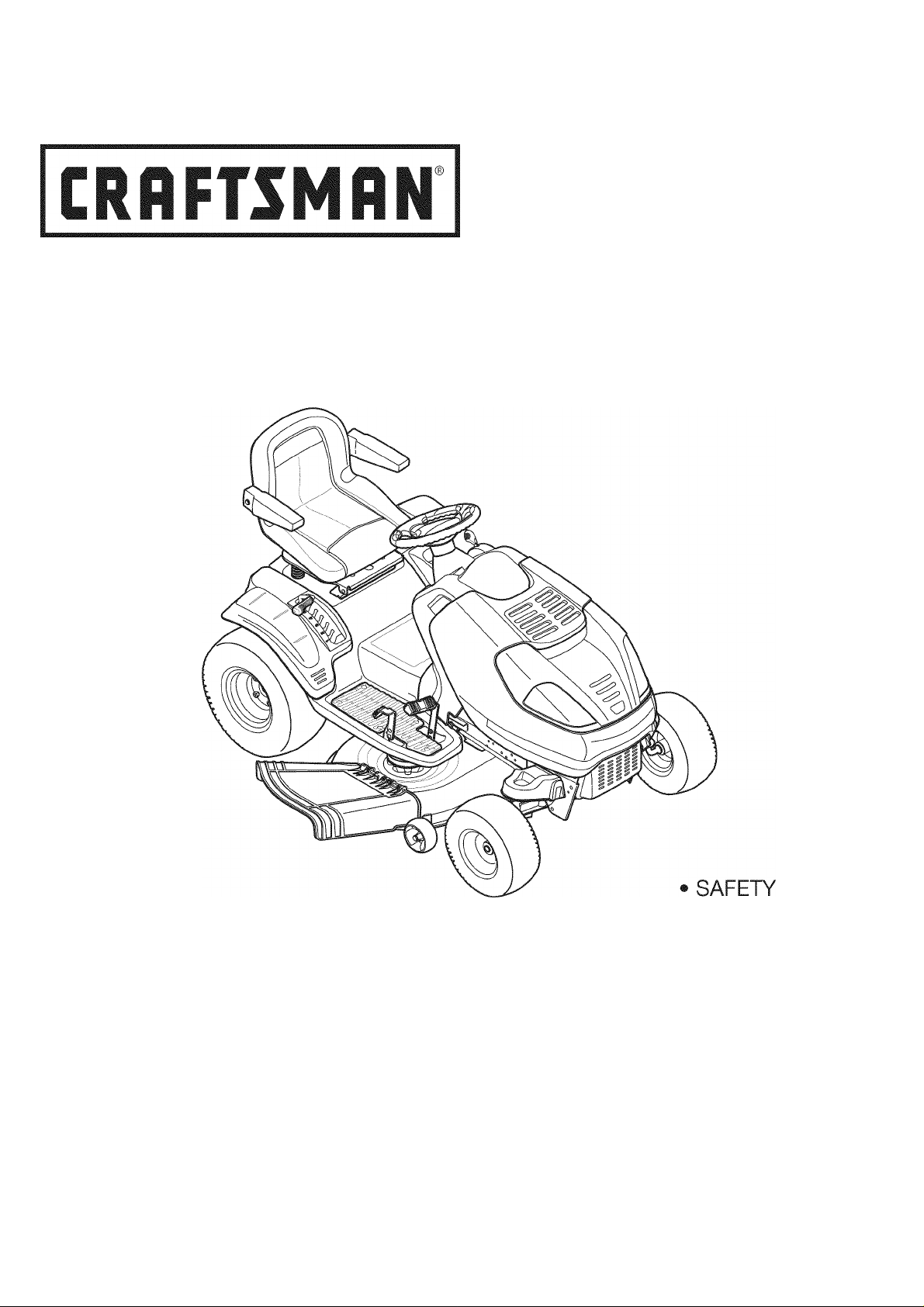

Page 1

Operator's Manual

REVOLUTION

ZERO TURN RIDING MOWER

Model No. 247.28933

For answers to your questions about this product,

call 1-800-659-5917.

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORM N0.769-04608A

• ASSEMBLY

• OPERATION

• MAINTENANCE

• PARTS LIST

• ESPAÑOL, p. 58

4/21/2009

Page 2

TABLE OF CONTENTS

Warranty Statement

Safe Operation Practices

Safety Labeis

Assembiy.......................................................Page 10

Standard Repiacement Parts & Attachments Page 10

Operation

Service SMaintenance

................................................

........................................

............................

..................................................

............................

Pages 3-8

Pages 11-17

Pages 18-29

Page 2

Page 9

Off-Season Storage.............................................Page 30

Troubieshooting

Parts List

Repair Protection Agreement..............................Page 57

Españoi................................................................Page 58

Service Numbers

..................................................

.................................................

......................................

Page 31

Pages 32-53

Back Page

WARRANTY STATEMEN

Craftsman Full Warranty

When operated and maintained according to all supplied instructions, if any non-expendable part of this riding equipment fails due to a defect in

material or workmanship within two years from the date or purchase, call 1-800-659-5917 to arrange for free in-home repair.

The frame and front axle will be repaired free of charge for five years from the date of purchase if defective in material or workmanship.

All of the above warranty coverage applies for only 90 days from the date of purchase if this riding equipment is ever used for commercial or

rental purposes.

In all cases, it repair proves impossible, the riding equipment will be replaced free of charge with the same or an equivalent model.

The battery will be replaced free of charge for 90 days from the date of purchase it defective in material or workmanship (our testing proves that it

will not hold a charge).

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

• Expendable items that become worn during normal use, including but not limited to blades, spark plugs, air cleaners, belts, and oil filters.

• Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage caused by towing objects beyond the capability of the

riding equipment, impacting objects that bend the frame or crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage caused by improper

storage, failure to use the proper grade and amount of engine oil, failure to keep the deck clear of flammable debris, or failure to maintain the

riding equipment according to the instructions contained in the operator's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale). In general, fuel should be used

within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

I

PRODUCT SPECIFICATIONS

Engine Oil: SAE 30

Fuel: Unleaded Gasoline

Spark Plug: Champion® RC12YC

Engine: Briggs & Stratton Platinum V-Twin

§ Sears Brands, LLC

I

Model Number

Serial Number

Date of Purchase.

MODEL NUMBER

J

........

........

Record the model number, serial number

and date of purchase above

Page 3

SAFETY INSTRUCTIONS

J

AWARNING

This symbol points out important safety instructions which, it not

followed, could endanger the personal safety and/or property of

yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with

these instructions may result in personal injury. When you see this

symbol, HEED ITS WARNING!

AWARNING

CALIFORNIA PROPOSITION 65

Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California

to cause cancer and birth defects or other reproductive harm.

Battery posts, terminals, and related accessories contain lead and

lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

GENERAL OPERATION

• Read, understand, and follow all instructions on the machine and

in the manual(s) before attempting to assemble and operate.

Keep this manual in a safe place for future and regular reference

and for ordering replacement parts.

• Be familiar with all controls and their proper operation. Know how

to stop the machine and disengage them quickly.

• Never allow children under 14 years old to operate this machine.

Children 14 years old and over should read and understand the

operation instructions and safety rules in this manual and should

be trained and supervised by a parent.

• Never allow adults to operate this machine without proper

instruction.

• To help avoid blade contact or a thrown object injury, keep

bystanders, helpers, children and pets at least 75 feet from the

machine while it is in operation. Stop machine it anyone enters

the area.

• Thoroughly inspect the area where the equipment is to be used.

Remove all stones, sticks, wire, bones, toys, and other foreign

objects which could be picked up and thrown by the blade(s).

Thrown objects can cause serious personal injury.

• Plan your mowing pattern to avoid discharge of material toward

roads, sidewalks, bystanders and the like. Also, avoid discharg

ing material against a wall or obstruction which may cause

discharged material to ricochet back toward the operator.

A DANGER

This machine was built to be operated according to the safe opera

tion practices in this manual. As with any type of power equipment,

carelessness or error on the part of the operator can result in serious

injury. This machine is capable of amputating fingers, hands, toes

and feet and throwing debris. Failure to observe the following safety

instructions could result in serious injury or death.

AWARNING

Your Responsibility—Restrict the use of this power machine to

persons who read, understand and follow the warnings and instruc

tions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

Always wear safety glasses or safety goggles during operation

and while performing an adjustment or repair to protect your eyes.

Thrown objects which ricochet can cause serious injury to the

eyes.

Wear sturdy, rough-soled work shoes and close-fitting slacks and

shirts. Loose fitting clothes and jewelry can be caught in movable

parts. Never operate this machine in bare feet or sandals.

Be aware of the mower and attachment discharge direction and

do not point it at anyone. Do not operate the mower without the

discharge cover or entire grass catcher in its proper place.

Do not put hands or feet near rotating parts or under the cutting

deck. Contact with the blade(s) can amputate hands and feet.

A missing or damaged discharge cover can cause blade contact

or thrown object injuries.

Stop the blade(s) when crossing gravel drives, walks, or roads

and while not cutting grass.

Watch tor traffic when operating near or crossing roadways. This

machine is not intended for use on any public roadway.

Do not operate the machine while under the influence of alcohol

or drugs.

Mow only In daylight or good artificial light.

Never carry passengers.

Disengage blade(s) before shifting into reverse. Back up slowly.

Always look down and behind before and while backing to avoid a

back-over accident.

Page 4

SAFETY INSTRUCTION

I

Slow down before turning. Operate the machine smoothly. Avoid

erratic operation and excessive speed.

Disengage blade(s), set parking brake, stop engine and wait until

the blade(s) come to a complete stop before removing grass

catcher, emptying grass, unclogging chute, removing any grass or

debris, or making any adjustments.

Never leave a running machine unattended. Always turn off

blade(s), set parking brake, stop engine and remove key before

dismounting.

Use extra care when loading or unloading the machine into a

trailer or truck. This machine should not be driven up or down

ramp(s), because the machine could tip over, causing serious

personal injury. The machine must be pushed manually on

ramp(s) to load or unload properly.

Muffler and engine become hot and can cause a burn. Do not

touch.

Check overhead clearances carefully before driving under low

hanging tree branches, wires, door openings etc., where the

operator may be struck or pulled from the machine, which could

result in serious injury.

Disengage all attachment clutches and depress the brake pedal

completely before attempting to start engine.

Your machine is designed to cut normal residential grass of a

height no more than 10”. Do not attempt to mow through unusually

tall, dry grass (e.g., pasture) or piles of dry leaves. Dry grass or

leaves may contact the engine exhaust and/or build up on the

mower deck presenting a potential fire hazard.

Use only accessories and attachments approved for this machine

by the machine manufacturer. Read, understand and follow all

instructions provided with the approved accessory or attachment.

Fora list of approved accessories and attachments, call 1-800

659-5917.

Data indicates that operators, age 60 years and above, are

involved in a large percentage of riding mower-related injuries.

These operators should evaluate their ability to operate the riding

mower safely enough to protect themselves and others from

serious injury.

If situations occur which are not covered in this manual, use care

and good judgment. Contact 1-800-659-5917 for information and

assistance.

SLOPE OPERATION

Slopes are a major factor related to loss of control and tip-over

accidents which can result in severe injury or death. All slopes require

extra caution. If you cannot back up the slope or it you feel uneasy on

it, do not mow it.

For your safety, use the Slope Guide included as part of this manual

to measure slopes before operating this machine on a sloped or hilly

area. If the slope is greater than 15 degrees as shown on the Slope

Guide, do not operate this machine on that area or serious injury could

result.

Do:

• Mow up and down slopes, not across. Exercise extreme caution

when changing direction on slopes.

• Watch tor holes, ruts, bumps, rocks, or other hidden objects.

Uneven terrain could overturn the machine. Tall grass can hide

obstacles.

• Use slow speed. Choose a low enough speed setting so that

you will not have to stop or shift while on the slope. Tires may

lose traction on slopes even though the brakes are functioning

properly. Always keep machine in gear when going down slopes

to take advantage of engine braking action.

• Follow the manufacturer’s recommendations for wheel weights

or counterweights to improve stability. For recommendations, call

1-800-659-5917.

• Use extra care with grass catchers or other attachments. These

can change the stability of the machine.

• Keep all movement on the slopes slow and gradual. Do not make

sudden changes in speed or direction. Rapid engagement or

braking could cause the front of the machine to lift and rapidly flip

over backwards which could cause serious injury.

• Avoid starting or stopping on a slope. If tires lose traction, disen

gage the blade(s) and proceed slowly straight down the slope.

Do Not:

• Do not turn on slopes unless necessary; then, turn slowly and

gradually downhill, if possible.

• Do not mow near drop-offs, ditches or embankments. The mower

could suddenly turn over if a wheel is over the edge of a cliff,

ditch, or it an edge caves in.

• Do not try to stabilize the machine by putting your foot on the

ground.

• Do not use a grass catcher on steep slopes.

• Do not mow on wet grass. Reduced traction could cause sliding.

• Do not attempt to coast downhill. Over-speeding may cause the

operator to lose control of the machine resulting in serious injury

or death.

• Do not tow heavy pull behind attachments (e.g. loaded dump cart,

lawn roller, etc.) on slopes greater than 5 degrees. When going

down hill, the extra weight tends to push the tractor and may

cause you to loose control, (e.g. tractor may speed up, braking

and steering ability are reduced, attachment may jack-knife and

cause tractor to overturn).

Page 5

SAFETY INSTRUCTIONS

J

CHILDREN

Tragic accidents can occur it the operator is not alert to the presence

of children. Children are often attracted to the machine and the mowing

activity. They do not understand the dangers. Never assume that

children will remain where you last saw them.

• Keep children out of the mowing area and In watchful care of a

responsible adult other than the operator.

• Be alert and turn machine off if a child enters the area.

• Before and while backing, look behind and down for small

children.

• Never carry children, even with the blade(s) shut off. They may

fall off and be seriously Injured or Interfere with safe machine

operation.

• Use extreme care when approaching blind corners, doorways,

shrubs, trees or other objects that may block your vision of a child

who may run Into the machine.

• To avoid back-over accidents, always disengage the cutting

blade(s) before shifting Into Reverse. If equipped, the “Reverse

Caution Mode” (blades operate while machine rides in reverse)

should not be used when children or others are around.

• Keep children away from hot or running engines. They can suffer

bums from a hot muffler.

• Remove key when machine Is unattended to prevent unauthorized

operation.

Never allow children under 14 years of age to operate this machine.

Children 14 and over should read and understand the Instructions and

safe operation practices In this manual and on the machine and should

be trained and supervised by an adult.

TOWING

• Tow only with a machine that has a hitch designed for towing. Do

not attach towed equipment except at the hitch point.

• Follow the manufacturers recommendation for weight limits tor

towed equipment and towing on slopes. For recommendations,

call 1-800-659-5917.

• Never allow children or others In or on towed equipment.

• On slopes, the weight of the towed equipment may cause loss of

traction and loss of control.

• Always use extra caution when towing with a machine capable of

making tight turns (e.g. “zero-turn” ride-on mower). Make wide

turns to avoid jack-knifing.

• Travel slowly and allow extra distance to stop.

• Do not coast downhill.

SERVICE

Safe Handling of Gasoline

To avoid personal injury or property damage use extreme care in

handling gasoline. Gasoline is extremely flammable and the vapors are

explosive. Serious personal injury can occur when gasoline is spilled

on yourself or your clothes which can ignite. Wash your skin and

change clothes immediately.

• Use only an approved gasoline container.

• Never fill containers inside a vehicle or on a truck or trailer bed

with a plastic liner. Always place containers on the ground away

from your vehicle before filling.

• When practical, remove gas-powered equipment from the truck

or trailer and refuel it on the ground. If this is not possible, then

refuel such equipment on a trailer with a portable container, rather

than from a gasoline dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. Do not use

a nozzle lock-open device.

• Extinguish all cigarettes, cigars, pipes and other sources of

ignition.

• Never fuel machine indoors.

• Never remove gas cap or add fuel while the engine is hot or run

ning. Allow engine to cool at least two minutes before refueling.

• Never over fill fuel tank. Fill tank to no more than Vi inch below

bottom of filler neck to allow space for fuel expansion.

• Replace gasoline cap and tighten securely.

• If gasoline is spilled, wipe it off the engine and equipment. Move

machine to another area. Wait 5 minutes before starting the

engine.

• To reduce fire hazards, keep machine free of grass, leaves, or

other debris build-up. Clean up oil or fuel spillage and remove any

fuel soaked debris.

• Never store the machine or fuel container inside where there is an

open flame, spark or pilot light as on a water heater, space heater,

furnace, clothes dryer or other gas appliances.

• Allow a machine to cool at least five minutes before storing.

Page 6

SAFETY INSTRUCTION

I

General Service

• Never run an engine indoors or in a poorly ventilated area. Engine

exhaust contains carbon monoxide, an odorless, and deadly gas.

