Craftsman 171264640, 171264630 Owner’s Manual

PROFESSIONAL

PROFESSIONAL ROUTER TABLE

MESA PROFESIONAL DE FRESADO

OWNER'S MANUAL

Models:

171.264630 (without Floor Stand)

171.264640 (with Floor Stand)

MANUAL DEL PROPIETARIO

Modelos

171.264630 (sin base)

171.264640 (con base)

WARNING: Before

operating product,

read this manual and

follow all its Safety and

Operating Instructions.

ADVERTENCIA:

Antes de utilizar este

producto, lea este

manual y siga todas

las instrucciones de

uso y seguridad.

Sears, Roebuck and Co., Hoffman Estates IL 60179 USA

171.264630 and 171.264640 04101 Printed in U.S.A. Hecho en los Estados Unidos

General Safety Instructions for Power Tools ............................................... 3

Additional Safety Instructions for Router Tables ........................................ 4

Introduction ..................................................................................................... 6

Optional Router Table Accessories ............................................................... 7

Unpacking and Checking Contents .............................................................. 8

Parts List ......................................................................................................... 8

Assembly ....................................................................................................... 13

Installation ..................................................................................................... 24

Switch Instructions ....................................................................................... 27

Operation ....................................................................................................... 34

Espa_ol .......................................................................................................... 42

2

SAFETY GUIDELINES - DEFINITIONS

This manual contains

information that is important for

you to know and understand.

This information relates to

protecting YOUR SAFETY and

PREVENTING EQUIPMENT

PROBLEMS. To help you

recognize this information, we

use the symbols to the right.

Please read the manual and pay

attention to these sections.

i-4LWARNINGI Failure to heed all safety and operating instructions and warnings regarding use of this

product can result in serious bodily injury.

I, DANGER I

URGENT SAFETY INFORMATION -

A HAZARD THAT WILL CAUSE

SERIOUS INJURY OR LOSS OF LIFE

IAWARNINGI

IMPORTANT SAFETY INFORMATION -

A HAZARD THAT MIGHT CAUSE

SERIOUS INJURY OH LOSS OF LIFE

I_C*UT'ON]

INFORMATION FOR PREVENTING

DAMAGE TO EQUIPMENT

I NOTE I

INFORMATION THAT YOU SHOULD

PAY SPECIAL A'I-FENTION TO

1. Know your power tool

Read the owner's manual carefully. Learn its

application and limitations as well as the specific

potential hazards peculiar to this tool.

2. Ground all tools (unless double insulated)

If tool is equipped with an approved three-

conductor cord and a three-prong grounding

type plug, it should be plugged into a three hole

electrical receptacle. If adapter is used to accom-

modate a two-hole receptacle, the

adapter wire must be attached to a known

ground (usually the screw securing receptacle

cover plate). Never remove third prong.

Never connect green ground wire to a terminal.

3. Keep guards in place

Maintain guards in working order, and in proper

adjustment and alignment.

4. Remove adjusting keys and wrenches

Form a habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it ON.

5. Keep work area clean

Cluttered areas and benches invite accidents.

Floor must not be slippery due to wax or sawdust.

6. Avoid dangerous environment

Do not use power tools in damp or wet locations or

expose them to rain. Keep work area well lighted.

Provide adequate surrounding work space.

7. Keep children away

All visitors should be kept a safe distance from

work area.

8. Make workshop child-proof

Use padlocks, master switches, or remove

starter keys.

9. Do not force tools

They will do the job better and safer at the rate

for which they were designed.

10. Use the right tool

Do not force tool or attachment to do a job it was

not designed to perform.

11. Wear correct apparel

Do not wear loose clothing, gloves, neckties

or jewelry (rings, wristwatches) that may get

caught in moving parts. Non-slip footwear is

recommended. Wear protective hair covering

to contain long hair. Roll long sleeves above

the elbow.

12. Use safety goggles (Head Protection)

Wear safety goggles (must comply with ANSI

Standard Z87.1) at all times. Also, use face or

dust mask, if cutting operation is dusty, and

ear protectors (plugs or muffs) during extended

periods of operation.

13. Secure work

Use clamps or a vise to hold work when

practical. It's safer than using your hands,

and both hands are free to operate tool.

14. Do not overreach

Keep proper footing and balance at all times.

15. Maintain tools with care

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

3

16. Disconnect tools before servicing

Before servicing, when changing accessories

such as blades, bits, cutters, etc.

17. Avoid accidental starting

Make sure switchis in OFF positionbefore

pluggingin.

18. Use recommended accessories

Consult the owner's manual for recommended

accessories and follow the instructions.The use

of improper accessories may cause hazards.

19 Never stand on tool

Serious injurycould occur if the toolis tipped or if

the cutting tool is accidentally contacted. DO NOT

store materials above or near the tool making it

necessary to stand on the tool to reach them.

20. Check damaged parts

Before further use of the tool, any guard or

other part that is damaged should be carefully

checked to ensure that it witl operate properly

and perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A

guard or any other part that is damaged should

be properly repaired or replaced.

21. Direction of feed

Feed work into a blade or cutter AGAINST the

direction of rotation of the blade or cutter only.

22. Never leave tool running unattended

Turn power OFF, DO NOT leave tool until it

comes to a complete stop.

23. Keep hands away from cutting area

24. Store idle tools

When not in use, toolsshould be stored in dry,

high or locked-up place - out of reach of children.

25. Do not abuse cord

Keep cord away from heat, oil and sharp edges.

26. Outdoor extension cords

When tool is used outdoors, use only extension

cords suitable for use outdoors and so marked.

27. Never use in an explosive atmosphere

Normal sparking of the motor could ignite fumes,

flammable liquids, orcombustible items.

28. Drugs, alcohol, medication

Do NOT operate tool while under the influence

of drugs, alcohol, or any medication.

Read and Understand this instruction book com-

pletely BEFORE using this product.

1. Always wear eye protection that complies with

ANSI Standard Z87.1.

2. Noise levels vary widely with location. To avoid

possible hearing damage, wear ear plugs or

ear muffs when using your router table for long

periods of time.

3. For dusty operations, wear a dust mask along

with safety goggles.

4. Follow the instructions in your router owner's

manual.

5. [_,WARNINGJ Vibrations, caused by the router

during use, can cause fasteners to become loose.

Before use and periodically during use, check all

fasteners to make sure that all are tight and

secure.

6. Do not use this product until all assembly and

installation steps have been completed. Make

sure you have read and understood all safety

and operational instructions in this manual and

the router owner's manual.

7. Make sure that the router bit is properly

positioned and clamped in the router before

making any cuts.

8. Do not use the router table as a workbench or

work surface. Doing so may damage it, causing it

to be unsafe to use. A workbench should be

used for this purpose.

9. This product is designed for cutting flat

workpieces. Do not cut or attempt to cut

workpieces that are not flat.

10. This product is designed for cutting wood

workpieces only. Do not use to cut metal

or other non-wood materials.

11. The use of auxiliary in-feed and out-feed

supports is strongly recommended when routing

long workpieces. Otherwise those workpieces

can cause the router table to tip over.

12. Keep hands clear of the router bits and

working area.

13. Make and use a push stick to move small

workpieces across the cutting area or purchase

9-25468 Router Table Guide Master.

14. Clean the router after use. The use of a wet/dry

vac or vacuum equipment is recommended.

15. Always make sure that work surface of the router

table is clean and free from dust, chips, and

foreign particles that can interfere with the cut

you are going to make. The use of a wet/dry

vac or vacuum equipment is recommended.

16. Check the function of the guard before each

use. Remove all dust, chips, and any other

foreign particles that can affect its function.

4

[^ ]

17 [ABLWARNINGj Never put your fingers under

the guard when the router is plugged into an

electrical outlet or when the router bit is rotating.

18. Always use the fence to guide the workpiece.

19. Always feed the workpiece AGAINST the

rotation of the cutter or router bit.

20. Router bits are extremely sharp; be extra careful

when handling and using them.

21. Make sure that the router bits being used are

sharp or have been properly resharpened. This

will permit fast, efficient, and SAFE routing.

22. Some routers, when positionedin an upside down

position (such as on a router table), willdrop or

fall out ofthe routerbase when the base clamp

is loosened to adjust height or depth of cut.

Therefore, itis extremely important to support

the router from below when making these

adjustments or whenever the base clamp

is loosened.

23. Always look under the router table at the router

switch when turning the router ON or OFF. DO

NOT touch anything but the switch when doing

this. NEVER reach under the router table for any

reason when the router is running, except to turn

itOFF.

24. I_,IIALWARNING I Before making any cut, make

sure the router is turned OFF, the router bit is

not rotating, and the power cord is unplugged

from the electrical outlet. Then, make absolutely

sure that the guard clears the router bit and the

workpiece. A trial pass, with the router turned

OFF and the router bit not turning, is strongly

recommended.

IA I

25. JA_WARNING] Never leave the router table

unattended while the router is running. Turn the

router OFF before leaving the router table for

any reason.

26. If ANY part is missing, DO NOT attempt to

assemble, install, or use your router table until

the missing parts have been found or replaced

and your router table has been properly and

correctly assembled per this manual.

27. NEVER use the floor stand as a ladder and DO

NOT stand on the router table.

CraftsmanProfessionalRouterTables,Model

171.264630orModel171.264640,feature

thefollowing:

• A large, 18" x 27" (486 square inches), precision

die-cast aluminum table top, machined to ensure

true flatness and smoothness.

•The table top has an 11-1/2" x 7-3/4" opening for

mounting routers through the table top.

• An 11-1/2" x 9" router adapter plate will attach to

all Craftsman routers.

• The top is coated with a special anti-friction

coating to ensure ease of use without discoloring

or marring the workpiece.

• Dual cast scales ensure parallel and accurate fence

placements for:

• Specialty woodworking joints

• Edge and face routing

• Panel raising

• Precision 4" high x 27" long extruded aluminum

fence incorporates the following features:

• Fence guides for parallel depth-of-cut

adjustment.

• Adjustability for proper bit clearance

• Dust collection port for 2-1/2" wet/dry

vacuum hose

• Unique offset formed jointing fence for 1/16"

edge jointing

• Precision formed fence also allows you to perform

the following operations:

• Fluting, veining, and molding

• Grooving up to the center of a 6 1/2" work piece

• Dual receptacle ON/OFF switch operates both a

router, vacuum, or light simultaneously:

• Switch has overload protection

• Is UL and CUL listed

• Floor stand, on model 171.264640, places

the router table at a convenient working height

with leveling feet for uneven floors

• ALSO INCLUDED:

• Snap in router bit storage panel for both 1/2"

and 1/4" shank router bits

• Miter gauge for cross grain routing at 90° and

60° in two directions

9-25188 Router Table Switch

• Switch mounts to the front of all Craftsman

router tables

• Front switch operates two receptacles on the

back of the switch

• Large switch paddle for ease in turning the

switch OFF

• Removable key prevents unauthorized use

when removed from the switch

• Has built-in circuit breaker

9-25468 Craftsman Guide Master Router Table

Push Shoe with Hold Down Stick

• Ideal for handling small work pieces on a

router table

• Aids in accurate measurement and router table

set-up

• Transforms into a miter gauge

• Provides a quick set-up for making 1/2" sliding

dovetail joints

9-26479 Craftsman Professional Large Router

Adapter Plate

• Molded glass-filled polycarbonate plastic

adapter plate mounts most non-Craftsman

routers to the 171.264630 and the

171,264640 Professional Router Tables

• Easy to follow instructions and mounting

templates supplied

• Adapter plate mounts to the router table using

fasteners supplied with router table

• Fasteners for mounting the router to the

adapter plate are not included and must

obtained separately

IMPORTANT NOTE: The drilling and the

countersinking of holes in the adapter plate

are necessary in order to mount the router

to the adapter plate. The screw heads must

be slightly below the top surface of the

adapter plate.

