Page 1

perator's

I:RnFrSMRN°

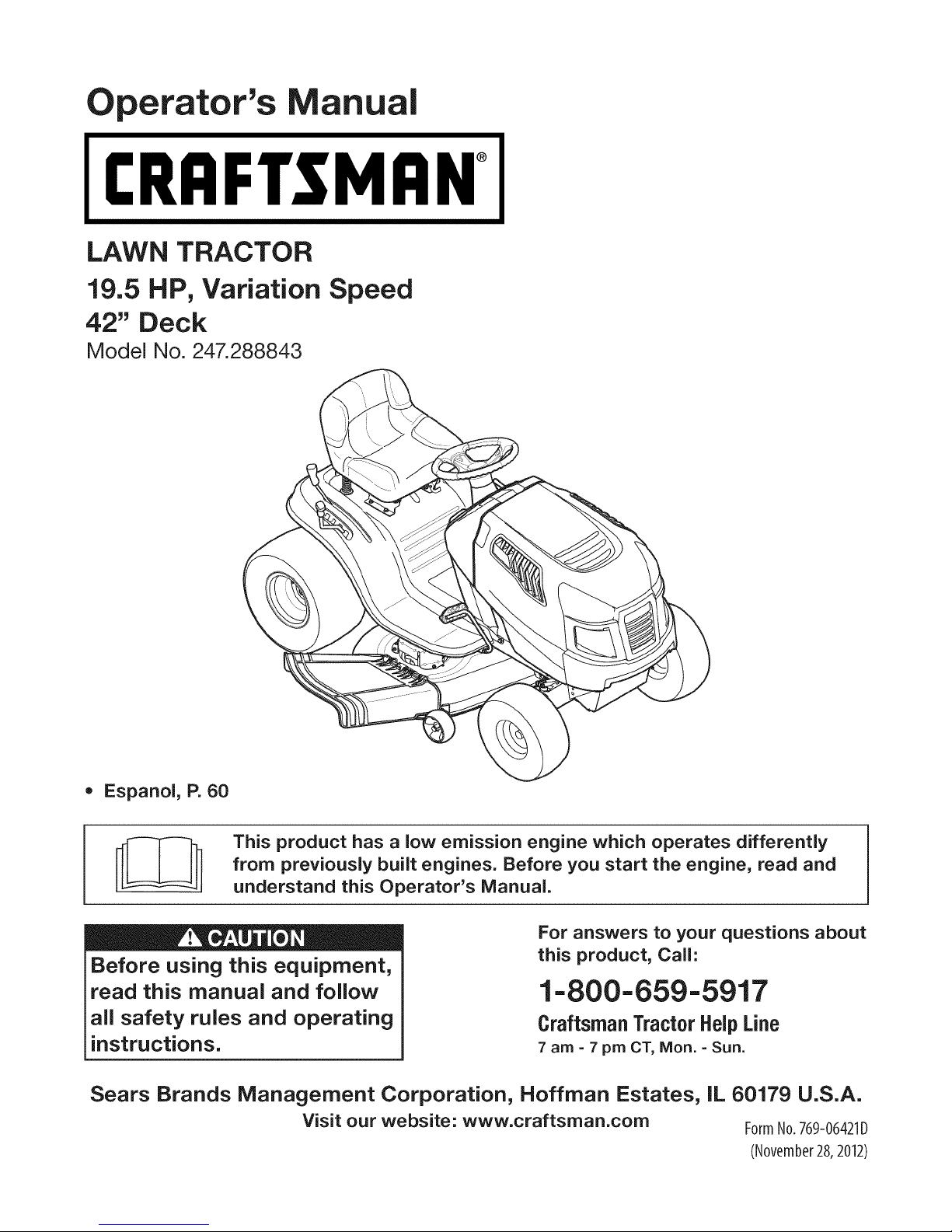

LAWN TRACTOR

19.5 HP, Variation Speed

42" Deck

Model No. 247.288843

• Espanol, P. 60

This product has a low emission engine which operates differently

from previously built engines. Before you start the engine, read and

understand this Operator's Manual.

Before using this equipment,

read this manual and follow

all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsman.com FormNo.769-06421D

For answers to your questions about

this product, Call:

1-800=659=5917

CraftsmanTractorHelpLine

7 am =7 pm CT, Mort. =Sun.

(November28,2012)

Page 2

Warranty Statement .......................................................... 2

Safety Instructions ............................................................ 3

Slope Gauge ..................................................................... 8

Assembly ........................................................................... 9

Operation ........................................................................ 11

Service and Maintenance .............................................. 17

Off-Season Storage ........................................................ 26

Trou bleshooting .............................................................. 27

Labels ............................................................................. 28

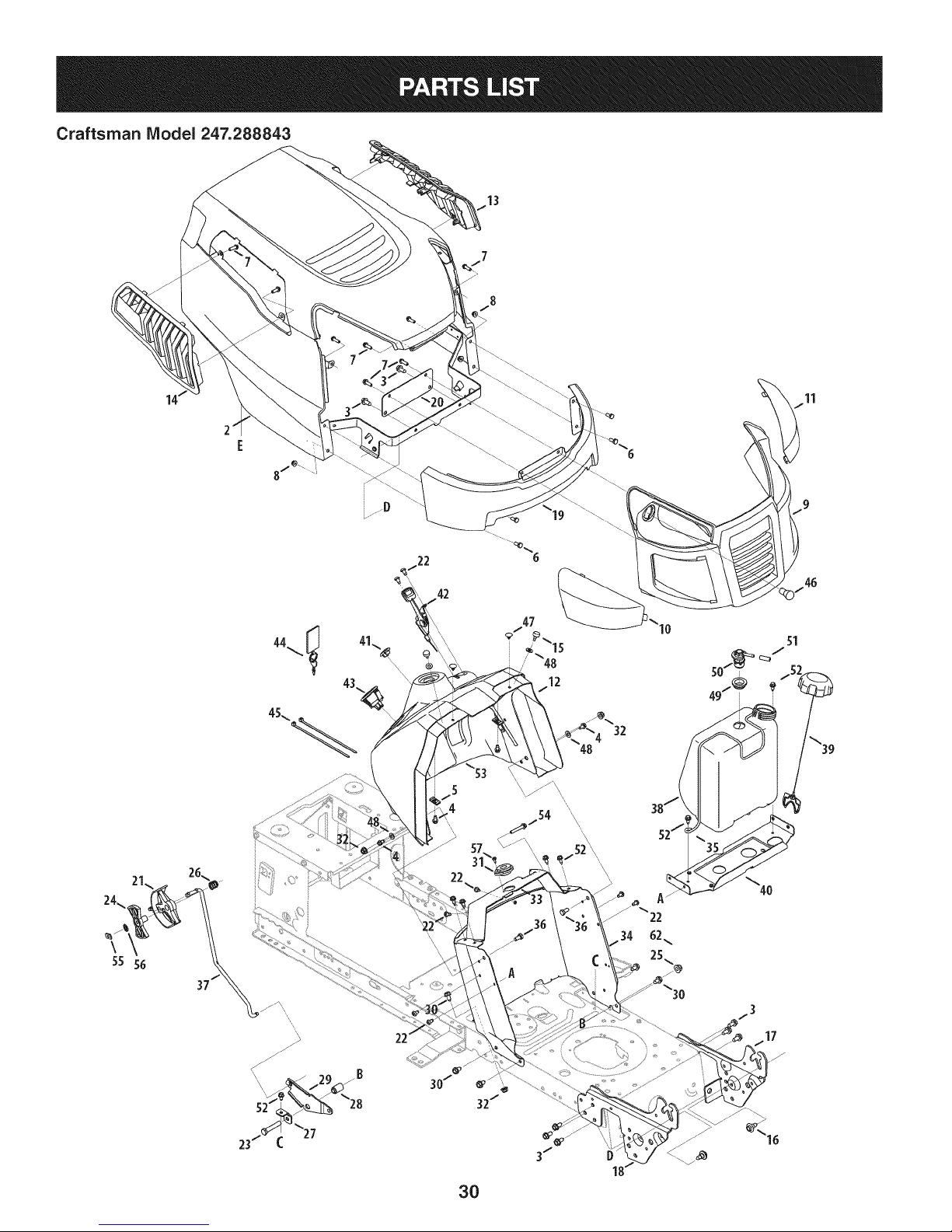

Parts List ......................................................................... 30

Espa_ol ............................................................................ 60

Service Numbers ............................................. Back Cover

CRAFTSMAN FULL WARRANTY

FORTWOYEARSfromthe dateofpurchase,allnon-expendablepartsofthis ridingequipmentarewarrantedagainstanydefectsinmaterialor

workmanship.Adefectivenon-expendablepartwillreceivefreein-homerepairor replacementif repairis unavailable.

BATTERYLIMITEDWARRANTY

FOR90 DAYSfromthe dateof purchase,thebattery(anexpendablepart)ofthis ridingequipmentiswarrantedagainstany defectsin materialor

workmanship.Anewbatterywillbesuppliedfreeof charge.Youare responsibleforthe laborcost of batteryinstallation.

ADDITIONALLIMITEDWARRANTIES

inthefollowingadditionalwarranties,youare responsibleforthelaborcostofpart installationafterthe secondyearfromthedateof purchase.

FORFiVEYEARSfromthedateof purchase,the frameof thisridingequipmentiswarrantedagainstany defectsin materialorworkmanship.A

newframewillbe suppfiedfreeof charge.

FORTENYEARSfromthe dateofpurchase,thefrontaxleofthisridingequipmentis warrantedagainstanydefectsin materialorworkmanship.

A newfrontaxlewill be suppliedfreeofcharge.

FORASLONGASITiSUSEDbytheoriginalownerafterthetenthyearfromthedateofpurchase,thecastironfrontaxle(ifequipped)ofthisriding

equipmentis warrantedagainstanydefectsinmaterialorworkmanship.Withproofofpurchase,anewcastironfrontaxlewillbesuppliedfreeofcharge.

WARRANTYSERVICE

Forwarrantycoveragedetailstoobtainfree repairor replacement,carl1-800-659-5917or visitthe web site:www.craftsman.com

inall casesabove,ifpartrepairor replacementis impossible,theridingequipmentwill be replacedfreeofchargewiththesameor anequivalent

model.

All oftheabovewarrantycoverageisvoidifthis ridingequipmentiseverusedwhileprovidingcommercialservicesorif rentedtoanotherperson.

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableparts(exceptbattery)thatcan wearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoblades,spark

plugs,air cleaners,belts,andoilfilters.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbytowingobjectsbeyondthecapabilityofthe

ridingequipment,impactingobjectsthat bendtheframe,axleassemblyor crankshaft,orover-speedingtheengine.

Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failuretousethepropergradeand amountofengineoil,failuretokeepthedeckclearofflammabledebris,orfailuretomaintainthe

ridingequipmentaccordingto theinstructionscontainedin theoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedor oxidized(stale).ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,or productlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,and youmayalsohaveotherrightswhichvaryfromstatetostate.

SearsBrands ManagementCor

_oration,Hoffman Estates, IL 60179

EngineOil: SAE30

Fuel: UnleadedGasoline

SparkPlug: Champion®RC12YC

© SearsBrands,LLC 2

Model Number:

Serial Number:

Dateof Purchase:

Recordthe modelnumber,serialnumber,

anddateof purchaseabove.

Page 3

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethe followingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm.

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknowntotheStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

GENERAL OPERATION

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder14yearsoldtooperatethis machine.

Children14yearsoldandovershouldreadandunderstandthe

operationinstructionsandsafetyrulesinthismanualandshould

betrainedandsupervisedbya parent.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Tohelpavoidbladecontactor a thrownobjectinjury,keep

bystanders,helpers,childrenandpetsat least75feetfromthe

machinewhile itisin operation.Stopmachineifanyoneenters

thearea.

• Thoroughlyinspecttheareawheretheequipmentistobe used.

Removeallstones,sticks,wire,bones,toys,andotherforeign

objectswhichcouldbe pickedupandthrownbythe blade(s).

Thrownobjectscancauseseriouspersonalinjury.

• Planyourmowingpatternto avoiddischargeofmaterialtoward

roads,sidewalks,bystandersandthelike.Also,avoiddischarg-

ingmaterialagainstawallorobstructionwhichmaycause

dischargedmaterialto ricochetbacktowardthe operator.

Your Responsibility--Restricttheuseof thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVE THESE INSTRUCTIONS!

• Alwayswearsafetyglassesor safetygogglesduringoperation

andwhileperformingan adjustmentorrepairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjuryto the

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesandjewelrycanbe caughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beawareofthemowerandattachmentdischargedirectionand

do notpointit at anyone.Donotoperatethemowerwithoutthe

dischargecoverorentiregrasscatcherinits properplace.

Donot puthandsorfeetnearrotatingpartsor underthe cutting

deck.Contactwiththe blade(s)canamputatehandsandfeet.

A missingordamageddischargecovercancausebladecontact

or thrownobjectinjuries.

• Stoptheblade(s)whencrossinggraveldrives,walks,orroads

andwhilenotcuttinggrass.

• Watchfortrafficwhenoperatingnearorcrossingroadways.This

machineis notintendedforuseonanypublicroadway.

• Donotoperatethemachinewhileunderthe influenceofalcohol

or drugs.

• Mowonly indaylightorgoodartificiallight.

Nevercarrypassengers.

• Disengageblade(s)beforeshiftingintoreverse.Backupslowly.

Alwayslookdownandbehindbeforeandwhile backingtoavoida

back-overaccident.

3

Page 4

• Slowdownbeforeturning.Operatethemachinesmoothly.Avoid

erraticoperationandexcessivespeed.

Disengageblade(s),setparkingbrake,stopengineandwaituntil

theblade(s)cometoa completestopbeforeremovinggrass

catcher,emptyinggrass,uncloggingchute,removinganygrassor

debris,or makinganyadjustments.

Neverleavea runningmachineunattended.Alwaysturnoff

blade(s),setparkingbrake,stopengineandremovekeybefore

dismounting.

Useextracarewhenloadingorunloadingthemachineintoa

trailerortruck.Thismachineshouldnotbedrivenupor down

ramp(s),becausethemachinecouldtip over,causingserious

personalinjury.Themachinemustbe pushedmanuallyon

ramp(s)to loador unloadproperly.

Mufflerandenginebecomehotandcancausea burn.Donot

touch.

Checkoverheadclearancescarefullybeforedrivingunderlow

hangingtree branches,wires,dooropeningsetc.,wherethe

operatormaybestruckor pulledfromthemachine,whichcould

resultinseriousinjury.

Disengageallattachmentclutchesanddepressthebrakepedal

completelybeforeattemptingto startengine.

Yourmachineisdesignedto cutnormalresidentialgrassofa

heightnomorethan10".Donotattemptto mowthroughunusually

tall,drygrass(e.g.,pasture)orpiles of dryleaves.Drygrassor

leavesmaycontacttheengineexhaustand/orbuilduponthe

mowerdeckpresentinga potentialfirehazard.

Useonlyaccessoriesandattachmentsapprovedfor this machine

bythe machinemanufacturer.Read,understandandfollowall

instructionsprovidedwiththe approvedaccessoryorattachment.

Fora list ofapprovedaccessoriesandattachments,call 1-800-

659-5917.

Dataindicatesthatoperators,age60yearsandabove,are

involvedin a largepercentageofridingmower-relatedinjuries.

Theseoperatorsshouldevaluatetheirabilityto operatetheriding

mowersafelyenoughto protectthemselvesandothersfrom

seriousinjury.

If situationsoccurwhicharenotcoveredinthismanual,usecare

andgoodjudgment.

SLOPE OPERATION

Slopesarea majorfactorrelatedtolossof controlandtip-over

accidentswhichcanresultinsevereinjuryor death.Allslopesrequire

extracaution.Ifyoucannotbackuptheslopeor ifyoufeeluneasyon

it, do notmowit.

Foryoursafety,usetheSlopeGuideincludedaspartofthismanual

to measureslopesbeforeoperatingthismachineona slopedor hilly

area.Iftheslopeisgreaterthan15degreesasshownonthe Slope

Guide,do notoperatethis machineonthatareaor seriousinjurycould

result.

Do:

o

Mowupanddownslopes,notacross.Exerciseextremecaution

whenchangingdirectionon slopes.

• Watchforholes,ruts,bumps,rocks,orotherhiddenobjects.

Uneventerraincouldoverturnthe machine.Tallgrasscanhide

obstacles.

Useslowspeed.Choosea lowenoughspeedsettingsothat

youwill nothaveto stopor shiftwhileon the slope.Tiresmay

losetractionon slopeseventhoughthe brakesarefunctioning

properly.Alwayskeepmachinein gearwhengoingdownslopes

totakeadvantageof enginebrakingaction.

• Followthemanufacturer'srecommendationsforwheelweightsor

counterweightsto improvestability.

Useextracarewithgrasscatchersor otherattachments.These

canchangethestabilityofthe machine.

Keepallmovementontheslopesslowandgradual.Donotmake

suddenchangesinspeedor direction.Rapidengagementor

brakingcouldcausethefrontofthemachinetolift andrapidlyflip

overbackwardswhichcouldcauseseriousinjury.

• Avoidstartingorstoppingonaslope.Iftireslosetraction,disen-

gagetheblade(s)andproceedslowlystraightdownthe slope.

DoNot:

• Donotturnon slopesunlessnecessary;then,turnslowlyand

graduallydownhill,ifpossible.

• Donotmowneardrop-offs,ditchesorembankments.The mower

couldsuddenlyturnoverifa wheelis overtheedgeofa cliff,

ditch,or ifan edgecavesin.

• Donottry to stabilizethemachinebyputtingyourfootonthe

ground.

• Donotusea grasscatcheronsteepslopes.

• Donotmowon wetgrass.Reducedtractioncouldcausesliding.

• Donotattempttocoastdownhill.Over-speedingmaycausethe

operatortolosecontrolofthe machineresultinginseriousinjury

or death.

• Donottowheavypull behindattachments(e.g.loadeddumpcart,

lawnroller,etc.)on slopesgreaterthan5 degrees.Whengoing

downhill,theextraweighttendstopushthe tractorandmay

causeyouto loosecontrol(e.g.tractormayspeedup,brakingand

steeringabilityarereduced,attachmentmayjack-knifeandcause

tractorto overturn).

4

Page 5

CHILDREN

Tragicaccidentscanoccuriftheoperatorisnotalert tothepresence

ofchildren.Childrenareoftenattractedtothemachineandthe mowing

activity.Theydonotunderstandthedangers.Neverassumethat

childrenwillremainwhereyoulastsawthem.

• Keepchildrenoutofthemowingareaand inwatchfulcareofa

responsibleadultotherthantheoperator.

• Bealert andturnmachineoff ifa childentersthearea.

• Beforeandwhilebacking,lookbehindanddownforsmall

children.

Nevercarrychildren,evenwiththe blade(s)shutoff.Theymay

falloffandbe seriouslyinjuredorinterferewithsafemachine

operation.

• Useextremecarewhenapproachingblindcorners,doorways,

shrubs,treesorotherobjectsthatmayblockyourvisionofachild

whomayrunintothe machine.

Toavoidback-overaccidents,alwaysdisengagethecutting

blade(s)beforeshiftingintoReverse.Ifequipped,the"Reverse

CautionMode"(bladesoperatewhilemachineridesinreverse)

shouldnotbe usedwhenchildrenor othersarearound.

Keepchildrenawayfromhotor runningengines.Theycansuffer

burnsfroma hotmuffler.

• Removekeywhenmachineisunattendedto preventunauthorized

operation.

Neverallowchildrenunder14yearsofagetooperatethismachine.

