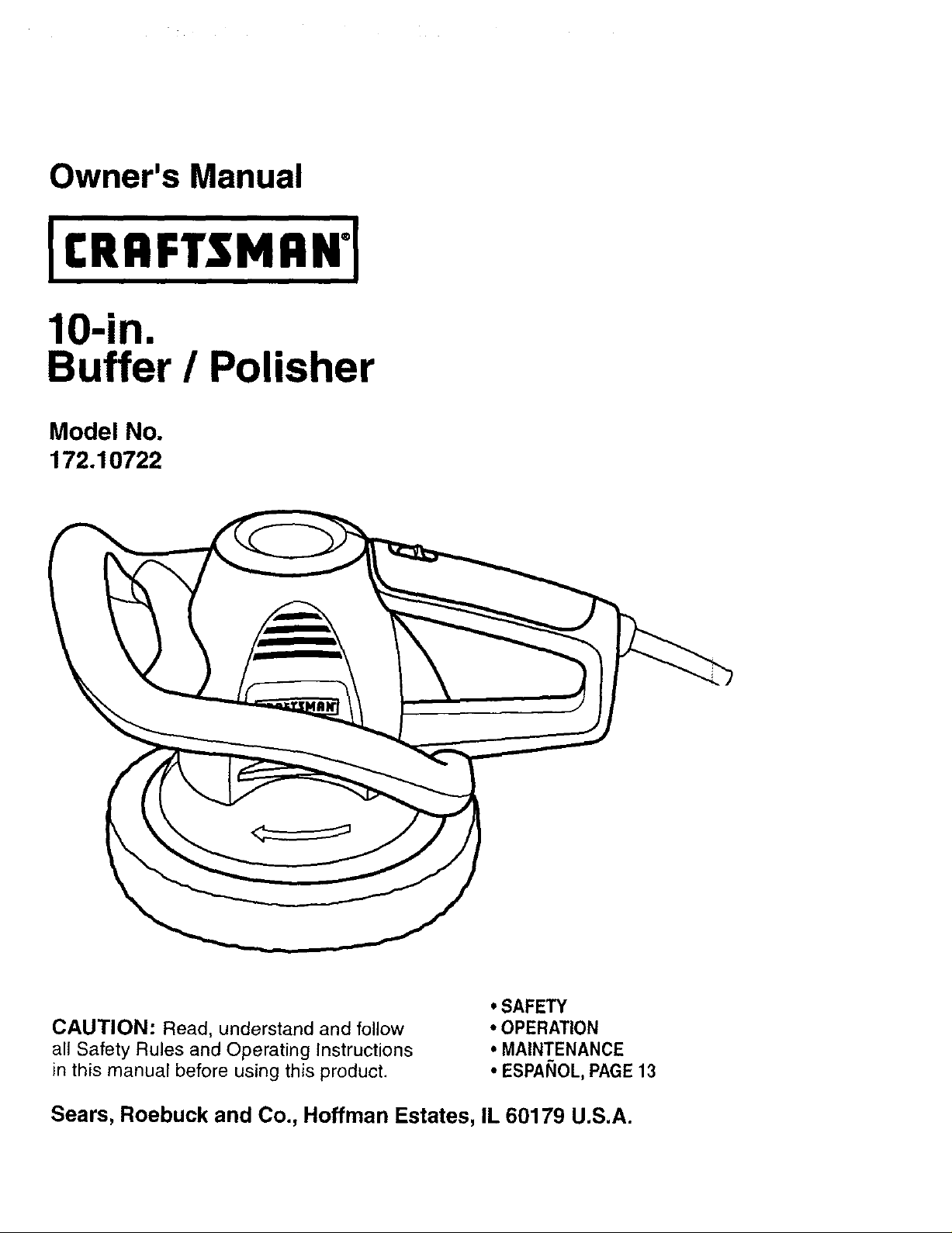

Owner's Manual

lO-in.

Buffer / Polisher

Model No.

172.10722

• SAFETY

CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions

in this manual before using this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

• OPERATION

• MAINTENANCE

• ESPANOL, PAGE 13

Warranty. ............................................................ Page 2

Safety Instructions ........................................... Page 3 - 5

Description ......................................................... Page 6

Operation ....................................................... Pages 7-10

Maintenance ...................................................... Page 11

Accessories ....................................................... Page 11

FULL ONE YEAR WARRANTY ON CRAFTSMAN

BUFFER/POLISHER

If this CRAFTSMAN Buffer/Polisher fails to give complete satisfaction

within one years from the date of purchase, RETURN ITTOTHE

NEAREST SEARS STORE IN THE UNITED STATES, and Sears will

replace it, free of charge.

If this CRAFTSMAN Buffer/Polisher is used for commercial or rental

purposes, this warranty applies for only 90 days from the date

of purchase.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

SAVETHESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

2

to follow all instructions listed below may result in electric shock, fire and/or

I WARNING: BE SURE to read and understand all instructions, Failure I

serious personal injury.

WORK AREA SAFETY

1. ALWAYS keep your work area clean and well lit. Cluttered and dark areas

invite accidents.

2. DO NOT operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. ALWAYS keep bystanders, children and visitors away while operating a

power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

1. Double insulated tools are equipped with a polarized plug (one blade is

wider than the other).This plug will fit in a polarized outlet only one way.

If the plug does not fit fully into the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to install a polarized outlet.

DO NOT change or alter the plug in any way.

2. Double insulation [] eliminates the need for the three wire

grounded power cord and grounded power supply

system. Applicable only to Class II (double insulated) tools.

3. ALWAYS avoid body contact with grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is grounded.

4. DO NOT expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

5. DO NOT abuse the cord, NEVER use the cord to carry the tools or pull

the plug from the outlet. Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords

increase the risk of electric shock.

I

6. When operating a power tool, outside, ALWAYS use an outdoor

extension cord marked "W-A ' or 'W . These cords are rated for outdoor

use and reduce the risk of electric shock.

7. ALWAYS make sure that your extension cord is in good condition. When

using an extension cord be sure to use one that is heavy enough to

carry the current that your tool will draw. A wire gauge (AWG) of at least

14 is recommended for an extension cord 25 feet or less in length. When

working outdoors ALWAYS use an extension cord that is suitable for outdoor

use. The cord's jacket will be marked WA. Smaller gauge wires have

greater capacity (16 gauge wire has more capacity than 18 gauge wire).

An undersized cord will cause a drop in line voltage, resulting in loss of

power and overheating.

3

PERSONAL SAFETY

1. ALWAYS stay alert, watch what you are doing and use common sense

when operating a power tool. DO NOTuse tool while tired or under the

influence of drugs, alcohol or medicabon. A moment of inattention while

operating power tools may result in serious personal injury.

2. ALWAYS dress properly. DO NOT wear loose clothing or jewelry. Pull

back long hair. Keep your hair, clothing and gloves away from moving

parts. Loose clothing, jewelry or long hair can be caught in moving parts.

