Page 1

Owner'sManual

Reciprocating Saw

Variable Speed

Double Insulated

Model Nos.

172.171040 (6.5 Amp)

172.171720 (7.5 Amp)

• SAFETY

CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions

in this manual before using this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

• OPERATION

• MAINTENANCE

• ESPAI_IOL

Page 2

Warranty. .................................................... Page 2

Safety Instructions ..................................... Pages 3-7

Safety Symbols .......................................... Page 7

Description ................................................. Page 8

Operation ................................................... Pages 8- 11

Maintenance .............................................. Pages 12-13

Accessories ............................................... Page 13

Service Numbers ....................................... Pages 14-16

FULL ONE YEAR WARRANTY ON CRAFTSMAN RECIPROCATING SAW

If this CRAFTSMAN Reciprocating Saw fails to give complete satisfaction

within one year from the date of purchase, RETURN IT TO THE NEAREST

SEARS STORE IN THE UNITED STATES, and Sears will replace it, free

of charge. If this CRAFTSMAN Reciprocating Saw is used for commercial

or rental purposes, this warranty applies for only 90 days from the date

of purchase.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffrnan Estates, IL 60179

SAVE THESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

Page 3

Failure to follow all instructions listed below may result in electric

I _ WARNING: BE SURE to read and understand all instructions.

shock, fire and/or serious personal Injury.

WORK AREA SAFETY

1. ALWAYS keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

2. DO NOT operate power tools In explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. ALWAYS keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

f. Double insulated tools are equipped with a polarized plug (one blade is

wider than the other.) This plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to Install a polarized outlet.

Do not change the plug in any way.

2. Double insulation [] eliminates the need for the three wire grounded power

cord and grounded power supply system. Applicable only to Class II

(double insulated) tools.

3. Before plugging in the tool, BE SURE that the outlet voltage supplied is

within the voltage marked on the tool's data plate. DO NOT use "AC only"

rated tools with a DC power supply.

4. ALWAYS avoid body contact with grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is grounded.

5. If operating the power tool In damp locations Is unavoidable,

ALWAYS use a Ground Fault Circuit Interrupter to supply power to

your tool. ALWAYS wear electrician's rubber gloves and footwear

in damp conditions.

6. DO NOT expose power tools to rain or wet conditions. Water entering

a power tool will increase the risk of electric shock.

7. DO NOT abuse the cord. NEVER use the cord to carry the tools or pull

the plug from the outlet. Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords

increase the risk of electric shock.

3

Page 4

ELECTRICAL SAFETY cont.

8. When operating a power tool outside, ALWAYS use an outdoor extension

cord marked "W-A" or 'W."These cords are rated for outdoor use and

reduce the risk of electric shock.

