Page 1

OWNER’S

MANUAL

MODEL NO.

247.287751

CRRFTSMflN

Caution:

Read and Follow

Ail Safety Rules

and Instructions

Before Operating

This Equipment

5 HORSEPOWER

20 TON

HYDRAULIC LOG SPLITTER

Assembly

Operation

Maintenance

Service and Adjustment

Repair Parts

SEARS, ROEBUCK AND CO., Chicago, iL 60684 U.S.A.

Page 2

CRAFTSMAN WARRANTY

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN LOG SPLITTER

For one year from the date of purchase, when this Craftsman Log Splitter is maintained, lubricated and tuned up ac

cording to the instructions in the owner’s manual. Sears will repair, free of charge, any defect in material and workmanship.

If this Craftsman Log Splitter is used for commercial or rental purposes, this warranty applies for only 30 days from

the date of purchase.

This warranty does not cover: Expendable items which become worn during normal use, such as spark plugs.

Repairs necessary because of operator abuse or negligence, including the failure to maintain the equipment accord

ing to the instructions contained in the owner's manual.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SERVICE CENTER/DEPARTMENT IN THE

UNITED STATES. This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO.

DEPT. 731CR-W SEARS TOWER

CHICAGO, IL 60684

OWNER’S INFORMATION

Record the following information about your unit so that you will be able to provide it in case of loss or theft.

DATE PURCHASED:

STORE WHERE PURCHASED: ADDRESS,

CITY:

__________________________________

___________________________________

STATE: _________

MODEL NO./CODE: 247.287751/______________________________________________

TELEPHONE:

MAINTENANCE AGREEMENT

A SEARS MAINTENANCE AGREEMENT IS AVAILABLE FOR THIS PRODUCT. CONTACT YOUR NEAREST

SEARS STORE FOR DETAILS.

TABLE OF CONTENTS

Page

Craftsman Warranty

Owner’s Information

Maintenance Agreement ... ............................................2

Rules for Safe Operation ....

Assembly Instructions

Operation Instructions............................

Adjustment

Maintenance

...................................................

...............................

..............................

.............................

...............................................

............................................2

............................................2

.....................................

........................................

.....................................

...............................

..................................

3, 4

5-8

9-11 Log Splitter Repair Parts

11, 12

12-15 How To Order Repair Parts

Page

Off-Season Storage

Trouble Shooting Guide...................................................

Important Information for Log Splitter Users . .17

How Your Log Splitter Operates

Hydrauiic Trouble Shooting Guide .... ................19

Engine Repair Parts

..........................................................

..................................

.................................................

.............................................................

............................................

................15

................

16

................

18

. . . 20, 21

. . .22-26

................28

Page 3

IMPORTANT

RULES FOR SAFE OPERATION

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL

SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE AT

TEMPTING TO OPERATE YOUR LOG SPLIHER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL IN

k

JURY. WHEN YOU SEE THIS SYMBOL-A HEED ITS WARNING.

A

AC

Your log splitter was built to be operated according to tbe rules for safe operation in this manual. As

with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. If you violate any of these rules, you may cause serious injury to yourself or others.

TRAINING

Before operating this splitter, read and understand this manual com

pletely. Become familiar with it for your own safety. To fail to do

so may cause serious injury. Do not allow anyone to operate your

splitter who has not read this manual. Keep this manual in a safe

place for future and regular reference and for ordering replacement

parts.

Never use your splitter for any other purpose than splitting wood.

It is designed for this use and any other use may cause an injury.

Your log splitter is a precision piece of power equipment, not a

playtoy. Therefore, excercise extreme caution at all times.

Never allow children to operate your log splitter. Do not allow adults

to operate it without proper instruction. Only persons well acquainted

with these rules of safe operation should be allowed to use your

log splitter.

Only the operator is to be near your log splitter during use. Keep

all others, including pets and children, a minimum of 20 feet away

from your work zone. Flying wood can be hazardous. If a helper

is assisting in loading logs, never activate the control until the helper

is clear of the area. More accidents occur when more than one per

son operates the log splitter than at any other time.

No one should operate this unit while intoxicated or while taking

medication that impairs the senses or reactions. A clear mind is

essential for safety. Never allow a person who is tired or otherwise

not alert to use your splitter.

DANGER

Only operate your splitter on level ground and not on the side of

a hill. It could tip, or roiling logs or poor footing could cause an

accident. Operating the splitter on level ground also prevents the

spillage of gasoline from the fuel tank.

Never attempt to mo\re the log splitter over hilly or uneven terrain

without a tow vehicle or adequate help.

Always block the wheels to prevent movement of log splitter while

in operation.

Check the fuel before starting the engine. Gasoline is an extremely

flammable fuel. Do not fill the gasoline tank indoors, when the engine

is running, or while the engine is still hot. Replace gasoline cap

securely and wipe off any spilled gasoline before starting the engine

as it may cause a fire or explosion.

Both ends of each log must be cut as square as possible to help

prevent the log from riding out of the splitter during operation.

A

OPERATION

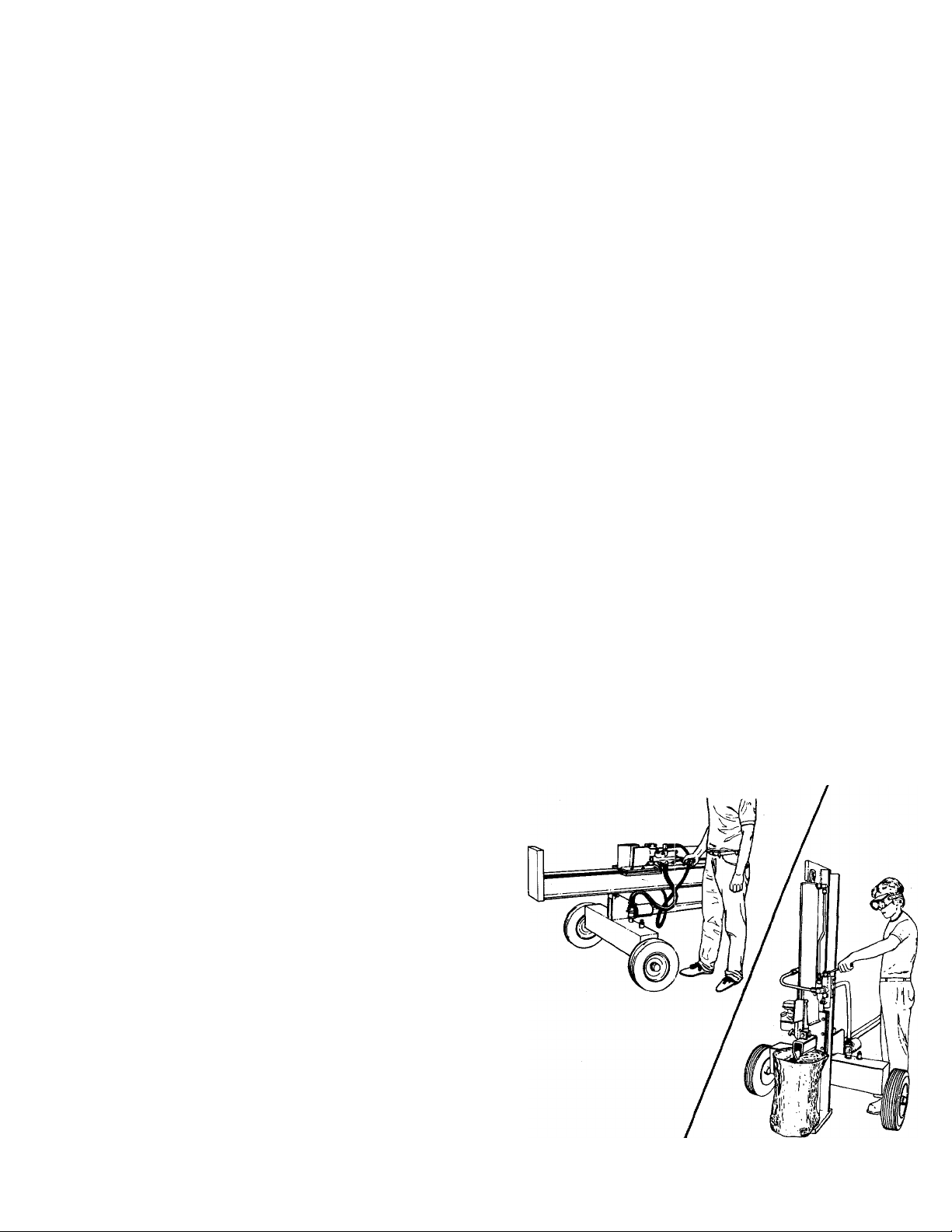

• Stand behind the reservoir tank when operating. See illustration.

PREPARATION

ik

Never wear loose clothing or jewelry that can be caught by moving

parts of your log splitter and pull you into it. Keep clothing away

from all moving parts of your log splitter.

Wear proper head gear to keep hair away from moving parts. Always

wear protective hearing devices as needed.

Always wear safety shoes. A dropped log can seriously injure your

foot.

Always wear safety glasses or goggles while operating your split

ter. A piece of splitting log could fly off and hit your eyes.

If you wear gloves, be sure they are tight fitting without loose cuffs

or draw strings.

Use your log splitter in daylight, or under good artificial light.

Never operate your splitter on slippery, wet, muddy or icy surfaces.

Safe footing is essential in preventing accidents. Never operate your

splitter while attached to a towing vehicle.

Page 4

• Know how to stop the unit and disengage the controls.

• Never place hands or feet between log and splitting wedge or be

tween log and end plate during forward or reverse stroke. To do

so may result in crushed or amputated fingers or toes, or worse,

you may lose an arm or foot.

• Do not straddle the splitter when using it. A slip in any position could

result in a serious injury.

• Do not step over your log splitter when the engine is running. You

may trip or accidentally activate the splitting wedge if you step over.

If you need to get to the other side, walk around.

• Never try to split two logs on top of each other. One may fly out

and injure you.

• When loading the log splitter, place your hands on the side of the

log, not at the ends. Never attempt to load your splitter while the

splitting wedge is in motion. You may get caught by the wedge and

injured.

• Only use your hand to operate the splitting wedge or control lever.

Never use your foot or a rope or any other extension device. This

could result in your ability to stop your splitter quickly enough and

cause injury.

• Always keep fingers away from any cracks that open in the log dur

ing splitting operation. They can quickly close and pinch or amputate

your fingers.

• Never attempt to split woods across the grain. Some types of wood

may burst or fly out of your splitter and result in injury to you or

a bystander.

• For logs that are not cut square, the longest portion of the log should

be rotated down and the most square end placed against the split

ting wedge.

