Page 1

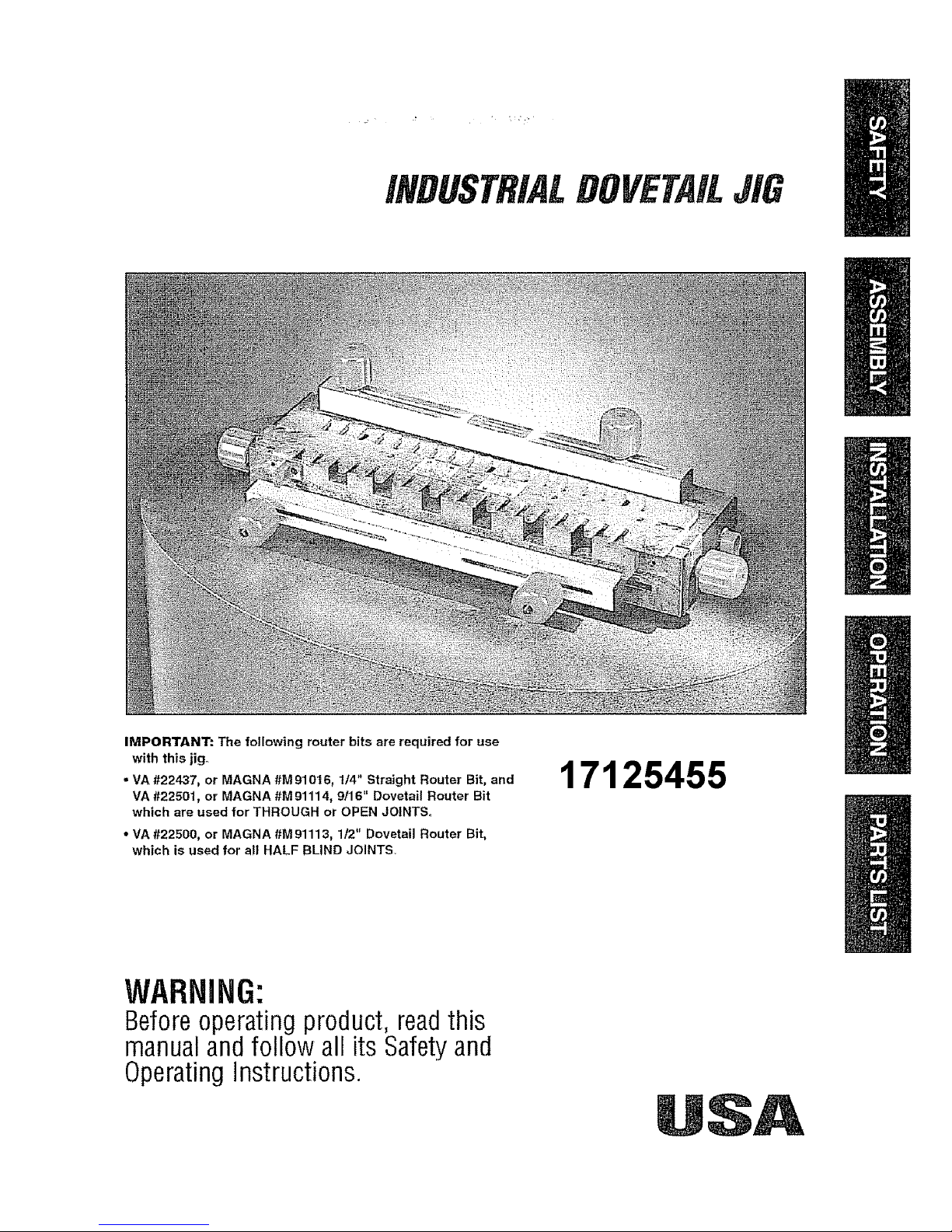

iNDUSTRiALDOVETAILJIG

IMPORTANT:. The fo!lowing router bits are required for use

with this jig-

• VA #22437, or MAGNA #M 910t6, 1/4" Straight Router Bit, and

VA #22501, or MAGNA #M91114, 9t16" Dovetail Router Bit

which are used for THROUGH or OPEN JOINTS.

• VA #22500, or MAGNA #M91113, 1t2" Dovetail Router Bit,

which is used for all HALF BLIND JOINTS.

17125455

WARNING:

Beforeoperatingproduct,readthis

manualandfollow all its Safetyand

OperatingInstructions.

Page 2

General Safety Instructions for Power Tools .......................................... 3

Additional Safety Instructions for Industrial Dovetail Jig ...................... 4

Introduction ............................................................................................ ... . 5

Unpacking and Checking Contents .......................................................... 5

Assembly ..................................................... 6

Assembly of the Right Side Template Support to the Dovetail Base .................. 6

Assembly of

Assembly of

Assembly of

Assembly of

Assembly of

Assembly of

the Top Clamping Bar to the Dovetail Base .................................... 7

the Front Clamping Bar to the Dovetail Base ............................... 9

the Cam Handles and Pivot Shaft to the Dovetail Base ................ 10

the Front Stop Blocks to the Dovetail Base ................................ 13

the Top Stop Blocks to the Dovetail Base ........................................ 14

the Clamping Knobs to the Dovetail Base .................................... 14

Assembly of the Templates .......................................................................................... 15

Alignment of the Templates ..................................................................................... 16

Assembly of the Adapter Plate to the Router. ..................................................... 18

Assembly of the Guide Bushing to the Router ....................................................... 21

Installation ........................................................................ . ... . . . ..... . . . . .......... 22

Operation

Styles of Dovetail Joints ........................................................................................ 24

Half Blind Flush Joint ......................................................................................... 24

Half Blind Flush Offset Joint ............................................................................. 25

Half Blind Rabbeted Joint ................................................................................. 25

Open or Through Joint .................................................................................... 26

Adjusting the Depth-of-Cut of the Router Bit ...................................................... 26

Clamping the Workpieces to the Dovetail Base ................................................ 28

Making Drawers with Half Blind Flush Joints ..................................................... 29

Making Drawers with Half Blind Flush Offset Joints .......................................... 35

Making Drawers with Half Blind Rabbeted Joints .................................................. 35

Making Projects with Open (Through) Joints ....................................................... 37

Parts List .................................................................................................... 47

Page 3

SAFETY GUIDELINES - DEFINITIONS

This manual contains informa-

tion that is important for you to

know and understand. This

information relates to protect-

ing YOUR SAFETY and

PREVENTING EQUIPMENT

PROBLEMS. To help you rec-

ognize this information, we use

the symbols to the righL

Please read the manual and

pay attention to these sections.

IADANGER I

URGENT SAFETYINFORMATION-A

HAZARDTHATWILLCAUSESERF

OtISINJURYORLOSSOFLIFE

I,AWARNINGI

IMPORTANTSAFETYINFORMA-

TION_A HAZARD THATMIGHT

CAUSESERIOUSINJURYORLOSS

OFLIFE

I CAUTION]

INFORMATIONFORPREVENTING

DAMAGETOEQUIPMENT

[ NoTE]

INFORMATIONTHATYOUSHOULD

PAYSPECIALAITENTIONTO

['_WARNINGI Failure to heed all safety and operating instructions and warnings regarding use of this

product can result in serious bodily injury

1. Know your power tool

Read the owner's manual carefuify Learn its

application and limitations as welt as the specific potential

hazards peculiar to this tool

2. Ground all tools (unless double insulated)

If tool is equipped with an approved three-conductor cord

and a three-prong grounding type plug, it should be

plugged into a three hole electrical receptacle If adapter is

used to accommodate a two-hole receptacle, the adapter

wire must be attached

to a known ground (usually the screw securing

receptacle cover plate) Never remove third prong

Never connect green ground wire to a terminal

3. Keep guards in place

Maintain in working order, and in proper adjustment and

alignment

4. Remove adjusting keys and wrenches

Form a habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it ON

5, Keep work area clean

Cluttered areas and benches invite accidents

Ftoor must not be slippery due to wax or sawdust

6. Avoid dangerous environment

Do not use power tools in damp or wet locations

or expose them to rain Keep work area well lighted

Provide adequate surrounding work space

7. Keep children away

All visitors should be kept a safe distance from work

area

8. Make workshop child-proof

Use padlocks, master switches, or remove starter keys

9. Do not force tools

Do not force tool or attachment to do a job it was

not designed to perform

10. Use the right tool

They wifl do the job better and safer at the rate

for which they were designed

11. Wear correct apparel

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches) that may get caught

in moving parts Nomstip footwear is recommended Wear

protective hair covering to contain long hair Roll long

sleeves above the elbow

12. Use safety goggles (Head Protection)

Wear safety goggles (must comply with ANSI Standard

Z87 1) at all times A_so, use face or

dust mask, if cutting operation is dusty, and ear

protectors (plugs or muffs) during extended periods of

operation

13, Secure work

Use clamps or a vise to hold work when practical it's safer

than using your hands, and both hands

are free to operate tool

14. Do not overreach

Keep proper footing and balance at all times

15. Maintain tools with care

Keep tools sharp and clean for best and safest

performance Follow instructions for lubricating

and changing accessories

Page 4

16. Disconnect tools before servicing

Before servicing, when changing accessories

such as blades, bits, cutters, etc

17. Avoid accidental starting

Make sure swilch is in OFF position before plugging in

18. Use recommended accessories

Consult the owner's manual for recommended accessories

and follow the instructions The use

of improper accessories may cause hazards

19, Never stand on tool

Serious injury could occur if the tool is tipped or ff the cut_

ring _oot is accidentally contacted DO NOT store materi-

als above or near the tool making it

necessary to stand on the toot to reach them

20. Check damaged parts

Before further use of the Iool, any guard or other

part that is damaged should be carefully checked to

ensure that it will operate properly and perform its

intended function Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation A guard or any other part that is

damaged should be properly repaired or replaced

21. Direction of feed

: Feed work into a blade or Cutter AGAINST the

direction of rotation of the blade or cutter only

22. Never leave tool running unattended

Turn power OFF DO NOT leave tool until it comes

to a comptele stop

23. Keep hands away from cutting area

24. Store idle tools

When not in use, tools should be stored in dry,

high or locked-up place - out of reach of children

25. Do not abuse cord

Keep cord away from heat, oil and sharp edges

26. Outdoor extension cords

When tool is used outdoors, use only extension

cords suitable for use outdoors and so marked

27. Never use in an explosive atmosphere

Normal sparking of the motor could ignite fumes,

flammable liquids, or combustible items

28. Drugs, alcohol, medication

DO NOT operate tool while under the influence

of drugs, alcohol, or any medication

Read and Understand this instruction book

completely BEFORE using this product

1 Always wear eye protection that complies with

ANSI Standard Z87 1

2 Noise levels vary widely To avoid possible hearing

damage, wear ear plugs or muffs when using the

Dovetail Jig for hours at a time

3 For dusty operations, wear a dust mask along

with safety goggles

4 Do not use this Dovetail Jig with router bits or

guide bushings other than those specified for the

cuts being made

5 Follow the instructions in your Router Owner's

Manual

6 Vibrations caused by the router during use can

cause fasteners to become loose Before use and

periodically during use, check all fasteners to make

sure thatthey are all are tight and secure

7 Do net use this product until all assembly installa-

tion steps have been completed, and you have read

and understand all safeb/and operational instruc-

tions in this manual, and the Router Owners Manual

8 Make sure that the router bit is properly positioned

in the router so that it does not contact the guide

bushing or the template when cutting

9 The Dovetail Jig must be securely mounted to a

workbench or other stable surface when in use The

front of the base should overhang the front ofthe

workbench by no more than 1/4" to provide clear-

ance when clamping workpieces to the Dovetail Jig

10 Do not use the Dovetail Jig as a work surface

Doing so may cause damage to the Dovetail Jig,

which can cause it to be unsafe to use Aworkbench

should be used for this purpose

11 This product is designed to cut fiat workpieces

Do not cut or attempt to cut workpieces that are

not flat or that are irregularly shaped.

12 This product is to be used for cutting wood work-

pieces only Do not use this product to cut metal

or any other non-wood material.

13 This product has been designed to cut work-

pieces having thicknesses of 3/8" to 1" Do not use

Ior workpieces of any other thicknesses

14 Do not clamp any workpieces to the Dovetail Jig

or make any adjustments to the Dovetail Jig unless

the router has been turned off, the router bit is not

turning, and the Router has been disconnected from

the electrical outlet

15 When setting "the-depth-of-cut" of the router

bit, make sure that the workpiece is clamped to the

Dovetail Jig in such a manner that the router bit

does not cut into the Dovetail base causing dam-

age to it or possible serious injury to you.

Page 5

16 L'_WARNING_ ALWAYS UNPLUG THE

ROUTER FROM THE ELECTRICAL OUTLET

BEFORE INSTALLING OR REMOVING ROUTER

BITS FROM THE ROUTER AND WHEN ADJUST-

ING THE CUTTING DEPTH OF THE ROUTER BIT;

OR WHEN INSTALLING OR CHANGING GUIDE

BUSHINGS.