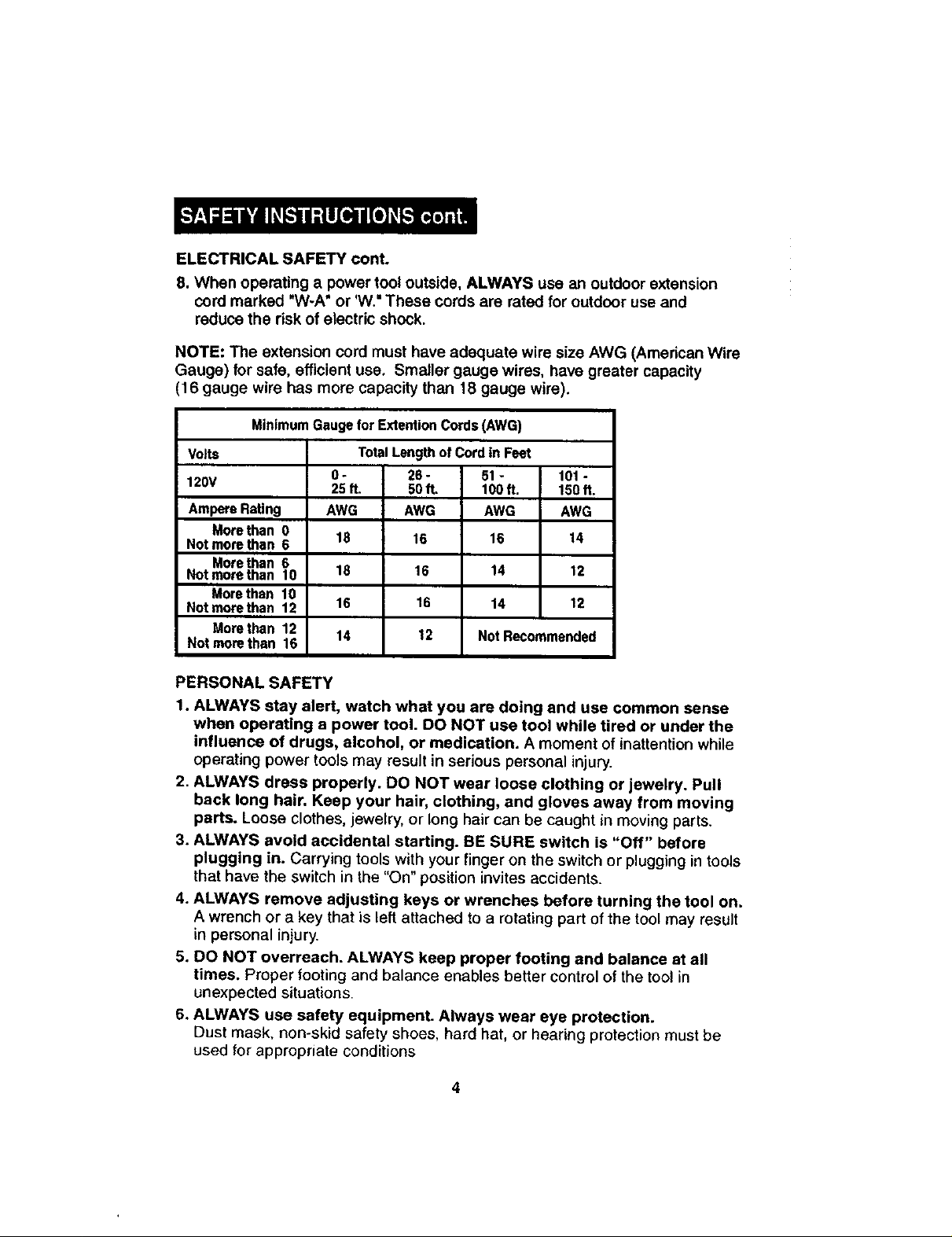

NOTE: The extension cord must have adequate wire size AWG (American Wire

Gauge) for safe, efficient use. Smaller gauge wires, have greater capacity

(16 gauge wire has more capacity than 18 gauge wire).

Minimum Gauge for Extention Cords (AWG)

Volts Total Length of Cord in Feet

120V 25 ft. 50 ft. 100 ft. 150 ft.

Ampere Rating AWG AWG AWG AWG

More than 0 18 16 16 14

Not more than 6

More than 6

Not more than 10 18 16 14 12

More then 10

Not more than 12 16 16 14 12

More than 12 14 12 Not Recommended

Not more than 16

0 - 26 - 51 - 101 -

PERSONAL SAFETY

1. ALWAYS stay alert, watch what you are doing and use common sense

when operating a power tool. DO NOT use tool while tired or under the

influence of drugs, alcohol, or medication. A moment of inattention while

operating power tools may result in serious personal injury.

2. ALWAYS dress properly. DO NOT wear loose clothing or jewelry. Pull

back long hair. Keep your hair, clothing, and gloves away from moving

parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

3. ALWAYS avoid accidental starting. BE SURE switch is "Off" before

plugging in. Carrying tools with your finger on the switch or plugging in tools

that have the switch in the "On" position invites accidents.

4. ALWAYS remove adjusting keys or wrenches before turning the tool on.

A wrench or a key that is left attached to a rotating part of the tool may result

in personal injury.

5. DO NOT overreach. ALWAYS keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool in

unexpected situations.

6. ALWAYS use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing protection must be

used for appropriate conditions

4

Page 5

TOOL USE AND CARE SAFETY

1. ALWAYS use clamps or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your

body is unstable and may lead to loss of control.

2. DO NOT force tool. Use the correct tool and blade for your application.

The correct tool and blade will do the job better and safer at the rate for

which it is designed.

3. DO NOT use tool if switch does not turn it "On" or "Off". Any tool that

cannot be controlled with the switch is dangerous and must be repaired.

4. ALWAYS disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such preventive

safety measures reduce the risk of starting the tool accidentally.

5. ALWAYS store idle tools out of reach of children and other untrained

persons.Tools are dangerous in the hands of untrained users.

6. ALWAYS maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edges are less likely to bind

and are easier to control.

