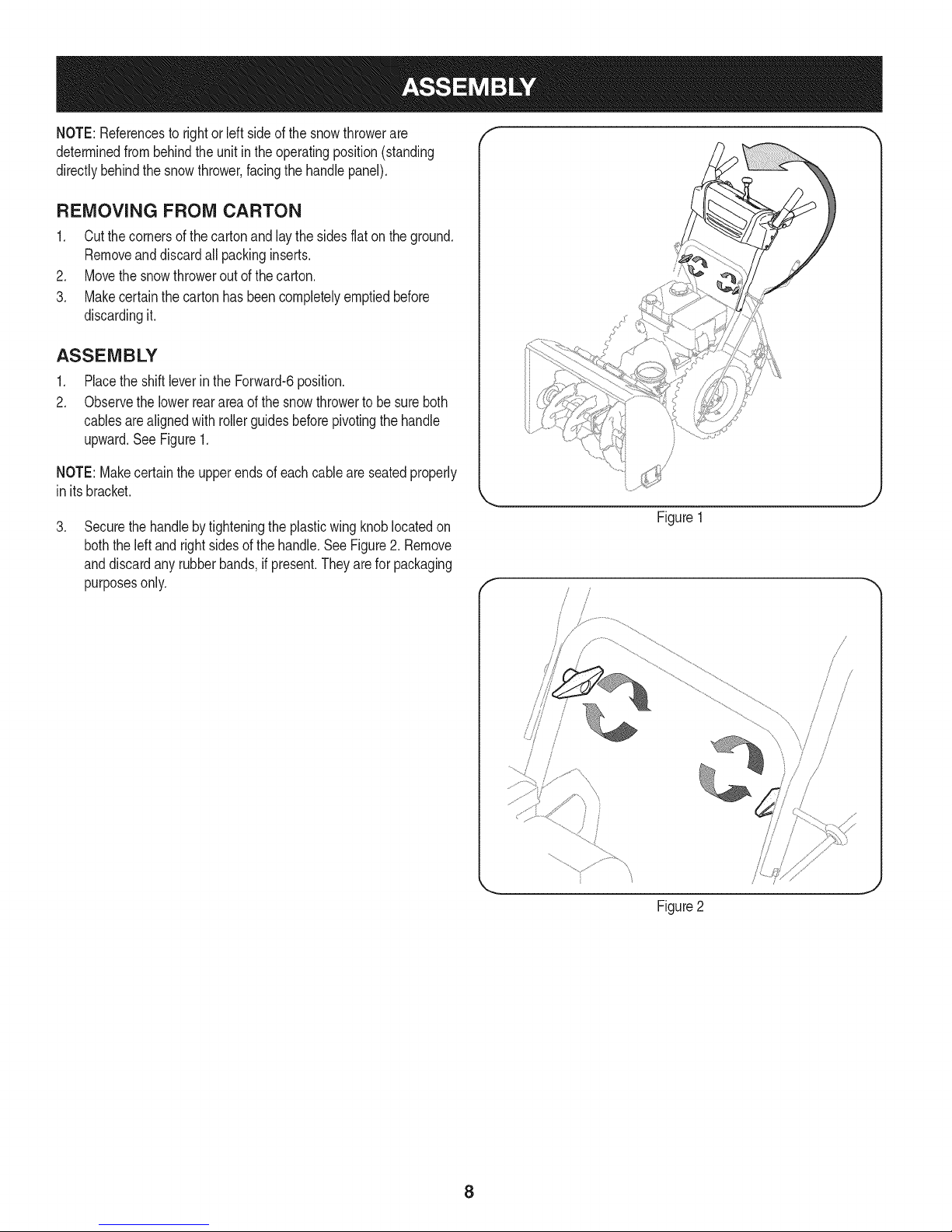

4. Pivotflangekeepersoutand positionthechuteassemblyoverthe

base.SeeFigure3.

5. Closetheflangekeepersto securethechuteassemblytothe

chutebase.SeeFigure4.Theflangekeeperswillclickinto place

whenproperlysecure.

NOTE:Ifthe flangekeeperswillnoteasilyclickintoplace,usethe

palmof yourhandtoapplyswift,firmpressuretothebackof each.

.

Removethecap,flatwasher,andhairpinclip fromtheendof

thechutedirectionalcontrol.

7.

Insertthe endofthechutedirectionalcontrolintothelower

bracketandsecurewiththe flatwasherandhairpinclipjust

removed.See Figure5.If necessary,thelowerbracketcan

beadjusted.Referto ChuteBracketAdjustmentinthe

Service& Maintenancesection.

f F

Figure4

Figure3

\

Figure5

J

9

Page 10

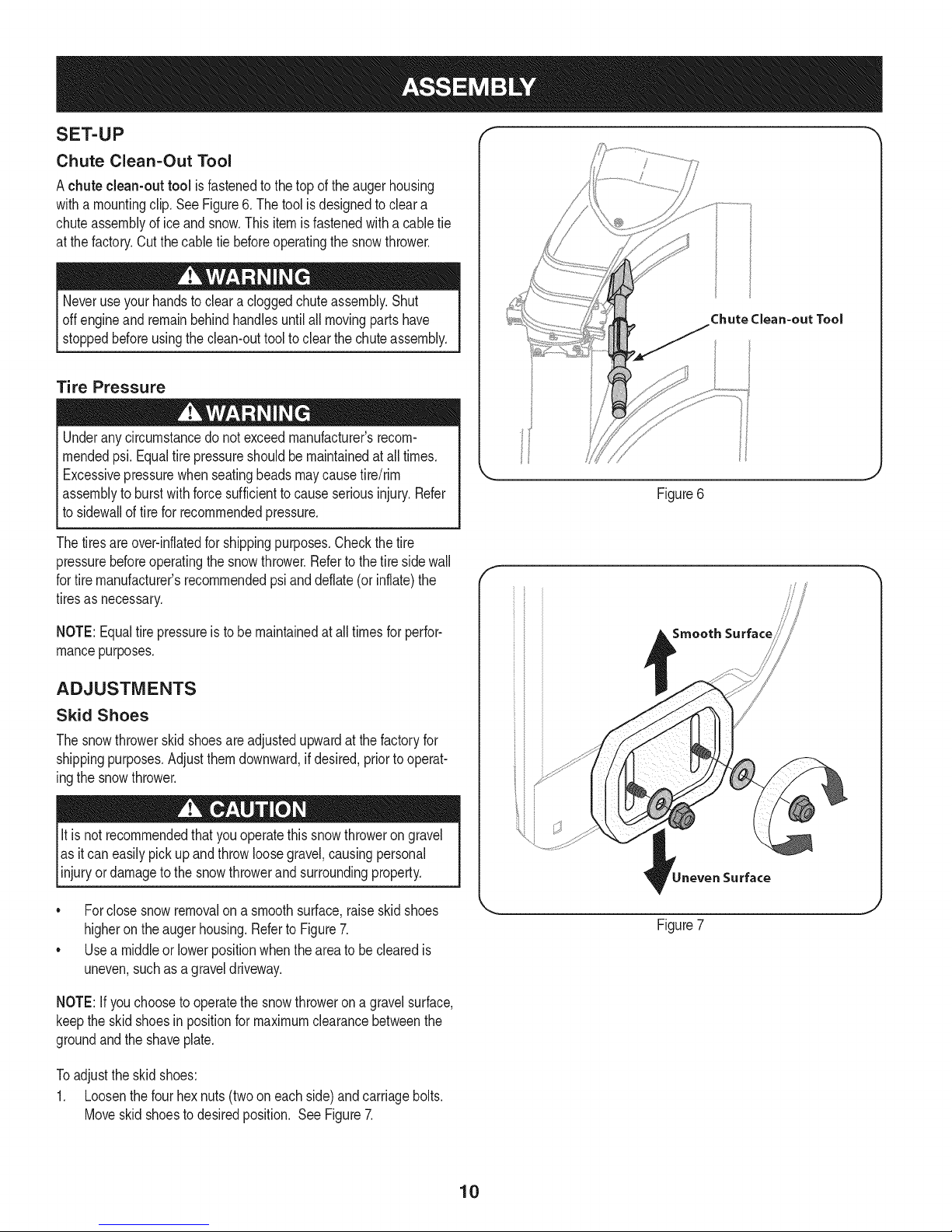

SET-UP

Chute Clean-Out Tool

Achute clean-out tool isfastenedtothe topofthe augerhousing

witha mountingclip.SeeFigure6.The toolisdesignedtocleara

chuteassemblyofice andsnow.Thisitemisfastenedwithacabletie

atthe factory.Cutthecabletiebeforeoperatingthesnowthrower.

Neveruseyour handsto cleara cloggedchuteassembly.Shut

offengineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeusingtheclean-outtooltoclear thechuteassembly.

Tire Pressure

Underanycircumstancedo notexceedmanufacturer'srecom-

mendedpsi.Equaltirepressureshouldbemaintainedat all times.

Excessivepressurewhenseatingbeadsmaycausetire/rim

assemblytoburstwithforcesufficienttocauseseriousinjury.Refer

tosidewallof tirefor recommendedpressure.

Thetiresareover-inflatedforshippingpurposes.Checkthetire

pressurebeforeoperatingthesnowthrower.Referto thetiresidewall

fortiremanufacturer'srecommendedpsianddeflate(orinflate)the

tiresasnecessary.

Chute Clean=out Tool

Figure6

f

NOTE:Equaltire pressureis tobe maintainedat alltimesforperfor-

mancepurposes.

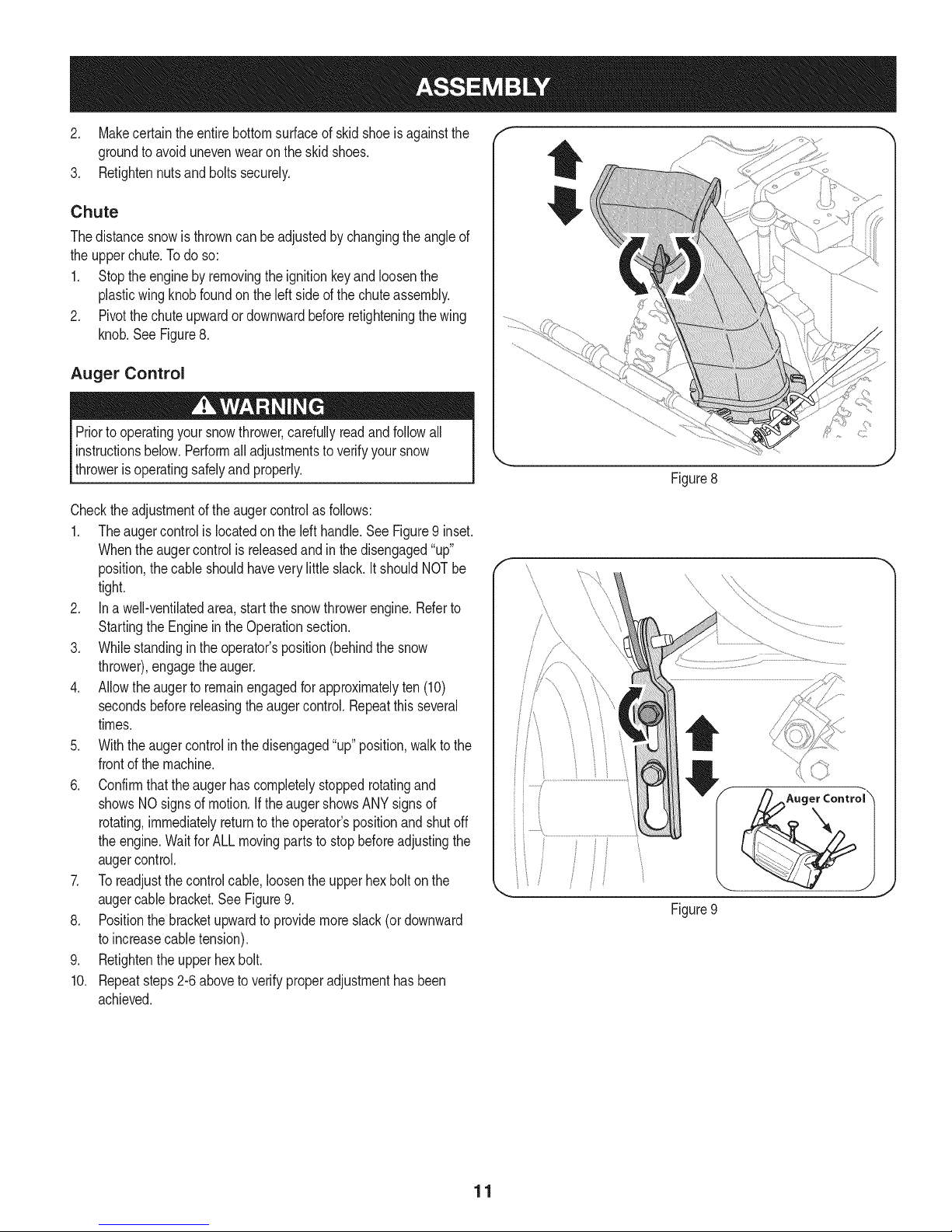

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,ifdesired,priortooperat-

ingthesnowthrower.

It isnotrecommendedthatyouoperatethis snowthrowerongravel

asit caneasilypickup andthrowloosegravel,causingpersonal

njuryordamageto thesnowthrowerandsurroundng property.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.Referto Figure7.

• Usea middleorlowerpositionwhentheareatobe clearedis

uneven,suchasa graveldriveway.

NOTE:If youchooseto operatethesnowthrowerona gravelsurface,

keepthe skidshoesin positionfor maximumclearancebetweenthe

groundandtheshaveplate.

Toadjustthe skidshoes:

1. Loosenthefourhexnuts(twooneachside)andcarriagebolts.

Moveskidshoestodesiredposition. SeeFigure7.

Smooth Surface

Surface

Figure7

10

Page 11

2, Makecertaintheentirebottomsurfaceof skidshoeis againstthe f

groundtoavoidunevenwearontheskidshoes, ....

3. Retightennutsandboltssecurely.

Chute

Thedistancesnowisthrowncan beadjustedbychangingthe angleof

theupperchute.Todo so:

1. Stoptheenginebyremovingthe ignitionkeyandloosenthe

plasticwingknobfoundontheleft sideof thechuteassembly.

2. Pivotthechuteupwardordownwardbeforeretighteningthewing

knob.See Figure8.

Auger Control

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentstoverifyyour snow

throwerisoperatingsafelyandproperly.

