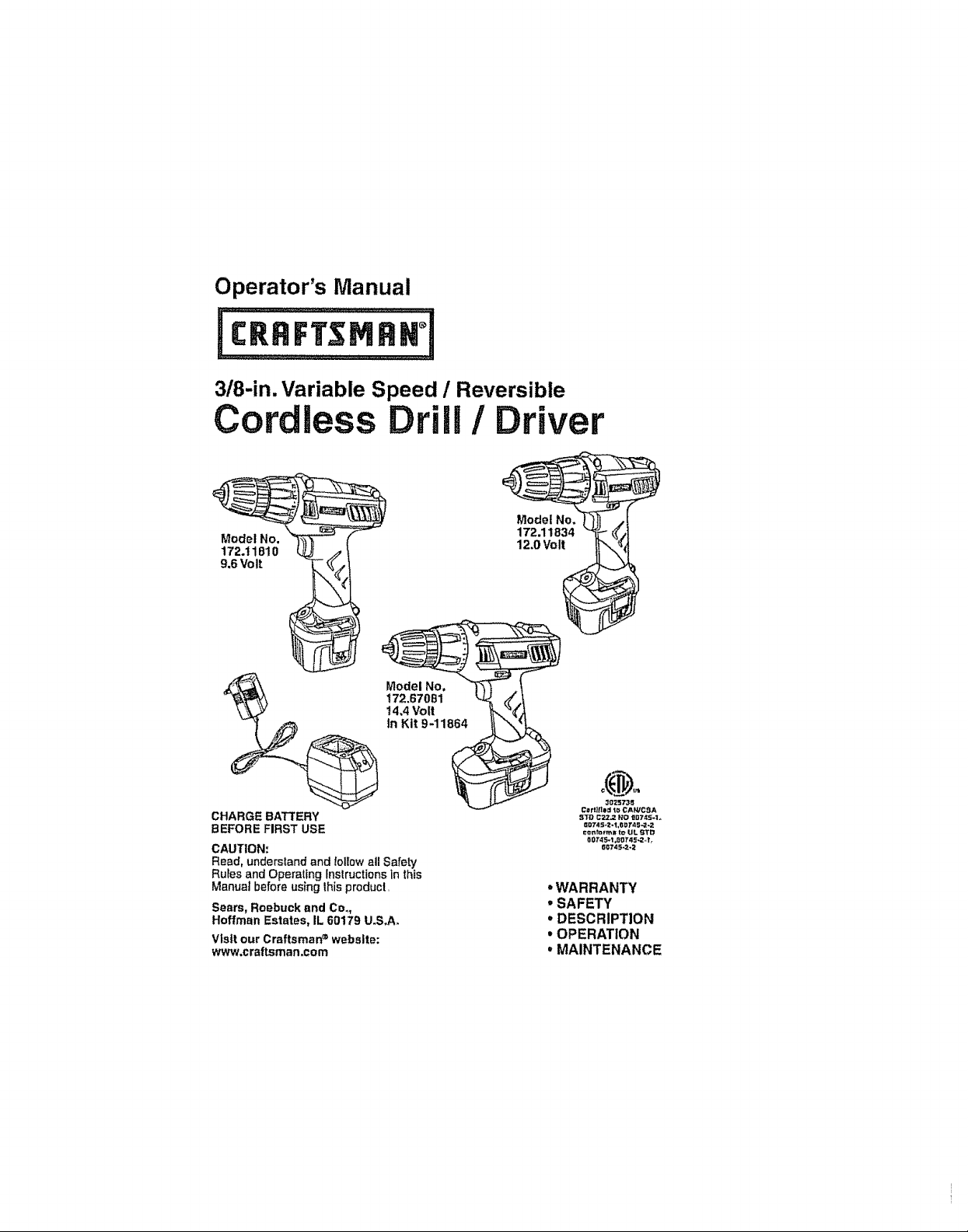

Craftsman 17211834, 17211810 Owner’s Manual

Operator's Manual

3/8-in. Variable Speed / Reversible

Co Drill/ river

Model No.

Model No,

172.t1810

9.6 Volt

Model No,

172.67081

14.4 Volt

In Kit 9-11864

172.11834

12.0Volt

CHARGE BATTERY

BEFORE FIRST USE

CAUTION:

Read, understand and ;followall Salety

Rules and Operating Instructions in this

Manual before using Ihis product,

Sears, Roebuck and Co.

Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman ® website:

www.craftsmamcom

• WARRANTY

• SAFETY

• DESCRIPTION

• OPERATION

• MAINTENANCE

Warranty ...................................................................................... Page 2

Salary SymbeL_ ....................................................................................... Page 3

Salety Inslructions ......................................................................................... Pages 4 - 10

Carton Contents ........................................................................................ Page 11

Description ............................................................. ........................... Pages 12- 13

Operalion ............................................................................................. Pages 14 - 22

Maintenance ..............................................................................................................................Pages 22 - 24

Accessories ........................................................................................................................ Pages 24 - 25

Repair Paris ...................................................................................................................................Page 2_6- 31

Sea_s Repair Parts Phone Numbers ...............................................................................Back Cover

ONEYEAR FULLWARRANTY ON CRAFTSMAN_TOOL

II IhiS Craitsman tool tat!s due to a defect in mateflal or workmanship within one year from

the dale of purchase, RETURN rrTo ANY SEARS STORE OR OTHER CRAFTSMAN

OUTLET IN THE UNITED STATES FOR FREE REPLACEMENT,

This warranty does not Include expendable parts such as lamps, batteries, bits or blades

II this Craftsman product is used for commercial or renlal purposes, this warranty applies

tot only 90 days from the date of purchase,

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state°

Sears. Roebuck and Co,, Hoftman Estales, tL 60t 79

SAVE THESE INSTRUCTIONSt

READ ALL INSTRLICTIONSt

I

I

f

f

I

f

[

f

I

I

I

I

t

I

l

t

1

1

I

[Z_ WARNING: Some dust created by using power toots contains chemicals known to !

the Stale of California to cause cancer and berth defects or other reproductive harm.

1

1

1

!

1

l

1

1

1

1

!

f

|

The purpose of safety symbols is to attract your attention 1opossible dangers_.

The safety symbols, and the explanations wi_hthem, deserve your careful

attention and understanding. The symbol warnings DO NOT by themselves

efimtnate any danger. The instructionsand warnings they give are no substitutes

for proper accident prevention measures..

Z_ WARNING: BE SURE to road and understand all safety Instructions in

this menus|, including all safety alert symbols such as "DANGER", "WARNING"

and "CAUTION", BEFORE using this drltlldriver. Failure to follow all instructions

sted below may result in electric shock, fire and/or serious personal injury.

SYMBOL MEANING

SAFETY ALERT SYMBOL: IndicatesDANGER,WARNING,OR

CAUTION. May be used in conjunction with other symbols or plctographso

Failure to obey this safety warning WILL result in death orserious injury to yourself or to others, Always follow the

safety precautions to reduce the risk of fire, electric shock

and personal injury.

t I Failure to obey this safety warning CAN result in death or

Z_WARNING ! serious Injury to yourself or to others_ Always follow the

CAUTION

[Z_ | Failure to obey this safety warntng MAY result in personal

DAMAGE PREVENTION AND INFORMATION MESSAGES

These inform usor o! Important Information andtor instructions that could lead to

equipment or other property damage if not fotlawed Each message Is preceded by the

word"NOTE:" as In the example below:

NOTE: Equipment andlor property damage may result if these instructions

are not followed.

WEAR YOUR

safety precautions to reduce the risk of fire, electric shock

and personal Injury.

Injury to yourself or others or property damage. Always

J

follow the safety precautions to reduce the risk of fire,

electric shock and personal injury.

Z'_WARNING: The operation of any drillldrlver can

result In foreign objects being thrown into your eyes,

which can result In severe eye damage. Before beginning

power tool operation, ALWAYS wear safety goggles or

safety glasses with side shield and s full-face shletd

when needed. We recommend a Wide Vision Safety

Mask for use over eyeglasses or standard safety glasses

with side shield, available at Sears Stores or other

Craftsman Outlets.

7-11-07

manual before using this drflltdriver. Failure to follow all instructions may result

I _ WARNING: BE SURE to read and understand all instructions in this

tn electric shock, fire and/or serious personal injury,

WORK AREA SAFETY

1_Keep your work area clean and well IlL Cluttered workbenches arid dark areas

invtte aecldenls,

2+DO NOT operate power tools in explosive atmospheres, such as tn the presence

of flammable liquids, gases, or dust+ Power tools create sparks which may Ignite

the dust or fumes°

3. Keep bystanders, children and visitors away while operating a power tool,

Distractions can cause you to lose control+

4., Make your workshop chlldproof w+lh padlocks and master switches, Lock toots

away when not in use+

5- MAKE SURE the work area has ample lighting so you can see the work and that

there ere no obslructions thai will interfere with safe operation BEFORE using your

cordless drtll t driver.

PERSONAL SAFETY

_o KNOW your cordless drill/driver, Read the operalor's manual carefully Learn the tool's

appficalions and l+mftations, as well as the specific potenliat hazards related to this looL

2. STAY ALERT, watch what you are doing and use common sense when operating

a power tool

3. DO NOT use power tools while tired or under the influence of drugs, alcohol or

medication. A moment of inaltantion while operating power tools may resull in

serious personal injury

4, DRESS properly. DO NOT wear loose clothing or jewelry. Pult back fang hair, Keep

your hair, clothing, and gloves away from moving paris Loose clottliog, or long hair

can be caught in moving parts. Air vents often cover moving parts and should

also be avoided,,

5. AVOID ace+dental starting Be sure trigger switch is In the "Locked OFF" position

before inserting battery pack., DO NOT eamj tools with your finger on the trigger swtlch,,

Carrying tools with your finger on the trigger switch or Inserting the battery pack tn tools

that have the switch In the "FORWARD" OR "REVERSE" position Invttes accidents,

6+Do not overreach= Keep proper footing and balance at all times, Proper tooling

and balance enables better conlrol of the tool in unexpected situations,

7-ALWAYS SECURE YOUR WORK. Use clamps or a vise to hold work when practical,,

It Is safer than uslng your hand and frees both hands to operale too]

8+USE SAFETY EQUIPMENT. Always wear eye protection, Dual mask, n0n, skid safely

shoes, hard hat, or hearing protection must be used tar appropriate conditions

9_ DO NOT USE ON A LADDER or unstable support. Stable footing on a sofid surface

enables belier control of the toot in unexpected situations.

