Page 1

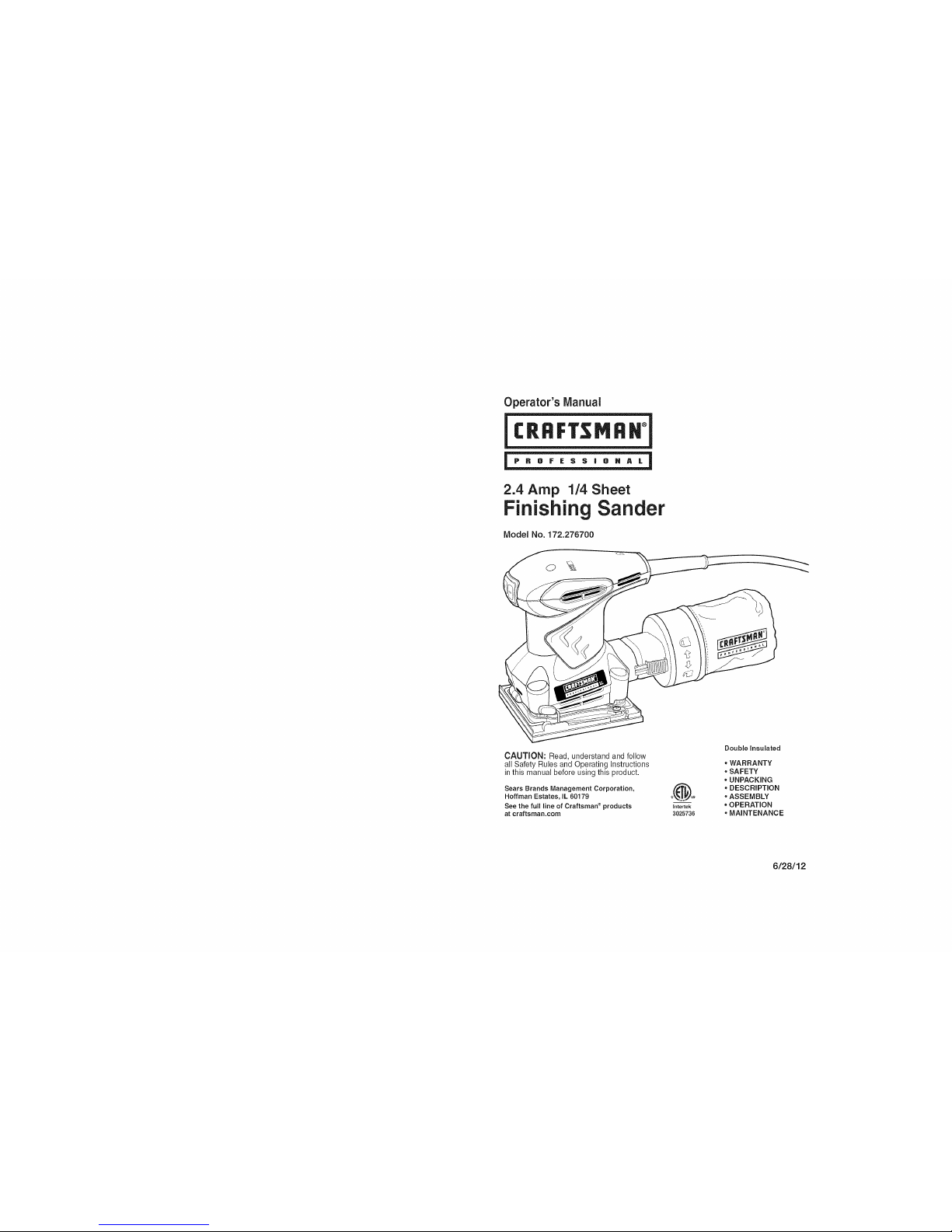

Operator's Manual

2.4 Amp 1/4 Sheet

Finishing Sander

Model No. 172.276700

CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions

in this manual before using this product.

Sears Brands Management Corporation,

Hoffman Estates, IL 60179

See the full line of Craftsman ®products

at craftsman.com

Intertek

3025736

Double Insulated

* WARRANTY

* SAFETY

* UNPACKING

* DESCRIPTION

* ASSEMBLY

* OPERATION

* MAINTENANCE

6/28/12

Page 2

Warranty .................................................................................... Page 2

Safety Symbols ........................................................................... Page 3

Safety instructions ....................................................................... Pages 4- 10

Unpacking .................................................................................. Page 10

Description .......................................................................................... Pages 11 - 12

Assembly. ............................................................................................ Pages 13- 17

Operation ............................................................................................ Pages 18 - 21

Maintenance ....................................................................................... Pages 22 - 23

Accessories ......................................................................................... Page 24

Parts List............................................................................................. Pages 25 - 26

CRAFTSMAN PROFESSIONAL ONE YEAR LiMiTED WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted

against any defects in material or workmanship. With proof of purchase,

a defective product will be replaced free of charge.

For warranty coverage details to obtain free replacement, visit the web

site: www.craftsman.com

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

SAVE THESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

I _WARNING: Some dust created by using power tools contains chemicals

known to the State of California to cause cancer and birth defects or other

reproductive harm.

Page 3

Thepurposeofsafetysymbolsistoattractyourattentiontopossibledangers.

Thesafetysymbolsandtheexplanationswiththemdeserveyourcarefulattention

andunderstanding.Thesymbolwarningsdonot,bythemselves,eliminateany

danger.Theinstructionsandwarningstheygivearenosubstitutesforproper

accidentpreventionmeasures.

