Page 1

Owner’s Manual

Riding Mower

Model No.

247.27022

CAUTION: Before

using this product,

read this manual and

follow all safety rules

and operating

instructions.

For answers to your questions about this product, call:

1-800-659-5917

Sears Craftsman Help Line

(5 am. - 5 pm., Mon. - Sat.)

Sears, Roebuck And Co., Hoffman Estates, IL 60179 U.S.A.

Visit our website; www.sears.com/craftsman

Printed in U.S.A.

>, ■ ■VV.WV.n w..

Safety

Operation

Maintenance

Storage

Español, Page 47

FORM NO. 769-00704A

(5/2003)

Page 2

TABLE OF CONTENTS

Content Page Content Page

Warranty Information..................

Safe Operation Practices

...........

Assembly....................................

Operation....................................

Maintenance...............................

Service & Adjustment.................

.............

.............

.............

.............

.............

.............

2

3

6

8 Slope Guide

13 Español

Off-Season Storage

Trouble-Shooting

Parts List

....................................

.......................

...............................

......................................

...................

16 Service Phone Numbers

............

...............

...............

...............

...............

...............

...............

23

23

25

45

47

Back Cover

RRANTY INFORMATION

LIMITED WARRANTY ON RIDING MOWER; For two (2) years from the date of purchase, if this Craftsman Riding Equipment is

maintained, lubricated and tuned up according to the instructions in the owner's manual, Sears will repair or replace free of

charge any parts that are found to be defective in material or workmanship according to the guidelines of coverage listed below.

Sears will also provide free labor for these applicable warranted parts for the two full years. During first 30 days of purchase,

there will be no charges to service the product at your home for issues covered by this warranty. (See exclusions below).

Foryour convenience, IN HOME warranty service will still be available afterthe first 30 days of purchase, but a trip charge will

apply. This charge will be waived if the product is dropped off at an authorized Sears location. For the nearest authorized Sears

location, please call 1-800-4-MY-HOME®. This warranty applies only while this product is within the United States.

EXCLUSIONS

This Warranty does not cover;

• Expendable items which become worn during normal use, including but not limited to blades, spark plugs, air cleaners,

belts, and oil filters.

* Standard Maintenance Servicing, oil changes or tune-ups

* Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, slumps, or glass.

• Repairs necessary because of operator abuse, including but not limited to, damage caused by towing objects beyond the

capability of the riding equipment, impacting objects that bend the frame or crankshaft, or over-speeding the engine.

* Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage caused

by improper storage, failure to use the proper grade and amount of engine oil, failure to keep the deck clear of flammable

debris, or failure to maintain the equipment according to the instructions contained in the owner’s manual.

* Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale), in general, fuel

should be used within 30 days of its purchase date.

• Norma! deterioration and wear of the exterior finishes, or product labei replacement.

• Riding equipment used for commercial or rental purposes.

LIMITED WARRANTY ON BATTERY

For ninety (90) days from date of purchase, if any battery included with this riding equipment proves defective in material or

workmanship and our testing determines the battery will not hold charge. Sears will replace the battery at no charge. During the

first 30 days of purchase, there wiii be no charges to replace the battery at your home. Afterthe first 30 days, foryour

convenience, IN-HOME warranty service will still be available but a trip charge will apply. This charge will be waived if the

Craftsman product is dropped of at an authorized Sears location. For the nearest authorized Sears location, please call 1 -800-4MY-HOME®. This battery warranty applies only while this product is within the United States. This warranty gives you specific

legal rights, and you may also have other rights, which vary, from state to state.

Sears, Roebuck and Co.,Dept.817WA, Hoffman Estates, IL60179

PRODUCT SPECIFICATIONS

Horsepower:

Engine Oil

Fuel

..............................

Spark Plug:

Engine:

ignition Key (Std.)

.................

.....................

...................

.........................

.........

............

............

............

............

............

............

10.0

48 oz. or 1.4 iiters

Unleaded Regular

P/N 491055

212907-0272

P/N 725-0201

Model Number

Serial Number..........................................................

Date of Purchase.....................................................

Record both serial number and date of purchase and keep

in a safe place for future reference.

...........................

247.27022

Page 3

PAIR PROTECTION AGREEMENT

Congratulations on making a smart purchase.Your new

Craftsman® product is designed and manufactured for years

of dependable operation. But like al! products, it may require

repair from time to time. That’s when having a Repair

Protection Agreement can save you money and aggravation.

Here’s what's included in the Agreement;

. Expert service by our 12,000 professional repair

specialists

Unlimited service and no charge for parts and

labor on all covered repairs

Product replacement if your covered product can’t

be fixed

Discount of 10% from regular price of service and

service-related parts not covered by the agreement;

also, 10% off regular price of preventive maintenance

check

Fast help by phone ~ phone support from a Sears

technician on products requiring in-home repair, plus

convenient repair scheduling

MPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol—heed its warning.

Purchase a Repair Protection Agreement now and protect

yourself from unexpected hassle and expense.

Once you purchase the Agreement, a simple phone call is ail

that it takes for you to schedule service. You can call anytime

day or night, or schedule a service appointment online. Sears

has over 12,000 professional repair specialists, who have

access to over 4.5 million quality parts and accessories.

Thai’s the kind of professionalism you can count on to help

prolong the life of your new purchase for years to come.

Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and

additional information call 1-800-827-6655. Sears Installation

Service

For Sears professional installation of home appliances,

garage door openers, water heaters, and other major home

items, in the U.S.A. call 1-800-4-MY-HOME®

WARNING: The Battery and Engine Exhaust contains chemicals known to the State of California

A

to cause cancer, birth defects or other reproductive harm. The battery and posts contain lead;

wash hands after handling.

WARNING: This machine was built to be operated according to the rules for safe operation in this

A

manual. As with any type of power equipment, carelessness or error on the part of the operator can result in

serious injury. This machine is capable of amputating hands and feet and throwing objects. Failure to

observe the following safety instructions could result in serious injury or death.

General Operation

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Save this manual for future and

regular reference and for ordering replacement parts.

2. Be familiar with all controls and their proper operation.

Know how to stop machine and disengage them quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand operation instructions and safety rules in this

manual and should be trained and supervised by parent.

4. Never allow adults to operate this machine without

proper instruction.

5. To help avoid blade contact or a thrown object injury,

keep bystanders, helpers, children and pets at least 75

feet from the machine while it is in operation. Stop

machine if anyone enters the area.

6. Thoroughly inspect the area where the equipment is to

be used. Remove all stones, sticks, wire, bones, toys,

and other foreign objects which could be picked up and

thrown by the blade(s). Thrown objects can cause

serious personal injury.

7. Plan your mowing pattern to avoid discharge of material

toward roads, sidewalks, bystanders and the like. Also,

avoid discharging material against a wall or obstruction

which may cause discharged material to ricochet back

toward the operator.

8. Always wear safety glasses or safety goggles during

operation and while performing an adjustment or repair to

protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

9. Wear sturdy, rough-soled work shoes and close-fitting

slacks and shirts. Loose fitting clothes and jewelry can be

caught in movable parts. Never operate this machine in

bare feet or sandals.

Page 4

10. Be aware of the mower and attachment discharge

direction and do not point it at anyone. Do not operate the

mower without the discharge cover or entire grass

catcher in its proper place.

11. Do not put hands or feet near rotating parts or under the

cutting deck. Contact with the blade(s) can amputate

hands and feet.

12. A missing or damaged discharge cover can cause blade

contact or thrown object injuries.

13. Stop the blade(s) when crossing gravel drives, walks, or

roads and while not cutting grass.

14. Watch for traffic when operating near or crossing

roadways. This machine is not for use on public roadway.

15. Do not operate the machine while under the influence of

alcohol or drugs.

16. Mow only in daylight or good artificial light. Never carry

passengers.

17. Disengage blade(s) before shifting into reverse. Back up

slowly. Always look down and behind before and while

backing to avoid a back-over accident.

18. Slow down before turning. Operate the machine

smoothly. Avoid erratic operation and excessive speed.

19. Disengage blade(s), set parking brake, stop engine and

wait until the blade(s) come to a complete stop before

removing grass catcher, emptying grass, unclogging

chute, removing any grass or debris, or making any

adjustments.

20. Never leave a running machine unattended. Always turn

off blade(s), place transmission in neutral, set parking

brake, stop engine and remove key before dismounting.

21. Use extra care when loading or unloading the machine

into a trailer or truck. This unit should not be driven up or

down ramp{s), because the unit could tip over, causing

serious persona! injury. The unit must be pushed

manualiy on ramp(s) to load or unload properly.

22. Muffler and engine become hot and can cause a burn. Do

not touch.

23. Check overhead clearances carefully before driving

under low tree branches, wires, door openings etc.,

where the operator may be struck or pulled from the unit,

which could result in serious injury.

24. Disengage all attachment clutches, depress the brake

pedal completely and shift into neutral before attempting

to start engine.

25. Your machine is designed to cut normal residential grass

of a height no more than 10". Do not attempt to mow

through unusually tall, dry grass (e.g., pasture) or piles of

dry leaves. Dry grass or leaves may contact the engine

exhaust and/or build up on the mower deck presenting a

potential fire hazard.

26. Use only accessories and attachments approved for this

machine by the machine manufacturer. Read,

understand and follow all instructions provided with the

accessory or attachment.

27. Data indicates that operators, age 60 years and above,

are involved in a large percentage of tractor-related

injuries. These operators should evaluate their ability to

operate the tractor safely enough to protect themselves

and others from serious injury.

28. If situations occur which are not covered in this manual,

use care and good judgment. Contact Sears service

center for assistance.

Slope Operation

Slopes are a major factor related to loss of control and tip

over accidents which can result in severe injury or death. All

slopes require extra caution. If you cannot back up the slope

or if you feel uneasy, do not mow it.

For safety, use the slope guide on page 45 to measure

slopes before operating this unit on a sloped or hilly area. If

the slope is greater than 15 degrees as shown on the slope

gauge, do not operate this unit there.

Do:

1. Mow up and down slopes, not across. Exercise extreme

caution when changing direction on slopes.

2. Watch for holes, ruts, bumps, rocks, or other hidden

objects. Uneven terrain could overturn the machine. Tail

grass can hide obstacles.

3. Use slow speed. Choose a low enough speed setting so

that you will not have to stop or shift whiie on the slope.

Tires may lose traction on slopes even though the brakes

are functioning properly. Always keep machine in gear

when going down slopes to take advantage of engine

braking action.

4. Follow the manufacturer’s recommendations for wheel

weights or counterweights to improve stability of the

machine. Use extra care with grass catchers or other

attachments. These can change stability of the machine.

5. Keep ail movement on the slopes slow and gradual. Do

not make sudden changes in speed or direction. Rapid

engagement or braking could cause the front of the

machine to lift and rapidly flip over backwards which

could cause serious injury.

6. Avoid starling or stopping on a slope. If tires lose traction,

disengage the blade(s) and proceed slowly straight down

the slope.

Do Not:

1. Do not turn on slopes unless necessary; then, turn slowly

and gradually downhill, if possible.

2. Do not mow near drop-off sites, ditches or embankments.

The mower could suddenly turn over if a wheel is over the

edge of a cliff, ditch, or if an edge caves in.

3. Do not try to stabiiize the machine by putting your foot on

the ground.

4. Do not use a grass catcher on steep slopes.

5. Do not mow on wet grass. Reduced traction could cause

sliding.

6. Do not shift to neutral and coast downhill. Over-speeding

may cause the operator to lose control of the machine

resulting in serious injury or death.

Children

1. Tragic accidents can occur if the operator is not alert to

the presence of children. Children are often attracted to

the machine and the mowing activity. They do not

understand the dangers. Never assume that children will

remain where you last saw them.

a. Keep children out of the mowing area and in

watchful care of a responsible adult other than the

operator.

b. Be alert and turn machine off if a child enters the

area.

c. Before and while backing, look behind and down

for small children.

Page 5

d. Never carry children, even with the blade(s) shut

off. They may fali off and be seriously injured or

interfere with safe machine operation.

e. Use extreme care when approaching blind

corners, doorways, shmbs, trees or other objects

that may block your vision of a child who may run

into the machine.

f. Disengage the cutting blade(s) before shifting in

reverse. The “No-Cut-ln Reverse” feature

emphasizes not to cut in reverse and to avoid

back-over accidents; do not defeat it.

g. Keep children away from hot or running engines.

They can suffer burns from a hot muffler.

h. Remove key when machine is unattended to

prevent unauthorized operation.

2. Never allow children under 14 years old to operate the

machine.Children14 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised by a

parent.

Safe Handling Of Gasoline

1. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers away from your vehicle before filling.

c. When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment

on a trailer with a portable container, rather than

from a gasoline dispenser nozzle.

d. Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling

is complete. Do not use a nozzle lock-open

device.

e. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

f. Never fuel machine indoors.

g. Never remove gas cap or add fuel while the

engine is hot or running. Allow engine to cool at

least two minutes before refueling.

h. Never over fill fuel tank. Fill tank to no more than

Va inch below bottom of filler neck to allow space

for fuel expansion.

i. Replace gasoline cap and tighten securely.

j. if gasoline is spilled, wipe it off the engine and

equipment. Move unit to another area. Wait 5

minutes before starting the engine.

k. To reduce fire hazards, keep machine free of

grass, leaves, or other debris build-up. Clean up

oil or fuel spillage and remove any fuel soaked

debris.

l. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace,

clothes dryer or other gas appliances.

m. Allow a machine to cool at least 5 minutes before

storing.

General Service

1. Never run an engine indoors or in a poorly ventilated

area. Engine exhaust contains carbon monoxide, an

odorless, and deadly gas.

2. Before cleaning, repairing, or inspecting, make certain

the blade(s) and all moving parts have stopped.

Disconnect the spark plug wire and ground against the

engine to prevent unintended starting.

3. Periodically check to make sure the blades come to

complete stop within approximately (5) five seconds after

operating the blade disengagement control. If the blades

do not stop within the this time frame, your unit should be

serviced professionally by an authorized dealer.

4. Check brake operation frequently as it is subjected to

wear during normal operation. Adjust/service as required.

5. Check the blade(s) and engine mounting bolts at

frequent intervals for proper tightness. Also, visually

inspect blade(s) for damage (e.g., excessive wear, bent,

cracked).

Replace the blade(s) with the original equipment

manufacturer's (O.E.M.) blade(s) only, listed in this

manual. “Use of parts which do not meet the original

equipment specifications may lead to improper

performance and compromise safety!”

6. Mower blades are sharp. Wrap the blade or wear gloves,

and use extra caution when servicing them.

7. Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

8. Never tamper with the safety interlock system or other

safety devices. Check their proper operation regulariy.

9. After striking a foreign object, stop the engine, disconnect

the spark plug wire(s) and ground against the engine.

Thoroughly inspect the machine for any damage. Repair

the damage before starting and operating.