_

TOOL USE AND CARE SAFETY

Z_ WARNING: BE SURE to read and understand all Instructions before

operating this dri!lldrIver. Failure to follow al! instructions listed below may result

in electric shock, fire and/or serious personal injury.

t. ALWAYS use clamps or other practical ways to secure and support the workplece

to a stable platform. Holding the work by hand or against your body ts unstable and

may feed to loss of control.

2 DO NOT force the tool Use the correct tool and accessory bit for your appt_catlono

The correct tool and bit will do the job better and safer at the rate for which it is designed,,

3_ DO NOT use the tool if trigger switch does not turn it "On" or "Off". Any tool that

cannot be controlled with the trigger switch is dangerous and must be repaired°

4. REMOVE the battery pack from the drill/driver or place the forward/reverse

selector switch with power lock.off in the "Lock Off" position before making

any adjustments, changing accessories or storing the toot. Such preventive

safety measures reduce the risk o! starling the too{ accidenlaUy,,

5 STORE idle tools out of the reach of children and other untrained persons,,

Tools are dangerous tn the hands of untrained users,

6 ALWAYS remove battery pack and store separately when drill/driver

Is not being used.

7 When battery pack Is not In use, keep It away from other metal objects like:

paper clips, coins, keys, nails, screws, or other small metal objects that can

make a connection from one terminal to the other. Shelling the battery terminals

together may cause bums to skin, sparks or a fire,

8. MAINTAIN tools with care. Keep cutting tools such as twist drill bits sharp and

clean. Properly maintained tools with sharp cutting edges are less likely to b_nd and are

easier to use and control

9 CHECK for mteatignment or binding of moving parts, breakage of parts, and any

olher condition that may affecl the tool's operatiom It damaged, have the fool serviced

bolero using., Many accidents are caused by poorfy maintained tools

10. USE ONLY accessories that are recommended for this tool. Accessories that may

be suitable for one tool may become hazardous when used on another tool.,

Sea page 24 for accessories.

t t Keep the too! and its handle dry, clean and free from oil and grease. Always use

a clean cloth when cleaning. Never use brake fluids, gasoline, petroleum-based

products, or any strong solvents to clean your tool. Fol!owtng Ibis lute will reduce

the risk of !ass of centre! and deterioration o{ the plaslic enclosure el the drill / driver,,

7-11-07

ELECTRICAL SAFETY

z_ WARNING: BE SURE to read and understand at1 Instructions before ]

operating this drllttddver_ Failure to follow all instructions listed below ruby

result in electric shock, fire andlor serious personal injury,

A battery operated toot with Integral batteries or a separate battery pack must be

recharged only with the specified charging stand/transformer for the battery. A

charger that may be suitable for one type of battery may create e risk of fire when

used with another battery,

t. Use battery operated toot only with specifically designated battery pack, Use of

any other batteries may create a risk of tire

2 Use battery only wtth charging standltransformer listed,

MODEL CHARGING STAND/TRANSFORMER BATTERY PACK

11810 9.6V CDT109GU-103iBHY41q 2.5V-200 mA, CDTt 0£GU-t 04(ABP309GU),

140302001 1323405, 1323424 and

1301390 t 6

11834120V CDT112GU-!03/BHY41455V-200mA, CDT112GU-104{ABP312GUt,

140302002 1322519,1322550,1322549,

1323412and130139017

67081 14AV (i_ kit118{;_) CDTtt4GU-103!BHY41-18 0V-200 mA, CDT114GU4 04(ABP314GU).

3..Do not abuse the cord on the charging stand. Never carry the charging stand/transformer

by its power cord. Never pull the power cord to remove the transformer from the power

out[eL Damage to the cord or charging stand/transformer could occur and create an

eleclric shock hazard. Keep cord away from heal, oil, sharp edges or moving part[;

Replace damaged cords Immediately Damaged cords increase the risk of electric shock

SAFETY SYMBOLS FOR YOUR TOOL

The label on your loci may Include the following symbols.

V .....................................................................................Volts

A...................................................................................Amps

Hz........................................................................................ Hertz

W.....................................................................................Walls

rain .....................................................................................Minutes

...........................................................................Alternating current

............................................................................... Dim_ cu_nl

nO ..................................................................................... No-loadspeed

[] ..............................................................................Class It conslruclion, Double lnsutaled

. Jmtn............................................................................Revolutions or Strokes per minute

.................................................................................Indicales danger, warning or caution°

SERVICE SAFETY

1 If any part of this cordless drillldrlver or charging stand/transformer Is missing

or should break, bend, or fail in any way; or should any component felt to perform

properly: have the missing, damaged or failed parts replaced BEFORE resuming operation

140302003 !3t0714, 1322518, 1323407,

1323426 and 130139014

It means altentlonl Your safety is tnvofvedo

I

l

t

f

r

i

I

I

t

I

I

I

1

1

1

1

J

!

1

1

1

t

i

1

i

!

1

l

t

SERVICE SAFETY conL

;2. Toot service must be pertormed only at a Sears Parts and Repair Center_Service

or maintenance performedby unqualifiedpersonnelcouldresultin s risk of tniury,

3, When servicing a toot, use only Identlcal replacement parts, Follow instructions

tn the maintenance section of this manual Use of unauthorizedpartsor failureto

followmaintenance Instructionsmaycreate a riskofefectdc shock or injury,

SPECIFIC SAFETY RULES FOR CORDLESS DRILL/DRIVERS

I _Know your cordless drlll/drlvero Read operator's manual carefully_ Learn its

applications and limitations, as well as the specific potential hazards related to

this toot. Following this rule wilt reduce the rlsk of electric shock, fire, or

serious Injury.

2 BE SURE that twist drill bits, screwdriver bits and other accessory attachments ere

properly and securely mounted in the chuck jaws BEFORE operating the drill / driver°

3..ALWAYS carefully inspect the material you are going to drtlt/ drive into. Drilling/driving

into nails, pipes and electrical wires can cause serious personal injury

4 HOLD DRI[.LI DRIVER by insulated gripping surfaces (handles) when performing

an operation where the toot may drttl/ drive Into hidden wiring. Contact with a

"live" wire wLt!make the exposed me_al pads of lhe tool "tive" and shock the operator

5. NEVER hold the piece being drilled In your hands or across your togs.

It is impodant to support sad clamp the workpieoe properly in order to minimize body

exposure, bit binding, or toss of control

6. Maintain a firm grip on the drill/driver lo resist stadtng torque.

7. Use sharp accessory bile on_y. For drilling in WOOD use twist drill bits, spade bits,

or power auger btts oFor METAL use high*speed steel twist drill bits For MASONRY

use carbide-tipped bits. For PLASTIC use Iow dd!ting speeds for maiedal wttha low

melting point, For SCREWDRIVtNG use the proper size screwdrtvtng bit for the

screwdrivlng application such as Phillips, slotted and square recess bits.

8. BE SURE the material to be drilled is stationary, anchored or clamped firmly. If drilling

thin material, use a back.up block to prevent damage to the material,

9. ONLY USE the specifically designated battery pack that was included with this

drill I driver and charging stand/transformer. Use of any other battery packs may

create a risk of injury and f]rao

10 Cordless tools do not have to be plugged Into an electrical outlet; therefore,

they are always in operating condition, Be aware of possible hazards when not

using your batter' t operated tool or when changing eccesaortes_ Following this

rule will reduce the risk of electric shock, fl_e, or serious personal intury

11 Do not place battery tools or their batteries near fire or heat, This will reduce the

risk of explosion end possible injury

12, Do not crush, drop or damage battery pack. Never use a battery pack or charging

stand!transformer that has been dropped or received a sharp blow. A damaged

battery peck is subjec! to explosion. Properly dispose of a dropped or damaged battery

pack immediately,,

l

7-11-07

SPECIFIC SAFETY RULES FOR CORDLESS DRILL/DRIVERS conL

13 Batteries vent hydrogen gas and can explode in the presence of a soume of

ignition, such as a pt!ot flghL To reduce the risk of personalinjury,neveruse any

cordless product in the presenceof open flame An explodedbattery can propeldebris

and chemicals If exposed, flush with water immediately,,

'_4oDo not charge battery pack In a damp or wet location, Followingthis rule will

reducethe riskof electric shock,

15_For best results, yourbatlery packshouldbe chargedine _ocationwherethe temperature

ismore than 5g°F butless that SO=F,Donot store battery outside or in vehicles,,

16 Under extreme usage or temperature condftionst battery leakage may occur.

If liquid comes In contact with your skin, wash Immediately with soap and water,

then neutralize with lemon Juice or vinegan If liquid gets Into your eyes, flush

them with clean water for at least 10 minutes, then seek Immediate medical

attention Following this rule will reduce the risk of serious personal Injury.

17 Save these instructions. Refer to them frequently and use them to instructothers

whomay use this tool If you toansomeone this toot,loan them theseinstructions also

to prevent misuseof the preducl and possible injury,,

SAFETY RULES FOR BATTERY CHARGING STAND/TRANSFORMER

Z_ WARNING; READAND UNDERSTAND ALL INSTRUCTIONS.Failure to

follow al! Instructions listed below may result In electric shock, fire and / or

serious personal Injury.

NOTE: Before using battery charging stand/transformer, read all Instructions

and cautionary markings In this manual, on battery charging stand/transformer,

battery pack, and drill / driver using battery pack to prevent misuse of the

products and possible Injury or damage.

!Ik CAUTION: USE ONLY the specifically designated battery charging

stand I transformer that was supplied with this drill / driver when charging the

battery pack.The use of any other battery charging stand t transformer could

damage the battery pack, and create a hazardous condition.