_,WARNING:Besuretoreadandunderstandallsafetyinstructionsinthis

manual,includingallsafetyalertsymbolssuchas"DANGER,""WARNING,"and

"CAUTION"beforeusingthisfinishingsander.Failuretofollowallinstructions

listedinthismanualmayresultinelectricshock,fireand/orseriouspersonalinjury.

SYMBOL SIGNAL MEANING

,_ SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, OR CAUTION.

May be used in conjunction with other symbols or pictographs.

_i, DANGER: Indicates a hazardous situation which, if not avoided, will result

in death or serious injury.This signal word is to be limited to the most extreme

situations. Always follow the safety precautions to reduce the risk of fire, electric

shock, and personal injury.

,_ WARNING: Indicates a hazardous situation which, if not avoided, could result

in death or serious injury. Always follow the safety precautions to reduce the risk

of fire, electric shock, and personal injury.

,_ CAUTION: Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

Damage Prevention and Information Messages

These inform the user of important information and/or instructions that could lead

to equipment or other property damage if they are not followed. Each message is

preceded by the word "NOTE;' as in the example below:

NOTE: Equipment and/or property damage may result if these instructions are not

followed.

WARNING: To ensure safety and reliability, all repairs

should be performed by a qualified service technician.

,_ WARNING: The operation of any power tools can result in

foreign objects being thrown into your eyes, which can result in

severe eye damage. Before beginning power tool operation,

always wear safety goggles or safety glasses with side shield

and a full face shield when needed. We recommend a Wide

Vision Safety Mask for use over eyeglasses or standard safety glasses with side

shields. Always use eye protection which is marked to comply with ANSI Z87.1

shields.

Page 4

,4k WARNING: Read all safety warnings and instructions. Failure to follow ]

the warnings and instructions may result in electric shock, fire and/or

J

serious injury.

Save all warnings and instructions for future reference.

The term power tool in the warnings refers to your electric (corded) power too! or

battery-operated (cordless) power tool.

WORK AREA SAFETY

1. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

3. Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

4. Make your workshop childproof with padlocks and master switches. Lock tools away

when not in use.

5. MAKE SURE the work area has ample lighting so you can see the work and that

there are no obstructions that will interfere with safe operation BEFORE using your

power tool.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools

may result in serious personal injury.

2. Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

3. Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have

the switch on invites accidents.

4. Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the power tool may result in personal injury.

5. Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

7. if devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

Page 5

TOOLUSEANDCARESAFETY

Z_ WARNING: BE SURE to read and understand all instructions before

operating this power tool. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious personal injury.

1. Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

2. Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

3. Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

4. Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

5. Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tools operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

6. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

7. Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool,

taking into account the working conditions and the work to be performed. Use of

the power tool for operations different from those intended could result in a hazardous

situation.

8. Use clamps or another practical way to secure and support the workpiece to a

stable platform.

9. Holding the work by hand or against your body leaves it unstable and may lead to

loss of control.

Z_ WARNING: Empty dust bag before storage to help prevent possible fire

hazard, especially when resin coating or linseed oil finishes have been sanded.

ELECTRICAL SAFETY

/_, WARNING: Do not permit fingers to touch

the terminals of plug when installing or removing

the plug from the outlet.

1. Double insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug

will fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in any way.

Or°o_er_e_d

Outlet Box --_

Page 6

ELECTRICAL SAFETY

2 Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with grounded power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

/_, WARNING: Double insulation DOES NOT take the place of normal safetyprecautions when operating this tool.

3. Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

4. Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

5. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

6. When operating a power tool outdoors, use an extension cord suitable for outdoor

use marked "W-A" or "W". Use of a cord suitable for outdoor use reduces the risk of

electric shock.

7. If operating a power tool in a damp location is unavoidable, use a Ground Fault

Circuit Interupter (GFCI) protected supply. Use of a GFCI reduces the risk of

electric shock.

