Craftsman 171264620 Owner’s Manual

SF./_S

OWNERS

CRAFTSMANo

MANUAL

Model No.

26462_0

PROFESSIONAL

MID-SIZED

ROUTER TABLE

WARNING:

Before operating

product, read this

manual and follow

all its Safety

and Operating

Instructions.

Sears, Roebuck and Co., Hoffman Estates IL 60179 USA

26462 12/00 Printed in U.S.A. 4 9LCN- 84

General Safety Instructions for Power Tools ................................................ 3

Additional Safety Instructions for Router Tables ......................................... 4

Introduction ........................................ .......................................................... '...5

Optional Router Table Accessories ............................................................... 5

Unpacking and Checking Contents ............................................................... 5

Assembly == = • == • • • • =m • =l • • • • • • • • • • • • • m• • • • • • • • • • • • • • • • • • • =, • • • • • • •= •m == • • • • • • • • • • =•== • •l • • • = • • =l • =• • 1=== • == • =•= • • =6

Tools Required ........................................................................................................................ 6

Router Table ............................................................................................................................. 6

Mounting Router to the Router Table .................................................................................... 7

Fence Assembly ...................................................................................................................... 8

Attachment of the Fence Assembly to the Router Table .................................................... 8

Attachment of the Overhead Guard to the Fence Assembly .............................................. 9

Push Block Assembly ............................................................................................................ 9

Push Block Assembly to the Router Table Fence ............................................................. 10

Miter Gauge Assembly ......................................................................................................... 10

Dust Collecting Attachment ................................................................................................. 10

Mounting Router Table to a Workbench or Work Surface ................................................ 10

Alternate Method ................................................................................................................... 11

Selecting and Installing the Router Table Inserts .............................................................. 11

Operation .................................................................................• • .....•.... .......... 12

General ................................................................................................................................... 12

Electrical Requirements / Switch Box Operation .............................................................. 12

Router and Switch Box Operations .................................................................................... 13

Using the Router Table ......................................................................................................... 14

Alignment of Unitized Fence to Miter Bar Slot .................................................................. 14

Adjusting Depth and Height of Cut ..................................................................................... 14

Routing Using Fence without the Push Block ................................................................... 14

Using Router Table as a Jointer (Full Edge Cutting) ...................................................... 14

Edge Cutting with Non-Piloted Router Bits .................................................................... 15

Edge Cutting with Piloted Router Bits ............................................................................ 15

Grooving, Fluting, and Veining ....................................................................................... 16

End Cutting using the Fence with the Push Block ........................................................... 16

Routing using the Miter Gauge ........................................................................................... 18

Parts List .............................................................................................................. 19

2

SAFETY GUIDELINES- DEFINITIONS

This manual contains informa-

tion that is important for you to

know and understand. This

information relates to protect-

ing YOUR SAFETY and

URGENT SAFETY INFORMATION -

A HAZARDTHAT WILL CAUSE

SERIOUS INJURY OR LOSS OF LIFE

IADANGER l

PREVENTING EQUIPMENT

PROBLEMS. To help you rec-

ognize this information, we use

the symbols to the right.

Please read the manual and

pay attention to these sections.

I_,WARNING

Failure to heed all safety and operating instructions and warnings regarding use of this

IMPORTANT SAFETY INFORMATION -

A HAZARD THAT MIGHTCAUSE

SERIOUS INJURY OR LOSS OF LIFE

I_WARNING]

product can result in serious bodily injury.

1. Know your power tool

Read the owner's manual carefully. Learn its applica-

tion and limitations as well as the specific potential

hazards peculiar to this tool.

2. Ground all tools (unless double insulated)

If tool is equipped with an approved three-conductor

cord and a three-prong grounding type plug, it

should be plugged into a three hole electrical recep-

tacle. If adapter is used to accommodate a two-hole

receptacle, the adapter wire must be attached to a

known ground (usually the screw securing receptacle

cover plate). Never remove third prong. Never con-

nect green ground wire to a terminal.

3. Keep guards in place

Maintain in working order, and in proper adjustment

and alignment.

4. Remove adjusting keys and wrenches

Form a habit of checking to see that keys and adjust-

ing wrenches are removed from tool before turning it

ON.