10. Never attempt to make adjustments or repairs to the

machine while the engine is running.

11. Grass catcher components and the discharge cover are

subject to wear and damage which could expose moving

parts or allow objects to be thrown. For safety protection,

frequently check components and replace immediately

with original equipment manufacturer’s (O.E.M.) parts

only, listed in this manual. “Use of parts which do not

meet the original equipment specifications may lead to

improper performance and compromise safety!“

12. Do not change the engine governor settings or over

speed the engine. The governor controls the maximum

safe operating speed of the engine.

13. Maintain or replace safety and instruction labels, as

necessary.

14. Obsen/e proper disposal laws and regulations for gas,

oil, etc. to protect the environment.

Your Responsibility

Restrict the use of this power machine to persons who

read, understand and follow the warnings and instructions

in this manual and on the machine.

Page 6

ASSEMBLY

Unpacking

1. Remove all screws and staples from the crate.

2. Holding sides of the crate firmly, lift top of the crate

up and set it aside. Avoid tire punctures.

3. Remove and discard plastic bag covering the unit.

4. Lift the rear of the mower past the bottom of the

crate. Repeat for the front.

5. Be sure the parking brake is disengaged. See

Figure 4 for location of the parking brake.

6. Roll unit out of the crate.

Loose Parts

Remove loose parts from the grass catcher and/or the

crate very carefully. Compare with list below.

• Muiching plug & side-discharge chute

• Oil drain hose

• Ignition keys

• Operator’s manual

NOTE: Reference to RIGHT or LEFT side of the tractor

in this manual is observed from operator’s position.

• Your riding mower is shipped with motor oil in the

engine. However, you must check the oil level

before operating. Be careful not to overfill.

3.

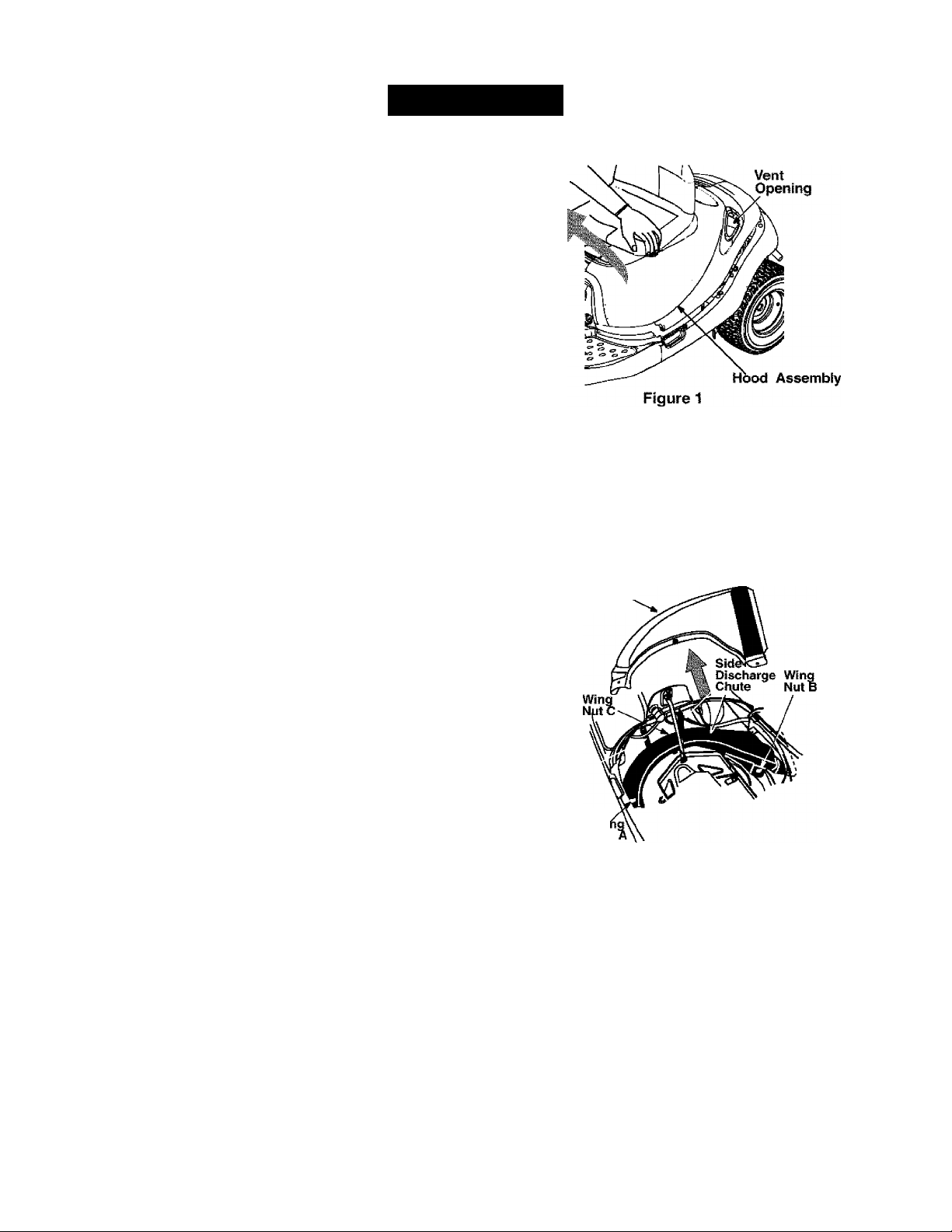

Remove the two wing nuts (A and B in Figure 2 )

from two ends of the grasscatcher chute.

4.

Loosen the wing nut (C in Figure 2 ) in the middle of

the chute. Do not remove.

5.

Slide the grasscatcher chute to the right and out of

the deck frame. Slide the side-discharge chute in

and place it on the deck so that the three wing nut

positions align with those on the deck.

Reinsert wing nuts A and B. Tighten all three.

6.

Grass Catcher

Chute ‘

Attaching Side-Discharge Chute

Your riding mower is shipped to you with the grass

catcher fully assembled on the unit. A side-discharge

chute and a muiching plug are included as loose parts.

Follow the instructions below to attach the sidedischarge chute.

WARNING: Do not operate the mower if the

A

1. Lower the cutting height adjustment lever to the

2. To access the grass catcher, lift the hood assembly

NOTE: Do not lift the hood assembly by the two vent

openings located behind the seat.

grass catcher, discharge chute or mulching

plug is not firmly installed on the mower.

lowest position.

from the left side of the hood only. Stand on the

right side of the unit and pivot the hood assembly

towards you until fully opened. See Figure 1.

Wi

Nut

Figure 2

Attaching Mulch Plug

While operating your riding mower, you have three

options; (i) to collect grass clippings in the grass

catcher, ^i) to discharge grass clippings on the side, or

(iii) to muich grass and recirculate clippings back to the

lawn. For the third option, attach the mulching plug to

the side-discharge chute and then to the deck.

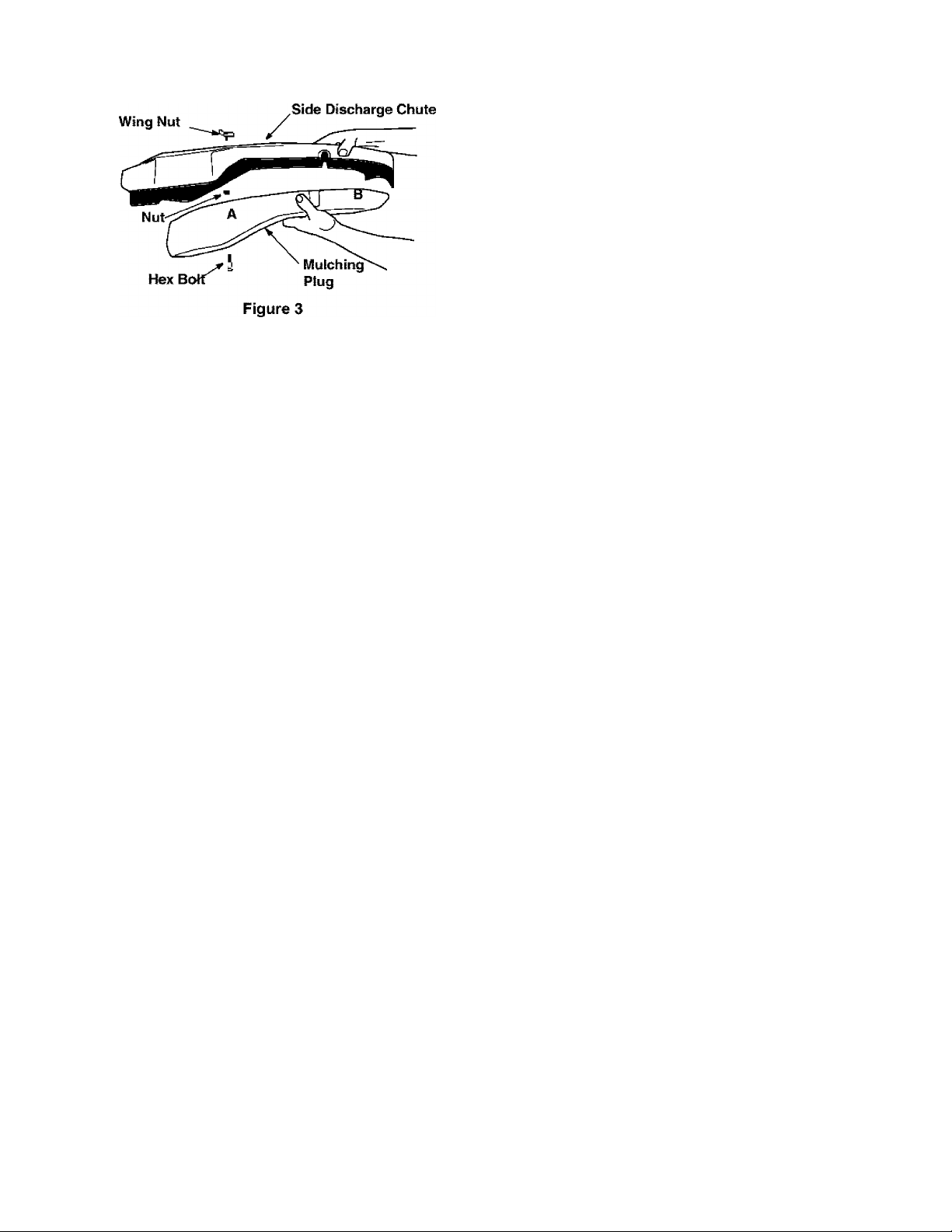

1. Put two hex bolts through the mulching plug at the

respective openings. See Figure 3 .

2. Place nuts over the hex bolts.

Page 7

3. Insert the plug into the side-discharge chute

aligning the two slots on two sides of the sidedischarge chute with those on the mulching plug.

4. To attach the mulching plug now to the unit, follow

earlier instructions to attach side-discharge chute

to the deck.

5. Place wing nut on each of the hex bolts and thread

a few turns. See Figure 3 . Check that the mulch

plug is aligned correctly within the discharge chute.

6. Tighten both wing nuts.

Page 8

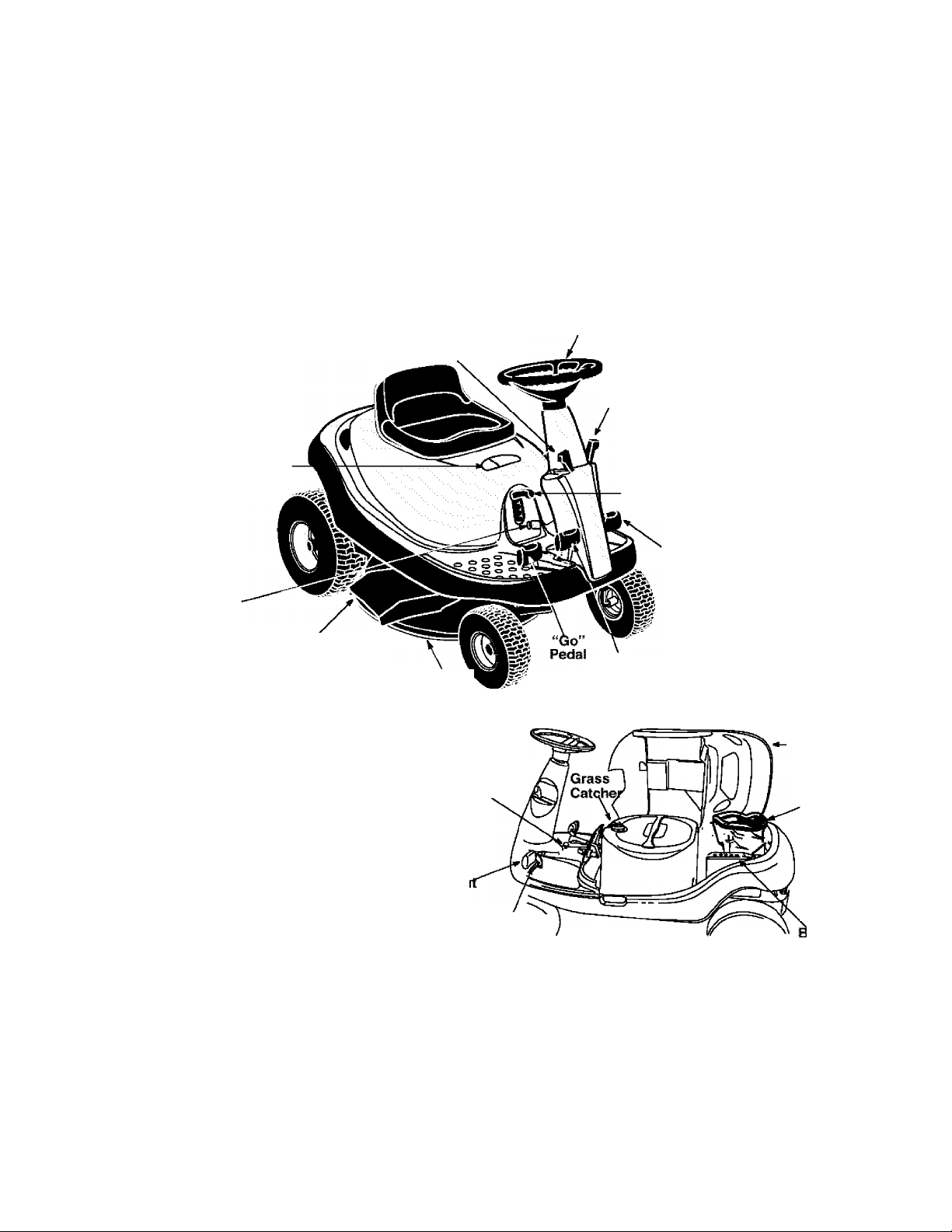

Know Your Riding Mower

Compare the illustrations in Figure 4 with your riding mower to familiarize yourself with the location of various

controls and adjustments.