3. ALWAYS avoid accidental starting. BE SURE switch is in the "Off"

position before plugging in. Carrying tools wi!,hyour finger on the switch or

plugging in tools that have the switch in the "On position invites accidents.

4. DO NOT overreach. ALWAYS keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool in

unexpected situations.

5. ALWAYS use safety equipment. Always wear eye protection.

/_ WARNING: ALWAYS wear safety glasses or eye I

shields when operating power tools.

I

TOOL USE AND CARE SAFETY

1. DO NOT force the tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate forwhich it is

designed.

2. DO NOT use the tool if the switch does not turn it "On" or "Off".

Any tool that cannot be controlled with the switch is dangerous and

must be repaired.

3. ALWAYS disconnect the plug from the power source before making

any adjustments, changing accessories or storing the tool. Such

preventive safety measures reduce the risk of starting the tool accidentally.

4. ALWAYS store idle tools out of the reach of children and other

untrained persons. Tools are dangerous in the hands of untrained users.

5. ALWAYS check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tool's operation.

If damaged, have the tool serviced before using. Many accidents are

caused by poorly maintained tools,

FOR USE WITH THIS TOOL MAY CREATE A HAZARDOUS CONDITION.

I WARNING: USEOFACCESSORIES THAT ARE NOT RECOMMENDED

6. ALWAYS use only the Craftsman accessories that are recommended for

this tool. Accessories that may be suitable for one tool can become

hazardous when used on another tool.

SERVICE SAFETY

1. Tool service MUST BE performed only by a Sears Parts and Repair Center.

Service or maintenance performed by unqualified personnel could result in a

risk of injury.

2. When servicing a tool, ALWAYS use only identical replacement parts.

Follow instructions in the maintenance section of this manual. Use of

unauthorized parts may create a risk of electric shock or injury.

IMPORTANT! READ ALL INSTRUCTIONS

5

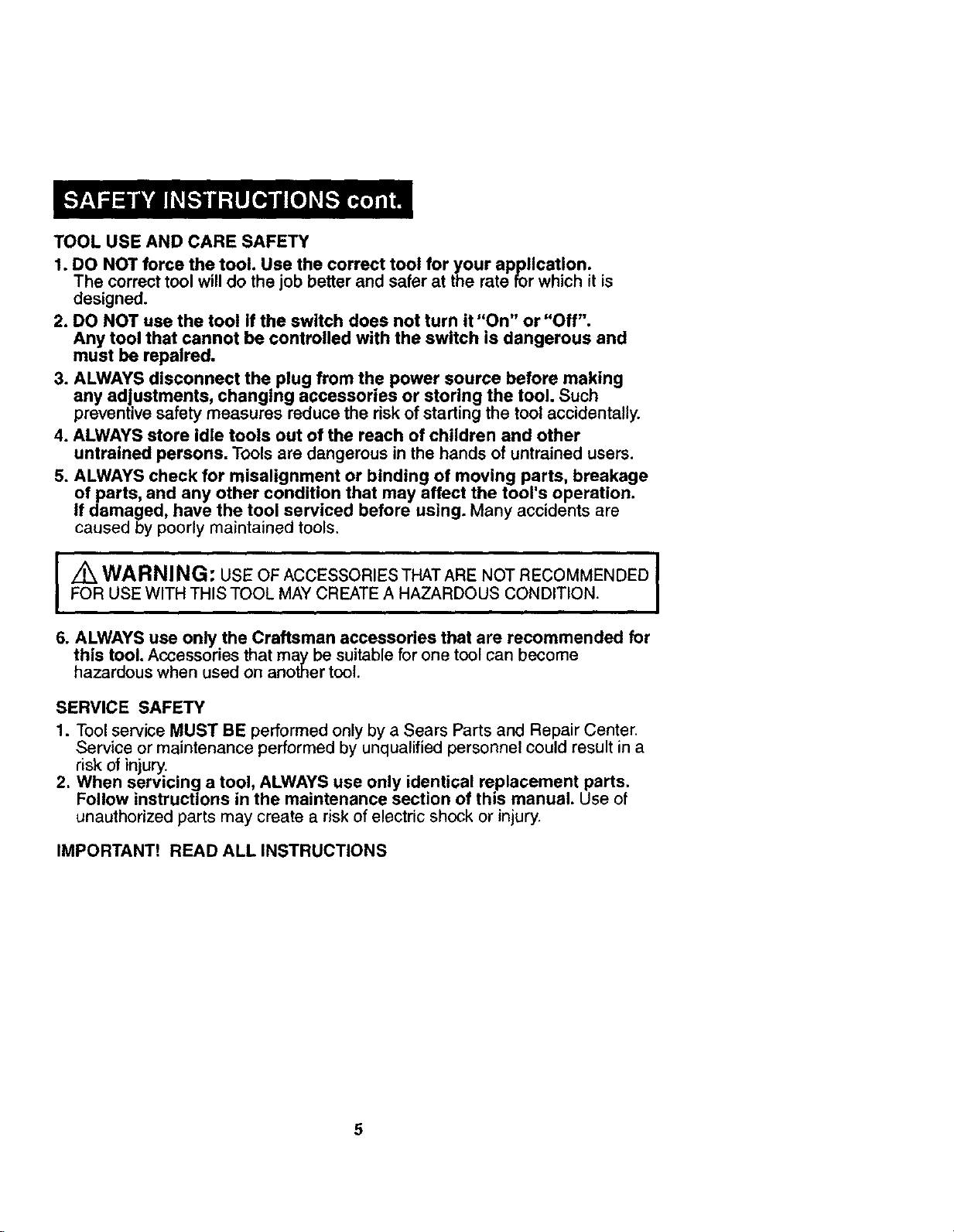

Your Craftsman Buffer/Polisher has built-in features to make yourjob easier

and more effic!ent. Theprecision-tuned counterweight system matches with

the orbital motion for a "swirl-free shine. The perimeter handle system provides

maximum balance, control and gripping comfort on any horizontal or vertical

surface. It also includes a hook and loop strip to help keep extension cord

securely plugged into buffer/polisher.

Perimeter Non-marring Top Cap Fig. 1

HandleSystem On/Off

Slide Switch

Stub Lengh

Cord

Hookand

LoopStrip

-- Foam Pad

Pad Diameter

Motor OPM 2800

Rating 120 volts, 60 Hz AC

Amps 1.1

Disposable Wax Applicator Bonnet for applying waxes

Reusable Terry Cloth Bonnet for applying and removing waxes,

and for polishing

Reusable Polishing Bonnets for final buffing and polishing to a

"Showroom" shine

6

BEFORE YOU BEGIN TO WAX, BUFF AND POLISH YOUR CAR:

1. Wash, clean and dry your vehicle.

2. Remove all road tar, excess grease spots and bug stains with a

general-purpose cleaner.

