Craftsman 171254841, 17125484 Owner’s Manual

OWNERS

I®

T

MANUAL

Model No.

171.254841

MANUAL DEL

PROPIETARIO

Modelo No.

171.254841

P OFESSIONAL

ROUTER CENTER

CENT O

P OFESlONAL

FRESADO

I

71255

0WNER8 MANUAL

DE

WARNING:

Before operating

product, read this

manual and follow

all its Safety

and Operating

Instructions.

ADVERTENCIA:

Antes de utilizar

este producto, lea

este manual y

siga todas las

instrucciones de

uso y seguridad.

Sears, Roebuck and Co., Hoffman Estates IL 60179 USA

171.254841 01/99 Printed in U,S.A. Hechoen los Estados Unidos

General Safety Instructions for Power Tools ............................................... 3

Additional Safety Instructions for Router Table .......................................... 4

Introduction ..................................................................................................... 5

Optional Router Table Accessories .............................................................. 6

Unpacking and Checking Contents .............................................................. 6

Assembly ......................................................................................................... 7

Installation ..................................................................................................... 14

Operation ....................................................................................................... 18

Parts List ....................................................................................................... 27

SAFETY GUIDELINES - DEFINITIONS

This manual contains informa-

tion that is important for you to

know and understand. This

information relates to protect-

ing YOUR SAFETY and

[_DANGER ]

URGENT SAFETY INFORMATION -

A HAZARD THAT WILL CAUSE

SERIOUS INJURY OR LOSS OF LIFE

INFORMATION FOR PREVENTING

DAMAGE TO EQUIPMENT

_CAUTION

PREVENTING EQUIPMENT

PROBLEMS. To help you rec-

I_WARNING

NOTE ]

ognize this information, we use

symbols to the right. Please

read the manual and pay

attention to these sections.

IMPORTANT SAFETY INFORMATION -

A HAZARD THAT MIGHT CAUSE

SERIOUS INJURY OR LOSS OF LIFE

INFORMATION THAT YOU SHOULD

PAY SPECIAL ATTENTION TO

,_WARNING Failure to heed all safety and operating instructions and warnings regarding use of this

product can result in serious bodily injury.

1. Know your power tool

Read the owner's manual carefully. Learn its appli-

cation and limitations as well as the specific potential

hazards peculiar to this tool.

2. Ground all tools (unless double insulated)

If tool is equipped with an approved three-conductor

cord and a three-prong grounding type plug, it

should be plugged into a three hole electrical recep-

tacle. If adapter is used to accommodate a two-hole

receptacle, the adapter wire must be attached to a

know n ground (usually the screw securing receptacle

cover plate). Never remove third prong. Never con-

nect green ground wire to a terminal.

3. Keep guards in place

Maintain in working order, and in proper adjustmeni

and alignment.

4. Remove adjusting keys and wrenches

Form a habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it ON.

5. Keep work area clean

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

6. Avoid dangerous environment

Do not use power tools in damp or wet locations or

expose them to rain. Keep work area welt lighted.

Provide adequate surrounding work space.

7. Keep children away

All visitors should be kept a safe distance from

work area.

8. Make workshop child-proof

Use padlocks, master switches, or remove starter keys.

9. Do not force tools

They will do the job better and safer at the rate for

which they were designed.

10. Use the right tool

Do not force tool or attachment to do a job it was not

designed to perform.

11. Wear correct apparel

Do not wear loose clothing, gloves, neckties or jew-

elry (rings, wristwatches) that may get caught in

moving parts. Non-slip footwear is recommended.

Wear protective hair covering to contain long hair.

Roll long sleeves above the elbow.

12. Use safety goggles (Head Protection)

Wear safety goggles (must comply with ANSI

Standard Z87.1) at all times. Also, use face or dust

mask, if cutting operation is dusty, and ear protec-

tors (plugs or muffs) during extended periods of

operation.

13. Secure work

Use clamps or a vise to hold work when practical.

It's safer than using your hands, and both hands are

free to operate tool.

14. Do not overreach

Keep proper footing and balance at all times.

15. Maintain tools with care

Keep tools sharp and clean for best and safest per-

formance. Follow instructions for lubricating and

changing accessories.

16.Disconnecttools beforeservicing

Beforeservicing,whenchangingaccessoriessuch

asblades,bits,cutters,etc.

17.Avoidaccidentalstarting

MakesureswitchisinOFFpositionbeforepluggingin.

18.Userecommendedaccessories

Consulttheowner'smanualforrecommended

accessoriesandfollowtheinstructions.Theuseof

improperaccessoriesmaycausehazards.

19.Neverstandon tool

Seriousinjurycouldoccurifthetoolistippedorif

thecuttingtoolisaccidentallycontacted.DONOT

storematerialsaboveornearthetoolmakingit nec-

essarytostandonthetooltoreachthem.

20,Checkdamagedparts

Beforefurtheruseofthetool,anyguardorotherpart

thatisdamagedshouldbecarefullycheckedto

ensurethatitwilloperateproperlyandperformits

intendedfunction.Checkforalignmentofmoving

pads,bindingofmovingpads,breakageofparts,

mounting,andanyotherconditionsthatmayaffect

itsoperation.Aguardoranyotherpartthatisdam-

agedshouldbeproperlyrepairedorreplaced.

21. Direction of feed

Feed work into a blade or cutter AGAINST the direc-

tion of rotation of the blade or cutter only.

22. Never leave tool running unattended

Turn power OFF. DO NOT leave tool until it comes

to a complete stop.

23. Keep hands away from cutting area

24. Store idle tools

When not in use. tools should be stored in dry, high

or locked-up place - out of reach of children.

25. Do not abuse cord

Keep cord away from heat, oil and sharp edges.

26. Outdoor extension cords

When tool is used outdoors, use only extension

cords suitable for use outdoors and so marked.

27. Never use in an explosive atmosphere

Normal sparking of the motor could ignite fumes,

flammable liquids, or combustible items.

28. Drugs, alcohol, medication

Do NOT operate tool while under the influence of

drugs, alcohol, or any medication.

Read and Understand this instruction book

completely BEFORE using this product.

1. Always wear eye protection that complies with

ANSI Standard Z87.1.

2. Noise levels vary widely with location. To avoid

possible hearing damage, wear ear plugs or ear

muffs when using your router table for long periods

of time.

3. For dusty operations, wear a dust mask along with

safety goggles.

4. Follow the instructions in your router owner's

manual.

5. IAIAIAWARNING II Vibrations, caused by the router

during use, can cause fasteners to become loose,

Before use and periodically during use, check all fas-

teners to make sure that all are tight and secure.

6. Do not use this product until all assembly and

installation steps have been completed. Make sure

you have read and understood all safety and opera-

tional instructions in this manual and the router

owner's manual.

7. Make sure that the router bit is properly positioned

and clamped in the router before making any cuts,

8. Do not use the router table as a workbench or

work surface. Doing so may damage it, causing it to

be unsafe to use. A workbench should be used for

this purpose.

9. This product is designed for cutting flat work-

pieces. Do not cut or attempt to cut workpieces that

are not flat.

10. This product is designed for cutting wood work-

pieces only. Do not use to cut metal or other non-

wood materials.

11. The use of auxiliary in-feed and out-feed sup-

ports is strongly recommended when routing long

workpieces. Otherwise those workpieces can cause

the router table to tip over.

12. Keep hands clear of the router bits and working

area.

13. Make and use a push stick to move small work-

pieces across the cutting area.

14. Clean the router after use. The use of a wet!dry

vac or vacuum equipment is recommended.

15. Always make sure that work surface of the router

table is clean and free from dust, chips, and foreign

particles that can interfere with the cut you are going

to make. The use of a wet/dry vac or vacuum equip-

ment is recommended.

16. The fence that comes with the router table has a

dust collector (if available on enclosed model) to

which a wet/dry vac can be attached. The use of a

wet/dry vac is recommended when using the fence.

17. Check the function of the guard before each

use. Remove all dust, chips, and any other foreign

particles that can affect its function. Adjust the

guard height so that it clears the router bit or the

workpiece, whichever is taller.

18. /A/Lm WARNINGJ Never put your fingers under

the guard when the router is plugged into an electri-

cal outlet or when the router bit is rotating.

19. Always use the fence to guide the workpiece.

DO NOT work freehand unless piloted router bits are

being used.

20. Always use piloted router bits for freehand rout-

ing of irregularly shaped workpieces.

21. Always feed the workpiece AGAINST the rotation

of the cutter or router bit.

22. Router bits are extremely sharp: be extra careful

when handling and using them.

23. Make sure that the router bits being used are

sharp or have been properly resharpened. This will

permit fast, efficient, and SAFE routing.

24. Some routers, when positioned in an upside

down position (such as on a router table), will drop

or fall out of the router base when the base clamp is

loosened to adjust height or depth of cut, Therefore,

it is extremely important to suppod the router from

below when making these adjustments or whenever

the base clamp is loosened.

25. Always look under the router table at the router

switch when turning the router ON or OFF. DO NOT

touch anything but the switch when doing this.

NEVER reach under the router table for any reason

when the router is running, except to turn it OFF.

26. ,_WARNING Before making any cut, make

sure the router is turned OFF. the router bit is not

rotating, and the power cord is unplugged from the

electrical outlet. Then, make absolutely sure that the

guard clears the router bit and the workpiece. A trial

pass, with the router turned OFF and the router bit

not turning, is strongly recommended.

27. I,A]I,luLWARNING j Never leave the router table

unattended while the router is running. Turn the router

OFF before leaving the router table for any reason.

Your Craftsman Professional Router Table comes

with the following:

• A unique 4" high unitized fence with fence guides

that provide parallel movement.

• Scales molded into the _able top that provide fast

and accurate fence adjusT, merit for making the fo!-

lowing items:

• tenons

o sliding dovetail joints

• tongue and groove joints

° edge and end grain cuts

• face cuts

• The unique fence also al!ows you to perform these

additional routing operations:

• veining

° fluting

° making crown molding

. making cuts up to 2-1 2" from the edge of the

workpiece toward the center of the workpiece

° A specially designed push block with a quick clamp

for back-up. It can clamp workpieces up to 4" wide

for end grain or edge routing.

• An accurate adjusting jointing fence that is quickly

adjustable to the proper depth of cut.

"A dust collector port on the fence to which most

wet/dry vacs can be attached.

• Extensions that provide a large work surface.

,, A switch, with overload protection, to control turning

the router ON and OFF. An additional accessory,

such as a wet/dry vac, can also be plugged into the

second receptacle.

° A floor stand for mounting the router table.

