Page 1

Owner's Manual

lC.. TSM

AiR COMPRESSOR

l O-gallon

1 HP

Off Lubricated

Model No. 16923

CAUTION:

Before using this product, read this

manual and follow all its Safety

Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

11/19/2012

Part No E106443

, Safety Instructions

, installation & Operation

, Maintenance & Storage

° Troubleshooting Guide

, Parts List

Page 2

TABLE OF CONTENTS

Page

Warranty ................................................................ see below

Safety Symbols ................................................................... 1

important Safety Instructions & Guidelines .............................................. 1

Specifications .................................................................... 2

Glossary ........................................................................ 2

Duty Cycle ....................................................................... 2

Parts & Features .................................................................. 3

installation & Assembly ............................................................. 4

Operating Procedures .............................................................. 6

Maintenance ..................................................................... 7

Storage ......................................................................... 7

Troubleshooting Guide ............................................................. 8

Exploded View ................................................................... 9

Parts List ...................................................................... 10

Service Number ........................................................... back cover

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted against any defects in material

or workmanship. A defective product will receive free repair or replacement if repair is unavailable.

For warranty coverage details to receive free repair or replacement, visit the web site: www.craftsman.com

This warranty is void if this product is ever used while providing commercial services or if rented to

another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Page 3

Safety Instructions

The information listed below should be read and

understood by the operator. This information is

given to protect the user while operating and stor-

ing the air compressor. We utilize the symbols

below to allow the reader to recognize important

information about their safety.

Indicates an imminently hazardous situation

which, if not avoided, will result in death or seri-

ous injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury.

When used without the safety alert symbol indi-

cates a potentially hazardous situation which, if

not avoided, may result in property damage.

Important Safety Instructions and Guidelines

* Save all instructions

Improper operation or maintenance of this product could result in serious injury and/or property

damage. Read and understand all of the warnings and safety instructions provided before using this

equipment.

The air compressor should be operated on a dedicated 15 amp circuit. If

the circuit does not have 15 free amps available, a larger circuit must be

used. Always use more air hose before utilizing extension cords. All exten-

sion cords used must be 12 gauge with a maximum length of 25 ft. The

circuit fuse type must be a time delay. Low voltage could cause damage to

the motor.

Risk of Moving Parts

Risk of Burns

If the air compressor is in operation, all guards and covers should be

attached or installed correctly. If any guard or cover has been damaged,

do not operate the equipment until the proper personnel has correctly re-

paired the equipment. The power cord should be free of any moving parts,

twisting and/or crimping while in use and while in storage.

There are surfaces on your air compressor that while in operation and

thereafter can cause serious burns if touched. The equipment should be

allowed time to cool before any maintenance is attempted. Items such as

the compressor pump and the outlet tube are normally hot during and after

operation.

Risk of Falling

Risk from Fl_Objects

Operation of the air compressor should always be in a position that is

stable. Never use the air compressor on a rooftop or elevated position that

could allow the unit to fall or be tipped over. Use additional air hose for

elevated jobs.

Always wear ANSI Z87.1 approved safety glasses with side shields when

the air compressor is in use. Turn off the air compressor and drain the air

tank before performing any type of maintenance or disassembly of the

hoses or fittings. Never point any nozzle or sprayer toward any part of the

body or at other people or animals.

Page 4

Important Safety Instructions & Guidelines

Risk to Breathing

Risk of Electrical Shock

Risk of

Explosion or Fire

Risk of Bursting

Avoid using the air compressor in confined areas. Always have adequate

space (12 inches) on all sides of the air compressor. Also keep children,

pets, and others out of the area of operation. This air compressor does

not provide breathable air for anyone or any auxiliary breathing device.

Spraying material will always need to be in another area away from the air

compressor to not allow intake air to damage the air compressor filter.

Never utilize the air compressor in the rain or wet conditions. Any electrical

issues or repairs should be performed by authorized personnel such as an

electrician and should comply with all national and local electrical codes.

The air compressor should also have the proper three prong grounding

plug, correct voltage, and adequate fuse protection.

Never operate the compressor near combustible materials, gasoline or

solvent vapors. If spraying flammable materials, locate the air compressor

at least 20 feet away from the spray area. Never operate the air compres-

sor indoors or in a confined area.

Always drain the air compressor tank daily or after each use. If the tank

develops a leak, then replace the air compressor. Never use the air com-

pressor after a leak has been found or try to make any modifications to the

tank. Never modify the air compressor's factory settings which control the

tank pressure or any other function.

Specifications

Pump .................. Oil-lube direct drive

Motor ................... 1.0 HP (Induction)

Bore ............................... 1.65"

Stroke .............................. 1.26"

Voltage Single Phase ............... 120 VAC

Minimum Circuit Requirement ........ 15 Amps

Air Tank Capacity ................ 10 Gallons

Cut-in Pressure ................... 105 PSI

Cut-out Pressure .................. 135 PSI

SCFM @ 90 PSI ....................... 2.4

Oil Capacity ................. 90 mL or 3 oz.

Oil Type .... SAE 30 Non-detergent Semi-Synthetic

Glossary

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of

measure for air delivery,

PSIG: Pounds per square inch gauge; a unit of

measure for pressure.

ASME: American Society of Mechanical Engineers,

Cafifornia Code: Unit may comply with California

Code 462 (I) (2)/(M) (2).

Cut-In Pressure: The air compressor will

automatically start to refill the tank when

the pressure drops below the prescribed

minimum.

Cut-Out Pressure: The point at which the motor

stops when the tank has reached maximum

air pressure.

Code Certification: Products that bear one or more

of the following marks: UL, CUL, ETL, CSA,

have been evaluated by OSHA-certified

independent safety laboratories and meet

the applicable Underwriters Laboratories

Standards for Safety.

Duty Cycle

This is a 50% duty cycle air compressor. Do not run the air compressor more than 30 minutes of

one hour. Doing so could damage the air compressor.

