1619X01301

Owner's Manual

Manual del propietario

Manuel du proprietaire

Professional Router Table

Mesa de fresado profesional

Table _ toupie professionnelle

Model/Modelo/Modele: 171.61181

@

@

-&WARNING:

Before operating product, read this manual and follow all its

Safety and Operating Instructions.

_ADVERTENCIA:

Antes de utilizar este producto, lea este manual y acate todas

las instrucciones sobre seguridad y uso.

-&AVERTISSEMENT :

Avant de vous servir de ce produit, lisez ce manuel et suivez toutes

ses consignes de securit6 et les instructions de fonctionnement.

• Safety

Instructions

• Parts List

• Assembly

• Operation

• Espa_ol, p. 34

• Frangais, p. 66

171.61181 02/10

Printed in China

Sears, Roebuck and Co., Hoffman Estates IL 60179 U.S.A.

www.sears.com/craftsman

1 619 X04 975 Rev. -

Impreso en China Imprim_ en Chine 02/10

f

! ONE-YEAR FULL WARRANTY ON CRAFTSMAN PROFESSIONAL TOOL

If this Craftsman tool fails due to a defect in material or workmanship within one year from the date

of purchase, CALL 1-800-4-MY-HOME _ TO ARRANGE FOR FREE REPAIR (or replacement if repair proves

impossible).

This warranty does not include expendable parts, such as lamps, batteries, bits or blades.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 _j

iMPORTANT SAFETY iNFORMATiON . .. 2=6

Optional Router Table Accessories ...... 7

Router Table Assembly ............. 12-21

Router Table Operation ............ 22=33

Parts List ......................... 8-11

I-_ I Read and understand the tool manual and these instructions for the use of this table with

WARNING your router. Failure to follow all instructions listed below may result in serious personal injury.

SAVE THESE iNSTRUCTiONS

Work Area

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks which

may ignite the dust or fumes.

Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to

lose control.

Electrical Safety

Grounded tools must be plugged into an outlet

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do

not use any adaptor plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet

is properly grounded, if the tools should electrically

malfunction or break down, grounding provides a low

resistance path to carry electricity away from the user.

Improper grounding can shock, burn, or electrocute.

Grounded tools are equipped with three-conductor cord

and three-prong type plugs. Before plugging in the tool,

be certain the outlet voltage suppfied is within the voltage

marked on the nameplate. Do not use "AC only" rated

tools with a DC power supply.

Double-insulated tools are equipped with a polarized

plug (one blade is wider than the other.) This plug will

fit in a polarized outlet only one way. If the plug does

not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in any way.

Double Insulation [] eliminates the need for the three-

wire grounded power cord and grounded power supply

system. Before plugging in the tool, be certain the outlet

voltage suppfied is within the voltage marked on the

nameplate. Do not use "AC only" rated tools with a DC

power supply.

Avoid body contact with grounded surfaces such

as pipes, radiators, ranges, and refrigerators.

There is an increased risk of electric shock if your body is

grounded, if operating the power tool in damp locations

is unavoidable, a Ground Fault Circuit interrupter must be

used to supply the power to your tool. Electricians'

rubber gloves and footwear will further enhance

your personal safety.

Don't expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to carry

the tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges, or moving parts.

Replace damaged cords immediately. Damaged cords

increase the risk of electric shock.

When operating a power tool outside, use an outdoor

extension cord marked "W-A" or "W." These cords are

rated for outdoor use and reduce the risk of electric

shock. Refer to "important information About Extension

Cords" in your router table manual.

Personal Safety

Stay alert, watch what you are doing, and use

common sense when operating a power tool.

Do not use tool while tired or under the influence

of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result

in serious personal injury.

Keep guards in place. Maintain the guards in working

order and in proper adjustment and alignment.

Avoid accidental starting. Be sure switch is "OFF"

before plugging in. Carrying tools with your finger on

the switch or plugging in tools that have the switch "ON"

invites accidents.

Remove adjusting keys or wrenches before turning

the tool "ON." A wrench or a key that is left attached to

a rotating part of the tool may result in personal injury.

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enable better

control of the tool in unexpected situations.

Use safety goggles (head protection). Wear safety

goggles (must comply with ANSI Standard Z87.1) at

all times. Wear non-slip footwear and a hard hat, if

appropriate. Also, use face or dust mask if cutting

operation is dusty and ear protectors (plugs or muffs)

during extended periods of operation.

Tool Use and Care

Use clamps or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and

may lead to loss of control.

Do not force tool. Use the correct tool for your

application. The correct tool will do the job better and

safer at the rate for which it is designed.

Do not use tool if switch does not turn it "ON" or

"OFF." Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Keep guards in place. Maintain the guards in working

order and in proper adjustment and alignment.

Store idle tools out of reach of children and other

untrained persons. Tools are dangerous in the hands

of untrained users.

Never leave tools running unattended. Turn the

power OFF. DO NOT leave tool until it comes to a

complete stop.

Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools, with sharp cutting

edges, are less likely to bind and are easier to control.

Any alteration or modification is a misuse and may result

in a dangerous condition.

Check for damaged guards or parts, misalignment, or

binding of moving parts, breakage of parts, and any

other condition that may affect the tool's operation, if

damaged, have the tool properly repaired or replaced

before using. Many accidents are caused by poorly

maintained tools. Develop a periodic maintenance

schedule for your tool.

Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be

suitable for one tool may become hazardous when used

on another tool.

Service

Tool service must be performed only by qualified

repair personnel. Service or maintenance performed by

unqualified personnel could result in a risk of injury. For

example: internal wires may be misplaced or pinched;

safety guard return springs may be improperly mounted.

When servicing a tool, use only identical replacement

parts. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric

shock or injury. Certain cleaning agents such as gasoline,

carbon tetrachloride, and ammonia may damage

plastic parts.

Lift router table only by the table edges. Lifting table by any other

surface could cause personal injury.

Do not use the router table until all assembly and installation

steps have been completed. Prior to each use, verify that

fasteners and the router clamps are tight. A loose table or router

is unstable and may shift in use, resulting in property damage or

serious personal injury.

Disconnect the router from the power supply before installing

router into the table, making adjustments, changing

accessories, removing the router from the table, performing

maintenance, or storing the tool. Such precautionary safety

measures reduce the risk of unintentional tool operation.

Do not plug router motor power cord into standard wall

outlet. Always plug router cord into the router table switch box.

Power tool switches and controls need to be within your reach in

emergency situations.

Do not permit fingers to touch terminals on the plug when

inserting or removing plug from the outlet. Risk of Electric Shock.

Before connecting router or vacuum to router table switch box,

ensure that the router or vacuum switch is off and that the

router table switch box is unplugged. Such precautionary safety

measures reduce the risk of unintentional tool operation.

Before using the router table, verify that the router is securely

clamped to the router table base. While working, periodically

check the router base fastener clamping tightness. Vibrations

from cutting operations can cause router motor clamps to loosen

and the router motor may fall from the table.

Before starting to work, ensure that the power cords from the

router accessories, the switch box, and the extension cord do

not and cannot come in contact with the router or any moving

parts of the router. Such precautionary safety measures reduce

the risk of injury due to loss of control.

Do not use the router table without the overhead guard

unless required by a particular cutting operation. Replace guard

immediately after completion of cutting operation. Remove all

dust, chips, and any other foreign particles that can affect its

function. The guard will aid in keeping hands from unintended

contact with the rotating bit.

Do not use bits that have a cutting diameter that exceeds

the clearance hole in the tabletop insert plate or insert rings.

The bit could contact the insert plate or insert ring, throwing

fragments.

Never use dull or damaged bits. Damaged bits can snap during

use. Dull bits require more force to push the workpiece, possibly

causing the bit to break or the material to kick back.

Handle sharp bits with care. Such precautionary safety measures

reduce risk of injury.

Do not alter insert ring or insert plate bit hole. Match the cutting

diameter of the bit to the inner diameter of the insert ring or

insert plate bit hole such that the difference is no less than

1/16 in. on a side. Insert rings are meant to reduce the gap between

the cutting diameter of the bit and the table so that workpieces

maintain full support of the table while routing.

Install bit in accordance with instructions in the router manual.

Securely clamp the router bit in the collet chuck before making

any cuts. Securing the bit before cutting reduces the risk of the bit

becoming loose during operation.

Never place your fingers near a spinning bit or under the guard

when the router is plugged in. Such precautionary safety measures

reduce the risk of injury.

Never hold the workpiece on the outfeed side of the bit. Pressing

the workpiece against the outfeed side of the fence may cause

material binding and possible kickback, pulling your hand into

the bit.

Guide the workpiece with the fence to maintain control of the

workpiece. Do not place the workpiece between the router bit

and fence while routing the edge. This placement will cause the

material to become wedged, making kickback possible.

Only use routers for working with wood, woodlike products,

plastic, or laminates. Do not use router and router table for

cutting or shaping metals. Be sure workpiece does not contain

nails or other hard objects. Cutting nails may cause loss of control

of the tool or workpiece.

Never start the tool when the bit is engaged in the material. The

bit-cutting edge may grab the material, causing loss of control of the

workpiece.

Feed the workpiece only against the rotation of the bit.

Do not "back feed" the workpiece into the bit. The bit rotates

counterclockwise as viewed from the top of the table. "Back

feeding" will cause the workpiece to "climb" up on the bit, pulling

the workpiece and possibly your hands into the rotating bit.

Do not feed the workpiece into the bit where the majority of the

workpiece is between the fence and the bit. This creates a "fence

trap" which is a hazardous situation due to the bit being exposed.

This will cause the work to "climb-cut" away from the tabletop and

may lead to loss of control during operation.

Do not cut material that is warped, wobbly, or otherwise

unstable. The router table is designed to cut fiat, straight,

and squared materials. If the material is slightly curved but

otherwise stable, cut the material with the concave side against

the table or fence. Cutting the material with the concave side up or

away from the table may cause the warped or wobbly material to roll

and kick back, causing the user to lose control.

Use auxiliary infeed and outfeed supports for long or wide

workpieces. Oversize workpieces without adequate support can flip

off the table or cause the table to tip.

Use push stick, vertically and horizontally mounted

featherboards (spring sticks), and other jigs to hold down the

workpiece. Push sticks, featherboards, and jigs eliminate the need

to hold the workpiece near the spinning bit.

Never let go of the workpiece when routing until the cut has

been completed and the workpiece is completely dear of the

bit. Such precautionary safety measures reduce the risk of injury

and property damage. Featherboards aid in holding the workpiece

in position when routing on a router table. They are not intended to

hold the workpiece in place alone when the workpiece is in contact

with the bit, or at any other time when the bit is turning.

Always hold the workpiece against the router table fence when

routing. Such precautionary measures increase accuracy in routing

and improve control of the workpiece, reducing the risk of injury.

Never leave the router unattended while it is running or before

it comes to a complete stop. Such precautionary safety measures

reduce the risk of injury and property damage.

Do not use the table as a workbench or work surface. Using it for

purposes other than routing may cause damage and make it unsafe

to use in routing.

Never stand on the table or use as a ladder or scaffolding.

The table could tip or the cutting tool could be accidentally

contacted.

When servicing the tool, use only recommended CRAFTSMAN

replacement parts. Follow instructions in the Maintenance

section of this manual Use of unauthorized parts or failure to

follow maintenance instructions can result in personal injury.

Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities contains chemicals known to

cause cancer, birth defects, or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks, cement, and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals,

work in a well-ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

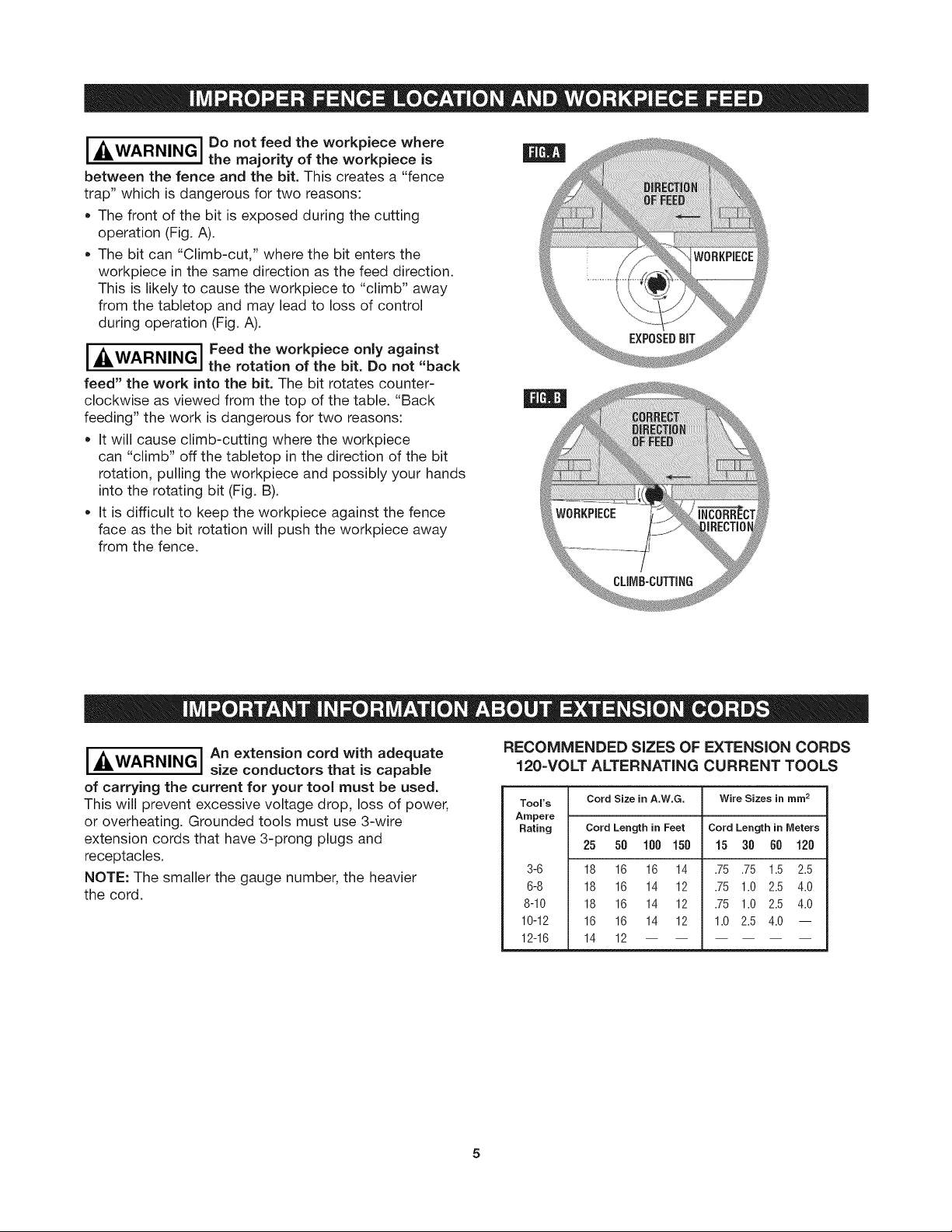

I _4LWARNINGI Do not feed the workpiece where

the majority of the workpiece is

between the fence and the bit. This creates a "fence

trap" which is dangerous for two reasons:

• The front of the bit is exposed during the cutting

operation (Fig. A).

• The bit can "Climb-cut," where the bit enters the

workpiece in the same direction as the feed direction.

This is likely to cause the workpiece to "climb" away

from the tabletop and may lead to loss of control

during operation (Fig. A).

I_IWARNINGI Feed the workpiece only against

the rotation of the bit. Do not "back

feed" the work into the bit. The bit rotates counter-

clockwise as viewed from the top of the table. "Back

feeding" the work is dangerous for two reasons:

• It will cause climb-cutting where the workpiece

can "climb" off the tabletop in the direction of the bit

rotation, pulling the workpiece and possibly your hands

into the rotating bit (Fig. B).

• It is difficult to keep the workpiece against the fence

face as the bit rotation will push the workpiece away

from the fence.

I_ WARNING I An extension cord with adequate

size conductors that is capable

of carrying the current for your tool must be used.

This will prevent excessive voltage drop, loss of power,

or overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles.

NOTE: The smaller the gauge number, the heavier

the cord.

RECOMMENDED SIZES OF EXTENSION CORDS

120-VOLT ALTERNATING CURRENT TOOLS

Tool's Cord Size in A.W.G. Wire Sizes in mm 2

Ampere

Rating Cord Length in Feet Cord Length in Meters

25 50 100 150 15 30 60 120

3-6

6-8

8-10

10-12

12-16

18 16 16 14

18 16 14 12

18 16 14 12

16 16 14 12

14 12

.75 .75 1.5 2.5

.75 1.0 2.5 4.0

.75 1.0 2.5 4.0

1.0 2.5 4.0 --

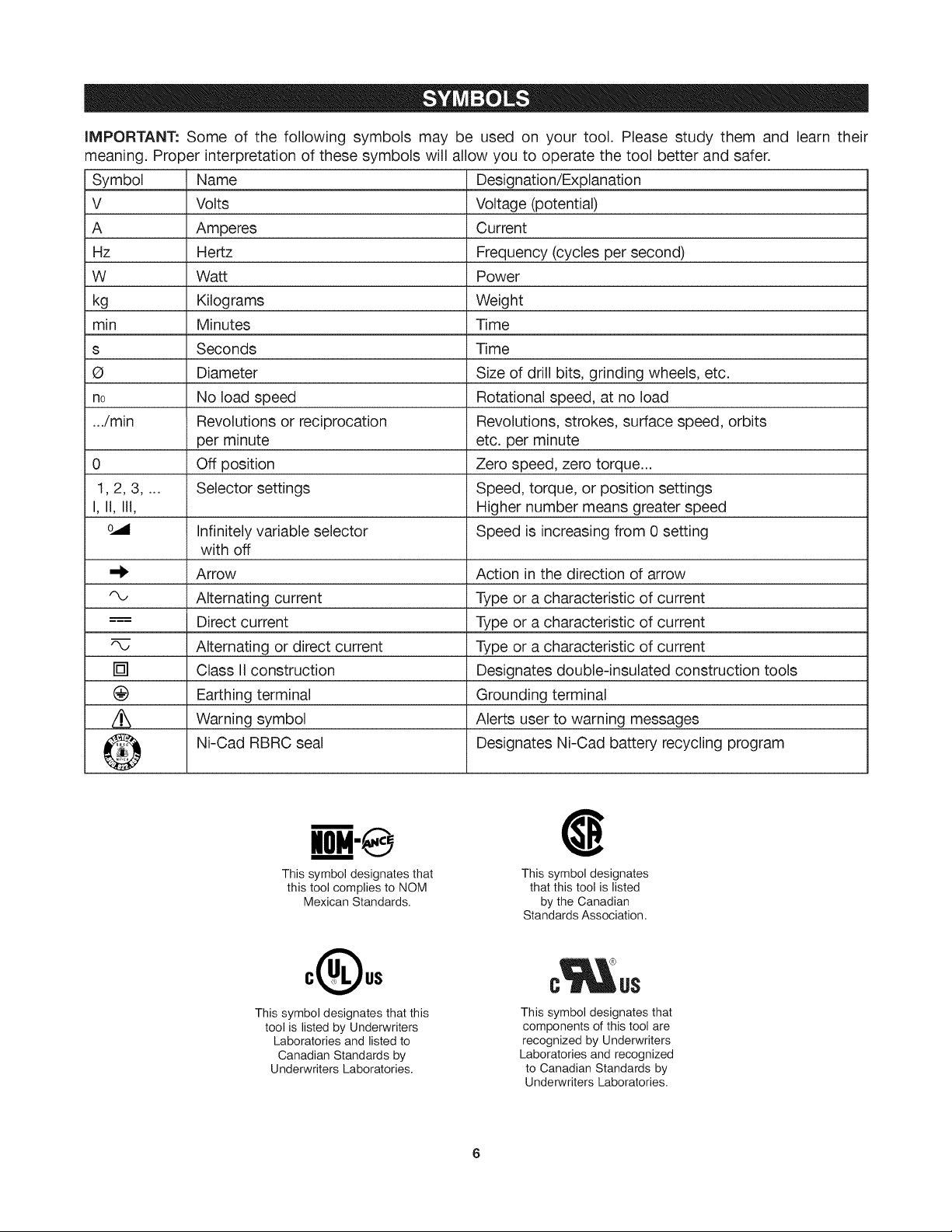

iMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their

meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilog rams Weight

min Minutes Time

s Seconds Time

Q Diameter Size of drill bits, grinding wheels, etc.

no No load speed Rotational speed, at no load

.../min Revolutions or reciprocation Revolutions, strokes, surface speed, orbits

per minute etc. per minute

0 Off position Zero speed, zero torque...

1,2, 3.... Selector settings Speed, torque, or position settings

I, II, Ill, Higher number means greater speed

Infinitely variable selector Speed is increasing from 0 setting

with off

=I_ Arrow Action in the direction of arrow

"_ Alternating current Type or a characteristic of current

---== Direct current Type or a characteristic of current

i

"_ Alternating or direct current Type or a characteristic of current

[] Class II construction Designates double-insulated construction tools

(_ Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling program

This symbol designates that

this tool complies to NOM

Mexican Standards.

