Page 1

Owner's Manual

®

7-in.

Buffer / Polisher

Model No.

172.107210

CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions

in this manual before using this product.

Sears Brands Management Corporation,

Hoffman Estates, IL 60179 U.S.A.

www.sears.com

3025736

Double Insulated

WARRANTY

•

SAFETY

•

UNPACKING

•

DESCRIPTION

•

OPERATION

•

MAINTENANCE

•

ACCESSORIES

•

7/11/12

Page 2

TABLE OF CONTENTS

SAFETY SYMBOLS

Warranty.........................................................................Page 2

Safety Symbols

...............………….................................

Page 3

Safety Instructions...............…………............................Pages 4 - 8

Unpacking......................................................................Page 9

Description.....................................................................Page 10

Operation...................…………………...........................Pages 11 - 15

Maintenance..................................................................Page 15

Accessories

CRAFTSMAN ONE YEAR LIMITED WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted

against any defects in material or workmanship. With proof of purchase,

a defective product will be replaced free of charge.

For warranty coverage details to obtain free replacement, visit the web site:

www.craftsman.com

This warranty does not cover the bonnets, which are expendable parts that

can wear out from normal use within the warranty period.

This warranty is void if this product is ever used while providing commercial

services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

..................................................................

Page 16

The purpose of safety symbols is to attract your attention to possible dangers.

The safety symbols and the explanations with them deserve your careful attention

and understanding. The symbol warnings do not, by themselves, eliminate any

danger. The instructions and warnings they give are no substitutes for proper

accident prevention measures.

WARNING: Be sure to read and understand all safety instructions in this

manual, including all safety alert symbols such as “DANGER,” “WARNING,” and

“CAUTION” before using this buffer/polisher. Failure to follow all instructions listed

in this manual may result in electric shock, fire and/or serious personal injury.

SYMBOL SIGNAL MEANING

SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, OR CAUTION.

May be used in conjunction with other symbols or pictographs.

DANGER: Indicates a hazardous situation which, if not avoided, will result

in death or serious injury. This signal word is to be limited to the most extreme

situations. Always follow the safety precautions to reduce the risk of fire, electric

shock, and personal injury.

WARNING: Indicates a hazardous situation which, if not avoided, could result

in death or serious injury. Always follow the safety precautions to reduce the risk

of fire, electric shock, and personal injury.

CAUTION: Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

Damage Prevention and Information Messages

These inform the user of important information and/or instructions that could lead

to equipment or other property damage if they are not followed. Each message is

preceded by the word “NOTE,” as in the example below:

NOTE: Equipment and/or property damage may result if these instructions are not

followed.

SAVE THESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

!

WARNING:

chemicals known to the State of California to cause cancer and birth defects

or other reproductive harm.

Some dust created by using power tools contains

2

WARNING: To ensure safety and reliability, all repairs

should be performed by a qualified service technician.

WARNING: The operation of any power tools can result in

foreign objects being thrown into your eyes, which can result in

severe eye damage. Before beginning power tool operation,

always wear safety goggles or safety glasses with side shield

and a full face shield when needed. We recommend a Wide

Vision Safety Mask for use over eyeglasses or standard safety glasses with side

shields. Always use eye protection which is marked to comply with ANSI Z87.1

shields.

3

Page 3

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS cont.

!

WARNING:

follow the warnings and instructions may result in electric shock, fire

and/or serious injury.

Read all safety warnings and instructions. Failure to

Save all warnings and instructions for future reference.

The term power tool in the warnings refers to your electric (corded)

power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

1. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite

the dust or fumes.

3. Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

4. Make your workshop childproof with padlocks and master switches. Lock

tools away when not in use.

5. MAKE SURE the work area has ample lighting so you can see the work and that

there are no obstructions that will interfere with safe operation BEFORE using your

power tool.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

2. Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

3. Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energizing power tools

that have the switch on invites accidents.

4. Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

5. Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

7. If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

TOOL USE AND CARE SAFETY

!

WARNING:

operating this tool. Failure to follow all instructions listed below may result

in electric shock, fire and/or serious personal injury.

1. Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

2. Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

3. Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

4. Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

5. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

6. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

7. Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool,

taking into account the working conditions and the work to be performed.