WARNING: The operation of any riding mower can result in foreign objects being thrown into the

A

operator’s eyes, causing severe eye damage. Always wear safety glasses before operating the mower, or

while performing any adjustments or repairs on it.

Grass Fill Level

Indicator

Ignition

Switch

Side Discharge

Chute

Throttle/Choke

Control

Cutting^

Deck

Parking

Brake

Steering Wheel

Shift Lever

Cutting Height

Adiustment Lever

Blade Engagement

Pedal

Brake

Pedal

- Hood

Assembly

Engine

Blade

Engagemer

Pedal

Figure 4

Throttle/Choke Control: Use to regulate the engine

speed and to start the engine.

“Go” Pedal: Use to regulate the ground speed of the

riding mower.

Ignition Switch: Use to turn the engine ON or OFF.

Shift Lever: Use to change direction of the mower.

Grass Fill Level Indicator: Use to determine the level

Blade''j ^

Lock

NOTE; Gas tank is not shown here

iattery

of grass clipping in the bag and when to empty it.

Parking Brake: Use to stop the mower from moving

while parked.

Blade Engagement Pedal: Use to engage or

disengage the blade.

Blade Lock: Use to lock blade at the engaged position.

Cutting Height Adjustment Lever: Use to raise and

Page 9

lower cutting deck which determines the cutting height.

Brake Pedal: Use to stop the mower’s forward or

reverse motion.

For Your Safety

• Know iocation and function of ail controis.

• Be sure blades and engine are stopped before

placing hands or feet near biades.

• Before leaving operator’s position, disengage

blade(s), place the shift lever in neutral, engage

parking brake, shut engine off and remove key.

Stopping the Riding Mower

1. Release blade engagement pedal all the way.

2. Release “Go" Pedal and depress the brake pedal.

3. When the mower comes to a complete stop, place

the shift lever in neutral.

4. Engage the parking brake by pulling up on the

parking brake knob.

5. Turn the ignition key to OFF position and remove

the key.

Safety Interiock

This unit is equipped with a safety interiock system for

your protection. The interiock safety switches are

connected to the brake pedal, the blade engagement

pedal, the shift lever, and the seat.

The purpose of the safety interlock system is threefold:

• To prevent the engine from starting unless the

brake pedal is depressed and the blade

engagement pedal is disengaged;

• To shut off the engine if the blade pedai is not

disengaged when the shift lever is put into reverse;

and

• To shut the engine off when the operator leaves the

seat without engaging the parking brake.

/k WARNING: To avoid the risk of serious

injury, do not operate the riding mower if the

interiock system is malfunctioning.

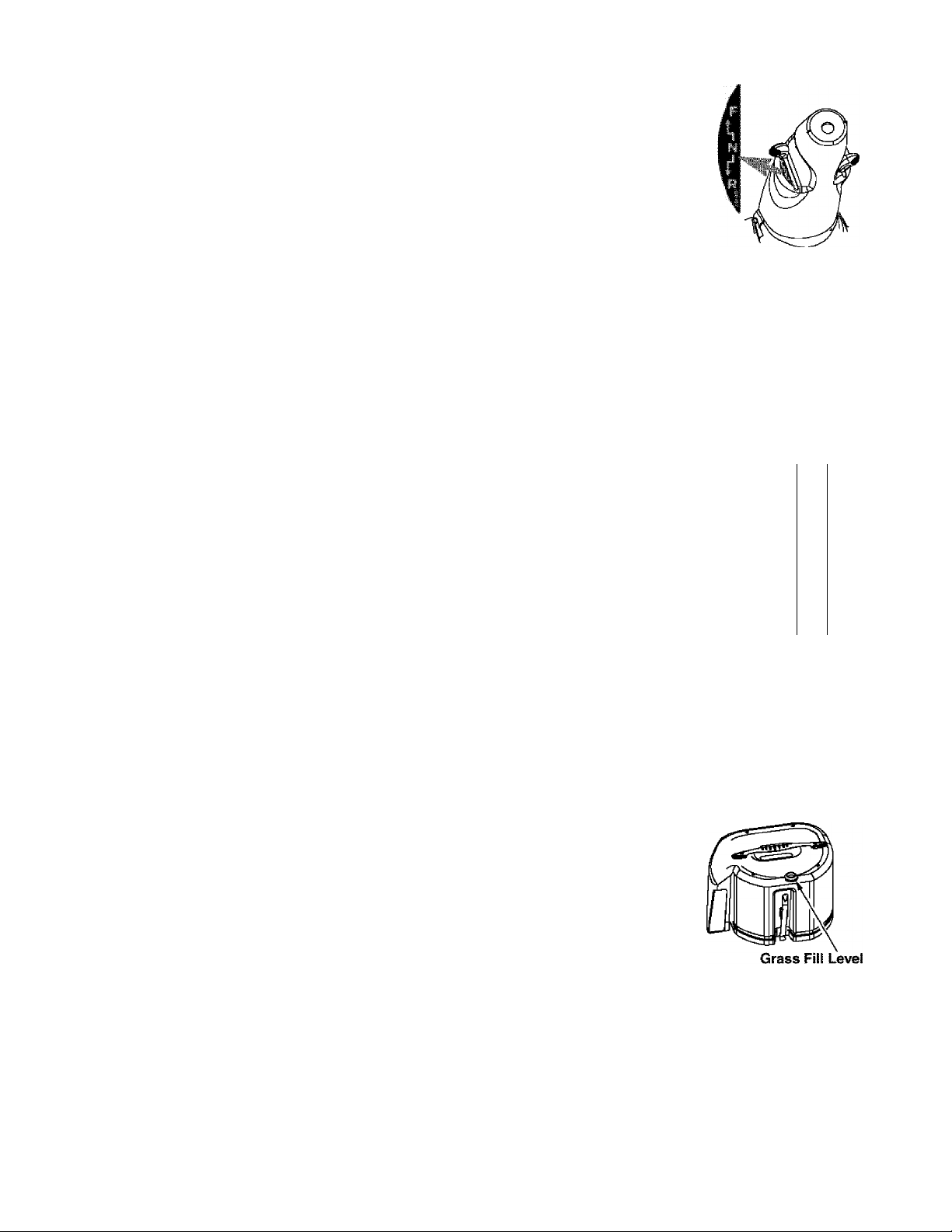

Using Shift Lever

This lever is used to regulate direction of the riding

mower. It can be set at forward, neutral, or reverse

settings. These settings are marked F, N, and R

respectively on the unit. This unit is designed not to

mow when the shift iever is in R position. (If the

blade is engaged while shift lever is at the R position,

the unit will shut off. To restart the unit, disengage the

blade.)

1. Before you move the shift lever to any of the

positions, depress the brake pedal and stop the

unit. Keep your foot on the brake pedal.

2. The shift iever is locked at

the N position. Move the

iever outwards (left) and

slide the lever upward to F

or downward to R position

as desired.

NOTE: Look to the rear and

make sure the path is free of

obstacles before positioning the

shift iever to the reverse.

3. Do not force the shift iever. If it does not shift,

release the brake pedal slightiy to line up the

shifting coliar in the transmission, then try to move

the shift lever.

4. Slowly release the brake pedal and take your foot

off the pedal. Always make sure that there is no one

in the way when you run the mower.

Using Throttle/Choke Control

The throttie/choke control is

used to increase or decrease

the speed of the engine.The

FAST and the SLOW positions

are marked with illustrations of

a rabbit and a turtle

respectively.

• For normal operation and

when using a grass

catcher, move the throttle/

choke control to the FAST position.

• For maximum charging of the battery and also for a

cooler engine white running, move the throttle/

choke control to the FAST position.

• For transport and to tow pull-behind attachments,

move the throttie/choke control to the SLOW.

Slow

m

m

—

_

Grass Fill Level Indicator

This indicator was designed

to add convenience to your

riding mower. While the

mower is running, air wilt flow

through the discharge chute

and into the grass catcher. If

the grass catcher is empty,

air flows through easily

pushing the bail up. If the

grass catcher is full, air does

not flow through it allowing the ball to fall. So if you see

the ball in the grass catcher fill level indicator falling

down, you should stop the mower and empty the bag.

Indicator

Page 10

Engine Model

This is a single cylinder, air-cooied engine. It is a low

emissions engine.

Symbols Used

Message Symbol

Safety alert

On off

Read owner’s manual

Oil

Fuel shut-off

Choke

Fuel

Stop

A

ÏÏÔ]

CQ

m

M

B

Using Parking Brake

To engage

1. Completely push the brake pedal down and stop

the unit.

2. With your right foot on the brake pedal, move the

shift lever to the neutral position.

3. Continuing to hold down the brake pedal with your

right foot, puli up the parking brake knob. Make

sure the parking brake holds the unit.

4. Release the brake pedal. Stop engine and remove

ignition key. Now your riding mower is parked.

To roloaso

5. Depress the brake pedal. The parking brake will be

automatically disengaged.

Before Starting

For hazard symbol meanings, refer to page 44.

NOTE: In the state of California, the 210000 series

engines covered in this manual are certified by the

California Air Resources Board to meet emissions

standards for250 hours. Such certification does not

grant the purchaser, owner or operator of this engine

any additional warranties with respect to the

performance or operational life of this engine. This

engine is warranted solely according to the product and

emissions warranties stated elsewhere in this manual.

Bore 3-7/16 in. (87.31 mm)

Stroke 2-17/64 in. (77.78 mm)

Displacement 21.00 cu. in. (344.1 cc)

IMPORTANT: For practical operation, the horsepower

loading should not exceed 85% of rated horsepower.

Engine power will decrease 3-1/2% for each 1,000 feet

(300 meters) above sea level and 1 % for each 10 F (5.6

C) above 77 F (25 C). Engine will operate satisfactorily

at an angle up to 15 degrees.

Engine Controls

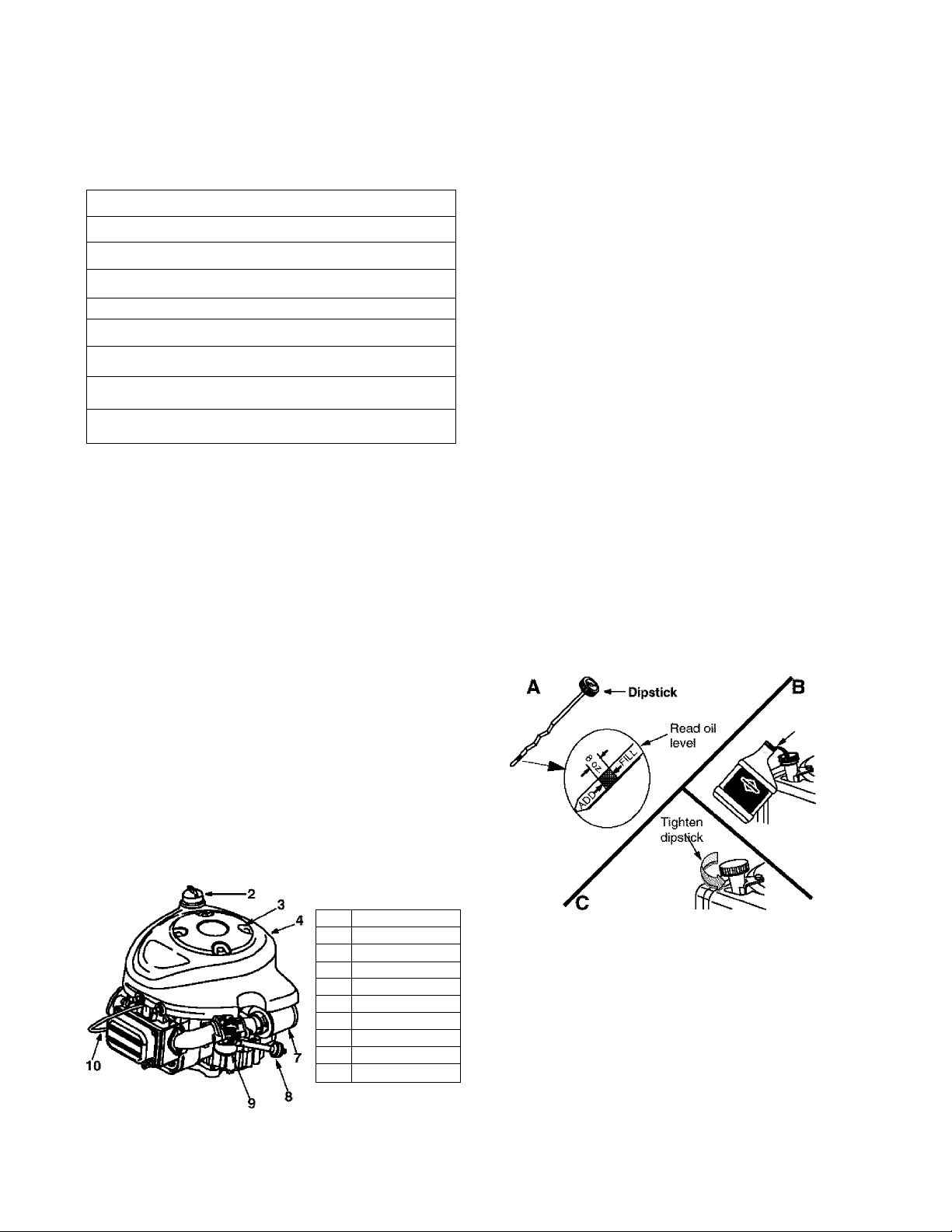

Filling Up Oil

NOTE: The riding lawn mower is shipped with oil in the

engine crankcase.

Check oil level in the engine oil sump before starting the

engine. (Oil sump capacity: 48 oz./l .4 liter)

1. Place the mower on level ground and flip the hood

assembly up to access the engine.

NOTE: Do not lift the hood assembly by the two vent

openings located behind the seat.

Fill up if

needed

Figure 5

1.

Oil drain*

2. Oil fill/DIpstick

Rotating Screen

3.

4. Blower Housing

Muffler*

5.

Electric Starter*

6.

7. Air Cleaner

Fuel Filter

8.

Carburetor

9.

10. Spark plug wire

' Not shown

10

Figure 6

2.

Remove dipstick and wipe it clean with cloth.

Replace and tighten the dipstick. Remove the

3.

dipstick again and check the oil level mark on it.

The oil level should be at FULL line on the dipstick.

See Figure 6A. If the level is short of that, add oil to

the oil fill slowly. Recheck the oil level on the

dipstick. If needed, add more oil. See Figure 6B. Do

not overfill.

4.

Place the dipstick in position and tighten to secure.

See Figure 6C.

Page 11

Type of Oil

1. Refer to the chart below for proper grade of oil.

2. Use a high quality detergent oil classified “For

service SF, SG,SH, SJ” or higher.

3. Do not use special additives.

Synthetic oil meeting ILSAC GF-2, API certification and

API service symbol with “SJ/CF Energy Conserving” or

higher is an acceptable oil at all temperatures. Use of

synthetic oil does not alter required oil change intervals.