Checktheadjustmentoftheaugercontrolas follows:

1. Theaugercontrolislocatedontheleft handle.SeeFigure9 inset.

Whentheaugercontrolis releasedandin thedisengaged"up"

position,thecableshouldhaveverylittleslack.ItshouldNOTbe

tight.

2. Ina well-ventibtedarea,startthe snowthrowerengine.Referto

StartingtheEngineinthe Operationsection.

3. Whilestandinginthe operator'sposition(behindthe snow

thrower),engagethe auger.

4. Allowtheaugertoremainengagedforapproximatelyten (10)

secondsbeforereleasingthe augercontrol.Repeatthisseveral

times.

5. Withtheaugercontrolin thedisengaged"up" position,walktothe

frontofthe machine.

6. Confirmthatthe augerhas completelystoppedrotatingand

showsNOsignsofmotion.If theaugershowsANYsignsof

rotating,immediatelyreturntothe operator'spositionandshutoff

theengine.WaitforALLmovingpartsto stopbeforeadjustingthe

augercontrol.

7. Toreadjustthecontrolcable,loosentheupperhexbolt onthe

augercablebracket.SeeFigure9.

8. Positionthe bracketupwardto providemoreslack(ordownward

toincreasecabletension).

9. Retightentheupperhex bolt.

10. Repeatsteps2-6aboveto verifyproperadjustmenthasbeen

achieved.

\

ii

Figure8

Figure9

11

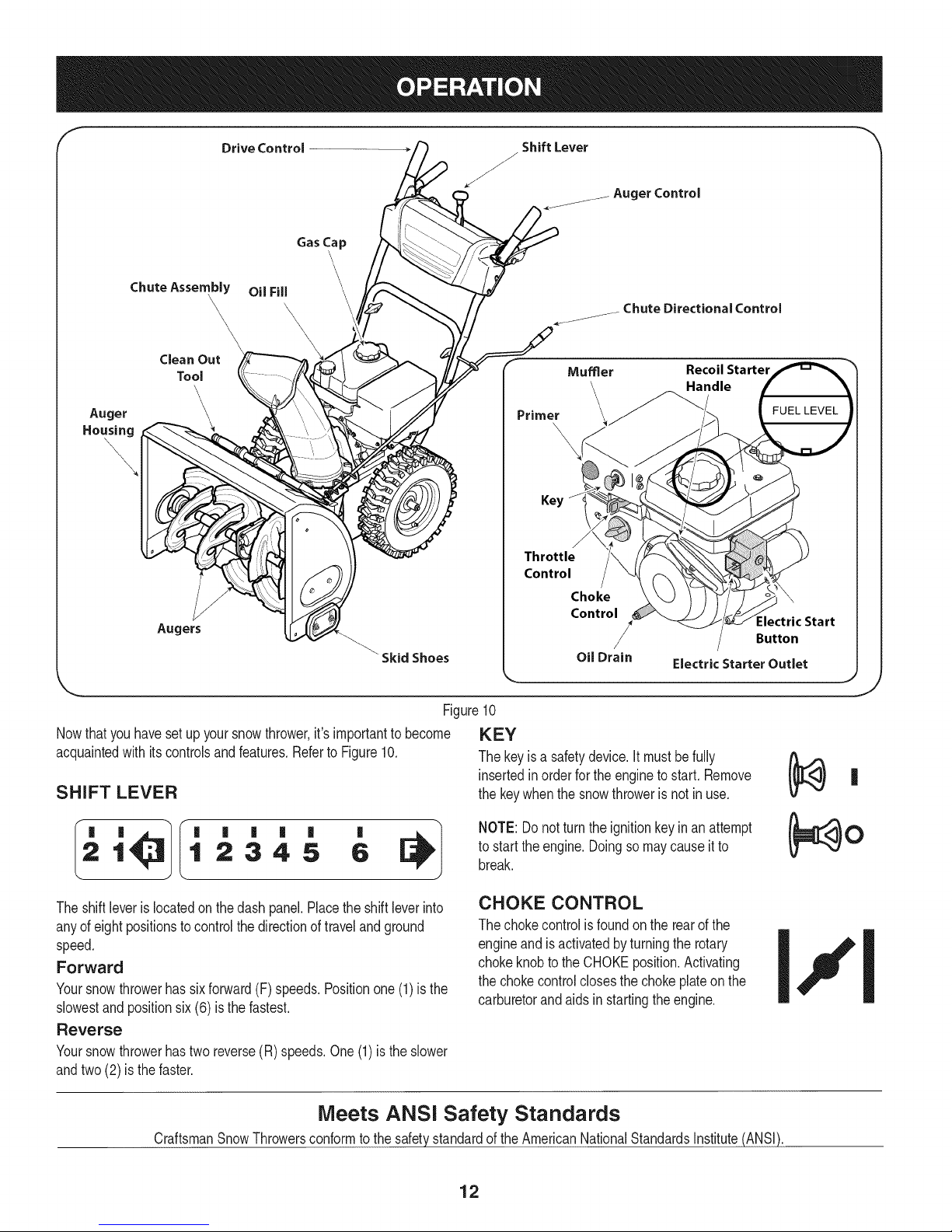

Page 12

f

Drive Control

Gas Cap

\

Shift Lever

J

Auger Control

ChuteAssembly

Auger

Housing

\,

OilFill

\\\\

\\

\

_jjjj Chute Directional Control

Mumer RecoilStarter

ndle

\

\

\

Key

Augers

Skid Shoes

Figure10

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome KEY

acquaintedwith itscontrolsandfeatures,RefertoFigure10, Thekeyisa safetydevice.It mustbefully

insertedinorderforthe enginetostart, Remove

SHIFT LEVER thekeywhenthesnowthroweris notin use,

J

1 2345 6

Theshiftleveris locatedonthedashpanel.Placetheshiftleverinto

anyof eightpositionstocontrolthedirectionoftravelandground

speed.

Forward

Yoursnowthrowerhassixforward(F) speeds.Positionone(1)is the

slowestandpositionsix(6) isthefastest.

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)is theslower

andtwo(2) isthefaster.

Meets ANSi Safety Standards

CraftsmanSnowThrowersconformtothe safetystandardof theAmericanNationalStandardsInstitute(ANSI).

'

NOTE:Donotturntheignitionkeyinan attempt

to startthe engine,Doingsomaycauseitto

break.

CHOKE CONTROL

Thechokecontrolis foundontherearof the

engineand isactivatedbyturningthe rotary

chokeknobto theCHOKEposition.Activating

thechokecontrolclosesthechokeplateon the

carburetorandaidsinstartingtheengine.

12

Page 13

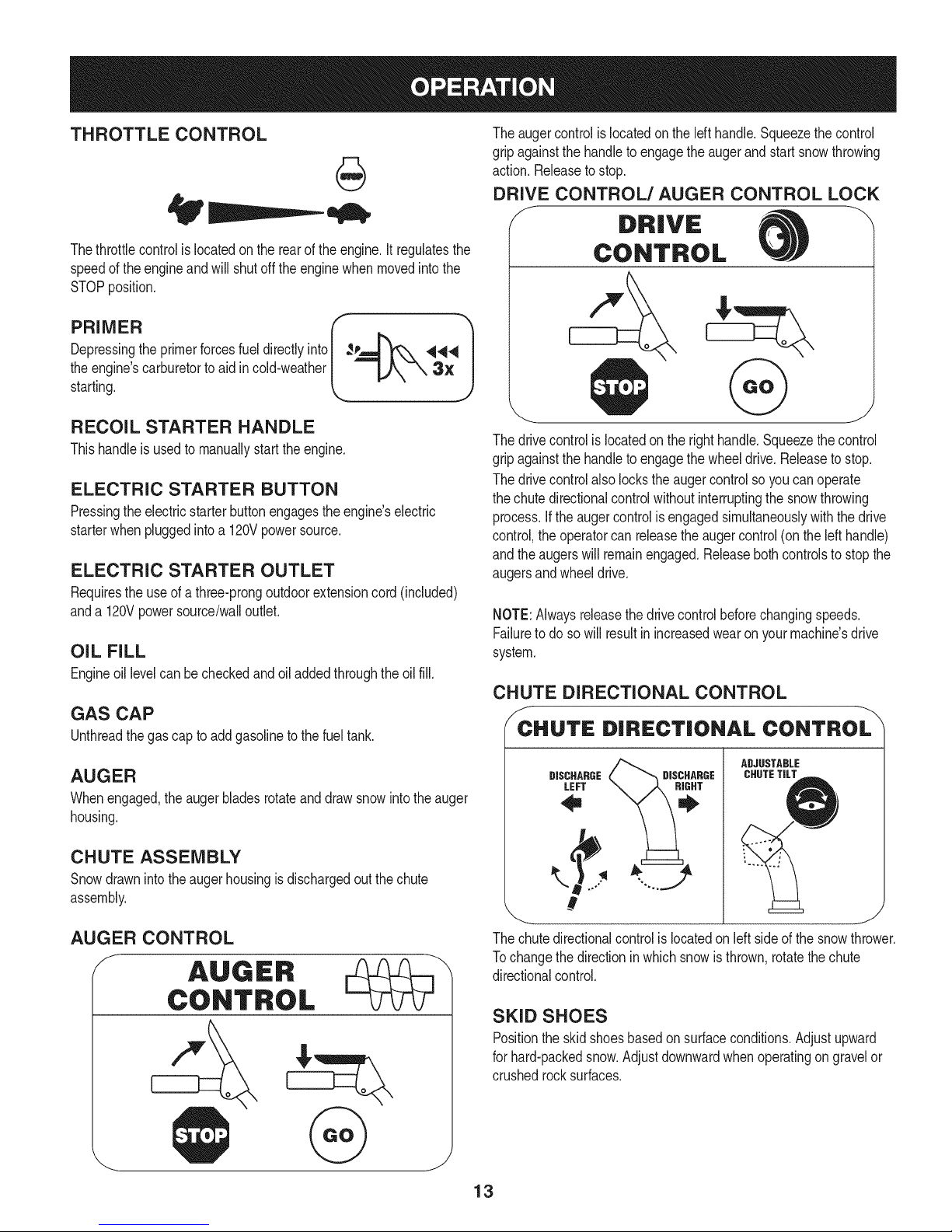

THROTTLE CONTROL

aiW'

Theaugercontrolis locatedon thelefthandle.Squeezethe control

gripagainstthehandleto engagetheaugerand startsnowthrowing

action.Releaseto stop.

DRIVE CONTROL/AUGER CONTROL LOCK

J DRIVE

Thethrottlecontrolis locatedon the rearoftheengine.It regulatesthe

speedof theengineandwillshutoff the enginewhenmovedintothe

STOPposition.

Depressingthe primerforcesfueldirectlyinto ___144

theengine'scarburet°rt° aid inc°'dweather k _"_'-_ 3" Jstarting.

RECOIL STARTER HANDLE

Thishandleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

OIL FILL

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

GAS CAP

Unthreadthegascap toaddgasolinetothefuel tank.

AUGER

Whenengaged,theaugerbladesrotateanddrawsnowintothe auger

housing.

r 1

CONTROL

Thedrivecontrolis locatedon the righthandle.Squeezethecontrol

gripagainstthehandleto engagethewheeldrive.Releasetostop.

Thedrivecontrolalsolockstheaugercontrolso youcanoperate

thechutedirectionalcontrolwithoutinterruptingthesnowthrowing

process.If the augercontrolisengagedsimultaneouslywiththedrive

control,the operatorcanreleasetheaugercontrol(onthe lefthandle)

andtheaugerswillremainengaged.Releaseboth controlstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failureto doso willresultinincreasedwearon yourmachine'sdrive

system.

CHUTE DIRECTIONAL CONTROL

/_CCHUTE DIRECTIONAL CONTROL

ADJUSTABLE

DISCHARGE DISCHARGE

LEFT

CHUTETILT

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedoutthechute

assembly.

AUGER CONTROL

,....

#

_ J

The chute directional control is located on left side of the snow thrower.

Tochange the direction inwhich snow is thrown, rotate the chute

directionalcontrol.

SKID SHOES

Positiontheskidshoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingon gravelor

crushedrocksurfaces.

13

Page 14

CLEAN-OUT TOOL

Neveruseyourhandstocleara cloggedchuteassembly.Shut

off engineandremainbehindhandlesuntilall movingpartshave

stoppedbeforeusingtheclean-outtooltoclear thechuteassembly.

Thechuteclean-outtoolisconvenientlyfastenedtothe rearofthe

augerhousingwitha mountingclip. Shouldsnowandice become

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. Releaseboththe AugerControlandthe DriveControl.

2. Stopthe engineby removingthe ignitionkey.

3. Removetheclean-outtoolfromtheclip whichsecuresittothe

rearofthe augerhousing.

4. Usetheshovel-shapedendof theclean-outtool to dislodgeand

scoopanysnowand icewhichhasformedin andnearthechute

assembly.

5. Refastenthe clean-outtool tothemountingclipontherearof the

augerhousing,reinserttheignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandinginthe operator'sposition(behindthesnow

thrower),engagethe augercontrolforafewsecondstoclearany

remainingsnowandice fromthechuteassembly.

BEFORE STARTING ENGINE

Read,understand,andfollowall instructionsandwarningsonthe

machineand inthismanualbeforeoperating.

Oil

Theunit wasshippedwith oil inthe engine.Checkoillevelbefore

eachoperationtoensureadequateoilinthe engine.Forfurther

instructions,refertothe stepsonpage16.

NOTE:Besuretochecktheengineon a levelsurfacewiththeengine

stopped.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. insertthecap/dipstickintotheoilfillerneck,butdo NOTscrewit

in.

3. Removetheoil fillercap/dipstick,ifthe levelislow,slowlyadd

oil (5%30, witha minimumclassificationof SF/SG)untiloillevel

registersbetweenhigh(H) andlow(L).

NOTE:Do notoverfill.Overfillingwithoil mayresultinenginesmoking,

hardstartingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Gasoline

Useautomotivegasoline(unleadedor lowleadedto minimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureor dirtygasoline.Avoidgetting

dirt,dust,or waterinthefuel tank.DONOTuse E85gasoline.

• Refuelina well-ventilatedareawiththe enginestopped.Donot

smokeorallowflamesor sparksinthe areawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthefueltank.After refueling,makesurethetank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuelvapor

mayignite,ifanyfuelisspilled,makesuretheareaisdrybefore

startingthe engine.

