Model No,

172.27696

, SAFETY

CAUTION: Read, understand and follow

all Safety Rules and Operating Instruc_Jons

in this manual before using th_s product.

• OPERATION

• MAINTENANCE

• ESPANOL

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Warranty. ....................................................................... Page

Safety Instructions ...................................................... Pages

Safety Symbols ....................................................... Page

Assembly. ...................................................................... Page

Operation .................................................................. Pages

Maintenance ................................................................. Pages

Accessories .................................................................. Page

ONE FULL YEAR WARRANTY ON CRAFTSMAN PROFESSIONAL TOOL

If this Craftsman Professfonal Tool fails to give complete satisfaction within one

year from the date of purchase, RETURN ITTOTHE NEAREST SEARS STORE

IN THE UNITED STATES, and Sears will replace it, free of charge.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Coo,Dept. 817 WA, Hoffman Estates, IL 60179

2

3-7

7

8-9

11

12-13

14-15

16

SAVE THESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

WARNING: BE SURE to read and understand all instructions. Failure

to follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

WORK AREA SAFETY

i. ALWAYS keep your work area clean and well lit. Cluttered benches and dark

areas inviteaccidents°

2. DO NOT operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Powertoolscreatesparks which

may ignite the dust or fumes°

3. ALWAYS keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control°

ELECTRICAL SAFETY

I. Double insulated tools are equipped with a polarized plug (one blade is

wider than the other.) This plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install a polarized outlet. DO NOT

change the plug In any way.

2. Double insulationQeliminates the need for thethree wire grounded power cord

and grounded power supply system. Applicable only to Class ii (double insulated)

tools°

3. Before plugging in the tool, BE SURE that the outlet vollage supplied is within the

voltage marked on the tool's data plate. DO NOT use "AC only" rated tools with a

DC power supply.

4. ALWAYS avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators, There is an increased risk of electric shock

if your body is grounded.

5. If operating the power tool in damp locations is unavoidable, ALWAYS use a

Ground Fault Circuit Interrupter to supply power to your tool. ALWAYS wear

electrician's rubber gloves and footwear in damp conditions.

6. DO NOT expose power tools to rain or wet conditions. Water entering a power

toot will increasethe risk of electric shock°

7. DO NOT abuse the cord. NEVER use the cord to carry the tools or pull the

plug from the outlet. Keep cord away from heat, oil, sharp edges or moving

parts. Replace damaged cords immediately. Damaged cords increase the risk

of electric shock°

8. When operating a power tool outside, At.WAYSuse an outdoor extension

cord marked "W-A" or "W". These cords are rated for outdoor use and reduce

the risk of electric shock_

NOTE: The extension cord must have adequate wire size AWG (American Wire

Gauge) for safe, efficientuse° Smaller gauge wires have greater capacity (16 gauge

wire has more capacity than 18 gauge wire).

PERSONAL SAFETY

1.ALWAYS stay alert, watch what you are doing and use common sense when

operating a power tool. DO NOT use tool while tired or under the influence of

drugs, alcohol or medication. A moment ofinattentionwhile operating power

tools may result in serious personal injury_

2. ALWAYS dress properly. DO NOT wear loose clothing or jewelry. Pull back

long hair, Keep your hair, clothing and gloves away from moving parts. Loose

clothing, jewelry or long hair can be caught inmoving parts.

3. ALWAYS avoid accidental starting. BE SURE switch is in the "Off" position

before plugging in. Carrying tools with your finger on the switch or plugging in

tools that have the switch in the "On" position invitesaccidents,

4. ALWAYS remove adjusting keys or wrenches before turning the tool on.

A wrench or a key that is left attached to a rotating part of the tool may result in

personal injury.

5. DO NOT overreach. ALWAYS keep proper footing and balance at all times.

Proper footingand balance enables better control of the tool in unexpected

situations.

6. ALWAYS use safety equipment. ALWAYS wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be used for

appropriate conditions

TOOL USE AND CARE SAFETY

1. ALWAYS use clamps or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body

is unstable and may lead to loss of control.

2. DO NOT force the tool. Use the correct tool for your application. The correct

tool will do the job better and safer at the rate forwhich itis designed.

3. DO NOT use the tool if the switch does not turn it "On" or "Off", Any tool that

cannot be controlled with the switch is dangerous and must be repaired.

4. ALWAYS disconnect the plug from the power source before making any

adjustments, changing accessories or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

5. ALWAYS store idle tools out of the reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users°

6, ALWAYS maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edges are less likely to bind and are

easier to control.

7. ALWAYS check for misalignment or binding of moving parts, breakage of

parts, and any other condition that may affect the tool's operation. If

damaged, have the tool serviced before using. Many accidents are caused by

poorly maintained tools.

TOOL USE AND CARE SAFETY CONT.

Z_WARNING: USE OF ACCESSORIESTHAT ARE NOT RECOMMENDED

FOR USE WITH THIS TOOL MAY CREATE A HAZARDOUS CONDITION.

8. ALWAYS use only accessories that are recommended for this tool.

Accessories that may be suitable for one toolcan become hazardous

when used on another toolo

SERVICE SAFETY

1. If any part of this sander is missing or should break, bend, or fail in any way;

or should any electrical component fail to perform properly: ALWAYS shutoff

the power switch and remove the saw plug from the power source and have the

missing, damaged or failed parts replaced BEFORE resuming operation.

2. Tool service must be performed only at a Sears Service Center. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

SAFETY RULES FOR SANDERS

1. NEVER use this or any power sander for wet sanding or liquid polishing,

Failure to follow this rute willincrease the riskof electrical shock,

ADDITIONAL RULES FOR SAFE OPERATION

, ,, ,,,, ,, , ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

.....................................

_WARNING: BE SURE to read and understand all instructions. Failure

to follow all instructions listed below may result in electric shock, fire and/or

serious personal injury.

1. Know your power tool. Read operator's manual carefully. Learn the

applications and limitations, as well as the specific potential hazards related

to this tool.

2. ALWAYS wear safety glasses or eye shields when using this sander.

Everyday eyeglasses have only impact-resistant lenses; they are NOT safety

glasses.

3. ALWAYS protect your lungs.Wear a face mask or dust mask if the operation

is dusty.

4. ALWAYS protect your hearing.Wear hearing protection during extended

periods of operation.

5. ALWAYS inspect the tool cords periodically and if damaged have them

repaired at your nearest Sears Service Center or other qualified Service

Facility, ALWAYS be aware of the cord location.

6. ALWAYS check for damaged parts. Before further use of the tool, a guard or

other part that is damaged should be carefully checked to determine if it will

operate properly and perform its intended function. Check for misalignment

or binding of moving parts, breakage of parts, and any other condition that

may affect the tool's operation. A guard or other part that is damaged,

should be properly repaired or replaced at an qualified Service Center.

i l lll i,i J/illJJJJiiJl/iJllJJiJii

i

ADDITIONALRULESFORSAFEOPERATIONCONT.

7.DONOT abuse the cord, NEVER use the cord to carry the tools or pull the

plug from the outlet. Keep cord away from heat, oil, sharp edges or moving

parts. Replace damaged cords immediately. Damaged cords increase the risk

of electricshock,

8, ALWAYS make sure that your extension cord is in good condition. When

using an extension cord be sure to use one that is heavy enough to carry

the current that your tool will draw. A wire gauge size (A,W.G,) of at least 16

is recommended for an extension 100 feet or less in length. Using an

extension cord that is over 100 feet in length is not recommended. If in

doubt, use the next heavier gauge. Smaller gauge wires, have greater

capacity (16 gauge wire has more capacity than 18 gauge wire).

An undersized cord will cause a drop in fine voltage, resulting in toss of power

and overheating,

9. ALWAYS inspect and remove all nails from lumber before sanding.

10. DO NOT use the tool while tired or under the influence of drugs, alcohol or

any medication.

11.SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to

instruct others who may use this tool. If someone borrows this tool, make

sure they have these instructions also.

Z_WARNING; Some dust particles created by power sanding, sawing;

grinding, drilling and other construction jobs contain chemicals known to

cause cancer, birth defects or other reproductive harm, Some examples of

these chemicals are:

• Lead from lead-based paints,

° Crystalline silica from bricks and cement and other masonry products°

• Arsenic and chromium from chemically treated lumber,

Your risk from these exposuresvaries, depending upon how often you do this

type of work. To reduce your exposure to these chemicals:

° Work in a well-ventilated area.

• Work with approved safety equipment, such as those dust masks thatare

specially designed to filter out microscopic particles.

ADDITIONAL RULES FOR SAFE OPERATION CONT.

WEAR YOUR

WARNING: The operation of any sander can

result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before

beginning power tool operation, ALWAYS wear safety

goggles or safety glasses with side shield and a full face

shield when needed. We recommend a Wide Vision

Safety' Mask for use over eyeglasses or standard safety

glasses with side shield, available at Sears Retail Stores.

The label of your tool may include the following symbols:

V ........................................................... Volts

A........................................................... Amps

Hz ......................................................... Hertz

W .......................................................... Watts

min ........................................................Minutes

,-,,., ....................................................... Alternating current

......................................................... .Direct current

Hz ........................................................... Frequency

no ........................................................ .No-load speed

[] .......................................................... Class II Construction

..Jmin .................................................... Revolutions or Strokes per minute

OPM ...................................................... Obits Per Minute

Z_ ........................................................... Indicates Danger, Warning or

Caution. It means attention!

Your safety is involved.

IMPORTANT! READ ALL iNSTRUCTIONS!

