Page 1

owners

manual

MODEL NO.

247.298760

CAUTION:

Read SAFETY

RULES and

INSTRUCTIONS

carefully

PART NO. 770-7762

CRAFTSMAN.

8H.P. FOUR SPEED

CHAIN DRIVE TILLER

• Assembly

• Operating

• Maintenance

• Repair Parts

SEIARS. ROEBUCK AND OO.. CtiioasoJlL 60684 U&A.

PRINTED IN U.S.A.

Page 2

annrrrrrryriTrTrrrrrnnr

rrnrrrrTBT-BTTTrrrrrrrrrrrnnnnrgTTTrrrrrm^TTVTvm

» Clll I

For one year from the date of purchase, Sears will repair any defect in material or

workmanship in this TILLER at no charge.

If the TILLER is used for commercial or rental purposes, this warranty applies for only

thirty days from the date of purchase.

Warranty service is available by contacting the nearest Sears store or Service Center

Z

throughout the United States.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

3uuum

FULL ONE YEAR WARRANTY

Sears, Roebuck and Co.

Sears Tower

BSC 41-3

Chicago, IL 60684

Page 3

IMPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this

manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manual

for proper fuel and amount.

Your tiller is a precision piece of power equipment, not a play thing. Therefore exercise extreme caution at

all times.

SAFE OPERATION PRACTICES FOR TILLERS

1. Read the Operating and Service Owner’s

Manual carefully. Be thoroughly familiar with

the controls and the proper use of the equip

ment.

2. Never allow children to operate a power tiller.

Only persons well acquainted with these rules

of safe operation should be allowed to use

your tiller.

3. Keep the area of operation clear of all

persons, particularly small children and pets.

4. Do not operate equipment when barefoot or

wearing open sandals. Always wear substan

tial footwear.

5. Do not wear loose fitting clothing that could

get caught on the tiller.

6. Do not start the engine unless the shift lever

is in the neutral (N) position.

11. Do not fill gasoline tank while engine is

running. Spilling gasoline on hot engine may

cause a fire or explosion.

12. Do not run the engine while indoors. Exhaust

gases are deadly poisonous.

13. Be careful not to touch the muffler after the

engine has been running, it is hot.

14. Before any maintenance work is performed or

adjustments are made, remove the spark plug

wire and ground it on the engine block for

added safety.

15. Use caution when tilling near buildings anc^

fences, rotating tines can cause damage or

injury.

16. Before attempting to remove rocks, bricks

and other objects from tines, stop the engine

and be sure the tines have stopped

completely. Disconnect the spark plug wire

and ground to prevent accidental starting.

7. Do not stand in front of the tiller while

starting the engine.

8. Do not place feet and hands on or near the

tines when starting the engine or while the

engine is running.

9. Do not leave the tiller unattended with the

engine running.

10. Do not walk in front of the tiller while the

engine is running.

A spark arrest muffler is available as an accessory part. The part number is listed in the parts section of this

manual. Check muffler legal requirements in your area

17. Check the ti>ie and engine mounting bolts at

frequent intervals for proper tightness.

18. Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working

condition.

19. Never store the equipment with gasoline in

the tank inside of a building where fumes may

reach an open flame or spark. Allow the

engine to cool before storing in any

enclosure.

NOTE

Page 4

INDEX

Warranty...................................................................2

Rules for Safe Operation..........................................3

Introduction.............................................................4

Hardware Pack........................................................5

Tiller Identification...................................................6

Assembly Instructions

Engine Preparation................................................10

Operation................................................................11

Controls

Tilling.......................................................................12

Cultivating...............................................................13

.................................................................

...........................................

12

Maintenance

Belt Replacement..................................................14

Care and Maintenance—Transmission

Careand Maintenance—Engine

Carburetor Adjustment.........................................16

7

Storage...................................................................17

Repair Parts—Tiller

List of Tiller Accessories

Repair Parts—Transmission

Repair Parts—Engine

How To Order Repair Parts

..........................................................

..............

...........................

..............................................

....................................

...............................

...........................................

...................

Back Cover

14

15

15

18

21

22

23

INTRODUCTION

This Product has been designed, engineered and manufactured to give you the best possible dependability

and performance.

Should you experience any problem you cannot easily remedy, please contact your nearest Sears, or

Simpson-Sears Service Department. They have welt qualified, competent trained technicians and the proper

tools to service or repair this unit.

PRE-ASSEMBLY

NOTE

The right and left side of your tiller

is determined from operator’s posi

tion.

Before any step is undertaken, the instructions

for that step should be read through.

MATERIALS REQUIRED:

1. Funnel (for gas and oil - NOTE: DO NOT MIX)

2. S.A.E.-30 Oil-For Service SC, SE, SD or MS

1V2 pints

TOOLS REQUIRED: See Figure 1

1. (1) Vz” Socket, open or box wrench.

2. (2) 9/16" Socket, open or box wrench.

3. (1) V4" Flat Screwdriver.

8

3. Gas (regular)

4. Cleaning rag

PARTS IN CARTON (See figure 2.)

Tail Piece

Handle—> á

Panel

^éar SbiM

Hardware

Pack

'S0¥p#

Stake

.Control

Pod

FIGURE 1.

FIGURE 2.

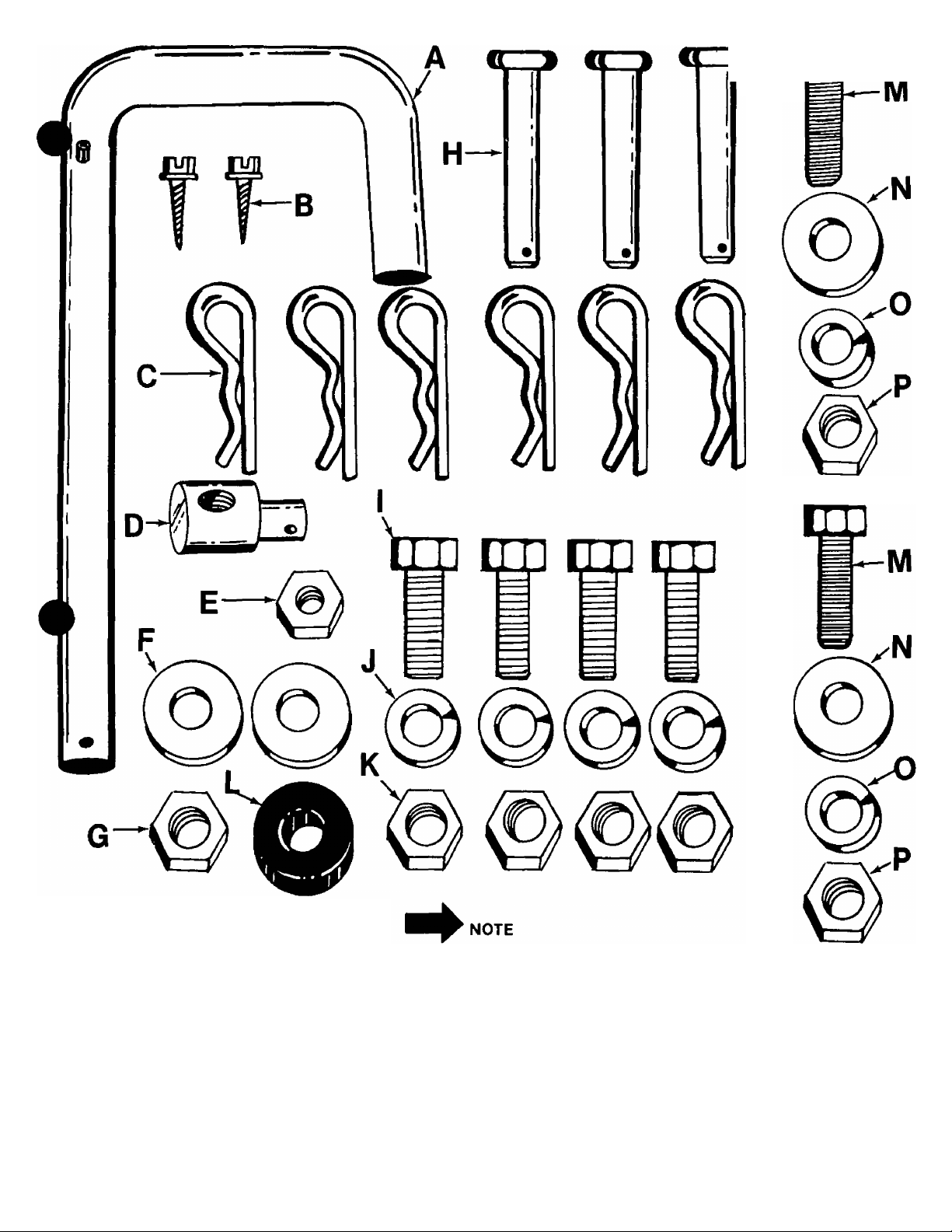

Page 5

IS

FIGURE 3. (SHOWN IN FULL SCALE)