9-26473 Craftsman Bit Storage Panel

• Easy snap-in installation

• Provides easy and convenient storage for up to

18 router bits

• Holds a mix of both 1/4" and 1/2" shank

router bits

9-26471 Craftsman Feather Board

• Mounts to 171.264630 and the 171.264640

Professional Router Tables only; cannot

be used on any other Craftsman or

non-Craftsman router tables

• Feather boards apply pressure to a workpiece

vertically down towards the table top and

or sideways towards the router table fence pro-

viding better control of the work piece

• Adjustable for both small and large

work pieces

• Not to be used on any other type of machinery

or accessory

9-26472 Precision Router Table Fence Assembly

• Mounts to all Craftsman Professional

Router Tables

• Extruded aluminum fence is fully adjustable

measuring 4" high and 27" long

• Fence opening is adjustable for different size

router bits providing greater support

• Exclusive "keyed"jointing feature straightens

workpiece edges for gluing

• Fence assembly has 2-1/2" diameter dust port

for wetJdry vacs with 2-1/2" diameter hoses

• Clear see through guard allows viewing of

the work area

• Incorporates T-slot design for mounting

feather boards

9-26477 Craftsman Enclosure Kit

• Converts the 9-26478 Craftsman Floor Stand

to a convenient storage cabinet

• Includes three panels, door, hinge, magnetic

latch, knob, and mounting hardware

9-26478 Craftsman Floor Stand

• Places router table at optimal working height

• Adjustable non-slip foot pads for leveling table

on uneven floor surfaces

• Two heavy-duty steel shelves for storage

• Will accept all Craftsman bench top router

tables available after 1997

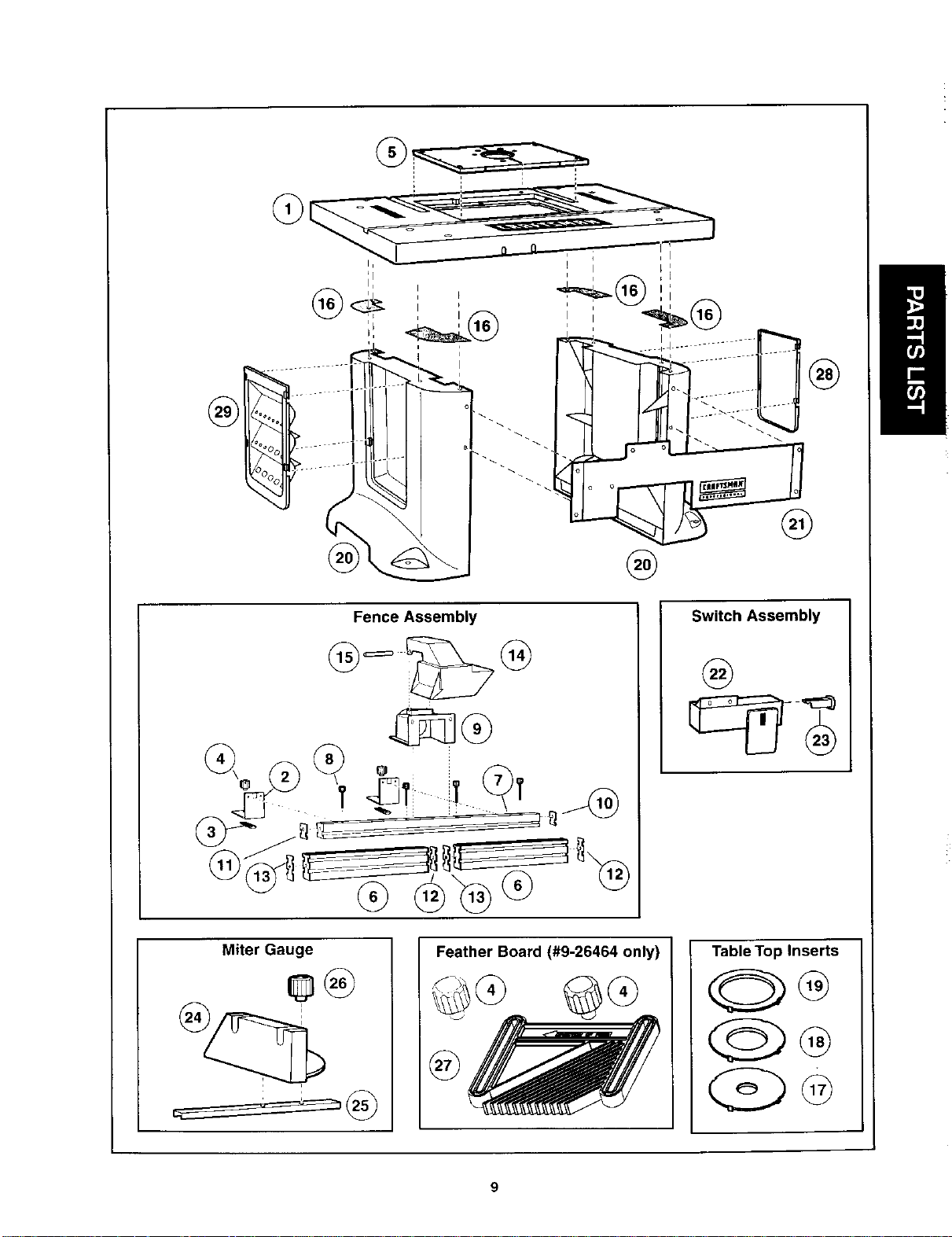

Referto PartsListbelowandonpages9-12

I^ 1

• IA_WARNINGI If ANY of the parts is missing,

DO NOT attempt to assemble, install, or use your

router table until the missing parts have been found

or replaced and your router table has been properly

and correctly assembled per this manual.

• For missing parts or technical assistance, call

1-800-624-0488.

WHENASSEMBLINGROUTERTABLE171.264640,DISREGARDOWNER'SMANUALFURNISHEDWiTHFLOORSTANDMODEL9-26478.

• In order to simplify handling and to minimize any

damage that may occur during shipping, your

router table comes unassembled.

• Separate all parts from the packaging materials

and check each part against the illustrations and

the parts lists on pages 9-12, to make sure that all

parts have been included. Do this before discarding

any of the packaging material.

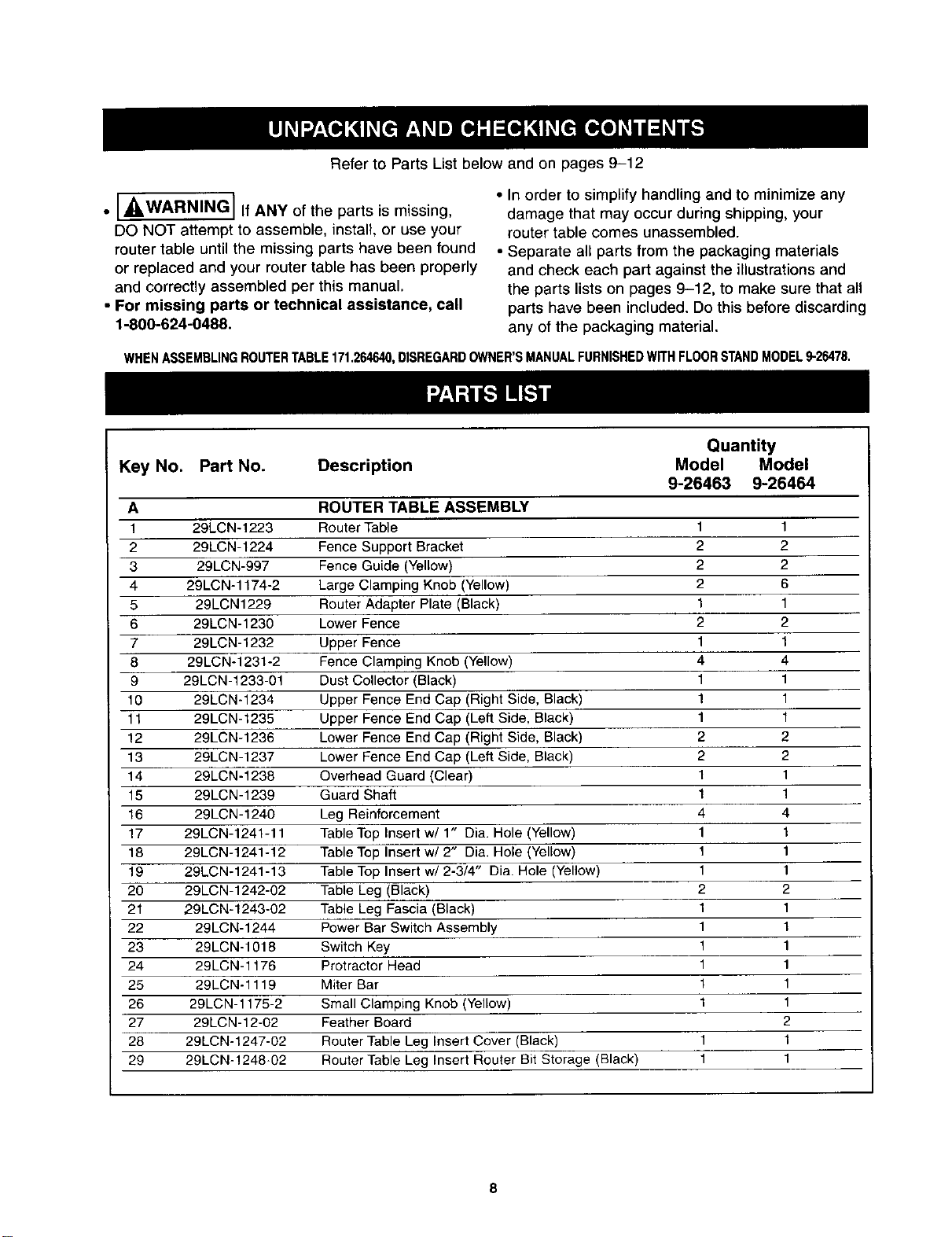

Quantity

Key No. Part No. Description Model Model

9-26463 9-26464

A ROUTER TABLE ASSEMBLY

1 29LCN-1223 Router Table 1 1

2 29LCN-1224 Fence Support Bracket 2 2

3 29LCN-997 Fence Guide (Yellow) 2 2

4 29LCN-1174-2 Large Clamping Knob (Yellow) 2 6

5 29LCN1229 Router Adapter Plate (Black) 1 1

6 29LCN-1230 Lower Fence 2 2

7 29LCN-1232 Upper Fence 1 1

8 29LCN-1231-2 Fence Clamping Knob (Yellow) 4 4

9 29LCN-1233-01 Dust Collector (Black) 1 1

10 29LCN-t 234 Upper Fence End Cap (Right Side, Black) 1 1

1t 29LCN-1235 Upper Fence End Cap (Left Side, Black) 1 1

12 29LCN-1236 Lower Fence End Cap (Right Side, Black) 2 2

13 29LCN-1237 Lower Fence End Cap (Left Side, Black) 2 2

14 29LCN-1238 Overhead Guard (Clear) 1 1

15 29LCN-1239 Guard Shaft 1 1

16 29LCN-1240 Leg Reinforcement 4 4

17 29LCN-1241-11 Table Top Insert w/1" Dia. Hole (Yellow) 1 1

18 29LCN-1241-12 Table Top Insert w/2" Dia. Hole (Yellow) 1 1

19 29LCN-1241-13 Table Top Insert w/2-3/4" Dia. Hole (Yellow) 1 1

20 29LCN-1242-02 Table Leg (Black) 2 2

21 29LCN-1243-02 Table Leg Fascia (Black) 1 1

22 29LCN-1244 Power Bar Switch Assembly 1 1

23 29LCN-1018 Switch Key 1 1

24 29LCN-1176 Protractor Head 1 1

25 29LCN-1119 Miter Bar 1 1

26 29LCN-1175-2 Small Clamping Knob (Yellow) 1 1

27 29LCN-12-02 Feather Board 2

28 29LCN-1247-02 Router Table Leg Insert Cover (Black) 1 1

29 29LCN-1248-02 Router Table Leg Insert Router Bit Storage (Black) 1 1

®

®

Miter Gauge

o@

Fence Assembly

Feather Board (#9-26464 only)

