Craftsman 17224360 Owner’s Manual

Owner's Manual

10-in. Compound

Miter Saw

Double Insulated

Model No,

172.24360

Save this manual for future reference.

CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions

in this manual before using this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit the Craftsman web page: www.sears.com/craftsman

g

• SAFETY

• FEATURES

• ADJUSTMENT

• OPERATION

• MAINTENANCE

° PARTS LIST

• ESPANOL

Warranty. ........................................................... Page 2

Safety Instructions .......................................... Pages 3 - 11

Safety Symbols ........................................... Page 10

Glossary of Terms ....................................... Pages 10-11

Product Specifications and Unpacking ............. Pages 11-12

Labels ............................................................... Pages 12-13

Loose Parts and Tools Needed ......................... Page 14

Description ........................................................ Pages 15-19

Adjustments ...................................................... Pages 19-27

Operation ...................................................... Pages 28-38

Maintenance ..................................................... Pages 38-39

Accessories ....................................................... Page 39

Repair Parts ...................................................... Pages 40-44

FULLONE-YEARWARRANTY

If this product fails due to a defect in materials or workmanship within

one year from the date of purchase, Sears will repair it free of charge.

Warranty service is available by returning this product

to the nearest Sears Service Center in the United States.

If this product is used for commercial or rental purposes,

this warranty applies only for 90 days from the date of purchase.

This warranty gives you specific legal rights,

and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

SAVE THESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

.............................................................................................................................................................................................................. i

Z_WARNING: BE SURE to read and understand all safety instructions

in this manual, including all safety alert symbols such as DANGER,

WARNING and CAUTION, BEFORE using this saw.

Failure to follow all instructions listed below may result inelectric shock,

fire and/or serious personal injury.

SAFETY SYMBOLS

The purpose of safety symbols is to attract your attention to possible dangers.

The safety symbols, and the explanations with them, deserve your careful

attention and understanding. The safety warnings DO NOT by themselves

eliminate any danger. The instructions and warnings they give are no

substitutes for proper accident prevention measures.

SYMBOL

Ak

/k

/k

MEANING

SAFETY ALERT SYMBOL: Indicates danger, warning or caution.

May be used in conjunction with other symbols or pictographs.

DANGER: Failure to obey a safety warning will result in

serious injury to yourself or to others. Always follow the safety

precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in

serious injury to yourself or to others. Always follow the safety

precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result

in property damage or personal injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire,

electric shock and persona_ injury.

NOTE: Advises you of information or instructions

vital to the operation or maintenance of the equipment.

/'rk WARNING: The operation of any saw can result in

foreign objects being thrown into your eyes, which can

result in severe eye damage. Before beginning power tool

operation, ALWAYS wear safety goggles or safety glasses

with side shield and a full face shield when needed. We

recommend A Wide Vision Safety Mask for use over

eyeglasses or standard safety glasses with side shield,

both available at Sears Retail Stores. ALWAYS wear eye

protection which is marked to comply with ANSI Z87.1.

3

ELECTRICAL SAFETY

1. Double Insulated tools are equipped with a polarized plug (one blade

is wider than the other).Thls plug will fit in a polarized outlet only one

way. If the plug does not fit fully into the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to install a polarized

outlet. DO NOT change or alter the plug in any way.

2. Double insulationu eliminates the need for the three wire grounded power

cord and grounded power supply system. Applicable only to Class II

(double insulated) tools.

3. Before plugging in the tool, BE SURE that the outlet voltage supplied is

within the voltage marked on the tool's data plate. DO NOT use "AC only"

rated tools with a DC power supply.

4. ALWAYS avoid body contact with grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is grounded.

5. If operating the power tool in damp locations is unavoidable,

ALWAYS use a Ground Fault Circuit Interrupter to supply power

to your tool. ALWAYS wear electrician's rubber gloves and footwear

in damp conditions.

6. DO NOT expose power tools to rain or wet conditions. Water entering

a power tool will increase the risk of electric shock.