Children14andovershouldreadandunderstandthe instructionsand

safeoperationpracticesinthismanualandon the machineandshould

betrainedandsupervisedbyan adult.

TOWING

Towonlywitha machinethathasa hitchdesignedfortowing.Do

notattachtowedequipmentexceptatthehitchpoint.

Followthemanufacturersrecommendationforweightlimitsfor

towedequipmentandtowingonslopes.

Neverallowchildrenor othersinoron towedequipment.

Onslopes,theweightof thetowedequipmentmaycauselossof

tractionandlossof control.

Alwaysuseextracautionwhentowingwitha machinecapableof

makingtightturns(e.g."zero-turn"ride-onmower). Makewide

turnstoavoidjack-knifing.

Travelslowlyandallowextradistanceto stop.

Donotcoastdownhill.

SERVICE

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

on yourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonly anapprovedgasolinecontainer.

Neverfill containersinsidea vehicleorona truckortrailerbed

witha plasticliner.Alwaysplacecontainersonthegroundaway

fromyourvehiclebeforefilling.

Whenpractical,removegas-poweredequipmentfromthe truck

or trailerandrefueliton theground.Ifthis isnotpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

Keepthenozzleincontactwiththerim of thefueltankor

containeropeningat all timesuntilfuelingiscomplete.Donot use

a nozzlelock-opendevice.

Extinguishall cigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

Neverremovegascapor addfuelwhiletheengineis hotor run-

ning.Allowengineto coolat leasttwominutesbeforerefueling.

Neveroverfillfueltank.Filltanktono morethan1/2inchbelow

bottomoffillernecktoallowspaceforfuelexpansion.

• Replacegasolinecap andtightensecurely.

• Ifgasolineisspilled,wipeitoff the engineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingthe

engine.

• Toreducefirehazards,keepmachinefreeof grass,leaves,or

otherdebrisbuild-up.Cleanup oilor fuelspillageandremoveany

fuelsoakeddebris.

• Neverstorethe machineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlight as ona waterheater,spaceheater,

furnace,clothesdryeror othergasappliances.

Allowa machineto coolatleastfiveminutesbeforestoring.

Page 6

GeneralService

• Neverrunanengineindoorsorinapoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorless,anddeadlygas.

• Beforecleaning,repairing,orinspecting,makecertainthe

blade(s)andallmovingpartshavestopped.Disconnectthespark

plugwireandgroundagainsttheenginetopreventunintended

starting.

• Periodicallychecktomakesurethebladescometocomplete

stopwithinapproximately(5)fivesecondsafteroperatingthe

bladedisengagementcontrol.Ifthebladesdonotstopwithinthe

thistimeframe,yourmachineshouldbeservicedprofessionally

byaSearsorotherqualifiedservicedealer.

• Checkbrakeoperationfrequentlyasitissubjectedtowearduring

normaloperation.Adjustandserviceasrequired.

• Checktheblade(s)andenginemountingboltsatfrequent

intervalsforpropertightness.Also,visuallyinspectblade(s)

fordamage(e.g.,excessivewear,bent,cracked).Replacethe

blade(s)withtheoriginalequipmentmanufacturer's(O.E.M.)

blade(s)only,listedinthismanual.Useofpartswhichdonot

meettheoriginalequipmentspecificationsmayleadtoimproper

performanceandcompromisesafety!

• Mowerbladesaresharp.Wrapthebladeorweargloves,anduse

extracautionwhenservicingthem.

• Keepallnuts,bolts,andscrewstighttobesuretheequipmentis

insafeworkingcondition.

• Nevertamperwiththe safetyinterlocksystemor othersafety

devices.Checktheirproperoperationregularly.

• Afterstrikinga foreignobject,stoptheengine,disconnectthe

sparkplugwire(s)andgroundagainstthe engine.Thoroughly

inspectthemachineforanydamage.Repairthedamagebefore

startingandoperating.

• Neverattempttomakeadjustmentsor repairstothe machine

whilethe engineis running.

• Grasscatchercomponentsandthedischargecoverare subject

towearanddamagewhichcouldexposemovingpartsor allow

objectsto bethrown.Forsafetyprotection,frequentlycheck

componentsand replaceimmediatelywithoriginalequipment

manufacturer's(O.E.M.)partsonly,listedinthis manual.Useof

partswhichdo not meettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!

• Donotchangetheenginegovernorsettingsorover-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofthe engine.

Maintainor replacesafetyandinstructionlabels,as necessary.

• Observeproperdisposallawsandregulationsforgas,oil,etc.to

protecttheenvironment.

• Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andthe U.S.EnvironmentalProtectionAgency(EPA),this product

hasanAverageUsefulLifeof seven(7)years,or 270hours

ofoperation.AttheendoftheAverageUsefulLife,buyanew

machineor havethemachineinspectedannuallybya Searsor

otherqualifiedservicedealerto ensurethatall mechanicaland

safetysystemsareworkingproperlyandnot wornexcessively.

Failuretodosocanresultinaccidents,injuriesor death.

DO NOT MODIFY ENGINE

Toavoid seriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththe governorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM)and

ThreeWayCatalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithan internalcombustionengineand

shouldnot beusedonor nearanyunimprovedforest-covered,

brushcoveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any).

Ifa sparkarrestoris used,it shouldbe maintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveis required

bylaw (Section4442of the CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws.Federallawsapplyonfederallands.

A sparkarrestorforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

6

Page 7

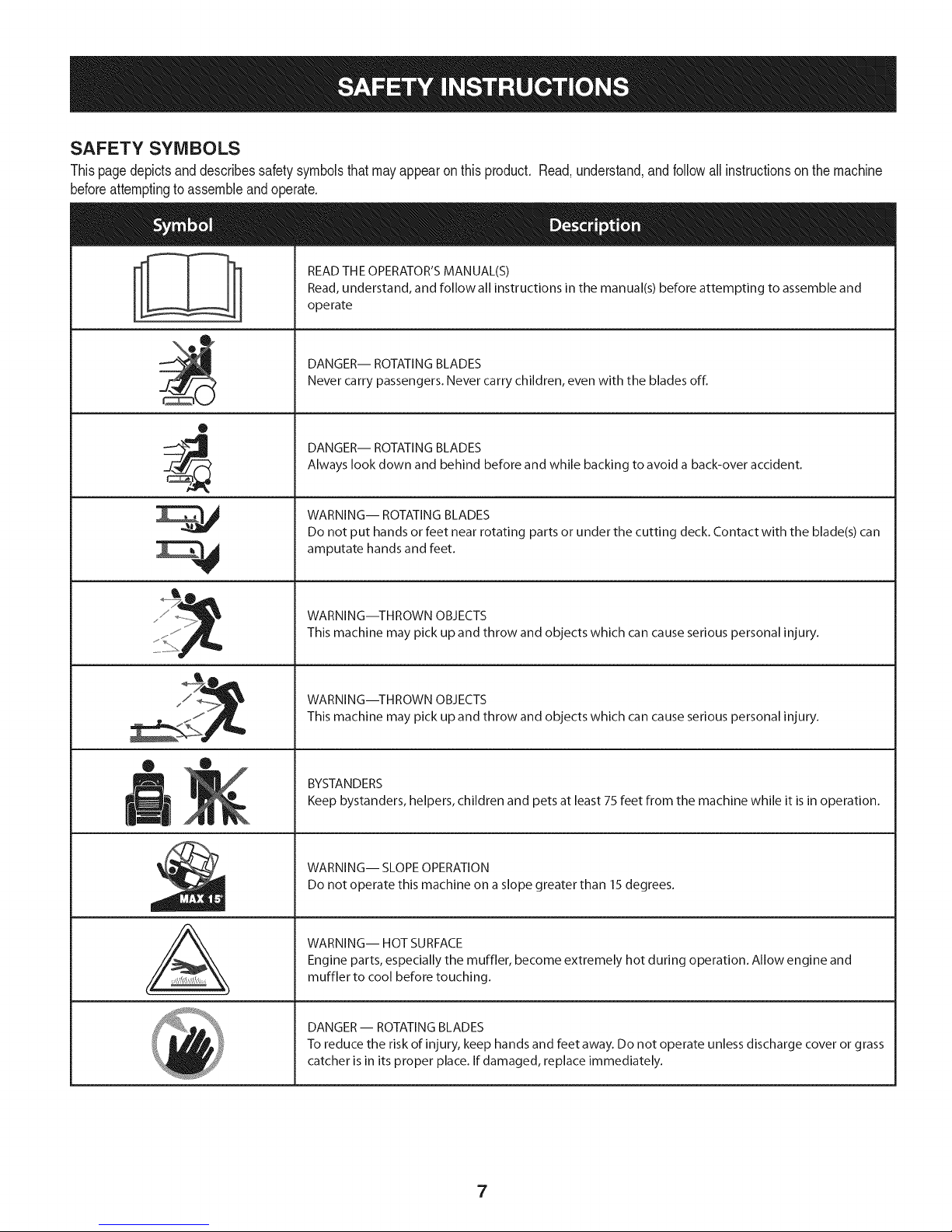

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct.Read,understand,andfollowallinstructionsonthemachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

DANGER-- ROTATING BLADES

Never carry passengers. Never carry children, even with the blades off.

O

DANGER-- ROTATING BLADES

Always look down and behind before and while backing to avoid a back-over accident.

WARNING-- ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the blade(s) can

amputate hands and feet.

A

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in operation.

WARNING-- SLOPE OPERATION

Do not operate this machine on a slope greater than 15 degrees.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

DANGER- ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover or grass

catcher is in its proper place. If damaged, replace immediately.

7

Page 8

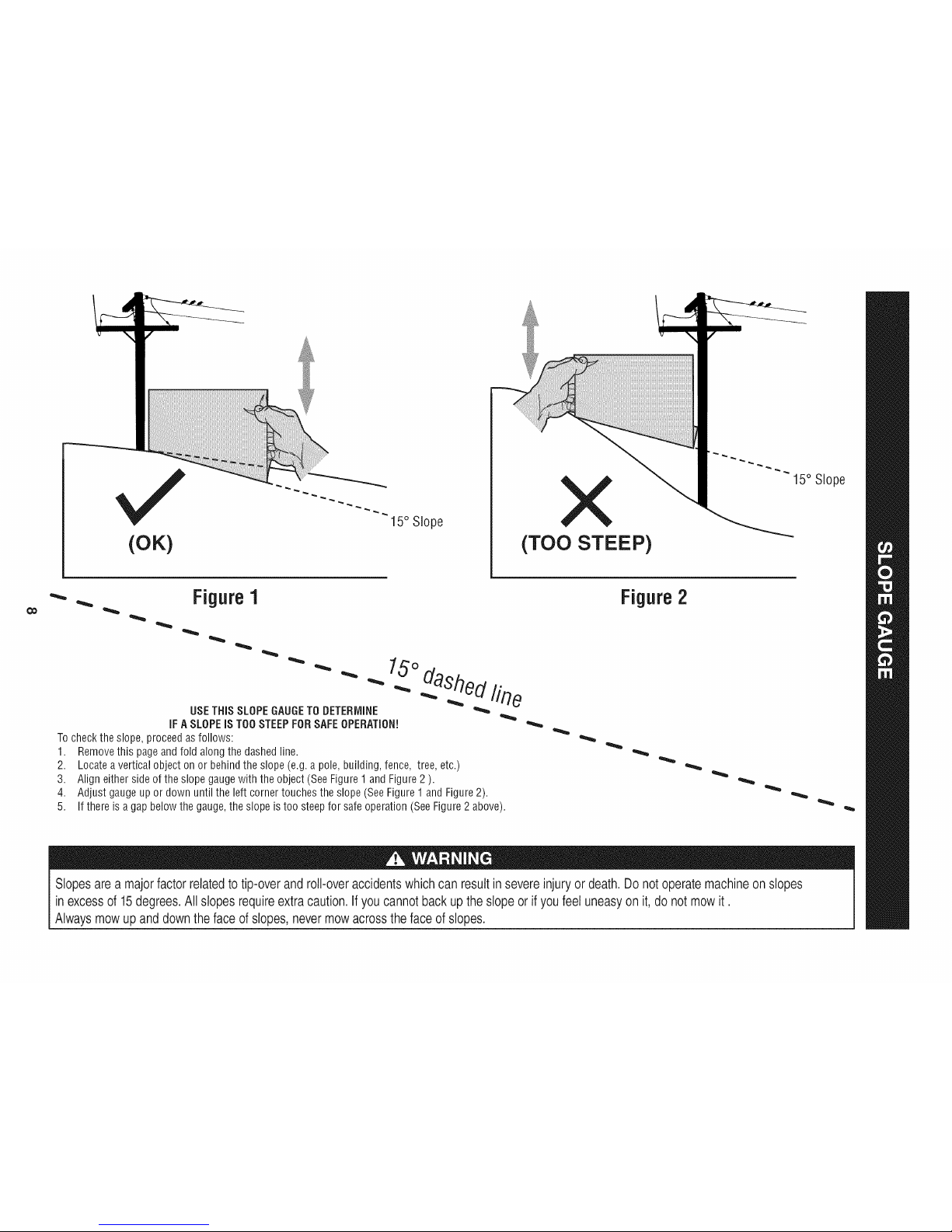

(OK)

15° Slope

X

(TOO STEEP)

15° Slope

'_. _ Figure1

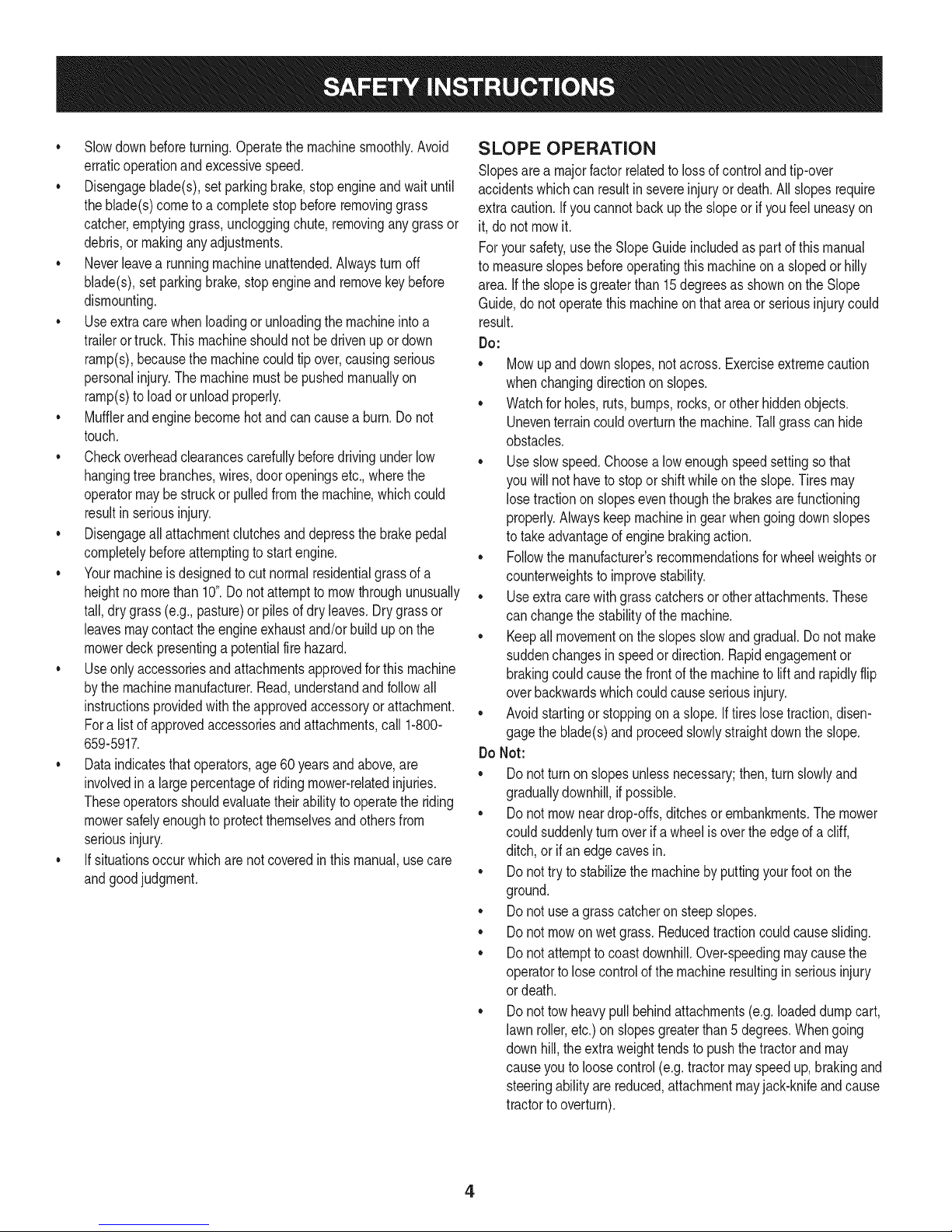

USETHISSLOPEGAUGETODETERMINE

IFA SLOPEIS TOOSTEEPFORSAFEOPERATION!

Tochecktheslope,proceedasfollows:

1. Removethis pageandfoldalongthe dashedline.

2. Locateaverticalobject onor behindtheslope (e.g.a pole, building,fence, tree,etc.)

3. Align eithersideofthe slopegaugewith theobject(SeeFigure1 and Figure2 ).

4. Adjust gaugeupor downuntil the left cornertouchestheslope(SeeFigure1and Figure2).

5.

15°

dashedline

If thereisagap belowthegauge,theslopeis too steepfor safeoperation(SeeFigure2 above).

Figure2

Slopesare a majorfactor relatedto tip-over and roll-overaccidents whichcan resultin severe injury or death. Do not operatemachine onslopes

in excessof 15 degrees.All slopes require extra caution. Ifyou cannotback up the slope orifyou feel uneasyon it, do not mowit.

Always mowup and down the face of slopes, never mowacrossthe face of slopes.

Page 9

iMPORTANT:Yourtractorisshippedwith motoroilin theengine.

However,youMUSTchecktheoil levelbeforeoperating.Refertothe

Service& Maintenancesectionforinstructionson checkingtheoil

level.

Attaching the Battery Cables

CALIFORNIA PROPOSITION 65

Batteryposts,terminals,andrelatedaccessoriescontainleadand

leadcompounds,chemicalsknowntotheStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

Whenattachingbatterycables,alwaysconnectthePOSITIVE(Red)

wireto its terminalfirst,followedby theNEGATIVE(Black)wire.

Forshippingreasons,bothbatterycablesonyourequipmenthave

beenleftdisconnectedfromtheterminalsat the factory.Toconnect

thebatterycables,proceedasfollows:

NOTE:ThepositivebatteryterminalismarkedPos.(+).Thenegative

batteryterminalis markedNeg.(-).

