Page 1

Operator’s Manual

PROFESSIONAL

[

3.0 Amp / 5-in. Diameter Cyclonic Dust-Air Separator (CDS) Collection System

Random Orbital Sander

Model No. 172.27673

CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions

in this manual before using this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman® website; www.sears.com/craftsman

3025736

Certified

to CAN/CSA-

C22.2 No.745-1,745-2-4

Conforms to UL

STD 745-1, 745-2-4

Double Insulated

• WARRANTY

• SAFETY

• UNPACKING

• DESCRIPTION

• ASSEMBLY

• OPERATION

• MAINTENANCE

Page 2

TABLE OF CONTENTS

Warranty..................................................................................................................Page 2

Safety Symbols.......................................................................................................Page 3

Safety Instructions......................................................................

Unpacking...............................................................................................................Pages 10-11

Description..............................................................................................................Pages 11-12

Assembly....................................................................................

Operation.................................................................................................................Pages 16-19

Maintenance............................................................................................................Pages 20 - 21

Accessories.............................................................................................................Page 21

Psrtlist......................................................................................................................Pages 22 - 23

Sears Repair Parts Phone Numbers

.....................................................................

ONE YEAR FULL WARRANTY ON CRAFTSMAN© PROFESSIONAL TOOL

If this Craftsman Professional Tool fails due to a defect in material or workmanship

within one year from the date of purchase, RETURN IT TO ANY SEARS STORE OR

PARTS AND REPAIR CENTER OR OTHER CRAFTSMAN OUTLET IN THE

UNITED STATES FOR FREE REPAIR (OR REPLACEMENT IS REPAIR PROVES

IMPOSSIBLE).

This warranty does not include expendable parts such as lamps, batteries, bits,

blades or sandpaper.

This warranty gives you specific legal rights, and you may have other rights, which

vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

...........................

.............................

Pages 4-10

Pages 13-16

Back Cover

SAVE THESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

AWARNING: Some dust created by using power tools contains chemicals

known to the State of California to cause cancer and birth defects or other

reproductive harm.

Page 3

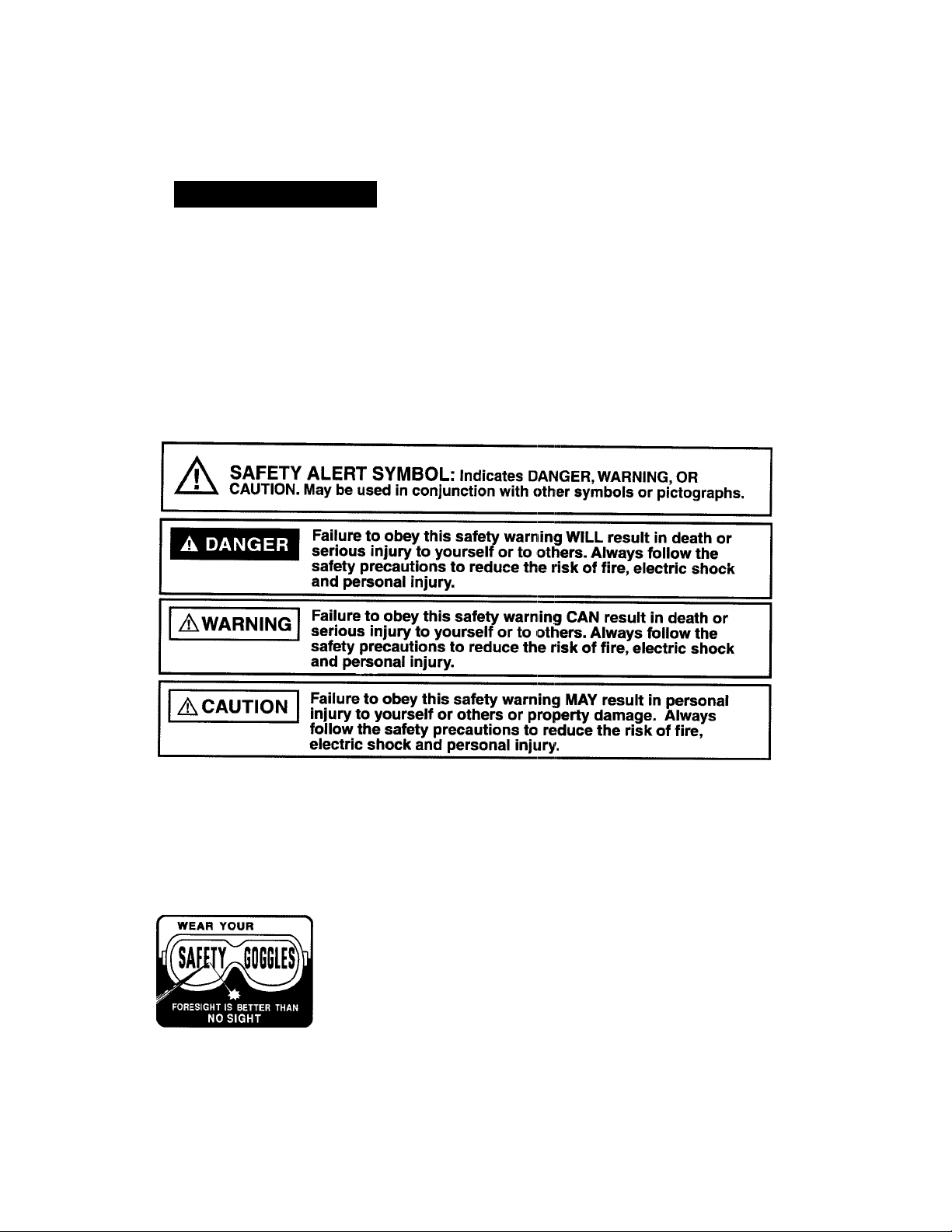

SAFETY SYMBOLS

The purpose of safety symbols is to attract your attention to possible dangers.

The safety symbols, and the explanations with them, deserve your careful

anention and understanding. The symbol warnings DO NOT by themselves

eliminate any danger. The instructions and warnings they give are no substitutes

for proper accident prevention measures.

4^ WARNING: BE SURE to read and understand all safety instructions in

this manual, including all safety alert symbols such as “DANGER”, “WARNING’

and “CAUTION”, BEFORE using this tool. Failure to follow all instructions

iisted below may resuit in electric shock, fire and/or serious personai injury.

SYMBOL MEANING

DAMAGE PREVENTION AND INFORMATION MESSAGES

These inform user of important information and/or instructions that could lead to

equipment or other property damage if not followed. Each message is preceded

by the word “NOTE:” as in the example below:

NOTE: Equipment and/or property damage may result if these instructions are

not followed.

/^WARNING: The operation of any power tool can result

in foreign objects being thrown into your eyes, which can

result in severe eye damage. Before beginning power tool

operation, ALWAYS wear safety goggles or safety glasses

with side shield and a full-face shield when needed.

We recommend a Wide Vision Safety Mask for use over

eyeglasses or standard safety glasses with side shield,

available at Sears Stores or other Craftsman Outlets.

Page 4

SAFETY INSTRUCTIONS

A WARNING: BE SURE to read and understand all instructions in this manual

before using this power tooi. Failure to follow all instructions may result in electric

shock, fire and / or serious personal injury.

WORK AREA SAFETY

1. Keep your work area clean and well lit. Cluttered workbenches and dark areas

invite accidents.

2. DO NOT operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. Power tools create sparks which may ignite the

dust or fumes.

3. Keep bystanders, children and visitors away while operating a power tool.

Distractions can cause you to lose control.

4. Make your workshop childproof with padlocks and master switches. Lock

tools away when not in use.

5. MAKE SURE the work area has ample lighting so you can see the work and that

there are no obstructions that will interfere with safe operation BEFORE using your

power tool.

PERSONAL SAFETY

1. KNOW your power tool. Read the operator’s manual carefully. Learn the tool’s

applications and limitations, as well as the specific potential hazards related to this tool.

2. STAY ALERT, watch what you are doing and use common sense when operating a

power tool.

3. DO NOT use tool while tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in serious personal

injury.

4. DRESS properly. DO NOT wear loose clothing or jewelry. Pull back long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothing, or long hair can

be caught in moving parts. Air vents often cover moving parts and should also be

avoided.

5. AVOID accidental starting. Be sure switch is in “OFF” position before plugging in.

DO NOT carry tools with your finger on the switch. Carrying tools with your finger on the

switch or plugging in tools that have the switch in the “ON” position invites accidents.

6. REMOVE adjusting keys or blade wrenches before turning a tool “ON”. A wrench that

is left attached to a rotating part of a tool may result in personal injury.

7. Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

8. ALWAYS SECURE YOUR WORK. Use clamps or a vise to hold work when practical.

It is safer than using your hand and frees both hands to operate tool.

9. USE SAFETY EQUIPMENT. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

Page 5

SAFETY INSTRUCTIONS cont.

TOOL USE AND CARE SAFETY

^ WARNING: BE SURE to read and understand all instructions before

operating this power tooi. Faiiure to foiiow all instructions listed below may

result in electric shock, fire and/or serious personai injury.

1. ALWAYS use ciamps or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body

is unstable and may lead to loss of control.

2. DO NOT force the tool. Use the correct tool for your application. The correct tool

will do the job better and safer at the rate for which it is designed.

3. DO NOT use the tool if switch does not turn it “On’’ or “Off”. Any tool that

cannot be controlled with the switch is dangerous and must be repaired.

4. DISCONNECT the plug from the power source before making any

adjustments, changing accessories or storing the tool. Such preventive

safety measures reduce the risk of starting the tool accidentally.

5. STORE idle tools out of the reach of children and other untrained persons.

Tools are dangerous in the hands of untrained users.

6. MAiNTAIN tools with care. Keep cutting tools sharp and clean. Properly maintained

tools with sharp cutting edges are less likely to bind and are easier to control.

7. Keep sandpaper clean, remove excess build-up of dust and debris. Replace

sandpaper when worn, this will provide better sanding results.

8. CHECK for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the tool’s operation. If damaged, have the

tool serviced before using. Many accidents are caused by poorly maintained tools.

9. USE ONLY accessories that are recommended for this tool. Accessories that

may be suitable for one tool may become hazardous when used on another tool.

WARNING: Empty dust bag before storage to help prevent possible fire

hazard, especialiy when resin coating or iinseed oii finishes have been sanded.

ELECTRICAL SAFETY

WARNING: Do not permit fingers to touch

the terminals of plug when installing or removing

the plug from the outlet.

1. Double insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug

will fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a

polarized outlet. Do not change the plug in any way.

qualified electrician to install a

Page 6

SAFETY INSTRUCTIONS cont.

ELECTRICAL SAFETY

A WARNING: Do not permit fingers to touch the terminais of piug when

instaliing or removing the piug from the outiet.

2. Double insulation 0 eliminates the need for the three-wire grounded power cord and

grounded power supply system. Applicable only to Class II (double-insulated) tools.

This tooi is a double insulated tool.

A WARNING: Double insulation DOES NOT take the place of normal safety

precautions when operating this tool.

3. BEFORE plugging in the tool, BE SURE that the outlet voltage supplied is within the

voltage marked on the tool’s data plate. DO NOT use “AC only” rated tools with

a DC power supply.

4. AVOID body contact with grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

5. DO NOT expose power tools to rain or wet conditions or use power tools in wet

or damp locations. Water entering a power tool will increase the risk of electric shock.

6. INSPECT tool cords for damage. Have damaged tool cords repaired at a Sears

Service Center. BE SURE to stay constantly aware of the cord location and keep it well

away from moving parts.