7. ALWAYS periodically inspect tool cords and extension cords for

damage. Have damaged cords repaired at a Sears Service Center.

BE SURE to stay constantly aware of the cord location and keep it

well away from the moving blade.

8. ALWAYS use the proper extension cord. and MAKE SURE the cord is

in good condition. ONLY USE a cord that is heavy enough to carry the

current your tool will draw. An undersized cord will cause a current drop

in line voltage resulting in a loss of power and overheating. A wire gauge size

AWG (American Wire Gauge) of at least 14 is recommended for an extension

cord 25 feet or less in length. If in doubt, use the next heavier size. Smaller

gauge wires, have greater capacity (14 gauge wire has more capacity than

16 gauge wire).

9. DO NOT abuse the cord. NEVER use the cord to pull the plug from the

outlet. Keep cord away from heat, o11,sharp edges or moving parts.

Replace damaged cords Immediately. Damaged cords increase the

risk of electric shock.

10. When operating a power tool outside, ALWAYS use an outdoor extension

cord marked "W-A" or "W". These cords are rated for outdoor use and

reduce the risk of electric shock.

4

............................................................................................................................................................................................................. i..

WORK AREA SAFETY

1. ALWAYS keep your work area clean and well lit. DO NOT leave tools or

pieces of wood on the saw while it is in operation. Cluttered benches and

dark areas invite accidents.

2. DO NOT operate power tools In explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. ALWAYS keep bystanders, children and visitors away while operating a

power tool. Distractions can cause you to lose control.

4. ALWAYS make your workshop childproof with padlocks and master

switches or by removing starter keys.

5. ALWAYS make sure the work area has ample lighting so you can see the

work and that there are no obstructions that will interfere with safe operation

BEFORE using your saw.

PERSONAL SAFETY

1. ALWAYS know your power tool. Read the operator's manual carefully,

learn the saw's applications and limitations, as well as, the specific potential

hazards related to this tool.

2. ALWAYS stay alert, watch what you are doing and use common sense

when operating a power tool. DO NOT use tool while tired or under the

influence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

3. ALWAYS dress properly. DO NOT wear loose clothing, gloves, neckties,

rings, bracelets or other jewelry that can get caught and draw you into

moving parts. Non-slip footwear is also recommended. Pull back long

hair. Keep your hair, clothing and gloves away from moving parts.

Loose clothing, jewelry or long hair can be caught in moving parts.

4. ALWAYS remove adjusting keys or wrenches before turning the tool on.

A wrench or a key that is left attached to a rotating part of the tool may result

in personal injury.

5. ALWAYS wear safety glasses with side shields. Everyday eyeglasses

have only impact resistant lenses, they are NOT safety glasses.

6. ALWAYS wear a dust mask to keep you from inhaling fine particles.

7. ALWAYS protect your hearing. Wear hearing protection during extended

periods of operation.

8. ALWAYS secure your work. Use clamps or a vise to hold work when

practical. It is safer than using your hand and frees both hands to operate tool.

9. DO NOT overreach. ALWAYS keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool in

unexpected situations

5

PERSONAL SAFETY cont.

10. ALWAYS avoid accidental starting.

BE SURE switch Is in the "Off" posVaonbefore plugging In.

11. NEVER stand on tool. Serious injury could occur if the tool is tipped or

if the blade is accidentally contacted.

TOOL USE AND CARE SAFETY

1. NEVER leave the tool running unattended. ALWAYS turn it off.

DO NOT leave the tool until it comes to a complete stop.

2. DO NOT use the tool if the switch does not turn tt "On" or "Off". Any

tool that cannot be controlled with the switch is dangerous. ALWAYS have

defective switches replaced at a Sears Service Center.

3. ALWAYS disconnect the plug from the power source before making any

adjustments, changing accessories or storing the tool. Such preventive

safety measures reduce the risk of starting the tool accidentally.

4. ALWAYS store idle tools out of the reach of children and other

untrained persons. Tools are dangerous in the hands of untrained users.