SAE Viscosity Grades

■ 30 '

.5W-30,10W-30

Type of Gasoline

• Use clean, fresh, regular unleaded gasoline with

minimum 85 octane rating.

• Do not use gasoline mixed with methanol, or

gasoline which has been stored for more than 30

days. Always purchase fuel in quantity that can be

used up within 30 days. Fresh fuel prevents gum

from forming in the fuel system or on carburetor.

• Do not mix gasoline with engine oil.

NOTE: Some fuels, called oxygenated or reformulated

gasoline, are blended with alcohol or ether. Using these

blends frequently can damage the fuel system or affect

performance. If engine performance is affected, use

gasoline with lower percentage of alcohol or ether.

N30

“F -20“

Starting temperature range anticipated before next oil change

* CAUTION: Aircooled engines run hotter than automotive

engines. The use of non-synthetic multi-viscosity oils (5W30,10W-30 etc.) in temperatures above 40°F will result in

higher than norma! oil consumption. When using a multi

viscosity oil, check oil level more frequently.

** CAUTION: SAE 30 Oil, if used below 40°F, will result in

hard starting and possible engine bore damage due to

inadequate lubrication.

0“ 20°

40'

60°

80° 100°

Battery

Ordinarily the battery is charged and ready for use; so

you will not have to charge it before starting. However,

if the battery is put into service for the first time after the

date shown on the side of the battery, you will have to

charge it for a minimum of one hour at 4-6 amps. Refer

to Service & Adjustments section of this manual for

instructions on charging the battery.

The battery is located under the hood assembly above

the left rear wheel. Refer to Figure 20 .

Filling Up Gasoline

WARNING: Fill fuel tank outdoors or in well-

dk

NOTE: On a riding mower which has already been

started and/or operated once immediately prior to this

gasoline fill-up, turn engine off and let cool at least two

minutes before removing gas cap.

1. Remove gas tank cap and fill tank to approximately

2. Replace cap on the gas tank and tighten to secure.

NOTE: If fuel spills on part of engine or vehicle, wait

until it evaporates before starting engine.

ventilated area, away from sparks, open

flames, pilot lights, heat and other ignition

sources.

1.5 inches below top of neck to allow for fuel

expansion. Be careful not to overfill.

Starting Engine

1. Be sure the wire is attached to the spark plug.

2. Depress the brake pedal with your right foot.

3. Set throttle/choke control in the CHOKE position

(all the way forward).

4. Place the shift lever in the NEUTRAL position.

5. Turn ignition key to the START position. Once the

engine starts, let key return to ON position.

6. Move throttle/choke control out of CHOKE position

and into FAST throttle position.

NOTE: If engine floods, set choke to OPEN/RUN

position, place throttle in FAST and crank until engine

starts.

Operating the Riding Mower

1. Depress the brake pedal so that the parking brake

is disengaged.

2. Place the shift lever in either the FORWARD or the

REVERSE position as you desire. Look to the rear

and check before backing up.

3. Release the brake pedal.

4. Depress the "Go“ Pedal.

5. To stop, release the "Go" Pedal and depress the

brake pedal.

6. Press the blade engagement pedal downward until

the blades are turning.The blades can be engaged

either while the mower is moving or standing.

WARNING: When the blades are engaged,

A

A

NOTE: Your riding mower is equipped with a blade lock

to keep the blade engaged without the operator having

to depress the blade pedal continuously. See Figure 4.

7. To engage the blade lock: While pressing down

keep hands and feet away from the discharge

opening, the blades or any part of the deck.

WARNING: Do not tip the equipment at an

angle which causes the gasoline to spill.

11

Page 12

on the biade pedal, push the blade lock down with

your heel. It should click into the “blade engaged”

position. To disengage the blade lock, simply push

down on the blade pedal and release the iock.

Stopping the Riding Mower

See page 9 for detailed instruction.

Using the Riding Mower

Observe safety rules listed on pages 3-5 of this manual

for safe operation of your riding mower. The

recommended mowing pattern is given below;

NOTE: Do not leave the key in the ON position when

you are not operating the mower. Such action will drain

the battery dead.

NOTE: Do not choke carburetor to stop engine.

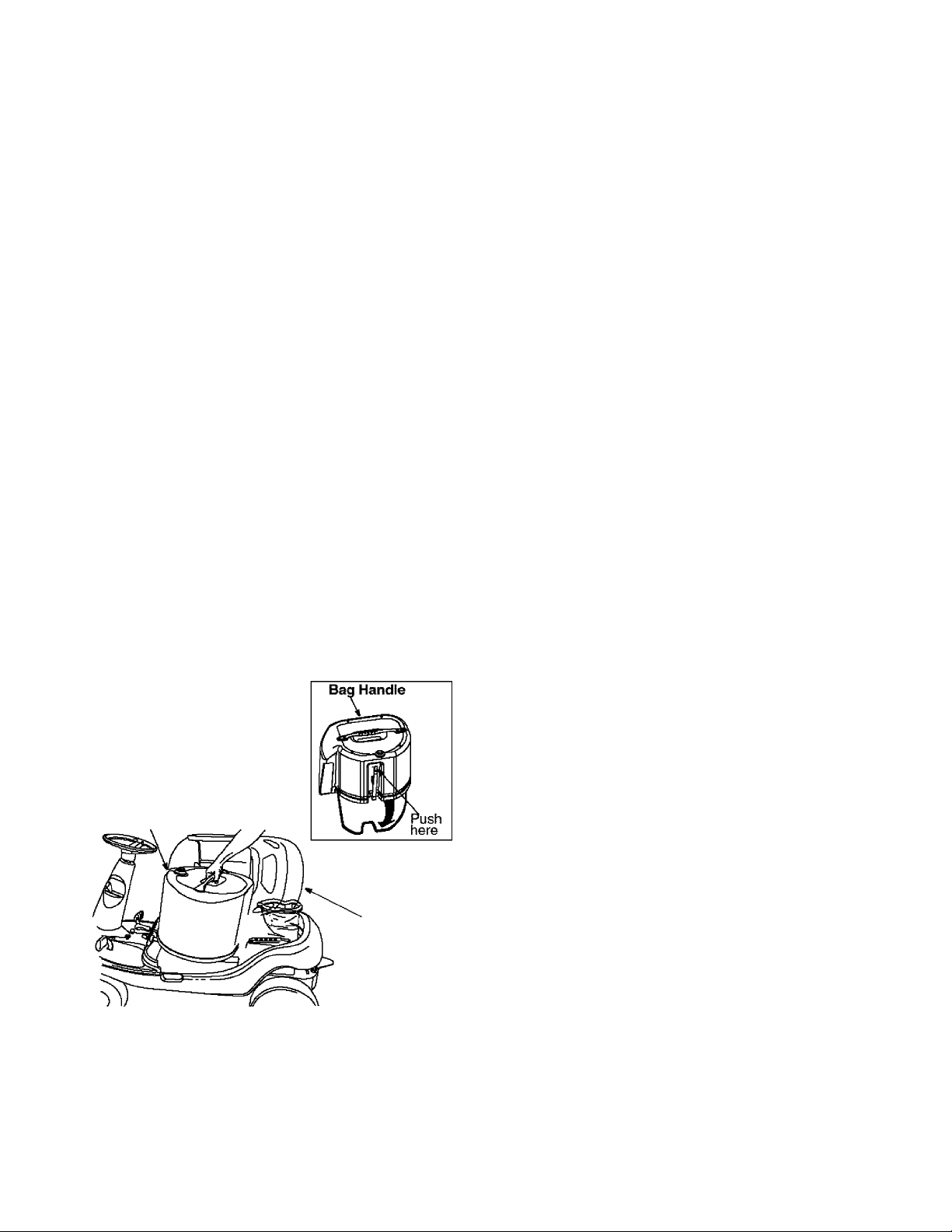

To Empty Grass Catcher

1.

Stop the mower completely, pull up on the parking

brake knob and take the ignition key out. Get off the

operator’s seat.

2.

Pivot the hood assembly up. Pull up the

grasscatcher bag by the handle and take it to the

proper disposal site. See Figure 7 .

Hold the bag away from your body. Push down on

3.

the bag lever and let the bottom section of the bag

fall downwards. Grass clippings will be disposed off

from the bottom. See Figure 7.

4.

Tap the bag on the ground so that the three legs of

the bag press against the ground. The bag lever

shouid snap close whiie you push the bag

downwards.

Replace the bag on to the mower making sure the

5.

bag is placed on the flange on top of the discharge

chute. Pivot the hood assembly down.

Grass Catcher

Bag

}!

j

V.,

-^J

'J

• Before mowing, make sure that the cutting deck is

leveled. For deck adjustment, refer to page 17.

• You can engage the blade by pressing on the biade

engagement pedal with your ieft foot whiie sitting at

the operator’s position.

• When mowing an area for the first time, watch out

for objects lying on the grass. If you strike a foreign

object, stop the engine. Remove wire from spark

plug and thoroughly inspect the riding mower for

any damage. Repair the damage before operating

it again.

• Avoid scalping the lawn by adjusting the cutting

height upwards and/or sharpening the blades.

• Mow at fuii throttle. Learn the terrain on which you

are mowing. For best mowing results, mow only

when the grass is dry.

• Mow grass often and in regular intervals so that you

can cut only 1/3 of the grass biade in one mowing.

• To empty grass bag, stop the riding mower

completely, engage the parking brake, and turn

the ignition off. This will prevent the hot engine

exhaust gas from browning the grass.

• Many communities no longer haui grass clippings

to landfills. Composting the clippings from your

grass catcher is a viable solution. For this you will

have to empty the grass catcher at the designated

composting site.

Figure 7

Hood

Assembly

Mulching

• Your riding mower is equipped with a mulching plug

to mulch the grass and recycle into the lawn instead

of collecting in the grasscatcher bag.

• Mulch only when the grass is dry. Mulching wet

grass may damage the underside of the deck

because wet grass tends to stick to it. Clean deck

thoroughly if you mulch wet grass.

• For effective mulching, overlap mowing paths so

that the clippings are distributed evenly.

12

Page 13

General Recommendations

WARNING: Always stop engine and disconnect spark plug wire before any maintenance or adjustments.

À

Always maintain safety and foliow instructions given below closely for smooth completion of job.

The warranty on this riding mower does not cover items that have been subjected to operator abuse or

negligence. To receive full value from the warranty, operator must maintain the riding mower as instructed in

this manual. Refer to the Maintenance Schedule below.

We do not recommend the use of pressure washers or garden hose to clean your unit. These may cause

damage to electrical components, spindles, pulleys, bearings or the engine. The use of water may shorten life

of your riding mower and reduce its serviceability

To ensure safe operation, ail nuts and bolts must be checked periodically for correct tightness.

Maintenance Schedule

Check blade, sharpen or replace if needed

Lube pivot points, steering shaft, gear

Lube deck linkage, front wheels

Change engine oil

Service air cleaner in engine

Service spark plug

Clean cooling system of the engine

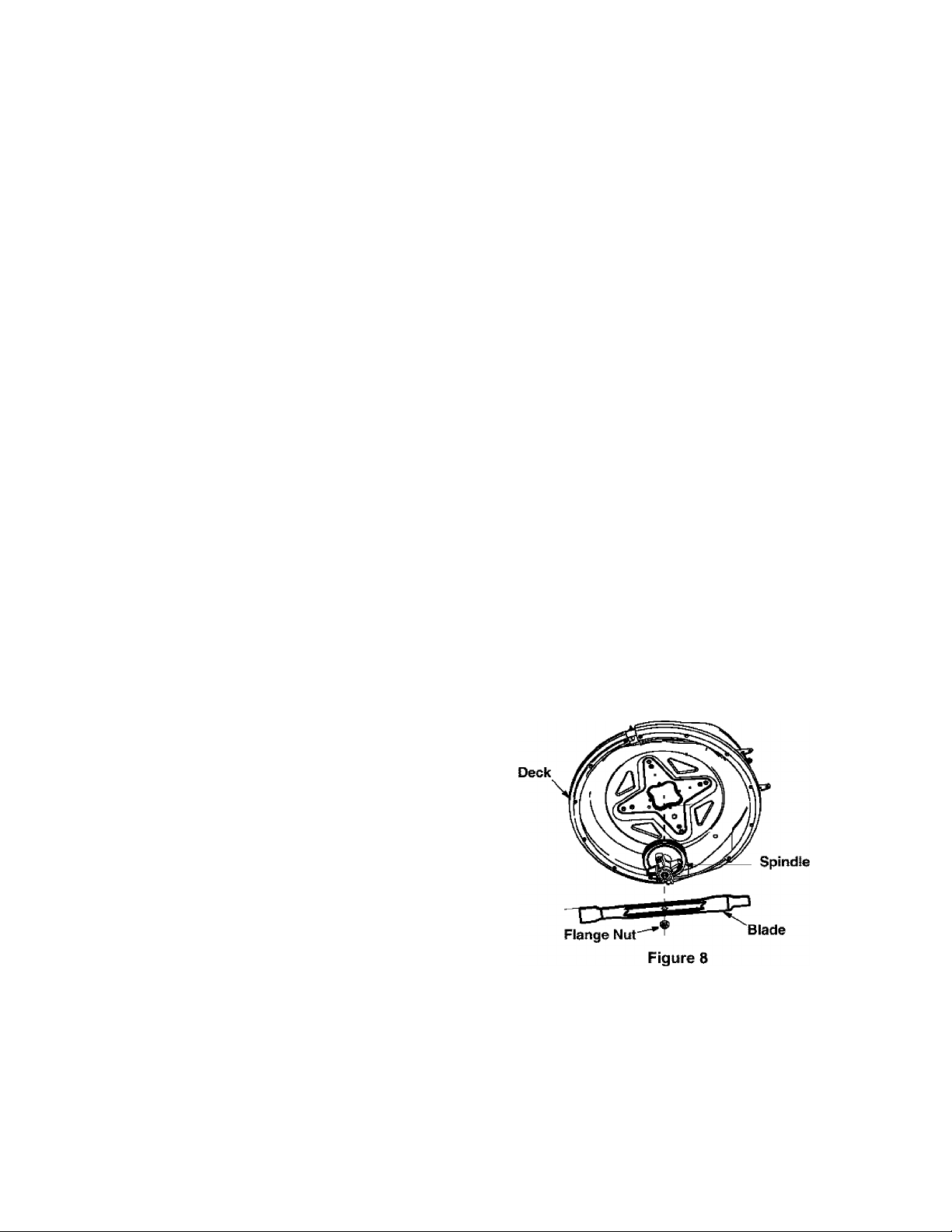

Blade Care

WARNING: Protect your hands by wearing

A

Removal

1. Remove the 5/8” hex flange nut which holds the

2. Remove blade from the spindle. See Figure 8.

heavy gloves or using a rag to grasp the cutting

blade. Avoid personal injury.

blade to the blade spindle.

rs rs

Reassembly

too hrs.