7. ALWAYS check for misallgnment or binding of moving parts, breakage

of parts, and any other condition that may affect the tool's operation.

If damaged, have the tool serviced before using. Many accidents are

caused by poorly maintained tools.

RECOMMENDED FOR USE WITH THIS TOOL MAY CREATE

I Ak WARNING: USE OF ACCESSORIES THAT ARE NOT

A HAZARDOUS CONDITION.

8. ALWAYS use only accessories that are recommended for this tool.

Accessories that may be suitable for one tool can become hazardous

when used on another tool.

Page 6

SERVICE SAFETY

1. Tool service MUST BE performed only at a Sears Service Center.

Service or maintenance performed by unqualified personnel

could result in a risk of injury.

2. When servicing a tool, ALWAYS use only Identical replacement parts.

Follow Instructions in the Maintenance section of this manual. Use of

unauthorized parts or failure to follow Maintenance instructions may create

a risk of electric shock or injury.

ADDITIONAL SPECIFIC SAFETY RULES

1. Know your power tool. Read operator's manual carefully. Learn the

applications and limitations, as well as the specific potential hazards

related to this tool. Following this rule will reduce the riskof electric shock,

fire or serious injury.

2. ALWAYS hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or its own

cord. Contact with a 'live" wire will make the exposed metal parts of the tool

"live" and shock the operator.

3. ALWAYS keep your hands away from cutting area. DO NOT reach under

the material being cut because the nearness of the blade to your hand is

hidden from your sight.

4. DO NOT use dull or damaged blades. Bent blades can break easily,

or cause kickback,

5. ALWAYS wear safety glasses or eye shields when using this saw.

ALWAYS wear a dust mask or respirator for applications which

generate dust.

6. ALWAYS protect your lungs. Wear a face mask or dust mask if the

operation is dusty. Following this rule will reduce the risk of serious

personal injury.

7. ALWAYS protect your hearing. Wear hearing protection during extended

periods of operation. Following this rule will reduce the risk of serious

personal injury.

8. ALWAYS inspect and remove all nails from lumber before sawing.

Following this rule will reduce the risk of sedous personal injury.

9. SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to

instruct others who may use this tool. If someone borrows this tool,

make sure they have these instructions also.

Page 7

ADDITIONALSPECIFICSAFETYRULEScont.

/t_ WARNING: Some dust particles created by power sanding,

sawing, grinding, drilling and other construction jobs contain

chemicals known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints,

, Crystalline silica from bricks and cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending upon how often you do this

type of work. To reduce your exposure to these chemicals:

• Work in a well-ventilated area.

• Work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic

particles.

Z_ WARNING: The operation of any saw can

result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before

beginning power tool operation, ALWAYS wear

safety goggles or safety glasses with side shield

and a full face shield when needed. We recommend

a Wide Vision Safety Mask for use over eyeglasses

or standard safety glasses with side shield, both available

at Sears Retail Stores.

The label on your tool may include the following symbols.

V ........................................................................... Volts

A........................................................................... Amperes

Hz ......................................................................... Hertz

W.......................................................................... Watts

rain ....................................................................... Minutes

_-' ........................................................................ Alternating current

.... ................................................................... Direct current

no ........................................................................ No-load speed

[] ........................................................................ Class II construction

.../min ................................................................... Revolutions or

reciprocation per minute

/_k ...................................................................... Indicates danger, warning

caution. It means attention!!!

Your safety is involved.

IMPORTANT! READ ALL INSTRUCTIONS

7

Page 8

Your 6.5 and 7.5-amp reciprocating saws have many built-in convenience

features for fast, efficient cutting. These features include a variable speed dial

that allows you to change the speeds for cutting a variety of materials. An

adjustable/pivoting shoe for maximum control in a variety of cuts and an

easy-to-grip rubber boot.

Rg. 1

_Variable

I tl -- .---TriggerSwitch

B,a o

_5_(_-_t_O e R_ubberBoot _Ha;dle

Input

Blade Stroke

BladeType

Rating

No-loadSpeeds

Before attempting to use any tool, be sure to familiarize yourself with all

the operating features and safety instructions.

Z_ WARNING: IF ANY PARTS ARE MISSING, DO NOT OPERATE

THIS SAW UNTIL THE MISSING PARTS ARE REPLACED. FAILURE TO

DO SO COULD RESULT IN POSSIBLE SERIOUS PERSONAL INJURY,

6.5 Amps or 7.5 Amps

11/8 in.