• Before cleaning, repairing, or inspecting, make certain the

blade(s) and all moving parts have stopped. Disconnect the spark

plug wire and ground against the engine to prevent unintended

starting.

• Periodically check to make sure the blades come to complete

stop within approximately (5) five seconds after operating the

blade disengagement control. If the blades do not stop within the

this time frame, your machine should be serviced professionally

by an authorized Sears Parts & Repair Center.

• Check brake operation frequently as It Is subjected to wear during

normal operation. Adjust and service as required.

• Check the blade(s) and engine mounting bolts at frequent

Intervals for proper tightness. Also, visually Inspect blade(s)

for damage (e.g., excessive wear, bent, cracked). Replace the

blade(s) with the original equipment manufacturer’s (O.E.M.)

blade(s) only, listed In this manual. Use of parts which do not

meet the original equipment specifications may lead to Improper

performance and compromise safety!

• Mower blades are sharp. Wrap the blade or wear gloves, and use

extra caution when servicing them.

• Keep all nuts, bolts, and screws tight to be sure the equipment Is

In safe working condition.

• Never tamper with the safety interlock system or other safety

devices. Check their proper operation regularly.

• After striking a foreign object, stop the engine, disconnect the

spark plug wire(s) and ground against the engine. Thoroughly

Inspect the machine for any damage. Repair the damage before

starting and operating.

• Never attempt to make adjustments or repairs to the machine

while the engine is running.

• Grass catcher components and the discharge cover are subject

to wear and damage which could expose moving parts or allow

objects to be thrown. For safety protection, frequently check

components and replace immediately with original equipment

manufacturer's (O.E.M.) parts only, listed In this manual. Use of

parts which do not meet the original equipment specifications may

lead to Improper performance and compromise safety!

• Do not change the engine governor settings or over-speed the

engine. The governor controls the maximum safe operating speed

of the engine.

• Maintain or replace safety and instruction labels, as necessary.

• Observe proper disposal laws and regulations for gas, oil, etc. to

protect the environment.

• According to the Consumer Products Safety Commission (CPSC)

and the U.S. Environmental Protection Agency (EPA), this product

has an Average Useful Life of seven (7) years, or 270 hours

of operation. At the end of the Average Useful Life, buy a new

machine or have the machine inspected annually by a Sears or

other qualified service dealer to ensure that all mechanical and

safety systems are working properly and not worn excessively.

Failure to do so can result In accidents, injuries or death.

DO NOT MODIFY ENGINE

To avoid serious injury or death, do not modify engine in any way.

Tampering with the governor setting can lead to a runaway engine and

cause it to operate at unsafe speeds. Never tamper with factory setting

of engine governor.

NOTICE REGARDING EMISSIONS

Engines which are certified to comply with California and federal

EPA emission regulations for SCRE (Small Cff Road Equipment) are

certified to operate on regular unleaded gasoline, and may include

the following emission control systems: Engine Modification (EM) and

Three Way Catalyst (TWC) If so equipped.

SPARK ARRESTOR

AWARNING

This machine is equipped with an internal combustion engine and

should not be used on or near any unimproved forest-covered,

brushcovered or grass-covered land unless the engine's exhaust

system Is equipped with a spark arrester meeting applicable local or

state laws (If any).

If a spark arrester Is used, it should be maintained in effective working

order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Cther

states may have similar laws. Federal laws apply on federal lands.

A spark arrester for the muffler is available through your nearest Sears

Parts and Repair Service Center.

Page 7

SAFETY INSTRUCTIONS

SAFETY SYMBOLS

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine

before attempting to assemble and operate.

Symbol Description

J

r

READ THE OPERATOR’S MANUAL(S)

Read, understand, and followall instructions in the manual(s) before attempting to assemble and

operate

DANGER— ROTATING BLADES

Never carry passengers. Never carry children, even with the blades off.

DANGER— ROTATING BLADES

Always look down and behind before and while backing to avoid a back-over accident.

WARNING— ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the blade(s)

can amputate hands and feet.

WARNING—THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING—THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

1#

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in

operation.

WARNING— SLOPE OPERATION

Do not operate this machine on a slope greater than 15 degrees.

WARNING—HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

DANGER — ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover or grass

catcher is in its proper place. If damaged, replace immediately.

Page 8

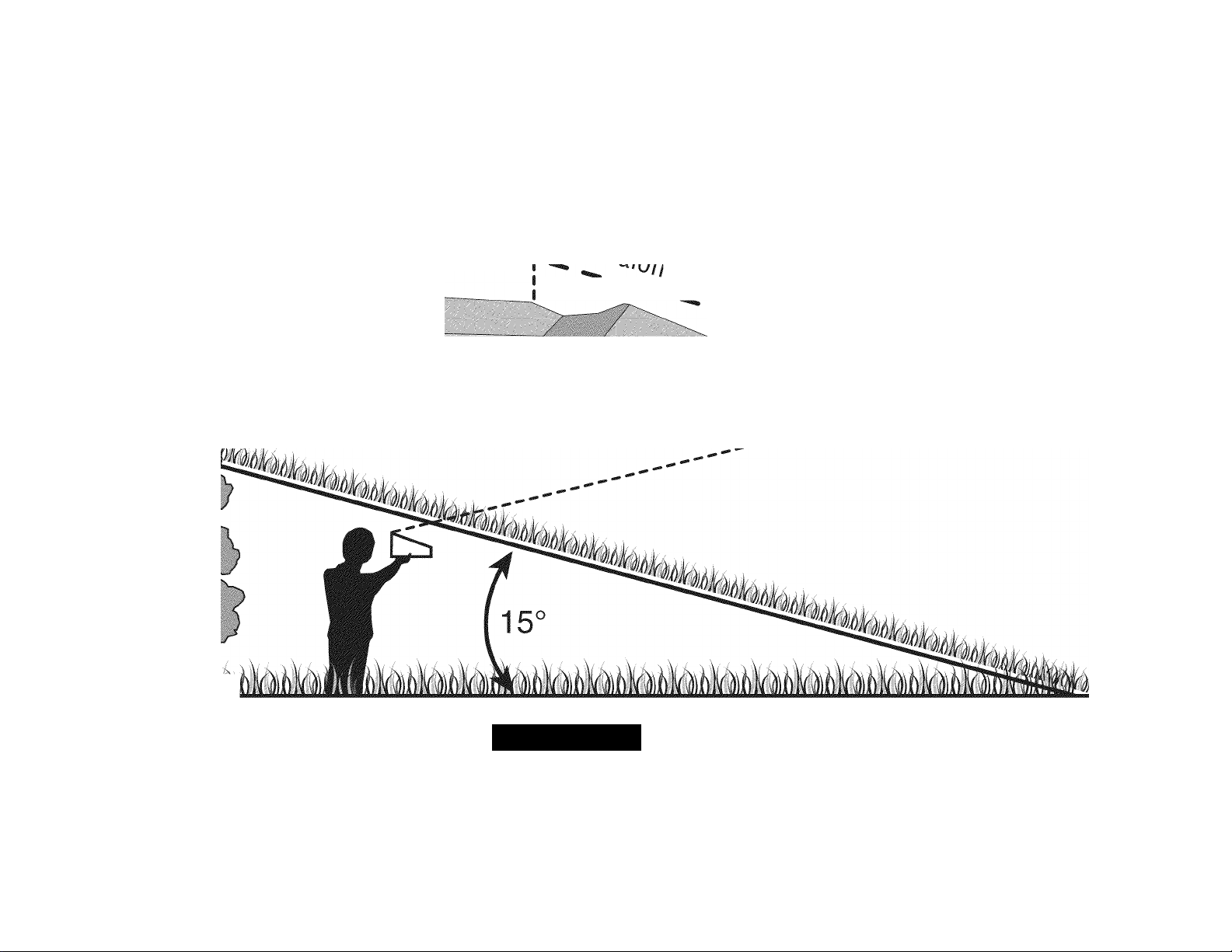

Sight and hold this level with a vertical tree...

^ J ^ Fold

or a corner

of

line frpn

a building.

or a fence post

sa /5<

^iope)

f

.••.*.»•■ 4 •. N. S

A WARNING

Use this page as a guide to determine slopes where you may not operate safely.

Do not operate your lawn mower on such slopes. Do not mow on inclines with a slope in excess of 15 degrees (a rise of approximately 2-1/2 feet every 10 feet). A riding mower

could overturn and cause serious injury. Operate riding mowers up and down slopes, never across the face of slopes.

Page 9

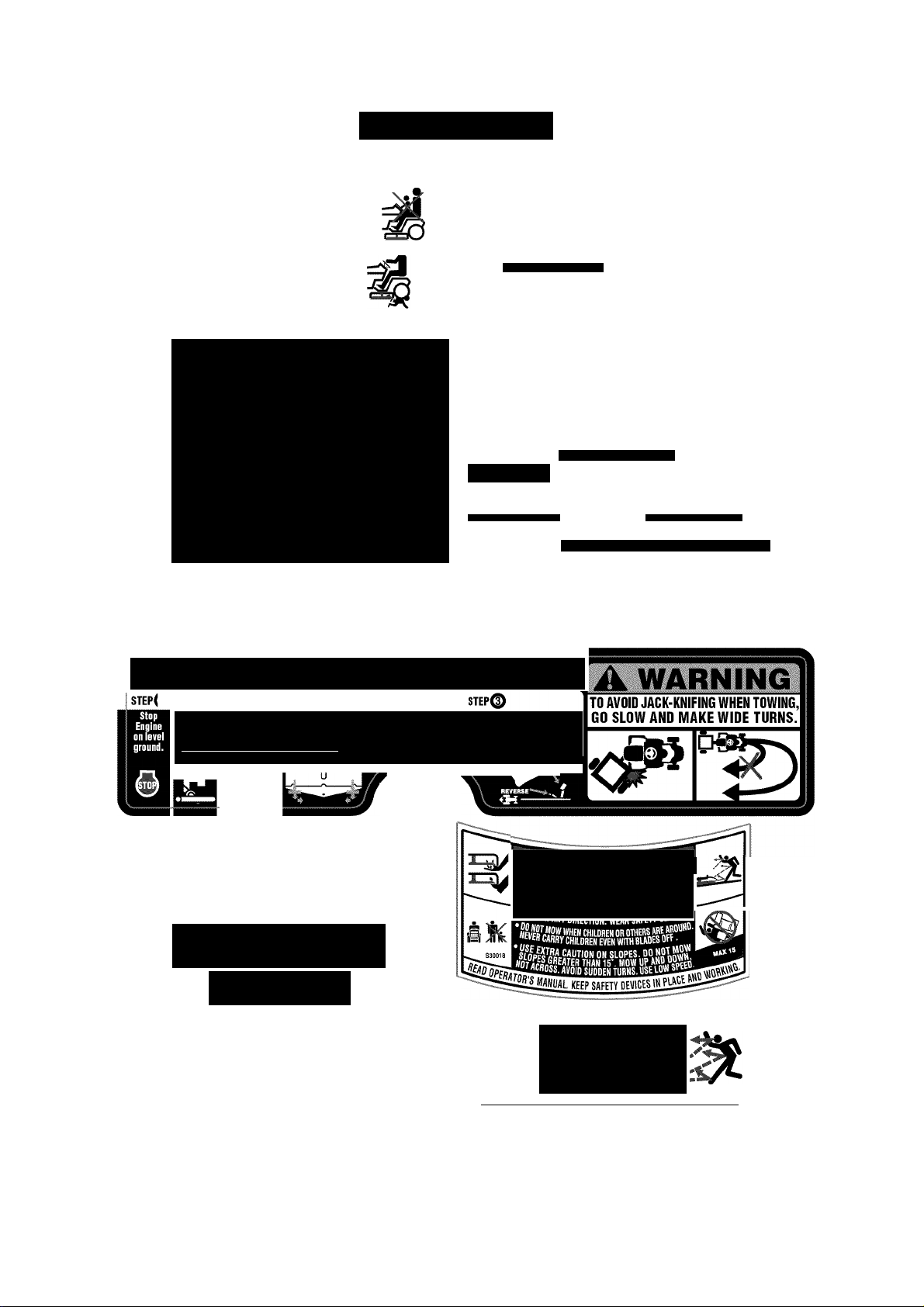

SAFETY LABEL

J

ROTATING BLADES CAL

SERIOUS INJURY OR DEATH

> DO NOT MOW WHEN CHILDREN OR OTHERS ,

ARE AROUND

> NEVER CARRY CHILDREN EVEN WITH

SLADE(S)OFF.

• LOOK DOWN AND BEHIND BEFORE

AND WHILE BACKING.

• MOWING IN REVERSE IS NOT RECOMMENDED.

A WARNING

TO AVOID SERIOUS INJURY OR DEATH

GO UP AND DOWN SLOPES, NOT ACROSS.

AVOID SUDDEN TURNS.

DO NOT OPERATE THE UNIT WHERE IT COULD SUP M TIP.

IF MACHINE STOPS GOING UPHILL, STOP RUDE(S)

AND RACK DOWNHILL SLOWLY.

KEEP SAFETY DEVICES (GUARDS, SHIELDS, AND SWITCHES,

ETC.) IN PLACE AND WORKING.

REMOVE OBJECTS THAT COULD BE THROWN BY THE BLABE(S).

KNOW LOCATION AND FUNCTION OF ALL CONTROLS.

BE SURE BUDE(S) AND ENGINE ARE STOPPED BEFORE

PUCING HANDS OR FEET NEAR BUDE(S).

BEFORE LEAVING OPERATOR'S POSITION, DISENGAGE BLADE(S),

ENGAGE PARKING BRAKE, SHUT WF AND REMOVE KEY.

READ OPERATOR'S MANUAL

1. DISENGAGE BLADES/PTO, fPOlVER TAKE OFF}

2. ENGAGE THE TRACTOR’S PARKING BRAKE.

3. SET THROTTLE TO FAST “RABBIT" POSITION AND PULL CHOKE KNOB OUT.

4. TURN KEY TO START ENGINE. AFTER START RELEASE KEY & DEACTIVATE CHOKE.

OPERATING MODES

NORMAL MOWING

/YOU MUST DISENGAGE BLADES PTO. (POIVER TAKE OFFi BEFORE

' TRAVELING IN REVERSE.

________

1. TURN KEY TO REVERSE CAUTION MODE POSITION.

2. DEPRESS REVERSE PUSH BUTTON. (RED INDICATOR LIGHT “ON”)

WHEN RED LIGHT IS “ON” MACHINE CAN BE OPERATED IN REVERSE

WITH MOWER BLADES ENGAGED.

mpommii mowing in reverse is not recommended.

3. AFTER RESUMING FORWARD OPERATION, RETURN KEY TO

“NORMAL MOWING” POSITION.

NOTE: IN BOTH modes, when operator leaves seat, engine will

STOP UNLESS PARKING BRAKE IS SET AND BLADES ARE DISENGAGED.

BRAKE/CLUTCH

(LOCATED ON DRIVERS 1£FT)

SEAT ADJUSTMENT

CAUTION MODE

¡HOW TO operate!

PEDAL

(LOCATED ON DRIVERS RIGHTl

PULL HANDLE UP TO MOVE SEAT FORWARD

TO PUSH RIDER, PULL OUT BOTH RELEASE LEVERS PRESS THE FORWARD

(OR REVERSE) DRIVE PEDAL CONTINUE TO HOLD PEDAL WHILE PUSHING.

31 STEP© Important! Release Bath Rods

. Pull lever out so elbow passes through the large part of the keyhole slotJt. Press aod HOLD either the

. Move lever ioward to the small part of the keyhole slot so that the forward or reverse drive

Ibow is locked agaiost the back of the hitch plate. pedal, cootioue to Hold pedal

Repeat to eogage the other release lever.___________ dowo while pushiog.

posmos I—.

_____^1___________

^'0"w«D

(LOCATIDOS

A danger ^

1l№,1

№.ts that can be thro«« Tf

TO REDUCE THE RISK OF INJURY, DO NOT

OPERATE UNLESS DISCHARGE COVER OR

GRASS CATCHER IS IN ITS PROPER PLACE.

IF DAMAGED, REPLACE IMMEDIATELY.

■7.VÍ-1

KEEP HANDS and FEET AWAY

A DANGER

KEEP HANDS AND FEET AWAY.

DO NOT OPERATE MOWER

UNLESS CHUTE DEFLECTOR

OR ENTIRE GRASS CATCHER IS

ASSEMBLE CHUTE DEFLECTOR TO THIS UNIT BEFORE OPERATING.

IN ITS PROPER PLACE.

®f«'OUS INJURY OR DEATH

AWAY FROM

Awarning

SHIELD MISSING

DO NOT OPERATE.