This symbol designates

that this tool is listed

by the Canadian

Standards Association.

0Q°s

This symbol designates that this

tool is listed by Underwriters

Laboratories and listed to

Canadian Standards by

Underwriters Laboratories.

This symbol designates that

components of this tool are

recognized by Underwriters

Laboratories and recognized

to Canadian Standards by

Underwriters Laboratories.

To purchase these and other accessories for your CRAFTSMAN router table and router, visit your local Sears

outlet, or go to www.craftsman.cem

9-26479 CRAFTSMAN Professional Large Router

Mounting Plate

• Molded glass-filled polycarbonate plastic

mounting plate mounts most touters to

the 9=61181 Router Table

• Fasteners for mounting the router to the

mounting plate are not included and must be

purchased separately

IMPORTANT NOTE: The drilling and the

countersinking of holes in the mounting plate are

necessary in order to mount the router to the

mounting plate. The screw heads must be slightly

below the top surface of the mounting plate.

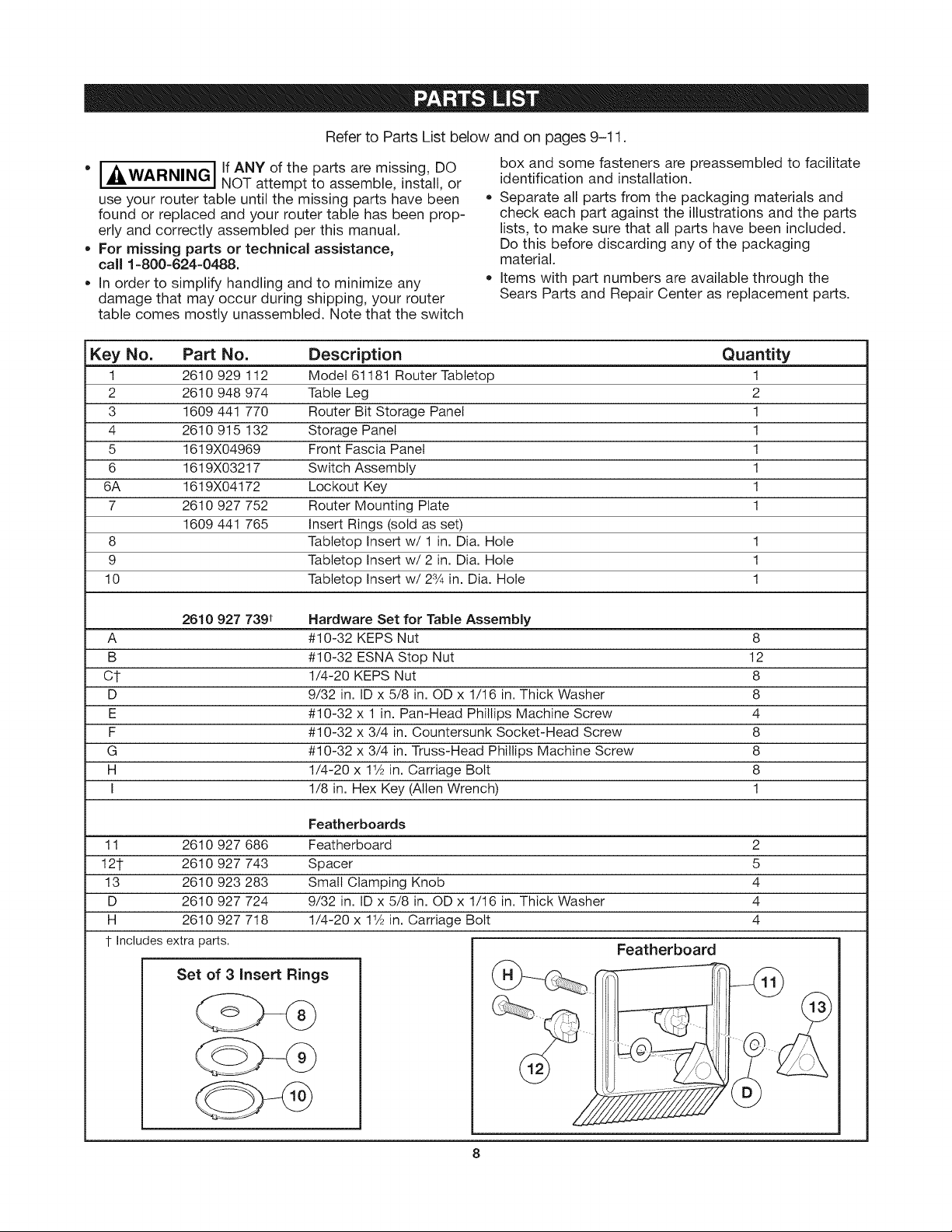

RefertoPartsListbelowandonpages9-11.

* I __ G I If ANY of the parts are missing, DO

,...WARNIN_, NOT attempt to assemble, install, or

!

use your router table until the missing parts have been

found or replaced and your router table has been prop-

erly and correctly assembled per this manual.

* For missing parts or technical assistance,

call 1-800-624-0488.

* In order to simplify handling and to minimize any

damage that may occur during shipping, your router

table comes mostly unassembled. Note that the switch

Key No. Part No. Description Quantity

1 2610 929 112 Model 61181 Router Tabletop 1

2 2610 948 974 Table Leg 2

3 1609 441 770 Router Bit Storage Panel 1

4 2610 915 132 Storage Panel 1

5 1619X04969 Front Fascia Panel 1

6 1619X03217 Switch Assembly 1

6A 1619X04172 Lockout Key 1

7 2610 927 752 Router Mounting Plate 1

1609 441 765 Insert Rings (sold as set)

8 Tabletop Insert w/1 in. Dia. Hole 1

9 Tabletop Insert w/2 in. Dia. Hole 1

10 Tabletop Insert w/23/4 in. Dia. Hole 1

box and some fasteners are preassembled to facilitate

identification and installation.

• Separate all parts from the packaging materials and

check each part against the illustrations and the parts

lists, to make sure that all parts have been included.

Do this before discarding any of the packaging

material.

Items with part numbers are available through the

Sears Parts and Repair Center as replacement parts.

2610 927 739t Hardware Set for Table Assembly

A #10-32 KEPS Nut 8

B #10-32 ESNA Stop Nut 12

C1- 1/4-20 KEPS Nut 8

D 9/32 in. ID x 5/8 in. OD x 1/16 in. Thick Washer 8

E #10-32 x 1 in. Pan-Head Phillips Machine Screw 4

F #10-32 x 3/4 in. Countersunk Socket-Head Screw 8

G #10-32 x 3/4 in. Truss-Head Phillips Machine Screw 8

H 1/4-20 x 11/2in. Carriage Bolt 8

I 1/8 in. Hex Key (Allen Wrench) 1

Featherboards

11 2610 927 686 Featherboard 2

121- 2610 927 743 Spacer 5

13 2610 923 283 Small Clamping Knob 4

D 2610 927 724 9/32 in. ID x 5/8 in. OD x 1/16 in. Thick Washer 4

H 2610 927 718 1/4-20 x 11/2in. Carriage Bolt 4

t Includes extra parts.

Featherboard

Set of 3 insert Rings

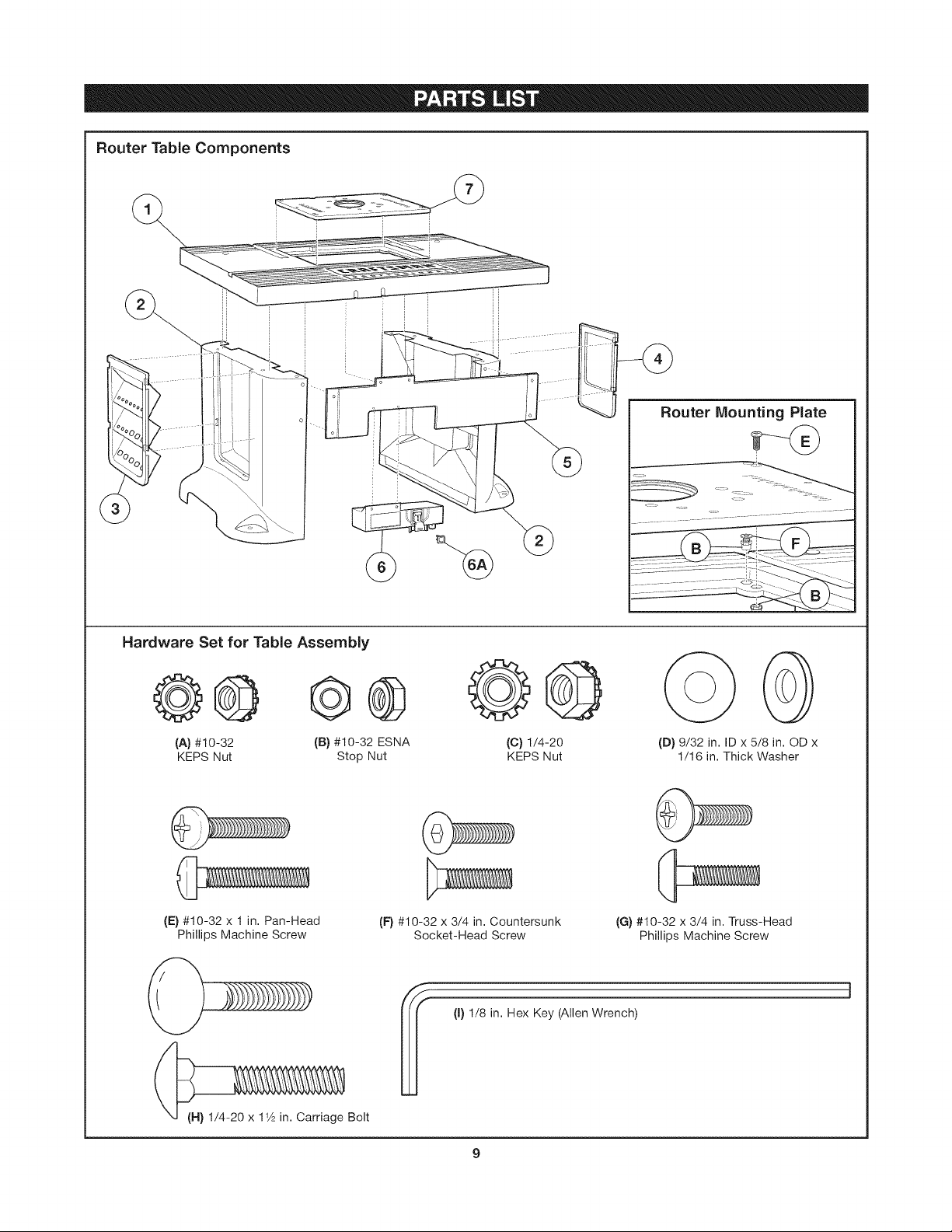

RouterTable Components

Router Mounting Plate

Hardware Set for Table Assembly

e® e® @@

(A) #10-32 (B) #10-32 ESNA (C) 1/4-20

KEPS Nut Stop Nut KEPS Nut

(E) #10-32 x 1 in. Pan-Head

Phillips Machine Screw

(F) #10-32 x 3/4 in. Countersunk

Socket-Head Screw

(I) 1/8 in. Hex Key (Allen Wrench)