5. ALWAYS maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edges are less likely to

bind and are easier to control. Follow instructions for lubricating and

changing accessories.

6. DO NOT force the tool, it will do the job better and more safely at the

rate for which it was designed.

7. ALWAYS use the right tool for the job. DO NOT force the tool or attachment

to do a job itwas not designed for. Use it only the way it was intended.

8. Before using this saw, ALWAYS check for damaged parts, including

guards for proper operation and performance. Also ALWAYS check the

alignment of moving parts, binding of moving parts, breakage of parts,

saw stability, mounting and any other condition that may affect the

tool's operation. If damaged, have the tool serviced at a Sears Service

Center before using. Many accidents are caused by poorly maintained tools.

I

RECOMMENDED FOR USE WITH THIS TOOL MAY CREATE

J/_WARNING: USE OF ACCESSORIES THAT ARE NOT I

A HAZARDOUS CONDITION.

9. ALWAYS use only accessories that are recommended for this tool.

Using improper accessories may cause the risk of serious injury.

See accessories section of this manual for proper accessories.

.................................................................................................................................................................................................................. i

I

ADDITIONAL SPECIFIC SAFETY RULES FOR MITER SAWS

1. Know your power tool. Read operator's manual carefully. Learn the

applications and limitations, as well as the specific potential hazards

related to this tool. Following this rule will reduce the risk of electric

shock, fire or serious injury.

2. ALWAYS firmly clamp or bolt your miter saw to a workbench or table

at approximately hip height.

3. ALWAYS be sure that all adjustments are secure BEFORE making a cut.

4. ALWAYS make sure that the miter table and saw (bevel function) are

locked in position BEFORE operating your saw. Lock the motor table by

securely tightening the miter lock handle. Lock the saw arm (bevel function)

by securely tightening the bevel lock knob.

5. ALWAYS use a clamp to secure the workpiece, when possible.

6. ALWAYS be sure the blade path is free of nails. ALWAYS carefully inspect

lumber and remove all nails BEFORE cutting.

7. ALWAYS be sure that the blade clears the workpiece. NEVER start the

saw with the blade touching the workpiece. ALWAYS allow the motor to come

up to full speed BEFORE starting a cut.

8. ALWAYS support long workpieces when cutting to minimize the risk of

the blade pinching or kickback. The saw may slip, walk or slide while

cutting long or heavy boards.

9. NEVER use a length stop on the free (scrap end) of a clamped workpiece.

NEVER hold onto or bind the free scrap end of the workpiece in any operation.

If a work clamp and length stop are used together, THEY MUST BOTH BE

INSTALLED on the same side of the saw table to prevent the saw from

catching the loose end and kicking up.

10. NEVER cut more than one piece at a time. DO NOT STACK more than

one workpiece on the saw table at a time.

11. ALWAYS avoid awkward operations and hand positions where a sudden

slip could cause your hand to move into the blade. ALWAYS make

sure that you have good balance. NEVER operate your saw on the floor

or in a crouched position.

12. NEVER stand or have any part of your body in line with the path of the blade.

13. ALWAYS only use the correct blades. Use the right blade size, style and

cutting speed for the material and the type of cut. DO NOT use blades with

incorrect size holes. NEVER use blade washers or blade bolts that are

defective or incorrect. The maximum blade capacity for this saw is 10 inches.

7

ADDITIONAL SPECIFIC SAFETY RULES FOR MITER SAWS cont.

14. ALWAYS keep blades clean, sharp and with the sufficient set.

Sharp blades minimize stalling and kickback.

15. DO NOT use dull or damaged blades. Bent blades can break easily,

or cause kickback.

16. DO NOT remove the saw's blade guards. NEVER operate the saw with

any guard or cover removed. MAKE SURE that all guards are operating

properly BEFORE each use.

17. NEVER hand hold a workplece that is too small to be clamped.

ALWAYS keep your hands clear of the '_o hands' zone.