17 NEVER LIFT THE ROUTER UPWARDS WHEN

THE ROUTER IS "ON", THE ROUTER BtT IS

ROTATING, AND THE GUIDE BUSHING IS NEAR

OR TOUCHING THE TEMPLATE, BECAUSE THIS

WILL CAUSE THE ROUTER BIT TO CUT INTO

THE TEMPLATE AND DAMAGE IT

• Your Vermont American Industrial Dovetail Jig is an

accessory that is used with Routers allowing you to

make drawers, chests, and similar items requiring

dovetail joints The joints are used to make the front,

back, and sides of the workpiece

• Your Industrial Dovetail Jig comes with two tem-

plates and two guide bushings for making halt-blind

and through or open joints

• Your Industrial Dovetail Jig also comes with a

universal router adapter plate that will permit the

Industrial Dovetail Jig to be used with most popular

routers

• The Dovetail Jig will allow you to make 1"spaced

flush, flush-offset, and 3/8" rabbeted half-blind

dovetail joints

• The Dovetail Jig will also allow you to make t"

spaced open, or through, dovetail joints

• Workpieces up to 16"wide can be accommodated

oWorkpieces with thicknesses between 3f8" and 1"

can be accommodated

• The Dovetail Jig Base has six pockets molded into

its front which are gauges to aid you setting the

"depth-of- cut" for commonly used depths: 3/8", I/2",

5/8", 3/4", 7/8", and 1"

• Vermont American router bits, #22501 and #22437,

or Magna router bits, #M91113 and #M91016,

WHICH MUST BE PURCHASED SEPARATELY, are

required for making the THROUGH or OPEN joints

• Vermont American router bit, #22500, or

Magna router bit, #M91114, WHICH MUST BE

PURCHASED SEPARATELY, is required for making

the HALF-BLIND ioints

• Your Vermont American Industrial Dovetail Jig

comes with two templates and two guide bushings

Each of the templates has a label, describing the

joint that can be cut with it, along with set-up

information, the router bit and the guide bushing

required, and the the stop block setting for a

particular joint

Refer to Parts List on Page 47

• tn order to simplify handling and to minimize any

damage that may occur during shipping, your

Industrial Dovetail Jig is packaged assembled

• Separate all loose parts from the packing materials

and check each one with the illustrations and list of

parts at the end of this manual to make sure that

all loose parts are present before discarding any

packaging material

.i,A ,,anypartsarem,ss,ngorcannot

be accounted for, do not attempt to assemble, instaIl,

or use the Industrial Dovetail Jig until the missing

parts have been obtained and the product has been

assembled correctly

• Contact customer service at 1-800-742-3869,ext 8359

for missing or replacement parts

Page 6

ALTHOUGHYOURINDUSTRIALDOVETAILJIG

COMESASSEMBLED,THEFOLLOWINGASSEM-

BLY INSTRUCTIONS ARE BEING INCLUDED FOR

REFERENCE PURPOSES SHOULD IT BECOME

NECESSARY FOR YOU TO DISASSEMBLE AND

REASSEMBLE THE DOVETAIL JIG

PROCEED TO THE SECTION ALIGNMENT OF

THE TEMPLATES AND THEN CONTINUE WITH

THE SECTIONS FOLLOWING ALIGNMENT OF

THE TEMPLATES

THE TEMPLATES MUST BE ALIGNED BEFORE

ANY ROUTING tS TO TAKE PLACE

TOOLS REQUIRED

- A medium sized Phillips screwdSver

° A smafl or medium adjustable wrench

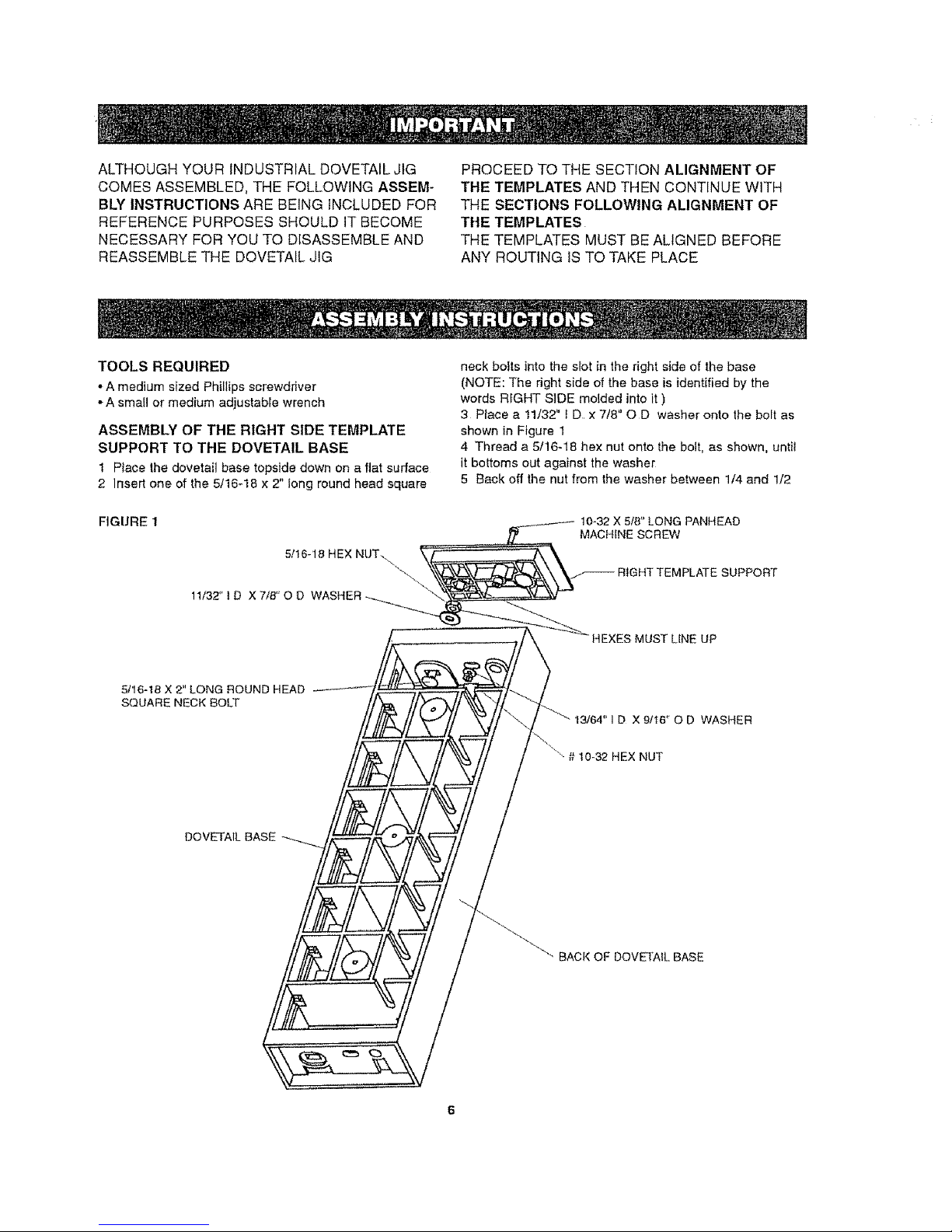

ASSEMBLY OF THE RIGHT SIDE TEMPLATE

SUPPORT TO THE DOVETAIL BASE

1 Ptace the dovetail base topside down on a fiat surface

2 insert one of the 5/16-18 x 2" long round head square

FIGURE 1

neck botts into the slot in the right side of the base

(NOTE: The right side of the base is identified by the

words RIGHT SIDE molded into it )

3 Place a 11/32" t D, x 7/8" OD washer onto the bolt as

shown in Figure 1

4 Thread a 5/16-18 hex nut onto the bolt, as shown, until

it bottoms out against the washer

5 Back off the nut from the washer between 1/4 and 1/2

10_32X 5/8" LONG PANHEAD

MACHINE SCREW

HEXES MUST LINE UP

5t16-18 X 2" LONG ROUND HEAD

SQUARE NECK BOLT

t3/64" I D X 9/t6" O D WASHER

"" # 10_32 HEX NUT

"" BACK OF DoVETAiL BASE

Page 7

!UrpSAlignthenutsothatthecomersofthenu_areverti-

calfyline_JUpasshownNotethealignmentofthehex

pocketinlhetemplatesupportTheboltshouldbefreeto

movesidetoside;ifitdoesnot,loosenthenut1/3turnor

untilthecornersofthenutpointupanddown

6 Assembletherighttemplatesupporttotherightsideof

the dovetail base so that the hex nut lines up and lits into

the hex pocket in the right template support (NOTE: The

right template support has the words RIGHT SIDE molded

into it for identification )

7 Assemble a #t0-32 x 5/8" long panhead machine screw,

a 13/64" I D x 9/16" O D washer, and a #10-32 hex nut to

lhe base as shown to hold the template support in place

Securely tighten thenut and screw : : •

8 The template support should move freely front to back

along the side of the base If it does not, it means that the

5/16-18 hex nut is too tight on the bolt and should be loos-

ened To do this, remove the fasteners assembled in step

7, and remove the template support; repeat steps 4

through 7

ASSEMBLE THE LEFT SIDE TEMPLATE SUPPORT TO

THE DOVETAIL BASE THE SAME AS THE RIGHT SIDE

TEMPLATE SUPPORT WAS ASSEMBLED.