9-25333CraftsmanProfessionalRouterAdapter

Plate,formountingnon-Craftsman 1/4" and 1/2"

shank routers to the router table. The holes for

mounting the router must be located and drilled by

the user. The fasteners for mounting the router to

the adapter plate are not included and must be

obtained separately.

Refer to Parts List on Page 27.

. Ii,_WARNING If ANY of the parts is missing,

DO NOT attempt to assemble, install, or use your

router table until the missing parts have been found

or replaced and your router table has been properly

and correctly assembled per this manual.

• Contact your local Sears Retail Outlet for missing

or replacement pads.

9-25468 Craftsman Guide Master Router Table

Push Shoe, aids in push shoe and hold down oper-

ations, aids in accurate measurement and router

table setup, transforms into a miter gauge, and gives

quick setup for 1/2" sliding dovetail joints.

9-25332 Craftsman Router Table Guide Bushing,

follows templates for repetitive routing of certain

shapes.

, In order to simplify handling and to minimize any

damage that may occur during shipping, your router

table comes unassembled.

° Separate all parts from the packaging materials

and check each part against the illustrations and the

parts list at the end of this manual, to make sure that

all parts have been included. Do this before discard-

ing any of the packaging material.

TOOLS REQUIRED

o Slotted and Phillips screwdriver.

, Small or medium sized adjustable wrench

(or a set of nutdrivers).

• Hammer•

ROUTER TABLE

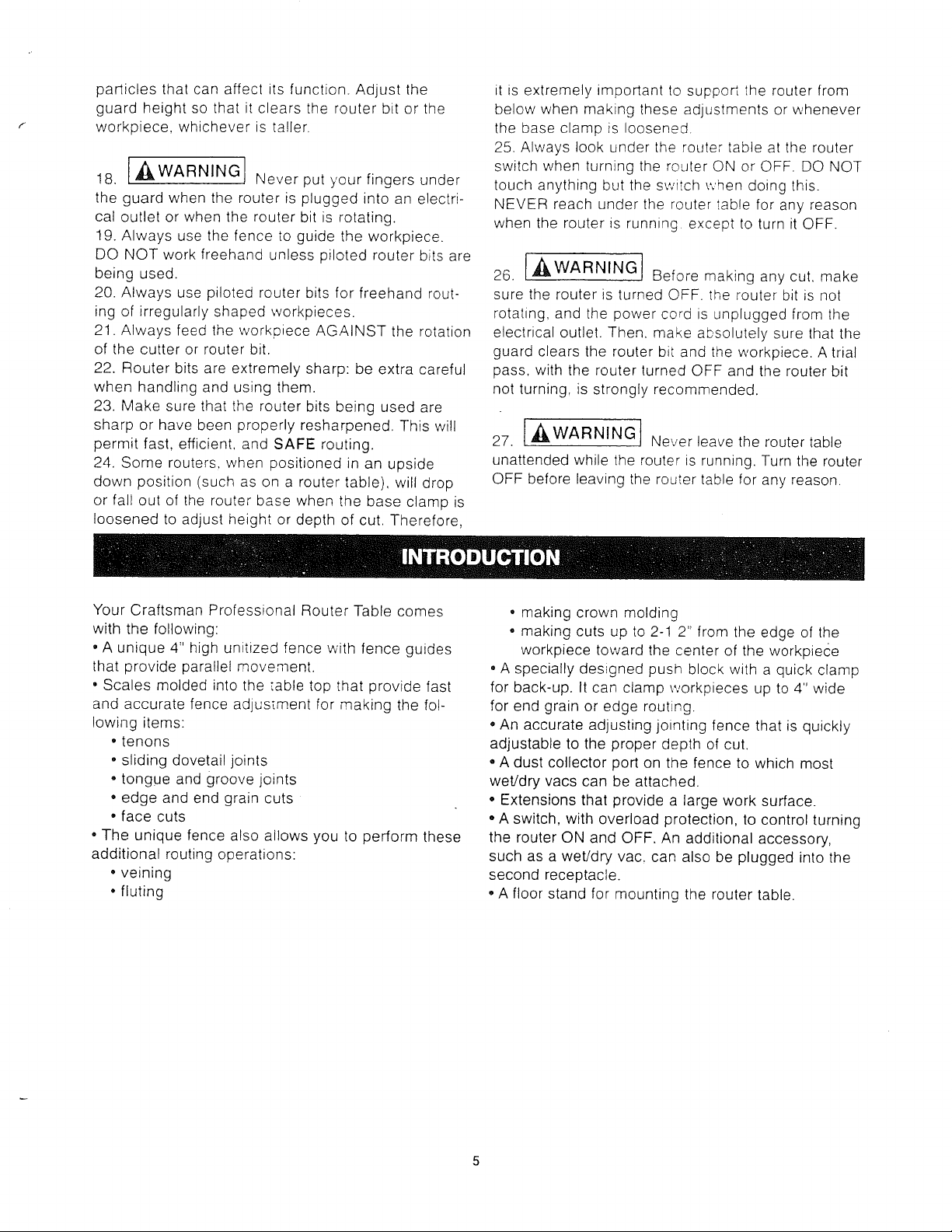

1. Lay the router table, top down. on a flat surface so

that the orientation of the table is as shown in Figure 1.

(BACK of the table is facing toward you.)

FIGURE 1

- qOb-Eq

TABLE /-_ "!0 32 X 1 2" LONG

! LEG J TRUSS HEAD MACHINE

/_

_J

•" _ {TYPICALI

SCREW (TYPICAL!

_I0 32 HEX KEPS bIUT

NOTE

]

] There are two hex shaped

recesses in the switch case into which the hex

"KEPS" nuts are placed, with the toothed washer

side of the nuts facing out of the recesses.

5. Securely TIGHTEN all fasteners.

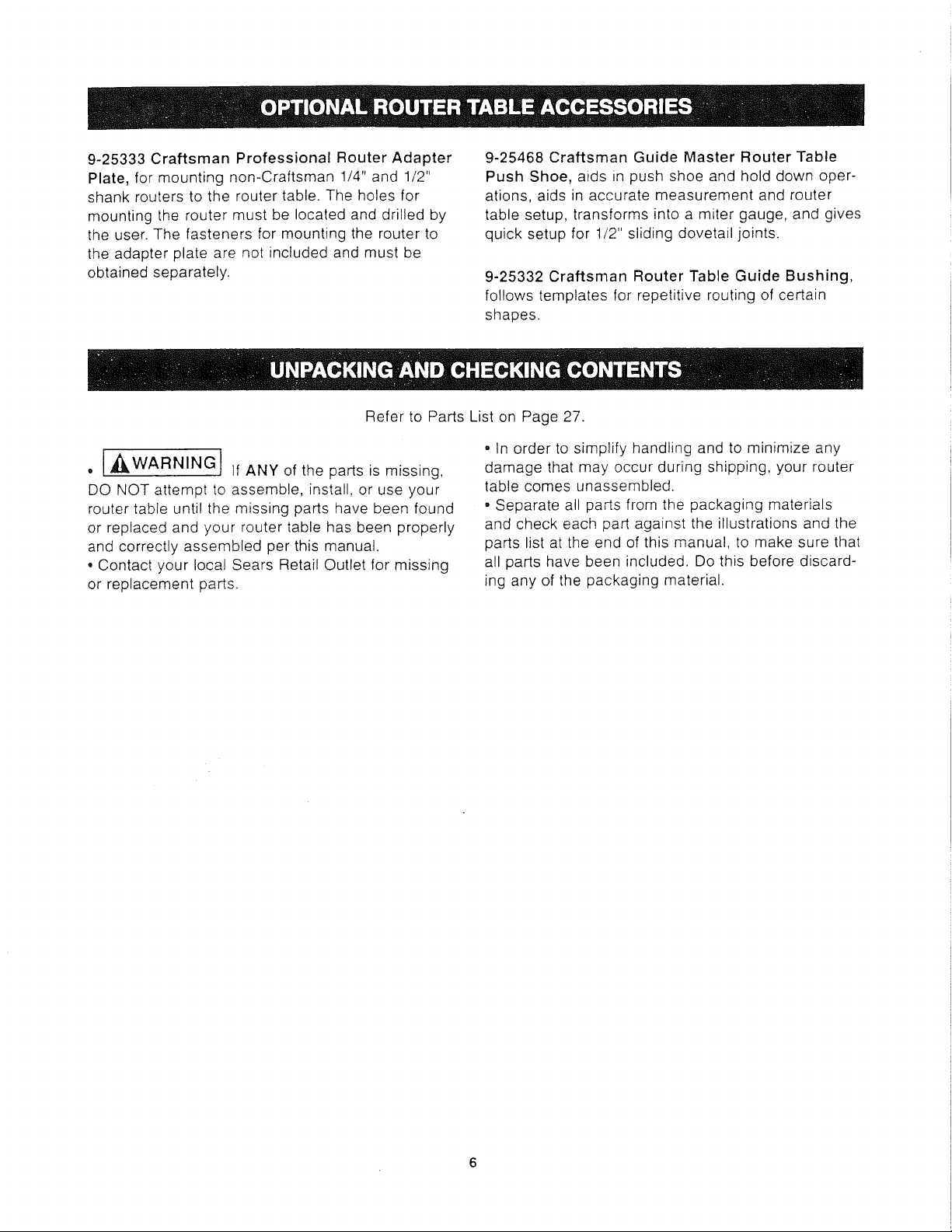

6. Assemble the remaining three table legs to the

table top using four #10-32 x 1/2" long truss head

machine screws and four #t0-32 hex "KEPS •' nuts

for each leg, as shown in Figure 2. (The BACK of

the table is facing toward you.)

7. Securely TIGHTEN all fasteners.

FIGURE 2

SWITCH

'\ RO_,-SR --

T&BLE

.... _ _. L_'-'..__, .... j÷ i'

1

BACK C:-

ROUTER -&BLE

/

2. Assemble a table leg to the table top using four

#10-32 x 1/2" long truss head machine screws and

four #10-32 hex "KEPS" nuts, as shown in Figure 1

and the Figure t, Assembly Detail. (Leg is shown in

the UPPER LEFT corner of router table.) DO NOT

TIGHTEN at this time.

3. Position the switch against the leg, as shown in

Figure 1, Assembly Detail.

4. Secure the switch to the leg and table top using

two #10-32 x 1/2" long truss head machine screws,

and two #10-32 hex "KEPS" nuts.

FIGURE 1, ASSEMBLY DETAIL

_ 10 32 X 1,2" LONG

=/ SCREW ITYPICAL)

ROUTER /!\ \ . _ -- ,10 32 HEX "KEPS" NUT

TABLE LEG _-- _ _ ' ITYP!CALI

MACHINE _ ---=- _ ...... :;-, . - {, "-

SCREW NUT "_ _'7;_" "_-1"> ' : ":

(TYP CALl _ * - _ :" = -" " _ ....