Use of the power tool for operations different from those intended could result in a

hazardous situation.

8. Use clamps or another practical way to secure and support the workpiece to

a stable platform.

9. Holding the work by hand or against your body leaves it unstable and may

lead to loss of control.

BE SURE to read and understand all instructions before

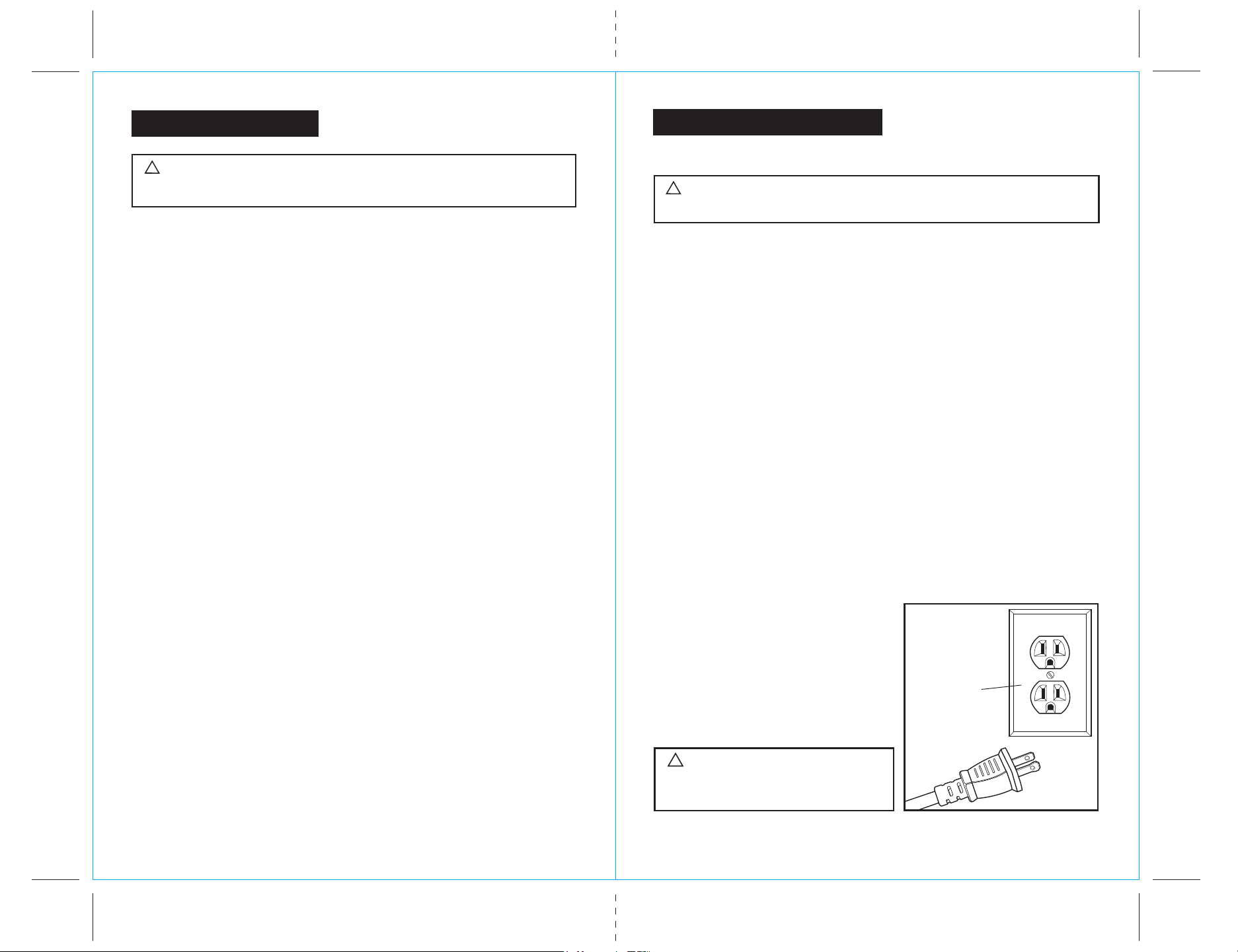

ELECTRICAL SAFETY

1. Double insulated tools are equipped

with a polarized plug (one blade is wider

than the other). This plug will fit in a

polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do

not change the plug in any way.