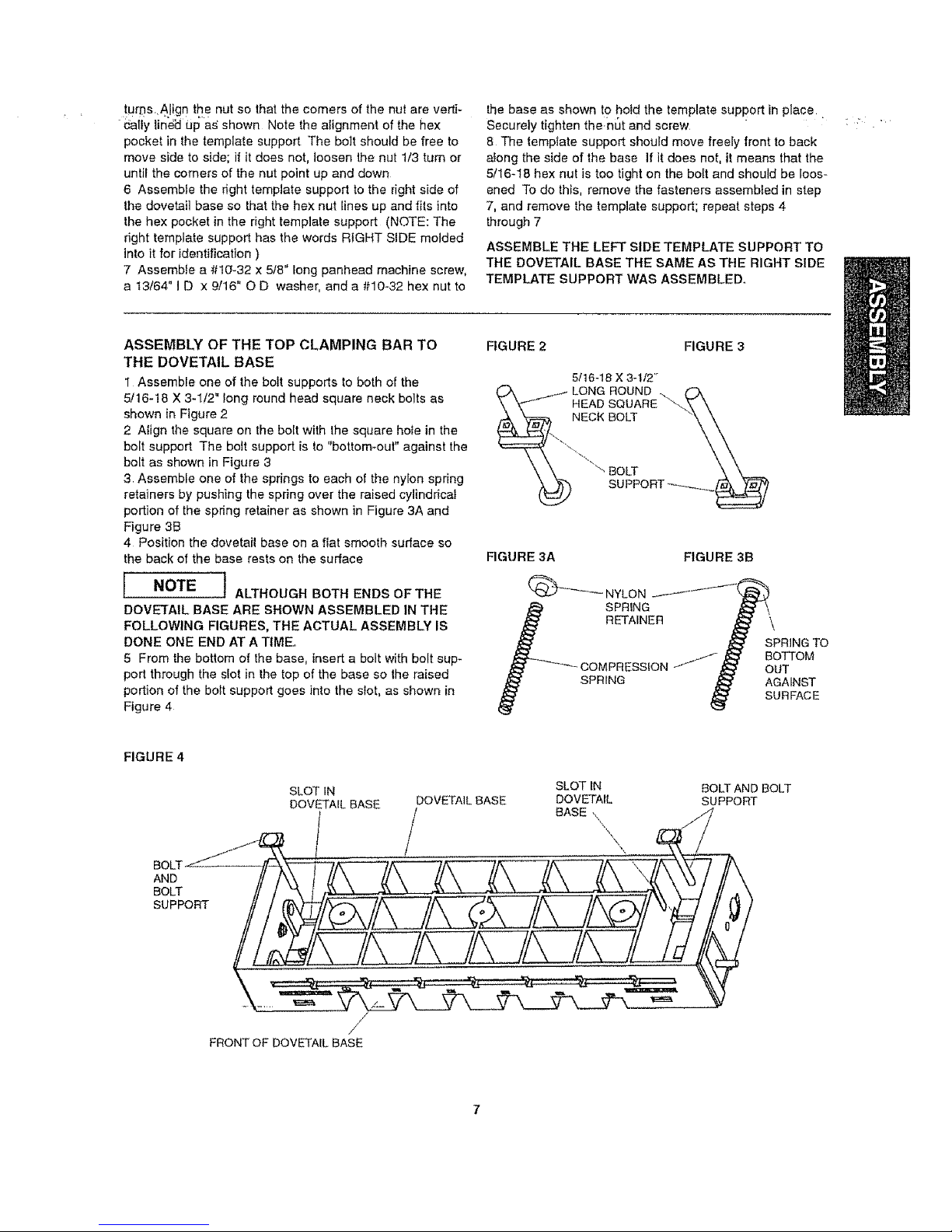

ASSEMBLY OF THE TOP CLAMPING BAR TO

THE DOVETAIL BASE

1 Assemble one of the bolt supports to both of the

5/16-18 X 3-l/2" long round head square neck bolts as

shown in Figure 2

2 Align the square on the bolt with lhe square hole in the

bolt support The bolt support is to "bottom-out" against the

bolt as shown in Figure 3

3, Assemble one of the spdngs to each of the nylon spring

retainers by pushing the spring over the raised cylindrical

portion of the spring retainer as shown in Figure 3A and

Figure 3B

4 Position the dovetail base on a fiat smooth surface so

the back of the base rests on the surface

[ NOTE ] ALTHOUGH BOTH ENDS OF THE

DOVETAIL BASE ARE SHOWN ASSEMBLED IN THE

FOLLOWING FIGURES, THE ACTUAL ASSEMBLY IS

DONE ONE END AT A TIMEo

5 From the bottom of the base, insert a bolt with bolt sup-

port through the slot in the top of the base so the raised

portion of the bolt support goes into the slot, as shown in

Figure 4

FIGURE 2

FIGURE 3A FIGURE 3B

(_ NYLON

SPRING

RETAINER

COMPRESSION /'J_f

SPRING

SPRING TO

BOTTOM

OUT

AGAINST

SURFACE

FIGURE 4

BOLT 11/

SLOT IN

DOVETAIL BASE DOVETAIL BASE

/ /

SLOT IN

DOVETAIL

BASE k

q

X

\

BOLT AND BOLT

SUPPORT

/

/

FRONT OF DOVETAIL BASE

Page 8

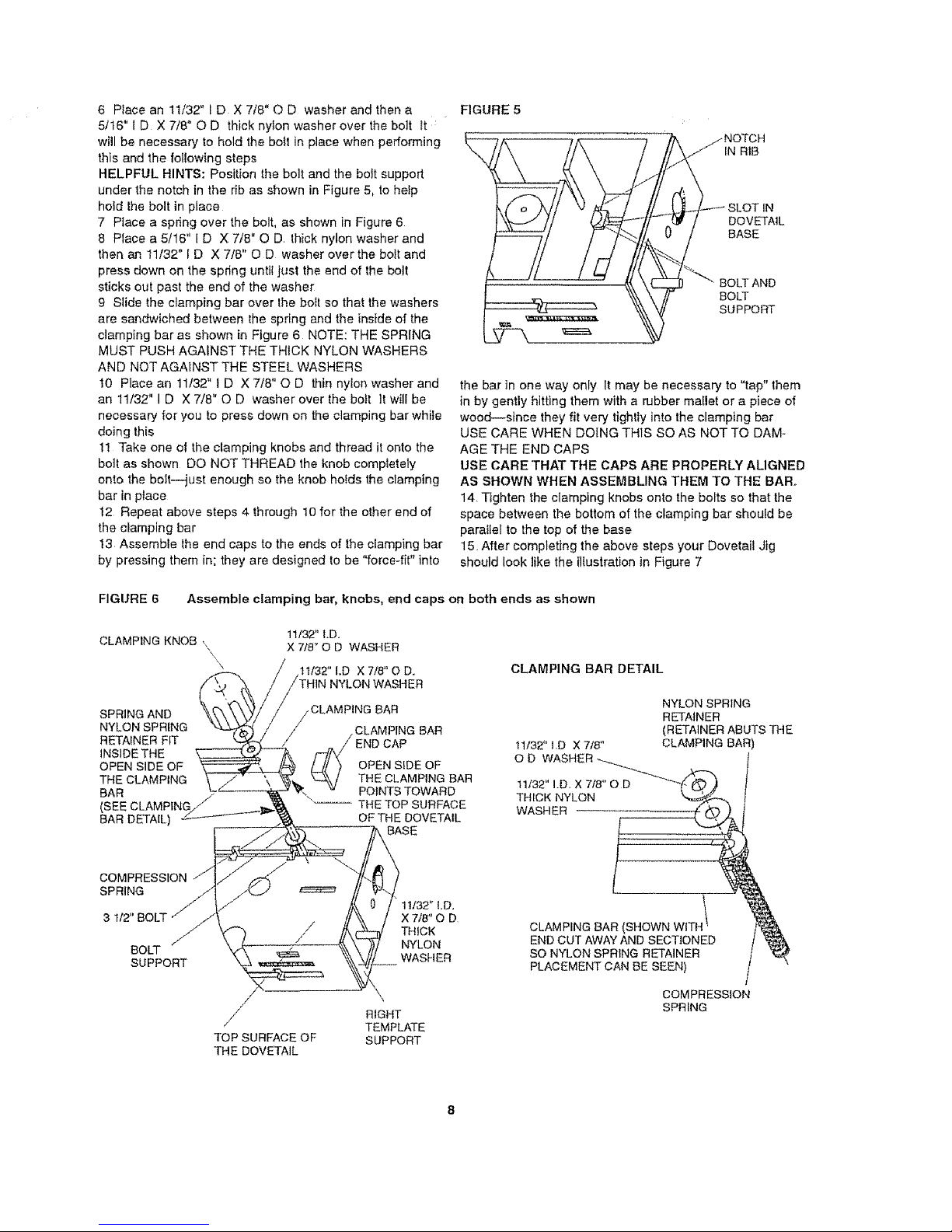

6 Placean11/32"IDX7/8"ODwasherandthena

5/16"ID X7/8"OD thicknylonwasherovertheboltIt

willbenecessarytoholdtheboilinplacewhenperforming

thisandthefollowingsteps

HELPFULHINTS:Positiontheboltandtheboltsupport

underthenotchintheribasshowninFigure5,tohelp

holdtheboltinplace

7 Placeaspringoverthebolt,asshowninFigure6

8 Placea5/16"IDX7/8"QD thicknylonwasherand

thenan!1/32"ID X7/8"OD washerovertheboiland

pressdownonthespringuntiljusttheendofthebolt

sticksoutpasttheendofthewasher

g Slidetheclampingbaroverthebollsothatthewashers

aresandwichedbetweenthespringandtheinsideofthe

clampingbarasshowninFigure6 NOTE:THESPRING

MUSTPUSHAGAINSTTHETHICKNYLONWASHERS

ANDNOTAGAINSTTHESTEELWASHERS

t0 Placean11/32"tD X7/8"OD thinnylonwasherand

an11/32"ID X7/8"ODwasheroverthebellItwilibe

necessaryforyoutopressdownontheclampingbarwhile

doingthis

11Takeoneoftheclampingknobsandthreaditontothe

boilasshownDONOTTHREADtheknobcompletely

ontothebolt--justenoughsotheknobhoidstheclamping

barinplace

t2 Repeatabovesteps4through10fortheotherendof

theclampingbar

13Assembletheendcapstotheendsoftheclampingbar

bypressingthemin;theyaredesignedtobe"force-fit"into

FIGURE5

j NOTCH

IN RIB

._---- SLOT IN

DOVETAIL

BASE

BOLT AND

BOLT

SUPPORT

the bar in one way only It may be necessary to "tap" them

in by gently hitting them with a rubber mallet or a piece of

wood--since they fit very tlgh|ty into the clamping bar

USE CARE WHEN DOING THIS SO AS NOT TO DAM-

AGE THE END CAPS

USE CARE THAT THE CAPS ARE PROPERLY ALIGNED

AS SHOWN WHEN ASSEMBLING THEM TO THE BAR,,

14. Tighten the clamping knobs onto the bolts so that the

space between the bottom of the clamping bar should be

parallel to the top of the base

15 After completing the above steps your Dovetail Jig

should look like the illustration in Figure 7

FIGURE 6 Assemble clamping bar, knobs, end caps on both ends as shown

CLAMPING KNOB , 11/32" I.D.

',\ X 7/8" O D WASHER

\

" !t/32" I.D X 7/8" O D.

CLAMPING BAR DETAIL

SPRING AND

NYLON SPRING

RETAINER FIT

]NSlDE THE

OPEN SIDE OF

THE CLAMPING

BAR

(SEE CLAMPING

BAR DETAIL)

COMPRESSION

SPRING

3 t12"

j/*

BOLT

SUPPORT

// l

//Z-

TOP SURFACE OF

THE DOVETAIL

CLAMPING BAR

•CLAMPING BAR

f_END CAP

L_.! ) OPEN SIDE OF

_-_\/ THE CLAMPING BAR

POINTS TOWARD

"_ THE TOP SURFACE

OF THE DOVETAIL

i BASE

€/1t132" I.D.

_, /X 7/8" O D

/THICK

-_ NYLON

__._WASHER

RIGHT

TEMPLATE

SUPPORT

NYLON SPRING

RETAINER

(RETAINER ABUTS THE

11/32" I,D X 7/8" CLAMPING BAR

O D WASHER __

WASHER .--[ _,

CLAMP,NG AB S.OWNW,THI

END CUT AWAY AND SECTIONED

SO NYLON SPRING RETAINER

PLACEMENT CAN BE SEEN)

COMPRESSION

SPRING

Page 9

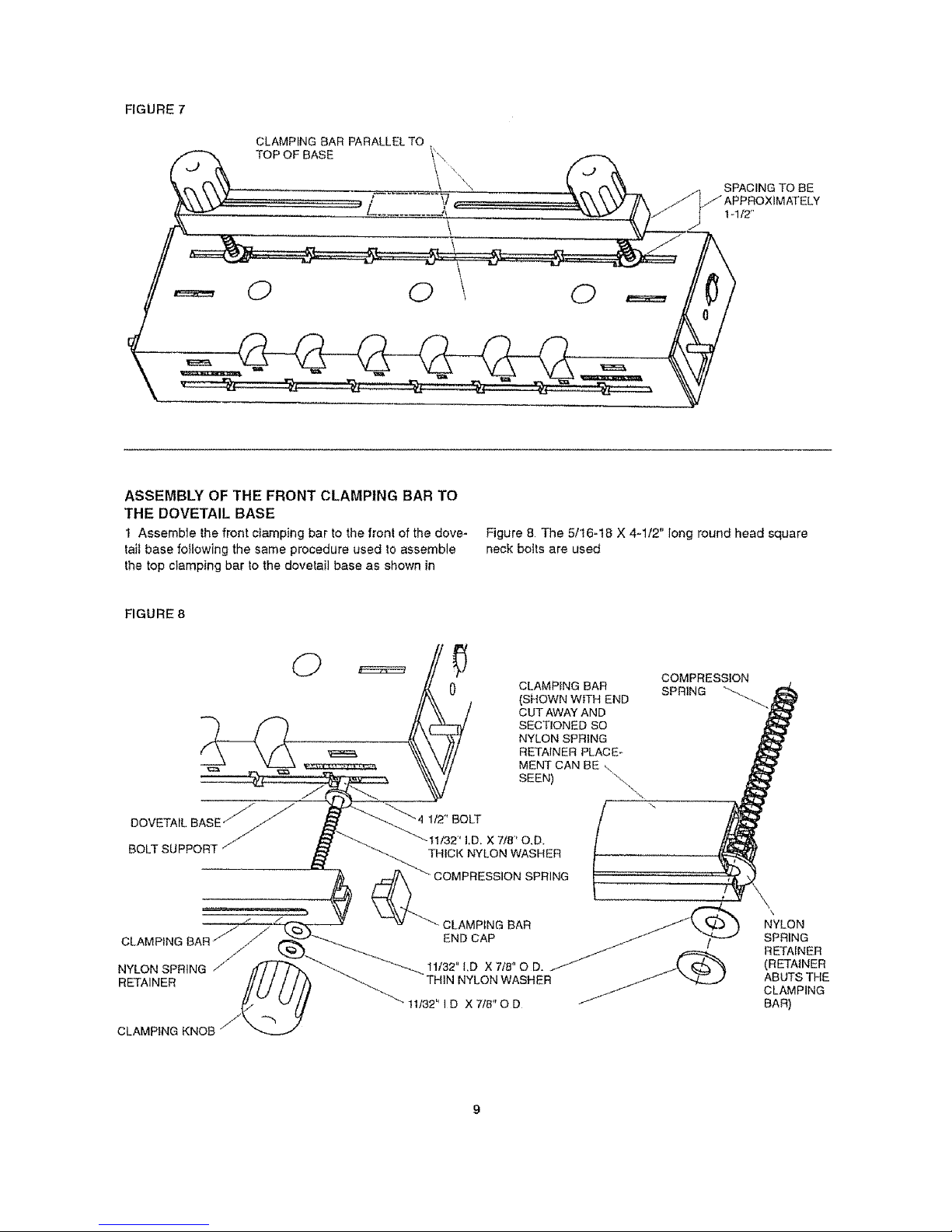

FIGURE7

CLAMPINGBARPARALLELTO

TOPOFBASE

0 0 0

SPACING TO BE

// APPROXIMATELY

t-112"

ASSEMBLY OF THE FRONT CLAMPING BAR TO

THE DOVETAIL BASE

t Assemble the front clamping bar !o the front of the dove-

tail base following the same procedure used Io assemble

the top clamping bar to the dovetail base as shown in

Figure 8 The 5/16-18 X 4-1/2" long round head square

neck bolts are used

FIGURE 8

DOVETAIL

BOLT SUPPORT j7

CLAMPING BAR f

NYLON SPRING /'t"

RETAINER

CLAMPING BAR

(SHOWN WITH END

CUT AWAY AND

SECTIONED SO

NYLON SPRING

RETAINER PLACE r

MENT CAN BE ,.

SEEN) "\,

\.

COMPRESSION

SPRING "__

1/2" BOLT

!1/32' I.D. X 7/8' O.D.

THICK NYLON WASHER

COMPRESSION SPRING

• CLAMPING BAR

END CAP

11132"I,D X 7/8" 0 D.

THIN NYLON WASHER

tt/32" I D X 7/8" O D

\\

\

NYLON

SPRING

RETAINER

(RETAINER

ABUTS THE

CLAMPING

BAR)

CLAMPING KNOB

Page 10

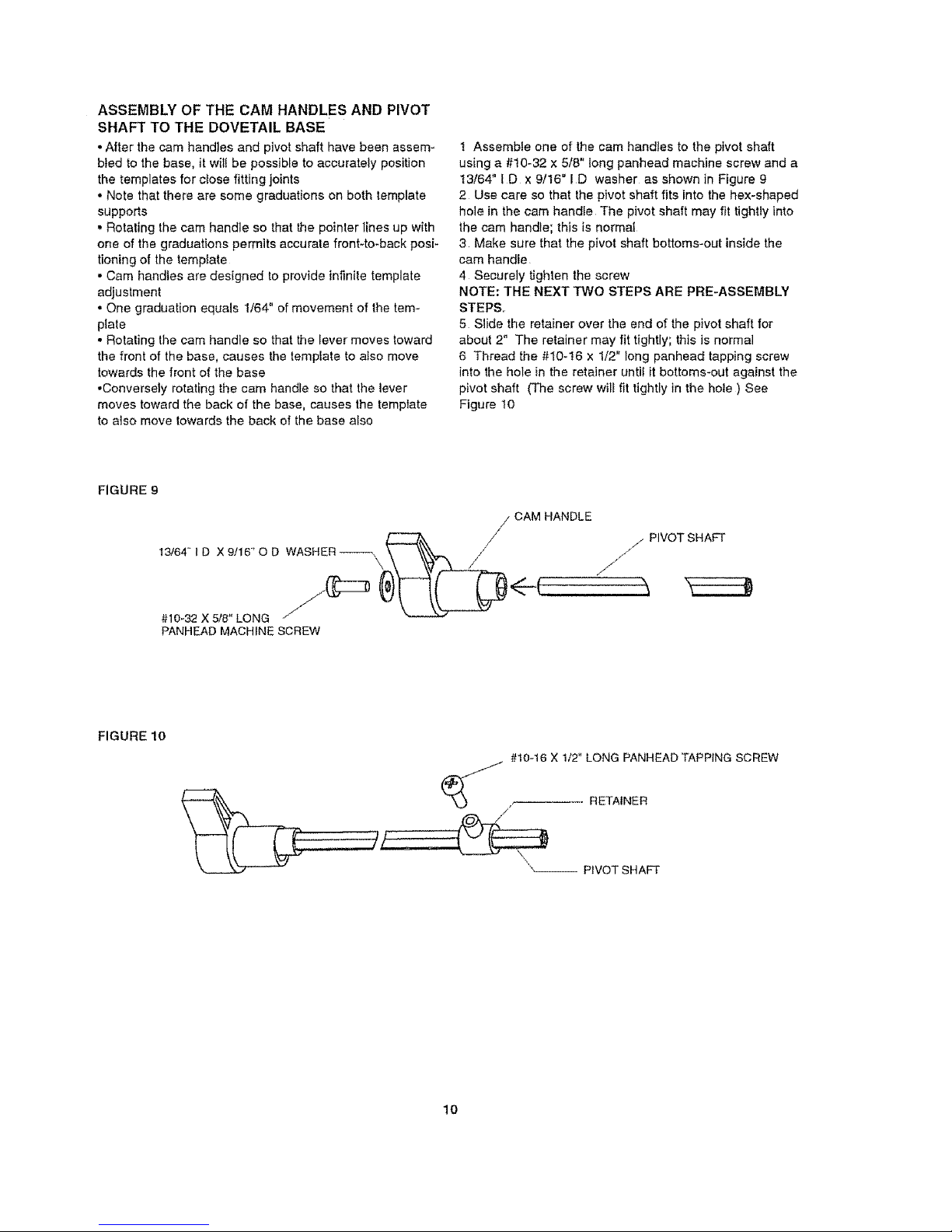

ASSEMBLYOFTHECAMHANDLESANDPIVOT

SHAFTTOTHEDOVETAILBASE

• After the cam handles and pivot shaft have been assem _

bled to the base, it wil! be possible to accurately position

the templates for close fitting joints

• Note that there are some graduations on both template

supports

• Rotating the cam handle so that the pointer lines up with

one of the graduations permits accurate front-to-back posi-

tioning of the template

• Cam handles are designed to provide infinite template

adjustment

• One graduation equals 1/64" of movement of the tem-

plate

• Rotating the cam handle so that the lever moves toward

the front of the base, causes the template to also move

towards the lront of the base

• Conversely rotating the cam handle so that the lever

moves toward the back of the base, causes the template

to also move Iowards the back of the base also

1 Assemble one of the cam handles to the pivot shaft

using a #10-32 x 5/8" tong panhead machine screw and a

13/64" I D x 9/16" ID washer as shown in Figure 9

2 Use care so that the pivot shaft fits into the hex-shaped

hole in the cam handle The pivot shaft may fit tightly into

the cam handle; this is normal

3 Make sure that the pivot shaft bottoms-out inside the

cam handie

4 Securely tighten the screw

NOTE: THE NEXT TWO STEPS ARE PRE-ASSEMBLY

STEPS.