' \ -- ROUTER TABLE

ASSEMB:_ v DETA'L

TRUSS HEAD MACHINE

f_

" _--<---- " E_ _..'--" .... 7 :,_,/_ >_UT -"=C'-

. '" DE,.

_--=I032 _E_ KEU5

....1...---.:, °

__ -- _10 32 X 1 2 LD_4G

BACK OF TABLE TRUSS HEAD ),!ACHtNE

ROUTER TABLE LEG

ROUTER

&

SCREW T'r clCAL;

EXTENSIONS TO THE ROUTER TABLE

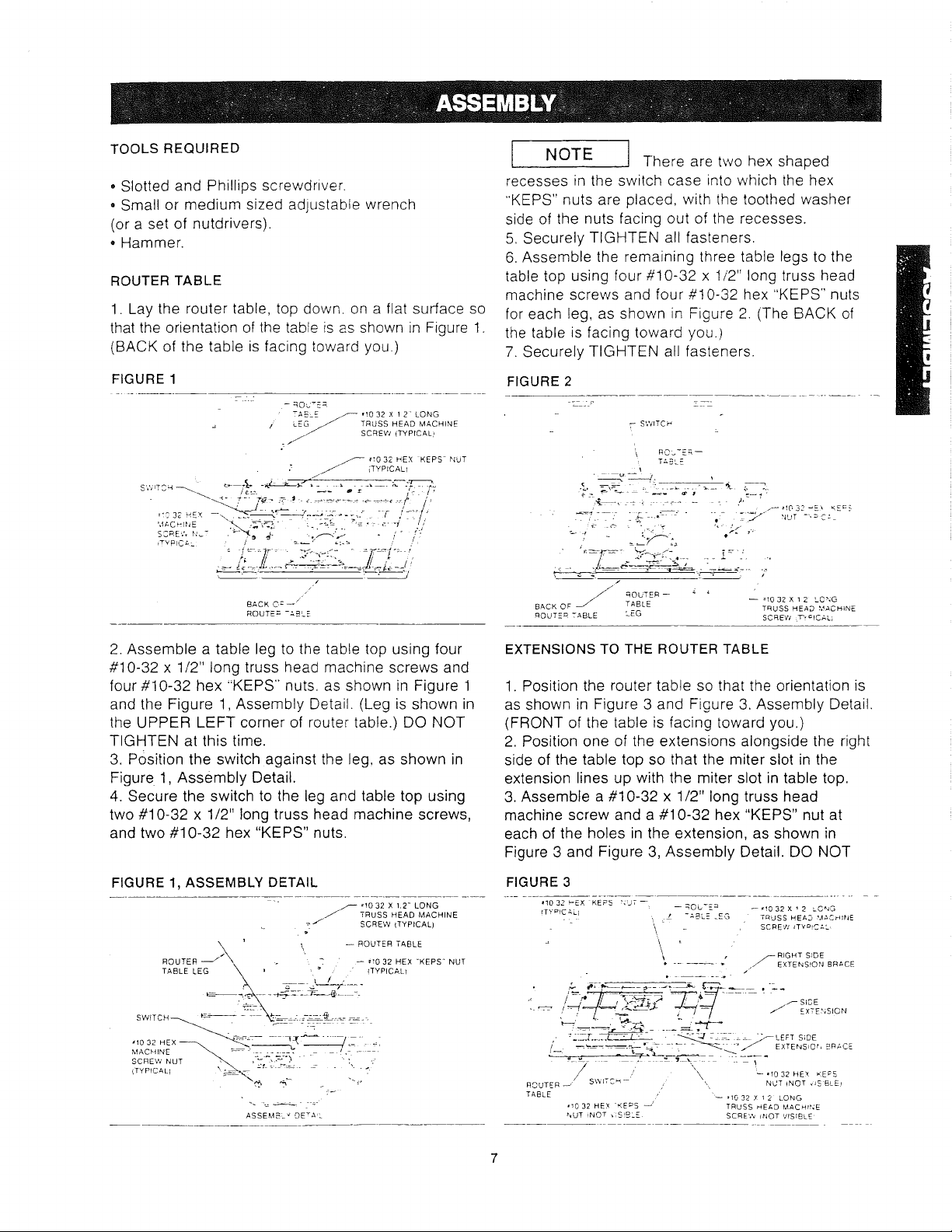

1. Position the router table so that the orientation is

as shown in Figure 3 and Figure 3, Assembly Detail.

(FRONT of the table is facing toward you.)

2. Position one of the extensions alongside the right

side of the table top so that the miter slot in the

extension lines up with the miter slot in table top.

3. Assemble a #10-32 x 1/2" long truss head

machine screw and a #10-32 hex "KEPS" nut at

each of the holes in the extension, as shown in

Figure 3 and Figure 3, Assembly Detail. DO NOT

FIGURE 3

_10 32 _EX KEPE !;_jT -- -- ROL'-En -- "10 32 X _ 2 LONG

ITYI_IB ALl

--_ \ c- -

• ,_ f',.":--r---,_ .... ,_ __- "-

,' " L. _ 'L --

__ __"- ...... -_L.-'-t--

ROUTER _-- S\%ITCH -- %, NUT INOT _lS BLEI

TABLE _'1032X 12 LONG

'10 32 HEX "KEPS --z TRUSS HEAD MACHI_4E

NUT _NOT _ IE!BLE SCRE','v Ib_OT VfSfBLE

,+ -*t. RLE _EG TRUSS HEAD &4,mCHI_4E

\ SCREW +TY_!CAL ,

..... _' / EXTENS!ON BR_CE

/_ RIGHT SIDE

EXTE tiSIOt't

/_ EXTENSIOn, BRACE

/ \_ '_ ,10 32 HEX KECE

FIGURE 3, ASSEMBLY DETAIL

ASSEMBLY CETAL

tighten fasteners at this time.

NOTE

I I The extensions are identified with

I

either an "R" for the RIGHT SIDE extension (29LCN-

988) or an "L" for the LEFT SIDE extension (29LCN-

989). The "R" or the "L" will be found on one of the

bent down or bent up ends of the extensions.

4. Assemble one of the RIGHT SIDE extension

braces (29LCN-988) to the table leg and the exten-

sion using #10-32 x 1/2" long truss head machine

screws and #10-32 hex "KEPS" nuts, as shown in

Figure 3 and Figure 3, Assembly Detail.

5. Assemble one of the LEFT SIDE extension braces

(29LCN-989) to the table leg and the extension using

#10-32 x 1/2" long truss head machine screws and

4'10-32 hex "KEPS" nuts, as shown in Figure 3.

6. While pressing down on the extension, tighten all

of the fasteners using the following sequence:

a. Those holding the extension to the table top.

b. Those holding the extension braces to the legs.

c. Those holding the extension braces to the

extension.

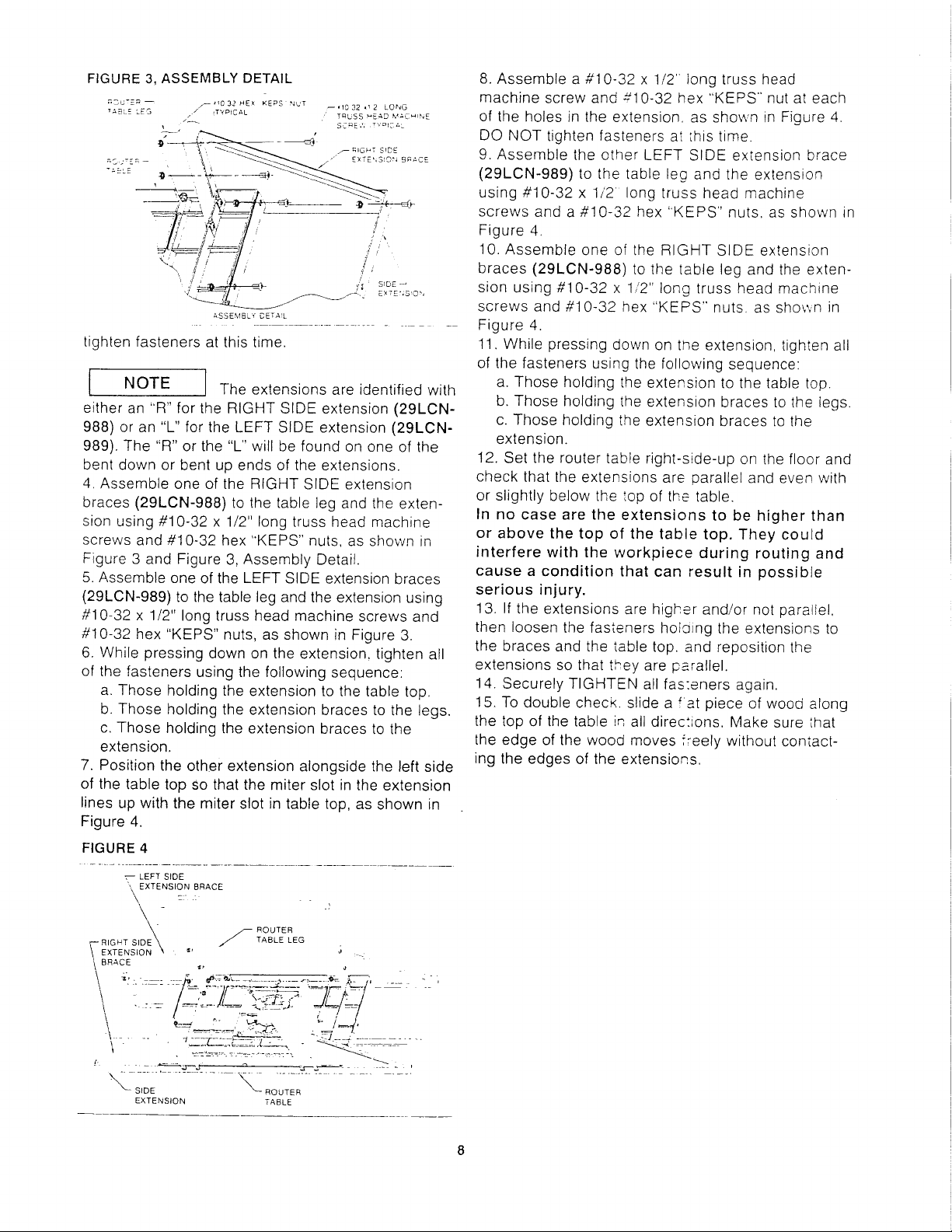

7. Position the other extension alongside the left side

of the table top so that the miter slot in the extension

lines up with the miter slot in table top, as shown in

Figure 4.