3. Make sure the work area is dry.

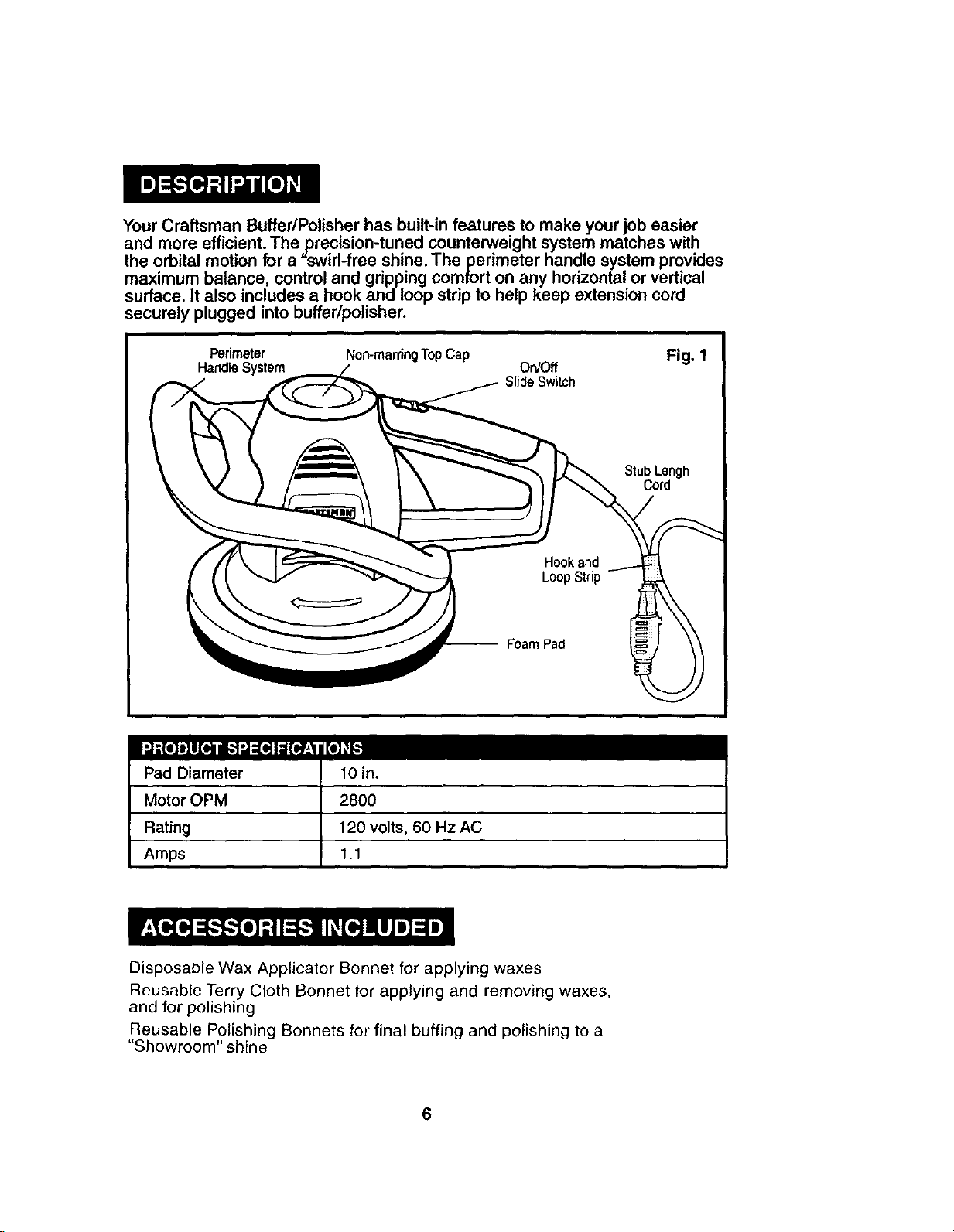

ATTACHING THE WAX APPLICATOR BONNET TO THE FOAM PAD

(See Figure 2)

WARNING: When changing accessories,

BE SURE that the switch is in the (OFF)

position and the cord is unplugged.

1. Place wax applicator bonnet on foam pad

as shown in Fig. 2.

2. ALWAYS make sure that the elastic strip

on the bottom of the bonnet is securely

tucked on the underside of the foam pad.

APPLYING WAX TO BONNET (See Figures 3 and 4)

IMPORTANT: DO NOT APPLY WAX

DIRECTLY ON CARt

APPLYING PASTE WAX TO BONNET

(See Figure 3)

1. Spread a heaping teaspoon of wax

evenly over entire surface of applicator

bonnet using a putty knife or any other

flat object (See Fig. 3).

Fig.

APPLYING LIQUID WAXTO BONNET

(See Figure 4)

1. Apply three swirls of wax over applicator

bonnet (See Fig. 4).

2. This should be enough to cover 1/4 of

car surface.

3. For the second and third applications,

only use about one half as much as on

first application. The bonnet will not

absorb as much wax on these

applications.

7

Fig._

TOTURNBUFFER/POLISHER"ON" OR "OFF"

Slide switch forward to turn tool "On",

slide it backwards to shut tool "Off".

NOTE: After plugging tool into extension

cord, loop extension cord over tool's stub

length plug. Then wrap hook and loop strip

around extension cord to secure it in place.

IMPORTANT; Read, understand and follow

all safety and user instructions in this

manual and all directions and warnings on

polishes and waxes.