18. NEVER perform any operaUon freehand. ALWAYS place the workpiece

to be cut on the miter table and position it firmly against the fence as a

backstop. ALWAYS use the fence.

19. ALWAYS keep your hands away from cutting area. DO NOT reach under

the material being cut or in the blade's cutting path with your fingers or hand

for any reason. ALWAYS turn the power off.

Z_WARNING: Blade continues to turn after power to saw cuts off.To avoid

possible serious injury, after releasing trigger switch to cut power, allow the saw

blade to stop rotating BEFORE raising the blade out of the workpiece.

20. NEVER reach behind, under or within three inches of the blade and its

cutting path with your hands or fingers for any reason.

21. NEVER reach to pick up a workpiece, a piece of scrap, or anything else

that is in or near the cutting path of the blade.

22. NEVER, for any reason, touch the blade or other moving parts during use.

23. ALWAYS release the power switch and allow the saw blade to stop

rotating BEFORE raising it out of the workpiece.

24. DO NOT turn the motor switch on and off rapidly. This could cause the

blade to loosen which could create a hazard. Should this ever occur, stand

clear and allow the saw blade to come to a complete stop. Disconnect the

saw from the power source and securely tighten the blade bolt.

25. ALWAYS turn off the saw before disconnecting it to avoid accidental

starting when reconnecting the saw to a power supply. NEVER leave

the saw unattended while connected to a power supply.

26. NEVER lift this tool by gripping the sliding miter fence.

27. SAVE THESE INSTRUCTIONS. Refer to them frequently and use them

to instruct others who may use this tool. If someone borrows this tool,

make sure they have these instructions also.

............................................................................................................................................................................................................................ i

ADDITIONAL SPECIFIC SAFETY RULES FOR MITER SAWS cont.

Z_ WARNING: Some dust partlcles created by power sanding,

sawing, grlndlng, drilllng and other construction jobs contain

chemlcals known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending upon how often you do this

type of work. To reduce your exposure to these chemicals:

•Work in a well-ventilated area.

• Work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic

particles.

Z_ WARNING: The operation of any saw can

result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before

beginning power tool operation, ALWAYS wear

safety goggles or safety glasses with side shield

and a full face shield when needed. We recommend

a Wide Vision Safety Mask for use over eyeglasses

or standard safety glasses with side shield, both available

at Sears Retail Stores.

SERVICE SAFETY

1. If any part of this miter saw is missing or should break, bend, or fail in

any way; or should any electrical component fail to perform properly:

ALWAYS shut off the power switch and remove the miter saw plug from

the power source and have the missing, damaged or failed parts

replaced BEFORE resuming operation.

2.Tool service must be performed only at a Sears Service Center. Service

or maintenance performed by unqualified personnel could result in a risk of injury.

3.When servicing a tool, ALWAYS use only identical replacement parts.

Follow instructions in the Maintenance Section of this manual. Use of

unauthorized parts or failure to follow Maintenance Instructions may create

a risk of electric shock or injury.

9

SERVICESAFETYcont.

Thelabelon yourtool may Include the following symbols.

V ........................................................................... Volts

A........................................................................... Amperes

Hz......................................................................... Hertz

W .......................................................................... Watts

mln ....................................................................... Minutes

"_" ........................................................................ Alternating current

----===--................................................................... Direct current

no ........................................................................ No-load speed

[] ........................................................................ Class II construction

.../rain ................................................................... Revolutions or

reciprocation per minute

./_ ...................................................................... Indicates danger, warning

caution. It means attention!!f

Your safety is involved.

IMPORTANT! READ ALL INSTRUCTIONS

GLOSSARY OF TERMS FOR WOODWORKING

Arbor

The shaft on which a blade or cutting tool is mounted.

Bevel Cut

A cutting operation made with the blade at any angle other than

90 ° to the miter table.

Cross Cut

A cutting or shaping operation made against the grain of the workpiece.