@

G

Switch Assembly

Table Top Inserts

©÷

Quantity

Key No. Part No. Description Model Model

9-26463 9-26464

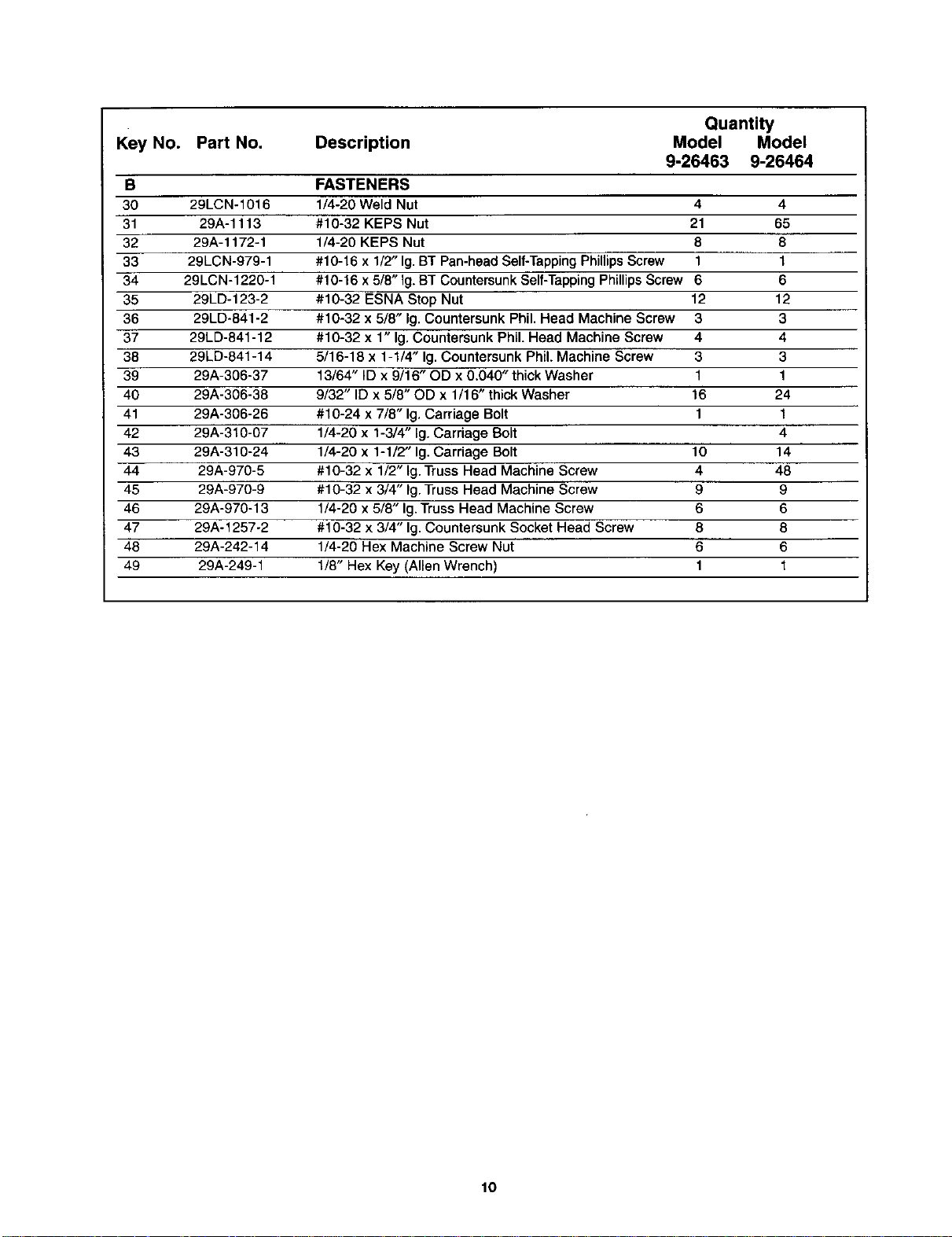

B FASTENERS

30 29LCN-1016 1/4-20 Weld Nut 4 4

31 29A-1113 #10-32 KEPS Nut 21 65

32 29A-1172-1 1/4-20 KEPS Nut 8 8

33 29LCN-979-1 #10-16 x 1/2" Ig.BT Pan-head Self-Tapping Phillips Screw 1 1

34 29LCN-1220-1 #10-16 x 5/8" Ig. BT Countersunk Self-Tapping Phillips Screw 6 6

35 29LD-123-2 #10-32 ESNA Stop Nut 12 12

36 29LD-841-2 #10-32 x 5/8" Ig. Countersunk Phil. Head Machine Screw 3 3

37 29LD-841-12 #10-32 x 1" Ig. Countersunk Phil. Head Machine Screw 4 4

38 29LD-841-14 5/16-18 x 1-1/4" Ig. Countersunk Phil. Machine Screw 3 3

39 29A-306-37 13/64" ID x 9/16" OD x 0.040" thick Washer 1 1

40 29A-306-38 9/32" ID x 5/8" OD x 1/16" thick Washer 16 24

41 29A-306-26 #10-24 x 7/8" Ig. Carriage Bolt 1 1

42 29A-310-07 1/4-20 x 1-3/4" [g. Carriage Bolt 4

43 29A-310-24 1/4-20 x 1-1/2" Ig. Carriage Bolt 10 14

44 29A-970-5 #10-32 x 1/2" Ig. Truss Head Machine Screw 4 48

45 29A-970-9 #10-32 x 3/4" Ig. Truss Head Machine Screw 9 9

46 29A-970-13 1/4-20 x 5/8" Ig. Truss Head Machine Screw 6 6

47 29A-1257-2 #10-32 x 3/4" Ig. Countersunk Socket Head Screw 8 8

48 29A-242-14 1/4-20 Hex Machine Screw Nut 6 6

49 29A-249-1 1/8" Hex Key (Allen Wrench) 1 1

10

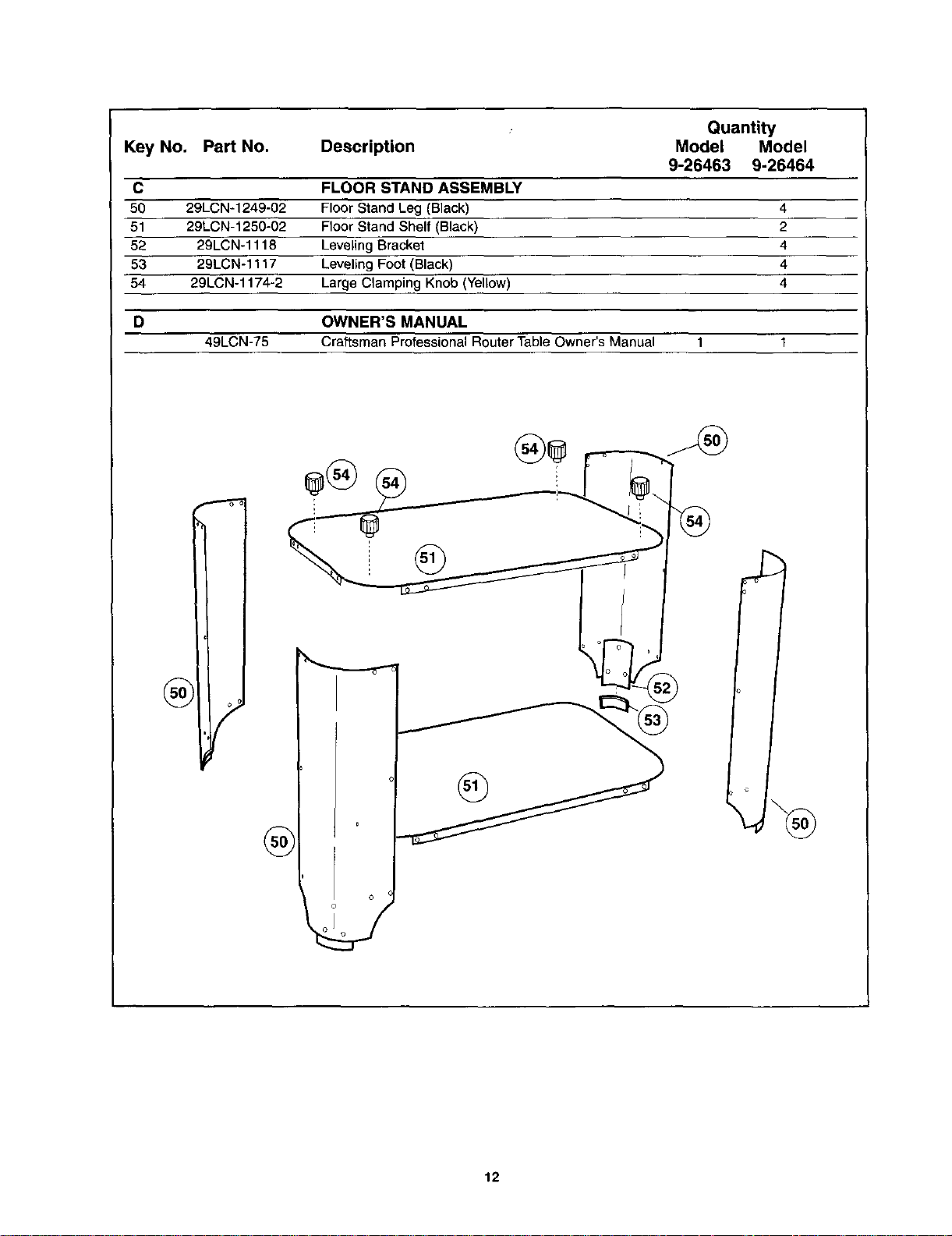

Use the guide below to identify the fasteners included with your Router Table.

Numbers in bold correspond to the key numbers in the parts list on page 10.

@@

(30) 1/4-20 Weld Nut

@@

@

(39) 13/64" ID x 9/16" OO

x 0.040" thick Washer

(41) #10-24 x 7/8" Ig. Round Head

Square Neck Bolt

(40) 9/32" ID x 5/8" OD x

1/16" thick Washer

(31) #10-32

KEPS Nut

©

@@ ©®@@

(32) 1/4-20 (38) #10-32 (48) 1/4-20 Hex

KEPS Nut ESNA Nut Machine Screw Nut

(43) 1/4-20 x 1-1/2" Ig. Carriage Bolt

(42) 1/4-20 x 1-3/4" Ig. Carriage Bolt

(44) #10-32 x 112" Ig. Truss Head

Phillips Machine Screw

(33) #10-16 x 1/2" Ig. BT

Pan-head Self-Tapping

Phillips Screw

(36) #10-32 x 518° Ig. Countersunk

Phillips Machine Screw

(48) #10-32 x 3/4" Ig. Truss Head Phillips

Machine Screw

(34) #10-16 x 5/8" Ig. BT

Countersunk Self-Tapping (36) 5/16-18 x 1-1/4" Ig. Countersunk Phillips Machine Screw

Phillips Screw

(37) #10-32 x 1" Ig, Countersunk Phillips

Machine Screw

(49) 1/8" Hex Key (Allen Wrench)

(46) 1/4-20 x 5/8" Ig Truss Head Phillips

Machine Screw

(47) #10-32 x 3/4" Ig Countersunk Socket

Head Screw

11

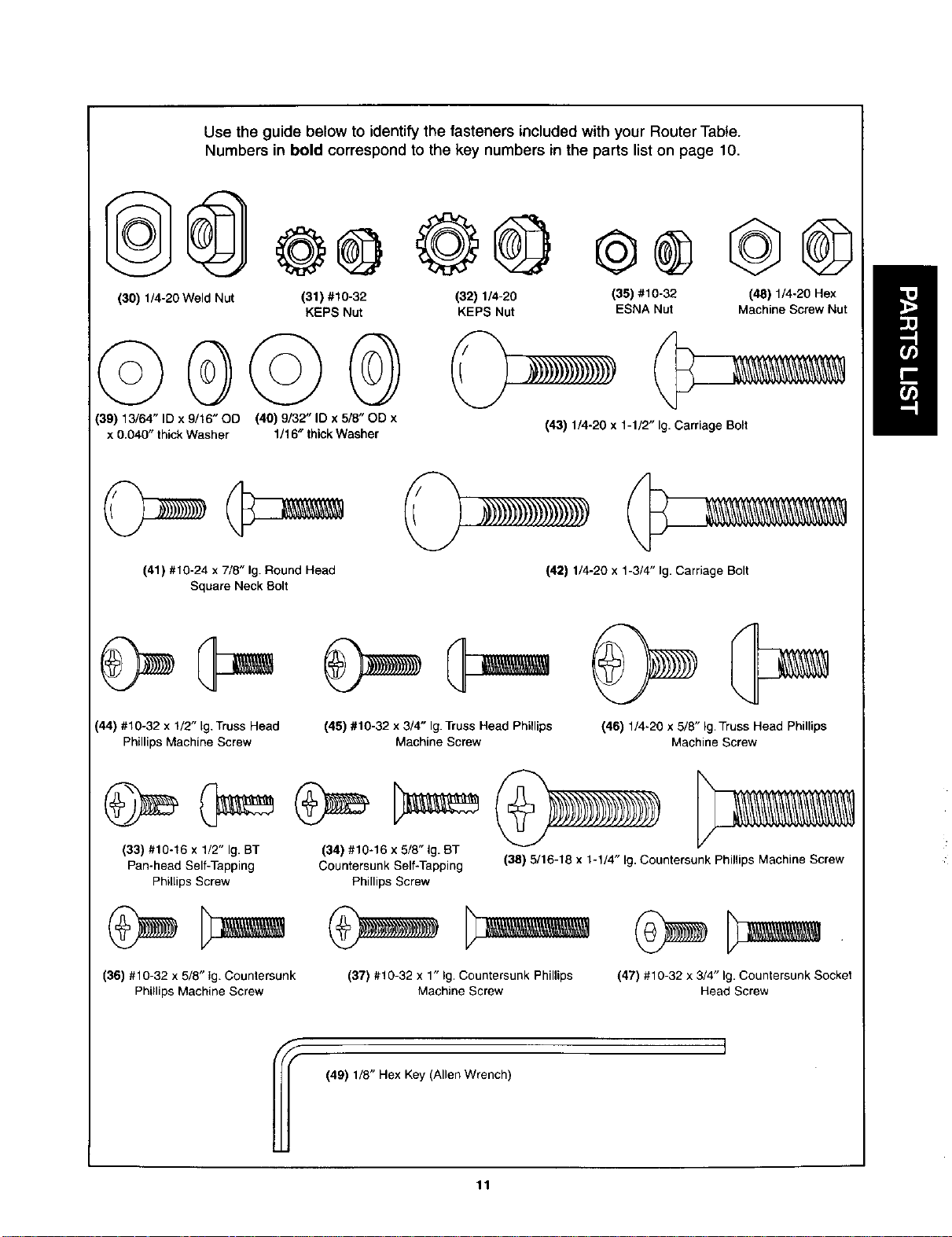

Quantity

Key No. Part No. Description Model Model

9-26463 9-26464

C FLOOR STAND ASSEMBLY

50 29LCN-1249-02 Floor Stand Leg (Black) 4

51 29LCN-1250-02 Floor Stand Shelf (Black) 2

52 29LCN-1118 Leveling Bracket 4

53 29LCN-1117 Leveling Foot (Black) 4

54 29LCN-1174-2 Large Clamping Knob (Yellow) 4

D OWNER'S MANUAL

49LCN-75 Craftsman Professional Router Table Owner's Manual 1 1

12

ASSEMBLING THE ROUTER TABLE

TOOLS REQUIRED (not included)

• Phillipsscrewdriver

• Small sized adjustable wrench

• Tape with adhesive backing

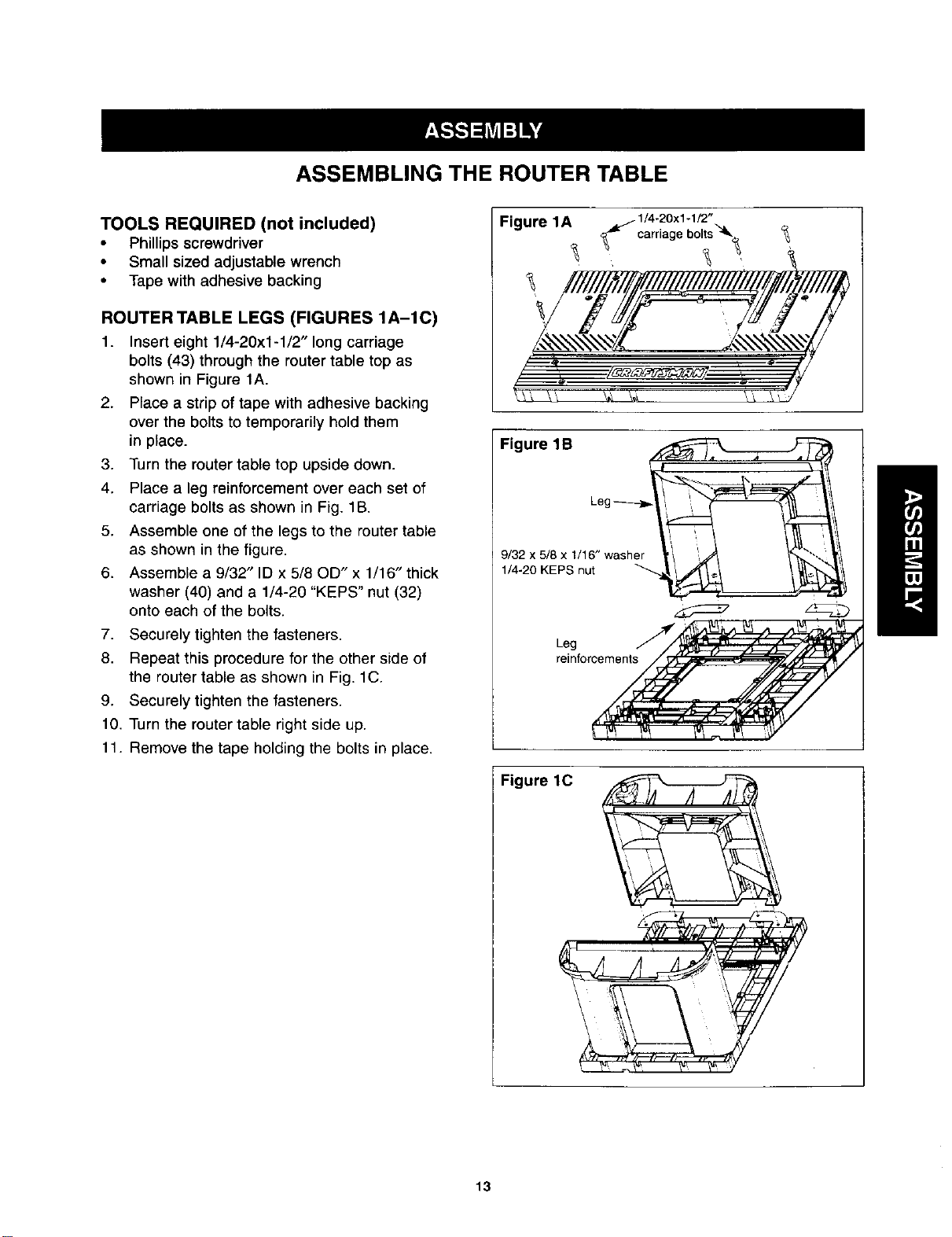

ROUTER TABLE LEGS (FIGURES 1A-lC)

1. Insert eight 1/4-20x1-1/2" long carriage

bolts (43) through the router table top as

shown in Figure 1A.

