Craftsman 17125490 Owner’s Manual

Save This Manua!_

For Future Reference

owners

manual

MODEL NO.

171.25490

CAUTION:

READ ALL

INSTRUCTIONS

CAREFULLY

CRRFTSMRH

INDUSTRIAL ROUTER TABLE

• assemb y

, operatinq

Sold bY SEARS. ROEBU(_KiAND CO., CH|CAGO,_i 6068_, U.S.A.

_ _ _..... _ .... L

Printed In U.S.A.

49LCN-39

WARNING: FAILURE TO HEED ALL SAFETY AND OPERATING INSTRUCTIONS AND WARNINGS REGARDING UI_tEI

OF THIS PRDDUCT CAN RESULT IN SERIOUS BODILY INJURY. ° !

GENERAL SAFETY INSTRUCTIONS

FOR POWER TOOLS

1. KNOW YOUR POWER TOOL

Read the owner's manual carelulty. Learn _ISapplicalion and

hmitations as we!l as the spot=tic potential hazards peculiar

Io thrs tool.

2. GROUND ALL TOOLS (UNLESS DOUBLE

INSULATED)

If tool is equipped with an _pproved 3-conductor cord end a

3-prong grounding type plug to tJ_.the proper grounding type

receptacle. The green cor:_,,ctor in the card ts the ground-

0ng wire. Never connect me green w=re to a lwe terminal.

3. KEEP GUARDS IN PLACE

in working order, and _nprope:"ad}ustmenI ar,d ahgnmenl.

4. REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checking tc see that keys and adjusbng

wrenches are removed 1ramtool before turning ]t on.

5. KEEP WORK AREA CLEAN

Cluttered areas ana ber_cnes _rvlte a-"c;cents. Floor musl

not be slippery due lc wax or sawdust

6. AVOID DANGEROUS ENVIRONMENT

Don'.*. use power Iools iB damp or wet IocalJons or expose

them to rain Keep work area welt i_ghled Pruvicle adequale

surrourld_n§ work space.

7. KEEP CHILDREN AWAY 19.

All vrsilors ,Should be I_ept _,safe d_tance from work area.

8. MAKE WORKSHOP KID-PROOF -

- with padlocks, maste, s_ltcnes, or 13yremov;ng starlet

, ,_ keYS.

13. SECURE WORK

Use clamps or a wse ,'o hold work when practical. Its safer

than using Four hand trees both hands to operate tool.

14. DON'T OVERREACH

Keep proper fooling arid balance at all limes.

15. MAINTAIN TOOLS WITH CARE

Keeps tools sharp and clean for best and safest parlor-

manta. Follow instructio'ls for lubricalmg and changing

accessorieS,

16, DISCONNECT TOOLS

before servicing: when cnaqcjlng accessor,,es such as blades,

bits cutters: etc

17. AVOID ACCIDENTAL STARTING

Make sure swllch is in "OFF' position belore p!ugglng ,'n,

18.

USE RECOMMENDED ACCESSORIES

Consult the owners manua_ for recommenOed., accessories.

Follow me mstruclions that accompany the accessories. The

use of improper accessones may cause hazards

NEVER STAND ON TOOL

Ser=ous iniur y could occur =fthe tool =s tipped Or If the cuTlicg

tool is accidentally contacted.

D3 not slore matenals above or near lhe loot sucl_that if is

necessary tQsiand on the Iooi to reach lhem

9. DON'T FORCE TOOL 20,

It will do the job better anc saler at lhe rate for ',,.rh_chmtwas

designed.

10. USE RIGHT TOOL

Don't force tool or atta--'hmenl to do a job _tw_s not destgne-.,d ::-_.! age of pads. mounting, ard any other coqdihons that may

Ior. " . ." .