• Keep your work area clean. Immediately remove split wood around

your splitter so that you do not stumble over it. Clean chips and

dirt off end plate (wood platform) after each log is split, or whenever

necessary to maintain flat contact between wood and end plate

(platform).

• Never move the log splitter while the engine is running.

• Never leave your log splitter unattended with the engine running.

Shut off the engine if you are leaving your splitter, even for a short

period of time. Someone could accidentally activate the splitting

wedge and be injured.

• Do not run engine in an enclosed area. Exhaust gases contain car

bon monoxide. This odorless gas can be deadly when inhaled.

• Be careful not to touch the muffler after the engine has been run

ning as it is HOT.

• If the equipment should start to vibrate abnormally, stop the engine

and check immediately for the cause. Vibration is generally a warn

ing of trouble.

• When cleaning, repairing or inspecting, make certain all moving parts

have stopped. Disconnect the spark plug wire and keep the wire

away from the plug to prevent accidental starting.

A

MAINTENANCE

Do not operate your splitter in poor mechanical condition or when

in need of repair.

Periodically check that all nuts, bolts, screws, hose clamps and

hydraulic fittings are tight to be sure equipment is in safe working

condition. Where appropriate, check all safety guards and shields

to be sure they are in the proper position. Never operate your split

ter with safety guards, shields or other protective features removed.

These safety devices are for your protection.

• Replace all damaged or worn parts such as hydraulic hoses and fit

tings immediately with manufacturer approved replacement parts.

• Do not change the engine governor settings or overspeed the engine.

This increases the hazard of personal injury. The maximum engine

speed is preset by the manufacturer and is within safety limits.

• Do not alter your splitter in any manner such as attaching a rope

or extension to the control lever or adding to the width or height

of the wedge. Such alterations may cause your splitter to be unsafe.

• Perform all recommended maintenance procedures before you use

your splitter.

• Do not service or repair your log splitter without disconnecting the

spark plug wire.

• Never store the equipment with gasoline in the tank inside of a

building where ignition sources are present, such as hot water and

space heaters, clothes dryers and the like. Allow the engine to cool

before storing in any enclosure.

• Always store gasoline in an approved, tightly sealed container. Store

the container in a cool, dry place. Do not store in a building where

ignition sources are present.

• To reduce fire hazard, keep engine free of grass, leaves, wood chips,

and excessive grease and oil.

• The hydraulic system of your log splitter requires careful inspec

tion, along with the mechanical parts. Be sure to replace frayed,

kinked, or otherwise damaged hydraulic components.

• Fluid escaping from a very small hole can be almost invisible. Do

not check for leaks with your hand. Escaping fluid under pressure

can have sufficient force to penetrate skin, causing serious personal

injury. Leaks can be located by passing a piece of cardboard or wood

over the suspected leak and looking for discoloration.

• Should it become necessary to loosen or remove any hydraulic fit

ting or line, be sure to relieve all pressure by shutting off the engine

and moving the control handle back and forth several times.

• Do not remove the cap from the hydraulic tank or reservoir while

your log splitter is running. Hot oil under pressure could cause injury.

• The pressure relief valve on your splitter is preset at the factory.

Do not adjust the valve. Only a qualified service technician should

perform this adjustment.

• Completely drain fuel tank prior to storage. This guards against ac

cumulation of fuel fumes which could result in a fire hazard.

• Never store log splitter outside without a waterproof cover. Rain

will cause rust on the inside of the cylinder.

A

TOWING

• This unit should not be towed on any street, highway or public road

without checking the existing federal, local or state vehicle re

quirements. Any licensing or modifications such as taillights, etc.,

needed to comply with the existing federal, local or state vehicle

requirements is the sole responsibility of the purchaser.

• Before towing, be certain the log splitter is correctly and securely

attached to the towing vehicle, and the safety chains are in place.

Leave slack in chains for turning allowance.

• Do not allow anyone to sit or ride on your splitter. They can easily

fall off and be seriously injured.

NOTE: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-covered

or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If

a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have similar

laws. Federal laws apply on federal lands. A spark arrester for the muffler is available at your Sears Authorized Service Center.

Page 5

ASSEMBLY

IMPORTANT: This unit has been shipped without

gasoline or oil in the engine. After assembly, refer to

operation section of this manual for proper fuel and

engine oil information.

UNPACKING

Remove the log splitter parts from the carton by cut

ting the corners of the carton. Make certain all parts

and literature have been removed from the carton

before the carton is discarded.

All hardware for assentbly of the log splitter has been

placed in position on the various parts.

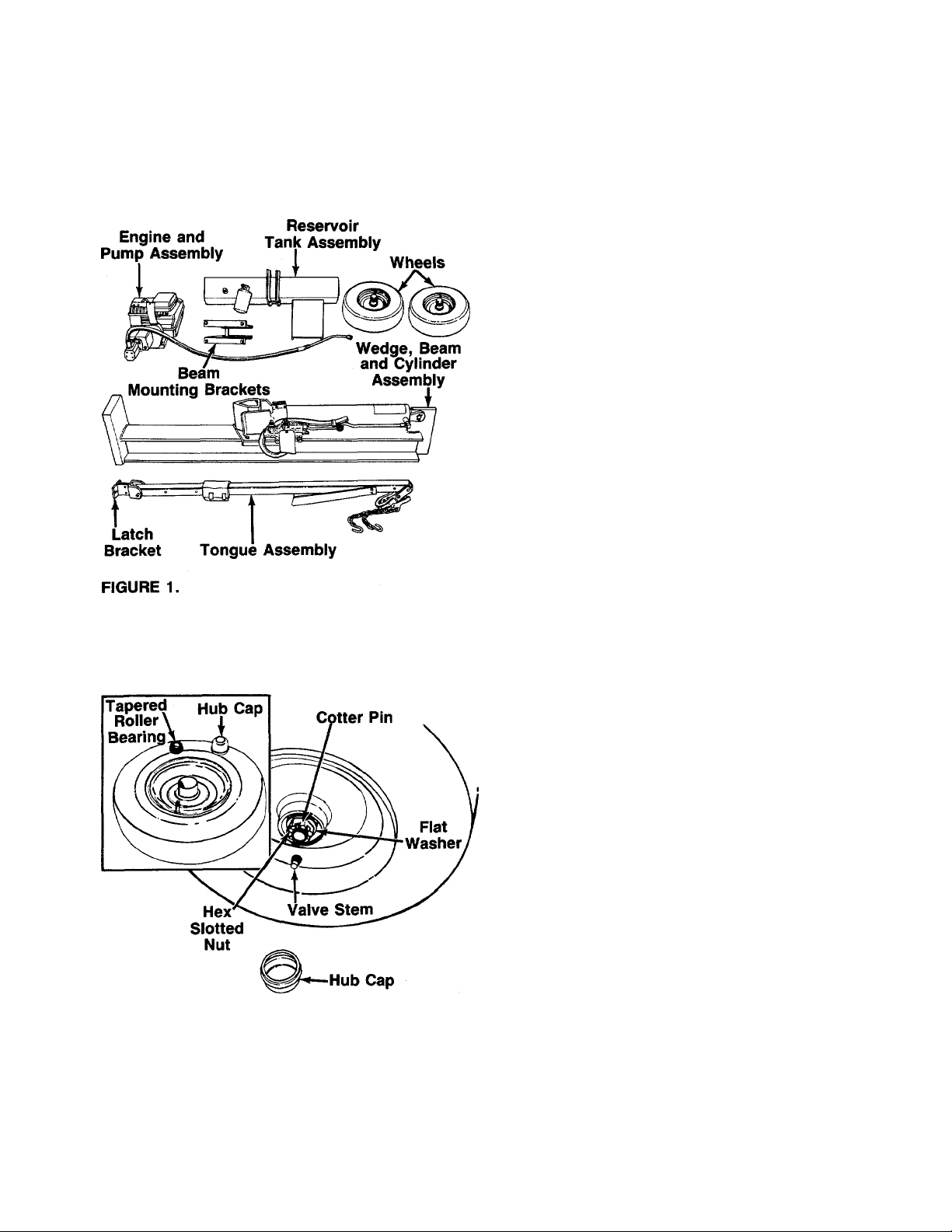

-PARTS IN CARTON (See figure 1)

Reservoir Tank Assembly

Engine and Pump Assembiy (Boited to bottom of

carton)

Tongue Assembiy

Wedge, Beam and Cylinder Assembly

TOOLS REQUIRED FOR ASSEMBLY

(2) 9/16" Wrenches*

(1) 5/8" Wrench*

(1) 11/16" Wrench*

(2) 1/2" Wrenches*

(1) Adjustable Wrench

(1) Knife (to remove cable tie)

(1) Screwdriver

‘Adjustable Wrenches may be used.

OTHER MATERIALS REQUIRED FOR ASSEMBLY:

Engine Oil

Unleaded Gasoline (regular grade gasoline is an

acceptable substitute)

Approximately 7.6 Gallons of Dexron II Automatic

Transmission Fluid

FIGURE 2.

INSTALLATION 01= WHEELS

Attach the wheels to the reservoir tank as follows. See

-figure 2.

• Pry off the hub caps which are attached to the

wheels. Remove one tapered roller bearing from in

side each wheel. See inset.

• Remove the cotter pin, hex slotted nut and flat

washer from each axle.

• Place one wheel on each axle, with the valve stem

facing outward.

• Pack the tapered roller bearings with wheel bearing

grease, and place one on each axle.

• Replace one flat washer on each axle. Secure with

hex slotted nut. Tighten slotted nut until snug, then

back off approximately 1/3 turn or until one of the

slots on the slotted nut lines up with the hole in the

axle.

• Check the assembly of the wheels. There should be

no side to side play, and the wheel should spin freely.

• Place hub caps in position on wheels and tap on with

a rubber maliet or plastic hammer.