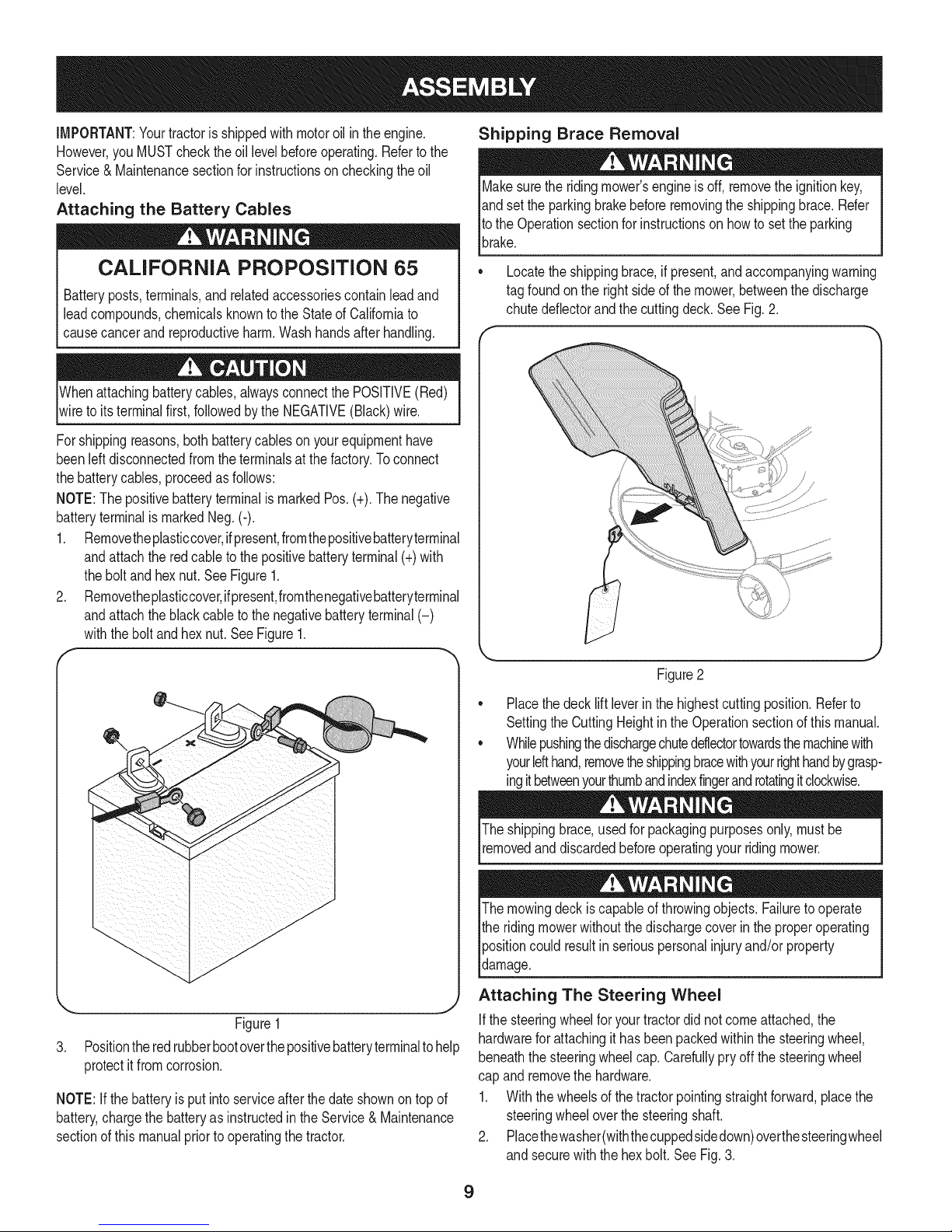

1. Removetheplasticcover,ifpresent,fromthepositivebatteryterminal

andattachthe redcabletothepositivebatteryterminal(+)with

theboltand hexnut.SeeFigure1.

2. Removetheplasticcover,ifpresent,fromthenegativebatteryterminal

andattachthe blackcableto thenegativebatteryterminal(-)

withtheboltandhex nut.SeeFigure1.

f

Shipping Brace Removal

Makesurethe ridingmower'sengineisoff,removetheignitionkey,

andset the parkingbrakebeforeremovingtheshippingbrace.Refer

ItotheOperationsectionfor instructionsonhowto setthe parking

lbrake.

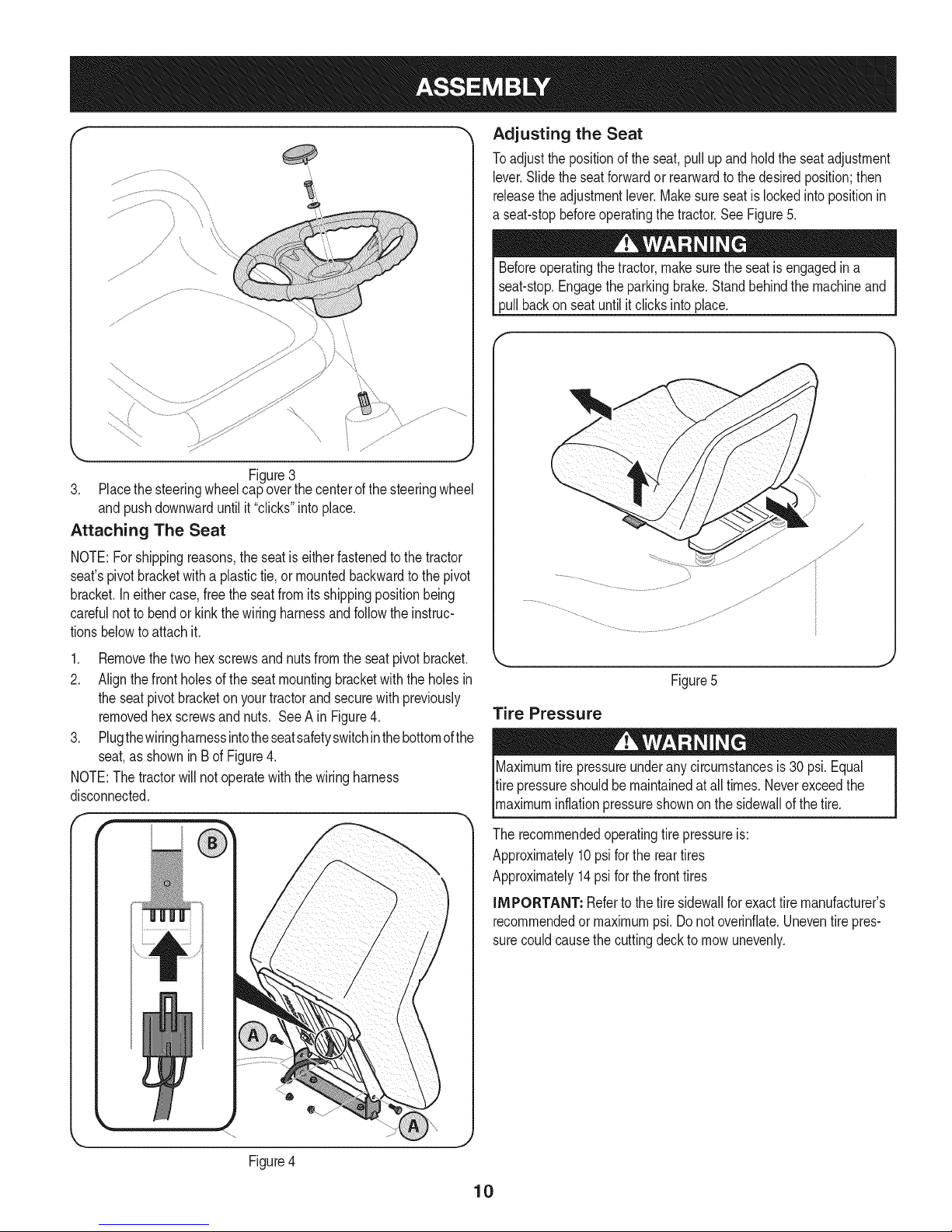

• Locatetheshippingbrace,ifpresent,andaccompanyingwarning

tagfoundonthe rightsideof the mower,betweenthedischarge

chutedeflectorandthe cuttingdeck.SeeFig.2.

Figure2

J

Figure1

3. Positiontheredrubberbootoverthepositivebatteryterminaltohelp

protectit fromcorrosion.

NOTE:If thebatteryisputinto serviceafterthedateshownon topof

battery,chargethebatteryas instructedintheService& Maintenance

sectionofthis manualpriortooperatingthetractor.

Placethedecklift leverinthe highestcuttingposition.Referto

SettingtheCuttingHeightin the Operationsectionofthismanual.

Whilepushingthedischargechuteddlectortowardsthemachinewith

yourlefthand,removetheshippingbracewithyourrighthandbygrasp-

ingitbetweenyourthumbandindexfingerandrotatingitclockwise.

Theshippingbrace,usedfor packagingpurposesonly,mustbe

removedand discardedbeforeoperatingyourridingmower.

Themowingdeckiscapableofthrowingobjects.Failureto operate

the ridingmowerwithoutthedischargecoverin theproperoperating

Ipositioncouldresultin seriouspersonalinjuryand/orproperty

ldamage.

Attaching The Steering Wheel

Ifthesteeringwheelforyourtractordid notcomeattached,the

hardwareforattachingithasbeenpackedwithinthe steeringwheel,

beneaththesteeringwheelcap.Carefullypryoff thesteeringwheel

capandremovethe hardware.

1. Withthe wheelsof thetractorpointingstraightforward,placethe

steeringwheeloverthesteeringshaft.

2. Placethewasher(withthecuppedsidedown)overthesteeringwheel

and securewiththehexbolt.SeeFig.3.

9

Page 10

f

Adjusting the Seat

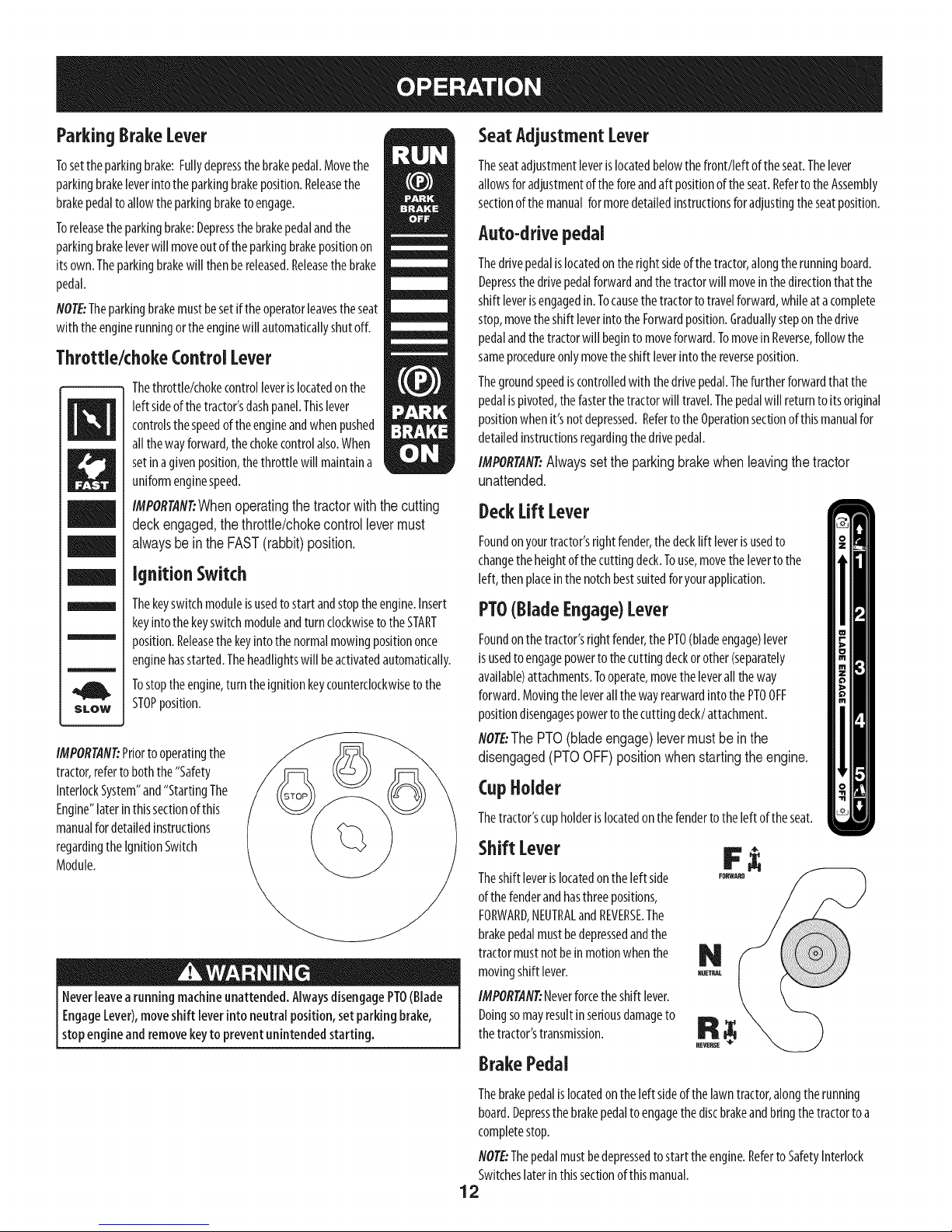

Toadjustthe positionof theseat,pullupandholdtheseatadjustment

lever.Slidetheseatforwardor rearwardtothedesiredposition;then

releasetheadjustmentlever.Makesure seatis lockedintopositionin

a seat-stopbeforeoperatingthe tractor.SeeFigure5.

Beforeoperatingthetractor,makesurethe seatis engagedina

seat-stop.Engagetheparkingbrake.Standbehindthe machineand

pull backon seatuntil it clicksintoplace.

\

3. Placethe steeringwheelcap overthecenterofthe steeringwheel

Figure3

andpushdownwarduntilit"clicks"intoplace.

Attaching The Seat

NOTE:Forshippingreasons,theseatiseitherfastenedtothetractor

seat'spivotbracketwitha plastictie,or mountedbackwardtothepivot

bracket.Ineithercase,free the seatfromits shippingpositionbeing

carefulnotto bendor kinkthewiringharnessandfollowtheinstruc-

tionsbelowtoattachit.

1. Removethetwo hexscrewsandnutsfromtheseatpivotbracket.

2. Alignthefrontholesof theseatmountingbracketwiththe holesin

theseatpivotbracketonyourtractorandsecurewith previously

removedhex screwsandnuts. SeeA in Figure4.

3. Plugthewiringharnessintotheseatsafetyswitchinthebottomofthe

seat,as shownin Bof Figure4.

NOTE:Thetractorwillnotoperatewiththe wiringharness

disconnected.

Figure5

Tire Pressure

Maximumtire pressureunderanycircumstancesis30 psi.Equal

tirepressureshouldbe maintainedatall times.Neverexceedthe

_maxmum nfatonpressureshownonthesdewa of thet re.

Therecommendedoperatingtirepressureis:

Approximately10psi forthe reartires

Approximately14psi forthefronttires

iMPORTANT: Refertothe tire sidewallforexacttiremanufacturer's

recommendedormaximumpsi.Donot overinfiate.Uneventirepres-

surecouldcausethecuttingdeckto mowunevenly.

Figure4

10

Page 11

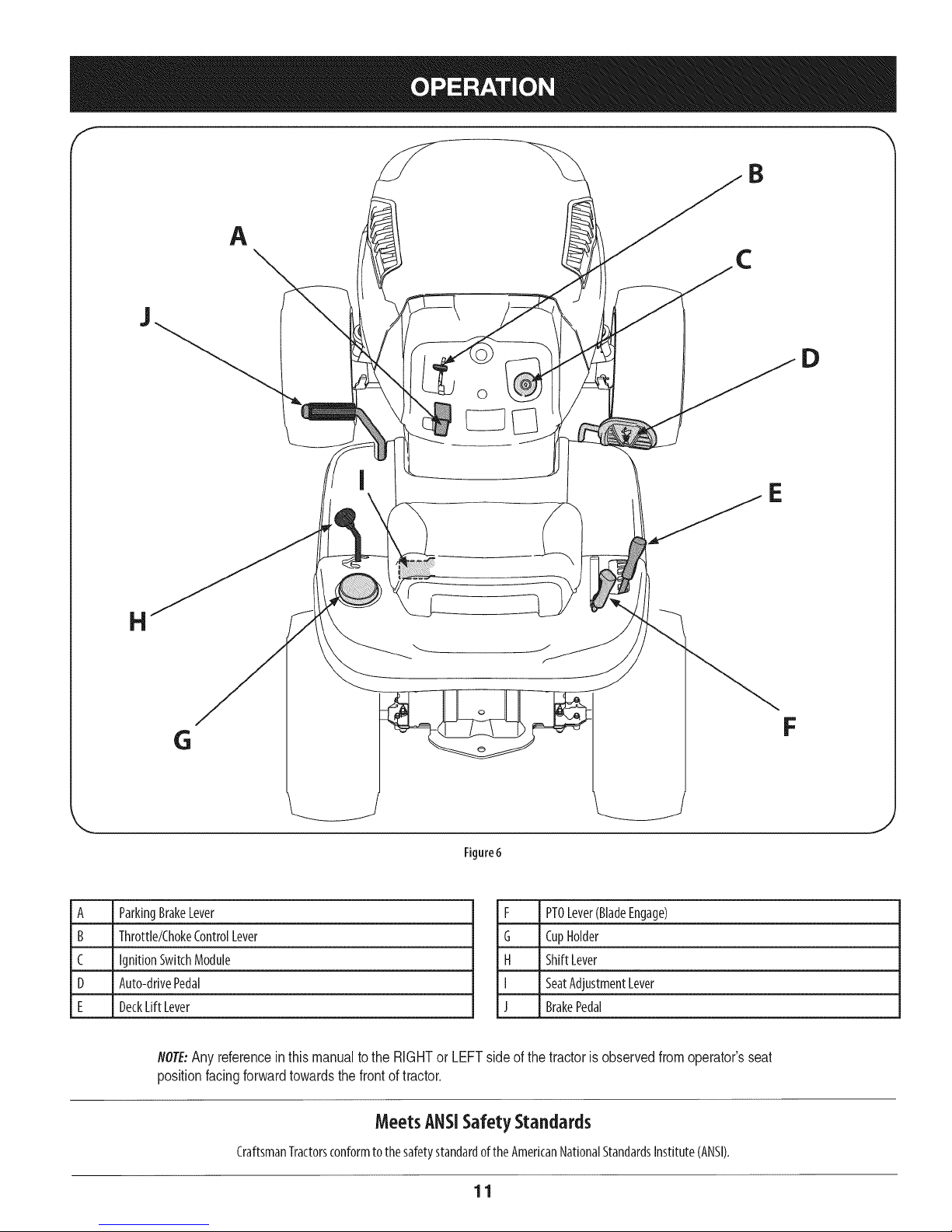

F

B

A

.I

D

©

E

H

G

A ParkingBrakeLever

B Throttle/ChokeControlLever

C IgnitionSwitchModule

D Auto-drivePedal

E DeckLift Lever

NOTE:Anyreferenceinthismanualto theRIGHTor LEFTsideofthetractoris observedfromoperator'sseat

positionfacingforwardtowardsthefrontoftractor.

F

Rgure6

F PTOLever(BladeEngage)

G CupHolder

H ShiftLever

I SeatAdjustmentLever

J BrakePedal

CraftsmanTractorsconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

MeetsANSiSafetyStandards

11

Page 12

ParkingBrakeLever

SeatAdjustmentLever

Tosettheparkingbrake:Fullydepressthebrakepedal.Movethe

parkingbrakeleverintotheparkingbrakeposition.Releasethe

brakepedaltoallowtheparkingbraketo engage.

Toreleasetheparkingbrake:Depressthebrakepedalandthe

parkingbrakeleverwillmoveoutoftheparkingbrakepositionon

itsown.Theparkingbrakewill thenbereleased.Releasethebrake

pedal.

NOTE:Theparkingbrakemustbesetiftheoperatorleavestheseat

with theenginerunningortheenginewill automaticallyshutoff.

Throttle/chokeControlLever

Thethrottle/chokecontrolleverislocatedonthe

leftsideofthetractor'sdashpanel.Thislever

controlsthespeedoftheengineandwhenpushed

m

m

allthewayforward,thechokecontrolalso.When

setinagivenposition,thethrottle will maintaina

uniformenginespeed.