11. WEAR RIGHT APPAREL

Do not wear =oose clolh,ng 9loves. neckt,,es or j_,,ve_-y (nngs,

wnsl walches} to get caught _n moving o_rts. Nonshp !be;-

wear is recommenoea. Wear protect;re hair covering to

comaip long ham Roll long sleeves auove the elbow.

iz use

SAFETY GOGQLES (Head Protection)

Wear Safely goggles (must comply with ANS ZB71) at all

hmes Also use race or dusl mask if c,J.qlna oper_lion ,s

dusry ar_:d ear prole"tors '.lZtUgS br mutts) clu'_ing, exienae:l

, per! .otis o! oper,allon.

CHECK DAMAGED PARTS

Before turlher use oi the- tool a guard or other par';,that _s

damaged should be caretMiy checked tOensure thai it will

operate properly and pedo,'m its intended function. Check

for aligRment of mowng oar'.s, bind=rig otmoving parts, break-

affecl _[soperation A guard or other par1 thai is damaged

sh.ou!a ae properly repaired or replaced.

21. DIRECTION OF FEED

Feed _,ork inlo a blade or cutter agains,: the direction of

mtZ..hon el lhe b_ade or Cutter ony.

22.

NEVER LEAVE TOOL RUNNING UNNATTENDED

Turn bower off. Dont te_ve_tool unlil..Jl comes t¢ a complele

S_Op

• ALWAYS USE EYE PROTECTION

The operation or ah_' power tool can result in

foreign objects being thrown irrlothe eyes, which

can result in severe eye damage. Always wear

safety goggles before commencing power tool

operation. Safety goggles are available at Sears

retail or catalog stores.

.

KEEP HANDS CLEAR OF BITS, AND WORKING

AREA.

3. MAKE AND USE A PUSH STICK TO MOVE

SMALL WORKPIECES ACROSS THE CUTTING

AREA.

=

KEEP ROUTER CLEAN AFTER EVERY USE,

CLEAN SAW DUST OF THE ROUTER. (ALSO

BLOW OUT INSIDE)•

=

YOUR ROUTER TABLE IS PROVIDED WITH A

DUST COLLECTING ATTACHMENT. ALWAYS

USE SHOP VAC FOR ALL ROUTING OPERA-

TIONS,

NOTE: Motors used on wood-working toots are

particulaMy susc_ptibie to the accumula-

tion o1'sawdust and wood chips, and

Should be blown out, or "vacuumed",

frequently to prevent interference with

normal me;or ventilation.

.

CHECK FUNCTION OF GUARD BEFORE EACH

USE. REMOVE ALL DUST AND CHIPS FROM

GUARD AREA AS NEEDED TO MAINTAIN

GUARD FUNCTION,

11.

WHEN END CUTTING ON WORKPIECES 4" WIDE

OR LESS, CLAMP AND HOLD AND FEED THE

WORKPIECE WITH THE PUSH BLOCK USING

BOTH HANDS AS SHOWN IN FIG, #25. KEEP

FINGERS CLEAR OF BIT WHEN MOVING WORK

PIECE ACROSS THE CUTTING AREA.

12.

ROUTER BITS ARE EXTREMELY SHARP,

Be exlra carefu; when working around them,

13.

SOME ROUTERS WHEN USED IN AN UPSIDE

DOWN POSITION SUCH AS ON A ROUTER

TABLE WILL FALL (OR DROP) OUT OF THE

ROUTER BASE WHEN THE BASE CLAMP IS

LOOSENED, IT IS THEREFORE ABSOLUTELY

NECESSARY TO SUPPORT THE ROUTER

MOTOR FORM BELOW WHEN THE BASE

CLAMP IS LOOSENED TO MAKE ADJUST

MENTS, OR FOR ANY OTHER REASON.

14.

ALWAYS LOOK UNDER THE TABLE AT THE

SWITCH WHEN TURNING THE ROUTER ON/OFF

AND TOUCH NOTHING BUT THE SWITCH.

NEVER REACH UNDER THE TABLEWHEN

ROUTER IS RUNNING FOR ANY OTHER

REASON.

NOTE:

it is far safer and convenient to use a "Sears

Craftsman 925C60 Router Table Switch

Package". This switch provides a key

operated ON/OFF button WhiCh allows very

fast and easy access when and if it becomes

necessary to turf, the router "OFF" quicldy.