I/2 in. Universal Shank

120 volts, 60 Hz AC

0 to 2400 SPM

I

Z_ CAUTION: DO NOT let familiarity with your saw make you

careless. Remember that a careless fraction of a second is sufficient

to cause severe injury.

/_ CAUTION: ALWAYS wear eye protection while operating this

power tool.

USING THE VARIABLE SPEED DIAL

Variable speed provides increased cutting versatility.

Simply rotate the dial from the slowest setting (1)

to the highest setting (6) depending upon the material being cut.

8

I

Page 9

Choosing the Correct Speed

The speed you use will depend on the type of materials that you are cutting:

1. Use high speeds for cutting wood.

2. Medium speed is best for non-ferrous materials.

3. Low speed is recommended for cutting metal.

NOTE-Material thickness and blade selection will also affect your speed

selection. As a general rule, as the material thickness increases, the speed

should be slower.

increase speed once the cut is started. Prolonged use at a very slow

i Ak CAUTION: usa averyslowspeedwhen beginningaCut.Then

speed may damage your sew.

BLADE INSTALLATION AND REMOVAL

This saw is designed to use all 1/2-in. universal shank blades.

plug from power source BEFORE assembling parts, making adjustments

I _ WARNING: To prevent personal injury, ALWAYS disconnect the

or changing blades.

Installing the Blade (Figure 2)

1. Unplug the saw.

2. Loosen blade clamp screw with

Allen wrench (included).

NOTE: DO NOT completely remove

the blade clamp screw. Just loosen

it enough to allow the blade to fit

between the blade clamp and the

reciprocating shaft.

3. Insert blade through the shoe

and line it up between the blade

clamp and the reciprocating shaft,

4. Insert the blade far enough in so that

the hole in the blade is positioned

over the "bump' or "stationary pin'.

Tighten screw with wrench.

NOTE: If the blade should break off and

the shank does not come outof the clamp,

loosen the screw. Then use a nail or other

pointed object to pry the blade shank off

of the "bump'or "stationary pin'.

Removing the Blade (Figure 3)

1. See Steps 1 and 2 in Installing the Blade above.

2. When screw is clear of the blade, pull blade shank

out of opening in blade clamp.

9

Page 10

ADJUSTING THE SLIDING/PIVOTING SHOE (Figure 4)

The shoe slides in or out to adjust the

depth of cut to material being cut for

maximum control and _onger blade _ita.

To Slide Shoe In or Out: (See Fig. 4)

1. Use the Allen wrench (included)

to loosen the 2 screws on

bottom of saw housing.

2. Slide shoe in or out to the depth

of cut that you desire and

retighten both screws.

NOTE: The shoe also pivots to provide

maximum control against the surface being cut.

To Pivot Shoe: (See Fig. 4)

1. Firmly hold saw and then pivot

shoe to desired position.

FLUSH CUTTING (Figure 5)

1. The compact design of the motor

housing and the adjustable shoe

on this saw allows you to make

extremely close cuts in floors,

comets and other extremely tight areas.

2. To obtain the maximum flush cutting

capability of this saw, make sure that

the shoe is in its closest position to the

saw housing.And the teeth of the blade

are facing as close as possible to the

work sudace,

WOOD CUTTING (Figure 6)

1. ALWAYS clamp the workpiece

down to prevent it from slipping.

2. P_ace the adjustable shoe and

the blade lightly against the

surface to be cut,

3. Turn on saw and allow it to come

to full speed before applying pressure

to the workpiece.

4. ALWAYS hold the saw firmly with both

hands while cutting.Whenever possible,

hold the adjustable shoe firmly against

the material to be cut. This willprevent

the saw from jumping orvibrating and

help minimize blade breakage.

NOTE: Wear gloves if cutting for long periods.

Fig. 6

10

Page 11

METAL CUTTING (Figure 7)

This saw has different metal cutting capacities depending upon the

type of blade being used and metal being cut.

1. ALWAYS clamp the work down to

prevent it from slipping.

2. Use a finer blade for ferrous metals and a

coarse blade for non-ferrous metals,

3. When cutting thin gauge sheet metals.

ALWAYS clamp wood on both sides of the

sheet. This will give you a clean cut without

excess vibration ortearing of the metal.

4. DO NOT force the cutting blade, Forcing

the blade will reduce blade life and cause

the blade to break.