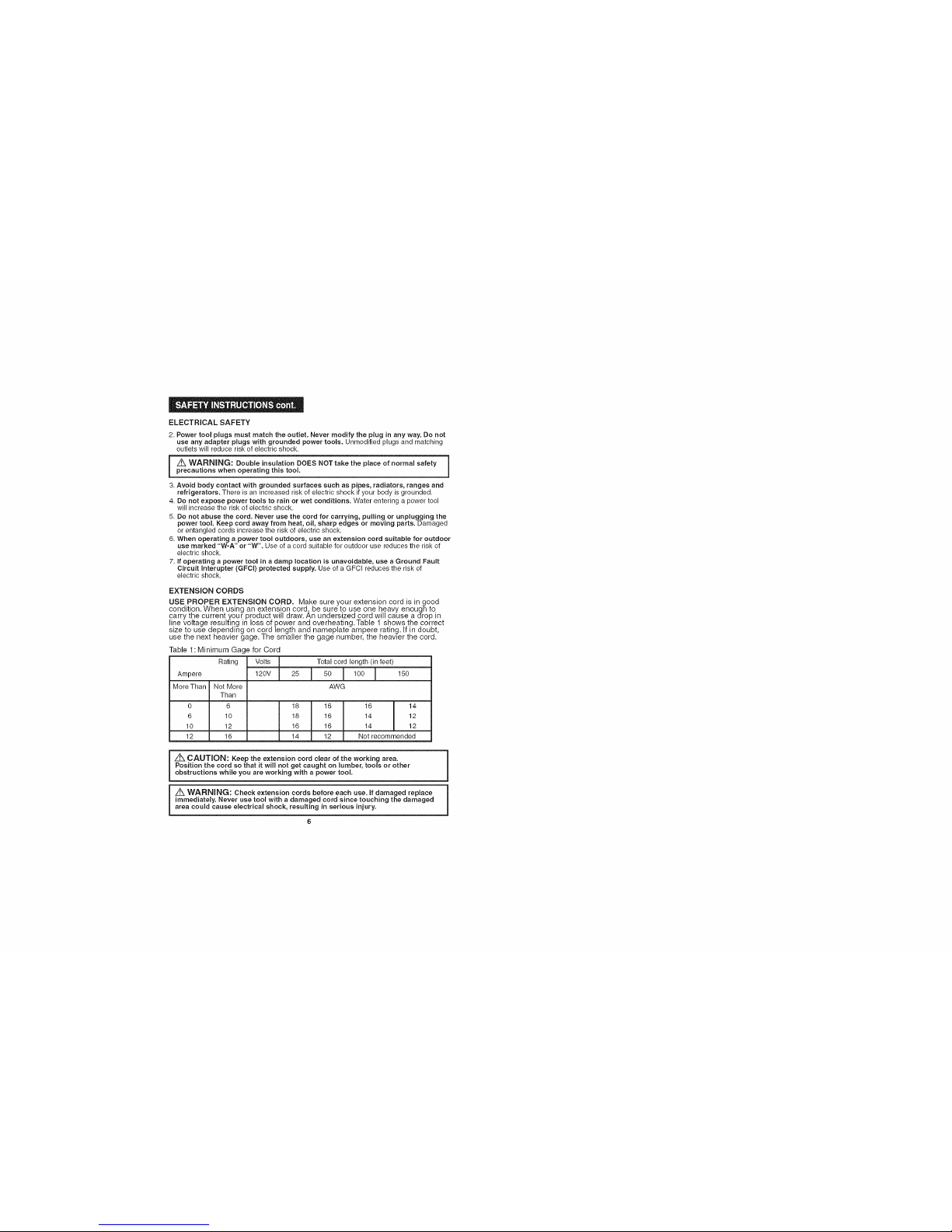

EXTENSION CORDS

USE PROPER EXTENSION CORD. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized cord will cause a c]rop in

line voltage resulting in loss of power and overheating.Table 1 shows the correct

size to use depending on cord length and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller the gage number, the heavier the cord.

Table 1:Minimum Gage for Cord

Rating Volts I Totalcord length (in feet)

Ampere

MoreThan Not More

Than

6

10

12

120vi 25i i leoI

AWG

0 18 16 16 I 14

6 18 16 14 ! 12

10 16 16 14 12

12 16 14 12 Not recommended

Z_ CAUTION: Keep the extension cord clear of the working area. ]

Position the cord so that it will not get caught on lumber, tools or other

J

obstructions while you are working with a power tool.

Z_ WARNING: Check extension cords before each use. If damaged replace ]

immediately. Never use tool with a damaged cord since touching the damaged

J

area could cause electrical shock, resulting in serious injury.

6

Page 7

SAFETY SYMBOLS FOR YOUR TOOL

The label or= your tool may include the following symbols.

V....................................................................... Volta

A ...................................................................... Amps

Hz.................................................................... Hertz

W..................................................................... Watts

min .................................................................. Minutes

.................................................................... Alternating current

................................................................... Direct current

no .................................................................... No-load speed

[] .................................................................... Class II construction, Double Insulated

RPM .......................................................... Revolutions per minute

SPM ........................................................... Strokes per minute

OPM .......................................................... Orbits per minute

z_ .................................................................... Indicates danger, warning or caution

It means attention! Your safety is involved.

SERVICE SAFETY

1. If any part of this tool is missing or should break, bend, or fail in any way;

or should any electrical component fail to perform properly: SHUT OFF the

power switch and remove the tool's plug from the power source and have the

missing, damaged or failed parts replaced BEFORE resuming operation.

2. Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

3. If the replacement of the supply cord is necessary, this has to be done by the

manufacturer or his agent in order to avoid s safety hazard.

SAFETY RULES FOR POWER SANDERS

1. HOLD TOOL by insulated gripping surfaces when sanding where tool may contact

hidden wiring, such as walls, floors, or its own power cord. Contact with a "live" wire will

make exposed metals parts of the tool "live" and shock the operator.

2. INSPECT FOR AND REMOVE all nails, screws, staples or any embedded pieces

of metal from surface to be sanded. These protrusions could damage the sandpaper,

the cushion of the sander and cause loss of control. Following this rule will reduce the

risk of serious personal injury and damage to the sander.

3. NEVER use this or any power sander for wet sanding or liquid polishing.

Failure to follow this rule will increase the risk of electric shock.

4. ALWAYS clamp the workpiece securely so it will not move under the sander.

Unsecured work could be thrown towards the operator, causing injury.

5. DO NOT force the sander. The weight of the sander supplies adequate

pressure. Let the sander and the grit on the sandpaper do the work.

6. DO NOT sand in any one place for too long. The sander's rapid action may

remove too much material and make the surface uneven.

Page 8

Z_ WARNING: Some dust crested by using power tools contains chemicals

known to the State of California to cause cancer and birth defects or other

reproductive harm. Some examples of these chemicals are:

° Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry products.

, Arsenic and chromium, from chemically treated lumber.

Your risk from these exposures varies, depending upon how often you do

this type of work. To reduce your exposure to these chemicals:

• Work in a well-ventilated area.

, Work with approved safety equipment, such as those dust masks that

are specially designed to filter out microscopic particles.

Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth,

eyes, or lay on the skin may promote absorption of harmful chemicals.

Z_ WARNING: Use of this tool can generate and/or disburse dust, which may

cause serious and permanent respiratory or other injury. Always use

NIOSH/OSHA approved respiratory protection appropriate for the dust exposure.