Page 10

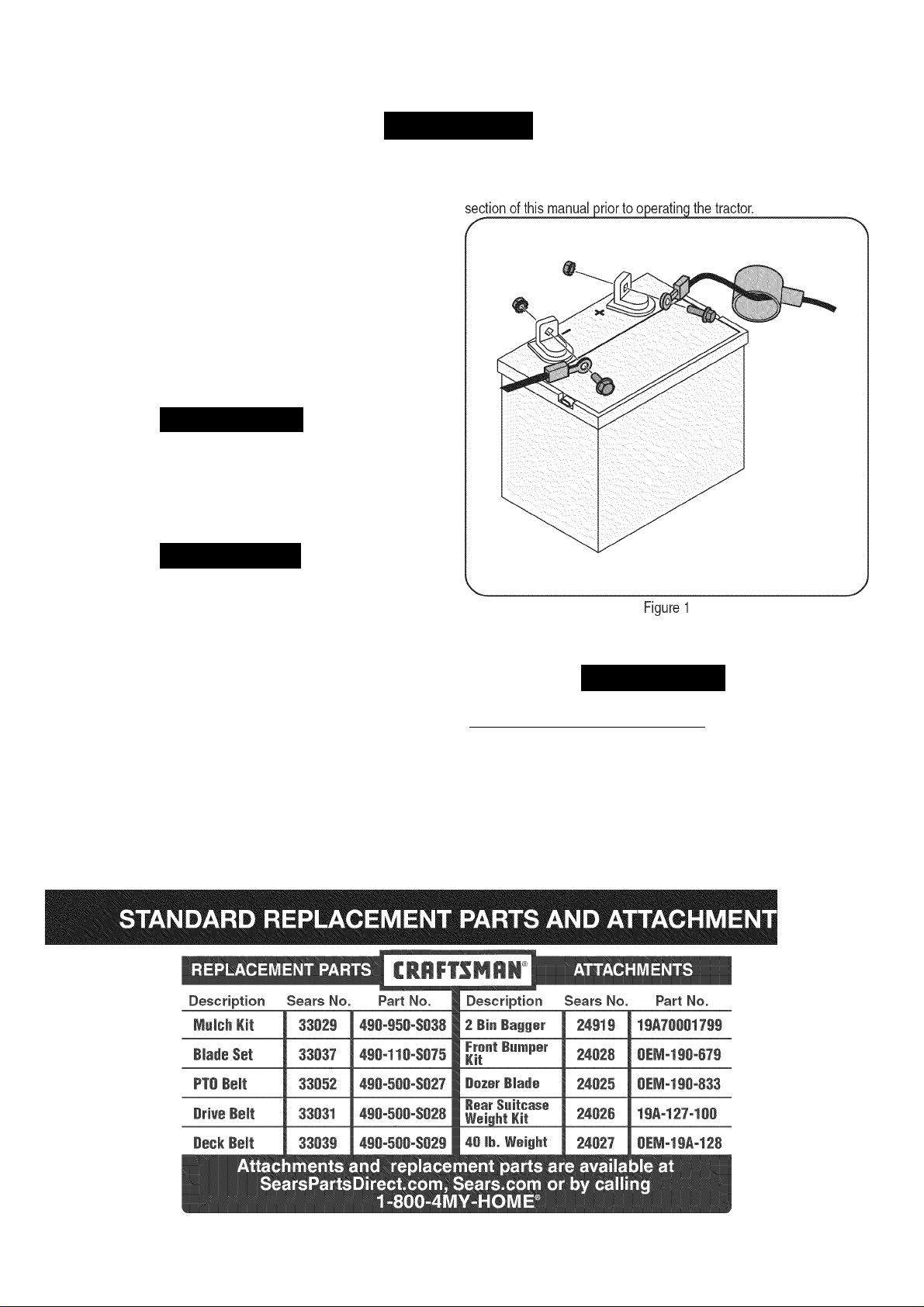

ASSEMBLY

IMPORTANT: Your tractor is shipped with motor oil in the engine.

However, you MUST check the oil level before operating. Refer to the

Service & Maintenance section for instructions on checking the oil

level.

OPENING THE TRACTOR HOOD

To attach the battery cables and check the engine oil level the hood

must be open. Locate the hood lift notch (Refer to Figure 2 on page 11)

at the front/center of the dash panel. Grasping the hood at the notch,

lift and pivot the hood forward to open.

ATTACHING THE BATTERY CABLES

AWARNING

CALIFORNIA PROPOSITION 65

Battery posts, terminals, and related accessories contain lead and

lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

A CAUTION

When attaching battery cables, always connect the POSITIVE (Red)

wire to its terminal first, followed by the NEGATIVE (Black) wire.

NOTE: If the battery is put into service after the date shown on top of

battery, charge the battery as instructed in the Service & Maintenance

For shipping reasons, both battery cables on your equipment may

have been left disconnected from the terminals at the factory. To

connect the battery cables, proceed as follows:

NOTE: The positive battery terminal is marked Pos. (+). The negative

battery terminal is marked Neg. (-).

1

.

Remove the plastic cover, it present, from the positive battery

terminal and attach the red cable to the positive battery terminal

(+) with the bolt and hex nut. See Figure 1.

Remove the plastic cover, if present, from the negative battery

terminal and attach the black cable to the negative battery

terminal (-) with the bolt and hex nut. See Figure 1.

Position the red rubber boot over the positive battery terminal to

help protect it from corrosion.

TIRE PRESSURE

AWARNING

Maximum tire pressure under any circumstances is 25 psi. Equal tire

pressure should be maintained at all times.

The tires on your unit may be over-inflated tor shipping purposes.

Reduce the tire pressure before operating the tractor. Recommended

operating tire pressure is approximately 10 p.s.i for the rear tires & 14

p.s.i. for the front tires. Check sidewall of tire for maximum p.s.i.

______________________

I

10

Page 11

OPERATION

\ 4

______

Figure 2

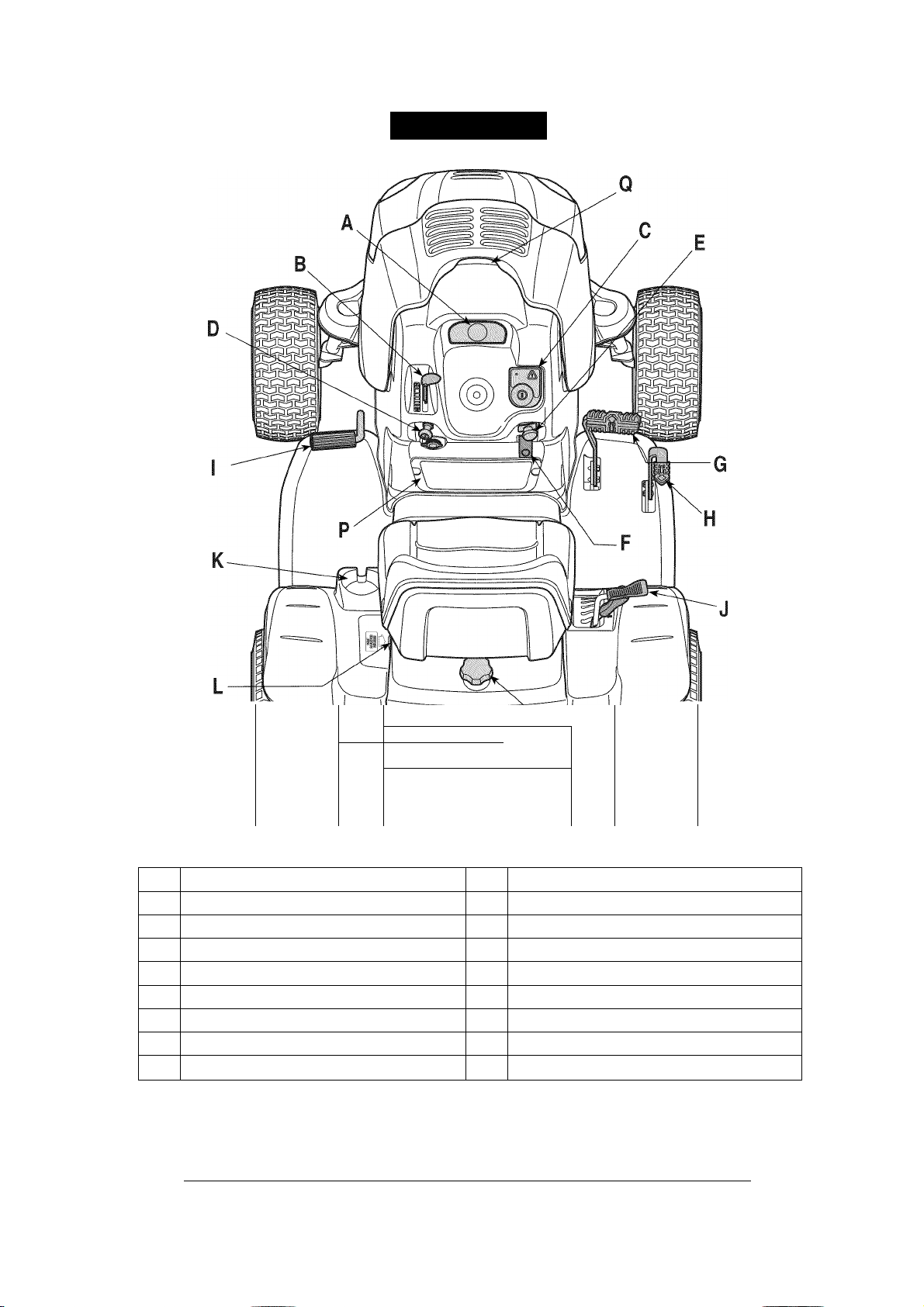

A Systems Indicator Monitor/ Hour Meter J Deck Lift Lever

B Throttle Control Lever K Cup Holder

C Key Switch Module L Seat Adjustment Lever

D Choke Control Knob M Fuel Fill Cap

E PTC (Blade Engage)Control Knob N IVT Transmission Release levers

F Parking Brake Lever 0 Fuel Level Window

G Forward Control Pedal P Cargo Net

H Reverse Control Pedal

I Brake Pedal

NOTE: Any reference in this manual to the RIGHT or LEFT side of the tractor is observed from operator's position.

if T

—

Hood Lift Notch

Q

Q^l^cnQ

QCLaiLiQ

□ Cr^WCilD

'"M

Meets ANSI Safety Standards

Craftsman Tractors conform to the safety standard of the American National Standards Institute (ANSI).

11

Page 12

OPERATION

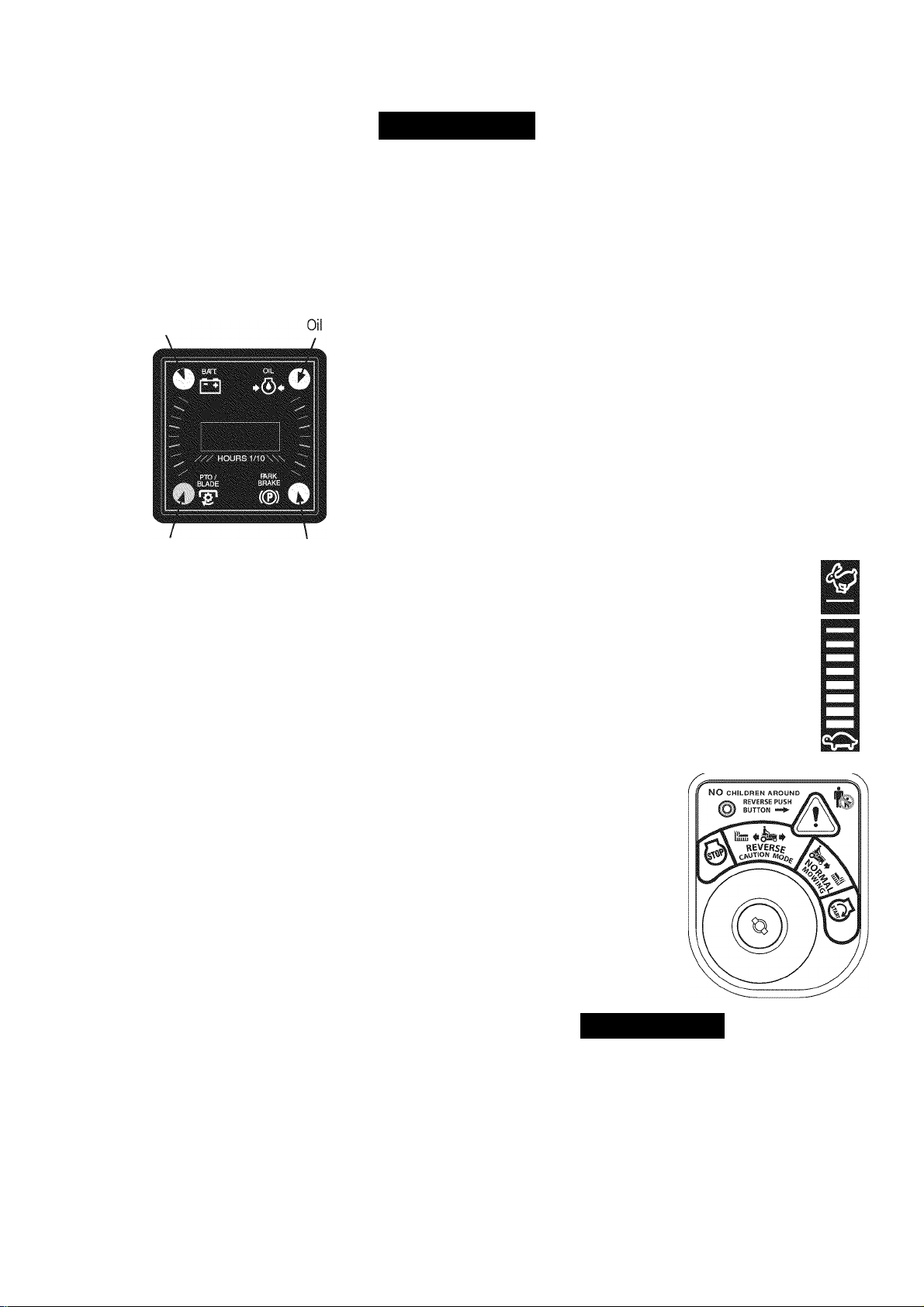

SYSTEMS INDICATOR MONITOR/HOUR

METER

Your tractor is equipped with a Systems Indicator Monitor as shown

in Figure 3. The monitor records the accumulated hours of tractor

operation, and displays the information on the LCD hour meter display

(tenths of an hour - rightmost digit). The monitor also has four indicator

lights that show the status of various functions of the tractor.

Battery

PTO

The system indicator monitor features are as follows:

Parking Brake

Figure 3

LCD Hour Meter Display

The hour meter display is activated when the key switch is turned to

either the “NORMAL MOWING” or the “REVERSE CAUTION MODE”

switch positions. When the key switch is turned to an on position,

the battery indicator light briefly illuminates and the battery voltage is

briefly displayed. The display then changes to the accumulated hours.

NOTE: A record of the actual hours of operation should be kept to

assure maintenance procedures are completed according to the

schedule in this manual.

The Indicator Monitor will also remind the operator of maintenance

intervals for changing the engine oil. The LCD will alternately flash

the recorded hours, “CHG” and “OIL” tor five minutes, after every 50

hours of recorded operation elapse. The maintenance interval lasts for

two hours (from 50-52, 100-102, 150-152, etc.). The LCD will flash as

described for five minutes every time the tractor's engine is started dur

ing this maintenance interval. Follow the oil change intervals provided

in the Service & Maintenance section of this Manual.

Battery Indicator Light

This indicator illuminates when the ignition switch it turned to an ON

position and the engine is not started.

This also illuminates to indicate the battery voltage has dropped below

11.5 (■+-0.5/-1.0) DC volts (the battery voltage is also displayed on the

hour meter). If this indicator and display come on during operation,

check the battery and charging system for possible causes and/or

contact your Sears Parts & Repair Service Center.

Oil Pressure Indicator Light

This warning lamp indicates low engine oil pressure. If this indicator

illuminates, stop the tractor immediately and check the engine oil level.

If the oil level is within the operating range, but the light remains on,

contact your Sears Parts & Repair Service Center.

NOTE: The oil pressure indicator may illuminate when the key switch is

turned to an on position, but should turn off when the engine is started.

PTO (Power Take-Off) Engaged Indicator Light

This indicator illuminates when the key switch is turned to the “START”

position while the PTO knob is in the “ENGAGED” position. Check this

indicator it the engine will not crank with the key switch in the “START”

position. Move the PTO knob to the “DISENGAGED” position.

Brake Engaged Indicator

This indicator illuminates when the key switch is turned to the “START”

position and the brake pedal is not fully depressed. Check this

indicator it the engine will not crank with the key switch in the “START”

position. If necessary, fully depress the brake pedal.

