Craftsman 171.254790 Owner's Manual

Save This Manual

For Future Reference

owners

miii

MODEL NO.

171.254790

CAUTION:

READ ALL

NSTRUCTONS

CAREFULLY

iIffl

ROUTER TABLE

FULL FUNCTION/UNITIZED. FENCE

Sold by SEARS, ROEBUCK AND CO., Chicago, DL 60684 U.S.A.

6107 1

MADE IN U.S.A.

Prhted in U.S.A. 4-92

WARNING: FAILURE TO HEED ALL SAFETY AND OPERATING INSTRUCTIONS AND WARNINGS REGARDING USE

OF THIS PRODUCT CAN RESULT IN SERIOUS BODILY INJURY.

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

12.

KNOW YOUR POWER TOOL

1.

Read the owner's manual carefully. Learn its application and limitations as well as the specific potential

hazards peculiar to this tool.

GROUND ALL TOOLS (UNLESS

2.

DOUBLE INSULATED)

If tool is equipped with an approved 3-conductor cord

and a 3-prong grounding type plug, it should be plugged

into a three hole electrical receptacle. If adapter is used

to accommodate a two-prong receptacle, the adapter

wire must be attached to known ground, (usually the

screw securing receptacle cover plate). Never remove

third prong. Never connect green ground wire to a

terminal.

KEEP GUARDS IN PLACE

3.

in

working order, and in proper adjustment and

alignment.

REMOVE ADJUSTING KEYS

4.

AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning

it

on.

KEEP WORK AREA CLEAN

5.

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

AVOID DANGEROUS ENVIRONMENT

6.

Don't use power tools in damp or wet locations or

expose them to rain. Keep work area well lighted.

Provide adequate surrounding work space.

7.

KEEP CHILDREN AWAY

All visitors should be kept a safe distance from work

area.

8.

MAKE WORKSHOP KID-PROOF

-

with padlocks, master switches, or by removing

starter keys.

DON'T FORCE TOOL

9.

It

will do the job better and safer at the rate for which

it

was designed.

USE RIGHT TOOL

10.

Don't force tool or attachment to do a job it was not

designed for.

WEAR RIGHT APPAREL

11.

Do not wear loose clothing, gloves, neckties or jewelry

(rings,

wrist watches) to get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair. Roll long sleeves

above the elbow.

USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANS Z871)

at all times. Also, use face or dust mask if cutting

operation is dusty, and ear protectors (plugs or muffs)

during extended periods of operation.

SECURE WORK

13.

Use clamps or a vise to hold work when practical.

It's

safer than using your hand, frees both hands to

operate tool.

14.

DON'T OVERREACH

Keep proper footing and balance at all times.

15.

MAINTAIN TOOLS WITH CARE

Keeps tools sharp and clean for best and safest performance. Follow instructions for lubricating and

changing accessories.

16.

DISCONNECT TOOLS

before servicing; when changinq accessories such as

blades, bits, cutters, etc.

17.

AVOID ACCIDENTAL STARTING

Make sure switch is in OFF" position before plugging in.

18.

USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended accessories.

the accessories. The use of improper accessories

may cause hazards.

19.

NEVER STAND ON TOOL

Serious -injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted.

Do not store materials above or near the tool such

that it is necessary to stand on the tool to reach them.

20.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to ensure that it will operate properly and perform its

intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its

operation. A guard or other part that is damaged

should be properly repaired or replaced.

21.

DIRECTION OF FEED

Feed work into a t,Iade or cuttor against the direction

of rotation of the blade or cutter only.

22.

NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn. power

complete stop.

Follow the instructions that accompany

off. Don't

leave tool until it comes to a

-

GENERAL SAFETY INSTRUCTIONS FOR THE ROUTER TABLE

WITH UNITIZED FENCE.

ALWAYS USE EYE PROTECTION

1.

The operation of any power tool can result in for-

eign objects being thrown into the eyes, which can

result in severe eye damage. Always wear safety

goggles before commencing power.tool operation.

Safety goggles are available at Sears retail or catalog stores.

KEEP HANDS CLEAR OF BITS, AND WORKING

2.

AREA

MAKE AND USE A PUSH STICK TO MOVE

3.

SMALL WORKPIECES ACROSS THE CUTTING

AREA.

4.

KEEP ROUTER CLEAN

AFTER EVERY USE, CLEAN SAW DUST OFF

THE ROUTER. (ALSO BLOW OUT INSIDE).

YOUR ROUTER TABLE IS PROVIDED WITH A

5.