Direct particles away from face and body.

z_ WARNING: Collected sanding dust from sanding surface coatings

(polyurethane, linseed oil, etc.) can self-ignite in sander dust bag or elsewhere

and cause fire. To reduce risk, empty dust bag frequently and strictly follow

sander manual and coating manufacturer's instructions.

z_ CAUTION: When working on metal surfaces, DO NOT use the dust bag or

a vacuum cleaner because sparks are generated. Wear safety glasses and s dust

mask. Due to the danger of fire, do not use your sander to sand magnesium

surfaces. Do not use for wet sanding.

SANDING PAINTS

SANDING LEAD BASED PAINT is NOT RECOMMENDED due to the difficulty of

controlling the contaminated dust. The greatest danger of lead poisoning isto children

and pregnant women.

Since it is difficult to identify whether or not a paint contains lead without a chemical

analysis we recommend the following precautions when sanding any paint:

• NO children or pregnant women should enter the work area where the

paint sanding is being done until all clean up is completed.

A dust mask or respirator should beworn by all persons entering the work

area. The filter should be replaced daily, or whenever (if) the wearer has

difficulty breathing.

Page 9

NOTE:Onlythosedustmaskssuitableforworkingwithleadpaintdustandfumesshould

beused.Ordinarypaintingmasksdonotofferthisprotection.Seeyourlocalhardware

dealerfortheproper(NIOSHapproved)mask.

•NOEATING,DRINKINGORSMOKINGshouldbedoneintheworkareato

preventingestingcontaminatedpaintparticles.Workersshouldwashand

cleanupBEFOREeatingdrinkingorsmoking.Articlesoffood,drink,or

smokingshouldNOTbeleftintheworkareawherecontaminateddustwould

settleonthem.

•Paintshouldberemovedinsuchamannerastominimizetheamountofdust

generated.

•Areaswherepaintremovalisoccurringshouldbesealedwithplasticsheeting

of4milsthickness.

•Sandingshouldbedoneinamannertoreducetrackingofpaintdustoutside

theworkarea.

•Allsurfacesintheworkareashouldbevacuumedandthoroughlycleaneddaily

forthedurationofthesandingproject.Vacuumfilterbagsshouldbechanged

frequently.

•Plasticdropclothsshouldbegatheredupanddisposedofalongwithanydust

chipsorotherremovaldebris.Theyshouldbeplacedinsealedrefusereceptacles

anddisposedofthroughregulartrashpick-upprocedures.Duringcleanup,children

andpregnantwomenshouldbeKEPTAWAYfromtheimmediateworkarea.

•Alltoys,washablefurnitureandutensilsusedbychildrenshouldbewashed

thoroughlybeforebeingusedagain.

ADDITIONALRULESFORSAFE OPERATION

I _ WARNING: BE SURE to read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire and/or

serious personal injury.

1. Harmful/toxic dusts will arise from sanding e.g. lead painted surfaces, woods and

metals. Contact with or inhalation of these dusts can endanger the health of operator

and bystanders. Always use eye glasses and dust mask.

2. Hearing protection should be worn when using the sander.

3. Always wear safety glasses or eye shields when using the sander. Everyday

eyeglasses have only impact-resistant lenses; they are not safety glasses.

Following this rule will reduce the risk of serious personal injury.

4. Remove the plug from the socket before carrying out any adjustment, servicing or

maintenance.

5. Fully unwind cable drum extensions to avoid potential overheating.

6. When an extension cable is required you must ensure it has the correct ampere rating

for your power tool and is in a safe electrical condition.

7. Ensure your mains supply voltage is same as indicated on the rating plate.

8. Your tool is double insulated for additional protection against a possible electrical

insulation failure within the tool.

9. Always check walls, floors and ceilings to avoid hidden power cables and pipes.

10. After long working periods external metal parts and accessories could be hot

11. If possible, ensure the work-piece is firmly clamped to prevent movement

12, Your sander is a hand held tool. do not clamp your sander.

13. Before sanding check the area is free of nails screws etc.

14 Never stop the sander by applying a force to the base plate.

9

Page 10

ADDITIONALRULESFORSAFEOPERATIONcont.

15.Onlyusepaperingoodcondition.Donotusetornorwornpaper.

16.Donotsandmaterialcontainingasbestosduetoahealthrisk.

17.Donotsandleadbasedpaintduetotheriskofleadpoisoning.

18.Donoteatordrinkintheworkingareaofthesander.

19.Donotallowpeopletoentertheworkingareawithoutwearingadustmask.

20.Wherepossible,sealofftheworkingareatocontainthedustforlaterremoval.

21.Yourtoolisdesignedfordrysandingonly,notwetsanding.

22.Yourtoolisdesignedforgeneralpurposelightpolishingofwoodandmetals.

23.Donotsandmagnesiummaterialduetotheriskoffire.

24.SAVETHESEINSTRUCTIONS.Refertothemfrequentlyandusethemtoinstruct

otherswhomayusethistool.Ifsomeoneborrowsthistool,makesuretheyhave

theseinstructionsalso.

Z_WARNING:ThispowertoolshouldNEVERbeconnectedtothepower

sourcewhenyouareassemblingparts,makingadjustments,installingor

removingsandpaper,cleaningorwhenitisnotinuse.Disconnectingthesander

willpreventaccidentalstarting,whichcouldcauseseriouspersonalinjury.

1.Removethesanderfromthestorage/ carry case and inspect itcarefully to make sure

that no breakage or damage has occurred during shipping.

2. Do not discard any of the packing materials until all parts are accounted for.

3. Included with your sander is a dust bag assembly, with vac adapter.

4. Also included is a paper punch template.

5. If any of the parts are damaged or missing (refer to PARTS LIST below), return the

sander to your nearest Sears store or Craftsman outlet to have the sander replaced.