2. Place a strip of tape with adhesive backing

over the bolts to temporarily hold them

in place.

3. Turn the router table top upside down.

4. Place a leg reinforcement over each set of

carriage bolts as shown in Fig. lB.

5. Assemble one of the legs to the router table

as shown in the figure.

6. Assemble a 9/32" ID x 5/80D" x 1/16" thick

washer (40) and a 1/4-20 "KEPS" nut (32)

onto each of the bolts.

7. Securely tighten the fasteners.

8. Repeat this procedure for the other side of

the router table as shown in Fig. 1C.

9. Securely tighten the fasteners.

10. Turn the router table right side up.

11. Remove the tape holding the bolts in place.

Figure

1A _" lc/4_2tgl "10/2;

Figure 1B

9/32 x 5/8 x 1/16" washer

1/4-20 KEPS nut

Leg _/

reinfor_

Figure lC

13

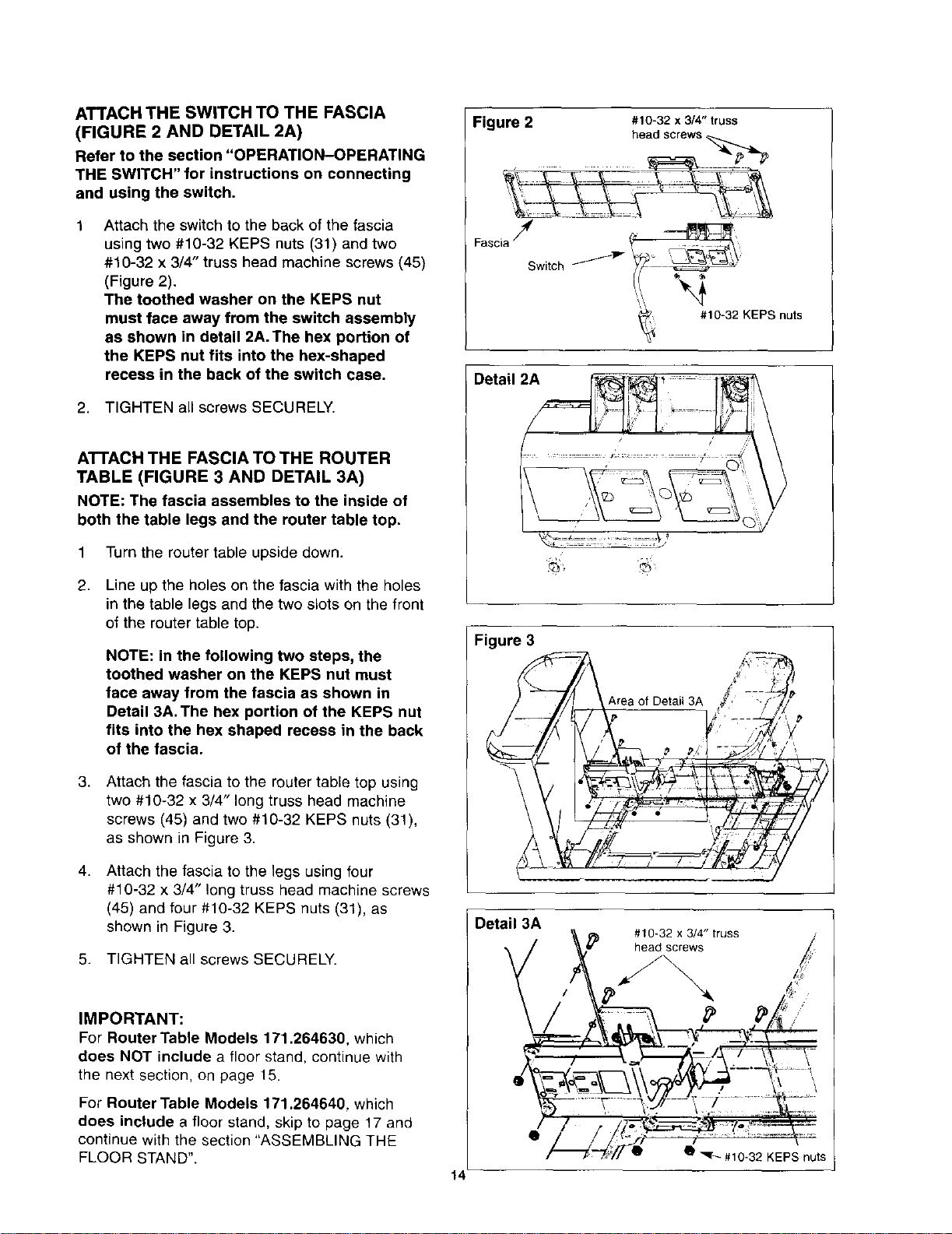

ATTACH THE SWITCH TO THE FASCIA

(FIGURE 2 AND DETAIL 2A)

Refer to the section "OPERATION-OPERATING

THE SWITCH" for instructions on connecting

and using the switch.

Attach the switch to the back of the fascia

using two #10-32 KEPS nuts (31) and two

#10-32 x 3/4" truss head machine screws (45)

(Figure 2).

The toothed washer on the KEPS nut

must face away from the switch assembly

as shown in detail 2A.The hex portion of

the KEPS nut fits into the hex-shaped

recess in the back of the switch case.

2. TIGHTEN all screws SECURELY.

ATTACH THE FASCIA TO THE ROUTER

TABLE (FIGURE 3 AND DETAIL 3A)

NOTE: The fascia assembles to the inside of

both the table legs and the router table top,

1 Turn the router table upside down.

Figure 2 #10-32 x 314" truss

head screws

/ ' _ 2 " "

Switch _ _ i:

-32 KEPS nuts

Detail 2A

2. Line up the holes on the fascia with the holes

in the table legs and the two slots on the front

of the router table top.

NOTE: in the following two steps, the

toothed washer on the KEPS nut must

face away from the fascia as shown in

Detail 3A.The hex portion of the KEPS nut

fits into the hex shaped recess in the back

of the fascia.

3.

Attach the fascia to the router table top using

two #10-32 x 3/4" long truss head machine

screws (45) and two #10-32 KEPS nuts (31),

as shown in Figure 3.

4,

Attach the fascia to the legs using four

#10-32 x 3/4" long truss head machine screws

(45) and four #10-32 KEPS nuts (31), as

shown in Figure 3.

5. TIGHTEN all screws SECURELY.

IMPORTANT:

For Router Table Models 171.264630, which

does NOT include a floor stand, continue with

the next section, on page 15.

For Router Table Models 171.264640, which

does include a floor stand, skip to page 17 and

continue with the section "ASSEMBLING THE

FLOOR STAND".

Figure 3

Detail 3A

14

tea of Detail 3A _<'_- _

_) #10-32 x 3/4" truss

head screws

Q "_- #10-32 KEPS nuts

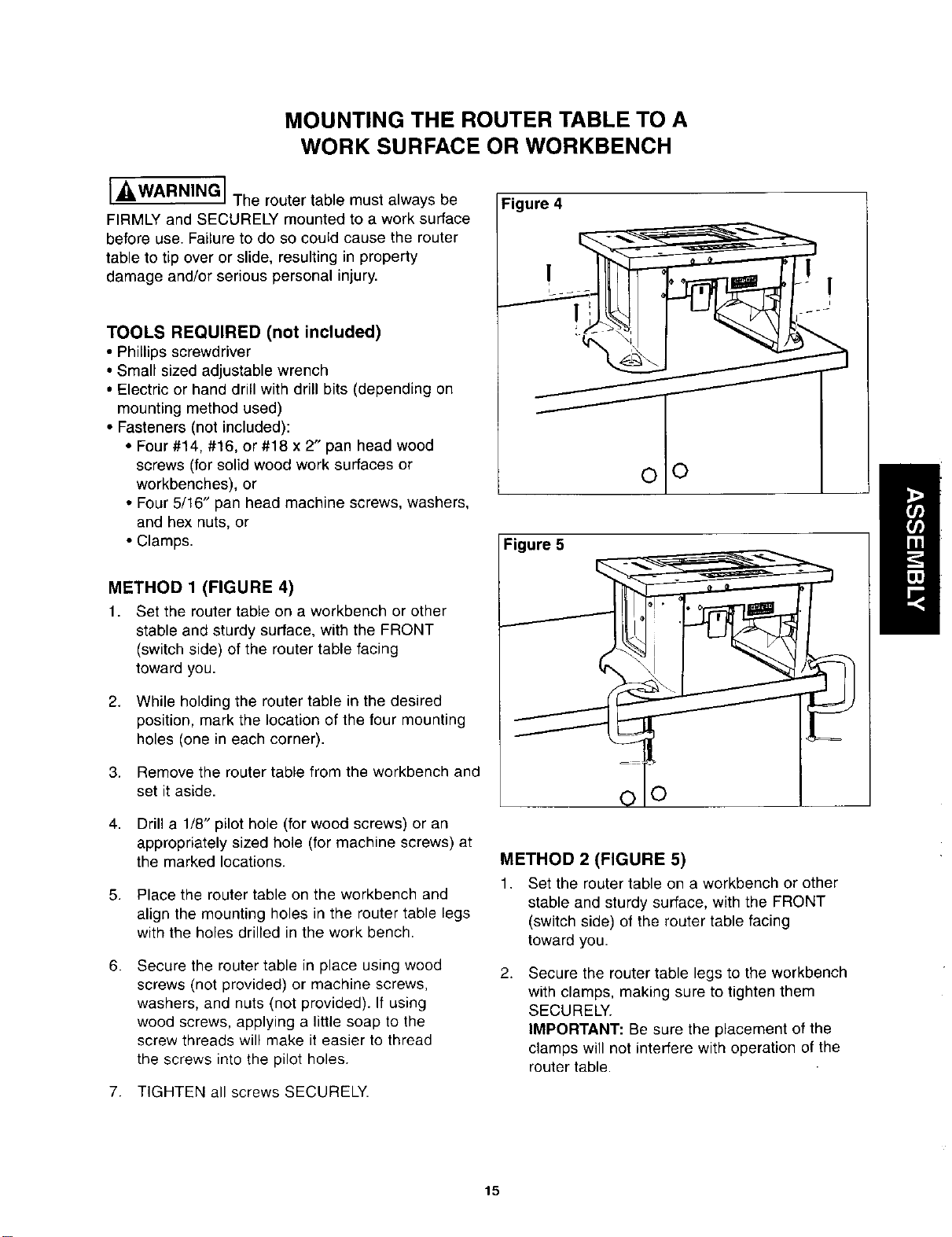

MOUNTING THE ROUTER TABLE TO A

WORK SURFACE OR WORKBENCH

Ii_,I=LWARNINGI The router table must always be

FIRMLY and SECURELY mounted to a work surface

before use. Failure to do so could cause the router

table to tip over or slide, resulting in property

damage and/or serious personal injury.

TOOLS REQUIRED (not included)

• Phillips screwdriver

• Small sized adjustable wrench

• Electric or hand drill with drill bits (depending on

mounting method used)

• Fasteners (not included):

• Four #14, #16, or #18 x 2" pan head wood

screws (for solid wood work surfaces or

workbenches), or

• Four 5/16" pan head machine screws, washers,

and hex nuts, or

• Clamps.

METHOD 1 (FIGURE 4)

1. Set the router table on a workbench or other

stable and sturdy surface, with the FRONT

(switch side) of the router table facing

toward you.

Figure 4

Figure 5

2. While holding the router table in the desired

position, mark the location of the four mounting

holes (one in each corner).

3. Remove the router table from the workbench and

set it aside.

4. Drill a 1/8" pilot hole (for wood screws) or an

appropriately sized hole (for machine screws) at

the marked locations.

5. Place the router table on the workbench and

align the mounting holes in the router table legs

with the holes drilled in the work bench.

6.

Secure the router table in place using wood

screws (not provided) or machine screws,

washers, and nuts (not provided). If using

wood screws, applying a little soap to the

screw threads will make it easier to thread

the screws into the pilot holes.

7. TIGHTEN all screws SECURELY.

METHOD 2 (FIGURE 5)

1, Set the router table on a workbench or other

stable and sturdy surface, with the FRONT

(switch side) of the router table facing

toward you.

2.

Secure the router table legs to the workbench

with clamps, making sure to tighten them

SECURELY.

IMPORTANT: Be sure the placement of the

clamps will not interfere with operation of the

router table.