7. DO NOT abuse the cord. NEVER use the cord to carry the tool by or to puli the

plug from the outlet. Keep cord away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

EXTENSION CORDS

Use a proper extension cord. ONLY use cords listed by Underwriters Laboratories (UL).

Other extension cords can cause a drop in line voltage, resulting in a loss of power and

overheating of tool. For this tool an AWG (American Wire Gauge) size of a least 14-gauge

is recommended for an extension cord of 25-ft. or less in length. Use 12-gauge for an

extension cord of 50-ft. Extension cords 100-ft. or longer are not recommended.

Remember, a smaller wire gauge size has greater capacity than a larger number

(14-gauge wire has more capacity than 16-gauge wire; 12-gauge wire has more capacity

than 14-gauge). When in doubt use the smaller number. When operating a power tool

outdoors, use an outdoor extension cord marked “W-A” or “W. These cords are rated for

outdoor use and reduce the risk of electric shock.

A\ CAUTION: Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on lumber, tools or other

obstructions while you are working with a power tool.

A. WARNING: Check extension cords before each use. if damaged replace

immediately. Never use tool with a damaged cord since touching the damaged

area could cause electrical shock, resulting in serious injury.

Page 7

SAFETY INSTRUCTIONS cont.

SAFETY SYMBOLS FOR YOUR TOOL

The label on your tool may include the following symbois.

V......................................................................Volts

A......................................................................Amps

....................................................................Hertz

W-....................................................................Watts

...................................................................Minutes

^.......................................................................Alternating current

...................................................................Direct current

f’o.....................................................................No-load speed

....................................................................

.................................................................Revolutions per minute

.................................................................

0PM

................................................................

A.......................................................................indicates danger, warning or caution.

SERVICE SAFETY

1. If any part of this tool is missing or should break, bend, or fail in any way;

or should any electrical component fail to perform properly: SHUT OFF the

power switch and remove the tool’s plug from the power source and have the

missing, damaged or failed parts replaced BEFORE resuming operation.

2. Tool service must be performed only at a Sears Service Center. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

3. When servicing a tool, use only identical replacement parts. Follow

instructions in the maintenance section of this manual. Use of unauthorized

parts or failure to follow maintenance instructions may create a risk of

electric shock or injury. '

Class II construction, Double Insulated

Strokes per minute

Orbits per minute

It means attention! Your safety is involved.

SAFETY RULES FOR POWER SANDERS

T HOLD TOOL by insulated gripping surfaces when sanding where tool may contact

hidden wiring, such as walls, floors, or its own power cord. Contact with a “live” wire will

make exposed metals parts of the tool “live” and shock the operator.

2. INSPECT FOR AND REMOVE all nails, screws, staples or any embedded pieces

of metal from surface to be sanded. These protrusions could damage the sandpaper,

the cushion of the sander and cause loss of control. Following this rule will reduce the

risk of serious personal injury and damage to the sander.

3. NEVER use this or any power sander for wet sanding or liquid polishing.

Failure to follow this rule will increase the risk of electric shock.

4. ALWAYS clamp the workpiece secureiy so it will not move under the sander.

Unsecured work could be thrown towards the operator, causing injury.

5. DO NOT force the sander. The weight of the sander suppiies adequate

pressure. Let the sander and the grit on the sandpaper do the work.

6. DO NOT sand in any one place for too long. The sander’s rapid action may

remove too much materiai and make the surface uneven.

Page 8

SAFETY INSTRUCTIONS cont.

A WARNING: Some dust created by using power tools contains chemicals

known to the State of California to cause cancer and birth defects or other

reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry products.

• Arsenic and chromium, from chemically treated lumber.

Your risk from these exposures varies, depending upon how often you do

this type of work. To reduce your exposure to these chemicals:

• Work in a well-ventilated area.

• Work with approved safety equipment, such as those dust masks that

are specially designed to filter out microscopic particles.

Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth,

eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may

cause serious and permanent respiratory or other injury. Always use

NIOSH/OSHA approved respiratory protection appropriate for the dust exposure.

Direct particles away from face and body.

As. WARNING: Collected sanding dust from sanding surface coatings

(polyurethane, linseed oil, etc.) can self-ignite in sander dust box or elsewhere

and cause fire. To reduce risk, empty dust box frequently and strictly follow

sander manual and coating manufacturer’s instructions.

As CAUTION: When working on metal surfaces, DO NOT use the dust box

or a vacuum cleaner because sparks are generated. Wear safety glasses and a

dust mask. Due to the danger of fire, do not use your sander to sand magnesium

surfaces. Do not use for wet sanding.

SANDING PAINTS

SANDING LEAD BASED PAINT is NOT RECOMMENDED due to the difficulty of

controlling the contaminated dust. The greatest danger of lead poisoning is to children

and pregnant women.

Since it is difficult to identify whether or not a paint contains lead without a chemical

analysis, we recommend the following precautions when sanding any paint:

• NO children or pregnant women should enter the work area where the

paint sanding is being done until all clean up is completed.

• A dust mask or respirator should be worn by all persons entering the work

area. The filter should be replaced daily, or whenever (if) the wearer has

difficulty breathing.

Page 9

SAFETY INSTRUCTIONS cont.

NOTE: Only those dust masks suitable for working with lead paint dust and fumes should

D6 usGQ. Ordinary painting masks do not offor this protoction. Sgg your local hardwaro

dealer for the proper (NIOSH approved) mask.

• NO EATING, DRINKING OR SMOKING should be done in the work area to

prevent ingesting contaminated paint particles. Workers should wash and

clean up BEFORE eating, drinking or smoking. Articles of food, drink, or

smoking should NOT be left in the work area where contaminated dust would

settle on them.

• Paint should be removed in such a manner as to minimize the amount of dust

generated.

• Areas where paint removal is occurring should be sealed with plastic sheeting

of 4 mils thickness.

• Sanding should be done in a manner to reduce tracking of paint dust outside

the work area.

• All surfaces in the work area should be vacuumed and thoroughly cleaned daily

for the duration of the sanding project. Vacuum filter bags should be changed

frequently.

• Plastic drop cloths should be gathered up and disposed of along with any dust

chips or other removal debris. They should be placed in sealed refuse receptacles

and disposed of through regular trash pick-up procedures. During clean up,

children and pregnant women should be KEPT AWAY from the immediate work

area.

• All toys, washable furniture and utensils used by children should be washed

thoroughly before being used again.

ADDITIONAL RULES FOR SAFE OPERATION

WARNING: BE SURE to read and understand all instructions.

Faiiure to foiiow ali instructions iisted beiow may resuit in eiectric shock, fire

and/or serious personai injury.

1. Know your power tooi. Read operator’s manuai carefuiiy. Learn the applications and

limitations, as well as the specific potential hazards related to this tool. Following this rule

will reduce the risk of electric shock, fire or serious injury.

2. ALWAYS wear safety glasses or eye shields when using this tool. Everyday

eyeglasses have only impact-resistant lenses; they are NOT safety glasses.

3. PROTECT your lungs. Wear a face mask or dust mask if the operation is dusty.

4. PROTECT your hearing. Wear appropriate personal hearing protection during use.

Under some conditions noise from this product may contribute to hearing loss.

5. ALL VISTORS AND BYSTANDERS MUST wear the same safety equipment that the

operator of the tool wears.

Page 10

SAFETY INSTRUCTIONS cont.

ADDITIONAL RULES FOR SAFE OPERATION cont.

6.

INSPECT the tool cords periodically and if damaged have them repaired

at your nearest Sears Service Center. ALWAYS BE AWARE of the cord location.

ALWAYS check the tool for damaged parts. Before further use of the tool,

a guard or other part that is damaged should be carefully checked to

determine if it will operate properly and perform its intended function. Check

for misaiignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool’s operation. A guard or other part that is

damaged shouid be properly repaired or repiaced at a Sears Service center.

SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to

instruct others who may use this tool. If someone borrows this tool, make

sure they have these instructions also.

UNPACKING

WARNING: This power tool should NEVER be connected to the power

source when you are assembling parts, making adjustments, installing or

removing sandpaper, cleaning or when it is not in use. Disconnecting the sander

will prevent accidental starting, which could cause serious personal injury.

1. Remove the sander from the carton and inspect it carefully to make sure

that no breakage or damage has occurred during shipping.

2. Do not discard any of the packing materiais untii all parts are accounted for.

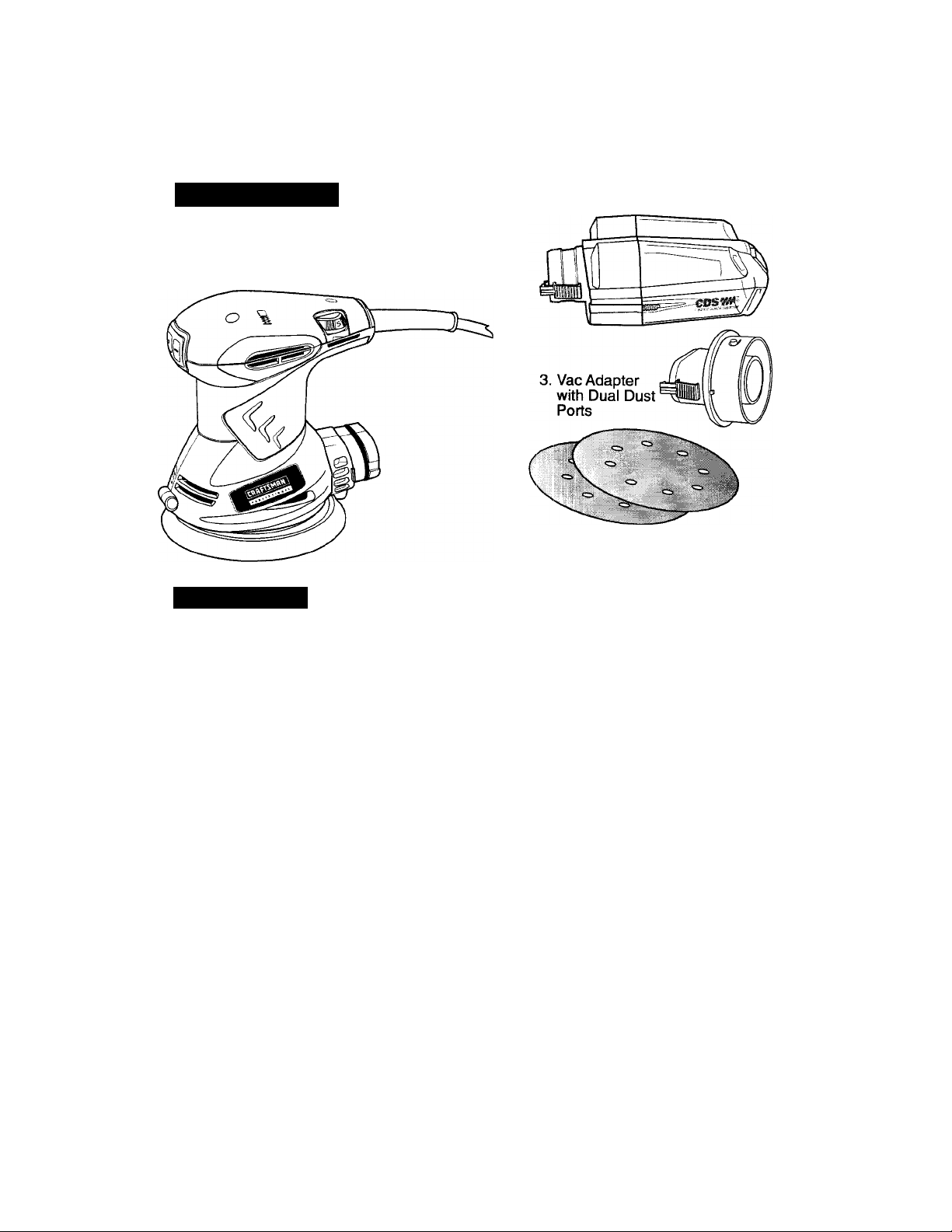

3. Included with your sander is a cyclonic dust box assembly.

4. 2 discs of hook and loop sandpaper are included; one fine grit, and one medium grit.