(D) 9/32 in. ID x 5/8 in. OD x

1/16 in. Thick Washer

(G) #10-32 x 3/4 in. Truss-Head

Phillips Machine Screw

(H) 1/4-20 x 11A in. Carriage Bolt

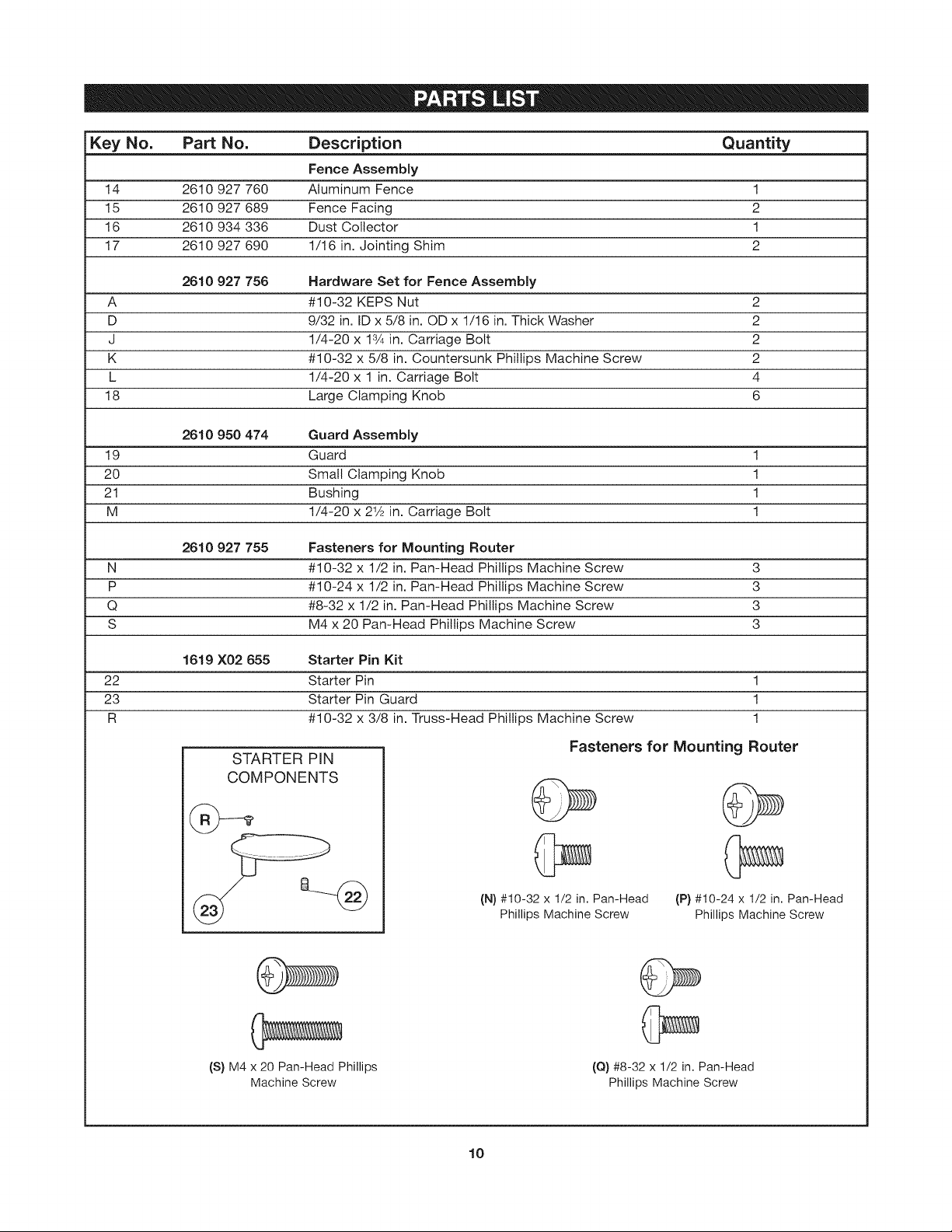

Key No. Part No. Description Quantity

Fence Assembly

14 2610 927 760 Aluminum Fence 1

15 2610 927 689 Fence Facing 2

16 2610 934 336 Dust Collector 1

17 2610 927 690 1/16 in. Jointing Shim 2

2610 927 756 Hardware Set for Fence Assembly

A #10-32 KEPS Nut 2

D 9/32 in. ID x 5/8 in. OD x 1/16 in. Thick Washer 2

J 1/4-20 x 13/4in. Carriage Bolt 2

K #10-32 x 5/8 in. Countersunk Phillips Machine Screw 2

L 1/4-20 x 1 in. Carriage Bolt 4

18 Large Clamping Knob 6

2610 950 474 Guard Assembly

19 Guard 1

20 Small Clamping Knob 1

21 Bushing 1

M 1/4-20 x 21/2in. Carriage Bolt 1

2610 927 755 Fasteners for Mounting Router

N #10-32 x 1/2 in. Pan-Head Phillips Machine Screw 3

P #10-24 x 1/2 in. Pan-Head Phillips Machine Screw 3

Q #8-32 x 1/2 in. Pan-Head Phillips Machine Screw 3

S M4 x 20 Pan-Head Phillips Machine Screw 3

1619 X02 655 Starter Pin Kit

22 Starter Pin 1

23 Starter Pin Guard 1

R #10-32 x 3/8 in. Truss-Head Phillips Machine Screw 1

STARTER PIN

Fasteners for Mounting Router

COMPONENTS

(S) M4 x 20 Pan-Head Phillips

Machine Screw

(N)#10-32 x 1/2 in. Pan-Head

Phillips Machine Screw

(Q) #8-32 x 1/2 in. Pan-Head

Phillips Machine Screw

(P) #10-24 x 1/2 in. Pan-Head

Phillips Machine Screw

10

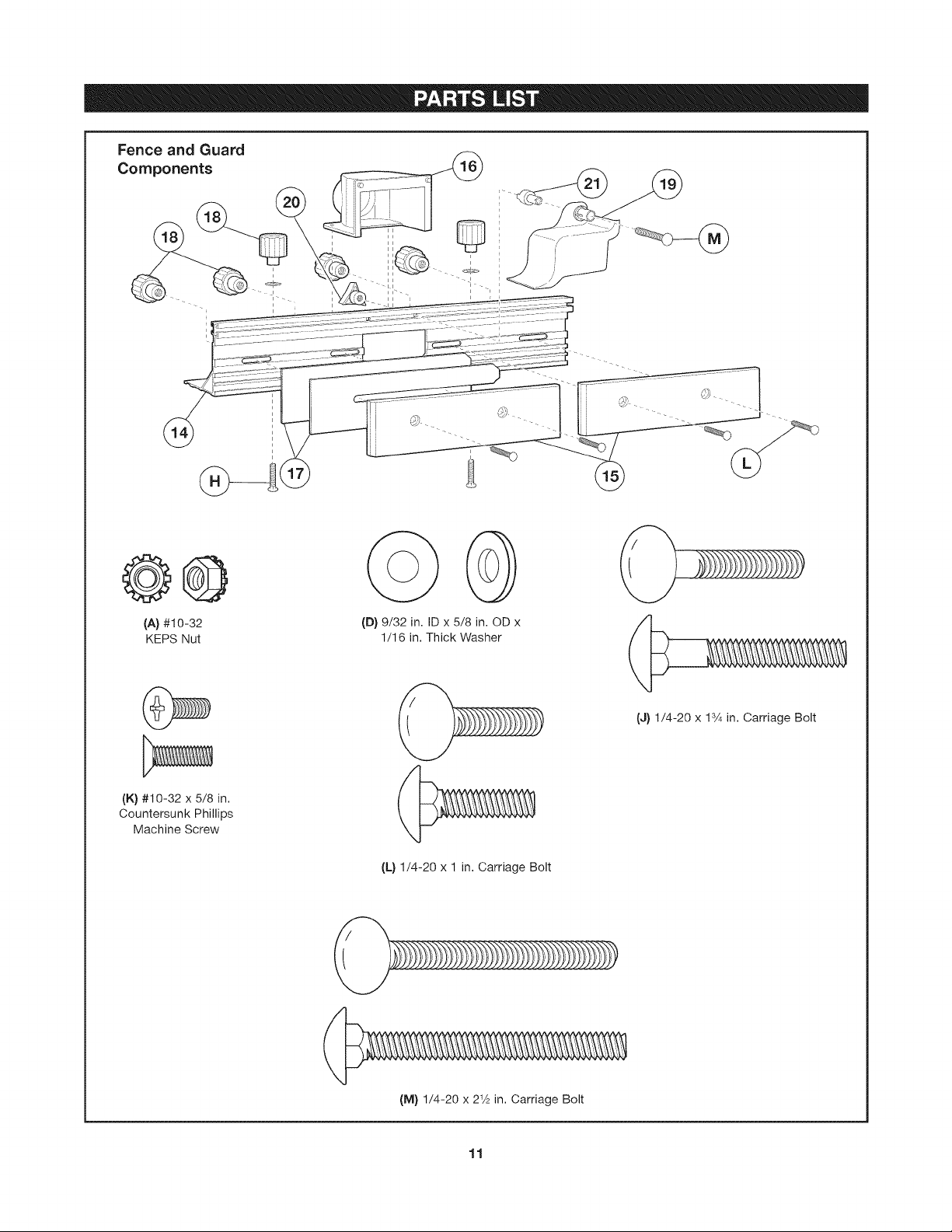

Fence and Guard

Components

@@

(A} #10-32

KEPS Nut

(K) #10-32 x 5/8 in.

Countersunk Phillips

Machine Screw

(D) 9/32 in. ID x 5/8 in. OD x

1/16 in. Thick Washer

(J) 1/4-20 x lS/4 in. Carriage Bolt

(L) 1/4-20 x 1 in. Carriage Bolt

(M) 1/4-20 x 21A in. Carriage Bolt

11

ASSEMBLING THE ROUTER TABLE

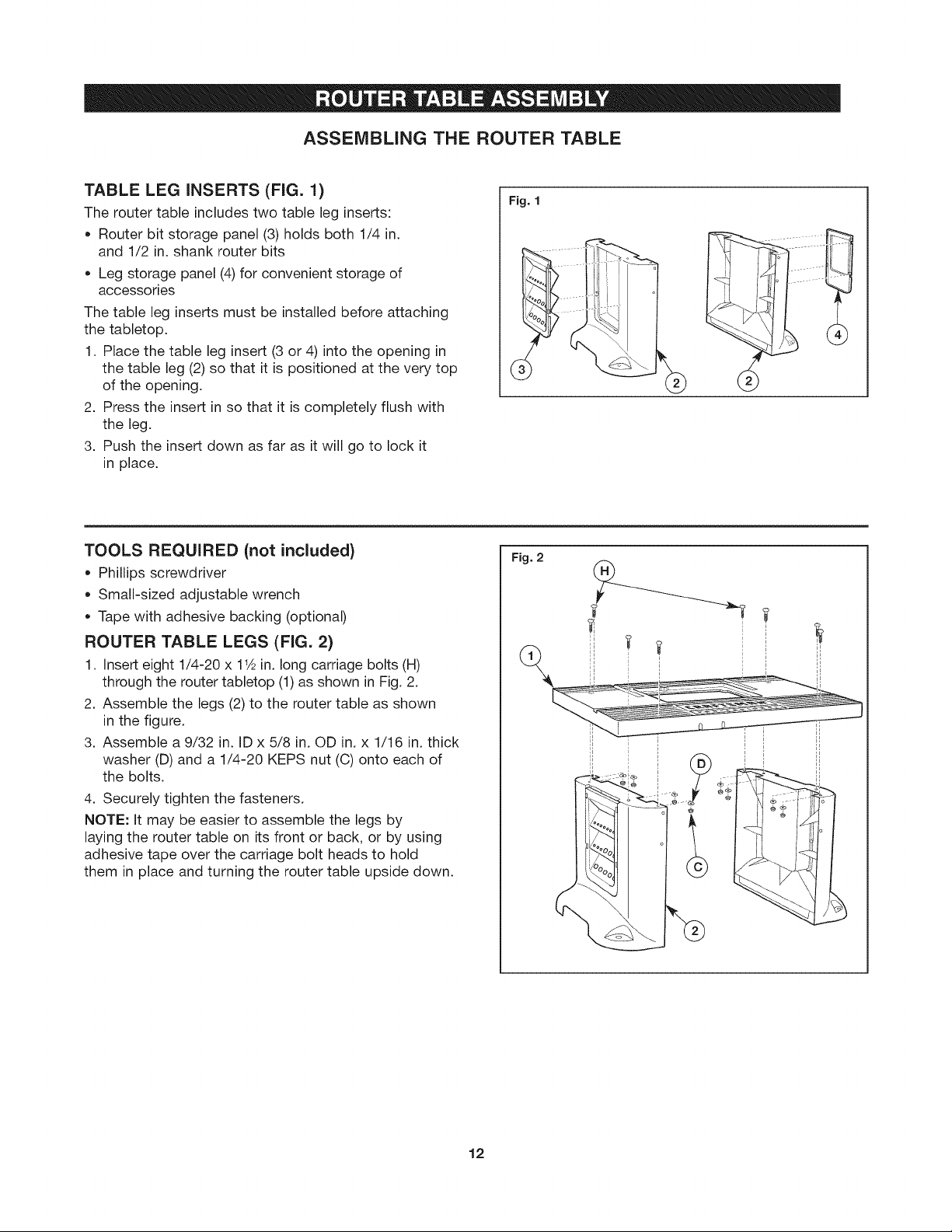

TABLE LEG iNSERTS (FIG. 1)

The router table includes two table leg inserts:

• Router bit storage panel (3) holds both 1/4 in.

and 1/2 in. shank router bits

Leg storage panel (4) for convenient storage of

accessories

The table leg inserts must be installed before attaching

the tabletop.

1. Place the table leg insert (3 or 4) into the opening in

the table leg (2) so that it is positioned at the very top

of the opening.

2. Press the insert in so that it is completely flush with

the leg.

3. Push the insert down as far as it will go to lock it

in place.

TOOLS REQUIRED (not included}

Phillips screwdriver

Small-sized adjustable wrench

Tape with adhesive backing (optional)

ROUTER TABLE LEGS (FIG. 2)

1. Insert eight 1/4-20 x 11½in. long carriage bolts (H)

through the router tabletop (1) as shown in Fig. 2.

2. Assemble the legs (2) to the router table as shown

in the figure.

3. Assemble a 9/32 in. ID x 5/8 in. OD in. x 1/16 in. thick

washer (D) and a 1/4-20 KEPS nut (C) onto each of

the bolts.

4. Securely tighten the fasteners.

NOTE: It may be easier to assemble the legs by

laying the router table on its front or back, or by using

adhesive tape over the carriage bolt heads to hold

them in place and turning the router table upside down.

Fig. 1

Fig. 2

©

12

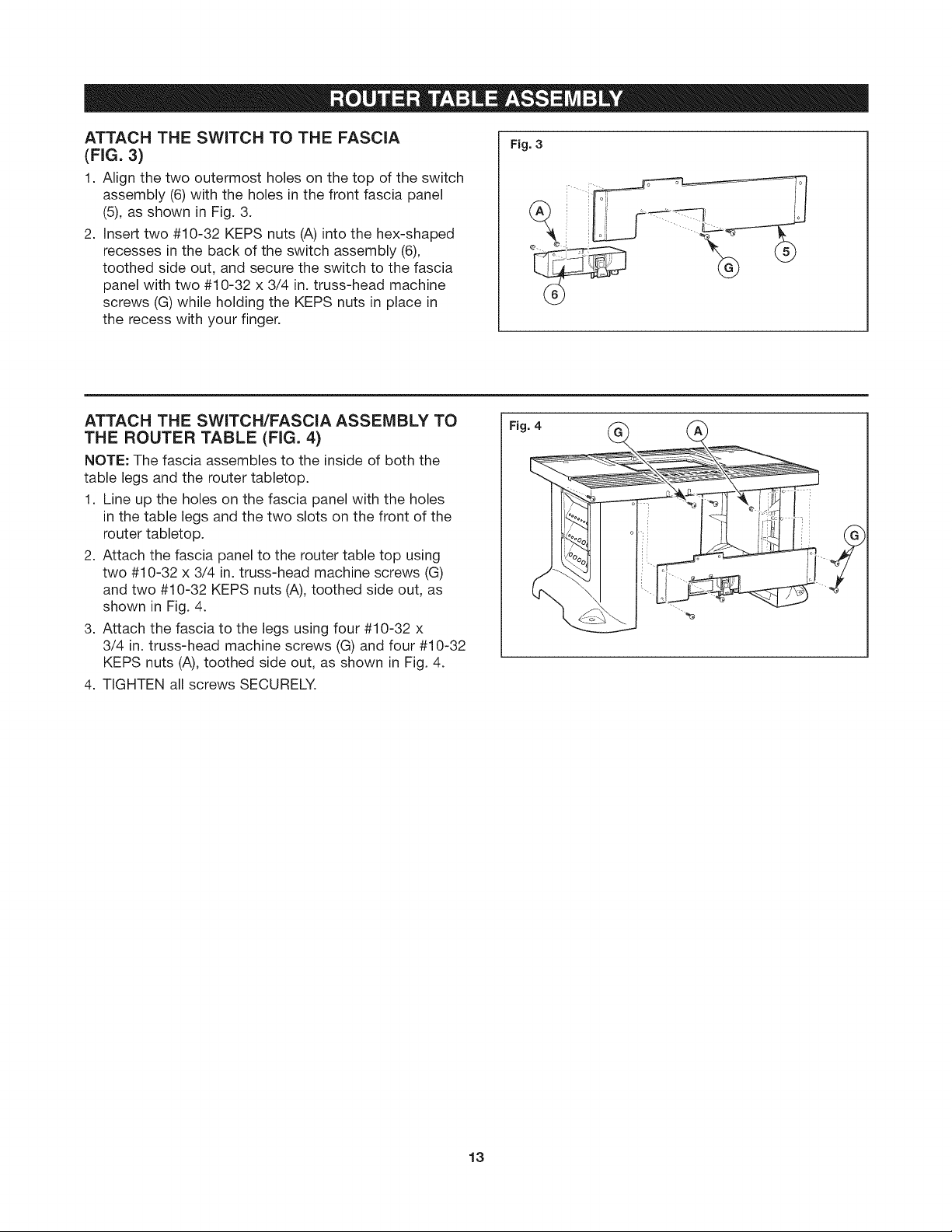

ATTACH THE SWITCH TO THE FASCIA

(FIG. 3)

1. Align the two outermost holes on the top of the switch

assembly (6) with the holes in the front fascia panel

(5), as shown in Fig. 3.

2. Insert two #10-32 KEPS nuts (A) into the hex-shaped

recesses in the back of the switch assembly (6),

toothed side out, and secure the switch to the fascia

panel with two #10-32 x 3/4 in. truss-head machine

screws (G) while holding the KEPS nuts in place in

the recess with your finger.

Fig. 3

ATTACH THE SWITCH/FASCIA ASSEMBLY TO

THE ROUTER TABLE (FIG. 4)

NOTE: The fascia assembles to the inside of both the

table legs and the router tabletop.

1. Line up the holes on the fascia panel with the holes

in the table legs and the two slots on the front of the

router tabletop.

2. Attach the fascia panel to the router table top using

two #10-32 x 3/4 in. truss-head machine screws (G)

and two #10-32 KEPS nuts (A), toothed side out, as

shown in Fig. 4.

3. Attach the fascia to the legs using four #10-32 x

3/4 in. truss-head machine screws (G) and four #10-32

KEPS nuts (A), toothed side out, as shown in Fig. 4.

4. TIGHTEN all screws SECURELY.

Fig. 4

13

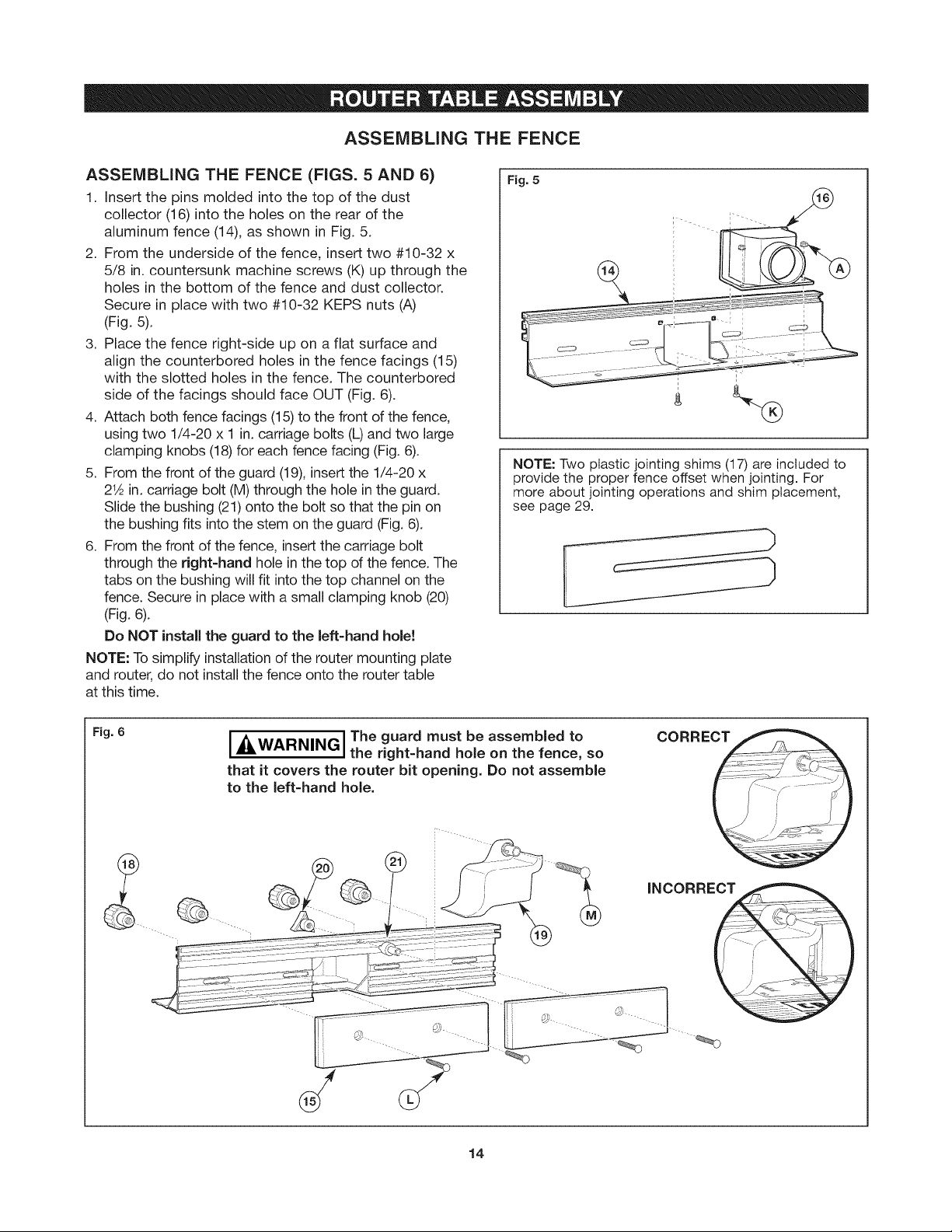

ASSEMBLING THE FENCE

ASSEMBLING THE FENCE (FIGS. 5 AND 6)

1. Insert the pins molded into the top of the dust

collector (16) into the holes on the rear of the

aluminum fence (14), as shown in Fig. 5.

2. From the underside of the fence, insert two #10-32 x

5/8 in. countersunk machine screws (K) up through the

holes in the bottom of the fence and dust collector.

Secure in place with two #10-32 KEPS nuts (A)

(Fig. 5).

3. Place the fence right-side up on a flat surface and

align the counterbored holes in the fence facings (15)

with the slotted holes in the fence. The counterbored

side of the facings should face OUT (Fig. 6).

4. Attach both fence facings (15) to the front of the fence,

using two 1/4-20 x 1 in. carriage bolts (L) and two large

clamping knobs (18) for each fence facing (Fig. 6).