7

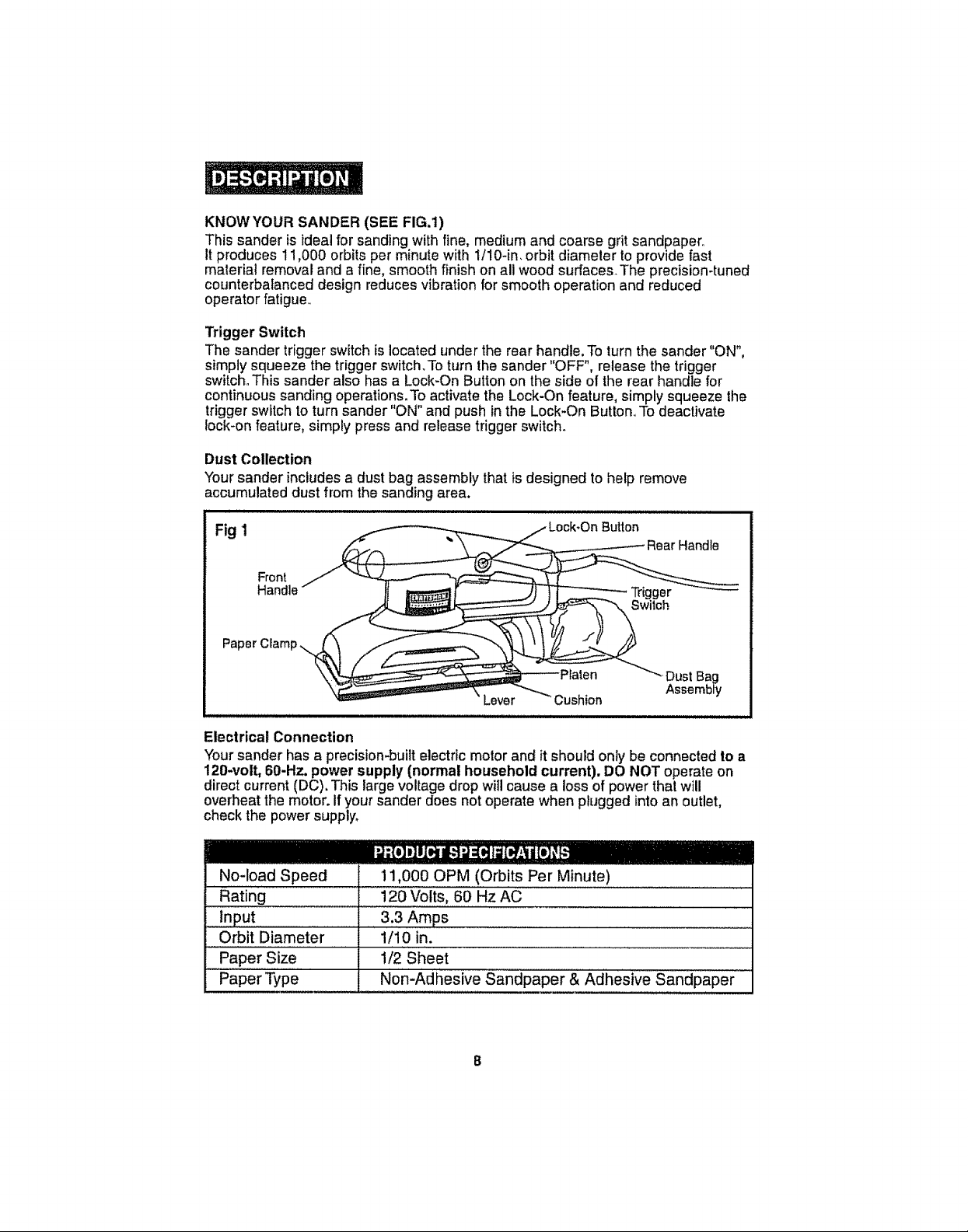

KNOWYOUR SANDER (SEE FIG.l)

This sander is ideal for sanding with fine, medium and coarse grit sandpaper,,

it produces 11,000 orbits per minute with 1/lO-in, orbit diameter to provide fast

material removal and afine, smooth finish on all wood surfaces, The precision-tuned

counterbalanced design reduces vibration for smooth operation and reduced

operator fatigue,,

Trigger Switch

The sander trigger switch is located under the rear handle. Toturn the sander "ON",

simply squeeze the trigger switch,To turn the sander "OFF", release the trigger

switch°This sander also has a Lock-On Button on the side of the rear handle for

continuous sanding operations,To activate the Lock-On feature, simply squeeze the

trigger switch to turn sander "ON" and push inthe Lock-On Button,,To deactivate

lock-on feature, simply press and release trigger switch,

Dust Collection

Your sander includesa dust bag assembly that isdesigned to help remove

accumulated dust from the sanding area.

Fig 1 Button

Handle

Front

Handle

Paper Clamp,,_,

'Cushion

Trigger

Switch

.,Dust Bag

Assembly

Electrical Connection

Your sander has a precision-builtelectric motor and it should only be connected to a

120-volt, 60-Hz. power supply (normal household current). DO NOT operate on

direct current (DC). This largevoltage drop will cause a loss of power that will

overheat the motor, If your sander does not operate when plugged into an outlet,

check the power supply,

No-load Speed 11,000 OPM (Orbits Per Minute)

Rating ..........120 Volts, 60 Hz AC

Input 3.3 Amps

Orbit Diameter 1/10 in. ".........

.......Paper Size 1/2 Sheet

Paper Type Non-Adhesive Sandpaper & Adhesive Sandpaper

WARNING: Your sander should NEVER be connected to the power

source when you are assembling parts, making adjustments, installing or

removing sandpaper, cleaning or when it is not in use. Disconnecting the sander

will prevent accidental starting, that could cause serious personal injury.

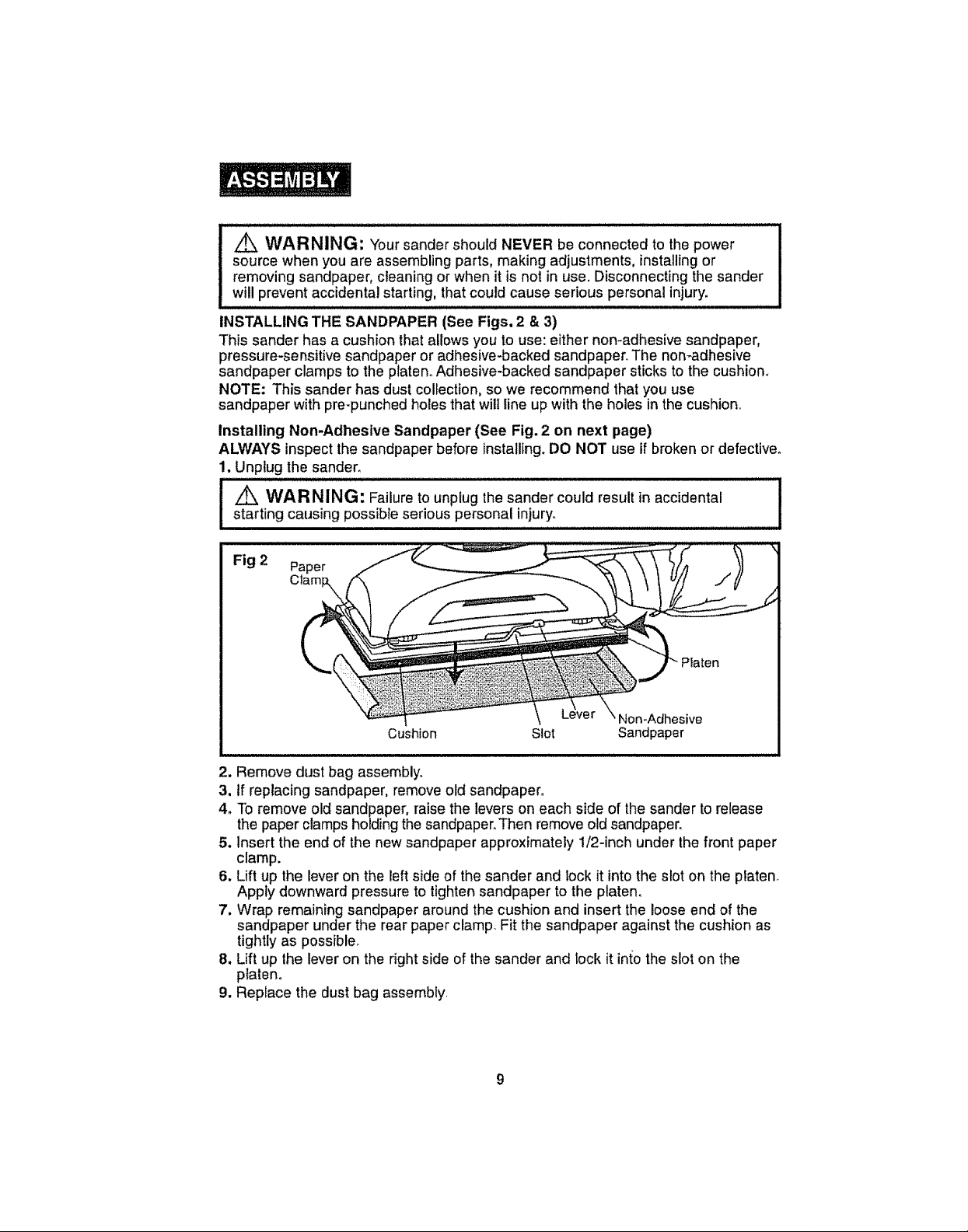

INSTALLING THE SANDPAPER (See Figs, 2 & 3)

This sander has a cushion that allows you to use: either non-adhesive sandpaper,

pressure-sensitive sandpaper or adhesive-backed sandpaper_The nomadhesive

sandpaper clamps to the ptatem Adhesive-backed sandpaper sticks to the cushiom

NOTE: This sander has dust collection, so we recommend that you use

sandpaper with pre-punched holes that wilI line up with the holes in the cushion,

Installing Non-Adhesive Sandpaper (See Fig. 2 on next page)

ALWAYS inspectthe sandpaper before installing.DO NOT use if broken or defective.

1. Unplug the sander_

J Z_ WAR NING: Failure to unplug the sander could result in accidental J

starting causing possible serious personal injury_

2. Remove dust bag assembly.

3, If replacing sandpaper, remove old sandpaper°

4. To remove old sandpaper, raise the levers on each side of the sander to release

the paper clamps holding the sandpaper. Then remove old sandpaper.