5. Dual Dust Port Vac Adapter is inciuded.

6. If any of the parts are damaged or missing (refer to F’AFiTS LIST below), return the

sander to your nearest Sears store or Craftsman outlet to have the sander replaced.

A WARNING: If any parts are missing, DO NOT operate this power tool until

the missing parts are replaced. Failure to do so could result in possible serious

personal injury.

10

Page 11

UNPACKING cont.

PARTS LIST (Fig. 1)

1. Sander

2. Cyclonic Dust Box

4, Two 5-in. Hook and Loop

Sanding Discs with Pre-Punched

Holes

DESCRIPTION

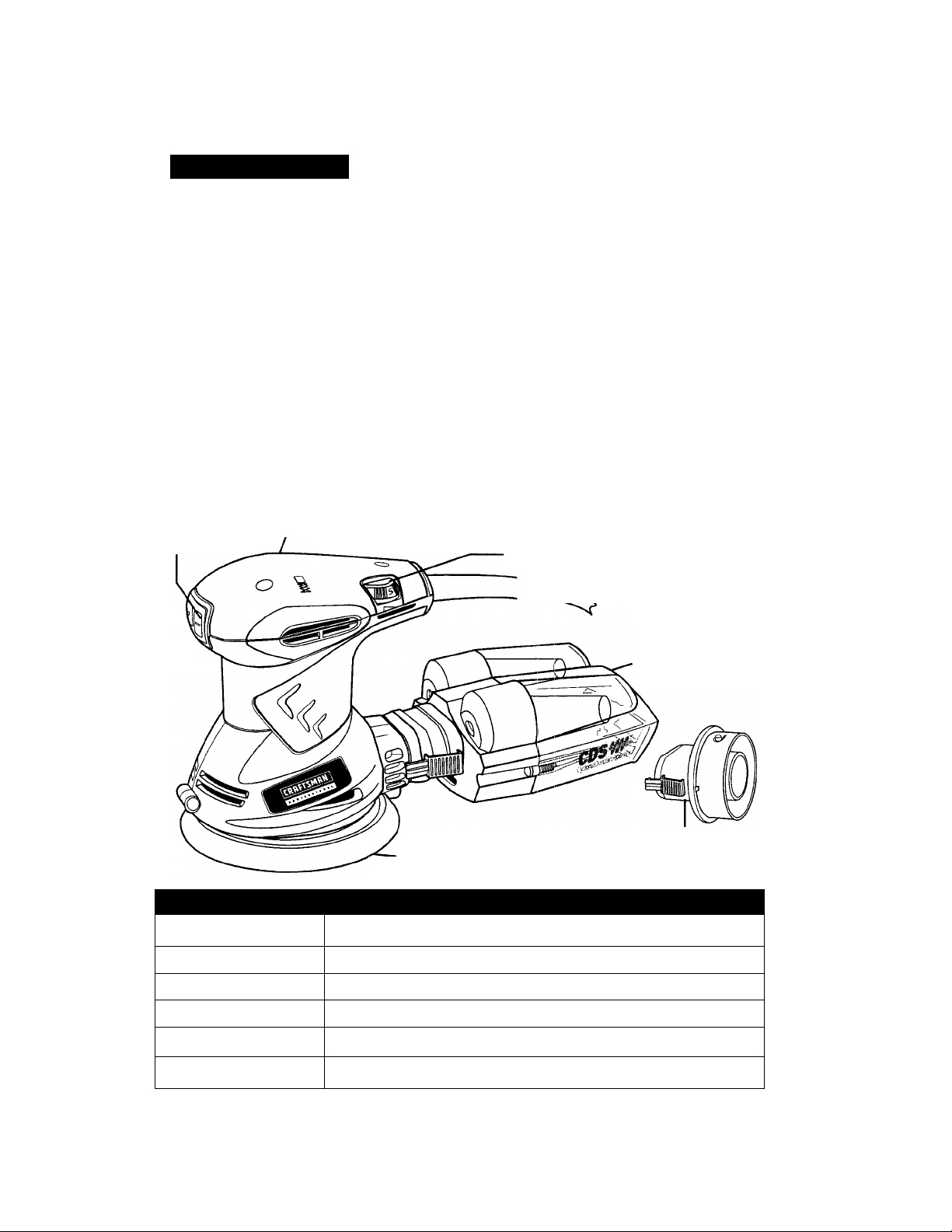

KNOW YOUR RANDOM ORBIT SANDER (Fig. 2)

NOTE: Before attempting to use your sander, familiarize yourself with all of the

operating features and safety requirements.

Your Professional 5” Random Orbit Sander has a precision-built electric motor and it should

be connected to a 120-volt, 60-Hz AC ONLY power supply (normal household current).

DO NOT operate on direct current (DC). The large voltage drop will cause a loss of power

and the motor will overheat. If the sander does not operate when plugged into correct

120-volt, 60-Hz AC ONLY outlet, check the power supply. This sander has a 10-ft., 2-wire

power cord (no adapter needed).

This Random Orbit Sander has the following features:

1. Powerful 3.0 amp motor provides the torque, power and durability for a variety

of continuous sanding applications.

2. Variable speed 5,000 to 12,000 OPM orbits per minute (no-load speed) is controlled

by variable speed dial. Match with the correct speed and sandpaper grit to the surface

being sanded for either fast material removal or a fine, smooth finish.

3. Random orbital action with 1/16-in. orbit diameter helps to provide a swirl free finish.

4. Ergonomically designed Palm Grip Handle with Molded-in Comfort Grip

for maximum balance, control, gripping comfort and reduced operator fatigue.

5. Precision-tuned counterbalanced system reduces vibration for smooth operation

and less operator fatigue.

5. Operator’s Manual

11

Page 12

DESCRIPTION cont.

This Random Orbit Sander has the foliowing features cont.:

6. On/Off rocker switch is conveniently located for easy control. Sealed to keep out

dust for long life.

7. Hook and Loop Backing Pad for easy attachment of hook and loop type sanding discs

with pre-punched holes.

8. High impact-resistant housing helps protect tool from damage and reduces weight.

9. Cyclonic Dust/Air Separator (CDS) Collection System Dust Box features advanced

air flow design with centrifugal force dust extraction that separates the dust particles

from the air flow as they enter the box. The clean air then flows out of the box while the

dust particles are trapped inside. This system provides more efficient dust collection than

the standard dust bag system.

10

Vac Adapter with Dual Dust Ports for Vac Hoses Allows connection to 1V4 or 2V2-inch

vac hose and wet / dry vac (sold separately).

11

Permanently lubricated 100% ball bearings for smooth operation and long life.

On/Off !

Rocker Switch

Fig 2

PRODUCT SPECIFICATIONS

No-load Speed

Rating

Input

Orbit Diameter

-----

Comfort Grip Handle

Variable Speed Dial

Cyclonic

Dust Box

. 5-in. Hook and Loop

Backing Pad

5000-12000 OPM orbits per minute variable speed

120 Volts, 60 Hz AC

3.0 Amps

1/16-inch

Vac Adapter with

Dual Dust Ports for

Vac Hoses

Sanding Disc Size

Paper Type

5-in. Diameter

Hook and Loop Discs with Pre-Punches holes

12

Page 13

ASSEMBLY

WARNING. Your sandor should NEVER be connected to the power source

when you are assembling parts, making adjustments, installing or removing

sandpaper, cleaning or when it is not in use. Disconnecting the sender will prevent

accidental starting, that could cause serious personal injury.

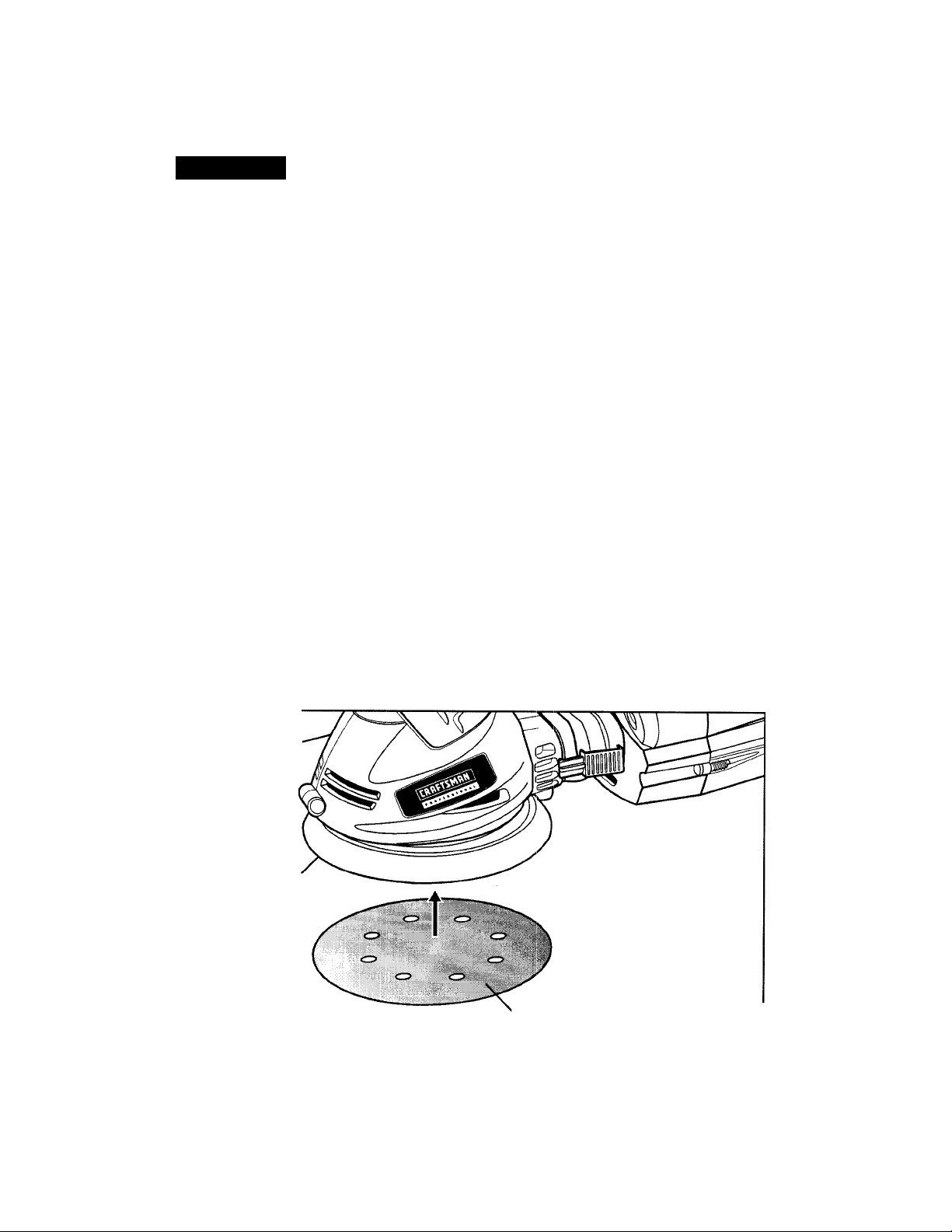

INSTALLING THE SANDPAPER (See Fig. 3)

ALWAYS inspect the sandpaper before installing. DO NOT use if broken or defective.

