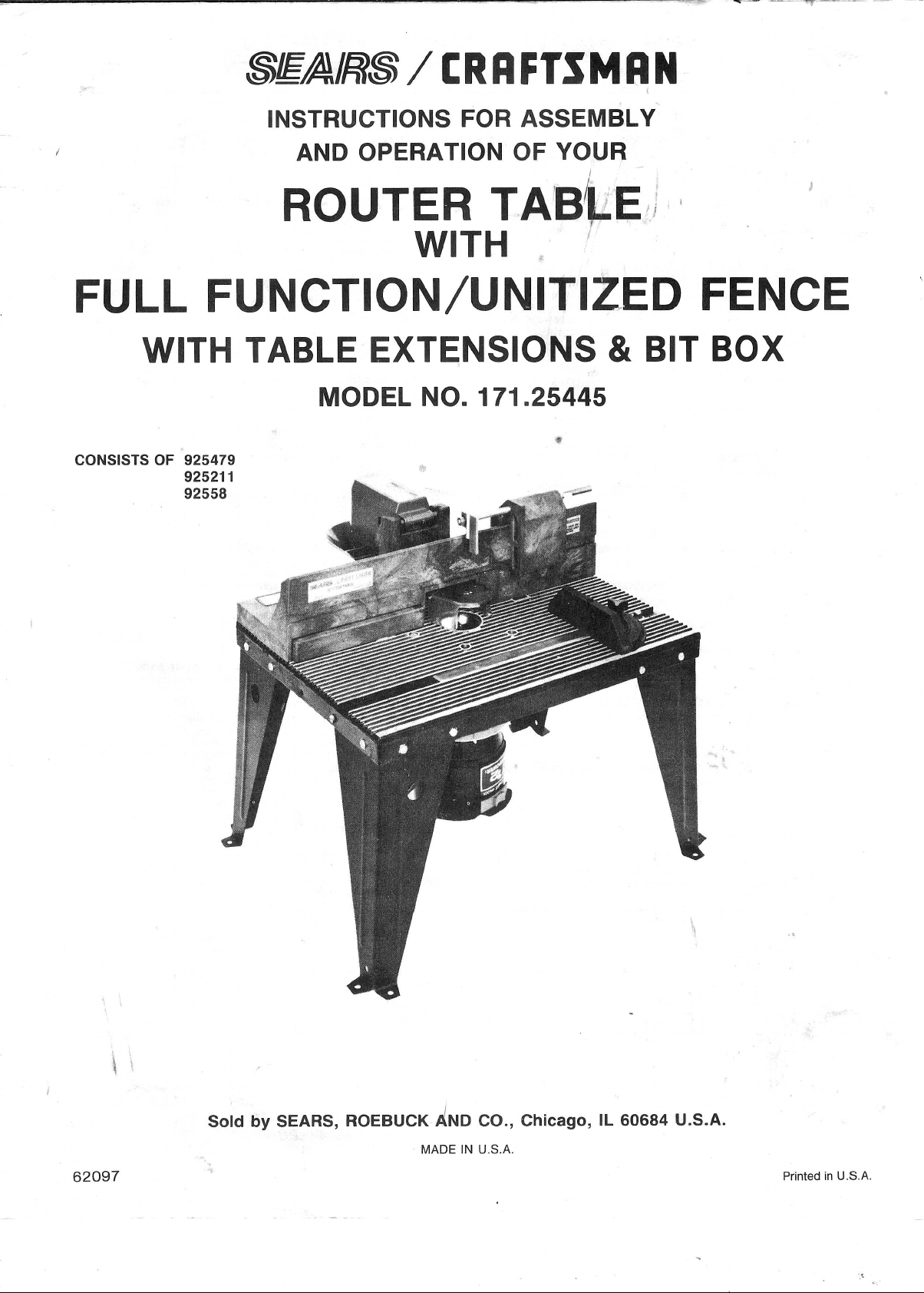

Page 1

Page 2

Page 3

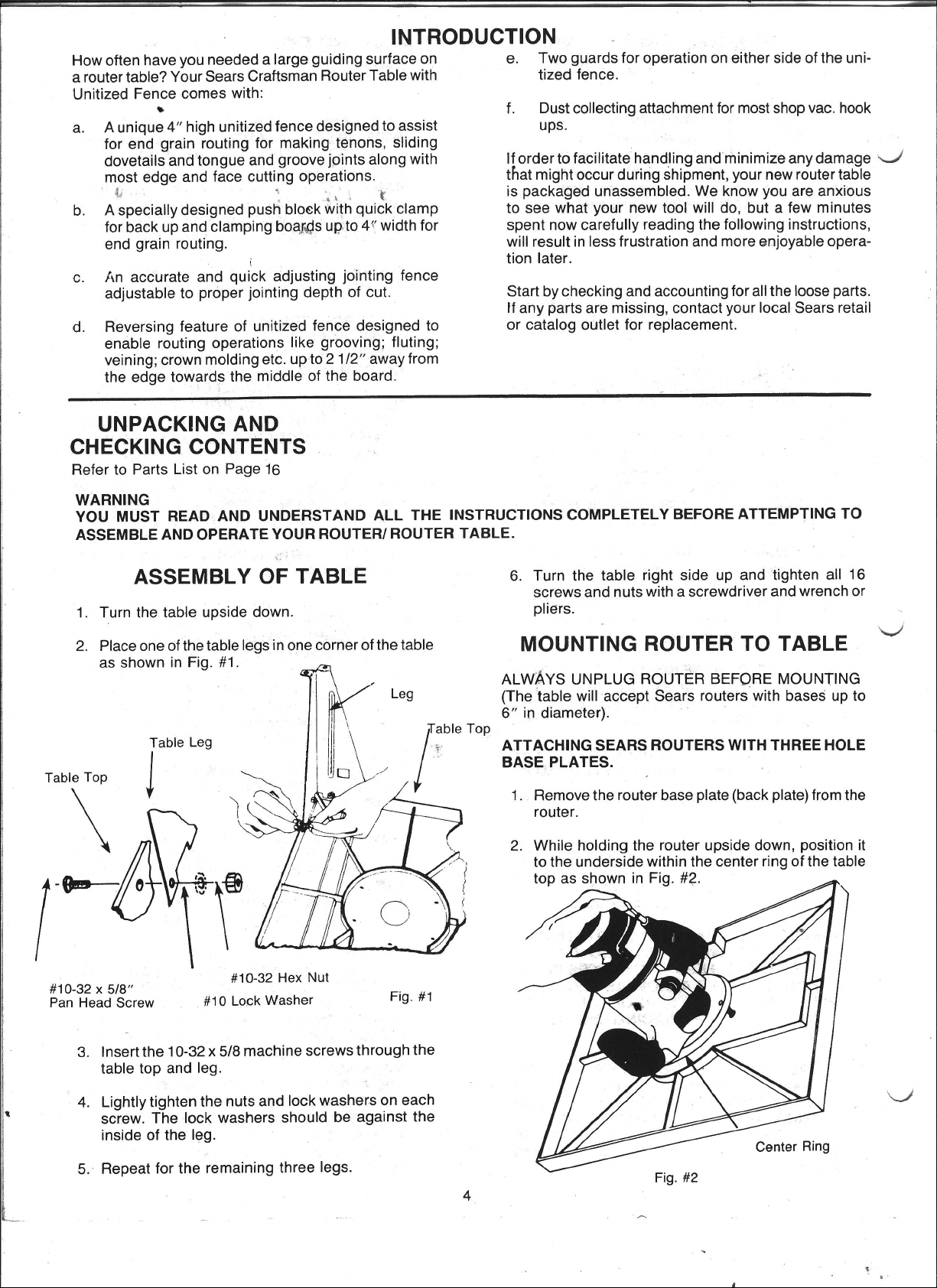

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

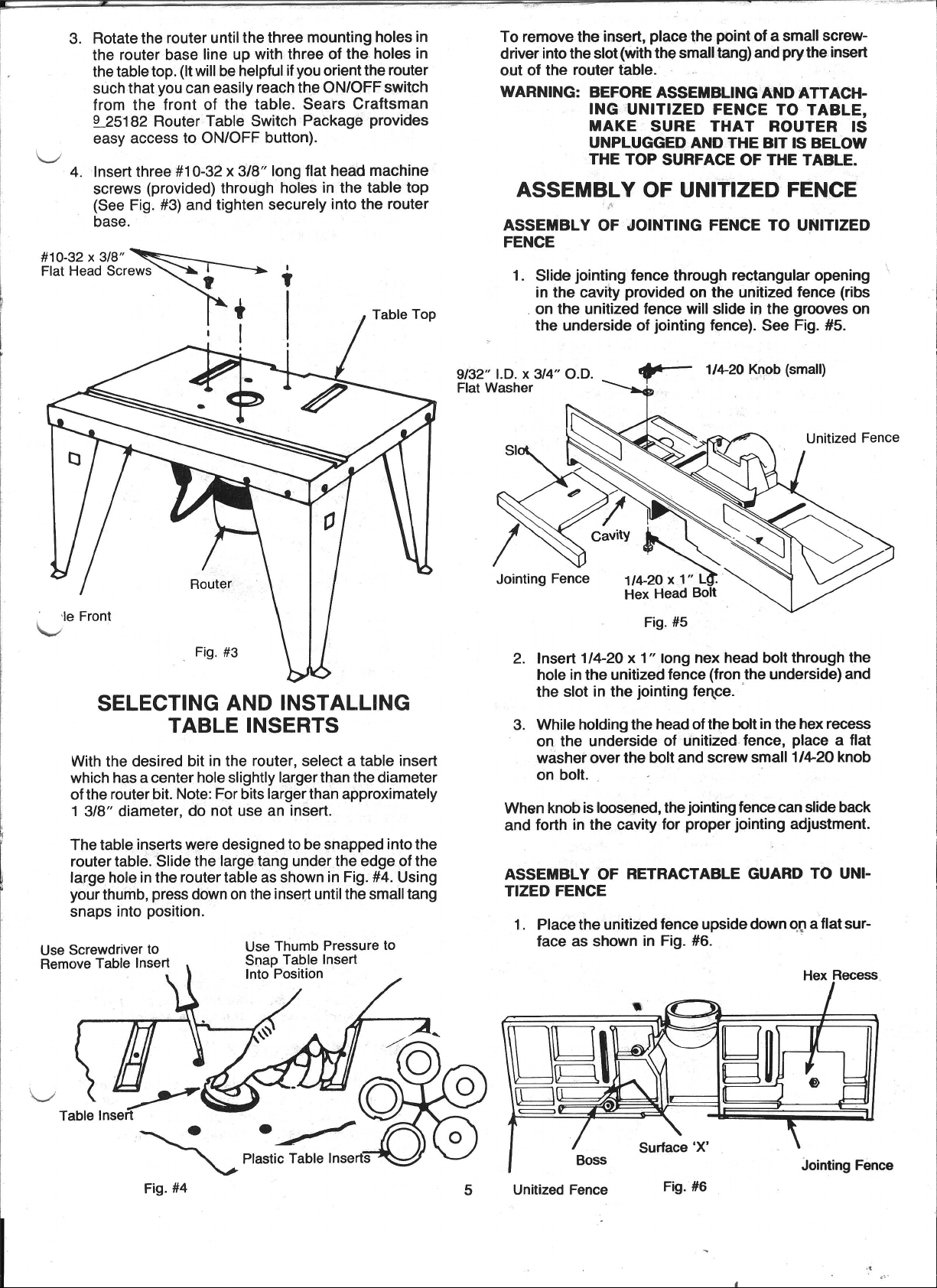

4.

Raise or lower the router until top cutting edge

bit

is

aligned with

owner's

manual for adjusting your router properly) .•

line'S'.

(Refer to your router's

AFTER MAKING THIS ADJUSTMENT, SE SURE

ROUTER

ROUTER

ENED

BASE

5.

Remove the board from the fence.

IS

SECURELY TIGHTENED

SASE, THE SIT

IN

THE ROUTER CHUCK, AND ROUTER

IS

TIGHTLY SECURED TO TABLE TOP.

IS

SECURELY TIGHT-

IN

of

THE

described before. (MAKE

SURE ROUTER

UNPLUGGED WHEN MAKING ADJUSTMENTS).

3.

Check your adjustments by turning the router

and feeding a piece of scrap wood a few inches

beyond router bit. Then stop and turn router 'OFF'.