!

WARNING:

to touch the terminals of plug when

installing or removing the plug from

the outlet.

Do not permit fingers

Cover of

Grounded

Outlet Box

4

5

Page 4

SAFETY INSTRUCTIONS cont.

SAFETY INSTRUCTIONS cont.

ELECTRICAL SAFETY cont.

2. Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with grounded power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

!

WARNING:

safety precautions when operating this tool.

3. Avoid body contact with grounded surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

4. Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

5. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

6. When operating a power tool outdoors, use an extension cord suitable for

outdoor use marked “W-A” or “W”. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

7. If operating a power tool in a damp location is unavoidable, use a Ground

Fault Circuit Interupter (GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock.

Double insulation DOES NOT take the place of normal

EXTENSION CORDS

USE PROPER EXTENSION CORD. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. Table 1 shows the correct size to

use depending on cord length and nameplate ampere rating. If in doubt, use the

next heavier gage. The smaller the gage number, the heavier the cord.

Table 1: Minimum Gage for Cord

Rating Volts Total cord length (in feet)

Ampere

More Than

0

6

10

12

!

CAUTION:

Position the cord so that it will not get caught on lumber, tools, parts of the

vehicle or other obstructions while you are working with a power tool.

!

WARNING:

replace immediately. Never use tool with a damaged cord since touching

the damaged area could cause electrical shock, resulting in serious injury.

Not More

Than

6

10

12

16

120V 25 50 100 150

AWG

18

18

16

14

Keep the extension cord clear of the working area.

Check extension cords before each use. If damaged

6

16

16

16

12

16

14

14

Not recommended

14

12

12

SAFETY SYMBOLS FOR YOUR TOOL

The label on your tool may include the following symbols.

V.......................................................................Volts

A......................................................................Amps

Hz....................................................................Hertz

W..................................................................... Watts

min..................................................................Minutes

....................................................................Alternating current

..................................................................Direct current

n

....................................................................No-load speed

o

....................................................................Class II construction, Double Insulated

RPM………………………............................. . .Revolutions per minute

SPM…...........................…………………….....Strokes per minute

OPM………………..........................………..... Orbits per minute

....................................................................Indicates danger, warning or caution.

!

It means attention! Your safety is involved.

SERVICE SAFETY

1. If any part of this tool is missing or should break, bend, or fail in any way;

or should any electrical component fail to perform properly: SHUT OFF the

power switch and remove the tool’s plug from the power source and have the

missing, damaged or failed parts replaced BEFORE resuming operation.

2. Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool

is maintained.

3. If the replacement of the supply cord is necessary, this has to be done by the

manufacturer or his agent in order to avoid a safety hazard.

SAFETY RULES FOR BUFFER / POLISHERS

!

WARNING:

FOR USE WITH THIS TOOL MAY CREATE A HAZARDOUS CONDITION.

1. Read, understand and follow all safety rules and user instructions in this manual

and all directions and warnings on polishes and waxes BEFORE using this

buffer / polisher.

2. Vehicle should be clean and dry before using your buffer polisher. Remove all road

tar, excess grease spots and bug stains.

3. ALWAYS make sure the vehicle’s surface is cool before washing and using the

buffer / polisher.

4. When changing accessories, BE SURE that the switch is in the OFF position and

the cord is unplugged.

5. DO NOT apply wax directly on car.

USE OF ACCESSORIES THAT ARE NOT RECOMMENDED

7

Page 5

SAFETY INSTRUCTIONS cont.

SAFETY INSTRUCTIONS cont.

SAFETY RULES FOR BUFFER / POLISHERS cont.

6. To avoid splashing wax, ALWAYS start and stop the buffer / polisher on or against

the surface to be polished.

7. After plugging in extension cord, loop extension cord over tool’s stub length plug.

Then wrap hook and loop strip around extension cord to secure it in place.

8. Place extension cord over your shoulder to keep it safely out of your way.

9. DO NOT apply excessive pressure against the work surface with this tool. The

random orbital motion feature on this tool will perform better when less pressure

is applied. Applying excessive pressure will slow the random orbital motion and

reduce the effectiveness of the tool.