The key can be removed to render the

switcM inoperable to unauthorized people.

7,

NEVER PUT YOUR FINGERS UNDER THE

GUARD WHEN THE ROUTER IS PLUGGED IN.

B,

ALWAYS USE THE ROUTER TABLE FENCE

TO GUIDE THE WORK. DO NOT WORK

FREEHAND.

When using the pilot type bits, keep the fences as

close to the pilot aspossible to provide additional

backup' and additional guidance and to avoid "

chances of an accident and possible personal

injury.

=

ALWAYS USE THE STARTING PIN AND

PILOTED BITS FOR FREE HAND ROUTING

IRREGULAR SHAPED WORKPIECES.

10,

ALWAYS FEED AGAINST THE ROTATION OF

THE CUTTER WHEN ROUTING ON THE

ROUTER TABLE,

15.

ONCE GUARD IS INSTALLED FOR ROUTING,

DO NOT REMOVE FOR ANY REASON.

MOUNT ROUTER TABLE FIRMLY AND SE-

16.

CURELY TO A WORK SURFACE BEFORE USE.

FAILURE TO DO SO COULD CAUSE TABLE TO

TIP OVER OR SLIDE DURING OPERATION

RESULTING tN PROPERTY DAMAGE AND/OR

SERIOUS BODILY INJURY,

17.

WARNING

BEFORE MAKING ANY CUT, UNPLUG ROUTER

AND MAKE ABSOLUTELY SURE THAT THE

GUARD CLEARS THE ROUTER BIT AND IS

FUNCTIONING NORMALLY.

18.

WARNING:

ROUTER VIBRATIONS SOMET;MES CAN

CAUSE FASTENERS FOR THE TABLE, THE -:

ROUTER AND THE UNITI2ED FENCE TO GET

LOOSEI PERIODICALLY CHECK FASTENERS

TO MAKE SURE THEY ARE TIGHT AND

SECURE.

INTRODUCTION

How otlen have you needea a large guiclingsurface on a

muter table? Your Sears Craftsman Industrial Router

Table wilh Unitized Fence comes with:

a. A unique 4" high unitized fence designed to

assist end grain routingfor making tenons,

sliding dovetails and tongue and groove joims

along with most edge and lace culling operations.

b. A specially designed pusMblock witMquick clamp for

back up and clamp;rig boards up to 4" wictthfor end

grain routing.

c. An accurate and quick adjusting jointing fence adjust-

able to proper jointing depth of cut.

d. A unitized lence designed to enable routing opera-

tions like grooving; Iluting; veining: crown molding etc.

up to 2 V2"away lrom the edge toward the middle of

the board.

UNPACKING AND CHECKING CONTENTS

e, Dust collecting attachment for most shop vac hook

ups.

To increase the work surface of your muter table, "Sears

Craftsman 925212 Industrial Roular Table Extensions"

are available as an optional produ= from Sears,

In order to simplifyhandling and minimize any damage

that might occur during shipment, your new rouler table

is packaged unassembled. We know you are anxious to

see w_al your new tool will do, but a few minutes spent

now carefully reading the following instructions, will

result in less frustration and more enjoyable operation

later.

Start bychecking and accounting for all the loose paMs.

If any parrs are missing, contact your local Sears retail or

catalog outlet for replacement.

WARNING: YOU MUST READ AND UNDERSTAND

ALL THE INSTRUCTIONS COMPLETELY BEFORE

ATTEMPTING TO ASSEMBLE AND OPERATE YOUR

ROUTER AND ROUTER TABLE.