Compound Miter Cut

A compound miter cut is a cut made using a miter angle and bevel

angle at the same time.

Freehand

Performing a cut without using a fence, miter gauge, fixture, work clamp, or

other proper device to keep the workpiece from twisting or moving during the cut.

Gum

A sticky, sap-based residue from wood products.

Miter Cut

A cutting operation made with the blade at any angle other than 90° to the fence.

Resin

A sticky, sap-based substance that has hardened.

Revolutions per Minute (RPM)

The number of turns completed by a spinning object in one minute.

Saw Blade Path

The area over, under, behind, or in front of the blade, as itapplies

to the workpiece°That area which will be or has been cut by the blade.

10

GLOSSARY OF TERMS FOR WOODWORKING cont.

Set

The distance that the saw blade tooth is bent

(or set) outward from the face of the blade.

Throw-Back

Throwing of a workpiece in a manner similar to a kickback. Usually associated

with a cause other than the kerr closing, such as a workpiece not being against

the fence, being dropped into the blade, or being placed inadvertently in contact

with the blade.

Through Sawing

Any cutting operation where the blade extends

completely through the thickness of the workpiece.

Workpiece

The item on which the cutting operation is being done. The surfaces of a

workpiece are commonly referred to as faces, ends and edges.

Throat Plate

A plastic throat plate inserted in the miter table that allows for blade clearance.

No Hands Zone

The area between the marked lines on the left and right side of the miter table

base. This zone is identified by no hands zone labels placed inside the marked

lines on the miter table base.

11

Your Compound Miter Saw has been shipped fully assembled,

except for the blade, miter lock handle, dust guide and dust bag.

1. Remove all packing materials from around your saw.

2. Carefully lift the saw from carton and place it on a level work surface.

The saw is heavy, so get help, if you need it, to help avoid injuring your back.

3. Do not discard the packing materials until you have carefully inspected

the saw for loose or damaged parts and successfully operated the saw.

4. This saw has been shipped with the saw arm secured in the down position.

To release the saw arm, push down on the top of the saw arm and cut the

tie wrap. Lift the saw arm by the handle.

IMPORTANT: Keep hand pressure on the saw arm while cutting

the tie wrap to prevent it from suddenly raising the wrapping iffully cut.

5. Carefully inspect all parts of the saw to make sure that no breakage

or damage has occurred during shipping.

/_WARNING: If any parts are missing, DO NOT operate this toot until

the missing parts are replaced. Failure to do so could result in possible

serious injury.