Season RëâssëmFF

Sharpening

1. When sharpening the biade, foiiow original angle of

grind as a guide. It is extremely important to grind

each cutting edge equally to prevent an

unbalanced blade.

2. Test the blade by balancing it on a round shaft

screwdriver. Remove metal from the heavy side

until it balances evenly.

WARNING: Unbalanced biade may cause

A

excessive vibration at high speeds, may damage

the riding mower and/or cause personal injury.

1.

Before reassembling the blade to the unit, lubricate

the spindle with light oil (or engine oil).

2.

Align “star” fitting on new blade with the “star” on

the spindle.

3.

Install the biade with the side of the biade marked

“Bottom” (or with part number) facing the ground

when the riding mower is in the operating position.

4.

Tighten the flange nut securely. See Figure 8.

Blade Mounting Torque: 70/90 ft.-lbs. maximum.

13

Page 14

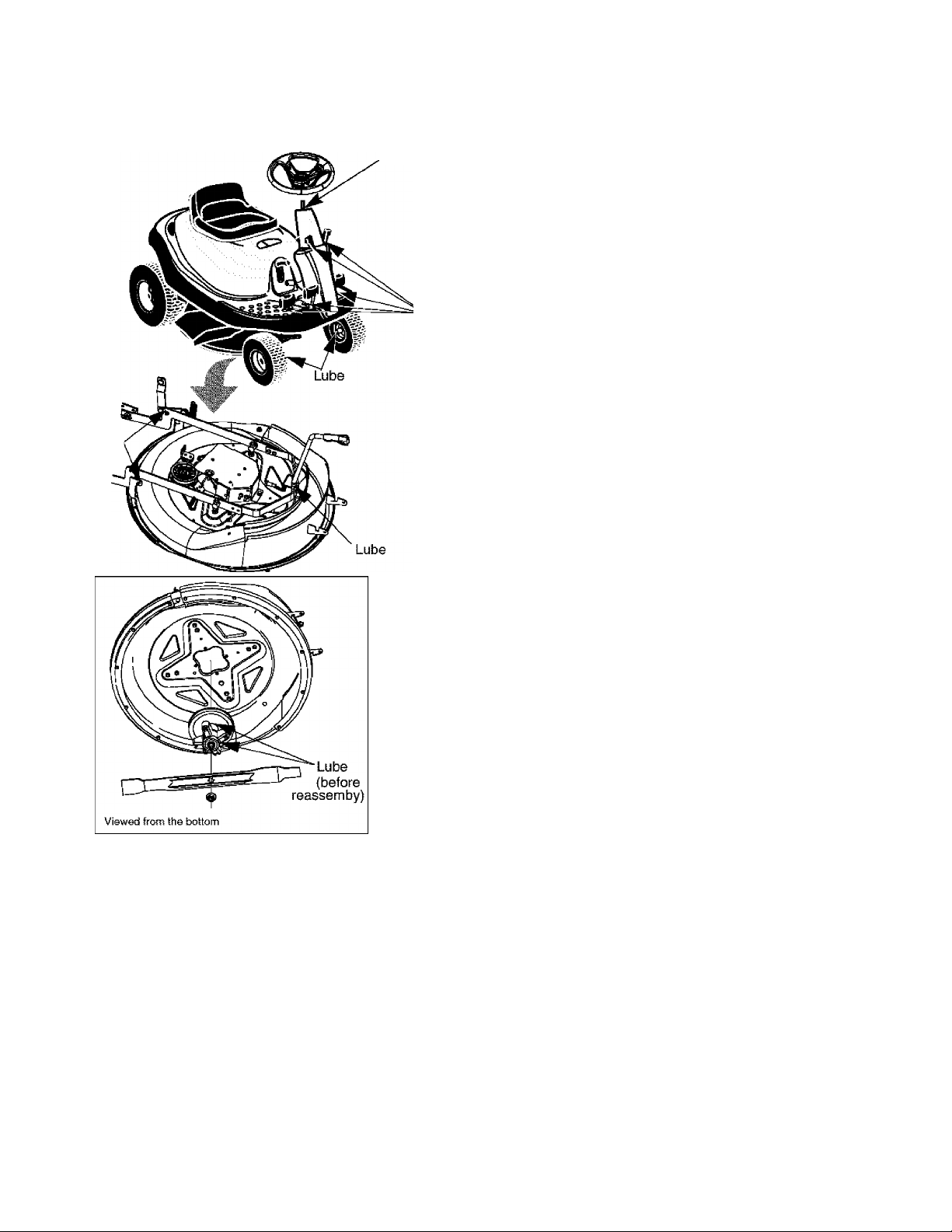

Lubrication

See Figure 9 for an iiiustration of the lube points

described below.

Lube

Luboi

Figure 9: Lubrication Chart

Blade Assembly; Lubricate blade assembly and

deck spindle oniy whiie reassembling the blade

either after sharpening or replacement.

Pivot Points: Lubricate pivot points with light oil

once a season.

Steering Shaft and Gear: Lubricate steering shaft

and spline at least once a season with light oil.

Lubricate teeth of the external steering gears with

automotive multi-purpose grease every 25 hours of

operation or once a season.

Linkage: Lubricate all deck linkage and height

adjustment iinkage with a light oil.

Front Wheels: Lubricate front wheels at least once

a season with automotive multi-purpose grease.

Lube

Engine

WARNING: Before performing any

A

• Change engine oil after first five to eight hours of

• Poor engine performance and flooding usually

• The spark plug shouid be cleaned and the gap

Cleaning Engine

1. Promptly wipe off any fuel or oil spilled on the

2. Clean the underside of the blade housing after

3. Using a brush or cloth, remove grass, chaff or

4. Keep the throttle iinkage, springs and controls free

5. If engine muffler is equipped with spark arrester

Air Cleaner

Service the air cleaner every 25 hours of operation.

Service more frequently if operating under extremely

dusty conditions. Locate air cleaner on engine.

1. Remove clamp and pull air cleaner from intake

2. Replace with air cleaner (Sears part # 698-973).

3. Reassemble the air cleaner.

Spark Plug

1. Clean area around the spark plug base.

2. Remove and inspect the spark plug.

3. Replace the spark plug if electrodes are pitted,

maintenance on the engine, disconnect the

spark plug wire and the battery to prevent

unintentional starting or sparking.

use, then every 50 hours or every season,

whichever comes earlier. Change oil every 25

hours when operating the riding mower under

heavy load or in high temperatures.

indicate that air cleaner shouid be serviced. Service

pre-cleaner and the cartridge every 25 hours of use

or once every season, whichever comes earlier.

Clean more frequently under dusty conditions. Also

replace air cleaner parts if these are very dirty.

reset every 100 hours of use or once a season,

whichever comes earlier.

machine with clean doth.

each mowing. Do not let clippings or debris

accumulate around the blade which may cause rust

on the deck.

debris from the finger guard on the engine daily to

prevent overheating of the engine. Do not clean

with a forceful spray of water since water

contaminates the fuel system.

of debris.

screen, remove and clean the screen regularly.

Replace if damaged or plugged with debris.Clean

muffler area and remove any grass or other debris

before operating the unit.

manifold.

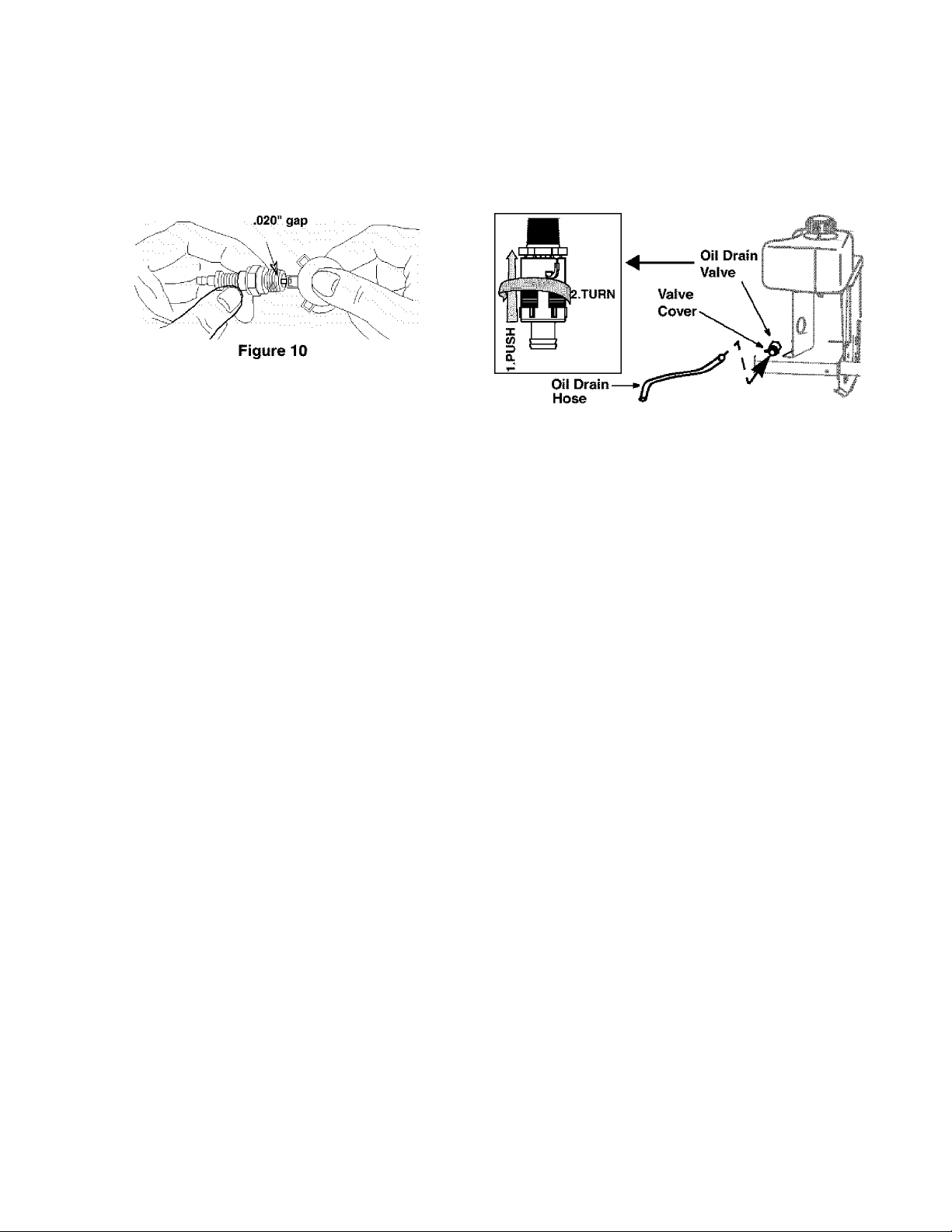

burned, or the porcelain is cracked. See Figure 10 .

14

Page 15

4. Ciean the spark plug and reset the gap to 0.020“ at

least once a season or every 100 hours of

operation. See Figure 10. Replace if necessary.

Refer to parts list section for part number.

NOTE: Do not sandblast spark plug. Spark plug should

be cleaned by scraping or wire brushing and washing

with a commercial solvent.

Changing Oil

Your riding mower has a plastic oil drain hose, packed

with the loose parts, for draining oil from the crankcase.

1.

Run the mower engine for a few minutes, and turn

the ignition key off. Make sure that the riding mower

is completely stopped and parking brake engaged.

2.

Lift the hood assembly to access the oii drain valve.

Remove yellow valve cover on the oil drain valve

3.

and attach one end of the oil drain hose to this

opening. This valve is located at the end of a 90

degree fitting near the fuel tank mounting bracket.

See Figure 11.

4.

Lead the other end of the oil drain hose into a

suitable container for collecting spent engine oil.

Grip oil drain valve, push In and turn counter

5.

clockwise until it stops. See Figure 11 inset. Pull out

the drain valve.

Wait til! oil has drained into container completely.

6.

7.

Grip oil drain valve, push in, then turn clockwise

until it stops.

Figure 11

Carefully disconnect the hose from the oil drain

8.

valve to avoid spillage on the equipment and

replace the yellow cap. Remove container and

dispose off the spent oil appropriately.

Remove dipstick from the oil fill on the engine.

9.

10. Fill up with fresh engine oil of appropriate grade.

Refer to the viscosity chart on page 11 for oil type.

11. Check oil level as instructed on page 10. Add more

oil if needed and tighten the dipstick securely.

12. Flip the hood assembly back.

15

Page 16

RVICE& ADJUSTMENTS

Adjustments

Brake Pedal

The brake pedal needs to contact the PTO (power take

off) switch for the engine to start. During normai

operation of the riding mower, the brake is subject to

wear and tear. Periodicaiiy check the brake by carrying

out the foiiowing test;

1. Release the parking brake and place the riding

mower in neutral.

2. Depress the brake pedal and try to roil the riding

mower. The tractor should not move. If the tractor

moves, adjust the brake.