1. Unplug the sender.

zìi WARNING: Failure to unplug the sander could result in accidental

starting causing possible serious personai injury.

NOTE: Remove cyclonic dust box assembly when installing sandpaper. ALWAYS

remember to reattach the cyclonic dust box assembly before beginning sanding

operation (see page 14, Fig. 4).

2. Align the holes in the sanding disc with the holes in the hook and loop backing pad.

NOTE: Holes in sanding disc must line up with holes in the backing pad in order for

the dust collection feature of the sander to function properly.

3. Press the sanding disc against the backing pad as firmly as possible.

NOTE: For best adhesion, we recommend that you clean the backing pad and the

sanding disc backing occasionally by brushing them lightly with a small brush.

Fig3

5-in.

Hook and Loop

Backing Pad

Sander

>5-in. Hook and Loop

Sanding Disc with

Pre-Punched holes

13

Page 14

ASSEMBLY cont.

DUST BOX / DUST COLLECTION

A WARNING: Collected sanding dust from sanding surface coatings

(poiyurethane, iinseed oii, etc.) can seif-ignite in sander dust box or elsewhere

and cause fire. To reduce risk, empty dust box frequentiy and strictiy follow

sander manual and coating manufacturer’s instructions.

A WARNING: When working on metai surfaces, DO NOT use the dust box

or a vacuum cleaner because sparks are generated. Wear safety glasses and a

dust mask. Due to the danger of fire, do not use your sander to sand magnesium

surfaces. Do not use for wet sanding.

CYCLONIC DUST/AIR SEPARATOR (CDS) COLLECTION SYSTEM

Dust Box features advanced air flow design with centrifugal force dust extraction that

separates the dust particles from the air flow as they enter the box. The clean air then flows

out of the box while the dust particles are trapped inside. This system provides more

efficient dust collection than the standard dust bag system.

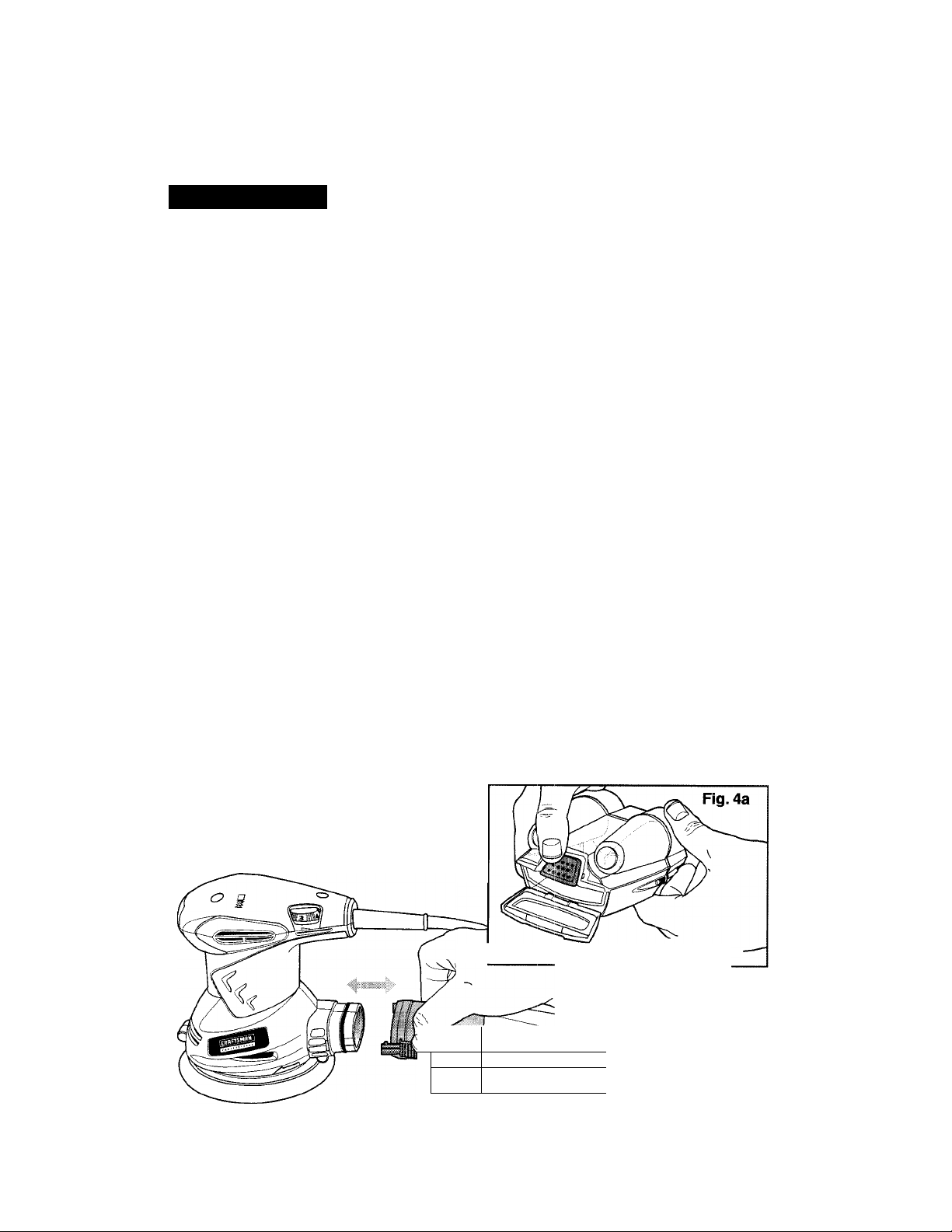

TO REMOVE AND EMPTY DUST BOX (See Fig. 4)

1. Unplug the sander.

A WARNING: Failure to unpiug the sander could result in accidental starting

causing possible serious personal injury.

2. Locate two tab connectors on either side of cyclonic dust box and squeeze together.

This disconnects dust box from sander.

3. Slide dust box off sander dust exhaust.

4. Cyclonic Dust box has black button on rear that pushes in to open a small door in rear

of box (see Fig. 4a). Dust can be emptied from this door. Shake box aggressively to

completely empty. To close door, simply push in until it clicks shut.

5. To reattach dust box, push box until

two tab connectors on sides catch

on to sander. You will hear them click.

6. Your sander is now ready to use.

Fig. 4

Door on rear of Cyclonic Dust Box

_____

3

Page 15

ASSEMBLY con.

TO REMOVE AND EMPTY DUST BOX cont.

NOTE: Empty dust box frequently so dust collection system works properly.

For more efficient operation, empty dust box when it is no more than 1/2 fuil

This wiil ailow better airfiow through the box.

WARNING: Empty dust box before storage to help prevent possible fire

hazard, especiaily when resin coating or linseed oil finishes have been sanded.

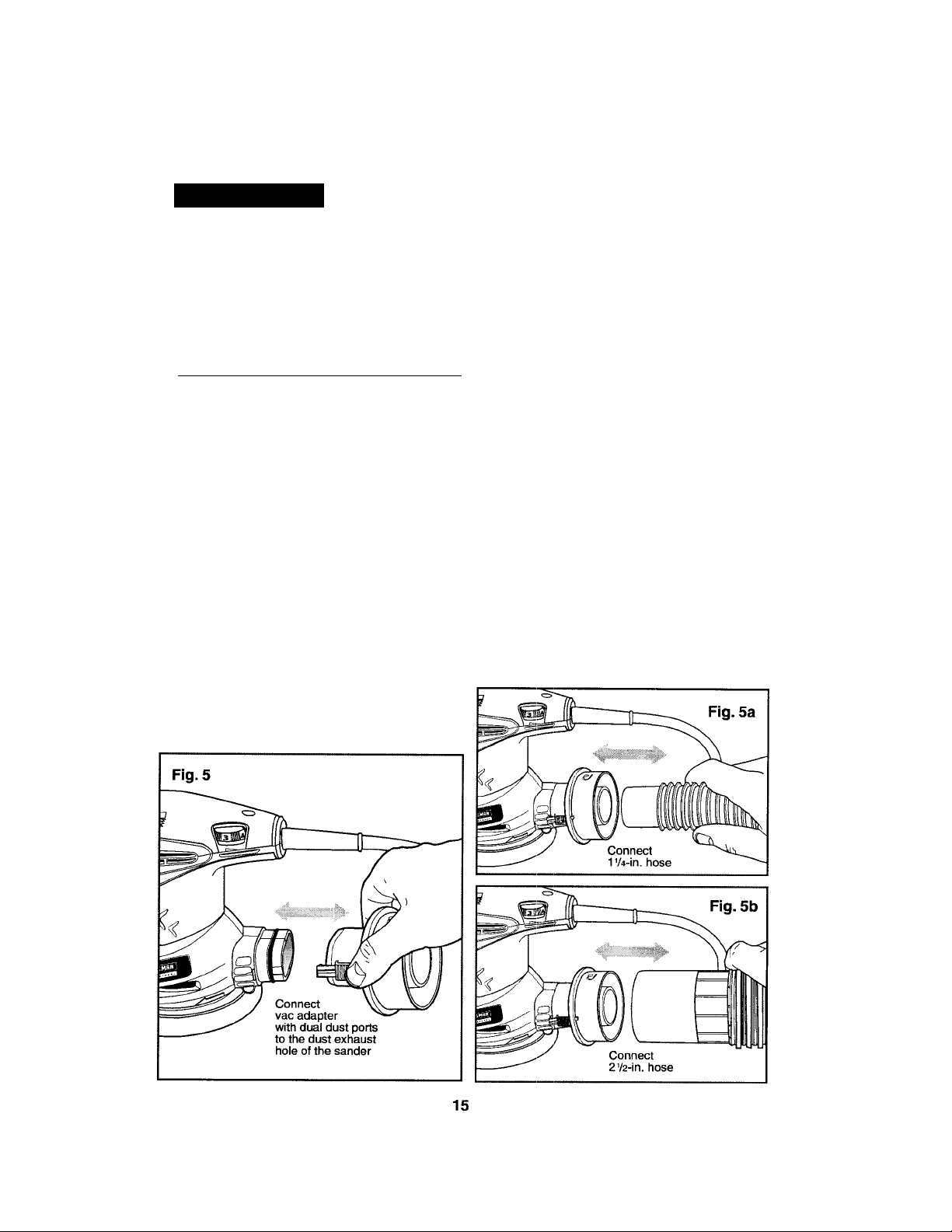

ATTACHING VAC HOSE TO THE DUAL DUST PORT ADAPTER (See Fig. 5,5a and 5b)

When sanding for extended periods of time, you can easiiy attach your sander to a vac

hose and wet/dry vac (sold separately).

1. Unplug the sander.

^ WARNING: Failure to unplug the sander could result in accidental

starting causing possible serious personal injury.

2. Locate two tab connectors on either side of cyclonic dust box and squeeze together.

This disconnects dust box from sander.

3. Slide dust box off sander dust exhaust hole and remove box from sander.

4. Attach the Vac Adapter with Dual Dust Ports to the dust exhaust hole of the sander.

5. Attach either a 1V4 or 2V2-in vac hose

onto the vac adapter’s dual dust ports

( see Fig. 5a and 5b).

6. Connect hose to wet/dry vac. Turn

vac on while operating sander.

Page 16

ASSEMBLY coni.

ATTACHING VAC HOSE TO THE DUAL DUST PORT ADAPTER cont.