Page 6

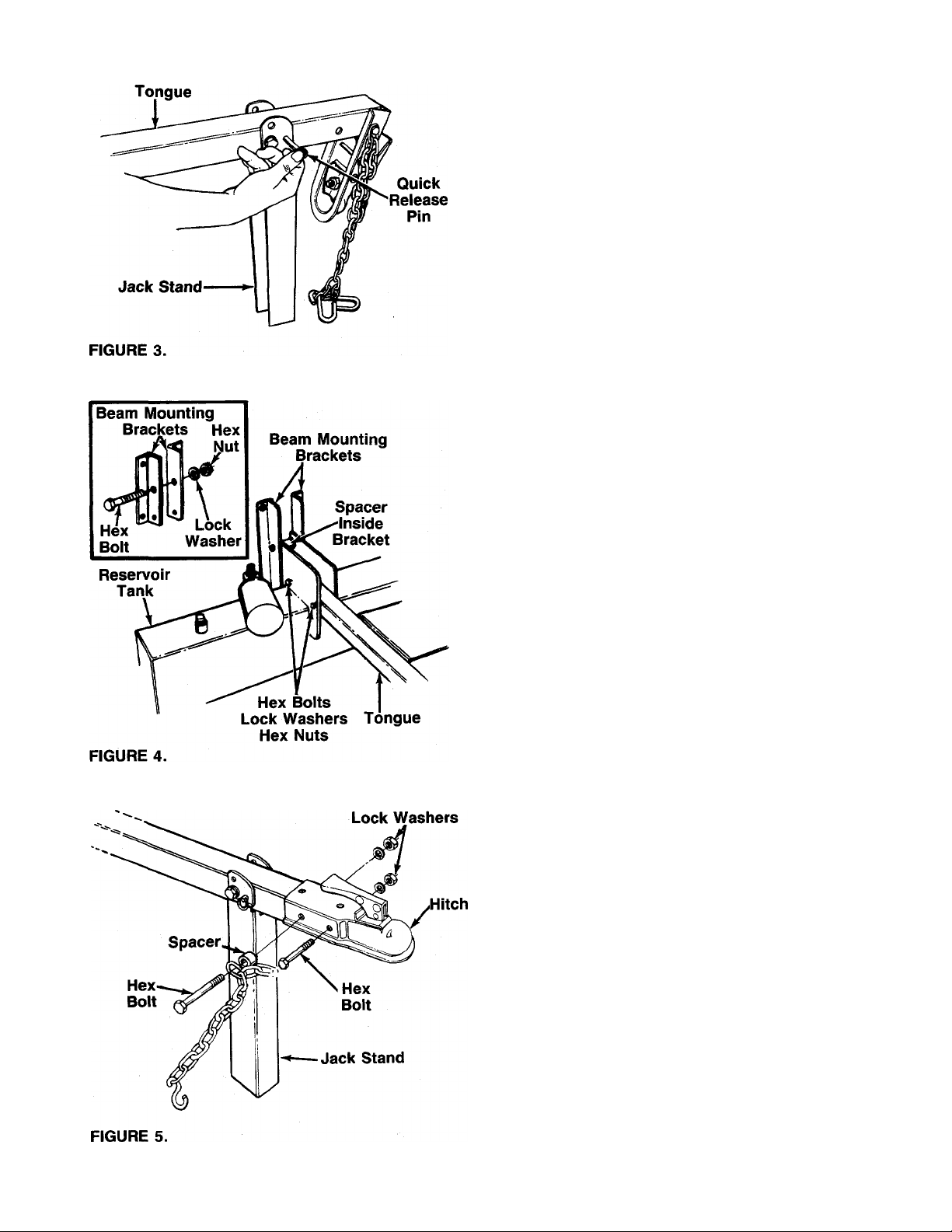

ATTACHING TONGUE TO RESERVOIR TANK

• The tongue is shipped with the jack stand aiready

attached to the tongue. The jack stand is in the

transport position. Remove the quick release pin.

Pivot the jack stand to the operating position (90°),

—and secure with the quick release pin. See figure 3.

NOTE: If necessary, loosen the bolt which holds the

hitch to the tongue, and pivot hitch out of the way.

• Remove the latch bracket which has been assem

bled to the other end of the tongue for shipping pur

poses only by removing another quick release pin.

Refer to figure 1. This bracket will be reassembled

to the beam on page 7. Replace the quick release

pin in the latch bracket.

• Remove the two hex bolts, lock washers and hex

nuts on the front of the reservoir tank. Two 9/16"

wrenches are required. Place the tongue In position,

and secure with hardware just removed. See figure

4.

ATTACHING THE BEAM MOUNTING BRACKETS

• Using two 3/4" or adjustable wrenches, remove the

hex nut, lock washer and hex bolt from the bracket

on the reservoir tank. Make certain the spacer re

mains inside the bracket on the reservoir tank. See

—figure 4.

• Place one beam mounting bracket against each side

of the bracket on the reservoir tank as shown in

figure 4. Secure with hardware just removed.

Hex Nuts

INSTALLING THE HITCH

• Using two 9/16" wrenches, remove the two long hex

bolts, lock washers and hex nuts which are assem

bled through the sides of the hitch and the tongue.

Do not remove the chain and spacer from the one

hex bolt.

• Place the hitch in position on the end of the tongue.

—Secure with hardware just removed. See figure 5.

Page 7

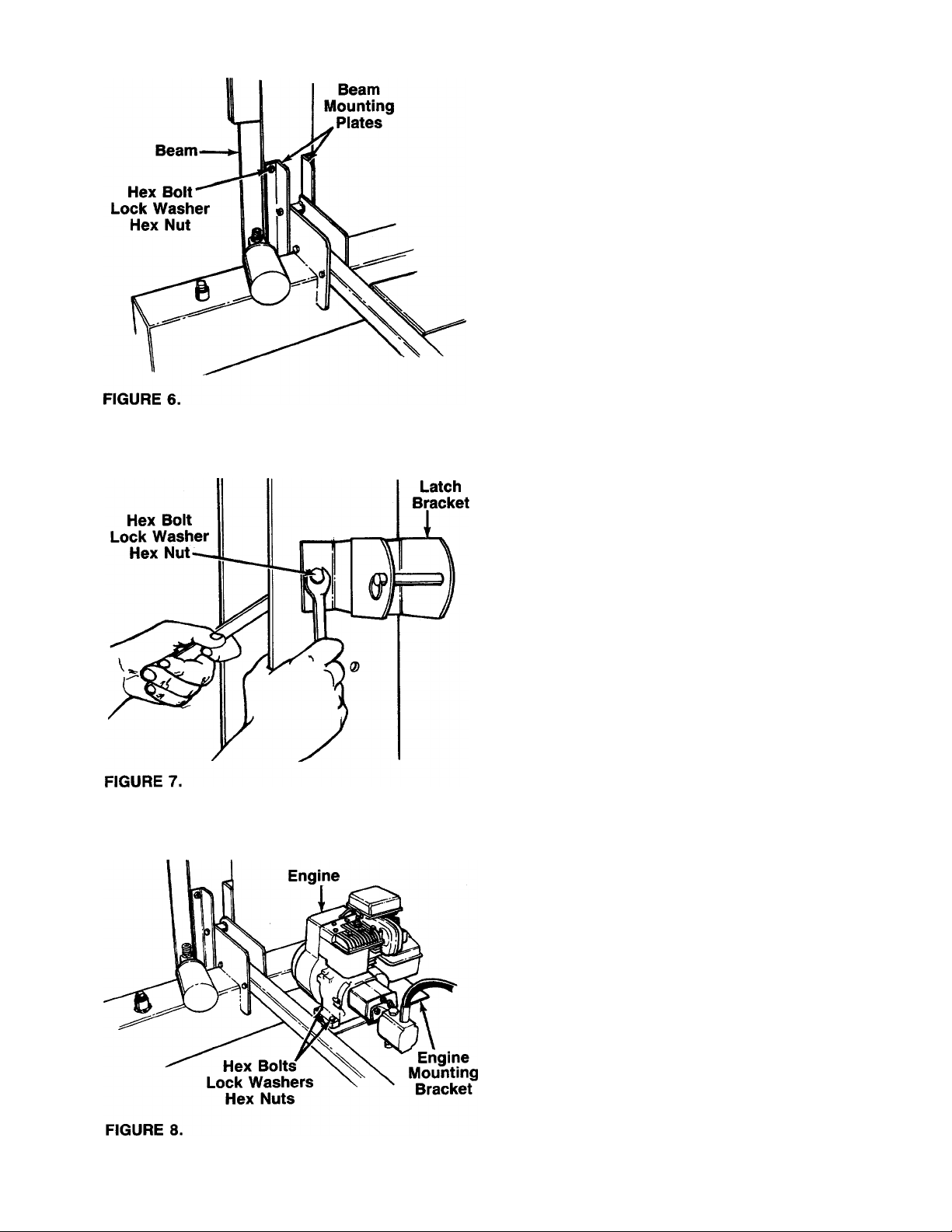

ATTACHING THE WEDGE, BEAM AND

CYLINDER ASSEMBLY

• Stand the wedge, beam and cylinder assembly

upright.

• Remove the four hex bolts, lock washers and hex

nuts from the beam mounting plates. A 5/8" and an

—11/16" wrench are required. See figure 6.

• Roll the reservoir tank assembly in position against

the beam. Secure the beam mounting plates to the

beam with hardware just removed. Tighten securely.

ATTACHING THE LATCH BRACKET

• Remove the two he>x bolts, lock washers and hex

nuts from the beam, using two 1/2" wrenches.

• With the beam still in the upright position, place the

—pivot latch on the beam as shown in figure 7. Secure

with hex bolts, lock washers and hex nuts just re

moved. Tighten securely.

ATTACHING THE ENGINE AND PUMP ASSEMBLY

• Using two 1/2" wrenches, remove the four hex bolts,

lock washers and hex nuts which secure the base

of the engine to the bottom of the shipping carton.

• Place the engine and pump assembly in position on

the engine mounting bracket as shown in figure 8.

—Secure with hardware just removed. Tighten

securely.

Page 8

ATTACHING THE CONTROL HANDLE

• The control handle and the return hose are attached

to the metal pressure tube with a cable tie for ship

ping purposes only. Cut and remove the cable tie.

• The bottom of the control handle is already attached

to the valve with a cotter pin and clevis pin. Remove

the second cotter pin and clevis pin which is attach

ed to the valve only. Place the handle in position,

and secure using the second cotter pin and clevis

—pin. See figure 9.

Control

Valve

Filter

Head

FIGURE 10.