WARNING: Do not adjust the brake while

A

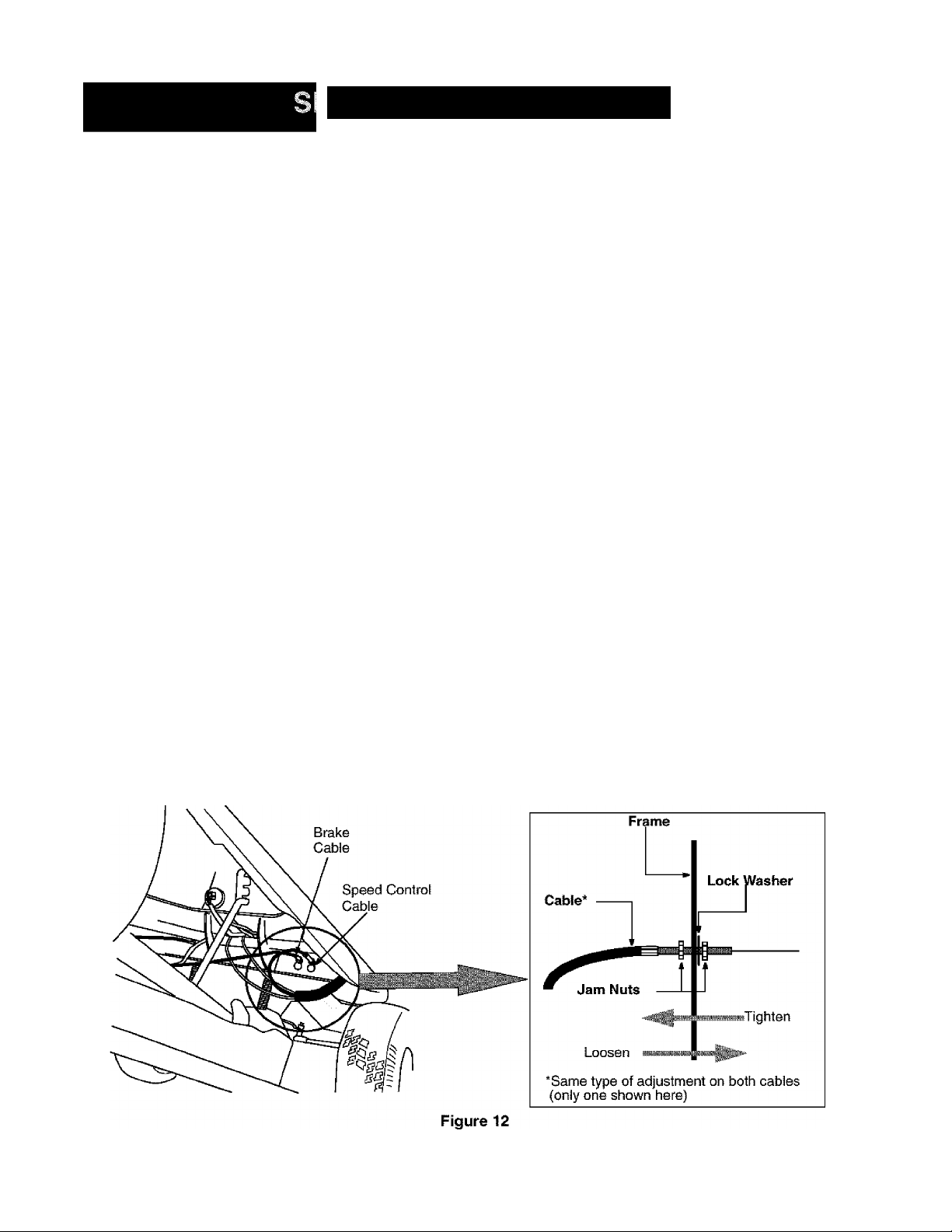

Adjustment to the brake pedal is made at the cable end.

See Figure 12.

1.

2.

3.

4.

5.

6.

7.

the engine is running. Be sure to block the

wheels of the riding mower before making any

adjustments on the brake cabie.

Set the parking brake and turn ignition key off.

Shift the cutting height iever to the iowest position.

Pivot the hood assembly up and remove the

grasscatcher bag and the side-discharge chute or

the mulching plug from the riding mower.

Disconnect wire from the spark plug.

Locate the brake cable on the right side under the

front housing. See Figure 12 .

Using a pair of 1/2” wrenches, loosen the jam nuts

and back the cable out to tighten or thread inward

to loosen. See Figure 12 inset.

Retighten the jam nuts when proper tension is

reached.

8. Unlock parking brake and repeat the test described

above. Readjust if necessary.

“Go” Pedal

Adjustment to the "Go" Pedal is made at the cabie end.

See Figure 12.

1. Set the parking brake and turn ignition key off.

2. Shift the cutting height lever to the iowest position.

3. Pivot the hood assembly up and remove the

grasscatcher bag and the side-discharge chute or

the mulching plug from the riding mower.

4. Disconnect wire from the spark plug.

5. Locate the speed control cable under the front

housing. See Figure 12.

6. Loosen the jam nuts and back the cable out to

tighten or thread inward to loosen as shown.

7. Retighten the jam nuts when proper tension is

reached.

8. Reconnect the spark plug wire and pivot the hood

assembly down.

Cutting Height

The deck cutting height adjustment lever is located on

the hood assembly. For a representation of the cutting

height positions, refer to Figure 4.

1.

Puli the lever out of the slot and slide it upward or

downward to the desired cutting height.

2.

Lower the cutting height to mow close to the

ground.

Raise the deck height to the highest position when

3.

you ride on a sidewalk or a road.

To mow tall or thick grass, first cut with height

4.

adjustment iever at the highest position, then cut

again with the lever at a lower position.

16

Page 17

Seat Position

The seat position on the riding mower can be adjusted

to maximize the operator’s convenience.

1. Stop the mower completely and engage the parking

brake. Turn ignition off.

2. Pivot the hood assembly up.

3. Loosen the four self-tapping screws on the bottom

of the seat.

4. Slide the seat forward or backward in the slot, and

position it as desired. Retighten the four screws.

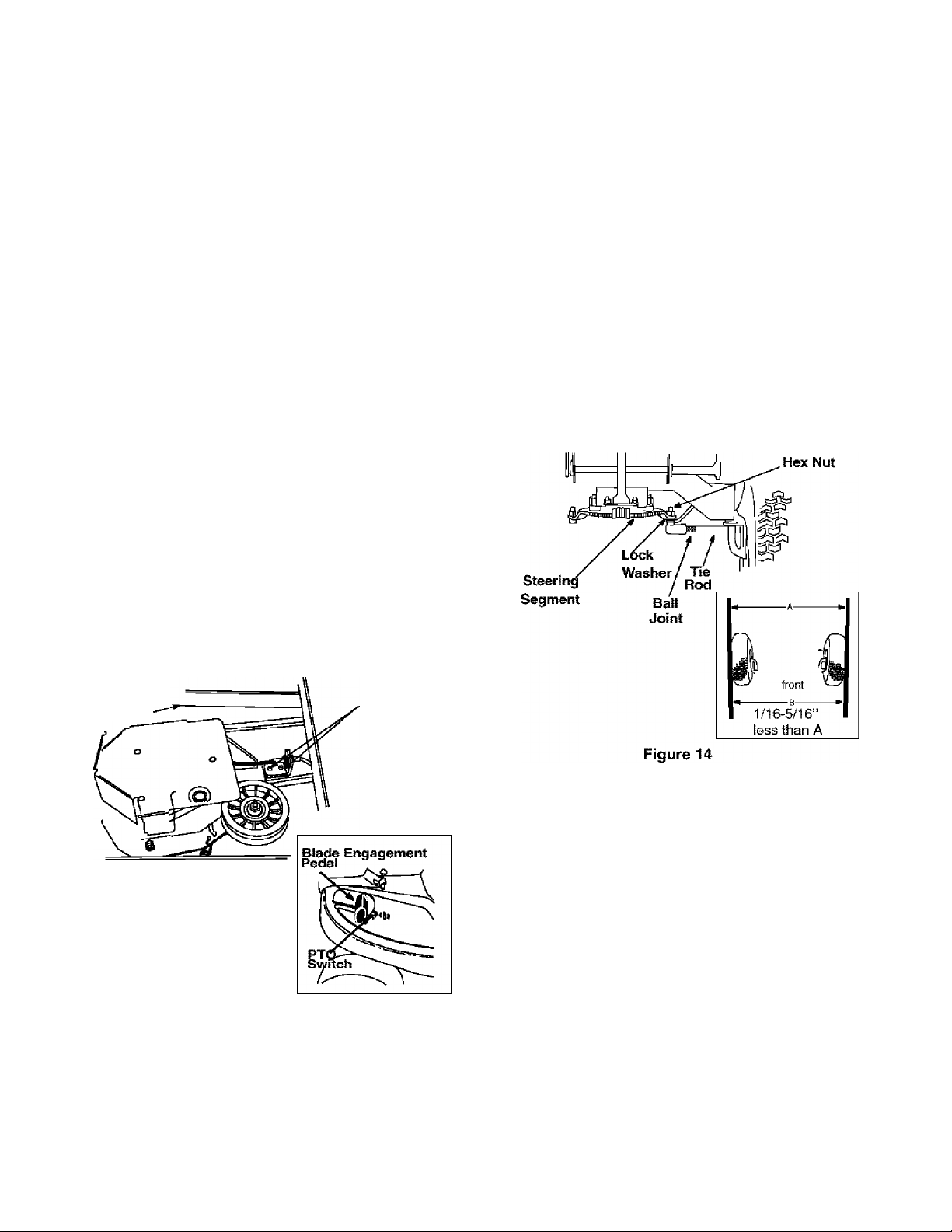

Blade Engagement Pedal

The blade engagement pedal should be adjusted so

that if you depress it about 3/4” from the front of the

blade brake slot, it will contact the PTO switch and

cause it to engage the deck belt.

Under normal operation, the blade engagement pedal

should not require frequent adjustment. However,

perform the following test periodically and make sure

that it is in fine working condition.

1. Pivot the hood assembly up and check if there is

enough slack on the deck engagement cable.

2. Depress the blade engagement pedal (about 3/4

inch) and check if the belt is engaging.

3. If the cable is tight or too loose or the belt is not

engaging, adjust the deck engagement cable.

2. If the beit is engaging sooner than when the biade

engagement pedal is 3/4” from the PTO switch,

tighten both hex nuts on the cabie. See Figure 13.

3. Repeat the blade engagement test and readjust if

necessary.

4. Pivot the hood assembly back.

Wheel Alignment

The front wheels should toe-in 1 /16-5/16 inch. To adjust

toe-in, follow these steps:

1.

Remove the 3/8” hex nut and lock washer which

hold the ball joint to the steering segment. See

Figure 14.

2.

Adjust the bail joint in or out until the wheels toe-in

approximately 1/16-5/16“ (Dimension “B” should

be approximately 1/16-5/16“ less than dimension

“A”}. See Figure 14.

Replace the ball Joint into the steering segment,

3.

and replace the 3/8” hex nut and the lock washer.

NOTE: The deck engagement cable will be correctly

adjusted when the cable moves approximately 1/2” off

centerline in both directions.

Deck

Engagement

Cable

Figure 13

Adjustment to the biade brake will have to be made at

the cable end. See Figure 13.

1. If the beit is slipping when you depress the biade

engagement pedal about 3/4”, loosen the two hex

nuts on the cable. See Figure 13.

Adjusting the Deck

There are three tests for checking deck leveling on the

riding mower. The results of each test will determine

what kind of leveling, if at all, the equipment needs.

IMPORTANT: Perform adjustments to the deck on a flat,

level surface. Before continuing with deck adjustment,

check air pressure in all four tires. Recommended air

pressure is 12 psi. Please note that the valve stems on

this riding mower are on the inside of the front wheels

and on the outside of the rear wheels.

Test 1: Checking Rear Deck Height Adjustment

1. Lift the hood assembly and remove grass catcher

from the riding mower. Place the deck in the

highest position.

2. Inspect rear of deck. If the deck is contacting the

cable bracket in front of the transmission, you will

have to adjust the rear deck height.

17

Page 18

Test 2: Checking Front to Rear Leveling

1.

Place the deck in the highest position.

2.

Wearing a pair of heavy work gioves to prevent

injury, rotate the cutting blade so that it is pointed

front to back and paraiiel to the rider. Depress and

lock the deck engagement pedal.

3.

Measure the distance from the front and the rear

tips of the biade to the ground.The front should be

approximately 1/4” to 3/8” lower than the rear.

4.

If the distance is higher, level the deck front to rear.

Test 3: Checking Side to Side Leveling

1.

Place the deck in the highest position.

2.

Wearing a pair of heavy work gioves to prevent

injury, rotate the cutting blade so that it is pointed

side to side and perpendicular to the rider. Depress

and lock the deck engagement pedal.

3.

Measure the distance from the tips of the blade to

the ground.

4.

If the two distances are unequal, level the deck

side to side.

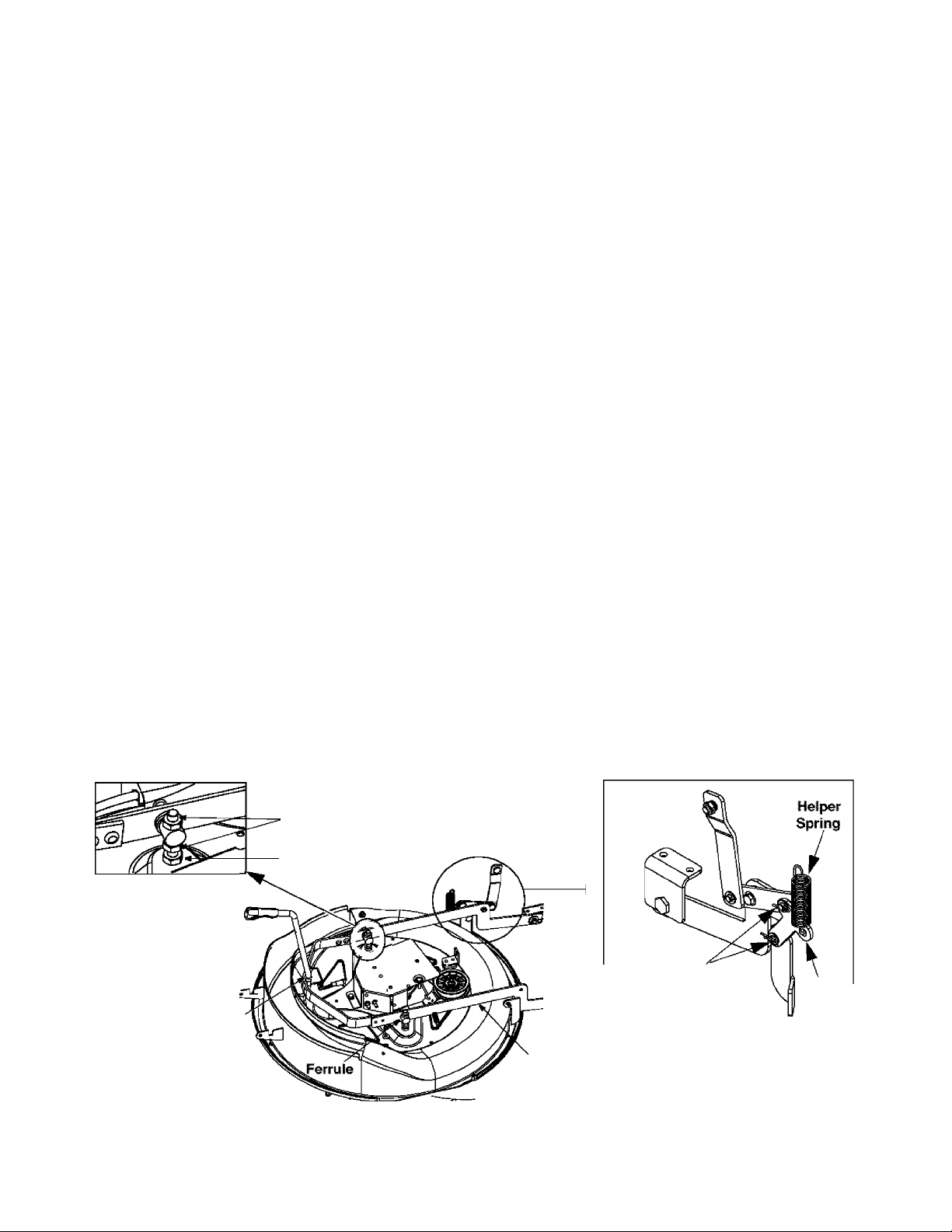

Adjusting Rear Deck Height

1. Completely loosen, but do not remove, the top hex

nut out of the three hex nuts that hold the hex bolt

and the ferrule on the deck hanger link assembly.