Z_ CAUTION:To reduce the risk of electric shock or damage to the battery

charging stand / transformer and battery pack, charge on_y the specifically

designated battery pack that was Included with thts drill / driver and the battery

charging stand / transformer, Charging other types of battery packs may cause

them to burst, causing personal [nlury and damage.

1 Donotusethebatterycharglngstandltransformeroutdoorsorexposetewetor

damp conditions° Water entering charging stand will Increase the risk of electric shock

;2 Use of an attachment with th_s batten/charging stand I transformer that Is not

recommended may result in a risk of tire, electric shock, or Injury to persons.

L-

SAFETY RULES FOR BATTERY CHARGING STAND/TRANSFORMER cont.

3 Do not abuse the cord on the battery chargfng stand ! tronsformer_ Never carry the

charging stand / transformer by itspower cord,, Never pull the power cord to remove lhe

Iransformer from the power outlet. Damage to the cord or charging stand I transtormer could

occur and create an elsclrt¢ shock hazard Keep cord away from heat, oil, sharp edges or

moving parts Repiace damaged cords immediately Damaged cords increase the dsk of

electric shock.

4 Make sure cord is located so that it will not be stepped on, tripped over, come in

contsct with sharp edges or moving parts, heat, otl, or otherwise subjected to

damage or stress,, This will reduce Ihe risk of accidental fails, which could cause injury.

and damage to the cord which could result in electdc shock.,

5 Keep cord and charging stand / transformer away from heat to prevent damage to

housing or Internal parts_

6. Do not let gasoline, oils, petroleum-based products, etc_ come In contact with

plastic parts. They conlain chemicals which can damage, weaken or destroy ptastic

7 An extension cord should not be used unless absolutely necessary, Use of improper

extension cord coutd result In a risk of fire and electric shock,, it an extension cord must be

used, make sure: a) Thai pins on plug of extension cord are the same number, size and

shape as those on the transformer, b) That extension cord is properly wired and in good

electrical condition, and c) That you use a proper extension cord. ONLY use cords

tiered by Underwriters Laboratories (UL} Other extension cords can cause a drop in line

voltage, resulting In a toss of power and overhealing of charging stand/transformer, An

AWG (American Wire Gauge) size of at least t4-gauge is recommended for an extension

cord of 25-it, or less in {englh Use 12.gauge for an exlension cord of 50-It

Extension cords lOg-it, or longer are not recommended.

8_ INSPECT tool cords for damage, De not operate charging stand with e dameged cord or

transformer, which could cause shorting and electric shock_ Have damaged Iool cords

repaired at a Sears Service Center

9, Do not operate charging stand I transformer if It has received a sharp blew, been dropped,

or otherwise damaged in any way.Take }t lo an authorized serviceman for electricalcheck to

determine tf the charging sland 1iransfmmer is ingood workingorder

10_Do not disassemble charging stand / transformer.Take it to a Sears Parts end Repair

Center when service or repair is required. Incorrect reassembly may result in a risk of

electric shock or li_e,

1t. Disconnect charging stand/transformer from the power supply when not in us_.

This will reduce the risk of eleclrie shock or damage if metal items should tat! Inlo the opening In

the charging sland it else witl help preventdamage during a power surge

12 Risk of electric shock, Do not touch un*insufated porlien o! output conneclor or un-_nsulaled

batlery terminal,

13 Save these instructions. Refer to them frequently and use them to instruct others who may

use this tool if you loan someone this tool.also lean them these inslructfons to prevent misuse

o! the productand possible injury

7-11-07

Z_ WARNING: Some dust crested by using power tools contains chemicals

known to the State of California to cause cancer and birth defects or other

reproductive harm,_Some examples of those chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products,

• Arsenic and chromium, from chemically lreated lumbar_

Your risk from these exposures varies, depending upon how often you do

this type of work.To reduce your exposure to these chemicals:

• Work in a well-ventilated area

• Work wtlh approved so{ely equipment, such as those dIdst masks that are specially

designed to iiiier oul microscopic parlicles.,

Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling and other construction activities.Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.,

Z_ WARNING: Use of thts tool can generate andlor disburse dust, which

may cause serious and permanent respiratory or other injury. Always use

NIOSWOSHA approved respiratory protection appropriate for the dust exposure.

Direct particles away from face and body.

ADDITIONAL RULES FOR SAFE OPERATION

WARNING: BE SURE to read and understand all tnstructfons. Failure to

follow all instructions listed may result in electric shock, fire and/or serious

personal injury.

I, Know your drill/driver. Read operator's manual carefully,, Learn the applications

and limitations, as well as the speclljc potential hazards related to this 1ooiFollowing

this rule wit{ reduce the risk of electric shock. {ire or serious inJury_

2., ALWAYS wear safety glasses or eye shields when using this drill/driver.

Everyday eyeglasses have only impac{-reslslanl lenses; they are NOT safety glasses,

3 PROTECT your lungs.Wear a {ace mask or dust mask if the operation Is dusty.

4. PROTECT your heartng_ Wear appropriate personae hearing protection during use.

Under some conditions noise from this produc! may centrfbule to hearing lasso

5. SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to Instruct

others who may use this tool. If someone borrows this tool, make sure they have

these Instructions also.

10

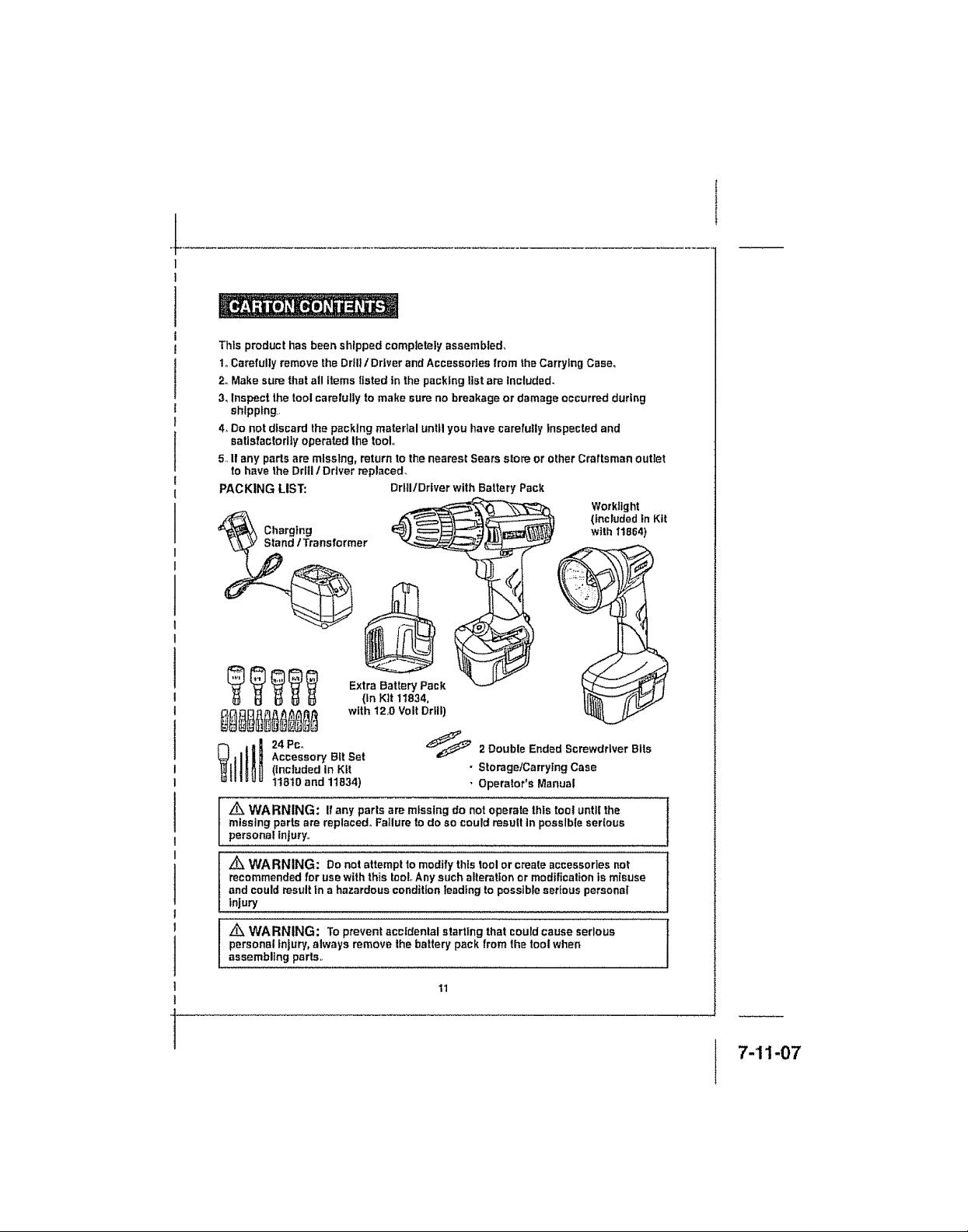

ThisproducthasbeenshippedcompJetefyassembled,

1_Carefully removethe Drill / Driver and Accessories from the Carrying Case,

2_,Make sure thatall items listed in the packing list are tncluded_

3, lnspect the tool carelulty to make sure no breakage or damage occurred during

shipping,,

4_Do notdiscard the packing material until you have carefully inspected and

saUsfactodty operated the logic

5, I! any pads are missing, return to the nearest Sears store or other Craftsman outlet

to have the Drfll 1Driver replaced,

PACKING LIST: Drill/Driver with Battery Pack

Worklight

(included;n Kit

with 11864)

Extra Battery Pack

(in Kit 11834,

with 12,0 Volt Drill)

Accessory Bit Sat

(included in Kit

11810 and 11834)