I Z_ WARNING: ff any parts are missing, DO NOT operate this power tool until

the missing parts are replaced. Failure to do so could result in possible serious

personal injury.

PARTS LIST (Fig. 1)

1. Sander

t Bag Assembly

___i Adapter 4. Paper Punch Template

5. Storage / Carry Case

__ dust ports 6. Operator's Manual

10

Page 11

KNOWYOURFINmSHINGSANDER (Fig. 2)

NOTE: Before attempting to use your sander, familiarize yourself with all of the /

operating features and safety requirements.

J

Your Professional 1/4-sheet finishing sander has a precision-built electric motor and it

should be connected to a 120-volt, 00-Hz AC ONLY power supply (normal household

current). DO NOT operate on direct current (DC).The large voltage drop will cause a loss

of power and the motor will overheat. If the sander does not operate when plugged into

correct 120-volt, 60-Hz AC ONLY outlet, check the power supply. This sander has a 8-ft.,

2-wire power cord (no adapter needed).

This Finishing Sander has the following features:

1. Powerful 2.4 amp motor provides the torque, power and durability for a variety of

continuous sanding applications.

2. 14,000 Orbits per minute (no load speed). Match correct sandpaper grit for the

surface being sanded for either fast material removal or a fine, smooth finish.

3. Random orbital action with 1/16-in. orbit diameter helps to provide a swirl free finish

4. Ergonomically designed Palm Grip Handle with Molded-in Comfort Grip for

maximum balance, control, gripping comfort and reduced operator fatigue.

5. Precision-tuned counterbalanced system reduces vibration for smooth operation

and less operator fatigue.

6. On/Off rocker is conveniently located for easy control. Sealed to keep out

dust for long life.

7. Heavy Duty Wire Form Sandpaper Clamps provides secure paper retention and

quick paper changes.

8. The Cushion located on the bottom of the sander accepts standard non-adhesive

sandpaper.

9. Uses 1/4-sheet sandpaper to provide a 16-sq. in. sanding surface.

10. Paper Punch Template for accurately making holes in sandpaper for dust collection

system.

11. Built-in Dust Collection System. Dust bag assembly with dual dust ports collects

dust from work surface through holes in platen, cushion and sanding sheets. Use

either the dust bag, or attach a 1 /4 or 2/2- nch vac hose and wet / dry vac (so d

separately) for dust collection. Helps keep work surface and area clean and extends

life of sanding sheets.

12. High impact-resistant housing helps protect tool from damage and reduces weight.

13. Permanently lubricated 100% ball bearings for smooth operation and long life.

14. Storage / Carrying Case for easy carrying and storage of sander and accessories.

Page 12

Fig 2

On/Off

RockerSwitch

Comfort Grip Handle

Dust

Bag Assembly

Lpter

with dual dust ports

Sandpaper

Platen Cushion

No-load Speed

Rating

Input

Orbit Diameter

Paper Size

Paper Type

14000 OPM (Orbits per Minute)

120 Volts, 60 Hz AC

2.4 Amps

1/16-in.

1/4 sheet

Non-Adhesive Sandpaper

12

Page 13

[Z_ WARNING: Your sander should NEVER be connected to the power source

i

when you are assembling parts, making adjustments, installing or removing

J

sandpaper, cleaning or when it is not in use. Disconnecting the sander will prevent

accidental starting, that could cause serious personal injury.

INSTALLING THE SANDPAPER (See Figs. 3, 3a, 3b on page 14 and Fig. 4 on page 15)

This sander has a cushion that allows you to use non-adhesive sandpaper. The

non-adhesive sandpaper clamps to the front and back of the platen and cushion.

This sander has a dust collection system that collects dust from the work surface through

holes located in the platen and cushion on the bottom of the sander. A paper punch

template is included for accurately punching holes into the 1/4-sheet sandpaper.

NOTE: Holes must be punched into the paper for the dust collection system to

3

work properly. See instructions on page 15 to punch holes.

J

installing Non-Adhesive Sandpaper (See Figs. 3, 3a and 3b)

Fig 3

Paper

Clamp

Paper

Goes

Under

Clamp

Platen

Non-Adhesive

Sandpaper

Platen

Slot

Paper Clamp Lever

13

Page 14

ALWAYSinspectthesandpaperbeforeinstalling.DONOTuseifbrokenordefective.

1.Unplugthesander.

I _ WARNING: Failure to unplug the sander could result in accidental startingcausing possible serious personal injury.

Installing Non-Adhesive Sandpaper (See Figs. 3,3a and 3b)

NOTE: Remove dust bag assembly when installing non-adhesive. ALWAYS

remember to reattach the dust bag assembly before beginning sanding operation

(see page 16, Fig. 5).

Paper Goes

Raise lever up Under Clamp

Fig 3b to clamp paper

2. If replacing sandpaper, remove old sandpaper.

3. Two paper clamp levers are located on each side of the sander and are locked into

a slot on top of the platen (see Fig. 3).

4. Raise these two levers "UP" and disengage them from the slots in the platen.

This will release the tension on the paper clamps located at the front and back of the sander

that hold the paper in position on the cushion (see Fig. 3a).

5. Remove old paper.

6. Insert front end of a new sheet of paper approximately 1/2-inch under the front paper clamp

(see Fig. 3b).

7. Lift up on the lever that controls the front paper clamp and lock it back into the slot on the

platen. This will securely clamp the paper to the front of the sander's cushion.