NOTE: A standard 1 V4-in. vac hose connection fits inside the smaiier diameter

hoie inside the duai dust port adapter, whiie a standard 2V2-in. vac hose

connection fits inside the iarger hoie of the duai dust port adapter

As. WARNING: When sender is not connected to vacuum, aiways instali the

Cyclonics dust box back on sander. Faiiure to do so couid cause sanding dust

or foreign objects to be thrown into the face or eyes, which couid resuit in

possible serious injury.

Zli WARNING: Coiiected sanding dust from sanding surface coatings

(poiyurethane, iinseed oil, etc.) can seif-ignite in sander dust box or eisewhere

and cause fire. To reduce risk, empty dust box frequently and strictly follow

sander manual and coating manufacturer’s instructions.

As CAUTION: When working on metai surfaces, DO NOT use the dust box

or a vacuum cieaner because sparks are generated. Wear safety giasses and

a dust mask. Due to the danger of fire, do not use your sander to sand

magnesium surfaces. Do not use for wet sanding.

OPERATION

Before attempting to use any tooi, be sure to famiiiarize yourseif with aii the

operating features and safety instructions.

A WARNING: iF ANY PARTS are MiSSING, DO NOT OPERATE YOUR

SANDER UNTiLTHE MISSiNG PARTS ARE REPLACED. FAILURE TO FOLLOW

THIS RULE COULD RESULT IN SERIOUS PERSONAL INJURY.

A WARNING: DO NOT let familiarity with your sander make you careless.

Remember that a careless fraction of a second is sufficient to cause severe injury.

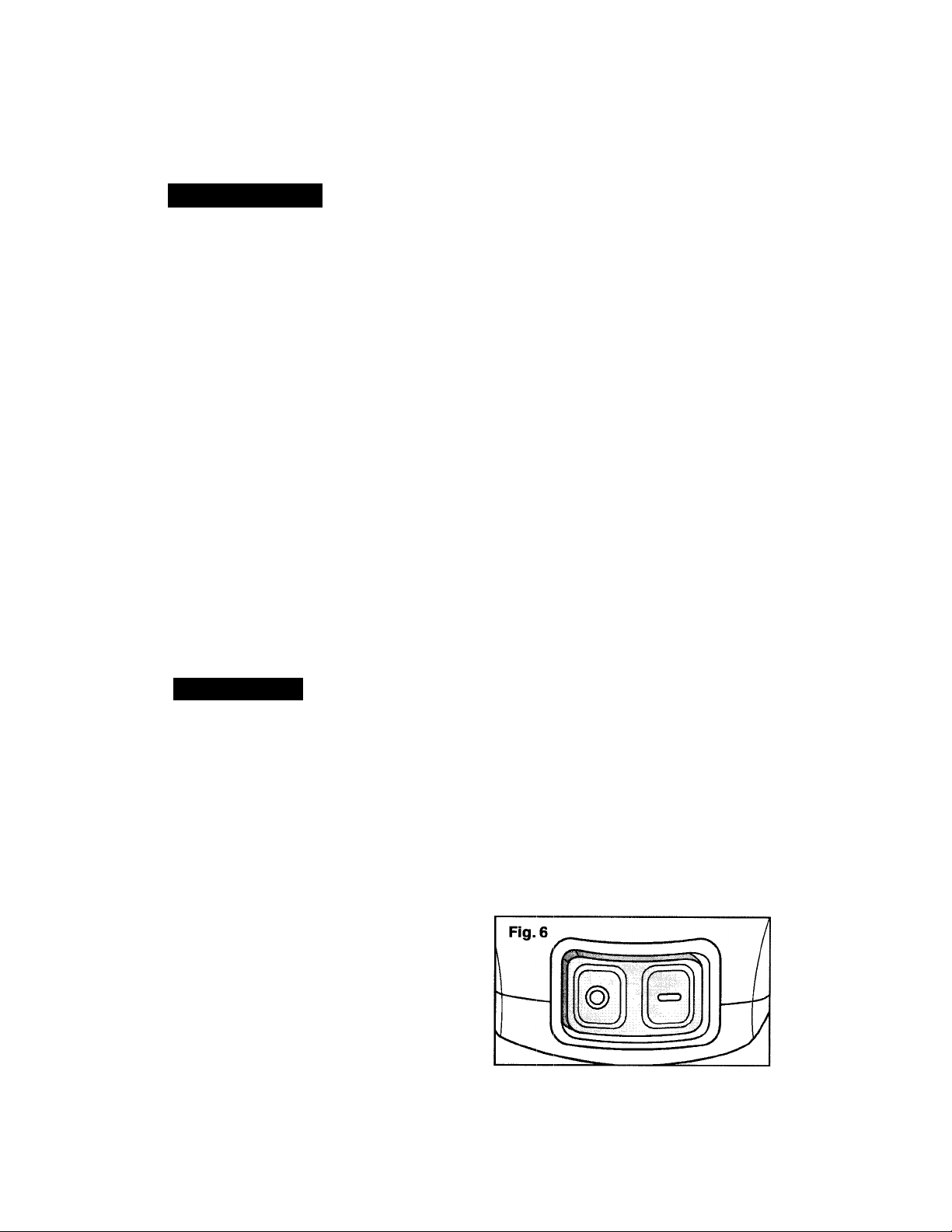

ON/OFF ROCKER SWITCH (see Fig. 6)

This switch is sealed to help keep out dust

for a longer life and is conveniently located

near the front of the palm grip handle.

Start the sander by pushing in the part of the

switch with the 0. Let the motor build to its

maximum speed before starting sanding

operation. To turn sander off, push side of

switch with the .

16

Page 17

OPERATION coni.

VARIABLE SPEED SWITCH (see Fig. 7)

The variable speed dial allows matching the correct

speeds to sandpaper grits and various surfaces and

materials being sanded for either fast material

removal or a fine smooth finish.

Rotate the dial from 1 to 6, with 1 being the

lowest speed and 6 the highest speed.

APPLICATIONS

Only use your sander for the applications listed below*.

• Sanding wood surfaces with various grits of sandpaper.

• Removing rust from steel surfaces with special sandpaper.

AWARNING: Due to the danger of fire, DO NOT use your sander to sand

magnesium surfaces. DO NOT use for wet sanding.

AwARNING: ALWAYS clamp the workpiece. An unsecured workpiece could

be thrown towards the operator, causing serious injury.

A CAUTION: When gripping the sander during use, ALWAYS be carefui not

to cover the air vents with your hands (see Fig. 9).

2. Place sander on workpiece so that all of sanding disc surface is in contact with workpiece.

3. Start the sander and move it slowly over workpiece, making successive passes in parallel

lines, circles, or crosswise movements.

17

Page 18

OPERATION cont.

USING YOUR SANDER cont. (see Fig. 8 on page 17)

4. Upon completion of sanding operation, turn sander off and wait until sanding disc comes

to a complete stop before removing from workpiece.

5. Extended periods of sanding may tend to overheat the motor. If this occurs, turn sander

off and wait until sanding disc comes to a compiete stop, then remove it from workpiece

Remove sanding disc, then turn sander on and run it free without a load (off the workoiece)

to cool the motor. '

SANDING TIPS

1. DO NOT force the sander. The weight of the sander supplies adequate pressure on

the workpiece. Let the sander and the sandpaper’s grit do the work.

• Applying additional pressure will only slow down the motor, wear the sandpaper

out faster and reduce the sender’s orbital speed.

• Excessive pressure will overload the motor and cause possible damage to the

sander from the motor overheating.

• Excessive pressure will also result in a poor quality finish.

2. Any existing finish or resin on wood may soften from the heat of the friction and cause

the sandpaper to load-up faster.

3. Inspect sandpaper frequently and change paper when grit is worn and not able to

perform properly. '

4. DO NOT sand in one spot for too long a time because the sender’s rapid action may

remove too much material and make the surface uneven.

SELECTING THE RIGHT SANDPAPER

Selecting the correct grit and type of sandpaper is an extremely important decision that

will allow you to achieve the best quaiity sanding finish.

1. Aluminum oxide, silicon carbide and other synthetic abrasives are best for power

sanding.

2. Natural abrasives such as flint and garnet are too soft for economical use in power

sanding.

3. Coarse grit wili remove the most material and finer grit virill give you the best finish in all

sanding operations.

4. The condition of the surface to be sanded wili determine which grit will do the job.

5. If the surface is rough:

• Start with a coarse grit and sand until the surface is uniform.

• Then use medium to remove any scratches left by the coarse grit.

• Then use a finer grit for finishing the surface.

18

Page 19

OPERATION cont.

As. WARNING;Empty dust box before storage to help prevent possible fire

hazard, especially when resin coating or linseed oil finishes have been sanded.

NOTE: Empty dust box frequently when sanding so dust collection system

works properiy.

ORBiTAL MOTiON (see Fig. 9)

As shown in Figure 9, the orbit of the sander is 1/16-in. in diameter so the sandpaper

moves in tiny circies at very high speed, allowing the sander to move easily.

This orbital action duplicates a “hand sanding” motion for more aggressive sanding as you

push the sander forward. This powerful orbital action is ideal for heavy-duty sanding

applications, such as:

1. Removing old finishes

2. Smoothing rough wood

3. Sanding stock down

to required dimensions

4. Finishing surfaces

that are to be painted.

FLUSH SANDING (See Fig. 10)

Flush sanding can be performed with the front edge of this sander. Upon completion

of sanding operation, turn sander off and wait until sanding disc comes to a complete

stop before removing from workpiece.

Page 20

MAINTENANCE

adjustments MUST be performed by a qualified service technician at a

Sears Service Center.

safety and reliability, repairs, maintenance and

A WARNING: For your safety, ALWAYS turn off switch and unplug sander

from the power source before performing any maintenance or cleaning.

It has been found that electric tools are subject to accelerated wear and possible

premature failure when they are used to work on fiber glass boats and sports cars,

wallboard, spackling compounds or plaster. The chips and grindings from these materials

are highly abrasive to electrical tool parts, such as bearings, brushes, commutators, etc.

Consequently, it is not recommended that this tool be used for extended work on ariy

fiberglass material, wallboard, spackling compound or plaster. During any use on these

materials, it is extremely important that the tool is cleaned frequently by blowinq with

an air jet.

Zfi WARNING: Always wear safety goggles or safety glasses with side shields

during power tool operations, or when blowing dust. If operation is dusty, also

wear a dust mask.

ROUTINE MAINTENANCE

A WARNING: DO NOT at any time let brake fluids, gasoline, petroleum-

based products, penetrating oils, etc. come in contact with plastic parts.

Chemicals can damage, weaken or destroy plastic, which may result in serious

personal injury.

Periodic maintenance allows for long life and trouble-free operation. A cleaning and

maintenance schedule should be maintained. As a common preventive maintenance

practice, follow these recommended steps:

WARNING: For your safety, ALWAYS turn off switch and unplug sander

from the power source before performing any maintenance or cleaning.

1. When work has been completed, clean the tool to allow smooth functioning of the tool

over time. Clean the tool with compressed air.

2. Use clean damp cloths to wipe the tool. Use a brush to brush off and clean the sender’s

Backing Pad.

3. Keep the motor air openings free from oil, grease and sawdust or woodchips, and

store tool in a dry place.

LUBRICATION

Your Craftsman® Professional Orbital Sander has been properly lubricated and is ready to

use. No further lubrication is needed under normal operating conditions. All bearings in the

sander are lubricated for the life of the tool.

20

Page 21

MAINTENANCE coni.

BRUSH REPLACEMENT (see Fig. 11,11a, 11b and 11c)

1. Unplug the Sander.

WARNING: Failure to unplug the sender could result in accidental

starting causing possible serious personal injury.

2. Remove (3) screws from top cover

of Sander and remove top cover (see Fig. 11).