LIST OF CONTENTS IN HARDWARE PACK:

A (1) “U”-Clevis Pin Vz” Dia.

B (2) Self Tapping Screws #8 x .62”

C (6) Hair Pin Cotters

D (1) Ferrule

E (1) Hex Center Locknut 5/16-18 Thread

F (2) Flat Washers

G (1) Hex Center Locknut 5/16-18 Thread

H (3) Clevis Pins

The letters listed below will be re

ferred to throughout the following

text for easier hardware identifica

tion.

I (4) Hex Screws 3/8-16 x 1.00”

J (4) Lockwashers 3/8”

K (4) Hex Nuts 3/8-16 Thread

L (1) Rubber Washer

M (2) Hex Screws 3/8-24 x 1.00"

N (2) Belleville Washer

O (2) Lockwashers 3/8”

P (2) Hex Nuts 3/8-24 Thread

Page 6

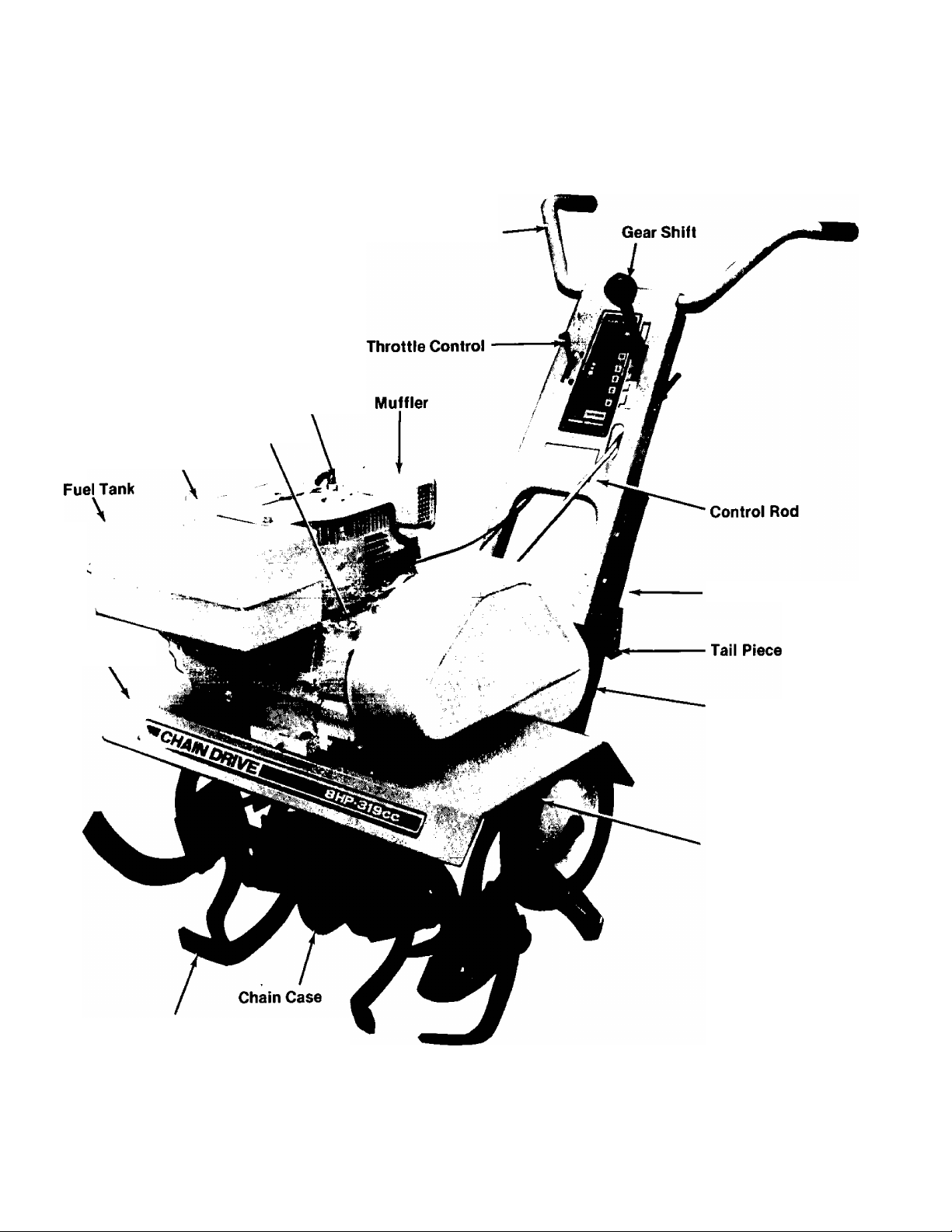

TILLER

IDENTIFICATION

Spark Plug

Oil Dipstick

Fuel Tank Cap

Handle Bar

Tine

Shield

Tine Assemblies

Depth Stake

Belt Cover

Wheel Yoke

Assembly

FIGURE 4.

Page 7

ASSEMBLY

INSTRUCTIONS

1. Handle Panel Attachment.

For shipping purposes, the handle mounting

brackets are pivoted down. With a 9/16” wrench

loosen the hex bolt holding the handle mount

brackets. See figure 5.

Pull handle mount brackets up so that the top hole

in bracket lines up with forward hole in chassis.

See figure 5.

NOTE

Do not tighten until all four bolts are

in place.

Four hex bolts (I), lockwashers (J) and hex nuts (K)

will be found in the hardware pack. See figure 7.

FIGURE 7.

2. Throttle Control Lever.

FIGURES.

Secure handle mount brackets with hex bolt (M),

belleville washer (N), lockwasher (O) and hex nut

(P). See figure 6.

FIGURE 6.

The handle panel is attached by sliding it down

over the handle brackets on the chassis and

installing four hex bolts in the lower holes of the

handle panel. Place bolts through the handle

panel; head to the outside. See figure 7,

Place throttle control lever up through the handle

panel and secure with two self tapping screws (B),

using a V4” flat screwdriver. See figured.

FIGURE 8.

3. Gear Shift Lever.

The shift lever is mounted to the handle panel in

the following steps.

A. Place the top hole of the shift lever over weld

bolt on handle panel. See figure 9.

B. Place one flat washer (F), rubber washer (L)

and the other flat washer (F) over weld bolt on

handle panel. See figure 9.

Page 8

C. Secure with hex center locknut (G). See figure

9.

FIGURE 9.

H^^NOTE

Tighten hex locknut just to the point

the rubber washer starts to

conn press.

4. Control Rod.

A. Place control rod through slot in handle panel,

hook end of rod goes towards the front of

tiller. See figure 10.

t"

Pivot Arm

Assembly

/

FIGURE 11.

Shift Lever

Second Hole

From Bottom

FIGURE 10.