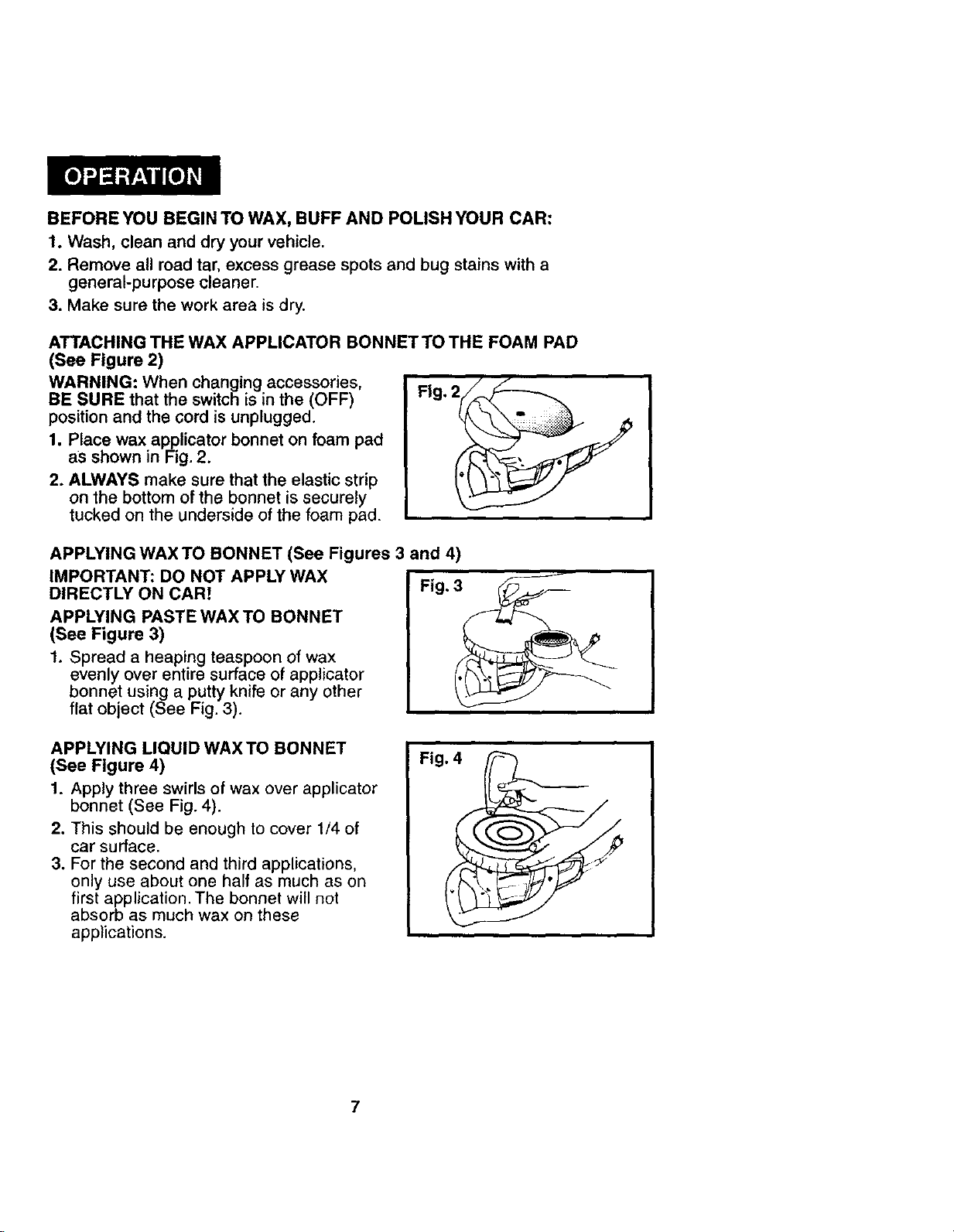

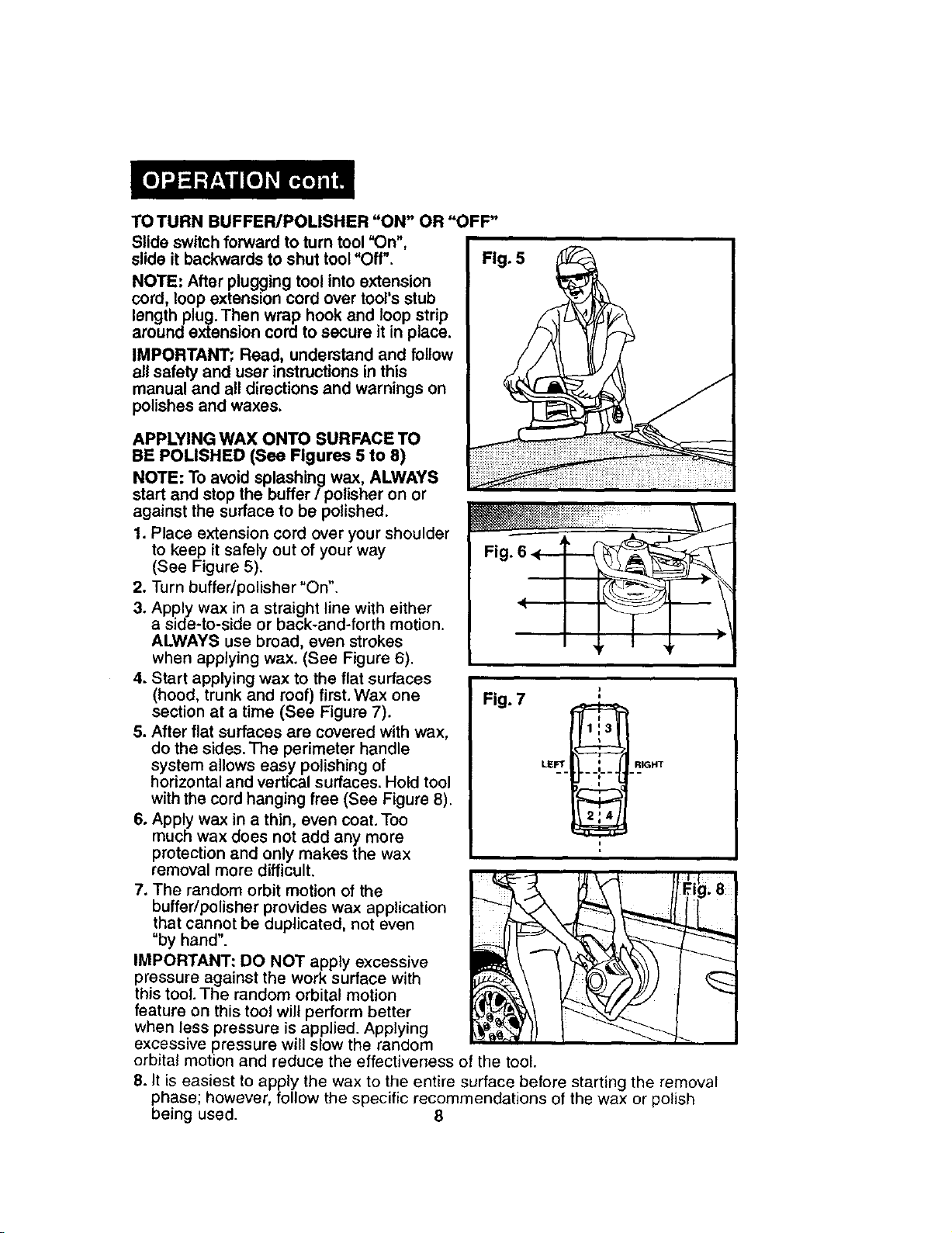

APPLYING WAX ONTO SURFACE TO

BE POLISHED (See Figures 5 to 8)

NOTE: To avoid splashinc wax, ALWAYS

start and stop the buffer / polisher on or

against the surface to be )olished.

1. Place extension cord over your shoulder

to keep it safely out of your way

(See Figure 5).

2. Turn buffer/polisher "On".

3. Apply wax in a straight line with either

a side-to-side or back-and-forth motion.

ALWAYS use broad, even strokes

when applying wax. (See Figure 6).