15

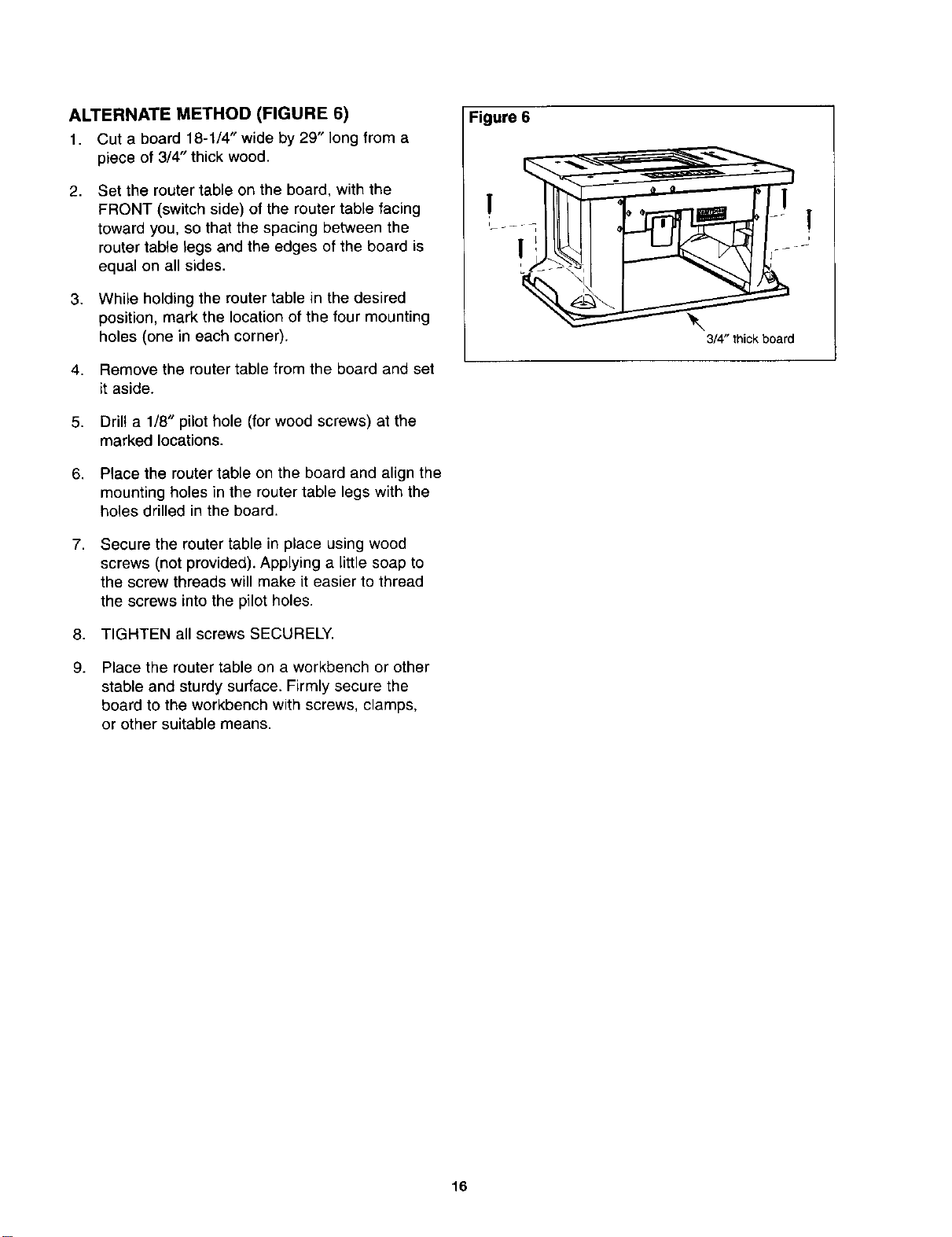

ALTERNATE METHOD (FIGURE 6)

1. Cut a board 18-1/4" wide by 29" long from a

piece of 3/4" thick wood.

2, Set the router table on the board, with the

FRONT (switch side) of the router table facing

toward you, so that the spacing between the

router table legs and the edges of the board is

equal on all sides.

3. While holding the router table in the desired

position, mark the location of the four mounting

holes (one in each corner).

4. Remove the router table from the board and set

it aside.

5. Drill a 1/8" pilot hole (for wood screws) at the

marked locations.

6. Place the router table on the board and align the

mounting holes in the router table legs with the

holes drilled in the board.

7,

Secure the router table in place using wood

screws (not provided). Applying a little soap to

the screw threads will make it easier to thread

the screws into the pilot holes.

Figure 6

8. TIGHTEN all screws SECURELY.

g. Place the router table on a workbench or other

stable and sturdy surface. Firmly secure the

board to the workbench with screws, clamps,

or other suitable means.

16

ASSEMBLING THE ROUTER TABLE FLOOR STAND

(Model 9-26464)

TOOLS REQUIRED (not included)

• Phillips screwdriver

• Small sized adjustable wrench

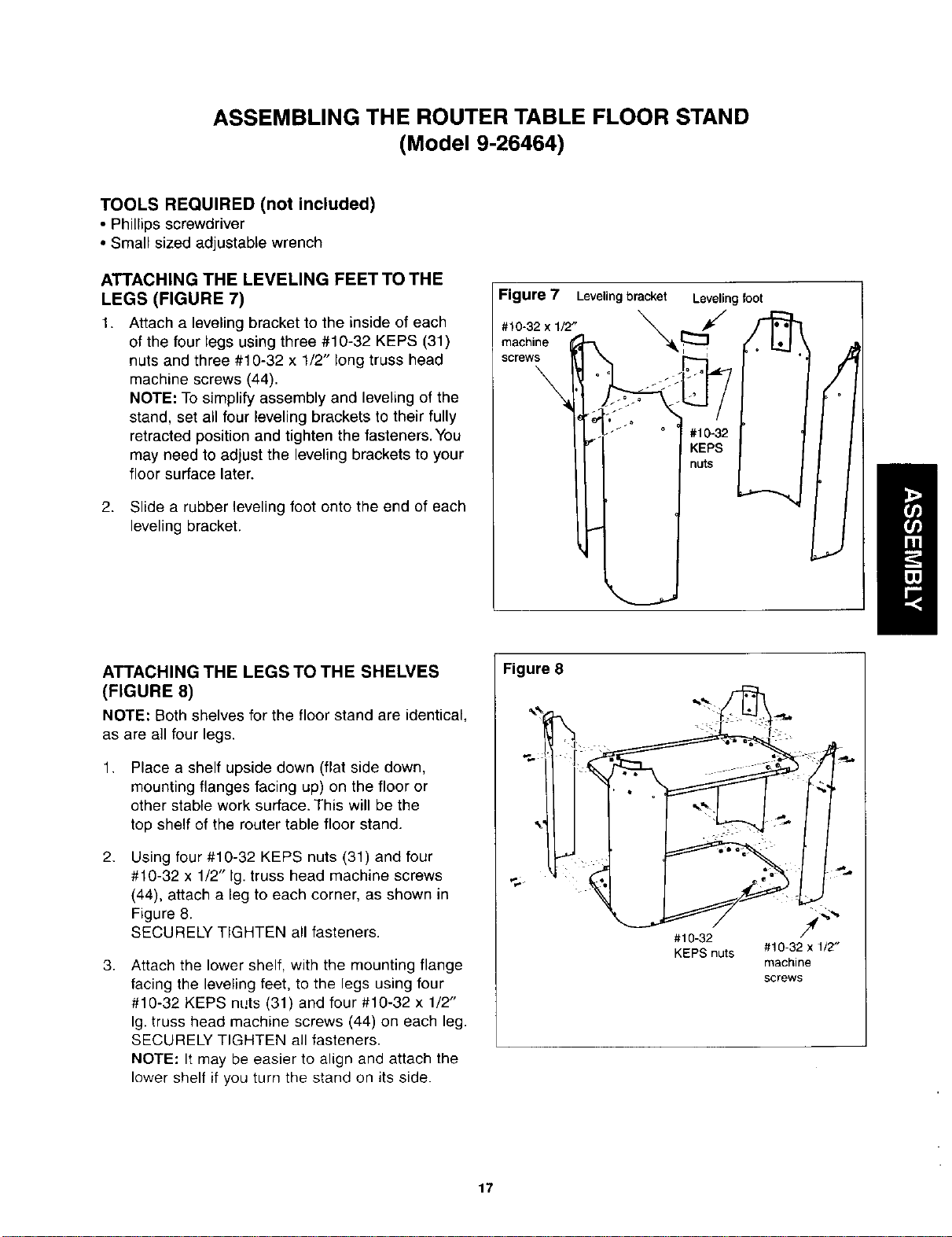

ATTACHING THE LEVELING FEET TO THE

LEGS (FIGURE 7)

1. Attach a leveling bracket to the inside of each

of the four legs using three #10-32 KEPS (31)

nuts and three #10-32 x 1/2" long truss head

machine screws (44).

NOTE: To simplify assembly and leveling of the

stand, set all four leveling brackets to their fully

retracted position and tighten the fasteners. You

may need to adjust the leveling brackets to your

floor surface later.

2. Slide a rubber leveling foot onto the end of each

leveling bracket.

Figure 7 Leveling bracket Levelir

#10-32 x 1/2 _ _,_

machine

screws

foot

/

D D

J

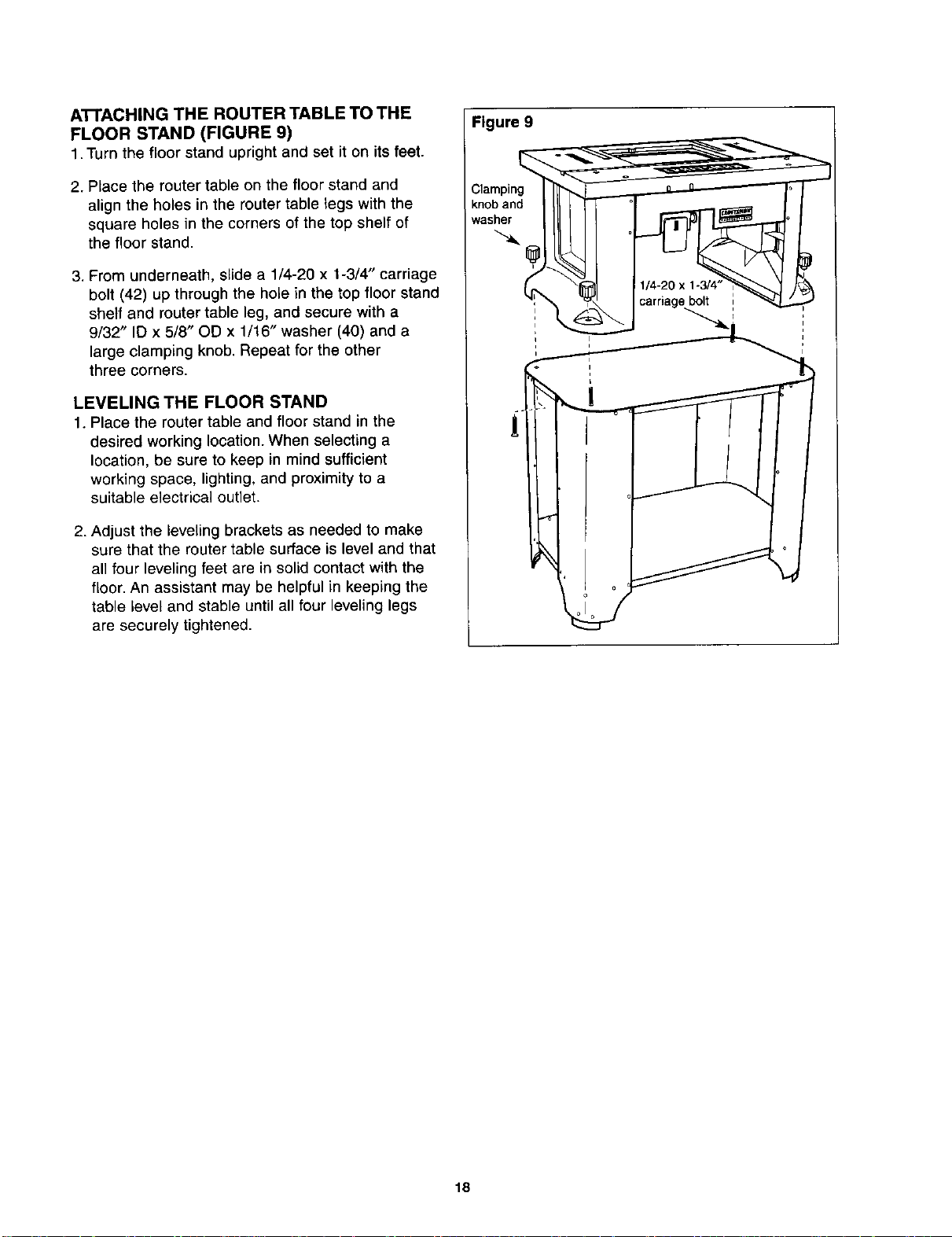

ATTACHING THE LEGS TO THE SHELVES

(FIGURE 8)

NOTE: Both shelves for the floor stand are identical,

as are all four legs.

1,

Place a shelf upside down (flat side down,

mounting flanges facing up) on the floor or

other stable work surface. This will be the

top shelf of the router table floor stand.

2.

Using four #10-32 KEPS nuts (31) and four

#10-32 x 1/2" Ig. truss head machine screws

(44), attach a leg to each corner, as shown in

Figure 8.

SECURELY TIGHTEN all fasteners.

3.

Attach the lower shelf, with the mounting flange

facing the leveling feet, to the legs using four

#10-32 KEPS nt_ts (31) and four #10-32 x 1/2"

Ig. truss head machine screws (44) on each leg.

SECURELY TIGHTEN all fasteners.

NOTE: It may be easier to align and attach the

lower shelf if you turn the stand on its side.

#10-32

KEPS nuts

#10-32 x 1/2"

machine

screws

17

ATFACHING THE ROUTER TABLE TO THE

FLOOR STAND (FIGURE 9)

1, Turn the floor stand upright and set it on its feet.

2. Place the router table on the floor stand and

align the holes in the router table legs with the

square holes in the corners of the top shelf of

the floor stand.

3. From underneath, slide a 1/4-20 x 1-3/4" carriage

bolt (42) up through the hole in the top floor stand

shelf and router table leg, and secure with a

9/32" ID x 5/8" OD x 1/16" washer (40) and a

large clamping knob. Repeat for the other

three corners.

LEVELING THE FLOOR STAND

1. Place the router table and floor stand in the

desired working location.When selecting a

location, be sure to keep in mind sufficient

working space, lighting, and proximity to a

suitable electrical outlet.

2. Adjust the leveling brackets as needed to make

sure that the router table surface is level and that

all four leveling feet are in solid contact with the

floor. An assistant may be helpful in keeping the

table level and stable until all four leveling legs

are securely tightened.