5. Insert the end of the new sandpaper approximately 1/2-inch under the front paper

clamp.

6. Lift up the lever on the left side of the sander and lock it into the slot on the platen°

Apply downward pressure to tighten sandpaper to the platen_

7. Wrap remaining sandpaper around the cushion and insert the loose end of the

sandpaper under the rear paper clamp. Fit the sandpaper against the cushion as

tightly as possible_

8. Lift up the lever on the right side of the sander and lock it int_othe slot on the

platen°

9. Replace the dust bag assembly

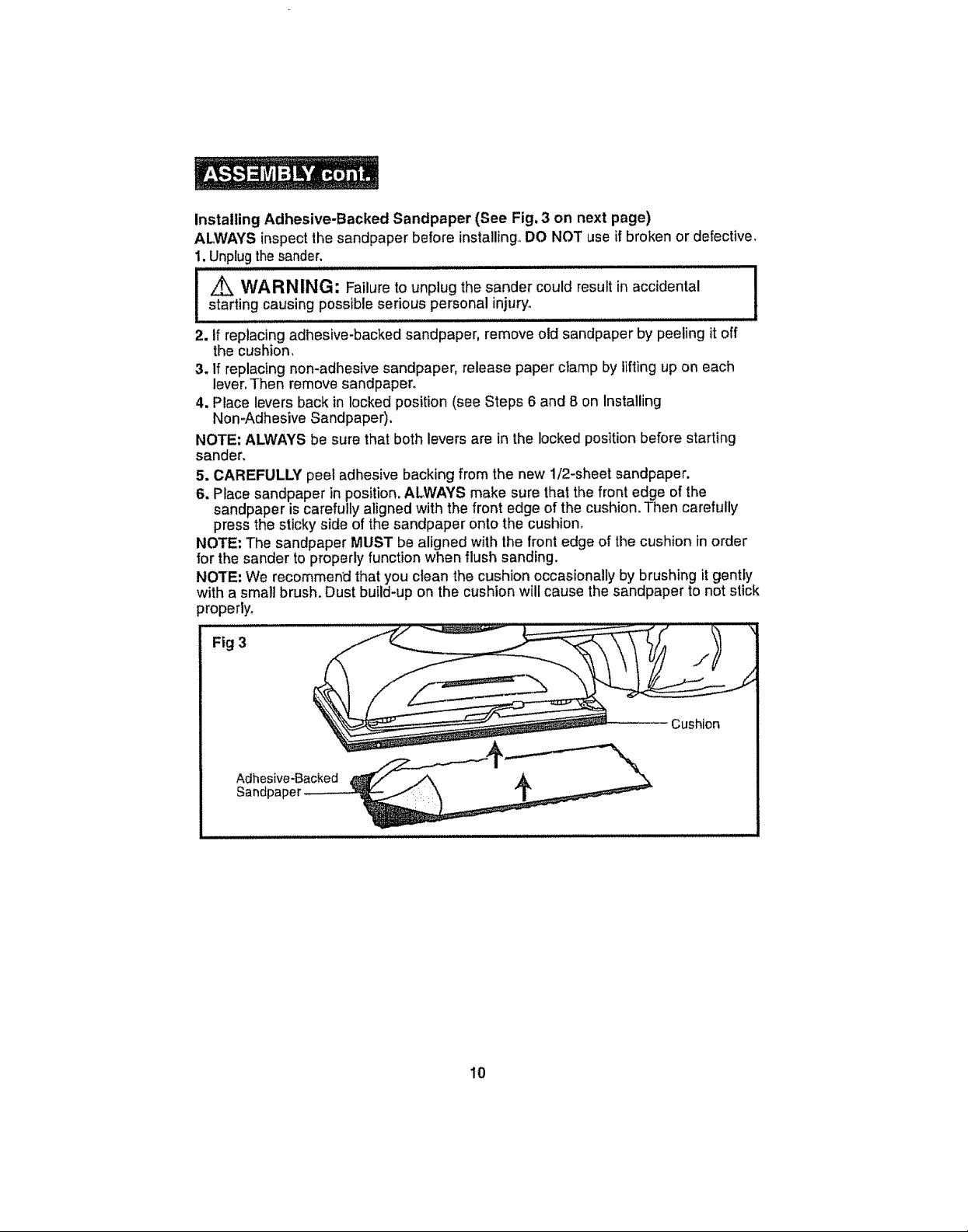

Installing Adhesive-Backed Sandpaper (See Fig, 3 on next page)

ALWAYS inspect the sandpaper before installing°DO NOT use ifbroken or defective,

1.Unplugthesander.

_ WARNING: Failure to unplug the sander could result in accidental

starting causing possible serious personal injury°

2. If replacing adhesive-backed sandpaper, remove old sandpaper by peeling it off

the cushion,

3. If replacing non-adhesive sandpaper, release paper clamp by lifting up on each

lever,Then remove sandpaper,

4, Place levers back in locked position (see Steps 6 and 8 on Installing

Non-Adhesive Sandpaper).

NOTE: ALWAYS be sure that both levers are in the locked position before starting

sander,

5. CAREFULLY peel adhesive backing from the new 1/2-sheet sandpaper.

6. Place sandpaper in position. ALWAYS make sure that the front edge of the

sandpaper is carefully aligned with the front edge of the cushion,Then carefully

press the sticky side of the sandpaper onto the cushion°

NOTE: The sandpaper MUST be aligned with the front edge of the cushion in order

for the sander to properly function when flush sanding,

NOTE: We recommend that you clean the cushion occasionally by brushing it gently

with a small brush, Dust build-up on the cushion will cause the sandpaper to net stick

properly_

Fig 3

Cushion

!

Adhesive-Backed

10

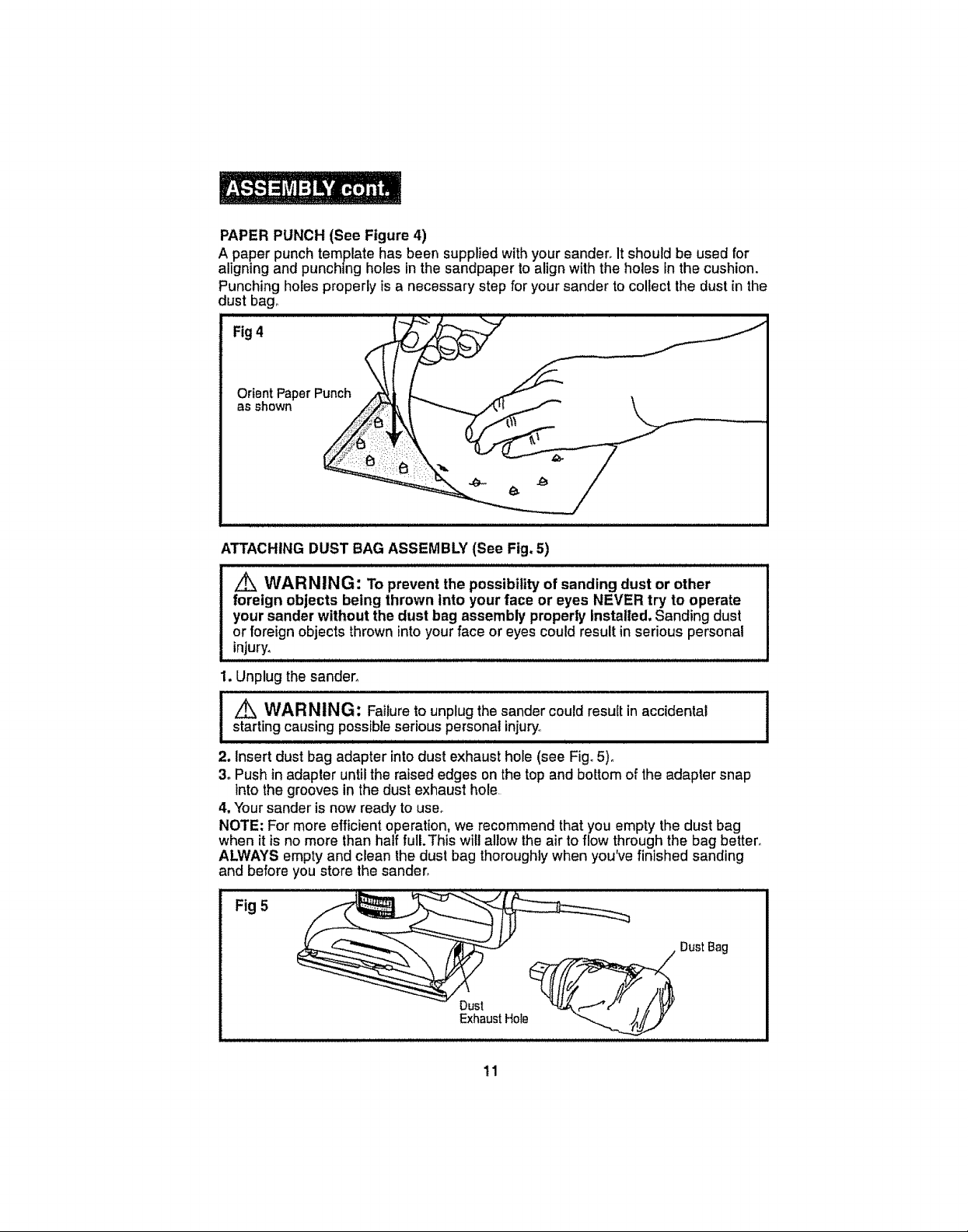

PAPER PUNCH (See Figure 4)

A paper punch template has been supplied withyour sander, Itshould be used for

aligning and punchingholes in the sandpaper to align with the holes In the cushion.