NOTE: Feed work

on

label on the frontside of unitized fence

(when facing

in

the direction of arrow shown

table front).

IS

'ON'

WARNING:

WHEN

ADJUSTING

HEIGHT

OF

ROUTER BIT FOR ANY DESIRED

CUT, MAKE

T AIN

THAT

THE

RETRACTABLE

SHOWN

SEE

THAT

FREELY

ITS NORMAL POSITION OVER

ABSOLUTELY

TOP OF BIT IS BELOW

INSIDE

SURFACE

GUARD

IN

FIG. #19. CHECK TO

GUARD

IN

AND OUT OF FENCE TO

RETRACTS

CER-

OF

AS

THE

(Retractable Guard not Shown

Clarity)

ROUTER TABLE HOLE. DO NOT

OPERATE ROUTER IF ANY PART

OF

THE

BIT

CONTACTS

THE

Small Knob

Jointing Fence

GUARD.

c----:;===~-

Inside Surface of Face of

Retractable

_G_u-:a:::rd==~~~~~~E~~~~~~=~JOinting

Fig. #19

"OTE:

The

procedure

described

Top of Bit

above

Fence

is

intended to provide a way of retracting and

holding the guard to have full access to the

router bit for making adjustments.

piece

to

be

routed could be substituted for

Work-

the scrap board for making adjustments.

4.

Loosen knob on jointing fence and move it out,

flush against the finished edge of scrap wood.

Retighten the knob.

lib:

==

on

~

________

Finished Edge Fig.

_____________________

See Fig. #20.

for.

#20

5. Repeat the test cut on the scrap wood.

6.

The router table

is

now ready for use.

NOTE: For best jointing results, take very shallow

cuts -

USING ROUTER

1/32"

or less.

TABLE FOR EDGE CUTTING WITH

NON-PILOTED BITS

~U~n~it~ized

Table Front

Fence

'--

USING RO'UTER

TABLE

AS JOINTER (FULL EDGE

CUTTING)

For maximum strength and accuracy, boards to

be

jointed together should be smooth and true. The edges

should be true to the workpiece surface. You can true

the edges on your router

1.

Check to see if face of jointing fence

the face of unitized fence.

on

jointing fence and push jointing fence inside the

cavity in unitized fence. Tighten knob

table using a straight bit.

is

flush with

If not, loosen small knob

on

jointing

fence.

NOTE: The jointing fence provides a continuous

support for the workpiece, as it is fed

beyond the router bit.

the gap created by the

by the router bit.

rial

2.

Adjust depth of cut (material you want to remove)

and router bit height

#18.

Tightly secure the fence and the router

as

It compensates for

removal of mate-

described before for Fig.

as

10

1.

Position the jointing fence such that its face

with the face of unitized fence. Tighten small knob

on jointing fence. See Fig. #21.

Large Knobs

Feed Workpiece

Direction of Arrow

Retractable Guard

Fig.

#21

is

flush

in

Table Front

Page 11

2. Adjust depth of cut (material you want to remove)

and router bit height

both

large knobs to lock fence on table. Tightly

secure the router. (MAKE

as

described before. Tighten

SURE ROUTER

IS

UNPLUGGED WHEN MAKING ADJUSTMENTS).

3.

Test cut a piece of scrap wood to make sure your

adjustments are satisfactory.

NOTE: Feed work in the direction of arrow shown

on

4.

The router table

label on frontside

(when facing

is

now ready for use.

table front).

of

unitized fence

NOTE: If you have purchased a MOLD MAKER

BIT SET (Sears Craftsman

~21255)

for

making moldings on your router table, set

the unitized fence

in

EDGE CUTTING

MODE for making the first cut on your

workpiece using Bit #25527.

See Fig. #22.

Unitized Fence in

Edge Cutting Mode

NOTE: If you have purchased RAIL AND STILE

CUTTERS

making cabinet door frames

table, MAKE

NESS

ness is more than

as shown

(Sears Craftsman

~21257)

on

your router

SURE THAT FRAME THICK-

is

not more than 3/4". If frame thick-

3/4", the top of the bit,

in

Fig. 'A' of Rail and Stile Cutters instructions, will interfere with retractable guard

on

your unitized fence. See Fig.

#24 and Fig. #19.