Figure 9

Clampin_

knob and I III I _ 1 __ I I

i I

L

1

18

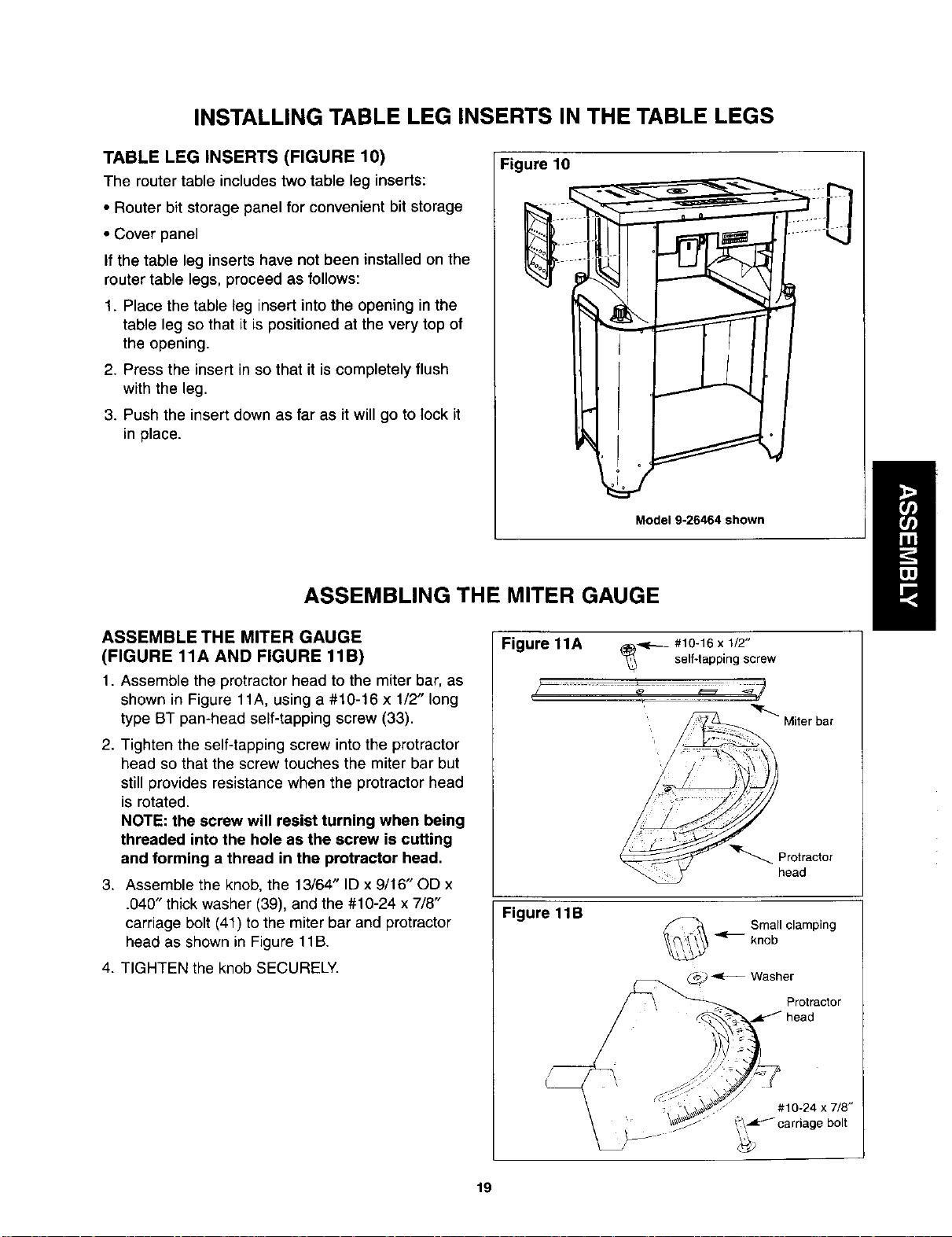

INSTALLING TABLE LEG INSERTS IN THE TABLE LEGS

TABLE LEG INSERTS (FIGURE 10)

The router table includestwo table leg inserts:

• Router bit storage panel for convenient bit storage

• Cover panel

If the table leg inserts have not been installed on the

router table legs, proceed as follows:

1. Place the table leg insert into the opening in the

table leg so that it is positioned at the very top of

the opening.

2. Press the insert in so that it is completely flush

with the leg.

3. Push the insert down as far as it willgo to lock it

in place.

Figure 10

h wn

ASSEMBLING THE MITER GAUGE

ASSEMBLE THE MITER GAUGE

(FIGURE 11A AND FIGURE 11B)

1, Assemble the protractorhead to the miter bar, as

shown in Figure 11A, using a #10-16 x 1/2" long

type BT pan-head self-tapping screw (33).

2. Tighten the self-tapping screw into the protractor

head so that the screw touches the miter bar but

still provides resistance when the protractor head

is rotated.

NOTE: the screw will resist turning when being

threaded into the hole as the screw is cutting

and forming a thread in the protractor head,

3. Assemble the knob, the 13/64" ID x 9/16" OD x

.040" thick washer (39), and the #10-24 x 7/8"

carriage bolt (41) to the miter bar and protractor

head as shown in Figure 11B.

4. TIGHTEN the knob SECURELY.

Figure 11A

S

Figure 11B

-__ #10-16 x 1/2"

self-tapping screw

, Miter bar

ro, aotor

Small clamping

knob

_ _ Washer

Protractor

#10-24 x 7/8"

\, carriage bolt

19

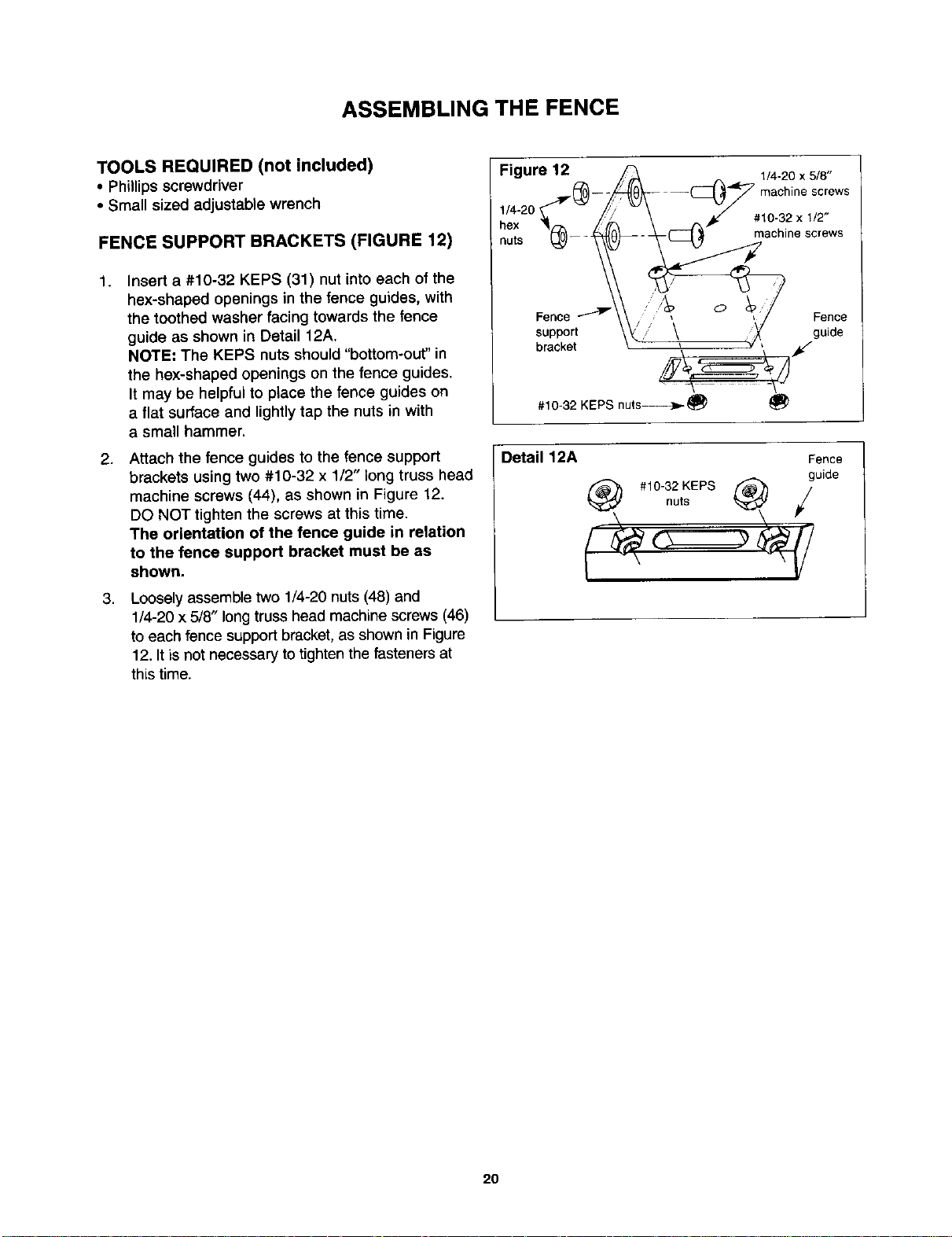

ASSEMBLING THE FENCE

TOOLS REQUIRED (not included)

• Phillips screwdriver

• Small sized adjustable wrench

FENCE SUPPORT BRACKETS (FIGURE 12)

1.

Insert a #10-32 KEPS (31) nut into each of the

hex-shaped openings in the fence guides, with

the toothed washer facing towards the fence

guide as shown in Detail 12A.

NOTE: The KEPS nuts should "bottom-out" in

the hex-shaped openings on the fence guides.

It may be helpful to place the fence guides on

a flat surface and lightly tap the nuts in with

a small hammer.

2*

Attach the fence guides to the fence support

brackets using two #10-32 x 1/2" long truss head

machine screws (44), as shown in Figure 12.

DO NOT tighten the screws at this time.

The orientation of the fence guide in relation

to the fence support bracket must be as

shown.

,

Loosely assemble two 1/4-20 nuts (48) and

1/4-20 x 5/8" long trusshead machine screws (46)

to each fence support bracket, as shown in Figure

12. It is not necessary to tighten the fasteners at

this time.

Figure 12 -- 1/4-20x 5/8"

(__ L- --(-_/_ machine screws

/ ,\ J#,o32xl,2

Fence / . _ _ Fence

support v// '\ '_/ guide

bracket , _/,

#10-32 KEPS nuts_

Detail 12A Fence

guide

_ #10-32KEPS _ /nuts

r\

2O

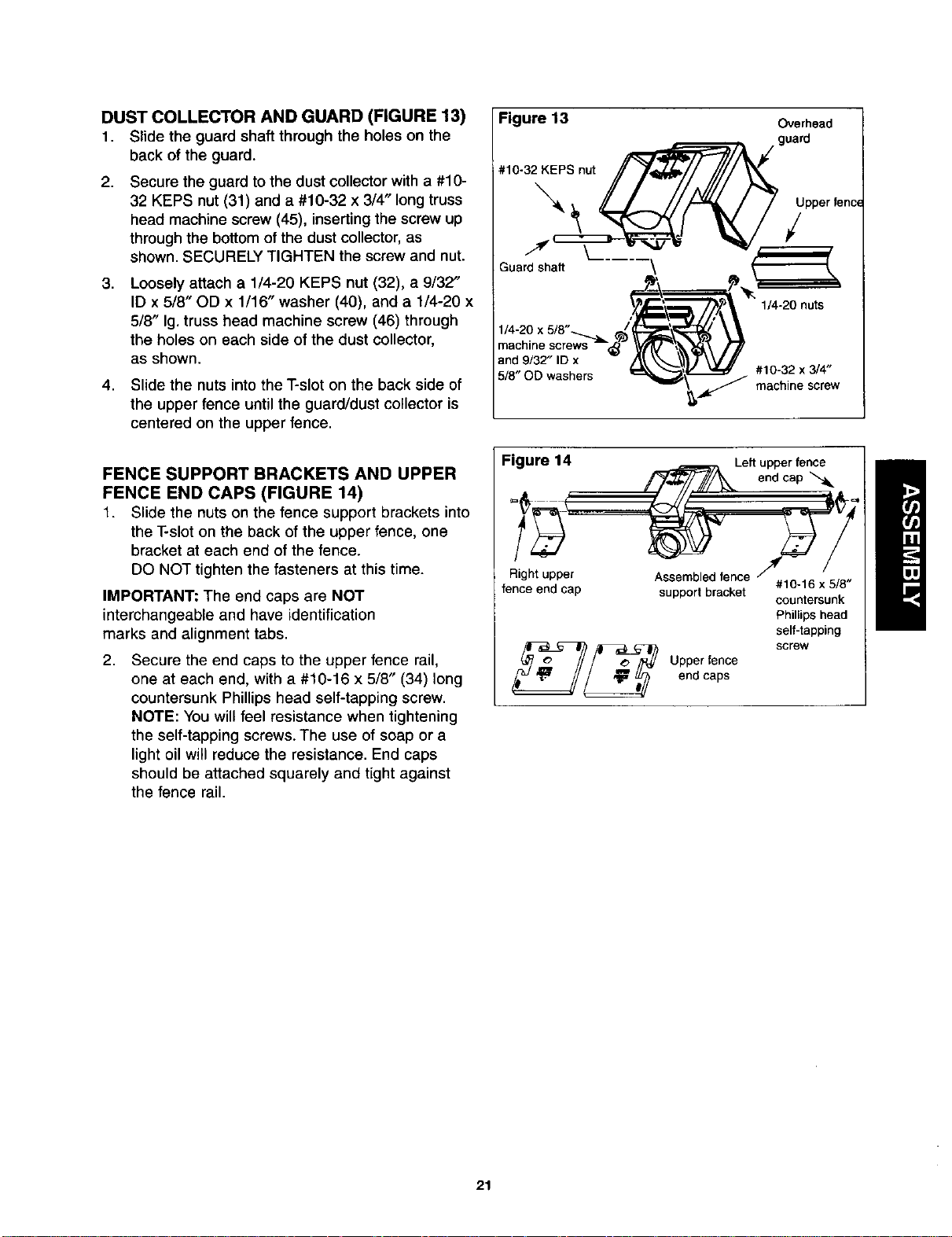

DUST COLLECTOR AND GUARD (FIGURE 13)

1. Slide the guard shaft through the holes on the

back of the guard.

2,

Secure the guard to the dust collector witha #10-

32 KEPS nut (31) and a #10-32 x 3/4" long truss

head machine screw (45), inserting the screw up

through the bottom of the dust collector, as

shown. SECURELY TIGHTEN the screw and nut.

3,

Loosely attach a 1/4-20 KEPS nut (32), a 9/32"

ID x 5/8" OD x 1/16" washer (40), and a 1/4-20 x

5/8" Ig. truss head machine screw (46) through

the holes on each side of the dust collector,

as shown.