IMPORTANT:Whenoperating the tractor with the cutting

deck engaged, the throttle/choke control lever must

always be inthe FAST (rabbit) position.

ignitionSwitch

Thekeyswitchmoduleisusedtostartandstoptheengine.Insert

mmmmmmm

SLOW

IMPORTANT:Priortooperatingthe

tractor,refertoboththe"Safety

InterlockSystem"and"StartingThe

Engine"laterinthissectionofthis

manualfordetailedinstructions

regardingtheIgnitionSwitch

Module.

Neverleavearunningmachineunattended.AlwaysdisengagePTO(Blade

EngageLever),moveshift [everintoneutralposition,set parking brake,

stopengineandremovekeyto preventunintendedstarting.

keyintothekeyswitchmoduleandturnclockwisetotheSTART

position.Releasethe keyintothe normalmowingpositiononce

enginehasstarted.Theheadlightswillbeactivatedautomatkally.

Tostoptheengine,turntheignitionkeycounterclockwiseto the

STOPposition.

Theseatadjustmentleverislocatedbelowthefront/left oftheseat.Thelever

allowsforadjustmentof theforeandaft positionof theseat.RefertotheAssembly

sectionofthemanualformoredetailedinstructionsforadjustingtheseatposition.

Auto-drivepedal

Thedrivepedalislocatedontherightsideofthetractor,alongtherunningboard.

Depressthedrivepedalforwardandthetractorwi[[moveinthedirectionthatthe

shiftleverisengagedin.Tocausethetractortotravelforward,whileata complete

stop,movetheshift[everintotheForwardposition.Graduallysteponthedrive

pedalandthetractorwill begintomoveforward.TomoveinReverse,follow the

sameprocedureonlymovetheshift [everintothereverseposition.

Thegroundspeediscontrolledwith thedrivepedalThefurtherforwardthatthe

pedalispivoted,thefasterthetractorwi[[travel.Thepedalwill returntoitsoriginal

positionwhenit'snotdepressed.Referto theOperationsectionofthis manualfor

detailedinstructionsregardingthedrivepedal

IMPORTANT:Always set the parking brake when leaving thetractor

unattended.

DeckLiftLever

Foundonyourtractor'srightfender,thedecklift leverisusedto

changetheheightofthecuttingdeck.Touse,movethelevertothe

left, thenplaceinthenotchbestsuitedforyourapplication.

PTO(BladeEngage)Lever

Foundonthetractor'srightfender,thePTO(bladeengage)lever

isusedto engagepowertothecuttingdeckorother(separately

available)attachments.Tooperate,movetheleveralltheway

forward.Movingthe leverallthewayrearwardintothe PTOOFF

positiondisengagespowertothecutting deck/attachment.

NOTE:ThePTO (blade engage) lever must be inthe

disengaged (PTO OFF) position when starting the engine.

CupHolder

Thetractor'scupholderislocatedonthefendertotheleftoftheseat.

Shift Lover

Theshiftleverislocatedontheleftside

ofthefenderandhasthreepositions,

FORWARD,NEUTRALandREVERSE.The

brakepedalmustbedepressedandthe

tractormustnotbeinmotionwhenthe

movingshiftlever.

IMPORTANT:Neverforcetheshift lever.

Doingsomayresultinseriousdamageto

thetractor'stransmission.

REVEP_E

BrakePedal

Thebrakepedalislocatedontheleftsideofthelawntractor,alongtherunning

board.Depressthebrakepedalto engagethediscbrakeandbringthetractortoa

completestop.

NOTE:Thepedalmustbedepressedtostarttheengine.Referto SafetyInterlock

Switcheslaterin thissectionofthismanual.

12

Page 13

Gasand OilFill-up

Oil

IMPORTAfl#Yourtractorisshippedwith motoroil intheengine.However,you

MUSTchecktheoillevelbeforeoperating.Becarefulnottooverfill.

Forinstructionsonhowtochecktheengineoil,refertoCheckingTheEngineOilin

theServiceandMaintenancesectionofthismanual.

Gasoline

Thegasolinetankislocatedunderthehood.Donotoverfill.

Useextremecarewhenhandling gasoline.Gasolineisextremelyflammable

andthe vaporsareexplosive.Neverfuelmachineindoorsorwhile the

engineishotor running. Extinguishcigarettes,cigars,pipes,andother

sourcesof gnt on.

NOTE:Purchasegasolineinsmallquantities.Donotusegasolineleftoverfromthe

previousseason,to minimizegumdepositsinthefuelsystem.

Thisengineiscertifiedtooperateonunleadedgasoline.Forbestresults,fill

thefueltankwith onlyclean,fresh,unleadedgasolinewith apumpsticker

octaneratingof 87orhigher.

Gasohol(upto10%ethylalcohol,90%unleadedgasolinebyvolume)isan

approvedfuel.Othergasoline/alcoholblends,suchasE85,arenotapproved.

MethylTertiaryButylEther(MTBE)andunleadedgasolineblends(upto a

maximumof 15%MTBEbyvolume)areapprovedfuels.Othergasoline/ether

blendsarenotapproved.

Fillfueltankoutdoorsorinwell-ventilatedarea.

Donotoverfillfueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

Neverremovegascaporaddfuelwhiletheengineishotorrunning.Allow

engineto coolatleasttwominutesbeforerefueling.

Ifgasolineisspilled,wipeit off theengineandequipment.Movemachineto

anotherarea.Wait5minutesbeforestartingtheengine.

ToAddGasoline

1. Turntheengineoffandletenginecoolatleast2minutesbeforeremoving

thefuelcap.Thegasolinetankislocatedunderthehood.Removethefuel

capbyturningitcounterclockwise.

2. Fillthefueltankwithgasoline.Useonlyclean,fresh(nomorethan30days

old),unleadedgasoline.Filltanktonomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

3. Reinstallthefuel cap.

IMPORTAN_Donotoverfillthetank.Filltanktonomorethan1/2inchbelow

bottomoffiller necktoallowspaceforfuelexpansion.SeeFigure7.

Figure7

Avoid Serious Injury or Death

Goupanddownslopes,notacross.

Avoidsuddenturns.

Donotoperatetheunitwhereitcouldsliportip.

Ifmachinestopsgoinguphill,stopbladesandbackdownhillslowly.

Donotmowwhenchildrenorothersarearound.

Nevercarrychildren,evenwith bladesoff.

Lookdownandbehindbeforeandwhilebacking.

Keepsafetydevices(guards,shields,andswitches)inplaceandworking.

Removeobjectsthat couldbethrownbytheblades.

Knowlocationandfunctionofallcontrols.

Besurebladesandenginearestoppedbeforeplacinghandsorfeet near

blades.

Beforeleavingoperator'sposition,stoptractor,disengageblades,engage

parkingbrake,shutengineoff,andremovekey.

Read Operator's Manual

Safety Interlock System

Thesafetyinterlocksystemisdesignedforsafeoperationofthetractor.Ifthis

systemshouldevermalfunction,donotoperatethetractor,Immediatelycontact

1-800-659-5917to havethesystemserviced.

Thesafetyinterlocksystempreventstheenginefromstartingunless

theparkingbrakeisengagedandthePTO(BladeEngage)leverisinthe

disengaged(OFF)position.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavestheseatbeforeengagingtheparkingbrake.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavesthetractor'sseatwiththe PTO(BladeEngage)leverengaged,

regardlessofwhethertheparkingbrakeisengaged.

13

Page 14

Theenginewill automaticallyshutoff if thePTO(BladeEngage)leveris

movedintotheengaged(ON)positionwith theshift leverinReverse.

Ignition Switch

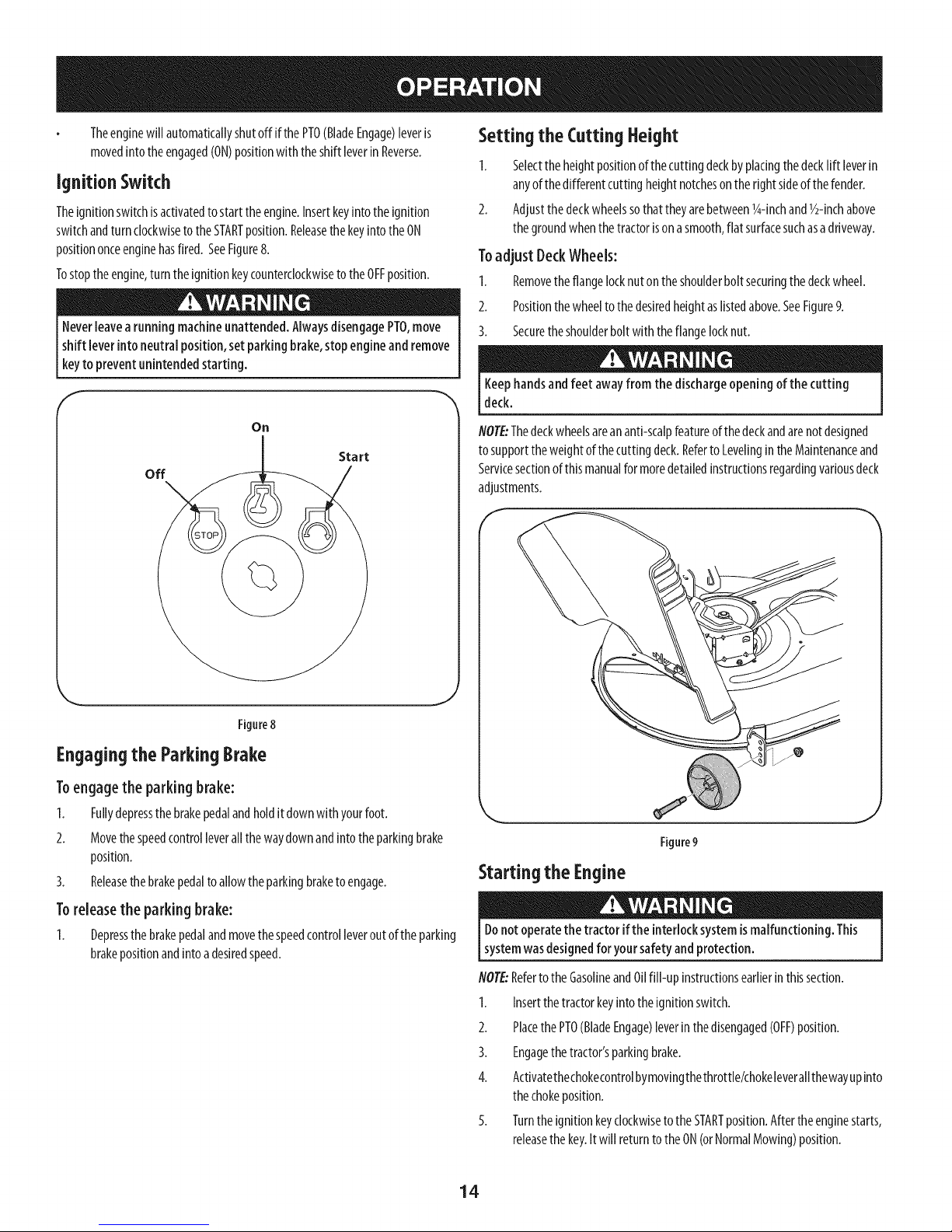

Theignitionswitchisactivatedtostarttheengine.Insertkeyintotheignition

switchandturnclockwisetotheSTARTposition.ReleasethekeyintotheON

positiononceenginehasfired. SeeFigure8.

Tostoptheengine,turntheignitionkeycounterclockwiseto theOFFposition.

Neverleavearunningmachineunattended.AlwaysdisengagePTO,move

shift leverinto neutralposition,setparkingbrake,stopengineandremove

keyto preventunintendedstarting.

f

On

Start

off

Setting the Cutting Height

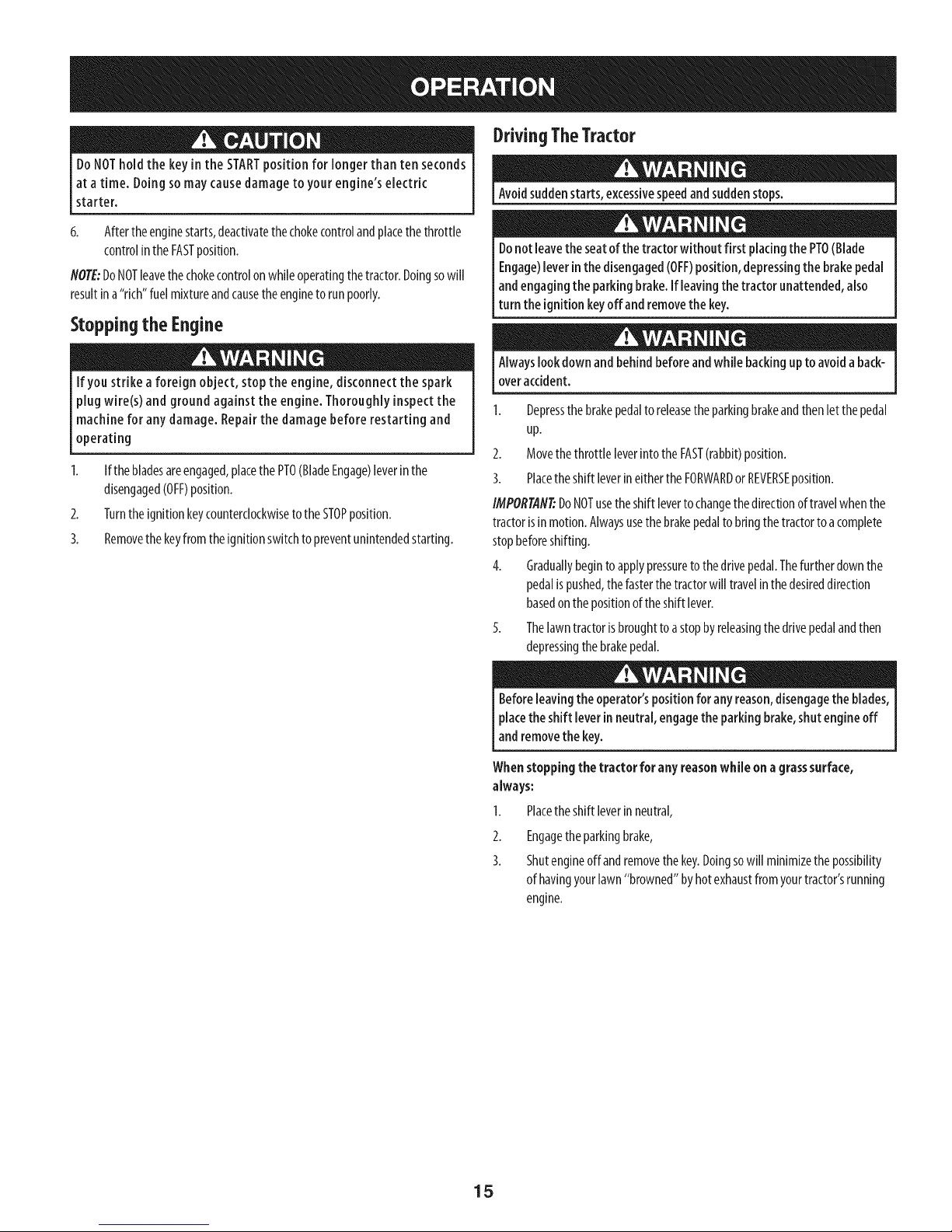

1. Selecttheheightpositionof thecuttingdeckbyplacingthedecklift leverin

anyofthedifferentcutting heightnotchesontherightsideofthefender.

2. Adjustthe deckwheelssothattheyarebetweenl_-inchand1/2-inchabove

thegroundwhenthetractorisonasmooth,flat surfacesuchasadriveway.

Toadjust DeckWheels:

1. Removetheflangelocknutontheshoulderboltsecuringthedeckwheel.

2. Positionthewheeltothedesiredheightaslistedabove.SeeFigure9.

3. Securetheshoulderboltwiththeflangelocknut.

Keephandsandfeet awayfrom the dischargeopening of the cutting

deck.

NOTE:Thedeckwheelsareananti-scalpfeatureofthedeckandarenotdesigned

tosupporttheweightofthecuttingdeck.RefertoLevelingintheMaintenanceand

Servicesectionof thismanualformoredetailedinstructionsregardingvariousdeck

adjustments.

Figure8

Engaging the Parking Brake

To engage the parking brake:

1. Fullydepressthe brakepedalandholdit downwithyourfoot.

2. Movethespeedcontrolleverallthewaydownandintotheparkingbrake

position.

3. Releasethebrakepedaltoallowtheparkingbraketo engage.

Toreleasethe parkingbrake:

1. Depressthebrakepedalandmovethespeedcontrolleveroutoftheparking

brakepositionandintoadesiredspeed.

J

Figure9

Starting the Engine

Donotoperatethe tractor ifthe interlocksystemismalfunctioning. This

systemwasdesignedforyoursafetyand protection.

NOTE:RefertotheGasolineandOilfill-up instructionsearlierinthissection.

1. Insertthetractorkeyintotheignitionswitch.

2. PlacethePTO(BladeEngage)leverinthedisengaged(OFF)position.

3. Engagethetractor'sparkingbrake.

4. ActivatethechokecontrolbymovingthethrotNe/chokeleverallthewayupinto

thechokeposition.

5. TurntheignitionkeyclockwisetotheSTARTposition.Aftertheenginestarts,

releasethekey.Itwill returntotheON(orNormalMowing)position.

14

Page 15

DoNOTholdthe key inthe STARTpositionfor longerthan ten seconds

at atime. Doingsomay causedamageto your engine's electric

starter.

6. Aftertheenginestarts,deactivatethechokecontrolandplacethethrottle

controlin theFASTposition.

NOTE:DoNOTleavethechokecontrolon whileoperatingthetractor.Doingsowill

resultina"rich"fuelmixtureandcausetheenginetorunpoorly.

Stopping the Engine

If you strike aforeign object, stop the engine, disconnectthe spark

plug wire(s) and ground against the engine. Thoroughlyinspectthe

machine for anydamage. Repairthe damage before restartingand

operating

Ifthebladesareengaged,placethe PTO(BladeEngage)leverinthe

disengaged(OFF)position.

2.

Turntheignitionkeycounterclockwiseto theSTOPposition.

3.

Removethekeyfromtheignitionswitchto preventunintendedstarting.

DrivingTheTractor

Avoidsuddenstarts,excessivespeedandsuddenstops.

Donotleavethe seatofthe tractor without first placingthe PTO(Blade

Engage)leverinthe disengaged(OFF)position,depressingthe brakepedal

andengaging the parkingbrake.If leavingthe tractor unattended,also

turn the ignition keyoffand removethe key.

Alwayslookdownand behindbeforeandwhile backingupto avoidaback-

overaccident.

1. Depressthebrakepedaltoreleasetheparkingbrakeandthenlet thepedal

up.

2. MovethethrottleleverintotheFAST(rabbit)position.

3. Placetheshift leverineithertheFORWARDor REVERSEposition.

IMPORTAN_DoNOTusetheshiftlevertochangethedirectionoftravelwhenthe

tractorisin motion.Alwaysusethebrakepedaltobringthetractorto acomplete

stopbeforeshifting.

4. Graduallybegintoapplypressuretothedrivepedal.Thefurtherdownthe

pedalispushed,thefasterthetractorwilltravelinthedesireddirection

basedonthepositionoftheshift lever.

5. Thelawntractorisbroughttoastopbyreleasingthedrivepedalandthen

depressingthebrakepedal.

Beforeleavingthe operator'spositionfor anyreason,disengagethe blades,

placethe shift leverin neutral,engagethe parking brake,shutengineoff

andremovethe key.

Whenstopping the tractor for anyreasonwhile onagrasssurface,

always:

I.

Placetheshift leverinneutral,

2.

Engagetheparkingbrake,

3.