• Avoidrepeatedorprolongedcontactwithskinor breathingof

)or.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuelthemachine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

1. Cleanaroundfuelfillbeforeremovingcap to fuel.

2. A fuel levelindicatorislocatedinthefueltank. SeeFigure10

inset.Becarefulnottooverfill.Filltank untilfuel reachesthe fuel

levelindicatortoallowspacefor fuel expansion.

STARTING THE ENGINE

Alwayskeephandsandfeetclearof movingparts.Donot usea

pressurizedstartingfluid.Vaporsareflammable.

NOTE:Allowtheengineto warmupfora fewminutesafter starting.

Theenginewill notdevelopfull poweruntilit reachesoperating

temperatures.

1. Makecertainboththe augercontrolanddrivecontrolareinthe

disengaged(released)position.

2. insertkeyintoslot. Makesureitsnapsintoplace.Donotattempt

toturn thekey.

NOTE:Theenginecannotstartwithoutthekeyfullyinsertedintothe

ignitionswitch.

Electric Starter

Theoptionalelectricstarterisequippedwitha groundedthree-wire

powercordand plug,andisdesignedtooperateon120voltAC

householdcurrent.Itmustbe usedwithaproperlygroundedthree-

prongreceptacleat all timestoavoidthepossibilityofelectricshock.

Followall instructionscarefullypriorto operatingtheelectricstarter.

DONOTuseelectricstarterinthe rain.

Determinethatyourhome'swiringisa three-wiregroundedsystem.

Aska licensedelectricianifyouarenotcertain.

Ifyou haveagroundedthree-prongreceptacle,proceedasfollows.

Ifyou donothavethe properhousewiring,DONOTusetheelectric

starterunderanyconditions.

1. Plugtheextensioncord intotheoutletlocatedon theengine's

surface.Plugtheotherendof extensioncord intoa three-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

14

Page 15

2. Movethrottlecontrolto FAST(rabbit)_T position.

3. Movechoketothe CHOKEIJl position(coldenginestart).If

engineiswarm,placechokein RUNposition.

4. Pushprimerthree(3)times,makingsuretocoverventholein

primerbulbwhen pushing.If engineiswarm,pushprimeronly

once.Alwayscoverventholewhenpushing.Coolweathermay

requireprimingtobe repeated.

5. Pushstarterbuttontostart engine.Oncetheenginestarts,im-

mediatelyreleasestarterbutton.Electricstarterisequippedwith

thermaloverloadprotection;systemwilltemporarilyshut-downto

allowstartertocool ifelectricstarterbecomesoverloaded.

6. Astheenginewarms,slowlyrotatethechokecontrolto RUN

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfora shortperiodoftime,andthenslowly

rotatethechokeinto RUNposition.

7. Afterengineisrunning,disconnectpowercordfromelectric

starter.Whendisconnecting,alwaysunplugtheendatthewall

outletbeforeunpluggingtheoppositeendfromtheengine.

Recoil Starter

Donotpullthestarterhandlewhilethe enginerunning.

1. Movethrottlecontrolto FAST(rabbit)_J_ position.

2. Movechoketothe CHOKEI,'_¢1position(coldenginestart).If

engineiswarm,placechokein RUNposition.

3. Pushprimerthree(3)times,makingsuretocoverventholewhen

pushing.Ifengineiswarm,pushprimeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingtobe

repeated.

4. Pullgentlyonthe starterhandleuntilitbeginstoresist,then

pullquicklyandforcefullytoovercomethe compression.Do

notreleasethehandleandallowitto snapback.Returnrope

SLOWLYto originalposition.Ifrequired,repeatthisstep.

5. Astheenginewarms,slowlyrotatethechokecontrolto RUN

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfora shortperiodoftime,andthenslowly

rotatethechokeinto RUNposition.

TO ENGAGE DRIVE

1. Withthethrottlecontrolinthe Fast(rabbit) '_ position,move

shiftleverintooneof thesix forward(F)positionsortwo reverse

(R)positions.Selectaspeedappropriatefor thesnowconditions

anda paceyou'recomfortablewith.

NOTE:When selectinga DriveSpeed,usethe slowerspeedsuntil

youarecomfortableandfamiliarwiththe operationofthesnow

thrower.

2. Squeezethedrivecontrolagainstthehandleandthe snow

throwerwillmove.Releaseitanddrivemotionwillstop.

NOTE:NEVERrepositionthe shiftlever(changespeedsordirection

oftravel)withoutfirstreleasingthedrivecontrolandbringingthesnow

throwertoa completestop.Doingsowill resultin prematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGER

1. Toengagetheaugerand startthrowingsnow,squeezethe auger

controlagainsttheleft handle.Releasetostoptheauger.

REPLACING SHEAR PINS

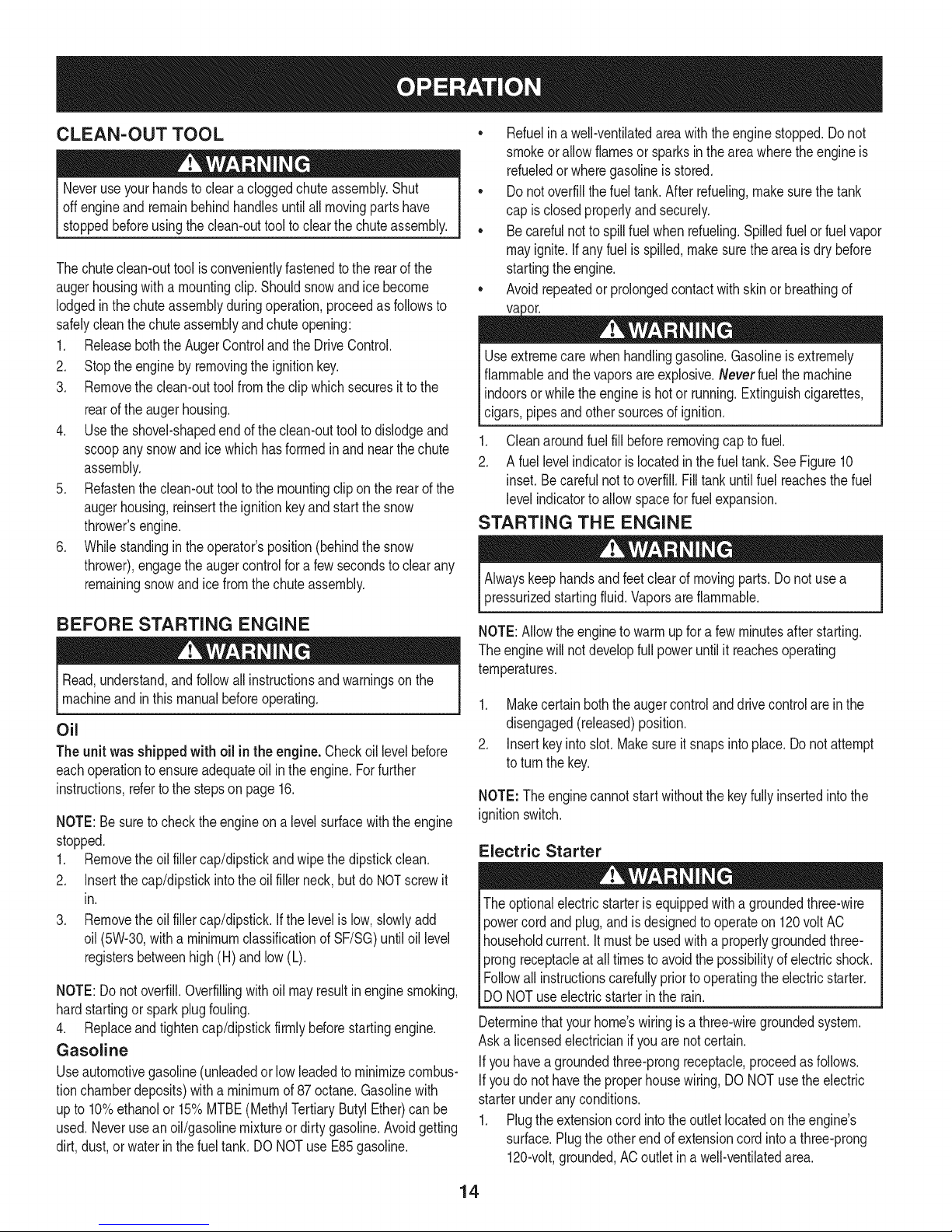

Eachaugerbladeis securedto thespiralshaftwitha shearpinand

bow-tieclip. Ifanaugerbladestrikesa foreignobjector icejam,the

pinwillshearoff topreventdamagetotheblade.Ifanaugerblade

doesnotturn,checkto seeifits pinhasshearedoff.SeeFigure11.

NEVERreplacethe augershearpinswithanythingotherthanSears

SKU#88389/0EMPart No.738-04124Areplacementshearpins.

Anydamagetothe augergearboxorothercomponentsas a resultof

[fa ngto dosow NOTbe coveredbyyoursnowthrowerswarranty.

Alwaysturnoff thesnowthrower'sengineandremovethekeypriorto

replacingshearpins.

Toavoid unsupervisedengineoperation,neverleavethemachine

unattendedwiththeenginerunning.Turnthe engineoffafteruseand

removekey.

STOPPING THE ENGINE

Afteryouhavefinishedsnow-throwing,runenginefora few minutes

beforestoppingtohelpdryoffany moistureontheengine.

1. MovethrottlecontroltoOFFposition.

2. Removethekey.Removingthe keywillreducethepossibilityof

unauthorizedstartingoftheenginewhileequipmentisnotin use.

Keepthekeyina safeplace.Theenginecannotstart withoutthe

key.

3. Wipeanymoistureawayfromthecontrolson theengine.

15

iJ

Figure11

s ¸......

Page 16

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

EachUseandevery5

hours

1st5 hours

Annuallyor25 hours

Annuallyor50 hours

Annuallyor100hours

BeforeStorage

1. Engineoil level

2. Looseor missinghardware

3. Unitand engine.

1. Engineoil

1. Sparkplug

2. Controllinkagesandpivots

3. Wheels

4. GearshaftandAugershaft

1. Engineoil

1. Sparkplug

1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Check

2. Lubewithlightoil

3. Lubewithmultipurposeautogrease

4. Lubewithlightoil

1. Change

1. Change

1. Runengineuntilit stopsfromlack

ENGINE MAINTENANCE

Checking Engine Oil

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrackof

completedmaintenancetasks.Tolocate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

offuel

f

Beforelubricating,repairing,or inspecting,disengageallcontrols

Iandstopengine.Waituntilall movingpartshavecometo a complete

_stop.

NOTE: Checktheoil levelbeforeeachuseto besurecorrectoil level

ismaintained.

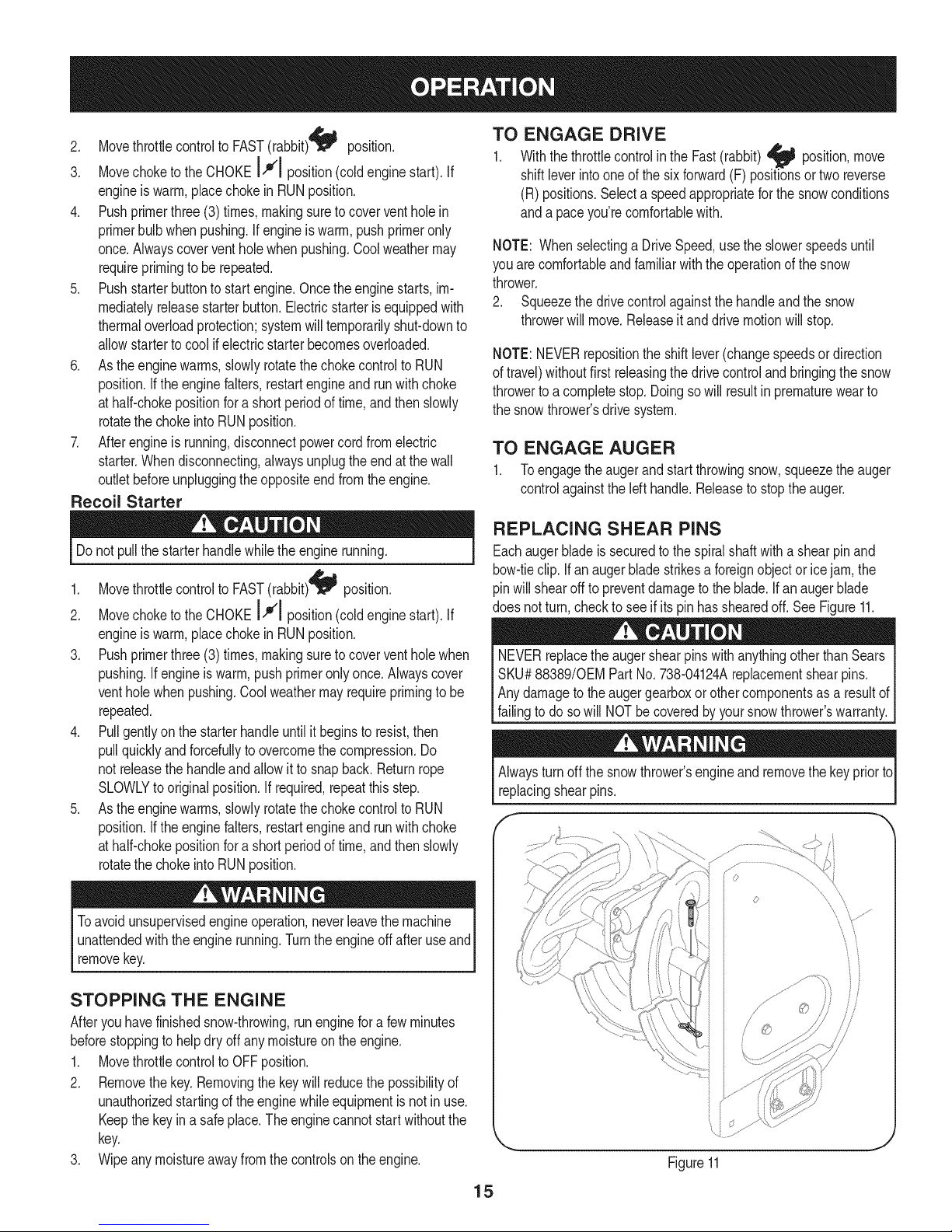

Whenaddingoilto theengine,referto viscositychart below.Engine

oilcapacityis 600ml(approx.20oz.). Donotover-fill.Usea4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG, SRMotoroilsclassifiedSG, SFwillshow

thisdesignationonthecontainer.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. Insertthe cap/dipstickintotheoilfiller neck,butdo NOTscrewit

in.