2

Page 5

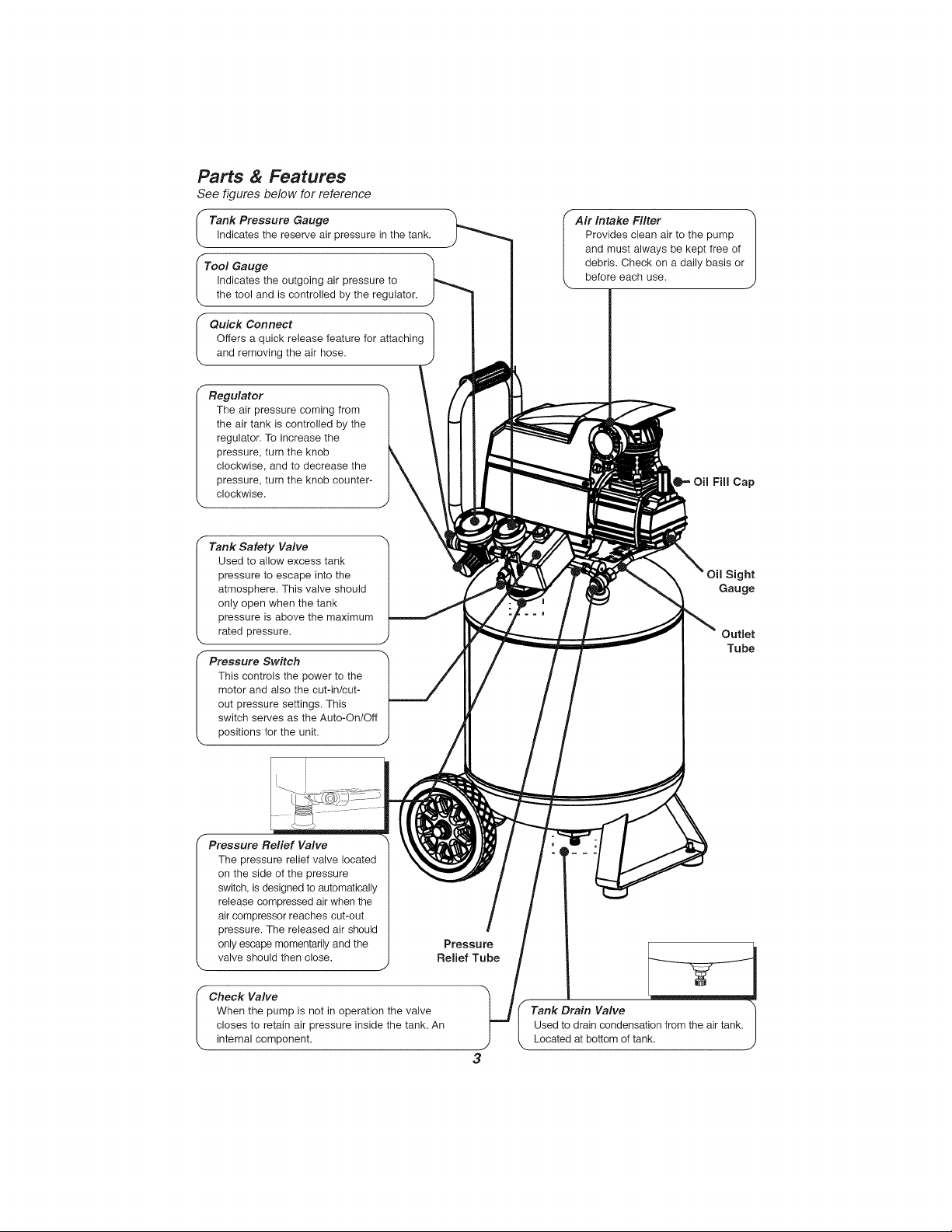

Parts & Features

See figures below for reference

I Tank Pressure Gauge

Indicates the reserve air pressure in the tank.

Indicates the outgoing air pressure to

the tool and is controlled by the regulator.

Offers a quick release feature for attaching

I Quick Connect -1

and removing the air hose.

The air pressure coming from

the air tank is controlled by the

regulator. To increase the

pressure, turn the knob

clockwise, and to decrease the

pressure, turn the knob counter-

clockwise.

Used to allow excess tank

pressure to escape into the

atmosphere. This valve should

only open when the tank

I Tank Safety Valve

pressure is above the maximum

rated pressure.

f Air Intake Filter

Provides clean air to the pump

and must always be kept free of

debris. Check on a daily basis or

before each use.

Oil Fill Cap

Sight

Gauge

Outlet

Tube

This controls the power to the

motor and also the cut-in/cut-

out pressure settings. This

I Pressure Switch

switch serves as the Auto-On/Off

positions for the unit.

Pressure Relief Valve

The pressure relief valve located

on the side of the pressure

switch, is designed to automatically

release compressed air when the

air compressor reaches cut=out

pressure. The released air should

only escape momentarily and the

valve should then close.

Check Valve

When the pump is not in operation the valve

closes to retain air pressure inside the tank. An

internal com

Preseute

Relief Tube

Tank Drain Valve

Used to drain condensation from the air tank.

Located at bottom of tank.

Page 6

installation & Assembly

The air compressor should be turned off, unplugged from the power source, the air bled from the

tank and the unit allowed time to cool before any maintenance is performed. Personal injuries could

occur from moving parts, electrical sources, compressed air or hot surfaces. The quick connect as-

sembly must be attached before use. Failure to assemble correctly could result in leaks and possible

injury. If unsure of assembly instructions or you experience difficulty in the assembly please call our

toll free number for assistance.

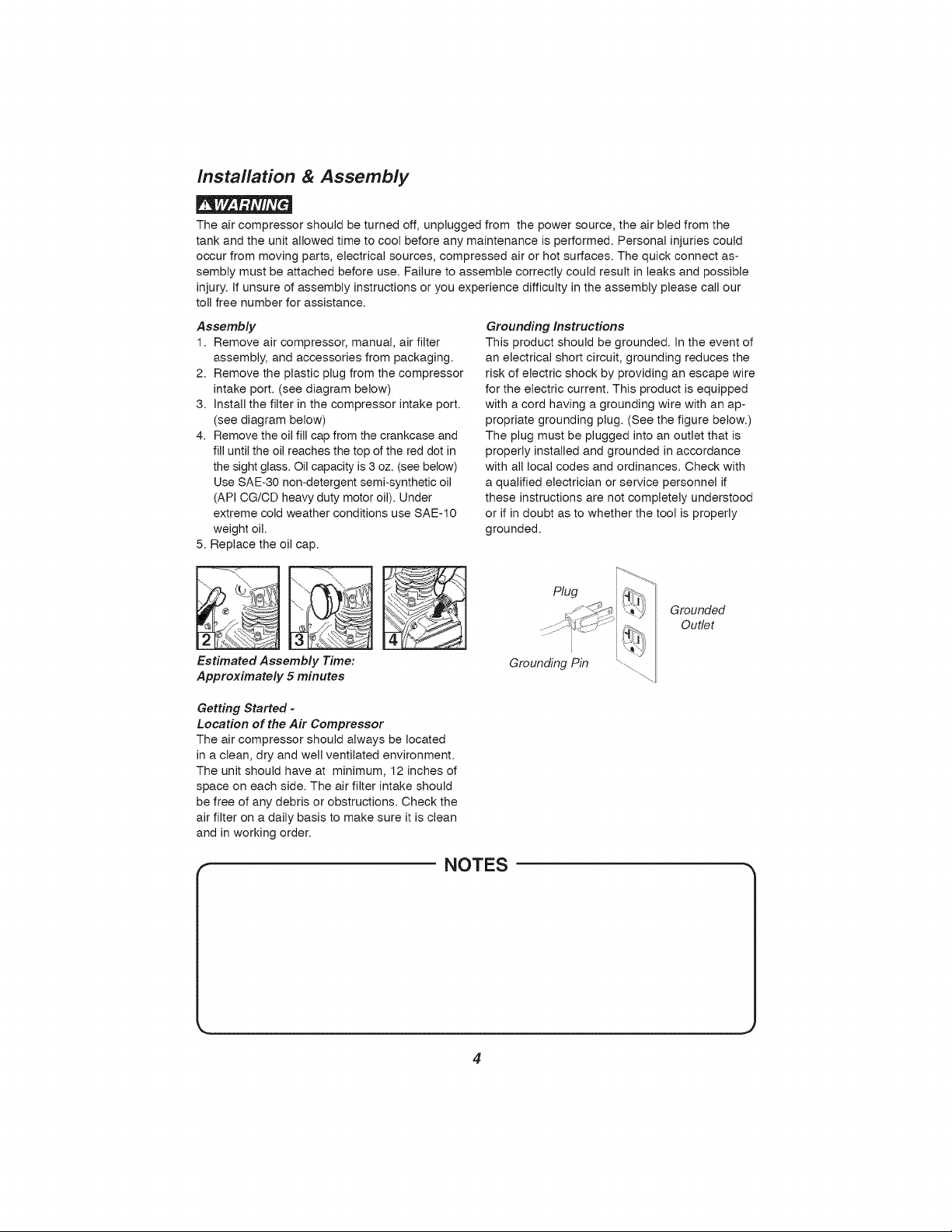

Assembly

1. Remove air compressor, manual, air filter

assembly, and accessories from packaging.

2. Remove the plastic plug from the compressor

intake port. (see diagram below)

3. Install the filter in the compressor intake port.

(see diagram below)

4. Remove the oil fill cap from the crankcase and

fill until the oil reaches the top of the red dot in

the sight glass. Oil capacity is 3 oz. (see below)

Use SAE-30 non-detergent semi-synthetic oil

(API CG/CD heavy duty motor oil). Under

extreme cold weather conditions use SAE-10

weight oil.

5. Replace the oil cap.

Grounding Instructions

This product should be grounded. In the event of

an electrical short circuit, grounding reduces the

risk of electric shock by providing an escape wire

for the electric current. This product is equipped

with a cord having a grounding wire with an ap-

propriate grounding plug. (See the figure below.)