4. Start applying wax to the flat surfaces

(hood, trunk and roof) first. Wax one

section at a time (See Figure 7).

5. After flat surfaces are covered with wax,

do the sides. The perimeter handle

system allows easy polishing of

horizontal and vertical surfaces. Hold tool

with the cord hanging free (See Figure 8).

6. Apply wax in a thin, even coat, Too

much wax does not add any more

protection and only makes the wax

removal more difficult.

7. The random orbit motion of the

buffer/polisher provides wax application

that cannot be duplicated, not even

"by hand".

IMPORTANT: DO NOT apply excessive

pressure against the work surface with

this tool. The random orbital motion

feature on this tool will perform better

when less pressure is applied. Applying

excessive pressure will slow the random

orbital motion and reduce the effectiveness of the tool.

8. It is easiest to apply the wax to the entire surface before starting the removal

phase; however, fellow the specific recommendations of the wax or polish

being used. 8

Fig. 5

Fig. 6 ,<---

Fig. 7

I1!3

LEF'3" ' RIGHT

..... I_ ....

I

>

APPLYING WAX ONTO SURFACE TO BE POLISHED cont. (See Figure 9)

9. Shut "Off" the buffer/polisher when

you have finished applying wax with

applicator bonnet.

10. Remove the wax applicator bonnet

and use it to hand polish all the

hard-to-reach surfaces (under

bumpers, around door handles, etc.).

(See Figure 9,)

11. Properly dispose of wax applicator

bonnet,

ATTACHING THE POLISHING BONNETTO THE FOAM PAD

(See Figure 10)

WARNING: When changing accessories,

BE SURE that the switch is in the

(OFF) position and the cord is unplugged.

1. Place the terry cloth bonnet on foam

pad as shown in Fig. 10.

2. ALWAYS make sure that the elastic

strip on the bottom of the bonnet is

securely tucked on the underside of the

foam pad.

BUFFING AND POLISHING - REMOVING THE WAX FROM THE SURFACE

(See Figure 11)

NOTE: Remove wax in the same order

as it was applied.

1. Place extension cord over your shoulder,

2. Turn buffer/polisher "On".

3. Buff and polish (remove wax) when it

has dried to an even haze.

NOTE: For best results, use long,

sweeping strokes in a criss-cross pattern

when removing wax.

4. Buff and polish the entire surface until all dried wax is removed. Remove the

bonnet from time to time and shake out the dried wax residue. A bonnet with

excess residue will cause streaking. You may need to replace the bonnet with

a new one if you can t get it clean enough to avoid streaking.

5. Use a clean terry cloth bonnet for final buffing and polishing. Or use a foam

polishing bonnet (sold separately) for the ultimate "showroom" shine

9

IMPORTANT: DO NOT apply excessive pressure against the work surface with

this tool. The random orbital motion feature on this tool will perform better when

less pressure is applied. Applyingexcessive pressure will slowthe random

orbiting motion and reduce the effectiveness of the tool.

CAR CARE TIPS

1. Wash and polish the car 3 to 4 times a year to help ensure paint protection.

2. Wash the car at least every 2 weeks with a car wash solution which will not

harm the finish or strip the wax. AVOID washing with household detergents.

3. Wash with a clean sponge and dry with a terry cloth towel to help prevent

dirt from scratching the paint. Start on the top and work down.

4. Remove bugs, bird droppings, tree sap and tar from the car's surface on a

daily basis.

5. ALWAYS make sure that the car's surface is cool before washing.

6. Avoid parking near sprinklers, because water spots are difficult to remove.

7. ALWAYS keep glass cleaner chemicals away from painted surfaces.

Spray the cleaner onto a towel, NOT directly on the windows.

10

1. Terry cloth bonnets can be machined washed in cold water, using a small

amount of detergent. Then machine dried at medium temperature.

HOWEVER, we recommend hand washing and air drying for longer

bonnet life.

2. Wax applicator bonnets should only be used once, and then disposed

of properly.

3. To prolong the life of the foam pad, ALWAYS store the buffer/polisher with

the pad face up.

4. Remove the bonnet from the foam pad when the buffer/polisher is not in use,

so the pad can dry out and retain its original shape.

5. DO NOT USE ABRASIVE COMPOUNDS WITH THIS TOOL.

6. DO NOT apply too much wax to the bonnet. Applying too much wax causes

the bonnet to become saturated and it will not last as long. THIS MAKES

POLISHING MORE DIFFICULT AND IT TAKES LONGER.

7. If the bonnet is continually coming off the pad, you may be using too much

wax.

8. If buffing seems difficult, you have used too much wax,

9. ONLY USE a mild soap solution and a damp sponge to clean the

buffer / polisher.

10. DO NOT immerse any part of the buffer / polisher in liquid.

Look for these Craftsman accessories, they are specially designed to make

your 10-in. Buffer/Polisher more efficient to use. Accessories are available at

your local Sears store or other Craftsman outlet.

Wax Applicator Bonnets

For applying waxes and polishes

Terry Cloth Bonnets

Use for removing wax and for buffing and polishing

Polishing Bonnets

For final buffing and polishing to a "showroom shine"

Quality Waxes

For the finest protection and appearance

CAUTION: ALWAYS remove accessories from tool before washing them.

11

NOTES

12

Manual del Usuario

Enceradora / Pulidora

de 10 pulgadas.

Modelo No.

172.10722

ATENCION: Antes de usar este proclucto, lea,

comprenda y siga todas las reglas de seguridad

y las instrucciones de funcionamiento incluidas

en este manual.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

• SEGURIDAD

• FUNCIONAMIENTO

• MANTENIMIENTO

Garantfa ................................................................ Page 14

Instrucciones de Seguridad ................................ Page 15-17

Descripci6n ............................................................ Page 18

Funcionamiento ................................................. Pages 19-22

Mantenimiento ....................................................... Page 23

Accesorios ............................................................. Page 23

GARANTIA COMPLETA DE UN AI_O DE LA

ENCERADORA/PULIDORA CRAFTSMAN

Siesta enceradora/pulidora CRAFTSMAN no le otorga completa

satisfacci6n dentro de un afio de la fecha de compra,

DEVUELVALA AL ALMACEN SEARS MAS CERCANO EN LOS

ESTADOS UNIDOS y Sears la reemplazar_ gratuitamente.

Siesta enceradora/pulidora CRAFTSMAN se usa para prop6sitos

comerciales o de arriendo, esta garantfa es vdlida solamente durante

90 dfas desde la fecha de compra.

Esta garantfa le otorga derechos legales especfficos y usted ademas

puede tener otros derechos que varfan de un estado a otto.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

iCONSERVE ESTAS INSTRUCCIONES!

iLEATODAS LAS INSTRUCCIONES!

14

instrucciones. El incumplimiento de todas las instrucciones indicadas a

I ADVERTENCIA: ASEGURESE de leer y comprender todas las

continuaci6n puede resuitar en choque el_ctrico, incendio y/o lesi6n personal grave.