THROTTLE CONTROL LEVER

The throttle control lever controls the speed of

the engine. When set in a given position, the

throttle will maintain a uniform engine speed.

IMPORTANT: When operating the tractor with

the cutting deck engaged, the throttle control

lever must always be in the FAST (rabbit)

position.

Fast

Position

Slow

Position

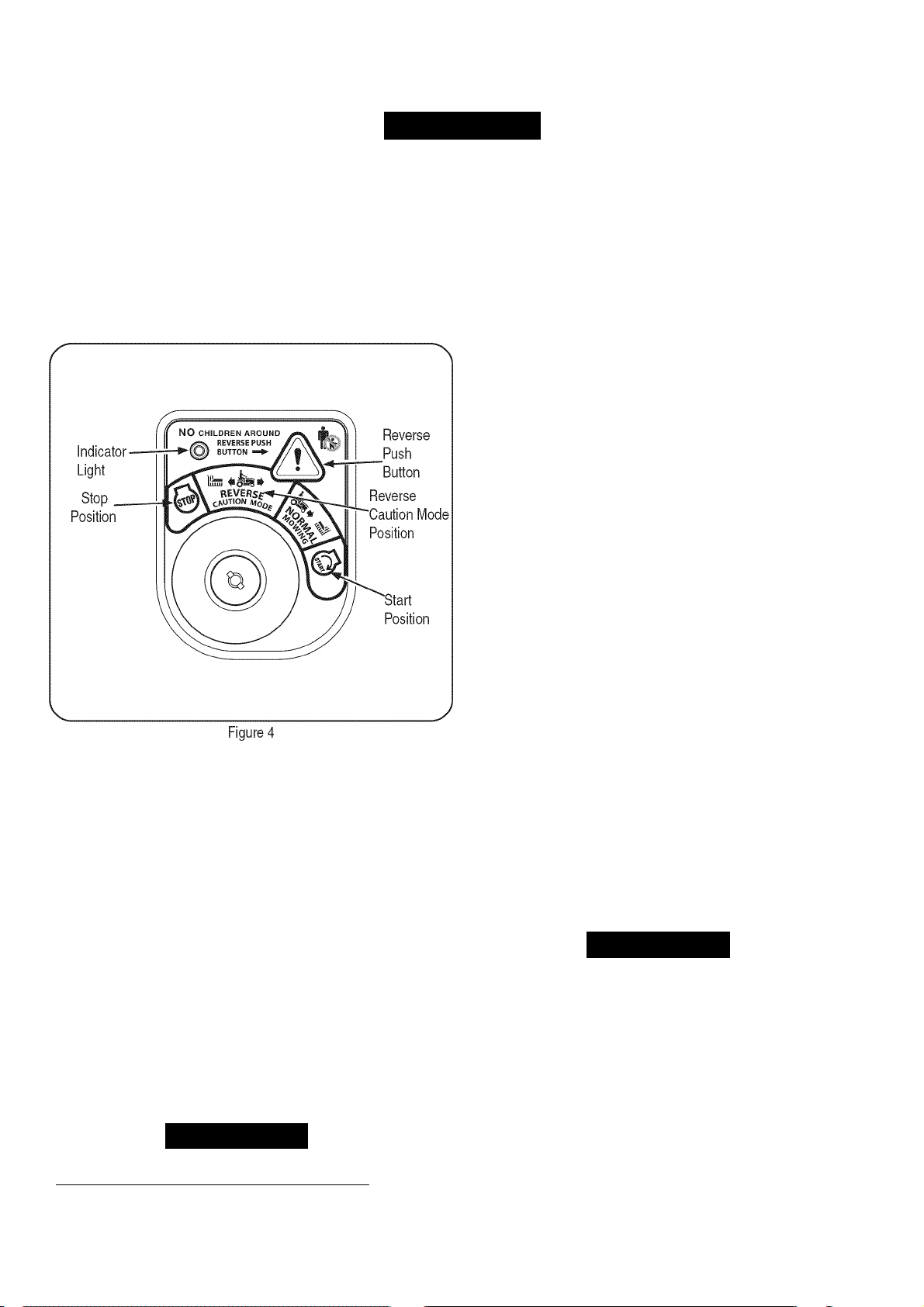

KEY SWITCH MODULE

The key switch module is used to

start and stop the engine. It is also

used to activate the Reverse Caution

Mode (blades operate while riding

in reverse). Insert key into the key

switch module and turn clockwise to

the START position. Release the key

into the normal mowing position once

engine has started.

To stop the engine, turn the ignition

key counterclockwise to the STOP

position.

V

Awarning

Never leave a running machine unattended. Always disengage PTO,

set parking brake, stop engine and remove key to prevent unintended

starting.

IMPORTANT: Prior to operating the tractor, refer to both “Safety

Interlock System” on page 14 and “Starting The Engine” on page 15

of this manual for detailed instructions regarding the Ignition Switch

Module and operating the tractor in REVERSE CAUTION MODE.

12

Page 13

CHOKE CONTROL

The choke control knob is located on the lower left side of the dash

panel and is activated by pulling outward. Activating the choke control

closes the choke plate on the carburetor and aids in starting the

engine.

PTO (BLADE ENGAGE) CON

TROL KNOB

To engage the electric PTO and provide power to

the cutting deck, pull outward on the PTO control

knob. Push the knob inward to disengage the PTO

and stop the cutting deck.

NOTE: The PTO Control Knob must be in the

disengaged (OFF) position when starting the

engine.

rfo^

* 6

S

O

.OFF

HFl

tractor.

DECK LIFT LEVER

The deck lift lever is located in the right fender and is used to change

the cutting height of the mower deck. The cutting heights range from

1-1/2” to 4”. Each of the six index notches represent an approximately

1/2” adjustment to the deck height.

1. To use, grasp the lift lever handle and pull slightly upward (rear

ward) while pivoting the lever inward and out of its index notch.

2. Move the lift lever as necessary to place in the notch best suited

for your application.

After changing the cutting height of the deck, you must check the

position of the deck front gauge wheels. They should be approximately

I

y2-inch above the ground when the tractor is on a smooth, flat surface

such as a driveway. Refer to “Service & Maintenance” later in this

manual.

PARKING BRAKE LEVER

NOTE: The parking brake must be set it the operator

leaves the seat with the engine running; otherwise the

engine will automatically shut off.

1

.

To set the parking brake, fully depress the brake

pedal and push the bottom of parking brake lever

inward. See the image to the right for parking brake

identification. Hold the lever in while removing your J

foot from the brake pedal. Both parking brake lever

and brake pedal will stay depressed.

To release the parking brake, depress the brake pedal slightly.

The parking brake lever will then return to its original position.

IMPORTANT: Always set the parking brake when leaving the tractor

unattended.

(©)

ñ

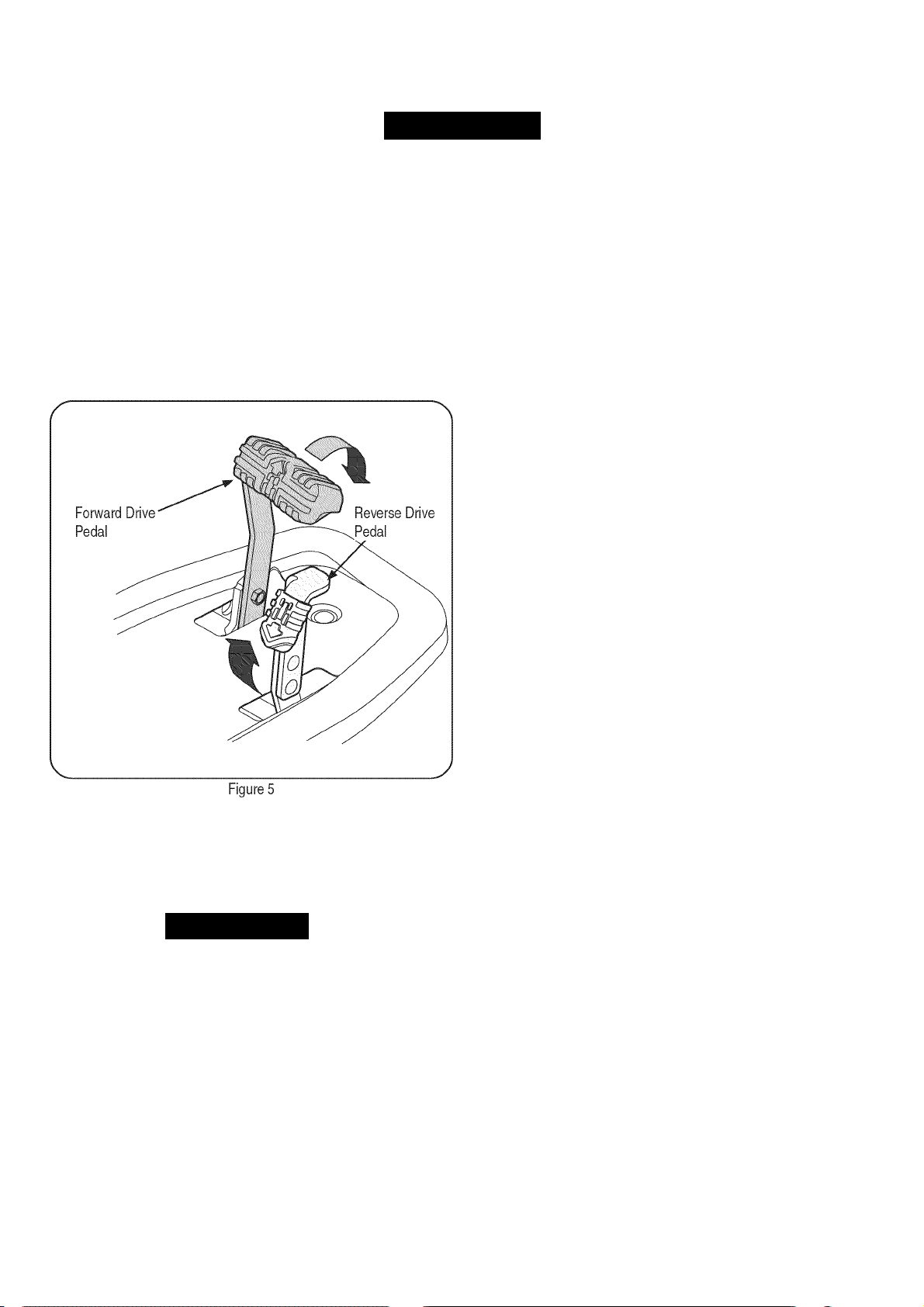

FORWARD CONTROL PEDAL

The forward control pedal is located on the right side of the tractor, at

the front of the right running board. Depress the forward control pedal

to cause the tractor to travel in the forward direction. The forward

ground speed of the tractor is directly affected by the distance the

pedal is depressed. The further the pedal is depressed, the faster the

tractor will travel. The tractor will slow and the pedal will return to its

original position when released.

REVERSE CONTROL PEDAL

The reverse control pedal is located in the right front running board

rearward of the forward control pedal. Depress the reverse control

pedal to cause the tractor to travel in reverse. The further the pedal is

depressed, the faster the tractor will travel. The tractor will slow and

the pedal will return to its original position when released.

CUP HOLDER

The tractor’s cup holder is located on the fender to the left of the seat.

SEAT ADJUSTMENT LEVER

The seat adjustment lever is on the left side of the seat. Use this lever

to adjust the seat forward or rearward to a comfortable operating

position. See the “Service & Maintenance” section later in this manual

for instructions.

FUEL FILL CAP AND FUEL LEVEL WINDOW

The fuel fill cap is located in the center of the rear fender. Pivot

the seat forward to fully access the fuel fill cap and fill the fuel

tank.

1. Turn the fill cap approximately 1 /4 turn and pull upward to

remove.

2. Push the cap downward on the fuel tank fill neck and turn

1/4 turn clockwise to tighten.

The level of fuel in the fuel tank can be viewed through the fuel

level window in the rear hitch plate.

CARGO NET

Conveniently located on the tractor’s dash panel, the cargo net can be

used to store personal items while operating the lawn tractor.

IVT (INFINITELY VARIABLE TRANSMISSION) RELEASE LEVERS

The IVT transmission release levers are located at the back of the

tractor above the rear hitch plate. When engaged, these levers open

a dump valve in each transmission which allows the tractor to be

manually pushed short distances. See “Moving the Tractor Manually”

later in this section for instructions.

13

Page 14

OPERATION

Awarning

Avoid Serious Injury or Death

Go up and down slopes, not across.

Avoid sudden turns.

Do not operate the unit where it could slip or tip.

If machine stops going uphill, stop blades and back downhill

slowly.

Do not mow when children or others are around.

Never carry children, even with blades off.

Look down and behind before and while backing.

Keep safety devices (guards, shields, and switches) in place

and working.

Remove objects that could be thrown by the blades.

Know location and function of all controls.

Be sure blades and engine are stopped before placing hands or

feet near blades.

Before leaving operator’s position, stop tractor, disengage

blades, engage parking brake, shut engine off, and remove key.

Read Operator’s Manual

OIL AND GAS FILL-UP

Oil

IMPORTANT: Your tractor is shipped with motor oil in the engine.

However, you MUST check the oil level before operating. See the

“Service and Maintenance” section.

Gasoline

Awarning

Use extreme care when handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Never fuel machine

indoors or while the engine is hot or running. Extinguish cigarettes,

cigars, pipes, and other sources of ignition.

NOTE : Purchase gasoline in small quantities. Do not use gasoline left

over from the previous season, to minimize gum deposits in the fuel

system.

Do not overfill fuel tank. Fill tank to no more than 1/2 inch below

bottom of filler neck to allow space for fuel expansion.

Never remove gas cap or add fuel while the engine is hot or run

ning. Allow engine to cool at least two minutes before refueling.

If gasoline is spilled, wipe it off the engine and equipment. Move

machine to another area. Wait 5 minutes before starting the

engine.

Turn the engine off and let engine cool at least 2 minutes before

removing the fuel cap. The gasoline tank is under the rear fender,

with the fuel fill cap located in the center of the rear fender.

The fuel cap is tethered to the tractor to prevent its loss. Do not

attempt to remove the cap from the tractor.

Fill the fuel tank with gasoline.

Reinstall the fuel cap.

SAFETY INTERLOCK SYSTEM

The safety interlock system is designed for safe operation of the trac

tor. If this system should ever malfunction, do not operate the tractor,

immediately contact your Sears Parts & Repair Service Center.

• The safety interlock system prevents the engine from starting

unless the parking brake is engaged and the PTO knob is in the

disengaged (OFF) position.

• The safety interlock system will automatically shut off the engine it

the operator leaves the seat before engaging the parking brake.

• The safety interlock system will automatically shut off the engine

it the operator leaves the tractor's seat with the PTO (Blade

Engage) knob engaged, regardless of whether the parking brake

is engaged.

• With the ignition key in the NORMAL MOWING position, the

electric PTO clutch will automatically shut off it the PTO knob is in

the engaged (ON) position and the drive pedal is depressed for

Reverse travel.

Awarning

Tampering with or attempting to bypass the Safety Interlock Switches

in any way will void your tractor’s warranty. Do not operate the tractor

it the interlock system is malfunctioning.

REVERSE CAUTION MODE

• This engine is certified to operate on unleaded gasoline. For best

results, fill the fuel tank with only clean, fresh, unleaded gasoline

with a pump sticker octane rating of 87 or higher.

• Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline by

volume) is an approved fuel. Other gasoline/alcohol blends, such

as E85, are not approved.

• Methyl Tertiary Butyl Ether (MTBE) and unleaded gasoline blends

(up to a maximum of 15% MTBE by volume) are approved fuels.

Other gasoline/ether blends are not approved.

• Fill fuel tank outdoors or in well-ventilated area.

Awarning

Use extreme caution while operating the tractor in the REVERSE

CAUTION MODE. Always look down and behind before and while

backing. Do not operate the tractor when children or others are

around. Stop the tractor immediately it someone enters the area.

The REVERSE CAUTION MODE position of the key switch module

allows the tractor to be operated in reverse with the blades (PTO)

engaged.

14

Page 15

OPERATION

J

IMPORTANT: Mowing in reverse is not recommended.

To use the REVERSE CAUTION MODE:

IMPORTANT: The operator MUST be seated in the tractor seat.

1. Start engine as instructed in the Starting The Engine section.

2. Turn the key from the NORMAL MOWING (Green) position to the

REVERSE CAUTION MODE (Yellow) position of the key switch

module. See Figure 4.

3. Depress the REVERSE PUSH BUTTON (Orange, Triangular

Button) at the top, right corner of the key switch module. The red

indicator light at the top, left corner of the key switch module will

be ON while activated. See Figure 4.

4. Once activated (indicator light ON), the tractor can be driven in

reverse with the cutting blades (PTO) engaged.