NOTE: We recommend that you spread a thin film of oil or other coolant along

the line of cut ahead of the saw. This will allow easier operation and help extend

blade life. When cutting aluminum, use kerosene,

POCKET CUTTING: Wood Only

(Figure 8)

1. Measure the surface area to be

I I_P_.._";_,_

cut and mark it clearly using a pen,

pencil or chalk.

J / i*

2. Install a pocket cutting blade

into saw.

3. Tip the saw backwards until the back

edge of the adjustable shoe is resting

on the work surface.

4. To avoid breaking the blade, start

the saw and use the slowest speed

to begin the cut. Then gradually

increase the speed as you start to out.

Rod( toolup tonormalcutting

positionafter bladehascut

throughmaterial,

5. Hold the saw handle firmly and begin

to make a slow, deliberate upward swing

with the handle of the saw.

6. The blade will begin to feed into the material.

7. ALWAYS be sure that the blade is completely through the material before

continuing with the pocket cut.

NOTE: in areas where blade visibility is limited, use the edge of the saw

guard as a guide.

11

Page 12

SERVICE

personnel may result in misplacing of internal wires and components,

I A_ WARNING: Preventive maintenance performed by unauthorized I

which could cause a serious hazard.

1. Tool service MUST BE performed only by a Sears Service Center.

Service or maintenance performed by unqualified personnel could result

In a risk of injury.

IMPORTANT NOTE: All service that requires opening the saw should only be

performed at a Sears Service Center.

2. When servicing a tool, ALWAYS use only identical replacement parts. Follow

instructions in the Maintenance Section of this manual. Use of unauthorized

parts or failure to follow Maintenance Instructions may create a risk of electric

shock or injury.

TOOL LUBRICATION

Your CRAFTSMAN Reciprocating Saw has been properly lubricated

and is ready to use.

1. In two to six months, depending on use, take your tool to the nearest Sears

Service Center for a complete cleaning, inspection and lubrication.

2. Tools used constantly on production jobs will need lubrication more often.

3. Tools that haven't been used for long periods of time should

be lubricated before you use them.

WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS

tool from the power source BEFORE cleaning or performing any

I _ WARNING: To avoid accidents, ALWAYS disconnect the

maintenance.

1. Only the parts shown on pages 14-15 are intended to be repaired or

replaced by the customer. All other parts represent an important part

of the double insulation system and should only be serviced at a

Sears Service Center.

12

Page 13

CLEANING

I Ak WARNING: To avoid accidents, ALWAYS disconnect the tool

from the power source BEFORE cleaning or performing any maintenance.

to the plasUc parts. These include gasoline, carbon tetrachloride.

chlorinated cleaning solvents, ammonia and household detergents

I _ CAUTION: Certain cleaning agents and solvents cause damage

that contain ammonia.

1. Use a clean cloth to remove dirt, carbon dust, etc.

2. Electric tools are subject to accelerated wear and possible premature failure

when they are used to work on fiber glass boats, sports cars, etc. The fiber

glass chips and grindings are highly abrasive to electrical tool parts, such as

bearings, brushes, commutators, etc. Consequently, it is not recommended

that this tool be used for extended work on fiber glass. During any use on

fiber glass, it is extremely important that the tool is cleaned frequently with

compressed air.

I _ WARNING: ALWAYS wear safety goggles when cleaning tools I

with compressed air.

IMPORTANT:

To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment MUST be performed by a Sears Service Center.

I

The following recommended accessories are currently available at

your local Sears Store.

BLADES

Sears has a large selection of reciprocating saw blades in a variety of lengths

and teeth per inch that are ideal for a wide variety of cutting needs, Choose

blades for cutting wood only, blades for metal cutting only and general-purpose

blades that cut wood or metal.

EXTENSION CORDS

Sears offers a large selection of extension cords that help extend your

working range.

I Z_ WARNING: The use of attachments or accessories that are not

recommended might be dangerous.

13

I

Page 14

ReciprocatingSaw-ModelNo.172.171040(6.5Amp),172.171720(7.5Amp)

The Model Numberwillbe foundon the Nameplate.Alwaysmention the Model No. inall correspondanceregardingyour tool