FIGURE 4

8. Assemble a #<10-32 x 1/2" long truss head

machine screw and _'10-32 hex "KEPS" nut at each

of the holes in the extension, as shown in Figure 4.

DO NOT tighten fasteners at this time.

9. Assemble the other LEFT SIDE extension brace

(29LCN-989) to the table leg and the extension

using #10-32 x 1/2 long truss head machine

screws and a #10-32 hex "KEPS" nuts, as shown in

Figure 4.

10. Assemble one of the RIGHT SIDE extension

braces (29LCN-988) to the table leg and the exten-

sion using #10-32 x 1/2" long truss head machine

screws and #10-32 hex "KEPS" nuts. as shov,.n in

Figure 4.

11. While pressing down on ti_e extension, tighten all

of the fasteners using the following sequence:

a. Those holding the extension to the table top.

b. Those holding the extension braces to the legs.

c. Those holding the extension braces to the

extension.

12. Set the router table right-side-up on the floor and

check that the extensions are parallel and even with

or slightly below the top of the table.

In no case are the extensions to be higher than

or above the top of the table top. They could

interfere with the workpiece during routing and

cause a condition that can result in possible

serious injury.

13. If the extensions are higher and!or not parallel.

then loosen the fasteners hoi0ing the extensions to

the braces and the table top. and reposition the

extensions so that they are parallel.

14. Securely TIGHTEN all fas:eners again.

15. To double check, slide a fat piece of wood along

the top of the table in all directions. Make sure that

the edge of the wood moves freely without contact-

ing the edges of the extensions,

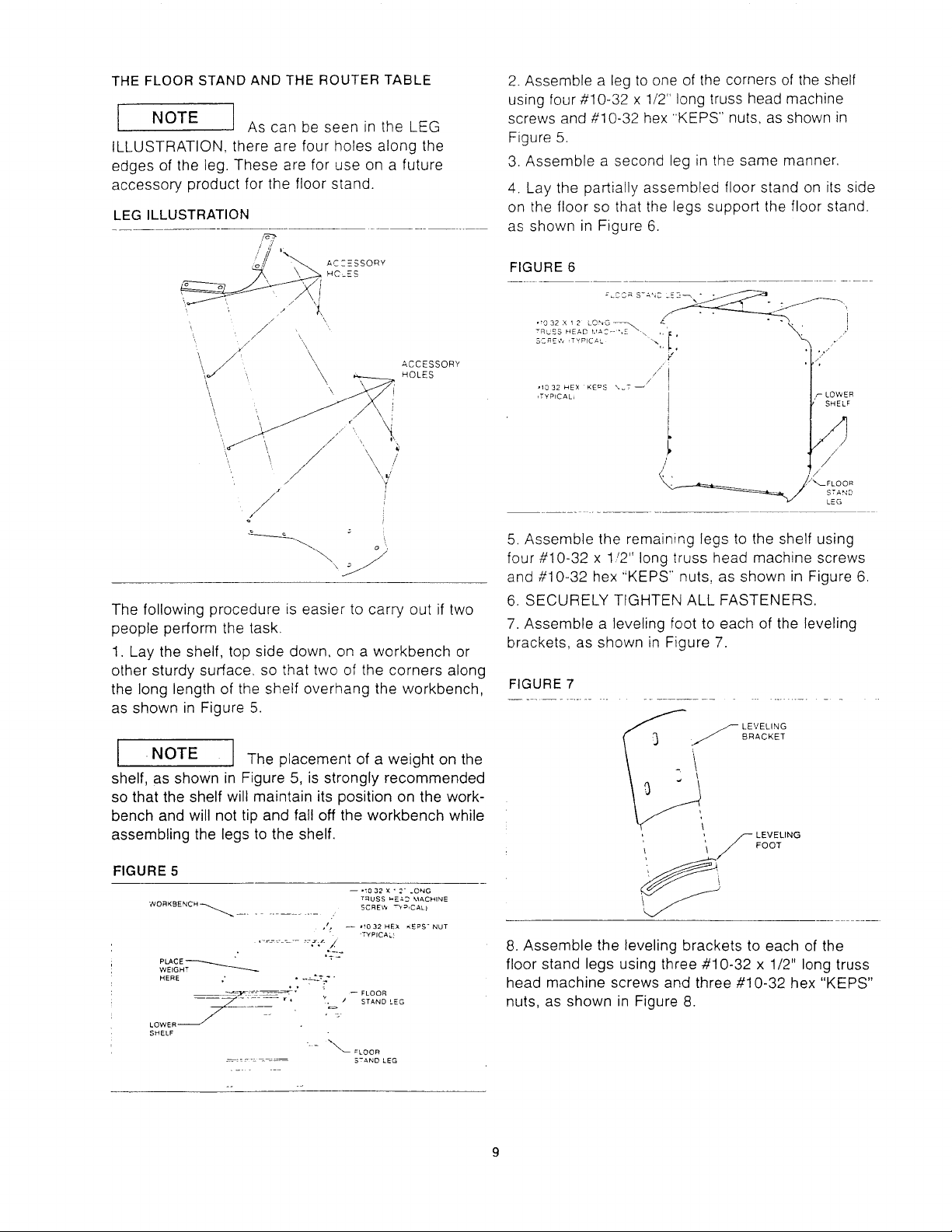

THE FLOOR STAND AND THE ROUTER TABLE

NOTE

As can be seen in the LEG

ILLUSTRATION, there are four holes along the

edges of the leg. These are for use on a future

accessory product for the floor stand.

LEG ILLUSTRATION

2. Assemble a leg to one of the corners of the shelf

using four #10-32 x 1/2" long truss head machine

screws and #10-32 hex KEPS" nuts, as shown in

Figure 5.

3. Assemble a second leg in the same manner,

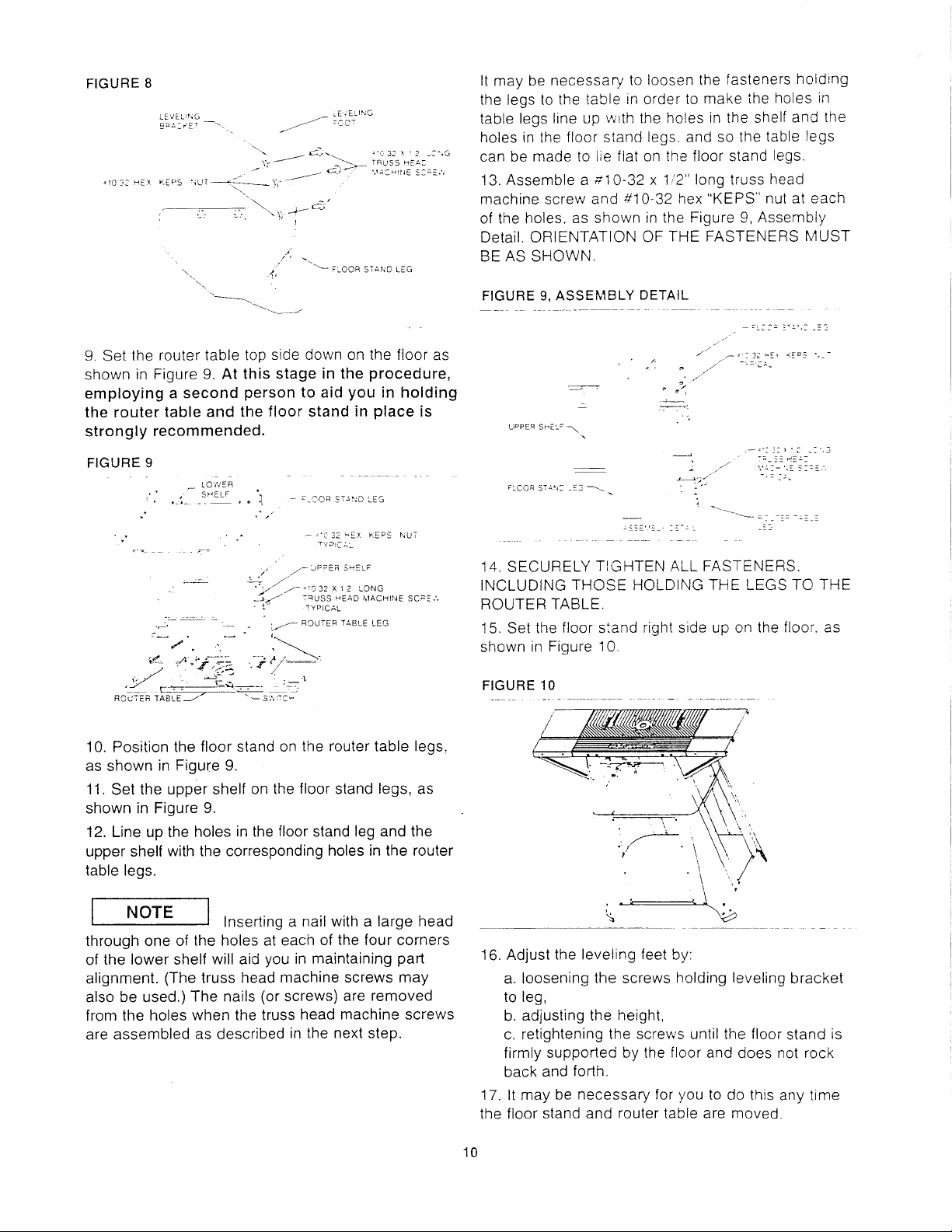

4. Lay the partially assembled floor stand on its side

on the floor so that the legs support the floor stand.

as shown in Figure 6.

ACCESSORY

HC=ES

r

,J HOLES

J

/

J

J

i -_

/ /

/

/

/-

./

. /

.g/Z

ACCESSORY

° l

The following procedure is easier to carry out if two

people perform the task.

1. Lay the shelf, top side down, on a workbench or

other sturdy surface, so that two of the corners along

the long length of the shelf overhang the workbench,

as shown in Figure 5.

NOTE

I I The placement of a weight on the

I

shelf, as shown in Figure 5, is strongly recommended

so that the shelf will maintain its position on the work-

bench and will not tip and fall off the workbench while

assembling the legs to the shelf.

FIGURE 6

;_C3 P_S-._'4- -- -

TRU'_S HEAD LtAC_ ",E '\ '_o /

S

..... ".L.

/

• 10 32 HEX KE_S X_T _/

_TYRICAL) z- LOWER

/

I

' SHELF

C

/

"k_FLOO,

5. Assemble the remaining legs to the shelf using

four//10-32 x 1/2" long truss head machine screws

and #10-32 hex "KEPS" nuts, as shown in Figure 6.