10. To prolong the life of the pad on the buffer / polisher, ALWAYS store the

buffer / polisher with the pad face up.

11. DO NOT USE ABRASIVE COMPOUNDS WITH THIS TOOL.

12. DO NOT immerse any part of the buffer / polisher in liquid.

!

WARNING:

chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonryproducts.

• Arsenic and chromium, from chemically treated lumber.

Your risk from these exposures varies, depending upon how often you do

this type of work. To reduce your exposure to these chemicals:

• Work in a well-ventilated area.

• Work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

Some dust created by using power tools contains

ADDITIONAL RULES FOR SAFE OPERATION

!

WARNING:

Failure to follow all instructions listed below may result in electric shock,

fire and / or serious personal injury.

1. Inspect the sponge pad before use. Do not use chipped, cracked or otherwise

defective products.

2. Ensure that the bonnets are fitted in accordance with the manufacturer's instructions.

3. Ensure that the bonnet is correctly mounted and tightened before use and run the

tool at no-load for 30 seconds in a safe position. Stop immediately if there is

considerable vibration or if other defects are detected. If this condition occurs, check

the machine to determine the cause.

4. For cleaning, personal protective equipment such as gloves and apron should be worn.

5. The wheel continues to rotate after the tool is switched off. Only withdraw the sponge

pad when the pad has stopped moving.

6. Do not use the polisher as a fixed tool.

7. SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to

instruct others who may use this tool. If someone borrows this tool, make

sure they have these instructions also.

BE SURE to read and understand all instructions.

Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth,

eyes, or lay on the skin may promote absorption of harmful chemicals.

!

WARNING:

may cause serious and permanent respiratory or other injury. Always use

NIOSH/OSHA approved respiratory protection appropriate for the dust

exposure. Direct particles away from face and body.

Use of this tool can generate and/or disburse dust, which

8

9

Page 6

UNPACKING

DESCRIPTION

!

WARNING:

source when you are assembling parts, making adjustments, installing or

removing bonnets, cleaning or when it is not in use. Disconnecting the tool

will prevent accidental starting, which could cause serious personal injury.

1. Remove the buffer / polisher from the carton and inspect it carefully to make sure

that no breakage or damage has occurred during shipping.

2. Do not discard any of the packing materials until all parts are accounted for.

3. Two bonnets are included: wax applicator bonnet for applying waxes, and a

reusable terry cloth bonnet for removing waxes and polishing.

4. If any of the parts are damaged or missing (refer to PARTS LIST below), return the

buffer / polisher to your nearest Sears store or Craftsman outlet to have the tool

replaced.

!

WARNING:

buffer / polisher until the missing parts are replaced. Failure to do so could

result in possible serious personal injury.

Your tool should NEVER be connected to the power

If any parts are missing, DO NOT operate this

PARTS LIST (Fig. 1)

Buffer / Polisher

KNOW YOUR BUFFER / POLISHER

NOTE: Before attempting to use your buffer / polisher, familiarize yourself

with all of the operating features and safety requirements.

Your Craftsman buffer / polisher has a precision-built electric motor and it should be

connected to a 120-volt, 60-Hz AC ONLY power supply (normal household current).

DO NOT operate on direct current (DC). The large voltage drop will cause a loss of

power and the motor will overheat. If the tool does not operate when plugged into

correct 120-volt, 60-Hz AC ONLY outlet, check the power supply. This buffer / polisher

has a stub length, 2-wire power cord (no adapter needed).

This Craftsman Buffer / Polisher has the following features:

1. Powerful 1.0 Amp permanent magnet Motor with 3800 Orbits per Minute

provides the power needed for quality waxing, buffing and polishing.

2. Precision tuned Counterweight system reduces vibration for smooth,

comfortable operation with less operator fatigue

3. Precision tuned Counterweight System matched with Orbital Motion provides

a “swirl-free” shine.

4. Ergonomically designed Perimeter Handle System provides maximum balance,

control and gripping comfort on any horizontal or vertical surface.

5. Hook and Loop Strip helps keep extension cord securely plugged into

buffer / polisher.

6. On / Off Slide Switch conveniently located for ease in control.

7. 7-in. diameter Foam Pad follows surface contours for efficient buffing / polishing.

Chemical resistant for long life.