B. Hook control rod in hole provided on pivot arm

assembly as shown In figure 11. Secure

control rod to pivot arm assembly with hair pin

cotter (C). See figure 11.

C. Please note there are three holes left on the

shift lever. Use the second hole from bottom

for the next step. See figure 12.

FIGURE 12.

D. Place shift lever in first gear and thread ferrule

(D) on end of control rod until ferrule lines up

with second hole on shift lever. See figure 13.

Secure with hair pin cotter (C). See figure 13.

FIGUREIS.

Page 9

NOTE

Shift lever and control rod must be

readjusted whenever you change the

handle height.

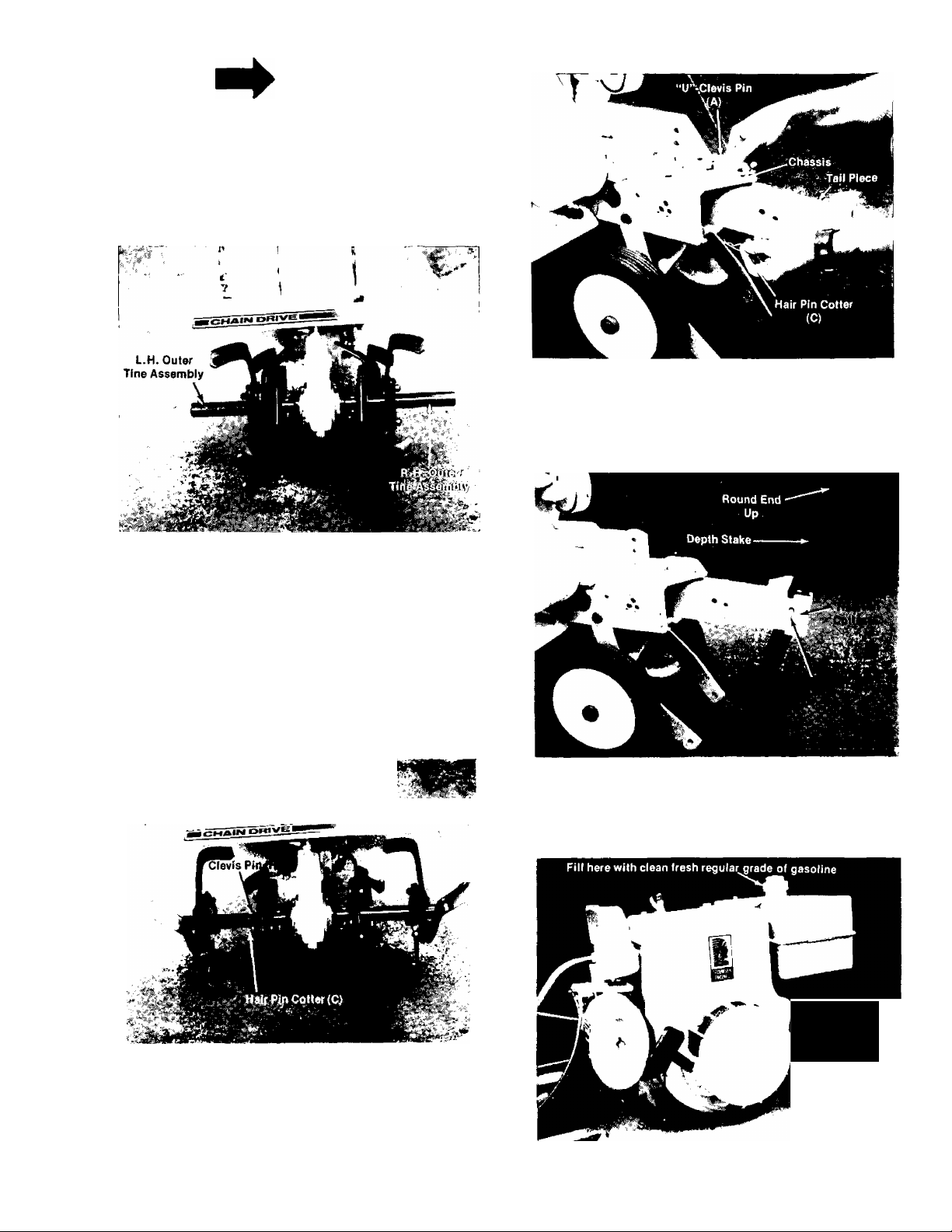

5. Tine Attachment

a. The outer tines have been reversed on the

tine shaft for shipping purposes. See

figure 14.

FIGURE 16.

7. Depth Stake Attachment.

Slide the depth stake into the tail piece (round end

up) and secure with clevis pin (H) and hair pin

cotter (C). See figure 17.

FIGURE 14.

Remove outer tines from the tine shaft and

reinstall with the tine hub facing inward as

illustrated in figure 15. Secure tines with clevis

pins (H) and hair pin cotters (C).

b. The inner tine assemblies have been

installed at the factory and in their correct

operating position and do not require

changing.

c. See tine adjustment for information on

changing width of tilling path, page 13.

I

FIGURE 17.

ENGINE

PREPARATION

FIGURE 15.

6. Tail Piece Attachment.

Slide the tail piece into the chassis and secure

with “U” clevis pin (A) and hair pin cotter (C). See

figure 16.

Oil Fill

Other Side of

Engine

FIGURE 18.

Page 10

OIL AND FUEL RECOMMENDATIONS

^CAUTION

A

Oil must be added before starting.

To start and operate your Tecumseh engine, you

wiil need the foliowing:

1. Fili crankcase with a clean, high quaiity deter

gent oii.

Be sure originai container is marked with

engine service classification “SC,” “SD,” or

“SE.”

For Summer (Above 32°F). Use SAE 30 oil.

(SAE 10W-30 or 10W-40 are acceptabie

substitutes.)

For Winter (Below 32°F). Use SAE 5W-30 oil.

(SAE 10W is an acceptable substitute.)

(Below 0“F Only) SAE 10W oil diluted with

10% Kerosene is acceptable.

Crankcase capacity is approximately 24

ounces (IV2 pints). See figure 19. Fill to full

mark on oil dipstick.

2. A fresh, clean, unleaded automotive gasoline.

(Leaded “Regular” grade gasoline is an

acceptable substitute.) See figure 20.

NEVER FILL FUEL TANK COMPLETELY. FILL

TANK TO WITHIN V4 TO INCH OF TOP OF

TANK TO PROVIDE SPACE FOR FUEL EXPAN

SION. WIPE ANY FUEL SPILLAGE FROM

ENGINE AND EQUIPMENT BEFORE STARTING

ENGINE.

NOTE

Use clean oil and fuel and store in

approved, clean covered containers.

Use clean fill funnels.

OPERATION

TO START ENGINE;

1. CAUTION: BE SURE NO ONE IS STANDING

IN FRONT OF THE TILLER WHILE THE

ENGINE IS RUNNING OR BEING STARTED.

FIGURE 19.

FIGURE 20.

FIGURE 21.

2. Place the shift lever in the neutral (N)

position. See figure 21.

FIGURE 22.

10

Page 11

3. Choke Engine. Push choke lever to choke

engine. See figures 22 and 23. Once the

engine starts, puil back on choke iever.

FIGURE 23.

4. Move the throttle control lever forward

FAST POSITION.See figure 24.

5. Stand at side of the tiiler, grasp the starter

handle and puil out rapidly. Return it slowly

to the engine. Repeat as necessary. See

figure 25.

If engine is warm, start with the con

trol in the “FAST” oosition. Choking

may not be necessary. See figure 24.

6. Move the throttle control to SLOW when

transporting the tiller. When the tiller is

being moved to or from the garden, the depth

bar should be pivoted forward until it engages

the depth bar retainer clip. The machine may

be moved under its own power, without

seriously damaging grass areas as long as it

is allowed to move freely. If the operator

to

holds back, it will start to dig.

CONTROLS

NOTE

FIGURE 24.

LOCATION AND USE.