See Figure 15 .

IMPORTANT: Do not try to loosen/ tighten bottom nut.

2.

Thread the middie nut as far down as possible.

Locate the lower links at the rear of the deck.

3.

Working on one side at a time, disconnect the

helper springs from them.

4.

Remove each lower link by removing both hair pin

clip and washers.

Reattach lower links as shown in Figure 15 inset.

5.

Front to Rear Leveling

1. Place the deck in the highest position.

2. Wearing a pair of heavy work gioves to prevent

injury, rotate the cutting blade so that it is pointed

front to back and paraiiel to the rider. Depress and

lock the deck engagement pedal.

3. Compietely loosen, but do not remove, the top hex

nut out of the three hex nuts that hold the hex bolt

and the ferrule on the deck hanger link assembly.

See Figure 15.

IMPORTANT: Do not try to loosen/ tighten bottom nut.

4.

Thread the middle nut as far down as possible.

5.

Keeping an equal number of threads above each of

the nuts, thread the upper nut down until the front

tip of the blade is 1/4” to 3/8” lower than the rear tip

of the blade. Note that threading this nut down will

raise the front of the deck.

6.

Thread the middle nut up against the base of the

ferrule. See Figure 15.

7.

Tighten the upper nut against the top of the ferrule

to lock adjustment.

Side to Side Leveling

1.

Place the deck in the highest position.

2.

Wearing heavy work gloves to prevent injury, rotate

the blade so that it is pointed side to side and

perpendicular to the rider. Depress and lock the

deck engagement pedal.

3.

Loosen the middle hex nut.

4.

Thread the top hex nut up or down in order to set

both tips of the biade at an equal height from the

ground. Remember to thread the nut down to raise

the deck, and thread up to lower the deck.

5.

Once the deck is level, thread the middle hex nut to

tighten against the ferrule. Make sure the cut is

even and the lift lever moves to all cutting heights.

Deck

Height

Lever

Loosen hex nuts

to adjust

Do not adjust hex nut

Figure 15

18

Hanger

Link

Remove Hairpin Clips

and Washers

Lower

Link

Page 19

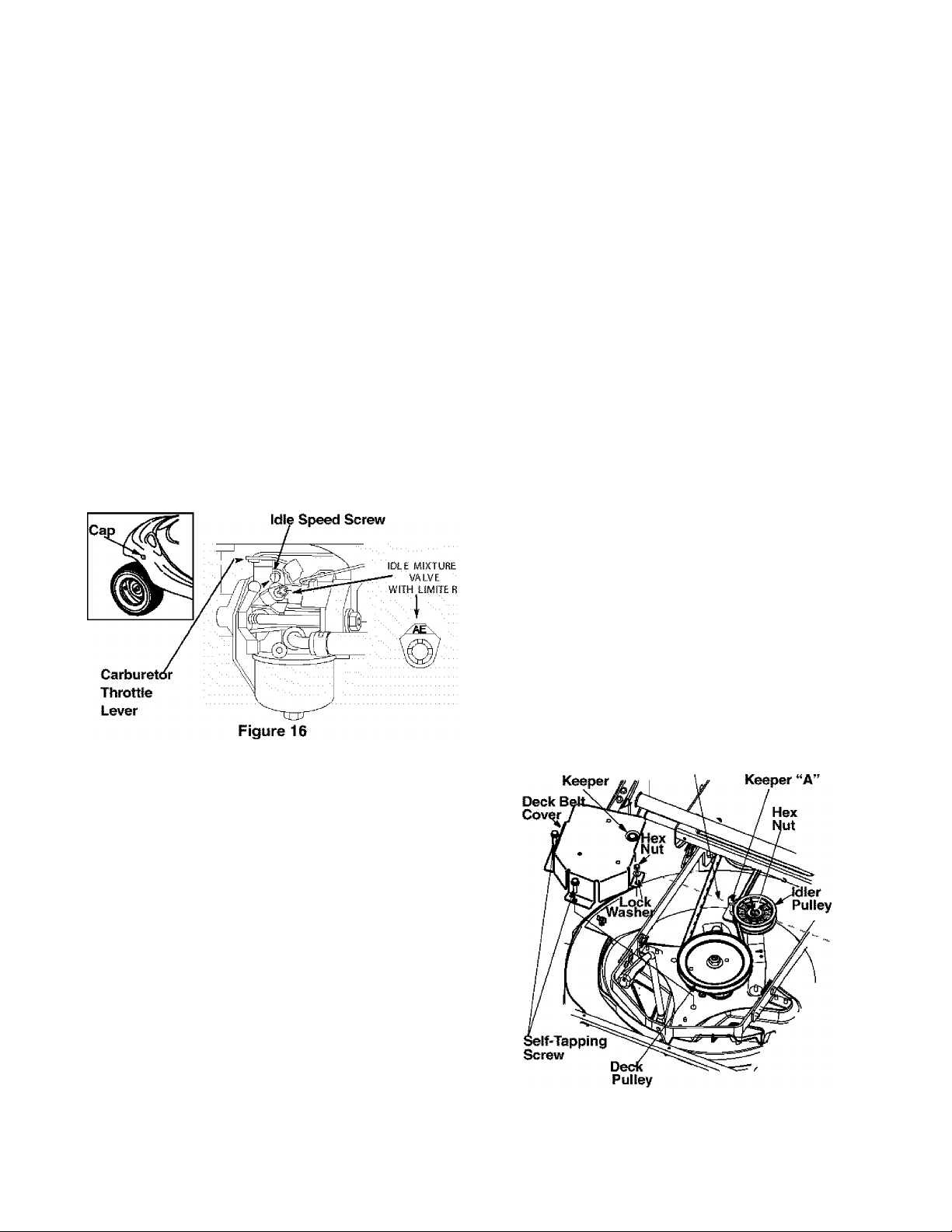

Adjusting the Carburetor

Differences in fuel, temperature, altitude or load may

require minor carburetor adjustments. The carburetor

on this engine is equipped with an idle mixture valve

with a limiter which allows some adjustment, and an

idle speed adjustment screw. Remember that the air

cleaner must be assembled to the carburetor before re

starting the engine. Refer to page 14 for detalis.

NOTE: Engines, operated at approximately 3000 to

5000 feet above sea level, may require a high altitude

carburetor nozzle. If your riding mower performs

erratically, contact Sears service center for the nozzle.

To adjust the carburetor, follow the steps below;

1. Start the engine and run it for at least 5 minutes to

warm up.

2. With the engine running, place throttle control in

SLOW position.

3. Lift the hood assembly up as instructed on page 7.

4. Remove the black cap from the rider frame. See

Figure 16 . Access the carburetor throttle lever and

idle speed screw from this opening.

the cranking or charging circuit where Insulation

may have rubbed through and exposed bare wire.

2. Replace the wire or repair with electrician’s tape if

the wire strands have not been damaged. Also look

for a wire pinched between body panels, burned by

the exhaust pipe or muffler, or rubbed against a

moving part.

3. Stop the riding mower and engage the parking

brake. Remove ignition key.

4. Pivot the hood assembly up. Disconnect the spark

plug wire and ground It.

5. Puli the fuse out of the lead wire.

6. RepI ace with new automotive fu se.

7. Make sure to reconnect the spark plug wire before

pivoting the hood assembly back.

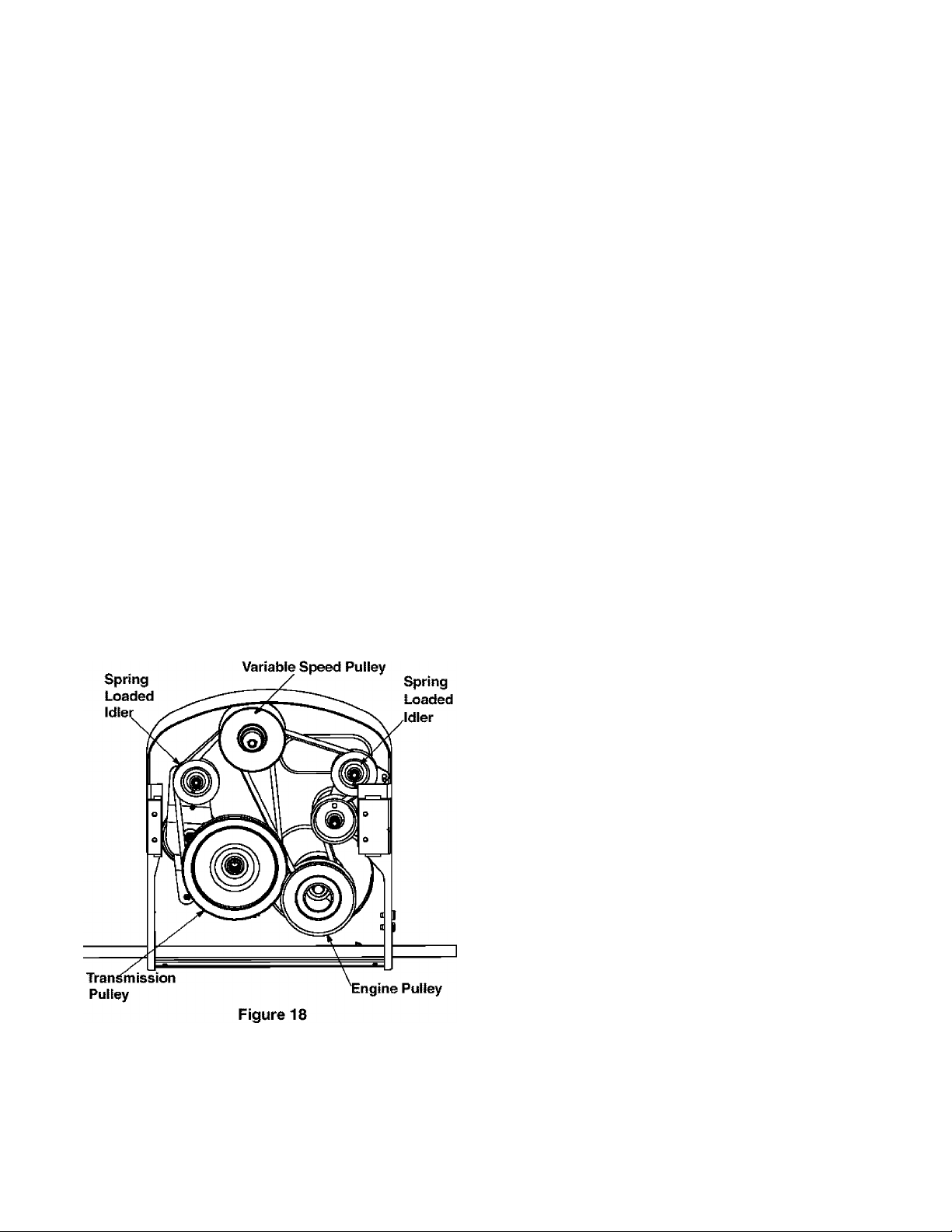

Belt Replacement

There are two drive belts and one deck belt in this unit;

follow description below to identify the belts.

• Deck belt goes from the deck pulley to the lower

sheave in engine pulley.

• Lower drive belt goes from the variable speed

pulley to the transmission pulley.

• Upper drive belt goes from the variable speed

pulley to the upper sheave of engine pulley.

Periodically check if these belts are too loose or

damaged. If so, replace with new belt.

Rotate carburetor throttle lever against the idle

5.

speed screw and hold it. Turn idle speed screw to

obtain 1750 rpm, using a tachometer to measure.

6.

Rotate idle mixture valve full travel clockwise and

then counter-clockwise. Do NOT remove limiter

caps. Do NOT force beyond limits.

7.

Place idle mixture valve in middle of travel.

8.

Move throttle control to FAST position. The engine

should accelerate smoothly. If it does not, adjust

Idle mixture valve counter-clockwise 1/8 turn.

9.

Replace the black cap on the riding mower frame

and put the hood assembly back.

Fuse Replacement

The fuse is located next to the spark plug under the rear

frame. Fuses seldom fail without a reason. If the fuse

biows, the source problem must be corrected or the

new fuse will blow again.

1. Check for loose connections in the fuse holder and

replace hoider if necessary. A dead short may be in

Deck Belt

1. Engage the parking brake and turn the ignition off.

Pivot the hood assembly up and remove the grass

catcher. Remove the spark plug wire.

2.

Put the deck at the lowest cutting height by

adjusting the cutting height adjustment lever to the

lowest position.

Imaginary

Belt

Line

Figure 17

Belt

19

Page 20

3. Using a 1 /2” socket wrench, remove two self

tapping screws, lock washer and hex nut that hold

the deck belt cover to the deck. See Figure 17. For

this, you will have to work from the top left side of

the riding mower. Remove the belt cover.

4. Using a 9/16” wrench, loosen the hex nut on the

idler pulley. See Figure 17.

5. Remove belt from around deck pulley, idler pulley,

and the engine pulley.

6. Place the new belt around the deck pulley and the

engine pulley making sure that the belt is routed

inside the belt keepers. There are two belt keepers

under the grass catcher, one on the idler and the

other under the deck belt cover. See Figure 17.

7. Reinstall deck belt cover and secure with two each

of self-tapping screw, lock washer and hex nut.

NOTE: Belt keeper “A” must be mounted on the outside

of the belt

8. Make sure to align the belt keeper in line with the

frame. See Figure 17.

NOTE: An imaginary line between the belt keeper and

idler pulley should be parallel to frame. See Figure 17.

9. Replace the grass catcher and pivot the hood

assembly back.

Lower Drive Belt

1. Remove the rear deck belt guard following first five

steps for deck belt removal. Remove belt from the

engine pulley. See Figure 18 .

4. Drop the pulley down and remove the belt.

5. Replace new belt and reassemble.

IMPORTANT: Make sure that the belt is routed inside of

belt keeper, and the belt keeper is reassembled in the

same location from where it was removed.

Upper Drive Belt

1. Remove the engine pulley using a 5/8” socket

wrench with a 6” extension. The engine pulley is

located in front of the transmission.See Figure 18 .

2. Drop the engine pulley down and remove the belt

from around it.

3. Push the idler bracket to the right and remove the

belt. See Figure 18 .

4. Replace belt and reassemble.

Battery Service

The battery is located under the hood assembly. The

positive battery terminal is marked (+); the negative

battery terminal is marked (-).

Safe Handling

• Shield eyes and protect skin and clothing when

handling battery acid (electrolyte) or a battery

containing acid.

• Keep sparks, flame, cigarettes and other sources of

ignition away. Remember that battery contains

explosive gases.

• Work in a well-ventilated area when filling

(activating), charging and using the battery.

2. Push the spring loaded idler, located on the left side

of the transmission, to the right. Remove belt from

around the idler and then the transmission pulley.