The plug must be plugged into an outlet that is

properly installed and grounded in accordance

with all local codes and ordinances. Check with

a qualified electrician or service personnel if

these instructions are not completely understood

or if in doubt as to whether the tool is properly

grounded.

Plug

Grounded

..... Outlet

Estimated Assembly Time:

Approximately 5 minutes

Getting Started -

Location of the Air Compressor

The air compressor should always be located

in a clean, dry and well ventilated environment.

The unit should have at minimum, 12 inches of

space on each side. The air filter intake should

be free of any debris or obstructions. Check the

air filter on a daily basis to make sure it is clean

and in working order.

Grounding Pin

NOTES

4

Page 7

Installation & Assembly

Improper installation of the grounding plug will result in a risk of electric shock. If repair or replace-

ment of the cord or plug is necessary, do not connect the grounding wire to either flat blade terminal.

The wire with insulation having an outer surface that is green with or without yellow stripes is the

grounding wire. Check with a qualified electrician or serviceman if the grounding instructions are not

completely understood, or if in doubt as to whether the product is properly grounded. Do not modify

the plug provided; if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

This product is for use on a circuit having a nominal rating of 120 volts and is factory-equipped with

a specific electric cord and plug to permit connection to a proper electric circuit. Make sure that the

product is connected to an outlet having the same configuration as the plug. No adapter should be

used with this product. If the product must be reconnected for use on a different type of electric circuit,

qualified service personnel should make the reconnection.

Extension Cords

Use only a 3-wire extension cord that has a 3-blade grounding plug, and a 3-slot receptacle that will

accept the plug on the product. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. Cords

must not exceed 25 feet and No. 12 AWG size must be used. An undersized cord will cause a drop in

line voltage resulting in loss of power and overheating.

Break In Procedures

No break in procedure is required by the user. This product is factory tested to ensure proper opera-

tion and performance.

NOTES

J

5

Page 8

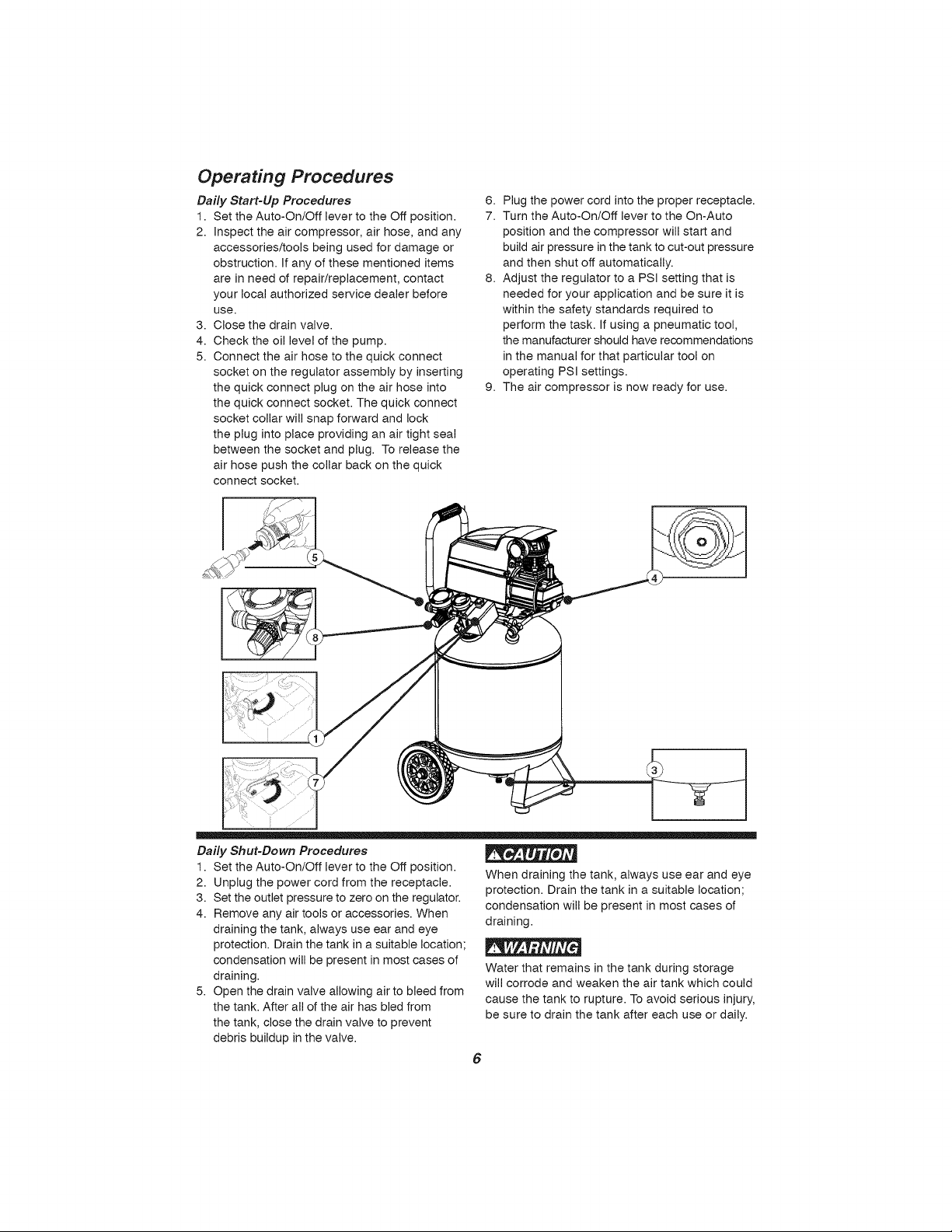

Operating Procedures

Daily Start-Up Procedures

1. Set the Auto-On/Off lever to the Off position.

2. Inspect the air compressor, air hose, and any

accessories/tools being used for damage or

obstruction. If any of these mentioned items

are in need of repair/replacement, contact

your local authorized service dealer before

use.

3. Close the drain valve.

4. Check the oil level of the pump.

5. Connect the air hose to the quick connect

socket on the regulator assembly by inserting

the quick connect plug on the air hose into

the quick connect socket. The quick connect

socket collar will snap forward and lock

the plug into place providing an air tight seal

between the socket and plug. To release the

air hose push the collar back on the quick

connect socket.

i

6. Plug the power cord into the proper receptacle.

7. Turn the Auto-On/Off lever to the On-Auto

position and the compressor will start and

build air pressure in the tank to cut-out pressure

and then shut off automatically.

8. Adjust the regulator to a PSI setting that is

needed for your application and be sure it is

within the safety standards required to

perform the task. If using a pneumatic tool,

the manufacturer should have recommendations

in the manual for that particular tool on

operating PSI settings.

9. The air compressor is now ready for use.

Daily Shut-Down Procedures

1. Set the Auto-On/Off lever to the Off position.

2. Unplug the power cord from the receptacle.

3. Set the outlet pressure to zero on the regulator.

4. Remove any air tools or accessories. When

draining the tank, always use ear and eye

protection. Drain the tank in a suitable location;

condensation will be present in most cases of

draining.

5. Open the drain valve allowing air to bleed from

the tank. After all of the air has bled from

the tank, close the drain valve to prevent

debris buildup in the valve.

When draining the tank, always use ear and eye

protection. Drain the tank in a suitable location;

condensation will be present in most cases of

draining.

Water that remains in the tank during storage

will corrode and weaken the air tank which could

cause the tank to rupture. To avoid serious injury,

be sure to drain the tank Nter each use or daily.