1. Shift Lever; The shift lever is located on the

left hand side of the handle panel. Left hand

is determined from the operator’s position,

standing behind the tiller.

A. Forward (F)—Move the lever to the right

and down (Forward) to set unit in motion.

See figure 26.

B. Neutral (N)—Move lever to center detent.

See figure 24.

C. Reverse (R)—Pull the lever back (upward)

slowly and intermittently. See figure 27.

FIGURE 25.

FIGURE 26.

11

Page 12

2. Throttle Control: The throttle control lever is

located on the right hand side of handle

panel.

A. Stop—Pull lever back (upward) to stop the

unit. See figure 21.

B. Start—Push lever forward (down) to start

unit. See figure 22.

FIGURE 27.

TILLING

,1. Adjust depth bar by removing clevis pin and

hair pin cotter, changing bar position, then

replacing hair pin cotter and clevis pin. See

figure 17.

A. Lowering the depth bar will slow the tiller

and make it till deeper.

B. Raising the depth bar will allow the tiller

to move faster and till shallower.

C. For normal tilling, set depth bar at the fifth

or sixth hole from the top.

2. Adjust wheel yoke by removing clevis pin and

hair pin cotter, changing wheel yoke height,

and replacing clevis pin. See figure 17.

A. Raising the wheel yoke will allow the

tiller to till deeper.

B. Lowering the wheel yoke will allow the

tiller to till shallower.

C. For normal tilling set wheel height at the

second or third hole from the top.

Extremely wet soil will cause soil to ball up or

clump.

When tilling in the Fall, all vines and long grass

should be removed. This will prevent vines from

wrapping around the tine shaft which slows titling

operation.

1. The best method will be determined by the

soil condition. In some soils, the desired depth is

obtained the first time over the garden. In other

soils, the desired depth is obtained by going over

the garden two or three times. In the latter case,

the depth stake should be lowered before each

succeeding pass over the garden, and passes

should be made across the length and width of the

garden alternately. Rocks which are turned up

should be removed from the garden area.

2. Handle Pressure: Further control of tilling

depth and travel speed can be obtained by

variation of pressure on the handles.

When using the depth bar a downward pressure

on the handles will increase the working depth

and reduce the forward speed. An upward

pressure on the handles will reduce the working

depth and increase the forward speed. The type of

soil and working conditions will determine the

actual setting of the depth bar and the handle

ground, while the tiller is resting on the tines.

CULTIVATING

For cultivating, a two to three inch depth is

desirable. Setting the wheels and depth bar so

that the wheels are about two inches above the

ground, while the tiller is resting on the tines and

depth bar, will allow the machine to work at

cultivating depth. The throttle should be set to

control forward movement to a slow walking

speed. With standard tines, the working width of

the machine is 26 inches. See figure 28.

TILLING HINTS

Soil conditions are important for proper titling.

The tines will not readily penetrate dry, hard soil.

This may contribute to excessive bounce and

difficult handling of the tiller. Hard soil should be

moistened prior to tilling.

FIGURE 28.

12

Page 13

Tilling width can be increased from 26 inches to

28 inches by removing the clevis pin and hair pin

cotter and sliding the outer tines out one (1) inch,

and replacing the clevis pin and hair pin colter.

See figure 29.

The compost should be worked in to a depth of six

to eight inches. This may be done by working the

length of the garden, and then by mixing separate

passes across its width. The addition of decayed

organic matter will substantially increase the

fertility of your garden. For proper decaying

action, fertilizer should be applied and worked in

with the mulch materials. The breaking up of the

leaves and straw and the mixing of it with the

several inches of soil cause the soil to hold

moisture longer and allow proper aeration of the

plant root system. This also retards the growth of

weeds.

The U.S. Department of Agriculture and various

state and local agencies offer published booklets

and expert advice on all phases of gardening.

They should be consulted regarding soil informa

tion, planting dates, and the most satisfactory

varieties of crop for your particular area.

FIGURE 29.

For cultivation, this may be reduced to 14 inches

by removing the outer tines. See figure 30.

W ■

FiGURE 30.

In laying out plant rows be sure to allow enough

width (14” to 15”) to permit cultivation between

the rows.

In growing corn or similar crops, check-row

planting will permit cross cultivation and

practically eliminate hand hoeing. The tiller has

many uses other than tilling and cultivating a

garden. One of these is the preparation of lawn

area for seeding. The tiller will prepare a deep

seed bed which will be free of hard untilled spots,

allowing a better stand of grass to grow. The tiller

is very useful for loosening hard soil for

excavation with a shovel. Your tiller may be used

for mixing compost in the pile, or for mixing it

with the soil in your garden. This should be done

after the soil has been broken to the full working

depth.

MAINTENANCE

BELT REPLACEMENT:

If belt replacement is required order belt or belts

by part number from your nearest Sears Service

Center.

FORWARD DRIVE BELT - Part No. 754-0232

Vz” X 20” long

REVERSE DRIVE BELT - Part No. 754-0231

Vz” X 28” long

Your tiller has been engineered with the above

belts and should not be replaced with an

off-the-shelf belt. The above belts are of special

material (Kevlar Tensile).

Removing and replacing the REVERSE DRIVE

BELT.

1. Remove the belt cover, by removing two (2)

self tapping screws, and one (1) hex nut. See

figure 31.

FIGURE 31.

13

Page 14

2. Push forward on the idler and lift belt off of

chain case pulley, idler pulley and variable

speed pulley. See figure 32.

FIGURE 32.

Removing and replacing

the FORWARD DRIVE

BELT.

1. To remove the forward drive belt you must

remove the reverse drive belt first. See.

removing the reverse drive belt section, steps

1 and 2.

2. Push the shift lever forward and lift off belt

from variable speed pulley and engine pulley.

See figure 33.

Engine:

1. You MUST CHANGE THE OIL in the crankcase

after the first two hours of operation of your

new engine and after each 25 hours of use

thereafter to ensure proper lubrication of

internal parts for trouble free operation and to

prevent costly repair due to excessive wear.

(Take care to remove dirt around dip stick.) Be

sure oil level is maintained full to mark. See

figure 19.

To change oil remove drain plug (figure 34) and tip

the tiller forward while engine is warm. Replace

drain plug. Remove oil dip stick and refill with

new oil of proper grade. Replace dip stick.

4AIN DRIVE

aHR-3

FIGURE 33.

CARE AND MAINTENANCE:

Transmission:

The transmission is pre-lubricated and sealed at

the factory. It requires no additional lubrication

unless the transmission is disassembled. To fill

with grease, lay the left half of the chain case on

its side, add 14 ounces of Plastilube #1 grease and

assemble the right half to it. This grease can be

from your nearest Sears Service Center. (Order

Part No. 737-0133.)

FIGURE 34.

2. Always use the PROPER FUEL in your engine.

Useonlya good grade of fresh, clean, regular

gasoline. Do not use gasoline that has been

sitting for a long period of time. Stale

gasoline may cause engine to run poorly or

not at all.

3. Keep your engine CLEAN. Wipe off all spilled

fuel and oil. Keep the engine clean of foreign

matter and be sure the cooling fins on the

cylinder are kept clean to permit proper air

circulation. You must REMEMBER that this is

an air cooled engine and free flow of air is

essential to proper engine performance and

life.

4. Your must SERVICE YOUR AIR CLEANER.

Clean every 10 operating hours, or more often

if used in extremely dusty or dirty areas.

Proceed as follows:

A. Remove wing nut, cover and filter.

B. Tap top or bottom of filter lightly on a fiat

surface to dislodge any dirt (low pressure

air blown carefully from inside of filter

may also be used)—or wash filter in water

t4

Page 15

and detergent solution and flush from

inside until water is clear. Be sure filter is

completely dry before reassembling to

engine. DO NOT OIL FILTER. IF IT IS

PUNCTURED, TORN OR UNCLEANABLE,

IT SHOULD BE REPLACED. Replacement

filters are available at your nearest

Authorized Sears Service Center.