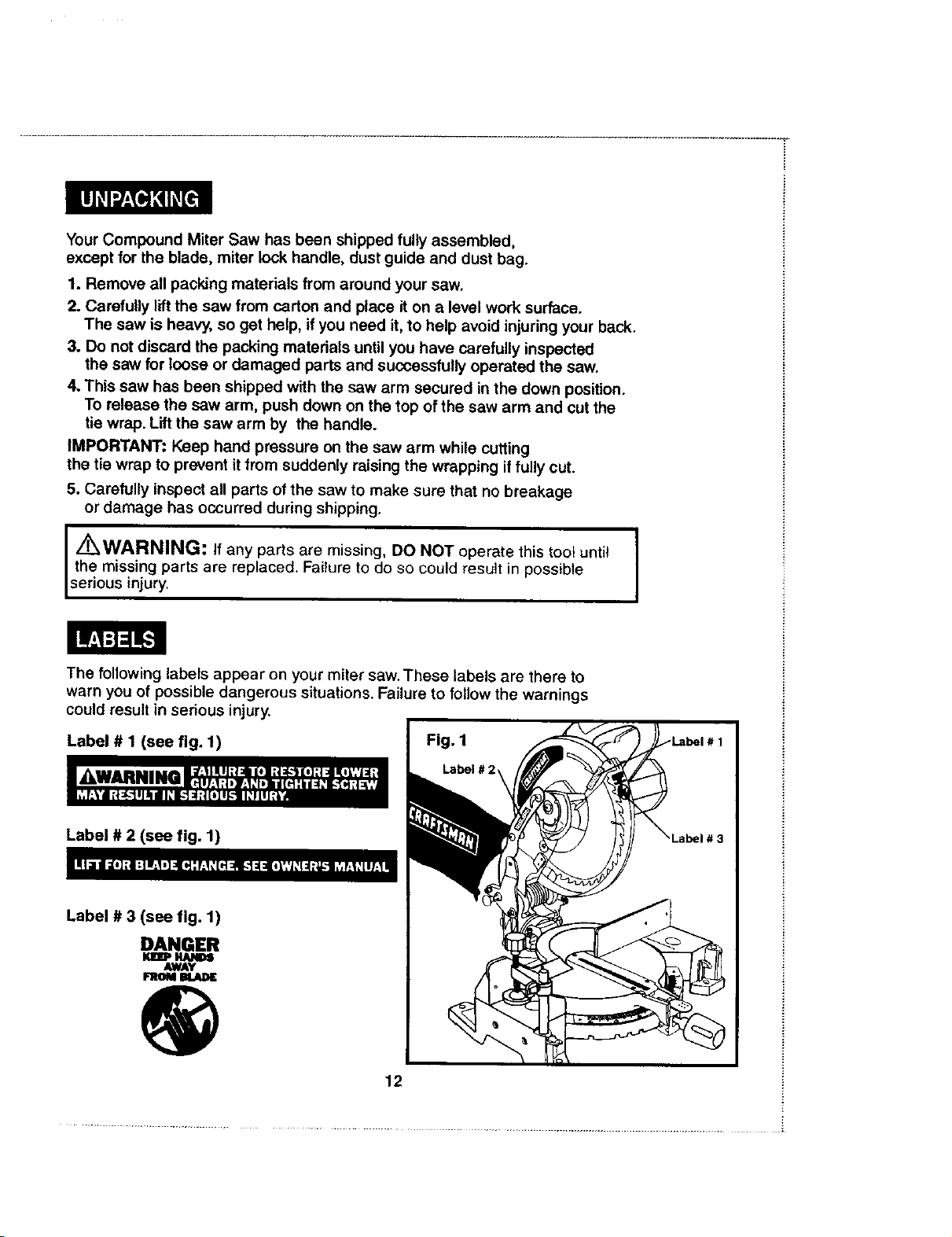

The following labels appear on your miter saw. These labels are there to

warn you of possible dangerous situations. Failure to follow the warnings

could result in serious injury.

Label # 1 (see fig. 1)

Label # 2 (see fig. 1)

Label # 3 (see fig. 1)