_, WARNING: If any parts are missing do not operate this tool until the

missing parts are replaced_Failure to do so could result in possible serEous

personal injury,,

Z_ WARNING: Do not attemptto modify this tool orcreate accessories not

recommendedfor usewith this tool,Any such alteration or modification is misuse

and couldresult in a hazardouscondition leading to possibleserious personal

injury

Z_ WARNING: To prevent accidental sfart|ng that could cause serious

personal injury, always remove the battery pack from the toot when

asserebltng parts,,

'_2 Double Ended Screwdriver Bits

• Storage/Carrying Case

• Operator's Manual

11

7-11-07

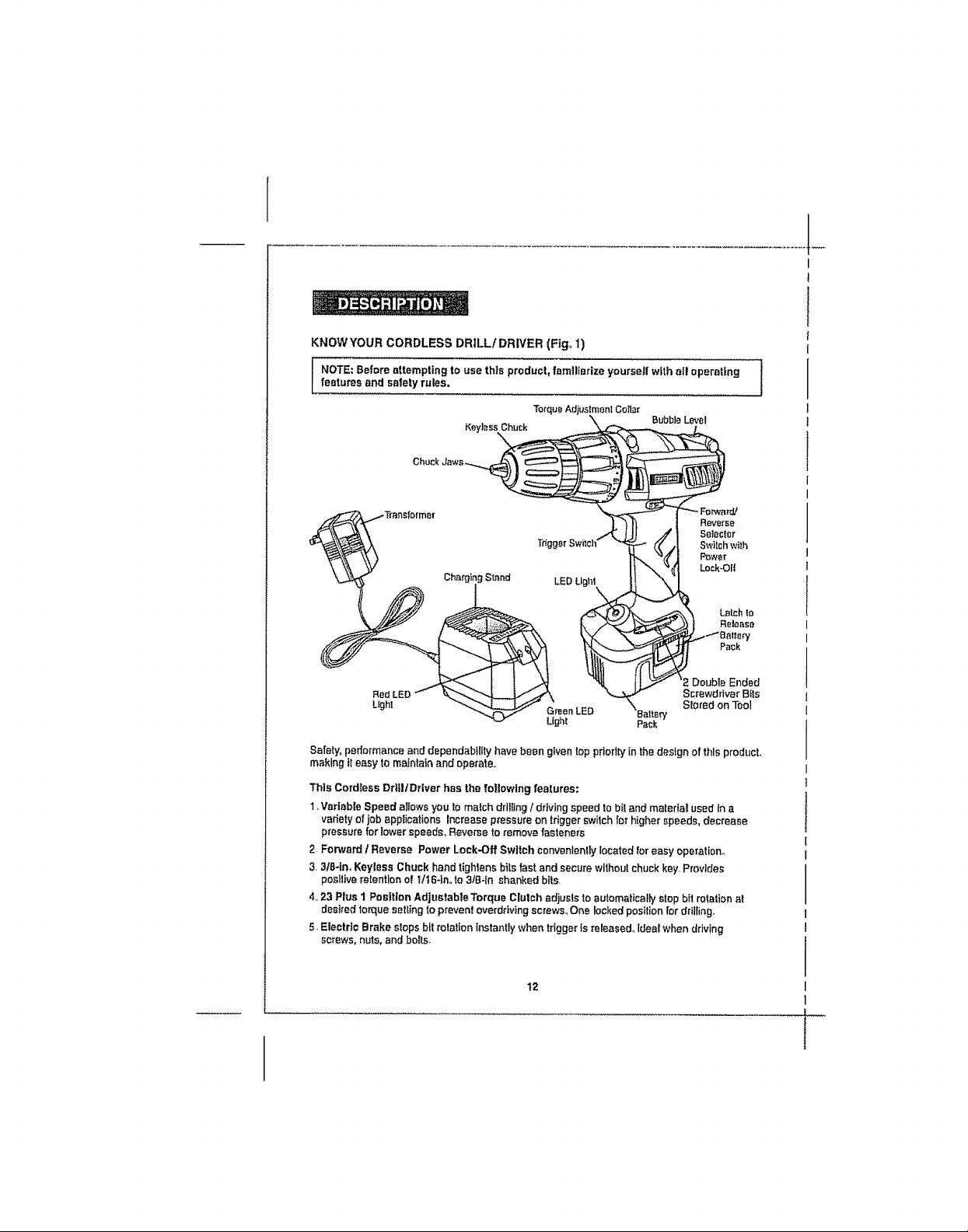

KNOW YOUR CORDLESS DRILL/DRIVER (Fig. 1)

I OTE: Before attemptin{] to use th}s product, familiarize yourself with all operating

features and safety rules.

Torque Adjustmenl Collar

Bubble Level

(( 11 Swllchwire

JL.._ '2 Double Ended

n LED

Safety,paflormanceand dependabilityhave been givenlop priorityin thedesignof this product.

makingil easyto maintain andoperate,,

Thla Cordless Drill/Driver has the following features:

I, Variable Speed allows you to malch drilIing/ driving speed Io bit and material used in a

variety of lob applications Increase pressure on trigger switch for higher speeds, decrease

pressure for !ower speeds,. Reverse to remove fasteners

2 Forward / Reverse Power Lock-Off Switch conveniently located for easy operation.

3.3t8-In_ Keyless Chuck hand tighlens bits fast and secure without chuck key Provides

positive retention o! ttl6*lnoto 3/B-In shanked bIls

4..23 Plus I Posltton Adjustable Torque Clutch adjusts lo automatically stop bit rotation a!

desired torque setting to prevenloverddving screws.. One lockedposition for drilling.

5 Electric Brake slops bit rotation tnstantfy when trigger is reteasado Idea; when driving

screws, nuts, and bolts.

Ballery

Pack

Screwdriver B_ts

SIored on Tool

i

12

_!

l

t

1

t

t

t

I

I

I

J

!

t

This Cordless DrtlllDriver has the following features eonL:

6 Bubble Level helps provide accurate fight aegis drilling and driving straight into workplace.

7 ErgonomIc "T" Handle Design with molded in comfort grip provides maximum control

added balance and gripping comlort,

8 LED Light illuminates drtllt drive area for hands free lighting _nany applicali0n,

9 Fan-cooled motor provides the torque and power needed lot a vadet.y of drilling and

driving applications.

10 Durable impactweslstant housing he!ps protect toot from damage and reduces weight,

11 The N_ckeFCadmfum battery packs recharge |n 3 to 6 hours under normal use,

and LED light on charger lndicalas when battery Is charging,

12 Includes: 2 double_nded screwdriver bits and Impact-resistant case for easy carrying

and storage.

13 The f 1810 - 9°6 Volt and 1t834 o12.0 Volt Drill Drivers also Include a 24-pc, Bit Set,

1

l

l

J

!

t

l

I

I

J

l

l

i

l

i

i

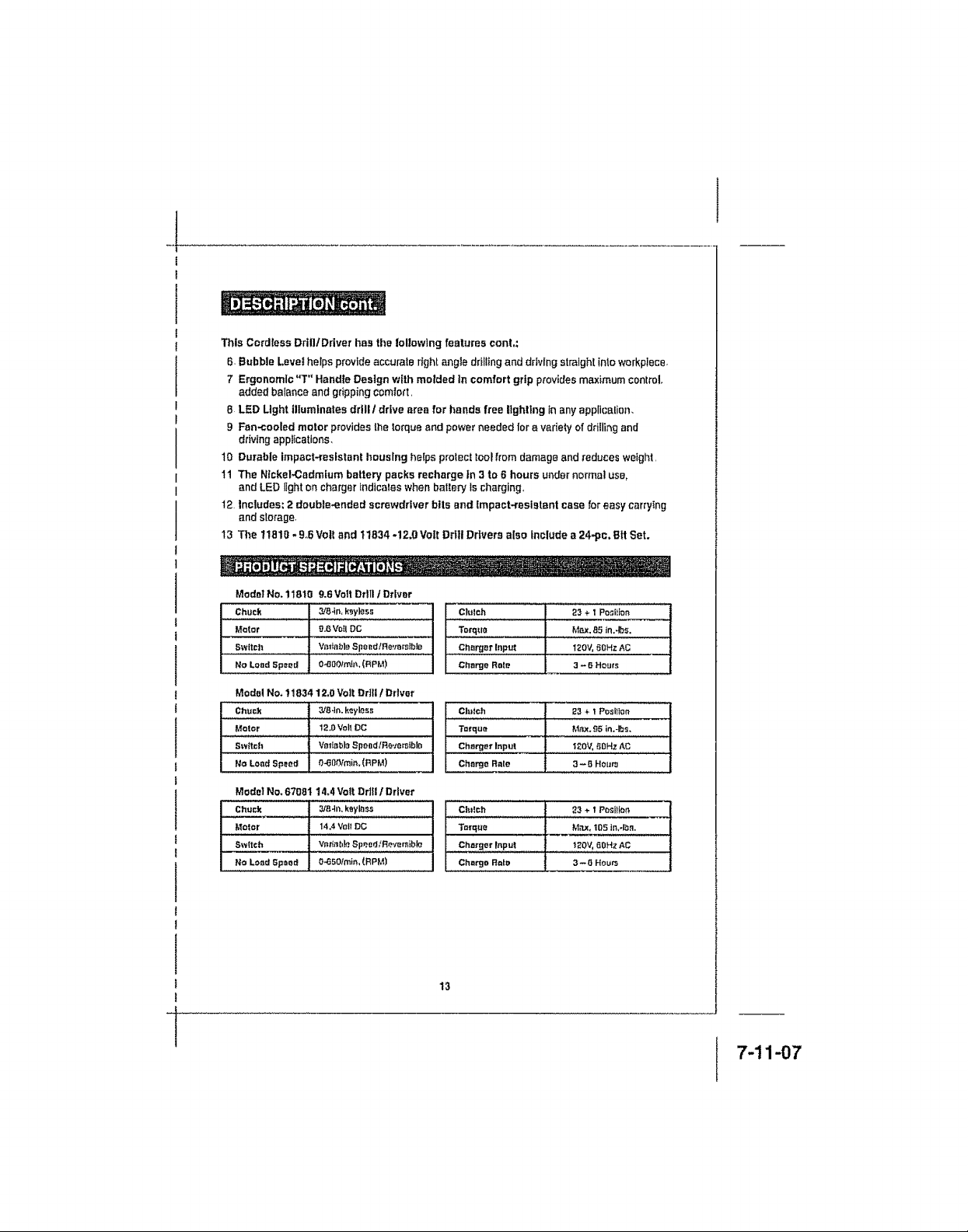

Mode} No, 11810 9,6 Volt Drill / Dtlver

Chuck 318-in, ksyless

Ma_or 0.8 VoEIDC

Switch V_dable Spend/Flevnrs_bte

No Lo_d Sp_ed O,600/mh_=,(RPM)

Model No, 11834 12,0 Volt Drill I Driver

Chuck 3lS.tn_keyloss

I Motor 12+.0Vail DC

Sw{tch VatIabb SpOodfRevo_b|o

NO Lor_d Sp_ed O-61_t_Imir_,(RPM)

Mode} No. 67081 14,4 Volt Drill I Driver

Chuck 3,rS4a.keylos_

Motor 14,4 Val_ DC

Sw_tch Vn_int_,Sp_',odiRevar_ibie

No Load ape_ O.650rmir_,(RPM)

Cluleh

To_quo

Charger Inpttt

Charge Rate

C]_dch 23 _ I Position

Tarqu_ ht_.x.9S in..-_s.