C. Before replacing filter, clean inside of

base and cover thoroughly.

D. Replace filter and cover making sure filter

is seated correctly between base and

cover. Tighten wing nut securely. See

figure 35.

NEVER RUN ENGINE WITHOUT COMPLETE AIR

CLEANER INSTALLED ON ENGINE.

E. With engine running at idle speed, adjust

idle adjust needle 1 /8 turn at a time,

clockwise and counterclockwise, until

engine runs smoothly.

Allow several seconds between each

adjustment for engine to adapt to new

setting.

High Speed Adjust Needle

FIGURE 35.

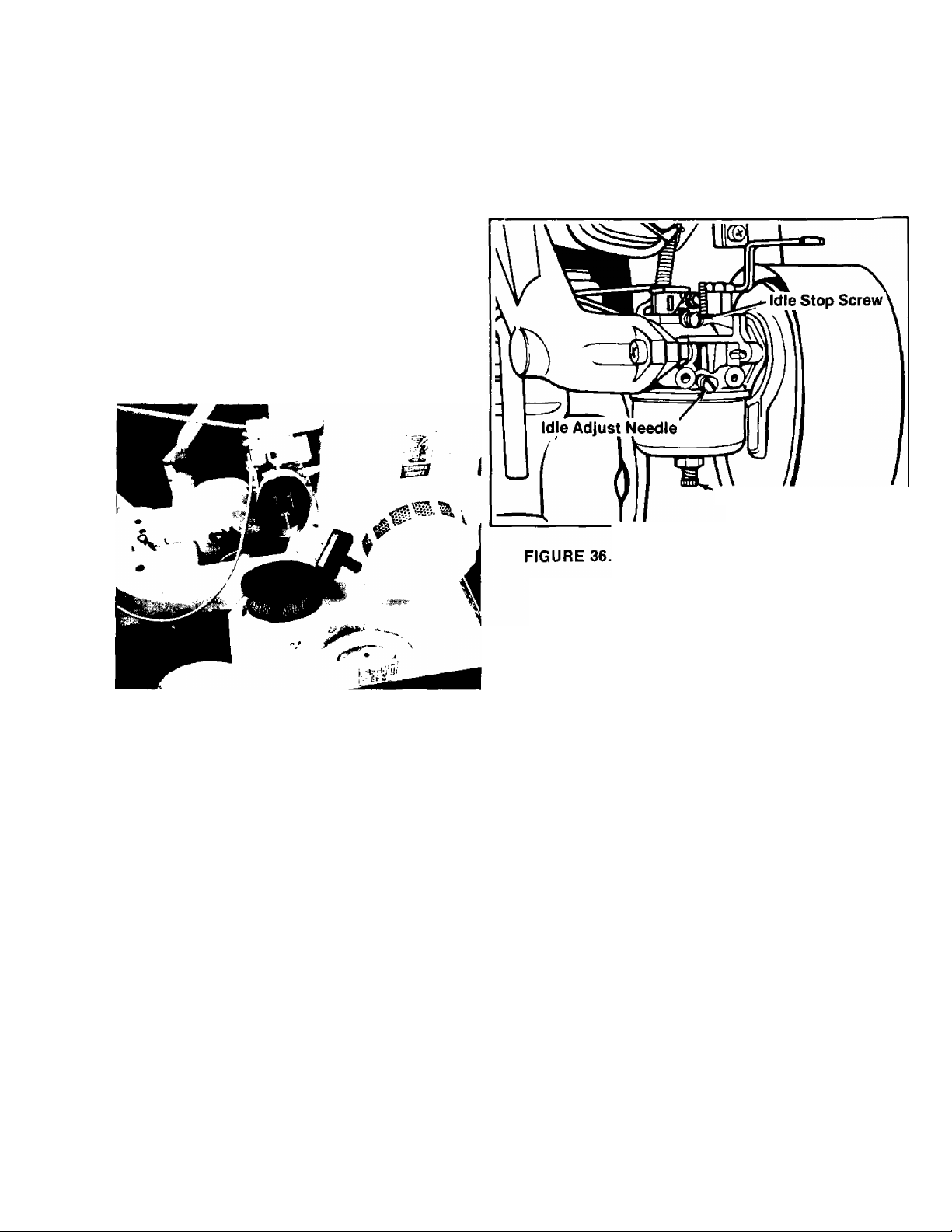

ADJUSTMENTS

DO NOT MAKE UNNECESSARY ADJUSTMENTS.

FACTORY SETTINGS ARE SATISFACTORY FOR

MOST APPLICATIONS AND CONDITIONS. IF

ADJUSTMENTS ARE NEEDED, PROCEED AS

FOLLOWS:

1. Carburetor Adjustments (See figure 36.)

A. High speed adjust needle is pre-set at the

factory. (1V2 turns open)

Re-adjustment should not be necessary.

B. Close idle adjust needle by turning

clockwise. Close finger tight only. Forcing

may cause damage.

C. Open idle adjust needle by turning VA

turns counterclockwise.

D. Start engine. Follow preceding starting

instruction. Run engine a few minutes to

warm it up.

2. Remote Control Adjustments (See figure 37.)

To obtain satisfactory engine performance,

the engine and remote equipment controls

must be adjusted properly. If it is necessary

to check the engine control adjustments,

proceed as follows:

A. Set remote equipment control at FAST or

HIGH SPEED and keep it in this position.

With control in this position, control lever

should touch high speed stop. If it does,

the controls are adjusted correctly and no

fOTther adjustment should be necessary.

If control lever does not touch high speed

stop, proceed to Instruction B.

B. Loosen clamp screw just enough so remote

control cable can be moved in cable clamp

(do not remove cable clamp from control

bracket or disconnect. Remote control

cable from control lever).

C. Move control lever so it is touching high

speed stop and hold it in this position.

With control lever in this position, tighten

clamp screw so that cable clamp will hold

remote control cable in place when remote

equipment control is used.

The engine controls should now be

adjusted correctly.

15

Page 16

Control Bracket

/ mu

FIGURE 37.

3. NEVER TAMPER WITH ENGINE GOVERNOR

WHICH IS FACTORY SET FOR PROPER

ENGINE SPEED. OVERSPEEDING ENGINE

ABOVE FACTORY HIGH SPEED SETTING

CAN BE DANGEROUS. IF YOU THINK THE

ENGINE GOVERNED HIGH SPEED NEEDS

ADJUSTING, CONTACT YOUR NEAREST

AUTHORIZED SEARS SERVICE CENTER,

WHO HAS THE PROPER EQUIPMENT AND

EXPERIENCE TO MAKE ANY NECESSARY

ADJUSTMENTS.

SPARKPLUG:

1. Remove the spark plug each time you change

the oil and inspect it. See figure 38.

A. The electrodes should be kept clean and

free OF CARBON. The presence of carbon

or excess oil will greatly deter proper

engine performance.

B. If possible, check the spark plug gap (area

between electrodes) using a wire feeler

gauge. This specification should be .030.

2. if you need a spark plug refer to the yellow

pages of your phone book under “Engines Gas

oline" for an authorized dealer.

STORAGE

If the tiller is not to be used for a while, the

following procedure should be followed. The

tines, depth bar, transmission and wheels should

be cleaned of all dirt, it is very important that the

unit be stored in a level position to prevent engine

oil from draining into the cylinder head cavity.

Engines on tillers to be stored between seasons

should be completely drained of fuel to prevent

gum deposits forming on essential carburetor

parts, and fuel tank.

///^

TILLER INSTRUCTIONS FOR WINTER

OPERATION (under 40*F.)

Engine Lubrication. Drain the summer engine oil

while engine is warm. Refill with new “winter

grade” oil. Run engine until warm to distribute the

new winter oil.