Punching holes properly is a necessary step for your sander to collect the dust in the

dust bag°

Fig4

Orient Paper Punch

as shown

ATTACHING DUST BAG ASSEMBLY (See Fig, 5)

WARNING: To prevent the possibility of sanding dust or other

foreign objects being thrown into your face or eyes NEVER try to operate

your sander without the dust bag assembly properly Installed. Sanding dust

or foreign objects thrownintoyourface or eyes couldresult in serious personal

injury,

1. Unplug the sander,

I_ WARNING: Failureto unplug the sander could result in accidental

starting causing possible'serious Personat injury_ ,

2. Insert dust bag adapter intodust exhaust hole (see Fig, 5)°

3, Push in adapter until the raised edges on the top and bottom of the adapter snap

intothe grooves in the dust exhaust hole.

4. Your sander is now ready to use°

NOTE; For more efficient operation, we recommend that you empty the dust bag

when it is no more than half fulLThis will allow the air to flow through the bag better_

ALWAYS empty and clean the dust bag thoroughly when you've finished sanding

and before you store the sander,

Fig 5

Dust Bag

Dust

ExhaustHole

11

i

TO REMOVE AND EMPTY DUST BAG (See Fig. 6)

1. Unplug thesander.

L_ WARNING: Failure tounplug the sander could result in accidental

starting causing possible serious personal injury.

lllllll llllll lllllll lllll i ill ill i i i i

2. Remove dust bag assembly from sander by firmly holding the adapter and pulling

straight out.

3, Remove dust bag from adapter (see Fig. 6).

4. Shake dust bag to empty.

5oPlace dust bag back onto the adapter.

6, Attach dust bag assembly back onto sander.

Fig 6

Dust Bag

Dust ?/_

Exhaus!Hole

ATTACHING THE VACUUM HOSE ADAPTER (See Fig. 7)

Your sander includes a vacuum hose adapter that easily attaches to the sander.

The adapter allows you to hook your sander up to your wet dry vac (sold separately).

1,Unplugthe sander..

I

L_ WAR NING: Failure to unplug thesander could result in accidental starting

causing possible serious personal injury..

i

2, Remove dust bag assembly from the sander by firmly holding the adapter and

pulling itstraight out.

3. Insert vacuum hose adapter into the dust exhaust hole.

4. Push in adapter until the raised edges on the top and bottom of the adapter snap

into the grooves in the dust exhaust hole.

5, Firmly attach the vacuum hose adapter to your vacuum hose.

6. Attach vacuum hose to vac.

Fig 7

Dust Exhaust Hole

_ Vacuum

Hose Adapler

12

Before attempting to use any toot, be sure to familiarize yourself with all the

operating features and safety instructions,

wARNING: IFAN', PARTSARE MISSING,DO ,,lOTOPERATEYOUR

SANDER UNTILTHE MISSING PARTS ARE REPLACED, FAILURETO

i

FOLLOWTHIS RULE COULD RESULT IN SERIOUS PERSONAL INJURY,

WARNING: DO NOT tet familiarity with your sander make you careless° I

Remember that a careless fraction of a second is sufficient to cause severe injury, I

WEAR YOUR

APPLICATIONS

Only use your sander for the applications listed below.

1. Sanding wood surfaces with various grits of sandpaper.

2. Removing rust from steel surfaces with special sandpaper.

!_ CAUTION: ALWAYS careful let hand cover the air vents,

i

I, ALWAYS clamp or otherwise secure the workpiece to prevent tt from moving

under your sander.

l "Z_"WARN'NG: Unsecured w°rk c°uld be thr°wn t°wards the °perat°r causing i,njury.

2. ALWAYS hold your sander in front and away from you, keeping it ctear of the

workpiece.

3. Start the sander by squeezing the trigger switch and then let the motor come up

to maximum speed_

4. Gradually lower the sander onto the workpiece with a slight forward movement°

(See Fig, 7°)

5. Move it slowly, using Fig 8

forward and backward

strokes°

Z_ WARNING: ALWAYS wear safety goggles or safety

glasses with side shield and a full face shield when

operating your sander,

Failure to do so could result in foreign objects being thrown into

your eyes, resulting in possible serious injury, If the sanding

operation is dusty, also wear a face or dust mask°

be not to

i ,i I,IlllII,/ll ,HIH/U,/,/ ,I IJ,H,H,,,H,,l,,,H,,,

,i i H, 'Hlll,I /llll II,,_

your

I

13

SANDINGTIPS

1. DO NOT force the sander. The weight of the sander supplies adequate pressure_

Let the sander and the sandpaper do the work.

A. Applying additional pressure will only slow the motor, wear the sandpaper out

faster and reduce sander speed.

B. Excessive pressure will overload the motor and cause possible damage to the

sander from the motor overheating.

C. Excessive pressure will also result in inferiorwork°

2. Any existing finish or resin on wood may soften from the heat of the friction°

3. DO NOT sand in one spot for too long a time because the the sander's rapid

action may remove too much material and make the surface uneven.

SELECTING THE RIGHT SANDPAPER

NOTE:This sander has dust collection, so we recommend that you use sandpaper

with pre-punched holes that wilt line up with the holes in the cushion.

Selecting the correct grit and type of sandpaper is an extremely important decision

that wilt allow you to achieve the best quality sanding finish°

1. Aluminum oxide, silicon carbide and other synthetic abrasives are best for power

sanding.

2oNatural abrasives such as flint and garnet are too soft for economical use in power

sanding.

3. Coarse grit will remove the most material and finer grit will give you the best finish

in all sanding operations°

4. The condition of the surface to be sanded will determine which grit win do the job_

5. If the surface Is rough:

A. Start with a coarse grit and sand until the surface is uniform.

B. Then use medium to remove any scratches left by the coarse grit.

C. Then use a finer grit for finishing the surface.

NOTE: ALWAYS continue sanding with each grit until the surface is uniform°

NOTE: DO NOT use the sander without sandpaper. This will damage the cushion..

i n,,,,l,,,,,Huu,,,,lluulllll ul,uu,

WARNING: DO NOT wear loose clothing orjewelry when operating i

sander. They could get caught in moving parts, causing serious injury. Keep head I

away from sander and sanding area. Hair could be drawn into sander, causing

seriousinjury. I

14

ORBITAL MOTION (See Fig. 9)

As shown in Figure 9, the orbit of the sander is 1/10-inch in diameter so the

sandpaper moves in tiny circles at high speed°

This orbital action duplicates a "hand sanding" motion for more aggressive

sanding as you push the sander forward, This powerful orbital action is ideal

for heavy-duty sanding applications, such as:

1, Removing old finishes

2. Smoothing rough wood Fig 9

3, Sanding stock down to

required dimensions

4. Finishing surfaces that

are to be painted

1/10-inOrbitat Motion

FLUSH SANDING (See Fig. 10)

Your sander will allow you

to flush sand corners.

You can use the front and

sides or your sander for

flush sanding..DO NOT

use the rear of the sander

for flush sanding.

ALWAYS remove the

sander from the workpiece

before turning it off.

REMOVE PRESSURE-SENSITIVE SANDPAPER BEFORE STORAGE

DO NOT store your sander with pressure-sensitive sandpaper still attached. The

heat generated by sanding causes the pressure-sensitive adhesive to flow and form

a tight bond between the cushion and the sandpaper.

ALWAYS remove the sandpaper soon after you have finished sanding to avoid

adhesive set up,When sandpaper is left on the cushion for an extended period of

time after use, the adhesive will set up and make the sandpaper difficult to remove.

The sandpaper may tear when removing itoIf this happens it makes it difficult to

clean the cushion for the next piece of sandpaper_

NOTE" if you do forget to remove the sandpaper after sanding, run your sander for a

few minutes to soften the adhesive backing before you try'toremove the sandpaper

15

GENERAL

I Z_ WARN ING: T° av°id accidents' ALWAYSdisc°nnect the t°°l fr°m the 1

power source BEFORE cleaning or performing any maintenance°

/_, WARNING: When servicing a tool, ALWAYSuse only identical

replacement parts, Use of any other parts may create a risk ofelectric shock or

injury and cause product damage.

All parts represent an important part of the double insulation system and should be

serviced only at a Sears Service Center.

Avoid using solvents when cleaning plastic parts° Most plastics are susceptible to

damage from various types of commercial solvents and may be damaged by their

use. Use clean cloths to remove dirt, carbon dust, etco

WARNING: DO NOT at anytime letbrakefluids, gasoline,petroleum-based

products, penetrating oils, etc.tocome incontact with plastic parts.They contain

chemicals that can damage, weaken ordestroy plastic.Use clean clothsto remove

dirt, carbon dust, etco

Itisa known fact that electric tools are subject to acceleratedwear and possible

premature failure when they are used to work on fiber glass,

wallboard, spackling compounds or piaster.The chips and grindings from these

materials are highly abrasive to electrical tool parts, such as bearings, brushes,

commutators, etc Consequently, it is not recommended that this tool be used for

extended work on any fiber glass material, wallboard, spackling compound, or

plaster. During any use on these materials, itis extremely important that the tool is

cleaned frequently by [blowing with an air jet.

EXTENSION CORDS

The use of any extension cord will cause some tossof power. To keep theloss at a

minimum and to prevent overheating, use an extension cord that is heavy enough to

carry the current that the tool will draw°

A wire gauge (_,;WG)of at least 16 isrecommended for an extensioncord 100 feet

or less in length. When working outdoors ALWAYS use an extension cord that is

suitable for outdoor use.The cord's jacket will be marked WAo

i = L

I Z_ CAUTION: Keepextension cords away from thecutting area, and position

I the cord so itwill not get caught on lumber, tools, etc. during the cutting operation_

WARNING: Check extension cords before each use. If damaged, replace

it immediately_NEVER use a toolwith adamaged cord because touching the

damaged area could cause electrical shock, resulting in serious injury

= =

16

EXTENSION CORDS CONT.

Extension cords that are suitable for use with yoursander are available at your

nearest Sears Store,

i,,,,1,1,,1,,,,i,,i,,i,iH,i,ii,,,l,,ll,,i, i,illlllill i wL,_

WARNING: ALWAYS wear safety goggles or safety glasses with side

shields when using this too! or blowing dusL If operation tsdusty, also wear a dust

mask.