5. Always look down and behind before and while backing to make

sure no children are around.

6. After resuming forward motion, return the key to the NORMAL

MOWING position.

IMPORTANT: The REVERSE CAUTION MODE will remain activated

until:

a. The key is placed in either the NORMAL MOWING position

or STOP position.

b. The operator leaves the seat. Follow the previous instruc

tions to re-activate.

STARTING THE ENGINE

Awarning

Do not operate the tractor if the interlock system is malfunctioning.

This system was designed for your safety and protection.

_________

1. Insert the tractor key into the key switch module.

2. Disengage the PTO (Blade Engage) knob.

3. Engage the tractor’s parking brake.

4. Pull the choke control knob outward into the full choke position (a

warm engine may not require choking).

5. Move the throttle control lever to the FAST position.

6. Turn the ignition key clockwise to the START position. After

the engine starts, release the key. It will return to the NORMAL

MOWING position.

IMPORTANT: Do not hold the key in the START position for longer

than ten seconds at a time. Doing so may cause damage to your

engine's electric starter.

7. After the engine starts, gradually push the choke knob fully inward

as the engine warms up.

NOTE: Do not use the choke control to enrich the fuel mixture, except

as necessary to start and warm up the engine.

IMPORTANT

Do not leave the seat of the tractor witfiout

1. Disengaging PTO knob

2. Depressing brake pedal

3. Engaging parking brake

If leaving the tractor unattended, also turn the

ignition key off and remove the key.

Avoid sudden starts, excessive speed and sudden

stops while driving the tractor.

Q/“'. r!/“'.? /^.r! in OYnoCC n.f 1

s not mow on slope in excess of 15 degrees (a rise

of

approximately 2-1./2 feet every 10 feet).

.........

........

y“ •■■ - )■ 1^/

Keep hands and feet away from the opening of the

cutting deck

Plan your mowing pattern lo avoia aiscnarge or

materials toward roads, sidev\/alks, bystanders and

the like. Also, avoid discharging material against

a wall or obstruction which may cause discharged

material to ricochet back toward the operator.

STOPPING THE ENGINE

Awarning

If you strike a foreign object, stop the engine and disconnect the

spark plug wire(s). Thoroughly inspect the machine tor any

damage. Repair the damage before restarting and operating.

1. If the blades are engaged, disengage the PTO.

2. Move the throttle control lever to midway between the half and fi

throttle. Then turn the ignition key counterclockwise to the OFF

position.

3. Remove the key from the ignition switch to prevent unintended

starting.

15

Page 16

OPERATION

I

DRIVING THE TRACTOR

IMPORTANT: Avoid sudden starts, excessive speed and sudden

stops.

NOTE: Your Revolution tractor is equipped with an innovative drive

system. It is normal for some forward movement of the tractor to occur

when the brake is released.

1. Briefly depress the brake pedal to release the parking brake.

Move the throttle lever into the FAST (rabbit) position.

2. To travel forward: Slowly depress the forward drive control pedal

until the desired speed is achieved. See Figure 5.

1. The steering wheel rotates approximately two full turns from its

stopping point on one side to its stopping point on the other, with

the center position being the straight ahead position.

2. Minor turns of the steering wheel from the center position

(approximately 10° to 15°) turn only the front axles and will result

in wider turns.

3. Increasing the turn of the steering wheel (beyond 10“-15°) results

in increasingly tighter turns. As the steering mechanism turns the

front wheels, it also changes the position of the transmission drive

control linkage to slow down the inner rear wheel in the turn, and

adjusts the speed of the outer wheel as necessary to complete

the desired turn. Turn the steering wheel back to the center

position as the turn is completed.

NOTE: It is not necessary to release the drive pedal when making a

turn. The change to the transmission linkage occurs regardless of how

far the drive pedal is depressed. When the steering wheel is straight

ened, the tractor will return to the speed set by the drive pedal.

4. Turning the steering wheel fully to its stop in either direction

will fully turn the front wheels, reverse the direction of the inner

wheel and adjust the outer wheel speed to execute a zero turn in

the chosen direction. Turn the steering wheel back to the center

position as the turn is completed.

NOTE: The steering wheel has to be turned all the way UNTIL IT

STOPS to complete a zero turn. As the steering wheel is turned further

toward its stop, the effort needed to turn the steering wheel increases.

To travel in reverse: Check that the area behind is clear, then

slowly depress the reverse drive control pedal until the desired

speed is achieved. See Figure 5.

Release the depressed drive pedal and depress the brake pedal

to stop the tractor.

Awarning

Do not leave the seat of the tractor without first placing the PTO/

Blade Engage knob in the disengaged (OFF) position and engaging

the parking brake. If leaving the tractor unattended, also turn the

engine off and remove the ignition key.

STEERING THE TRACTOR

Your Revolution tractor is equipped with an innovative steering system.

Turning the steering wheel not only turns the front wheels, but also

adjusts the position of the drive control linkage of the transmissions

that drive the tractor. This steering system allows you to vary the radius

of turns from a normal wide U-turn down to a zero turn (a tight “aboutface” turn). Some practice may be needed to become accustomed to

the steering of your tractor. The steering works as follows:

IMPORTANT: Making tight or zero turns on grass will greatly increase

the potential for damage to the turf.

DRIVING ON SLOPES

IMPORTANT: Refer to the SLOPE GAUGE on page 8 to help deter

mine slopes where you may operate the tractor safely.

• Mow up and down slopes, never across.

• Watch tor holes, ruts, bumps, rocks, or other hidden objects.

Uneven terrain could overturn the machine. Tall grass can hide

obstacles.

• Avoid turns when driving on a slope. If a turn must be made, turn

downhill on the slope. Turning uphill increases the possibility of a

tractor rollover.

• Avoid stopping when driving up a slope. If it is necessary to stop

while driving up a slope, start up smoothly and carefully to reduce

the possibility of flipping the tractor over backward.

ENGAGING THE PARKING BRAKE

NOTE: The parking brake must be set if the operator leaves the seat

with the engine running or the engine will automatically shut off.

To set the parking brake:

1. Press the brake pedal completely down with your left foot and

hold it that position.

2. Push the parking brake lever downward and hold it in that

position.

16

Page 17

OPERATION

J

3. Remove your foot from the brake pedal.

4. Release pressure from the parking brake lever.

After completing step 3, the brake pedal should remain In the down

position. It it doesn’t, the parking brake is not engaged. Repeat steps

1-4 to engage the parking brake.

To disengage the parking brake, lightly press the brake pedal.

AWARNING

Never leave a running machine unattended. Always disengage PTO,

set parking brake, stop engine and remove key to prevent unintended

starting.

ENGAGING THE PTO

Engaging the PTO transfers power to the cutting deck or other

(separately available) attachments. To engage the PTO:

1. Move the throttle control lever to the FAST (rabbit) position.

2. Pull the PTO/Blade Engage knob outward into the engaged (ON)

position.

NOTE: Always operate the tractor with the throttle lever in the FAST

(rabbit) position for the most efficient use of the cutting deck or other

(separately available) PTO driven attachments.

MOWING

2. Shut engine off and remove the key.

Doing so will minimize the possibility of having your lawn “browned” by

hot exhaust from your tractor’s running engine.

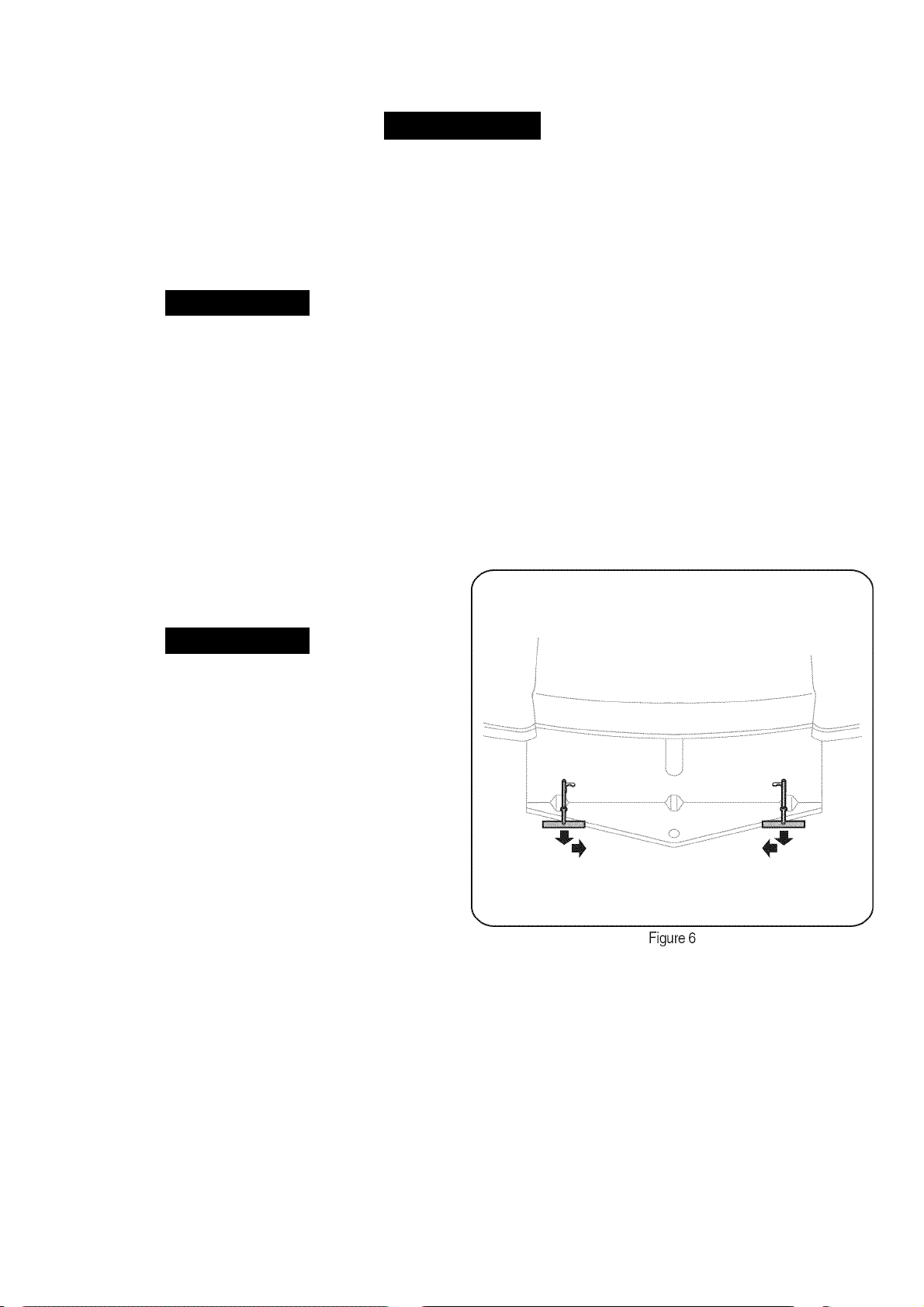

MOVING THE TRACTOR MANUALLY

If tor any reason the tractor will not drive or you wish to move the

tractor, engage the two transmission release levers to manually move

the tractor short distances.

IMPORTANT: Never tow or drag the tractor with the rear wheels on the

ground. Even with the release levers engaged. Doing so will damage

the transmissions.

To engage a release lever:

1. Pull the lever rearward so that the elbow passes through the

larger/rounded part of the keyhole slot.

With the elbow of the lever outside (rearward) of the hitch plate,

push the lever inward in the small part of the keyhole slot so that

lever’s elbow is locked against the back of the hitch plate.

Repeat to engage the other release lever to allow the tractor to be

manually moved. See Figure 6.

AWARNING

To help avoid blade contact or a thrown object injury, keep bystand

ers, helpers, children and pets at least 75 feet from the machine

while it is in operation. Stop machine it anyone enters the area.

This tractor is equipped with one of Craftsman’s high quality cutting

decks. The following information will be helpful when using the cutting

deck with your tractor.

• Do not mow at high ground speed, especially it a mulch kit or

grass collector is installed.

• For best results it is recommended that the first two laps be cut

with the discharge thrown towards the center. After the first two

laps, reverse the direction to throw the discharge to the outside

for the balance of cutting. This will give a better appearance to the

lawn.

• Do not cut the grass too short. Short grass invites weed growth

and yellows quickly in dry weather.

• Mowing should always be done with the engine at full throttle.

• Under heavier conditions it may be necessary to go back over the

cut area a second time to get a clean cut.

• Do not attempt to mow heavy brush and weeds and extremely tall

grass. Your tractor is designed to mow lawns, not clear brush.

• Keep the blades sharp and replace the blades when worn. Refer

to the “Service & Maintenance” section of this manual for proper

blade sharpening instructions.

IMPORTANT: When stopping the tractor for any reason while on a

grass surface, always:

1. Engage the parking brake.

* •

4. To move the tractor manually, the brake must be disengaged by

releasing the parking brake and depressing the forward or reverse

drive pedal. Continue to hold the drive pedal while pushing.

5. To disengage, move the lever to align its elbow with the larger/

rounded part of the keyhole slot and release the lever back

through the hitch plate.

NOTE: The transmission will NOT engage when the release lever is

pulled out. Return the lever to its normal position prior to operating the

tractor.

HEADLIGHTS

The tractor headlights are turned on whenever the ignition switch is

turned to either of the run positions.

17

Page 18

SERVICE AND MAINTENANCE

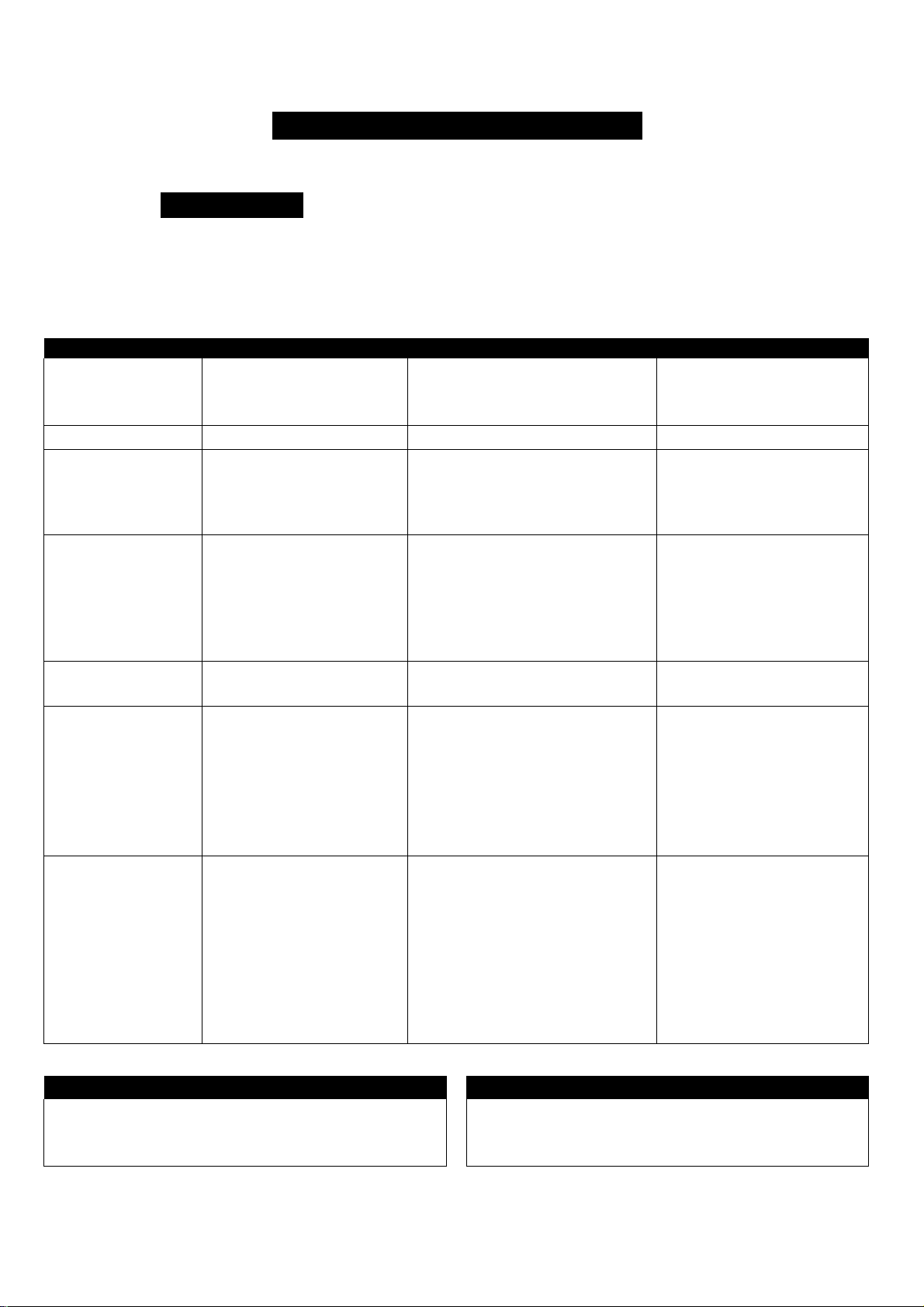

MAINTENANCE SCHEDULE

Awarning

Before performing any type of maintenance/service, disengage all

controls and stop the engine. Wait until all moving parts have come to

a complete stop. Disconnect spark plug wire and ground it against the

engine to prevent unintended starting. Always wear safety glasses during

operation or while performing any adjustments or repairs.