Shutengineoffand removethekey.Doingsowill minimizethepossibility

ofhavingyourlawn"browned"byhotexhaustfromyourtractor'srunning

engine.

15

Page 16

DrivingOnSlopes

RefertotheSLOPEGAUGEintheSafetyInstructionssectionofthe manualtohelp

determineslopeswhereyoumayoperatethistractorsafely.

Donotmowon inclineswith a slopeinexcessof 15degrees(ariseof

approximately2-112feet every10feet). Thetractor couldoverturnand

causeseriousinjury.

Mowupanddownslopes,NEVERacross.

Exerciseextremecautionwhenchangingdirectiononslopes.

Watchfor holes,ruts,bumps,rocks,orotherhiddenobjects.Uneventerrain

couldoverturnthemachine.Tallgrasscanhideobstacles.

Avoidturnswhendrivingonaslope.Ifa turnmustbemade,turndownthe

slope.Turningupaslopegreatlyincreasesthechanceof arollover.

Avoidstoppingwhendrivingupaslope.If it isnecessarytostopwhile

drivingupaslope,startupsmoothlyandcarefullytoreducethepossibility

offlippingthetractoroverbackward.

Engagingthe Blades

Engagingthe PTO(BladeEngage)transferspowertothecuttingdeckorother

(separatelyavailable)attachments.Toengagetheblades,proceedasfollows:

1. Movethethrottle/chokecontrollevertotheFAST(rabbit)position.

2. GraspthePTO(BladeEngage)leverandpivotit allthewayforwardintothe

engaged(ON)position.

3. Keepthethrottleleverinthe FAST(rabbit)positionforthemostefficientuse

ofthecutting deckorother(separatelyavailable)attachments.

NOTE:Theenginewillautomaticallyshutoff ifthe PTOisengagedwith theshift

leverinpositionforreversetravelwiththeignitionkeyin theONposition.

Mulching

Amulchkitisavailableasanattachment.Mulchingisaprocessofrecirculating

grassclippingsrepeatedlybeneaththecuttingdeck.Theultra-fineclippingsare

thenforcedbackintothe lawnwheretheyactasanaturalfertilizer.

Amulchkitcanbepurchasedthroughtheretaillocationinwhichyoupurchased

thistractor.Formoreinformation,simplycontactSearsat 1-800-659-5917.

Mowing

Tohelpavoidbladecontactorathrown object injury, keepbystanders,

helpers,childrenandpetsat least75;feet from the machinewhile it isin

operation.Stopmachineif anyoneentersthearea.

Thefollowinginformationwill behelpfulwhenusingthecuttingdeckwith your

tractor:

Planyour mowing pattern to avoiddischargeof materialstoward roads,

sidewalks,bystandersandthe like.Also,avoiddischargingmaterialagainst

awallor obstructionwhichmaycausedischargedmaterialto ricochetback

towardthe operator.

Donotmowat highgroundspeed,especiallyiramulchkitorgrasscollector

isinstalled.

Forbestresultsit isrecommendedthatthefirsttwo lapsbecutwith the

dischargethrowntowardsthecenter.Afterthefirst twolaps,reversethe

directiontothrowthedischargeto theoutsideforthebalanceofcutting.

Thiswill giveabetterappearanceto thelawn.

Donotcutthegrasstooshort.Shortgrassinvitesweedgrowthandyellows

quicklyindryweather.

Mowingshouldalwaysbedonewiththeengineatfullthrottle.

Underheavierconditionsit maybenecessaryto gobackoverthecutareaa

secondtimeto getacleancut.

DoNOTattemptto mowheavybrushandweedsandextremelytall grass.

Yourtractorisdesignedtomowlawns,NOTclearbrush.

Keepthebladessharpandreplacethebladeswhenworn.RefertoCutting

Bladesin theServicesectionofthismanualforproperbladesharpening

instructions.

Headlights

ThelampsareONwheneverthetractor'sengineisrunning.

Thelampsturn OFFwhentheignitionkeyismovedto theSTOPposition.

Usingthe DeckLiftLever

Toraisethecuttingdeck,movethedecklift levertothe left,thenplaceitinthe

notchbestsuitedfor yourapplication.Referto SettingTheCuttingHeightearlierin

thissection.

16

Page 17

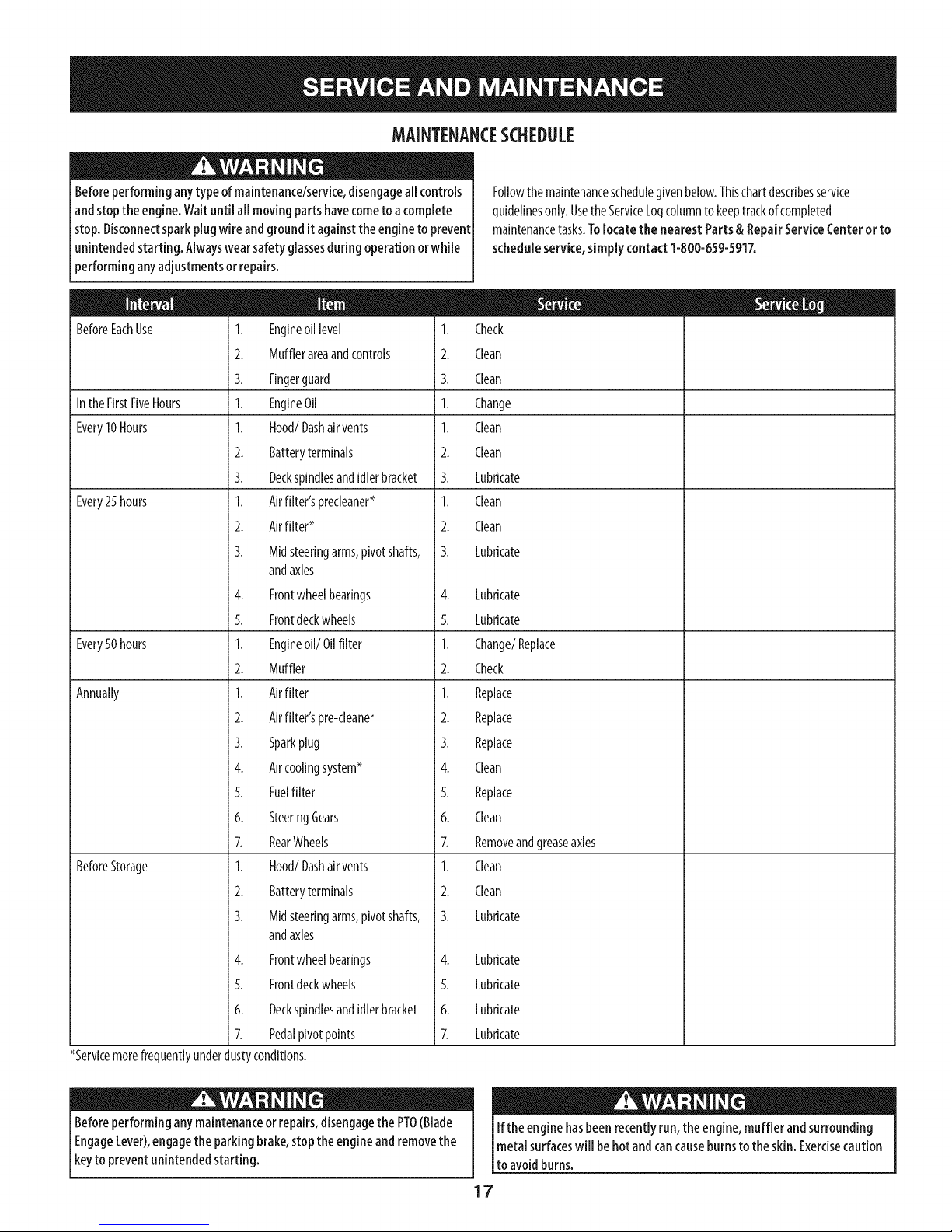

MAINTENANCESCHEDULE

Beforeperforminganytype ofmaintenance/service,disengageallcontrols

andstopthe engine.Waituntil all movingpartshavecometoacomplete

stop.Disconnectsparkplugwireandgroundit againstthe engineto prevent

unintendedstarting. Alwayswearsafetyglassesduring operationorwhile

performing anyadjustmentsor repairs.

BeforeEachUse 1. Engineoil level 1.

2. Mufflerareaandcontrols 2.

3. Fingerguard 3.

Inthe FirstFiveHours 1. EngineOil 1.

Every10Hours I. Hood/Dashairvents I.

2. Batteryterminals 2.

3. Deckspindlesandidlerbracket 3.

Every25hours 1. Airfilter'sprecleaner* 1.

2. Airfilter* 2.

3. Midsteeringarms,pivotshafts, 3.

andaxles

4. Frontwheelbearings 4.

5. Frontdeckwheels 5.

Every50hours 1. Engineoil/Oil filter 1.

2. Muffler 2.

Annually 1. Airfilter 1.

2. Airfilter'spre-cleaner 2.

3. Sparkplug 3.

4. Aircoolingsystem* 4.

5. Fuelfilter 5.

6. SteeringGears 6.

7. RearWheels 7.

BeforeStorage 1. Hood/Dashairvents 1.

2. Batteryterminals 2.

3. Midsteeringarms,pivotshafts, 3.

andaxles

4. Frontwheelbearings

5. Frontdeckwheels

6. Deckspindlesandidlerbracket

7. Pedalpivotpoints

*Servicemorefrequentlyunderdustyconditions.

4. Lubricate

5. Lubricate

6. Lubricate

7. Lubricate

Followthe maintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumnto keeptrackofcompleted

maintenancetasks.Tolocate the nearestParts&RepairServiceCenteror to

scheduleservice,simplycontact1-800-659-5917.

Check

Clean

Clean

Change

Clean

Clean

Lubricate

Clean

Clean

Lubricate

Lubricate

Lubricate

Change/Replace

Check

Replace

Replace

Replace

Clean

Replace

Clean

Removeandgreaseaxles

Clean

Clean

Lubricate

Beforeperforminganymaintenanceor repairs,disengagethePTO(Blade

EngageLever),engagethe parkingbrake,stopthe engineandremovethe

keyto preventunintendedstarting.

Ifthe enginehasbeenrecentlyrun,the engine,muffler andsurrounding

metalsurfaceswill behot andcancauseburnsto the skin. Exercisecaution

to avoidburns.

17

Page 18

Engine Maintenance

Checkingthe EngineOil

OnlyusehighqualitydetergentoilratedwithAPIserviceclassificationSF,SG,

SH,or SJ.Selecttheoil'sSAEviscositygradeaccordingtotheexpectedoperating

temperature.Followthechartbelow.Althoughmulti-viscosityoils(5W20,10W30,

etc.)improvestartingin coldweather,theywill resultinincreasedoilconsumption

whenusedabove32°ECheckyourengineoillevelmorefrequentlyto avoidpossible

enginedamagefromrunninglowonoil.

f

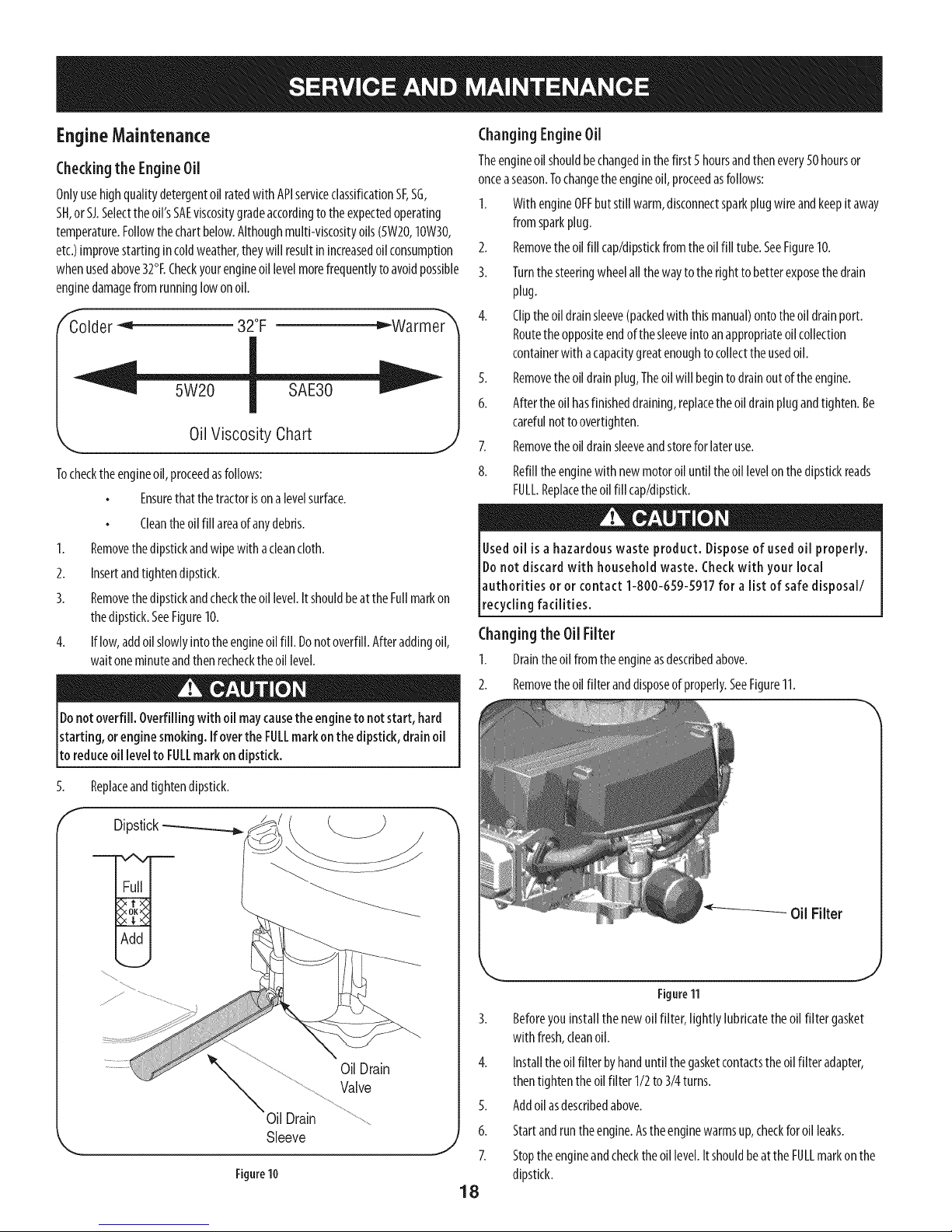

Colder _ 32°F _Warmer

Oil Viscosity Chart

Tochecktheengineoil,proceedasfollows:

Ensurethatthetractorisonalevelsurface.

Cleantheoilfill areaof anydebris.

1. Removethedipstickandwipewith acleancloth.

2. Insertandtightendipstick.

3. Removethedipstickandchecktheoillevel.ItshouldbeattheFullmarkon

thedipstick.SeeFigure10.

4. Iflow,addoilslowlyintotheengineoilfill. Donotoverfill.Afteraddingoil,

waitoneminuteandthenrechecktheoillevel.

J

ChangingEngineOil

Theengineoilshouldbechangedinthefirst5hoursandthenevery50hoursor

onceaseason.Tochangetheengineoil,proceedasfollows:

I. WithengineOFFbutstill warm,disconnectsparkplugwireandkeepitaway

fromsparkplug.

2. Removetheoilfill cap/dipstkkfromtheoilfill tube.SeeFigure10.

3. Turnthesteeringwheelallthewaytothe righttobetterexposethedrain

plug.

4. Cliptheoildrainsleeve(packedwith thismanual)ontotheoil drainport.

Routetheoppositeendofthesleeveintoanappropriateoilcollection

containerwith acapacitygreatenoughtocollecttheusedoil.

5. Removetheoildrainplug,Theoilwill begintodrainoutoftheengine.

6. Aftertheoil hasfinisheddraining,replacetheoildrainplugandtighten.Be

carefulnottoovertighten.

Removetheoildrainsleeveandstoreforlateruse.7.

8.

Refilltheenginewith newmotoroil untiltheoil levelonthedipstickreads

FULL.Replacetheoilfill cap/dipstick.

Usedoil is a hazardouswaste product. Disposeof used oil properly.

Donot discard with household waste. Checkwith your local

authorities or or contact 1-800-659-5917 for a list of safe disposal/

recycling facilities.

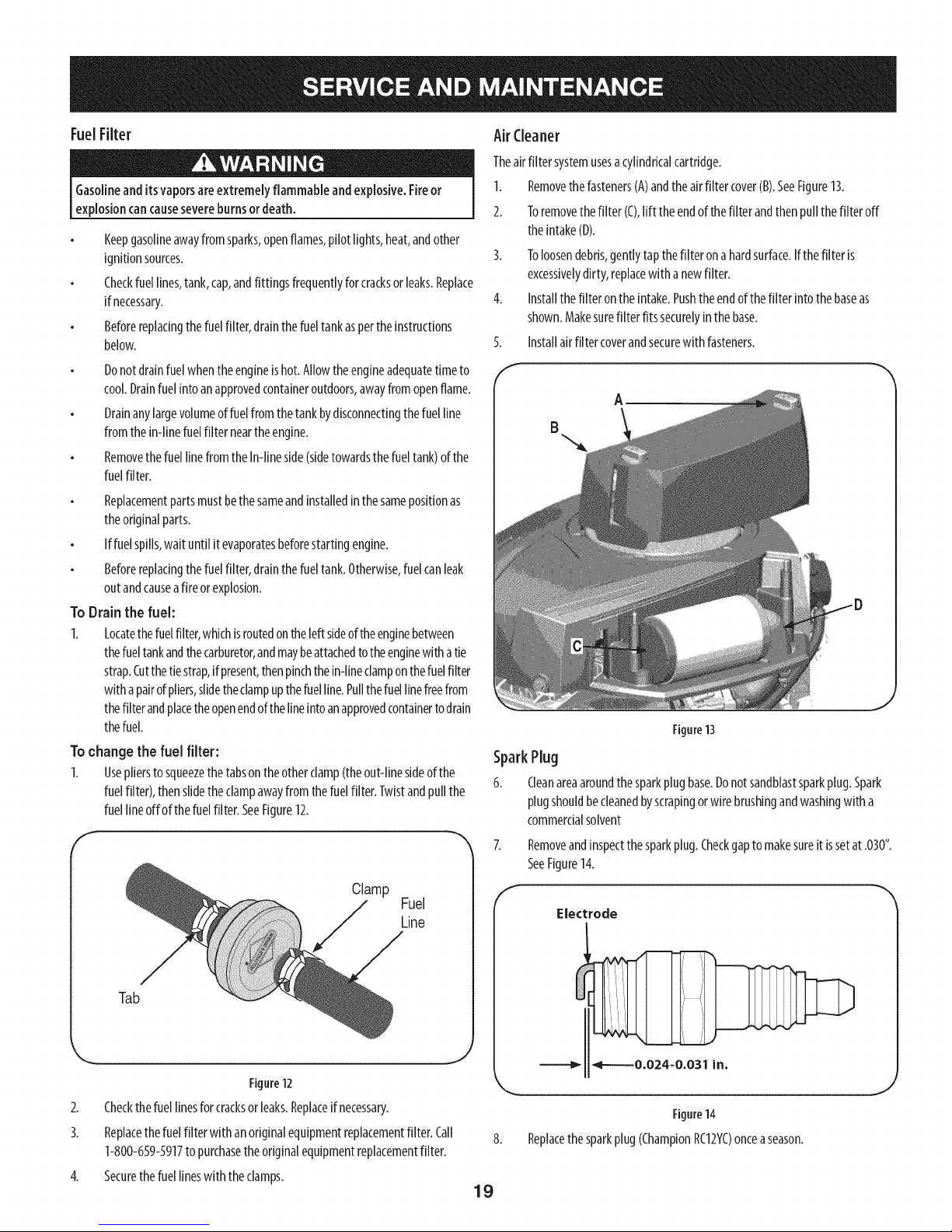

Changingthe Oil Filter

I. Draintheoil fromtheengineasdescribedabove.

2. Removetheoilfilteranddisposeofproperly.SeeFigure11.

Donotoverfill. Overfilling with oil maycausethe engineto notstart, hard

starting, orenginesmoking.If overthe FULLmarkonthe dipstick,drainoil

to reduceoillevelto FULLmarkondipstick.