8. One Wax Applicator Bonnet for applying wax.

9. One Reusable Terry Cloth Bonnet for removing wax and polishing.

10. Non-marring Flat Top of buffer / polisher provides a stable base when applying

wax to bonnets and changing bonnets.

11. Permanently lubricated Ball Bearings for smooth, efficient operation.

12. Lightweight, High-impact Resistant Housing reduces weight, helps protect

tool from damage.

Reusable Terry

Cloth Bonnet

Operator’s Manual

10

Wax

Applicator

Bonnet

11

Page 7

DESCRIPTION cont.

OPERATION cont.

KNOW YOUR BUFFER / POLISHER cont.

Perimeter

Handle System

PRODUCT SPECIFICATIONS

Pad Diameter 7-in.

Motor OPM 3800

Rating 120 volts, 60 Hz AC

Amps

1.0

Non-marring Flat Top Cap

On/Off

Slide Switch

Hook and

Loop Strip

Foam Pad Base

Fig. 2

Stub Lengh

Cord

OPERATION

Before attempting to use your tool, familiarize yourself with all of the operating

features and safety requirements.

!

WARNING:

BUFFER / POLISHER UNTIL THE MISSING PARTS ARE REPLACED.

FAILURE TO DO SO COULD RESULT IN POSSIBLE SERIOUS PERSONAL

INJURY.

IF ANY PARTS ARE MISSING, DO NOT OPERATE THIS

BEFORE YOU BEGIN TO WAX, BUFF AND POLISH YOUR CAR:

1. Remove all road tar, excess grease spots and bug stains with a general-purpose

cleaner.

2. Wash, clean and dry your vehicle.

3. Make sure the work area is dry.

ATTACHING THE WAX APPLICATOR BONNET TO THE FOAM PAD

(See Figure 3)

!

WARNING:

accessories, BE SURE that the switch is

in the OFF position and the cord is

unplugged.

1. Place wax applicator bonnet on foam pad

as shown in Fig. 3.

2. ALWAYS make sure that the elastic strip

on the bottom of the bonnet is securely

tucked on the underside of the foam pad.

APPLYING WAX TO BONNET (See Figures 4 and 5)

IMPORTANT: DO NOT APPLY WAX DIRECTLY

ON CAR!

Applying Paste Wax to Bonnet (See Figure 4)

1. Spread a heaping teaspoon of wax evenly over

entire surface of applicator bonnet using a

putty knife or any other flat object (See Fig. 4).

Applying Liquid Wax to Bonnet (See Figure 5)

1. Apply three swirls of wax over applicator

bonnet (See Fig. 5).

2. This should be enough to cover 1/4 of car

surface.

3. For the second and third and fourth applications,

only use about one half as much as on first

application. The bonnet will not absorb as

much wax on these applications.

When changing

Fig. 4

Fig. 5

Fig. 3

!

CAUTION:

tool.

ALWAYS wear eye protection while operating this power

12

13

Page 8

OPERATION cont.

OPERATION cont.

RUNNING YOUR BUFFER / POLISHER AND WAXING VEHICLE

1. After plugging tool into extension cord, loop

extension cord over tool’s stub length plug.

Fig. 6

Then wrap hook and loop strip around

extension cord to secure it in place.

2. To avoid splashing wax, ALWAYS start and

stop the buffer / polisher against the surface

to be polished.

3. Place the extension cord over your shoulder

to keep it safely out of your way (see Fig. 6).

4. Place buffer / polisher against vehicle and

turn buffer / polisher ON by sliding switch

to On position.

5. Apply wax in a straight line with either a

side-to-side or back and forth motion.

ALWAYS use broad, even strokes when

applying wax (See Fig. 7).

6. Start applying wax to the flat surfaces (hood,

Fig. 7

trunk and roof) first. Wax one section at a

time (see Fig. 8).

7. After flat surfaces are covered with wax,

do the sides. The perimeter handle system

allows easy polishing of horizontal and

vertical surfaces. Hold tool with the cord

hanging free (see Fig. 9).

Fig. 8

8. Apply wax in a thin, even coat. Too much wax

does not add any more protection and only

makes the wax removal more difficult.

9. The random orbit motion of the buffer /

LEFT RIGHT

polisher provides was application that cannot

be duplicated, not even “by hand”.