Follow the maintenance schedule given below. This chart describes

service guidelines only. Use the Service Log column to keep track of

completed maintenance tasks. To locate the nearest Sears Service

Center or to schedule service, simply contact Sears at

1-800-4-MY-HOME®.

Interval

Before Each Use 1. Engine oil level 1. Check

2. Muffler area and controls 2. Clean

3. Finger guard 3. Clean

In the First Five Flours 1. Engine Oil 1. Change

Every 10 Flours 1. Flood/ Dash air vents 1. Clean

2. Battery terminals 2. Clean

3. Deck spindles and idler 3. Lubricate

bracket

Every 25 hours 1. Air filter’s precleaner* 1. Clean

2. Air filter* 2. Clean

3. Mid steering arms, pivot 3. Lubricate

shafts, and axles

4. Front wheel bearings 4. Lubricate

5. Front deck wheels 5. Lubricate

Every 50 hours 1. Engine oil/ Oil filter 1. Change/ Replace

2. Muffler 2. Check

Annually 1. Air filter 1. Replace

2. Air filter’s pre-cleaner 2. Replace

3. Spark plug 3. Replace

4. Air cooling system* 4. Clean

5. Fuel filter 5. Replace

6. Steering Gears 6. Clean

7. Rear Wheels 7. Remove and grease axles

Before Storage 1. Flood/ Dash air vents 1. Clean

2. Battery terminals 2. Clean

3. Mid steering arms, pivot 3. Lubricate

shafts, and axles

4. Front wheel bearings 4. Lubricate

5. Front deck wheels 5. Lubricate

6. Deck spindles and idler 6. Lubricate

bracket

7. Pedal pivot points 7. Lubricate

‘Service more frequently under dusty conditions.

Item

Service Service Log

AWARNING

Before performing any maintenance or repairs, disengage the PTC,

engage the parking brake, stop the engine and remove the key to

prevent unintended starting.

Awarning

If the engine has been recently run, the engine, muffler and sur

rounding metal surfaces will be hot and can cause burns to the skin.

Exercise caution to avoid burns.

18

Page 19

SERVICE AND MAINTENANCE

J

ENGINE MAINTENANCE

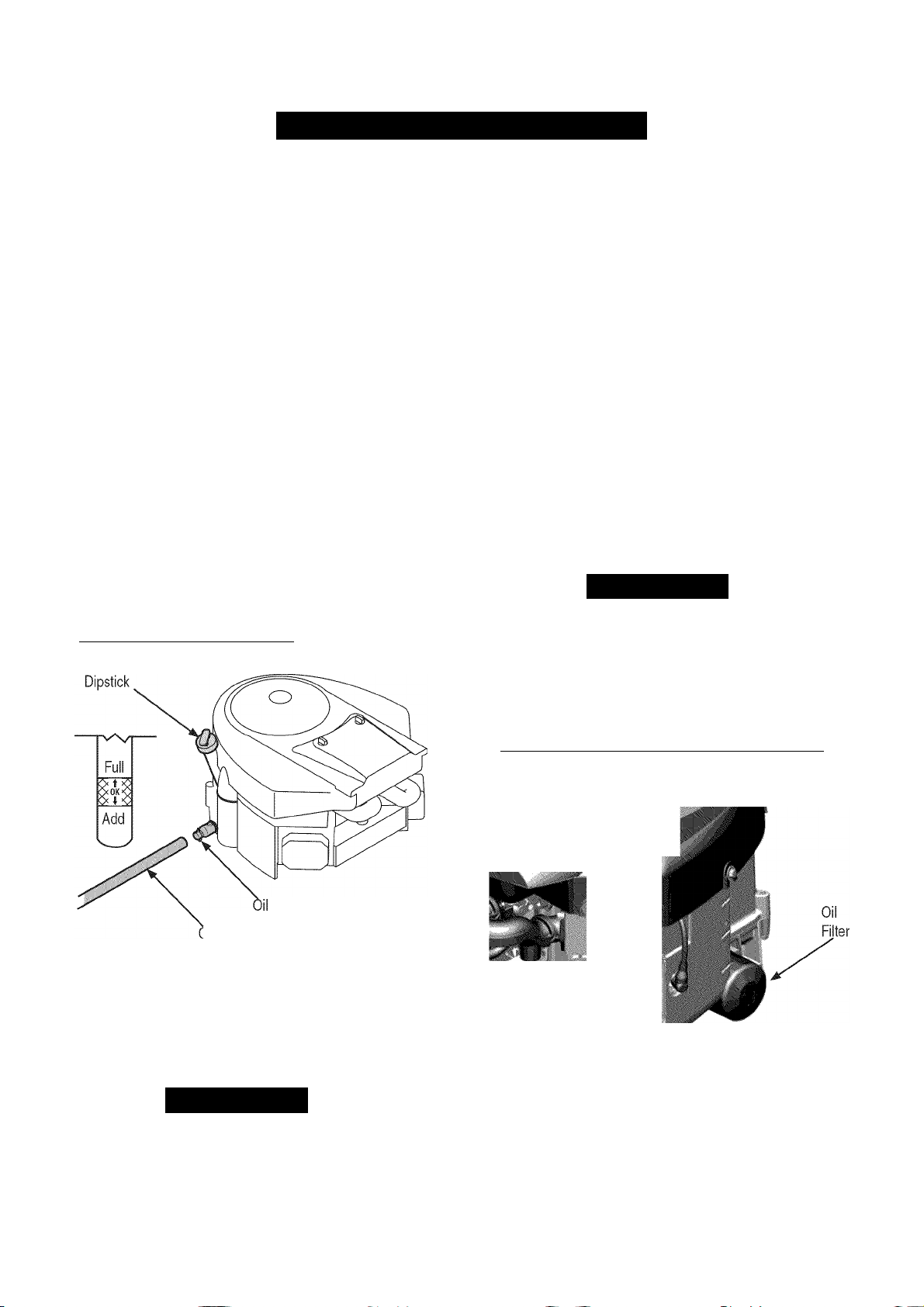

Checking the Engine Oil

Only use high quality detergent oil rated with API service classification

SF, SG, SH, or SJ. Select the oil's SAE viscosity grade according to

the expected operating temperature. Follow the chart below.

/Colder

5W20

■32°F

SAE30

•-WarmeA

Oil Viscosity Chart

Although multi-viscosity oils (5W20,10W30, etc.) improve starting

in cold weather, they will result in increased oil consumption when

used above 32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

To check the engine oil, proceed as follows:

1.

Ensure that the tractor is on a level surface.

2.

Clean the oil fill area of any debris.

3.

Remove the dipstick and wipe with a clean cloth.

4.

Insert and tighten dipstick.

5.

Remove the dipstick and check the oil level. It should be at the

Full mark on the dipstick. See Figure 7.____________________

Changing Engine Oil

The engine oil should be changed in the first 5 hours and then every

50 hours or once a season. To change the engine oil, proceed as

follows:

1. With engine CFF but still warm, disconnect spark plug wire and

keep it away from spark plug.

2. Pop off the protective cap on the end of the oil drain valve to

expose the drain port. See Figure 7.

3. Remove the oil fill cap/dipstick from the oil fill tube. See Figure 7.

4. Push the oil drain hose (packed with this manual) onto the oil

drain port. Route the opposite end of the hose into an appropriate

oil collection container with a capacity great enough to collect the

used oil.

5. Release the valve by twisting and pulling the valve out. The oil will

begin to drain out of the engine.

6. After the oil has finished draining, press the two tabs inward and

push the oil drain valve back in to lock the valve closed. Remove

the hose, twist and push in to lock valve, and re-cap the end of

the oil drain valve to keep debris from entering the drain port.

7. Refill the engine with new motor oil until the oil level on the

dipstick reads FULL. Replace the oil fill cap/dipstick.

A CAUTION

Used oil is a hazardous waste product. Dispose of used oil properly.

Do not discard with household waste. Check with your local authori

ties or Sears Service Center for safe disposal/recycling facilities.

Drain

Jil Drain

Hose

If low, add oil slowly into the engine oil fill. Do not overfill. After

adding oil, wait one minute and then recheck the oil level.

Replace and tighten dipstick.

Valve

Figure 7

A CAUTION

Do not overfill. Cverfilling with oil may cause the engine to not start,

hard starting, or engine smoking. If over the FULL mark on the

dipstick, drain oil to reduce oil level to FULL mark on dipstick.

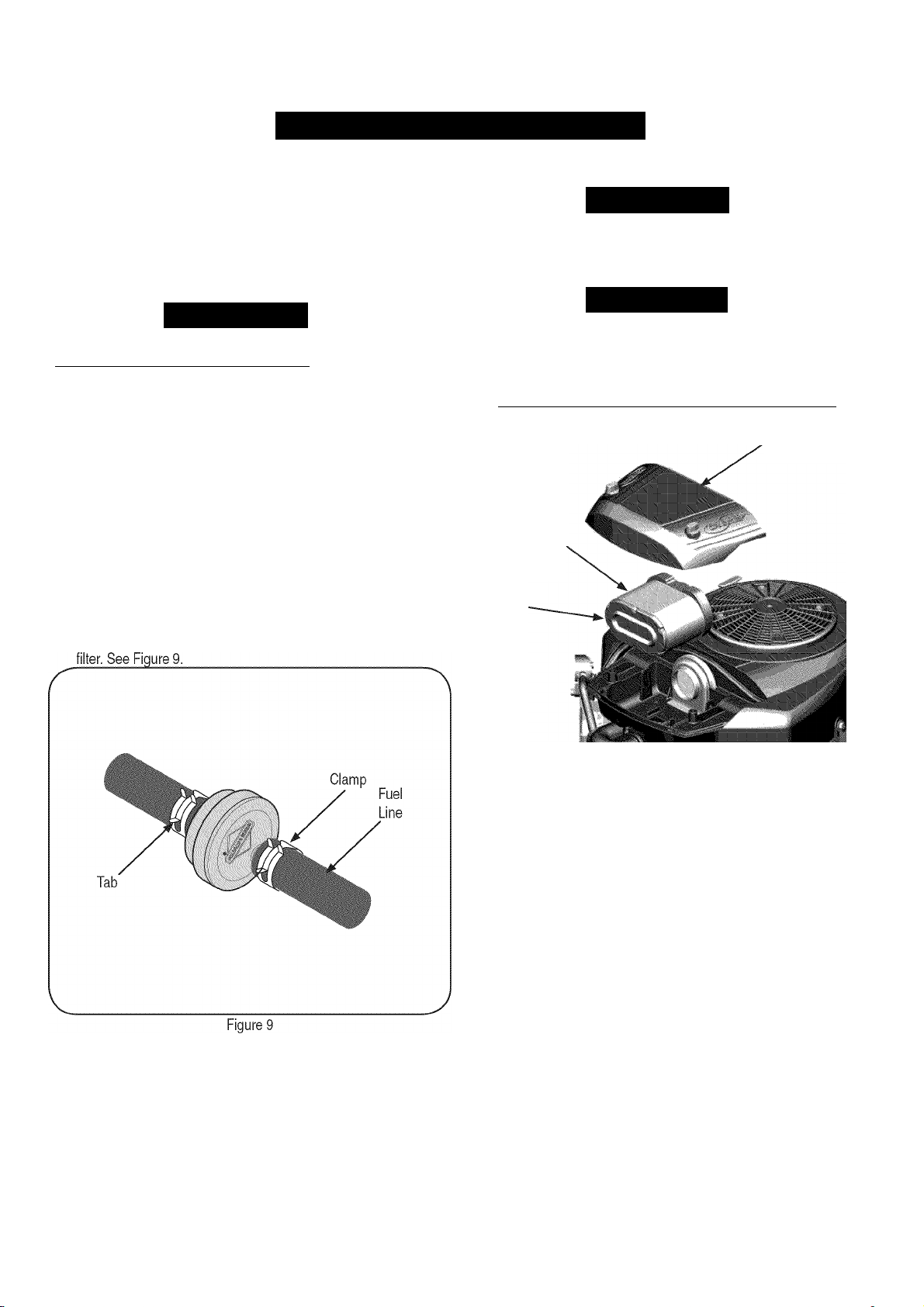

Changing the Oil Filter

1. Drain the oil from the engine as described above.

2. Remove the oil filter and dispose of properly. See Figure 8.

m

■

■

»

Figure 8

Before you install the new oil filter, lightly lubricate the oil filter

gasket with fresh, clean oil.

4.

Install the oil filter by hand until the gasket contacts the oil filter

adapter, then tighten the oil filter 1/2 to 3/4 turns.

19

Page 20

SERVICE AND MAINTENANCE

5. Add oil as described above.

6. Start and run the engine. As the engine warms up, check for oil

leaks.

7. Stop the engine and check the oil level. It should be at the FULL

mark on the dipstick.

Fuel Filter

AWARNING

Gasoline and its vapors are extremely flammable and explosive. Fire

or explosion can cause severe burns or death.____________________

Keep gasoline away from sparks, open flames, pilot lights, heat,

and other ignition sources.

Check fuel lines, tank, cap, and fittings frequently for cracks or

leaks. Replace if necessary.

Before replacing the fuel filter, drain the fuel tank or close the fuel

shut-off valve.

Replacement parts must be the same and installed in the same

position as the original parts.

If fuel spills, wait until It evaporates before starting engine.

Before replacing the fuel filter, drain the fuel tank or close the fuel

shut-off valve. Otherwise, fuel can leak out and cause a tire or

explosion.

Use pliers to squeeze tabs on the clamps, then slide the clamps

away from the fuel filter. Twist and pull the fuel lines off of the fuel

Air Cleaner

AWARNING

If filters, or covers are not installed correctly serious injury or death

could result from backfire. Do not attempt to start the engine with

them removed.

A CAUTION

Do not use pressurized air or solvents to clean the air cleaner

cartridge.

Remove the air filter cover.

To remove the air filter, lift the end of the filter. See Figure 10.

Cover

Pre-cleaner

Filter

A

3. Check the fuel lines for cracks or leaks. Replace it necessary.

4. Replace the fuel filter with an original equipment replacement

filter.

5. Secure the fuel lines with the clamps.

Figure 10

Remove the pre-cleaner from the filter.

To loosen debris, gently tap the filter on a hard surface. If the filter

is excessively dirty, replace with a new filter.

Wash the pre-cleaner in liquid detergent and water. Allow It to

thoroughly air dry. Do not oil the pre-cleaner.

6.

Assemble the dry pre-cleaner to the filter.

7.

Install the filter into the engine base and push down until the filter

snaps in place.

Install the cover.