3. Removetheoil fillercap/dipstick.Iflevelis low,slowlyaddoiluntil

oil levelregistersbetweenhigh(H) andlow(L).SeeFigure12.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Changing Engine Oil

NOTE:Changetheengineoilafterthe first5 hoursof operationand

oncea seasonorevery50 hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthefuel tankisempty.

Besurefuel fillcapis secure.

1 •

_i!_!iiii_ii!i!jili iiiI iiiii_H

marks

Figure12

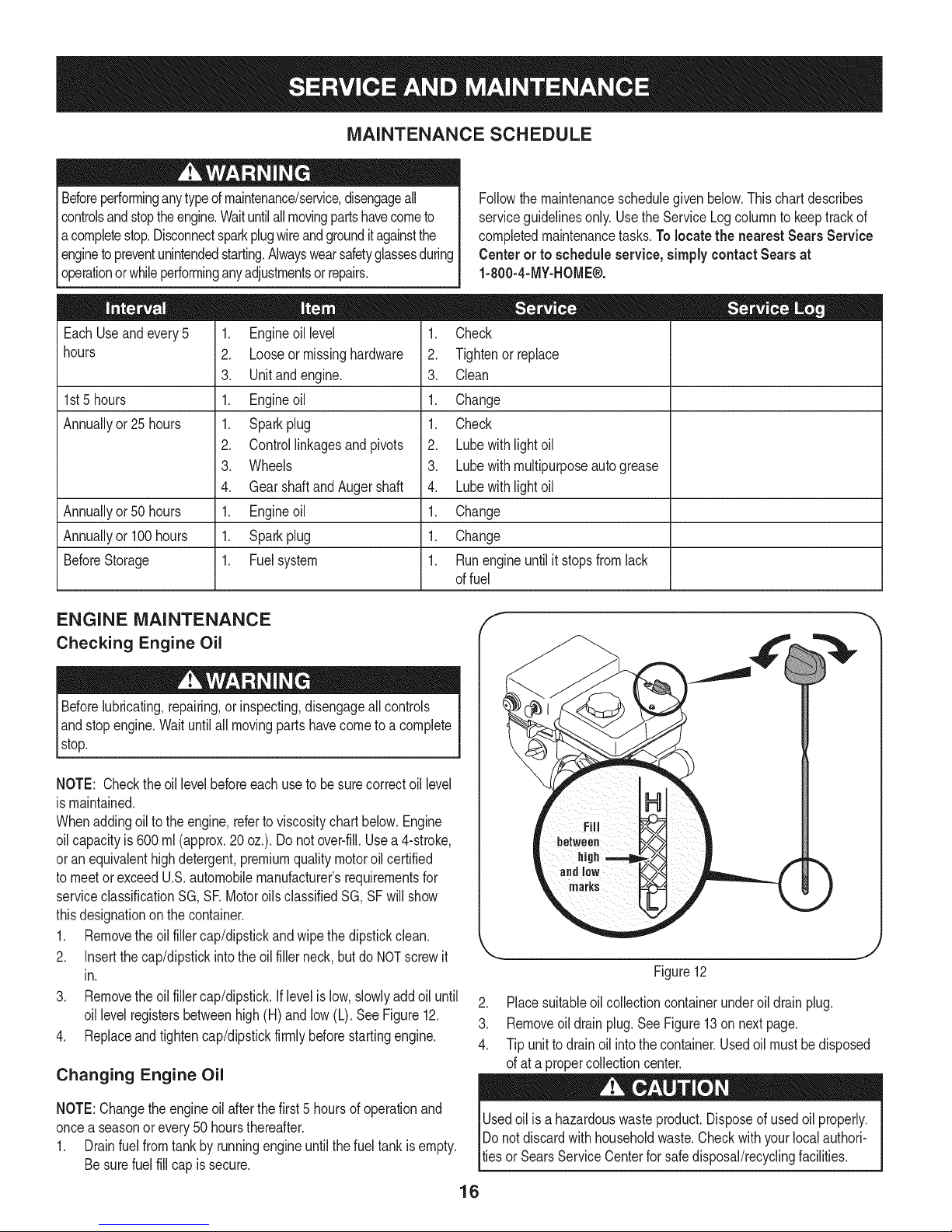

2. Placesuitableoilcollectioncontainerunderoil drainplug.

3. Removeoil drainplug.SeeFigure13on nextpage.

4. Tipunitto drainoil intothecontainer.Usedoilmustbedisposed

ofat a propercollectioncenter.

Usedoil isahazardouswasteproduct.Disposeofusedoil properly.

IDo notdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

lties or SearsServiceCenterfor safedisposal/recyclingfacilities.

16

Page 17

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththerecommendedoil andchecktheoil level.See

RecommendedOil Usagechart.Theengine'soil capacityis20

ounces.

(%-400 -200 0o 200 400

("c) -300 -200 -10° 0°

DONOTuse nondetergentoilor 2-strokeengineoil.Itcould shorten

theengine'sservicelife.

Oil Drain

Plug

7. Reinstalltheoilfillercap/dipsticksecurely.

afterhandling usedoil.

Checking Spark Plug

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplugremoved.

Iftheenginehasbeenrunning,themufflerwillbevery hot.Becareful

notto touchthemuffler.

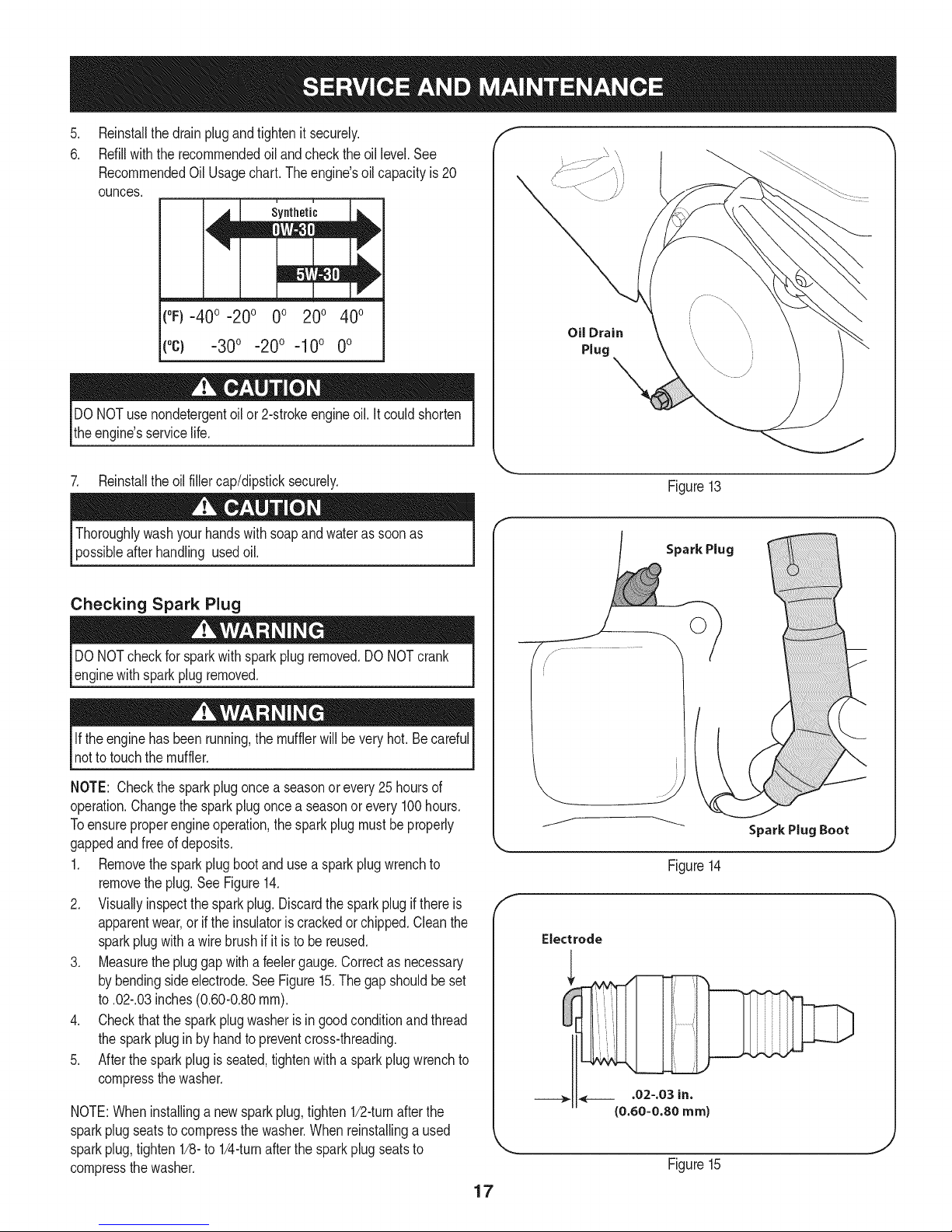

NOTE: Checkthe sparkplugonceaseasonorevery25hoursof

operation.Changethesparkplugoncea seasonor every100hours.

Toensureproperengineoperation,the sparkplugmustbeproperly

gappedandfreeof deposits.

1. Removethesparkplugbootandusea sparkplugwrenchto

removetheplug.See Figure14.

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereis

apparentwear,orif the insulatoris crackedor chipped.Cleanthe

sparkplugwitha wirebrushifitis to be reused.

3. Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure15.Thegapshouldbeset

to.02-.03inches(0.60-0.80ram).

4. Checkthatthe sparkplugwasheris ingoodconditionandthread

thesparkplugin byhandto preventcross-threading.

5. Afterthesparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatsto compressthe washer.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthesparkplugseatsto

compressthewasher.

Figure13

Spark Plug

O

J

Figure14

Electrode

.02-.03 in.

{0.60-0.80 ram)

Figure15

17

Page 18

become hotandcan inc.

LUBRICATION

Gear Shaft

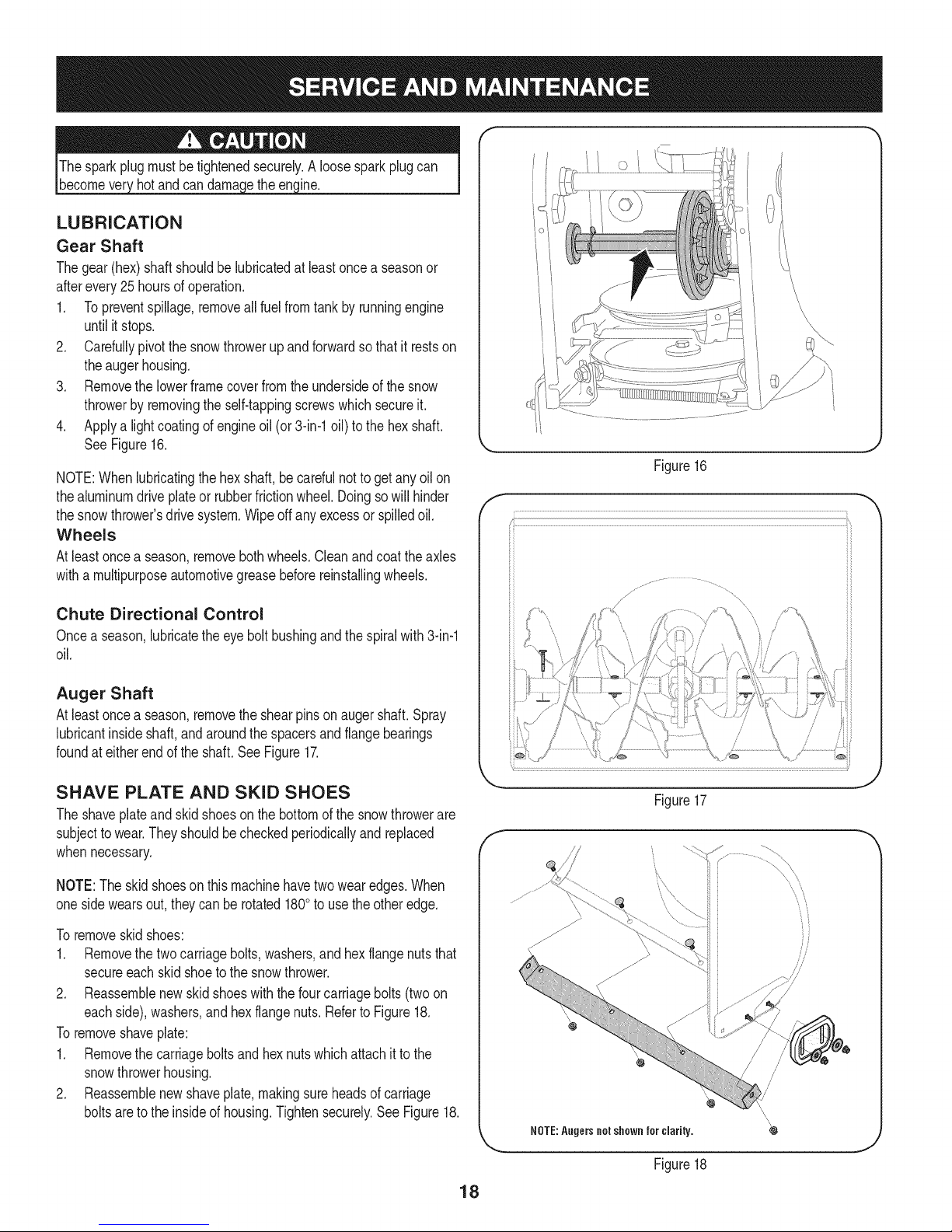

Thegear(hex)shaftshouldbe lubricatedat leastonceaseasonor

afterevery25 hoursofoperation.

1. Topreventspillage,removeallfuel fromtank byrunningengine

untilit stops.

2. Carefullypivotthesnowthrowerupandforwardsothat itrestson

theaugerhousing.

3. Removethe lowerframecoverfromthe undersideofthesnow

throwerbyremovingthe self-tappingscrewswhichsecureit.

4. Applya lightcoatingofengineoil (or3-in-1oil) tothe hexshaft.

SeeFigure16.

NOTE:Whenlubricatingthehexshaft,be carefulnotto getanyoilon

thealuminumdriveplateor rubberfrictionwheel.Doingsowill hinder

thesnowthrower'sdrive system.Wipeoffanyexcessorspilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

Chute Directional Control

Oncea season,lubricatethe eyeboltbushingand thespiralwith3-in-1

oil.