ChaftjerInput I_OV,BDHz AC

Charg_ Rate ;3-S Hour'J

C_tdch 23 ÷ I PosI|_r_

T_rque M,"_. 105 in.ol_n.

Cha_'get Input _'OV, 60Hz AC

Chargo Rat_ 3--S Hr_urs

13

23 + I Position

Ml_. 85 In.,.tbt;.

•I2OV,5t3Hz AC

3 - 6 Hour._

7-11-07

T

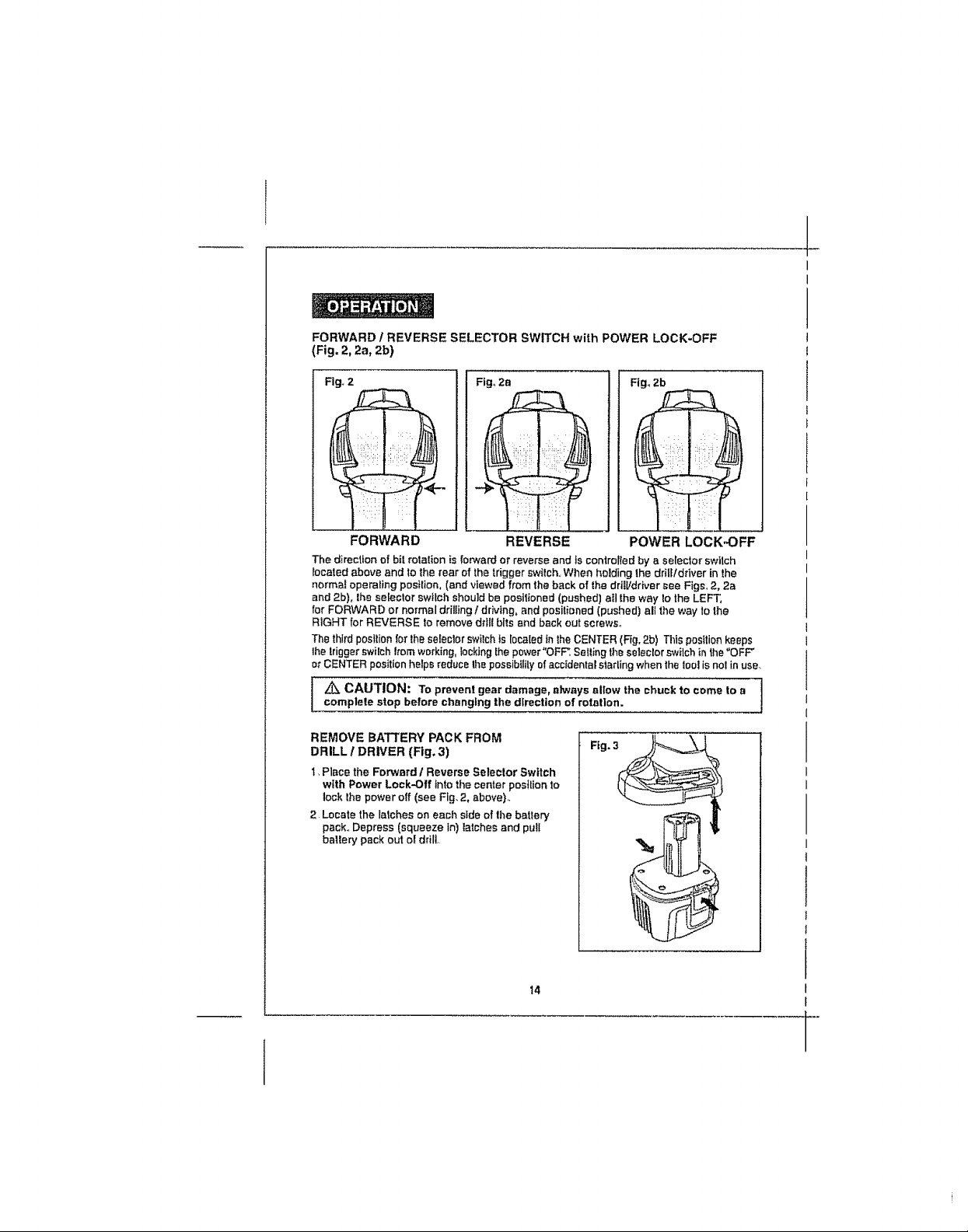

FORWARD / REVERSE SELECTOR SWITCH with POWER LOCK-OFF

(Fig, 2, 2a, 2b)

Fig, 2

FORWARD

The direction of bit rotation is !orward or reverse and is controlted by a selector switch

Iocated above and to the rear of the trigger switch., When holding the dri|tlddver in the

normal operating position, (and viewed from the back of the driiI!driver see Figs, 2, 2a

and 2b), the selector switch should be posilioned (pushed) a_lthe way 1o the LEFT,

for FORWARD or normal drilling I driving, and positioned (pushed) all the way to the

RIGHT for REVERSE to remove ddll bits alld back out screws°

The third position forlhs selector switch is lccaled in the CENTER (Fig, 2b) This position keeps

lhe trigger swilch Item working, locking the power"OFF Selling the selector switch in the "OFF

or CENTER position helps reduce Ihe possibility of accidental starling when the tool is nol in use,

l Z_ CAUTION: To prevent gear damage, ekvays altow the chuck to come to a ]complele stop before changing the direction of rotation.

REMOVE BATTERY PACK FROM

DRILL / DRIVER (Fig, 3)

1,Place theForward / Reverse Selector Switch

with Power Lock-Off intothecenter posttionto

lock the power off (see Fig,2, above),,

2 Locate the latches on eachs_deof tile batlary

peck,,Depress (squeeze in) latches and pull

battery pack out o! drill,

Fig° 2a

REVERSE

Fig_ 2b

POWER LOCK-OFF

14

,.-1

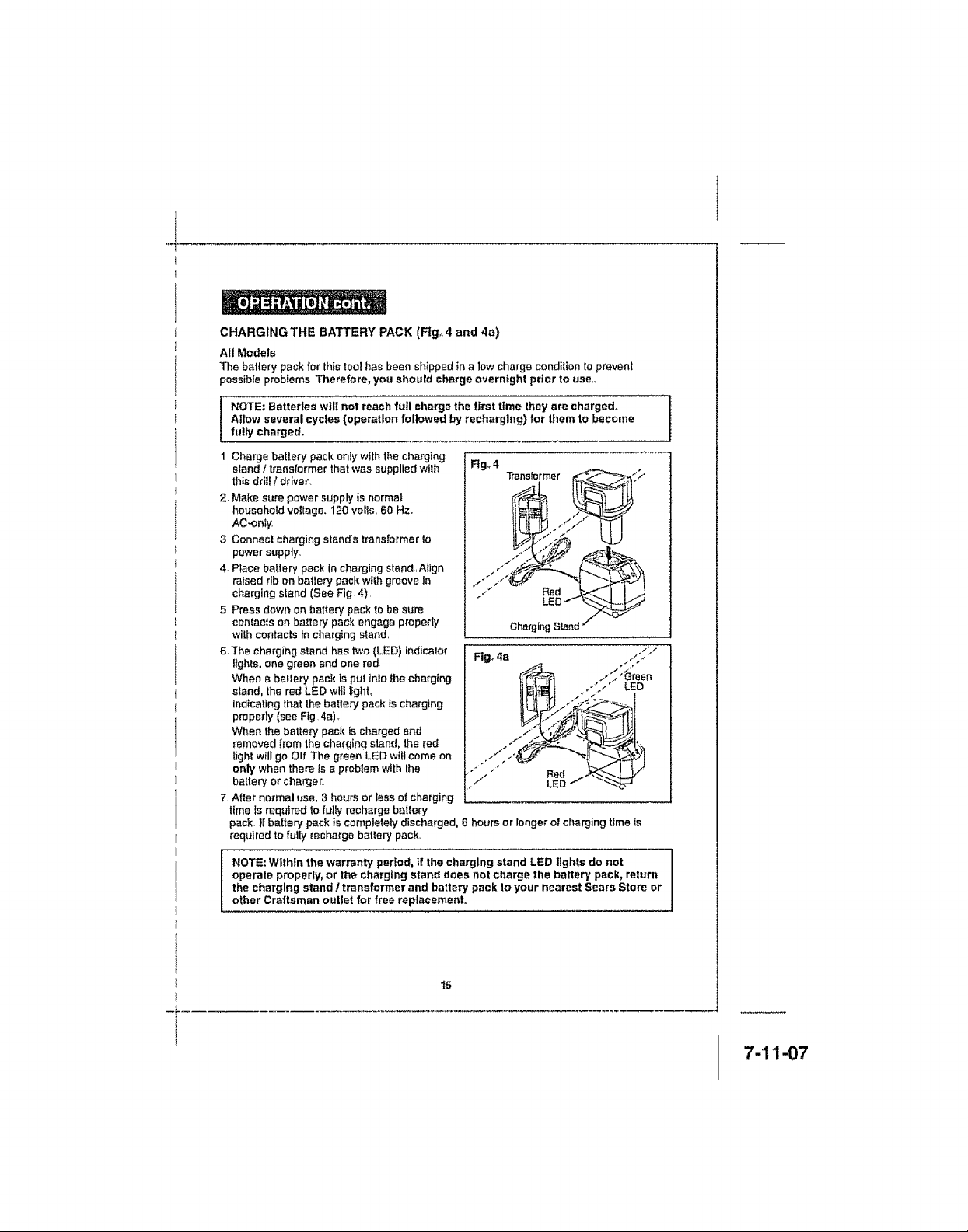

CHARGINGTHE BATTERY PACK (Fig° 4 and 4a)

All Models

The battery pack lot this tool has been shipped in a low charge condilion to prevent

possible problems. Therefore, you should charge overnight prior to use..