DANGER

KUP HANDS

AWAY

FROM

12

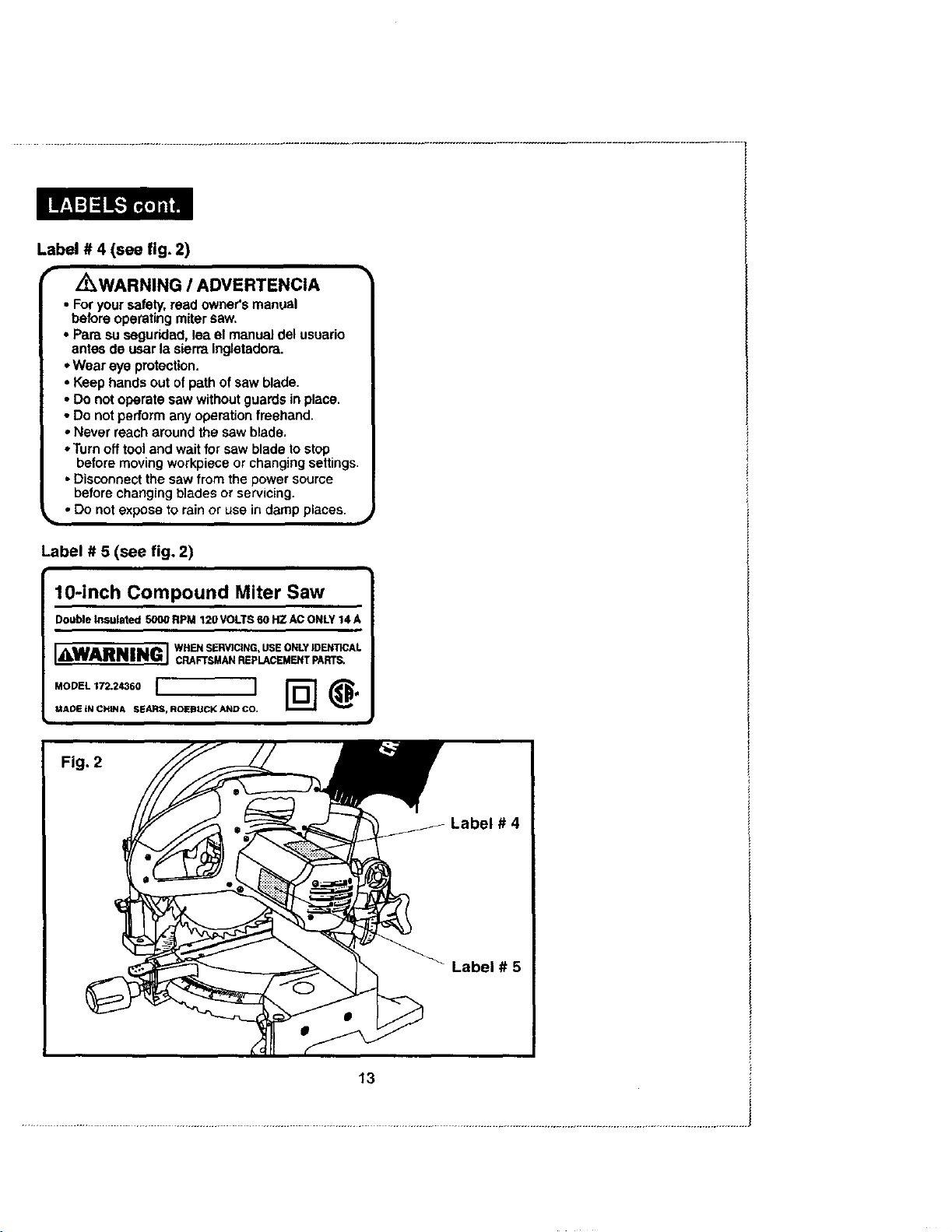

Label# 4 (see fig. 2)

r Z_WARNING / ADVERTENCIA •

• For your safety, read owner's manual

before operating metersaw,

• Para su seguridad, lea el manual del usuario

antes de usar la sierra ingletadora,

,,Wear eye protection.

• Keep hands out of path of saw blade.

• Do not operate saw withoutguards in place.

• Do not perform any operation freehand.

• Never reach around the saw blade,

• Turn off tool and wait for saw blade to stop

before moving workpiece or changing settings.

• Disconnect the saw from the power source

before changing blades or servicing.

• • Do not expose to rainor use in damp places. ,_

Label # 5 (see fig. 2)

10-inch Compound Miter Saw

DoubleInsulated5000RPM120VOLTS60HZACONLY14A

[_,WARNING WHEN SERVICING, USE ONLYIDENTICAL

!. CRAFTSMAN REPLACEMENT PARTS.

.OO,L,O.2-°oI '

MADE tN CHtNA S_ARSf ROEBUCK AND CO.