DUST COLLECTING ATTACHMENT. ALWAYS

USE SHOP VAC. FOR ALL ROUTING OPERATIONS REQUIRING USE OF FRONT SIDE OF

UNITIZED FENCE. (FRONT SIDE IS THE SIDE

WITH THE CRAFTSMAN LABEL).

NOTE: Motors used on wood-working tools are

particularly susceptible to the accumulation of sawdust and wood chips, and

should be blown out, or "vacuumed", frequently to prevent interference with normal motor ventilation.

CHECK FUNCTION OF GUARD BEFORE EACH

6.

USE. REMOVE ALL DUST AND CHIPS FROM

GUARD AREA AS NEEDED TO MAINTAIN

GUARD FUNCTION.

NEVER PUT YOUR FINGERS UNDER THE

7.

GUARD WHEN THE ROUTER IS PLUGGED IN.

ALWAYS USE THE ROUTER TABLEFENCE TO

8.

GUIDE THE WORK. DO NOT WORK FREE

-HAND.

When using pilot type bits, keep the fences as close

to the pilot as possible to provide additional backup

and additional guidance and to avoid chances of

an accident and possible personal injury.

ALWAYS FEED AGAINST THE ROTATION OF

9.

THE CUTTER WHEN ROUTING ON THE

ROUTER TABLE. FEED WORKPIECES IN THE

DIRECTION OF THE ARROW AS SHOWN ON

THE LABEL ON THE SIDE OF THE FENCE

BEING USED (WHEN FACING THE TABLE

FRONT).

WHEN END CUTTING ON WORKPIECES 4"

11.

WIDE OR LESS, CLAMP AND HOLD AND FEED

THE WORKPIECE WITH THE PUSH BLOCK

USING BOTH HANDS AS SHOWN IN FIG. #27.

KEEP FINGERS CLEAR OF BIT WHEN MOVING

WORKPIECE ACROSS THE CUTTING AREA.

NEVER PLACE YOUR HANDS LOWER THAN

THE TOP OF RETRACTABLE GUARD.

12.

ROUTER BITS ARE EXTREMELY SHARP.

Be extra careful when working around them.

SOME ROUTERS WHEN USED IN AN UPSIDE

13.

DOWN POSITION (SUCH AS ON A ROUTER

TABLE) WILL FALL (OR DROP) OUT OF THE

ROUTER BASE WHEN THE BASE CLAMP IS

LOOSENED. IT IS THEREFORE ABSOLUTELY

NECESSARY TO SUPPORT THE ROUTER

MOTOR FROM BELOW WHEN THE BASE

CLAMP IS LOOSENED TO MAKE ADJUSTMENTS, OR FOR ANY OTHER REASON.

14.

ALWAYS LOOK UNDER THE TABLE AT THE

SWITCH WHEN TURNING THE ROUTE.R

ON/OFF AND TOUCH NOTHING BUT THE

SWITCH. NEVER REACH UNDER THE TABLE

WHEN ROUTER IS RUNNING FOR ANY OTHER

REASON.

NOTE: It is far more safe and convenient to use

a "Sears Craftsman 25182 Router Table

Switch Package". This switch provides a

key operated ON/OFF button which allows

very fast and easy access when and if it

becomes necessary to turn the router

"OFF" quickly. The key can be removed

to render the switch inoperable to unautho-

rized people.

15.

ONCE BOTH GUARDS ARE INSTALLED FOR

ROUTING, DO NOT REMOVE THEM FOR ANY

REASON.

16.

MOUNT ROUTER TABLE FIRMLY AND

SECURELY TO A WORK SURFACE BEFORE

USE. FAILURE TO DO SO COULD CAUSE

TABLE TO TIP OVER OR SLIDE DURING OPERATION RESULTING IN PROPERTY DAMAGE

AND/OR SERIOUS BODILY INJURY.

WARNING:

17.

BEFORE MAKING ANY CUT, UNPLUG ROUTER

AND RETRACT GUARD TO MAKE ABSOLUTELY SURE THAT RETRACTABLE GUARD

CLEARS THE ROUTER BIT, AND THE GUARD

IS FUNCTIONING NORMALLY. SEE FIG. #19.

FOR ALL EDGE CUTTING AND END CUTTING

10.

OPERATIONS, USE FRONT SIDE OF UNITIZED

FENCE. USE BACK SIDE OF FENCE ONLY FOR

ROUTING OPERATIONS AWAYFROM EDGE

ON THE UNDERSIDE OF WORKPIECE SUCH AS

GROOVING; FLUTING; VEINING; CROWN

MOLDJNG ETC.

WARNING:

18.