3. Locate the (2) Carbon Brush / Brush Holder

Assemblies (see Fig. 11a). They are connected

to red wire lead terminals and are in position

on each side of the armature.

4. Carefully lift these (2) assemblies (see Fig. 11a and 11b)

out of their positions (NOTE: Remember how

they are positioned so that you can put them

back in position correctly.)

5. Check the ends of the carbon brushes (see Fig. 11b)

for wear. If either brush has less than 1/4-in. length

of carbon remaining, replace both. DO NOT

REPLACE ONE SIDE WITHOUT REPLACING

THE OTHER.

6. To replace assemblies, disconnect

the red wire lead terminals from the

assemblies (see Fig. 11c), attach

new assemblies to the lead terminals

and place the assemblies back into

their original positions next to the

armature. Make sure the curvature

of the end of the brushes matches

the curvature of the armature and

that the brushes move freely in

brush holder assemblies.

7. Reassemble the top cap with the

(3) screws and do not overtighten.

21

Page 22

ACCESSORIES

WARNING: The use of attachments or accessories that are not

recommended for this tool might be dangerous and could result in serious injury.

Sears and other Craftsman® outlets offer a selection of Craftsman Professional Random

Orbit Sander accessories designed for all your sanding applications.

5-inch, 8 Hole, Hook and Loop Sanding Discs come in very fine, fine,

medium and coarse grit.

Visit your local Sears store or other Craftsman outlets or shop sears.com/craftsman for

all of the accessories for your random orbital sander.

22

Page 23

PARTS LIST

5-in. Dia. Random

Orbital Sander with Cyclonics

MODEL NUMBER 172.27673

I t

N3

CO

Page 24

The model number will be found on the nameplate

of the Random Orbital Sander. Always mention the model

number when requesting parts and service for your tool.

22(7)

Page 25

PARTS LIST cont.

5-in. Dia. Random

Orbital Sander with Cyclonics

MODEL NUMBER 172.27673

The model number will be found on the nameplate

of the Random Orbital Sander. Always mention the model

number when requesting parts and service for your tool.

N3

.b

Item No.

1

2

3

4

5

6

7

8

101

9

10

11

12

13

102

14

15

16

17

18

19

20

21

22

23

24

103

25

Parts No.

200T0040159000A-00

200T0030119000A-00 Carbon brush

2PES04Q7000000A-00 Power cord

2PGA17T4001OOOA-00

2PES04Q1010000A-00

200T0280179000A-00 Inner wire

2PES04Q0004000A-00

2PES04Q0011000A-00

2PES04Q2000000A-00 Rotor

200T0070003000A-00

200W8000006000A-00

200T0020005000A-00

20TA9520072000A-00

2PES04Q0007000A-00 Fan

2PES04Q4000000A-00

2PES03A1102000A-00

200W8000047000A-00 Bail bearing 6202

2PES04Q4001OOOA-00

200W3200029000A-00

2PES02A00110OOA-00

200W3000059000A-00

2PES04Q0006000A-00

2PES03A2000000A-00

200W4000035000A-00

2PES04Q0002000A-00 Top cover

200W4000032000A-00

2PES04Q3000000A-00 Stator asm

2PES04Q3001OOOA-00

Part Description

Brush holder ssemblv

Speed adiustment knob

Variable speed board

Left wind baffle

Brand label

Bearing sleeve

Ball bearing 607-2z-p63

Dust proof ring

Armature

Bracket seat

Bracket

Bracket

Screw washer assembly M4x20

Washer

Screw M4x 16

Brake ring

Base plate

Screw ST4.2x16

Screw ST4.2x13

Bracket

Qty.

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

7

1

6

1

1

Item No.

26

27

28

29

30

31

32

33

34

35

38

39

40

105

41

42

43

44

45

46

47

48

49

50

51

52

53

Parts No.

20TA9500080000A-00

200W4000052000A-00

2PES02A0002000A-00

200W0020265000A-00

200W4000005000A-00

2PES04Q6001OOOA-00

200W8500003000A-00

2PES04Q0003000A-00

200T0200005000A-00

2PES04Q5001OOOA-00

2PES04Q0001OOOA-00

2PES04Q0005000A-00

200T0080024000A-00

2PES02A0900000A

200W4000009000A.-00

2PES02A0901OOOA-00

2PES02A0907000A-00

2PES02A09110OOA-00

200W4000006000A-00

2PES02A0912000A-00

2PES02A0902000A-00

200T0050034000A-00

2PES02A0905000A-00

2PES02A0904000A-00

2PES02A0903000A-00

200T0050208000A-00

2PES02A0906000A-00

Part Description

Stator

Screw ST4.2X55

Switch cover

Switch

Screw ST3.5x8 2

Press plate 1

Ball bearing 6000 1

Housing

Cord damp

Dust port

Rated label

Right wind baffle

0 ring 3x34

dust collector box assembly

Screw ST3.5x16

HlIQt nnrt ■j

Airproof strip 1

Dust proof board 1

Screw ST3.5x10

Cyclone Duct 1

Dust collector

Compression spring

Airproof patch

Button

Rear cover

Torsional spring

Pin

Qty.

1

2

1

1

1

1

1

1

1

1

1

2

3

1

1

1

1

1

1

2

Page 26

Get it fixed, at your home or ours!

Your Home

For expert troubleshooting and home solutions advice:

manage fitt^ home

www.managemyhome.com

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME® Call anytime, day or night

(1-800-469-4663) (U.S.A. and Canada)

www.sears.com

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location of the nearest

Sears Parts & Repair Service Center

www.sears.ca

1 -800-488-1222 (U.S.A.) 1 -800-^169-4663 (Canada)

www.sears.com

To purchase a protection agreement on a product serviced by Sears:

1 -800-827-6655 (USA.) 1 -800-361 -6665 (Canada)

Рага pedir servicio de reparación

a domicilio, у pana ordenar piezas:

1-888-SU-HOGAR®

(1-888-784-6427)

© Sears Brands, LLC

® Registered Trademark / ™ Trademark / Service Mark of Sears Brands, LLC

® Marca Registrada / ™ Marca de Fábrica / Marca de Servicio de Sears Brands, LLC

Marque de commerce / Marque déposée de Sears Brands, LLC

www.sears.ca

Au Canada pour service en français:

1-eOO-LE-FOYER^c

(1-800-533-6937)

www.sears.ca

Page 27

Manual del Operador

I P B

OFESSIONAL

J

3.0 Amperios/5-pulg. Diámetro

Separador Cyciónica de Polvo-Aire (CDS)

Sistema de la Colección

Lijadora Orbital Aleatoria

Modelo No. 172.27673

PRECAUCIÓN: Lea, entienda y siga todas las Normas

de Seguridad e Instrucciones de Operación en este

Manual antes de usar este producto.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 EE.UU.

Visite nuestra página Web Craftsman®; www.searsxom/craftsman

3025736

Certified

to CAN/CSA-

C22.2 No.745-1,745-2-4

Conforms to UL

STD 745-1, 745-2-4

Doble Aislamiento

• GARANTÍA

• SEGURIDAD

• DESEMPACADO

• DESCRIPCIÓN

• ENSAMBLAJE

OPERACIÓN

MANTENIMIENTO

Page 28

INDICE

Garantía

Símbolos de Seguridad

Instrucciones de Seguridad

Desempacado

Descripción

Ensamblaje

Operación.......................................

Mantenimiento

Accesorios.................................................

Números de Teléfono de Partes de Repuesto de Sears

..............................

..............

...........

...................................

...................................

...........................................

.......................................

GARANTÍA DE UN AÑO COMPLETO SOBRE PRODUCTOS PROFESIONAL

CRAFTSMAN©

Si esta herramienta profesional Craftsman falla debido a defectos en los materiales

o mano de obra entre un año desde la fecha de compra, REGRÉSELA A CULAQUIER

TIENDA SEARS U OTRA PUNTA DE VENTA CRAFTSMAN EN LOS ESTADOS

UNIDOS PARA Reparación Gratis (O REEMPLAZO SI ES IMPOSIBLE REPARARLA).

Esta garantía no incluye partes desechadles tales como lámparas, pilas, puntas

u hojas y papel.

Esta garantía le otorga derechos legales específicos y es possible que usted tenga

otros derechos, los cuales varían de un estado a otro.

OC

27

28-34

OH oo

OC.QC

sJ\J

07_/in

44-45

46

Sears, Roebuck and Co., Hoffman Estates, IL 60179

¡GUARDE ESTAS INSTRUCCIONES!

¡LEATODAS LAS INSTRUCCIONES!

ADVERTENCIA: Algún polvo generado por el uso de herramientas

eléctricas contiene químicos conocidos por el estado de California por causar

cáncer y defectos de nacimiento u otros defectos para la reproducción.

26

Page 29

SÍMBOLOS DE SEGURIDAD

El proposito de los símbolos de seguridad es llamar su atención con respecto a los posibles

peligros. Los símbolos de seguridad y la explicación de ellos merecen cuidadosa atención

y comprensión. La advertencia de los símbolos NO elimina ningún peligro en sí Las

instrucciones y advertencias que brindan no son sustitutas de las medidas correctas de

prevención de accidentes.

ADVERTENCIA: ASEGÚRESE de ieer y comprender todas ias

instrucciones de seguridad de este manual, incluyendo todos los símbolos de

alerta de seguridad como “PELIGRO”, “ADVERTENCIA” y “PRECAUCIÓN”

ANTES de utilizar esta herramienta. El incumplimiento de las instrucciones

enumeradas a continuación puede producir descargas eléctricas, incendio y/o

lesiones personales graves.

SIGNIFICADO DE LOS SIMBOLOS

SÍMBOLO DE ALERTA DE SEGURIDAD: indica PELIGRO,

A

ADVERTENCIA O PRECAUCIÓN. Pueden usarse en conjunción con otros

símbolos o pictogramas.

A PELIGRO

A AnuEDTCKir'iA incumplimiento de esta advertencia de seguridad

Za AUVtn I tNUIA PUEDE resultar en la muerte o lesiones oraves oara i

A PRECAUCIÓN

MENSAJES DE INFORMACIÓN Y PREVENCIÓN DE PELIGRO

Estos mensajes brindan al usuario información y/o instrucciones importantes que podrían

conducir al daño de los equipos u otros daños materiales si no se cumpliesen. Cada mensaje

es precedido por la palabra “NOTA;” como en el siguiente ejemplo:

NOTA: Se pueden producir daños a los equipos u otros daños materiales si no se

siguen estas instrucciones.

I El incumplimiento de esta advertencia de seguridad RESULTARÁ

I en la muerte o lesiones graves para usted u otros. Siempre siga

las precauciones de seguridad para reducir el riesgo de

incendio, descarga eléctrica y lesiones personales.

PUEDE resultar en la muerte o lesiones graves para usted

u otros. Siempre siga las precauciones de seguridad para

reducir el riesgo de incendio, descarga eléctrica y

lesiones personales.

El incumplimiento de esta advertencia de seguridad PUEDE

resultar en lesiones personales para usted u otros o daños

a la propiedad. Siempre siga las precauciones de seguridad

Sara reducir el riesgo de incendio, descarga eléctrica y

P'

le

ésiones personales.

A ADVERTENCIA: El funcionamiento de cualquier

herramienta eléctrica puede causar la proyección de objetos

extraños hacia los ojos lo cual puede ocasionar daños

graves en los ojos. Antes de poner en funcionamiento

una herramienta eléctrica, SIEMPRE use gafas de seguridad

o anteojos de seguridad con protector lateral y protector

facial completo cuando sea necesario. Recomendamos el

uso de una máscara de seguridad de visión amplia para

usar sobre los anteojos o anteojos de seguridad estándar

con protector lateral, disponibles en las tiendas Sears

u otros puntos de venta Craftsman.