Figure16

f

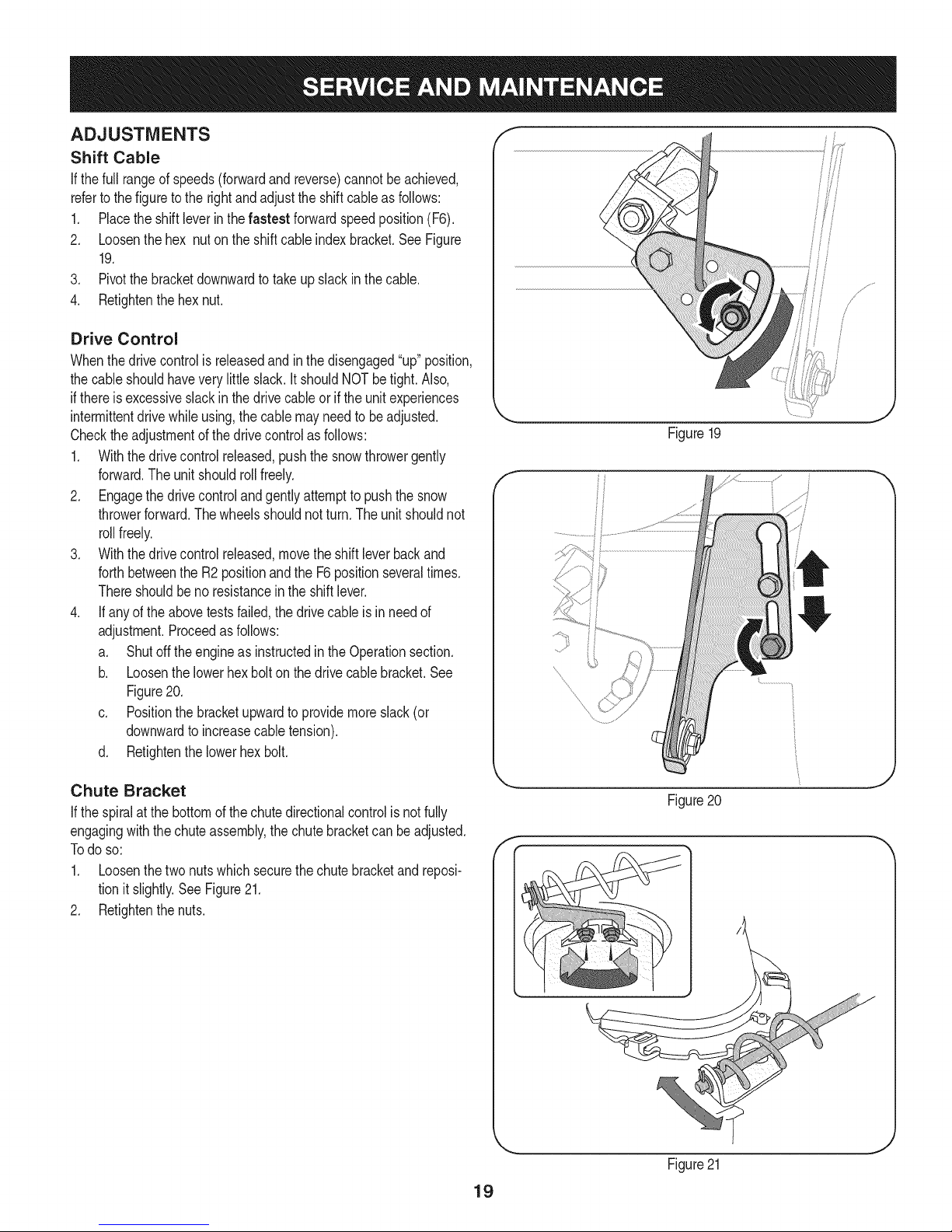

Auger Shaft

Atleastoncea season,removetheshearpinson augershaft.Spray

lubricantinsideshaft,andaroundthe spacersandflangebearings

foundat eitherendoftheshaft.SeeFigure17.

SHAVE PLATE AND SKID SHOES

Theshaveplateand skidshoesonthebottomof thesnowthrowerare

subjecttowear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

NOTE:Theskidshoeson thismachinehavetwowearedges.When

onesidewearsout,theycan be rotated1800to usetheotheredge.

Toremoveskidshoes:

1. Removethetwocarriagebolts,washers,andhex flangenutsthat

secureeachskidshoetothe snowthrower.

2. Reassemblenewskidshoeswiththefourcarriagebolts(twoon

eachside),washers,andhex flangenuts.RefertoFigure18.

Toremoveshaveplate:

1. Removethecarriageboltsand hexnutswhichattachit tothe

snowthrowerhousing.

2. Reassemblenewshaveplate,makingsureheadsofcarriage

boltsaretothe insideof housing.Tightensecurely.SeeFigure18.

Figure17

NOTE:Augers not shown for clarity.

/

/

/

/

Figure18

18

Page 19

ADJUSTMENTS

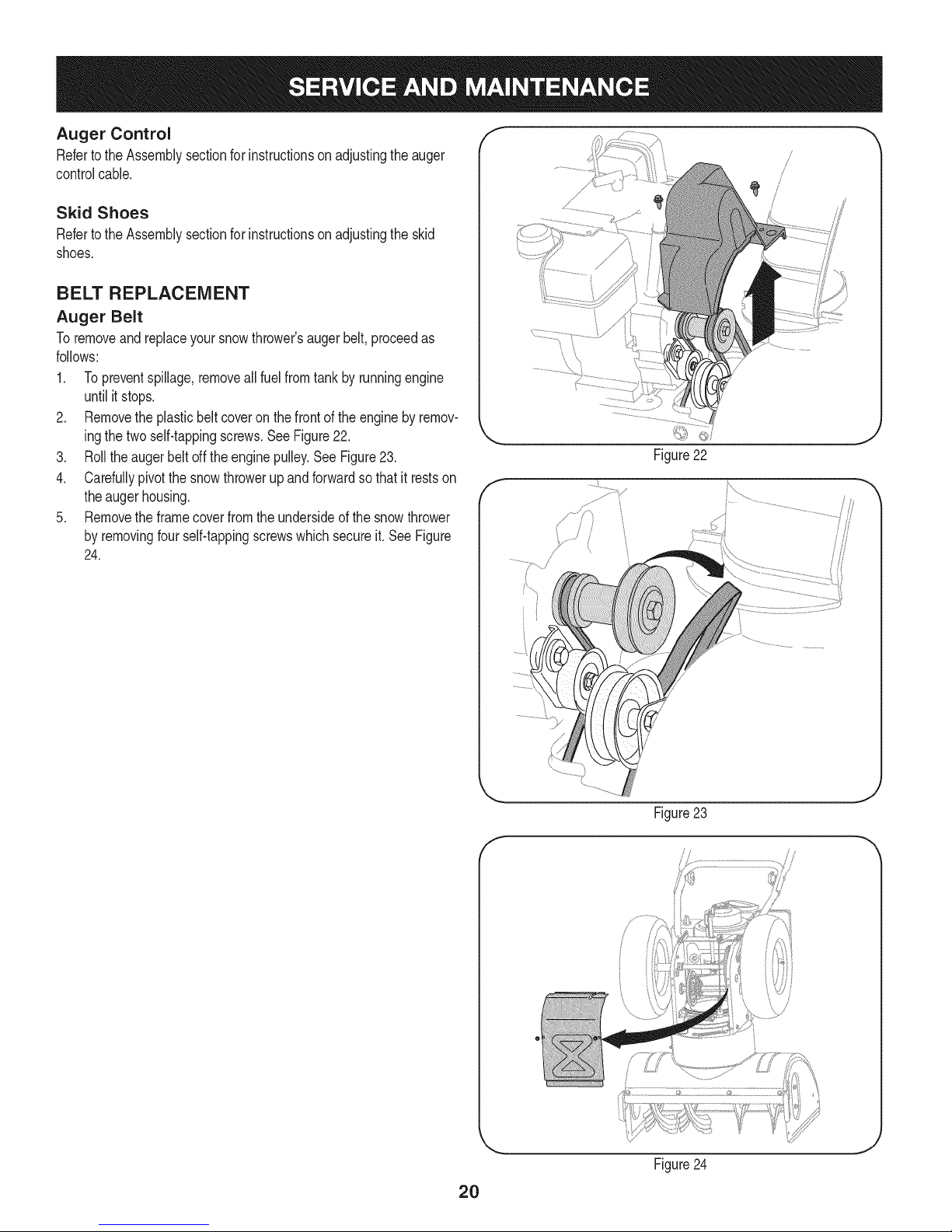

Shift Cable

If thefull rangeof speeds(forwardandreverse)cannotbeachieved,

referto thefigureto therightandadjusttheshiftcableas follows:

1. Placetheshiftleverin thefastest forwardspeedposition(F6).

2. Loosenthehex nuton theshiftcableindexbracket.SeeFigure

19.

3. Pivotthebracketdownwardto takeupslackinthecable.

4. Retightenthehexnut.

Drive Control

Whenthedrivecontrolis releasedandinthedisengaged"up"position,

thecableshouldhaveverylittle slack.It shouldNOTbetight.Also,

ifthereisexcessiveslackin thedrive cableorifthe unitexperiences

intermittentdrivewhileusing,the cablemayneedtobeadjusted.

Checktheadjustmentofthedrivecontrolasfollows:

1. Withthedrivecontrolreleased,pushthesnowthrowergently

forward.Theunitshouldrollfreely.

2. Engagethe drivecontrolandgentlyattempttopushthesnow

throwerforward.Thewheelsshouldnotturn.Theunitshouldnot

rollfreely.

3. Withthedrivecontrolreleased,movethe shiftleverbackand

forthbetweenthe R2positionandtheF6positionseveraltimes.

Thereshouldbeno resistancein the shiftlever.

4. If anyofthe abovetestsfailed,thedrivecableisin needof

adjustment.Proceedasfollows:

a. Shutoff theengineas instructedinthe Operationsection.

b. Loosenthelowerhexboltonthe drivecablebracket.See

Figure20.

c. Positionthebracketupwardtoprovidemoreslack(or

downwardto increasecabletension).

d. Retightenthelowerhexbolt.

Figure19

f

Chute Bracket

If thespiralatthe bottomofthechutedirectionalcontrolis notfully

engagingwiththechuteassembly,the chutebracketcanbeadjusted.

Todo so:

1. Loosenthetwonutswhichsecurethechutebracketandreposi-

tionit slightly.See Figure21.

2. Retightenthenuts.

Figure20

f

Figure21

19

Page 20

Auger Control f "_

Refertothe Assemblysectionforinstructionsonadjustingtheauger

controlcable.

Skid Shoes

Refertothe Assemblysectionforinstructionsonadjustingtheskid

shoes.

BELT REPLACEMENT

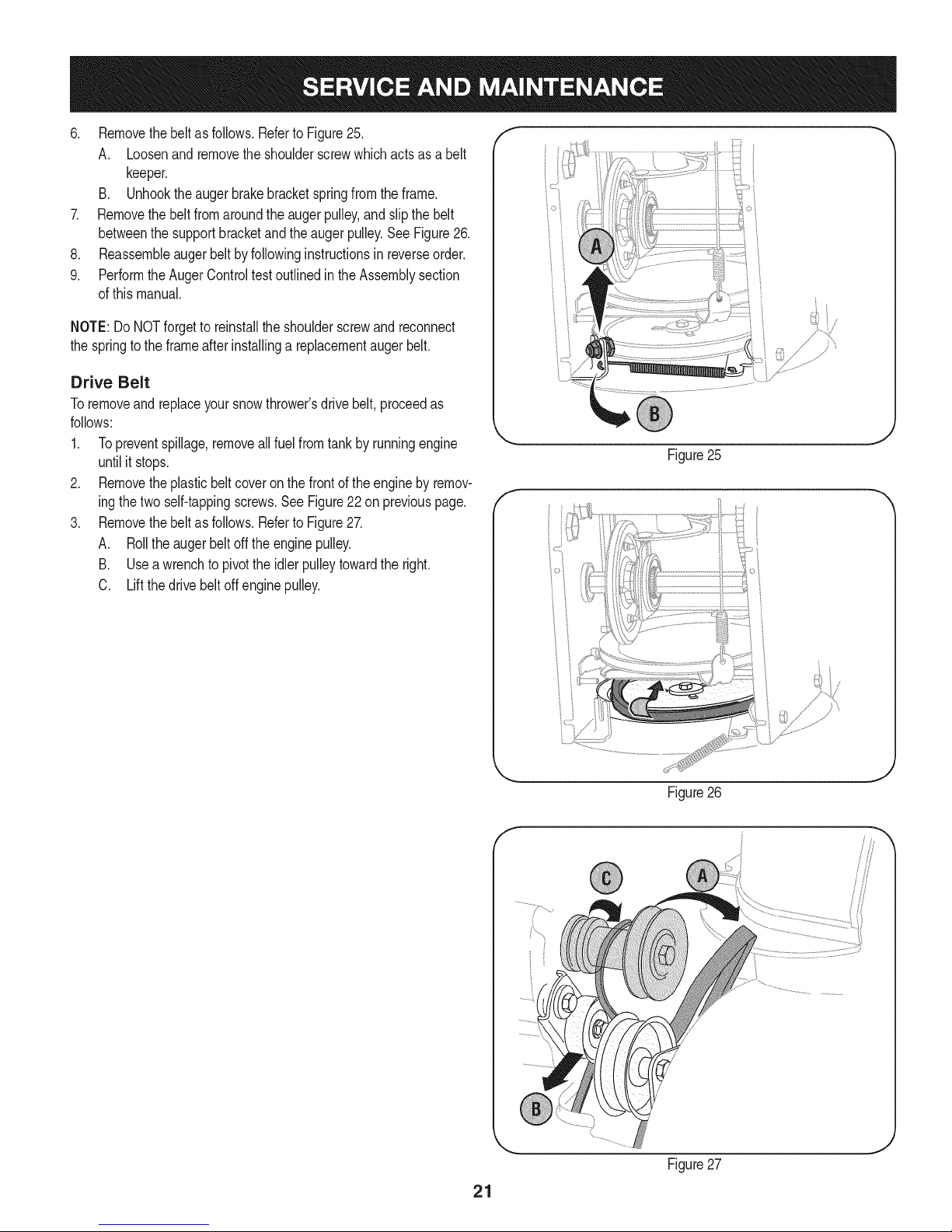

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedas

follows:

1. Topreventspillage,removeallfuel fromtank byrunningengine

untilitstops.

2. Removethe plasticbeltcoveronthefrontof theenginebyremov-

ingthetwoself-tappingscrews.SeeFigure22.

3. Rolltheaugerbeltoff theenginepulley.SeeFigure23.

4. Carefullypivotthesnowthrowerupandforwardsothat itrestson

theaugerhousing.