See Figure 18 .

3. Using a 9/16” socket, remove bolt, spacer and the

flat washer from the variable speed pulley.

WARNING: Do not short battery terminals

A

A

by making a connection between either two

battery posts or between the positive terminal,

marked + on the battery, and the riding mower

frame. Before installing battery, remove metal

bracelets, wristwatch bands, rings etc. from

your person.

Always keep the rubber boot positioned over the

positive terminal to prevent shorting.

Connect positive terminal first to prevent sparks

from accidental grounding.

Do not use the riding mower battery to start other

vehicles.

WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds. Wash hands after handling.

Always keep battery cables and terminals clean

and free of corrosive build-up.

After cleaning, apply a light coat of petroleum jelly

or grease to both terminals.

If removing the battery for any reason, disconnect

the NEGATIVE (black) wire from its terminal first,

followed by the POSITIVE (red) wire.

20

Page 21

• When re-instaliing battery, aiways connect the

POSITIVE (red) wire to its terminal first, followed by

the NEGATIVE (black) wire.

IMPORTANT: Be certain that wires are connected to the

correct terminals; reversing them could change polarity

and cause damage to the engine's alternating system.

9. Disconnect the positive (+) jumper cable from the

positive (+) post of the good battery.

10. Disconnect the other end of the positive (+) jumper

cabie from the solenoid.

11. Replace boot over the forward most terminal from

where you removed it in Step 1. See Figure 19.

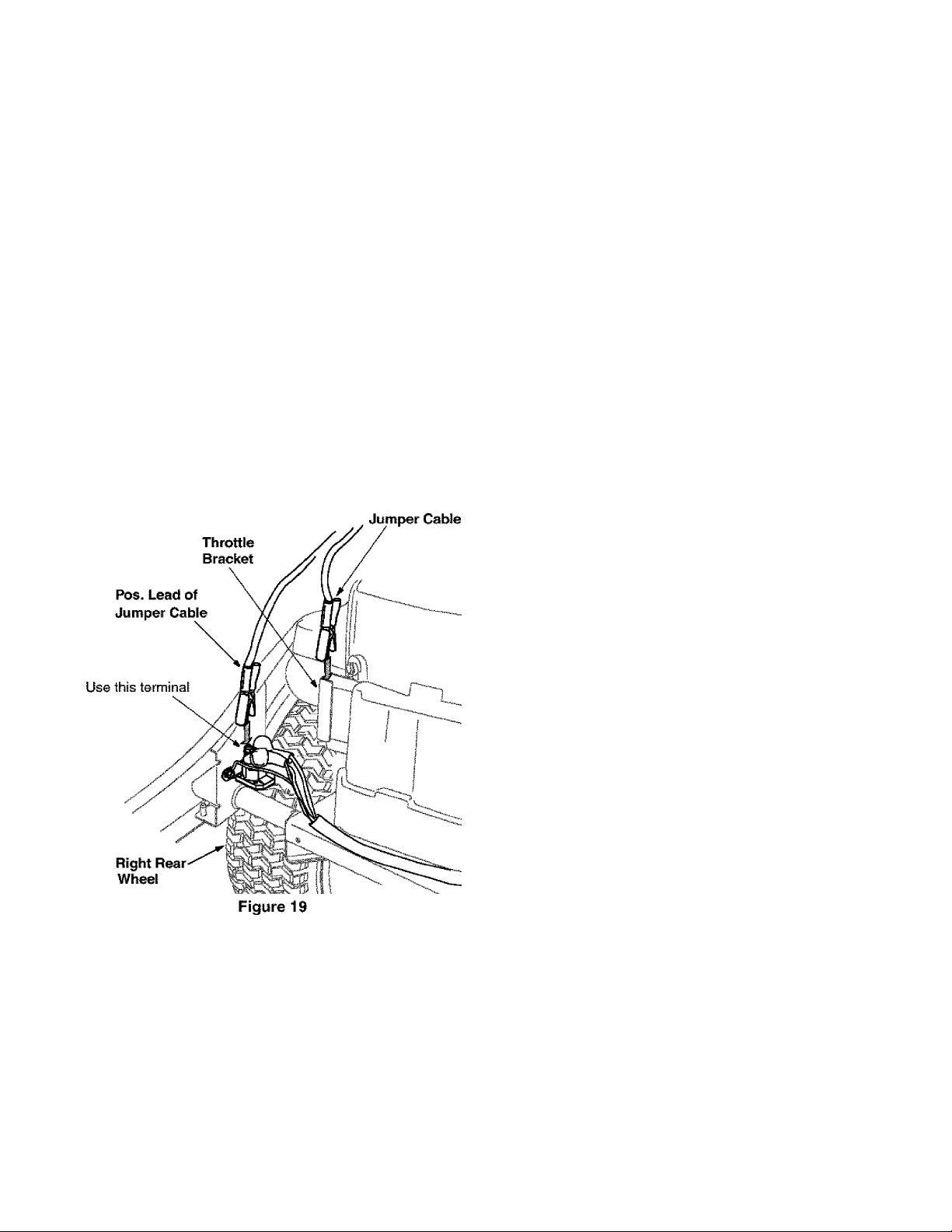

To jump-start the battery

NOTE: This riding mower is equipped with a remote

battery charging terminal on the soienoid on the right

side of the frame under the hood. Foliow the

instructions below to use this terminai.

• Do not Jump-start directly at the battery.

• Do not allow positive and negative cable clamps to

touch each other.

• Do not jump-start a damaged or frozen battery.

1. Puii back the boot from the forward most terminal

connected to the soienoid. See Figure 19.

2. Connect the positive (+) lead of the jumper cable to

this terminal. See Figure 19.

Neg. Lead of

To charge the battery

If battery is new or if the riding mower has been stored

for an extended period of time, charge the battery for

one hour with a battery charger (output 6 amps) before

using your riding mower. Read safe operating

instructions on battery charger before starting this job.

IMPORTANT: If a charger with 6 amps output is not

available, use a lower output charger for a longer

charging period. However, do not use a charger with

higher than 6 amps output.

If a charger is not avaiiable, but the battery is abie to

start the riding mower, run the mower for a minimum of

one hour of mowing to charge the battery with the

engine’s charging system.

NOTE: Use the remote terminai on the solenoid to

charge the battery. Do not charge at the battery.

1. Puil back the boot from the forward most terminal

connected to the solenoid. See Figure 19.

2. With the battery charger off, connect the positive

(+) lead of the charger cabie to this terminal. See

Figure 19.

3. Connect negative (-) iead of the charger cable to

the throttle bracket.

4. Turn the battery charger on. Charge the battery

until the indicator on the charger shows fuii charge.

5. Turn battery charger off. Disconnect the negative

charger cable (marked -} from the throttle bracket.

6. Disconnect the positive charger cabie (marked +)

from the solenoid terminal.

7. Replace boot over the forward most terminal (from

where you removed it in Step 1). See Figure 19.

3. Connect the other end of the positive (+) jumper

cable to the positive (+) post of the good battery.

4. Connect one end of the negative (-} jumper cabie to

the negative (-) post of the good battery.

5. Connect the other end of the negative (-} cable to

the throttle bracket. See Figure 19.

6. Start the tractor and leave it running to charge the

battery.

7. Disconnect the negative (-) jumper cable from the

tractor.

8. Disconnect the other end of the negative (-} jumper

cabie from the negative (-) post of the good battery.

To Remove Battery

1.

Make sure that the riding mower is stopped

completely. Lift the hood assembly up to access the

battery.

2.

Remove the wing nuts securing the battery hold

down rods to the battery cover.

3.

Puii the battery cover up and keep it away.

4.

Loosen the screw at the negative terminal and

remove the cable.Repeat at the other terminal.

5.

Remove the battery.

Attaching Battery Cables

1. Remove wing nut on the battery hold-down rod at

each end of the battery cover. See Figure 20.

2. Remove the battery cover from the battery to

access the terminals.

21

Page 22

3. Puii the boot up and remove screw from positive

terminal with a wrench.

4. Attach the red battery cabie to this positive terminal

and tighten secureiy. See Figure 20 .

5. Remove screw from negative terminal with a

wrench.

WARNING: Be careful not to contact any

A

6.

7.

A

8.

9.

CAUTION: Do not place your hand around the bottom

edge of the hood assembly; it may get pinched between

the hood assembiy and grass catcher or the frame rail.

adjacent metal part or short across posts.

Attach the black battery cable to this negative

terminal on the battery and tighten securely. See

Figure 20.

Reposition the battery cover on top of the battery,

making sure it goes over the flange of the nearby

heat shield. See Inset A in Figure 20. Tuck away

the battery cables completely under the battery

cover. See Inset B in Figure 20 . Check to ensure

that the cables pass easily through slots in the

battery cover.

WARN ING: Keep battery cables away from

the engine exhaust system.

Reinstall wing nuts on the battery hold-down rods

and tighten.

Place right hand on the left side of the seat and

slowiy lower the hood assembly until fully closed.

VV WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds. Wash hands after handling.

Wmg Nut

Negative

Terminal

Positive

Terminal

------

-----

Wing Nut

- Battery Cover

.

^

\J

Screw ■

A

\\ \

B

-----------

told-down

Rod

- Battery

Cable

i

Heat/^

Shield

*

Figure 20

Cabl/^^^

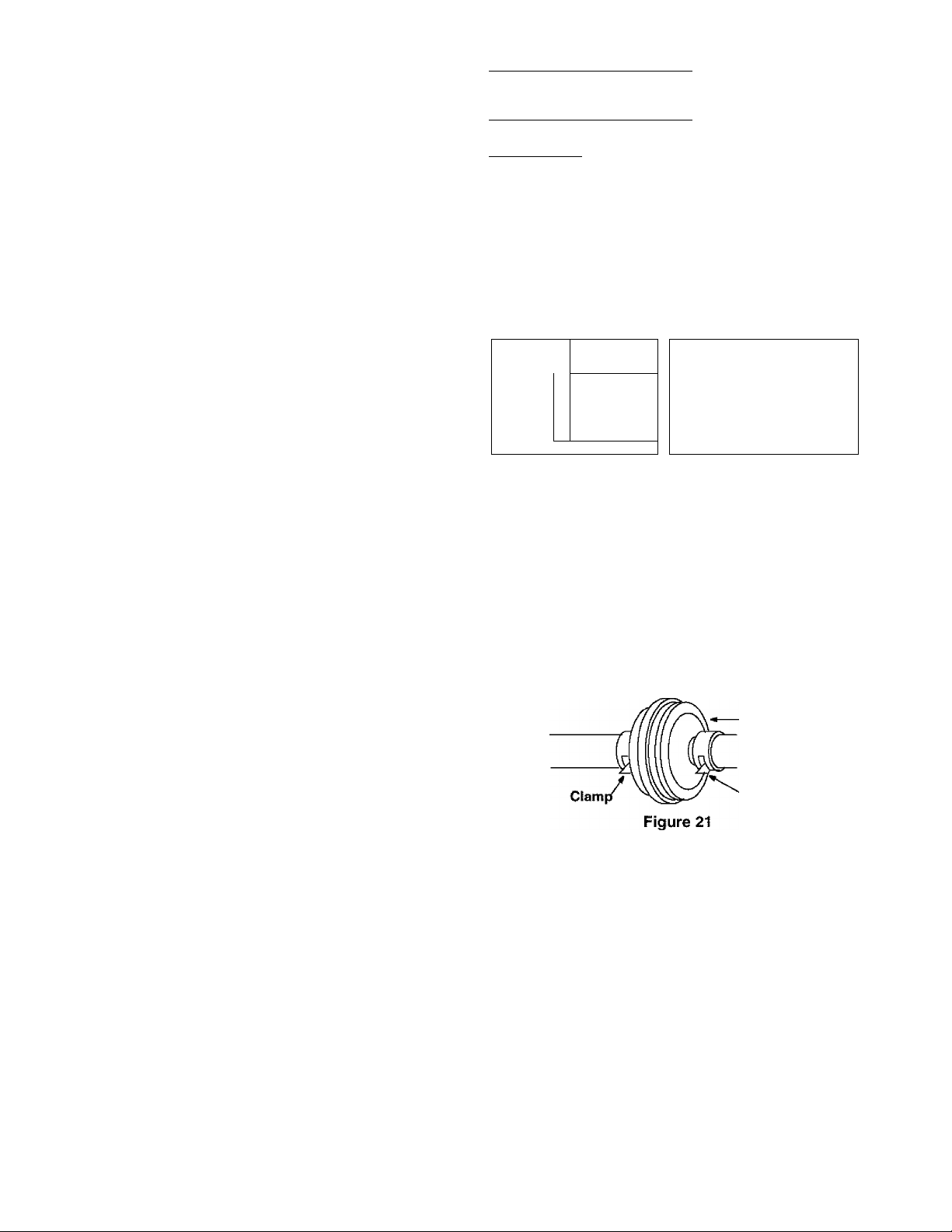

Fuel Filter

WARNING: Drain fuel tank or close fuel

A

Your unit is equipped with a replaceable in-line fuel

filter. Loosen the clamps and replace filter whenever

contamination or discoloration is noticed. See Figure

21. Order replacement filter from Sears service, center.

shut-off valve before replacing fuel filter.

Otherwise fuel can leak creating a fire/

explosion hazard.

Fuel Filter

22

Clamp

Page 23

FF-SEASON STORAG

If the machine is to be inoperative for a period longer

than 30 days, prepare for storage as follows.

Battery

1. Charge battery fully. The battery loses some of its

charge each day when the unit is not used. NEVER

store battery without a full charge. Recharge

battery before returning to service or every two

months, whichever occurs first.

2. When storing unit for extended periods, disconnect

battery cables and remove the battery from the unit.

3. Ciean dirt and chaff from cylinder, cylinder head

fins, blower housing, rotating screen and muffler.

Engine

Engines, stored over 30 days, need speciai attention to

prevent gum formation in the fuel system or on the

carburetor.

1.

If fuel tank contains oxygenated or reformulated

gasoline, that is gasoline blended with alcohol or

ether, run engine until dry.

2.

If fuel tank contains gasoline, either run engine till

dry or add an additive to the gas. If you are using

additive, run the engine for several minutes to

circulate the additive through the carburetor.

Change oil on a warm engine.

3.

4.

Remove spark plug and pour about one ounce of

engine oil into cylinder. Replace the spark plug and

crank engine slowly to distribute the oil.

5.

Clean engine of debris, chaff or grass clippings.

Store engine and riding mower in a ciean, dry area

6.

far away from stove, furnace, water heater or

similar appliances using a pilot light or any other

sparking device.

Riding Mower

1.

Ciean the engine and the entire unit thoroughly.

2.

Lubricate all pivot points. Wipe the entire machine

with an oiled rag to protect the surfaces.

Transport the mower with fuel tank empty. Store

3.

unit in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

4.