6

Page 9

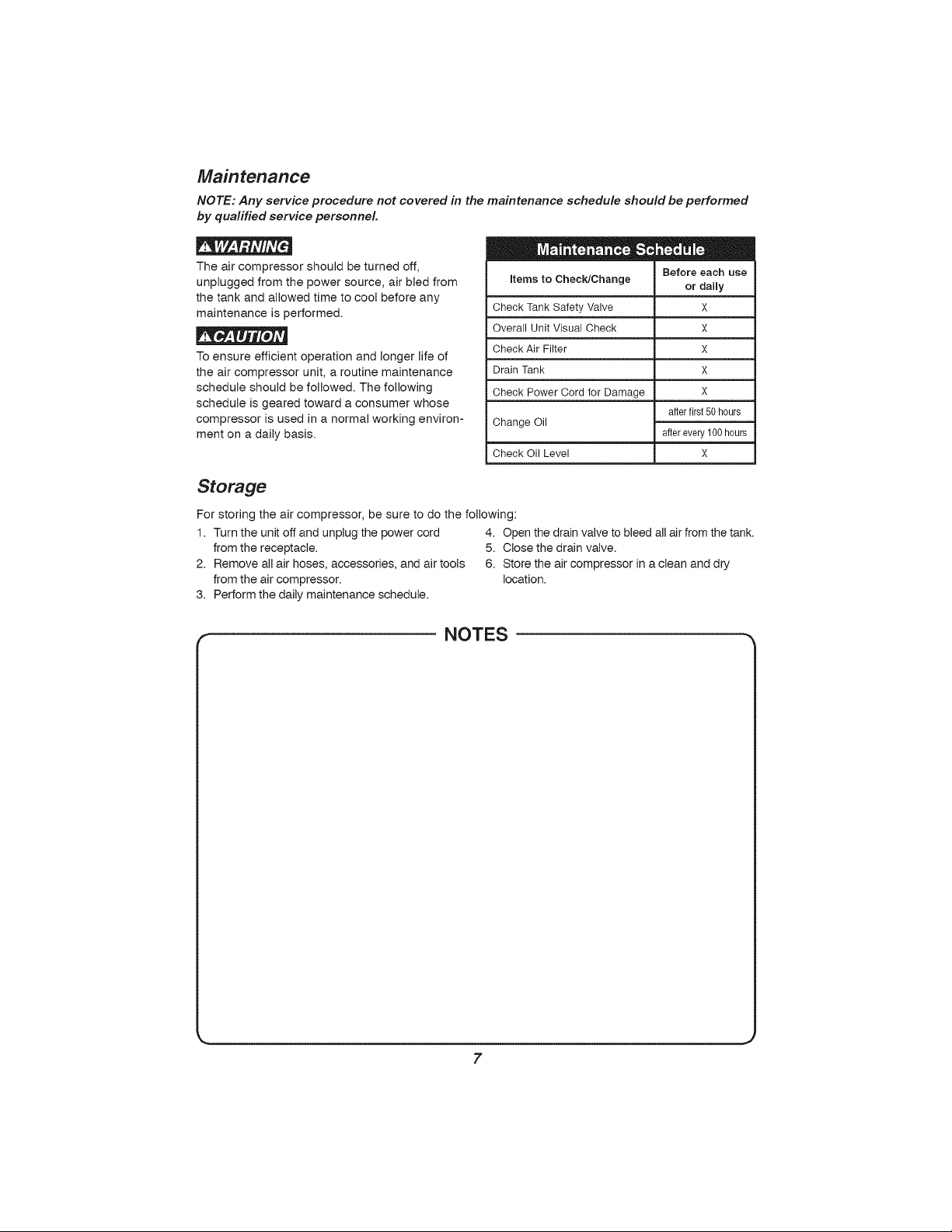

Maintenance

NOTE: Any service procedure not covered in the maintenance schedule should be performed

by qualified service personnel

The air compressor should be turned off,

unplugged from the power source, air bled from

the tank and allowed time to cool before any

maintenance is performed.

To ensure efficient operation and longer life of

the air compressor unit, a routine maintenance

schedule should be followed. The following

schedule is geared toward a consumer whose

compressor is used in a normal working environ-

ment on a daily basis.

Items to Check/Change

Check TankSafety Valve

Overall Unit Visual Check

Check Air Filter

DrainTank

Check PowerCord for Damage

Change Oil

Check 0il Level X

Before each use

or daily

X

X

X

X

X

afterfirst50hours

afterevery100hours

Storage

For storing the air compressor, be sure to do the following:

1. Turn the unit off and unplug the power cord 4. Open the drain valve to bleed all air from the tank.

from the receptacle. 5. Close the drain valve.

2. Remove all air hoses, accessories, and air tools 6. Store the air compressor in a clean and dry

from the air compressor, location.

3. Perform the daily maintenance schedule.

NOTES

7

Page 10

Troubleshooting Guide

The air compressor should be turned off and unplugged from the power source before any mainte-

nance is performed as well as the air bled from the tank and the unit allowed time to cool. Personal

injuries could occur from moving parts, electrical sources, compressed air, or hot surfaces.

PROBLEM POSSIBLE CORRECTION

Air leaks at the check A defective check valve results in a constant air leak at the pressure relief

valve or at the pres- valve when there is pressure in the tank and the compressor is shut off.

sure relief valve. Drain the tank, then remove and clean or replace the check valve.

Air leaks between Be sure of proper torque on head bolts, if leak remains, contact a service

head and cylinder, technician.

Air leak from safety Operate the safety valve manually by pulling on the ring. If the valve con-

valve, tinues to leak when in the closed position, it should be replaced.

Pressure reading on If there is an excessive amount of pressure drop when the accessory is

the regulated pressure used, replace the regulator.

gauge drops when an

accessory is used. NOTE:

Adjust the regulated pressure under flow conditions (while accessory is

being used). It is normal for the gauge to show minimal pressure loss

during initial use of the tool.

Excessive tank pres- Move the Auto-On/Off lever to the Off position. If the unit doesn't shut off,

sure. unplug it from the power source and contact a service technician.

Motor will not start. Make sure power cord is plugged in and the switch is on. Inspect for the

Excessive moisture in Remove the water in the tank by draining after each use. High humidity

the discharge air. environments will cause excessive condensation. Utilize water filters on

proper size fuse in your circuit box. If the fuse was tripped, reset it and

restart the unit. If repeated tripping occurs, replace the check valve or

contact a service technician.

your air line.

NOTE:

Water condensation is not caused by compressor malfunction. Be sure

the compressor's air output is greater than your tool's air consumption

rate.

Air leaks from the tank Never drill into, weld or otherwise modify the air tank or it will weaken.

body or tank welds. The tank can rupture or explode. Compressor cannot be repaired. Dis-

continue use of the air compressor.