Pressure

Hose

Suction-

Hose

Pump

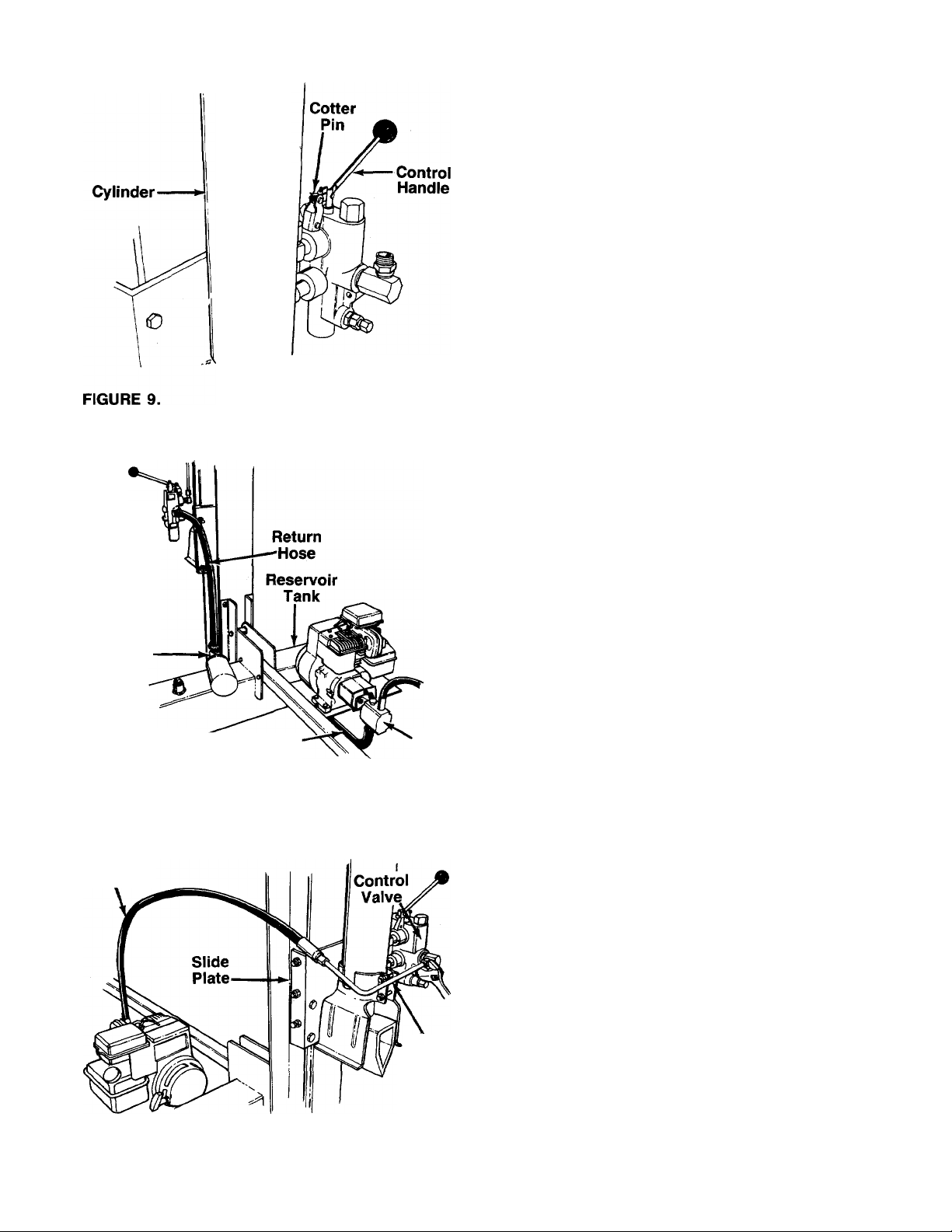

ATTACHING THE HOSES

SUCTION HOSE

• The suction hose is attached to the reservoir tank,

beneath the engine mounting plate. Loosen the hose

clamp on the free end of the hose using a

screwdriver.

• Attach the end of the hose to the fitting on the bot-

—tom of the pump. See figure 10. Place the hose

clamp at the base of the fitting, and tighten securely.

RETURN HOSE

• The return hose is attached to the bottom of the

valve. Loosen the hose clamp on the free end of the

hose using a screwdriver.

• Attach the end of the hose to the fitting on top of the

filter head. See figure 10. Place the hose clamp at

the base of the fitting, and tighten securely.

PRESSURE HOSE

The pressure hose is attached to the top of the pump.

-Route the hose as shown in figure 11. Place the metal

pressure tube in position on the fitting on top of con

trol valve. Secure with the compression nut on the

pressure tube, using an adjustable wrench. Make cer

tain the metal pressure tube is positioned so that the

pressure hose is above the slide plate as shown.

FIGURE 11.

Metal

Pressure

Tube

FINAL ASSEMBLY

• Make certain all nuts, bolts and hose clamps are

tightened securely.

• Before operating the log splitter, make certain to

follow the “Initial Preparation” instructions in the

Operation Section, page 9.

Page 9

OPERATION

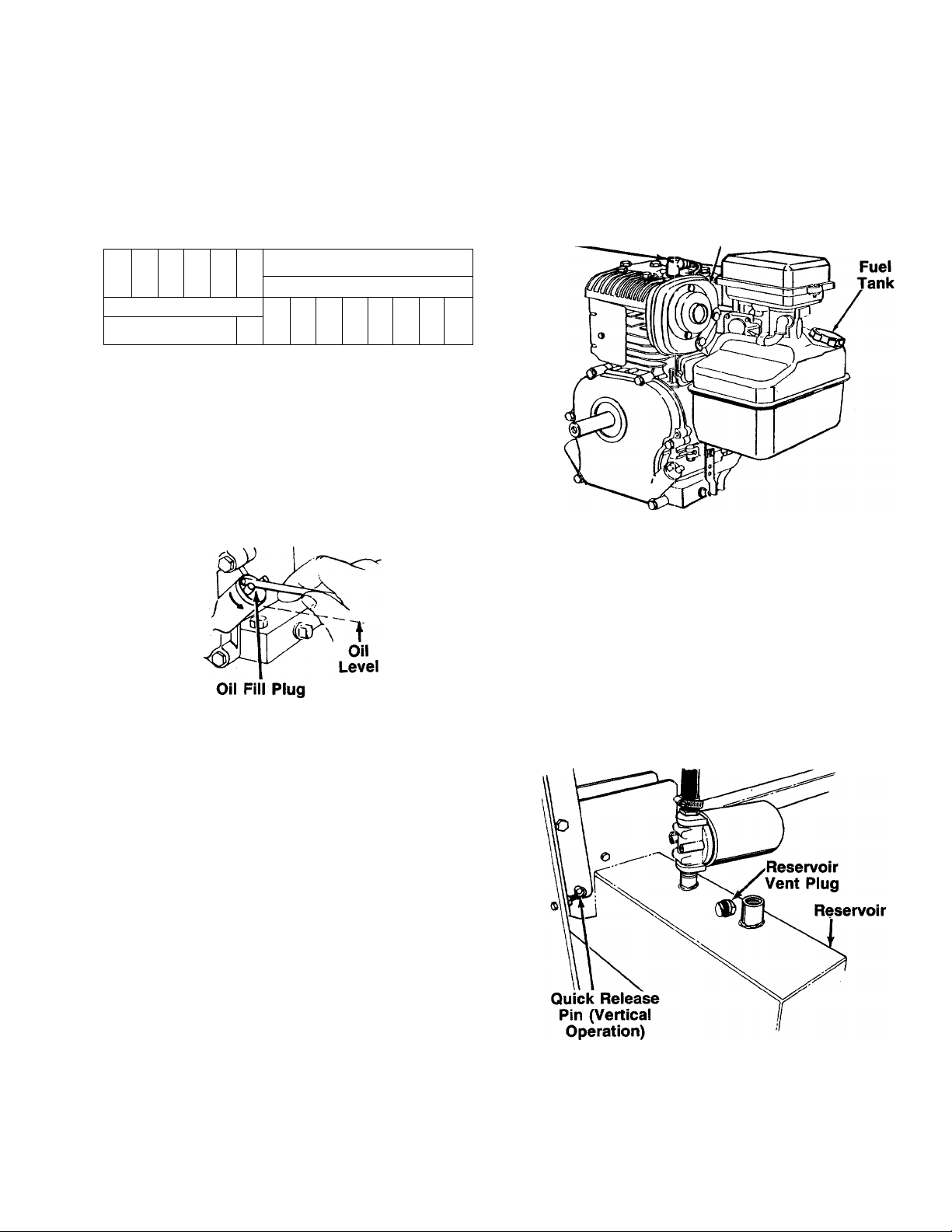

GAS AND OIL FILL-UP

NOTE: Engine is shipped without oil. Fill crankcase with

oil before starting. Be very careful not to allow dirt to

enter the engine when checking or adding oil or fuel.

Recommended SAE Viscosity Grades

nr

30Wor10W30 >

C 5W30

'rnrn

0

-20° 0° 32°

60°

80

Temperature range expected before next oil

change. All oils must be A.P.I. service classification

SD, SE or SF.

• Fill engine with oil by removing oil fill plug. See figure

12. With engine level, fill engine with oil to point of

overflowing. Capacity is 1 Va pints. Replace oil fill

plug.

00°

carburetor are empty. Use fresh fuel next season. See

storage section of this manual for additional infor

mation.

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

Spark

____

Muffler

Plug,

Wire

and

Cover

FIGURE 13.

NOTE: Use clean oil and fuel. Store in approved, clean,

covered containers. Use clean fill funnels.

FIGURE 12.

• Fill fuel tank. See figure 13. Use fresh, clean, un

leaded automotive gasoline. Capacity is 3 quarts.

WARNING: FILL TO WITHIN Va INCH OF

TOP OF FUEL TANK TO PREVENT

A

SPILLS AND TO ALLOW FOR FUEL EX

PANSION. IF GASOLINE IS ACCIDENTLY

SPILLED, MOVE LOG SPLITTER AWAY

FROM AREA OF SPILL. AVOID

CREATING ANY SOURCE OF IGNITION

UNTIL GASOLINE VAPORS HAVE DIS

APPEARED.

Caution: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and forma

tion of acids during storage. Acidic gas can damage

the fuel system of an engine while in storage. To avoid

engine problems, the fuel system should be emptied

before storage for 30 days or longer. Drain the gas tank,

start the engine and let it run until the fuel lines and

INITIAL PREPARATION

• Place log splitter on a firm, level surface. For ver

tical operation, remove the quick release pin from

the latch bracket. Place the beam in the vertical posi

tion. Place the quick release pin through the holes

in the beam mounting plates and the brackets on the

reservoir tank. See figure 14.

FIGURE 14.

• Lubricate the beam area where beam will slide with

engine oil (DO NOT USE GREASE). Make certain

to oil both front and back of the beam face.

Page 10

• Fill the reservoir tank as follows.

a. Remove reservoir vent plug. See figure 14. Using

Dexron II automatic transmission fluid, fill reser

voir to the top. Replace vent plug securely.

b. Disconnect the spark plug wire. Prime the pump

by pulling the recoil starter, to turn the engine

over, approximately 10 times. Reconnect the

spark plug wire.

c. Start engine. Use the control handle to extend the

wedge to the far extended position. Leave the

wedge in this position (do not retract).

d. Refill tank to within 1 ¥2" to 2" from the top of the

tank. Total capacity of system is approximately

7.6 gallons.

e. Now retract the wedge. Extend and retract the

wedge fully 10 to 12 complete cycles to remove

trapped air in the system (system is “self

bleeding”).

f. Refill the reservoir to within 1V

top of the tank. Much of the original fluid has been

drawn into the cylinder and hoses. Make certain

to refill the reservoir, to prevent extreme damage

to the hydraulic pump. Failure to refill the tank will

2

" to 2" from the

void your warranty.