20

Page 21

SERVICE AND MAINTENANCE

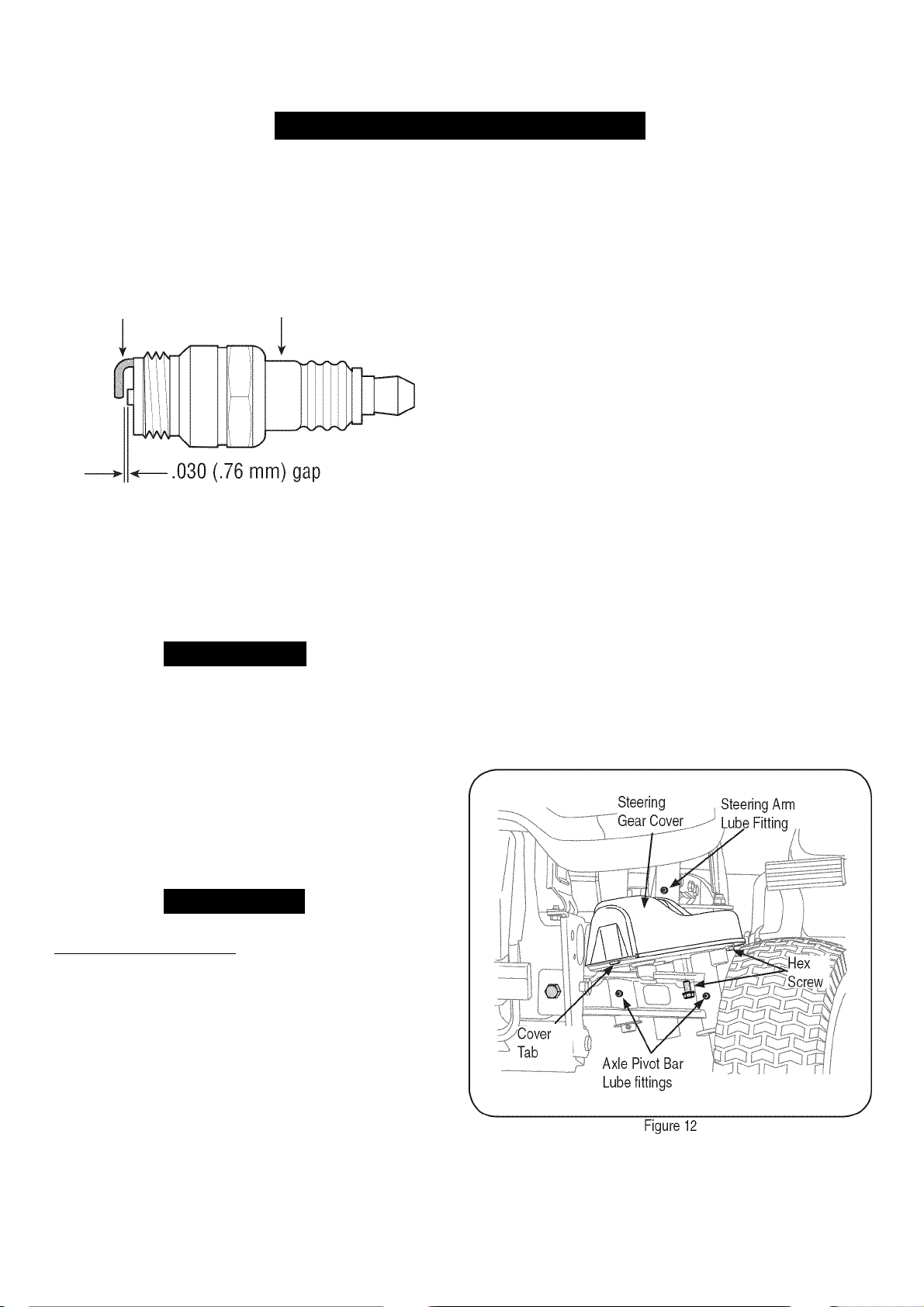

Spark Plug

1. Clean area around the spark plug base. Do not sandblast spark

plug. Spark plug should be cleaned by scraping or wire brushing

and washing with a commercial solvent

2. Remove and inspect the spark plug. Check gap to make sure it is

set at .030”. See Figure 11.

Electrode

3. Replace the spark plug (Champion® RC12YC) once a season .

Muffler

• Inspect muffler periodically, and replace if necessary. Replace

ment parts for the muffler must be the same and installed in the

same position as the original parts.

Awarning

Temperature of muffler and nearby engine areas may exceed 150° F

(65°C). Avoid contact with these areas.

Clean Engine

• Daily or before every use, clean grass, chaff or accumulated

debris from engine. Keep linkage, spring, and controls clean.

• Keep area around and behind muffler free of any combustible

debris.

• Keeping engine clean allows air movement around engine.

• Engine parts should be kept clean to reduce the risk of overheat

ing and ignition of accumulated debris.

Porcelain

Figure 11

J

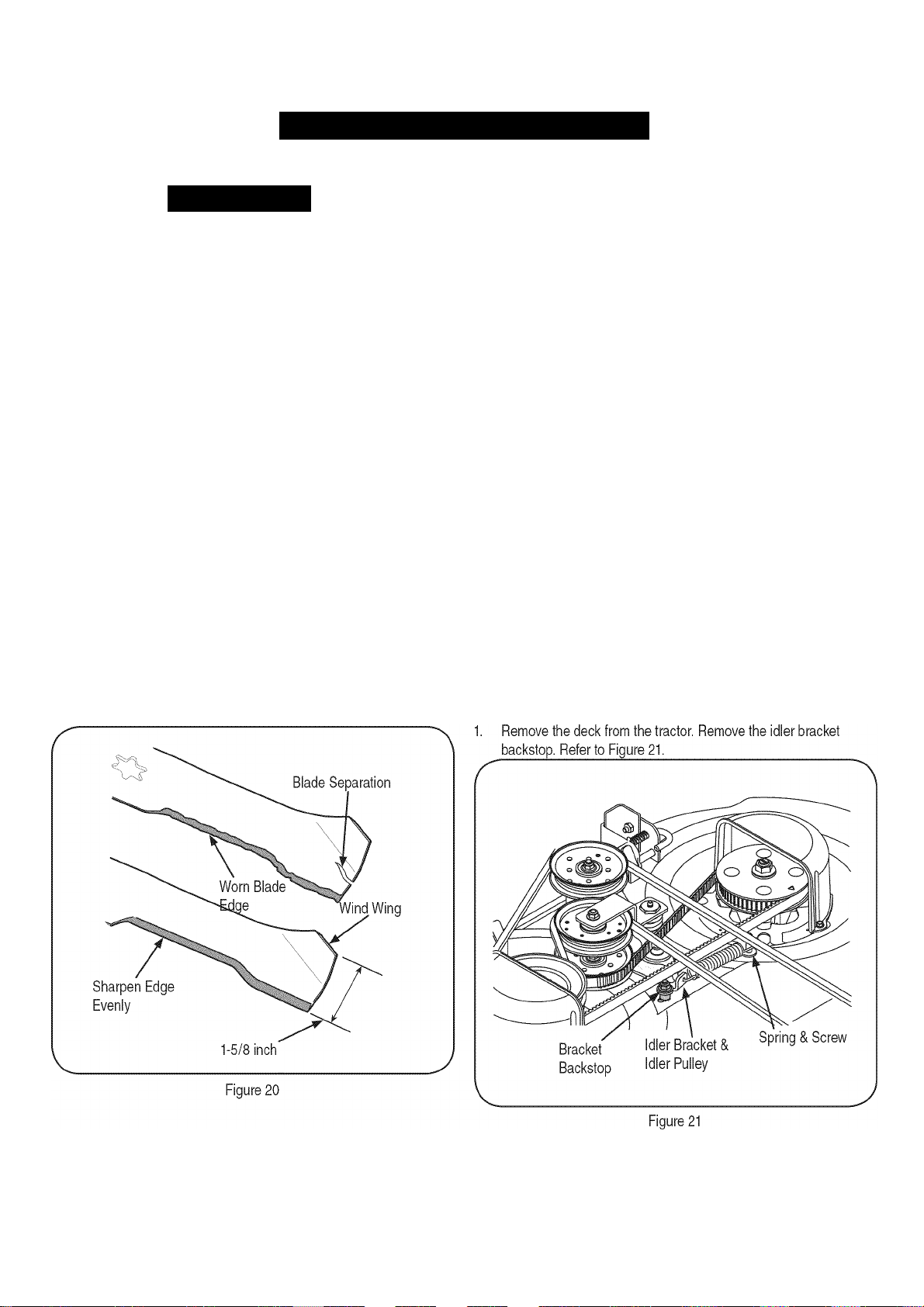

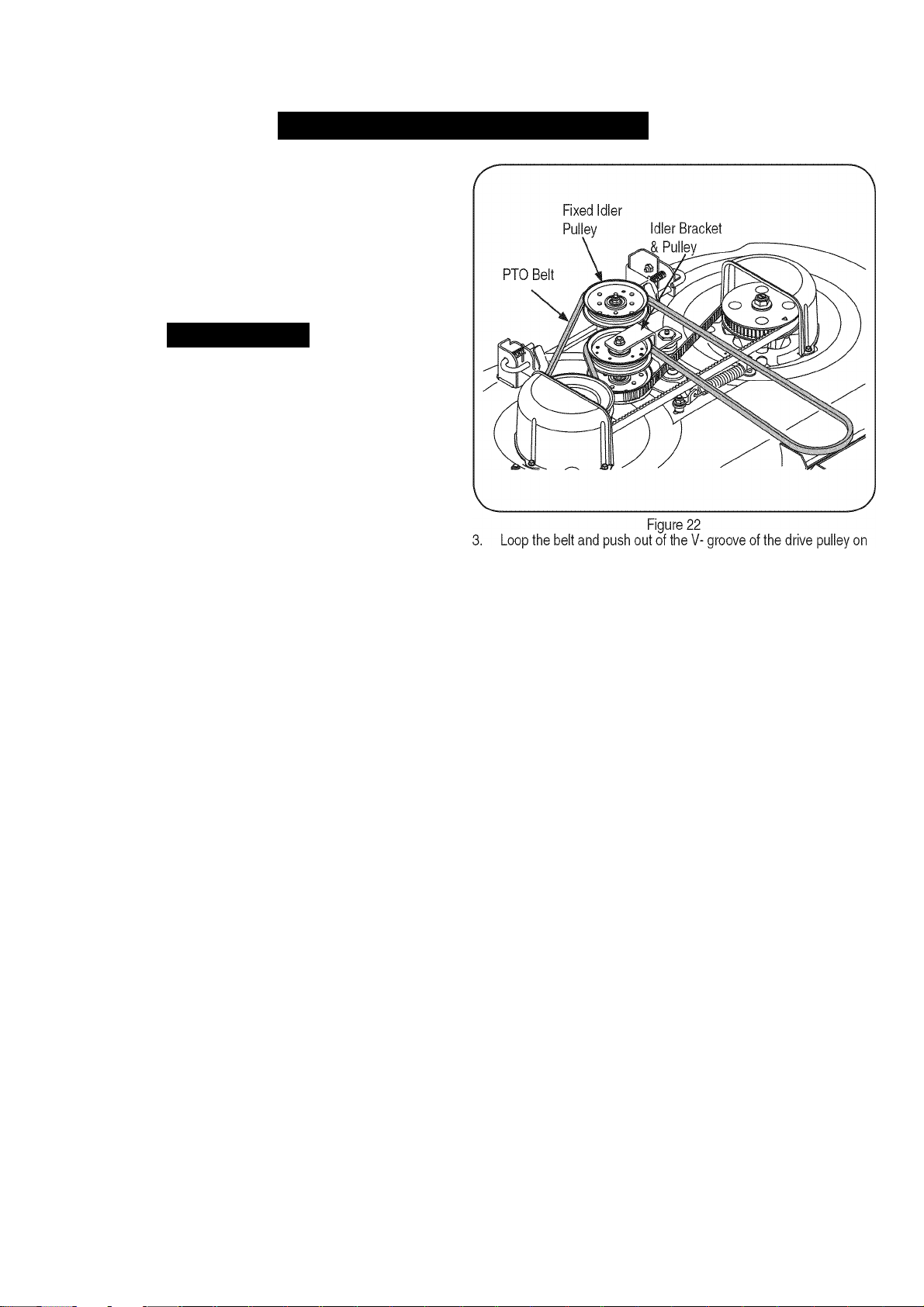

Deck Spindles and Idler Bracket

Lubricate the deck spindles and idler bracket with a No. 2 multipurpose

lithium grease after every 10 hours of operation.

• The deck spindle lube fittings are in the spindle housings, and

can only be accessed from the underside of the deck.

• Lubricate the idler bracket through the lube fitting in the top of the

shoulder bolt. Use a pressure grease gun to lubricate the spindles

and idler bracket.

Pivot Points & Linkage

Lubricate all the pivot points on the drive system, parking brake and lift

linkage at least once a season with light oil.

Rear Wheels

The rear wheels should be removed from the axles once a season.

Lubricate the axles and the rims well with an all purpose grease before

re-installing them.

IVT Transmission

The IVT transmission is sealed at the factory and is maintenance free.

The fluid level cannot be checked and cannot be changed. Keep the

area around the transmission cooling fan free of grass and debris at all

times.

Steering

The steering arms, pivot shafts, and axles must be lubricated it ever

the steering effort increases, or after every 25 hours of operation.

Lubricate using a pressure grease gun and a No. 2 multipurpose

lithium grease.

1. Apply grease through the lube fitting on the RFI and LH (right

hand and left hand, from operator's position) steering arms which

are located at rearward end of the two steering drag links. See

Figure 12.

A CAUTION

Do not use water to clean engine parts. Water could contaminate fuel

system. Use a brush or dry cloth.

Carburetor Adjustment

• The carburetor on this engine is not adjustable.

LUBRICATION

Front Wheel Bearings

Lubricate the front wheel bearings with a No. 2 multipurpose lithium

grease after every 25 hours of operation. The lube fittings are located

in the rim hub inside each front wheel.

______________________________

Locate the lube fittings for the pivot shaft and axle on the front of

one end of the axle pivot bar. Apply grease through the two lube

fittings, then repeat to lubricate the other end of the pivot bar. See

Figure 12.

21

Page 22

SERVICE AND MAINTENANCE

TIRES

Awarning

Never exceed the maximum inflation pressure shown on the sidewall

of tire. Refer to the tire sidewall for exact tire manufacturer’s recom

mended or maximum psi. Do not overinflate.

The recommended operating tire pressure is:

• Approximately 10 psi for the rear tires

• Approximately 14 psi for the front tires

IMPORTANT: Uneven tire pressure could cause the cutting deck to

mow unevenly.

CLEANING STEERING GEARS

Once a year, or it a tight spot is experienced when turning the steering

wheel, remove the steering gear cover on each end of the pivot bar

and clean the two steering gears.

1. From beneath the cover base plate on each end of the pivot bar,

remove the three hex screws securing the steering gear cover.

Remove the covers and clean the gears. It is not necessary to

lubricate the gears. Refer to Figure 12.

2. Insert the tab of the LH steering gear cover into the square hole

in the LH base plate, position the cover, and secure with the three

hex screws. Do not over tighten. Repeat to install the cover on the

RH side.

CLEANING THE TRACTOR AND DECK

Any fuel or oil spilled on the machine should be wiped off promptly. Do

NOT allow debris to accumulate around the deck pulleys or any other

part of the machine.

Periodically remove the belt covers and remove any accumulated

grass clippings from around the spindle pulleys and the deck belt.

IMPORTANT: The use of a pressure washer to clean your tractor is

NOT recommended. It may cause damage to electrical components,

spindles, pulleys, bearings or the engine.

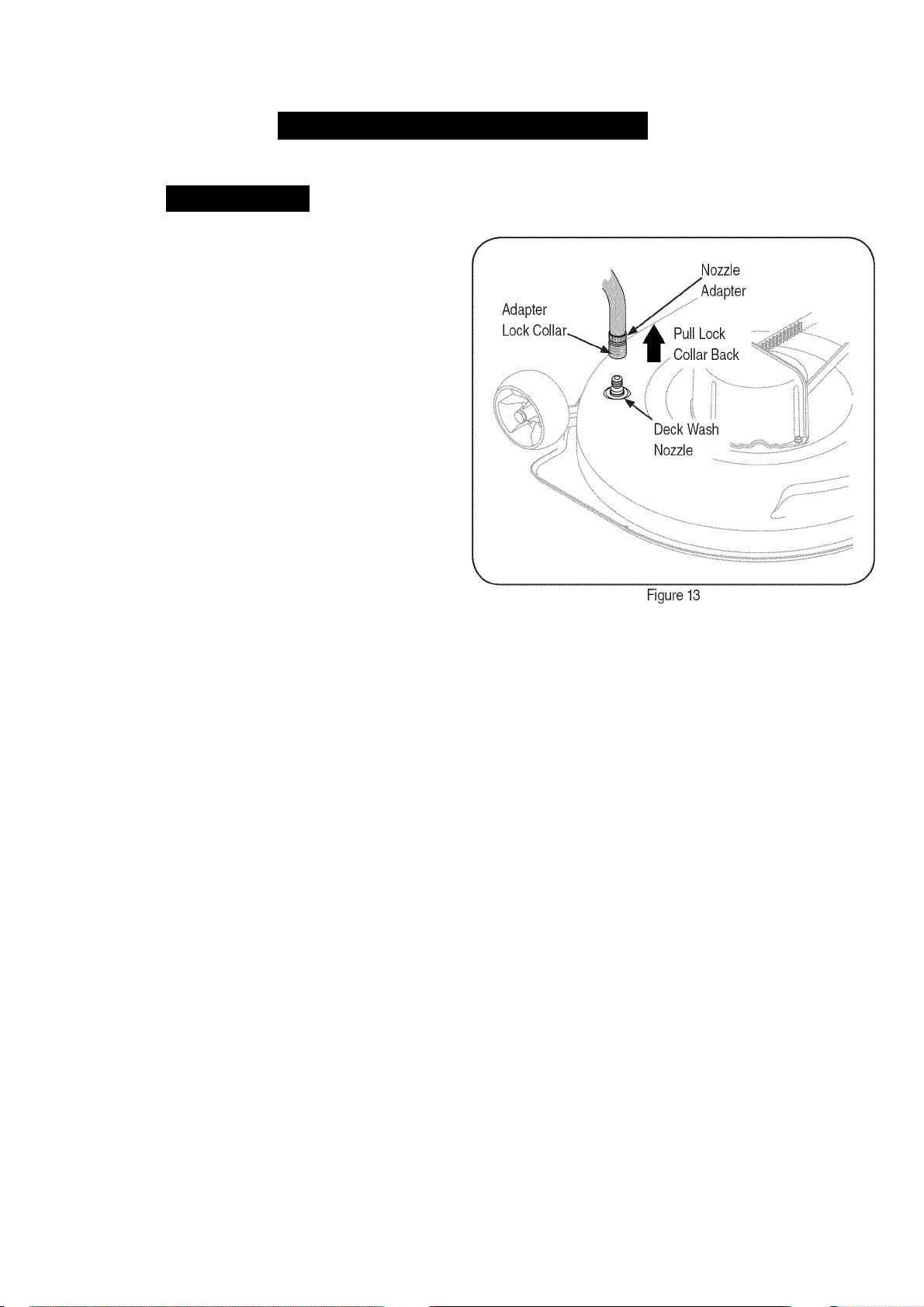

4. Pull back the lock collar of the nozzle adapter and push the

adapter onto the deck wash nozzle at the left end of the mower

deck. Release the lock collar to lock the adapter on the nozzle.