4. Slide the nuts into the T-slot on the back side of

the upper fence until the guard/dust collector is

centered on the upper fence.

and 9/32" ID x

5/8" OD washers

1/4-20 nuts

#10-32 x 3/4"

machine screw

FENCE SUPPORT BRACKETS AND UPPER

FENCE END CAPS (FIGURE 14)

1. Slide the nuts onthe fence support brackets into

the T-slot on the back of the upper fence, one

bracket at each end of the fence.

DO NOT tighten the fasteners at this time.

IMPORTANT: The end caps are NOT

interchangeable and have identification

marks and alignment tabs.

2. Secure the end caps to the upper fence rail,

one at each end, with a #10-16 x 5/8" (34) long

countersunk Phillips head self-tapping screw.

NOTE: You will feel resistance when tightening

the self-tapping screws. The use of soap or a

light oil will reduce the resistance. End caps

should be attached squarely and tight against

the fence rail.

Figure 14 _ Left upperfence

fence end cap support bracket

__ Upper fence

end caps

#10-16 x 5/8"

countersunk

Phillips head

self-tapping

screw

21

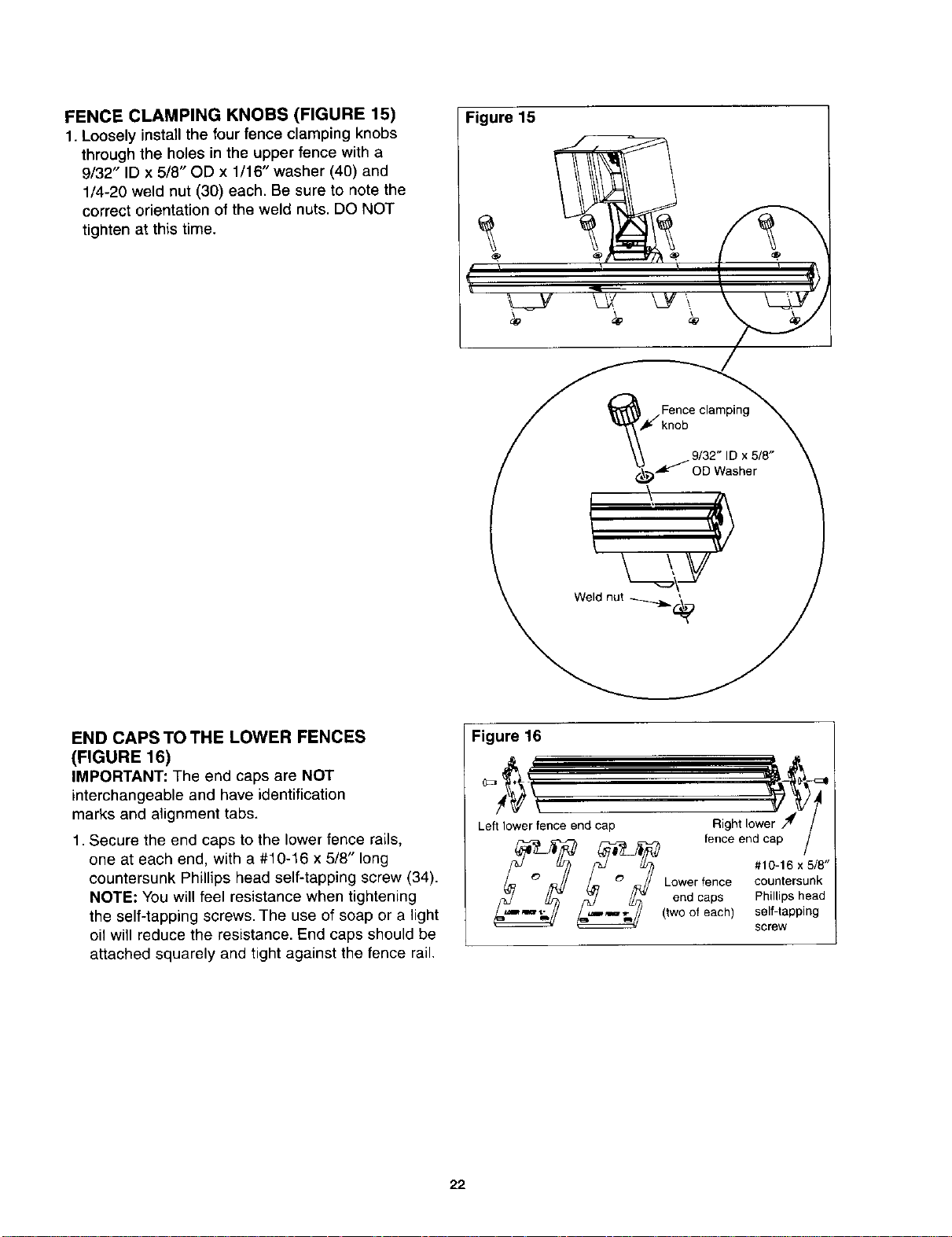

FENCE CLAMPING KNOBS (FIGURE 15)

1. Loosely installthe four fence clamping knobs

through the holes in the upper fence with a

9/32" ID x 5/8" OD x 1/16" washer (40) and

1/4-20 weld nut (30) each. Be sure to note the

correct orientation of the weld nuts. DO NOT

tighten at this time.

Figure 15

END CAPS TO THE LOWER FENCES

(FIGURE 16)

IMPORTANT: The end caps are NOT

interchangeable and have identification

marks and alignment tabs.

1. Secure the end caps to the lower fence rails,

one at each end, with a #10-16 x 5/8" long

countersunk Phillips head self-tapping screw (34).

NOTE: You will feel resistance when tightening

the self-tapping screws. The use of soap or a light

oil will reduce the resistance. End caps should be

attached squarely and tight against the fence rail.

Figure 16

i I

Left lower fence end cap

_ _ Lower fence

22

f

end caps

(two of each)

#10-16 x 5/8"

countersunk

Phillips head

self-lapping

screw

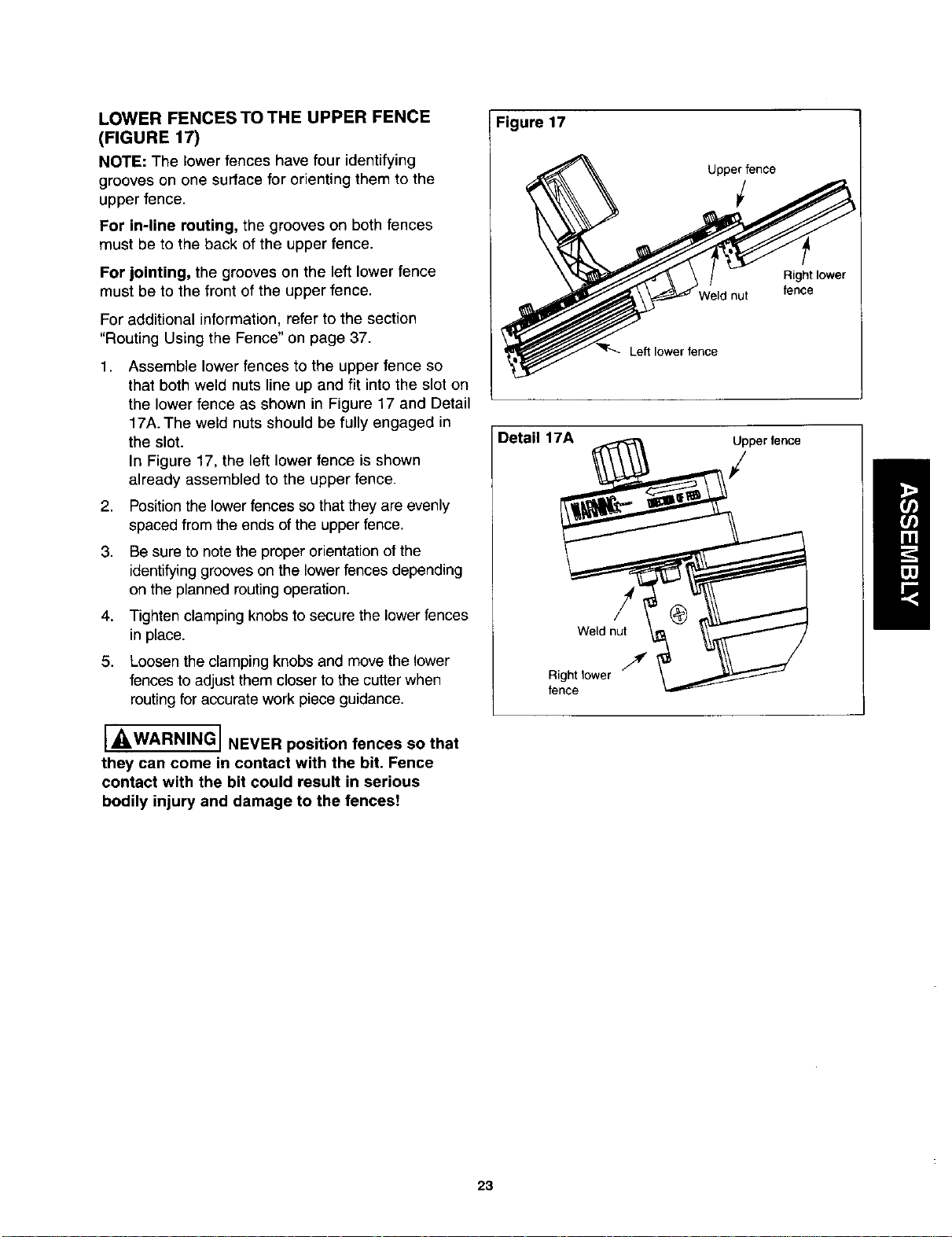

LOWER FENCES TO THE UPPER FENCE

(FIGURE 17)

NOTE: The lower fences have four identifying

grooves on one surface for orienting them to the

upper fence.

For in-line routing, the grooves on both fences

must be to the back of the upper fence.

Figure 17

1

Upper fence

For jointing, the grooves on the left lower fence

must be to the front of the upper fence.

For additional information, refer to the section

"Routing Using the Fence" on page 37.

1. Assemble lower fences to the upper fence so

that both weld nuts line up and fit into the slot on

the lower fence as shown in Figure 17 and Detail

17A.The weld nuts should be fully engaged in

the slot.

In Figure 17, the left lower fence is shown

already assembled to the upper fence.

2. Position the lower fences so that they are evenly

spaced from the ends of the upper fence.

3. Be sure to note the proper orientation of the

identifying grooves on the lower fences depending

on the planned routing operation.

4. Tighten clamping knobs to secure the lower fences

in place.

5. Loosen the clamping knobs and move the lower

fences to adjust them closer to the cutter when

routing for accurate work piece guidance.

Detail 17A

Right lower

fence

Right lower

Weld nut fence

Left lower fence

Upper fence

Weld nut

S

I_,WARNINGI NEVER position fences so that

they can come in contact with the bit. Fence

contact with the bit could result in serious

bodily injury and damage to the fences!

23

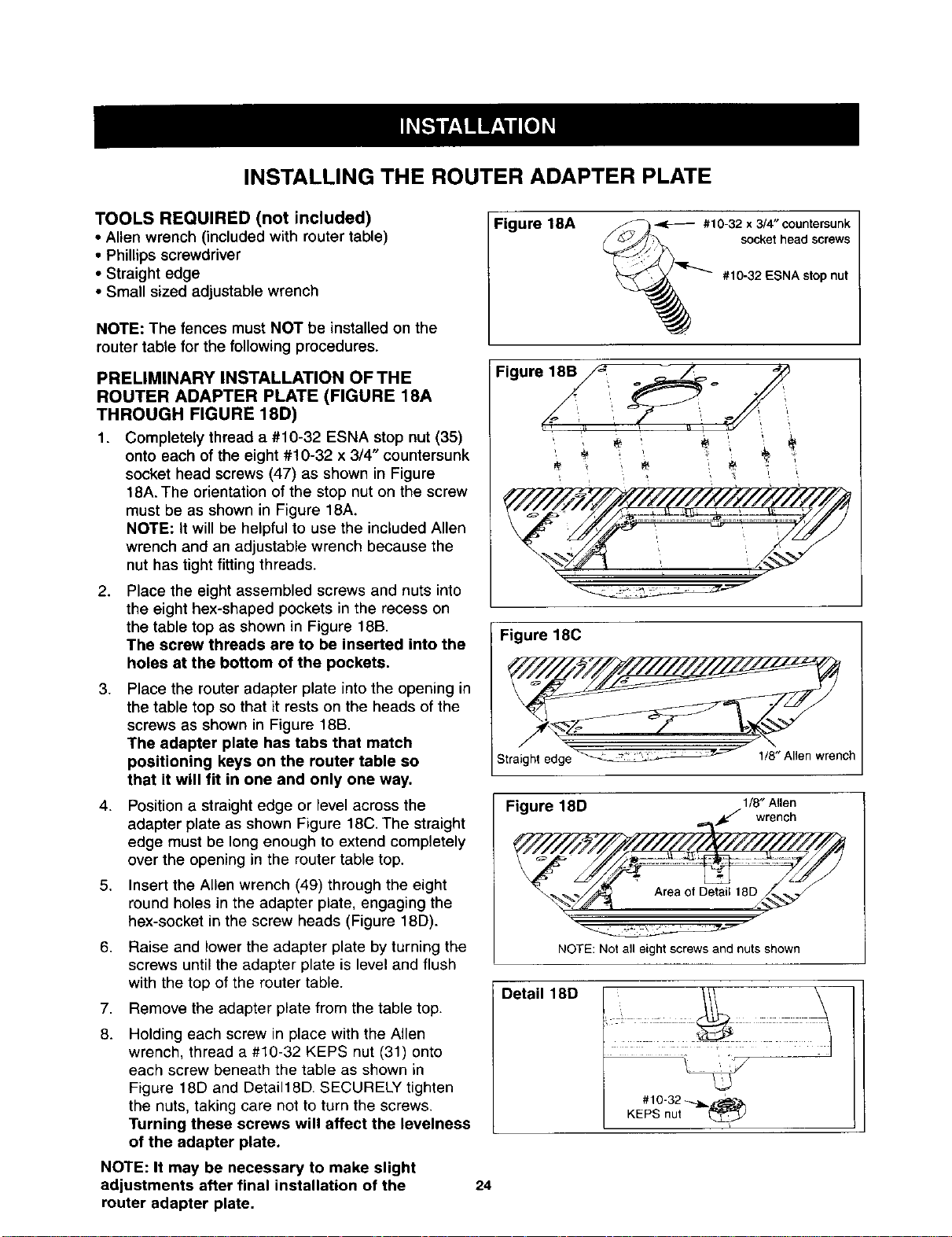

INSTALLING THE ROUTER ADAPTER PLATE

TOOLS REQUIRED (not included)

• Allen wrench (included with router table)

• Phillips screwdriver

• Straight edge

• Small sized adjustable wrench

NOTE: The fences must NOT be installed on the

router table for the following procedures.