5. Keep work area clean

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

6. Avoid dangerous environment

Do not use power tools in damp or wet locations or

expose them to rain. Keep work area well lighted.

Provide adequate surrounding work space.

7. Keep children away

All visitors should be kept a safe distance from

work area.

8. Make workshop child-proof

Use padlocks, master switches, or remove starter keys.

I CAUT'ONI

INFORMATION FOR PREVENTING

DAMAGE TO EQUIPMENT

I NOTE I

INFORMATION THAT YOU SHOULD

PAY SPECIAL ATTENTION TO

9. Do not force tools

They will do the job better and safer at the rate for

which they were designed.

10. Use the right tool

Do not force tool or attachment to do a job it was not

designed to perform.

11. Wear correct apparel

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches) that may get caught

in moving parts. Non-slip footwear is recommended.

Wear protective hair covering to contain long hair.

Roll long sleeves above the elbow.

12. Use safety goggles (Head Protection)

Wear safety goggles (must comply with ANSI

Standard Z87.1) at all times. Also, use face or dust

mask, if cutting operation is dusty, and ear protec-

tors (plugs or muffs) during extended periods of

operation.

13. Secure work

Use clamps or a vise to hold work when practical. It's

safer than using your hands, and it frees both hands

to operate tool.

14. Do not over reach

Keep proper footing and balance at all times.

15. Maintain tools with care

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

16. Disconnect tools before servicing

Before servicing, when changing accessories such

as blades, bits, cutters, etc.

17. Avoid accidental starting

Make sure switch is in OFF position before plugging in.

18. Use recommended accessories

Consult the owner's manual for recommended

accessories and follow the instructions. The use of

improper accessories may cause hazards.

19. Never stand on tool

Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted. DO NOT

store materials above or near the tool making it nec-

essary to stand on the tool to reach them.

20. Check damaged parts

Before further use of the tool, any guard or other

part that is damaged should be carefully checked to

ensure that it will operate properly and perform its

intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or any other part that is

damaged should be properly repaired or

replaced.21. Direction of feed

Feed work into a blade or cutter AGAINST the

direction of rotation of the blade or cutter only.

22. Never leave tool running unattended

Turn power OFF. DO NOT leave tool until it comes to

a complete stop.

23. Keep hands away from cutting area

24. Store idle tools

When not in use, tools should be stored in dry, high

or locked-up place - out of reach of children.

25. Do not abuse cord

Keep cord away from heat, oil and sharp edges.

26. Outdoor extension cords

When tool is used outdoors, use only extension

cords suitable for use outdoors and so marked.

27. Never use in an explosive atmosphere

Normal sparking of the motor could ignite fumes,

flammable liquids, or combustible items.

28. Drugs, alcohol, medication

DO NOT operate tool while under the influence of

drugs, alcohol, or any medication.

Read and Understand this instruction book

completely BEFORE using this product.

1. Always wear eye protection that complies with ANSI

Standard Z87.1.

2. Noise levels vary widely with location. To avoid pos-

sible hearing damage, wear ear plugs or ear muffs

when using your router table for long periods of time.

3. For dusty operations, wear a dust mask along

with safety goggles.

4. Follow the instructions in your router owner's manual.

5.L_'WARNINGJ Vibrations, caused by the router

during use, can cause fasteners to become loose.

Before use and periodically during use, check all

fasteners to make sure that all are tight and secure.

6. Do not use this product until all assembly and instal-

lation steps have been completed. Make sure you have

read and understood all safety and

operational instructions in this manual and the

router owner's manual.

7. Make sure that the router bit is properly positioned

and clamped in the router before making any cuts.

8. Do not use the router table as a workbench or work

surface. Doing so may damage it, causing it

to be unsafe to use. A workbench should be used

for this purpose.

9. This product is designed for cutting flat workpieces.

Do not cut or attempt to cut workpieces that are not

flat.

10.This product is designed for cutting wood

workpieces only. Do not use to cut metal or other non-

wood materials.

11.The use of auxiliary in-feed and out-feed

supports is strongly recommended when routing long

workpieces. Otherwise those workpieces can cause

the router table to tip over.

12. Keep hands clear of the router bits and working

area.

13. Make and use a push stick to move small

workpieces across the cutting area.