13

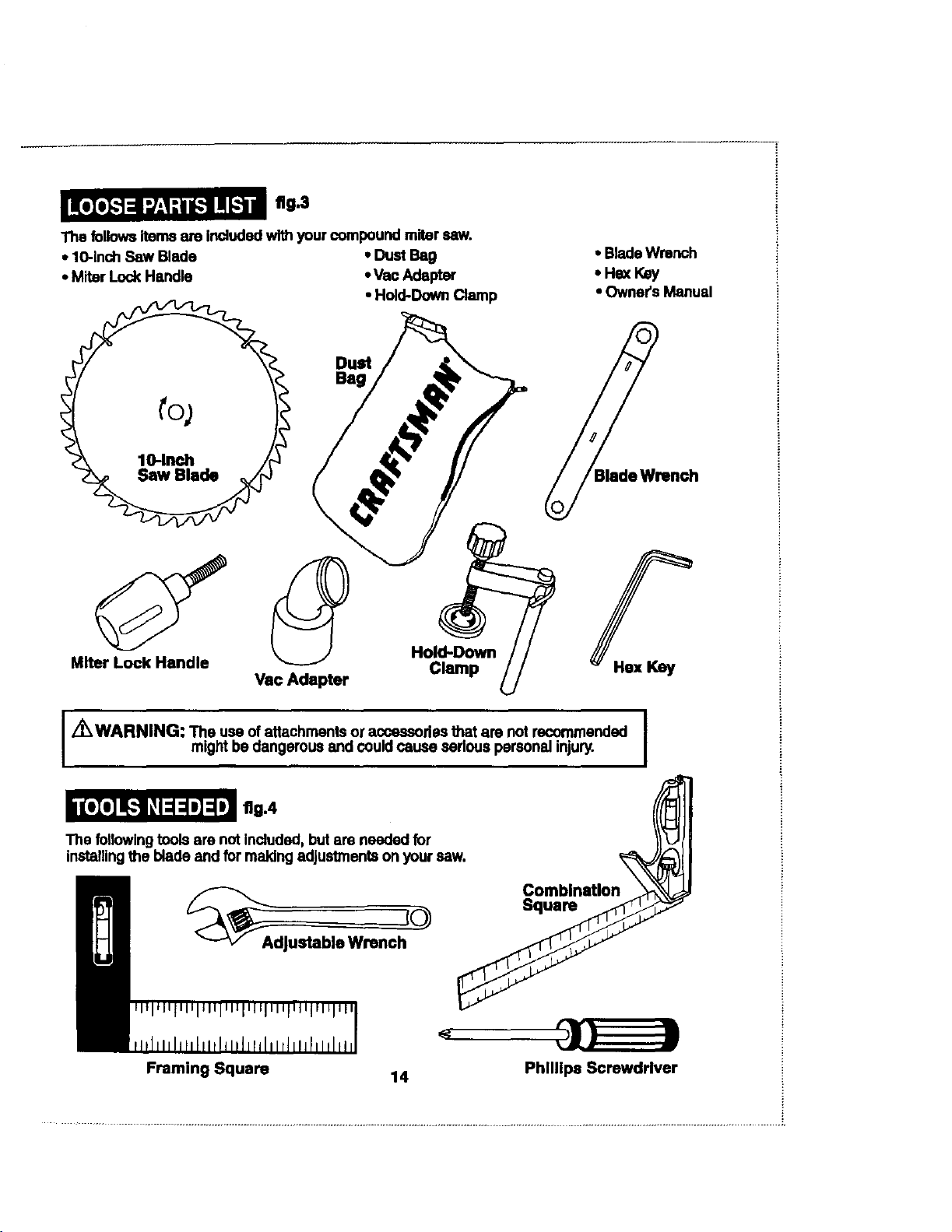

fig.3

The followsitemsare includedwi_ your compoundmiter saw.

• 10-1nchSaw Blade • Dust Bag

• Miter Lock Handle • Vex:Adapter

• Hold-Down Clamp

Beg

• BladeWrench

* He_ Key

• Owners Manual

DuM _ren

Clamp U

Z_IWARNING: The use of attachments or acsessodes that are not recommended I

might be dangerous and coud cause sar ous personal injury. I

riga

The followingtools are not included, but are needed for

installingthe blade and for makingadjustments on your saw.

Combination

Squam

CO

dJustable Wrench

ch

I

Framing Square

14

Phillips Screwdrlver

Loading...

Loading...