5. From the front of the guard (19), insert the 1/4-20 x

2_ in. carriage bolt (M) through the hole in the guard.

Slide the bushing (21) onto the bolt so that the pin on

the bushing fits into the stem on the guard (Fig. 6).

6. From the front of the fence, insert the carriage bolt

through the right-hand hole in the top of the fence. The

tabs on the bushing will fit into the top channel on the

fence. Secure in place with a small clamping knob (20)

(Fig. 6).

Do NOT install the guard to the left-hand hole!

NOTE: To simplify installation of the router mounting plate

and router, do not install the fence onto the router table

at this time.

Fig. 5

NOTE: Two plastic jointing shims (17) are included to

provide the proper fence offset when jointing. For

more about jointing operations and shim placement,

see page 29.

Fig. 6

I_, I The guard must be assembled to

WARNING, the right-hand hole on the fence, so

that it covers the router bit opening. Do not assemble

to the left-hand hole.

14

CORRECT

s_

iNSTALLiNG THE ROUTER MOUNTING PLATE

TOOLS REQUIRED

• 1/8" Allen wrench (I) (included)

• Phillips screwdriver (not included)

• Straight edge (not included)

• Small-sized adjustable wrench (not included)

NOTE: The fence must NOT be installed on the router

table for the following procedures.

PRELiMiNARY iNSTALLATiON OF THE

ROUTER MOUNTING PLATE (FIGS. 7-9)

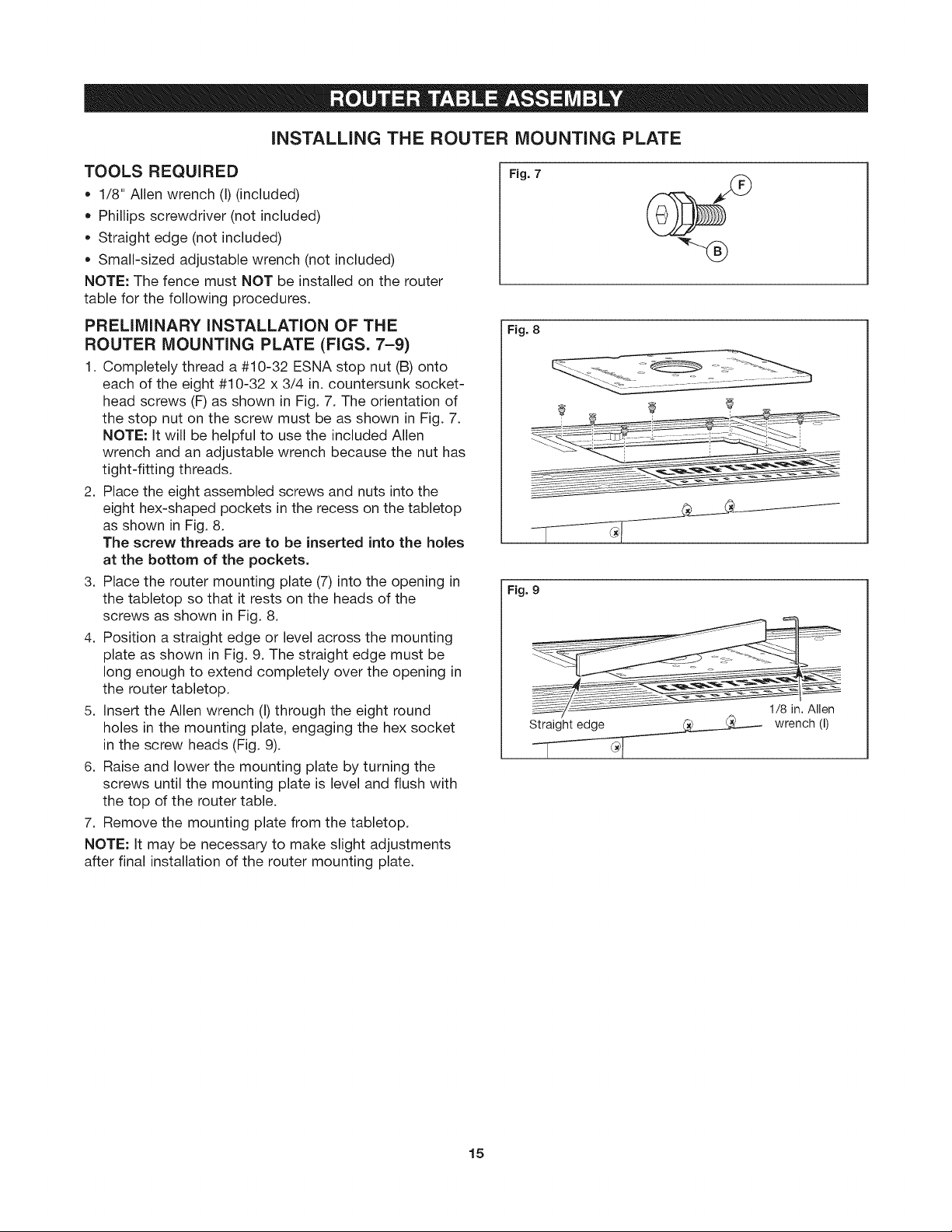

1. Completely thread a #10-32 ESNA stop nut (B) onto

each of the eight #10-32 x 3/4 in. countersunk socket-

head screws (F) as shown in Fig. 7. The orientation of

the stop nut on the screw must be as shown in Fig. 7.

NOTE: It will be helpful to use the included Allen

wrench and an adjustable wrench because the nut has

tight-fitting threads.

2. Place the eight assembled screws and nuts into the

eight hex-shaped pockets in the recess on the tabletop

as shown in Fig. 8.

The screw threads are to be inserted into the holes

at the bottom of the pockets.

3. Place the router mounting plate (7) into the opening in

the tabletop so that it rests on the heads of the

screws as shown in Fig. 8.

4. Position a straight edge or level across the mounting

plate as shown in Fig. 9. The straight edge must be

long enough to extend completely over the opening in

the router tabletop.

5. insert the Allen wrench (I) through the eight round

holes in the mounting plate, engaging the hex socket

in the screw heads (Fig. 9).

6. Raise and lower the mounting plate by turning the

screws until the mounting plate is level and flush with

the top of the router table.

7. Remove the mounting plate from the tabletop.

NOTE: it may be necessary to make slight adjustments

after final installation of the router mounting plate.

Fig. 7

Fig. 8

Fig. 9

Straight edge

1/8 in. Allen

wrench

(I)

15

I-_ I Before using the router table, verify that the router is securely clamped to the router table

WARNING, base. While working, periodically check the router base fasteners clamping tightness.

Router motor vibration can loosen fasteners during use, causing the router to fall from the table.

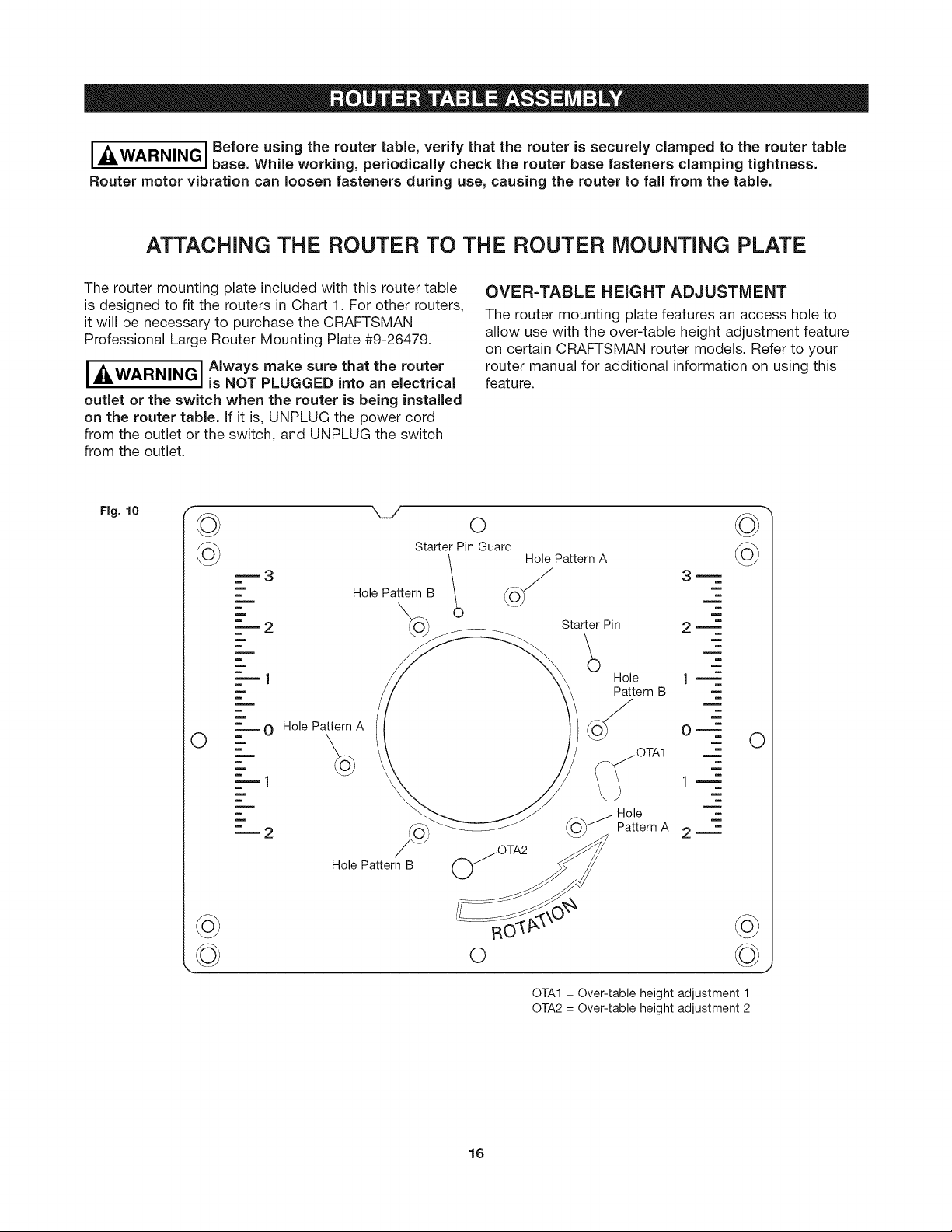

ATTACHING THE ROUTER TO THE ROUTER MOUNTING PLATE

The router mounting plate included with this router table

is designed to fit the routers in Chart 1. For other routers,

it will be necessary to purchase the CRAFTSMAN

Professional Large Router Mounting Plate #9-26479.

i_&WARNINGI Always make sure that the router

outlet or the switch when the router is being installed

on the router table. If it is, UNPLUG the power cord

from the outlet or the switch, and UNPLUG the switch

from the outlet.

Fig. 10

is NOT PLUGGED into an electrical

©

====3

HolePattern B

O

m

m

m

m

m

m

O Hole Pattern A

Starter Pin Guard

OVER=TABLE HEIGHT ADJUSTMENT

The router mounting plate features an access hole to

allow use with the over-table height adjustment feature

on certain CRAFTSMAN router models. Refer to your

router manual for additional information on using this

feature.

o

0 HolePattern A

Starter Pin

Hole

Pattern B

2 m

1 m

O m

©

m

m

m

=

m

m

m

O

©

_=---1

"2

Hole Pattern B

_OTA2

O

16

lm

Hole

Pattern A

OTA1 = Over-table height adjustment 1

OTA2 = Over-table height adjustment 2

2 m

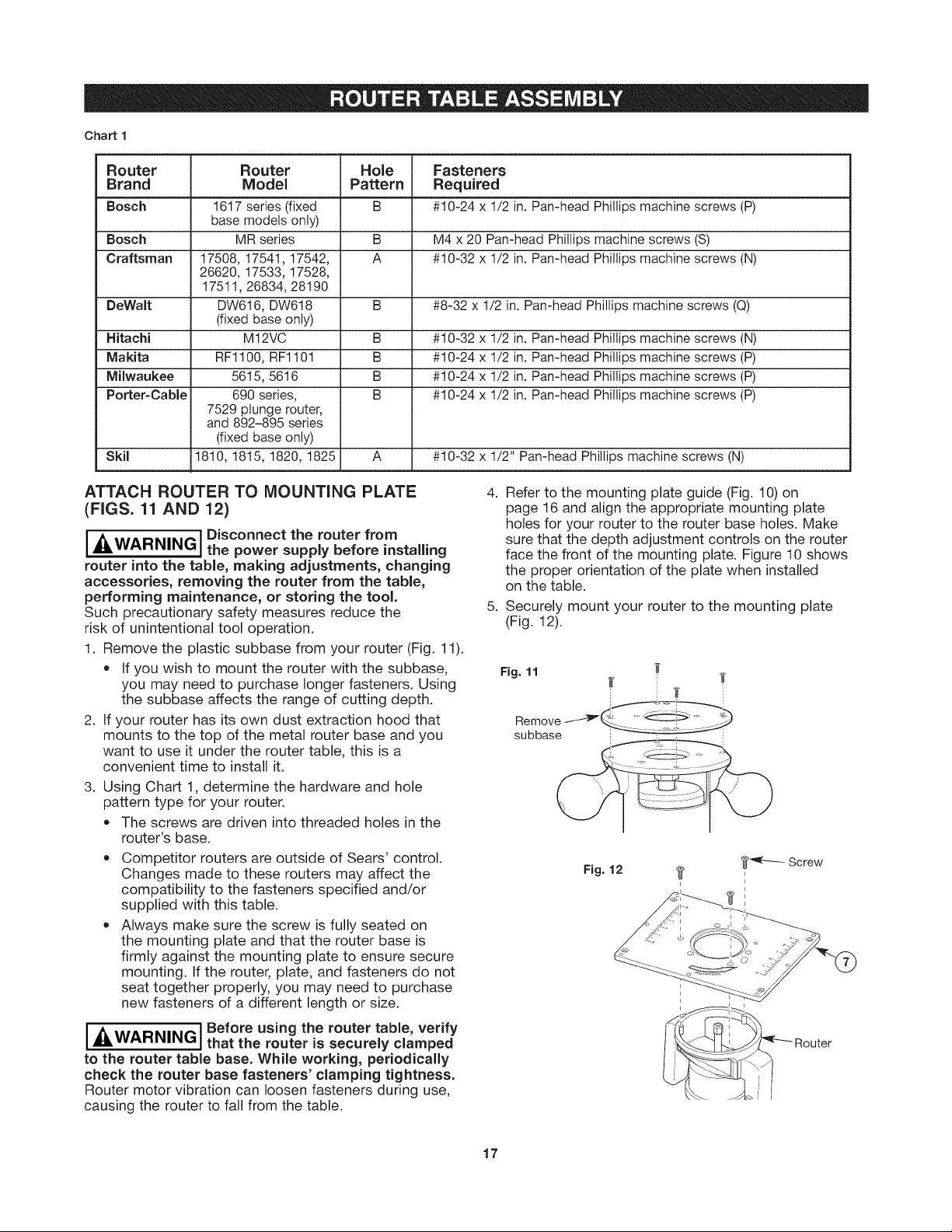

Chart 1

Router Router Hole Fasteners

Brand Model Pattern Required

Bosch 1617 series (fixed B #10-24 x 1/2 in. Pan-head Phillips machine screws (P)

Bosch MR series B M4 x 20 Pan-head Phillips machine screws (S)

Craftsman 17508, 17541, 17542, A #10-32 x 1/2 in. Pan-head Phillips machine screws (N)

DeWalt DW616, DW618 B #8-32 x 1/2 in. Pan-head Phillips machine screws (Q)

Hitachi M12VC B #10-32 x 1/2 in. Pan-head Phillips machine screws (N)

Makita RF1100, RF1101 B #10-24 x 1/2 in. Pan-head Phillips machine screws (P)

Milwaukee 5615, 5616 B #10-24 x 1/2 in. Pan-head Phillips machine screws (P)

Porter-Cable 690 series, B #10-24 x 1/2 in. Pan-head Phillips machine screws (P)

Skil 1810, 1815, 1820, 1825 A #10-32 x 1/2" Pan-head Phillips machine screws (N)

base models only)

26620, 17533, 17528,

17511, 26834, 28190

(fixed base only)

7529 plunge router,

and 892-895 series

(fixed base only)

ATTACH ROUTER TO MOUNTING PLATE

(FIGS. 11 AND 12)

I _i' I Disconnect the router from

WARNING the power supply before installing

router into the table, making adjustments, changing

accessories, removing the router from the table,

performing maintenance, or storing the tool.

Such precautionary safety measures reduce the

risk of unintentional tool operation.

1. Remove the plastic subbase from your router (Fig. 11).

• If you wish to mount the router with the subbase,

you may need to purchase longer fasteners. Using

the subbase affects the range of cutting depth.

2. If your router has its own dust extraction hood that

mounts to the top of the metal router base and you

want to use it under the router table, this is a

convenient time to install it.

3. Using Chart 1, determine the hardware and hole

pattern type for your router.

• The screws are driven into threaded holes in the

router's base.

Competitor routers are outside of Sears' control.

Changes made to these touters may affect the

compatibility to the fasteners specified and/or

supplied with this table.

Always make sure the screw is fully seated on

the mounting plate and that the router base is

firmly against the mounting plate to ensure secure

mounting. If the router, plate, and fasteners do not

seat together properly, you may need to purchase

new fasteners of a different length or size.

4. Refer to the mounting plate guide (Fig. 10) on

page 16 and align the appropriate mounting plate

holes for your router to the router base holes. Make

sure that the depth adjustment controls on the router

face the front of the mounting plate. Figure 10 shows

the proper orientation of the plate when installed

on the table.

5. Securely mount your router to the mounting plate

(Fig. 12).

Fig. 11 _ i o_[

Remove_ J " _i:_ ..... _"

subbase

I-_ I Before using the router table, verify

WARNING, that the router is securely clamped

to the router table base. While working, periodically

check the router base fasteners' clamping tightness.

Router motor vibration can loosen fasteners during use,

causing the router to fall from the table.

17

FINAL iNSTALLATiON OF THE ROUTER

MOUNTING PLATE (FIG. 13)

1. Place the router mounting plate, with router attached,

on the leveling screws in the tabletop. NOTE: Be care-

ful not to trap the cord between the router mounting

plate and the router tabletop.

2. Recheck the router mounting plate to be sure it is

level. If necessary, adjust the leveling screws with the

Allen wrench as needed.

3. Secure the router mounting plate (7) to the table with

four #10-32 x 1 in. pan-head Phillips machine screws

(E) through the inner corner holes in the plate and four

#10-32 ESNA stop nuts (B) from the underside of the

tabletop in the recesses provided (Fig. 13). Tighten the

screws snugly, but do not overtighten.