See Figure 13.

5. Turn the water on.

6. While sitting in the operator's position on the tractor, re-start the

engine and place the throttle lever in the FAST (rabbit) position.

7. Move the tractor's PTO (Blade Engage) into the ON position.

Remain in the operator's position with the cutting deck engaged

fora minimum of two minutes, allowing the underside of the

cutting deck to thoroughly rinse.

8. Move the tractor's PTO (Blade Engage) into the OFF position.

Turn the ignition key to the STOP position to turn the tractor's

engine off.

9. Pull back the lock collar of the nozzle adapter to disconnect the

adapter from the nozzle.

Using Deck Wash System^“

Use the Deck Wash System™ to rinse grass clippings from the deck's

underside and prevent the buildup of corrosive chemicals. Your trac

tor's deck is equipped with a water nozzle on the left end of the deck.

Complete the following steps AFTER EACH MOWING:

1. Drive the tractor to a level, clear spot on your lawn, near enough

to a water sillcock (spigot) for your garden hose to reach.

IMPORTANT: Make certain the tractor’s discharge chute is directed

AWAY from your house, garage, parked cars, etc.

2. Disengage the PTO (Blade Engage), set the parking brake, and

stop the engine.

3. Thread the nozzle adapter (packaged with your tractor's Opera

tor's Manual) onto the end of your garden hose.

BATTERY

The battery is sealed and is maintenance-free. Acid levels cannot be

checked.

• Always keep the battery cables and terminals clean and free of

corrosive build-up.

• After cleaning the battery and terminals, apply a light coat of

petroleum jelly or grease to both terminals.

• Always keep the rubber boot positioned over the positive terminal

to prevent shorting.

IMPORTANT: If removing the battery for any reason, disconnect

the NEGATIVE (Black) wire from its terminal first, followed by the

POSITIVE (Red) wire. When re-installing the battery, always connect

the POSITIVE (Red) wire its terminal first, followed by the NEGATIVE

(Black) wire. Be certain that the wires are connected to the correct

terminals; reversing them could change the polarity and result in

damage to your engine’s alternating system.

22

Page 23

SERVICE AND MAINTENANC

J

Charging the Battery

If the tractor has not been put into use for an extended period of

time, charge the battery with an automotive-type 12-volt charger for a

minimum of one hour at six amps.

AWARNING

Batteries give off an explosive gas while charging. Charge battery in

a well ventilated area and keep away from an open flame or pilot light

as on a water heater, space heater, furnace, clothes dryer or other

gas appliances.

Cleaning the Battery

Clean the battery by removing it from the tractor and washing with

a baking soda and water solution. If necessary, scrape the battery

terminals with a wire brush to remove deposits. Coat terminals and

exposed wiring with grease or petroleum jelly to prevent corrosion.

Battery Failures

Some common causes for battery failure are:

• Incorrect initial activation • undercharging

• Overcharging • corroded connections

• Freezing

These failures are NOT covered by your tractor’s warranty.

Seat

AWARNING

After adjusting the seat or before driving the tractor, make sure that

the seat adjustment lever is engaged in the seat index plate and

that the seat will not move. Do not adjust the seat while the tractor

is being driven. Adjusting the seat while the tractor is moving could

cause the operator to lose control of the tractor.__________________

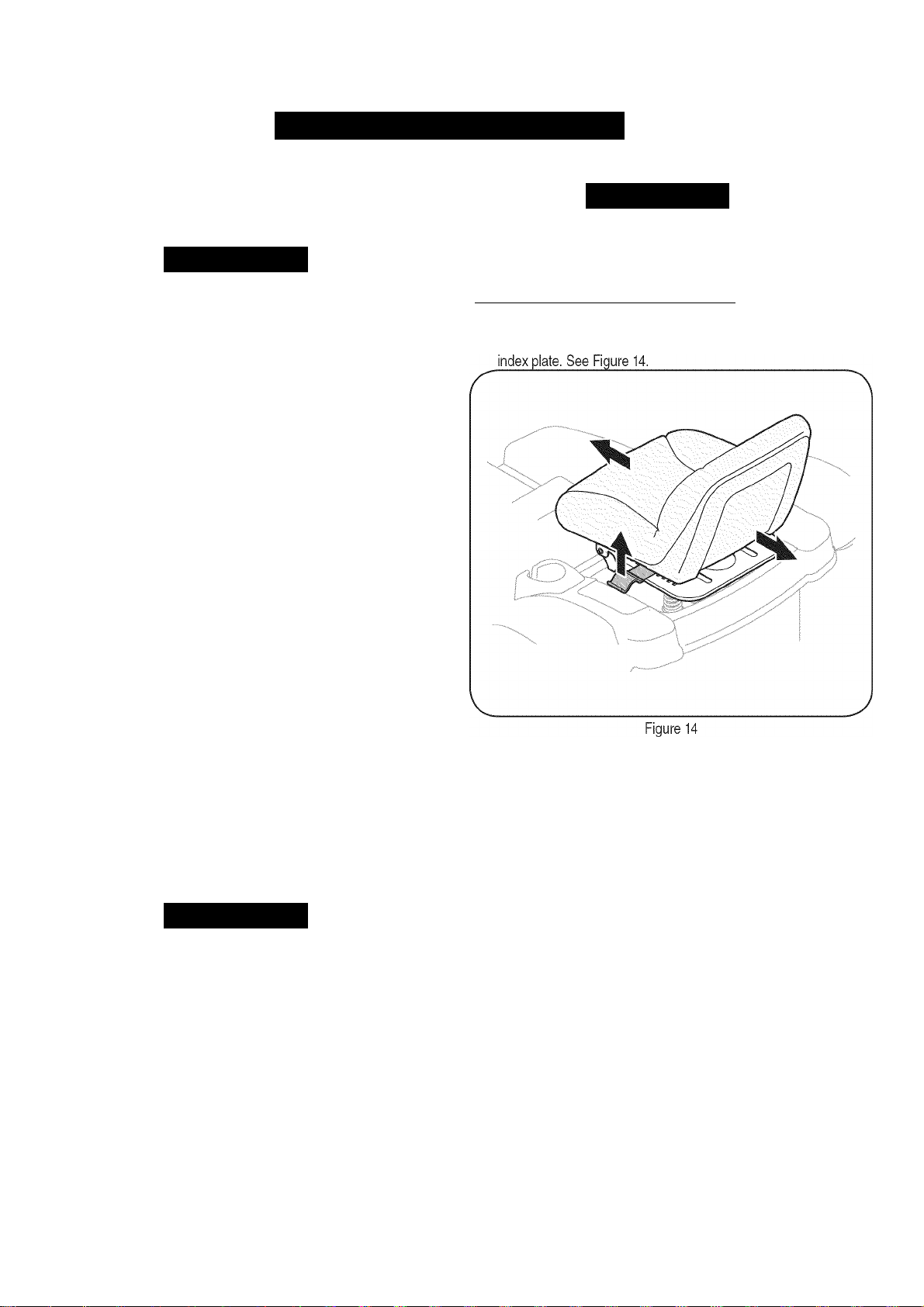

1. While sitting in the seat, grasp the seat adjustment lever on the

left side of the seat and pull it upward to disengage from the seat

CHECKING MAIN HARNESS FUSE

• A 20 amp fuse is installed in your tractor’s wiring harness to

protect the tractor’s electrical system from damage caused by

excessive amperage.

• If the electrical system does not function, or your tractor’s engine

will not crank, first check to be certain that the fuse has not blown.

• The fuse can be found inside of the dash panel behind the battery

tray. You may need to remove the battery to gain access to the

fuse. Always use a fuse with the same amperage capacity for

replacement.

NOTE: A second fuse holder can be found inside the dash panel. This

fuse holder is used for the optional 12 volt power outlet.

ADJUSTMENTS

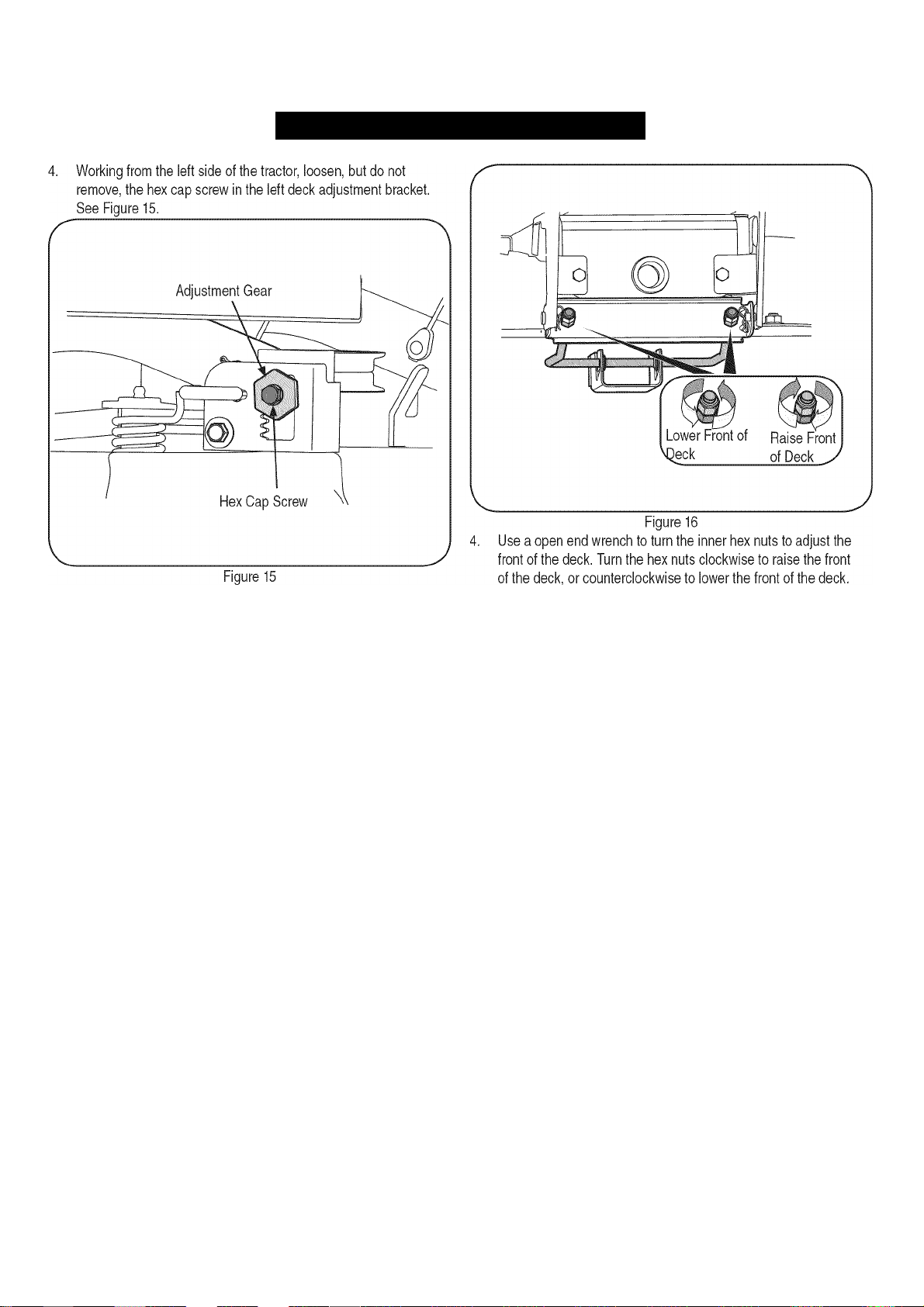

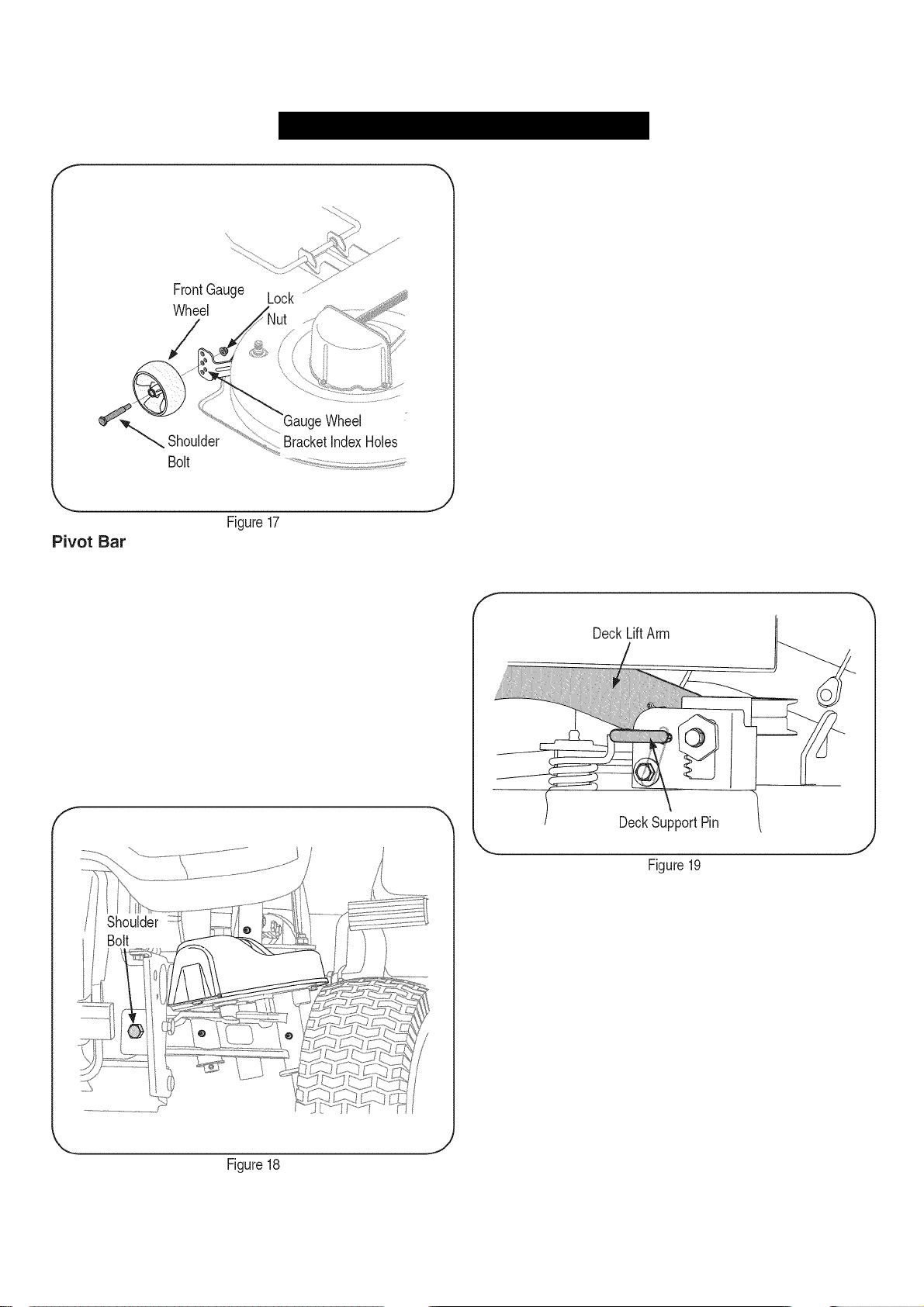

AWARNING

Never attempt to make any adjustments while the engine is running,

except where specified in the operator’s manual. Disconnect spark

plug wire(s) before performing any adjustments, repairs or mainte

nance.

Steering and Transmission Linkage

The steering tie rod and drag links and the related transmission linkage