14. Clean the router after use. The use of a wet/dry vac

or vacuum equipment is recommended.

15. Always make sure that work surface of the router

table is clean and free from dust, chips, and foreign

particles that can interfere with the cut you are

going to make. The use of a wet/dry vac or vacuum

equipment is recommended.

16. Check the function of the guard before each use.

Remove all dust, chips, and any other foreign parti-

cles that can affect its function.

17. '_WARNINGI Never put your fingers under the

overhead guard when the router is plugged into an

electrical outlet or when the router bit is rotating.

18. Always use the fence to guide the workpiece.

19. Always feed the workpiece AGAINST the rotation

of the cutter or router bit.

20. Router bits are extremely sharp; be extra careful

when handling and using them.

21. Make sure that the router bits being used are sharp

or have been properly resharpened. This will permit

fast, efficient, and SAFE routing.

22. Some routers, when positioned in an upside down

position (such as on a router table), will drop

or fall out of the router base when the base clamp is

loosened to adjust height or depth of cut. Therefore, it

is extremely important to support the router from

below when making these adjustments or whenever

the base clamp is loosened.

23. Always look under the router table at the router

switchboxwhenturningtherouterONorOFF.DO

NOTtouchanythingbuttheswitchboxwhendoing

this.NEVERreachundertheroutertableforanyrea-

sonwhentherouterisrunning,excepttoturnit OFF.

I

A

24.[ WARNING J Before making any cut, make

sure the router is turned OFF, the router bit is not

rotating, and the power cord is unplugged from the

electrical outlet. Then, make absolutely sure that the

overhead guard clears the router bit and the work-

piece. A trial pass, with the router turned OFF and the

router bit not turning, is strongly recommended.

25.l _WARNINGJ Never leave the router table

unattended while the router is running. Turn the router

OFF before leaving the router table for any reason.

I

26. If ANY of the parts is missing, DO NOT attempt

to assemble, install, or use your router table until the

missing parts have been found or replaced and your

router table has been properly and correctly assem-

bled per this manual.

/ I

27.[ _L, DANGER JNever use the floor stand as a

ladder and DO NOT stand on the router table.

Your Craftsman Router Table comes with the following:

• A unique 4" high unitized fence with fence guides that

provide parallel movement.

• Rulers molded into the table top that provide fast

and accurate fence adjustment for making the

following items:

- Tenons

- Sliding dovetail joints

- Tongue & groove joints

- Face cuts

• The unique fence also allows you to perform these

additional routing operations:

9-26478 Craftsman Router Table Floor Stand,

places router table at a convenient working height,

has adjustable floor levelers, and two steel shelves

for storage.

9-25468 Craftsman Guide Master RouterTable Push

Shoe, aids in push shoe and hold down operations,

accurate measurement and router table set-up,

transforms into a miter gauge, and gives quick set-up

for 1/2" sliding dovetail joints.

9-25333 Craftsman Industrial Router Adapter Plate,

for mounting non-Craftsman 1/4" and 1/2" reuters to

- Veining

- Fluting

- Making crown molding

- Making cuts up to 2-1/2" from the edge of the

workpiece toward the center of the workpiece

• A specially designed push block with a quick clamp

that can clamp work pieces up to 4" wide, for end grain

or edge routing.

• An accurate jointing fence that is quickly adjustable to

the proper depth of cut.

• A dust collector port on the fence to which most 2-1/2"

wet/dry vac hoses can be attached.

the router table. The holes for mounting the router

must be located and drilled by the user. The fasteners

for mounting the router to the adapter plate are not

included and must be obtained separately.

9-26478 Craftsman Router Table Floor Stand,

places router table at a convenient working height,

has adjustable floor levelers, and two steel shelves

for storage.

Refer to Parts List on page 19.

• /AI[jIAWARNINGj If ANY of the parts is missing,

DO NOT attempt to assemble, install, or use your

router table until the missing parts have been

found or replaced, and your router table has been

properly and correctly assembled per this manual.

• Contact your local Sears Retail Outlet for missing or

replacement parts.

• In order to simplify handling and to minimize any

damage that may occur during shipping, your router

table comes unassembled.

• Separate all parts from the packaging materials and

check each part against the illustrations and

the parts list at the end of this manual, to make

sure that all parts have been included. Do this before

discarding any of the packaging material.