5.

Replaceandtightendipstick.

f

OilDrain

Valve

Oil Drain

Sleeve

Figure10

Figure11

3. Beforeyouinstallthenewoil filter, lightlylubricatetheoil filter gasket

with fresh,cleanoil.

4. Installtheoilfilter byhanduntilthegasketcontactsthe oilfilteradapter,

thentightentheoilfilter 1/2to3/4turns.

5. Addoilasdescribedabove.

6. Startandruntheengine.Astheenginewarmsup,checkforoil leaks.

7. Stoptheengineandchecktheoillevel.ItshouldbeattheFULLmarkonthe

dipstick.

18

Page 19

FuelFilter

Gasolineanditsvaporsareextremelyflammableandexplosive.Fireor

explosioncancausesevereburnsordeath.

Keepgasolineawayfromsparks,openflames,pilotlights,heat,andother

ignitionsources.

Checkfuellines,tank,cap,andfittingsfrequentlyforcracksorleaks.Replace

if necessary.

Beforereplacingthefuelfilter,drainthefueltankaspertheinstructions

below.

Donotdrainfuelwhentheengineishot.Allowtheengineadequatetimeto

cool.Drainfuelintoanapprovedcontaineroutdoors,awayfromopenflame.

Drainanylargevolumeoffuelfromthetankbydisconnectingthefuel line

fromthe in-linefuelfilter neartheengine.

Removethefuellinefromthe In-lineside(sidetowardsthefueltank)ofthe

fuelfilter.

Replacementpartsmustbethesameandinstalledinthesamepositionas

theoriginalparts.

Iffuelspills,wait untilit evaporatesbeforestartingengine.

Beforereplacingthefuelfilter,drainthefueltank.Otherwise,fuelcanleak

outandcauseafireorexplosion.

To Drain the fuel:

1. Locatethefuelfilter,whichisroutedontheleftsideof theenginebetween

thefueltankandthecarburetor,andmaybeattachedtotheenginewith atie

strap.Cutthetie strap,if present,thenpinchthein-lineclamponthefuelfilter

withapairofpliers,slidetheclampupthefuelline.Pullthefuellinefreefrom

thefilterandplacetheopenendofthelineintoanapprovedcontainertodrain

thefuel.

Tochange the fuel filter:

1. Useplierstosqueezethetabsontheotherclamp(theout-linesideofthe

fuelfilter),thenslidetheclampawayfromthefuelfilter. Twistandpullthe

fuellineoff ofthefuelfilter.SeeFigure12.

Clamp

Fuel

Line

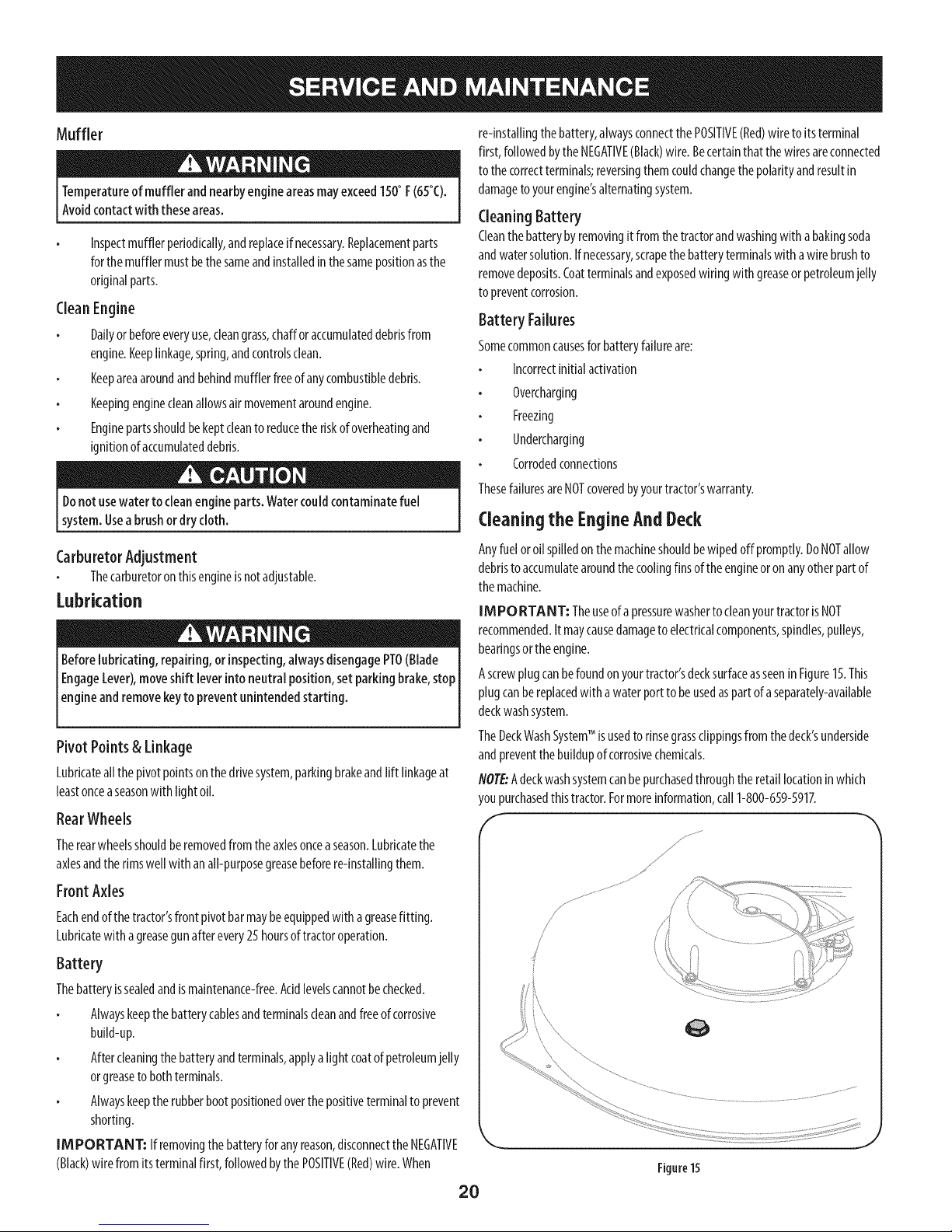

Air (:leaner

Theairfilter systemusesacylindricalcartridge.

1. RemovethefastenersCA)andtheairfiltercover(B).SeeFigure13.

2. Toremovethefilter (C),lift theendofthefilter andthenpullthefilter off

theintake(D).

3. Toloosendebris,gentlytapthefilter onahardsurface.Ifthefilter is

excessivelydirty, replacewith a newfilter.

4. Installthefilteronthe intake.Pushtheendofthefilter intothebaseas

shown.Makesurefilterfitssecurelyin thebase.

Installairfilter coverandsecurewith fasteners.5.

f

A

Figure13

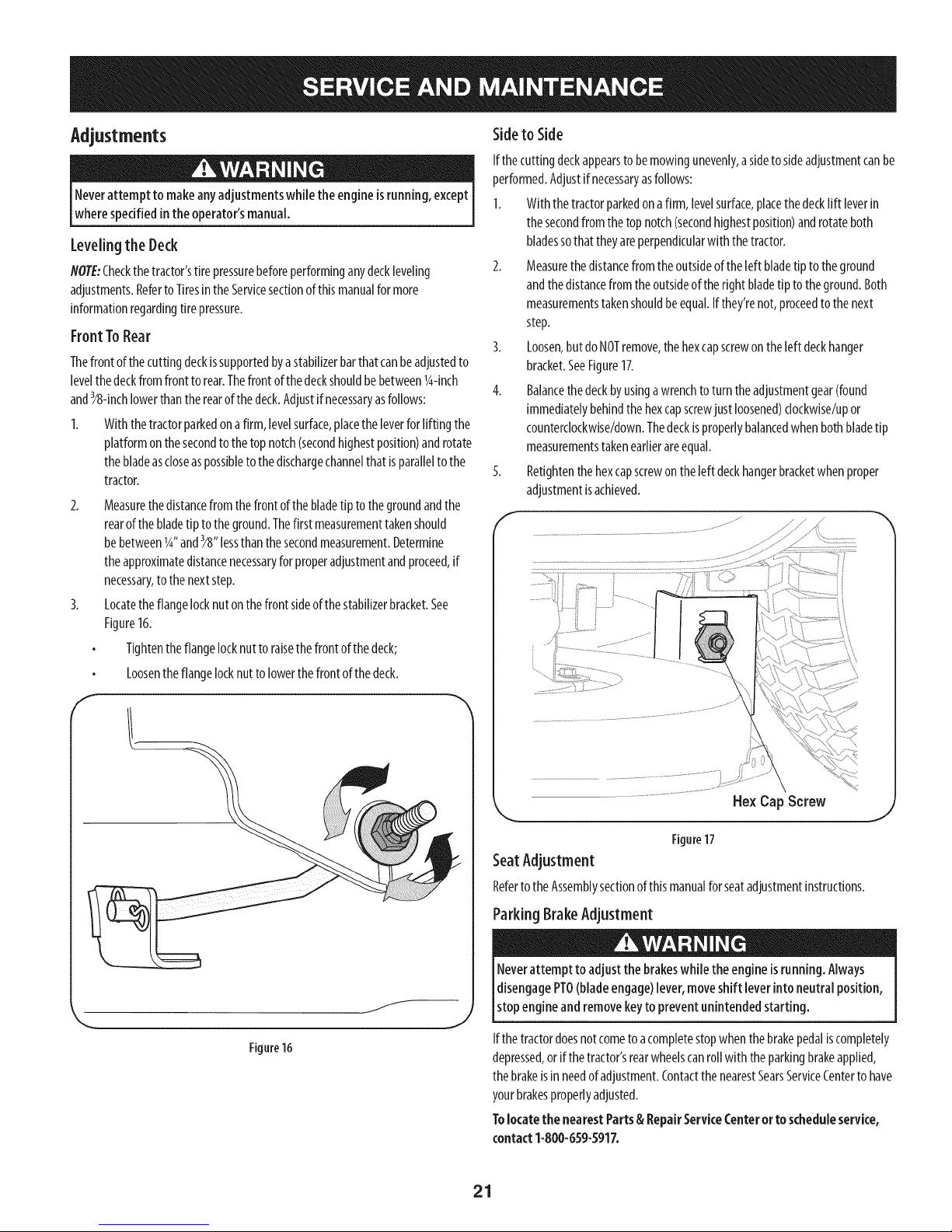

SparkPlug

6.

Cleanareaaroundthesparkplugbase.Donotsandblastsparkplug.Spark

plugshouldbecleanedbyscrapingorwirebrushingandwashingwith a

commercialsolvent

Removeandinspectthesparkplug.Checkgaptomakesureitissetat.030".

SeeFigure14.

f

Electrode

Tab

Figure12

2. Checkthefuellinesforcracksorleaks.Replaceifnecessary.

3. Replacethefuelfilterwith an originalequipmentreplacementfilter.Call

1-800-659-5917to purchasetheoriginalequipmentreplacementfilter.

4. Securethefuellineswiththeclamps.

J

Figure14

Replacethesparkplug(ChampionRC12YC)onceaseason.

19

Page 20

Muffler

Temperatureof muffler andnearbyengineareasmayexceed150° F(65°Q.

Avoidcontactwith theseareas.

Inspectmufflerperiodically,andreplaceif necessary.Replacementparts

forthemufflermustbethesameandinstalledinthesamepositionasthe

originalparts.

CleanEngine

Dailyorbeforeeveryuse,deangrass,chafforaccumulateddebrisfrom

engine.Keeplinkage,spring,andcontrolsdean.

Keepareaaroundandbehindmufflerfreeof anycombustibledebris.

Keepingenginecleanaflowsairmovementaroundengine.

Enginepartsshouldbekeptcleantoreducetheriskofoverheatingand

ignitionofaccumulateddebris.

re-installingthebattery,alwaysconnectthePOSITIVE(Red)wire toitsterminal

first, followedbytheNEGATIVE(Black)wire.Becertainthatthewiresareconnected

tothecorrectterminals;reversingthemcouNchangethepolarityandresultin

damageto yourengine'salternatingsystem.

CleaningBattery

Cleanthebatterybyremovingitfromthetractorandwashingwith abakingsoda

andwatersolution.Ifnecessary,scrapethebatteryterminalswith awirebrushto

removedeposits.Coatterminalsandexposedwiringwithgreaseorpetroleumjelly

topreventcorrosion.

Battery Failures

Somecommoncausesfor batteryfailureare:

Incorrectinitialactivation

Overcharging

Freezing

Undercharging

Corrodedconnections

Donotusewaterto deanengineparts.Watercouldcontaminatefuel

system.Usea brushordry cloth.

CarburetorAdjustment

Thecarburetoronthisengineisnotadjustable.

Lubrication

Before

lubricating,repairing, orinspecting,alwaysdisengagePTO(Blade [

EngageLever),moveshift leverinto neutral position,set parking brake,stopI

engneandremovekeytoprevent un ntendedstart rig. I

Pivot Points& Linkage

Lubricateallthepivotpointsonthedrivesystem,parkingbrakeandlift linkageat

leastonceaseasonwith lightoil.

RearWheels

Therearwheelsshouldberemovedfromtheaxlesonceaseason.Lubricatethe

axlesandtherimswellwith anall-purposegreasebeforere-installingthem.

Front Axles

Eachendofthetractor'sfrontpivotbarmaybeequippedwith agreasefitting.

Lubricatewith agreasegunafterevery25hoursoftractoroperation.

Battery

Thebatteryissealedandismaintenance-free.Acidlevelscannotbechecked.

Alwayskeepthebatterycablesandterminalsdeanandfreeofcorrosive

build-up.

Aftercleaningthebatteryandterminals,applyalightcoatof petroleumjelly

orgreasetobothterminals.

Alwayskeeptherubberbootpositionedoverthe positiveterminaltoprevent

shorting.

IM PORTANT: Ifremovingthebatteryforanyreason,disconnecttheNEGATIVE

(Black)wirefromitsterminalfirst,followedbythePOSITIVE(Red)wire.When

J

2O

ThesefailuresareNOTcoveredbyyourtractor'swarranty.

Cleaningthe EngineAndDeck

Anyfueloroilspilledonthemachineshouldbewipedoff promptly.DoNOTallow

debristoaccumulatearoundthecoolingfinsoftheengineoronanyotherpartof

themachine.

IMPORTANT: Theuseofa pressurewashertocleanyourtractorisNOT

recommended.Itmaycausedamageto electricalcomponents,spindles,pulleys,

bearingsortheengine.

Ascrewplugcanbefoundonyourtractor'sdecksurfaceasseenin Figure15.This

plugcanbereplacedwith a waterporttobeusedaspartofaseparately-available

deckwashsystem.

TheDeckWashSystemTM isusedtorinsegrassclippingsfromthedeck'sunderside

andpreventthebuildupofcorrosivechemicals.

NOTE:Adeckwashsystemcanbepurchasedthroughtheretaillocationinwhich

youpurchasedthistractor.Formoreinformation,carl1-800-659-5917.

/

Figure15

Page 21

Adjustments SidetoSide

Ifthecuttingdeckappearsto bemowingunevenly,asidetosideadjustmentcanbe

performed.Adjustifnecessaryasfollows:

Neverattempt to makeanyadjustmentswhile theengineisrunning,except

wherespecifiedinthe operator'smanual.

Levelingthe Deck

NOTE:Checkthetractor'stirepressurebeforeperforminganydeckleveling

adjustments.RefertoTiresintheServicesectionofthismanualformore

informationregardingtirepressure.

FrontToRear

Thefrontofthecuttingdeckissupportedbyastabilizerbarthatcanbeadjustedto

levelthedeckfromfrontto rear.Thefrontofthedeckshouldbebetween1A-inch

and_8-inchlowerthantherearofthedeck.Adjustif necessaryasfollows:

1. Withthetractorparkedona firm, levelsurface,placetheleverforliftingthe

platformonthesecondtothetop notch(secondhighestposition)androtate

thebladeascloseaspossibletothedischargechannelthat isparalleltothe

tractor.

2. Measurethedistancefromthefrontofthe bladetiptothegroundandthe

rearofthe bladetip totheground.Thefirstmeasurementtakenshould

bebetweenlg,,and3/8"lessthanthesecondmeasurement.Determine

theapproximatedistancenecessaryforproperadjustmentandproceed,if

necessary,to thenextstep.

3. Locatetheflangelocknutonthefrontsideofthestabilizerbracket.See

Figure16.

Tightentheflangelocknuttoraisethefrontofthedeck;

Loosentheflangelocknuttolowerthefrontofthedeck.

f

1. Withthetractorparkedonafirm,levelsurface,placethedeckliftleverin

thesecondfromthetopnotch(secondhighestposition)androtateboth

bladessothattheyareperpendicularwiththetractor.

2. Measurethedistancefromtheoutsideoftheleft bladetiptotheground

andthedistancefromtheoutsideoftherightbladetip to theground.Both

measurementstakenshouldbeequal.Ifthey'renot,proceedto thenext

step.

3. Loosen,butdoNOTremove,thehexcapscrewontheleft deckhanger

bracket.SeeFigure17.

4. Balancethedeckbyusinga wrenchtoturn theadjustmentgear(found

immediatelybehindthehexcapscrewjust loosened)clockwise/upor

counterclockwise/down.Thedeckisproperlybalancedwhenbothbladetip

measurementstakenearlierareequal.

5. Retightenthehexcapscrewontheleft deckhangerbracketwhenproper

adjustmentisachieved.

Figure16

Hex Cap Screw

Figure17

SeatAdjustment

RefertotheAssemblysectionofthismanualforseatadjustmentinstructions.

ParkingBrakeAdjustment

Neverattempt to adjust the brakeswhilethe engineisrunning.Always

disengagePTO(bladeengage)lever,moveshift leverintoneutral position,

J

stopengineand removekeyto preventunintendedstarting.

Ifthetractordoesnotcometoacompletestopwhenthebrakepedaliscompletely

depressed,or ifthetractor'srearwheelscanrollwiththeparkingbrakeapplied,

thebrakeis inneedofadjustment.ContactthenearestSearsServiceCentertohave

yourbrakesproperlyadjusted.

Tolocatethe nearestParts& RepairService(enter orto scheduleservice,

contact 1-800-659-5917.

21

Page 22

Cutting DeckRemoval

Toremove the cutting deck, proceed as follows:

1. Placethe PTO(BladeEngage)leverinthe disengaged(OFF)positionand

engagetheparkingbrake.

2. Lowerthedeckbymovingthedecklift leverintothe bottomnotchonthe

rightfender.