8. Smooth out the sheet of paper by pressing it tightly against the bottom of the cushion

(front to back).

g. Insert back end of paper into back paper clamp, fit sandpaper as tightly as possible, and lift

up on paper clamp lever to lock into place. This will securely clamp the paper to the back of

the sander's cushion. The sandpaper should now be positioned tightly against the cushion

from front to back, securely clamped in place.

NOTE: ALWAYS be sure that both paper clamp levers are in the locked position on ]

the platen and both paper clamps have the sandpaper securely clamped to the bottom

1

of the cushion before starting sanding operation.

14

Page 15

PAPER PUNCH (See Fig. 4)

A paper punch template is included with sander so you can punch properly aligned holes

into the sandpaper. This is done after the paper is installed onto the sander.

To punch holes, line up the front and side of the sander over the paper punch template as

shown in Fig. 4, then lower the sander onto the template while applying pressure. Make

sure the holes are punched all the way through the paper and clear the holes in the

sander's cushion and platen.

I NOTE: Punching holes properly is a necessary step for the dust collection |

]

system to operate properly.

J

Fig 4

f

DUST BAG / DUST COLLECTION

Z_ WARNING: Collected sanding dust from sanding surface coatings

(polyurethane, linseed oil, etc.) can self-ignite in sander dust bag or elsewhere

and cause fire. To reduce risk, empty dust bag frequently and strictly follow

sander manual and coating manufacturer's instructions.

z_ WARNING: When working on metal surfaces, DO NOT use the dust bag or

a vacuum cleaner because sparks are generated. Wear safety glasses and a dust

mask. Due to the danger of fire, do not use your sander to sand magnesium

surfaces. Do not use for wet sanding.

15

Page 16

TOREMOVEANDEMPTYDUSTBAG(Fig.5,5aand5b)

1.Unplugthesander.

Z_ WARNING: Failureto unplug the sander could result inaccidental starting 1

causing possible serious personal injury.

l

2. Locate (2) tab connectors on either side of vac adapter/dust bag assembly and

squeeze. Pull assembly straight back and off of dust exhaust hole (see Fig. 5).

3. Turn dust bag assembly counterclockwise (embossed arrows show unlock and lock

rotation) and remove bag from vac adapter (see Fig. 5a, 5b).

Exhaust Hole

Dual Dust Ports

/\_. I'_:( Fig. 5a Fig. 5b

_.\/ _"_-_>_X._. ,Countercbckwise

__for OFF DustBag

z (,/ _,> f _J \ Dust Bag

VacAdapter _ _ _',,"%/A h

for ON "_ _/ _ _ " VacAdapterwith Dual Dust

Ports

4. Empty bag by shaking aggressively until completely empty. Wipe dust and debris from

the vac adapter.

5. Reattach the bag assembly back onto the vac adapter, and reattach back onto the sander.

NOTE: Empty dust bag frequently so dust collection system works properly ]

Z_ WARNING: Empty dust bag before storage to help prevent possible fire 1

hazard, especially when resin coating or linseed oil finishes have been sanded.

J

16

Page 17

NOTE:Formoreefficientoperation,werecommendthatyouemptythedustbag

when it is no more than half full. This will allow the air to flow through the bag

better. ALWAYS empty and clean the dust bag thoroughly when you've finished

sanding and before you store the sander.

ATTACHING VAC HOSE TO THE DUST COLLECTION SYSTEM (See Fig. 6, 6a and 6b)

When sanding for extended periods of time, you can easily attach your sander to a vac

hose and wet/dry vac (sold separately).

• Unplug the sander•

Z_ WARNING: Failure to unplug }

the sander could result in accidental

starting causing possible serious

personal injury.

2. Remove dust bag assembly from the

vac adapter (see page 16, Fig. 5a and 5b).

3. Connect vac adapter with dual dust

ports to dust exhaust hole of sander

(see Fig. 6).

4• Attach either a 11/4 or 21/2-in vac hose

onto the vac adapter's dual dust ports

( see Fig. 6a and 6b).

Fig. 6

ig. 6a

(

5• Connect hose to wet / dry vac•Turn vac on while operating sander•

Z_ WARNING: When sander is not connected to vacuum, always install

dust bag back on sander. Failure to do so could cause sanding dust or foreign

objects to be thrown into the face or eyes which could result in possible

serious injury.

NOTE: A standard 11/4-in. vac hose connection fits inside the smaller diameter hole

inside the dust exhaust, while a standard 2r/2-in. vac hose connection fits inside the

larger hole of the dust exhaust.

17

Page 18

Beforeattempting to use any tool, be sure to familiarize yourself with all the

operating features and safety instructions.

Z_ WARNING: IF ANY PARTS ARE MISSING, DO NOT OPERATEYOUR

SANDER UNTIL THE MISSING PARTS ABE REPLACED. FAILURE TO FOLLOW

THIS RULE COULD RESULT IN SERIOUS PERSONAL INJURY.

z_ WARNING: DO NOT let familiarity with your sander make you careless.

Remember that a careless fraction of a second is sufficient to cause severe injury.

]

ON/OFF ROCKER SWITCH (see Fig. 7)

This switch is sealed to help keep out dust

for a longer life and is conveniently located

near the front of the palm grip handle.

Start the sander by pushing in the part of the

switch with their. Let the motor build to its

maximum speed before starting sanding

operation. To turn sander off, push side of

switch with the [].

APPLICATIONS

Only use your sander for the applications listed below.

* Sanding wood surfaces with various grits of sandpaper.

* Removing rust from steel surfaces with special sandpaper.

[z_ WARNING: Due to the danger of fire, DO NOT use your sander to sand

magnesium surfaces. DO NOT use for wet sanding.

[ _WARN[NG: ALWAYS clamp the workpiece. An unsecured workpiece could

be thrown towards the operator, causing serious injury.