6. SECURELY TIGHTEN ALL FASTENERS.

7. Assemble a leveling foot to each of the leveling

brackets, as shown in Figure 7.

FIGURE 7

f

r_ /_/ BRACKET

t

!

LEVELING

\

t

FIGURE 5

WORKBENCH_ ............. ,

PLACE _

WEIGHT _-

_r _.... - -- FLOOR

....... r , _. "" STAND LEG

SHELF

-- "10 32 X " 2" _ONG

Tquss _E_'D MACHINE

SCREW _,CAL)

/ -- "!032 HEX ,',EroS- NUT

'TYPICAL_

_LOOR

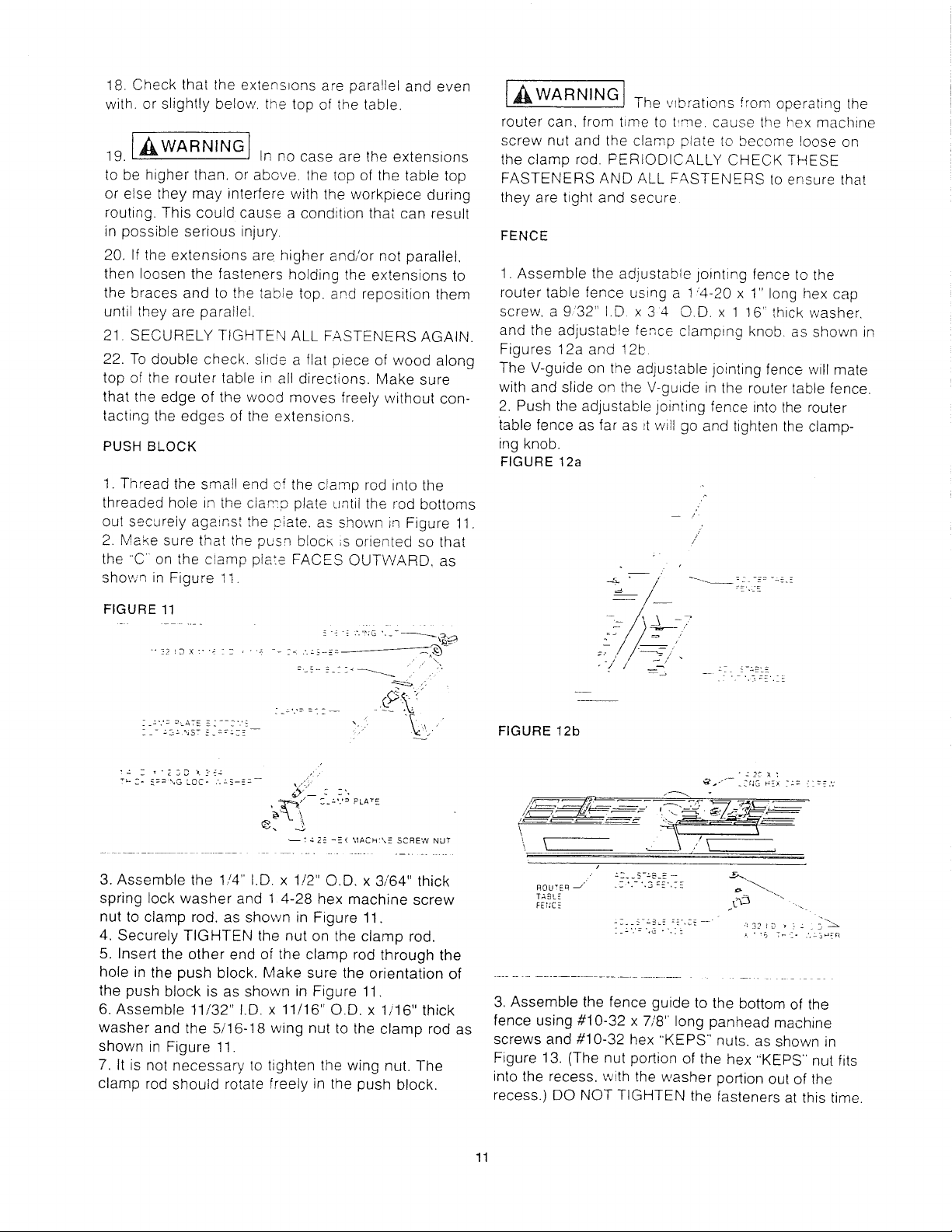

8. Assemble the leveling brackets to each of the

floor stand legs using three #10-32 x 1/2" long truss

head machine screws and three #10-32 hex "KEPS"

nuts, as shown in Figure 8.

FIGURE 8

LEVEL!NG //-- _,:©_

" _"_ _ ":C 32 × ! 2 -C';G

j_'["

,1032 HEX KEPS _'_gT_'_'i -_ .

:" .::, :..%

\ 4',

\

_E_ELING

Sg_E,',

FLOOR STAND LEG

9. Set the router table top side down on the floor as

shown in Figure 9. At this stage in the procedure,

employing a second person to aid you in holding

the router table and the floor stand in place is

strongly recommended•

It may be necessary, to loosen the fasteners holding

the legs to the table in order to make the holes in

table legs line up with the holes in the shelf and the

holes in the floor stand legs. and so the table legs

can be made to lie fiat on the floor stand legs.

13. Assemble a ,_I0-32 x 1/2" long truss head

machine screw and #10-32 hex "KEPS" nut at each

of the holes, as shown in the Figure 9, Assembly

Detail. ORIENTATION OF THE FASTENERS MUST

BE AS SHOWN.

FIGURE 9, ASSEMBLY DETAIL

//./"

._ //- _ :.C._ _

__- .. . .

UPPER S_EL_ _

f'" _ =_ 12 _, <E_a - -

• /

e ,

FIGURE 9

• , ,._ SHELF , . _ - :_r2OR _<T-_'ID LEG

• • * -- :'0 32 _E: _, KEPS NUT

." . T,,p_CL L

ROCTEB TABLE_ _ "_ S,',:TC _

LOWER

• i

,_ t * /

_, _ ,,_ ROUTER TABLE LEG

), //--:uPPER SHELF

"".._ _ =:O 32 X i 2 LONG

- / TqUSS HEAD MACHh"4E SC_E,',

• [ TYPICAL

10. Position the floor stand on the router table legs,

as shown in Figure 9.

11. Set the upper shelf on the floor stand legs, as

shown in Figure 9.

12. Line up the holes in the floor stand leg and the

upper shelf with the corresponding holes in the router

table legs.

NOTE

I I Inserting a nail with a large head

I

through one of the holes at each of the four corners

of the lower shelf will aid you in maintaining part

alignment. (The truss head machine screws may

also be used.) The nails (or screws) are removed

from the holes when the truss head machine screws

are assembled as described in the next step.

_._f/ '¢_:- ".E _ Z:E.'.

_LCOR STANC -E2_

:_E"-2_- 2--: L _E.2

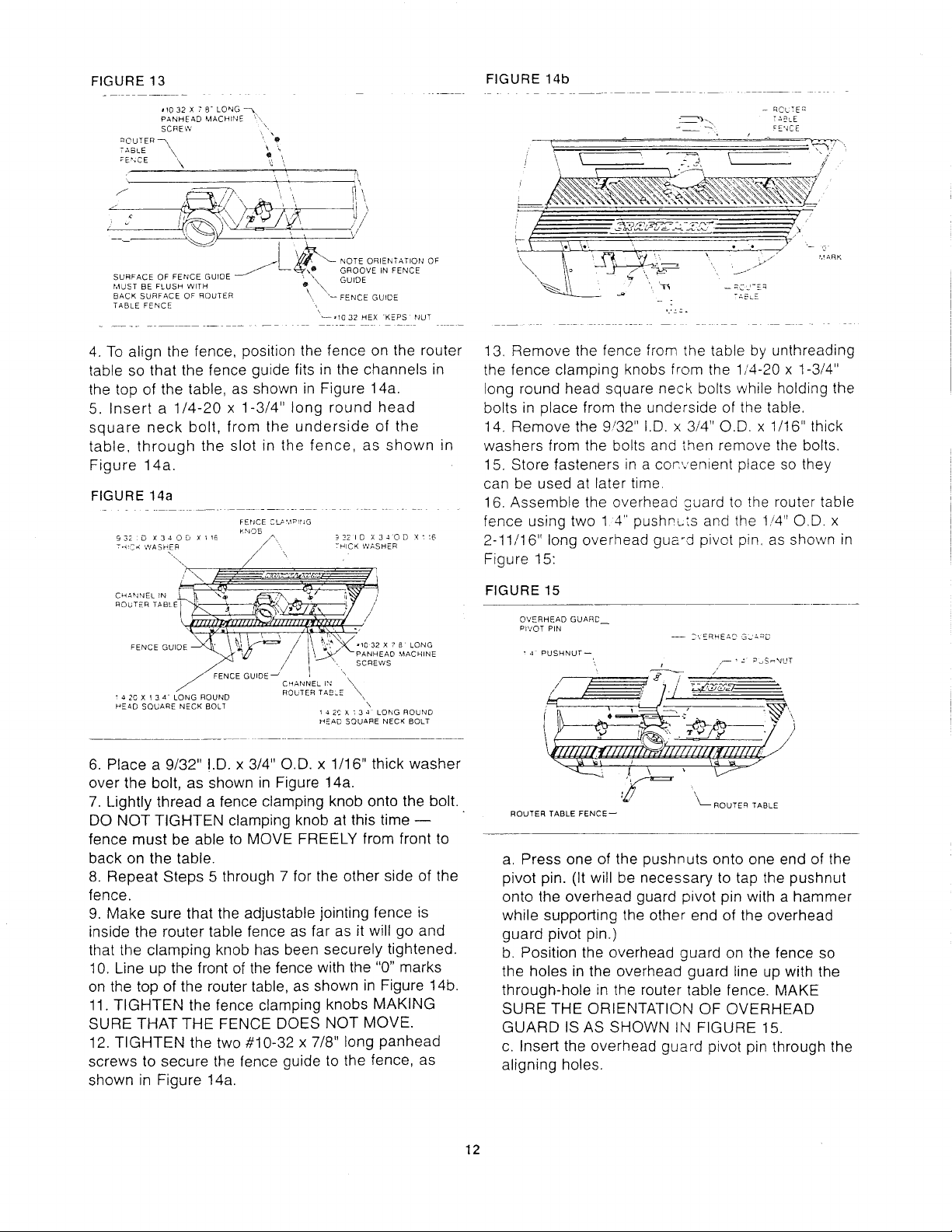

14. SECURELY TIGHTEN ALL FASTENERS.

INCLUDING THOSE HOLDING THE LEGS TO THE

ROUTER TABLE.