5

TOOLS REQUIRED

• Phillips screwdriver.

° Small or medium sized adjustable wrench

(or a set of nutdrivers).

° Electrical with 5/32" drill bit.

• Hammer

ROUTER TABLE

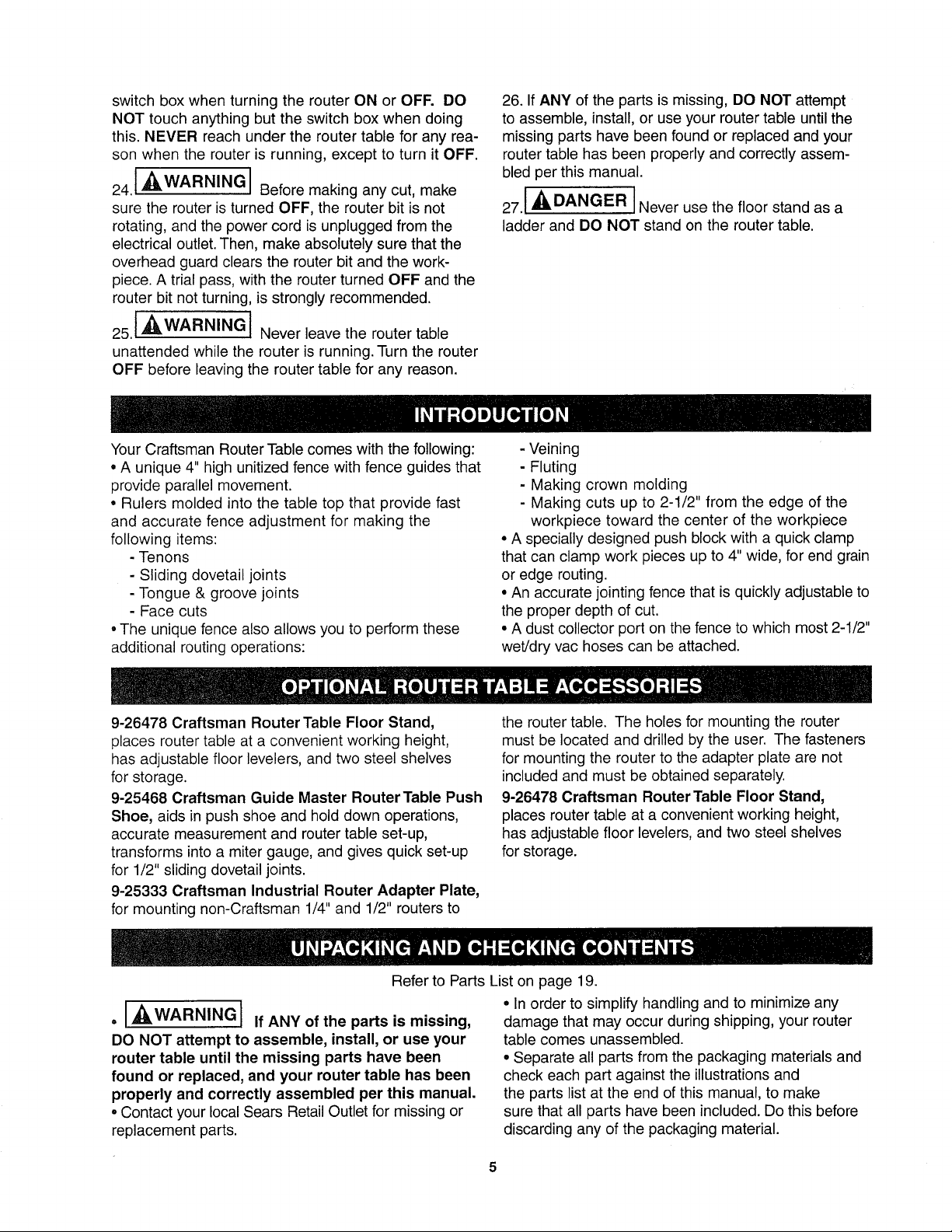

1. Position the router table top (Part No. 29LCN-981)

as shown in Figure 1, with the bottom of the table top

facing toward you.

2. Position the table legs (Part No. 29LCN-1283)

relative to the router table top as shown in Figure 1.