Allow several cycles (operation followed by recharging} for them to become

I NOTE: Batteries wtll not reach full charge the first ttme they are charged.

fully charged.

1 Charge battery pack onfy with the charging

stand f transformer that was supplied wilh

this drill/ driver.

2 Make sure power suppty is normal

household voltage. 120 volls, 60 Hz.

AC,onty,

3 Connect charging stand's transformer Io

power supply.

4 Place battery pack in charging stand., Align

raised rib on battery pack with groove In

charging stand (See Fig 4).

5, Press down on battery pack to be sure

contacls on battery pack engage properly

with contacts in charging stand,

6The charging stand has two (LED) indicator

lights, one green and one red

When a battery pack ls put into the charging

stand, the red LED wtll light,

indicating that the battery pack is charging

properly (see Fig 4a),

When the battery pack is charged and

removed Irom the charging stand, the red

light will go Off The green LED will come on

only when there is a problem with the

battery or charger,,

7 After normal use, 3 hours or less of charging

time ts required to fu]ty recharge battery

pack IIbattery pack iscompletely discharged, 6 hours or longer of charging time is

required to fully recharge battery pack,

Fig. 4

Transformer

operate properly, or the charging stand does not charge the battery pack, return

the charging stand / transformer and battery pack to your nearest Sears Store or

I OTE: Within the warranty period, tf the charglng stand LED lights do not

other Craftsman outlet for free replacement°

15

7-11-07

CHARGINGTHE BATTERY PACK conL (Fig. 4 and 4a)

B.The battery packwift becomeslightiy warm to the touch while charging This is normal

anddoes not indicatea problem,

9. Donot place the battery chargingstand t transformer tn an area of extremeheat or cold,

itwillwork best at normal room temperalure.

10.When baitery pack becomes fuIly charged, unplug battery charging stand I lransformer

from powersupply and remove lhe battery pack.

L_ CAUTION: If at any time during the charging process the green LED

light ls iIlumtneted, remove the battery pack tram the charging stand. Replace

the battery pack, and if the green LED light still comes on, take the charging

stand t transformer In to be repaired / replaced.

L_ CAUTION: If at any point during the charging process neither of the LEDs

are lit, remove the batter=/pack from the charging stand to avoid damaging the

producL Do not insert another battery,, Return the charging stand / translormer

and battery pack to your nearest service center for service or replacement.

CHARGING A HOT BATTERY PACK

When using your tool continuously, the batteries in your batlery pack will become hot

You should let a hot battery pack coot down for approximately 30 minutes before

attempting to recharge-

NOTE: A hot battery pack only occurs when prolonged continuous use of your drill/driver

causes the batterfes to became hot. It does net occur with typical use.Within the

warranty period, if the battery pack becomes hot with typical use, return the charging

stand/kansformer, and battery pack to your nearest Sears store or other Craftsman outlet

for free replacemenL

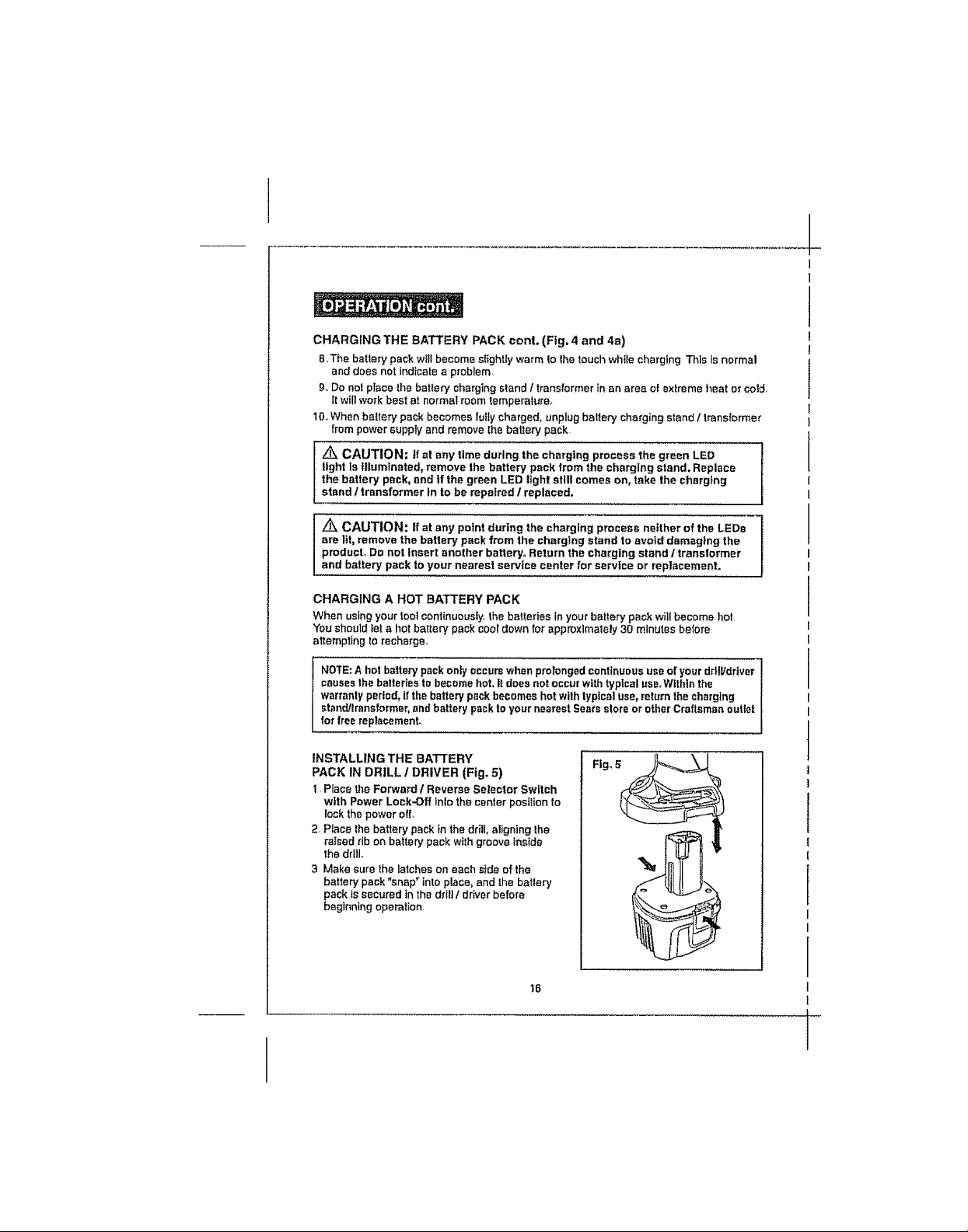

INSTALLING THE BATTERY

PACK IN DRILL/DRIVER (Fig. 5)

t. Place the Forward / Reverse Selector Swttch

wlth Power Lock-Off inlo the center posilion to

lock the power off,

2. Place lhe battery pack in the drill, aligning the

raised rib on battery pack with groove inside

the drill,

3 Make sure the latches on each side of the

battery pack "snap" into place, and the batlery

pack is secured tn the drill I driver before

beginningoperation.

16

..... l

Ak CAUTION: When placing battery pack in the tool, be sure raised rib on

battery pack aligns with the bottom of the drill and latches Into place properly.

Improper Installation of the battery pack can cause damage to internal

components.

WARNING: Cordless Battery Tools are always in operating condition when

the battery pack Is installed in the tool.Therefore the Forward / Reverse Selector

Switch with Power Lock.Off should always be in the center position, locking the

power off, when the tool is not In use or when you are carrying it at your side.