Page 11

Craftsman Air Compressor Model 16923

Exploded View

3-- 2 __"_

/

65 --\

\

\

........ 39

Page 12

Craftsman Air Compressor Model 16923

Parts List

Ref. Kit Part Ref. Kit Part

# # Number Description Qty # # Number Description Qty

1 3 Screw, M6 X 1.0ram 4 25 3 E100248 Capacitor, Starting 1

2 3 Washer, Lock M6 8 8ram

3 3 E100227 Head, Cylinder 1 27 3 Nut, M8x1.25, ZDC 6

4 1 & 3 Gasket, Head to Valve 1

5 3 E100228 Plate, Valve 2 29 N/A

6 3 E100229 Valve Reed 2 30 3 Assembly, Motor/Pump, 1

7 1 & 3 Gasket, Valve Plate 1

8 1 & 3 Gasket, Cylinder to 1

9 2&3 E101113 Cylinder 1

10 3 Screw, SHC M6 x 1.0 4 33 6 Nut, Comp, 3/8" 2

11 1 & 3 Gasket, Cylinder, 1

12 2 & 3 Eccentric for L1 1 36 5 Ferrule, 1/4" 2

13 2 & 3 Nut, Hex, M6x1.0 3 37 5 Nut, Comp, 1/4" 2

14 2 & 3 Screw, SHC M6 x 1.0 1 38 5 Tube, Relief 1/4" 1

18 2&3 L1 Piston/Connecting 1 39 Tank/Frame Assy, 10 1

16 1 & 3 Bafflefor L1 1 40 Washer, Flat M6 2

17 3 E100087 Cap, Oil Fillw/o-ring 1 41 E101037 Isolator, Rubber 2

18 3 E100566 Cover, Crankcase 1 42 Screw, SHC, M6 x 1.0 2

19 3 E100078 Plug, oil sightw/seal 1 43 E100098 Valve, Drain Multi-Turn 1

20 3 Screw, HFH M5 x 0.8 4 44 7 Nut, Hex MlOx1.28 2

21 3 Motor Assembly/Pump 1

22 3 E100860 Fan, Motor F1 125mm 1 M10x1.25x45rnrn

23 3 Ring,Snap,Outer, 15mm 1 48 E101340 Cord, Power16/3 AWG 1

24 3 E100247 Capacitor,Running 1

X 30ram

Plate 28 N/A

Valve Plate

x 20MM 34 6 Tube, Outlet 3/8" 1

Lower 38 E101362 Valve, Check LH 1

x 20MM Aluminum

RodAssembly Gallon, L110VWS

for L1 x 25mm

x 18MM (Yellow Zinc

Dich Plate) 48 7 Washer, Flat MIO 2

Housing, L1B2

26 3 Washer, Tooth Lock, 2

6.5MM TALL

L1B2w/RHExhaust

31 E100809 Fitting, EIbow,3/8NPT 1

x 3/8 Comp

32 6 Ferrule, 3/8" 2

Aluminum Finned

46 7 Wheel, Black Hub 2

47 7 Bolt, Shoulder, 2

type ST 6' long

i NOTES 1

10

Page 13

Craftsman Air Compressor Model 16923

Parts List

Ref. Kit Pert

# # Number Description Qty

49 E100853 Nipple, 1/4"NPT X 1

50 E102611 Valve, Safety 1

51 E102857 Nipple, 1/4"NPT X 1

52 E100059 Regulator, Square 1

53 E100307 Quick Connect, Brass 1

54 E103369 Gauge, Pressure, 1

55 E104074 Ring, BezelTool(50 1

56 E106477 Assy, Switch, Pressure 1

57 E103363 Gauge, Pressure, 1

58 E104568 Ring, BezelTank(38 1

59 Screw, Hex Flange 4

60 E101335 Handle 1

61 E105883 Grip, Rubber 1

62 4 Cover, Filter 1

63 4 E100435 Element, Intake Filter 1

35MM

43MM

Body LHFlow

(50mm 135 PSI R/L,

1/4' NPT)

mm)

(135 PSI)

(38mm w/135 PSI R/L)

mm)

Head, MSX0.8X15mm

Note: Any part/kit number field without a number is not avail-

able. Descriptions are provided for reference only. The Kit #

column represents that the part being offered is available in a

kit. One of each part per kit will be offered.

Kit numberand parts that are included are as follows:

Kit No. Part No. Description No.

1 E100959 Kit,GasketRebuild 4,7,8,11,16

2 E100251 Kit, Piston- (Note:Order 9,12thru15

3 E105154 Kit, L1B2 Motor/Pump 1- 27,30

4 E100794 Kit, Air Filter 62-64

5 E105953 Kit, 1/4"CuPressure 36-38

6 E105952 Kit, 3/8" AluminumOutlet 32-34

7 E102192 Kit, Wheel (this kit isfor 44-47

GasketKit#1,aswell,

when orderingthis kit)

Assy. w/RH Exhaust

ReliefTube

Tube

onewheelonly)

Reference

NOTES

64 4 Base, Air Filter 1

65 Screw, Hex Flange 6

Head, MSX0.8Xl0mm

66 E105615 Shroud 1

67 Bolt, SHCM8x 1.25 x 4

25mm (ZDC Plate)

68 Washer, Lock, M8 4

69 Washer, Flat M8 4

70 E101802 Strain Relief, 16/3 1

AWG ST

11

Page 14

Manual de

i

COMPRESOR DE AIRE

37.9 iitros

1 HP

Lubricada con aceite

# de Modelo 16923

PRECAUCION:

Antes de usar el producto, lea este

manual y siga sus reglas e instruc-

clones de seguridad.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

11/19/2012

Part No. E106443

* Instrucciones y pautas de

seguridad importantes

* Instalaci6n y ensamblaje

* Procedimientos de operaci6n

* MantenimientoyAImacenamiento

* Diagn6stico y correcci6n de fa#as

* Lista de las piezas

Page 15

CONTENIDO

P&gina

Garanfia ................................................................ esta p&gina

Simbolos de seguridad ............................................................ 15

Instrucciones y pautas de seguridad importantes ........................................ 15

Especificaciones ................................................................. 16

GIosario ........................................................................ 16

Ciclo de trabajo .................................................................. 16

Partes y caracteristicas ............................................................ 17

Instalaci6n y ensamblaje ........................................................... 18

Procedimientos de operaci6n ....................................................... 20

Mantenimiento ................................................................... 21

AImacenamiento ................................................................. 22

Diagn6stico y correcci6n de fallas .................................................... 22

Vista esquem_.tica ............................................................... 23

Lista de las piezas ............................................................... 24

NOmero de servicio ........................................................ Contratapa

UN AKIO DE GARANTiA DE CRAFTSMAN

DURANTE UN AIqO desde la fecha de compra, este producto tiene garantia contra defectos en los

materiales o en la fabricaci6n. Los productos defectuosos se reparar_.n gratuitamente o se reempla-

zar&n sin coste si la reparaci6n no es possible.

Para conocer los detalles de cobertura de la garanfia con el fin de obtener una reparaci6n o un reem-

plazo, visite el sitio web www.craftsman.com

Esta garanfia no es v_.lida si el producto se utiliza para proporcionar servicios comerciales o si se

alquila a un tercero.

Esta garanfia le proporciona derechos legales especificos yes posible que adem&s tenga otros

derechos, dependiendo del pais o el estado.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 EE. UU.

Page 16

Instrucciones de seguridad

El operador debe leer y entender la informaci6n si-

guiente. Esta informaci6n se ofrece para proteger

al usuario durante la operaci6n y el almacenaje

del compresor. Los simbolos siguientes son los

que se utilizan para indicar al lector informaciOn

que es importante para su seguridad.

Indica una situaci6n de riesgo inminente que,

de no evitarse, provocaria lesiones graves o la

muerte.

Indica una situaciOn potencialmente peligrosa

que, de no evitarse, podria provocar lesiones

graves o la muerte.

Indica una situaci6n potencialmente peligrosa

que, de no evitarse, podria provocar lesiones

menores o moderadas.

AI aparecer sin el simbolo de alerta de se-

guridad, indica una situaciOn potencialmente

peligrosa que, de no evitarse, podria causar

dafios materiales.

Instrucciones y pautas de seguridad importantes

* Guarde todas las instrucciones

La operaciOn y el mantenimiento inadecuados de este producto pueden provocar lesiones graves y

dafios materiales. Antes de utilizar este equipo, lea y entienda las advertencias e instrucciones de

seguridad aqui contenidas.

El compresor de aire se debe operar desde un circuito dedicado de 15

amperes. Si el circuito no dispone de una capacidad de 15 amperes,

se debe usar un circuito de mayor capacidad. Si es necesario, antes de

emplear una extension electrica, aflada una manguera de aire mas larga.

Las extensiones electricas deben ser de calibre 12 y tener una Iongitud

maxima de 7.6 metros. El fusible del circuito debe ser de acci6n

retardada. Un voltaje demasiado bajo puede dafiar el motor.

Riesgo por partes en

movimiento

Antes de operar el compresor, todos los protectores y cubiertas deben

estar instalados correctamente. Si alguno de los protectores o cubiertas

esta dafiado, no opere el equipo sino hasta que personal calificado repare

el problema. El cable de corriente se debe mantener alejado de las partes

moviles del equipo y no debe torcerse ni prensarse durante su empleo ni

al ser almacenado.

Ries_ o de guemaduras

Rico de caida

Riesgo de lanzamiento

de objetos

En su compresor hay superficies que, de ser tocadas durante y despues

de su operaci6n, pueden causar quemaduras graves. Antes de darle

mantenimiento al equipo, se ledebe dejar enfriar. Por Io normal, durante y

despues de su operaci6n, ciertas partes como la bomba del compresor y

el tubo de salida estaran calientes.