Door Frame Thickness

Must Not Be More

than

3/4"

USING ROUTER

Fig. #24

TABLE

FOR END CUTTING

When routing on ends of workpiece for making tenons,

sliding dovetails and tongue and groove joints, the workpiece must be made smooth with both edges and ends

made true to each other and its surfaces.

for

WITH PILOTED TYPE BITS

When bits with pilots are used to control the cutting

de):>th:

1.

Position the jointing fence

with non-piloted bits.

2. Move the unitized fence back only enough to permit the pilot to control the cutting depth.

ing the unitized fence as close to the pilot as

possible

vent chances of

injury.

Retractable Guard not Shown for

:::Iarity)

will serve

an

See Fig. #23.

Router Bit #25527

Fig. #22

in

the same manner as

Position-

as

a back-up, and will help pre-

accident, and possible personal

8~§fE~~~~~Unitized

NOTE: The push block and clamp plate assembly will

EXAMPLE: CUTTING TENONS

1. Make certain that jointing fence

tion with its face flush with that of unitized fence.

2.

Mount push block assembly on unitized fence as

shown before in Figs. #12a and #12b.

3.

Install proper table insert into the table top hole.

4. Mark

close to the end to be cut. Line 'A' for FULL

OF CUT (total

remove) and line

OF TENON. See

Workpiece Side

Against Face of

Fence

not accommodate workpiece wider than 4".

is

lines'

A' and

locked

'8'

on the edge of the workpiece

in

posi-

DEPTH

amount of material you want to

'8'

for FULL DESIRED HEIGHT

Fig. #25.

Wing Nut

Line

'B'

I

Fig. #23

Piloted Bit

Feed Workpiece in

Direction of Arrow

Table Front 11

Edge of Table Top Hole

Max. Width

4"

Page 12

WARNING: DO

3/8"

Max. Depth of Cut

NOT

SET

DEPTH

MORE

DEPTH OF CUT IS MORE THAN

3/8",

PIECE

WILL INTERFERE WITH PORTION

'P'

WILL

FENCE AND HENCE YOU

NOT BE ABLE TO SLIDE WORKPIECE ACROSS

THE CUT. SEE

THAN

THE EDGE

WHEN SLIDING ACROSS

OF GUARD. THE GUARD THEN

NOT

3/8"

'E'

RETRACT

THE BIT TO MAKE

FIG. #27.

Fig. #26

OF

CUT

(FIG. #26). IF

OF WORK-

INSIDE

WILL

1

~

Max. Depth of Cut

NOTE/

6.

Slide workpiece close to the bit and adjust unitized

fence and the router

outer most cutting edge of bit

'A' and top cutting edge

'B'. See Fig. #25. Tightly secure the fence and the

router

AND

7.

Slide push block and therefore workpiece back to

let guard swing out to its normal position

in Fig. #27.

8.

Turn router and shop vac 'ON'. While holding push

block

FENCE with both hands (Fig. #27) and FINGERS

AT SAFE DISTANCE ABOVE GUARD AND SPINNING BIT,

FULL DEPTH

STOP

ENOUGH BEYOND SPINNING BIT TO ALLOW

GUARD TO RETRACT OUT FULLY TO ITS NORMAL POSITION).

Tighten wing nut just enough to clamp

workpiece

ING

sliding motion of push block which

may

finished tenon surface when cut.

#29.

as

described before

HEIGHT OF CUT.

and GUIDING WORKPIECE AGAINST

feed workpiece across the bit to make

FEED

in

position. OVERTIGHTEN-

wing nut could cause binding

result

in

variations and/or steps

See Fig.

as

described before so that

is

aligned with line

of

bit

is

aligned with line

in

ADJUSTING DEPTH

as

OF CUT

UNTIL

IN

ONE PASS.

WORKPIECE

(DO

IS FAR

in

the

in

turn

in

the

shown

NOT

Portion 'P'

..

Direction of Feed

..

Fig. #27

5.