15. Set the floor stand right side up on the floor, as

shown in Figure 10.

FIGURE 10

16.

Adjust the leveling feet by:

a. loosening the screws holding leveling bracket

to leg,

b. adjusting the height,

c. retightening the screws until the floor stand is

firmly supported by the floor and does not rock

back and forth.

17. It may be necessary for you to do this any time

the floor stand and router table are moved.

10

18.Checkthattheextenstonsareparallelandeven

with.orslightlybelow,thetopofthetable.

19.[A }[,,_WARNINGj Innocasearetheextensions

tobehigherthan.orabove,thetopofthetabletop

orelsetheymayinterferewiththeworkpieceduring

routing.Thiscouldcauseaconditionthatcanresult

inpossibleseriousinjury.

20.Iftheextensionsarehigherand/ornotparallel.

thenloosenthefastenersholdingtheextensionsto

thebracesandtothetabietop.andrepositionthem

untiltheyareparallel.

2I. SECURELYTIGHTENALLFASTENERSAGAIN.

22.Todoublecheck,slideaflatpieceofwoodalong

topoftheroutertableinalldirections.Makesure

thattheedgeofthewoodmovesfreelywithoutcon-

tactingtheedgesoftheextensions.

PUSHBLOCK

1.Threadthesmallendoftheclamprodintothe

threadedholeintheclampplateuntiltherodbottoms

outsecurelyagainsttheplate,asshowninFigure11.

2.Makesurethatthepushblockisorientedsothat

the'C ontheclampplateFACESOUTWARD,as

showninFigure1t.

{,_WARNING The v{brations from operating the

router can, from time to t_me. cause the hex machine

screw nut and the clamp plate to become loose on

the clamp rod. PERIODICALLY CHECK THESE

FASTENERS AND ALL FASTENERS to ensure that

they are tight and secure

FENCE

1. Assemble the adjustable jointing fence to the

router table fence using a 1'4-20 x 1" long hex cap

screw, a 9'32" I.D x 34 O.D. x 1 16" thick washer.

and the adjustab!e fence clamping knob. as shown in

Figures 12a and 12b

The V-guide on the adjustable jointing fence will mate

with and slide on the V-guide in the router table fence.

2. Push the adjustable jointing fence into the router

table fence as far as _twill go and tighten the clamp-

ing knob.

FIGURE 12a

/

/

FIGURE 11

"'22!DX:'": 27 ' "'4 -- --< .'.a3--_-=__'_

2_-". '= -*':._.TE -2--2".'£ ,..

Z-- :_-" NST -:_:::EE

T_ C- _='_ ",G LQC* .'._-S-E:-- ,,,<,;

t4 2_. -E'( MACH:X-_- SCREW NUT

3. Assemble the 1,/4'. I.D. x 1/2" O.D. x 3/64" thick

spring lock washer and 1 4-28 hex machine screw

nut to clamp rod. as shown in Figure 11.

4. Securely TIGHTEN the nut on the clamp rod.

5. Insert the other end of the clamp rod through the

hole in the push block. Make sure the orientation of

the push block is as shown in Figure 11.

6. Assemble 11/32" I.D. x 11/16" O.D. x 1/16" thick

washer and the 5/16-18 wing nut to the clamp rod as

shown in Figure 11.

7. It is not necessary to tighten the wing nut. The

clamp rod should rotate freely in the push block.

'&_-7

a7. _-a_LE

FIGURE 12b

"z2CX:

', \ ,,' \ ,

/

_' _Z'.-'.S =£',7B o- _"_,ROU*_Eq

TABLE _

FEr;CE L >_

[-:'.'= ',G -',i-

3, Assemble the fence guide to the bottom of the

fence using #10-32 x 7/8" long panhead machine

screws and #10-32 hex "KEPS" nuts. as shown in

Figure 13. (The nut portion of the hex "KEPS" nut fits

into the recess, with the washer portion out of the

recess.) DO NOT TIGHTEN the fasteners at this time.

' ' _B 7_ Z" .'.ZB"_ER

11

FIGURE 13

SURFACE OF FENCE GUfDE " \, GUIDE

MUST BE FLUSH WITH _ \_

BACK SURFACE OF ROUTER ' '_ FENCE GUIDE

TABLE FENCE

,O GROOVE IN FENCE

_'10 32 HEX 'KEPS NUT

FIGURE 14b

-- RCLTE q

--- "P:i / FENCE

\,/

NOTE ORIENTATION OF

4. To align the fence, position the fence on the router

table so that the fence guide fits in the channels in

the top of the table, as shown in Figure 14a.

5. Insert a 1/4-20 x 1-3/4" long round head

square neck bolt, from the underside of the

table, through the slot in the fence, as shown in

Figure 14a.

FIGURE 14a

F El'ICE C L_ !,lPrNO

9,32 :D X34OD Xll£ _321D X34OD Xt:6

TH!CK WASHER THICK WASHER

",, X

E:U'DEJ 11" SCREWS

4 20 X 13 4- LONG ROUND ROUTER TABLE '_\

HEAD SQUARE NECK BOLT

KNOB

, \ '

CHANNEL 154

i 4 2c x t 3 4 LONG ROUND

HEAD SQUARE NECK BOLT

x

6. Place a 9/32" !.D. x 3/4" O.D. x 1/16" thick washer

over the bolt, as shown in Figure 14a.

7. Lightly thread a fence clamping knob onto the bolt.

DO NOT TIGHTEN clamping knob at this time --

fence must be able to MOVE FREELY from front to

back on the table.

8. Repeat Steps 5 through 7 for the other side of the

fence.

9. Make sure that the adjustable jointing fence is

inside the router table fence as far as it will go and

that the clamping knob has been securely tightened•

10. Line up the front of the fence with the "0" marks

on the top of the router table, as shown in Figure 14b.

11. TIGHTEN the fence clamping knobs MAKING

SURE THAT THE FENCE DOES N©T MOVE.

12. TIGHTEN the two #10-32 x 7/8" long panhead

screws to secure the fence guide to the fence, as

shown in Figure 14a.

13. Remove the fence from the table by unthreading

the fence clamping knobs from the 1/4-20 x 1-3/4"

long round head square neck bolts while holding the

bolts in place from the underside of the table.

14. Remove the 9!32" I.D. x 3/4" O.D. x 1/16" thick

washers from the bolts and then remove the bolts.

15. Store fasteners in a cor:venient place so they

can be used at later time.

16. Assemble the overhead guard to the router table

fence using two 14" pushnLts and the 1/4" O,D. x

2-11/16" long overhead guard pivot pin, as shown in

Figure 15:

FIGURE 15

OVERHEAD GUARD

PP,IOT PIN

• 4 PUSHNUT--

l_ '_'_ ROUTER TABLE

ROUTER TABLE FENCE--

-- D'.ERHEAD GL'_=D

t

a. Press one of the pushnuts onto one end of the

pivot pin. (It will be necessary to tap the pushnut

onto the overhead guard pivot pin with a hammer

while supporting the other end of the overhead

guard pivot pin.)

b. Position the overhead guard on the fence so

the holes in the overhead guard line up with the

through-hole in the router table fence• MAKE

SURE THE ORIENTATION OF OVERHEAD

GUARD ISAS SHOWN IN FIGURE 15.

c. Insert the overhead guard pivot pin through the

aligning holes.

12

d. Press the second pushnut onto the other end of

the overhead guard pivot pin in the same manner

as in Step a.

e. Move the overhead guard up and down a few

times to ensure that it moves freely.

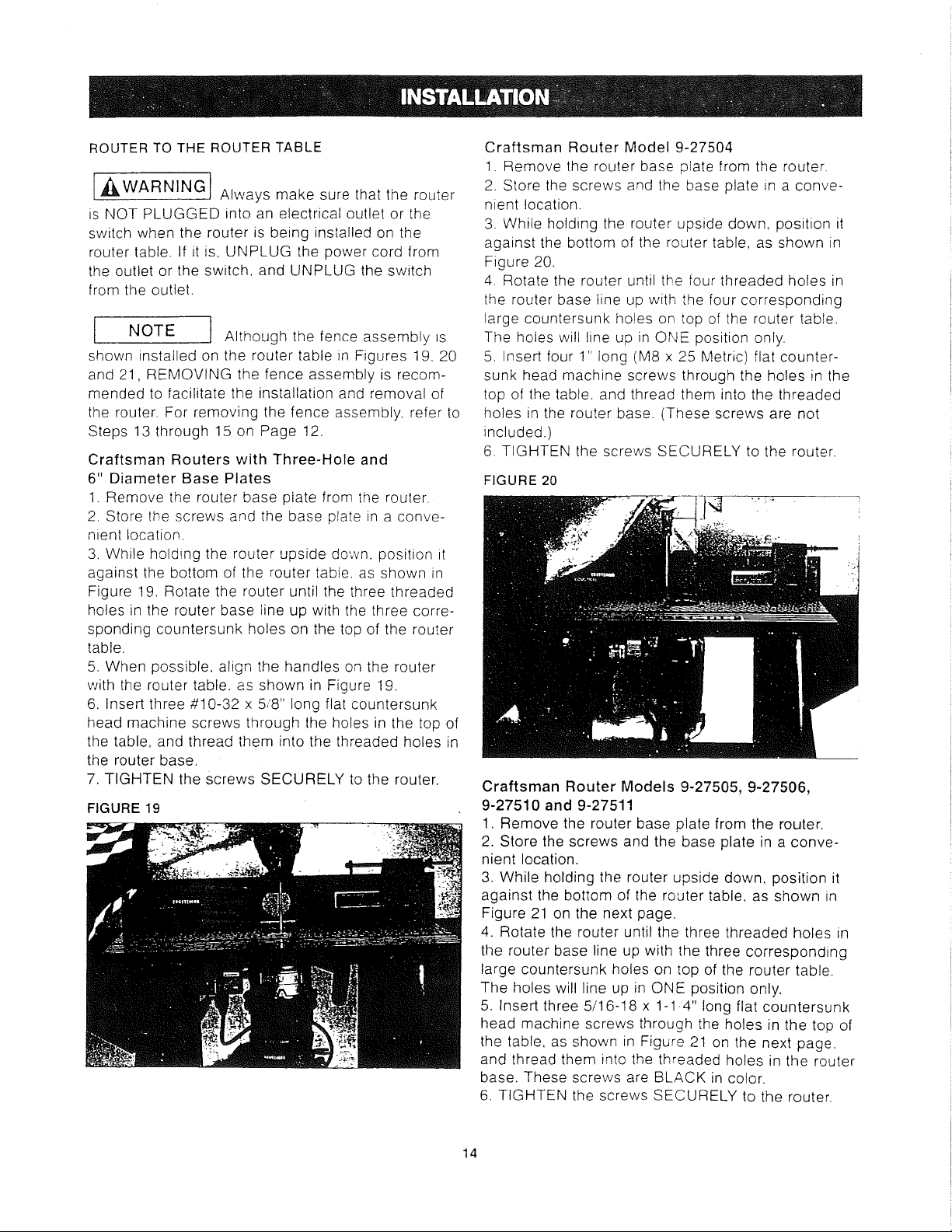

MITER GAUGE

1. Assemble the protractor head to the miter bar, as

shown in Figure 17. using a #10-32 x 1/2" long truss

head machine screw.

tA/LLLWARNING J Once the overhead guard has

been assembled to the fence, DO NOT remove it for

any reason. Its removal can result in an unsafe oper-

ating condition that can result in possible bodily injury.