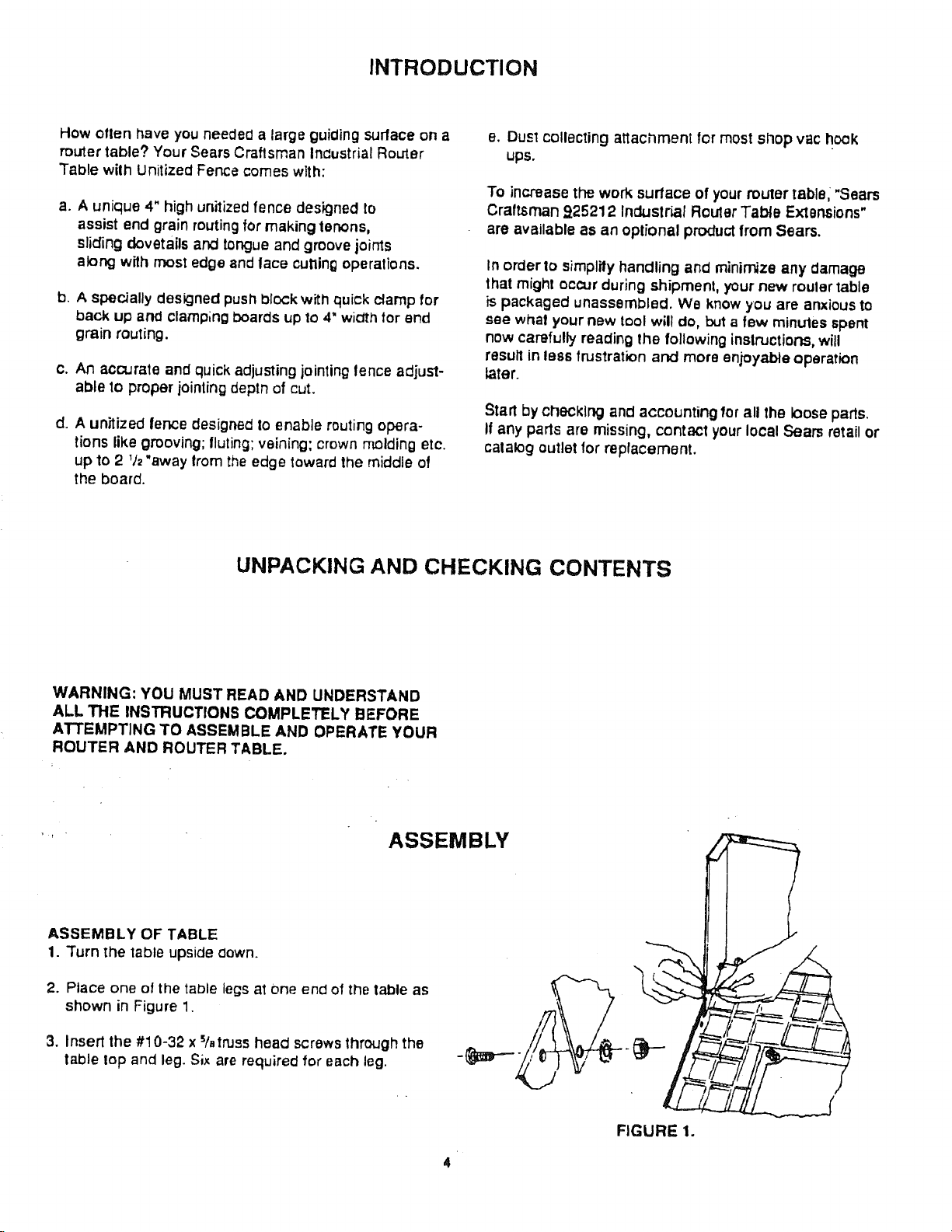

ASSEMBLY

ASSEMBLY OF TABLE

1. Turn _he table upside clown.

2. Place one of the table legs al one end of the table as

shown in Figure 1.

3. Insert the #10-32 x %truss heacl screws through the

table lop and leg. Six are required for each leg.

FIGURE 1.

screw. The lock washers should be against the

inside ol the leg.

5. Repeat for the remaining leg.

8. Turn the table righl side up and tighten all 12 screws

and nuls with a wrench or pliers.