Note that the legs are positioned to the inside of the

table top sides.

B

l

I NOTE I Legs are positioned to the back

edge of the router table, as shown in Figures 1 and 3.

3. Position the leg spacers, two per leg, as shown in

Figure 2. Spacers MUST be positioned at the two

holes in the front of the router table, as shown in

Figure 2. Note that only the second V-slot will be used

to secure the leg from the side in the front of the table,

also noted in Figure 2.

4. Secure each table leg using five (5) #10-32 x 5/8"

long truss head machine screws, two (2) #10-32 x

1-3/4" long truss head machine screws and seven (7)

#10-32 hex "KEPS" nuts. See Figure 3 for a detail of

how the leg is secured to the back area of the table.

5. Repeat steps 3 and 4 for the other leg.

6. SECURELY TIGHTEN all fasteners at this time.

FIGURE 1

Head Machine Screw\ /#10-32 Hex r.eps"

Router_ \(Typical' 5 places)k_ / ///_ Nut (Typmal)

Table _--_'_// \ k_' _ / _'/ /_

•e,

FIGURE 2 - Front Corner of Router Table and Leg

Router _

Table Leg _/ \\\\

Cut Away_\ "

_///fY 7/I'7" Leg

10-32 Hex "Keps" ]

ical) /

Spacer

View_

_k_Y-. 7 x 1-3/4"

Second V-Slot-_'_;_._ _ ///

to be used for _ik_/'/ J

securing Leg _'

#10-32 x 5/8" Long Truss /

Head Machine Screw

(Typical)

/ "_ Truss

FIGURE 3 - Back Corner of Router Table and Leg

Table

Leg

Router

Table

#10-32 Hex ,

"Keps" Nut,

4 places

(Typical)