5. Removetheframecoverfromthe undersideofthe snowthrower

byremovingfourself-tappingscrewswhichsecureit.SeeFigure

24.

Figure22

f

J

Figure 23

f

//

J

Figure24

2O

Page 21

6. Removethebeltasfollows.RefertoFigure25.

A. Loosenandremovetheshoulderscrewwhichactsasabelt

keeper.

B. Unhooktheaugerbrakebracketspringfromtheframe.

7. Removethebeltfromaroundtheaugerpulley,andslipthebelt

betweenthesupportbracketandtheaugerpulley.SeeFigure26.

8. Reassembleaugerbeltbyfollowinginstructionsinreverseorder.

9. PerformtheAugerControltestoutlinedintheAssemblysection

ofthismanual.

NOTE:DoNOTforgettoreinstalltheshoulderscrewandreconnect

thespringtotheframeafterinstallingareplacementaugerbelt.

Drive Belt

Toremoveandreplaceyoursnowthrower'sdrivebelt,proceedas

follows:

1. Topreventspillage,removeallfuelfromtankby runningengine

untilit stops.

2. Removetheplasticbelt coveronthe frontoftheengineby remov-

ingthetwoself-tappingscrews.SeeFigure22on previouspage.

3. Removethebeltas follows.Referto Figure27.

A. Rolltheaugerbeltofftheenginepulley.

B. Useawrenchto pivottheidlerpulleytowardthe right.

C. Liftthe drivebeltoffenginepulley.

Figure25

Figure26

Figure27

21

Page 22

4, Carefullypivotthesnowthrowerupandforwardsothatitrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideofthesnowthrower

byremovingtheself-tappingscrewswhichsecureit.Referto

Figure24,

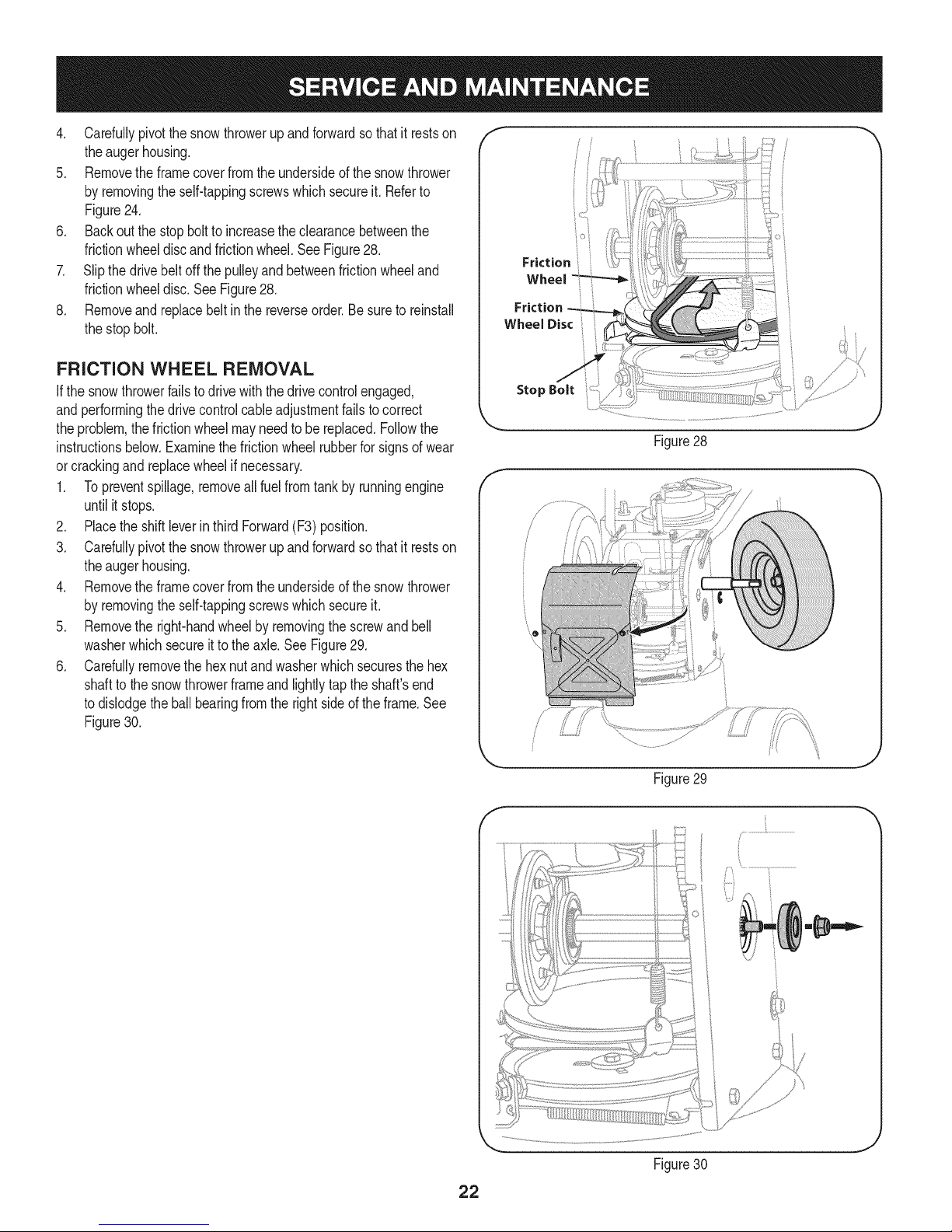

6. Backoutthestopbolttoincreasetheclearancebetweenthe

frictionwheeldiscandfrictionwheel,SeeFigure28,

7. Slipthedrivebeltoffthepulleyandbetweenfrictionwheeland

frictionwheeldisc,SeeFigure28,

8, Removeandreplacebeltinthereverseorder,Besuretoreinstall

thestopbolt.

FRiCTiON WHEEL REMOVAL

Ifthe snowthrowerfailstodrive withthedrivecontrolengaged,

andperformingthedrivecontrolcableadjustmentfailstocorrect

theproblem,thefrictionwheelmayneedtobe replaced.Followthe

instructionsbelow.Examinethefrictionwheelrubberforsignsof wear

orcrackingandreplacewheelif necessary.

1. Topreventspillage,removeallfuel fromtank byrunningengine

untilit stops.

2. Placethe shiftleverin thirdForward(F3)position.

3. Carefullypivotthesnowthrowerupandforwardsothat itrestson

theaugerhousing.

4. Removetheframecoverfromthe undersideofthe snowthrower

byremovingtheself-tappingscrewswhichsecureit.

5. Removethe right-handwheelbyremovingthescrewandbell

washerwhichsecureitto theaxle.See Figure29.

6. Carefullyremovethehexnutandwasherwhichsecuresthe hex

shaftto thesnowthrowerframeand lightlytaptheshaft'send

todislodgetheballbearingfromthe rightsideof theframe.See

Figure30.

i° i

Friction ;,

Wheel

Stop Bolt

Figure28

/ ii

22

J

Figure29

f

J

Figure30

Page 23

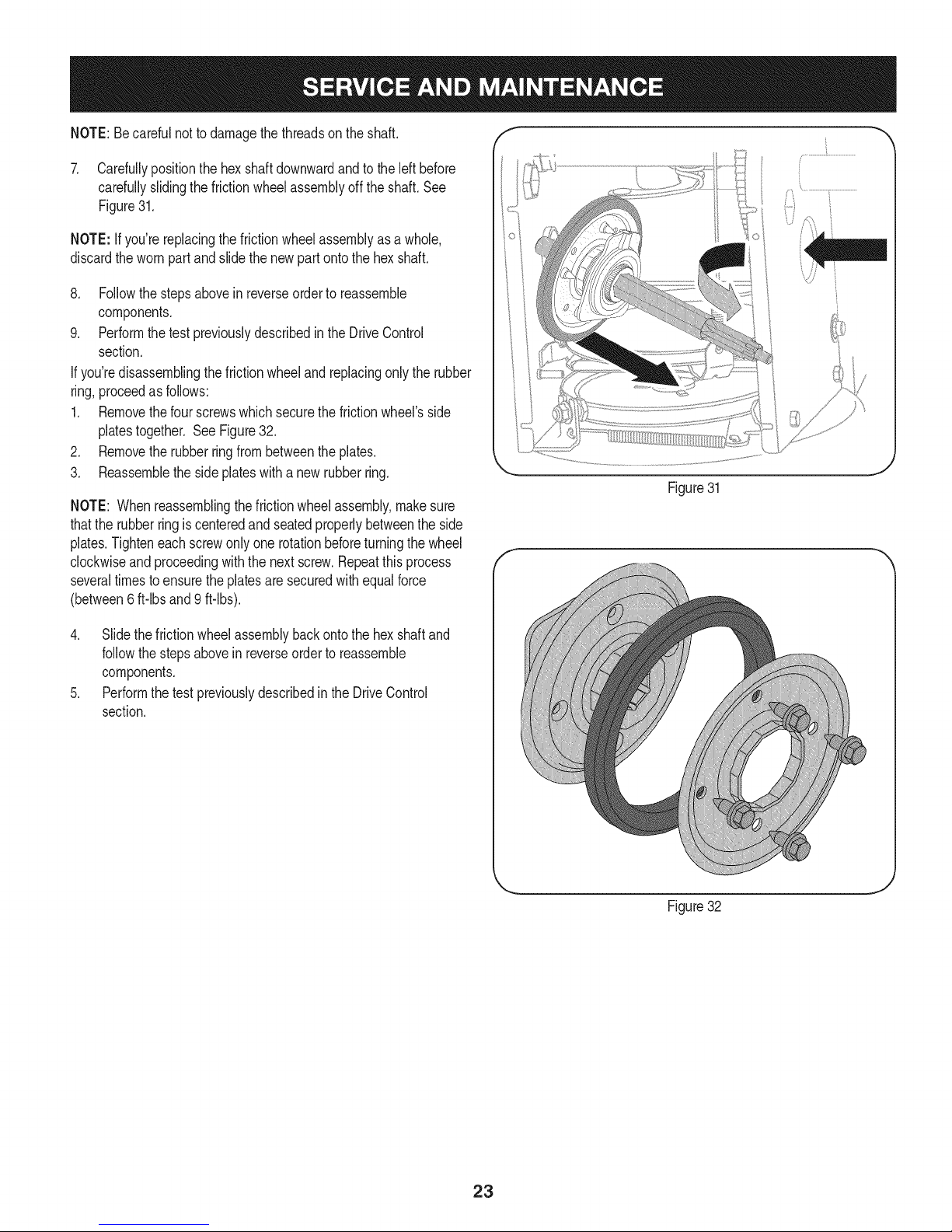

NOTE:Becarefulnot todamagethethreadson theshaft,

7. Carefullypositionthehexshaftdownwardandto theleft before

carefullyslidingthefrictionwheelassemblyoffthe shaft.See

Figure31.

NOTE:Ifyou'rereplacingthefrictionwheelassemblyasa whole,

discardthewornpartand slidethe newpartontothehexshaft.

8. Followthe stepsaboveinreverseorderto reassemble

components.

9. Performthetest previouslydescribedintheDriveControl

section.

If you'redisassemblingthefrictionwheeland replacingonly therubber

ring,proceedasfollows:

1. Removethefourscrewswhichsecurethe frictionwheel'sside

platestogether.SeeFigure32.

2. Removetherubberringfrombetweenthe plates.

3. Reassemblethesideplateswitha newrubberring.

NOTE: Whenreassemblingthefrictionwheelassembly,makesure

thattherubberringis centeredand seatedproperlybetweenthe side

plates.Tighteneachscrewonlyone rotationbeforeturningthe wheel

clockwiseandproceedingwiththenextscrew.Repeatthisprocess

severaltimestoensuretheplatesaresecuredwithequalforce

(between6 ft-lbsand 9 ft-lbs).

Figure31

4. Slidethefrictionwheelassemblybackontothehexshaftand

followthestepsabovein reverseordertoreassemble

components.

5. Performthetestpreviouslydescribedin theDriveControl

section.

t j

Figure32

23

Page 24

Ifthe snowthrowerwillnot be usedfor30 daysor longer,or ifit isthe endofthesnowseasonwhenthe lastpossibilityof snowis gone,the

equipmentneedstobestoredproperly.Followstorageinstructionsbelowtoensuretop performancefromthesnowthrowerformanymoreyears.

PREPARING ENGINE

Enginesstoredover30daysneedtobedrainedoffueltoprevent

deteriorationandgumfromforminginfuel systemoronessential

carburetorparts.Ifthegasolineinyourenginedeterioratesduring

storage,youmayneedto havethecarburetor,andotherfuelsystem

components,servicedor replaced.

1. Removeall fuelfromtank byrunningengineuntil itstops.Donot

attempttopourfuel fromtheengine.

2. Changetheengineoil.

3. Removesparkplugandpourapproximately1oz.(30 rnl)ofclean

engineoil intothecylinder.Pullthe recoilstarterseveraltimesto

distributetheoil,and reinstallthesparkplug.

4. Cleandebrisfromaroundengine,andunder,around,andbehind

muffler.Applya lightfilmofoilon anyareasthatare susceptible

torust.

• Storeina clean,dry andwellventilatedareaawayfromanyap-

pliancethatoperateswithaflameor pilotlight,suchas a furnace,

waterheater,or clothesdryer.Avoidany areawitha spark

producingelectricmotor,orwherepowertoolsareoperated.

Neverstoresnowthrowerwithfuelintank indoorsorinpoorlyventi-

latedareas,wherefuelfumesmayreachanopenflame,sparkor pilol

lightas ona furnace,waterheater,clothesdryerorgasappliance.

PREPARING SNOW THROWER

Whenstoringthe snowthrowerin anunventilatedormetalstor-

age shed,careshouldbetakentorustprooftheequipment.Using

a lightoilor silicone,coattheequipment,especiallyanychains,

springs,bearingsandcables.

• Removealldirt fromexteriorofengineandequipment.

• Followlubricationrecommendations.

• Storeequipmentin a clean,dryarea.

• Inflatethetirestothe maximumPSi.Referto tiresidewall.

• If possible,avoidstorageareaswithhighhumidity.

• Keepthe enginelevelinstorage.Tiltingcancausefueloroil

leakage.

24

Page 25

Enginefailstostart

Enginerunningerratically/

inconsistentRPM(huntingor

surging)

Excessivevibration

Lossofpower

Unitfailstopropelitself

Unitfailstodischargesnow

1. ChokecontrolnotinCHOKEposition.

2. Sparkplugwire disconnected.

3. Faultysparkplug.

4. Fueltankemptyor stalefuel.

5. Enginenotprimed.

6. Keynot inserted.

7. Extensioncordnotconnected(when

usingelectricstartbutton,on modelsso

equipped).