LUBRICATION

All of the bearings in this toolare lubricated with a sufficient amount of high-grade

lubricant for the life of the tool under normal operating conditions, Therefore, no

further lubrication isrequired,

The following recommended accessories are currently available at your local Sears

Store.

ALUMINUM OXIDE SANDING SHEETS WITH PAPER BACKING (1/2 SHEET):

X-Fine, Fine, Medium, Coarse

PRESSURE SENSITIVE ADHESIVE PAPER BACKED SHEETS (1/2 SHEET):

X-Fine, Fine, Medium, Coarse

THE FOLLOWING STANDARD 4V_.X 11-IN. SANDING SHEETS

CAN BE CUTTO FITYOUR SANDER

NON-LOADING ALUMINUM OXIDE SANDING SHEETS

X-Fine, Fine, Medium, Coarse

..... uu,1,1,,,,11,1,

! '_ wARN |NG : The use Of attachments Or accessories that are not I

recommended might be dangerous°

17

NOTES

18

Manual dei Usuario

Lijadora De Cojin

De 1/3 De Hoja

Modelo No.

172.27696

%

ATENCION: Lea, comprenda y siga todas

las Reglas de Seguridad y las instrucciones

en este manual antes de usar esta herramienta.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 EE.UU.

• SEGURIDAD

• FUNClONAMIENTO

• MANTENIMIENTO

Garantia ..................................................................... P_.gtna 2

Instrucciones de Segurida ......................................... PAginas 3-7

Sfmbotos de Seguridad .............................................. PAglna

Descripci6n ................................................................ P_glnas 8-9

Montaje ...................................................................... P_.glna

Funcionamiento .......................................................... P_,glnas

Mantenimiento ............................................................ PAg_nas

Accesorios .................................................................. P_.glna

GARANT[A COMPLETA DE UN AI_O DE LA HERRAMIENTA

PROFESIONAL CRAFTSMAN

Si esta herramienta profesional Craftsman no es de su total satisfacct6n

durante el primer aSo a partir de la fecha de compra, DEVUELVALA A LA

TtENDA SEARS MAS CERCANA EN ESTADOS UNIDOS y Sears la

reemplazar_ sin costo alguno.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears, Roebuck and Co., Dept, 817 WA, Hoffman Estates, IL 60179

11

12-I3

14-15

16

iCONSERVE ESTAS INSTRUCCIONES!

iLEA TODAS LAS INSTRUCCIONES!

2

i_ ADVERTENCIA: ASEGURESE de leer y comprender todas las

I instrucciones.Elincumplimientodetodas lasinstruccionessiguientespuede

I produclr un choque ei_ctrico, incendio y/o lesiones personales graves.

SEGURIDAD DEL AREA DE TRABAJO

1. Slempre mantenga el lugar de trabajo limplo y blen Iluminado. Losbancos de

trabajo desordenados y mal iluminados favorecen los acctdentes.

2, NO utilice las herramientas el_ctricas en una atm6sfera explosiva, tal como

en presencia de liquidos inflamables, gases o polvo. Lasherramientas

el_ctrfcas crean chispasque pueden inftamarel polvo o losvapores.

3. Siempre mantenga a los espectadores, nifios o visitantes a una distancia

prudente cuando est_ utilizando una herramienta el_ctrica. Las distracciones

pueden hacerle perder el control.

SEGURIDAD ELt_CTRICA

!. Las herramientas con aislamtento doble est_n equipadas con un enchufe

polarizado (una hoja de contacto es mds ancha que laotra.) Esteenchufe

puede colocarse en un tomacorriente polartzado en una s61a direcci6n. St el

enchufe no calza bien en el tomacorriente, invierta el enchufe. Si todavfa no

calza, p6ngase en contacto con un electricista calificado para que instale un

tomacorriente adecuado. NO modifique el enchufe de ninguna manera.

2. El aislamiento doble [] elimina la necesidad del cord6n el_ctrico lrifilar puesto a

tierra y del sistema de alimentaci6n de energ[a puesto a tierra. Esto se aplica s61o

alas herramientas de Clase II(de doble aislamiento)

3. Antes de enchufar la herramienta, ASEGURESE que el interruptorde voRaje

corresponde at indicado en la placa de informaciSnde la herramienta. NO USE

"CA solamente" en herramientas que dicen CC

4. SIEMPRE evite el contacto del cuerpo con las superficies puestas a tierra

tales como tuberias, radiadores, cocinas y refrigeradores. Existemayor

riesgo de sufrir cheque el_ctrico si su cuerpo est_ a tierra_

5. Si no puede evitar usar su herramienta en lugares h_medos, SIEMPRE use

Interruptor de Circuito de Falla aTierra para proporcionar energia a el

herramienta. En ambientes h_3medos use siempre guantes de electricista y

calzado.

6. NO exponga las herramlentas el_ctricas a la Iluvta nl a amblentes h_medos.

Cuando entra agua a una herramienta el6ctrica, se aumenta el riesgo de sufrir un

choque el_ctrico.

7. NO abuse del cord6n el_ctrico. Nunca transporte la herramienta pot el

cord6n nt tire del cord6n para desenchufarla, Mantengael cord6n alejado

del calor, del aceite, bordes afilados o piezas m6viles. Reemplace

inmediatamente los cordones el_ctricos que est_n dafiados. Los cordones

daSados aumentan el riesgo de sufrir un choque el_ctrico.

8. Cuando utilice una herramienta el_ctrica al aire libre, use un cord6n de

extensi6n marcado "W-A" o "W"° Estos cordones est_naprobados para uso al

aire libre y reducen el riesgo de choque el_ctricoo

NOTA: El cord6n de extensi6n debe tenet et tamaSo de alambre adecuado AVVG

(American Wire Gauge) para uso eficiente y seguro Alambres de calibre m_s

pequeSo tienen mayor capacidad (alambre de calibre 16tiene m_s capacidad que

et alambre de 18)o

SEGURIDAD PERSONAL

1, SIEMPRE mant_ngase alerta, observe Io que estd haciendo y use sentido

com_n cuando estd cansado o bajo la influencia de drogas, alcohol o

medicamentos. Un momento de distracciSn cuandoest_ trabajandocon las

herramientas el_ctricas, puede ocasionar una lesi6n personal grave.

2. SIEMPRE use vestimenta adecuada. NO use ropas sueltas o joyas.

Am_rrese el cabello largo. Mantenga su cabello, ropas y guantes alejados

de las piezas m6viles. Las ropas sueltas, las joyas o el cabello largo pueden

quedar atrapados en las piezas m6viles_

3. StEMPRE evite la puesta en marcha accidental. AsegL_rese de que el

interruptor est_ en ia posici6n "Off" (apagado) antes de enchufar la

herramienta, Se puede producir un accidente si transporta la herramienta con su

dedo en el interruptor o si enchufa la herramienta cuando el interruptor est& en la

posiciSn "On" (encendido).

4. SIEMPRE saque las Ilaves de ajuste o llaves inglesas antes de poner en

marcha la herram|enta. Si se deja una Ilave inglesa o una Ilave de ajuste en una

pieza mSvil o en una pieza giratoria de laherramienta, se puede producir una

lesi6n personal.

5. NO use ta herramienta a una distancia demaslado alejada. Mantenga

S1EMPRE un buen equilibrlo y una posici6n ftrme. Elbuen equilibrio y la

posiciSn firme permiten un mejor control de la herramienta en situaciones

imprevistas.

6, SIEMPRE use equipo de seguridad. Use SIEMPRE lentes protectores. Se

debe usar m&scaras contra el polvo, zapatos de seguridad antirresbaladizos, casco

de seguridad o protecci6n auditiva de acuerdo con las circunstancias.

USO Y CUIDADO DE LAS HERRAMIENTAS DE SEGURIDAD

1, SIEMPRE use mordazas u otto m_todo pr_ctlco para asegurar y apoyar la

piezade trabajo en una plataforma estable. Sisujeta el trabajocon lamano o

contra su cuerpo queda inestabley puedeconducir a ta p6rdidade control.

2. NO fuerce la herramtenta. Use la herramienta apropiada para el trabajo.

La herramienta correcta har& el trabajo mejor y de manera m_s segura, a la

velocidad para la cual fue diseSadao

3. NO use la herramienta si el interruptor no funciona debidamente, Es

peligroso si la herramienta no puede ser controlada con el interruptory pot Io

tanto debe ser reparadao

4. SIEMPRE desenchufe la herramienta antes de hacer algun ajuste, cambiar

accesorios o guardarla. Estas medidas preventivas de seguddad reducen el

riesgo de que la herramienta se ponga en marcha accidentalmente,

5. SIEMPRE guarde tas herramientas lejos del alcance de los niSos y de otras

personas inexpertas. Las herramientas son peligrosas en manos de personas

inexpertaso

6, SIEMPRE mantenga bien cuidadas las herramientas. Las herramientas

cortantes deben mantenerse afiladas y limpias. Las herramientas que se

manttenen bien cuidadas y bien afiladas tienen menos probabitidad de atascarse

y se pueden controlar mds f_cilmente..

7. SIEMPRE veriftque sl hay plezas desalineadas o atascadas, st hay plezas

quebradas o st extste cualquter otra situaci6n que pueda afectar el

funcionamiento de la herramienta, Si la herramienta est_ daSada, debe

repararse antes de usarla nuevamente. Muchos accidentes son causados debido

al mal estado de tasherramientaSo

USOY CUIDADO DE LAS HERRAMIENTAS DE SEGURIDAD cont.

Z_ ADVERTENCIA: uso DE ACCESORIOSNO RECOMENDADOSPARA

SER USADOS CON ESTA HERRAMIENTA PUEDEN CREAR UNA SITUACION

PELIGROSA

8. SIEMPRE use solamente los accesorlos recomendados pot el fabrtcante

para su modelo, Los accesorios que pueden ser adecuados para una

herramienta, pueden ser peligrosossi se utilizan en otra.