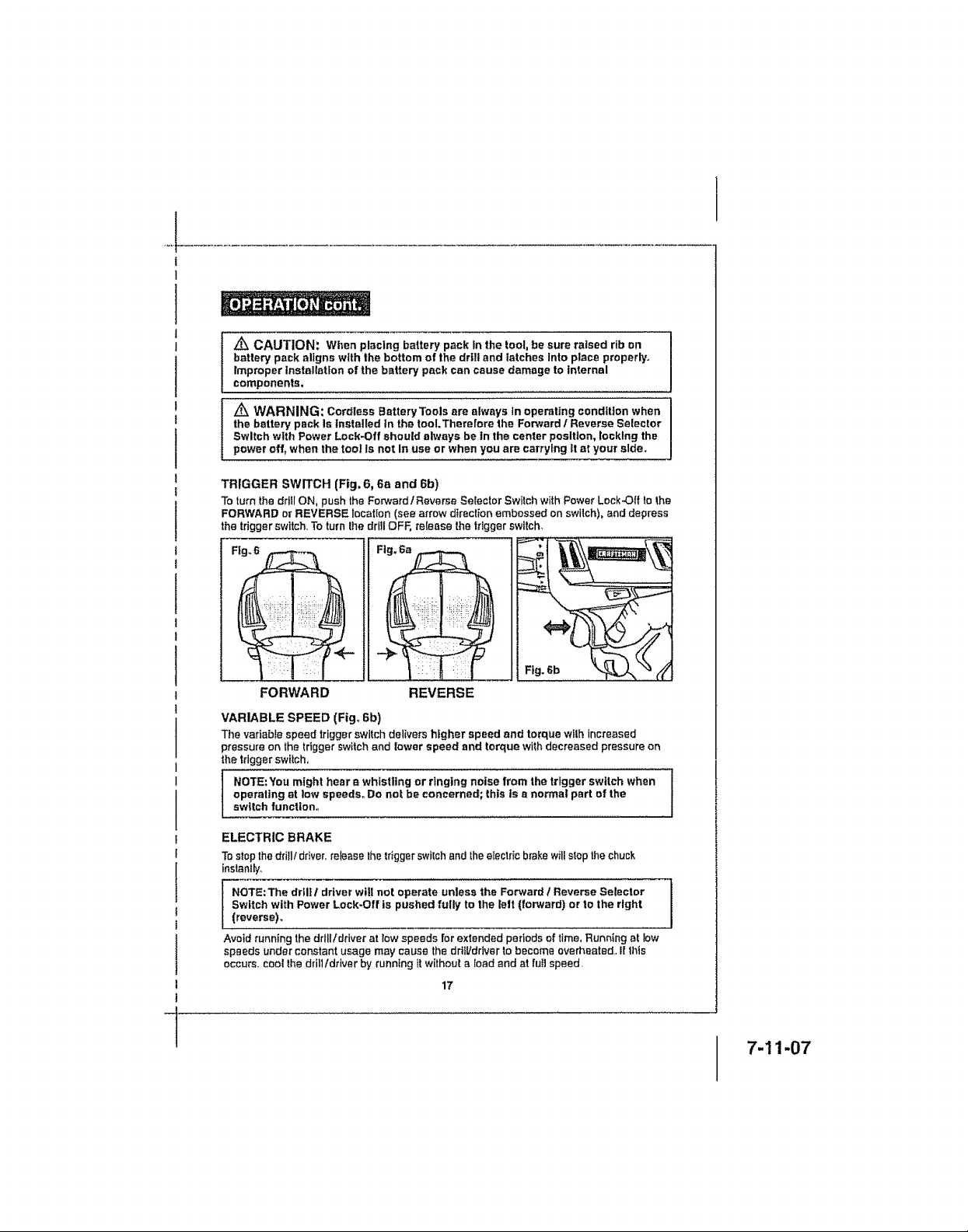

TRIGGER SWITCH (Fig. 6, 6a and 6b)

Toturn thedrill ON, push the Forward/Reverse So{actor Switch withPower Lock-Off to lhe

FORWARD or REVERSE location (sea arrow direction embossed on swilch), and depress

the triggerswitch.To turn the drt!lOFF,release the triggerswttch_

FORWARD REVERSE

VARIABLE SPEED (Fig. 6b)

The variablespeed triggerswitchdelivershigher speed and torque with increased

pressureon the triggerswitch end lower speed and torque withdecreased pressure on

the triggerswitch,

NOTE:You might hear a whistling or ringing noise from the trigger switch when |

operating at low speeds° Do not be concerned; this ts e normal part of the

switch functiorto

ELECTRIC BRAKE

To slop the drill/driver, release the trigger switch and lhe eiectric brake will stop the chuck

instantly,,

NOTE: The drill/driver will not operate unless the Forward / Reverse Selector

Switch with Power Lock"off is pushed fully to the left (forward) or to the rtght

(reverse).

Avoid running the drill/driver at low speeds for extended periods of time, Running al low

speeds under constant usage may cause the drt!_drtver to become overheated., ff this

occurs, cool ihe drill/driver by running it without a Iced and at futi speed.

17

1

/

7-11-07

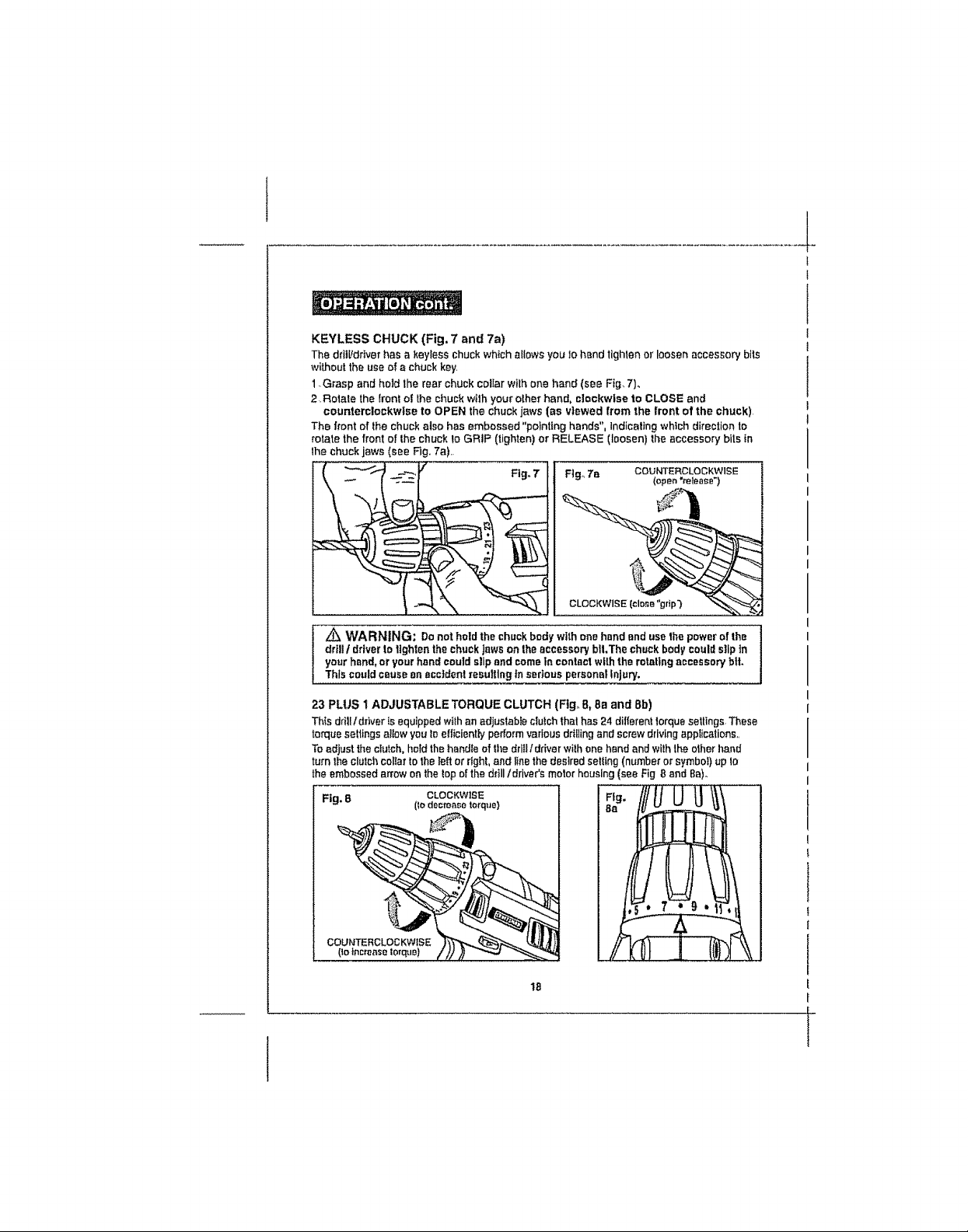

KEYLESS CHUCK (Fig. 7 and 7a)

The ddtltddver has a keyless chuck which allows you ]o bond lighten or loosen accessory bits

without the use of a chuck k-_y.

1. Grasp and hold !he rear chuck collar wtih one hand (see Fig. 7),.

2. Rotate the front el the chuck with your other hand, clookwfse to CLOSE and

counterclockwise to OPEN the chuck jaws (as viewed from the front of the chuck)

The front of lhe chuck also has embossed "pointing hands", Indicating whtch direction to

rotate the front of the chuck lo GRIP (tighten) or RELEASE (loosen) the accessory bits in

lhe chuck jaws (see F3g.7a)..

Fig. 7a COUNTERCLOCKWISE

(open'release")

Z_ WARNING: Do not hold the chuck body with one hand and use the power of the

drill / driver to tighten the chuck Jaws on the accessory blloThe chuck body could slip in

your hand, or your hand could slip and come In contact with the rotating accessory bit.

This could cause an accident lresulttng In serious personal Injury.

23 PLUS 1 ADJUSTABLE TORQUE CLUTCH (Fig. 8, 8a and 8b)

Thls drill/driver ts equipped wflh an adjustable clutch that has 24 different lorque settings. These

torque settings allow you 1oefficiently perform various drilling and screw driving applications,.

To adjust the clutch, hold the handle of the dri)lldriver with one hand and with the other hand

turn lha clulch collar to the left or rlgtll, and line the desired sel!ing (number or symbo!) up to

the embossed arrow on the top of the ddll/driver's motor housing (see Fig 8 and Be).

Fig. 6 CLOCKWISE Fig "U U _ 'l\,t !