SEGURIDAD EN EL LUGAR DETRABAJO

1. SIEMPRE mantenga el lugar de trabajo limpio y bien iluminado. Los bancos

de trabajo desordenados y la falta de iluminaci6n favorecen los accidentes.

2. NO utilice las herramlentas el_ctricas en atm6sferas explosivas, tal eomo

en presencla de Ifquidos Inflamables, gases o polvo, l_as herramientas

el_ctricas crean chispas que pueden inflamar el polvo o los vapores

3. SIEMPRE mantenga a los espectadores, nlfios o vlsitantes a una

dtstancia prudente cuando est6 utilizando una herramlenta el_ctrica.

Las distracciones pueden hacerle perder el control.

SEGURIDAD ELECTRICA

1. Las herramientas con aislamiento doble estdn equipadas con un

enchufe polarizado (una hoja de contacto es mas ancha que la otra.)

Este enchufe puede colocarse en un tomacorriente polarizado en una

sola direcci6n. Si el enchufe no calza bien en el tomacorriente, invlerta

el enchufe. Si todavfa no calza, p6ngase en contacto con un electricista

calificado para que instale un tomacorriente polarizado. NO modifique

el enchufe de ninguna manera.

2. El [] de aislamiento doble elimina la necesidad del cord6n el6ctrico trifilar

puesto a tierra y del sistema de alimentaci6n de energia puesto a tierra.

Aplicable solamente a las herramientas de la Ctase II (con aislamiento doble).

3. SIEMPRE evite ¢ontacto del cuerpo con las superficies puestas a tierra,

tal eomo tuberias, radiadores, estufas y refrigeradores. Existe mayor

riesgo de sufrir choque el6ctrico si su cuerpo est_ a tierra,

4. No exponga las herramientas el6ctricas a la Iluvia ni a ambientes

hOmedos. Si penetra agua a una herramienta el_ctrica, se aumenta el

riesgo de sufrir un choque el6ctrico.

5. NO abuse del cordon el6ctrico. NUNCA tire del cord6n para transportar

ni para desenchufer las herramientas. Mantenga el cordbn alejado del

calor, del aceite, hordes afilados o piezas m6viles. Reemplace

inmediatamente los cordones que est6n dafiados. Los cordones dahados

aumentan el riesgo de sufrir un choque el0ctrico.

6. Cuando utilice una herramienta el6ctrica al aire libre, SIEMPRE use un

cord6n de extensi6n marcado "W-A" o "W". Estos cordones estan

aprobados para uso al alre fibre y reducen el riesgo de choque el6ctrico,

7, SIEMPRE asegfirese de que el cord6n de extensi6n est6 en buen estado.

Cuando use un cord6n de extensi6n asegl_rese de usar uno cuyo

calibre sea suficiente para portar la corriente que necesita su

herramienta. Se recomienda un cord6n de extensi6n de por Io menos calibre

14 (AWG) para un cord6n de extensi6n de 25 pies o menos de largo. Cuando

trabaje al aire Iibre SlEMPRE use un cord6n de extensi6n adecuado para uso

al alre libre, El forro del cord6n estarzi marcado WA. Mientras rods pequefio

es el n6mero del calibre, mayor es la capacidad del cordbn (un cord6n

de calibre 16 tiene mayor capacidad que un cord6n de calibre 18).

Un cord6n de calibre inferior causar_ una perdida en el voltaje de Iinea

resultando en perdida de potencia y sobrecalentamiento,

15

SEGURIDAD PERSONAL

1, SIEMPRE mant_ngase alerta, observe Io que est,, haciendo y use

sentido comun cuando est6 usando una herramlenta el6ctrica. NO use

la herramienta cuando estd cansado o bajo la infiuencia de drogas,

alcohol o medicinas. Un momento de distracci6n cuando estd trabajando

con las herramientas eldctricas, puede ocasionar una lesi6n personal grave.

2. SIEMPRE use vestimenta adecuada. NO use ropas sueltas ni joyas.

Atese el cabello largo. Mantenga su cabello, ropas y guantes alejados

de las plezas m6viles. Las ropas sueltas, las joyas o el cabello largo pueden

quedar atrapados en las piezas m6viles.

3. SIEMPRE evite la puesta en marcha accidental. ASEGURESE de que el

interruptor est6 en la posiclon "Off" (apagado) antes de enchufar la

herramlenta. Si transporta la herramienta con su dedo en el interruptor o si

enchufa la herramienta con el interruptor en la posici6n "On" (encendido)

causard algmlnaccidente,

4. NO use la herramienta a una distancia demas!ado alejada. SIEMPRE

mantenga un buen equilibrio y una posici6n firme. El buen equilibfio y

una posici6n firme permiten controlar mejor la herramienta en situaciones

inesperadas,

5. SIEMPRE use equipo de seguridad. Siempre use lentes protectores.

ADVERTENCIA: SIEMPRE use lentes

protectores o gafas con protecci6n lateral cuando trabaje

con herrarnientas electricas.

16

USOY CUIDADODELAS HERRAMIENTAS

1. NO fuerce la herramlenta. Use la herramienta correcta para el traba|o

que estd realizando. La herramienta correcta realizard el trabajo mejor y de

manera rods segura si se usa a la velocidad para la cual ha sido diseSada.

2. NO use la herram|enta si el interruptor no funclona debidamente,

Es peligroso si la herramienta no puede set controlada con el interruptor y

por Io tanto debe set reparada.

3. SIEMPRE desenchufe la herram|enta antes de hacer algdn ajuste,

camblar accesorios o guardarla. Estas medidas preventivas de seguridad

reducen el riesgo de que la herramienta se ponga en marcha accidentalmente.

4. SIEMPRE guarde las herramlentas que no use lejos del alcance de los

nl_os y de otras personas inexpertas. Las herramientas son peligrosas en

manos de personas inexpertas.

5. SIEMPRE verifique el alineamiento de las piezas m6viles, si estdn

atascadas o si hay rotura de piezas y cualquier otro estado que pueda

afectar su funcionamiento. Si se da_a, haga reparar la herramienta

antes de usarla. Muchos accidentes son causados per herramientas

mantenidas en mal estado.

ADVERTENCIA: EL USO DE ACCESORIOS QUE NO HAN SIDO I

RECOMENDADOS PARA USAR CON ESTA HERRAMIENTA PUEDE CREAR

UNA SITUACION DE PELIGRO.

6. SIEMPRE use solamente los accesorios Craftsman que se recomiendan

para esta herramienta. Los accesorios que pueden ser adecuados para una

herramienta pueden ser peligrosos cuando se usan en otra herramienta.

I

I

SEGURIDAD SOBRE LAS REPARACIONES

1. La reparacibn de las herramientas DEBE SER efectuada solamente por un

Centro de Repuestos y Reparaci6n Sears. La reparaci6n o rnantenimiento

efectuado por personal no especializado puede causar una lesi6n.