SERVIClO TECNICO SEGURO

1. Si cualquier pieza de esta lijadora faltara, se rompiera, doblara o fallara de

cualquier manera, o si cualquier componente el_ctrico deja de funcionar

correctamente: SIEMPRE apague el interruptory desenchufe la herramienta dey

haga reemplazar laspiezas faltantes o daSadas ANTES de continuar usando la

herramienta.

2. El servlcto a la herramienta debe ser realizado _nicamente en un Centro de

Servicio Sears, Si personal no calificado realiza el mantenimiento o reparaci6n

de la herramienta, se puede crear un peligro de lesiSn personal.

REGLAS DE SEGURIDAD PARA LIJADORAS

1. NUNCA use esta o cualquier otra lijadora mecdnica para lijar superficies

hdmedas o para pulir con lfquido. El incumplimientode esta regla puede

aumentar la posibilidad de un choque ei_ctrico.

REGLAS ADICIONALES PARA FUNCIONAMIENTO SEGURO

Z_ ADVERTENCIA: ASEGURESE de leer y comprenda todas las

instrucciones. El incumplimiento de todas las instrucciones siguientes

puede producir un choque el_ctrico, incendio y/o lesiones personales

graves.

1. Conozca su herramienta, Lea cuidadosamente el manual del usuario.

Aprenda sus aplicaciones y limitactones asi como tambi_n los riesgos

potenciales especfficos relacionados con esta herramienta.

2. Use SIEMPRE lentes de seguridad o pantailas cuando use esta lijadora. Los

anteojos regulates tlenen solamente lentes resistentes al impacto; ellos no

son lentes de seguridad.

3. SIEMPRE proteja sus pulmones. Utilice una mdscara contra el polvo si la

operacibn de corte va a despedir mucho polvo.

4, SIEMPRE proteja su audici6n. Uttlice protecci6n para los oidos durante

periodos prolongados de funcionamiento.

5. SIEIVIPRE tnspeccione peri6dicamente los cordones de la herramienta y si

estdn daSados, hdgalos reparar por su Centro de Servicio de Sears m_s

cercano u otro Centro de Servicio Autorizado. Siempre est_ atento a la

ubicaci6n del cord6n.

6. SIEMPRE Inspeccione por piezas daSadas. Antes de segutr utllizando la

herramienta, inspeccione para determinar si alg_n protector o cualquier pieza

que est8 dafiada funcionar_ debidamente. Verifique la alineaci6n de las

piezas m6viles, st estz_natascadas o si hay rotura de plezas, revise ademds el

montaje y cualquier otra condici6n que pueda afectar su funcionamtento. Si

se daSa un protector o cualquier otra pteza, debe ser reparada o

reemplazada pot un centro de servicio autorizado.

REGLASADICIONALESPARAFUNCIONAMIENTOSEGUROcont.

7.NOabusedelcordbn.NUNCAuseelcord6nparaIlevariaherramientao Io

tiredelenchufe.Mantengaelcord6nalejado del caior, del aceite y de los

bordes filosos o repuestos en movimiento. Reemplace inmediatamente los

cordones el_ctricos que est_n da_ados. Loscordones dahados aumentan el

riesgo de sufrir un choque ei_ctrico.

8. SIEMPRE asegurese que su cord6n de extensi6n est_ en buenas

condiciones, Cuando use un cord6n de extensi6n aseg_rese de usar uno

!o suficientemente resistente para la corriente que necesita su herramtenta.

Para un cord6n de extension de 100 pies o menos de largo se recomienda

por to menos el calibre 16 (A,W.G,), El uso de un cord6n de extensi6n de

m_s de 100 pies de largo no se recomienda. Si tiene dudas, use el calibre

superior siguiente, Alambres de calibre pequeSo tienen mayor capacidad

(alambre de calibre 16 tiene m_s capacidad que el alambre de calibre lB.

Un cord6n de poco taSo causar& baja de voltaje, Io que provocar& baja de

energfa y recalentamiento,

9. SIEMPRE inspeccione y saque todos los clavos de la madera antes de lijar.

10. NO haga funcionar esta herramienta cuando est_ bajo la influencia de

drogas, alcohol o haya tornado medicina.

11. CONSERVE ESTAS INSTRUCCIONES. Consr31telas con frecuencta y Liselas

para ayudar a otros que puedan usar esta herramienta. Si usted presta e

sta herramienta a otra persona, entregue tambi_n las instrucciones.

Z ADVERTENCIA: Atgunas part_culas de polvo creada al lijar con una

herramienta, moler, taladrar y hacer otros trabajos de construcci6n contienen

qufmicos que se sabe pueden producir c&ncer, defectos al nacer u otros

daSos reproductivos. Algunos ejemplos de estos qu_micos son:

• Plomo de las pinturas a base de plomo,

• Sflice cristalino a partir de ladrillos y cemento y otros productos de albaSiteria.

• Ars6nico y cromo a partir de maderas tratadas con quimicos

Su riesgo a estas exposiciones varia, dependiendo de la frecuencia con que

hace este tipo de trabajo, Para rectucir su exposici6n a estos qufmicos:

°Trabaje en un _rea bien ventilada.

=Trabaje con equipo de seguridad aprobado, como por ejemplo m&scaras para

polvo diseSadas especfficamente para filtrar las particulas microsc6picas,

6

REGLAS ADICIONALES PARA FUNCIONAMIENTO SEGURO cont.

USE $US

Z_ ADVERTENCIA: La utilizaci6n de cualquier

lijadora puede causar la proyecci6n de objetos extraSos a

sus ojos, Io cual puede ocasionar dafios oculares severos.

Antes de comenzar a usar la herramienta mec_nica,

SIEMPRE use sus lentes protectores o pantallas de

seguridad con protecci6n lateral y una m&scara completa

cuando sea necesario. Recomendarnos una M_scara de

Visi6n Amplia para usar sobre sus lentes protectores o

lentes de seguridad est#,ndar, con protecci6n lateral,

disponible en los Almacenes Sears.

La etiqueta en su herramienta puede incluir los siguientes sfmbolos.

V........................................................... Voltios

A........................................................... Amperios

Hz ......................................................... Hertz

W............................................................ Watts

min ....................................................... Minutos

............................................................ Corriente Atterna

......................................................... Corriente Continua

Hz......................................................... Frecuencia

no .......................................................... Velocidad sin carga

[] ......................................................... Construcci6n Clase II

../min ................................................... Revoluciones o Golpes por Minuto

OPM ....................................................... Orbitas por Minute

z_ ........................................................... Indica peligro, advertencia o atenci6no

Puede usarse conjuntamente con otros

s[mbolos o pictogramas.

ilMPORTANTE! iLEATODAS LAS INSTRUCCIONES!

CONOZCA SU LIJADORA (Ver Figura !)

Esta lijadora es ideal para lijarcon papel de lija delgado, mediano y _sperooLa

misma genera 11.0005rbitas por minuto con un di&metro de 5rbita de 1/10pulgopara

ofrecer remociSn r&pida de materiales y un acabado lifo y de calidad en todas las

superficies de madera. El diseSo contrabalanceado con calibrado de precisiSn reduce

la vibraciSn para ofrecer un funcionamiento suave y reducir ia fatiga del usuario

Gatiilo

E_gatfllo de la lijadoraest_ ubicado bajo la manija trasera_ Para encender la lijadora

"ON" simplemente apriete el gattllo. Para apagar la tijadora "OFF", suelte el gatillo.

Esta lijadora tambi_n tiene un BotSn de Bloqueo en Marcha en el costado de la

manija trasera para operaciones de lijado continuo. Para activar la Caracterfstica de

Bloqueo en Marcha simplemente apriete el gatilto para dejar la lijadora encendida

"ON" y presione el BotSn de B!oqueo en MarchaoPara desact var esta caracter[stica,

simplemente suelLeel gatilloo

Guardapolvo

Su lijadora incluye una bolsa guardapolvo dise_ada para ayudar a sacar el polvo

acumulado en el _rea lijada.

Fig 1 de Bloqueo en Marcha

ija Trasera

Manija

Delantera

del Papel

Palanca

Plattna de BoIsa

Cojfn Guardapolvoy

Montaje

Conexi6n el_ctrlca

Su lijadoratiene un motor el_ctricoconstruidoa precisi6n. Debe ser conectado

s61oa una fuente de alimentaci6n de 120 voltios, 60 Hz, CA (la corriente normal

del hogar). NO haga funcionar esta herramientaconcorriente continua(CC). Una

baja stgnificativade voltaje puede causar p_rdida de potenciay recalentamlentodel

motor. Si su herramtenta no funciona cuando est,, enchufada, vuelva a verificarla

fuente de alimentaci6no

Velocidad sin carga 11,000 OPM (Orbits Per Minute)

P0tencia nominal 120 volts, 60 Hz AC

AlimentaciSn 3.3 A

............................. i ........... ..............................................

Di_,metro de la Orbita 1/10 putg

TamaS.0 del Papel de. Liiar . 1/2.de.hoia ...............

Tipo de papel No Autoadhesivo/Autoadhesivo

Z_ ADVERTENClA: Su lijadora NO debe estar enchufada en la fuente de

alimentaciOn cuando estO ins/alando repuestos, haciendo ajustes, instalando o

reemptazando el papel de lijar, limpi&ndola o cuando no est_ en uso. At

desenchufar su lijadora evitar_ la puesta en marcha accidental que podria

provocar una lesion personal grave.

NSTALACION DEL PAPEL DE LIJAR (Ver Figuras 2 y 3)

Esta lijadora tiene un cojfn que le permite usar: ya sea papel de lijar no adhesivo

que se sujeta en la platina o papel de lijar adhesivo con forro autoadhesivo que se

adhiere al cojfn,.