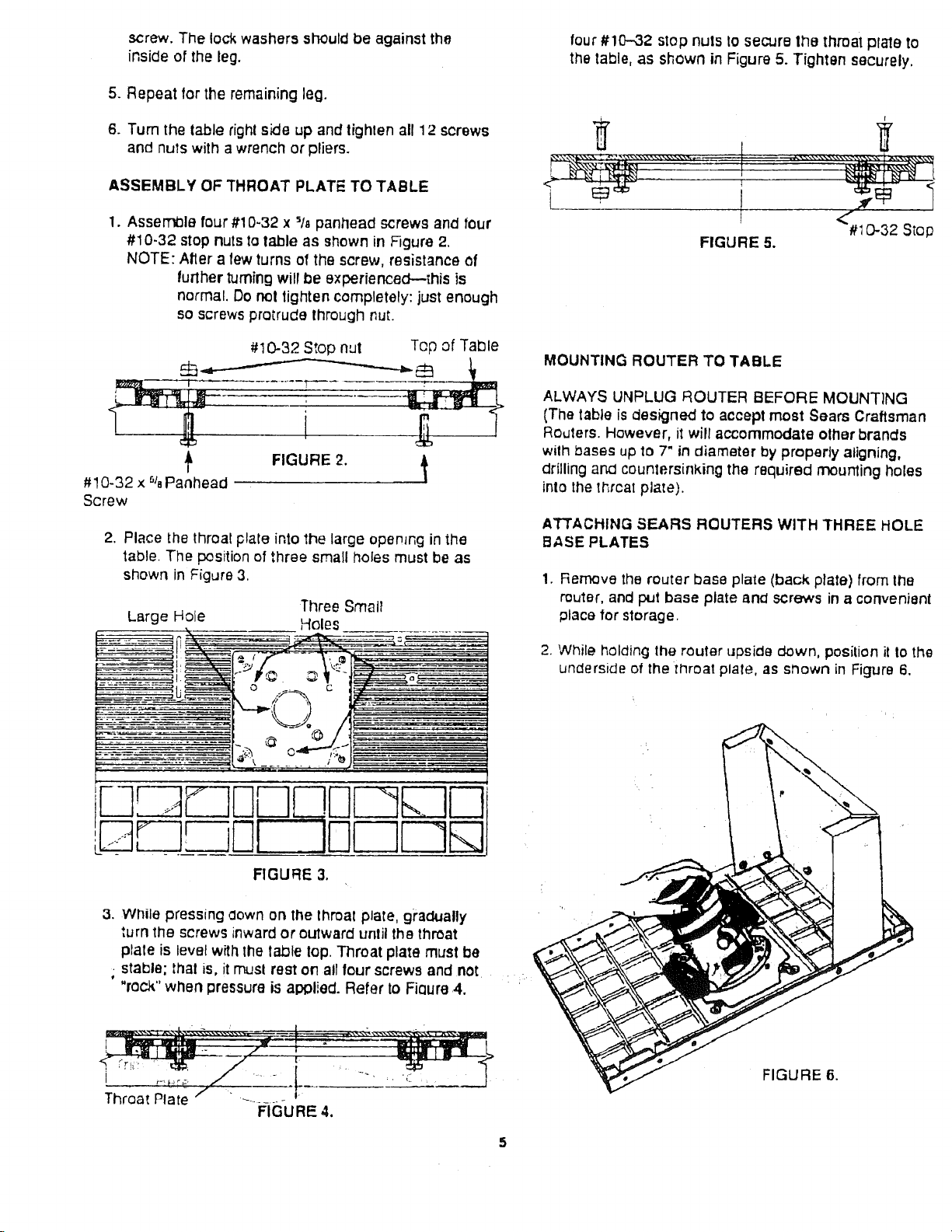

ASSEMBLY OF THROAT PLATE TO TABLE

four #10--32 stop nuts 1osecure the throat plate to

the table, as shown in Figure 5. Tighten securely.

1. Assernl31e four #10-32 x % panhead screws and four

#10-32 stop nuts to table as shown in Figure 2,

NOTE: After a low turns of the screw, resistance of

further turning wilt be experienced---this is

normal. Do not tighten completely: just enough

so screws protrude through nut.