TO REMOVE THE ROUTER AND/OR ROUTER

MOUNTING PLATE

Fig. 13

i__WARNING I Make sure that the router is NOT

installing into the table, removing from table, making

adjustments, or changing accessories. Router could

accidentally start.

THE FENCE MUST BE REMOVED FROM THE ROUTER

TABLE WHEN REMOVING OR REINSTALLING THE

ROUTER MOUNTING PLATE.

plugged into a power outlet when

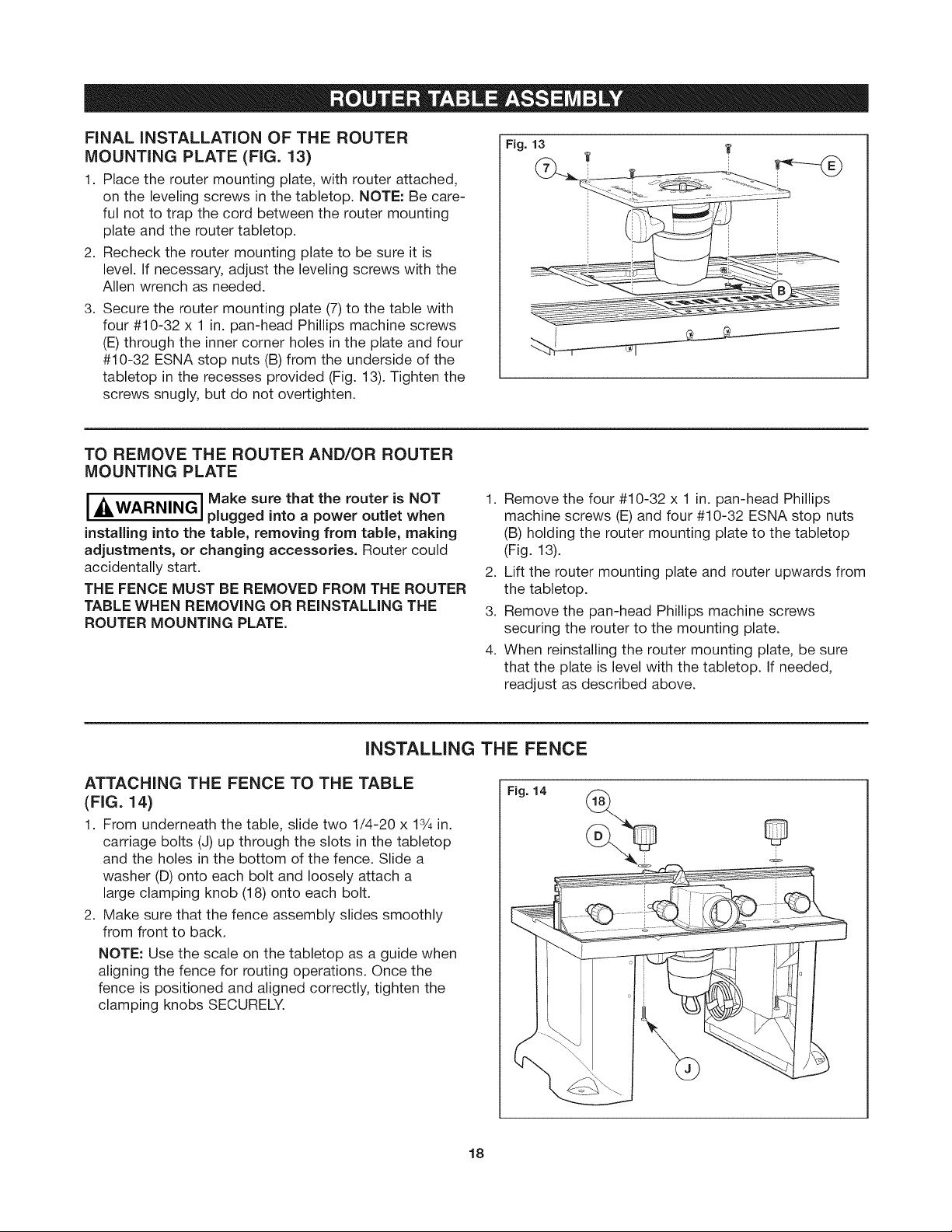

INSTALLING THE FENCE

ATTACHING THE FENCE TO THE TABLE

(FIG. 14)

1. From underneath the table, slide two 1/4-20 x 13/4in.

carriage bolts (J) up through the slots in the tabletop

and the holes in the bottom of the fence. Slide a

washer (D) onto each bolt and loosely attach a

large clamping knob (18) onto each bolt.

2. Make sure that the fence assembly slides smoothly

from front to back.

NOTE: Use the scale on the tabletop as a guide when

aligning the fence for routing operations. Once the

fence is positioned and aligned correctly, tighten the

clamping knobs SECURELY.

1. Remove the four #10-32 x 1 in. pan-head Phillips

machine screws (E) and four #10-32 ESNA stop nuts

(B) holding the router mounting plate to the tabletop

(Fig. 13).

2. Lift the router mounting plate and router upwards from

the tabletop.

3. Remove the pan-head Phillips machine screws

securing the router to the mounting plate.

4. When reinstalling the router mounting plate, be sure

that the plate is level with the tabletop. If needed,

readjust as described above.

Fig. 14

18

MOUNTING THE ROUTER TABLE TO A WORK SURFACE OR WORKBENCH

I_4=WARNINGI Before operating, make sure the

installed) is placed on and secured to a solid, flat,

level surface and will not tip. Use of auxiliary in-feed

and out-feed supports is necessary for long or wide

workpieces. Long workpieces without adequate support

can cause the router table to tip over.

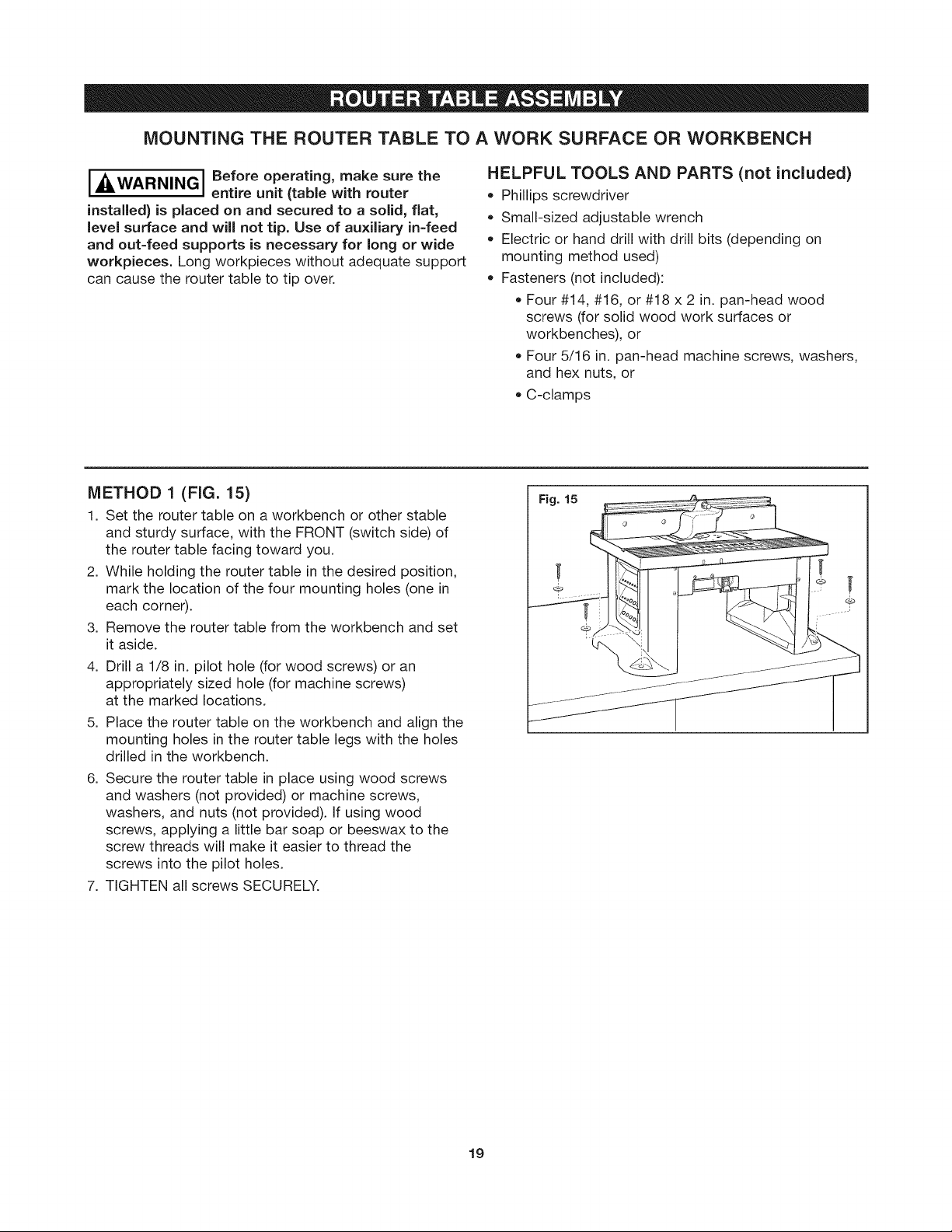

METHOD 1 (FIG. 15)

1. Set the router table on a workbench or other stable

and sturdy surface, with the FRONT (switch side) of

the router table facing toward you.

2. While holding the router table in the desired position,

mark the location of the four mounting holes (one in

each corner).

3. Remove the router table from the workbench and set

it aside.

4. Drill a 1/8 in. pilot hole (for wood screws) or an

appropriately sized hole (for machine screws)

at the marked locations.

5. Place the router table on the workbench and align the

mounting holes in the router table legs with the holes

drilled in the workbench.

6. Secure the router table in place using wood screws

and washers (not provided) or machine screws,

washers, and nuts (not provided). If using wood

screws, applying a little bar soap or beeswax to the

screw threads will make it easier to thread the

screws into the pilot holes.

7. TIGHTEN all screws SECURELY.

entire unit (table with router

HELPFUL TOOLS AND PARTS (not included)

• Phillips screwdriver

Small-sized adjustable wrench

Electric or hand drill with drill bits (depending on

mounting method used)

Fasteners (not included):

Four #14, #16, or #18 x 2 in. pan-head wood

screws (for solid wood work surfaces or

workbenches), or

Four 5/16 in. pan-head machine screws, washers,

and hex nuts, or

C-clamps

Fig. 15

19

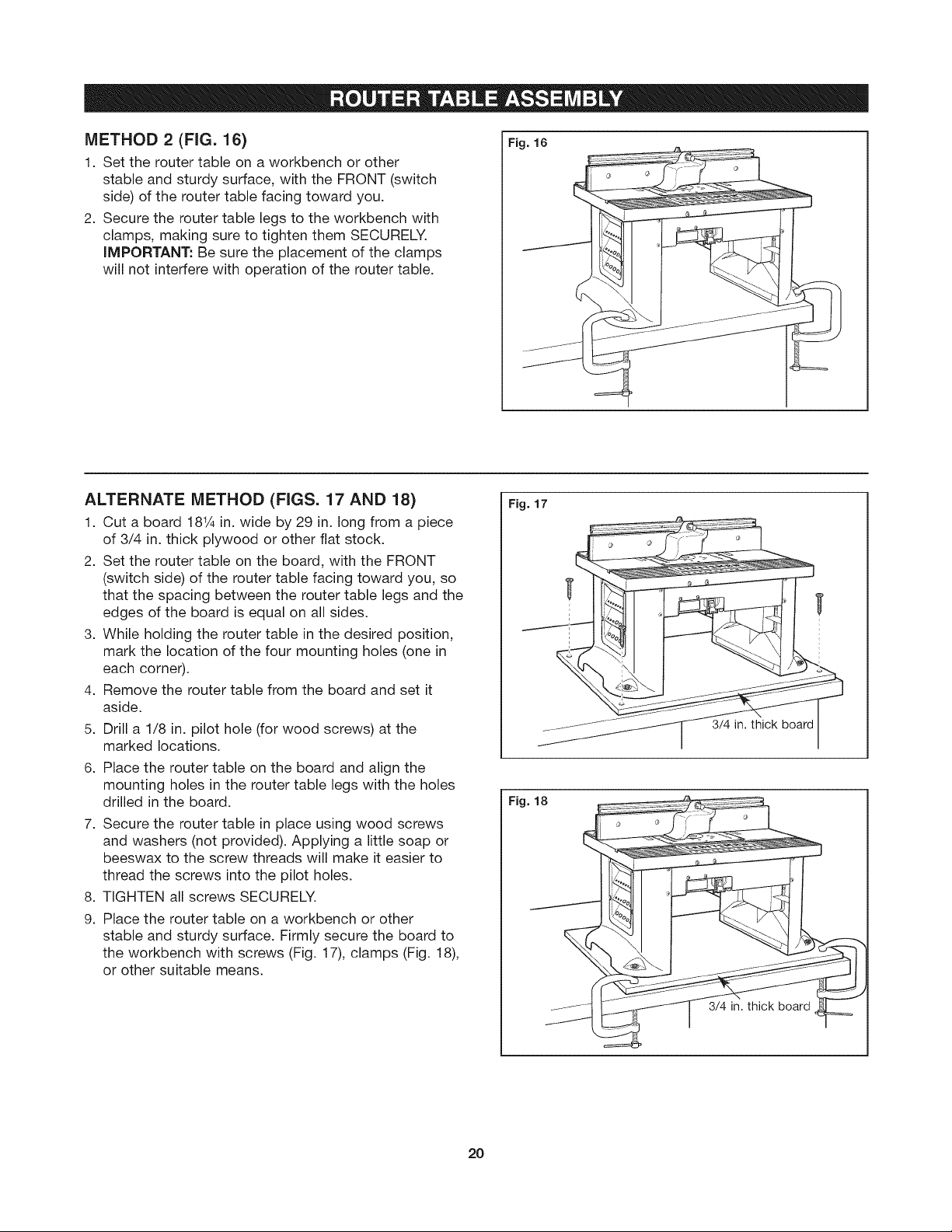

METHOD 2 (FIG. 16)

1. Set the router table on a workbench or other

stable and sturdy surface, with the FRONT (switch

side) of the router table facing toward you.

2. Secure the router table legs to the workbench with

clamps, making sure to tighten them SECURELY.

iMPORTANT: Be sure the placement of the clamps

will not interfere with operation of the router table.

Fig. 16

ALTERNATE METHOD (FIGS. 17 AND 18)

1. Cut a board 184¼in. wide by 29 in. long from a piece

of 3/4 in. thick plywood or other flat stock.

2. Set the router table on the board, with the FRONT

(switch side) of the router table facing toward you, so

that the spacing between the router table legs and the

edges of the board is equal on all sides.

3. While holding the router table in the desired position,

mark the location of the four mounting holes (one in

each corner).

4. Remove the router table from the board and set it

aside.

5. Drill a 1/8 in. pilot hole (for wood screws) at the

marked locations.

6. Place the router table on the board and align the

mounting holes in the router table legs with the holes

drilled in the board.

7. Secure the router table in place using wood screws

and washers (not provided). Applying a little soap or

beeswax to the screw threads will make it easier to

thread the screws into the pilot holes.

8. TIGHTEN all screws SECURELY.

9. Place the router table on a workbench or other

stable and sturdy surface. Firmly secure the board to

the workbench with screws (Fig. 17), clamps (Fig. 18),

or other suitable means.

Fig. 17

4

3/4 in. thick board

Fig. 18

20

3/4 in. thick board

I _ILWARNING I Disconnect the router from the

router into the table, making adjustments, changing

accessories, removing the router from the table,

performing maintenance, or storing the tool. Such

precautionary safety measures reduce the risk of

unintentional tool operation.

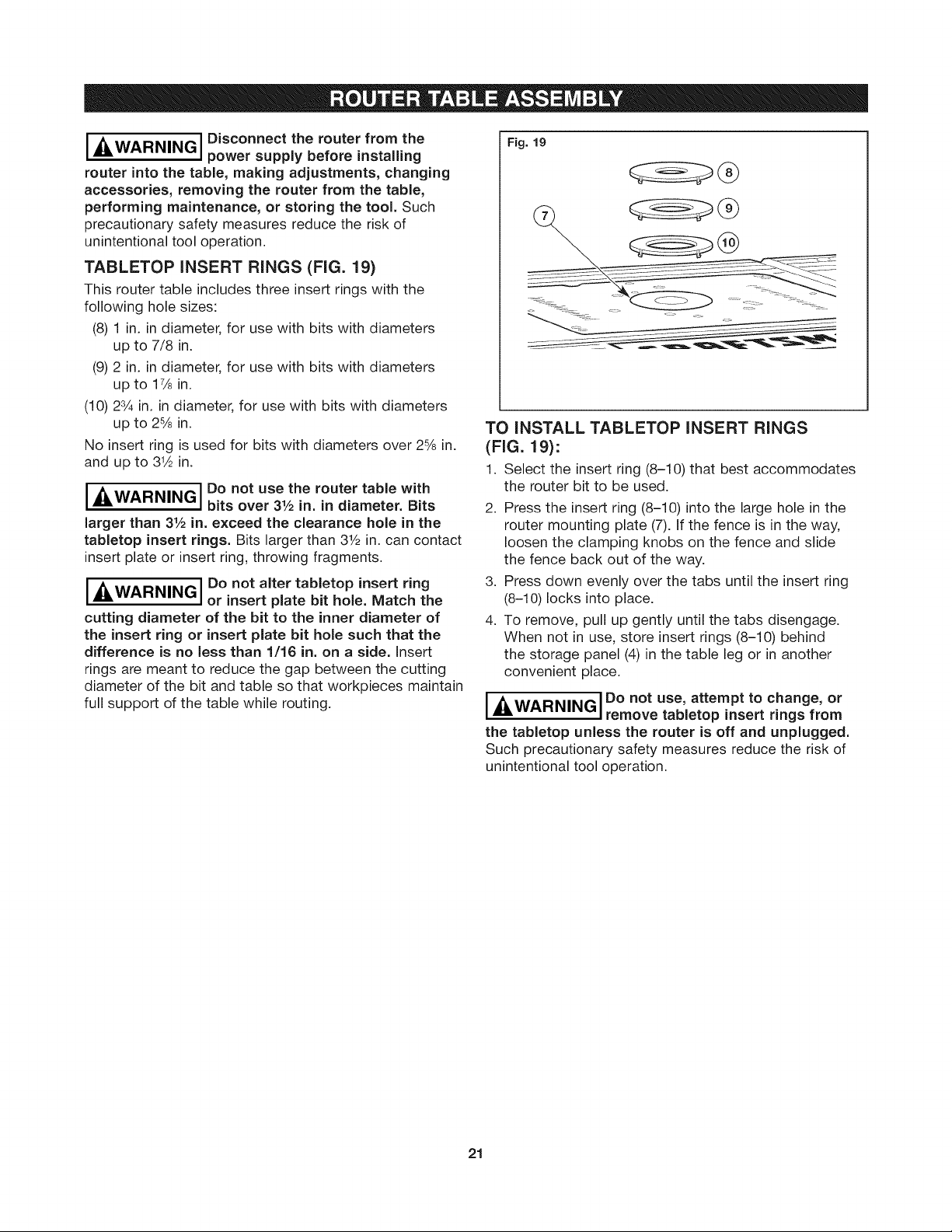

TABLETOP INSERT RINGS (FIG. 19)

This router table includes three insert rings with the

following hole sizes:

(8) 1 in. in diameter, for use with bits with diameters

up to 7/8 in.