NOTA" Esta lijadora tiene guardapolvo, asf que recomendamos et uso de papel

de lijar con hoyos pre-perforados que se van a alinear con los hoyos en el cojin.

instalaci6n del Papel de Lijar no Adhesivo

(Ver Figura 2 en la pdgina sigulente)

SIEMPRE inspeccione el papel de lijar antes de instalarlo. No use papel roto o

defectuoso.

1. Desenchufe su lijadora.

_ ADVERTENClA: Si no desenchufa su lijadora, se puede producir lapuesta en marcha accidental causando una lesion graven

Fig 2 Sujetador

del Papet

Pape| de

Cojin Ranura Aclhesivo

Lijar no

Ptatina

2. Saque la botsa guardapolvo

3. Si est,, reemplazando et papel de lijar, saque el papet antiguoo

4. Para sacar el papel de lijar antiguo, levante las palancas en cada lado de la

lijadora para levantar el sujetador de papel que sostienen el papel de lijar.

5. tnserte el extremo de una nueva hoja de papel, aproximadamente 1/2 pulgadas

debajo det sujetador del papel delanteroo

6, Levante la palanca del lado izquierdode la lijadora y bloquOela en la ranura de la

platina. Optima hacia abajo para adaptar el papel de lijar a la platina.

7. Enrolle el papel de lijar alrededor del cojin e inserte el extremo suelto del papet de

lijar bajo el sujetador del papel trasero, Cotoque bien lirme el papel de tijar contra

el cojin..

8. Levante la palanca situada en e! lado derecho de la lijadora y bloqu_eta en la

ranura de la platinao

9, Reemplace la bolsa guardapolvo.

9

Instalact6ndelPapeldeLijarconForroAutoadhestvo(VerFigura3)

SIEMPREinspeccioneelpapel de lijar antes de instalarlooNO use papel roto o

defectuoso.

1.Desenchufesulijadora

_ ADVERTENClA: si no desenchufa su lijadora, se puede producir

la puesta en marcha accidental causando una lesiSn grave.

2. Si est,_ reemplazando el papel de tijar, saque el papel antiguo despeg_ndolo del

cojfno

3. Si est_ reemplazando el papel de lijar no adhesivo, desenganche el sujetador del

papel tevantando cada una de las palancas y luego saque el papel de lijar.

4. Ponga las palancas de vuelta a la posiciSn de bloqueo (ver Paso 6 y 8 en

InstatarPapel de Lijar No Adhesivo)o

NOTA: SIEMPRE vedfique que las palancas est_n en la posiciSn bioqueada antes

de comenzar a lijar.

5. Despegue CUIDADOSAMENTE el protector del adhesivo de la nueva hoja de

papel de lijar de 1/2

6. Ponga el papel de lijar en posiciSn. SIEMPRE aseg_trese que el borde delantero

del papel de lijar est_ alineado con el borde delantero del coj[n, luego

cuidadosamente oprima el lado con adhesivo contra el cojfno

NOTA: El papel de lijar DEBE estar alineado con el borde delantero del cojfn para

que la lijadora funcione cuando se lije al ras,,

NOTA: Se recomienda que iimpie et cojfn peri6dicamente pas&ndole una escobtlla

pequeSa_ El polvo acumulado en el cojin puede impedir que el papel se adhiera

adecuadamente.

Fig 3

Oojfn

I

Papelde Ujar

Adhesivo

10

PERFORADORADEPAPEL(VetFigura4)

Esta lijadora incluyeuna plantilla de perforaciSn de papeL La misma debe ser

utilizada para alinear y perforar agujeros en el papelde lija con los agujeros del cojin..

La perforaci6n de agujeros adecuada es un paso necesario para que la lijadora

Jueda recoger el polvo en la bolsa para el polvo.

Fig4

Oriente la

perforadora de

papel como

se muestra

INSTALACION DE LA BOLSA GUARDAPOLVO (Ver Figura 5)

/_, ADVERTENCIA: Para evitar la posibilidad de que objetos extraSos

o el polvo del lijado penetre a sus ojos, NUNCA trate de hacer funcionar la

lijadora sin la bolsa guardapolvo debidamente Instalada. Si alguna materia

extra_ao el polvo del tijado saita a sus ojoso a su cara puede causar una lesiSn

personalgrave°

1, Desenchufe su lijadora.

Z_ ADVERTENCIA: St no desenchufa su lijadora, se puede producir la

puesta en marcha accidental causando una iesi6n grave.

2. Inserte eladaptador de la bolsa guardapolvo en el agujero de escape del polvo

(Ver Figura 5)°

3. Empuje el adaptador hacia adentro hasta que las muescas, en laparte superior e

inferior del adaptador, calcen en las ranuras del agujero de escape de] polvo,.

4. Su tijadora ahora est,. lista para ser usadao

NOTA: Para un funcionamiento mds eficaz, vacre la bolsa guardapolvo cuando

est_ a medio Ilenar. Esto permitir,_que el aire circule mejor a trav_s de la bolsa.

SIEMPRE vac{e y limpie bien la bolsa guardapotvo cuando termine de lijar y antes

de guardar la lijadorao

Fig 5

Agujerode escapedel polvo

11

i

Bolsa

Guardapolvo

COMO SACAR Y VACIAR LA BOLSA GUARDAPOLVO (Ver Figura 6)

1. Desenchufe su lijadora.

Z_ ADVERTENClA: Si no desenchufa su lijadora, se puede producir la

puesta en marcha accidental causando una lesi6n grave.

2, Saque la bolsa guardapolvo de ia lijadora sosteniendo firmemente el adaptador y

tire de 61derecho hacia afuera.

3. Luego saque labotsa guardapolvo del adaptador (Ver Figura 6).

4, Sacuda la bolsa para vaciarla.

5. Cotoque nuevamente la bolsa en et adaptador..

6. Vuelva a colocar la bolsa guardapotvo en la lijadora_

Fig 6

Bolsa

Guardapolvo

Agujerodeescapedei polvo

INSTALACION DEL ADAPTADOR PARA MANGUERA DE ASPIRADORA

(Ver Figura 7)

Su lijadora incluye un adaptador de manguera de aspiradora el cual se conecta

f&citmente a la tijadora. Et adaptador permite conectar su lijadora con su aspiradora

de taller (se venden por separado)o

1,Desenchufesu lijadora.

Z_ ADVERTENCIA: Si no desenchufa su lijadora,se puede producir la I

puesta en marcha accidental causando una lesiSn grave. J

2. Saque la bolsa guardapolvo de la iijadora para sostener firmemente el adaptador

y tire de 61derecho hacia afuera.

3. Inserte el adaptador para manguera de aspiradora en el agujero de escape del

potvo.

4, Empuje el adaptador hacia adentro hasta que las muescas en fa parte superior e

inferior del adaptador calcen en las ranuras del agujero de escape del polvo.

5, lnstale firmemente el adaptador para manguera de aspiradora en una manguera

de asptradorao

6. Conecte la manguera de la aspiradora a la aspiradorao

Fig 7

Adaptador para

Manguera de

Aspiradora

12

Antes de intentar usar cualquier herramienta, asegurese de, familiarizarce con

todas las caracteristicas de funcionamiento y con los requerimientos de

seguridad.

/_ ADVERTENCIA: sI FALTACUALQUIERA DE LOS REPUESTO, NO

HAGA FUNCIONAR SU LIJADORA HASTA QUE REEMPLACE LOS

REPUESTO. EL NO SEGUIR ESTA REGLA PUEDE RESULTAR EN UNA

LESION PERSONAL SERIA

ADVERTENCIA: NO permita que su familiaridad con la lijadora

interfiera con su atenci6n y prudencia. Recuerde que un descuido de una fracciSn

de segundo puede causar una lesi6n grave°

II II ill J i i .lllll..i

Z_ ADVERTENCIA: Use SIEMPRE gafas protectoras

o lentes de seguridad con protecci6n lateral cuando haga

funcionar su iijadora.

De to contrario puede que le salten objetosextra_os a sus ejos,

causando una posible Tesi6ngrave, En los ambientes con

demasiado polvo use tambi_n una m_.scarapara el polvoo

APLICACIONES

Use s61osu Iijadora para las aplicaciones que se listan a continuaci6n:

!. Lijado de superficies de madera con papel de lijar de distintos granos,.

2. Sacar el 5xido de superficies de acero con papel de lijar especial,

_ ATENCION: SIEMPRE tenga cuidado que su mane no cubra los

respiraderos de aire,

I. StEMPRE fije o sujete de alguna manera la pieza en que est,, trabajando para

evitar que se mueva al ser lijada..

l _ ADVERTENCIA: La pieza de trabajo que no est_ sujeta puede ser

lanzada hacia el usuario causando una lesiSn_

2. SlEMPRE sostenga su lijadora en frente y alejada de usted, manteni_ndola sin

tocar la pieza de trabajo,

3. Ponga en marcha la lijadora apretando el gatillo y luego deje que el motor venga

a velocidad m_ximao

4. Baje gradualmente la Fig 8

lijadora hacia la

p_ezade trabajo con

un ligero movimiento

hacia adelanteo

(Ver Figura 8,)

5, Mu_vala lentamente

usandopasadas

hacia adelante y

hacia atr,=Ss.

13

l lll ill ll.ll

i

I

DATOS PARA LIJAR

1. NO fuerce la lijadora° El peso de la herramienta ofrece presi6n adecuada, por Io

tanto deje que el papel de tijar y la lijadora hagan el trabajoo

A. Si aplica presi6n adicional solamente conseguir,_ hacer m&s lento el motor,

desgastar m_,s r&pidamente el papel de lijar y reducir enormemente la

velocidad de la lijadorao

B. La presi6n excesiva har_ que el motor se recaliente causando posible daSo al

motor y puede resultar en un trabajo deficiente.

C. La presiSn excesiva tambi_n causar_, un trabajo de calidad inferior°

2. Cualquier acabado o resina de la madera puede ablandarse con el calor de ta

fricciSn.