Position workpiece between clamp plate and push

block such that its side

of the unitized fence, the end to be cut

on the edge

with

lines 'A' and

workpiece

wing nut

clamp plate stays oriented on workpiece as shown

in

Fig. #25. (This will retract guard inside the fence

and provide access to the bit for making adjustments. MAKE

WHEN

PIECE

of

the table top hole and edge marked

'8'

in

this position by snugly tightening the

on

clamp rod while making sure that

SURE ROUTER

POSITIONING AND CLAMPING WORK-

AND MAKING ADJUSTMENTS).

is

held flush against face

is

facing the router bit. Clamp

IS

UNPLUGGED

is

resting

NOTE: Clamp

to check your adjustments before making

your finished cut.

9.

Turn router and shop vac 'OFF'. Unclamp workpiece, and slide push block back.

10. Position and clamp the opposite side of workpiece

in the same manner as described

sure the wing nut

piece

in

position and end to

edge of

#9.

11

. To cut ends of the tenon, position and clamp work-

piece

except edge of workpiece

against face

resting on edge of table top hole. See Fig. #28.

Repeat steps

table top hole). Repeat steps #7, #8, and

in

and test cut a piece of scrap wood

in

is

tight just enough to clamp work-

be

cut is resting

the same manner as

of

fence and end to be cut should

#7,

#8,

#9,

EdQe

Face of Unitized Fence

in

step

should

and #10.

of Workpiece Flush Against

Step

#5

be

held flush

#5

(make

on

the

above

be

12

Page 13

NOTE: When cutting tenons, always clamp work-

piece with end to be cut resting

on

edge

of table top hole. This will minimize steps

in

finished tenon surface (Fig. #29) due to

variations

in

the table top flatness.

Steps

Tenon

Fig. #29

in

Finished

Surface

DO

NOT CONNECT SHOP

SIDE

OF

FENCE.

THE

VAC.

WHEN USING BACK-

HOSE

WILL

HINDER

OPERATION.

For maximum accuracy, one edge of your workpiece

(edge sliding against the fence) must be true and

straight.

1.

Set up your fence

Remove

hex head b

b

O!~

Clll

large knobs and 1/4-20 x 1 3/4"

ts,

turn the unitized fence around and

attach it back to table with backside of fence

as

follows:

Ig.

facing the table front. See Fig. #30. (MAKE SURE

ROUTER IS UNPLUGGED

WHEN REMOVING

AND ATTACHING FENCE TO TABLE).

WARNING: ALWAYS CUT FULL DEPTH

ON

ALL 4 SIDES OF TENON IN ONE

PASS ACROSS

THE

SIDES

STEPS

TIONS

OR

ARE

ISHED TENON SURFACE,

THEM

PAPER

WITH WOOD CHISEL, SAND

OR

THE BIT. ONCE

ARE

CUT

OTHER

NOTICED

FILE, ETC.

AND IF

IMPERFEC-

ON FIN-

CLEAN

DO

NOT TRY

TO CLEAN THEM BY RE-SETTING

WORKPIECE ON ROUTER

AND FENCE.

WORKPIECE MAY

TABLE

INTERFERE WITH GUARD (SEE

FIG.

#27 ABOVE) WHICH

IN

TURN

WILL PREVENT IT FROM SLIDING

ACROSS

THE BIT.

OPERATION - ROUTING USING

BACKSIDE OF UNITIZED FENCE

USE BACKSIDE OF FENCE ONLY FOR ROUTING

OPERATIONS

SIDE OF WORKPIECE SUCH

ING; VEINING; CROWN MOLDING, ETC.

AWAY FROM EDGE ON THE UNDER-

AS

GROOVING; FLUT-

Table Front

#30

Fig.

2.

Raise guard and let it lean against the fence.

ALWAYS UNPLUG THE ROUTER BEFORE MAKING

ANY SETTING, ADJUSTMENTS, OR CHANGING

BITS.

WHEN ROUTING ALWAYS FEED AGAINST THE

gOTATION OFTHE CUTTER. FEED WORKPIECE

'

rHE

DIRECTION OF ARROW AS SHOWN ON LABEL

IN

ON THE SIDE OF FENCE BEING USED (when facing

the table front).

13

3.

Position the fenee behind the router bit for the

desired cutting depth (the distance of the cut from

in

the edge of the workpiece, as shown

Fig. #31).

Page 14

NOTE; When routing deep cuts (controlled by

router

bit)'

in

a workpiece, remove material in increments to prevent your router

from

overloading. Repeat operation with

several passes until the desired depth

is

achieved.