ROUTER VIBRATIONS SOMETIMES CAN

CAUSE FASTENERS FOR THE TABLE, THE

ROUTER AND ThE UNITIZED FENCE TO QET

LOOSEI PERIODICALLY CHECK FASTENERS

TO MAKE SURE THEY ARE TIGHT AND

SECURE.

INTRODUCTION

e

How often have you needed a large guiding surface on

a router table? Your Sears Craftsman Router Table with

Unitized Fence comes with:

A unique 4" high unitized fence designed to assist

a.

for end grain routing for making tenons, sliding

dovetails and tongue and groove-joints along with

most edge and face cutting operations.

A specially designed push bloek with quick clamp

b.

for back up and clamping boards up to 4" width for

end grain routing.

An accurate and quick adjusting jointing fence

c.

adjustable to proper jointing depth of cut.

Reversing feature of unitized fence designed to

d.

enable routing operations like grooving; fluting;

veining; crown molding etc. up to 2 1/2" away from

the edge towards the middle of the board.

Two guards for operation on either side of the unitized fence.

f.

Dust collecting attachment for most shop vac. hook

ups.

If order to facilitate handling and minimize any damage

that might occur during shipment, your new routertable

is packaged unassembled. We know you are anxious

to see what your new tool will do, but a few minutes

spent now carefully reading the following instructions,

will result in less frustration and more enjoyable operation later.

Start by checking and acôounting for all the loose parts.

If

any parts are missing, contact your local Sears retail

or catalog outlet for replacement.

UNPACKING AND

CHECKING CONTENTS

Refer to Parts List on Page 16

WARNING

YOU MUST READ AND UNDERSTAND ALL THE INSTRUCTIONS COMPLETELY

ASSEMBLE AND OPERATE YOUR ROUTER! ROUTER TABLE.

6.

Turn the table right side up and tighten all 16

screws and nuts with a screwdriver and wrench or

pliers.

MOUNTING ROUTER TO TABLE

ALWAYS UNPLUG ROUTER BEFORE MOUNTING

(The table will accept Sears routers with bases up to

6" in diameter).

ATTACHING SEARS ROUTERS WITH THREE HOLE

BASE PLATES.

1.

Remove the router base plate (back plate) from the

router.

2.

While holding the router upside down, position it

to the underside within the center ring of the table

top as shown in Fig. #2.

1.

2.

Table Top

ASSEMBLY OF TABLE

Turn the table upside down.

Place one of the table legs in one corner of the table

as shown in Fig. #1.

Leg

BEFORE ATTTING

TO

#10-32

Pan Head Screw

5/8"

x

Insert the 10-32 x 5/8 machine screws through the

3.

table top and leg.

Lightly tighten the nuts and lock washers on each

4.

screw. The lock washers should be against the

inside of the leg.

Repeat for the remaining three legs.

5.