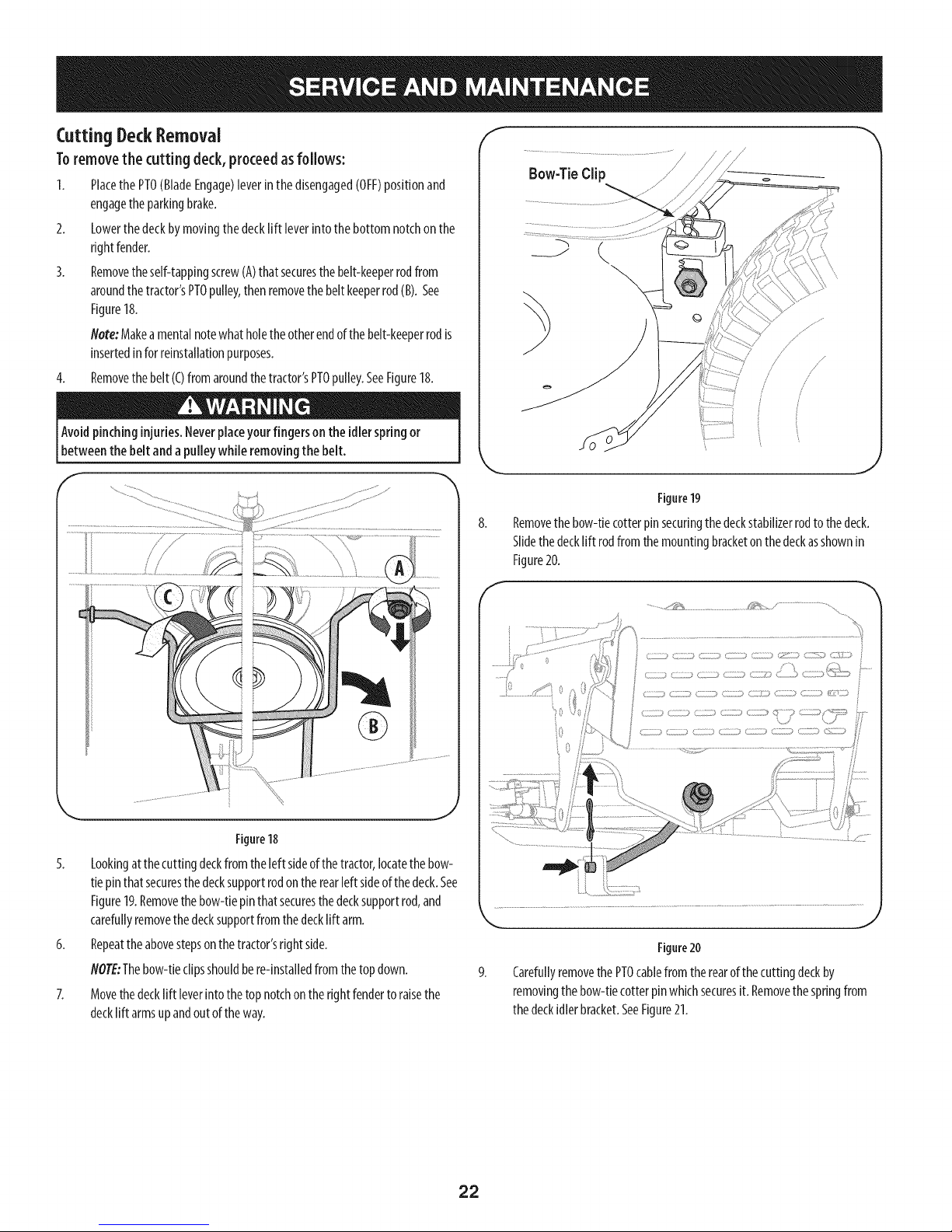

3. Removetheself-tappingscrew(A)thatsecuresthebelt-keeperrodfrom

aroundthetractor'sPTOpulley,thenremovethebeltkeeperrod(B).See

Figure18.

Note:Makeamentalnotewhatholetheotherendofthebelt-keeperrodis

insertedinfor reinstallationpurposes.

4. Removethebelt (C)fromaroundthetractor'sPTOpulley.SeeFigure18.

///

Bow-TieClip

Avoidpinchinginjuries.Neverplaceyour fingersonthe idlerspringor

betweenthe belt anda pulleywhile removingthe belt.

..... .........................! ......

Figure18

5. Lookingat thecuttingdeckfromtheleftsideofthetractor,locatethebow-

tiepinthatsecuresthedecksupportrodontherearleftsideofthedeck.See

Figure19.Removethebow-tiepinthatsecuresthedecksupportrod,and

carefullyremovethedecksupportfromthedecklift arm.

6. Repeattheabovestepsonthetractor'srightside.

NOTE:Thebow-tieclipsshouldbere-installedfromthetopdown.

7. Movethedecklift leverintothetopnotchontherightfendertoraisethe

decklift armsupandoutoftheway.

\

,J

Figure19

Removethebow-tiecotterpinsecuringthedeckstabilizerrodto thedeck.

Slidethedeckliftrodfromthemountingbracketonthedeckasshownin

Figure20.

f

..................._,@_.................................._,: _/ .......................................

....../

i ..................4_1 0

J

Figure20

9. Carefullyremovethe PTOcablefromtherearofthecuttingdeckby

removingthe bow-tiecotterpinwhichsecuresit. Removethespringfrom

thedeckidlerbracket.SeeFigure21.

22

Page 23

2. Connecttheotherendofthecabletothe(positive+)postofthejumper

//

battery.

3. Connectthesecondcable(negative-) to theotherpostofthejumper

battery.

4. Connecttheotherendofthenegativecableto theengineblockofthe

tractor,awayfromthebattery.Attachto anunpaintedparttoassureagood

connection.

Ifthejumperbattery isinstalledonavehicle(i.e.car,truck),doNOTstart

the vehicle'senginewhenjumpstarting yourtractor.

5. Startthetractor(asinstructedearlierinthissectionof thismanual).

6. Setthetractor'sparkingbrakebeforeremovingthejumpercables,inreverse

orderofconnection.

Charging

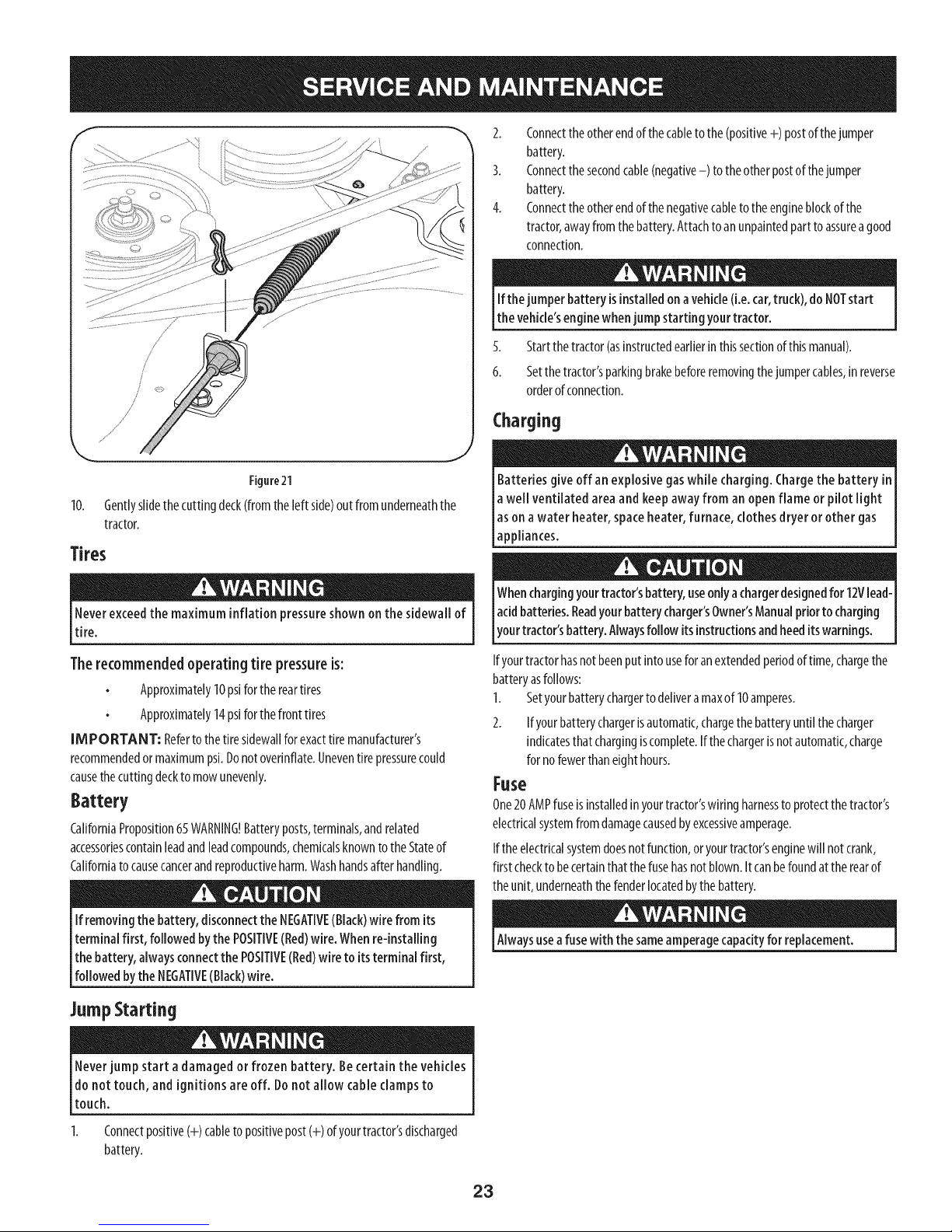

Figure21

10. Gentlyslidethecuttingdeck(fromtheleft side)outfromunderneaththe

tractor,

Tires

Neverexceedthe maximum inflation pressureshown on the sidewall of

tire.

Therecommendedoperating tire pressureis:

Approximately10psiforthereartires

Approximately14psiforthefronttires

IMPORTANT: Refertothetiresidewallforexacttiremanufacturer's

recommendedor maximumpsi.Donotoverinflate.Uneventirepressurecould

causethecuttingdeckto mowunevenly.

Battery

CaliforniaProposition65WARNING!Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductiveharm.Washhandsafterhandling.

Ifremovingthe battery, disconnectthe NEGATIVE(Black)wire from its

terminalfirst, followed by the POSITIVE(Red)wire.Whenre-installing

the battery,alwaysconnectthe POSITIVE(Red)wire to itsterminal first,

followedbythe NEGATIVE(Black)wire.

Batteries

awell ventilated areaand keepawayfrom an openflame or pilot light [

asona water heater,spaceheater, furnace, clothes dryer or other gas [

lapp antes. J

Whenchargingyourtractor'sbattery,useonlyachargerdesignedfor 12Vlead-

[acidbatteries.Readyourbatterycharger'sOwner'sManualpriortocharging

[yourtractor'sbattery.Alwaysfollow itsinstructionsandheeditswarnings.

Ifyourtractorhasnotbeenputintouseforanextendedperiodoftime,chargethe

batteryasfollows:

1. Setyourbatterychargertodelivera maxof 10amperes.

2. Ifyourbatterychargerisautomatic,chargethebatteryuntilthecharger

giveoff an explosive gaswhile charging. Chargethe battery in[

indicatesthatchargingiscomplete.If thechargerisnotautomatic,charge

fornofewerthaneighthours.

Fuse

One20AMPfuseisinstalledinyourtractor'swiringharnessto protectthetractor's

electricalsystemfromdamagecausedbyexcessiveamperage.

Iftheelectricalsystemdoesnotfunction,oryourtractor'senginewillnotcrank,

firstcheckto becertainthatthefusehasnotblown.It canbefoundattherearof

theunit,underneaththefenderlocatedbythebattery.

Alwaysuseafusewith thesameamperagecapacityfor replacement.

JumpStarting

Neverjump start adamaged or frozen battery. Becertain the vehicles

do not touch, and ignitions are off. Donot allow cable clamps to

touch.

Connectpositive(+)cableto positivepost(+) ofyourtractor'sdischarged

battery.

23

Page 24

CuttingBlades

Shutthe engineoff andremoveignitionkeybeforeremoving the cutting

blade(s)for sharpeningorreplacement.Protectyourhandsbyusingheavy

[g oveswhengraspngthebade.

Periodicallyinspectthe bladeand/or spindleforcracksordamage,

[especiallyafter you'vestruckaforeignobject.Donotoperatethemachine

[until damagedcomponentsarereplaced.

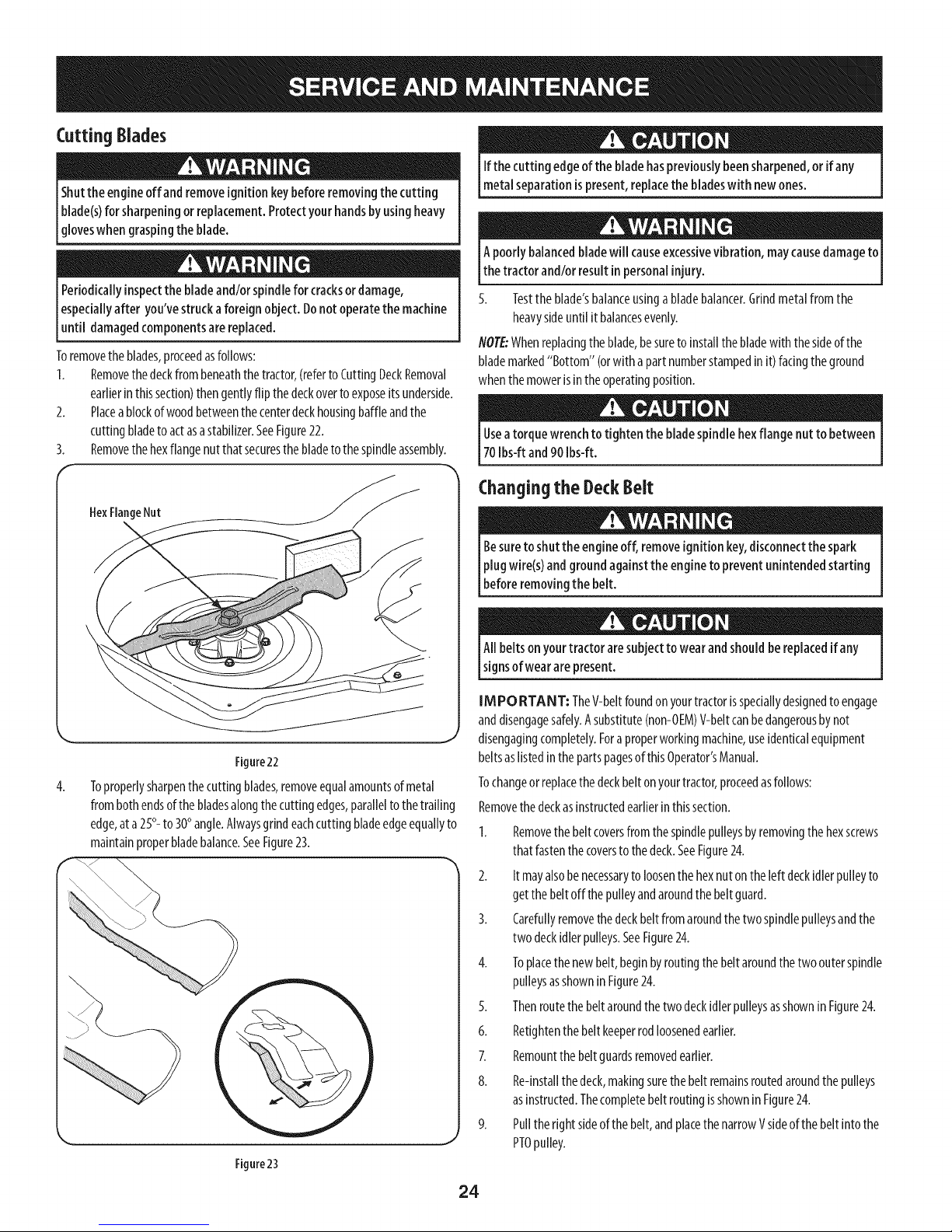

Toremovetheblades,proceedasfollows:

1. Removethedeckfrombeneaththetractor,(refertoCuttingDeckRemoval

earlierin thissection)thengentlyflipthedeckovertoexposeitsunderside.

2. Placeablockofwoodbetweenthecenterdeckhousingbaffleandthe

cuttingbladetoactasastabilizer.SeeFigure22.

3. Removethehexflangenutthatsecuresthe bladeto thespindleassembly.

HexFlangeNut

Ifthe cuttingedgeofthe bladehaspreviouslybeensharpened,or ifany

metalseparationispresent,replacethe bladeswith newones.

Apoorlybalancedbladewill causeexcessivevibration, maycausedamageto

the tractor and/orresultinpersonalinjury.

5. Testtheblade'sbalanceusingabladebalancer.Grindmetalfromthe

heavysideuntilit balancesevenly.

NOTE:Whenreplacingtheblade,besuretoinstallthebladewiththesideofthe

blademarked"Bottom" (orwitha partnumberstampedinit)facingtheground

whenthemowerisintheoperatingposition.

Useatorquewrenchto tighten thebladespindlehexflangenut to between

70Ibs-ftand 90Ibs-ft.

Changing the DeckBelt

Besureto shutthe engineoff, removeignitionkey,disconnectthe spark

plugwire(s)and groundagainstthe enginetoprevent unintendedstarting

beforeremovingthe belt.

Figure22

4.

Toproperlysharpenthecutting blades,removeequalamountsof metal

frombothendsofthe bladesalongthecuttingedges,paralleltothetrailing

edge,ata25°-to 30° angle.Alwaysgrindeachcuttingbladeedgeequallyto

maintainproperbladebalance.SeeFigure23.

\

Figure23

All beltsonyourtractor aresubjecttowear andshouldbe replacedifany

signsofwearare present.

IMPORTANT: TheV-beltfoundonyourtractorisspeciallydesignedtoengage

anddisengagesafely.Asubstitute(non-OEM)V-beltcanbedangerousbynot

disengagingcompletely.Foraproperworkingmachine,useidenticalequipment

beltsaslistedinthe partspagesofthisOperator'sManual.