IMPORTANT: DO NOT apply excessive

pressure against the work surface with this tool.

The random orbital motion feature on this tool

will perform better when less pressure is

applied. Applying excessive pressure will slow

the random orbital motion and reduce the

effectiveness of the tool.

10. It is easiest to apply the wax to the entire

surface before starting the removal phase;

however, follow the specific

recommendations of the wax or polish

being used.

123

RUNNING YOUR BUFFER / POLISHER AND WAXING VEHICLE cont.

11. When you have finished applying wax with

the applicator, bonnet, SHUT OFF the

Fig. 10

buffer / polisher before removing from the

car’s surface.

12. Remove the wax applicator bonnet and use

it to hand polish all the hard-to-reach

surfaces (under bumpers, around door

handles, etc.) (see Fig. 10).

13. Properly dispose of wax applicator bonnet.

ATTACHING THE POLISHING BONNET TO THE FOAM PAD (Fig. 11)

!

WARNING:

When changing

Fig. 11

accessories, BE SURE that the switch is

in the OFF position and the cord is

unplugged.

1. Place the terry bonnet on foam pad as

shown in Fig. 11.

2. ALWAYS make sure that the elastic strip

on the bottom of the bonnet is securely

tucked on the underside of the foam pad.

BUFFING AND POLISHING - REMOVING THE WAX FROM THE SURFACE

(See Fig. 12)

NOTE: Remove wax in the same order in which

Fig. 12

it was applied.

1. Wait until wax has dried to an even haze

4

on vehicle.

2. Place extension cord over your shoulder.

3. Turn buffer / polisher ON.

Fig. 9Fig. 9

IMPORTANT: DO NOT apply excessive

pressure against the work surface with this tool.

The random orbital motion feature on this tool

will perform better when less pressure is applied. Appling excessive pressure will

slow the random orbital motion and reduce the effectiveness of the tool.

NOTE: For best results, use long, sweeping strokes in a criss-cross pattern when

removing wax.

4. Buff and polish the entire surface until all dried wax is removed. Remove the

bonnet from time to time and shake out the dried wax residue. A bonnet with

excess residue will cause streaking. You may need to replace the bonnet with a

new one if you can’t get it clean enough to avoid streaking.

5. Use a clean terry cloth bonnet for final buffing and polishing. Or use a foam

polishing bonnet (sold separately) for the ultimate “showroom” shine.

14

15

Page 9

OPERATION cont.

ACCESSORIES

CAR CARE TIPS

1. Wash and polish the car 3 to 4 times a year to help ensure paint protection.

2. Wash the car at least every 2 weeks with a car wash solution which will not harm

the finish or strip the wax. AVOID washing with household detergents.

3. Wash with a clean sponge and dry with a terry cloth towel to help prevent dirt from

scratching the paint. Start on the top and work down.

4. Remove bugs, bird droppings, tree sap and tar from the car’s surface on a daily

basis.

5. ALWAYS make sure that the car’s surface is cool before washing.

6. Avoid parking near sprinklers, because water spots are difficult to remove.

7. ALWAYS keep glass cleaner chemicals away from painted surfaces. Spray the

cleaner onto a towel, NOT directly on the windows.

MAINTENANCE

1. Terry cloth bonnets can be machine washed in cold water, using a small amount

of detergent. Machine dry at medium temperature. HOWEVER, we recommend

hand washing and air drying for longer bonnet life.

2. Wax applicator bonnets should only be used once, then disposed of properly.

3. Remove the bonnet from the foam pad when the buffer / polisher is not is use,

so the pad can dry out and retain its original shape.

4. To prolong the life of the foam pad, ALWAYS store the buffer / polisher with the

pad face up.

5. NEVER USE ABRASIVE COMPOUNDS WITH THIS TOOL.

6. DO NOT apply too much wax to the bonnet. Applying too much wax causes the

bonnet to become saturated and it will not last as long. THIS MAKES

POLISHING MORE DIFFICULT AND IT TAKES LONGER.

7. If the bonnet is continually coming off the pad, you may be using too much wax.

8. If buffing seems difficult, you have used too much wax.

9. ONLY USE a mild soap solution and a damp sponge to clean the buffer / polisher.

10. DO NOT immerse any part of the buffer / polisher in liquid.

!