5 Slide the retainer over the end of the pivot shaft for

about 2" The retainer may fit tightly; this is normal

6 Thread the #10-16 x 1/2" long panhead tapping screw

into the hole in the retainer until it bottoms-out against the

pivot shaft (The screw will fit tightly in the hole ) See

Figure 10

FIGURE 9

13/64"1D X 9/16_'O D WASHER _\

\

#10_32.X5/8" LONG /

PANHEAD MACHINE SCREW

/ CAM HANDLE

/ _ PIVOT SHAFT

J j

<--LT-,:

FIGURE 10

#10-16 X 1/2" LONG PANHEAD TAPPING SCREW

_ RETAINER

/

x\__ PIVOT SHAFT

10

Page 11

7 LoosenthescrewaboutoneturnRemovetheretainer

fromtheshaftandsetitasidetemporarily

8Assernblethepivotshaftwithcamhandletothebaseby

insertingtheendofthepivotshaftthroughtheholesinthe

righttemplatesupportandthebase

9 MAKESURETHEORIENTATIONOF THE CAM HAN-

DLE IS AS SHOWN IN FIGURE 11

10 Place the retainer at the location shown in Figure 12

and push the pivot shaft through THE ORIENTATION OF

FIGURE 11

CAM HANDLE

PIVOT SHAFT ._

HOLE IN BASE

THE RETAINER RELATIVE TO THE CAM HANDLE WITH

SCREW MUST BE AS SHOWN

NOTE: THE RETAINER MAY FIT TIGHTLY ON THE

PIVOT SHAFT; THIS IS NORMAL,,

11 Continue pushing the pivot shaft through the holes and

the retainer until the end of the pivot shaft extends out of

the teft template support as show in Figure 12

12 Make sure the end of the cam handle fits into the hole

in the base as shown

// RETAINER

RIGHT TEMPLATE

DOVETAIL BASE /

RGURE 12

CAM

HANDLE

HOLE IN BASE

PIVOT SHAFT

i,vo

• ._ ........ HOLE tN

BASE

iA ............../LJJ

11

Page 12

13Withthecamhandlepushedinagainstthebase,

positiontheretaineragains!thesidewallofthebase,as

showninFigure13Theretainershouldbarelytouchthe

sidewallofthebaseThepurposeoftheretaineristo

preventorminimizetheside-to-sideofthecamhandleand

pivotshaft

14Assembletheothercamhandletotheotherendofthe

pivotshaftusinga13/64"1Dx9/16"ODwasherand

a#10-32X5/8"longpanheadmachinescrew,asshownin

Figure14

15Makesurethatthecamhandlelinesupwiththecam

handleattheotherendofthepivotshaftandthattheend

of the cam handle fits into the hole in the base

16 Tighten the screw securely

17 Rotate one of the cam handles-It should rotate freely

and move the template supports

18 If this does not happen, loosen the screw on the retain-

er and move the retainer away from the side wall slightly

19 Securely retighten the screw

20 If there is too much side-to-side movement (play) of

the cam handles; loosen the screw in the retainer and

move the retainer closer to the side wall of the base

21 Securely retighten the screw

FIGURE 13

_LOF BASE

FIGURE 14

LEFT TEMPLATE SUPPORT

j PIVOT SHAFT

/

J // / #t0_32 X 5/8" LONG

\

\ X 9/16" O D WASHER

\" CAM HANDLE

12

Page 13

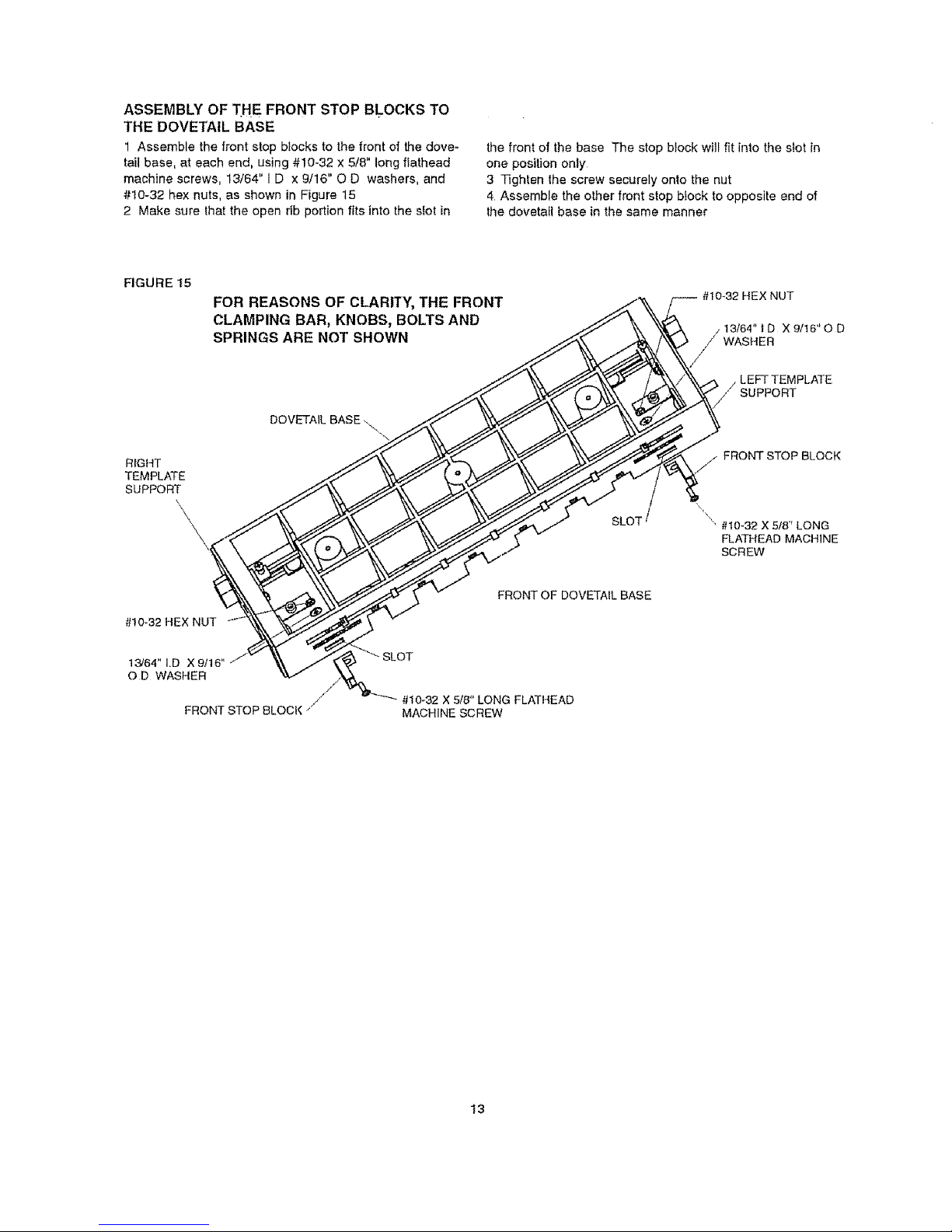

ASSEMBLY OF THE FRONT STOP BLOCKS TO

THE DOVETAIL BASE

1 Assemble the front stop blocks to the front of the dove-

tail base, at each end, using #10-32 x 5/8" long flathead

machine screws, 13/64" I D x 9/16" O D washers, and

#!0-32 hex nuts, as shown in Figure 15

2 Make sure that the open rib portion fits into the slot in

the front of the base The stop block will fit into the slot in

one position only

3 Tighten the screw securely onto the nut

4 Assemble the other front stop block to opposite end of

the dovetail base in the same manner

FIGURE 15

FOR REASONS OF CLARITY, THE FRONT

CLAMPING BAR, KNOBS, BOLTS AND

SPRINGS ARE NOT SHOWN

DOVETAIL BASE

RIGHT _

TEMPLATE ../.,.._ \'_ 7

SUPPORT _____/_\ _ "_

\\

OD WASHER V /i,'_&.

FRONT STOP BLOCK /

,,o 32HExNUT

/L%;f PLATE

_T_// FRONT STOP BLOCK

" #10-32 X 5/8" LONG

FLATHEAD MACHINE

SCREW

FRONT OF DOVETAIL BASE

#t0-,32 X 5/8" LONG FLATHEAD

MACHINE SCREW

t3

Page 14

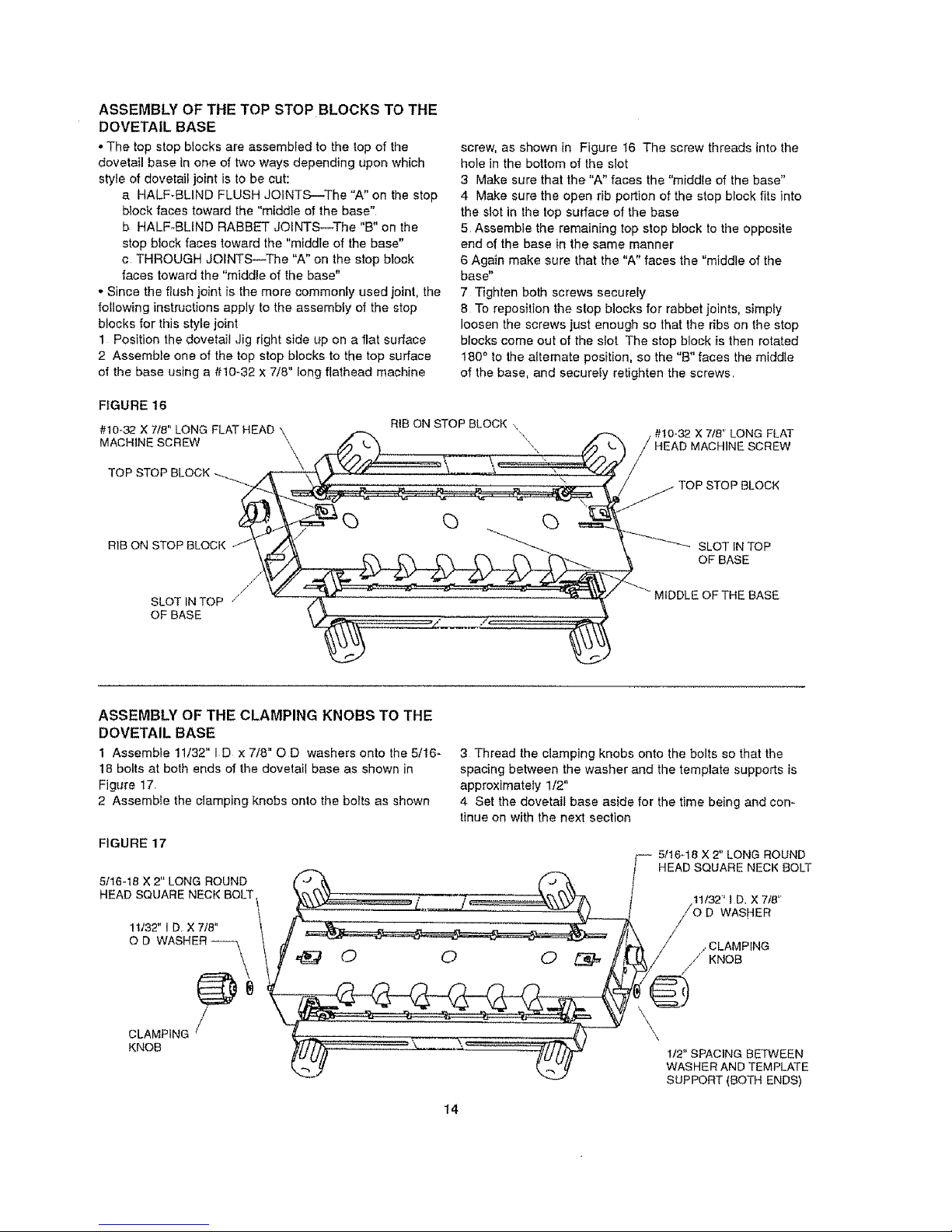

ASSEMBLY OF THE TOP STOP BLOCKS TO THE

DOVETAIL BASE

• The top stop blocks are assembled to the top of the

dovetail base in one of two ways depending upon which

style of dovetail joint is to be cut:

a HALF-BLIND FLUSH JOINTS--The "A" on the stop

block faces toward the "middle of the base"

b HALF-BLIND RABBET JOiNTS--The "B" on the

stop block faces toward the "middle of the base"

c THROUGH JOINTS---The "A" on the stop block

faces toward the "middle of the base"

, Since the flush joint is the more commonly used joint, the

following instructions apply to the assembly of the stop

blocks for this style joint

1 Position the dovetait Jig right side up on a flat surface

2 Assemble one of the top stop blocks to the top surface

of the base using a #10-32 x 7/8" long flathead machine

screw, as shown in Figure t6 The screw threads into the

hole in the bottom of the slot

3 Make sure that the "A" faces the "middte of the base"

4 Make sure the open rib portion of the stop block fits into

the slot in the top surface of the base

5 Assemble the remaining top stop block to the opposite

end of the base in the same manner

6 Again make sure that the "A" faces the "middle of the

base"

7 Tighten both screws securely

8 To reposition the stop blocks for rabbet joints, simpty

loosen the screws just enough so that the dbs on the stop

blocks come out of the slot The stop block is then rotated

180 ° to the attemate position, so the "B" faces the middle

of the base, and securefy retighten the screws

FIGURE 16

#10-32 X 7/8" LONG FLAT HEAD \

MACHINE SCREW

\

TOP STOP BLOCK

RIB ON STOP BLOCK ,

\\

#10-32 X 7/8" LONG FLAT

MACHINE SCREW

RIB ON STOP BLOCK

/'

SLOT IN TOP //

OF BASE

SLOT IN TOP

OF BASE

BASE

ASSEMBLY OF THE CLAMPING KNOBS TO THE

DOVETAIL BASE

1 Assemble 11/32" ID x 7/8" O D washers onto the 5/!6-

18 bolts at both ends of the dovetail base as shown in

Figure 17.