#10-32 Stop nut Top of Talkie

#10-32 x % Panhead

Screw

2. Place the throat plate into 1he large opemng in the

table. The position of three small holes must be as

shown in Figure 3.

Large Hole

Three Small

Holes

FIGURE 5.

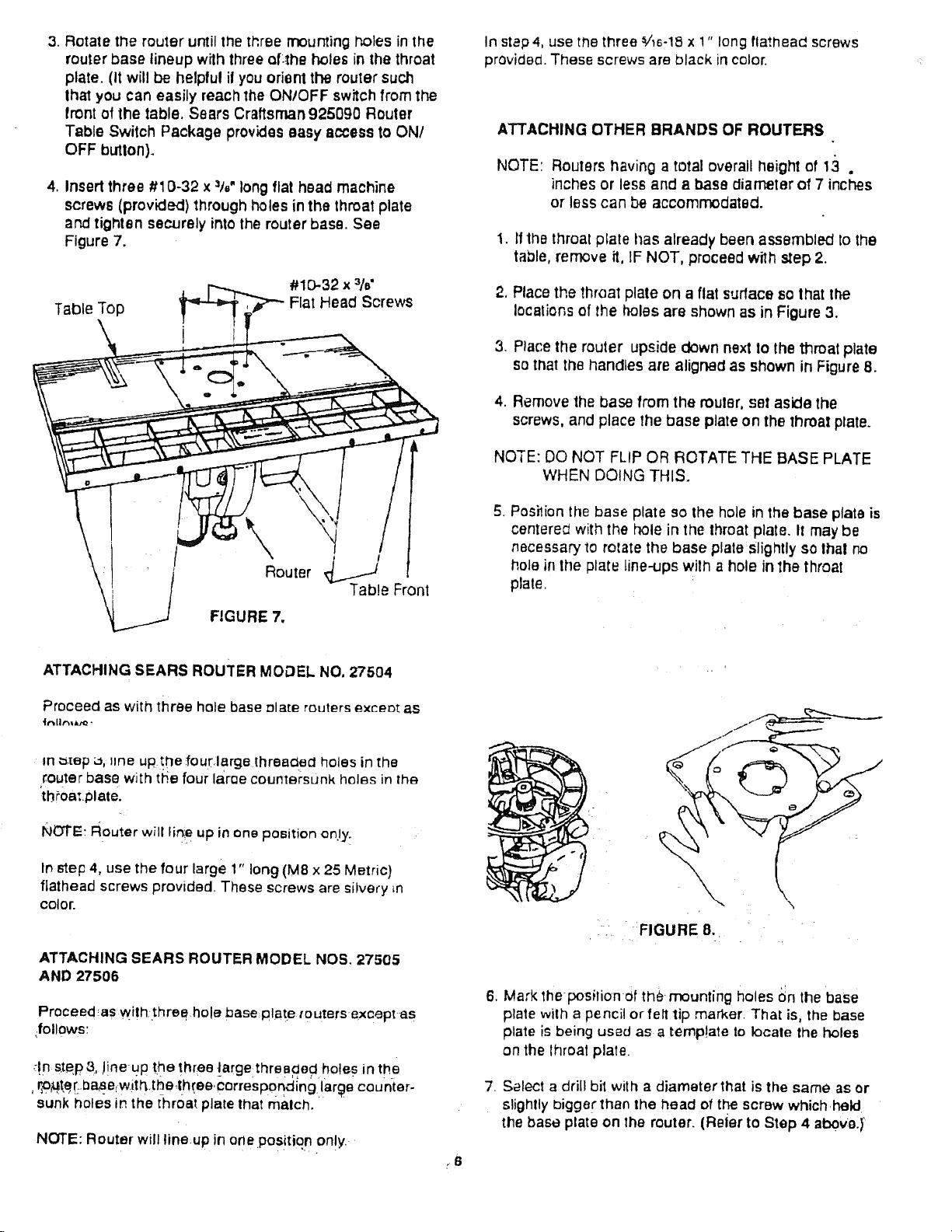

MOUNTING ROUTER TO TABLE

ALWAYS UNPLUG ROUTER BEFORE MOUNTING

(The table is designed to accept most Sears Craftsman

Routers. However, i1will accommodate other brancls

with bases up to 7" in diameter by properly aligning,

drilling and countersinking the required mounting holes

into the thrcat plate).