(9) 2 in. in diameter, for use with bits with diameters

up to 1% in.

(10) 2% in. in diameter, for use with bits with diameters

up to 2% in.

No insert ring is used for bits with diameters over 2% in.

and up to 3% in.

I A WARNING I Do not use the router table with

I ALL I

larger than 31/2 in. exceed the clearance hole in the

tabletop insert rings. Bits larger than 31/2 in. can contact

insert plate or insert ring, throwing fragments.

I A WARNING I Do not alter tabletop insert ring

IAll I

cutting diameter of the bit to the inner diameter of

the insert ring or insert plate bit hole such that the

difference is no less than 1/16 in. on a side. Insert

rings are meant to reduce the gap between the cutting

diameter of the bit and table so that workpieces maintain

full support of the table while routing.

power supply before installing

bits over 31/2 in. in diameter. Bits

or insert plate bit hole. Match the

Fig. 19

TO INSTALL TABLETOP INSERT RINGS

(FIG. 19):

1. Select the insert ring (8-10) that best accommodates

the router bit to be used.

2. Press the insert ring (8-10) into the large hole in the

router mounting plate (7). If the fence is in the way,

loosen the clamping knobs on the fence and slide

the fence back out of the way.

3. Press down evenly over the tabs until the insert ring

(8-10) locks into place.

4. To remove, pull up gently until the tabs disengage.

When not in use, store insert rings (8-10) behind

the storage panel (4) in the table leg or in another

convenient place.

._WARNING Do not use, attempt to change, or

I I remove tabletop insert rings from

the tabletop unless the router is off and unplugged.

Such precautionary safety measures reduce the risk of

unintentional tool operation.

21

SWITCH CONTROL BOX

[_,WARNINGI Do not plug router motor power

must be plugged into the router table switch. Power

tool switches and controls need to be within your reach

in emergency situations.

GENERAL iNFORMATiON

The power switch is designed for use with most

CRAFTSMAN Router Tables. it provides the convenience

of an ON (RESET)-OFF switch at the front of the table,

thus eliminating the need to reach underneath the table

to turn the router ON and OFF.

The power switch also provides an optional

simultaneous ON-OFF control of an additional

accessory, such as a light, wet/dry vac, etc.

The switch has an internal, resettable circuit

breaker to provide overload protection.

cord into standard wall outlet. It

ELECTRICAL REQUIREMENTS

The switch box cord should only be plugged into a

14-gauge (or heavier), three-wire extension cord with

a three-hole grounding receptacle and three-prong

grounding plug. The extension cord must be plugged

into a matching outlet that has been installed by a

licensed electrician and grounded in accordance with

all local codes and ordinances.

DAMAGED OR WORN EXTENSION CORDS ARE

NOT TO BE USED AND ARE TO BE REPLACED

IMMEDIATELY.

The electrical outlets at the back of the switch box will

accept three-hole extension cords.

The electrical receptacles at the back of the switch box

will accept either three-prong or two-prong plugs from a

router or accessory.

In the event of a malfunction or breakdown, grounding

provides the path of least resistance for electrical current

in order to reduce the risk of electrical shock. This switch

box is equipped with an electrical cord that has an

equipment-grounding connector and a grounding plug.

DO NOT modify the plug from the switch if it does not

plug into the extension cord. Obtain an extension cord

with the proper outlet.

improper connection of the equipment-grounding

conductor can result in risk of an electrical shock.

The conductor with insulation that has a green outer

surface, with or without yellow stripes, is the equipment-

grounding conductor.

DO NOT CONNECT THE EQUIPMENT-GROUNDING

CONDUCTOR TO A LIVE TERMINAL.

Check with a licensed electrician if the grounding

instructions are not completely understood or if there

is doubt as to whether the electrical outlet or extension

cord is properly grounded.

I A WARNINGI Do not permit fingers to touch

iAu=, ]

or removing the plug from the outlet. Risk of Electric

Shock.

IAWARNING I Use the switch box only when

IAUL I

table. Use only with a router that has also been

properly installed on a properly assembled router

table. Such precautionary safety measures reduce

the risk of injury due to loss of control.

I_& WARNING J Do not exceed a total combined

the router and any accessories such as a light or

wet/dry vacuum. The switch has a rating of 15 amps.

CONNECTING THE ROUTER POWER CORD

TO THE SWITCH

[__ J Before connecting router to router

WARNING table switch box, ensure that the

router switch is OFF, and that the router table switch

box is unplugged. Such precautionary safety measures

reduce the risk of unintentional tool operation.

1. Plug the router power cord into one of the electrical

outlets on the back of the switch box.

2. Form the excess power cord into a coil.

3. Wrap two pieces of friction tape or strong cord around

the coiled cord at opposite sides of the coil.

4. Allow some slack so that the cord does not become

stretched when it is plugged into the switch box

outlets.

5. If desired, at this time plug the power cord from an

accessory, such as a wet/dry vac or light, into the

other outlet.

I,_WARNINGJ efore starting to work, ensure

router, accessories, the switch case, and the

extension cord do not and cannot come in contact

with the router or any moving parts of the router.

Such precautionary safety measures reduce the risk

of injury due to loss of control.

terminals of the plug when inserting

properly assembled to the router

rating of 15 amps when connecting

that the power cords from the

22

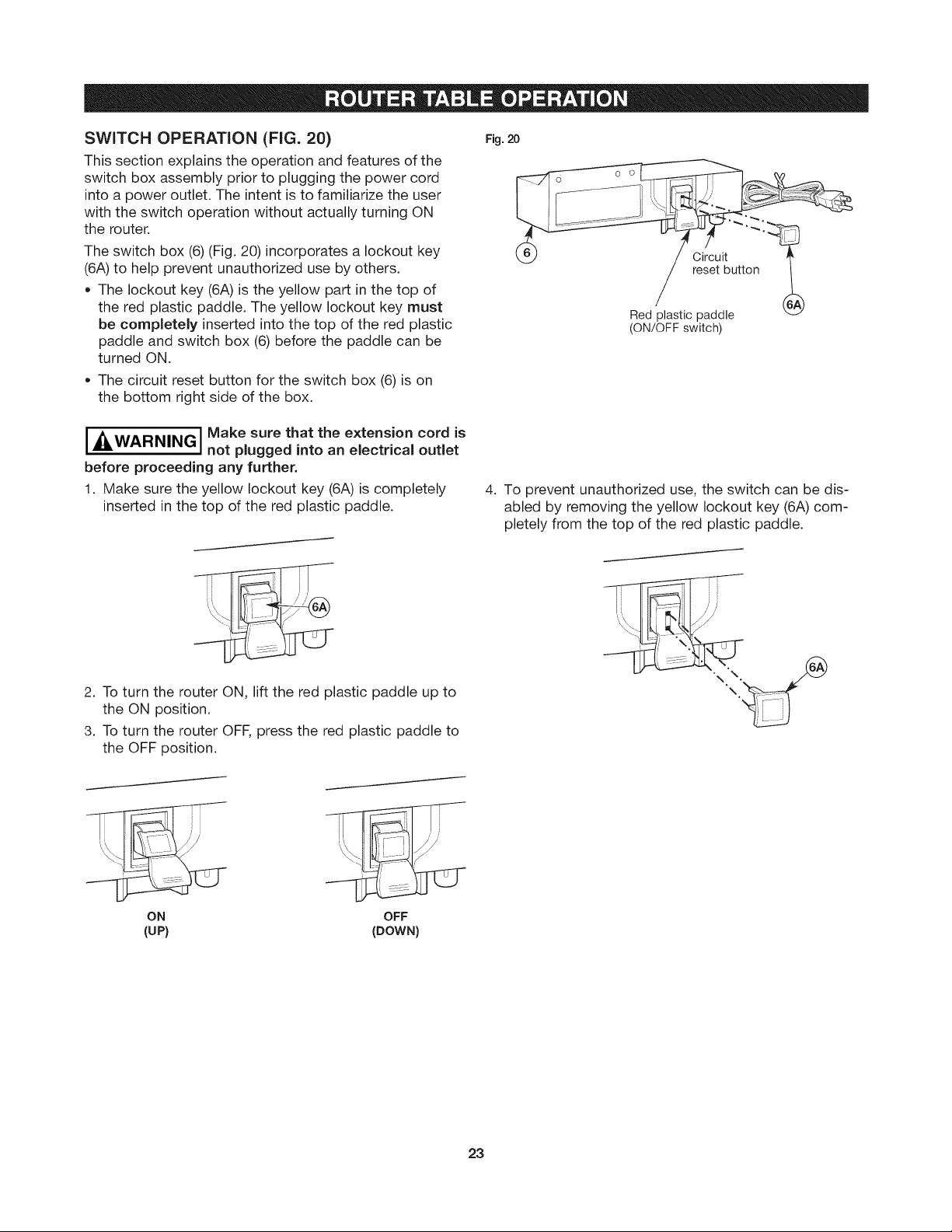

SWITCH OPERATION (FIG. 20)

This section explains the operation and features of the

switch box assembly prior to plugging the power cord

into a power outlet. The intent is to familiarize the user

with the switch operation without actually turning ON

the router.

The switch box (6) (Fig. 20) incorporates a lockout key

(6A) to help prevent unauthorized use by others.

• The lockout key (6A) is the yellow part in the top of

the red plastic paddle. The yellow lockout key must

be completely inserted into the top of the red plastic

paddle and switch box (6) before the paddle can be

turned ON.

The circuit reset button for the switch box (6) is on

the bottom right side of the box.

Fig. 20

Circuit

reset button

Red plastic paddle

(ON/OFFswitch)

i _&WARNINGI Make sure that the extension cord is

before proceeding any further.

1. Make sure the yellow lockout key (6A) is completely

inserted in the top of the red plastic paddle.

2. To turn the router ON, lift the red plastic paddle up to

the ON position.

3. To turn the router OFF, press the red plastic paddle to

the OFF position.

not plugged into an electrical outlet

4. To prevent unauthorized use, the switch can be dis-

abled by removing the yellow lockout key (6A) com-

pletely from the top of the red plastic paddle.

ON

(UP)

OFF

(DOWN)

23

[ kWARNING I Before proceeding any further,

is in the OFF position and the switch lever is in the

OFF position.

[. kWARNINGI Never leave the router unattended

comes to a complete stop.

[__WARNING I Before starting to work, ensure that

accessories, the switch case, and the extension cord

do not and cannot come in contact with the router

or any moving parts of the router. Such precautionary

safety measures reduce the risk of injury due to loss

of control.

The switch power cord can now be plugged into the

extension cord.

make sure the switch on the router

while it is running or before it

the power cords from the router,

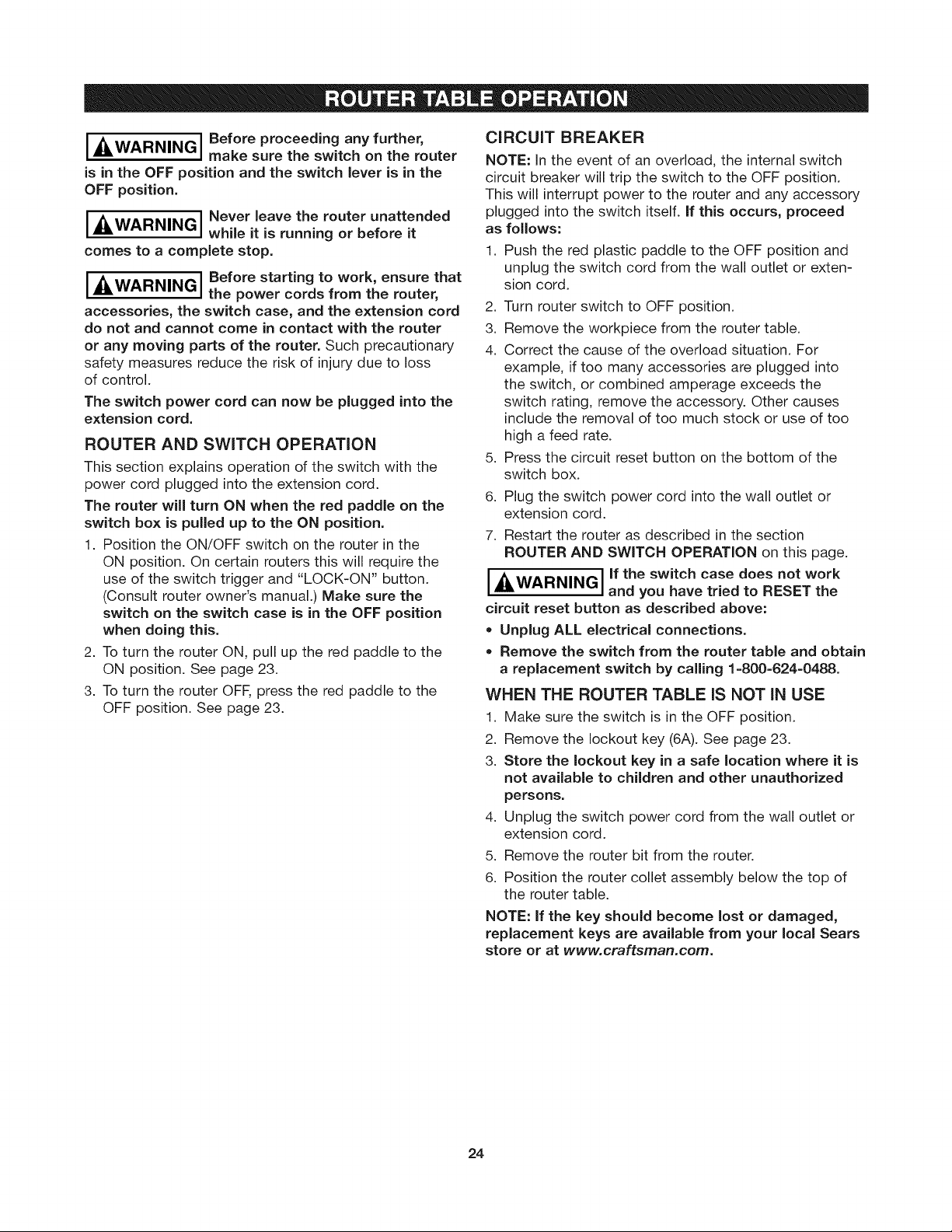

ROUTER AND SWITCH OPERATION

This section explains operation of the switch with the

power cord plugged into the extension cord.

The router will turn ON when the red paddle on the

switch box is pulled up to the ON position.

1. Position the ON/OFF switch on the router in the

ON position. On certain routers this will require the

use of the switch trigger and "LOCK-ON" button.

(Consult router owner's manual.) Make sure the

switch on the switch case is in the OFF position

when doing this.

2. To turn the router ON, pull up the red paddle to the

ON position. See page 23.

3. To turn the router OFF, press the red paddle to the

OFF position. See page 23.

CIRCUIT BREAKER

NOTE: in the event of an overload, the internal switch

circuit breaker will trip the switch to the OFF position.

This will interrupt power to the router and any accessory

plugged into the switch itself. If this occurs, proceed

as follows:

1. Push the red plastic paddle to the OFF position and

unplug the switch cord from the wall outlet or exten-

sion cord.

2. Turn router switch to OFF position.

3. Remove the workpiece from the router table.

4. Correct the cause of the overload situation. For

example, if too many accessories are plugged into

the switch, or combined amperage exceeds the

switch rating, remove the accessory. Other causes

include the removal of too much stock or use of too

high a feed rate.

5. Press the circuit reset button on the bottom of the

switch box.

6. Plug the switch power cord into the wall outlet or

extension cord.

7. Restart the router as described in the section

ROUTER AND SWITCH OPERATION on this page.

I^WARNING Ill the switch case does not work

In J

circuit reset button as described above:

* Unplug ALL electrical connections.

* Remove the switch from the router table and obtain

a replacement switch by calling 1-800-624-0488.

and you have tried to RESET the

WHEN THE ROUTER TABLE IS NOT IN USE

1. Make sure the switch is in the OFF position.

2. Remove the lockout key (6A). See page 23.

3. Store the lockout key in a safe location where it is

not available to children and other unauthorized

persons.

4. Unplug the switch power cord from the wall outlet or

extension cord.

5. Remove the router bit from the router.

6. Position the router collet assembly below the top of

the router table.

NOTE: If the key should become lost or damaged,

replacement keys are available from your local Sears

store or at www.craftsman.com.