2 Assemble the clamping knobs onto the bolts as shown

FIGURE 17

5/16-18 X 2" LONG ROUND

HEAD SQUARE NECK BOLT

1t132" I D X 7/8"

OD

3 Thread the clamping knobs onto the bolts so that the

spacing between the washer and the template supports is

approximately 1/2"

4 Set the dovetail base aside for the time being and con-

tinue on with the next section

5/16-18 X 2" LONG ROUND

HEAD SQUARE NECK BOLT

/ CLAMPING

// KNOB

CLAMPING /

KNOB

14

\

1/2" SPACING BETWEEN

WASHER AND TEMPLATE

SUPPORT (BOTH ENDS)

Page 15

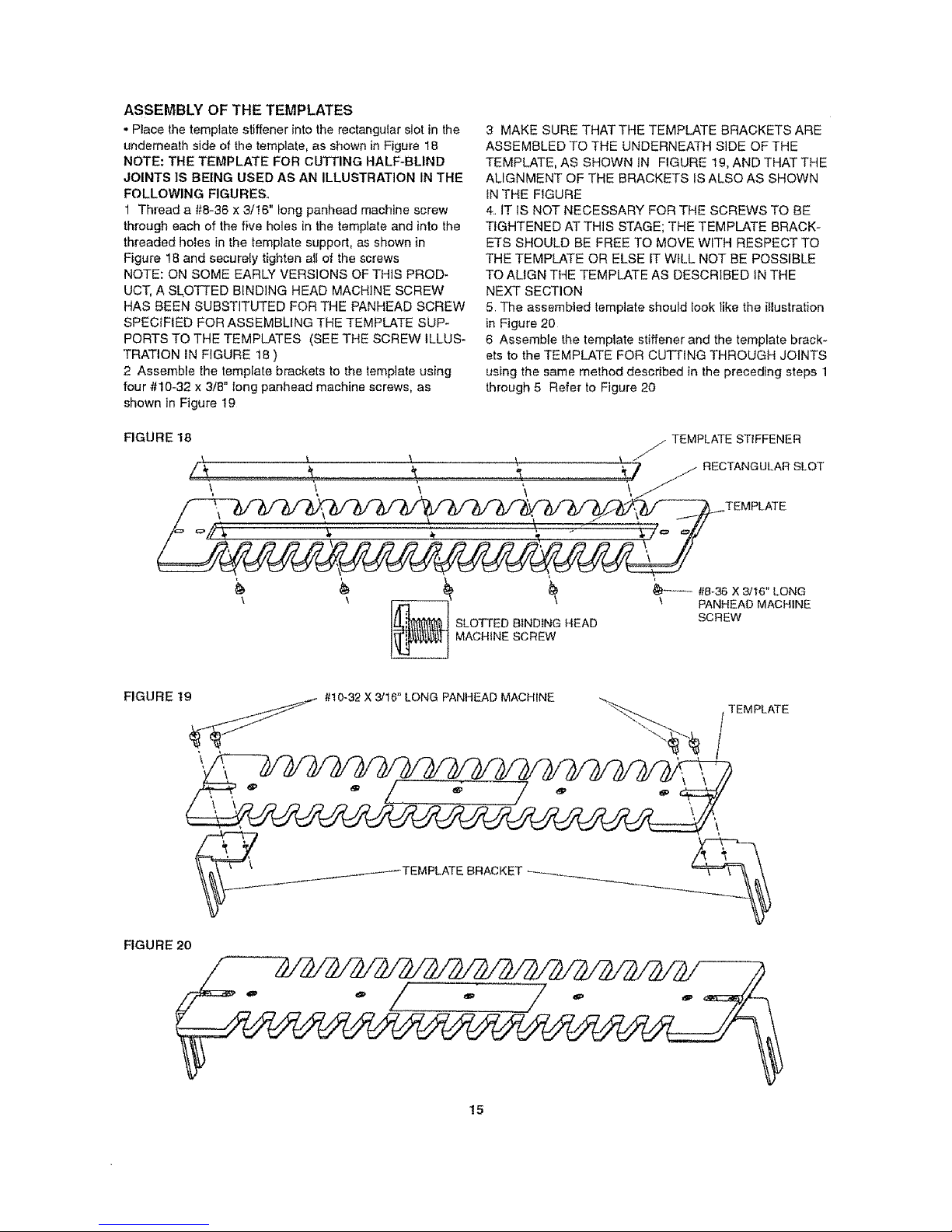

ASSEMBLY OF THE TEMPLATES

• Ptace the template stiffener into the rectangular slot in the

underneath side of the template, as shown in Figure 16

NOTE: THE TEMPLATE FOR cUTTING HALF-BLIND

JOINTS 1S BEING USED AS AN ILLUSTRATION IN THE

FOLLOWING FIGURES.

1 Thread a #8-36 x 3/16" long panhead machine screw

through each of the five holes in the template and into the

threaded holes in the template support, as shown in

Figure 18 and securely tighten all of the screws

NOTE: ON SOME EARLY VERSIONS OF TH1S PROD-

UCT, A SLOTTED BINDING HEAD MACHINE SCREW

HAS BEEN SUBSTITUTED FOR THE PANHEAD SCREW

SPECIFIED FOR ASSEMBLING THE TEMPLATE SUP-

PORTS TO THE TEMPLATES (SEE THE SCREW ILLUS-

TRATION IN FIGURE 18 )

2 Assemble the template brackets to the template using

four #10-32 x 3/8" long panhead machine screws, as

shown in Figure t9

3 MAKE SURE THAT THE TEMPLATE BRACKETS ARE

ASSEMBLED TO THE UNDERNEATH SIDE OF THE

TEMPLATE, AS SHOWN IN FIGURE lg, AND THAT THE

ALIGNMENT OF THE BRACKETS iS ALSO AS SHOWN

IN THE FIGURE

4., IT IS NOT NECESSARY FOR THE SCREWS TO BE

TIGHTENED AT THIS STAGE; THE TEMPLATE BRACK-

ETS SHOULD BE FREE TO MOVE WITH RESPECT TO

THE TEMPLATE OR ELSE IT WILL NOT BE POSSIBLE

TO ALIGN THE TEMPLATE AS DESCRIBED iN THE

NEXT SECTION

5 The assembled template should took like the illustration

in Figure 20

6 Assemble the template stiffener and the template brack-

ets to the TEMPLATE FOR CUTTING THROUGH JOINTS

using the same method described in the preceding steps 1

through 5 Refer to Figure 20

FIGURE 18

\ \ \

!_' _ TEMPLATE STIFFENER

RECTANGULAR SLOT

TEMPLATE

\ \ \

SLOTTED BINDING HEAD

MACHINE SCREW

_--- #8-36 X 3/t6" LONG

\ PANHEAD MACHINE

SCREW

\

\ '\

\

/TEMPLATE BRACKET "_--,o

TEMPLATE

FIGURE 20

15

Page 16

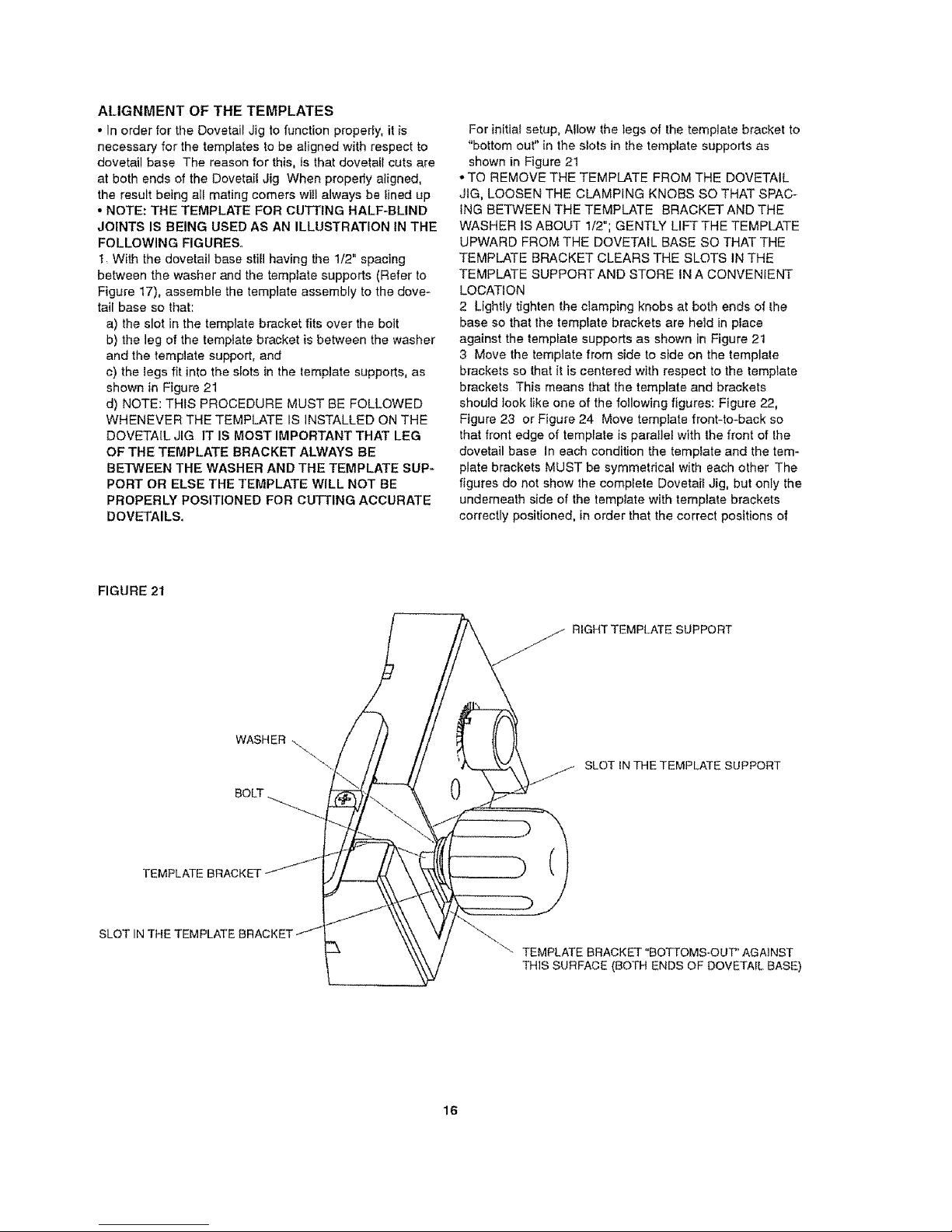

ALIGNMENTOFTHETEMPLATES

• In order for the Dovetail Jig to function properly, it is

necessary' for the templates to be aligned with respect to

dovetail base The reason for this, is that dovetail cuts are

at both ends of the Dovetail Jig When properly aligned,

the result being all mating comers wi}l always be lined up

• NOTE: THE TEMPLATE FOR CUTTING HALF-BLIND

JOINTS IS BEING USED AS AN ILLUSTRATION IN THE

FOLLOWING FIGURES°

t= With the dovetail base stiB having the 1/2" spacing

between the washer and the template supports (Refer to

Figure 17), assemble the template assembly to the dove-

tail base so that:

a) the slot in the template bracket fits over the bo_t

b) the leg of the template bracket is between the washer

and the template support, and

c) the legs fit into the slots in the template supports, as

shown in Figure 21

d) NOTE: THIS PROCEDURE MUST BE FOLLOWED

WHENEVER THE TEMPLATE iS INSTALLED ON THE

DOVETAIL JIG IT IS MOST IMPORTANT THAT LEG

OF THE TEMPLATE BRACKET ALWAYS BE

BETWEEN THE WASHER AND THE TEMPLATE SUP-

PORT OR ELSE THE TEMPLATE WILL NOT BE

PROPERLY POSITIONED FOR CUTTING ACCURATE

DOVETAILS,

For initia! setup, Allow the legs of the template bracket to

"bottom out" in the slots in the template supports as

shown in Figure 21

• TO REMOVE THE TEMPLATE FROM THE DOVETAIL

JIG, LOOSEN THE CLAMPING KNOBS SO THAT SPAC-

ING BETWEEN THE TEMPLATE BRACKET AND THE

WASHER IS ABOUT 1/2"; GENTLY LIFTTHE TEMPLATE

UPWARD FROM THE DOVETAIL BASE SO THAT THE

TEMPLATE BRACKET CLEARS THE SLOTS IN THE

TEMPLATE SUPPORT AND STORE IN A CONVENIENT

LOCATION

2 Lightly tighten the clamping knobs at both ends of the

base so that the template brackets are he]d in place

against the template supports as shown in Figure 21

3 Move the template from side to side on the templale

brackets so Ihat it is centered with respect to the template

brackets This means that the template and brackets

should took like one of the following figures: Figure 22,

Figure 23 or Figure 24 Move template front-to-back so

that front edge of template is parallel with the front of the

dovetail base In each condition the template and the tem-

plate brackets MUST be symmetrical with each other The

figures do not show the complete Dovetail Jig, but only the

underneath side of the tempJate with template brackets

correctly positioned, in order that the correct positions of

FIGURE 21

jj RtGHTTEMPLATE SUPPORT

BOLT

/ SLOT tN THE TEMPLATE SUPPORT

TEMPLATE BRACKET

SLOT

L

TEMPLATE BRACKET "BOTTOMS-OUT" AGAINST

THIS SURFACE (BOTH ENDS OF DOVETAIL BASE)

16

Page 17

FIGURE22

(

O O

DISTANCE BETWEN THESE

SURFACES MUST BE EQUAL

AT BOTH ENDS

TEMPLATE BRACKET

CONDITION ONE: TEMPLATE BRACKETS PROTRUDE BEYOND TEMPLATES

FIGURE 23

'O

TEMPLATE BRACKET

CONDITION TWO: TEMPLATE PROTRUDES BEYOND TEMPLATES BRACKETS

FIGURE 24

rLr

olio

________---_ TEMPLATE

AT BOTH ENDS

0

-TEMPLATE BRACKET

CONDITION THREE: TEMPLATE EVEN WITH TEMPLATE BRACKETS

17

Page 18

4 Afterthetemplatebracketshavebeencorrectlyposi-

tionedonthetemplatesecurelytightenthefourscrews

holdingthe template brackets to the template

5 Remove the template assembly from the base and set it

aside for now

6 Align the other template assembly in the same manner

IT SHOULD BE NOTED THAT YOU MAY FIND, THAT

AFTER MAKING SOME SAMPLE CUTS, SLIGHT

FIGURE 25

TEMPLATE BRACKET ,\

THE TEMPLATE EXTENDS

BEYOND THE TEMPLATE

BRACKET

ADJUSTMENTS MAY BE REQUIRED HOW TO MAKE

THESE ADJUSTMENTS IS EXPLAINED IN TWO OF THE

FOLLOWING SECTIONS: "TROUBLESHOOTING FOR

HALF BLIND JOINTS" or "TROUBLESHOOTING FOR

OPEN (THROUGH) JOINTS"