2. Cuando efectde reparaciones en una herramienta, SIEMPRE use

solamente repuestos legftimos. Siga las instrucciones indicadas en la

secci6n Mantenimiento de este manual. El uso de repuestos no autorizados

puede crear un riesgo de choque electrico o lesi6n.

ilMPORTANTE! LEA TODAS LAS INSTRUCCIONES

17

Suenceradora/pulidoraCraftsmantiene caracteristicas incorporadas que

facilitan y hacen mds eficiente su trabajo. El sistema de contrapeso ajustado a

precisi6n armoniza con el movimiento orbital Iogrando un briUo "sin remolinos".

El sistema de empuSadura alrededor del perimetro proporciona m_,ximo

equilibrio y control, y permite poder sujetarla con comodidad en cualquier

superficie horizontal o verti,cakTambi_n incluye una cinta autoadherente para

ayudar a mantener el cordon de extensi6n firmemente enchufado en la

enceradora/pulidora.

SisternadeEmpuSadura

alrededordelperimetro

Didmetm del Disco

Motor (Orb. por Min.)

Potencia Nominal

DiscodeMontaje Fig. 1

deEspuma On/Off'

Cable

El_=ctrico

Corto

CJnta

Auloadherente _

--Disco de Espuma k k_

10 pulg.

2800

120 voltios, 60 Hz CA

Amps

Bonete aplicador de cera desechable para aplicar ceras

Bonete de tela de toalla reusable para aplicar y retirar ceras y pulido final

Bonetes pulidores reusables para lustrado y pulido final y Iograr un brillo de

"sala de exposici6n"

1,1

18

ANTES DE COMENZAR A PASAR LA CERA, LUSTRE Y PULA SU

AUTOMOVIL:

1. Lave, limpie y seque su vehiculo.

2. Retire todo el alquitrdn proveniente del camino, rnanchas de grasa y

manchas de insectos con un limpiador para todo uso.

3. AsegLirese de que el drea de trabajo est_ seca,

INSTALACION DEL BONETE APLICADOR DE CERA EN EL DISCO

DE ESPUMA (Ver Figura 2)

ADVERTENCIA: Cuando cambie accesorios,

ASEGURESE de que el interruptor este en

la posici6n ('OFF') (Apagado) y que el

cord6n electrico estd desenchufado,

1. Coloque el bonete aplicador de cera en el

disco de espuma como se muestra en la

Fig. 2.

2. SIEMPRE asegerese de que el eldstico

Fig. 2 .

que se encuentra en la parte inferior del bonete est_ firmemente insertado

en el lado inferior del disco de espuma.

APLICACION DE LA CERA EN EL BONETE (Ver Figuras 3 y 4)

IMPORTANTE: iNO APLIQUE_ LA CERA

DIRECTAMENTE EN EL VEHICULO[

APLICACION DE CERA EN PASTA EN EL

BONETE (Ver Figura 3)

1. Extienda una cucharadita Ilena de cera

uniformemente sobre toda la superficie del

bonete aplicador usando una espatula o

cualquier otro objeto piano (Ver Fig. 3),

APLICACION DE CERA LIQUIDA EN EL

BONETE (Ver Figura 4)

1. Aplique tres espirales de cera en el

bonete aplicador (Ver Fig. 4).

2. Esta cantidad serfa suficiente para cubrir

1/4 de la superficie del vehl'culo.

3. Para la segunda y tercera aplicaci6n, use

solamente aproximadamente la mitad de

Io que uso en la primera aplicaci6n.

El bonete ya no absorbera tanta cantidad

de cera en estas ultimas aplicaciones

19

Fig. 4

PARA ENCENDER ("ON") O APAGAR ("OFF") LA ENCERADORA/PULIDORA

Deslice el interrupter hacia adelante a la posici6n

"On" para encender la hen'a.mienta, deslfcelo

hacia atrds la posici6n "Off para apagar la

herramienta.

NOTA: Despu6s de enchufar la herramienta en

el cord6n de extensi6n, entrelace el cord6n de

extensi6n en el enchufe del cable el_ctrico corto

de la herramienta. Luego enrolle la cinta

autoadherente alrededor del cord6n de extensi6n

para asegurarlo en su lugar.

IMPORTANTE: Lea, comprenda y siga todas las

instrucciones de seguridad y del usuario

indicadas en este manual y todas las

instrucciones de use y advertencias sobre los

pulidores y ceras.

APLICACION DE LA CERA EN LA SUPERFICE

QUE VA A SER PULIDA (Ver Figuras 5 a 8)

NOTA: A fin de evitar salpicaduras de cera,

SIEMPRE encienda y apague la

enceradora/pulidora manteni6ndola sobre o

contra la superficie que estd siendo pulida.

1. Coloque el cord6n de extensi6n sobre su

hombre (Ver Figura 5).

2. Encienda la enceradora/pulidora.

3. Aplique la cera en Ifnea recta con movimiento

_a sea de lade a lade o de atrds hacia adelante.

uando aplique la cera SIEMPRE use pasadas

amplias y uniformes (Ver Figura 6).

4. Comience aplicando primero cera en las

superficies planas (cap6, portaequipajes

y techo). Encere de una secci6n a la vez

(Vet Figura 7).

5. Despu_s de que todas las superficies planas

est_n cubiertas con cera, siga con los costados.

El sistema de empui_adura alrededor del

perfmetro le permite pulir con facilidad las

superficies horizontales y verticales. Sostenga

la herramienta dejando colgar el cord6n

electrico. (Ver Figura 8).

6. AplJque la cera en forma de una capa delgada

y uniforme. Si coloca demasiada cera no est,1

agregando m_s protecci6n y adem_s despu6s es m_ls diffcil retirarla

7. El movimiento orbital aleatoric de la enceradera/pulidora permite una perfecta

aplicaci6n de la cera, Io cual no Iograria ni ann si la aplicara a mane'.

IMPORTANTE: Con esta herramienta NO es necesario aplicar presi6n excesiva

contra la superfieie de trabajo. El movJmiento orbital aleatoric de esta herramienta

funciona meier cuando se aplica menos presi6n. Si se aplica presion excesiva se

har_l mas lento el movimiento orbital aleatoric y se reducir& la eficacia de la

herramienta.

8. Es preferible aplicar la cera sobre toda la superficie antes de comenzar lafase

de remoci6n; sin embargo, siga las recomendaciones especfficas de la cera o

puliclor que est_ siendo usada. 20

÷

Fig. 7

uK, ...!. ._.r

_'ti3

1,

APLICACION DE LA CERA EN LA SUPERFICIE OUE SERA PULIDA

(Ver Figura 9)

9. Apague la lustradora/pulidora cuando

haya terminado de aplicar la cera con

el bonete aplicador.