No. Part No. Delmdptlon Quantity No. Pert No. Description Quantity

1 B09.0.05.1 Cover 1 29 W57,04.0 Screw 2

2 W57.56.0 Screw Set 2 30 W61.52.0 Loop 1

3 W57.36.0 Screw Set 4 31 W50.03.3 Ball Beedng 1

4 W57.57,0 Screw Set 2 32 B09.0.08 BearingPressPlate 1

5 B09.0.09 Bracket 1 33 TB51.03.01 Rotor 1

6 W57.02.0 Screw 1 34 W50.11.3 Ball Bearing 1

7 B08.3.53 Blade Clamp 1 35 T05.02.05 Beedng Sleeve 1

8 W51.52.0 Roller Pin 1 36 W55.70.0 Screw 2

9 B09.0.12 Gasket 1 37 B00.0.07.1 Fan Baffle 1

10 T15.02.00 Seal 1 38 TB50.03.01 Stator 1

11 W07,02 SlidingBeadng 1 39 B09.0.15.1 IdentificationI.abel 1

,Jk

12 B09.2.01 RedprocalingShaft 1 40 B09.0.01.1 Shell 1

13 B09.0.11 Yoke Plate 1 41 T02.11.00 Brush 2

14 T14,03.01 Washer 1 42 W55.06.0 Screw 4

15 B09.1.01 RollerBeadng 1 43 T03.09.00 Brush Holder 2

16 B09.1.02 Small Shaft 1 44 T04.01.01 Brush Spdng 2

17 TB01,01 Gear 1 45 W02.23 Switch 1

18 W50.03.0 Bell Bearing 1 46 W02,24 Speed Adiuster 1

19 TB02.01 Spindle 1 47 B09.0.14.1 Nameplate 1

20 TA05.04 Loop 1 48 B09.0.03.1 Right Handle 1

21 W50.12.0 Ball Beadng 1 49 T08.01.07 Cord Clamp 1

22 T14.01.03 Press Plate 1 50 W55.58.0 Screw 2

23 W57,36.0 Screw Set 1 51 T05.01,06 Cord Protector 1

24 B09.0.06 Gear Case 1 52 W01.32.21 Cord and Plug 1

25 W55.76.0 Screw 4 53 W05.09 Wrench 1

26 B09.0.04.1 Rubber Sleeve 1 54 B09.0,02.1 Left Handle 1

27 B09.0.13 Framework 1 55 W55,75.1 Screw 8

28 B09.3.00 Baffle Plate 1

SEE BACK PAGEFOR PARTSORDERING INSTRUCTIONS

Page 15

27

(dtuv g'Z) 0eL LZL'_/-L'(dtuv S'9) 0t_0LLL'¢/-L"SONIOpOl/_-MeS6up,eooad!ooEI

Page 16

Your Home

"%iiii!i!i_iiii!

:::;:::::::::2

::::::::

For repair in your home of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold itl

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME =_ Anytime, day or night

(1-800-469-4663) (U.S.A. and Canada)

www,sesrs,com www.sears.ca

_:::::::

::: :+:,:.:

::::::_::::::::

::::::::

._.:.:+:.x

::::,::+:

::::::,:

:::::,::

:;::::::

For repair of carry-in products like vacuums, lawn equipment,

and electronics, call or go on-line for the nearest

Sears Parts and Repair Center.

Our Home

1-800-488-1222 Anytirne, day or night (U.S.A. only)

www.sears.com

::::_:_:_::::::

:_:_;???::

To purchase a protection agreement (U,S.A.) or maintenance

:_:_::::::

:::::::_:_:_:_'_' 1-800-827 -6655 (U.SJ_) 1-800-361 -6665 (C_ada)

:::::::::::::

I;EE:I

::::::::

:::;.:::

::::::::::q:

::::::::::::

...............Para pedir servicio de reparaci6n

;;::::::

::::::::::;::

:I:_:E_:I:I: a O,

............... domicili y para ordenar piezas

:::::::

::::::::::::;;

;:::::::::

agreement (Canada) on a product serviced by Sears:

Au Canada pour service an f_s: ..............

1-800*LE FOYER _c ..........

1-888-SU-HOGAR su (1-8_533_937) : :::::...............

:::::::h

:::::::::;:;::::

;:::::::::::::

::::::::

i!iiiiiiii ! !

::::::,:,:

:?::::::

:::::::::::;:::

::,::,:+:<

::_::::::

:_:_:::::::::::_

:::::::::

::::::

©Sears, _ andCo

® Registered TradeMark / ;_,1_rademark / s_ Service Mark of Sears, Roebuck 8rid Co

® Ma_¢_ Regislr,_d2, , _'_ Ma_ca de F hrica ! s_ M_ Ca de Servlt_ o de Sears, Roebuck arid Co

_"_ M_fque _Je comll_elce / _u Marque depos_e de Se;_rs, Roebuck arid Co

16

Loading...

Loading...