7 Remove the template assembly from the base and

set it aside for now (Figure 25 below, is an example of

INCORRECTLY positioned template brackets )

TEMPLATE ,

\,,\

o o

BRACKET EXTENDS

BEYOND THE

TEMPLATE

CONDITION FOUR: THIS CONDITION IS NOT CORRECT -

TEMPLATE BRACKET EXTENDS BEYOND THE TEMPLATE AND

THE TEMPLATE EXTENDS BEYOND THE TEMPLATE BRACKET

• SIMPLY MAKE SURE BRACKETS ABE POSmONED THE SAME AT EACH END

ASSEMBLY OF THE ADAPTER PLATE TO THE

ROUTER

[A¢kWARNING]

ALWAYS MAKE SURE THATTHE ROUTER IS q*URNED

OFF" AND THATTHE ELECTRICAL CORD HAS BEEN

UNPLUGGED FROM THE ELECTRICAL OUTLET

BEFORE ASSEMBLING THE ADAPTER PLATE AND A

GUIDE BUSHING TO THE ROUTER; OR WHEN MAKING

ANY ADJUSTMENTS, OR CHANGING ROUTER BITS IN

THE ROUTER

1 Remove any router bit currently installed in the router

FIGURE 26

SCREW ':a_'_,

i i

J I

t I

I I

1 I

t I

SCREW "b"_\

I I

I I

I I

t I

I I

I I

I I

I I

I I

I I

i i

2 Remove the router base plate now on the router, by

removing the screws holding the base plate to timerouter

3 Depending on the make of router, either three or four of

the loIIowing screw types and sizes will have been used:

a) #8 ( 164 dia) Pan Head Screw

b) #t0 (I90 din) Pan Head Screw

c) #8 ( 164 din) Flat Countersunk Head Screw

d) #10 ( t90 dia) Flat Countersunk Head Screw

4 Compare the screws removed with those shown in

Figure 26

SCREW 'c"

I 1

I 1

I 1

i 1

i t

SCREW "d"

I t

i *

18

Page 19

5 If the screws look like Screw "a" or Screw "b", use either

three or four of the 13/64" ID x 15/32" OD washers when

installing the adapter plate to the router as shown in

Figure 27

6 Your Dovetail Jig comes with four countersunk bushings

with an 11/64" hole and four countersunk bushings with a

13/64" hole Refer to Figure 28

FIGURE 27

7 If the screws look like Screw "c", use either three or four

of the bushings with an 11/64" din hofe when installing

the adapter plate to the router as shown in Figure 29

8 If the screws look like Screw "d", use either three or four

of the bushings with a 13/64" dia hole when installing the

adapter plate to the router as shown above in Figure 29

FIGURE 28

SCREW

PAN HEAD

SCREW

, PAN HEAD SCREW

i/WASHER

//PAN HEAD SCREW

(_jWASHER

4

4

0 11/32

--O t1/64

O 25/64

F O 13/64

FIGURE 29

HEAD

SCREW

BUSHING--.-.

WITH Oll/64

HOLE

SCREW

BUSHING

Oll/64 HOLE

d_ #8 FLAT HEAD SCREW

'_ BUSHING WITH Otl/64 HOLE

"-_,\ _j #8 FLAT HEAD SCREW

\, '0_ / BUSHING WITH

\ _/Oll/64 HOLE

PLATE

19

Page 20

Thefiguresbelowshowtheviewsoftheadapterplateasit

wouldappearwheninstalledonarouterwiththerouter

turnedoverwiththerouterbasefacingupward

Threeofthemostpopularmountingholeconfiguralions

areshown

Figure30showsthemountingarrangementusingthree

screws

Figure31showsthemountingarrangementusingfour

screwswhenthescrewsareat45degreestothesideof

the front of the router

Figure 32 shows the mounting arrangement using four

screws when the screws are in line with the front of the

router

In most cases, the adapter plate will fit your router

However, in those cases where the router is extremely

smatl or extremely large, rated at 1-3/4 HP or larger, the

adapter plate cannot be used

g Set the router upside down on a workbench or other flat

stable surface

10 Position the adapter plate on the router so that the

threaded holes in the router base line-up with slots (or

holes) in the adapter plate

The recessed arrow in the adapter plate should point

FIGURE 30

©

©

toward the front of the router)

11 Line-up the center of the hole in the adapter plate with

the collet hole in the router This will ensure accurate cuts

I2 Using the screws removed in Step 2 above, in combi_

nation with either the washers or countersunk bushings,

assemble the adapter plate Io the router if the bushing are

used the heads of the screws must be flush with, or slight-

ly below the top of the bushing

THE TOPS OF THE SCREWS MUST NOT PROTRUDE

ABOVE THE TOP SURFACE OF THE ADAPTER PLATE

If for some reason the countersunk head screws being

used are too short, too long, or protrude above the top of

the adapter plate, obtain pan head screws that are 1/4" or

3/8" long with the proper thread from a hardware store or

DYI outlet Use these with the washers, instead of the

bushings, to assemble the adapter plate to the router

t3 TIGHTEN ALL SCREWS SECURELY

14 Check to see that center of the router co]Iet hole still

lines-up with the large center ho_e in the adapter plate

15 If it does not loosen the screws and reposition the

adapter plate so the hole Iines-up with the router collet hole

16 TIGHTEN ALL SCREWS SECURELY

FIGURE 32

©

©

/

FIGURE 31

©°@ ©

2O

Page 21

ASSEMBLY OF THE GUIDE BUSHING TO THE

ROUTER

1 Place the router upside down on a flat surface For cer-

tain touters it may be necessary to support the router for it

to remain in this position

2 Place the proper guide bushing required for the type of

dovetail to be cut under the router adapter plate as shown

in Figure 33

3 MAKE SURE THAT THE ORIENTATION OF THE

GUIDE BUSHING IS AS SHOWN

4 Position the guide bushing so that the three threaded

holes in the guide bushing line-up with the countersunk

holes in the adapter plate

5 Thread a #10-32 x 3/8" long flathead machine screw

into each of the holes

6 SECURELY TIGHTEN THE SCREWS Refer to Figure

34

FIGURE 33

#10-32 X 3/8" LONG_

FLATHEAD MACHINE SCREW

_/ / #10-32 X 3/8" LONG

\ _J FLATHEAD MACHINE SCREW

ADAPTER PLATE

/ ROUTER

s/

/

GUt0

BUSH1NG

ASSEMBLY

(1/2" DIAMETER

SHOWN)

NOTE THE

ORIENTATION

OFTHE GUIDE

BUSHING

FIGURE 34

GUIDE BUSHING ASSEMBLY

(1/2" DIAMETER SHOWN) "_

NOTE THE ORIENTATION

OFTHE GUIDE BUSHING

ROUTER

2t

Page 22

[J_"]"m_WARNING' THE DOVETAIL JiG MUST ALWAYS

BE FIRMLY AND SECURELY MOUNTED TO A SOLID

AND FIRM WORK SURFACE, SUCH AS A WORK-

BENCH, BEFORE USE FAILURE TO DO SO COULD

CAUSE THE DOVETAIL JIG TO TIP OVER OR SLIDE

ALONG THE WORK SURFACE, RESULTING IN PROP-

ERTY DAMAGE AND SERIOUS PERSONAL INJURY

MOUNTING THE DOVETAIL JIG TO A WORK SURFACE

OR WORKBENCH USING CLAMPS

USING THIS MOUNTING METHOD ALLOWS YOU TO

MOUNT THE DOVETAIL JIG SO THAT IT CAN BE EASF

LY INSTALLED, FOR USE, AND REMOVED, FOR STOR_

AGE, WITHOUT PERMANENTLY TAKING UP SPACE ON

YOUR WORKBENCH

1 Make a solid wood mounting board, 32" long x 6-1/4"

wide x 3/4" thick

2 Remove the template assembly from the dovetail base if

there is one there currently

3 Ddll three 1/8" diameter holes, 3/4" deep into the mount-

ing board as shown in illustration

4 Position the Dovetail Jig on the top of the mounting

board so the holes in the base line up with the drilled

holes in the mounting board

5 Secure the Dovetail Jig to the mounting board using

three t3/64" I.D. x 9/16" O D washers and three #10-16

x 1" long panhead self tapping screws as shown in

Figure 35

g Applying a small amount of soap to the screw threads

will make it easier to thread the screws into the holes

10 Line up the front of the mounting board with the front

of a workbench or other sturdy surface

11 Using two clamps, such as C-clamps, firmly clamp the

Dovetail ,Jig to the workbench by clamping on the mount-

ing board as shown in Figure 36 and Figure 36A

12 Make sure that the mounting board lines up with the

front of the workbench

FIGURE 35

_ / // / //2

TO THE FRONT OF THE ,_"_'_ ,_ 1/8" DIAMETER DRILL

DOVETAIL BASE

TO THE FRONT OF THE .....

DOVETAIL BASE

_ i

//

22

Page 23

FIGURE 36

CLAMP HERE

CLAMP HERE

FRONT SURFACE

OF THE MOUNT-

ING BOARD

FRONT SURFACE OF

THE WORKBENCH

FRONT SURFACE OF THE BASE

FIGURE 36A

FRONT SURFACE OF THE BASE

FRONT SURFACE OF THE MOUNTING BOARD

FRONT SURFACE OF THE WORKBENCH

23

Page 24

STYLES OF DOVETAIL JOINTS

• Four different styles of dovetail joints can be made with

the Dovetail Jig using your router

• These joints are described in the following sections

Haft Blind Flush Joint

• The Half Blind Flush Joint is used when the height of

both Ihe drawer front and the drawer back is the same

height as the drawer sides; and the length of both the

drawer front and the drawer back is the same as the width

of the drawer

See Figure 37

NOTE: THE NORMAL DEPTH OF CUT FOR A HALF

BLIND FLUSH JOINT IS 318",

FIGURE 37

/ DRAWER FRONT (PiN PIECE)

/

F

DRAWER SIDE (TAIL PIECE)

"_- DRAWER SiDE (TAIL PIECE)

TAILS

\

DRAWER BACK (PIN PIECE) /

24

Page 25

Half Btin d Flush Offset Joint

oThe Half Blind'Flush Offset JOint is used when_

The height of both the drawer front and the drawer back is

the same height as the drawer sides; the length of the

drawer front is 1/8" longer (1/16" on a side) than the width

of the drawer; and the length of the drawer back is the

same as the width of the drawer

FIGURE 38

1/!6" OFFSET ...

See Figure 38

*To obtain the offset, cut a 1/16" deep by 3/8" wide rabbet

on the opposite ends on the inside of the drawer front

NOTE: THE NORMAL DEPTH OF CUT FOR A HALF

BLIND FLUSH OFFSET JOINT IS 3t8".

DRAWER FRONT (PIN PIECE)

DRAWER SIDE (TALLPIECE)

-_RSIDE (TAIL PIECE)

/

DRAWER BACK (PIN PIECE) J

Haft Blind Rabbeted Joint

• The Half Blind Rabbeted Joint is used when:

The drawer fronl overlaps the opening for the drawer on el!

four sides of the of the drawer opening (top, bottom, and

two sides) that is; the length of the drawer front is 3/4"

longer (3/8" on a side) than the width of the drawer; the

height of the drawer front is atso 3/4" higher (3/8" on side)

than the height of the drawer; the length of the drawer back

FIGURE 39

DRAWER SIDE

is the same as the widlh of the drawer; and the height of

the drawer back is the same as the height of the drawer

See Figure 39

• To obtain this joint, cut a 3/8" deep by 3/8" wide rabbet

around the inside periphery of the drawer '_ront

NOTE: THE NORMAL DEPTH OF CUT FOR A HALF

BLIND RABBETED JOINT !S 318'L.