USING YOUR SANDER (See Fig. 8, on page 19)

1. ALWAYS clamp and secure the workpiece to prevent it from moving under sander.

2. ALWAYS hold your sander in front and away from you, keeping it clear of the workpiece.

3. Start the sander and let the motor build to its maximum speed.

4. Gradually lower the sander onto the workpiece with a slight forward movement.

5. Move the sander slowly, guiding it in a forward and backward motion.

6. ALWAYS remove the sander from the workpiece before turning it off.

18

Page 19

[Z_ CAUTION: When gripping the sander during use, ALWAYS be careful not

"11

to cover the air vents with your hands (see Fig. 8).

]

Fig. 8

Air Vents

/

\

SANDING TIPS

1. DO NOT force the sander. The weight of the sander supplies adequate pressure on

the workpiece. Let the sander and the sandpaper's grit do the work.

• Applying additional pressure will only slow down the motor, wear the sandpaper

out faster and reduce the sander's orbital speed.

• Excessive pressure will overload the motor and cause possible damage to the

sander from the motor overheating.

. Excessive pressure will also result in a poor quality finish.

2. Any existing finish or resin on wood may soften from the heat of the friction and cause

the sandpaper to load-up faster.

3. Inspect sandpaper frequently and change paper when grit is worn and not able to

perform properly.

4. DO NOT sand in one spot for too long a time because the sander's rapid action may

remove too much material and make the surface uneven.

SELECTING THE RIGHT SANDPAPER

Selecting the correct grit and type of sandpaper is an extremely important decision that

will allow you to achieve the best quality sanding finish.

1. Aluminum oxide, silicon carbide and other synthetic abrasives are best for power

sanding.

2. Natural abrasives such as flint and garnet are too soft for economical use in power

sanding.

3. Coarse grit will remove the most material and finer grit will give you the best finish in all

sanding operations.

19

Page 20

SELECTINGTHE RIGHT SANDPAPER cont.

4. The condition of the surface to be sanded will determine which grit will do the job.

5. If the surface is rough:

• Start with a coarse grit and sand until the surface is uniform.

. Then use medium to remove any scratches left by the coarse grit.

o Then use a finer grit for finishing the surface.

NOTE: ALWAYS continue sanding with each grit until the surface is uniform.

NOTE: DO NOT use the sander without sandpaper. This will damage the cushion.

Z_ WARNING: DO NOT wear loose clothing or jewelry when operating sander.

They could get caught in moving parts, causing serious injury. Keep head away from

sander and sanding area. Hair could be drawn into sander, causing serious injury.

l z_ WARNING:Empty dust bag before storage to help prevent possible firehazard, especially when resin coating or linseed oil finishes have been sanded.

l OTE: Empty dust bag frequently when sanding so dust collection systemworks properly.

ORBITAL MOTION (Fig. 9)

As shown in Figure 9 the orbit of the sander is 1/16-in in diameter so the sandpaper

moves in tiny circles at very high speed, allowing the sander to move easily.

This orbital action duplicates a "hand sanding" motion for more aggressive sanding as

you push the sander forward. This powerful orbital action is ideal for heavy-duty sanding

applications, such as:

1. Removin_i old finishes 3. Sanding stock down to required dimensions

2. Smoothin_ rough wood 4. Finishing surfaces that are to be painted

Fig. 9

20

Page 21

FLUSHSANDING (See Fig. 10)

Your sander will allow you to flush sand corners.

You can use the front and sides of your sander for flush sanding, DO NOT use the rear

of the sander for flush sanding.

ALWAYS remove the sander from the workpiece before turning it off,

Fig. 10

Page 22

l _ WARNING:Toensure safety and reliability, repairs, maintenance and

adjustments MUST be performed by a qualified service technician at a

Sears Service Center.

Z_ WARNING: For your safety, ALWAYS turn off switch and unplug sanderfrom the power source before performing any maintenance or cleaning.

It has been found that electric tools are subject to accelerated wear and possible

premature failure when they are used to work on fiber glass boats and sports cars,

wallboard, spackling compounds or plaster. The chips and grindings from these materials

are highly abrasive to electrical tool parts, such as bearings, brushes, commutators, etc.

Consequently, it is not recommended that this tool be used for extended work on any

fiberglass material, wallboard, spackling compound or plaster. During any use on these

materials, it is extremely important that the tool is cleaned frequently by blowing with

an air jet.

[Z_ WARNING: Always wear safety goggles or safety glasses with side shields

1

during power tool operations, or when blowing dust. If operation is dusty, also

J

wear a dust mask.

ROUTINE MAINTENANCE

/_ WARNING: DO NOT at any time let brake fluids, gasoline, petroleum-

based products, penetrating oils, etc. come in contact with plastic parts.

Chemicals can damage, weaken or destroy plastic, which may result in serious

personal injury.

Periodic maintenance allows for long life and trouble-free operation. A cleaning and

maintenance schedule should be maintained. As a common preventive maintenance

practice, follow these recommended steps:

/_, WARNING: For your safety, ALWAYS turn off switch and unplug sander

from the power source before performing any maintenance or cleaning.

1. When work has been completed, clean the tool to allow smooth functioning of the tool

over time. Clean the tool with compressed air.

2. Use clean damp cloths to wipe the tool.

3. Keep the motor air openings free from oil, grease and sawdust or woodchips, and store

tool in a dry place.

LUBRICATION

Your Craftsman _ Professional Pad Sander has been properly lubricated and is ready to use.

No further lubrication is needed under normal operating conditions. All bearings in the

sander are lubricated for the life of the tool.