#10-32 Hex Nut

#10 Lock Washer

Fig. #1

Center Ring

--

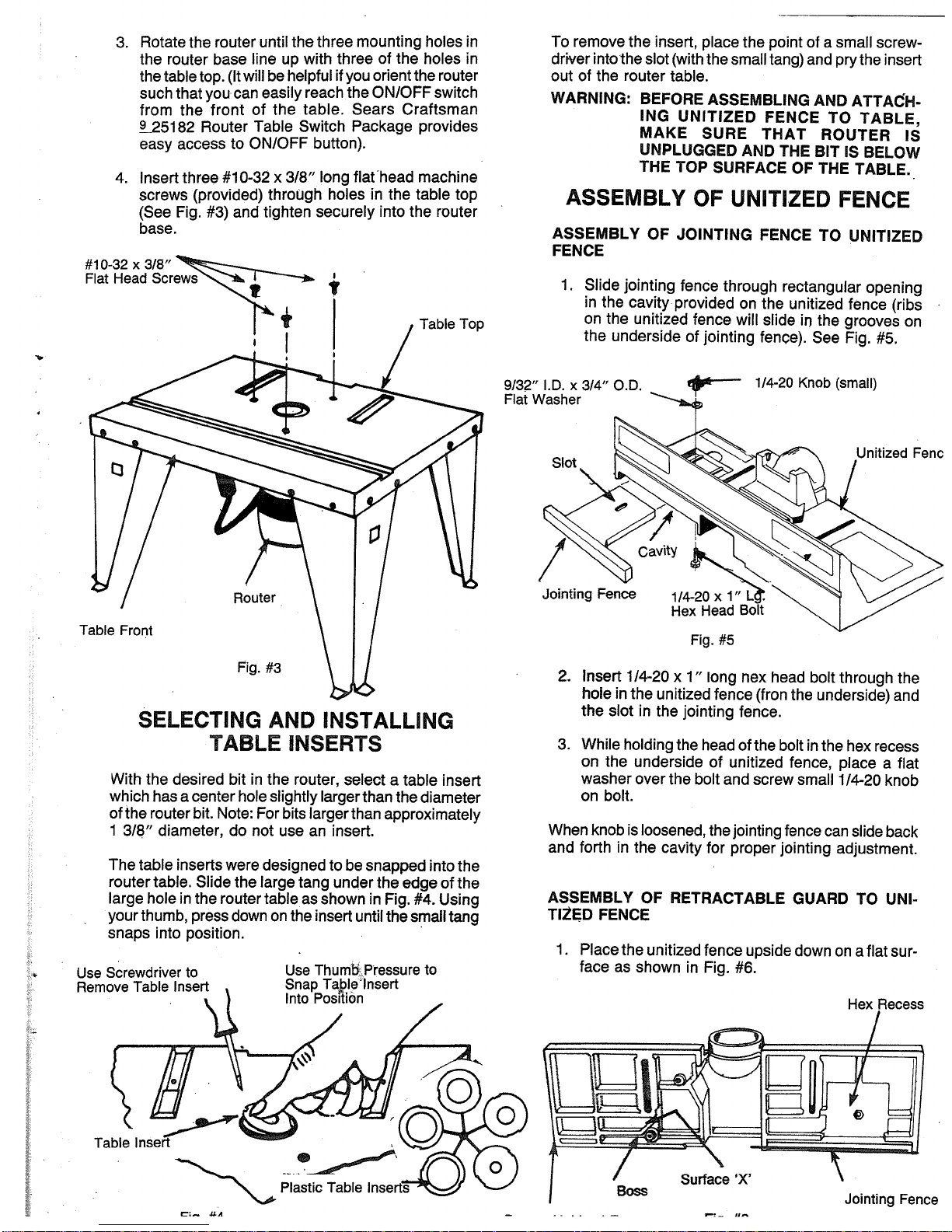

Rotate the router until the three mounting holes in

3.

the router base line up with three of the holes in

the table top. (It will be helpful if you orient the router

such that you can easily reach the ON/OFF switch

from the front of the table. Sears Craftsman

25182 Router Table Switch Package provides

easy access to ON/OFF button).

Insert three #10-32 x 3/8" long flat head machine

4.

screws (provided) throUgh holes in the table top

(See Fig. #3) and tighten securely into the router

base.

To remove the insert, place the point of a small screwdriver into the slot (with the small tang) and pry the insert

out of the router table.

WARNING: BEFORE ASSEMBLING AND ATTACH-

ING UNITIZED FENCE TO TABLE,

MAKE SURE THAT ROUTER IS

UNPLUGGED AND THE BIT IS BELOW

THE TOP SURFACE OF THE TABLE.

ASSEMBLY OF UNITIZED FENCE

ASSEMBLY OF JOINTING FENCE TO UNITIZED

FENCE

1.

Slide jointing fence through rectangular opening

in the cavity provided on the unitized fence (ribs

on the unitized fence will slide in the grooves on

the underside of jointing fence). See Fig. #5.

9/32"I.D.x3/4" O.D.

rii vvasnr

- 1/4-20 Knob (small)

Unitized Fenc

SELECTING AND INSTALLING

TABLE INSERTS

With the desired bit in the router, select a table insert

which has a center hole slightly larger than the diameter

of the router bit. Note: For bits larger than approximately

1

3/8" diameter, do not use an insert.

The table inserts were designed to be snapped into the

router table. Slide the large tang under the edge of the

large hole in the router table as shown in Fig. #4. Using

your thumb, press down on the insert until the small tang

snaps into position.

Use Screwdriver to

Remove Table Insert

Use Thumbs Pressure to

Snap TaIeinsert

Into Position

Fig. #5

2.

Insert 1/4-20 x 1" long flex head bolt through the

hole in the unitized fence (fron the underside) and

the slot in the jointing fence.

3.

While holding the head of the bolt in the hex recess

on the underside of unitized fence, place a flat

washer over the bolt and screw small 1/4-20 knob

on bolt.

When knob is loosened, the jointing fence can slide back

and forth in the cavity for proper jointing adjustment.

ASSEMBLY OF RETRACTABLE GUARD TO UNITIED FENCE

1.

Place the unitized fence upside down on a flat sur-

face as shown in Fig. #6.

Hex Recess

.iLA

,-- ',.

Loading...

Loading...