PRELIMINARY INSTALLATION OF THE

ROUTER ADAPTER PLATE (FIGURE 18A

THROUGH FIGURE 18D)

1. Completely thread a #10-32 ESNA stop nut (35)

onto each of the eight #10-32 x 3/4" countersunk

socket head screws (47) as shown in Figure

18A. The orientation of the stop nut on the screw

must be as shown in Figure 18A.

NOTE: it will be helpful to use the included Allen

wrench and an adjustable wrench because the

nut has tight fittingthreads.

2,

Place the eight assembled screws and nuts into

the eight hex-shaped pockets in the recess on

the table top as shown in Figure 18B.

The screw threads are to be inserted into the

holes at the bottom of the pockets.

3.

Place the router adapter plate into the opening in

the table top so that it rests on the heads of the

screws as shown in Figure 18B.

The adapter plate has tabs that match

positioning keys on the router table so

that it will fit in one and only one way.

4,

Position a straight edge or level across the

adapter plate as shown Figure 18C. The straight

edge must be long enough to extend completely

over the opening in the router table top.

5.

Insert the Allen wrench (49) through the eight

round holes in the adapter plate, engaging the

hex-socket in the screw heads (Figure 18D).

6,

Raise and lower the adapter plate by turning the

screws until the adapter plate is level and flush

with the top of the router table.

7,

Remove the adapter plate from the table top.

8.

Holding each screw in place with the Allen

wrench, thread a #10-32 KEPS nut (31) onto

each screw beneath the table as shown in

Figure 18D and Detai118D. SECURELY tighten

the nuts, taking care not to turn the screws.

Turning these screws will affect the levelness

of the adapter plate.

NOTE: It may be necessary to make slight

adjustments after final installation of the

router adapter plate.

Figure 18A _--_ _ #10-32 x 3/4" countersunk

_ socket head screws

'_''_ #10-32 ESNA stop nut

F,0",o,y

Figure 180

Straight edge" " _': _ _ " 1/8"Allen wrench

Figure 18D 1/8"Allen

NOTE: Not all eight screws and nuts shown

Detail 18D

#10-32 _,_ '

KEPS nut

24

ATTACHING THE ROUTER TO THE ROUTER ADAPTER PLATE

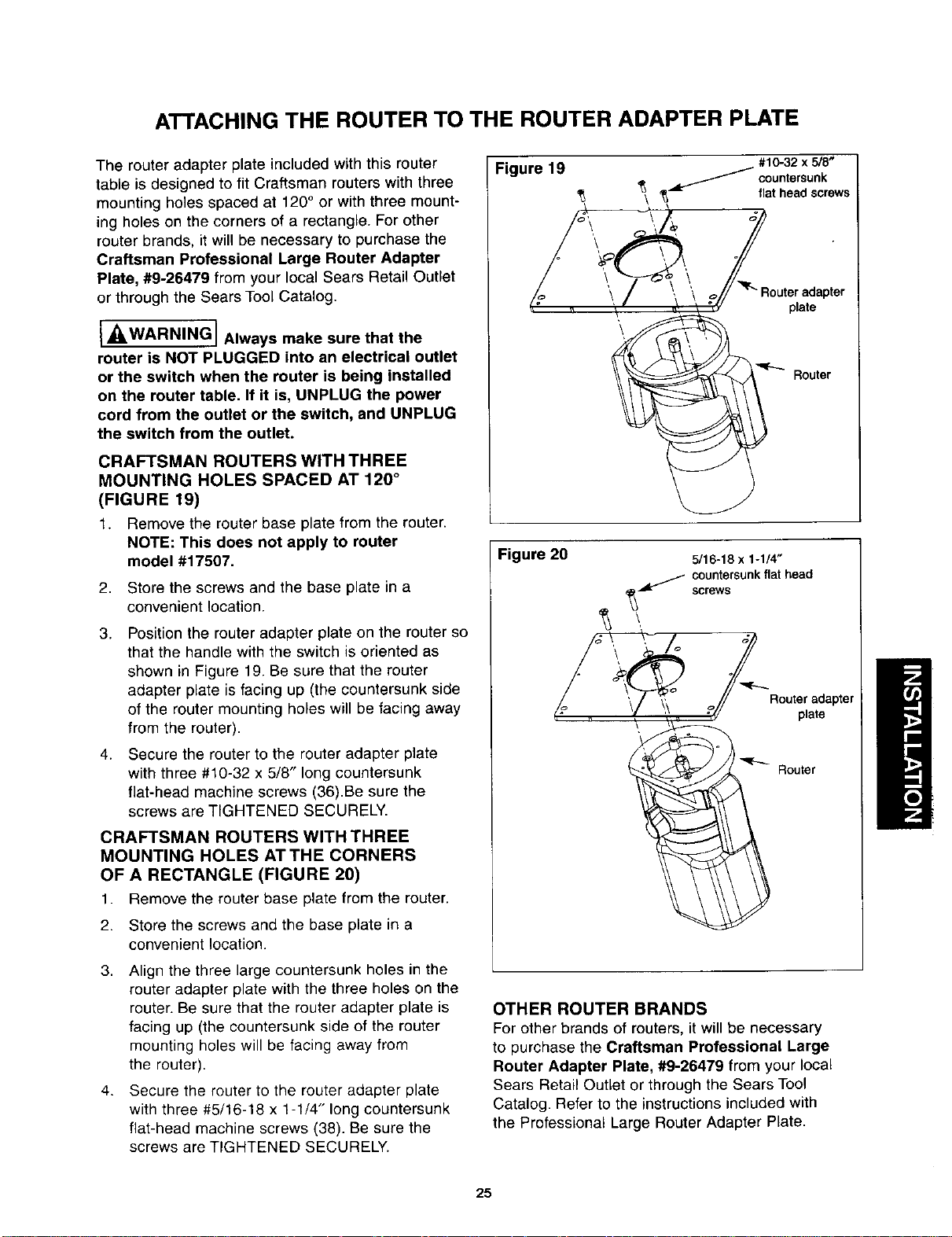

The router adapter plate included with this router

table is designed to fit Craftsman touters with three

mounting holes spaced at 120° or with three mount-

ing holes on the corners of a rectangle. For other

router brands, it will be necessary to purchase the

Craftsman Professional Large Router Adapter

Plate, #9-26479 from your local Sears Retail Outlet

or through the Sears Tool Catalog.

/^ /

[AILWARNINGI Always make sure that the

router is NOT PLUGGED into an electrical outlet

or the switch when the router is being installed

on the router table. If it is, UNPLUG the power

cord from the outlet or the switch, and UNPLUG

the switch from the outlet.

CRAFTSMAN ROUTERS WITH THREE

MOUNTING HOLES SPACED AT 120 °

(FIGURE 19)

1. Remove the router base plate from the router.

NOTE: This does not apply to router

model #17507.

2. Store the screws and the base plate in a

convenient location.

3. Position the router adapter plate on the router so

that the handle with the switch is oriented as

shown in Figure 19. Be sure that the router

adapter plate is facing up (the countersunk side

of the router mounting holes will be facing away

from the router).

4. Secure the router to the router adapter plate

with three #10-32 x 5/8" long countersunk

flat-head machine screws (36).Be sure the

screws are TIGHTENED SECURELY.

CRAFTSMAN ROUTERS WITH THREE

MOUNTING HOLES ATTHE CORNERS

OF A RECTANGLE (FIGURE 20)

1. Remove the router base plate from the router.

2. Store the screws and the base plate in a

convenient location.

Figure 19

S countersunk

_ flat head screws

#10-32 x 5/8"

"qF-_

Figure 20 5/16-18 x 1-1/4_"

countersunk flat head

_" screws

- o

Routeradapter

plate

Router

plate

Router

3. Align the three large countersunk holes in the

router adapter plate with the three holes on the

router. Be sure that the router adapter plate is

facing up (the countersunk side of the router

mounting holes will be facing away from

the router).

4. Secure the router to the router adapter plate

with three #5/16-18 x 1-1/4" long countersunk

flat-head machine screws (38). Be sure the

screws are TIGHTENED SECURELY.

OTHER ROUTER BRANDS

For other brands of routers, itwill be necessary

to purchase the Craftsman Professional Large

Router Adapter Plate, #9-26479 from your local

Sears Retail Outlet or through the Sears Tool

Catalog. Refer to the instructions included with

the Professional Large Router Adapter Plate.

25

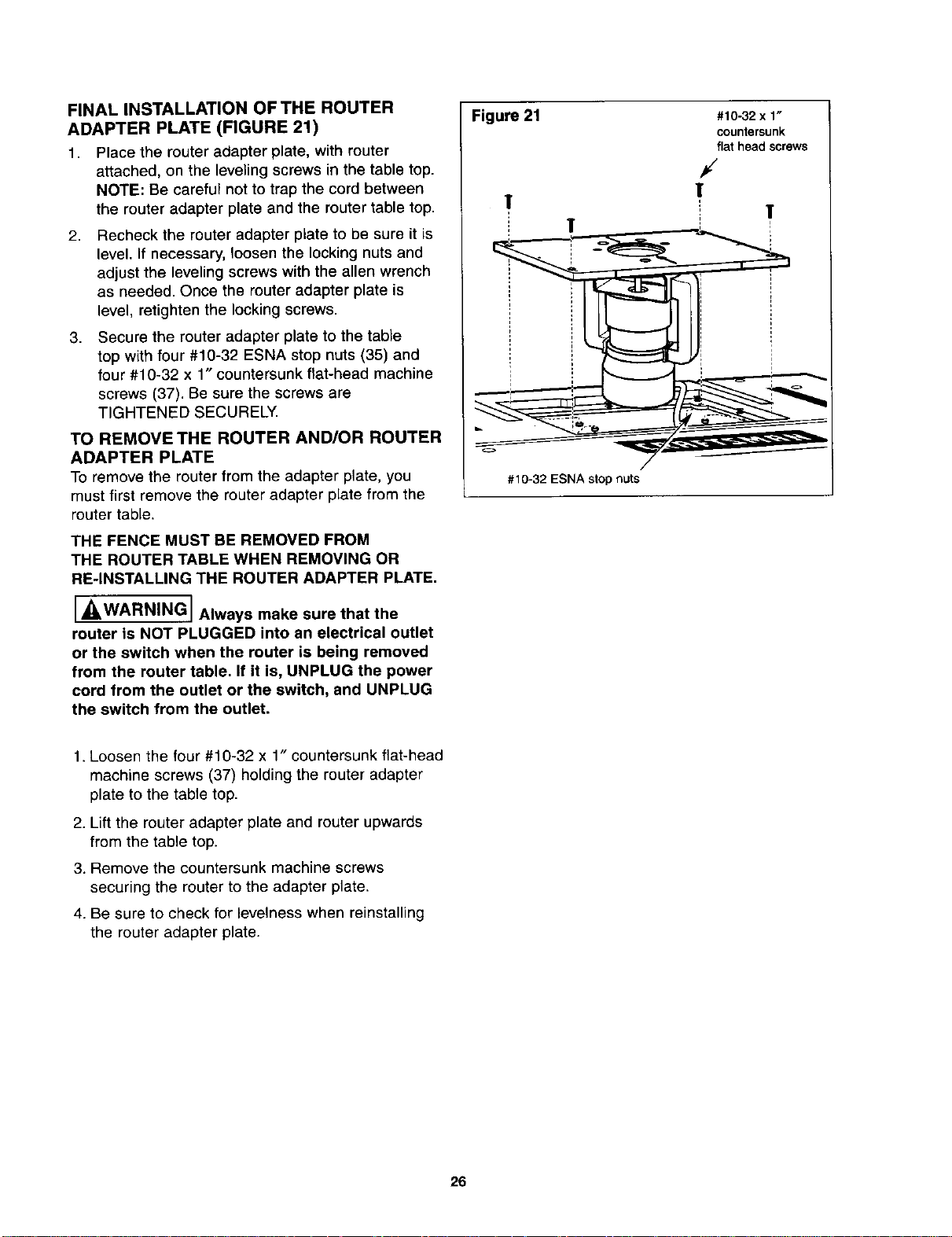

FINAL INSTALLATION OF THE ROUTER

ADAPTER PLATE (FIGURE 21)

1. Place the router adapter plate, with router

attached, on the leveling screws in the table top.

NOTE: Be careful not to trap the cord between

the router adapter plate and the router table top.

2. Recheck the router adapter plate to be sure it is

level, if necessary, loosen the locking nuts and

adjust the leveling screws with the allen wrench

as needed. Once the router adapter plate is

level, retighten the locking screws.

3. Secure the router adapter plate to the table

top with four #10-32 ESNA stop nuts (35) and

four #10-32 x 1" countersunk fiat-head machine

screws (37). Be sure the screws are

TIGHTENED SECURELY.

TO REMOVE THE ROUTER AND/OR ROUTER

ADAPTER PLATE

To remove the router from the adapter plate, you

must first remove the router adapter plate from the

router table.

THE FENCE MUST BE REMOVED FROM

THE ROUTER TABLE WHEN REMOVING OR

RE-INSTALLING THE ROUTER ADAPTER PLATE.

Figure 21

!

#10-32 ESNA stop nuts

#10-32 x 1_

countersunk

flat head screws

J

!

!

[_,WARNINGI Always make sure that the

router is NOT PLUGGED into an electrical outlet

or the switch when the router is being removed

from the router table. If it is, UNPLUG the power

cord from the outlet or the switch, and UNPLUG

the switch from the outlet.

1. Loosen the four #10-32 x 1" countersunk flat-head

machine screws (37) holding the router adapter

plate to the table top.

2. Lift the router adapter plate and router upwards

from the table top.

3. Remove the countersunk machine screws

securing the router to the adapter plate.

4. Be sure to check for levelness when reinstalling

the router adapter plate.

26

Loading...

Loading...