NOTE: Some fluid may overflow from the vent plug as

the system builds heat and the fluid expands and seeks

its own level.

TO START ENGINE

• Place throttle control lever on the engine in FAST

position. See figure 15.

• Place choke lever in CHOKE position.

NOTE: A warm engine may not require choking.

• Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope will

pull slightly harder at this point). Let the rope rewind

slowly.

• Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on the starter handle. Let the rope

rewind slowly. Do not let starter handle snap back

against starter.

• Repeat preceding instructions 3 and 4 until engine

fires. When engine starts, move choke lever halfway

between CHOKE and RUN.

• Move throttle control lever to IDLE position for a few

minutes warm-up. Gradually move choke lever to

RUN position as engine warms up.

NOTE: In order to idle smoothly, a new engine may re

quire 3 to 5 minutes running above slow idle speed.

Idle speed has been adjusted to be correct after this

break-in period.

• If weather is cold, run wedge up and down beam 6

to 8 times to circulate the hydraulic fluid, which will

warm and thin the fluid.

WARNING: DO NOT OPERATE THE LOG

SPLITTER WITHOUT THE PROPER

A

AMOUNT OF TRANSMISSION FLUID IN

THE RESERVOIR TANK.

BEFORE STARTING

Before each use, check the following:

• Place log splitter on a firm, level surface. For ver

tical operation, remove the quick release pin from

the latch bracket. Place the beam in the vertical posi

tion. Place the quick release pin through the holes

in the beam mounting piates and the brackets on the

reservoir tank. See figure 14.

• Remove the vent piug and check the fluid level. Fluid

level should be IVa" to 2" from the top of the tank.

IMPORTANT: Reservoir tank must be full as instructed.

Low fluid level will damage the pump and void your

warranty.

• Lubricate the beam area where beam will slide with

engine oil (DO NOT USE GREASE). Make certain

to oil both front and back of the beam face.

• Fill gasoline tank as instructed on page 9.

• Attach spark plug wire and cover to spark plug. See

figure 13.

•

TO STOP ENGINE

• Move throttle control lever to OFF position.

• Disconnect spark plug wire from spark plug to pre

vent accidental starting while equipment is unat

tended.

USING THE LOG SPLITTER

Use the log splitter only on a level, hard surface.

Never stand next to the splitting wedge when

operating the log splitter. Always stand behind the

reservoir tank. See figures 16 and 17. Never attempt

to cut a log in half sideways. Always split the log

lengthwise. Maximum length of log to be split is 24".

10

Page 11

WARNING: ALWAYS USE THE LOG

SPLITTER IN THE VERTICAL POSITION

A

The control handle has three positions:

FORWARD—Push the control handle down for vertical

operation, push it forward for horizontal operationsplitting wedge moves toward the end plate. Con

trol handle will return to neutral position as soon as

handle is released.

NEUTRAL (Middle position)—Splitting wedge stops

in place.

REVERSE—Push the control handle upward for ver

tical operation, push it toward the rear for horizontal

operation—Splitting wedge returns. The control han

dle will lock in the reverse position, and will return

to neutral automatically when the reverse stroke is

complete.

ONLY WHEN SPLITTING HEAVY LOGS.

• Move the control handle to reverse position to return

the splitting wedge.

WARNING: IIF THE FLUID BECOMES EX

CESSIVELY HOT AT ANY TIME DURING

A

OPERATION, STOP THE UNIT AND

ALLOW THE FLUID TO COOL DOWN.

MAXIMUM PERFORMANCE WILL NOT BE

OBTAINED FROM OUR LOG SPLITTER IF

THE FLUID IS TOO HOT. USE EXTREME

CAUTION AS CONTACTING HOT FLUID

COULD RESULT IN SERIOUS PERSONAL

INJURY.

TO OPERATE LOG SPLITTER:

• Set throttle at maximum speed (3450-3600 RPM).

• Place the log upright, on top of end plate for vertical

operation, and on top of beam for horizontal

operation.

• Push the control handle to forward position until the

splitting wedge just contacts the log. Release the

control handle.

• Step behind the reservoir tank (see figures 16 or

17) and push the control handle in forward position

until the log is split.

TO TRANSPORT LOG SPLIHER

• Lower the beam to its horizontal position. Make cer

tain the latch bracket is latched securely around the

tongue and secured with the quick release pin.

• Remove the quick release pin which secures the jack

stand. Pivot it up against the tongue, and secure with

the quick release pin.

• Attach the hitch to a towing vehicle, making certain

to latch securely. Attach the safety chains to the tow

ing vehicle.

ADJUSTMENT

SPLITTING WEDGE

As normal wear occurs, periodically adjust the bolts on

the slide plate (beneath the splitting wedge) as follows

to eliminate the excess; space between the wedge plate

and the beam. See figure 18.

11

Page 12

Hex Bolts

Bolts

FIGURE 18.

• Loosen the three hex bolts on top of the slide plate

(beneath the splitting wedge).

• Back the two adjustment bolts on the side of the slide

plate out slowly until the wedge assembly will slide

on the beam. Tighten the lock nuts securely against

the base of the slide plate to hold the bolts in this

position.

• Retighten the three hex bolts on top of the slide plate.

Start engine and allow to warm for five minutes.

With throttle in FAST position, close needle valve

clockwise (). until engine Starts to lose speed

(lean mixture). Then slowly open needle valve

counterclockwise () until engine JUST BEGINS

to run unevenly. This mixture should be rich enough

for best performance under load.

Place throttle control in IDLE position:

a.

If engine idles, no further adjustment is

necessary.

b.

If engine idles too fast, turn idle speed adjusting

screw counterclockwise ( ) until slower speed

is obtained.

c. If engine dies, turn idle speed adjusting screw 'A

turn clockwise (/^ ). Place throttle control in

FAST position and restart engine.

d. Move throttle control to IDLE position. If engine

does not idle, repeat step c.

• Test the engine by splitting. If engine tends to stall

or die out, it usually indicates that the mixture is

slightly lean and it may be necessary to open ( f~\ )

the needle valve slightly to provide a richer mixture.

This richer mixture may cause a slight unevenness

in idling.

CARBURETOR ADJUSTMENT

WARNING: IF ANY ADJUSTMENTS ARE

MADE TO THE ENGINE WHILE THE

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude or

load.

NOTE: A DIRTY AIR CLEANER WILL CAUSE ENGINE

TO RUN ROUGH. BE CERTAIN AIR CLEANER IS

CLEAN AND ATTACHED TO THE CARBURETOR

BEFORE ADJUSTING CARBURETOR. DO NOT

MAKE UNNECESSARY ADJUSTMENTS. FACTORY

SETTINGS ARE SATISFACTORY FOR MOST AP

PLICATIONS AND CONDITIONS.

Never attempt to change maximum engine speed. It

is pre-set at the factory and shouid be changed only

by a qualified service technician who has the necessary

equipment.

The Carburetor may need re-adjusting if engine lacks

power or does not idle properly. If adjustments are

needed, proceed as follows.

• Close needle valve (see figure 19) clockwise

() finger tight only. Forcing may cause damage.

Then open 1V2 turns counterclockwise ( ).

ENGINE IS RUNNING (e.g. CAR

BURETOR), KEEP CLEAR OF ALL MOV

ING PARTS. BE CAREFUL OF HEATED

SURFACES AND MUFFLER.

MAINTENANCE

WARNING: ALWAYS STOP THE ENGINE

AND DISCONNECT THE SPARK PLUG

A

RESERVOIR FLUID

Check the hydraulic fluid level in the log splitter reser

voir tank before each use. Fluid level should be 1-1/2"

to 2” from the top of the tank.

Change the hydraulic fluid in the reservoir every 100

hours of operation. Disconnect the suction hose from

the bottom of the reservoir tank, and drain the fluid in-

WIRE BEFORE PERFORMING ANY

MAINTENANCE OR ADJUSTMENTS.

12

Page 13

to a suitable container. Refill using only Dexron II

automatic transmission fluid, as instructed in the “In

itial Preparation” section of this manual, page 9. Also,

make certain to change the hydraulic filter.

Capacity is VA pints. Refer to “Gas and Oil Fill-Up”

on page 9.

• Replace oil fill plug.

NOTE: Drain the fluid and flush the reservoir tank and

hoses with kerosene whenever any repair work is per

formed on the tank, hydraulic pump or valve. Con

taminants in the fluid will damage the hydraulic

components. (Should be performed by your SEARS

Service Center.

WARNING: USE EXTREME CAUTION

WHEN WORKING WITH KEROSENE, AS

A

IT IS AN EXTREMELY FLAMMABLE

FLUID.

HYDRAULIC FILTER

Change the hydraulic filter every 50 hours of operation.

Use only a 10 micron hydraulic filter. Order part number

723-0405.

BEAM AND SPLiniNG WEDGE

Lubricate both sides of the beam where it contacts the

splitting wedge with engine oil before each use to ob

tain years of service. However, normal wear will occur.

The wedge plate on the log splitter is designed so the

gibs on the side of the wedge plate can be easily re

moved and rotated and/or turned over for even wear.

Make certain to readjust the adjustment bolts so wedge

moves freely, but no excess space exists between the

wedge plate and beam.

HOSE CLAMPS

Check the hose clamps on the suction hose (attached

to bottom of the pump) for proper tightness before each

use. Check the hose clamps on the return hose at least

once a season.

AIR CLEANER

The air cleaner prevents damaging dirt, dust, etc., from

entering the carburetor and being forced into the engine

and is important to engine life and performance.

Never run your engine without air cleaner complete

ly assembled.

TO SERVICE AIR CLEANER:

Clean cartridge at three month intervals or every 25

hours, whichever occurs first. See figure 20. Service

more often under dusty conditions.

• Loosen screws and tilt cover as illustrated.

• Carfeully remove pre-cleaner and cartridge.

• Clean cartridge by tapping gently on a flat surface.

If very dirty, replace cartridge and pre-cleaner or

clean as follows;

a. Wash in a low or non-sudsing detergent and

warm water solution. CAUTION: Do not use

petroleum solvents such as kerosene to clean

cartridge.

b. Rinse thoroughly with flowing water from inside

out until water is clear.

c. Allow cartridge to stand and air dry thoroughly

before using. DO NOT OIL CARTRIDGE OR

PRE-CLEANER. DO NOT USE PRESSURIZED

AIR TO CLEAN OR DRY CARTRIDGE.