Use oil “for service” SC, SD, or SE. Use 5W-20 or

5W-30. If not available, use 10W, or 10W-30.

Fuel. Replace any summer gasoline on hand or in

the fuel tank with fresh winter-grade gasoline. Use

lead-free or leaded “regular” grade automotive

gasoline. Winter fuels have additives for faster

starting. Keep fuel tank full.

NOTE

Many automotive gasolines no long

er contain “de-icer.” A can of gas

line de-icer fluid added to yourgasoline supply will help maintain the

engine’s winter reliability.

Cold Starting Hints

1. Be sure to use proper winter-grade oil and

gasoline.

2. Declutch all possible external loads.

3. Set governor control at low-speed position.

4. Turn carburetor needle valve approximately

1 /8 turn counterclockwise. (Richer fuel

mixture) This will improve cold weather

starting and operation.

16

Page 17

NOTES

17

Page 18

Repair Parts 8-H.P. Tiller Model 247.298760

18

29 27

Page 19

Repair Parts 8-H.P. Tiller Model 247.298760

REF.

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

1

PART

NO.

710-0160

Hex Wash. Hd. AB-Tapp Scr.

DESCRIPTION

#8 X .62” Lg.*

2

04777

3

4

5

01166

710-0253

715-0119

Handle Ass’y.

Grip

Hex Scr. 3/8-16 X 1.00” Lg.‘

Spring Roll Pin 5/32” Dia. x

1.12” Lg.

6

04602

7

710-0451

8

04586

9

711-0599

06811

714-0145

732-0322

736-0119

714-0145

712-0798

”U”-Clevis Pin .500” Dia.

Carr. Bolt 5/16-18 x .75” Lg.*

“□’’-Channel Plate

Clevis Pin

Depth Bar

Internal Cotter Pin

Depth Bar Spring Clip

L-Wash. 5/16” Scr.*

Internal Cotter Pin

Hex Nut 3/8-16 Thd.*

736-0169 L-Wash. 3/8” Scr*

06805

736-0105

710-0152

710-0118

Handle Brkt.—L.H.

Bell. Wash. 3/8” I.D.

Hex Scr. 3/8-24 X 1.00” Lg.*

Hex Sems Scr. 5/16-18 x

.75” Lg.*

736-0169

712-0241

736-0253

741-0116

734-0584

L-Wash. 3/8” Scr*

Hex Nut 3/8-24 Thd.*

Bell. Wash.

Flange Brg. w/Flats .631 I.D.

Wheel Ass’y. Comp.

738-0318 Shid. Bolt .625” Dia. x 2.75”

Lg. V2-2O Thd. 52

712-0267

Hex Nut 5/16-18 Thd.*

REF.

PART

NO.

28

29

30

31

32

NO.

736-0119

736-0921

L-Wash. 5/16” Scr*

L-Wash. 1/2” Scr*

712-0239 Hex Cent. L-Nut V2-20 Thd.

06813

06792

Wheel Yoke Ass’y.

Engine “U”-Channel Ass’y.—

DESCRIPTION

L.H.

33

34

712-0267

710-0322

Hex Nut 5/16-18 Thd.*

Hex Sems Scr 5/16-18 x

1.00” Lg.

06794

35

Engine “U”-Channel Ass’y.—

R.H.

36

06806 Handle Brkt.—R.H.

37

38

39

40

41

42

43

711-0599

736-0119

712-0267

06816

712-0267

06807

710-0599

Clevis Pin

L-Wash. 5/16” Scr*

Hex Nut 5/16-18 Thd.*

“□’’-Channel Brkt. Ass’y.

Hex Nut 5/16-18 Thd.*

Tail Piece

Thread Rolling Scr. V4-20 x

.50” Lg.

44

712-0158

45

736-0159

46

735-0126 Rubber Wash.

47

747-0271

48

04810

49

746-0272

Hex Cent. L-Nut 5/16-18 Thd.

FI-Wash. .344 I.D. x .87” O.D.

Control Rod

Shift Lever

Throttle Control Ass’y.

Comp.

50

714-0145 Internal Cotter Pin

51

53

711-0198

731-0189

720-0183

Ferrule

Knob—Throttle Control

Ball Knob—Shift Lever

•Standard Hardware Items—May Be Purchased Locally.

19

Page 20

Repair Parts 8-H.P. Tiller Model 247.298760

-----

29

—30

31

20

Page 21

Repair Parts 8-H.P. Tiller Model 247.298760

REF.

NO.

10

11

12

13

14

15

16

17

18

19 04900

20

21

1 22

23

24

25

26

27

PART 1

NO.

1 .

^52-0663 Engine Tecumseh Model

DESCRIPTION

HM80-15162E

2

710-0599 Thread Rolling Scr. V4-20 x .62” Lg.

.50” Lg.

3

04899 Belt Cover

4

04896

Front Belt Guard Support

Ass’y.

5

6

7

8

9

736-0114

710-0121

717-0390

736-0142

756-0313

Internal L-Wash. V2” Dia.

Hex Scr. V2-20 X .15 Special

Variable Speed Pulley Ass’yFI-Wash. .281 I.D. x .50O.D.

X .63

Idler Pulley

712-0262 Hex Jam Nut 3/8-24 Thd.

756-0305

Pulley 4.50” Dia.

736-0231 FI-Wash. 5/16” I.D. x 1.120”

O.D.

736-0119

710-0573

L-Wash. 5/16” Scr.* 43

Hex Scr. 5/16-18 x 1.25” Lg.*

710-0230 Hex Scr. V4-28 x .50” Lg.*

754-0231

754-0232

712-0239

“V”-Belt V2” X 28” Lg.

”V”-Belt V2” X 20” Lg.

L-Nut V2-2O Thd.

Friction Wheel Ass’y.

710-0191

736-0169

736-0258

Hex Scr. 3/8-24 x 1.25” Lg.*

L-Wash. 3/8” Scr.*

FI-Wash. 3/8” I.D. x 1.00”

O.D.

756-0306

714-0133

750-0229

Engine Pulley

Sq. Key 3/16 x 1.50” Lg.

Spacer .635” I.D. x .88 O.D. x

1.035” Lg.

732-0376

710-0599

Extension Spring

Hex Tapp Scr. V4-20 x .50”

Lg.

REF.

NO.

30 10844

PART

NO.

28

04898

29

715-0124 Spring Pin Spiral 5/32 Dia. x

Belt Guard Support—Rear

DESCRIPTION

Sheave Half

31 741-0139 Ball Bearing

32

750-0146 Spacer

33 04893

34 747-0271

35

738-0140

36

711-0494

37

710-0515

714-0115

38

Idler Arm Ass’y.

Control Rod 3/8” Rod *

Shid. Bolt .437 Dia. x .180

Spacer .510 I.D. x .760 O.D.

X .390” Lg.

Hex Scr. V2-2O X 3.50” Lg.

Cotter Pin 1/8” Dia.*

39 04889 Pivot Arm Ass’y.

40

714-0145 Internal Cotter Pin V2” Dia.

41 711-0599

42

742-0175

742-0174

44

06797 Outer Tine Adapter Ass’y.

45

04695 Outer Tine Ass’y. Comp.—

Clevis Pin

Tine—L.H.

Tine—R.H.

L.H.

46

712-0241 Hex Nut 3/8-24 Thd.*

47

736-0169

48

710-0191 Hex Scr. 3/8-24 x 1.25” Lg.*

49

06821

L-Wash. 3/8” Scr.*

Inner Tine Ass’y. Comp.—

L.H.

50 06798 Inner Tine Adapter Ass’y.

51 712-0267

52 736-0170

53 06822

Hex Nut 5/16-18 Thd.*

Shakeproof Washer

Inner Tine Ass’y. Comp.—

R.H.

54

04696

Outer Tine Ass’y. Comp.—

R.H.

55

04776 Tine Shield

56

710-0442

Hex Scr. 5/16-18 x 1.50” Lg.*

•Standard Hardware Items—May Be Purchased Locally.