DRAWER FRONT (PIN PIECE)

3/8" WIDE RABBETAROUND THE

PERIPHERY OF THE DRAWER FRONT

TAIL

DRAWER S_DE (TAIL PIECE)

DRAWER BACK (PtN PIECE)

25

Page 26

Open or Through Joint

• The Open or Through Joint is similar to the Half Blind

Joint except that joint seams are visible on the front, back,

and sides of the workpiece; on the Half Blind Joints, the

seams are visible only on the sides of the workpiece

• Although this style of joint can be also used for drawers,

its most popular use is for making boxes, and small and

large chests

• The height of both the front and the back of the drawer

or chest is the same height as the sides of the drawer or

chest; and the length of both the front and the back of the

drawer or chest is the same as the width of the drawer or

chest

See Figure 40

FIGURE 40

NOTE: THE DEPTH OF CUT IS DETERMINED BY THE

THICKNESSES OF THE FRONT, BACK AND SIDE

PIECE&

• The front and back pieces (sometimes called "tail

pieces") are cut independentIy from the side pieces (some-

times called "pin pieces")

- The "pin pieces" are cut first using one edge of the tem-

plate and a dovetail router bit The depth of cut is equal to

the thickness of the "tail pieces"

• The "tail pieces" are cut next using the other edge of the

template and a straight router bit The depth of cut is equal

to the thickness of the "pin pieces" Adjustments are made

at this point to oblain joint fit

ADJUSTING THE DEPTH-OF-CUT OF THE

ROUTER BIT

r__ ,t

[,_._,WARNINGJ ALWAYS MAKE SURETHATTHE

ROUTER tS "TURNED OFF" AND THAT THE ELECTRI-

CAL CORDHASBEENUNPLUGGEDFROMTHE

ELECTRICAL OUTLET BEFORE ASSEMBLING OR

REMOVING ROUTER BITS TO THE ROUTER,

• You will note that there are six pockets along the front

surface of the dovetail base, and that they are identified by

a dimensions such as 3/8, lt2,-up to 1 These pockets are

used to set the depth-of-cut of a router bit

To use proceed as follows:

- DO NOT USE WITH A TEMPLATE ASSEMBLED TO

THE BASE

o DO NOT INSTALL ROUTER BITS TO THE ROUTER

UNLESS THE CORRECT GUIDE BUSHING HAS BEEN

ASSEMBLED TO THE BASEPLATE FIRST

1 Install the desired router bit to the router as explained in

your Router Owner's Manual See Figure 41

A MINIMUM ROUTER BIT SHANK ENGAGEMENT OF

3/4" IS REQUIRED IN THE COLLET OF THE ROUTER

2 TIGHTEN THE COLLET NUT SECURELY

3 Position the router over the pocket with the required

depth-of-cut

I_CAUTION i MAKE SURE THAT THE ROUTER

BIT ISALIGNED WITH OR CENTERED IN THE HOLE IN

THE GUIDE BUSHING. TO DO THIS,LOOSEN SCREWS

HOLDING BASE OR ADAPTER PLATE TO ROUTER,

CENTER GUIDE BUSHING HOLE WITH RESPECT TO

ROUTER BIT AND RETtGHTEN SCREWS SECURELY_

ROUTER BIT ,, BASEPLATE

GUIDE

BUSHING

FIGURE 41

26

Page 27

4 Gradually move the router bit outward, by using the

depth-of-cut feature on the router, until the tip of the router

bit touches the bottom of the pocket, as shown in

Figure 42 and Figure 42A

5 Lock the router in position

6 The desired depth-of-cut has been set

7 To set a depth-of-cut NOT provided for on the dovetail

base, simply place the unused template on the router

baseplate, as shown in Figure 43 The height _rom the

baseplate to the end or tip of the router bit will then be the

required depth of cut

FIGURE 42

l,t_ II_._,CAUTION i WHEN SETTING THE DEPTH OF

CUT, MAKE ABSOLUTELY SURE THAT THE COLLET

NUT DOES NOT CONTACT (TOUCH) THE GUIDE BUSH-

ING THIS CAN CAUSE THE GUIDE BUSHING TO HEAT

UP EXCESSIVELY DURING CUTTING WHICH CAN

CAUSE DAMAGE TO THE TEMPLATE TO CORRECT

THIS SITUATION OR PREVENT IT FROM OCCURRING

REPOSITtON THE ROUTER BIT IN THE ROUTER

ROUTER

ROUTER BIT \

POCKET

FIGURE 42A

ROUTER

ROUTER BIT /

'" POCKET

FIGURE 43

TEMPLATE ti I 1' --j OEPT.O CUT

27

Page 28

CLAMPING THE WORKPIECES TO THE

DOVETAIL BASE

- The clamping bars have been specially designed to allow

lhe clamping forces to be applied next to the workpieces

for more efficient clamping This is accomplished by' being

able to position the clamping knobs in close proximity or

next to the workpieces

• Figure 44 illustrates the positioning of the ctamping bars

and the clamping knobs when the workpieces are clamped

to the LEFT SiDE of the Dovetail Jig

• Figure 45 illustrates the positioning of the clamping bars

and the clamping knobs when the workpieces are clamped

to the RIGHT SIDE of the Dovetail Jig

- Note the closeness of the clamping knobs to the work-

pieces When not in use etamping knobs and the support-

ing bolts and springs are free to be moved atong the slots

in the base

• CAUTION: WHEN CLAMPING, MAKE SURE THAT THE

CLAMPING KNOBS ARE NOT POSITIONED SO CLOSE

TO THE WORKPIECES THAT THE WASHERS BECOME

TRAPPED UNDER THE WORKPIECES

,, FOR ACCURATE JOINTS, THE WORKPIECES MUST

"BUTT-UP" AGAINST BOTH THE TOP AND THE FRONT

STOP BLOCKS TO ENSURE THE EXACT POSITIONING

OF THE WORKPIECES

• TO ENSURE ACCURATE JOINTS AND SAFE OPERA-

TION, WOOD SHAVINGS AND ACCUMULATED DUST

MUST BE REMOVED FROM THE DOVETAIL JIG

BEFORE EACH SETUP, EITHER BY USING A BRUSH

OR BY VACUUMING

FIGURE 44

INSIDE SURFACE OF DRAWER

FRONT (OR BACK) FACES UP _ .._._._,----_ WORKPIECE CLAMPED TO

// THE TOP OF THE BASE

TOP STOP BLOCK ,_.._. _y

LEAR

(

OF HEV,O.KP,ECES

,Ns,oESUBFAOEOF°RAWERS'DE WORKPIECEC.AMPEOTO

FAOESO0 T,-,EFRONTOFT.EBASE

FIGURE 45

WORKPfECE CLAMPED TO THE TOP OF THE

TOP CLAMPING BAR.,

iNSIDE SURFACE

• TOP STOP BLOCK

FRONT CLAMPING BAR

WASHER MUST BE CLEAR OF THE WORKPIECES "_/

INSIDE SURFACE

WASHER MUST BE

CLEAR OF THE

WORKPIECE

FRONT STOP BLOCK

WORKPIECE CLAMPED TO

THE FRONT OF THE BASE

28

Page 29

MAKING DRAWERS WITH HALF BLIND

FLUSH JOINTS

• The thickness of both the front and back (pin pieces)

must be at least 1/2" The thickness of the sides (tail

pieces) must be at least 3/8 _

A partial tail will be cut for side (tai! piece) thicknesses up

to 9/16" This is norma_ and will not affect the joint or its

appearance

o Figure 46 shows a drawer and the workpieces that make

it up This figure is similar to Figure 38, except that it

shows the workpieces unassembled (or an exploded view

of the drawer)

• In addition, the figure shows where the four comers of

the drawer are cut on the Dovetail Jig

CORNERS 1 AND 3 are cut on the LEFT SIDE of the

Dovetail Jig

CORNERS 2AND 4 are cut on the RIGHT SIDE of the

Dovetail Jig

• TdaJ cuts are strongly recommended using scrap wood to

ensure that the final workpieces are of the desired quality

FIGURE 46

CORNER #1

(CUT AT THE LEFT SIDE OF

THE DOVETAIL ,JIG)

(CUT AT THE RIGHT SIDE OF

THE DOVETAIL ,JIG)

SURFACE LINES UP

WITH FRONT STOP,

BLOCKS \,

\

H

DRAWER .\

RIGHT ",

DRAWER FRONT -\

/

/

INSIDE OF DRAWER

SURFACE LINES UP WITH

FRONT STOP BLOCKS

/

SURFACE LINES

UP WITH TOP

STOP BLOCKS

-\

"- DRAWER BACK

CORNER

(CUT AT THE RIGHT SIDE OF

THE DOVETAIL JIG)

(CUT AT THE LEFT SIDE OF

TIDE DOVETAIL ,JIG)

LEFT SiDE

OUTSIDE OF

DRAWER

29

Page 30

GENERALPREPARATIONS

a Theworkpiecescomprisingthedrawer,that is, front,

back, ]eft side, and right side should be cut to the proper

length, width, and thickness(es)

b Make sure that all surfaces are smooth and square with

each of the other surfaces

c Line up the workpieces on a flat surface, standing on

edge, as shown in Figure 47

d With a soft lead pencil mark the front, back, left side,

and right side, as shown in Figure 47 This is to aid you in

positioning the workpieces on the Dovetail Jig, prior to cut-

ting the dovetails

e Assemble the 40" guide bushing to the router base-

plate, as described in a previous section This the smaller

of the two guide bushings furnished with this product

f lnslall Vermont American #22500 or Magna #Mg 1113

dovetail router bit, to the router as described in your

Router Owner's Manual Shank engagement should be a

minimum of 3/4"

FIGURE 47

MARK "DRAWER FRONT TOP SURFAC E . MARK 'W"

MARK "1" _ _.._.._'-I'"_/_

MARK "DRAWER \ __

RIGHTSIDE TOP \. \ ",, \ \

"'" MARK

INSIDE SURFACE"

MARK

/ MARK "DRAWER RIGHT

/ SIDE _NSIDE SURFACE"

r

; ; . MARK

/ MARt{ "DRAWER BACK ' "DRAWER

; .,,,-" ,' LEFT SIDE

, I TOP SURFACE"

\ MARK "DRAWER

", LEFT SIDE

", INSIDE SURFACE"

'. \ (SHOWN HIDDEN)

\

\

MARK "DRAWER BACK INSIDE SURFACE" (SHOWN HIDDEN)

IAII, CAUT!ONI MAKE SURE THATTHE ROUTER BiT

IS ALIGNED WITH OR CENTERED IN THE HOLE tN THE

GUIDE BUSHING TO DO THIS, LOOSEN SCREWS

HOLDING BASE PLATE OR ADAPTER PLATE TO

ROUTER, CENTER GUIDE BUSHING HOLE WtTH

RESPECT TO ROUTER BIT AND RETIGHTEN SCREWS

SECURELY

] CAUTION/ WHENSETTING7HEDEPTHOF

CUT, MAKE ABSOLUTELY SURE THAT THE COLLET

NUT DOES NOT CONTACT (TOUCH) THE GUIDE BUSH-

ING THIS CAN CAUSE THE GUIDE BUSHING TO HEAT

UP EXCESSIVELY DURING CUTTING WHICH CAN

CAUSE DAMAGE TO THE TEMPLATE TO CORRECT

THIS SITUATION OR PREVENT it FROM OCCURRING,

REPOSITtON THE ROUTER BIT IN THE ROUTER

40" DIA GUIDE BUSHfNG ,_,,

VERMONT

AMERICAN #22500

OR

MAGNA #M911!3

DOVETAIL

ROUTER BIT

\

\

\

E

30

Page 31

gAdjustthedepthofcutto3/8"usingthedepthgaugeon

thebaseoftheDovetailJig,asdescribedinaprevious

section

Thissettingisapproximateandsomeadjustmentmaybe

required

h Positionbothofthetopstopblockssothatthe"A"faces

the"middleofthebase"asshowninFigure48 '

i Positionthecamhandlesothatthepointerpointstothe

centergraduationasshowninFigure48

FIGURE48 LEFTTOPSTOPBLOCK 'A"FACESTOWARDMIDDLE

OFBASE

. "A" FACES TOWARD MIDDLE

_ OFB___ASE _ / RIGHT TOP STOP BLOCK

/- ....... 7_------------_-\\V,_ 1A_ /

I

//_/ POINTER POINTS

' It _./ TO CENTER

___ !'[i"V _',","'_ii]ii_, , /_ _ RIGHT FRONT STOP BLOCK

"\ LEFT FRONT STOP BLOCK \ _"'_

THE FOLLOWING DESCRIBES THE PROCEDURE TO

BE FOLLOWED FOR CUTTING CORNERS 1 AND 3

1 FOR CORNER #1, position the drawer front on the top

of the base so that it lines up with the front of the base and

the top surface abuts the left top stop block THE INSIDE

OF THE DRAWER FRONT FACES AWAY FROM THE

TOP OF THE BASE The words "INSIDE SURFACE"

marked in (d) in the Section, GENERAL PREPARATIONS,

should be visible

2 Ughtly clamp the drawer front in place

3 Position the drawer RIGHT side against the front of the

base so that the top surface abuts the left front stop block

THE INSIDE OF THE DRAWER S_DE FACES AWAY

FROM THE FRONT OF THE BASE

The words "INSIDE SURFACE" marked in (d) in the

Section, GENERAL PREPARATIONS, should be visible.

4 Line up the workpieces so that the end of the drawer

side lines up with the drawer front as shown in Figure 49

5 Securely clamp the drawer side to the base

6 Securely clamp the drawer front to the base

7 Make sure that the parts remain lined up

FIGURE 49

DRAWER FRONT

THE END OF THE DRAWER

SIDE MUST BE LEVEL AND \-._%

FLUSH WITH THE INSIDE "_,.

SURFACE OF THE DRAW_

%.,

ER FRONT (OR BACK)

'tNSfDE SURFACE" SHOULD BE

VISIBLE ON THIS SURFACE

AUXILIARY TEMPLATE

TOP OFTHE BASE/' SUPPORT (AS NEEDED)

\

" FRONT OF THE BASE

DRAWER RIGHT SIDE

"INSIDE SURFACE" SHOULD BE

NOTE: WORKPIECES WILL BE POSITIONED ON THE JIG AS VISIBLE ONTHIS SURFACE

31

Page 32

FIGURE5O

/ DOVETAIL TEMPLATE

/" FOR HALF BLIND JOINT

/

//

(

WASHER

8 Assembfe the DOVETAIL TEMPLATE FOR HALF BLIND

JOINTS to the Dovetait Jig so that THE TEMPLATE

BRACKETS FiT BETWEEN THE WASHERS AND THE

TEMPLATE SUPPORTS as shown Figure 50

NOTE: MAKE SURE THE TEMPLATE CLAMPING

KNOBS ARE LOOSE TO MAKE TEMPLATE ADJUST-

MENT, AFTER ADJUSTMENT IS MADE, RETtGHTEN

TEMPLATE CLAMPING KNOBS.