(to tncto,..setorque)

fie decreasetQrque} us" J

18

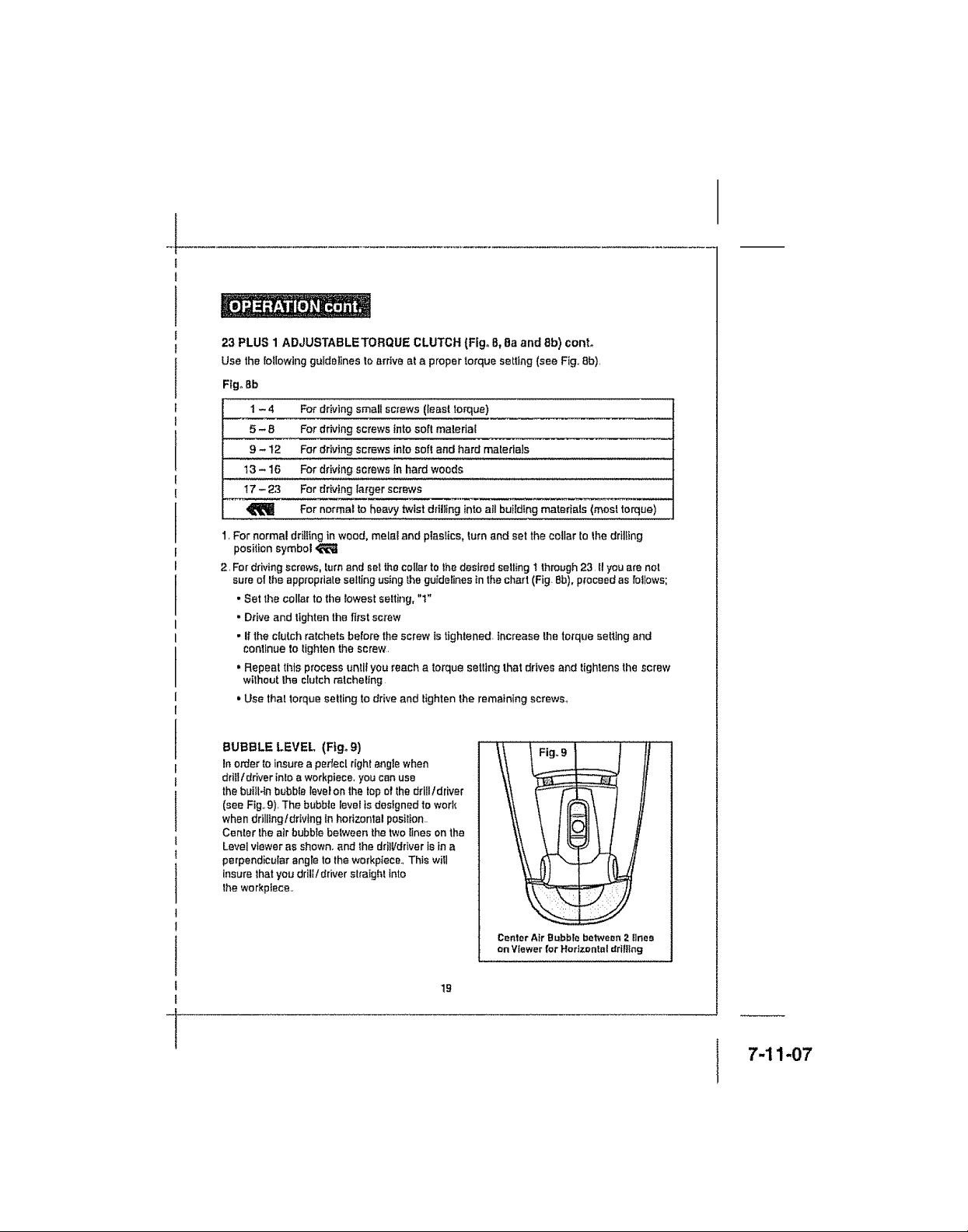

!

23 PLUS 1 ADJUSTABLE TORQUE CLUTCH (Fig. 8, 8a and 8b) cent.

Use thefollowing guidelines to arrive at a proper torque settIng {see Fig,,8b),

Fig. 8b

1-4

5-B

9-12

13-16

17 -23

1. For normal drilling in wood, metal and ptasfics, turn and set the collar to the drilling

position symbol _i

2. For driving screws, turn and set the cellar to the desired setting t through 23 II you are net

sure of the appropriate selling using the guidelines in the chart (Fig. Bb), proceed as i'ollows:

,,Sat the collar to the lowest setting, "t"

=Dtive and tighten the first screw

• if the clutch ratchets before the screw ts tightened. Increase the torque selling and

continue to tighten the screw.

,' Repeat this process until you reach a torque setting that drives and ttghlens the screw

without the clutch raichelIng

,,Use that torque setting to drive and tighten the remaining screws,

For driving small screws (least torque)

For driving screws Into soft material

For driving screws inlo soft and hard materials

For driving screws In hard woods

For driving target screws

For normal to heavy twist ddlling into atl building materials (most torque)

BUBBLE LEVEL (Flg_ 9)

In older to insure a pe_ect right angle when

drifltdriver inlo a werkpiece, you can use

the buill-tn bubble level on the top of the ddtlldriver

(see Fig.. 9). The bubbte torsi ts designed to work

when drilling/driving In horizontal position..

Center theairbubblebetween the two lineson the

Level viewer as shown, and the drill!driver is in a

perpendicufar angle to the wo_kpiecs., This will

insure that you drill/driver etaeight into

lhe workpiece..

19

Center Atr Bubble between 2 tines

on Viewer for Horizontal drilling

7-11-07

Ftg.10

and 1Oa

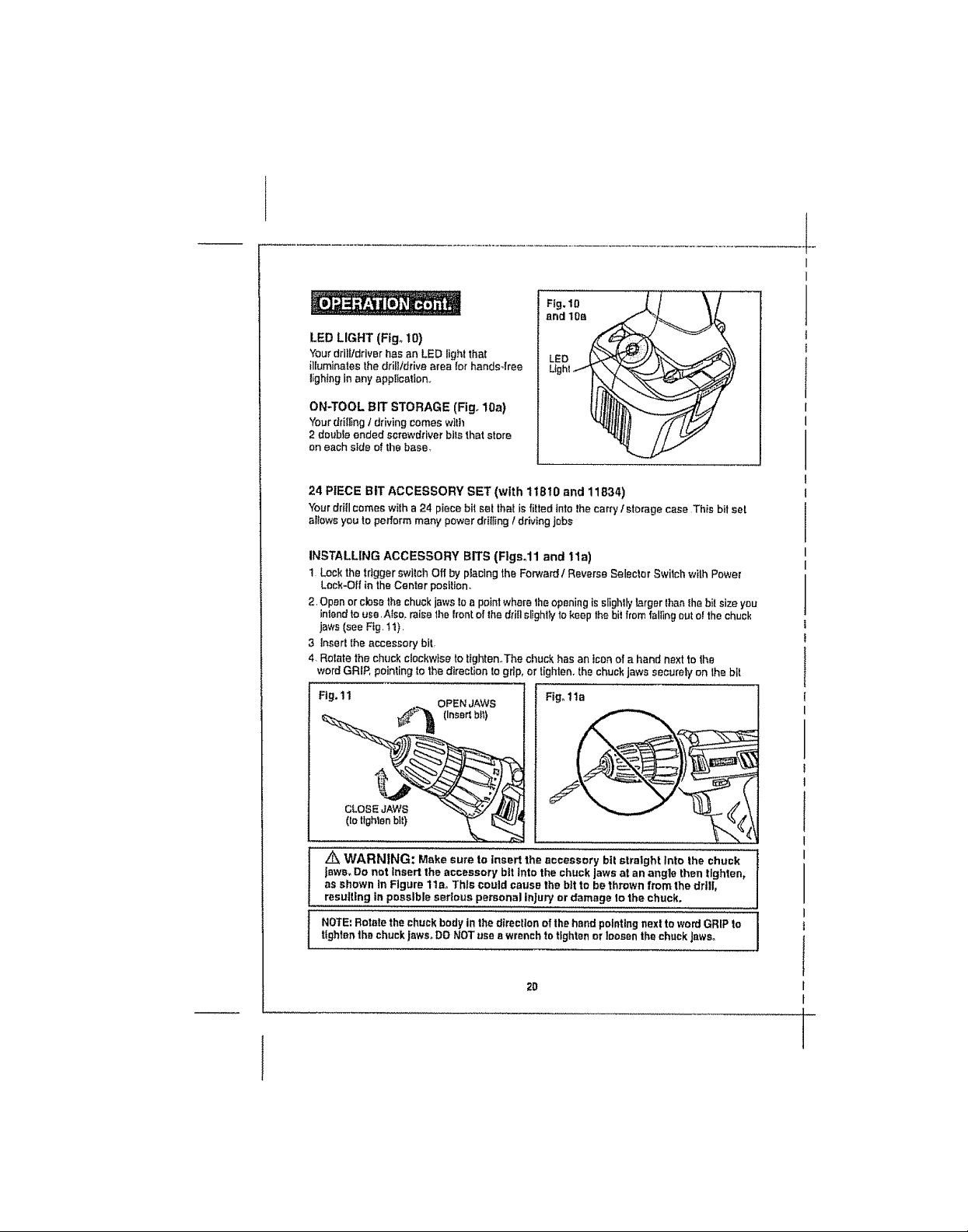

LED LIGHT (Fig. 10)

Yourdrilltdriverhasan LED lightthat

illuminates the driltldrive area ior hands-free

lighlng in any application.,

ON-TOOL BIT STORAGE (Fig, 10a)

YourdrillingI drivingcomeswith

2 double ended screwdriverblls that store

on each side ofthe base_

24 PIECE BIT ACCESSORY SET (with ! t8t0 and 11834)

Your dritl comes with a 24 piece bit set thai is fitted into the carry I storage case Tl_is bil sol

allows you to pedorm many power drilting I driving jobs

INSTALLING ACCESSORY BITS (Flgs.11 and 11a)

t Lock the trigger switch Off by placlng the Forward/Reverse Selector Switch with Power

Lock-Off in the Center position.

2. Open or close the chuck jaws to a point where the opening is slightly larger than lhe bit size you

intend to use .Atso. raise the trent of lhe driil slightly to keep the bff from falling out e! the chuck

jaws (see Fig. tl).

3 inserl the accessory bit

4 Relate the chuck clockwise to tighten.. The chuck has an tcon of a hand next to the

word GRIP, pointing to the dtreclion lo grip, or tighten, the chuck jaws securely on lhe bit

L

I

1

Fig. 11 OPEN JAWS Flg_ 11 a

'_ (Insert bit)

WARNING: Make sure to insert the accessory bit straight Into the chuck

Jaws. Do not Insert the accessory bit into the chuck Jaws at an angle then tighten,

as shown in Flgurs 11a. This could cause the bit to be thrown from the drill,

resulting in posstble serious personal in.fury or damage to the chuck.

NOTE: Rotate the chu_k body in the direction of the hand pointing next to word GRIP to

tighten the chuck jews° DO NOT use e wrench to tfghten or loosen the chuck jaws.

2O

Loading...

Loading...