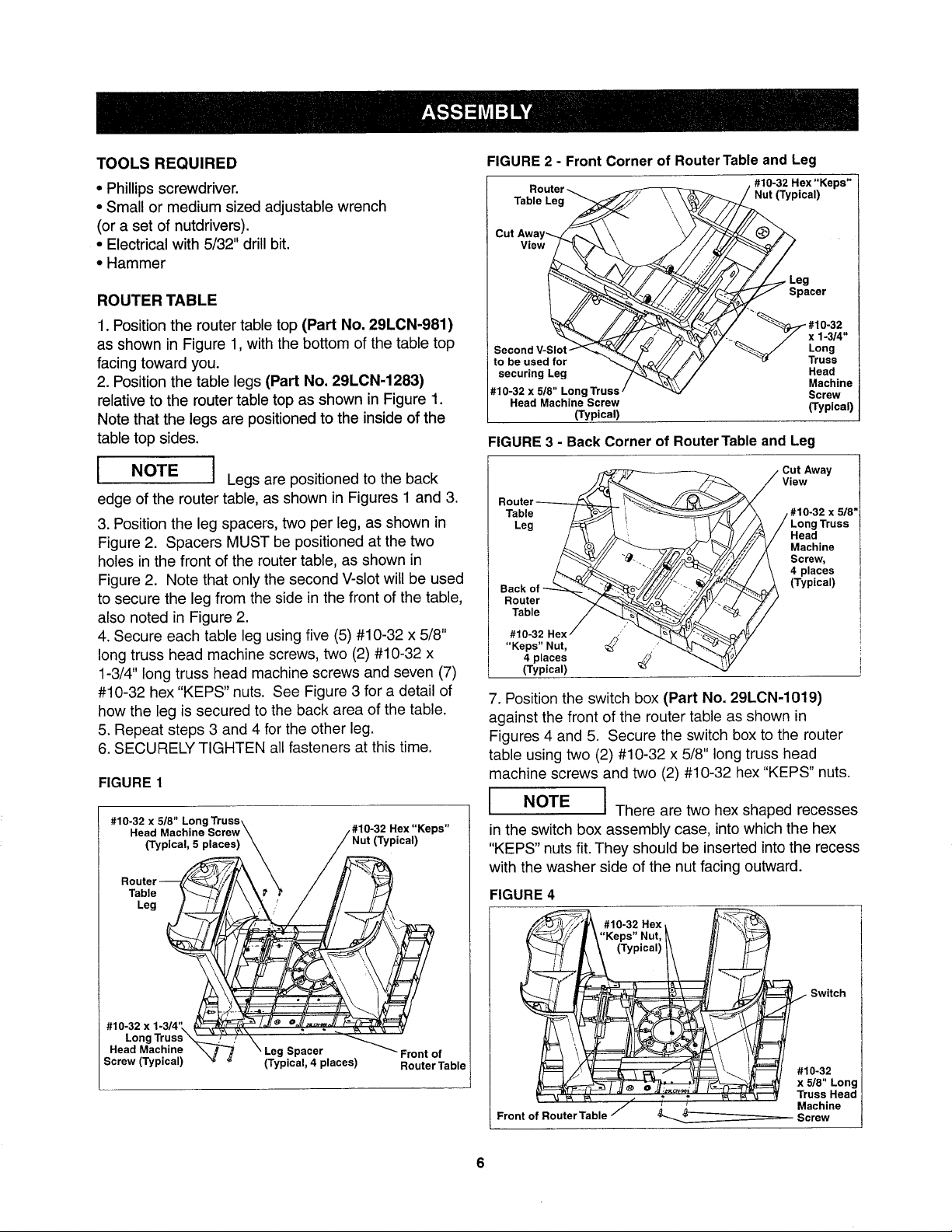

7. Position the switch box (Part No. 29LCN-1019)

against the front of the router table as shown in

Figures 4 and 5. Secure the switch box to the router

table using two (2) #10-32 x 5/8" long truss head

machine screws and two (2) #10-32 hex "KEPS" nuts.

I

I

I NOTE I There are two hex shaped recesses

in the switch box assembly case, into which the hex

"KEPS" nuts fit. They should be inserted into the recess

with the washer side of the nut facing outward.

FIGURE 4

#10-32 Hex t

'Keps" Nut, _ H/

.10-32

/v -_ Long

Head

Machine

Screw

(Typical)

Cut Away

View

#10-32 x 5/8'

Long Truss

Head

Machine

Screw,

4 places

(Typical)

-32xl- _ k_

I #10-32 x 5/8" LongTruss\ ,,.

#1°LongT-uss .; " _

Head Mac_F" _ \ Leg Spacer . _ Front of

_crew (=yp=cai) '_ _ (Typmal, 4 places) RouterTable

(Typical)/_ l/ _,

- _ _ Switch#10-32

Front of Router Table _--....___ Screw

/

6

x 5/8" Long

Truss Head

Machine

FIGURE 5 FIGURE 7

#10-32 Hex "Keps"_

Nut, (Typical)_ -_,- _ / Router

_,_ _ --///_ \\/ Leg

_ _ ,_/ / Table

Switch_ "_

Front of--.

Router

Table

#10-32 518" Long

Truss Head Machin

Screw, (Typical)

_ #10-32 x 518" Long

i _ Flat Countersunk

i _ i Head Machine

Y ! Screw

'_ '_ '_ w/Phillips Recess

MOUNTING ROUTER TO THE ROUTER TABLE

I WARNINGI ALWAYSUNPLUGROUTER

BEFORE MOUNTING.

Craftsman Routers with Three-Hole and 6"

Diameter Base Plates

1. Remove the router base plate (back plate) from the

router.

2. Store the screws and the base plate in a convenient

location.

3. While holding the router upside down, position the

router against the bottom of the router table as shown

in Figure 6. Rotate the router until the three threaded

holes in the router base line up with the three corre-

sponding countersunk holes in the top of the router

table. (The router handles should be oriented as shown

in Figure 6.)