TILLER ACCESSORIES

Til-Row Attachment 8” Furrower

Leveling/Snow-Blade Kit

V-Bar Cultivating Kit

Drag Stake Cultivating Kit Cultivating Shields

V-Bar Frame

4-pt. Cultivator Tines 13 X 5.00—6 Pneumatic Traction Tires

Hiller/Furrower

Depth Gauge Wheels

6-Tang Universal Cult.

Drag Stake

THESE ACCESSORIES ARE AVAILABLE IN THE

SEARS BIG SPRING CATALOG..

21

15” Sweep Cult./Hoe

32” Leveling Rake

32” Leveling/Snow-Blade

Wheel Weights

Tire Chains (Pr.)

Wheel Weights F/Leveling Snow-Blade

Page 22

Repair Parts 8-H.P. Tiller Model 247.298760

28fO|' f 29 30 3) 1

NOTE: Use 14 ounces of

Plastilube #1

Order Part No. 737-0133

Repair Parts Transmission 04907

REF.

NO.

1

2

3

4

5

PART

NO.

750-0315

738-0182

721 -0132

04885

741-0155

COLOR

CODE

DESCRIPTION

Spacer .657 I.D. x .78 O.D.

X 2.19

Jack Shaft

Gasket for Housing

Housing Half—L.H.

Bail Bearing .625 I.D. x

NEW

PART

REF.

N

1.375 O.D.

05034

6

7

750-0229

756-0264

8

Bearing Housing

Spacer .625 I.D. x .88 O.D.

X1.035

Chain Case Pulley 6.00”

Dia. (380)

756-0262

Chain Case Pulley 6.00”

Dia. (385)

9

710-0643 Hex Scr. 5/16-18x1.00”

Lg. Special

10

736-0119

11

736-0231 FI-Wash. 5/16 I.D. X 1.125

L-Wash.5/16” Scr.*

O.D. x .125

12

710-0599 Hex Wash. Hd. Self Tapp.

Scr. V4-20 x .50” Lg.

14

712-0267 Hex Nut 5/16-18 Thd.“*

710-0644 Hex Scr. 3/8-16 X 3.25” Lg.

15

721-0102

16

17

712-0138 Hex Nut V4-28Thd.*

736-0329

18

19

736-0259 FI-Wash. 1.0” I.D. X 1.62

Oil Seal 1” I.D. X 1.357 O.D.

L-Wash. V4” Scr.*

O.D. X.090

20

750-0314

'For faster service obtain standard nuts, bolts, and washers locally. If these items cannot be ob

tained locally, order by part number and size as shown on parts list.

Spacer 1.0”I.D.x 2.0” O.D.

X.68

22

PART

36

NO.

06800

710-0195

721 -0133

741-0198

712-0798

736-0169

710-0322

710-0538

04886

748-0229

713-0206

713-0131

713-0186

748-0855

713-0187

738-0320

NO.

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

37 713-0182

713-0181

38

738-0308

39

715-0114

40

714-0133

41

COLOR

CODE

DESCRIPTION

Tine Shaft Ass’y.

Hex Scr. V4-28x.62”Lg.‘

Gasket for Bearing Hsg.

Bearing Housing Ass’y.

HexNut3/8-16Thd.*

L-Wash.3/8” Scr.*

HexSemsScr. 5/16-18x

1.00” Lg.*

Hex Scr. 5/16-18 x .62”

Lg. Special

Housing Half—R.H.

Hex Flanged Bearing .630

I.D.

Sprocket 10 Teeth x .500

Pitch

#41 Chain V2” Pitch x 33

Links Endless

#42 Chain V2” Pitch x 48

Links Endless

Flange Bearing .628 I.D.

#50 Chain 5/8” Pitch x 28

Links Endless

Sprocket Shaft

Sprocket Bearing Sleeve

Ass’y.

Sprocket Sleeve Ass’y.

Sprocket Shaft

Spring Pin Spiral V4” Dia.

X1.5” Lg.

Sq. Key 3/16 X1.50” Lg.

NEW

PART

N

Page 23

TE CU MSE H 4- aCL E EN GIN E

MODEL NUMBER: HM80-155162E

126

124

92-^\76'^-d^

82 83 >

97- 77 161

/ti -7

128 149

23

Page 24

TE CU MSE H 4- acU E NG INE

MODEL NUMBER: HM80-155162E

Ref.

No.

10

11

12

13

14

15

16

17

19

20

21

22

22

22

23

24

24

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

43

44 27878A

44 27880A

45

46

47

48

50

51

52

53

54

Part Ref.

No.

1

2

3

4

5

6

7

8

9

55

56

34348

27652

32630

27642 Plug, Oil drain

30699C

30700 Yoke, Governor

650494

29642

29916

29826

29216 Nut, Square, 10-32

650548

33364 Lever, Governor

29918

30322 Nut & Lockwasher., 8-32

29536

650561

33365B

29783

33245 Gear, Crankshaft

34329 Piston, Pin & Ring Assy. (Std.) (Incl.

34330

34331

27888

34332

34333

34334

32591C

650662A

34242

34034

34143

*33253 Gasket, Cylinder cover

33367A Cover, Cylinder (Incl. Nos. 32, 33 &

33368

31950

31845 Shaft, Mechanical governor

30588A

29193

30591

33369

28763

30590A Washer, Flat

650488

650493

34035

34036

27882

27881

32581

650489

34235

32589

650737 Screw, Hex washer hd. taptite, 1/4-20

33662

650490

34030

8116

Part Name

Cylinder Assy, (Incl. Nos. 2,3&4)

Pin, Dowel

Seal, Oil

Rod Assy., Governor (Incl. Nos. 6&

7)

Screw, Fil. hd. Sefns, 6-40x 5/16

Ring, Retaining

Clamp, Governor lever

Screw, Hex washer hd., 10-32 x 3/4

Screw, Hex washer hd., 8-32 x 5/16

Lockwasher, No. 8 E.T.

Baffle, Blower housing

Screw, Hex hd. Sems, 1 /4-20 x 5/8

Crankshaft Assy. (Incl. Nos. 20&21)

Pin, Crankshaft gear

Nos. 23&24)

Piston, Pin & Ring Assy. (.010 oversize) (Incl. Nos. 23& 24)

Piston, Pin 8e Ring Assy. (.020 oversize) (Incl. Nos. 23& 24)

Ring, Piston pin retaining

Ring Set, Piston (Std.)

Ring Set, Piston (.010 oversize)

Ring Set, Piston (.020 oversize)

Rod Assy., Connecting (Incl. Nos. 26

&27)

Bolt, Connecting rod

Dipper, Oil

Lifter, Valve

Camshaft (Mech. Compression Release)

34)

Bushing, Crankshaft

Seal, Oil

Spool, Governor

Ring, Retaining

Gear Assy., Governor (Incl. No. 40)

Bracket, Governor gear

Screw, Hex washer hd. shakeproof.

10-32 X 19/32

Screw, Hex hd. Sems, 1/4-20 x 1-1/4

Screw, Hex hd. Sems, 1/4-20 x 1-3/4

Valve, Intake (Std.) (Incl. No. 47)

Valve, Intake (1/32" oversize) (Incl.

No. 47)

Valve, Exhaust (Std.) (Incl. No. 47)

Valve, Exhaust (1/32"oversize) (Incl.

No. 47)

Cap, Upper valve spring

Spring, Valve

Cap, Lower valve spring

Screw, Hex hd. Sems, 1/4-20x 5/8

Wire, Ground

Key, Flywheel

X 1/2

Hub & Screen Assy., Starter

Washer, Belleville

Nut, Hex

Head, Cylinder

Part

No.

57

58 6021A

59 650727

60 650691

61 33272

63

65

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91 650788

92

93

94

95

96

97

108

109

110

112

115

119

120

121

122

123

124

126

128

143

144

145

146

147

No.