1. EnginerunningonCHOKE.

2. Stalefuel.

3. Waterordirt infuelsystem.

4. Over-governedengine.

1. Loosepartsor damagedauger.

1. Sparkplugwire loose.

2. Gascap ventholeplugged.

1. Drivecableinneedof adjustment.

2. Drivebeltlooseor damaged.

3. Wornfrictionwheel.

1. Chuteassemblyclogged.

2. Foreignobjectlodgedin auger.

3. Augercablein needof adjustment.

4. Augerbeltlooseordamaged.

5. Shearpin(s)sheared.

1. Movechokecontrolto CHOKEposition.

2. Connectwireto sparkplug.

3. Clean,adjustgap,or replace.

4. Filltankwithclean,freshgasoline.

5. Primeengineasinstructedinthe OperationSection.

6. Insertkeyfully intotheswitch.

7. Connectoneendof the extensioncordtotheelectric

starteroutletandthe otherendtoa three-prong

120-volt,grounded,ACoutlet.

1. Movechokecontrolto RUNposition.

2. Filltankwithclean,freshgasoline.

3. Drainfueltankby runningengineuntil itstops.Refill

withfreshfuel.

4. ContactyourSearsParts& RepairCenter.

1. Stopengineimmediatelyand disconnectsparkplug

wire.Tightenall boltsand nuts.Ifvibrationcontinues,

haveunit servicedbya SearsParts& RepairCenter.

1. Connectandtightensparkplugwire.

2. Removeiceand snowfromgascap. Becertainvent

holeisclear.

1. Adjustdrivecontrolcable.Referto Serviceand

Maintenancesection.

2. Replacedrive belt.Referto Serviceand Mainte-

nancesection.

3. Havefrictionwheelreplacedata SearsParts&

RepairCenter.

1. Stopengineimmediatelyand disconnectsparkplug

wire.Cleanchuteassemblyandinsideofauger

housingwithclean-outtoolor a stick.

2. Stopengineimmediatelyand disconnectsparkplug

wire.Removeobjectfromaugerwith clean-outtool

ora stick.

3. Adjustaugercontrolcable.RefertoAssembly

section.

4. Replaceaugerbelt.Referto Serviceand Mainte-

nancesection.

5. Replacewith newshearpin(s).

Chutefailstoeasilyrotate180 1. Disassemblechutecontroland reassembleas

1. Chuteassembledincorrectly.

degrees directedintheAssemblysection.

NEED HORE HELP?

Yot,Fttfind. th_ answer a!ld mo_e on ma_age_y_ifeocom _ for free]

Find this and att your other product manua[s ontine.

Get answers from our team of home experts.

Get a personalized maintenance p[an for your home.

Find information and tools to he[p with home projects.

managemylife

b_e'_g_t_/_eyeu by Sea_s

25

Page 26

Craftsman Snow Thrower Model 247.985360

/

i

26

Page 27

Craftsman Snow Thrower IViodel 247.985360

D = 0 0

731-2635 SnowRemovalToolMount

2. 684-04057A-0637 ImpellerAssembly,12"Dia.

3. 710-0347 HexScrew,3/8-16,1.75,Gr5

4. 710-0451 Bolt,Carriage,5/16-18,.750Grl

5. 710-04484 Screw, 5/16-18,0.750

6. 710-0703 Screw,Carriage,1/4-20,.750,Gr5

7. 712-04063 Nut,FlangeLock,5/16-18,Nylon

8. 712-04064 Nut,FlangeLock,1/4-20,Nylon

9. 712-04065 Nut,FlangeLock,3/8-16,Nylon

10. 714-04040 CotterPin,Bow-tie

11. 725-0157 Cable,Tie,3/16x .05x7.4

12. 926-04012 Nut,Push-on,.25Dia

13. 731-04705D Chute,Adapter5" Dia

14. 732-04460 Spring,Extension,.38ODx 4.59

15. 736-0174 Washer,Wave,.625x .885x.015

16. 736-0242 Washer,Bell,.340x .872x .060

17. 946-04230A ClutchCable,Auger,47.23"

18. 931-2643 SnowRemovalTool

19. 738-0143 Screw,Shoulder,.498x .34,3/8-16

20. 938-0281 Screw,Shoulder,.625x .17,3/8-16

21. 738-04124A ShearPin,.25x 1.50

22. 941-0245 Bearing,HexFlangex.75 ID

23. 941-0309 Bearing,Ball,.75IDx 1.85OD

24. 756-04224 FlatPulley,Idler, 2.75OD

25. 790-00075 Housing,Bearing,1.85ID

26. 790-00080B Bracket,AugerIdlerw/Brake

27. 918-04171B GearboxAssembly,Auger,24"

28. 684-04265-4044 HousingAssembly,Auger24"

D = O

684-04107-0637

30. 684-04108-0637

31. 731-04870

32. 736-0188

33. 741-0493A

34. 790-00087A-0637

35. 790-00120-4044

36. 731-06439

37. 918-0123A

38. 918-0124A

39. 921-0338

40. 741-0662

41. 710-0642

42. 711-04285

43. 914-0161

SpiralAssembly,LH

SpiralAssembly,RH

Spacer,1.25ODx.75 IDx 1.00

Washer,Flat,.76x 1.49x.06

Bushing,Flange,.80IDx .91OD

Housing,1"HexBearing

ShavePlate,2.25x 23.66

SlideShoe

Housing,Gearbox,RH

Housing,Gearbox,LH

Seal,Oil, .750x 1.00x .125

Bearing,Flange,.75x 1.0x .59

Screw,Self-tapping,1/4-20,0.750

Axle,Auger,24"

Key,Hi-pro3/16x5/8

44. 715-04021 Pin,Dowel,.25ODx 1.2

45. 917-04126 Shaft,Worm.75OD

46. 917-04861 Gear,Worm20T

47. 718-04071 Collar,Thrust

48. 721-0325 Plug,1/4x .437

49. 721-0327 Seal,Oil, .75x 1x .131

50. 936-0351 Washer,Flat,.760IDx 1.50D

51. 736-3084 Washer,Flat,.51x 1.12

52. 741-0663 Bearing,Flange,.75x 1.0x .925

53. 741-0661A Bearing,Flange,.75x 1.00x .975

54. 936-0159 Washer,Fiat,.349x .879x .063

55. 710-0276 Screw,Carriage,5/16-18x 1.00

27

Page 28

Craftsman Snow Thrower Model 247.985360

f

. --J

,; //

/ !

/; /i

\

//

,/

28

Page 29

Craftsman Snow Thrower IViodel 247.985360

D = " 0

631-04133A HandleAssembly,ClutchLock,LH

2. 631-04134B HandleAssembly,ClutchLock,RH

3. 684-04111B HandleAss'y,Engage,LH

4. 684-041120 HandleAss'y,Engage,RH

5: J631-04131B LChute,Lower(Inc!.Ref.# 27,Qty.3)

6. 790-00248C-0637 Bracket,Panel

7. 914-0145 ClickPin

8. 710-04586 Screw,1/4-20x 1.625

9. 790-00219-4044 Panel,Handle,(nocutout)

10. 710-1233 Screw,Machine,#10-24,1.375

11. 914-0104 Pin,Cotter,.072x 1.13

12. 712-04063 Nut,FlangeLock,5/16-18,Nylon

13. 749-04190A-0637 Handle,Upper,RH

14. 936-0185 Washer,Fiat,.375x .738x .063

15. 720-0274 Grip,1.0IDx5.0

16. 720-04039 Knob,Shift,Black

17. 735-0234 Grommet,.44IDx .94 ODx .50

18. 926-0100 Cap,Push,3/8 Rod

19. 732-0193 Spring,.39 x .60x .88

20. 920-0284 Knob,5/16-18,Black

21. 720-0201A CrankKnob,1.0Dia.x 3.2, Black

22. 749-04138A-0637 Handle,Lower

23. 935-0199A Bumper,Rubber,.62 ODx .22

24. 736-0262 Washer,Fiat,.385x .870x .092

=

25. 738-04118 Bolt,Shoulder,5/16-18x0.905

26. 738-04348 Screw,Shoulder,.43x 1.3,1/4-20

D = W

731-04869A Chute,FlangeKeeper

28. 946-04397A Cable,SpeedSelector

29. 749-04191A-0637 Handle,Upper,LH

30. 747-04263 EyeBolt,ChuteCrank

31. 790-00313-0637 Sh!flLever

32. 731-04912B Chute,Lower,5.0Dia.

33. 710-0276 Bolt,Carriage,5/16-18,1.0

34. 710-04071 Bolt,Carriage,5/16-18,1.0

35. 710-0451 Bolt,Carriage,5/16-18,.750

36. 731-04426A Chute,Upper,w/Label

37. 936-0159 Washer,.349x .879x .063

38. 941-0475 Bushing,Plastic,.380

39. 784-5647-0637 Bracket,ChuteCrank

40. 684-04104-0637 CrankAssembly,Chute

41. 710-0572 Screw,Carriage,5/16-18,2.25

42. 710-04484 Screw,5/16-18,2.25,Gr5

43. 684-04250 Rod,Pivot

44. 710-04326 Screw,#8-16x.50

45. 710-3069 Screw,1/4-20x.50

46. 712-04081A Nut,Hex,1/4-20

47. 731-04894D Plate,Lock

48. 731-04896B Cam,ClutchLock

49. 731-06471 HandlePanelCover

50. 732-04219C Spring,ClutchLock

51. 732-04238 Spring,Torsion,.8156IDx .3038

29

Page 30

Craftsman Snow Thrower IViodel 247.985360

A

A

3O

/

/

/

/

Page 31

Craftsman Snow Thrower IViodel 247.985360

I = 0 0

656-04055 DiscAssembly,FrictionWheel

2. 684-04153 FrictionWheelAssembly,5.50D

3. 684-04154B-0637 SupportBracket,FrictionWheel

4. 684-04156A ShiftAssembly,Rod

5. J710-0627 J HexScrew,5/16-24,.750,Gr5

6. 710-0788 Screw,1/4-20,1.000

7. 710-1652 Screw,1/4-20x .625

8. 712-04065 Nut,FlangeLock,3/8-16,Nylon

9. 712-0417A Nut,Flange,5/8-18

10. 914-0126 Key,HiPro,3/16x 3/4 Dia.

11. 916-0104 E-ring,.500Dia.

12. 716-0136 E-ring,Retaining,.875Dia.

13. 916-0231 E-ring,.750Dia.

14. 917-04209A HexShaft,.8125,7-Tooth

15. 917-04230A Gear,80-Tooth

16. .726-0221 Speed Nut,.500

17. 932-0264 ExtensionSpring

18. 736-0242 Washer,Bell,.340x .872x .060

19. 936-0287 Washer,Flat,.793x 1.24x .060

20. 736-04161 Washer,Flat,.75x 1.00x .060

21. 790-00289A-0637 Plate,Cover

22. 738-04439 ShoulderScrew

23. 738-04184A Screw,Shoulder,.37x .105,1/4-20

24. 738-0924A Screw,1/4-28,.375

25. 941-0245 Bearing,HexFlangex .75ID

26. 941-0563 Bearing,Ball,17x 40x 12

27. 946-04229B ClutchCable,Wheel,44.95"

28. 935-04054 Rubber,FrictionWheel,5.50D

29. 748-0190 Spacer,.508IDx .75ODx .68

30. 756-0625 Roller,Cable

31. 790-00096-0637 FrontGuideBracket,AugerCable

32. 790-00180A-4044 Frame

33. 790-00206A-0637 GuideBracket,AugerCable

34. 790-00207C GuideBracket,DriveCable

35. 790-00316-0637 Cover,Frame

36. 634-04167A-0911 LHWheelAssembly

634-04168A-0911 RHWheelAssembly

D = O e

731-04873 Spacer,1.25x .75x 3.0

38. 938-04168 Axle,.75x22"

39. 936-0329 Washer,Lock, 1/4

40. 710-0809 HexScrew,1/4-20,1.25,Gr5

41. 710-0191 HexScrew,3/8-24,1.25,Gr8

42. 710-0672 HexScrew,5/16-24,1.25,Gr5

43. 710-0654A Screw,Seres,3/8-16,1.00

44. 710-1245B HexScrew,5/16-24,.875,Gr8

45. 710-0896 Screw,1/4-20x .625

46. 926-04012 Nut,Push-on,.25 Dia.

47. 731-04792A Cover,Belt

48. 732-04308A Spring,Torsion,.850 IDx .354

49. 736-0247 Washer,Flat, .406x 1.25x.157

50. 936-0119 Washer,Lock.3125

51. 736-0505 Washer,Flat, .34x 1.50x.150

52. 748-04053A Pulley,Adapter,.75 Dia.

53. 748-04112B Spacer,Shoulder,.317x.50x .102

54. 750-04303 Spacer,.875IDx 1.185OD

55. 750-04477A Spacer,.340x.750x.360

56. 954-04050 Belt,AugerDrive

57. 954-04260 Belt,WheelDrive

58. 756-04109 Pulley,AugerDrive,8.1x .5

59. 756-04113 Pulley,Half,V x2.600OD

60. 756-04252 Pulley,Half,3/8-Vx 1.7160OD

61. 790-00208C IdlerBracket,Wheel Drive

62. 684-04169 Idler PulleyAssembly

63. 750-04571 Spacer,Shoulder,.26x .79x .538

64. 735-04099 Plug,3/8 ID

65. 735-04100 Plug,1/2ID

66. 712-04064 Nut,FlangeLock,1/4-20,Nylon

67. 710-0751 HexScrew,1/4-20,.620,Gr5

68. 732-04311A Spring,Torsion,.750IDx .968

69. 712-04063 Nut, FlangeLock,5/16-18,Nylon

70. 936-3015 Wash.,Flat,.469x .875x .105

71. 790-00217A-0637 PivotBracket,SpeedSelector

72. 790-00218A-0637 ShiftBracket,SpeedSelector

73. 952Z270-SUA ReplacementEngine

31

Page 32

Craftsman Engine Model 270=SUA For Snow Model 247.985360

24

23

23

m

l

i

i19

!

i

120

i

i

i

i20

!