• Install cartridge and pre-cleaner. Then close cover

and fasten screws securely.

Screw

Spacer

ENGINE LUBRICATION

Your four-cycle engine will normally consume some oil;

therefore, check engine oil level regularly—approxi

mately every five hours of operation and before each

usage. Stop engine and wait several minutes before

checking oil level. With engine level, the oil must be

even with the oil fill (refer to figure 12). Change engine

oil after the first five hours of operation, and every

twenty-five hours thereafter.

• Drain oil while engine is warm.

a. Remove oil drain plug. Refer to figure 12. Catch

oil in a suitable container.

b. When engine is drained of all oil, replace drain

plug securely.

• Refill with fresh oil. Above 32°, use oil labeled SAE

30W or 10W30. Below 32°, use oil labeled 5W20.

Pre-Cleaner

Cartridge

Base

FIGURE 20.

CLEAN ENGINE

Clean engine periodically. Remove dirt and debris with

a cloth or brush. Cleaning with a forceful spray of water

is not recommended as water could contaminate the

fuel system.

13

Page 14

Yearly or every 25 hours, whichever occurs first,

remove the blower housing and clean the areas shown

in figure 21 to avoid overspeeding, overheating and

engine damage. Clean more often if necessary.

A

WARNING: NEVER HIT THE PUMP

SHAFT IN ANY MANNER, AS ANY BLOW

WILL CAUSE PERMANENT DAMAGE TO

THE PUMP.

WARNING: PERIODICALLY CLEAN MUF

FLER AREA TO REMOVE ALL GRASS,

A

DIRT AND COMBUSTIBLE DEBRIS.

Clean Out

> Chaff and Dirt

FIGURE 21.

SPARK PLUG

The spark plug should be cleaned and the gap reset

to .030" at least once a season or every 50 hours of

operation. See figure 22. Spark plug replacement is

recommended at the start of each season. Refer to

engine parts list for correct spark plug type.

NOTE: Do not blast clean spark plug. Spark plug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

When replacing the flexible pump coupling, proceed

as follows.

• Place the coupling half onto the engine shaft. Make

certain there is clearance between the coupling half

and the engine. Tighten the set screw.

• Mount the pump onto the coupling support bracket.

Tighten securely.

• Carefully slide coupling half onto pump shaft (make

certain set screw is loose). Slide the key into place

on the shaft.

• Install the nylon “spider” insert into coupling half on

the engine shaft.

• Place the coupling shield in position on the hex bolts.

Rotate the keyway on the pump shaft so it is toward

the bottom.

• Attach the coupling support bracket to the hex bolts,

carefully sliding the coupling half over the “spider”

insert. Secure coupling shield and coupling support

bracket with lock washers and hex nuts. Tighten

securely.

• Adjust the two coupling halves (steel) so there is be

tween .010" and .060" clearance between the two

halves (at least the thickness of a matchbook cover,

up to 1/16" maximum). See figure 23. Tighten the

set screw in the coupling half on the pump shaft.

MUFFLER

Do not operate the log splitter without a muffler or

tamper with the exhaust system. Damaged mufflers or

spark arresters could create a fire hazard. Inspect

periodically, and replace if necessary. If your engine

is equipped with a spark arrester screen assembly,

remove every 50 hours for cleaning and inspection.

Replace if damaged.

FLEXIBLE PUMP COUPLER

The flexible pump coupler is a nylon “spider” insert,

located between the pump and engine shaft. The align

ment is very critical. Over a period of time, the coupler

will harden and deteriorate. For a replacement flexible

pump coupler, order part number 717-0891.

NOTE: Make certain proper clearance is obtained

before tightening set screw.

PUMP

TIRE PRESSURE

Check sidewall of tire for manufacturer’s recommended

maximum tire pressure. If this information does not ap

pear on your tire, maximum tire pressure under any cir

cumstances is 30 p.s.i. Equal pressure should be

maintained on both tires.

14

Page 15

INSTALLATION OF TIRE TO RIM

WARNING: THE FOLLOWING PRO

CEDURE MUST BE FOLLOWED WHEN

A

Be certain rim is clean and free of rust.

Lubricate both the tire and rim generously.

Never inflate to over 30 p.s.i. to seat beads. Ex

cessive pressure when seating beads may cause

tire/rim assembly to burst with force sufficient to

cause serious injury.

It is important to prevent gum deposits from forming

in essential fuel system parts such as the carburetor,

fuel hose or fuel tank during storage. Also, experience

indicates that alcohol blended fuels (called gasohol or

using ethanol or methanol) can attract moisture which

leads to separation and formation of acids during

storage. Acidic gas can damage the fuel system of an

engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow

these instructions.

• Drain the fuel tank. Start the engine, and let it run

until the fuel lines and carburetor are empty.

REMOVING OR INSTALLING A TIRE TO

THE RIM.

OFF-SEASON STORAGE

* •

Remove spark plug, pour approximately ¥2 ounce

(approximately one tablespoon) of engine oil into

cylinder and crank slowly to distribute oii. Replace

spark plug.

• Clean the engine and the entire log splitter

thoroughiy.

• Wipe unit with an oiled rag to prevent rust, especial

ly wedge and beam.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rustproof the equipment by coating with a light

oil or silicone.

• The tongue can be removed and reattached in an

upright position as shown in figure 24 to take less

space when storing.

• Store unit in a ciean, dry area.

WARNING: DO NOT DRAIN FUEL WHILE

A

Drain all the oil from the crankcase (this should be

done after the engine has been operated and is stiil

warm) and refill the crankcase with fresh oil.

Protect the inside of the engine for storage as

follows.

SMOKING, OR IF NEAR AN OPEN FIRE.

FIGURE 24.

15

Page 16

TROUBLE SHOOTING GUIDE

Trouble

Engine fails to start

Engine runs erratic

Possible Cause(s)

1. Fuel tank empty, or stale fuel.

2. Blocked fuel line.

3. Spark plug wire disconnected.

4. Faulty spark plug.

1. Unit running on CHOKE.

2. Spark plug wire loose.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Dirty air cleaner.

6. Carburetor out of adjustment.

Engine overheats 1. Engine oil level low.

2. Air flow restricted.

3. Carburetor not adjusted properly.

Corrective Action

‘1. Fill tank with clean, fresh gasoline.

2. Clean fuel line.

3. Connect wire to spark plug.

4. Clean, adjust gap or replace.

1. Move choke lever to OFF position.

2. Connect and tighten spark plug

wire.

3. Clean fuel line; fill tank with clean

fresh gasoline.

4. Drain fuel tank. Refill with fresh

fuel.

5. Clean air cleaner as instructed in

Maintenance section.

6. Adjust carburetor (see Carburetor

Adjustment in Adjustment section

of this manual).

1. Fill crankcase with proper oil.

2. Remove blower housing and

clean as instructed in

Maintenance section.

3. Adjust carburetor (see Carburetor

Adjustment in Adjustment section

of this manual).

Will not split logs Reservoir fluid level low. Check and fill reservoir tank as

instructed in Operation section

of this manual.

Leaking cylinder 1. Broken seals.

2. Scored cylinder.

1. Replace seals.*

2. Replace cylinder.*

NOTE: For repairs beyond the minor adjustments iisted above, piease contact your nearest SEARS Service

Center.

*Shouid be performed by your SEARS Service Center only.

16

Page 17

IMPORTANT INFORMATION FOR LOG SPLITTER USERS

ALWAYS:

Use clean fluid and check fluid level regularly

Use Dexron II Automatic Transmission Fluid

Use a filter (clean or replace regularly)

Use a breather cap on fluid reservoir

Keep end of reservoir return tube below fluid level

Make certain pump is mounted and aligned properly

Use a flexible “spider” type coupling between engine

and pump driveshafts

Keep hoses clear and unblocked

Bleed air out of hoses before operating

Flush and clean hydraulic system before startup after

any malfunction or servicing

Use “pipe dope” on all hydraulic fittings

Allow time for warmup before splitting wood

Prime the pump before initial startup by turning over

the engine with spark plug disconnected

Split wood with the grain (lengthwise) only

NEVER:

Use fluid below 0° F., or above 150° F.

Use a solid engine/pump coupling

Force pump when mounting

Operate through relief valve for more than several

seconds

Attempt to adjust unloading or relief valve settings

without pressure gauges

Operate with air in hydraulic system

Use Teflon tape on hydraulic fittings

Warm up engine apart from pump in cold weather

Attempt to cut wood across the grain

CONDITIONS WHICH WILL VOID YOUR WARRANTY

1. Failure to maintain proper fluid level in reservoir will void your warranty, causing permanent damage to

pump by allowing air to be drawn into pump. Fluid will become foamy. Refer to “Initial Preparation” in the

Operation Section of this manual.

2. Changing the relief valve setting or pressure adjustment of control valve without proper knowledge and

instruction from the factory will void your warranty. A very minor adjustment could destroy the structural and

safety limits for which the unit was designed. The system will produce more power than the structure will

withstand. Higher pressure could cause the hoses to burst, cylinder to rupture and intense fluid releases,

which could result in serious personal injury.

3. Disassembling the pump will void your warranty. If replacment is necessary, merely disconnect and replace.

Do not attempt to adjust pump settings, as they are adjusted by the manufacturer at the factory.

4. Use of incorrect hydraulic fluid will void your warranty. Use only Dexron II automatic transmission fluid.

Any other type of fluid must be approved by a direct factory representative.

5. The flexible pump coupler must be inspected regularly. Allowing the coupler to deteriorate will void your

warranty. Deterioration of spider insert and prolonged use after deterioration will destroy pump bearings and

engine bearings, along with total destruction of coupler hubs.

6. Improper beam lubrication will cause premature wear and looseness. Lubricate the beam regularly. Lack

of lubrication will void your warranty.

7. Improper adjustment of splitting wedge will void your warranty. Become familiar with the proper tolerance

required for adjustment of the splitting wedge as instructed in the adjustment section of this manual.

a. If wedge is too loose, cylinder beam and wedge wear will result. Allowing the wedge to loosen and be

used under operating stress will cause damage which will not be covered under warranty.

b. If wedge is too tight, severe beam damage will result which will not be covered under warranty.

8. Do not overheat the hydraulic system. Excessive heat will destroy the hydraulic system with hardened 0-rings

and excessive friction.

9. Do not attempt to start in temperatures under 20° F. without pre-heating fluid in reservoir. Excessively

cold fluid cannot circulate and draw into pump. Warranty will be void.