IaA aSam a ■ ■ a i ^ ^ ^ 2 ^ _ 21 _ _

27

Page 30

INSTRUCCIONES DE SEGURIDAD

A ADVERTENCIA: Asegurase de leer y entender todas las instrucciones en

este manual antes de usar esta herramienta. No seguir todas las instrucciones

podría resultar en descargas eléctricas, incendio yío iesiones personaies graves.

SEGURIDAD DEL AREA DE TRABAJO

1. Mantenga su área de trabajo iimpia y bien iiuminada. Los bancos de trabajo

desorganizados y las áreas oscuras invitan a los accidentes.

2. NO opere herramientas eiéctricas en atmósferas explosivas, como por ejempio

en presencia de líquidos, gases o poivos infiamables. Las herramientas eléctricas

crean chispas que podrían encender el polvo o los gases.

3.

SIEMPRE mantenga a los observadores, niños y visitantes aiejados ai utiiizar una

herramienta eiéctrica. Las distracciones podrían ocasionar que usted pierda el control.

Haga su taiier a prueba de niños con candados e interruptores maestros. Guarde las

herramientas bajo llave cuando no las utiliza.

5.

ASEGURESE de que el área de trabajo cuenta con ampiia iluminación para que

pueda ver el trabajo y que no haya obstrucciones que interferirán con una operación

segura ANTES de usar su herramienta.

SEGURIDAD PERSONAL

1. CONOZCA su herramienta eiéctrica. Lea el manual del operador cuidadosamente.

Aprenda las aplicaciones y limitaciones de la herramienta, asi como peligros

pontenciales específicos relacionados con esta herramienta.

2. MANTÉNGASE ALERTA, mire lo que hace y utilice sentido común al operar una

herramienta eléctrica.

3. NO use la herramienta cuando esté cansado o bajo la influencia de drogas, alcohol

o medicación. Un momento de distracción mientras hace funcionar ias herramientas

eléctricas podría resultar en lesiones personales graves.

4. Vísta apropiadamente. NO use ropa suelta o joyas. Recoja el cabello largo. Mantenga

su cabello, ropa y guantes lejos de las peizas móviles. La ropa suelta o cabello largo

podrían quedar atrapados en las piezas móviles. Las aperturas de ventilación a menudo

cubre piezas móviles y también deben evitarse.

5. EVITE encender accidentalmente la herramienta. Asegúrase de que el interruptor se

encuentre en posición de APAGADO. Transportar las herramientas con un dedo en

el interruptor o enchufar la herramienta mientras el interruptor se encuentre en la

posición ENCENDIDO invita a accidentes.

6. RETIRE las llaves de ajuste de las hojas o llaves de tuercas antes de encender la

herramienta. Una llave de ajuste que queda conectada a una pieza rotativa de la

herramienta podría resultar en lesiones personaleís.

7. No se extienda para alcanzar sobre la herramienta. Mantenga el pie firme así

como el balance en todos momentos. Pie y equilibrio apropiados permiten

un mejor control de la herramienta en posiciones inesperadas.

8. ASEGURE SIEMPRE SU TRABAJO. Use abrazaderas o un tornillo para sostener el

trabajo cuando sea práctico. Es más seguro que usar sus manos y libera ambas manos

para operar la herramienta.

9. USE EQUIPO DE SEGURIDAD. Use SIEMPRE protección para los ojos. Máscaras

anti-polvo, zapatos de seguridad antideslizantes casco o protección para los oídos

deben usarse en condiciones que lo requieran.

28

Page 31

INSTRUCCIONES DE SEGURIDAD coni.

SEGURIDAD EN EL USO Y CUIDADO DE LA HERRAMIENTA

ADVERTENCIA: asegúrase de leer y entender todas las instrucciones

en este manuai antes de usar esta herramienta. No seguir todas las instrucciones

podrid TGSUltdr ©n dGScsrgss ©léctricss, fncGndío y/o Igsíoiígs pGrsonalGs gravGS.

1

SIEMPRE use abrazaderas u otra manera práctica de asegurar y apoyar la pieza

de trabajo sobre una plataforma estable. Sostener el trabajo con las manos o contra

el cuerpo es instable y podría resultar en pérdida de control.

2.

NO fuerce la herramienta. Use la herramienta correcta para su aplicación.

La herramienta correcta hará el trabajo de manera mejor y más segura para lo cual fue

diseñada.

NO use ia herramienta si el interruptor no ia Encienda o Apaga. Toda herramienta

que no puede ser controlada por el interruptor es peiigrosa y debe ser reparada.

DESCONECTE ei enchufe de ia fuente de alimentación antes de hacer cualquier

ajuste, cambiar ios accesorios o guardar la herramienta. Tales medidas prevenidas

reducen el riesgo de encender la herramienta accidentalmente.

5.

GUARDE las herramientas sin usar fuera del alcance de los niños y otras personas

no capacitadas. Las herramientas son perigrosas en las manos de usuarios no capacitados.

6.

DELE a las herramientas un mantenimiento cuidadoso. SiEMPRE mantenga las

herramientas limpiadas y en buen orden de trabajar.

7.

Mantenga ia hoja de papel de lijar limpiada, y saca acumulación excesivo de polvo

y aserrín. Reemplaza hijo de papel de lijar cuando gastado. Este provea resultes mejores

de lijar.

8. VERiFiQUE si ias piezas móviies están desalineadas o se atascan, se rompen o si

existe alguna otra condición que podría afectar la operación de la herramienta. Si está

dañada, la herramienta debe recibir mantenimiento antes del uso. Muchos accidentes

ocurren debido a herramientas con un mantenimiento pobre.

9. USE sóio ios accesorios recomendados para esta herramienta. Los accesorios

aptos para una herramienta podrían ser dañinos si se utilizan con otra herramienta.

Al ADVERTENCIA: Vacia la caja guardapolvo antes de almacenamiento,

ayudar prevenir el fuego possible, particularmente cuando capa de resina o

aceite de linaza han sido lijados.

SEGURIDAD ELECTRICA

Al ADVERTENCIA: No permita que los dedos

hagan contacto con las terminales del enchufe

mientras instala o quita el enchufe del tomacorriente.

Las herramientas con aisiamiento doble están

equipadas con un enchufe polarizado (una hoja es

más amplia que ia otra). Este enchufe encajará en

un tomacorriente polarizado de un solo modo. Si el

enchufe no entra por completo en el tomacorriente,

déle la vuelta. Si sigue sin entrar, póngase en contacto

con un electricista competente para instalar un

tomacorriente polarizado. No haga ningún tipo de

cambio en el enchufe.

29

Page 32

INSTRUCCIONES DE SEGURIDAD

SEGURIDAD ELÉCTRICA

2. Doble Aislamiento 0 elimina la necesidad de un cordón de alimentación con

conexión a tierra de tres alabres y un sistema de suministro de energía con conexión

a tierra. Aplica sólo para herramientas Clase II (con doble aislamiento). Esta

herramienta tiene doble aislamiento.

ADVERTENCIA: El aislamiento doble NO reemplaza las precauciones

de seguridad normaies ai operar esta herramienta.

3. ANTES de enchufar la herramienta, ASEGÚRASE de que el voltaje de al toma provisto

se encuentre en el rango de voltaje marcado en la placa de identificación de la

herramienta. NO use herramientas con clasificación CA solamente en una fuente de

alimentación CC.

4. EViTE el contacto del cuerpo con superficies conectadas a tierra, tales como

tuberías, radiadores, estufas de cocina y refrigeradores. Hay mayor riesgo de que se

produzcan descargas eléctricas si su cuerpo está conectado a tierra.

5.

NO exponga ias herramientas eiéctricas a ia liuvia ni a condiciones húmedas ni

use ias herramientas eiéctricas en ubicaciones húmedas o mojadas. El agua que

ingresa a la herramienta eléctrica incrementará el riesgo de descargas eléctricas.

6.

iNSPECCiONE el cordón de la herramienta para verificar ia presencia de daños.

Soiicite ai Centro de Servicio Sears que repare todo cordón dañado. ASEGÚRASE

de estar constantemente atento a la ubicación del cordón y manténgalo lejos de partes

en movimiento.

7. NO abuse dei cordón. NUNCA use ei cordón para trasladar la herramienta ni lo

haie para sacar ia toma dei enchufe. Reempiace todo cordón dañado de inmediato.

Los cordones dañados incrementan el riesgo de descargas eléctricas.

CABLES DE EXTENSIÓN

Utilice un cordón de extensión adecuado. Utilice SOLAMENTE los cordones autorizados

por Underwriters Laboratories (UL). Cualquier otro cable de extensión puede ocasionar una

caída en la tensión de línea resultando en pérdida de potencia y recalentamiento de la

herramienta.

Para esta herramienta, la escala de calibres norteamericanos para alambres y cables o AWG

(por sus siglas en inglés) recomienda un tamaño mínimo de calibre 14 para un cordón de

extensión de 25 pies o de una longitud menor. Utilice calibre 12 para los cordones de extensión

de 50 pies. No se recomiendan los cordones de extensión de 100 pies o de iarga.

Recuerde que un tamaño de caiibrador de aiambres más pequeño tiene una capacidad

más grande que un número mayor (el alambre de calibre 12 tiene una capacidad más grande

que el de calibre 14). Si tiene alguna duda, utilice el calibre de un diámetro menor. Al utilizar

una herramienta eléctrica a la intemperie, utilice un cordón de extensión para intemperie marcado

“W-A” o “W”. Estos cordones tienen capacidad nominal para uso a la intemperie y reducen el

riesgo de que se produzcan descargas eléctricas.

30

Page 33

INSTRUCCIONES DE SEGURIDAD cont.

SIMBOLOS DE SEGURIDAD PARA SU HERRAMIENTA

La etiqueta en su herramienta pueda inciuir ios símboios siguientes.

.......................................................................

A.......................................................................Amperios

.....................................................................Hercios

W-.....................................................................Vatios

inin....................................................................Minutos

....................................................................

=........................................................................Corriente continua

Voltios

Corriente alterna

^0 .....................................................................Velocidad libre de carga

B.......................................................................Construcción Clase II, Doble aislamiento

.................................................................Revoluciones por minuto

SPM..................................................................Carreras (Strokes) por minuto

OPM..................................................................Órbitos por minuto

....................................................................

SEGURIDAD EN EL SERVICIO TÉCNICO

1. Si cualquier parte se pierde, se rompe, se dobla o falla de cualquier forma; o si

cualquier componente eléctrico no funciona adecuadamente: APAGUE el interruptor

de potencia^ desenchufe la lijadora de la fuente de energía y haga reemplazar la parte

perdida, dañada o que no funciona ANTES de utilizar nuevamente.

2. El servicio técnico de la herramienta se debe realizar solamente en un Centro de

servicio técnico de Sears. El servicio técnico o mantenimiento que se realice por

personal no calificado podría producir riesgo de lesiones.

3. Cuando realice ei servicio técnico de una herramienta, utilice solamente las piezas

de repuesto idénticas. Respete las instrucciones de la sección de mantenimiento

de este manual. Si se utilizan partes no autorizadas o no se respetan las instrucciones

de mantenimiento, se puede crear un riesgo de descarga eléctrica o lesión.

lindica peligro, advertencia o precaución.

Significa: ¡¡¡Atención!!! Su seguridad se encuentra

comprometida.

REGLAS DE SEGURIDAD PARA LAS LIJADORAS DE PODER

1. Sujeta la herramienta por las agarres con superficies insuladas cuando lijas en donde

la herramienta contactará cableado escondido, come paredes, suelos, o su cordón.