*34031

650713

33636 Plug, Spark (Champion J-8 or equiva-

34251

Canada tions require RJ-17LM resistor spark

28423

28424

*27896

28425

27627

650128

*27915

33877

650378

*33861

30088A

29752

30705 Line, Fuel

26460

33876

33461A Control Assy., Speed (Incl. Nos. 82,

650549

31342

33371

33878

33374

27793

28942

33375B

29747A

610973

33013

650760

33273

650128

29919

34154

34155

650665

650561

29752

33756

650729

31E38

31297

*29673

34156

32387A

34374

28820

*27272

33266

33268

33269A

Part Name

Gasket, Cylinder head

Screw, Hex hd. cap, 5/16-18 x 1-1/2

Screw, Special hex hd. tapped.

5/16-18x1-3/4

Washer, Flat

Cover, Cylinder head

Screw, Hex hd., 5/16-18 x 5/8

lent) Exceotfor Canada

Resistor Spark Plug (Canadian Regula-

plug)

Body, Breather

Element, Breather

Gasket, Breather cover

Cover, Valve spring

Tube, Breather

Screw, Fil. slotted hd. Sems, 10-24 x

1/2

Gasket, Intake pipe

Pipe,Intake

Screw, Fil, hd. Sems, 5/16-18 x 1-1/8

Gasket, Carburetor

Screw, Fil. hd. Sems, 1 /4-28 x 1

Nut& Lockwasher, 1/4-28

Clamp, Fuel line

Gasket, Stator

83, 86&92)

Screw, Fil. hd., 5-40x 7/16

Spring, Compression

Link, Governor lever-to-bellcrank

Link, Governor lever-to-throttle

Spring, Extension

Clip, Conduit

Screw, Hex hd. Sems, 10-32 x 3/8

Housing, Blower

Screw, Hex hd. Sems, 5/16-24 x 3/4

Screw, Hex hd. spin-lock thread

forming, 5/16-18 x 3/4

Terminal Assy.

Cover, Starter bubble

Screw, Pan hd., taptite, 8-32 x 7/16

Extension, Blower housing

Screw, Fil. slotted hd. Sems, 10-24 x

1/2

Screw, Hex washer hd. Sems, taptite.

8-32 x 1/2

Plate, Fuel tank mounting

Bracket, Tank mounting

Screw, Hex washer hd. Sems, self-tap,

1/4-14x7/8

Screw, Hex hd. Sems, 1 /4-20 x 5/8

Nut& Lockwasher, 1/4-28

Muffler

Screw, Hex hd., 5/16-18 x 3-3/16

Plate, Muffler locking

Dipstick, Oil (Incl. No. 123)

Gasket, Dipstick

Tank Assy., Fuel (Incl. No. 126)

Cap, Fuel filler

Decal, Instruction

Screw, Fil. hd. Sems, 10-32 x 1/2

Gasket, Air cleaner

Bracket, Air cleaner

Element, Air cleaner

Cover, Air cleaner

* Indicates Parts Included in

Gasket Set, Ref. No. 165.

24

Page 25

TK UM SEH 4 -a OE EN GI NE

Ref.

No,

148

149

161

162

Part

No,

33267

650513

631979

610842

Part Name

Bracket, Air cleaner

Nut, Wing, 1/4-20

Carburetor (Incl. No. 75)

Magneto (The complete magneto is

not available as an assembly. The

magneto number is shown for refer

ence purposes only. Order component

parts individually, as shown in parts

list.)

MODEL NUMBER: HM80-155162E

Ref.

No.

163

165

Part

No.

590479

33279C

694138

Part Name

Starter, Rewind

Gasket Set (Incl. items marked *)

Owners Manual

^IndicatesParts Included in

Gasket Set, Ref. No. 165.

CARBURETOR NO. 631979

I > I

\ I

*io23ol '

24 ”

—

Ref.

No.

6 650417

8 630735

9 631753

Part

No.

631979 Carburetor

631776

1

631970

2

3 631778

4

650506

630766 Spring, Idle regulating screw

5

5A

630738

7

631812 Shaft & Lever Assy., Choke

Shaft & Lever Assy., Throttle

Spring, Throttle return

Shutter, Throttle

Screw, Rd. hd., 4-40 x 3/16

Spring, Main adjustment screw

Screw, Idle regulating

Spring, Choke return

Shutter, Choke

Part Name

10 *630748 Plug, Welch

11 *631027 Plug, Welch

12 *631021

13 631022 Clip, Inlet needle

14

632019 Float, Carburetor

*631024

15

16 631867 Bowl, Float

17 632043 Spring

Inlet Needle, Seat & Clip Assy.

(Incl. No. 13)

Shaft, Float

18 631183 Washer, Felt

21 27110

22

*631583

23 630740

24

*630898 Screw, Idle adjustment

25 *631028

631803

26

27

631184 Washer

28 631972

29 631971

30

630739 Washer, Flat

31 631978

Gasket, Bowl-to-body

Adjustment Screw Assy., Main

(Incl. Nos. 5A,21,23&30)

"0" Ring, Adjustment screw

Gasket, Bowl-to-body

Fuel Fitting

Retainer, Seal

Seat, Oust

Repair Kit (Incl. items marked *)

25

Page 26

MAGNETO NO. 610842

The complete magneto is not

available as an assembly. The

.magneto number is shown for

reference purposes only. Order

component parts individually,

as shown in parts list.

Ref.

No.

1 610841

lA 610934

2

3

4

6

7

8

9

10

11

13

14

15

16

17

14

18

20

Part

No.

610842

30551

610947

610957

30547A

610385 Washer, Terminal

610408 Nut, Terminal

29181 Screw and Washer Assembly,

610593

33356 Tab, Ground terminal

30560A Coil Assembly (Incl. No. 14)

30554 Wire, Ignition lead

30548A

30545

305618

30549

31311

Magneto

Flywheel (Inch No. 1A)

Fan

Spripig, Breaker box dust cover

Cover, Oust

Gasket, Dust cover

Breaker Assembly

Breaker

Screw, Condenser fastening

Condenser

Core and Plate Group

Stator Assembly (Incl. Nos. 2, 3,

4, 6 thru 16,18 & 20)

Felt, Cam wiper

Clip, Coil lodKing

Part Name

REWIND STARTER NO. 590479

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

Part

No.

590479

590480

590481

590482

32024

590483

590484

590485

590486

590456

590487

590387

590488

Part Name

Rewind Starter

Screw, Center

Cam, Dog

Spring, Brake

Washer, Brake

Ring, Retainer

Dog

Spring, Dog

Pulley & Bearing Assy.

Rope, Starter

Spring & Keeper Assy.

Handle Assy., Starter

Housing Assy., Starter

26

Page 27

Page 28

owners

manual

HOW TO ORDER

REPAIR PARTS

The Model Number will be found stamped on a plate attached to the

chassis. Always mention the Model Number when requesting service or

repair parts for your tiller.

All parts listed herein may be ordered through SEARS ROEBUCK AND CO.

or SIMPSON SEARS LIMITED RETAIL or CATALOG STORE.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING

INFORMATION AS SHOWN IN THIS LIST.

1. The PART NUMBER

2. The MODEL NUMBER 247.298760

3. The PART DESCRIPTION

4. The NAME OF MERCHANDISE- Tiller

MODEL NO.

247.298760

Sears

SERVICE

is at

Yoar

SERVICE

If the parts you need are not stocked locally, your order will be

electronically transmitted to a Sears Repair Parts Distribution Center for

expedited handling.

Your Sears merchandise takes on added value when you discover that Sears

has over 2,000 Service Units throughout the country. Each is staffed by

Sears-trained, professional technicians.

SBARa ROEBUCK AND GO.» ChicsaeoJlL 60684 UJSLA.

PART NO. 770-7762

PRINTED IN U.S.A.

Loading...

Loading...