PROTRACTOR

Back Side of

Unitized

Fenc:e

Router Bit

Fig.

#31

4. Securely tighten both knobs and LOWER THE

GUARD

5.

Make the cut by sliding straight edge of workpiece

OVER THE BIT.

against the fence. Use a push stick as shown

Fig.

#32

. (For each successive cut, the fence would

need to be readjusted).

NOTE: Test cut a piece of scrap wood before mak-

ing your finish cut. Feed workpiece

direction of arrow shown

on

in

the

fence label

(Fig. #32).

in

Feed Workpiece

of Arrow Shown

the Direction

on

this Label

in

Your protractor will serve

port

is

needed for routing small workpieces or ends of

as

a handy

aid

when extra sup-

large workpieces. See Fig. #33.

Workpiece

Fig. #33

Miter Bar

Slot

NOTE: FOR ALL ROUTING OPERATIONS REQUIR-

ING USE OF MITER

THE FENCE, BE SURE

WITH MITER BAR SLOT

GAUGE ALONG WITH

TO

ALIGN FENCE

B~FORE

MAKING

ANY CUTS . SEE FIG. #17.

Back Side of

Unitized Fence

Fig. #32

Table

Front

14

Page 15

WARNING: FAILURE

USE OF THIS PRODUCT,

TABLE

OWNER'S

TO

MANUALS,

HEED

ALL

ALONG

ASSEMaL

WITH THOSE OPERATING

CAN RESULT IN SERIOUS

Y,

SAFETY,

AND OPERATI NG INSTRUCTIONS A

INSTRUCTIONS

BODilY

INJURY.

AND

WARNINGS

IN

ND

THE

WARNINGS

ROUTER

REGARDING THE

AND

THE ROUTER

~1E~/Rl~

/[RAFTSMAN

....cNERAL: The Router Table Extensions are used with

the 25443, 25444, 25475 and 25479, Router Table. The

extensions increase the length of the router table resulting in a larger work surface, allowing convenient additional support when routing long workpieces.

The extensions

CANNOT be used with the 25457 and

25473, Router Tables.

Eight screws, nuts, flat washers, and lockwashers are

packaged with this product which are necessary when

sembling the extensions to the

They are

Router

NOT used with the 25443, 25444, and 25479

Tab

les because those Router Tables come with a

sufficient quantity of fasteners

the

extensions to those Router Tables while the 25475

25475,

to

Router Table.

permit the assembly of

as-

does not.

NOTE:

proceed

EXTENSIONS

If

your Router Table has not been assembled yet,

to

the following section,

TO

THE ROUTER TABLE.

ASSEMBLING

If

your Router

THE

Table has already been assembled and used proceed as

follows:

a.

DISCONNECT THE POWER CORD TO THE ROUTER

FROM THE ELECTRICAL OUTLET.

b.

Remove any router bit that

c.

Lower the router so the router bit chucking nut is below

is

now

in

the router.

the top surface of the table .

, Remove all accessories, such

.l

and fences from table.

as

guards, miter gauge,

e. Place the table, top side down, on a flat surface and

disassemble the four legs from the table by removing

th~

screws, nuts, and washers that hold the legs in

place.

f.

Proceed to the following section.

ASSEMBLING

THE

EXTENSIONS

TO

THE ROUTER

TABLE.

Refer to the section in your Router Table Owner's Manual

concerning the assembly of the legs to the table .

ROUTER TABLE

EXTENSIONS

NO. 25211

2.

MAKE

SECUREL

3. Turn the table top side

extensions are even with

IN NO CASE

HIGHER

THEY

DURING ROUTING

CAN RESULT

4. If the extensions are

loosen the screws holding

tion them so they are even with or slightly lower than

the top

SCREWS AND

5. To double check, slide a flat piece of wood along the

top of the table in both directions. Make sure that the

end

edge

6. Continue with assembly

scribed

cessories and guards

WARNING:

PRESS

THEY

THAT

INJURY

SURE

ALL

Y:

TIGHTENED

SHOULD

THAN

MAY

of

THE

INTERFERE

IN

POSSIBLE

the table.

NUTS

of

the wood

of

the extension

in

the Owner'S

DO

moves

NOT

HEA VIL Y ON

MAY

BE

DAMAGED

CAN RESULT IN

DURING

ROUTING.