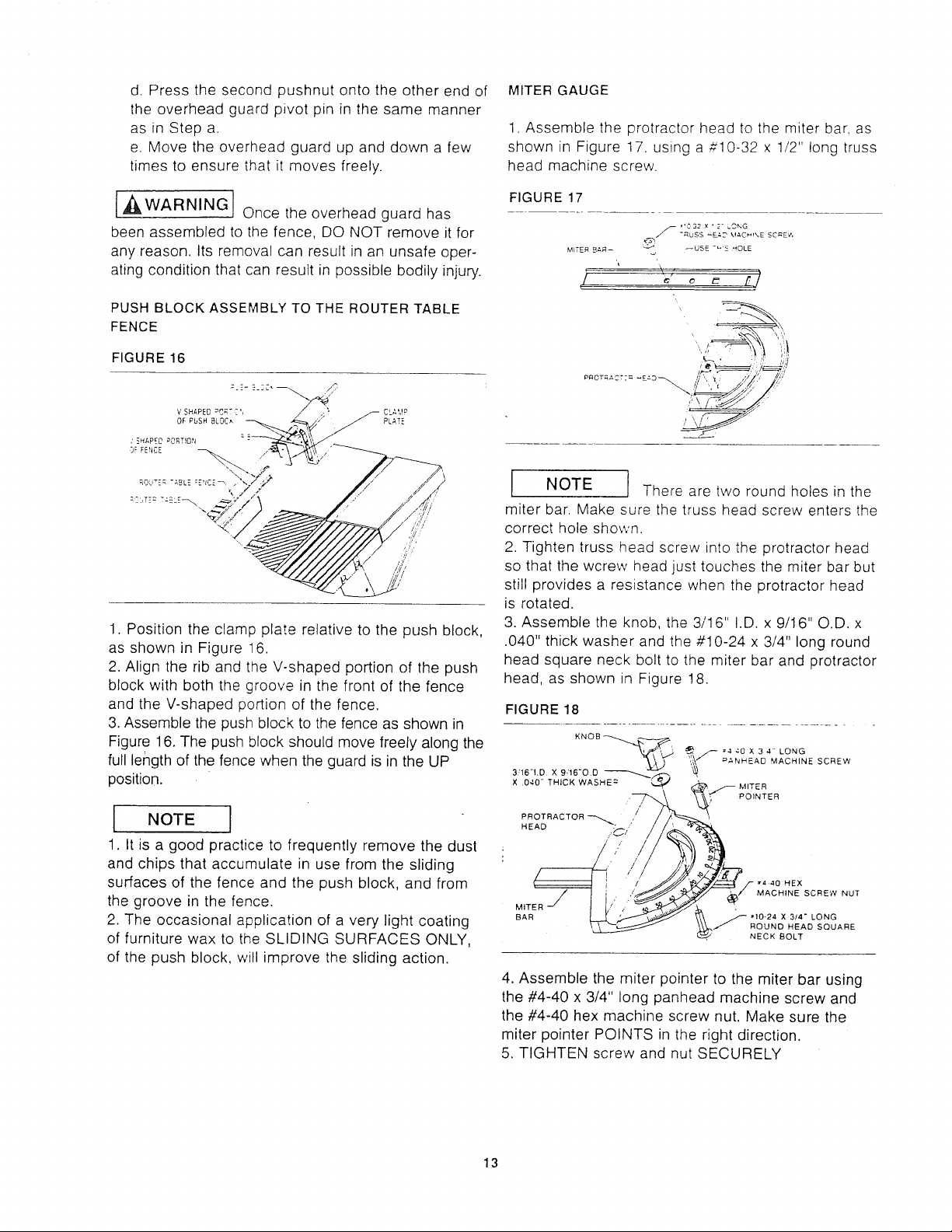

PUSH BLOCK ASSEMBLY TO THE ROUTER TABLE

FENCE

FIGURE 16

1. Position the clamp plate relative to the push block,

as shown in Figure I6.

2. Align the rib and the V-shaped portion of the push

block with both the groove in the front of the fence

and the V-shaped portion of the fence.

3. Assemble the push block to the fence as shown in

Figure 16. The push block should move freely along the

full length of the fence when the guard is in the UP

position.

NOTE J

1. It is a good practice to frequently remove the dust

and chips that accumulate in use from the sliding

surfaces of the fence and the push block, and from

the groove in the fence.

2. The occasional application of a very light coating

of furniture wax to the SLIDING SURFACES ONLY,

of the push block, will improve the sliding action.

FIGURE 17

"0 32 X ' 2- LCNG

M_TER BA,q- --USE -_'2 '40LE

._S -'qUSS "EA3 MACMr-,E SCP_E¢,

i "'oo ,.j>

NOTE ] There are two round holes in the

miter bar. Make sure the truss head screw enters the

correct hole shown.

2. Tighten truss head screw into the protractor head

so that the wcrew head just touches the miter bar but

still provides a resistance when the protractor head

is rotated.

3. Assemble the knob, the 3/16" I.D. x 9/16" O.D. x

.040" thick washer and the #10-24 x 3/4" long round

head square neck bolt to the miter bar and protractor

head, as shown in Figure !8.

FIGURE 18

_1_ :4 40 X 3 4" LONG

3:16"1.D X 9:16"O D _ _/,,_-,

X .040- THICK WASHE= _

KNOB _ _%//--

=JNHEAD MACHINE SCREW

,,-7%-

i r4 40 HEX

Tg%gg¢oSOUARE

4. Assemble the miter pointer to the miter bar using

the #4-40 x 3/4" long panhead machine screw and

the #4-40 hex machine screw nut. Make sure the

miter pointer POINTS in the right direction.

5. TIGHTEN screw and nut SECURELY

13

ROUTER TO THE ROUTER TABLE

[,_WARNING] Always make sure that the router

is NOT PLUGGED into an electrical outlet or the

switch when the router is being installed on the

router table. If it is, UNPLUG the power cord from

the outlet or the switch, and UNPLUG the switch

from the outlet.

NOTE

l J Although the fence assembly Js

shown installed on the router table in Figures 19, 20

and 21, REMOVING the fence assembly is recom-

mended to facilitate the installation and removal of

the router, For removing the fence assembly, refer to

Steps 13 through 15 on Page 12.

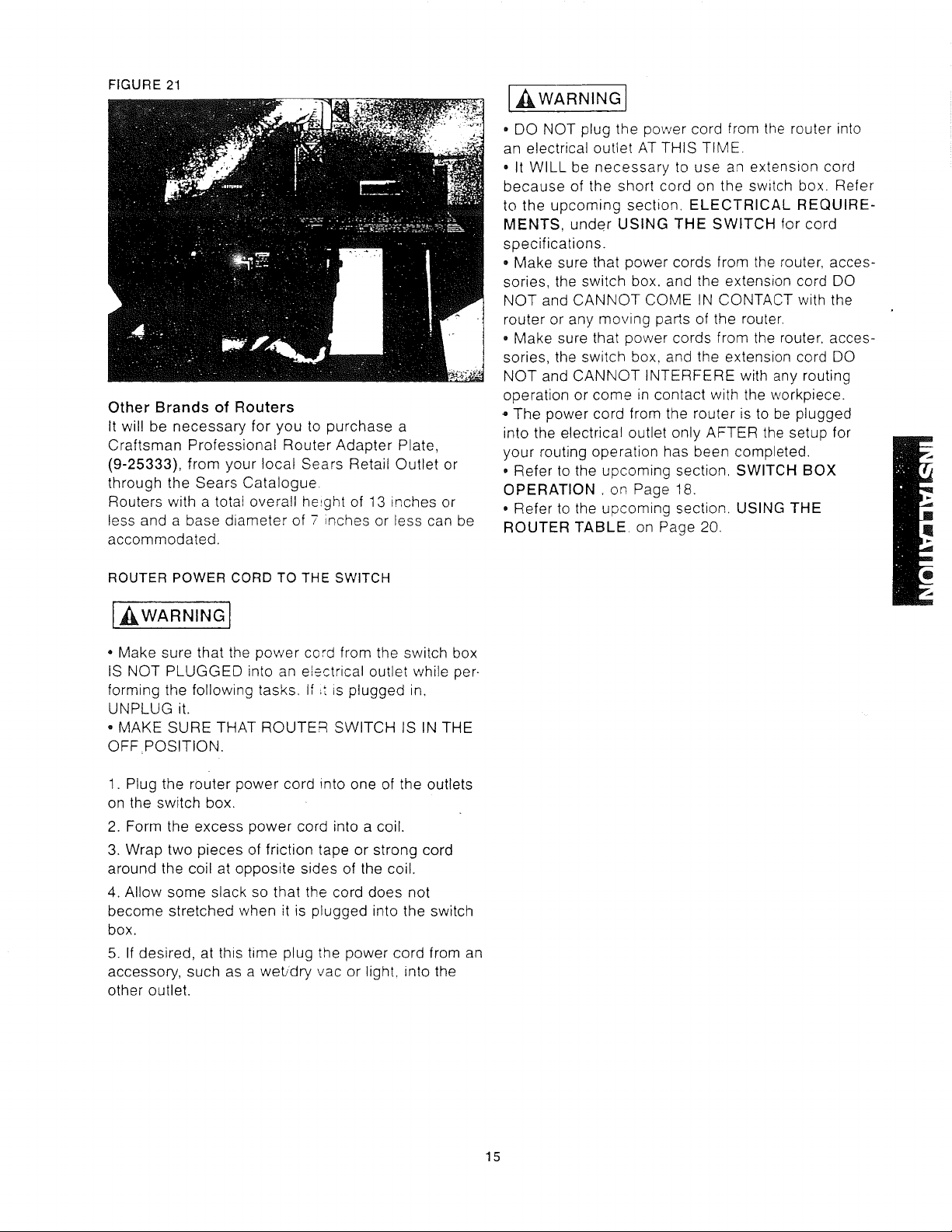

Craftsman Routers with Three-Hole and

6" Diameter Base Plates

1. Remove the router base plate from the router.

2. Store the screws and the base plate in a conve-

nient location.