22

Page 23

BRUSH(soldseparately)REPLACEMENT(seeFig.11,11a,11band1lc)

1.Unplugthesander.

z_ WAIRNJNG: Failure to unplug the sander could result in accidental

starting causing possible serious personal injury.

2. Remove (3) screws from top cover

of sander and remove top cover (see Fig. 11).

3. Locate the (2) Carbon Brush / Brush Holder

Assemblies (see Fig. 11 a). They are connected

to red wire lead terminals and are in position

on each side of the armature.

4. Carefully lift these (2) assemblies (see Fig. 1la and 11 b)

out of their positions (NOTE: Remember how

they are positioned so that you can put them

back in position correctly.)

5. Check the ends of the carbon brushes (see Fig. 1 lb)

for wear. If either brush has less than 1/4-in. length

of carbon remaining, replace both. DO NOT

REPLACE ONE SIDE WITHOUT REPLACING

THE OTHER.

6. To replace assemblies, disconnect

the red wire lead terminals from the

assemblies (see Fig. 11 c), attach

new assemblies to the lead terminals

and place the assemblies back into

their original positions next to the

armature. Make sure the curvature

of the end of the brushes matches

the curvature of the armature and

that the brushes move freely in

brush holder assemblies.

7. Reassemble the top cap with the

(3) screws and do not overtighten.

Fig. 11a

Fig. 11

Fig. 11c

Carbon Brush/

Brush Holder

Assemblies

23

Page 24

z_ WARNING: The use of attachments or accessories that are notrecommended for this tool might be dangerous and could result in serious injury.

Sears and other Craftsman ®outlets offer a selection of Craftsman Professional Random

Orbit Sander accessories designed for all your sanding applications.

1/4 Sheet Sandpaper in Very Fine, Fine, Medium and Coarse Grit available in

non-adhesive.

Visit your local Sears store or other Craftsman outlets or shop sears.com/craftsman for

all of the accessories for your random orbital sander.

]

24

Page 25

1/4 Sheet Pad Sander

_ MODEL NUMBER 172.276700

The modelnumberwill be found onthe nameplateofthe Sheet PadSander.

Alwaysmentionthe modelnumberwhenorderingpartsforyour tool,

Toorderparts call, 1-800-469-4663

.-.... @ "® i

Page 26

i_,l=_.tlL-_'a_rUl 1/4 Sheet Pad Sander

MODEL NUMBER 172.276700

Themodel numberwill be foundonthenameplateof the SheetPad Sander,

Alwaysmentionthe model numberwhen ordering partsfo ryour tool,

Toorder parts call,1-800-469-4663

Item No.

1

2

101

3

4

5

6

7

8

9

10

11

12

102

13

14

15

103

16

17

18

19

20

21

22

Parts No.

200T00401 59000A-00

200T0030119000A-00

2 PPS07Q3000000A-00

200WS000037000A-00

2 PPS02A0301000A-00

200W4000004000A-00

2 PPS02A0304000A-00

2 PPS02A0311000A-00

2 PPS02A0312000A-00

200T0090003000A-00

2 PPS02A0302000A-00

2 PPS04A0009000A-00

200W3000059000A-00

2 PPS02A7000000A-00

2 P PS02 B0305000A -00

2 PPS02A0303000A-00

200W4000034000A-00

2 PPS07Q2000000A-00

200T0070003000A-00

200WS000006000A-00

200T0020005000A-00

20TAg 520072000A-00

2 PPS07Q0007000A-00

2 PPS04A0005000A-00

2 PPS07Q0005000A-00

Part Description Qty. Item No. Parts No. Part Description Qty.

i

Brush holder ssemblv 2 23 200W4000032000A-00 Screw M4.2x1 3 8

Carbon br ush 2 24 2PPS02A0221 000A-00 Dust proof ring 1

Soleplate 1 25 2PPS07Q0003000A-00 Left housing 1

Ball bearinq 6001 1 26 2PPS07Q0001000A-00 Brand label 1

Airproof ring 1 27 2PPS07Q0006000A-00 Top cover 1

Screw M3.Sx6 2 104 2PPS07Q1000000A-00 Stator asm 1

Compression bloc 2 28 2PES04Q3001000A-00 Bracket 1

Clamp 2 29 20TA9500081000A-00 Stator 1

Wire cap 2 30 200W4000052000A-00 Screw M4.2x55 2

Rubber pin 1 31 2PES02A0002000A-00 Switch cover 1

Base plate 1 32 200W0020265000A-00 Switch 1

Washer 1 33 200W4000005000A-00 Screw M3.5 x8 2

Screw M4x16 1 34 2PES04Q6001000A-00 Press plate 1

Foamy Board Assembly 1 35 200W8500003000A-00 Ball bearing 6000 1

aluminium plate 1 36 2PES04Q0003000A-00 Housing 1

Foamy plate 1 37 200T0200005000A-00 Cord clamp 1

Screw M4.2x16 11 38 2PES04Q7000000A-00 Power cord 1

Rotor 1 39 200 T0280179000A-00 Inner wire 3

Bearing sleeve 1 ......... 105 ................2PES04Q5000000A-00 Dust collecto r ba_ .....................

Ball bearing 607-2z 1 40 2PES04Q5001000A-00 Dust port 1

Dust proof ring 1 41 2PES04Q5102000A-00 Dust bag body 1

Armature 1 ...............42 ...........................2PES04Q510_3000A-O0 _Dust bag ............................................................! ......................

Fan 1 43 2PPS07Q0002000A-00 Rated label 1

Oscillaiing column 2 44 2PPS07Q0004000A-00 Right housing t

Wind baffle 1 45 200T0080024000AA-00 O ring 3x34 1

Page 27

27

Page 28

28

Loading...

Loading...