10. Repair any leaks in hydaulic system immediately. Unattended leaks will cause air to enter system and/or

decrease fluid level in reservoir, causing damage to the hydraulic system which will not be covered by warranty.

17

Page 18

HOW YOUR LOG SPLITTER OPERATES

Cylinder Rod

r"

Reservoir

THE PUMP

A two-stage log splitter pump has one large and one

small gear section, using common inlet and outlet ports.

Below a preset pressure (called unloading pressure)

a check valve between the two gear sections allows

both flows to combine. Together, the two gear sections

create a large volume flow which produces rapid

cylinder movement under low load conditions.

Above unloading pressure, a pilot pressure line(which

simulates actual pressure at the cylinder) activates the

unloading valve, which causes the flow to bypass the

large gear section and return to the pump inlet area.

The small gear section is now operating alone, and will

generate the higher pressure necessary for the actual

log splitting operation.

The original factory setting for the unloading valve is

designed to provide maximum flow while remaining

below engine stalling load. Note: Splitting capability

is not affected by the setting of the unioading valve.

Do not attempt to adjust or reset it without a

pressure gauge (should be performed by an

authorized SEARS Serve Center only).

THE DIRECTIONAL VALVE AND CYLINDER

From the pump, oil flows to a four way, three position

directional valve. At the neutral position this valve

directs the flow back to the oil reservoir, bypassing the

cylinder. When the directional valve is directing the flow

to the back of the cylinder, the cylinder rod extends

quickly until it meets significant resistance. Upon

reaching unloading pressure, movement of the shaft

High Volume

Low Pressure

Gear Section

Cylinder

Piiot

Pressure

Line

Pump

Low Voiume

High Pressure

Gear Section

will slow but will continue forward. If the pressure

reaches a preset maximum (called relief valve pressure)

the relief valve, located within the directional valve, will

allow the flow to bypass the cylinder and return to the

reservoir. This can happen when the cylinder rod meets

excessive resistance, or when it reaches the end of its

stroke and can move no farther.

Note: Never operate at relief valve pressure for more

than a few seconds.

When the directional valve is directing the flow to the

front of the cylinder, the rod will retract quickly since

it is encountering no resistance. The relief valve will

momentarily bypass the flow at the end of the return

stroke but the directional valve should then automatical

ly return to the neutral position, directing the flow direct

ly into the reservoir. This serves to protect the pump

from possible damage due to prolonged operation at

relief valve pressure.

Because of the potential for system damage, the relief

valve is carefully and precisely preset by the

manufacturer.

Note: The user should not attempt to adjust or

change the setting of the relief valve.

OPERATIONAL PROBLEMS

If you have trouble with your log splitter, please refer

to the Hydraulic Trouble Shooting Guide on page 19.

Note: Readjustment of valves or disassembly of

pump should be performed by your SEARS Service

Center only.

18

Page 19

HYDRAULIC TROUBLE SHOOTING GUIDE

Problem Probable Cause(s)

Cylinder rod will not

move

Slow cylinder shaft

speed while

extending and

retracting

Engine runs but

wood will not split,

or wood splits too

slowly

A Broken driveshaft

B Loose shaft coupling

C Gear sections damaged

D Damaged relief valve

E Hydraulic lines blocked

F Too little oil to pump

G Damaged directional valve

H Blocked directional valve

A Gear sections damaged

B Excessive pump inlet vacuum

C Slow engine speed

D Damaged relief valve

E Too little oil to pump

F Air in oil

G Directional valve leaking internally

H Internally damaged cylinder

A Small gear section damaged

B Pump check valve leaking

C Excessive pump inlet vacuum

D Low relief valve setting

E Too little oil to pump

F Air in oil

G Directional valve leaking internally

H Overloaded cylinder

1 Internally damaged cylinder

Corrective Action

A Return unit for authorized repair

B Correct engine/tpump alignment as necessary

C Return unit for authorized repair

D Return directional valve for authorized repair

E Flush and clean hydraulic system

F Add oil to reservoir

G Return unit for authorized repair

H Flush and clean hydraulic system; return

unit for authorized repair

A Return unit for authorized repair

B Make certain pump inlet hoses are clear

and unblocked—use short, large

diameter inlet hoses

C Return unit for authorized repair

D Return unit for authorized repair

E Add oil to reservoir

F Add oil, clean reservoir, make certain oil

return tube is below oil level

G Return unit for authorized repair

H Return unit for authorized repair

A Return unit for authorized repair

B Return unit for authorized repair

C Make certain pump inlet hoses are

clear and unblocked; use short, large

diameter inlet hoses

D Adjust valve while using pressure gauge*

E Add oil to reser/oir

F Add oil, clean reservoir, make certain oil

return tube is below oil level

G Return unit for authorized repair

H Do not attempt to split wood against the grain

1 Return unit for authorized repair

Engine stalls during

splitting

Engine will not turn

or stalls under low

load conditions

Leaking pump shaft

seal

'Should be performed by an authorized SEARS Service Center only.

A Low horsepower/weak engine

B High relief valve setting

C High unloading valve setting

D Overloaded cylinder

A Engine/pump misalignment

B Frozen or seized pump

C Low horsepower/weak engine

D Hydraulic lines blocked

E Blocked directional valve

A Broken driveshaft

B Engine/pump misalignment

C Gear sections damaged

D Poorly positioned shaft seal

E Plugged oil breather

A Return unit for authorized repair

B Adjust valve while using pressure gauge*

C Adjust valve while using pressure gauge*

D Do not attempt to split wood against the grain

A Correct alignment as necessary

B Return unit for authorized repair

C Return unit for authorized repair

D Flush and clean hydraulic system

E Flush and clean hydraulic system; return

unit for authorized repair

A Return unit for authorized repair

B Correct alignment as necessary

C Return unit for authorized repair

D Return unit for eiuthorized repair

E Make certain reservoir is properly vented

19

Page 20

SEARS CRAFTSMAN 5 H.P. LOG SPLITTER MODEL NO. 247.287751

Repair Parts

20

Page 21

SEARS CRAFTSMAN 5 H.P. LOG SPUTTER MODEL NO. 247.287751

Repair Parts

:ey

10.

PART

NO.

1 736-0119

710-0117

2

710-0237 Hex Bolt 5/16-24 x .62" Lg.

3

4 710-0363 Hex Bolt 5/16-24 X 4" Lg.

712-0123 Hex Nut 5/16-24 Thd.

5

714-0122 Sq.-Key 3/16 x .75

6

7 717-0891 Flexible Coupling

L-Wash. 5/16" I.D.*

Hex Bolt 5/16-24 X 1" Lg. 50

DESCRIPTION

8 717-0936 Two Volume Pump

9 719-0278

726-0132

10

Coupling Shield

Hose Clamp 5/8" 63

11 727-0427 Suction Hose 1" I.D.

12 727-0432 High Pressure Hydraulic

Hose 56"

13 721-0168 Bearing Seal

14 781-0097 Rear Coupling Support Brkt.

781-0098 Front Coupling Support Brkt.

15

16 781-0337A

17 710-0409 Hex Bolt 5/16-24 x 1.75" Lg.*

18 710-3160 Hex Bolt 1/2-20 x 4" Lg.—Gr. 5

712-0123 Hex Nut 5/16-24 Thd.*

19

Tank Ass’y. Complete

20 712-0333 Nut 1/2 BL NF-20

21 736-0119 L-Wash. 5/16" I.D.*

22

736-0921

23 737-0236

24 750-0739 Pivot Bushing .75" O.D.

781-0312

25

26 735-0639 Spark Plug Cover

27

723-0405

29

723-0406

30 726-0146

31 727-0309 Return Hose %" |.D. x 30" Lg.

32 737-0235 %" Dia. Hose Barb

33 712-0359 Slotted Nut 3A-16 Thd.

34 714-0162

734-0873

35

734-1016

36

734-0872

734-1017 Rim Only

734-0255

37 741-0107

38

736-0351

40 710-0117

41

710-0514

42

710-3029

43 711-0820

44

712-0123

45 712-3017

712-3067

46

47

736-0119

736-0169

48

L-Wash. 1/2" I.D.*

Pipe Plug

Strainer Ass’yFilter Element

Filter Head

Adjustable Hose Clamp

Cotter Pin 5/32"

Hub Cap

Wheel Ass’y. Comp.

Tire Only

Air Valve

Roller Bearing w/Race

FI-Wash. .760" I.D. X 1.5" O.D.

Hex Bolt 5/16-24 x 1" Lg.*

Hex Bolt 3/8-16 X 1" Lg.-Gr. 5

Hex Bolt 7/16-20 X 1.25" Lg.—

Gr. 5

Quick Release Pin

Hex Nut 5/16-24 Thd.*

Hex Nut 3/8-16 Thd.—Gr. 5

Hex Patch L-Nut 7/16-20 Thd.

L-Wash. 5/16" I.D.*

L-Wash. 3/8" I.D.*

KEY

NO.

PART

NO.

736-0171

49

781-0315 Beam Mtg. Plate

781-0334

51

52

781-0340 Vertical Beam Ass’y.

57

130202-3116-01

60 717-0885B

61 714-0203 External Cotter Pin

62 715-0206 Cylinder Mtg. Pin

717-0942

64

727-0307

727-0440

65

66 737-0171

67 737-0192

L-Wash. 7/16" I.D.*

Beam Latch Bracket

Engine—Briggs & Stratton

5 H.P. No. 130202-3116-01

Hydraulic Cylinder 4" Dia.

Control Valve—3200 PSI

Metal Pressure Tube Vz" O.D.

Pressure Tube Vz" Dia.

90° Solid Male Adapter

90° Solid Male Adapter

DESCRIPTION

68 737-0235 %" Dia. Hose Barb

69 737-0238 Pipe Nipple Vz NPT

73 710-1010

74

710-1018

710-1032

75

76

712-0239 Hex L-Nut 1/2-20 Thd.

77

712-0333 Nut 1/2 BL NF-20 Thd.

712-3001

78

79 736-0921

80 750-0743

81 781-0323B

87 781-0345A

88 781-0350A

89 781-0351

90 781-0352A

91

781-0356

710-0521

95

96 710-3130

97

711-0820

99 712-0375

100 712-0798

101

713-0338 Chain—Tow Hitch

102 727-0311

103 736-0169

104

736-0185

750-0507

105

106 781-0316

107

781-0358

710-3144

113

114

712-0430

116 781-0168A

117

720-0231

118 747-0709

—

770-6741F

Hex Bolt 1/2-20 X 3" Lg. (Gr. 8)

Hex Bolt 1/2-20 X 2.75" Lg.—

Gr. 8

Hex Bolt 3/8-24 X 1.5" Lg.

Hex Jam Nut 3/8-24 Thd.—Gr. 5

L-Wash. 1/2" I.D.