24

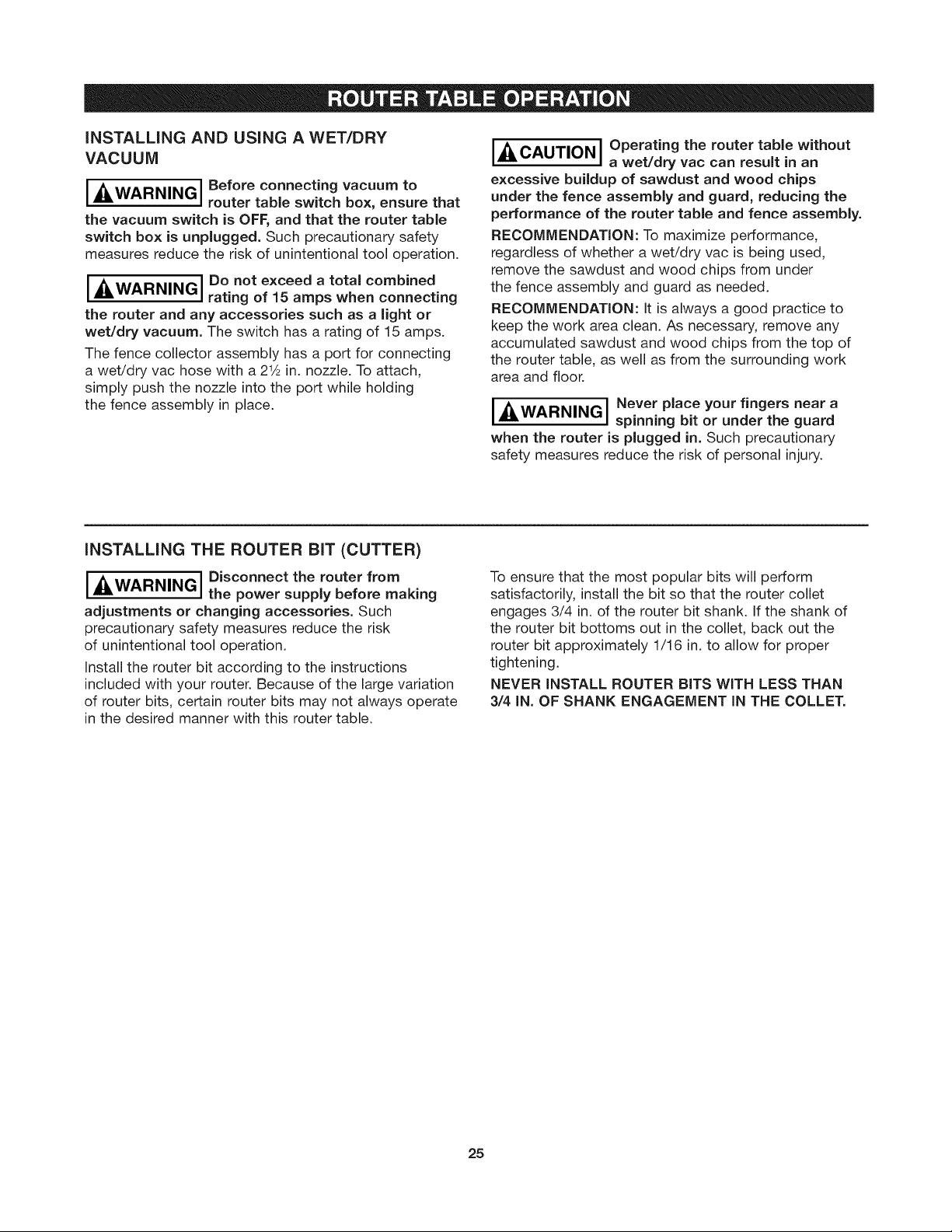

iNSTALLiNG AND USING A WET/DRY

VACUUM

I A WARNING I Before connecting vacuum to

[AUL I

the vacuum switch is OFF, and that the router table

switch box is unplugged. Such precautionary safety

measures reduce the risk of unintentional tool operation.

_&WARNINGI Do not exceed a total combined

the router and any accessories such as a light or

wet/dry vacuum. The switch has a rating of 15 amps.

The fence collector assembly has a port for connecting

a wet/dry vac hose with a 2 _&in. nozzle. To attach,

simply push the nozzle into the port while holding

the fence assembly in place.

router table switch box, ensure that

rating of 15 amps when connecting

iNSTALLiNG THE ROUTER BiT (CUTTER)

IAWARNINGI Disconnect the router from

[AUk I

adjustments or changing accessories. Such

precautionary safety measures reduce the risk

of unintentional tool operation.

Install the router bit according to the instructions

included with your router. Because of the large variation

of router bits, certain router bits may not always operate

in the desired manner with this router table.

the power supply before making

[=_ J Operating the router table without

CAUTION a wet/dry vac can result in an

excessive buildup of sawdust and wood chips

under the fence assembly and guard, reducing the

performance of the router table and fence assembly.

RECOMMENDATION: To maximize performance,

regardless of whether a wet/dry vac is being used,

remove the sawdust and wood chips from under

the fence assembly and guard as needed.

RECOMMENDATION: it is always a good practice to

keep the work area clean. As necessary, remove any

accumulated sawdust and wood chips from the top of

the router table, as well as from the surrounding work

area and floor.

I_lk / Never place your fingers near a

WARNING, spinning bit or under the guard

L

when the router is plugged in. Such precautionary

safety measures reduce the risk of personal injury.

To ensure that the most popular bits will perform

satisfactorily, install the bit so that the router collet

engages 3/4 in. of the router bit shank. If the shank of

the router bit bottoms out in the collet, back out the

router bit approximately 1/16 in. to allow for proper

tightening.

NEVER INSTALL ROUTER BITS WITH LESS THAN

3/4 IN. OF SHANK ENGAGEMENT IN THE COLLET.

25

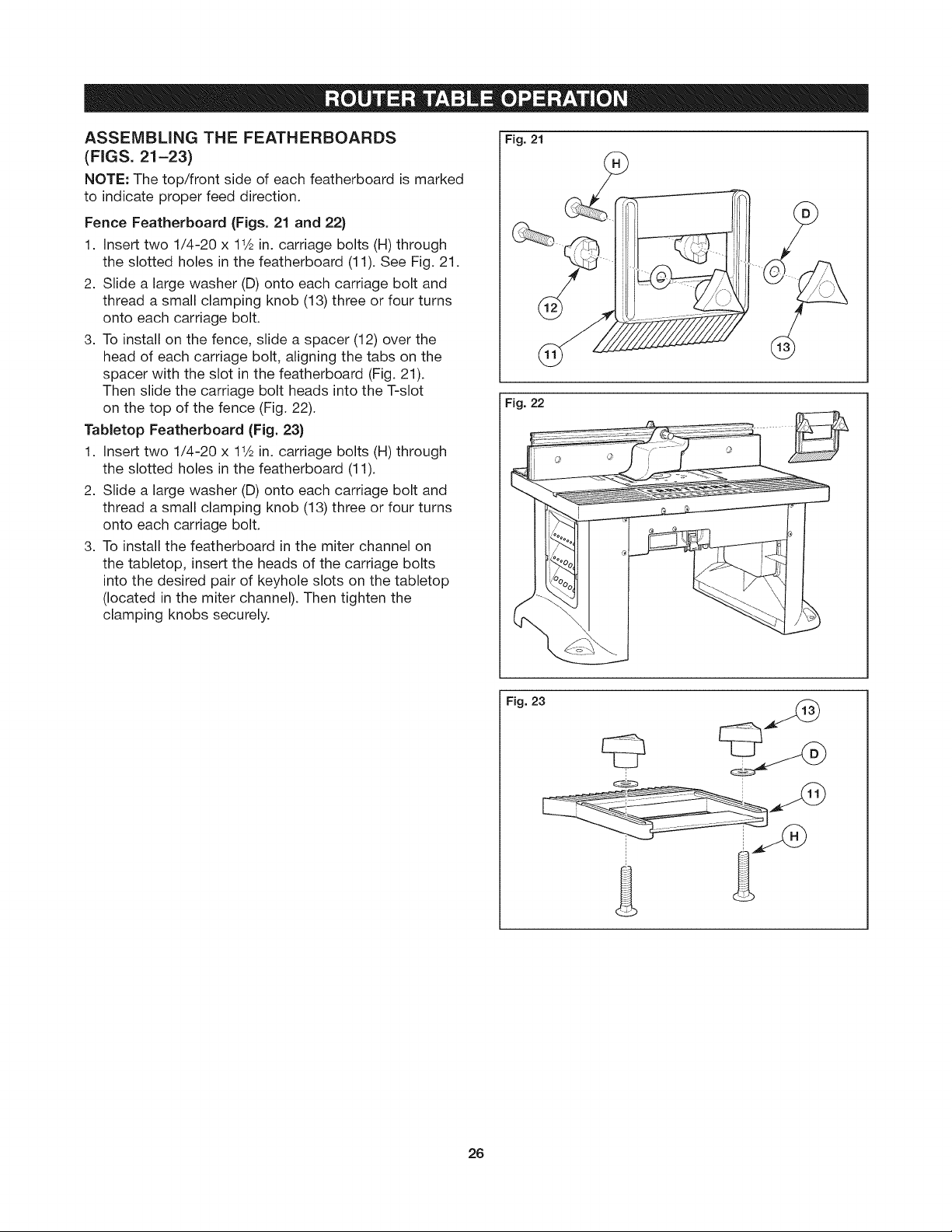

ASSEMBLING THE FEATHERBOARDS

(FIGS. 21-23)

NOTE: The top/front side of each featherboard ismarked

to indicate proper feed direction.

Fence Featherboard (Figs. 21 and 22)

1. Insert two 1/4-20 x 11& in. carriage bolts (H) through

the slotted holes in the featherboard (11). See Fig. 21.

2. Slide a large washer (D) onto each carriage bolt and

thread a small clamping knob (13) three or four turns

onto each carriage bolt.

3. To install on the fence, slide a spacer (12) over the

head of each carriage bolt, aligning the tabs on the

spacer with the slot in the featherboard (Fig. 21).

Then slide the carriage bolt heads into the T-slot

on the top of the fence (Fig. 22).

Tabletop Featherboard (Fig. 23)

1. Insert two 1/4-20 x 11& in. carriage bolts (H) through

the slotted holes in the featherboard (11).

2. Slide a large washer (D) onto each carriage bolt and

thread a small clamping knob (13) three or four turns

onto each carriage bolt.

3. To install the featherboard in the miter channel on

the tabletop, insert the heads of the carriage bolts

into the desired pair of keyhole slots on the tabletop

(located in the miter channel). Then tighten the

clamping knobs securely.

Fig. 21

Fig. 22

%

26

Fig. 23

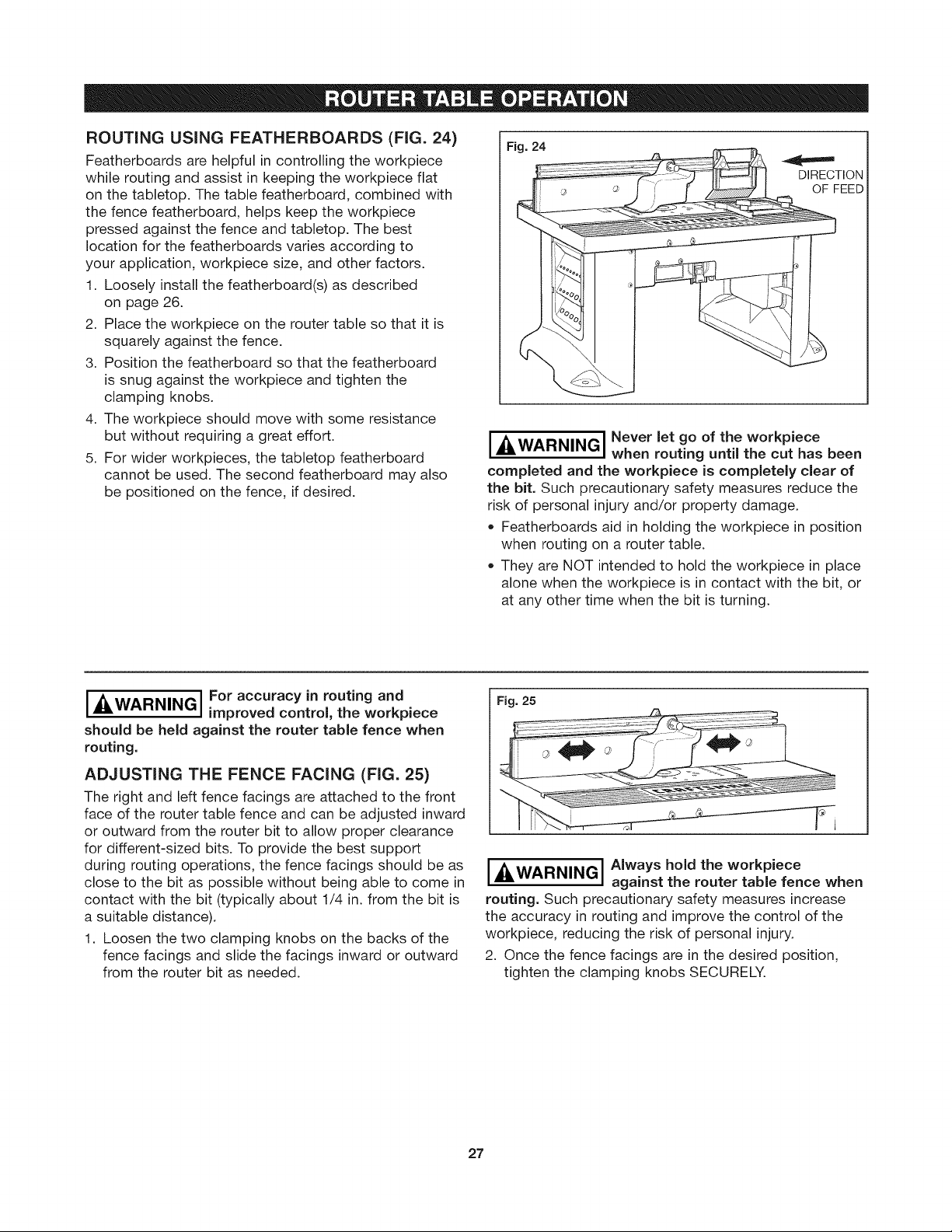

ROUTINGUSING FEATHERBOARDS (FIG. 24)

Featherboards are helpful in controlling the workpiece

while routing and assist in keeping the workpiece flat

on the tabletop. The table featherboard, combined with

the fence featherboard, helps keep the workpiece

pressed against the fence and tabletop. The best

location for the featherboards varies according to

your application, workpiece size, and other factors.

1. Loosely install the featherboard(s) as described

on page 26.

2. Place the workpiece on the router table so that it is

squarely against the fence.

3. Position the featherboard so that the featherboard

is snug against the workpiece and tighten the

clamping knobs.

4. The workpiece should move with some resistance

but without requiring a great effort.

5. For wider workpieces, the tabletop featherboard

cannot be used. The second featherboard may also

be positioned on the fence, if desired.

Fig. 24

DIRECTION

OF FEED

I I Never let go of the workpiece

.ZLWARNING, when routing until the cut has been

completed and the workpiece is completely clear of

the bit. Such precautionary safety measures reduce the

risk of personal injury and/or property damage.

• Featherboards aid in holding the workpiece in position

when routing on a router table.

• They are NOT intended to hold the workpiece in place

alone when the workpiece is in contact with the bit, or

at any other time when the bit is turning.

I .4LWARNINGI For accuracy in routing and

should be held against the router table fence when

routing.

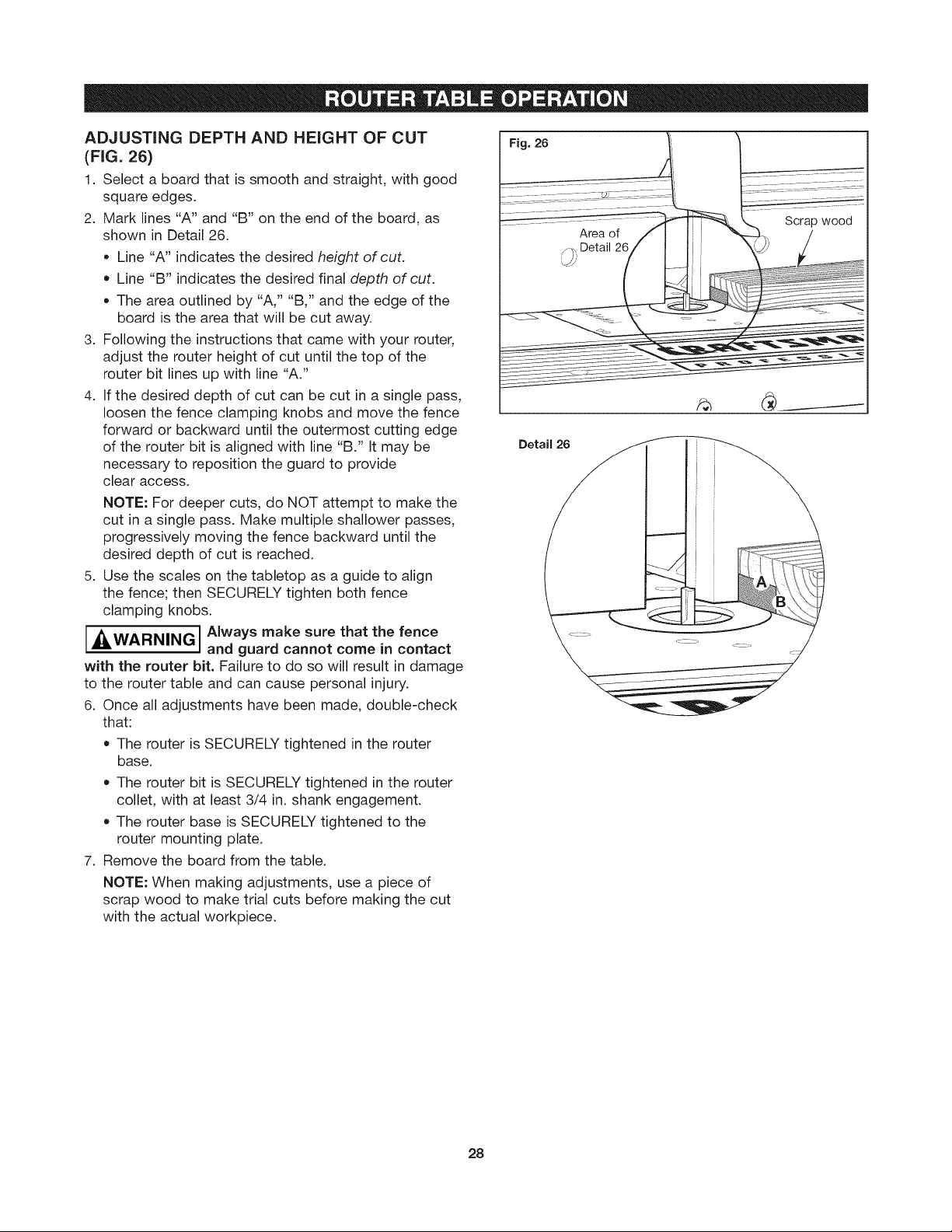

ADJUSTING THE FENCE FACING (FIG. 25)

The right and left fence facings are attached to the front

face of the router table fence and can be adjusted inward

or outward from the router bit to allow proper clearance

for different-sized bits. To provide the best support

during routing operations, the fence facings should be as

close to the bit as possible without being able to come in

contact with the bit (typically about 1/4 in. from the bit is

a suitable distance).

1. Loosen the two clamping knobs on the backs of the

fence facings and slide the facings inward or outward

from the router bit as needed.

improved control, the workpiece

Fig. 25

I =_WARNING I Always hold the workpiece

routing. Such precautionary safety measures increase

the accuracy in routing and improve the control of the

workpiece, reducing the risk of personal injury.

2. Once the fence facings are in the desired position,

tighten the clamping knobs SECURELY.