FIGURE 6

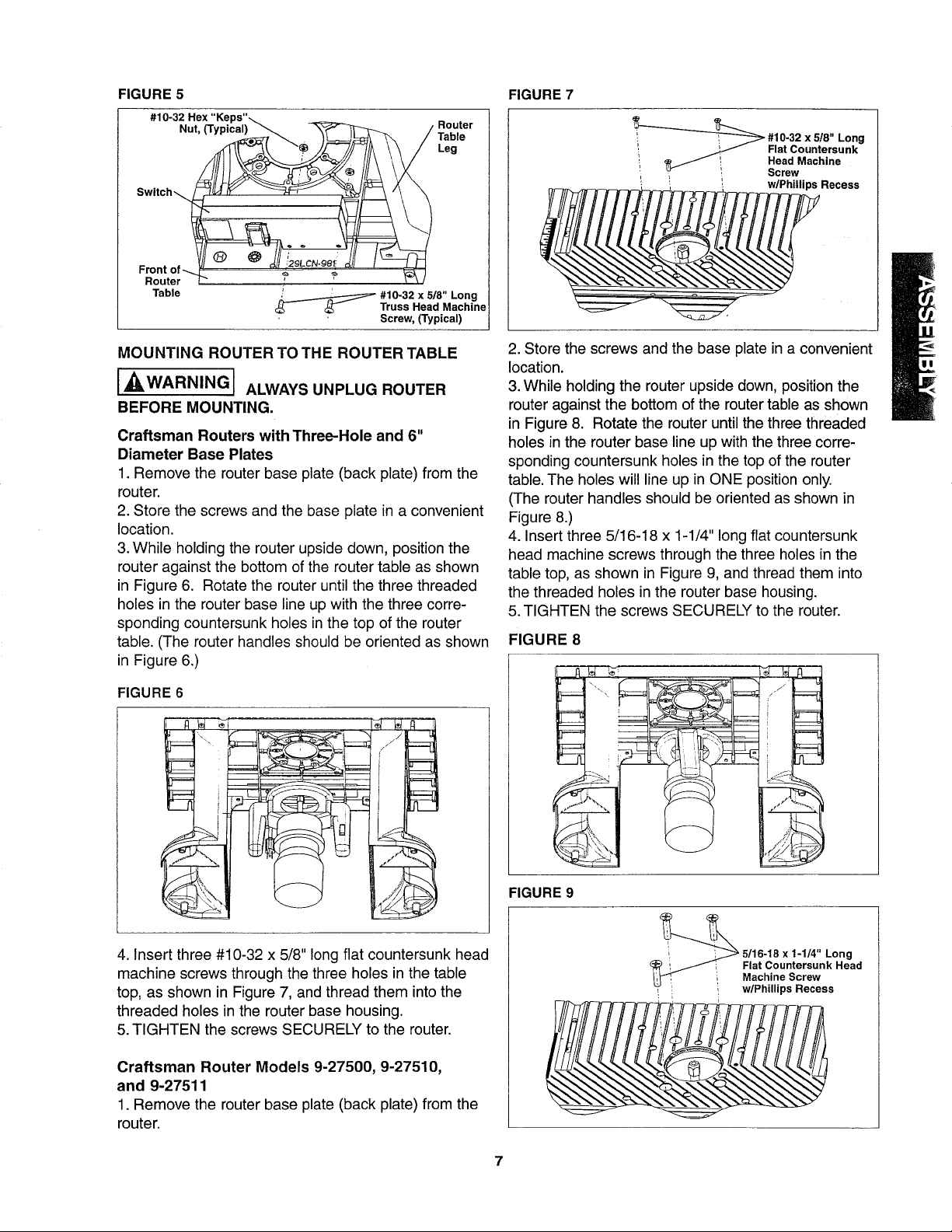

2. Store the screws and the base plate in a convenient

location.

3.While holding the router upside down, position the

router against the bottom of the router table as shown

in Figure 8. Rotate the router until the three threaded

holes in the router base line up with the three corre-

sponding countersunk holes in the top of the router

table. The holes will line up in ONE position only.

(The router handles should be oriented as shown in

Figure 8.)

4. Insert three 5/16-18 x 1-1/4" long flat countersunk

head machine screws through the three holes in the

table top, as shown in Figure 9, and thread them into

the threaded holes in the router base housing.

5.TIGHTEN the screws SECURELY to the router.

FIGURE 8

i

4. Insert three #10-32 x 5/8" long flat countersunk head

machine screws through the three holes in the table

top, as shown in Figure 7, and thread them into the

threaded holes inthe router base housing.

5. TIGHTEN the screws SECURELY to the router.

Craftsman Router Models 9-27500, 9-27510,

and 9-27511

1. Remove the router base plate (back plate) from the

router.

FIGURE 9

7

x 1-1/4" Long

Flat Countersunk Head

i Machine Screw

', w/Phillips Recess

Loading...

Loading...