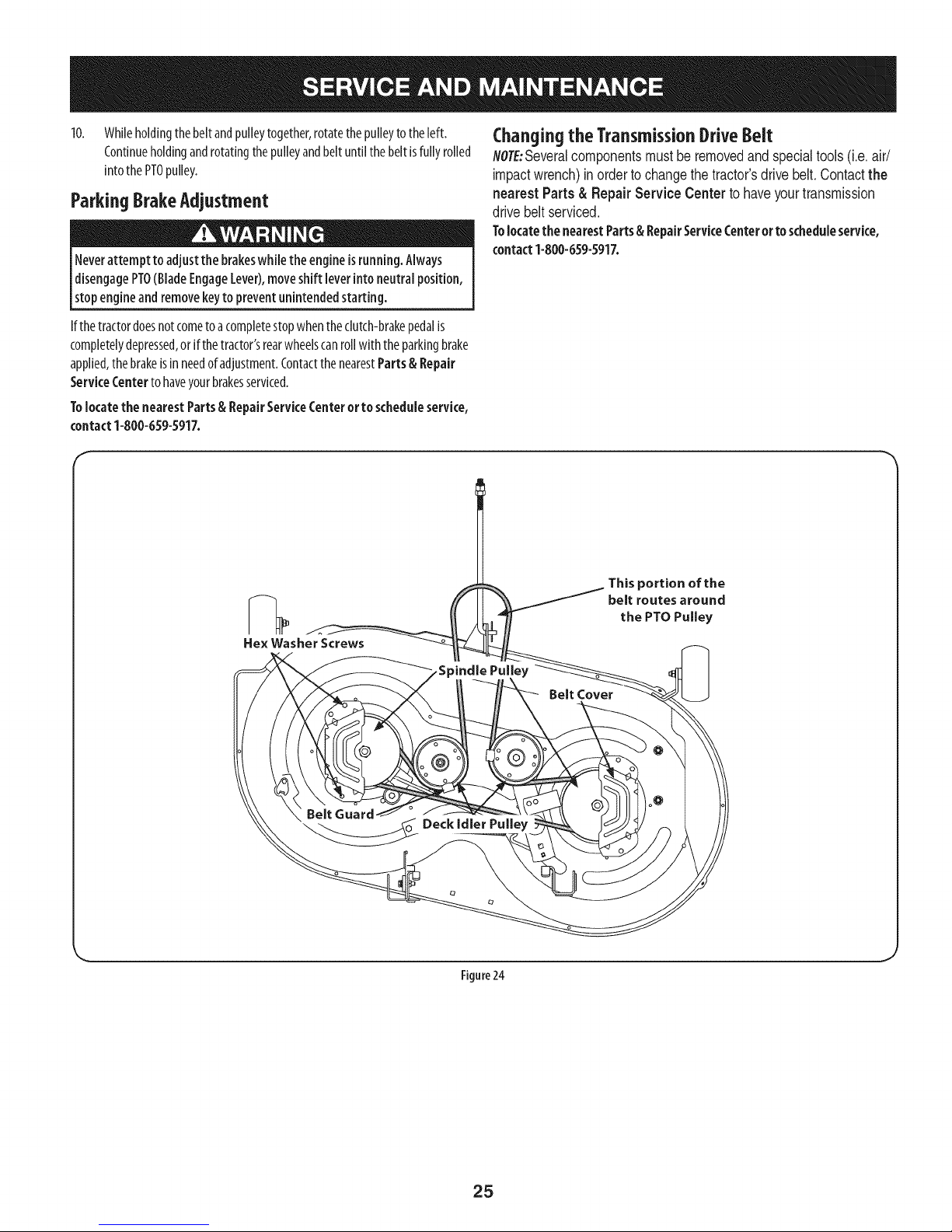

Tochangeorreplacethedeckbeltonyourtractor,proceedasfollows:

Removethedeckasinstructedearlierinthissection.

1. Removethebeltcoversfromthespindlepulleysbyremovingthehexscrews

thatfastenthecoversto thedeck.SeeFigure24.

2. Itmayalsobenecessaryto loosenthehexnutontheleft deckidlerpulleyto

getthebeltoffthepulleyandaroundthebeltguard.

3. Carefullyremovethedeckbeltfromaroundthetwo spindlepulleysandthe

twodeckidlerpulleys.SeeFigure24.

4. Toplacethenewbelt,beginbyroutingthebeltaroundthetwoouterspindle

pulleysasshownin Figure24.

5. Thenroutethe beltaroundthetwodeckidlerpulleysasshownin Figure24.

6. Retightenthe beltkeeperrodloosenedearlier.

7. Remountthebeltguardsremovedearlier.

8. Re-installthedeck,makingsurethebeltremainsroutedaroundthepulleys

asinstructed.Thecompletebeltroutingisshownin Figure24.

9. Pulltherightsideofthebelt,andplacethenarrowVsideofthebeltintothe

PTOpulley.

24

Page 25

10. Whileholdingthebeltandpulleytogether,rotatethepulleyto theleft.

Continueholdingandrotatingthepulleyandbeltuntilthebeltisfully rolled

intothePTOpulley.

ParkingBrakeAdjustment

Neverattempt to adjustthe brakeswhile theengineisrunning.Always

disengagePTO(BladeEngageLever),moveshift [everinto neutralposition,

stopengineandremovekeyto preventunintendedstarting.

Ifthetractordoesnotcometoacompletestopwhentheclutch-brakepedalis

completelydepressed,orif thetractor'srearwheelscanrollwiththeparkingbrake

applied,thebrakeisinneedofadjustment.Contactthe nearestParts& Repair

ServiceCenterto haveyourbrakesserviced.

Tolocate the nearestParts& RepairServiceCenterorto scheduleservice,

contact1-800-659-5917.

f

Changing the TransmissionDrive ieit

NOTE:Several components must be removed and special tools (i.e. air/

impact wrench) in order to change the tractor's drive belt. Contact the

nearest Parts & Repair Service Center to have your transmission

drive belt serviced.

Tolocatethe nearestParts& RepairServiceCenterorto scheduleservice,

contact1-800-659-5917.

J

Figure24

25

Page 26

Neverstorelawn tractor with fuelintankindoorsor inpoorlyventilated

areaswherefuelfumes mayreachanopen flame,spark,or pilot light ason

afurnace,waterheater,clothesdryer,or gasappliance.

PreparingTheEngine

IM PORTANT: Fuelleft inthefueltankduringwarmweatherdeterioratesand

will causeseriousstartingproblems.

Topreventgumdepositsfromforminginsidetheengine'scarburetorandcausing

possiblemalfunctionoftheengine,thefuelsystemmustbeeithercompletely

emptied,orthegasolinemustbetreatedwith astabilizertopreventdeterioration.

I. Ifusingafuelstabilizer:

a. Readtheproductmanufacturer'sinstructionsandrecommendations.

b. Addtoclean,freshgasolinethecorrectamountofstabilizerforthe

capacityofthefuelsystem.

c. Fillthefueltankwith treatedfuelandruntheenginefor2-3minutesto

getstabilizedfuelintothecarburetor.

2. Ifemptyingthefuelsystem:

a. Donotdrainfuelwhentheengineishot.Allowtheengineadequate

timetocool.Drainfuelintoanapprovedcontaineroutdoors,awayfrom

openflame.

b. Drainanylargevolumeoffuelfromthetankbydisconnectingthe

fuellinefromthe in-linefuelfilter neartheengine.Seethecomplete

instructionsforDrainingTheFuellaterinthissection.

Gasolineisextremelyflammableand canbeexplosiveundercertain

conditions. Draingasolinebeforestoring theequipment for extended

periods.Drainfuelonly into anapprovedcontaineroutdoors,awayfrom

anopenflame. Allowengineto cool.Extinguishcigarettes,cigars,pipes,

andothersourcesof ignition priorto drainingfuel. Storegasolineinan

approvedcontainerinsafelocation.

DrainingTheFuel

1. Locatethefuelfilter,whichislocatedontheleftsideoftheengine,andmay

beattachedtotheenginewith a tiestrap.

2. Cutthetiestrap,ifpresent,thenpinchthe in-lineclamponthefuelfilter

with apairofpliers,slidetheclampupthefuel line.

3. Pullthefuellinefreefromthefilterandplacetheopenendof thelineinto

anapprovedcontainertodrainthefuel.

PreparingThelawn tractor

Cleanandlubricatetractorthoroughlyasdescribedinthelubrication

instructions.

2. Donotuseapressurewasherorgardenhosetocleanyourunit.

3. Storemowerinadry,cleanarea.Donotstorenexttocorrosivematerials,

suchasfertilizer.

c. Reconnectthefuellineandruntheengineuntilit startstofalter,then

usethechoketokeeptheenginerunninguntilall fuelinthecarburetor

hasbeenexhausted.

d. Disconnectthefuellineanddrainanyremaininggasolinefromthe

system.

Gasolineisatoxicsubstance.Disposeofgasolineproperly.Contactyour

localauthoritiesforapproveddisposalmethods.

3. Removethesparkplugandpourone(1)ounceofengineoil throughthespark

plugholeintothecylinder.Crankthe engineseveraltimestodistributethe

oil. Replacethesparkplug.

26

Page 27

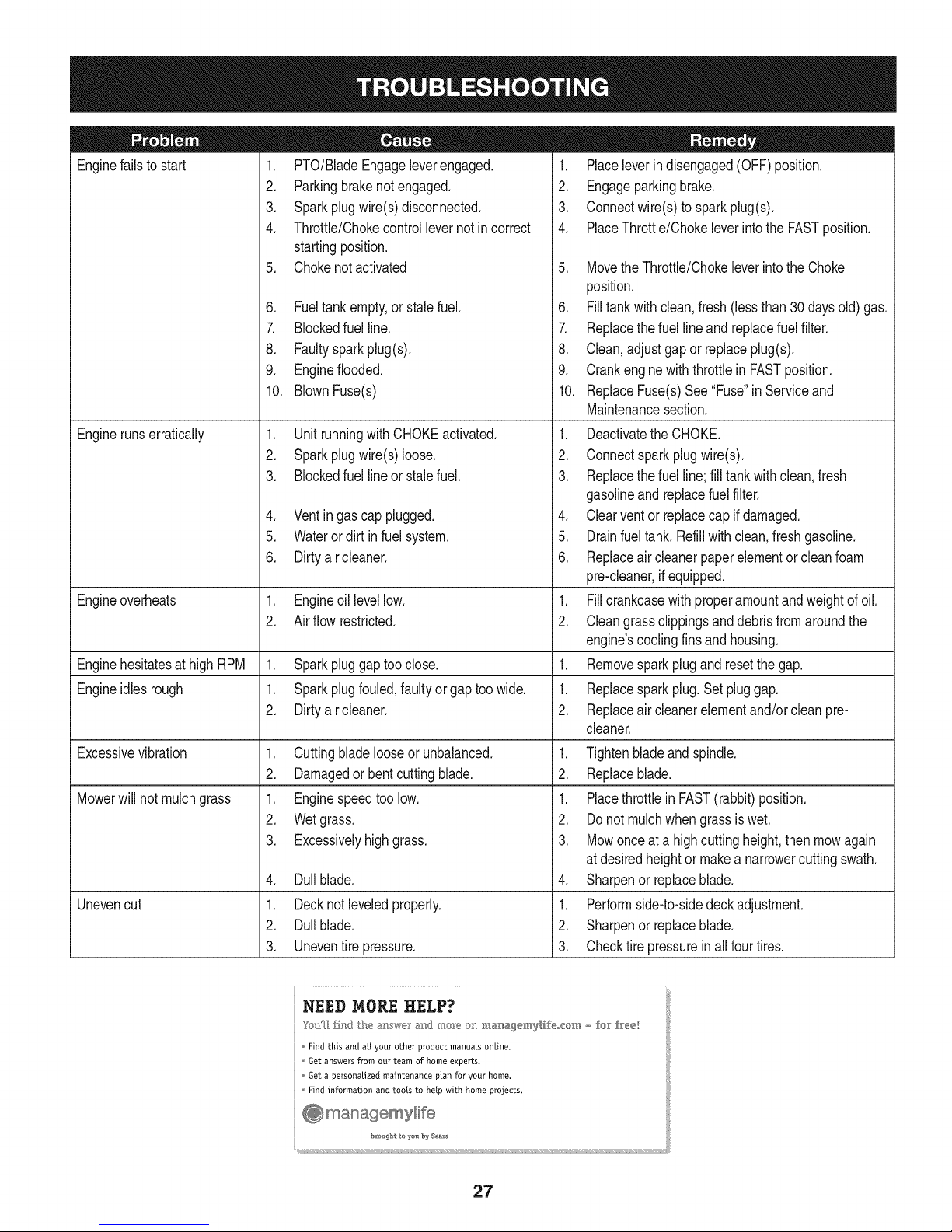

Enginefailstostart

1. PTO/BladeEngageleverengaged.

2. Parkingbrakenotengaged.

3. Sparkplugwire(s)disconnected.

4. Throttle/Chokecontrollevernotincorrect

4. PlaceThrottle/ChokeleverintotheFASTposition.

startingposition.

5. Chokenotactivated

6. Fueltankempty,orstalefuel.

7. Blockedfuel line.

8. Faultysparkplug(s).

9. Engineflooded.

10. BlownFuse(s)

Enginerunserratically

1. UnitrunningwithCHOKEactivated.

2. Sparkplugwire(s)loose.

3. Blockedfuel lineor stalefuel.

4. Ventingas cap plugged.

4. Clearventor replacecapifdamaged.

5. Wateror dirtinfuelsystem.

6. Dirtyair cleaner.

Engineoverheats 1. Engineoillevellow. 1.

2. Air flowrestricted. 2.

Enginehesitatesat high RPM 1. Sparkpluggaptoo close. 1.

Engineidlesrough 1. Sparkplugfouled,faultyorgaptoowide. 1.

2. Dirtyair cleaner. 2.

Excessivevibration

1. Cuttingbladelooseor unbalanced.

2. Damagedorbentcuttingblade.

Mowerwillnotmulchgrass

1. Enginespeedtoolow.

2. Wetgrass.

3. Excessivelyhighgrass.

Unevencut

4. Dullblade.

1. Decknot leveledproperly.

4. Sharpenor replaceblade.

2. Dullblade.

3. Uneventire pressure.

1. Placeleverindisengaged(OFF)position.

2. Engageparkingbrake.

3. Connectwire(s)to sparkplug(s).

5. MovetheThrottle/Chokeleverintothe Choke

position.

6. Filltankwithclean,fresh(lessthan30daysold)gas.

7. Replacethe fuellineandreplacefuelfilter.

8. Clean,adjustgapor replaceplug(s).

9. Crankenginewiththrottlein FASTposition.

10. ReplaceFuse(s)See"Fuse"inServiceand

Maintenancesection.

1. Deactivatethe CHOKE.

2. Connectsparkplugwire(s).

3. Replacethe fuelline;filltankwithclean,fresh

gasolineandreplacefuelfilter.

5. Drainfueltank.Refillwithclean,freshgasoline.

6. Replaceair cleanerpaperelementorcleanfoam

pre-cleaner,ifequipped.

Fillcrankcasewithproperamountandweightof oil.

Cleangrassclippingsanddebrisfromaroundthe

engine'scoolingfinsandhousing.

Removesparkplugandresetthe gap.

Replacesparkplug.Setpluggap.

Replaceair cleanerelementand/orcleanpre-

cleaner.

1. Tightenbladeandspindle.

2. Replaceblade.

1. Placethrottlein FAST(rabbit)position.

2. Donotmulchwhengrassiswet.

3. Mowonceat a highcuttingheight,thenmowagain

atdesiredheightor makea narrowercuttingswath.

1. Performside-to-sidedeckadjustment.

2. Sharpenor replaceblade.

3. Checktirepressureinallfour tires.

NEED MORE HELP?

Find this and a[[ your other product manuals online.

Get answers from our team of home experts.

Get a personalized maintenance ptan for your home.

Find information and tools to help with home projects.

27

Page 28

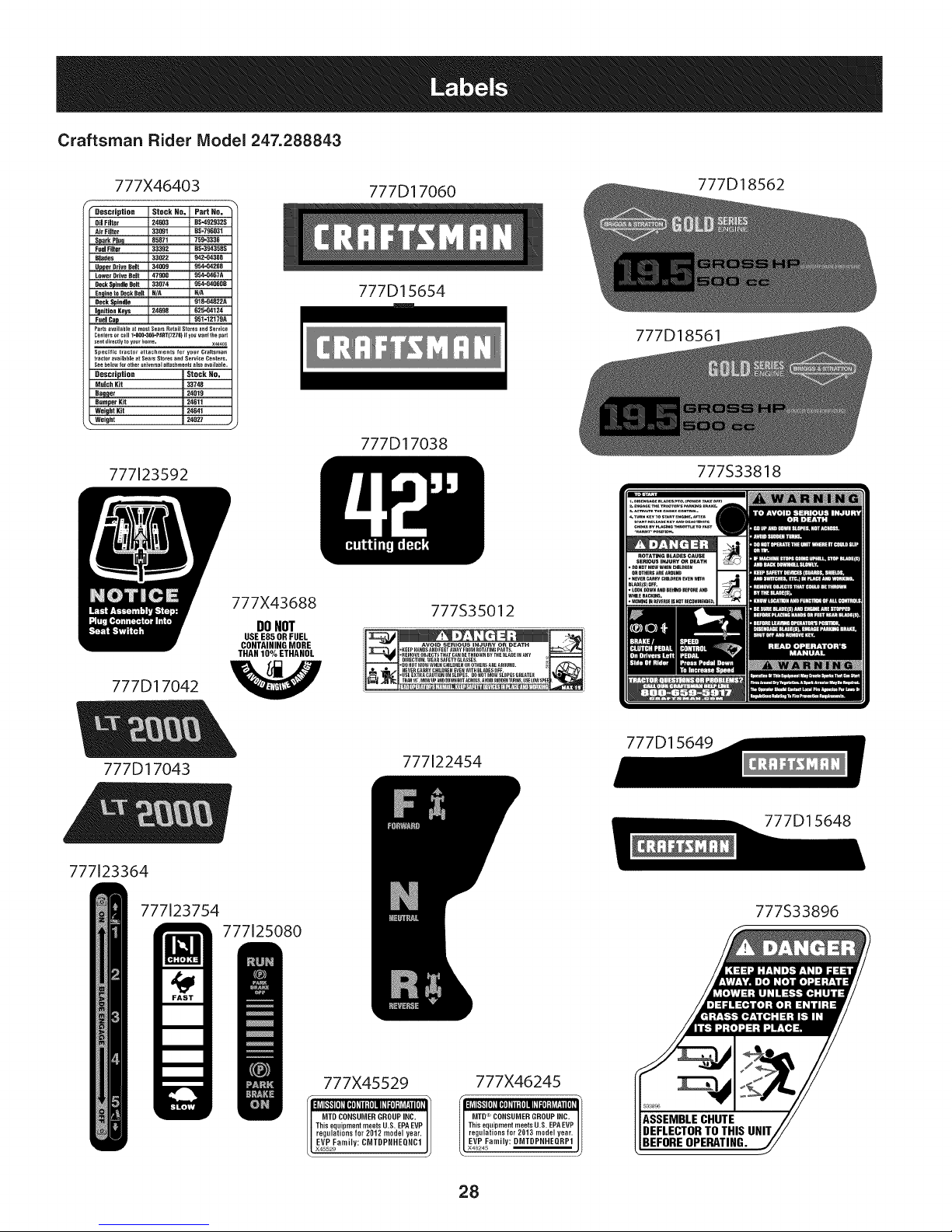

Craftsman RiderModel 247.288843

777X46403 777D17060 777D18562

• Description Stock NO. Part No.

Oil Filter 24683 D3-492932S

Air Filter 33991 D3-796931

Spark PJuq 89371 759"3336

Fuel Filter 33392 D3-3983983

DJades 33022 942"04308

_er Drive Belt 34909 954_68208

Lower Drive Bait 47900 95_08878

Deck S_ndle Belt 33074 954=OdD60D

Enq81eto Deck DOlt H/A N]A

Deck Spindle 918-048228

Igeltten Keys 24698 625-94124

Fuel Cap 951-121798

Pa+tsavmilahleatmosl Sears RetailSt+resamdSe+vi+e

Ce_+e_or_.II I-SOO._+-PART(7_TS)ifW" wan+thepart

sent_irectlvto yo_Phome. ×+_o3

Spec_f+c tractor attachments for yo,r Craftsman

tm_tor_va+lableat Se_rs St_es an_ Se_v_e Centers.

See _elo_for mhe_un+vers_lanac_mentsalsoavml_le.

Dascriptialm Stock Ha=

M.lch Kit 33788

Ba91]er 24019

Bumper Klt _611

WeiuhtKit 34641

_, Weight

777123592

J

777D15654

777D18561

777D17038

777S33818

777D17042

777D17043

777123364

777123754

777X43688

DONOT

USE E85 OR FUEL

CONTAINING MORE

THAN 10% ETHANOL

777125080

777S35012

•REMOVEOBJECTSTHATCANBETHROWNBYTHEeLADEINABY

DIRECTION.W_ARSAFETYGLASSES.

•DOHOTMOWWHEHCHILDHEHOROTHERSAREAROUHD.

[ HEVERCARRYCHILDREHEVEHWITHBLADESOFF.

•USEEXTRACAUTIONONSLOPE&O0HOTmOWSLOPESGREATER

777122454

777D15649