SCREWS

up

and check to see that the

or

slightly below the table top.

TOP

OF

WITH

CAUSING

AND NUTS ARE

THE

EXTENSIONS BE

THE TABLE OR ELSE

THE WORKPIECES

A CONDITION THAT

SERIOUS INJURY .

higher

than the top of the table,

the

extensions and reposi-

SECURELY

ONCE

AGAIN.

TIGHTEN

freely without contacting the

next

to the table.

of

the Router Table as de-

Manual

previously

PLACE

THE

POSSIBLE

or reassemble the ac-

removed.

HEAVY OBJECTS OR

EXTENSIONS OR ELSE

CAUSING

A CONDITION

SERIOUS BOOIL Y

ALL

1.

To assemble the Table Extensions to the Router Table,

place the table, top side down, on a smooth, flat surface, and position the Table Extensions relative to the

as

table

bling the legs to the table

making sure to tighten the screws marked

followed by the screws marked

shown. Now follow the procedure for assem-

in

the Owner's Manual,

"A"

"B".

The screws, that

normally just hold the legs to the table, will now also

hold the extensions on the table.

49L

-23

first

Sold

by

Chicago,

MADE

SEARS,

IL

IN

U.S.A.

60684

ROEBUCK

U.S.A.

AND

CO.,

3-89

Page 16

PARTS LIST FOR CRAFTSMAN ROUTER TABLE

MODEL

NO"

171"254790

36---10.<

II~

15--r

39

1

~

I

G3

~

___

-**

-34

17

21

2

~

Key

No.

"13

"14

"15

20

Part No. Description Quan.

1

31L-431 Router Table Top 1

31

L-429

2

·3

F29A·306· 14

"4

F29A·489-3 Hex HD Bolt 114-20 x 1

•

"5

F29A-242-2

31L-559 Miter Bar 1

6

31L-438 Pointer 1

7

F29A-264-8

"8

29L-183

9

29L-293 Protractor Head

10

11

31L-560 Knob

29L-202

12

29A-298-13 Flat Hd. Mach. Screw #10-32 x

29A-509-1

29A·306-15

16

29A-310-5 Carriage Boll

17

29L-646

18

29L-650 Guard

19

29L-647 Guard (Retractable)

29L-649

Table Leg

Flat Washer

Hex. Mach.

Pan Hd.

Grooved Pin

Plastic

1110

1/

1 0 Flat Washer 1

Unitized Fence 1

Jointing Fence 1

9/32

I.D. x 3/4 O.D.

3/4

Ig.

Screw Nut 1/10-32 17

Mach.

3/16

Insert

Lock Wasfler

1110-24

Screw #10-32 x

dia. x 5/8 type D

x 3/4 Ig. 1

5/16

3/8

16

Key

No.

Part No.

21

29L·648

4

3

2

1

1

1

1

5

3

1

1

22

29L·651

23

29L·652

"24

F·29A·246-1 2

25 29L-654

"26

F-29A-252-8

"27 F-29A-306-27

"28

29A-264-7

"29

F-29A-327-3

"30

F-29A-306-26

"31

F-29A-653

32 29L·660

29L-659

33

34 45A-289

45A-290

35

45A-297

36

37

29L-655

F29A-242-8

38

39

45A·292

Description

Push Block

Clamp Rod

Clamp Plate

Hex Hd. Bolt

Spring

Wing Nut

5/16

Pan Hd. Mach.

114" Lock Washer (Helical)

#8

Flat Washer

#8-10

114-20

1/4-20

Labea(Self Adhesive)

Label

Label

Vacuum Hose Reducer

Hex Nut

Label (Self Adhesive)

114-20 x

5/16-18

Flat Washer

Screw #10-32 x 5/8 Ig.

3/16

x 9/16

Lg.

Pan

Knob (large)

Knob (small)

(Self Adhesive)

(Self Adhesive)

114-28

1"

I.D. x

Hd.

Plasform Screw

Ig.

1I20.D.

Quan.

1

1

1

1

1

1

1

16

1

1

1

2

1

1

2

1

1

1

1

-"

"Hardware item - may

be

purchased locally.

16

Loading...

Loading...