El compresor siempre se debe operar en una posici6n estable. Nunca

utilice el compresor sobre un techo o en una posici6n elevada desde

donde podr[a caer o volcarse. AI trabajar en posiciones elevadas, utilice

una manguera de aire mas larga.

AI emplear el compresor, siempre utilice anteojos de seguridad con

protectores laterales que cumplan con la norma ANSI Z87.1. Antes de

Ilevar a cabo cualquier clase de mantenimiento y antes de desconectar las

mangueras y acopladores, apague el compresor y drene el tanque de aire.

Nunca apunte la boquilla o rociador hacia ninguna parte de su cuerpo ni

del de otros seres.

15

Page 17

Instrucciones y pautas de seguridad importantes

Riesgo para la

res_iraci6n

Riesgo de descargas

el_ctricas

Riesgo de explosi&n

Rie_llido

Evite utilizar el compresor de aire en areas encerradas. Siempre tenga

un espacio libre adecuado (30 cm.) en todos los lados del compresor.

Tambien mantenga fuera del area de operaci6n a mascotas, niflos y otras

personas. Este compresor de aire no provee aire que pueda ser respirado

ni empleado con un dispositivo respiratorio auxiliar. El material de rociado

siempre debera estar en otra zona, alejado del compresor de aire, para

evitar que el aire aspirado dafle el filtro del compresor.

Nunca utilice el compresor de aire bajo Iluvia o en lugares mojados. Los

problemas electricos deben ser reparados por personal autorizado, tal

como seria un electricista, y deben cumplir con las normas el6ctricas

nacionales y locales. El compresor tambien debe tener la clavija apropiada

de tres terminales y contar con un suministro el6ctrico que sea del voltaje

correcto y con un fusible de protecci6n adecuado.

Nunca opere el compresor cerca de materiales combustibles, gasolina ni

vapores de solventes. Si est& rociando materiales inflamables, coloque el

compresor a una distancia de cuando menos 6 metros del &rea de rocia-

do. Nunca opere el compresor de aire en interiores o en lugares cerrados.

Drene el compresor diariamente o despues de cada utilizaci6n. Si el

tanque tiene una fuga, reemplace el compresor. No utilice el compresor si

se ha detectado una fuga, nitrate de modificar el tanque. Nunca modifique

los ajustes de fabrica del compresor que controlan la presi6n del tanque y

demas funciones.

Especificaciones

Bomba ...................... De impulsJ6n

................ directa, lubricada con aceite

Motor ................... 1.0 HP (Inducci6n)

Di&metro .......................... 42 mm

Carrera ........................... 32 mm

Voltaje monof&sJco ................. 120 VAC

Glosario

CFM: Pies cQbicos por minuto.

SCFM: Pies cQbicos est&ndar por minuto; unidad

de medici6n de suministro de aire.

PSIG: Libras por pulgada cuadrada sobre la

presi6n atmosf@ica; unidad de medici6n de

presi6n.

ASME: Sociedad estadounidense de ingenieros

mecanicos.

Cddigo de California: La unidad puede cumplir

con el c6digo de Oalifornia 462 (I) (2)/(M) (2).

Capacidad de tanque de aire ... 37,8 litros / 10

galones US

PresJ6n de conexJ6n ............... 105 PSI

PresJ6n de desconexi6n ............ 135 PSI

Presi6n de parada ....... 861.8 KPa / 125 PSI

Pies cQbJcos por mJnuto (SCFM) a 90 LPPC. 2.4

Capacidad del aceite ........ 90 ml o 3 onzas.

Tipo de aceite .................. SAE 30 / no

detergente - semi-sintetico

Presidn de arranque: El compresor arranca

automaticamente cuando la presi6n baja a menos

del minimo prescrito.

Presion de parada: Presi6n de aire que tiene que

alcanzarse en el tanque para que se detenga el

motor.

CertificaciSn de codigo: Los productos que tienen

alguna o varias de las siguientes marcas han sido

evaluados por laboratorios de seguridad indepen-

dientes certificados por OSHA, y cumplen con las

normas de seguridad de Underwriters Laboratories:

UL, CUL, ETL, CSA.

Ciclo de trabajo

Este compresor tiene un cJclo de trabajo de 50%. Nunca opere el compresor por m&s de 30 minutos

cada hora. De hacerlo, podrJa dafiarlo.

16

Page 18

Partes y caracteristicas

Como referencia, vea las figuras abajo.

I Manometro de presion de! tanque

Indica la presi6n de la reserva de aire del tanque.

SMan6metro para herramientas

I Indica la presi6n de salida del aire que

I entra en la herramienta, la cual que es

Lcontrolada por el regulador.

I onector de acoplamiento rapido

Permite conectar y desconectar

ra.pidamente la manguera del aire.

Regulador

La presi6n del aire que sale del

tanque es controlada por el

regulador. Para aumentar la

resi6n, gire la perilla en direcci6n

de las manecillas; para disminuirla,

gire la perilla en direcci6n

contraria alas manecillas.

Valvula de seguridad del tanque

Permite que el exceso de presi6n

en el tanque escape hacia el

medio ambiente. Esta valvula

s61o se abrir_, cuando la presi6n

en el tanque este por encima de

la presi6n mb.xima nominal del

modelo.

Interruptor de presion

Controla el suministro electrico

en el motor y tambien los ajustes

de presi6n de arranque y presi6n

de parada. Este interruptor sirve

como posici6n de autoencendido

y apagado (Auto-On/Off) de la

unidad.

r Filtro del aire

Suministra aire limpio a la

bomba. Siempre debe conser

ratio limpio. Reviselo diari

amente o antes de cada uso.

\

Tap6n de

lienado de

aceite

Visor de

aceite

Tubo de

salida

r

Valvula de alivio de presidn

Esta valvula, que se encuentra en el

costado del interruptor de presi6n, esta.

diseSada para liberar aire comprimido de

manera automatica cuando el compresor

Ilegue a la presi6n de parada. El aire s61o

deber_, escapar durante un instante,

cerr&ndose la valvula se cerrar& en seguida.

Valvula de retencion

Cuando la bomba no esta en operaci6n, esta v&lvula

se cierra para retener la presi6n de aire dentro del

tanque. Es un componente intemo.

Tubo de alivio

de presi6n

17

Valvula de drenaje

Suministra aire limpio a la bomba. Siempre

debe conservarlo limpio. Reviselo diari

amente o antes de cada uso.

Page 19

Ensamblaje

Antes de realizar cualquier instalaci6n y ensamblaje al compresor de aire, se Io debe apagar y

desconectar del generador, adem&s de purgar el aire del tanque y darle suficiente tiempo para enffi-

arse. Existe el riesgo de que las partes mdviles, la fuente electrica, el aire comprimido y las superfi-

cies calientes provoquen lesiones. El ensamble del regulador debe estar instalado antes de usar el

compresor. Un ensamblaje inadecuado puede ser causa de fugas y posiblemente de lesiones. Si

no esta seguro de entender las instrucciones de ensamblaje o tiene dificultad para Ilevar a cabo el

armado, por favor Ilame a su departamento local de servicio.

Ensamblaje

1. Remueva el compresor de aire, manual,

ensamblaje del filtro de aire y accesorios de

la empaquetadura.

2. Remueva el tap6n de pl&stico de la salida de

aire del compresor. (ver abajo)

3. Instalar el filtro dentro de la entrada de aire

del compresor. (ver abajo)

4. Quite el tap6n de relleno de aceite del c_.rter

y Ilenelo hasta que el aceite alcance la

parte superior del punto rojo en el visor. La

capacidad del aceite es de 88 ml (3 oz

US) (Vea abajo). Utilice el aceite no deter

gente / semi-sintetico SAE 30 (aceite de

uso pesado para motor API CG/CD). Durante

condiciones clim&ticas de fr[o extremo, utilice

aceite de tipo SAE-10.5. Coloque nueva

mente latapa del tanque de aceite.