ATTACHING SEARS ROUTERS WITH THREE HOLE

BASE PLATES

1. Remove the router base plate (back plate) from the

router, and put base plate an_ screws in a convenient

place for storage.

2. While holding the router upside down, position il to the

underside of the throat plate, as shown in Figure 6,

#I 0-32 Stop

L oOo__o.0oo _

LJ.__ uF-IOEOEOE

FIGURE 3.

3. While pressing sown on the lhroal plate, gradually

turn the screws inward or outward until the throat

plale is level with the taOle lop. Throat plate must be

; stable; thai is, it musl rest on all lout screws and not .

"rock"when pressure is al:_lied. Refer to Flours .4. '

I

i

f

Throat Plate " ......... "

[

FIGURE 4.

FIGURE 6.

3.RotatetherouteruntilthethreemountingI'_olesinthe

router base lineup with three af4he holes in the throat

plate. (It will be helpful il you orient the router such

Ihat you can easily reach the ONIOFF switch from the

front ofthe table. Sears Craftsman 925090 Router

Table Switch Package provides easy access to ON/

OFF button).

4, Insert three #10-32 x =t6"long flat head machine

screws (provided) through holes in the throat plate

and tighten securely,into the router base. See

Figure 7,

#10-32 x 3/€

Table Top

Flat Head Screws

In st_p 4, use the three _/'_s-18x !" long flathead screws

provided. These screws are black incolor.

ATTACHING OTHER BRANDS OF REUTERS

NOTE: Reuters having a total overall height of 13 .

inches or less and a base diameter of 7 inches

or less can be accommodated.

1.11the throal plate I_as already been assembled to the

table, remove it, IF NOT, proceed wilh step 2.

2. Place the throe1 plate on a flat surface so that the

locations of the holes are shown as in Figure 3.

3. Place the router upside down next to the throat plate

so that the handles are aligned as shown in Figure 8.

4. Remove the base from the rouler, set aside the

screws, and place the base plate on the lhroat plate.

NOTE: DO NOT FLIP OR ROTATE THE BASE PLATE

WHEN DOING THIS.

\

Router

Tab!e Front

FIGURE 7.

ATTACHING SEARS ROUTER MODEL NO. 27504

Proceed as with three hole base elate reuters exceot; as

in =.tap _, line uptrie lout:large threacted holes in the

router base with the four la.ri3e counler_unk hi31_s in lh_

ith£oat.platel

NOTE: Router willlin_.eup in one position on.ly.

In step 4, use the four large 1" long (MS x 25 Metric)

flathead screws provided. These screws are silvery in

color.

ATTACHING SEARS ROUTER MODEL NOS, 27505

AND 27506

Proceed_as with three hole base plate touters exoeptas

_follows:

!n step& !!ne-up me three targe;threa_ec! holes in the

r.o_terhaae.wi.tl3the,three,correspond ng lare counter-

sunk holes in the throat plate lhat rnalch.

NOTE: Router will lineup in one position only.

5. Posilion the base plate so the hole in the base plata is

centere_ withthe hole in the throat plate. It may be

necessary to relate the base plate slightly so Ihal no

hole in the plate line-ups with a hole in 1he throat

plate•

i

i';. " :FIGURE 8.

6, Mark the-positionOf tile.mounting holes On the base

plate with a pencil or felt tip marker. That is, the base

plate is being used as atemp!ate to locale the holes

on the lhroal plate.

7. Select a drill bll with a diameter that is the same as or

slightly Digger than the head of the screw which.held

the base plate on the router. (Reler to Step 4 above.)"

_S

Loading...

Loading...