10. Retire el bonete aplicador de cera y

(Jselo para pulir a mano aquellas

superficies que son diffciles de alcanzai

(debajo de los parachoques, alrededor

de las manijas de las puertas, etc.).

(Ver Figura 9.)

11. Descarte et bonete aplicador de

cera de manera apropriada.

INSTALACION DEL BONETE PULIDOR EN EL DISCO DE ESPUMA

(Ver Figura 10)

ADVERTENClA: Cuando cambie

accesorios, ASEGURESE de que el

/, ___ Fig. 10

interrupter est_ en la posici6n (OFF')

(Apagado) y que el cord6n electrico estb

desenchufado.

1. Coloque el bonete de tela de toalla en

el disco de espuma como se muestra

en la Fig. 10.

2. SIEMPRE asegL_rese de que el elastico

que se encuentra en la parte inferior del

bonete est_ firmemente insertado en el lado inferior del disco de espuma.

LUSTRADO Y PULIDO - REMOCION DE LA CERA DE LA SUPERFICIE

(Ver Figura 11)

NOTA: Retire la cera en el mismo orden

en que fu_ aplicada.

1, Coloque el cord6n de extensi6n sobre

su hombro.

2. Encienda la enceradoraJpulidora.

3. Lustre y pula (retire la cera) cuando la

cera se haya secado y tenga la

apariencia de una bruma uniforme,

NOTA: Para obtener mejores resultados,

use pasadas entreoruzadas largas y amplias para sacar la cera.

4. Lustre y pula toda la superficie hasta que se haya sacado toda la cera seca.

De vez en cuando retire el bonete y sac6dalo para desprender los residuos

de cera seca, Un bonete que tenga demasiados residuos causar& veteado.

Puede que sea necesario cambiar el bonete por uno nuevo si no puede

limpiarlo bien de manera que no cleje marcas.

5. Use un bonete de tela de toalla para el lustrado y pulido final. O use un

bonete pulidor de cera (vendido por separado) para obtener el brillo final de

"sala de exposici6n".

21

IMPORTANTE: Con esta herramienta NO es necesario aplicar presi6n

excesiva contra la superficie de trabajo. El movimiento orbital aleatorio de esta

herramienta funciona mejorcuando se aplica menos presibn. Si se aplica

presibn excesiva se har& mas lento el movimiento orbital aleatorio y se

reducir& la efieacia de la herramienta.

CONSEJOS PARA EL CUIDADO DEL AUTOMOVIL

1. Lave y pula el autom6vil 3 a 4 veces al aSo para proteger la pintura.

2. Lave el autombvil pot Io menos cada 2 semanas con una solucibn de lavar

autos que no daSe el acabado ni extraiga la cera. EVITE usar detergentes

domdsticos para lavar el autom6vil.

3. Lave con una esponja limpia y seque con una toalla para evitar que la

suciedad raspe la pintum. Comience en la parte superior y siga hacia abajo.

4. Limpie diariamente los insectos, suciedad de pajaros, sabia de arboles y

alquitr_n de la superficie del autom6vil.

5. SIEMPRE asegt_rese de que la superficie del autom6vil este fria antes de

lavarlo.

6. Evite estacionar cerca de rociadores de cespecl pues las manchas de agua

son dificiles de quitaro.

7. SIEMPRE mantenga los productos quimicos de limpiar vidrios alejados de

las superficies pintadas° Rocie el limpiador en una toalla, NO directamente

en las ventanas.

22

1. Los bonetes de tela de toalla pueden ser lavados en la lavadora en agua

frfa, usando una pequeSa cantidad de detergente. Despues sequelos en la

secadora usando temperatura mediana. SIN EMBARGO, recomendamos

que se laven a mano y se sequen al aire para prolongar la vida _til del

bonete.

2. Los bonetes aplicadores de cera deben ser usados solamente una vez y

luego descartarlos de manera apropiada.

3. Para prolongar la duraciSn del disco de espuma, SIEMPRE guarde la

enceradora/pulidora con el disco hacia arriba.

4. Retire el bonete del disco de espuma cuando la enceradora/pulidora no

est_ en uso, de manera que el disco se pueda secar y retener su forma

original.

5. NO USE COMPUESTOS ABRASIVOS CON ESTA HERRAMIENTAo

6. NO aplique demasiada cera en el bonete. Si aplica demasiada cera el

bonete puede saturarse y no durara mucho. ESTO HARA MAS DIFIClL EL

PULIDOY DEMORARA MASTIEMPO EN HACERLO.

7. Si el bonete se sale a menudo del disco, puede que est6 usando

demasiada cera.

8. Si es dificil lustrar ia superficie puede que haya usado demasiada cera.

9. USE SOLAMENTE una solucion con jabon suave y una esponja mojada

para limpiar la enceradora/pulidora.

10. NO sumerja ninguna pieza de la enceradora/pulidora en ningt_n liquido.

Busque estos accesorios Craftsman; han sido diseSados especialmente para

aumentar la eficiencia de su enceradoraJpulidora de 10 pulg. Los accesorios

est&n disponibles en su Almac_n Sears local o en cualquier otro almacen que

distribuya productos Craftsman.

Bonetes Aplicadores de Cera

Para aplicar cera y pulidores

Bonetes de Tela de Toalla

Para retirar la cera, lustrar y pulir

Bonetes Pulidores

Para el lustrado y pulido final y obtener un brillo de "sala de exposicion"

Ceras de Calidad

Para una mejor proteccion y apariencia

ATENClON: SlEMPRE retire los accesorios de la herramienta antes de lavarlos.

23

iiii!i_i!ili!_!

Your Home

Forrepair in your home of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters,

1-800-4-MY-HOME ® Anytime,day ornight

(1-800-469-4663) (U.S.A.and Canada)

www.sears.com www,sears.ca

Our Home

::::.:,::

For repair of carry-in products like vacuums, lawn equipment,

and electronics, call or go on-line for the nearest

Sears Parts and Repair Center.

1-800-488-1222 Anytime, day or night (U.S.A. only)

www.sears.com

To purchase a protectionagreement (U.S.A.) ormaintenance

agreement (Canada) on a product serviced by Sears:

1-800-827-6655 (u.s._.)

Parepedir servicio de reparaci6n

a domicilio,y paraordenarpiezas:

1-888-SU-HOGAR s_

(1-888-784-6427)

© Sea_s,Fk_bu_ and Co.

® Registered Trademark / TMTrademark / s_ Service Mark of Sears, Roebuck and Co.

® Marca Registrada / TMMarca de F. brica / su Marca de Servicio de Sears, Roebuck and Co.

uc Marque de commerce / _o Marque deposee de Sears, Roebuck and Co.

1-800-361-6665 (Canada)

Au Canada pour service enfran_:.,ais:

1-800-LE-FOYERMc

(1-800-533-6937)

www.sears.oa

i

Loading...

Loading...