3. While holding the router upside down. position it

against the bottom of the router table, as shown in

Figure 19. Rotate the router until the three threaded

holes in the router base line up with the three corre-

sponding countersunk holes on the top of the router

table.

5. When possible, align the handles on the router

with the router table, as shown in Figure 19.

6. Insert three #10-32 x 5/8" long flat countersunk

head machine screws through the holes in the top of

the table, and thread them into the threaded holes in

the router base.

7. TIGHTEN the screws SECURELY to the router.

FIGURE 19

]

Craftsman Router Model 9-27504

1. Remove the router base plate from the router.

2. Store the screws and the base plate in a conve-

nient location.

3. While holding the router upside down, position it

against the bottom of the router table, as shown in

Figure 20.

4. Rotate the router until the four threaded holes in

the router base line up with the four corresponding

large countersunk holes on top of the router table.

The holes will line up in ONE position only.

5. Insert four 1" long (M8 x 25 Metric) flat counter-

sunk head machine screws through the holes in the

top of the table, and thread them into the threaded

holes in the router base. (These screws are not

included.)

6. TIGHTEN the screws SECURELY to the router.

FIGURE 20

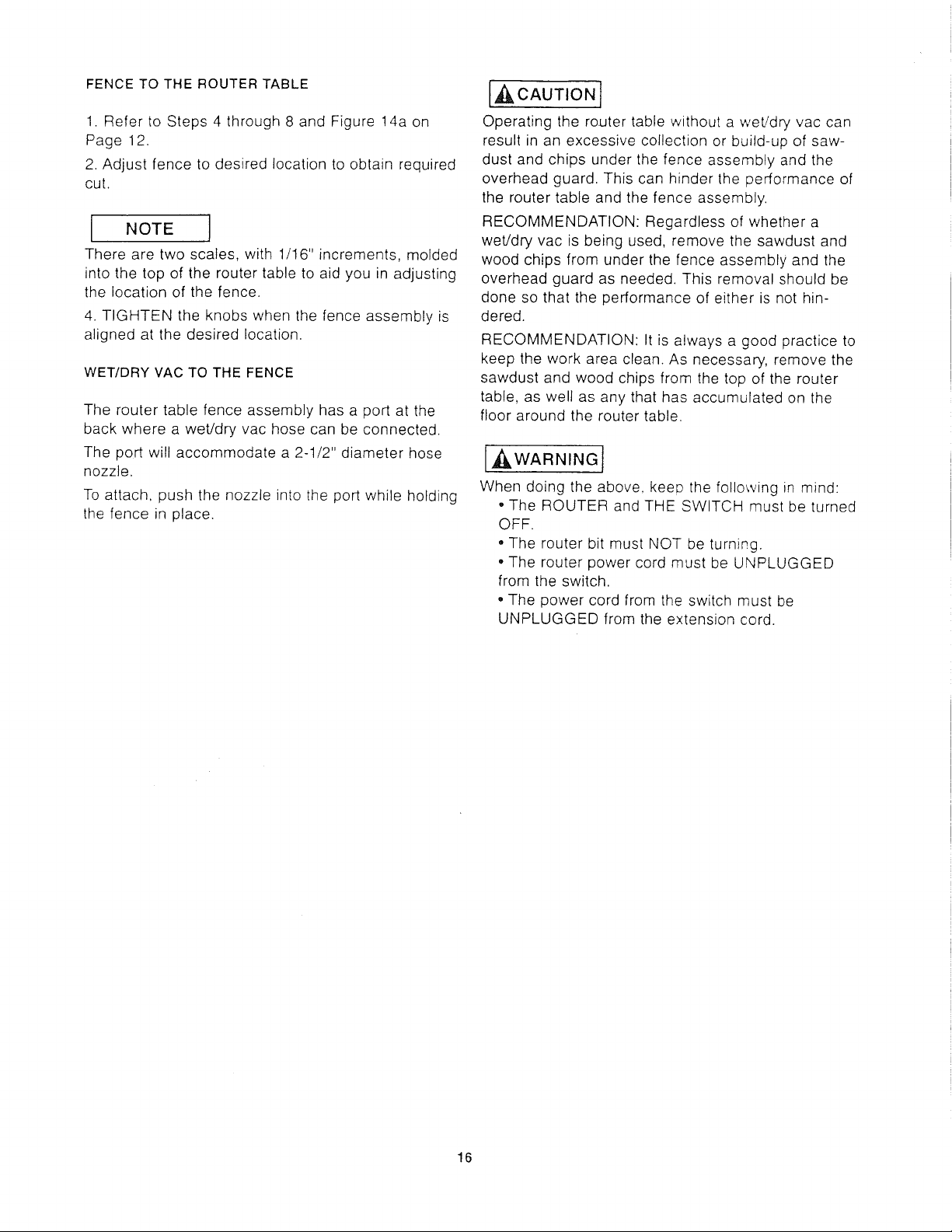

Craftsman Router Models 9-27505, 9-27506,

9-27510 and 9-27511

1. Remove the router base plate from the router.

2. Store the screws and the base plate in a conve-

nient location.

3. While holding the router upside down, position it

against the bottom of the router table, as shown in

Figure 21 on the next page.

4. Rotate the router until the three threaded holes in

the router base line up with the three corresponding

large countersunk holes on top of the router table.

The holes will line up in ONE position only,

5. Insert three 5/16-18 x 1-1 4" tong flat countersunk

head machine screws through the holes in the top of

the table, as shown in Figure 21 on the next page,

and thread them into the threaded holes in the router

base. These screws are BLACK in color.

6. TIGHTEN the screws SECURELY to the router.

14

FIGURE21

Other Brands of Routers

It will be necessary for you to purchase a

Craftsman Professional Router Adapter Plate,

(9-25333), from your local Sears Retail Outlet or

through the Sears Catalogue.

Routers with a total overall height of 13 inches or

less and a base diameter of 7 inches or less can be

accommodated.

[ ,WARNING]

• DO NOT plug the power cord from the router into

an electrical outlet AT THIS TIME.

• It WILL be necessary to use an extension cord

because of the short cord on the switch box. Refer

to the upcoming section. ELECTRICAL REQUIRE-

MENTS, under USING THE SWITCH for cord

specifications.

• Make sure that power cords from the router, acces-

sories, the switch box. and the extension cord DO

NOT and CANNOT COME IN CONTACT with the

router or any moving parts of the router.

° Make sure that power cords from the router, acces-

sories, the switch box, and the extension cord D©

NOT and CANNOT INTERFERE with any routing

operation or come in contact with the workpiece.

-. The power cord from the router is to be plugged

into the electrical outlet only AFTER the setup for

your routing operation has been completed.

• Refer to the upcoming section. SWITCH BOX

OPERATION. on Page 18.

• Refer to the upcoming section. USING THE

ROUTER TABLE. on Page 20_

ROUTER POWER CORD TO THE SWITCH

,_.WARNING

• Make sure that the power cord from the switch box

IS NOT PLUGGED into an electrical outlet while per-

forming the following tasks. If it is plugged in.

UNPLUG it.

o MAKE SURE THAT ROUTER SWITCH IS IN THE

OFF pOSITION.

1. Plug the router power cord into one of the outlets

on the switch box.

2. Form the excess power cord into a coil.

3. Wrap two pieces of friction tape or strong cord

around the coil at opposite sides of the coil.

4. Allow some slack so that the cord does not

become stretched when it is plugged into the switch

box.

5. If desired, at this time plug the power cord from an

accessory, such as a web'dry vac or light, into the

other outlet.

15

FENCE TO THE ROUTER TABLE

1. Refer to Steps 4 through 8 and Figure !4a on

Page 12.

2. Adjust fence to desired location to obtain required

cut.

NOTE I

There are two scales, with 1/16" increments, molded

into the top of the router table to aid you in adjusting

the location of the fence.

4. TIGHTEN the knobs when the fence assembly is

aligned at the desired location.

WET/DRY VAC TO THE FENCE

The router table fence assembly has a port at the

back where a wet/dry vac hose can be connected.

The port will accommodate a 2-1/2" diameter hose

nozzle.

To attach, push the nozzle into the port while holding

the fence in place.

,_CAUTION I

Operating the router table without a wet/dry vac can

result in an excessive collection or build-up of saw-

dust and chips under the fence assembly and the

overhead guard. This can hinder the performance of

the router table and the fence assembly.

RECOMMENDATION: Regardless of whether a

wet/dry vac is being used, remove the sawdust and

wood chips from under the fence assembly and the

overhead guard as needed. This removal should be

done so that the performance of either is not hin-

dered.

RECOMMENDATION: It is always a good practice to

keep the work area clean. As necessary, remove the

sawdust and wood chips from the top of the router

table, as well as any that has accumulated on the

floor around the router table.

,_WARNING

When doing the above, keel_ the following in mind:

oThe ROUTER and THE SWITCH must be turned

OFF.

o The router bit must NOT be turning.

• The router power cord must be UNPLUGGED

from the switch.

• The power cord from the switch must be

UNPLUGGED from the extension cord.

16

TABLE TOP INSERTS TO THE ROUTER TABLE

This router table comes with three table top inserts in

the following hole sizes:

o 1-1/4" diameter, for use with router bits with diame-

ters up to 1-1/8"

• 1-7/8" diameter, for use with router bits with diame-

ters up to 1-3/4"

o 2-1/8" diameter, for use with router bits with diame-

ters up to 2"

• For router bits with diameters between 2" and 2-3/4"

the table top inserts are not used. See Figure 22.

FIGURE 22

I,_WARNINGJ A 2-3/4" diameter router bit is the

LARGEST router bit that can be SAFELY used on

this router table.

1. Select the table top insert that accommodates the

router bit to be used.

2. Assemble the insert to the table top by pressing it

into the large hole in the top of the router table, as

shown in Figure 23.

3. Press down equally over the tabs on the insert so

that the tabs snap into place.

4. To remove, insert a finger in the insert hole and

gently pull up until the tabs disengage the hole.

When not in use. store the inserts in a convenient

place.

[,_WARNING] DO NOT attempt to remove insert

from the table top unless the router bit has been

removed from the router.

FIGURE 23

17

Loading...

Loading...