5. Coloque nuevamente la tapa del tanque de

aceite

Instrucciones de conexiSn a tierra

Este producto se debe conectar a tierra. En caso

de cortocircuito, la conexi6n a tierra reduce el

riesgo de descargas electricas al ofrecer una

ruta de escape para la cordente electrica. Este

producto cuenta con un cable que tiene un

alambre de tierra y una clavija con terminal de

tierra (ver la figura a continuaci6n). La clavija

debe enchufarse en un tomacorriente instalado y

puesto a tierra segQn las normas locales. Hable

con un electricista o agente de servicio calificado

si no entiende completamente estas instruc-

clones, o si tiene dudas sobre la correcta puesta

a tierra de la herramienta.

Tomacorrientes

con conexidn a

tierra

Tiempo estimado de ensamblaje:

Aproximadamente 5 minutos

Primer paso:

Ubicaci6n del compresor de aire

El compresor de aire siempre debe estar en un

medio ambiente limpio, seco y bien ventilado.

La unidad debe tener pot Io menos 30 cm de

espacio libre en cada lado. La toma del filtro

de aire debe estar limpia y sin ningQn tipo de

obstrucciones. Por favor revise diariamente el

filtro de aire para comprobar que este limpio yen

correcto estado de funcionamiento.

Terminal de ....

tierra ....

18

Page 20

Instalacidn y ensamblaje

Una conexi6n a tierra inadecuada puede provocar una descarga electrica. Si necesita reparar o

cambiar el cable o la clavija, no conecte el alambre de tierra a ninguna de las terminales planas. El

alambre de tierra es el de color verde, con o sin franjas amarillas. Si no entiende completamente

las instrucciones de conexi6n a tierra, o si tiene dudas sobre la correcta puesta a tierra de la her-

ramienta, hable con un electricista o agente de servicio calificado. No modifique la clavija que viene

con el equipo; si no puede enchufarla en el tomacorriente, Ilame a un electricista calificado para que

le instale el tomacorriente adecuado.

Este producto est& disefiado para trabajar en un circuito con un voltaje nominal de 120 voltios y

est& equipado con un cable y clavija que permiten su conexi6n a un circuito electrico apropiado.

AsegQrese de que el producto este conectado a un tomacorriente con la misma configuraci6n que la

clavija. No se debe usar un adaptador con este equipo. Si se debe conectar el equipo a un circuito

electrico de diferente tipo, consiga la ayuda de personal calificado para realizar la reconexi6n.

Cables de extensi6n

S61o utilice un cable de extensi6n de tres alambres con una clavija con extensi6n a tierra de tres

terminales que pueda enchufarse en un tomacorriente de tres orificios. AsegQrese de que su cable

de extensi6n este en buenas condiciones. Si utiliza un cable de extensi6n, compruebe que sea de la

capacidad de corriente que requiere su equipo. Las extensiones no deben ser de m&s de 25 pies (7.6

m) de largo y deben tener cable de calibre 12 AWG. Un cable m&s delgado provocar_, una caida en

el voltaje de linea, Io que provocaria una perdida de potencia y sobrecalentamiento.

Procedimiento initial de preparaci6n

No se requiere un procedimiento inicial de preparaci6n. Este producto ha sido probado en la f&brica

para asegurar su operaci6n y desempefio adecuados.

NOTAS

19

J

Page 21

Procedimientos de operaci6n

Procedimiento diario de arranque

1. Ponga el interruptor Auto-On/Off en la

posici6n de apagado (Off).

2. Verifique que el compresor del aire, la

manguera de aire y todos los accesorios/

herramientas utilizados, no tengan dafios ni

obstrucci6n. Si algunas de las piezas descritas

requieren raparaci6n/reemplazo, Ilame a su

tienda autorizada local de servicio, antes de

usar el compresor.

3. Cierre la v_.lvula de drenaje.

4. Revise el nivel de aceite de la bomba.

5. Enchufe la manguera del aire dentro del

conector de acoplamiento r&pido de la unidad

del regulador, insertando la clavija de conexi6n

r_.pida en la manguera del aire, dentro del

conector de acoplamiento r&pido. El collarin

del conector de acoplamiento r&pido saltar&

hacia adelante, sujetando la clavija y har_.

una junta entre el conector y la clavija. Para

desconectar la manguera del aire, empuje hacia

atr_.s el collarin del conector de acoplamiento

r&pido. _ _ _ , .

6. Enchufe el cable de corriente en un

tomacorriente apropiado.

7. Mueva el interruptor Auto-On/Off a la posici6n

de encendido (Auto-On); el compresor

deber& arrancar, acumulando la presi6n del

aire en el tanque hasta Ilegar a la presi6n de

apagado, momento en el cual se apagar_, de

manera autom&tica.

8. Ajuste el regulador a la presi6n de aire

recomendada (PSI) para su aplicaci6n,

cercior&ndose de que este dentro de las

normas de seguridad para Ilevar a cabo la

tarea. Para las herramientas neum&ticas, el

manual delfabricante debetenet recomendaciones

sobre su presi6n de operaci6n (PSI).

9. Ahora el compresor del aire est& listo para

ser usado.

Procedimiento diario de apagado

1. Ponga el interruptor en la posici6n de

apagado (Off).

2. Desconecte el cable del tomacorriente.

3. Ponga en cero el regulador de presi6n de salida.

4. Desconecte las herramientas y los accesorios.

Siempre use protecci6n para los oidos y los

ojos al drenar el tanque. Drene el tanque

en un lugar adecuado; en casi todos los casos

habr& presencia de condensaci6n en el drenaje.

5. Abra la v&lvula de drenaje permitiendo que

escape el aire del tanque. Cuando haya

salido del tanque todo el aire, cierre la v&lvula

de drenaje para evitar que entre suciedad. 20

AI drenar el tanque utilice protecci6n para oidos

y ojos. Drene el tanque en un lugar apropiado;

en la mayoria de las ocasiones al drenar saldr_.

condensaci6n.

Si no drena el tanque al almacenarlo, en su in-

terior quedar& agua que Io corroer& y debilitar&,

Io cual puede provocar su ruptura. Para evitar

lesiones graves, drene el tanque diariamente o

despues de cada uso.

Page 22

Mantenimiento

NOTA: Cualquier procedimiento de servicio que no est_ cubierto en el programa de manten-

imiento que sLgue deber# ser efectuado el personal de servicio calificado.

Antes de dar mantenimiento al equipo, se debe

apagar y desconectar del tomacorriente, asi

como purgar el aire del tanque y permitir que la

unidad se enfrie.

A fin de asegurar una operaci6n eficiente y una

larga vida del compresor, debe seguir un pro-

grama de mantenimiento de rutina. El siguiente

programa de mantenimiento est& enfocado al

consumidor cuyo compresor es usado en un

Asuntos paraverificar/cambiar

Revisarlavalvuladeseguridad del

tanque

Revisarvisualmenteelaspecto general

delaunidad

Revisarelfiltrodeaire

Drenareltanque

Verificarqueelcableelectriconoesteda_ado

medio ambiente normal y diariamente.

Cambiar el aceite

Verifiear el nivel del aceite

Almacenamiento

Para almacenar el compresor, asegQrese de hacer Io siguiente:

1. Apague la unidad y desconecte el cable

electrico del tomacorriente.

2. Quite del compresor las mangueras, accesorios

y herramientas de aire.

4. Abra la v_.lvula de drenaje para drenar el aire

del tanque.

5. Cierre la v&lvula de drenaje.

6. Guarde el compresor en un lugar limpio y seco.

3. Lleve a cabo el programa de mantenimiento de

rutina.

NOTAS

Antes de cada

use o diariamente

x

x

x

x

Despu_sdelas

primeras50horas

Despu_sdeeada

1O0horas

X

21

Page 23

Diagn6stico y correcci6n de failas

Antes de dar mantenimiento al equipo, se le debe apagar y desconectar del tomacorriente, asi como

purgar el aire del tanque y permitir que la unidad se enfrie. Las partes en movimiento, las fuentes

electricas, el aire comprimido y las superficies calientes pueden provocar lesiones.