WARNING:

recommended for this tool might be dangerous and could result in serious

injury.

Sears and other Craftsman® outlets offer a large selection of Craftsman

buffer / polisher accessories designed for all your buffing and polishing

applications.

Look for these Craftsman accessories. They are specially designed to make

your 7-in. Buffer / Polisher more efficient to use.

Wax Applicator Bonnets for applying waxes and polishes.

Terry Cloth Bonnets use for removing wax and for buffing and polishing.

Polishing Bonnets for final buffing and polishing to a “showroom” shine.

Quality Waxes for the finest protection and appearance.

Visit your local Sears store or other Craftsman outlets or shop

sears.com/craftsman for all of the accessories for your buffer / polisher.

The use of attachments or accessories that are not

16

17

Page 10

7-in. Buffer / Polisher

MODEL NUMBER 172.107210

PARTS LIST

The model number will be found on the nameplate of the buffer/polisher.

Always mention the model number in all correspondence regarding your tool.

18

PARTS LIST

7-in. Buffer / Polisher

MODEL NUMBER 172.107210

The model number will be found on the nameplate of the buffer/polisher.

Always mention the model number in all correspondence regarding your tool.

Item No. Custom Parts No. Parts No. Parts Description Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

201

17

18

19

202

20

21

22

24

60

25

26

27

28

33

34

35

37

38

203

39

40

41

42

43

52

53

10721-1-00

10721-2-00

10721-3-00

10721-4-00

10721-5-00

10721-6-00

10721-7-00

10721-8-00

10721-9-00

10721-10-00

10721-11-00

10721-12-00

10721-13-00

10721-14-00

10721-15-00

10721-16-00

10721-201-00

10721-17-00

10721-18-00

10721-19-00

10721-202-00

10721-20-00

10721-21-00

10721-22-00

10721-24-00

10721-60-01

10721-25-00

10721-26-00

10721-27-00

10721-28-00

10721-33-00

10721-34-00

10721-35-00

10721-37-00

10721-38-00

10721-203-00

10721-39-00

10721-40-00

10721-41-00

10721-42-00

10721-43-00

10721-52-00

10721-53-00

SW01.01.27-00

ST05.01.03-00

ST08.01.07-00

SW55.57.0-00

SA30.0.09.0-01

SA30.0.01-01

SA30.0.04-01

SA30.0.13-00

ST05.04.32-00

SA30.0.03-00

SW02.44-00

SW09.01-00

ST25.35.02.1-00

SA30.0.06-00

SW56.22.1-00

STA50.12.00-00

SA30.2.00

STA51.12.00-00

SW50.11.3-00

SA30.2.01-00

SA30.6.00

SW55.18.1-00

SA30.5.01-00

SW50.14.3-00

SA30.6.10-00

SW60.05.0-00

SA30.0.07-00

SA30.012-00

ST02.16.00-00

ST03.14.00-00

SA30.0.11.0-01

SA30.0.02-01

SW55.58.1-00

SA30.0.05-00

SA30.4.04-00

SA30.4.00

SA30.4.03-00

SA30.4.01-00

SA30.4.02-00

SW55.58.1-00

SW56.18.1-00

SA30.1.00.2-00

ST19.02.00-00

19

Cord & Plug

Cord Protector

Cord Clamp

Screw

Brand

Left Housing

Top Cover

Cushion Block

Rubber Pole

Switch Pusher

Switch

Terminal Block

Inner Wiring 110

Square Nut

Screw

Stator

Stator Set

Rotator

Bearing

Balance Block7

Plate Set

Screw

Press Plate

Ball Bearing

Base Plate

Washer

Screw

Rubber-Gasket

Carbon Brush

Brush Holder

Nameplate

Right Housing

Screw

Screw

Ring

Handle Set

Position Block

Top-handle7

Bottom-handle7

Screw

Screw

Rectifier-Connector

Hook And Loop

1

1

1

2

1

1

1

1

2

1

1

1

1

4

2

1

1

1

2

1

1

3

1

1

1

1

1

2

2

2

1

1

10

2

2

1

1

2

1

8

2

1

1

Loading...

Loading...