9 Make sure that the short fingers on the template, as

shown in Figure 50, faces toward the front of the base

10 Make sure that the template is flush and parallel with

the workpieces clamped to base Far narrow drawer fronts,

the use of an auxiliary support for the template is recom-

mended Its purpose is to aid in supporting the router while

cutting It can be made from a piece of scrap wood; but its

thickness must be the same as the drawer front (Refer to

Figure 49)

11 Clamp the temptate in place by tightening the clamping

knobs

12 I'_WARNINGI BEFORE MAKING ANY CUTS

MAKE SURE THAT THE BIT WILL NOT CUT INTO THE

BASE OR ANY OTHER COMPONENT OF THE DOVE-

TAIL JIG,, THIS CAN CAUSE DAMAGE TO THE DOVE-

TAIL JIG; OR LOSS OF CONTROL OF THE ROUTER

WHICH CAN RESULT IN SERIOUS BODILY INJURY,, A

TRIAL RUN WITH THE ROUTER TURNED OFF AND

UNPLUGGED FROM THE ELECTRICAL OUTLET IS

STRONGLY RECOMMENDED°

13 TURN THE ROUTER ON

14 Cut the dovetail by moving the router from LEFTTO

RIGHT, with the guide bushing fol!owing the template DO

NOT FORCE ANYTHING; MOVE THE ROUTER IN SLOW

AND SMOOTH FASHION

15 To ensure a smooth and uniform joint, retrace the pre-

vious cut by moving the router from RIGHT TO LEFT with

the guide bushing again fo_$owing the template

t6 _'_')L],,M,WARNING,NEVER LIFT THE ROUTER

UPWARDS WHEN THE ROUTER IS ON AND THE

ROUTER BIT ROTATING OR WHEN THE GU|DE BUSH-

ING IS NEAR TO OR TOUCHING THE TEMPLATE° THIS

CAN CAUSE DAMAGE TO THE DOVETAIL JIG; OR

LOSS OF CONTROL OF THE ROUTER WHICH CAN

RESULT IN SERIOUS BODILY INJURY,,

17 After the cut has been made, the workpieces should

look like those illustrated in Figure 51

FIGURE 51

DRAWER

DOVETAIL CUTS

/

DRAWER /

RIGHT SIDE

32

Page 33

18 Remove the workpieces from the Dovetail ,Jig and

check how the workpieces fit together Some adjustments

may be required

Refer to the section TROUBLESHOOTING on page 37

19 FOR CORNER #3, position the drawer back on the top

of the base so that it lines up with the front of the base and

the top edge surface abuts the left top stop block THE

INSIDE OF THE DRAWER BACK FACES UP The words

"INSIDE SURFACE" marked in (d) in the Section, GENER-

AL PREPARATIONS, should be visible See Figure 52

20 Lightly clamp the drawer back in place

21 Position the drawer LEFT side against the front of the

base so that the top surface abuts the left front stop block

THE INSIDE OF THE DRAWER SIDE FACES UP The

words "INSIDE SURFACE" marked in (d) in the Section,

GENERAL PREPARATIONS, should be visible

22 Line up the workpieces so that the end of the drawer

side lines up with the drawer back as shown in Figure 52

23 Continue as in Steps 5 through 16 above

24 After the cut has been made, the workpieces should

took like those illustraied in Figure 53

25 Remove the workpieces from the Dovetail Jig and

check how the workpieces fit together Some adjustments

may be required

Refer to the section TROUBLESHOOTING on page 37

FIGURE 52

I _,'_INSIDESURFACE" SHOULD BE VISIBLE

ON THIS SURFACE

/TOP OF THE BASE / AUXILIARY TEMPLATE SUPPORT

// _ (AS NEEDED)

// ..... .... •

DF_A"AER LEFT SiDE / __"" "INSIDE SURFACE" SHOULD BE VISIBLE

ON THIS SURFACE

FIGURE 53

DRAWER BACK \

DOVETAIL

DRAWER LEFT SIDE

33

Page 34

THEFOLLOWINGDESCRIBESTHEPROCEDURETO

BEFOLLOWEDFORCUTTINGCORNERS2AND4

CORNERS2AND4arecutinthesamewayas1and3

except they are positioned on the right side of the Dovetail

Jig as shown Figure 54

. [,_CAUTION I BEFORE MAKING ANY CUTS

MAKE SURE THAT THE BIT WILL NOT CUT INTO THE

BASE OR ANY OTHER COMPONENT OF THE DOVE-

TAIL JIG,, THIS CAN CAUSE DAMAGE TO THE DOVE-

TAIL JIG,,

• I"_cAUTION t NEVER LIFT THE ROUTER

UPWARDS WHEN THE ROUTER IS ON AND THE

ROUTER BIT ROTATING OR WHEN THE GUIDE BUSH-

ING IS NEAR TO OR TOUCHING THE TEMPLATE° THIS

CAN CAUSE DAMAGE TO THE DOVETAIL JIG.

• After the cut has been made, the workpieces should fook

Iike those illustrated in Figure 53

• The finished front, back, and sides should look iike those

in Figure 46

• Before gluing the front, back, and sides together,

some provision must be made for installing the bot-

tom, such as dadoing or cutting a groove around the

inside of the drawer parts°

• Your drawer is now ready to be glued together

FIGURE 54

TOP OF THE BASE \

\

AUXILIARY(AsNEEDED)TEMPLATESUPPORT \\ _\

'INSIDE SURFACE" SHOULD BE

VISIBLE ON THIS SURFACE

DRAWER BACK

/

/

FRONT OF THE BASE "/

DRAWER RIGHT SIDE

"iNSIDE SURFACE" SHOULD BE VrSIBLE ON THIs SURFACE

NOTE: WORKPIECES WILL BE POSITIONED ON THE JIG AS

34

Page 35

MAKING DRAWERS WITH HALF BLIND FLUSH

OFFSET JOINTS

GENERAL PREPARATIONS

a The iength of the drawer front is 1/8" Ionger than the

length of the drawer back

b When cutting comers 1 and 4; the cam handle is rotated

two graduations toward the back of the base, thus moving

the template !/32" toward the back of the base (Refer to

Figure 55)

NOTE: MAKE SURE THE TEMPLATE CLAMPING

KNOBS ARE LOOSE TO MAKE TEMPLATE ADJUST-

MENT, AFTER ADJUSTMENT IS MADE, RE'TIGHTEN

TEMPLATE CLAMPING KNOBS,

c When cutting corners 2 and 3; the cam handle is posi-

tioned vertically, as shown in Figure 48

d All other GENERAL PREPARATIONS are the same as

those used for "MAKING DRAWERS WITH HALF BLfND

FLUSH JOtNTS"

THE PROCEDURE FOR CUTTING THESE JOINTS IS

THE SAME AS THAT USED FOR "MAKING DRAWERS

WITH HALF BLIND FLUSH JOINTS"

• After aI1 dovetail cuts have been made, cut a 1/16" deep

by 3/8" deep rabbet on opposite ends of the drawer front

• The finished front, beck, and sides should look like those

in Figure 38

• Before gluing the front, back, and sides together, some

provision must be made for installing the bottom, such

RGURE 55

"A" FACES \ BACK OF

MIDDLE OF BASE \\ THE BASE

\

\

POINTER POINT5

TO THE SECOND GRADUATION

TOWARD THE BACK OF THE BASE

FROM THE CENTER GRADUATION

as dadoing or cutting a groove around the inside of the

drawer parts

oYour drawer is now ready to be glued together

• Remove the pencil markings by light sanding or with a

soft eraser after the drawer parts have been glued

together

35

Page 36

MAKING DRAWERS WITH HALF BLIND

RABBETED JOINTS

GENERAL PREPARATIONS

a The length of the drawer front is 3/4" longer than the

tength of the drawer back

b The height of the drawer front is 314" higher than the

height of the drawer back and drawer sides

• IT tS EXTREMELY iMPORTANT THAT THE TEMPLATE

BE PROPERLY ALIGNED WHEN MAKING THESE

JOINTS, OR ELSE, IN ADDITION TO THE JOINT SPAC-

iNG NOT BEING EQUAL, AS SHOWN 1N FIGURE 60

BELOW, THE TOP SURFACES OF THE SIDES, FRONT,

AND BACK WILL NOT "LINE-UP" PROPERLY EITHER

REFER TO THE SECTION "ALIGNMENT OF THE TEM-

PLATES" (Figure 60 illustrates a Flush Dovelail Joint)

-All other GENERAL PREPARATIONS, except as noted

below in the procedure, are the same as those used for

"MAKING DRAWERS WITH HALF BLIND FLUSH

J Of NTS"

THE PROCEDURE FOR CUTTING CORNERS 1 AND 4

IS THE SAME AS THAT USED FOR "MAKING DRAW-

ERS WITH HALF BLIND FLUSH JOINTS" EXCEPT

° Position BOTH top stop blocks so that the "B" faces the

middle of the base as shown in Figure 56

° Use the side of the tempiate that has the longest fingers

• Position the template and workpieces as shown in

Figure 57 Cut the dovetail as described in the section,

MAKING DRAWERS WITH HALF BLIND FLUSH JOINTS

• Before gluing the front, back, and sides together,

some provision must be made for installing the bot-

tom, such as dadoing or cutting a groove around the

inside of the drawer parts

• Your drawer is now ready to be glued together

• Remove the penciI markings by fight sanding or with a

soft eraser after the drawer parts have been giued

together

FIGURE 56

LEFT TOP STOP BLOCK

,/"B" FACES TOWARD MIDDLE OF BASE

/-/

'B" FAC ES TOWARD

OF BASE

/ RIGHT TOP STOP BLOCK

/

/

/

POINTER POINTS TO

CENTER GRADUATION

\"LEFT FRONT STOP BLOCK

\ RIGHT FRONT STOP BLOCK

FIGURE 57

/ DOVETAIL TEMPLATE FOR

_ .......... / HALF BLlND JOINTS

CLAMP NaKNOa ii--%n - " ..... I - Z /it / OLAMPINGK.OB

_ASHER

,_L..__' --m'_._.__---_: ........... _ ..... i .,C,,,

TEMPLATEORAOKET

36

Page 37

TROUBLESHOOTING

o If the joint is too loose: INCREASE the depth of cut by

INCREASING the amount by which the router bit extends

beyond the baseplate by t/64" to 1/32" and make a trial

cut Continue adjusting until desired joint fit is attained

° If the joint is too tight: DECREASE the depth of cut by

DECREASING the amount by which the router bit extends

beyond the baseplate by 1/64" to 1/32" and make a trial

cut Continue adjusting until desired joint fit is attained

• If the joint is too shallow: Refer to Figure 58 Loosen

the clamping knobs holding the template brackets and

move the template INWARD half the additional deplh

needed by tuming the cam handles Retighten the clamp-

ing knobs

° If the joint is too deep: Refer to Figure 59 Loosen the

clamping knobs holding the template brackets and move

the template OUTWARD by turning the cam handles half

the distance needed Retighten the clamping knobs

° If the joint is not uniformly spaced from top surface

of drawer: Refer to Figure 60 (See the Section "ALIGN-

MENT OF THE TEMPLATES" ) With the template clamped

to the base, loosen the four screws securing the template

to the template brackets, and move the template slightly to

the left Tighten the four screws and make a trial cut if

moving the template to the left did not correct the condi-

tion, but made it worse, loosen the screws and move the

template to the right a small amount Tighten the four

screws and make a trial cut Continue moving the template

to the right until the condition is completely correcled

MAKE SURE TO SECURELY TIGHTEN THE FOUR

SCREWS If moving the template to the left improves the

condition, continue moving the template to the left until the

condifion is completely corrected Make sure the template

remains parallel to the front of the dovetail base MAKE

SURE TO SECURELY TIGHTEN THE FOUR SCREWS

AFTER THE TEMPLATES HAVE BEEN CORRECTLY

REALIGNED, THEY SHOULD REQUIRE NO FURTHER

ADJUSTMENTS IF THEY ARE HANDLED WITH CARE

RGURE 58 - JOINT IS TOO SHALLOW

DRAWER FRONT

DRAWER

BACK

FIGURE 59 - JOINT IS TOO DEEP

DRAWER FRONT ...

DRAWER

LEFT SIDE

DRAWER _\

BACK

_- SIDE

EXTENDS

OUT PAST

FRONT

_SIDE

EXTENDS

OUT PAST

FRONT

BACK

EXTENDS

OUT

PAST

SIDE

BACK

EXTENDS

OUT PAST

SIDE

FIGURE 60 - JOINT SPACING IS NOT UNIFORM

SPACING GREATER

THAN DRAWER FRO_ f_l _

DRAWER BACK J'

/

DRAWER LEFT SIDE j

j"

SPACING LESS THAN

DRAWER BACK

DRAWER FRONT

37

Page 38

MAKING PROJECTS WITH OPEN (THROUGH)

JOINTS

• The thickness of both the front and the back (tail pieces)

must be between 3/8" and 1"

• The thickness of the sides (pin pieces) must also be

between 3/8" and 1"

• Figure 61 shows a project and the workpieces that make

if up This figure is similar to Figure 40, except that it

shows the workpieces unassembied

• Trial cuts are strongly recommended using scrap wood to

ensure that the final workpieces are of the desired quality

GENERAL PREPARATIONS

a. The workpieces comprising the project, that is, front,

back, left side and right side should be cut to the proper

length, width and thickness(es)

b Make sure that all surfaces are smooth and square with

each of the other surfaces

c Line up the workpieces on a flat surface, standing on

edge, as shown in Figure 62

d.. With a soft lead pencil mark the front, back and two

sides, as shown in Figure 62, also. This is to aid you

in positioning the workpieces on the Dovetail Jig, prior

to

cutting the dovetails.

e Position both of the top stop blocks so that the "A" faces

the "middle of the base" as shown in Figure 48

f Position the cam handle so that the pointer points to the

center graduation as shown in Figure 48

FIGURE 61

PROJECT

RIGHT SIDE

CORNER#1

CORNE_ SURFACE LINES

PROJECT FRONT\ _ UP WITH FRONT

.............. /_ STOP BLOCKS

/yv

//SURFACE LINES UP WITFI

FRONT STOP BLOCK

/

"_--_'-_0 UTSIDE I

OR%EOT

_" PROJECT SACK

-_CTLEFT SIDE

CORNER#_ CORNE_

38

Page 39

FIGURE 62

MARK

MARK "PROJECT

BACK OUTSIDE

SURFACE"

MARl,( "PROJECT FRONT TOP SURFACE" \

MARl( "1"

MAflK"PROJECTFRONTOUTSIDE t

SURFACE" (SHOWN HIDDEN)

MARt( "PROJECT RIGHT SIDE OUTSIDE

SURFACE" (SHOWN HIDDEN)

MARK"PROJECT

// BACKTOP SURFACE"

/

/ MARK "PROJECT

LEFT SIDE TOP

SURFACE"

MARt( "PROJECT

LEFT SIDE OUTSIDE

SURFACE"

THE FOLLOWING DESCRIBES THE PROCEDURE TO

BE FOLLOWED FOR CU_ING THE PROJECT RIGHT

SIDE AND THE PROJECT LEFT SIDE

NOTE: THESE WORKPtECES MUST BE CUT FIRST

BECAUSE ANY JOINT FIT ADJUSTMENTS THAT MAY

BE REQUIRED CAN ONLY BE MADE WHEN CUTTING

THE PROJECT FRONT AND PROJECT BACK-THAT iS,

THE DRAWER FRONTAND THE PROJECT BACK ARE

FIT TO THE SIDES

1 Assembfe the 1/2" guide bushing to the router base-

plate, as described in a previous section This is the larger

of the two guide bushings furnished with this product

2 Install Vermont American #22501 or Magna #Mg1114, to

the router as described in your Router Owners Manual

Shank engagement should be a minimum of 3,/4"

I,_CAUTION 1MAKE SURE THAT THE ROUTER BIT

IS ALIGNED WITH OR CENTERED IN THE HOLE iN THE

GUIDE BUSHING TO DO THIS, LOOSEN SCREWS

HOLDING BASE PLATE OR ADAPTER PLATE TO

ROUTER, CENTER GUIDE BUSHING HOLE WITH

RESPECT TO ROUTER BIT AND RETIGHTEN SCREWS

SECURELY

t._i_lt,_,CAUTtON1 WHEN SETTING THE DEPTH OF