27

against the router table fence when

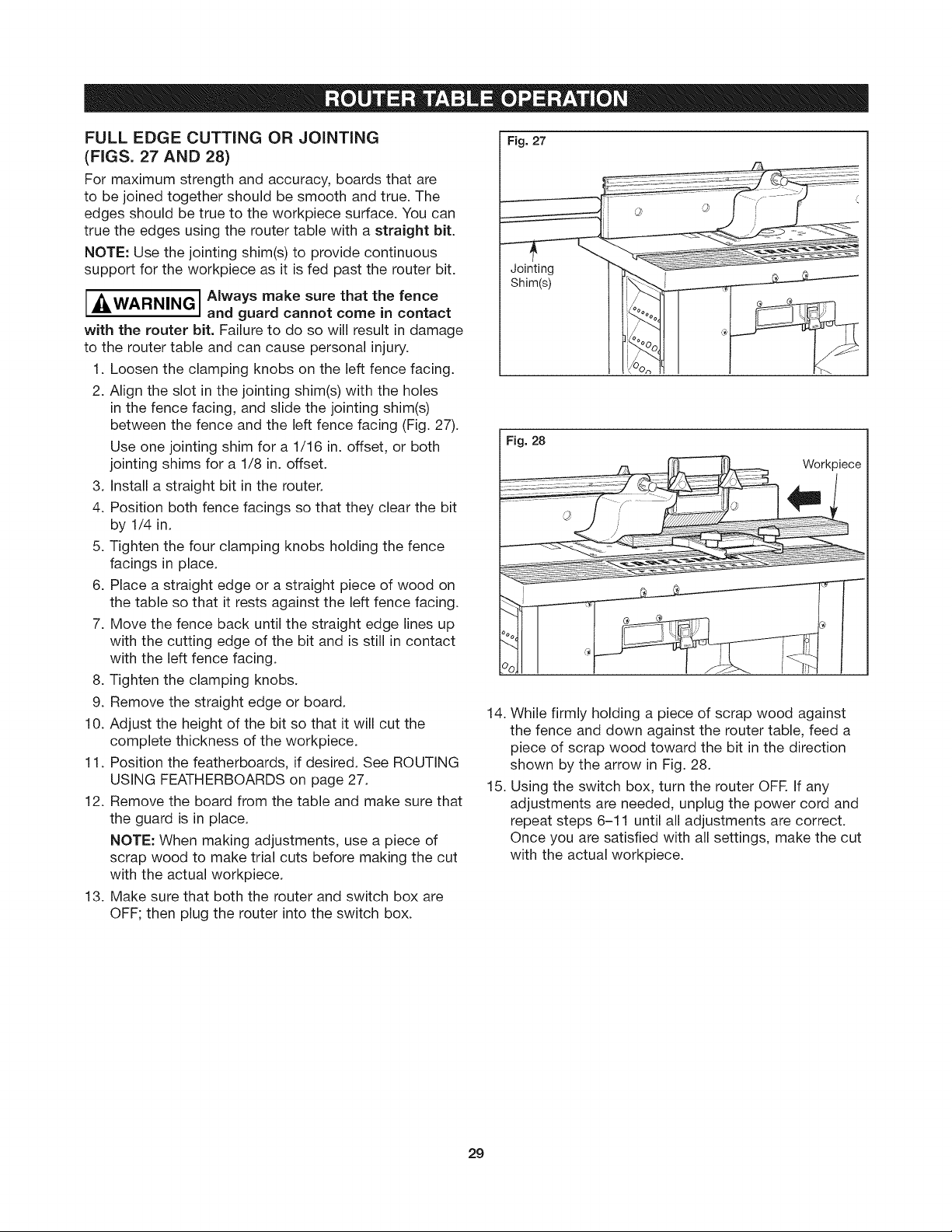

ADJUSTING DEPTH AND HEIGHT OF CUT

(FIG. 26)

1. Select a board that is smooth and straight, with good

square edges.

2. Mark lines "A" and "B" on the end of the board, as

shown in Detail 26.

• Line "A" indicates the desired height of cut.

• Line "B" indicates the desired final depth of cut.

The area outlined by "A," "B," and the edge of the

board is the area that will be cut away.

3. Following the instructions that came with your router,

adjust the router height of cut until the top of the

router bit lines up with line "A."

4. If the desired depth of cut can be cut in a single pass,

loosen the fence clamping knobs and move the fence

forward or backward until the outermost cutting edge

of the router bit is aligned with line "B." It may be

necessary to reposition the guard to provide

clear access.

NOTE: For deeper cuts, do NOT attempt to make the

cut in a single pass. Make multiple shallower passes,

progressively moving the fence backward until the

desired depth of cut is reached.

5. Use the scales on the tabletop as a guide to align

the fence; then SECURELY tighten both fence

clamping knobs.

A WARNING I Always make sure that the fence

with the router bit. Failure to do so will result in damage

to the router table and can cause personal injury.

6. Once all adjustments have been made, double-check

that:

The router is SECURELY tightened in the router

base.

The router bit is SECURELY tightened in the router

collet, with at least 3/4 in. shank engagement.

The router base is SECURELY tightened to the

router mounting plate.

7. Remove the board from the table.

NOTE: When making adjustments, use a piece of

scrap wood to make trial cuts before making the cut

with the actual workpiece.

and guard cannot come in contact

Fig. 26

Detail 26

Area of

/)_ Detail 2_

Lm'

28

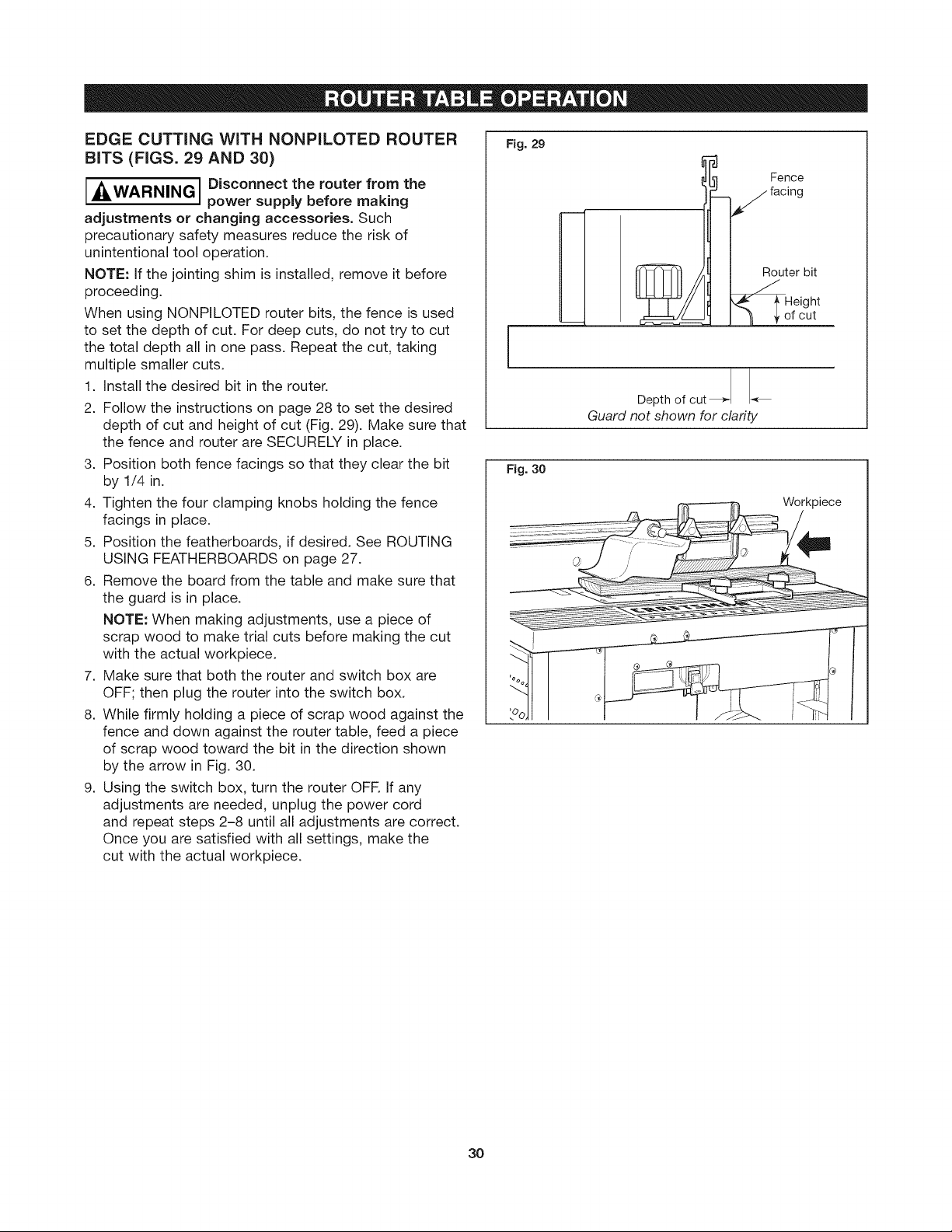

FULL EDGE CUTTING OR JOINTING

(FIGS. 27 AND 28)

For maximum strength and accuracy, boards that are

to be joined together should be smooth and true. The

edges should be true to the workpiece surface. You can

true the edges using the router table with a straight bit.

NOTE: Use the jointing shim(s) to provide continuous

support for the workpiece as it is fed past the router bit.

AWARNING I Always make sure that the fence

B;I I

with the router bit. Failure to do so will result in damage

to the router table and can cause personal injury.

1. Loosen the clamping knobs on the left fence facing.

2. Align the slot in the jointing shim(s) with the holes

in the fence facing, and slide the jointing shim(s)

between the fence and the left fence facing (Fig. 27).

Use one jointing shim for a 1/16 in. offset, or both

jointing shims for a 1/8 in. offset.

3. Install a straight bit in the router.

4. Position both fence facings so that they clear the bit

by 1/4 in.

5. Tighten the four clamping knobs holding the fence

facings in place.

6. Place a straight edge or a straight piece of wood on

the table so that it rests against the left fence facing.

7. Move the fence back until the straight edge lines up

with the cutting edge of the bit and is still in contact

with the left fence facing.

8. Tighten the clamping knobs.

9. Remove the straight edge or board.

10. Adjust the height of the bit so that it will cut the

complete thickness of the workpiece.

11. Position the featherboards, if desired. See ROUTING

USING FEATHERBOARDS on page 27.

12. Remove the board from the table and make sure that

the guard is in place.

NOTE: When making adjustments, use a piece of

scrap wood to make trial cuts before making the cut

with the actual workpiece.

13. Make sure that both the router and switch box are

OFF; then plug the router into the switch box.

and guard cannot come in contact

Fig. 27

Jointing

Shim(s)

Fig. 28

Workpiece

14. While firmly holding a piece of scrap wood against

the fence and down against the router table, feed a

piece of scrap wood toward the bit in the direction

shown by the arrow in Fig. 28.

15. Using the switch box, turn the router OFR If any

adjustments are needed, unplug the power cord and

repeat steps 6-11 until all adjustments are correct.

Once you are satisfied with all settings, make the cut

with the actual workpiece.

29

EDGE CUTTING WiTH NONPILOTED ROUTER

BiTS (FIGS. 29 AND 30)

A WARNING I Disconnect the router from the

AlL I

adjustments or changing accessories. Such

precautionary safety measures reduce the risk of

unintentional tool operation.

NOTE: if the jointing shim is installed, remove it before

proceeding.

When using NONPILOTED router bits, the fence is used

to set the depth of cut. For deep cuts, do not try to cut

the total depth all in one pass. Repeat the cut, taking

multiple smaller cuts.

1. Install the desired bit in the router.

2. Follow the instructions on page 28 to set the desired

depth of cut and height of cut (Fig. 29). Make sure that

the fence and router are SECURELY in place.

3. Position both fence facings so that they clear the bit

by 1/4 in.

4. Tighten the four clamping knobs holding the fence

facings in place.

5. Position the featherboards, if desired. See ROUTING

USING FEATHERBOARDS on page 27.

6. Remove the board from the table and make sure that

the guard is in place.

NOTE: When making adjustments, use a piece of

scrap wood to make trial cuts before making the cut

with the actual workpiece.

7. Make sure that both the router and switch box are

OFF; then plug the router into the switch box.

8. While firmly holding a piece of scrap wood against the

fence and down against the router table, feed a piece

of scrap wood toward the bit in the direction shown

by the arrow in Fig. 30.

9. Using the switch box, turn the router OFF. if any

adjustments are needed, unplug the power cord

and repeat steps 2-8 until all adjustments are correct.

Once you are satisfied with all settings, make the

cut with the actual workpiece.

power supply before making

Fig. 29

Fence

Router bit

[

I eightof cut

!

Depth of cut

Guard not shown for clarity

Fig. 30

Workpiece

3O

EDGE CUTTING WITH PILOTED ROUTER BiTS

(FIGS. 31 AND 32)

I,_WARNING I Disconnect the router from the

adjustments or changing accessories. Such

precautionary safety measures reduce the risk

of unintentional tool operation.

NOTE: if the jointing shim is installed, remove it before

proceeding.

1. Install the desired piloted bit in the router.

2. Follow the instructions on page 28 to set the desired

height of cut (Fig. 31). Make sure that the router is

SECURELY in place.

3. Adjust the router table fence back just enough that

the pilot on the router bit will control the depth of cut.

The router bit pilot should just barely protrude past

the fence facings. Tighten the fence clamping knobs

SECURELY.

4. Position both fence facings so that they clear the bit

by 1/4 in.

5. Tighten the four clamping knobs holding the fence

facings in place.

6. Remove the board from the table and make sure that

the guard is in place.

NOTE: When making adjustments, use a piece of

scrap wood to make trial cuts before making the cut

with the actual workpiece.

7. Make sure that both the router and switch box are

OFF; then plug the router into the switch box.

8. While firmly holding a piece of scrap wood against the

fence and down against the router table, feed a piece

of scrap wood toward the bit in the direction shown

by the arrow in Fig. 32.

9. Using the switch box, turn the router OFF. if any

adjustments are needed, unplug the power cord

and repeat steps 2-8 until all adjustments are correct.

Once you are satisfied with all settings, make the cut

with the actual workpiece.

power supply before making

Fig. 31

[

Fig. 32

[

Depth of cut_,

Guard not shown for clarity

Workpiece

Clearance

between fence

and bit

Router bit

pilot

Piloted

I eight

of cut

W

31

GROOVING, FLUTING, AND VEINING

(FIGS. 33 AND 34)

Fig. 33

Location of cut

j __WARNING I Disconnect the router from the

power supply before making

adjustments or changing accessories. Such

precautionary safety measures reduce the risk

of unintentional tool operation.

NOTE: if the jointing shim is installed, remove it before

proceeding.

When performing these routing operations, the use

of featherboards and a push shoe is recommended.

For best results and maximum accuracy, the side of the

workpiece that will be against the fence must be square

and straight.

1. Install the desired end-cutting bit in the router.

2. Follow the instructions on page 28 to set the desired

depth of cut (location of cut) and height of cut

(Fig. 33). Make sure that the fence and router

are SECURELY in place.

iMPORTANT: For deep cuts, do not try to cut the total

depth (controlled by the router bit height) all in one

pass. Repeat the cut, taking smaller cuts until

the desired depth is reached.

3. Position both fence facings so that they provide

continuous support of the workpiece.

4. Tighten the four clamping knobs holding the fence

facings in place.

5. Position the featherboards, if desired. See ROUTING

USING FEATHERBOARDS on page 27.

6. Remove the board from the table and make sure that

the guard is in place.

NOTE: When making adjustments, use a piece of

scrap wood to make trial cuts before making the cut

with the actual workpiece.

7. Make sure that both the router and switch box are

OFF; then plug the router into the switch box.

8. While firmly holding a piece of scrap wood against the

fence and down against the router table, feed a piece

of scrap wood toward the bit in the direction shown

by the arrow in Fig. 34.

9. Using the switch box, turn the router OFR If any

adjustments are needed, unplug the power cord

and repeat steps 2-8 until all adjustments are correct.

Once you are satisfied with all settings, make the cut

with the actual workpiece.

Fence

facing

End cutting

Height

of cut

Guard not shown for clarity

Fig. 34

32

USING A MITER GAUGE

Fig. 35

The miter gauge slot may be used with most

stationary table saw miter gauges that measure

3/4 in. wide x 3/8 in. deep°

NOTE: For ALL routing operations requiring the use of

the miter gauge with the fence, BE SURE to align the

fence using the scales on the top of the router table

before making any cuts. Miters can be cut by loosening

the knob on the protractor head, turning the protractor

head up to 60 ° in either direction and retightening the

protractor head knob.

USING THE STARTER PiN FOR EDGE FORMING OF CURVES

The starter pin (22) is used instead of the fence for

operations that involve routing curves in the workpieceo

It should be used only with bits that have pilot bearings.

Thread the starter pin into the threaded hole in the

mounting plate and tighten securely with a slotted

screwdriver (Fig. 36).

Attach the starter pin guard (23) to the mounting plate

by threading a #10-32 x 3/8 in. truss-head machine

screw (R) through the hole in the guard post and into

the threaded hole in the mounting plate° Align the guard

with the hole in the mounting plate so it is over the bit

and securely fasten the guard in place.

• Always use the starter pin guard when routing with the

starter pin.

When using the starter pin, the feed direction of the

workpiece is always right to left across the front of the

bit (Fig. 37).

Set the workpiece against the front of the starter pin

and swing it slowly into the bit.

While routing, make sure the workpiece is always in

contact with the bit's pilot bearing.

Fig. 37

Miter gauge (not

Starter

pin

DIRECTION

IAWARNING I Use starter pin guard for this

ILL [

type of operation. Do not attempt

to rout very small workpieces. Keep fingers clear

of spinning bit.

Pilot bearing bit

33

fGARANTJA COMPLETA DE UN A_lO SOBRE ESTA HERRAMIENTA CRAFTSMAN PROFESSIONAL "_

Siesta herramienta Craftsman fallara debido a un defecto en el materiaJ o en la mano de obra dentro deJ

aSo de la fecha de adquisici6n, LLAME AL 1-800-4-MY-HOME ® PARA ORGANIZAR UNA REPARACION

GRATUITA {oun reemplazo si la reparaci6n resulta imposible).

Esta garantia no incluye piezas prescindibJes, tales como I_mparas, baterias, brocas o cuchillas.

Esta garantia le otorga derechos legales especificos y usted puede contar con otros derechos, que

pueden variar de estado a estado.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 j

INFORMACION DE SEGURJDAD

IMPORTANTE ............................. 34-38 Montaje de la mesa de fresado .............. 44-53

Accesorios opcionales ........................ 39 Operaci6n de la mesa de fresado ............ 54-65

Liste de partes ............................ 40-43

I'_ I Lea y entienda el manual de se fresador y estas instrucciones. El incumplimiento de todas lasADVERTENCIA instrucciones indicadas a continuaci6n puede dar lugar a lesiones personales graves.

CONSERVE ESTAS INSTRUCCIONES

Area de trabajo

Mantenga el _rea de trabajo limpia y bien iJuminada. Las

mesas desordenadas y las Areas oscuras invitan a que se

produzcan accidentes.

No utilice herramientas mec_nicas en atm6sferas

explosivas, tales como las existentes en presencia de

liquidos, gases o polvos inflamables. Las herramientas

mec&nicas generan chispas y 6stas pueden dar lugar a la

ignici6n del polvo o los vapores.