3, NO lije durante mucho tiempo en un mismo punto, pues la acci6n r,_pidade la

lijadora puede sacar demasiado material dejando la superficie disparejao

SELECCION DEL PAPEL DE LIJAR ADECUADO

NO'[A:Esta tijadora tiene una bolsa guardapolvo, as{ que recomendamos el uso de

papel lija con agujeros prefabricadosque se van a alinear con los agujeros en e!

coj_n.

Es muy importante seleccionar el grano y el tipo correcto del papel de lijar que le

permitird Iograr un lijado de alia calidad,

1_El Oxido de aluminio, carburo de silicio y otros abrasivos sint_ticos son mejores

para lijar con herramientaso

2, Los abrasivos naturales, tales como el pedernal y el granate son demasiado

suaves para ser econ6micos cuando se utflizan en lijadoras mec_.nicaso

3. El grano &spero eliminar_, la mayor{a de los materiales y el grano m&s fino

producir& elmejor acabado en todas las operaciones de lijado.

4. El estado de la superficie a ser lijada determinar,_ que grano har& mejor eltrabajoo

5. SI la superficie es _spera:

A. Comience con un papel de lijar de grano ,_spero y lije hasta que la superficie

quede uniforme.

B. El grano mediano puede entonces usarse para sacar ralladuras dejadas por el

grano m_,s_speroo

C. Entonces use el grano m&s fino para terminar la superficie.

NOTA: SIEMPRE continue lijando con cada grano hasta que la superficie se vea

uniforme.

NOTA: NO use la lijadora sin tenet papel de lijar instalado. De Iocontrario dafar_

el cojln.

I Z_ ADMERTENCIA: NO use joyas o ropa sueltas cuando trabaje con la

lijadorao Elias pueden quedar atrapadas en las piezas mSviles causando fesiones

graves. Mantenga la cabeza alejada de la lijadora y del _,reaque se est,. lijando.

Etcabello puede ser atrafdo hacia la lijadoracausando tesi,ones

I q'L I I ill I I I II I I Iig raves _

I I I I

14

MOVIMIENTO ORBITAL (Ver Flgura 9)

Como se muestra en la Figura 9, el movimlento orbitalde la lijadoraes 1/10 de

pulgada de di&metro, de forma tal que el papel de lijar se mueve en pequefios

drculos a una velocidad muy alta.

Esta acci6n orbital duplica un movimiento de "lijado a mano", para un lijado m_s

agresivo impulse la lijadora hacia delante. Esta poderosa acci6n orbital es ideal para

aplicaciones de lijado considerable, tales como:

1, Sacar acabados antiguos

2. Suavizar madera &spera Fig 9

3. Lijar hasta reducir a la

dimensiSn deseada

4. Acabar superficies que s

e van a pintar

Movtmiento Orbital

de 1/10 pulg,,

LIJADO AL RAS (Ver Figura 10)

Su lijadora le permitir,_lijar

los rincones al ras. Puede

Fig 10

usar el frente y costado de

su lijadora para lijado al ras.

NO use la parte trasera de

la lijadora para lijado al ras.

SIEMPRE levante la

lijadora de la pieza de

trabajo antes de apagarla,,

REMOCION DEL PAPEL DE LIJAR ANTES DE GUARDAR LA LIJADORA

NO guarde ia tijadora con el papel de lijar autoadhesivo instalado, El calor producido

durante el iijadoderrite el adhesive sensitivo a la presi6ny forma una adhesi6n firme

entre el cojin y et papel de lijar.

StEMPRE saque el papel de lijarinmediatamentedespu_s de haberterminado de lijar

paraevitar que la adhesi6n sea excesivaoSi se deja el papel de lijaren el cojin durante

un periodo de tiempo prolongado despu_s de! uso, el adhesivo se endurecer_ y ser_

muy diffcil despu6s sacarto.

El papel de tijar puede romperse cuando se sacaoSi esto sucede es diffcil limpiar el

cojfn para instalar el siguiente pedazo de papel de lijar.

r-,IOTA;Si olvida sacar el papel de lijar despu_s de haber terminado de lijar, lije

nuevamente por algunos minutos para ablandar el adhesivo antes de intenlar sacar

el pape! de lijar.

15

GENERALIDADES

Z_ ADVERTENCIA: Para evitar accidentes, SIEMPRE desenchufe la

herramienta ANTES de limpiarta o hacerle mantenimiento,

Z_ ADVERTENCIA: Cuando efectue reparaciones auna herramient'a'i"""'i

SIEMPRE use s61orepuestos legitimos. Eluse de cualquier otro repuesto puede

crear un riesgo de cheque el_ctrico o lesionesy causar da_os al producto_ I

Todas las piezas representan una parte importante det sistema de aislamiento

dobfe y deben ser reparadas per un t6cnico de servicio caftficado de Sears.

Evite usar solventes cuando limpie las piezas de pl#,stico.La mayorfa de los pl_sticos

son susceptibles adiversos tipos de solventes comerciales y pueden daRarse con su

use. Use paros timpios para sacar la suciedad, polvo de carb6n, etco

z_ ADVERTENCIA: NO permita que l[quido de frenos, gasolina, productes

a base de petrRleo, etc. entren en contacto con las piezas de plAstico bale

ninguna circunstancia. Estas sustancias contienen productosqu[micos que

pueden dafiar, debilitar o destruir el pl_.sticooUse paros limpios para remover et

sucio, el polvo de carbRn, etc.

Es un hecho comprobado que las herramientas el_ctricas sufren desgaste acelerado

y posible falla prematura cuando se utilizan en libra de vidrio,

madera laminada, compuestos obturadores o yeso Las astillas y el polvo

de la libra de vidrio son attamente abrasives para loscojinetes, escobillas,

conmutadores, etc. Per 1otantono se recomienda que esta herramienta se use para

trabajo prolongado en cualquier material de libra de vidrio, madera laminada,

compuestos obturadores o yeso, Durante cualquier use de estos materiales, es

extremadamente importanteque la herramienta se limpie con frecuencia, sopl#,ndola

con un chorro de aire.

CORDONES DE EXTENSION

E!use de cualquier cord6n de extensiRncausar,_ cierta p_rdida de potencia. Para

mantener la p_rdida a un minimo y evitar el recalentamiento de la herramienta,

asegt3rese de usar un cordRn de extensiRn Iosuficientemente grueso come para

transportar ta corriente que necesitar& su herramienta. Para un cord6n de extensiRn

de 100 pies o menos de largo se recomienda per Io menos el calibre 16 (AoW.G.).

Cuando trabaje al aire libre, SIEMPRE use un cordRn de extensi6n adecuado para

use al aire libre. La envoltura del cordRn estar#, marcada con tas letras WA.

ATENCION: Mantenga los cordones de extensiRnalejados de la zona del

lijado y coloque el cordRn cuando est_ lijandode tal manera que no se enrede en

tamadera, herramientas, etc_

ii llllllll l llll i i i Hi ,ml

Z_ ADVERTENCIA: Revise los cordones de extensiRn antes de cada uso_ I

Si est_n daRados reempl&celos inmediatamente. NUNCA use una herramienta con

un cordRn daRado pues al tocar el lugardafiado puede causar un cheque el_ctrico

que resulte enuna iesiRngrave.

16

I

CORDONES DE EXTENSION cont,

Los cordones de extensi6n adecuados para usar con su lijadora est#,n disponibtes

en su Almac_n Sears m,_scercanoo

ADVERTENCIA: SIEMPRE use lentesprotectores olentes de

seguridad con protectores lateralescuando utilice una herramienta mecdnicao

cuandoest_ soplandopolvo.En losambtentescon demasiado potvo use tambidn

una m,_scarapara el polvo.

,..,H.,=.,=,L .H.=, i t i

LUBRICACION

Todos los cojinetes en esta herramienta han sido lubricados con cantidad suficiente

de lubricantede alta calidad para durar, bajo condieionesnormales de

funcionamiento, toda la vida _til de la herramienta..Por Io tanto, no se requiere de

lubricaci6nadicionaL

Los siguientes accesorios son recomendados y est&n disponibles en la actualidad

en los Almacenes Sears.

Lib,MINAS DE LIJADO DE ALIJMINA CON BASE DE PAPEL (1/2 LAMINA):

Extra,,Delgada, Delgada, Mediana, i_spera

LAMINAS ADHESIVAS SENSIBLES ALA PRESION CON BASE DE PAPEL

(1t2 LAMINA):

Extra-Delgada, Delgada, Mediana, Aspera

LAS SIGUIENTES LAMINAS DE LIJADO ESTANDAR DE 4"ft2X11 PULG.

PUEDEN SER CORTADAS PARA AJUSTARSE A SU LIJADORA

LAMINAS DE LIJADO DE ALt)MINA SIN CARGA

Extra-Delgada, Delgada, Mediana, Aspera

17

Getit fixed; at yourhome or Ours!

Your Home

For repair in your home of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items Bikegarage door openers and water heaters_

1-800-4-MY-HOME _ Anytime,dayor night

(1-800-469-4663) (U SA andCanada)

www.sears.com www.sears,ca

Our Home

For repair of carry-in products like vacuums, lawn equipment,

and electronics, call or go on-line for the nearest

Sears Parts and Repair Center,

1-800-488-1222 Anytime.dayornight(USA.. only)

wwwosears.com

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (USA) 1-800-361-6665 (Canada)

Pare pedirservicio de reparaciSn

a domicilio, y para ordenar piezas:

1-888-SU.HOGAR sM

(1.888-784.6427)

© Sears, Roebuck and Co,

® Registered Trademark t "m Trademark I aMService Mark of Soars, Roebuck and Co

® Marco Registrada t "I'MMarco de F- brica / B_Marco de SePJicio de Sears, Roebuck and Co

_c Marque de commerce / M_Marque ddpos_e de Sears. Roebuck and Co

Au Canada pour service en frangais:

1.800-LE_FOYERMc

(14300-533-6937)

WWW S8ai's,,Oa

Loading...

Loading...