Contacto con un alambre “vivo" haré todos partes metales expuestas de la herramienta

“viva” y da descarga eléctrica al operador.

2. Inspeccione y quita todos ios clavos, tornillos, grapas o cualquieres pedazos de metal

enterrados del superficie ser lijado. Estas prominencias podian dañar al papel de lijar, el

almohadilla del lijador, y causa pérdida de control.

3. NUNCA use esta o cualquier otra lijadora eléctrica para lijar superficies mojados o para

pulir con líquido. El incumplimiento de esta regia puede aumentar la posibilidad de un

choque eléctrico.

4. SIEMPRE prensas bien la pieza de trabajo así que no mueva bajo la lijadora. Trabajo

no asegurado puede ser lanzado hacia el operador, causando lesiones.

5. NO fuerce la lijadora. El peso de la unidad proporciona una presión suficiente. Deje el

trabajo a la lijadora y al disco de lija.

6. NO lije demasiado tiempo en un lugar. La rápida acción de la lijadore puede desprender

demasiado material, dejando desigual la superficie.

31

Page 34

INSTRUCCIONES DE SEGURIDAD cont.

^ADVERTENCIA: Algún polvo generado por el uso de herramientas

eléctricas contiene químicos conocido por el estado de California por causar

cáncer y defectos de nacimiento u otros defectos para la reproducción. Algunos

ejemplos de estos químicos son:

• El plomo de las pinturas a base de plomo.

• La sílice cristalina de los ladrillos, el cemento y otros productos de albañilería.

El riesgo de estas exposiciones varía, dependiendo de la frecuencia con que realiza

este tipo de trabajo. Para reducir su exposición a estos químicos:

Evite el contacto prolongado con el polvo de lijadoras, sierras, pulidoras, perforadoras

eléctricas y otras actividades de la construcción. Utilice ropa de protección y lave las

áreas expuestas con agua y jabón. Si permite que el polvo ingrese a su boca, ojos o

permanezca en la piel, se puede fomentar la absorción de químicos nocivos.

• El arsénico y el cromo, de la madera tratada químicamente.

• Trabaje en áreas bien ventiladas.

• Trabaje con los equipos de seguridad aprobados, tales como máscaras

contra el polvo que están especialmente diseñadas para filtrar partículas

microscópicas.

LIJANDO LAS PINTURAS

Lijando las pinturas con base de plomo NO SE RECOMIENDA debido a la dificultad de

control el polvo contaminado. El peligro más grande de el envenenamiento de plomo está

para niños y mujeres embarazados.

Puesto que es tan difícil identificar si una pintura contiene plomo sin una análisis químico,

recomendamos los precauciones siguientes cuando lijando cualquier pintura.

• Ningún niño o mujer embarazada debe entrar al área de trabajo donde se esté lijando

pintura hasta después de haber terminado con su limpieza.

• Todas las personas que entren en el área de trabajo deberán usar una máscara contra

el polvo o un respirador. El filtro debe reemplazarse todos los días, o ni bien el

usuario tenga dificultades para respirar.

32

Page 35

INSTRUCCIONES DE SEGURIDAD coni.

nota. Deben usarse únicamente máscaras contra el polvo aptas para trabajar con polvo

o vapores de pintura de plomo. Las máscaras comunes para pintar no ofrecen esta

protección. Consulte con su distribuidor local acerca de la máscara adecuada (aprobada

por NIOSH).

• NO SE DEBE COMER, BEBER O FUMAR en el área de trabajo para evitar la

ingestión de partículas de pintura contaminadas. Los trabajadores deben lavarse

y limpiarse ANTES de comer, beber o fumar. Los artículos de comida, bebida o

fumar NO deben dejarse en el área de trabajo donde serían alcanzadas por el

polvo contaminado.

• La pintura debe removerse de tal forma que minimice la cantidad de polvo generado.

• El área en la cual se remueve la pintura debe centrarse con paneles de plástico

de 4 milésimas de pulgada de espesor.

• Se debe lijar de tal forma que reduzca el transporte del polvo de la pintura fuera

del área de trabajo.

• Todas las superficies del área de trabajo deben aspirarse y limpiarse bien todos

los días durante todo el transcurso del proyecto de lijado. Las bolsas y filtros de la

aspiradora deben reemplazarse frecuentemente.

• Las telas protectoras de plástico deben recolectarse y desecharse junto con todos

los demás residuos. Deben colocarse en recipientes sellados y desecharse a través

de los procedimientos normales de recolección de residuos. Durante la limpieza,

los niños y las mujeres embarazadas deben MANTENERSE FUERA del área de trabajo.

• Todos los juguetes, muebles lavables y utensilios utilizados por niños deben lavarse

bien antes de volver a usarlos.

REGLAS ADICIONALES PARA UN FUNCIONAMIENTO SEGURO

^ ADVERTENCIA: ASEGÚRASE de leer y entender todas las instrucciones

en este manuai antes de usar esta herramienta. No seguir todas ias

instrucciones podría resultar en descargas eléctricas, incendio y/o lesiones

personales graves.

1. Conozca su herramienta eléctrica. Lea cuidadosamente el manual de operaciones.

Aprenda las aplicaciones y limitaciones así como ios peligros potenciales específicos

relacionados con esta herramienta. El seguimiento de esta norma reducirá el riesgo de

que se produzca alguna descarga eléctrica, incendio o lesión grave.

2. USE gafas de seguridad o viseras oculares mientras usa esta herramienta. Los

anteojos de todos los días tienen soiamente lentes resistentes al impacto y NO SON

anteojos de seguridad.

3. PROTEJA sus pulmones. Utilice una máscara para la cara o mascarilla antipolvo si ia

operación es polvorienta.

4. PROTEJA sus oídos. Use protección auditiva personal adecuada. Bajo algunas

condiciones, ei ruido de este producto puede contribuir a ia pérdida auditiva.

5. TODOS LOS VISITANTES Y PERSONAS PRESENTES DEBEN utilizar el mismo

equipo de seguridad que ei usuario de ia herramienta.

6. INSPECCIONE los cables de la herramienta periódicamente y, si están dañados,

repárelos en su Centro de Servicio Sears mas cercano. TENGA PRESENTE

SIEMPRE la ubicación del cable.

33

Page 36

INSTRUCCIONES DE SEGURIDAD cont.

REGLAS ADICIONALES PARA UN FUNCIONAMIENTO SEGURO cont.

7. SIEMPRE verifique ias herramientas para determinar si existen partes dañadas.

Antes de usar más la herramienta, asegúrese de que no haya ningúna pieza dañada

o otra condición que afecta la operación. Una pieza dañada debe ser reparada o repuesta

en un Centro de Servicio Sears.

CONSERVE ESTAS INSTRUCCIONES. Remítase a ellas frecuentemente

y utilícelas para capacitar a otras personas que puedan utilizar esta herramienta.

Si alguien le pide esta herramienta prestada, asegúrese de que se lleve también

estas instrucciones.

DESEMPACADO

/di ADVERTENCIA: NUNCA debería conectar la herramienta a la fuente de

energía cuando arme las partes, haga ajustes, instale o quite las hojas, limpie o

cuando la herramienta no esté en uso. Al desconectar la herramienta, evita que

ésta se encienda acidentaimente, lo cual podría causar lesiones personales graves.

1. Saque la lijadora del cartón y inspecciónela con cuidado para asegurarse de que ho

hayan ocurrido roturas o daños durante el envío.

2. No deseche ningún material de embalaje hasta que se cuente con todos los contenidos.

3. Su lijadora viene con un módulo ciclónico recolector de polvo.

4. Incluye dos discos de papel de lija “gancho y vuelta”; uno de grano fino y otro

mediano.

5. Incluye un conector doble adaptador para aspiradora.

6. Si algunas de las partes está dañada o no se encuentra (remítase a la Lista De

Repuestos de abajo), regrese la lijadora al comercio Sears o al punto de venta de

Craftsman más cercano para que se la cambien.

/di ADVERTENCIA: Si falta alguna parte, NO utilice esta lijadora hasta que

se reemplace la parte que falta. Si no se hace esto podrían producirse posibles

lesiones personales graves.

34

Page 37

DESEMPACADO cont.

PARTS LIST (Fig. 1)

1. Lijadora

DESCRIPCION

2. Caja ciclónica recolector de polvo

pulgadas con agujeros

preperforados

5. Manual del Usuario

CONOZCA DU LIJADORA ORBITAL ALEATORIA (Fig. 2)

NOTA: Antes de intentar utilizar la lijadora, familiariicese con todas las

características de funcionamiento y requisitos de steguridad.

Su Lijadora Orbital Aleatoria Profesionál de 5” tiene un motor electrónico de precisión y

debe conectarse ÚNICAMENTE a un tomacorriente de 120 voltios, 60 Hz CA (suministro

doméstico normal). NO la conecte a corriente continua (CC). La gran caída de voltaje

causaría pérdidas de potencia y el motor se recalentaría. Si la lijadora no funciona al

enchufarla a un tomacorriente de 120 voltios, 60 Hz, CA SOLAMENTE revise la

alimentación. Esta lijadora tiene un cable de alimentación de 10 pies, 2 conductores

(no necesitan adaptador).

Esta Lijadora Orbital Aleatoria tiene las siguientes características:

1. Potente motor de 3.0 amperios proporciona el torque, potencia y durabilidad para una

variedad de aplicaciones de lijado continuas.

2. 5000 a 12000 órbita por minuto (velocidad sin carga) controlada por una dial variable

de velocidad. Ajuste la velocidad correcta y el grano del papel de lija de acuerdo a la

superficie a lijar para remover material rápidamente o lograr un acabado fino y suave.

3. Movimiento orbital aleatorio con un diámetro de 1/16” ayuda a obtener un acabado

sin marcas.

4. Soporte diseñado económicamente con moldura confortable para un máximo

balance, control, confort de sujeción y reducción de fatiga para el operador.

5. Sistema de compensación con ajuste de precisión reduce la vibración para un

funcionamiento suave y menor fatiga del operador.

35

Page 38

DESCRIPCIÓN coni.

Esta Lijadora Orbital Aleatoria tiene las siguientes características cont.:

6. Interruptor de eje de balancín encendido-apagado ubicado convenientemente

7.

Almohadilla con ganchos para facilitar el acoplamiento de discos de lija tipo "qancho

y vuelta con agujeros preperforados .

8.

Cubierta de alta resistencia a impactos ayuda a proteger la herramienta y reduce su peso.

9.

Separador Cyclónica de Polvo/Aire (CDS) Sistema de la Colección Caja de Polvo

ofrece diseño avancado de flujo de aire con extracción de polvo por fuerza centrífuga

que separa la partículas de polvo del flujo de aire cuando ingresa en la caja. El aire

limpio sale de la caja mientras que la partículas de polvo quedan atrapadas en ella.

Este sistema provee una recolección de polvo más eficiente que los sistemas comunes

con bolsa.

10.

Conexión Adaptadora Doble para Manguera de Aspiradora permite conectar

mangueras de 1 14” o 2 ¥2" y aspiradoras para materiales secos o húmedos

(vendido separado).

11.

Rodamientos esféricos permanentemente lubricados al 100% para un

funcionamiento ininterrumpido y de larga duración.

■ . .. — —- . « uuii^auu buiivciiieiiiemer

nara faf-ilitar al

para facilitar el control. Sellado contra el polvo para prolongar su vida útil.

____________________________________i____i___

____________

■ ..

....

Interruptor de

eje de balancín

Confortable Agarre de Palma Manija

encendido-apagado

Fig2

ESPECIFICACCIONES DEL PRODUCTO