Spacer 3/8" I.D. X 3/4" O.D.

Wedge Mtg. Ass’y.

Pusher Back Plate

Fixed Side Gib

Adj. Gib 2" Lg.

Adj. Gib Shim 10" Lg.

Floating Gib Plate

Hex Bolt 3/8-16 X 3" Lg.-Gr. 8

Hex Bolt 3/8-16 X 3.25" Lg.—

Gr. 8

Quick Release Pin

Hex L-Nut 3/8-16 Thd.

Hex Nut 3/8-16 Thd.*

Hitch Coupler

L-Wash. 3/8

FI-Wash. .406" I.D. X .75

Spacer .38" I.D. X .625" O.D.

Tongue Tube

Jack Stand Ass’y.

Hex Bolt 3/8-16 X 2" Lg.-Gr. 5

Hex Insert L-Nut 3/8-16 Thd.

Stripper Half

Ball Knob

Control Handle

Owner’s Manual

"Common Hardware—May be Purchased Locally.

21

Page 22

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130202-3116-01

Repair Parts

SEE REPAIR

INSTRUCTION

MANUAL.

22

Page 23

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130202-3116-01

Repair Parts

1

\

30^

32 4

29

28

615

★ SPEQALTDOLS RKHJIREO

TO INSTALL

SEE REBMR INSTBUCTtON

■>5 MANUAL

|358 GASKET SEfI

tlOIODECflKifl

22

23

Page 24

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130202-3116-01

Repair Parts

24

Page 25

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130202-3116-01

Repair Parts

KEY

NO.

1

2

PART

NO.

395990

297565

Cylinder Assembly

Bushing—Cylinder

Note: Requires special tools

for installation.

3

5

7

8

9

10

11

12

13

14 93369

15

299819 Seal—Oil

211542

*270383

294178

*27549

93394 Screw—Breather Mtg. Sem

66578

*270080

*270125

*270126

93368

91249

Head—Cylinder

Gasket—Cylinder Head

Breather—Valve Chamber

Gasket—Valve Cover

Grommet—Breather Tube

Gasket—Crankcase—.015"

Thick (Standard)

Gasket—Crankcase—.005"

Thick

Gasket—Crankcase—.009"

Thick

Screw—Cylinder Head

(2-3/32" Long)

Screw—Cylinder Head

(2-15/32" Long)

Plug—Pipe, 1/4" Std. Square

Head

To Replace Crankshaft Gear

Pin, Order Part No. 230978

16

18

19

397103

398078

297603

Crankshaft

Cover Ass’y.—Crankcase

Bushing—Crankcase Cover

Note: Requires special tools

for installation.

20

21 66768 Plug—Oil Filler

22

23

24 222698

25

294606 Seal—Oil

93032

297229

298904 Piston Ass’y —Standard

298905

298906

298907

Screw—Crankcase Cover

Mounting Sem

Flywheel—Magneto

Key—Flywheel

Piston Ass’y.—.010" O.S.

Piston Ass’y.—.020" O.S.

Piston Ass’y.—.030" O.S.

PISTON RING SETS:

Note: For Chrome Piston Ring

Set—Standard Size—Order

Part No. 299742.

26

27 26026

28

29 299430

298982

298983 Ring Set—.010" O.S. Piston

298984

298985 Ring Set—.030" O.S. Piston

298909

298908 Pin Ass’y.—Piston—.005" O.S.

Ring Set—Standard Piston

Ring Set—.020" O.S. Piston

Lock—Piston Pin

Pin Ass’y.—Piston—Standard

Rod Ass’y.—Connecting

Note: For Connecting Rod

with .020" undersize Crankpin

30

31 221876

32

33

221890

92296 Screw—Connecting Rod

211119

Bore—Order No. 390459.

Dipper—Connecting Rod

Lock—Conn. Rod Screw

Valve—Exhaust

DESCRIPTION

KEY

NO.

34

35

36

37 222443

40

45

46 212733

52 *271936 Gasket—Carburetor Mounting

55

56

57 490179 Spring-Rewind Starter

58

59 230228

60 66728

65

66

67

68 63770 Ball—Clutch

70 298799 Ratchet—Rewind Starter

71 394506 Washer—Clutch Retainer

73 221923 Screien—Starter Pulley

74

75 224061

81 222263 Lock—Screw (3/8" Dia.

90 490533

95 93499 Screw—Throttle Valve to Shaft

96 223793

97

108

118

124 93357 Screw-Hex. Head

127 220352 Plug—Welch

127A 223789 Plug-Welch (Mixing Chamber)

127B 223472

149 26336

152

153 490589 Screw Ass’y.

154 93527

163 271935

180

181

190

191

200 223886

201

202

203 280720 Crank—Bell

204 222962 Bushing—Governor Lever

PART

NO.

261044

260552 Spring—Intake Valve

26478 Spring—Exhaust Valve

93312

260642 Tappet—Valve

299431 Housing—Rewind Starter

295871 Pulley—Rewind Starter

66884 Rope—Rewind Starter—63"

94128 Scrfiw—Stamped Steel

399671

394897 Housing—Starter Clutch

93490 Scr(}w—Sem

490048 Shaft and Lever—Throttle

491177

231533

260575 Spring—Throttle Adjustment

490554

490075 Cap—Fuel Tank

94094

*271928 Gasket—Fuel Tank Mounting

262280

262270

Valve—Intake

Guard—Flywheel

Retainer—Valve Spring

Gear—Cam

(2)

Long

If longer rope is required,

order rope No. 66894 and cut

to length.

Pin—Starter Grip

Grip—Starter Rope

Housing Mtg. Sem

Clutch Ass’y.—Rewind Starter

Washer—Spring

Bolt Holes)

Carburetor Assembly

Sem

Throttle—Carburetor

Valve Group—Choke

Valve—Needle

Plug—Welch (Well)

Spring—Needle Valve

Screw—Machine, Rd. Hd.—

5-40 X 5/8"

Gasket—Air Cleaner Mounting

Tank Assembly—Fuel

Screw—Fuel Tank Mounting

Sem

Guide—Air

Link—Governor

Link—Throttle

(Flat)

DESCRIPTION

25

Page 26

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130202-3116-01

Repair Parts

KEY

NO.

205

208

209

216

219

220

222 490649 Bracket—Control

223

224 93491 Rivet—Governor Control Lever

227

230

256

300 393615

304

305

306

307

308

333 397358 Armature Assembly

335

337 298809 Plug—Spark IV2" High—

346

356

358

373

383

392 262328

394

414

432

433

434

435

467

526

527 223786

528

529

PART

NO.

231520 Screw—Shoulder

262279

262283 Spring—Governor

262359

391737 Gear—Governor

221551

223455 Lever—Governor Control

490374 Lever Ass’y-—Governor

222450

223813

490169 Housing—Blower

93158 Screw—Blower Housing

221511 Shield—Cylinder

93490 Screw—Cylinder Shield

221512 Cover—Cylinder Head

93414 Screw—Armature Mtg. Sem

93705

398808 Wire—Ground

397145 Gasket Set

92987 Nut—Hex

89838

270026 Diaphragm

220982 Washer

221377

93265

210959 Cover—Diaphragm

93141 Screw—Diaphragm Cover

280715 Knob—Control

94409 Screw—Tank Bracket

231526 Tube—Breather

67838

Rod—Control

Link—Choke

Washer—Thrust

Mounting

Washer—Governor Lever

Crank—Bell

Muffler—Exhaust

Mounting

Mounting Sem

Screw—Sem

Wrench—Spark Plug

Spring—Fuel Pump Diaphragm

Cap—Spring

Pin—Diaphragm Cover

Mounting Sem

Clamp—Breather Tube

Grommet—Breather Tube

DESCRIPTION

37-42 M.M.

KEY

NO.

535 491435

542

552 231079

562 92613

592

608

611

613 93935 Screw—Hex. Hd. Shoulder

614 93306 Cotter—Hairpin

615

616

621 396847 Switch—Stop

634 271853

643

643A

655

676

679

680

741 261696

779

851

869

870

871 262001 Guide—Exhaust Valve

916

966

967 491588

968

969 490073

971 94018 Screw—Air Cleaner

987 398970 Seal—Throttle Shaft

995

1012

1016

1019

PART

NO. DESCRIPTION

Element—Air Cleaner

93572

231082 Nut—Hex.—10-24

390463 Starter Ass’y.—Rewind

391813 Fuel Pipe and Clip Assembly

93307

231077 Crank—Governor (V

280737

280726 Retainer—Air Filter

222598 Anchor Spring

393757

270382

221839 Washer Choke Shaft (Brass)

262276 Link—Bell Crank

221798 Cable Terminal—Ignition

211787 Seat—Intake Valve (Standard)

211172

280321 Gear Rack—Governor

490074 Base—Air Cleaner

223765

223887

490507 Link—Retainer

490817 Spacer

491100 Decal (Label) Kit

Screw

Bushing—Governor Crank

(1/4" I.D.)

Boit—Governor Lever

Retainer—E-Ring

4

" Dia.)

Washer—Throttle Shaft (Foam)

Retainer—Foam Element

Deflector—Exhaust

Washer Choke Shaft (Foam)

Gear—Timing

Seat—Exhaust Valve

(Standard)

Note: For Options see Repair

Manual.

Note: 63709 Guide—Intake

Valve. See Repair Instruction

Manual.

Filter—Air

Cover—Air Cleaner

Screw—Cover Mtg.

Link Bracket

"Included in Gasket Set-

Part No. 397145.

26

Page 27

OWNER’S

MANUAL

CRAFTSMAN®

5 HORSEPOWER

20 TON

HYDRAULIC LOG SPLITTER

MODEL NO.

247.287751

HOW TO ORDER

REPAIR PARTS

Each log splitter has its own model number. Each engine

has its own model number.

The model number for your log splitter will be found on

a label attached to the frame.

The model number for the engine will be found on the

blower housing of the engine adjacent to the spark plug.

All parts listed herein may be ordered through Sears,

Roebuck and Co. Service Centers and most Retail Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE

THE FOLLOWING INFORMATION:

* PRODUCT - “20 Ton Hydraulic Log Splitter”

* MODEL NUMBER - 247.287751

* ENGiNE MODEL NO. - 130202-3116-01

SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

770.6741 F 8/90

* PART NUMBER

* PART DESCRiPTiON

“Your Sears merchandise has added value when you

consider that Sears has service units nationwide staffed

with Sears trained technicians... professional technicians

specifically trained on Sears products, having the parts,

tools and equipment to insure that we meet our pledge

to you.. .we service what we sell.”

Printed in U.S.A.

Loading...

Loading...