!

i

121

i

i

122

i

i

i

i23

!

i

i

124

i

951-11282

710-05001

951-14190

951-11289

712-04214

710-04915

951-10642B

2

21

m = 0 O

MufflerAssembly

MufflerStud

MufflerStudKit

MufflerGasket

Nut- M8

Bolt- M6X 12Zin

MufflerShroud

32

Page 33

Craftsman Engine Model 270=SUA For Snow Model 247.985360

41 _42

m

34

35

36

37

39

4O

41

42

43

951-10634

712-04213

951-11284

951-10757

951-10637

731-05632

951-10640

951-10635

710-04943

°0

Shroud-Engine

Nut

ChokeKnob

ThrottleKnob

Switch-Ignition

IgnitionKeySwitch

PushRod-Choke

Air FilterHeating

Bolt-M61X28MSpec

37

35

D = O O

33

Page 34

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.985360

131-6asketKit-Complete

132-6asketKit-External

133- CompleteEngine

34

Page 35

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.985360

m

5O

51

52

53

54

55

56

57

58

59

6O

61

62

63

64

65

66

67

68

69

951-12111

951-11632

951-12007

951-11633

710-04915

951-11113

951-11573

951-14053

736-04461

951-11902

714-04078

951-11575

951-11369

951-10307

951-11247A

951-11576

715-04092

715-04096

951-11371

951-12125

951-11246

D = O

PistonRingSet

PistonPinSnapRing

Piston

PistonPin

Bolt- M6X 12Zin

Shield- Air

ConnectingRodAssembly

GovernorShaft

Washer

GovernorSeal

CotterPin

CamshaftAssembly

Bearing

Key:Flywheel

CrankshaftKit

(Incl.62,63,64,74,79)

GovernorGear/Shaft

Pin-Dowel

DowlPin9X14

CrankcaseCoverGasket

CrankcaseCover

CrankcaseCoverKit

(Incl.62,68-74)

m

7O

71

73

74

75

76

77

78

79

130

131

132

133

710-04932

951-11283

951-11577

951-11368

951-11249

951-11060B

951-11350

736-04440

710-04906

951-11370

951-10641

951-11059A

951-10661B

952Z270-SUA

D = O O

Bolt

Oil FillPlugAssembly

O-Ring15.8X 2.5

OilSeal

CrankcaseKit

(Incl.59,62,74,75,79)

ShortblockAssembly

(Incl.4,21,27-29,44,46,

47,50-53,56-79)

Oil DrainPipe

Washer

Bolt- DrainPlug

OilSeal

Oil DrainAssembly

GasketKit-Complete

(Incl.4,21,27-29,32,44,

58,59,68,74,77,79)

GasketKit-External

(Incl.4,21,27-29,32,77)

CompleteEngine

35

Page 36

Craftsman Engine Model 270-SUA For Snow Model 247.985360

18

15

13

44 _p 49 46 _46

129

_ U" -"45

17

131-GasketKit-Complete

132-GasketKit-External

133-CompleteEngine

36

Page 37

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.985360

m

1

2

3a

3b

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

44

45

46

47

48

49

129

131

132

133

710-04968

951-11054A

731-07059

726-04101

951-11565

951-12000

951-11892

751-11124

751-11123

951-11893

710-04902

951-12002

951-12003

951-12004

951-11894

710-04933

951-11895

951-10722B

951-10292

951-11572

951-10648

951-11899

715-04108

951-10647A

951-10647A

951-12626

951-11059A

951-10661B

952Z270-SUA

D = O O

FlangeBoltM6

ValveCover

Hose-Breather

Clamp-BreatherHose

ValveCoverGasket

IntakeValveSpringRetainer

RockerArmAssembly

Nut- PivotLockin

Nut- ValveAdjust

RockerArm

Bolt- Pivot

ExhaustValveAdjuster

ExhaustValveSpringRetainer

ValveSpring

IntakeValveSeal

Bolt- M8X 55Zin

PushRodGuide

CylinderHeadAssembly

(Incl.4-14,16,17,21,27-29,

44,48,49)

Plug:Spark

Gasket-CylinderHead

Kit-PushRod

Tappet

Pin-Dow110X 16

ValveKit

ValveKit

ValveCoverKit

GasketKit-Complete

(Incl.4,21,27-29,32,44,

58,59,68,74,77,79)

GasketKit-External

(Incl.4,21,27-29,32,77)

CompleteEngine

37

Page 38

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.985360

134-CarburetorKit- Deni

135- CarburetorKit-Huayi

27

w

38

Page 39

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.985360

m

25

26

27

28

29

30

30

31

31

32

33

134

135

a

b

C

d

e

f

g

h

I

J

k

I

I1q

n

o

P

q

r

s

t

U

V

W

X

Y

710-04939

710-04910

951-11567

951-11896

951-11569A

951-10639A

951-11824

951-14026A

951-14027A

951-11897

951-11112

951-14154

951-12788A

n/a

n/a

n/a

n/a

710-05469

736-04638

n/a

n/a

n/a

n/a

951-11699

951-11906

n/a

n/a

n/a

951-12875

n/a

n/a

n/a

951-11589

n/a

951-11348

710-04945

951-11349

710-04938

D = W O

Stud-Carb

Stud- M6X 105

Gasket-CarbInsulator

CarburetorInsuiat

CarburetorGasket

Primer

PrimerBulb

CarburetorAssembly- Huayi

CarburetorAssembly- Deni

CarburetorGasket

Bracket-ChokeControl

CarburetorKit- Deni

(Incl.h,n,o,p,q,r,s,t,u,x)

CarburetorKit- Huayi

(Incl.h,n,o,p,q,r,s,t,u,x)

ChokeShaft

ChokePlate

ThrottleShaft

ThrottlePlate

ScrewM3x5

LockWasher

Gasket,ThrottlePlate

IdleJet Assembly

IdleSpeedAdjustingScrew

MixtureScrew

PrimerHose

HoseClamp

CarburetorBody

FloatPin

EmulsionTube

FloatNeedleValve

MainJet

NeedleValveSpring

Float

FuelBowlGasket

FuelBowl

FuelBowlGasket

FuelBowlMountingBolt

FuelDrainPlugGasket

FuelDrainPlug

39

Page 40

Craftsman Engine IViodel 270-SUA For Snow IViodel 247.985360

82

84

85

m

8O

81

82

83

84

85

86

87

88

90

91

92

93

951-10646

951-11110

710-04940

710-04919

951-12416

951-10934

951-10911

712-04209

710-04915

951-10663A

736-04455

710-04974

951-14151

D = O O

IgnitionCoil

Shield- Air Flow

Bolt

Bolt- FlangeM6

Flywheel

CoolingFan

StarterCup

Nut- M14

Bolt- M6X 12Zin

FanCoverComplete

FlatWasher-Recoil

FlangeBoltM6

RecoilStartAssembly

4O

Page 41

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.985360

95 102 _---115

,114

115

m

94

95

96

97

98

99

101

102

103

104

105

106

9s- 97 9s

94

951-10758

710-05103

951-11108

951-11935

951-10664

951-10665

951-11106

712-04212

710-04908

951-11700

951-10650

710-04915

ThrottleControlAssembly

Bolt-M6X 12

Shield- Governor

GovernorSpring

Spring-ThrottleReturn

Rod-Governor

Bracket-Governor

Nut- M6

Bolt- M6X 21 Gov

HoseClamp-Oarb

Kit-FuelLine

Bolt- M6X 12Zin

D = O 0

105

104

105

m

107

108

109

110

111

112

113

114

115

116

117

951-11914

710-04905

710-04915

951-11913

951-11381

951-10656

951-11904

951-12482

951-12533

951-11933

951-10653B

D = O 0

Engine/DipstickCover

Bolt

Bolt- M6X 12Zin

Oil FillTubeAssembly

O-Ring

DipstickTube

O-RingDipstick

DipstickAssy

FuelCap

FuelLevelIndicator

FuelTank

41

Page 42

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.985360

23

m

i

1118

1

1

1

i119

!

i

i 120

1

1

1

1121

1

1

1

i 122

!

i

i 123

1

1

1

i 124

!

!

i

i 125

1

1

i 126

1

1

1

i 127

!

i

1

i 128

1

710-04914

951-11680

951-11114

712-05015

710-04965

710-04935

710-05182

715-04088

951-10645A

710-04915

951-11109

D = O !

Bolt- FlangeM6

FlexibleClamp

Bracket-SwitchHousingMount

Nut

ScrewM4X 55

Screw- M4X 60

Bolt-M6X 32

Pin- Dowel

ElectricStarter

Bolt- M6X 12Zin

Shield- BlowerHousing

42

Page 43

Craftsman Snow Thrower Model 247.985360

777S32636

1001 J,nO-NV:llO

7VnNVW S,HOIVH3dOQV3H"G

"S3OVJHflS]3AVH9H09NIlV_3d0

N3HMN011nv3VUIX]3sn"$830N¥1S181¥398VH3SI0

1O3Ul0U3A3N'S]lSnPNI 8133r80 NMOUHLQIOM 01 "_

"3NIHOVW9NIOIAS]S80 9NI99033Nn

3UOJ38o3aa01S3MH SIUVd9NIAO_J]]V ]llNn S3]ONVH

QNIH38NIV_3UQNV'3NIGH3dOIS'SH]A3]HOlfl]O30VON3SIQ"8

"31flH330UVHOSIO9010NilOl 1001LflO-NV3]33Sfl"_

"133JONVSONVH31VlfldWVNV3U39flV_0U]]]_d_l HIlM

lOVlNO3"U39flVONV83113dWI9NllVlOUWOSJIVMVd33H"L

777S32236

777D16340

777X43688

NOT

/IUSI_E85 ORFUEL

CONTAININGMORE

THAN10% ETHANOL

)

777D16341

777122363

777123030

777D18044

777D16355

777123031

43

Page 44

MTD CONSUMER GROUP INC (MTD), the California Air Resources Board (CARB)

and the United States Environment Protection Agency (U. S. EPA)

Emission Control System Warranty Statement

(Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLSYSTEMCOVERAGEISAPPLICABLETOCERTIFIEDENGINESPURCHASEDINCALIFORNIAIN2005ANDTHERE-

AFTER,WHICHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODELYEAR2005ANDLATERENGINESWHICHAREPURCHASEDAND

USEDELSEWHEREINTHEUNITEDSTATES.

Californiaandelsewherein theUnitedStatesEmissionControlDefectsWarrantyCoverage

TheCaliforniaAir ResourcesBoard(CARB),U.S.EPAandMTDarepleasedto explaintheemissionscontrolsystemwarrantyonyourmodelyear

2006andlatersmalloff-roadengine.InCalifornia,newsmalloff-roadenginesmustbe designed,builtand equippedtomeettheStatesanti-smog

standards.Elsewhereinthe UnitedStates,newnon-road,spark-ignitionenginescertifiedfor model2005andlater,mustmeetsimilarstandardsset

forthbythe U.S.EPA.MTDmustwarrantytheemissioncontrolsystemonyourengineforthe periodoftimelistedbelow,providedtherehasbeen

noabuse,neglector impropermaintenanceofyoursmalloff-roadengine.

Youremissioncontrolsystemmayincludepartssuchasthecarburetor,fuel-injectionsystem,theignitionsystem,andcatalyticconverter,fueltanks,

fuellines,fuel caps,valves,canisters,filters,vaporhoses,clamps,connectors,andotherassociatedemission-relatedcomponents.

Whereawarrantableconditionexists,MTDwill repairyoursmalloff-roadengineat nocostto yourincludingdiagnosis,partsand labor.

MANUFACTURER'S WARRANTY COVERAGE:

Thisemissionscontrolsystemiswarrantedfor twoyears.Ifanyemission-relatedpartonyourengineis defective,thepartwill berepairedor

replacedbyMTD.

OWNER'S WARRANTY RESPONSIBILITIES:

Asthe smalloff-roadengineowner,youareresponsibleforthe performanceofthe requiredmaintenancelistedinyourOwner'sManual.MTD

recommendsthatyouretainall yourreceiptscoveringmaintenanceson yoursmalloff-roadengine,butMTDcannot denywarrantysolelyfor the

lackofreceiptsor foryourfailureto ensuretheperformancetoallscheduledmaintenance.

Asthe smalloff-roadengineowner,youshouldhoweverbeawarethat MTDmaydenyyourwarrantycoverageif yoursmalloff-roadengineorpart

hasfaileddue toabuse,neglect,impropermaintenanceor unapprovedmodifications.

Youare responsibleforpresentingyoursmalloff-roadengineto an AuthorizedMTDServiceDealeras soonasa problemexists.Thewarranted

repairsshouldbe completedina reasonableamountoftime,nottoexceed30 days.

Ifyouhaveanyquestionsregardingyourwarrantyrightsand responsibilities,you shouldcontacta MTDServiceRepresentativeat 1-800-800-7310

andaddressisMTDCONSUMERGROUP,RO.Box361131,ClevelandOH,44136-0019.

DEFECTS WARRANTY REQUIREMENTS FOR 1995 AND LATER SMALL OFF-ROAD ENGINES:

Thissectionappliesto 1995andlatersmalloff-roadengines.Thewarrantyperiodbeginsonthedatetheengineor equipmentisdeliveredtoan

ultimatepurchaser.

(a) GeneralEmissionsWarrantyCoverage_

MTDmustwarranttothe ultimatepurchaserandeachsubsequentpurchaserthatthe engineis:

(1)Designed,built,andequippedsoasto conformwithallapplicableregulationsadoptedbytheAirResourcesBoardpursuantto itsauthorityin

Chapters1and2,Part5, Division26of the HealthandSafetyCode;and

(2) Freefromdefectsinmaterialsandworkmanshipthatcausethe failureofa warrantedparttobeidenticalin all materialrespectsto the partas

describedin theenginemanufacturer'sapplicationforcertificationfora periodof twoyears.

.(b)The warrantyonemissions-relatedpartswillbe interpretedas follows:

(1)Anywarrantedpartthatisnot scheduledfor replacementas requiredmaintenanceinthewritteninstructionsrequiredby Subsection(c)

mustbewarrantedforthewarrantyperioddefinedinSubsection(a)(2).Ifanysuchpartfailsduringtheperiodof warrantycoverage,it mustbe

repairedor replacedbyMTDaccordingto Subsection(4)below.Anysuchpartrepairedor replacedunderthewarrantymustbewarrantedfor

theremainingwarrantyperiod.

(2)Anywarrantedpartthat isscheduledonlyfor regularinspectioninthewritteninstructionsrequiredbySubsection(c) mustbewarrantedfor

thewarrantyperioddefinedinSubsection(a)(2).A statementinsuchwritteninstructionsto theeffectof"repairor replaceasnecessary"will