PROBLEMA POSlBLE CORRECCION

Fuga de aire en la v&l- Una v&lvula de retenci6n defectuosa provoca una fuga de aire constante

vula de retenci6n o en en la v&lvula de alivio cuando est& apagado el compresor teniendo

la v&lvula de alivio, presi6n de aire. Drene el tanque y quite y limpie o cambie la v&lvula de

Fugas de aire entre la Compruebe el apriete de los pernos de la cabeza. Si continQa la fuga,

cabeza y el cilindro. Ilame a un tecnico de servicio.

Fuga de aire en la

v_.lvula de seguridad.

La presi6n indicada

en el man6metro de

presi6n.

Presi6n excesiva en el

tanque.

El motor no arranca.

Humedad excesiva en

el aire de salida.

retenci6n.

Opere manualmente la v&lvula de seguridad tirando del anillo. Si el

tanque continQa teniendo una fuga estando la v&lvula en posici6n cer-

rada, esta deber& ser cambiada.

Sial usar un accesorio hay una caida excesiva de presi6n, cambie el

regulador.

NOTA:

Ajuste la presi6n regulada bajo condiciones de flujo (mientras se utiliza

un accesorio). Es normal que el man6metro indique una caida de presi6n

minima al comenzar a utilizar la herramienta.

Apague el interruptor de encendido. Si la unidad no se apaga,

desconectela del tomacorriente y comuniquese con un tecnico de servicio.

Compruebe que el cable de corriente est& enchufado y que el interruptor

est& encendido. Compruebe que el fusible de la caja de circuitos sea de

la capacidad adecuada. Si se ha disparado, restablezcalo y rearranque

la unidad. Si el fusible se dispara con frecuencia, revise la v_.lvula de

retenci6n o Ilame a un tecnico de servicio.

Saque el agua del tanque dren&ndolo despues de cada vez que se use.

En los medios ambientes de alta humedad habr_, un exceso de conden-

saci6n; instale filtros de agua en su linea de aire.

NOTA:

La condensaci6n no es provocada pot una falla en el compresor. Com-

pruebe que la salida de aire del compresor sea mayor que el consumo

de aire de su herramienta.

Fugas de aire en el Nunca taladre, suelde o modifique de ninguna manera el tanque, pues se

cuerpo o la soldadura debilitar&. El tanque podria romperse o explotar. El tanque no puede ser

del tanque, reparado. Ya no utilice el compresor de aire.

22

Page 24

Compresor de aire - Modelo 16923

Vista esquem_tica

3o _\\\

65--,

\

\

\

\

61

36-- ".... 33

32

33

....... 39

23

Page 25

Compresor de aire - Modeio 16923

Lista de/as

# de # de # de descripci6n de cant.

ref. kit parte parte

1 3 Tornillo, M6 X 1.0 mm 4

2 3 Arandela de freno M6 8

3 3 E100227 Culata decilindro 1

4 1 & 3 Junta de culata, placa 1

5 3 E100228 Placa devalvula 2

6 3 E100229 Wlvula 2

7 1 & 3 Junta, placa devalvula 1

8 1 & 3 Junta de cilindro, placa 1

9 2&3 E101113 Cilindro 1

10 3 i Torntllo, SHC M6 x 1.0 4

11 1 & 3 Junta decilindro - 1

12 2 & 3 Excentrico para L1 1

13 2&3 I Tuerca, Hex, M6xl.0 3

14 2&3 Tornillo, SHC M6 x 1.0 1

15 2 & 3 Conjunto, piston / 1

16 1 & 3 Deflector para L1 1

17 3 E100087 Tap6n de relleno de 1

18 _ 3 , E100566 TapadecarterparaL1 i 1

19 3 E100078 Tap6n, visor denivel 1

20 3 i Torntllo, HFH M5 x 0.8 4

21 3 Conjunto de Motor/caja 1

22 3 E100860 Ventilador, motorF1 1

23 3 i Anillo elastico,exterior, 1

24 3 E100247 Condensadorde marcha 1

25 3 E100248 Condensadorde 1

26 3 Arandela de freno con 2

27 3 i Tuerca, M8x1.25, ZDC 6

X3Omm

de valvula

de valvula

i .

x 20mm

inferior

x 20mm

biela L1

aceite / sin anillo

de aceite/ con junta

i .

x 18mm (cincado en

amarillo)

de bomba, L1B2

125mm

15 mm

arranque

dientes, 8 mm

i

6.5 mm de alt.

# de # de # de descripci6n de cant.

ref. kit parte parte

28 N/A

29 N/A

30 3 Conjunto,Motor/bomba, 1

31 E100809 Conexi6n en code, 1

32 6 Casquillo, 3/8 pulg. 2

33 8 Tuerca, compresion, 2

34 6 Tube de salida 3/8 1

35 E101362 Wlvula de seguridad, 1

36 5 Casquillo, 3/8 pulg. 2

37 5 Tuerca, compr. 3/8 2

38 5 Tube, alivio de presion, 1

39 Conjunto detanque/ 1

40 Arandela, plana M6 2

41 E101037 Aislador, caucho 2

42 Tornillo, SHC, M6x 1.0 2

43 E100098 Wlvula, drenaje- 1

44 7 Tuerca, Hex MlOx1.28 2

45 7 Arandela, plana MIO 2

46 7 Rueda,cubo negro 2

47 7 Pernode espald6n, 2

48 E101340 Cord6n electrico,16/3 1

49 E100853 Boquilla, 1/4 pulg.NPT 1

50 E102611 Wlvula, seguridad 1

51 E102857 Boquilla, 1/4 pulg.NPT 1

52 E100059 Regulador, Estructura 1

L1B2conescape

izquierdo

3/8NPT x 3/8 pulg.

compr.

3/8 pulg.

pulg.de alum. con

aletas

puertosuperior

pulg.

1/4 pulg. Alum.

Armazon, 10 galones,

L1IOVWS

x 25 mm

Multivuelta

M10x1.25x45mm

AWGtipo ST, 6pi de

Iongitud

X35 mm

X43 mm

cuadrada - Caudal izq.

24

Page 26

Compresor de aire - Modelo 16923

Lista de las piezas

# de # de # de descripcidn de

ref. kit parte parte

53 E100307 Conexion rapida, laton 1

54 E103369 Manometro de presion, 1

(50 mm 135 PSI Der./

Izq. 1/4 pulg NPT)

55 E104074 Aro manometro/her- 1

ramientas (50 ram)

56 E106477 Conjunto, interruptor, 1

presion (135 PSI)

57 E103363 Manometro de presion, 1

(38 mm w/135 PSI -

Der./Izq. )

58 E104568 Aro manometro/ 1

tanque (38 mm)

59 Tornillo, Hex embri- 4

dado, MSX0.8X15 mm

60 E101335 Agarradera 1

61 E105883 Toma, caucho 1

62 4 Tapa, filtro 1

63 4 E100435 Elemento, filtro de 1

entrada de aire

64 41 Base, filtro de aire 1

65 Tornillo, Hex embri-

dado, MSX0.8Xl0 mm

66 E105615 Caja 1

Nota: Cualquier campo paralos numeros/juegos de piezas que

cant.

no tengan un numero especifico de pieza, indica que no esta

disponible. Lasdescripciones se proveen solamente como

referencias. La columna con elnumero de juego indica que la

pieza ofrecida esta disponible como parte de unjuego. Una de

cada una de las piezas esta ofrecida.

Los numeros de los juegos y las piezas que estan incluidos se

describen acontinuacion:

Juego

# Pedido# Nombredeljuego Compo-

1 E100959 Juego, Juntas de 4,7,8,11,16

2 E100251 Juego, PistOn-(Nota: 9,12

3 E105154 Juego- Conjunto, 1 - 27,30

4 E100794 Juego, Filtrodeaire 62-64

5 E105953 Juego, Tuba de alivio 36-38

6 E105952 Juego, Tubo de salida 32-34

7 E102192 Juego, Rueda (Este 44-47

reemplazo

Pidaeljuegodejuntas hasta15

#1, tambien,cuando

pida estejuego)

Motor/Bomba,L1B2 con

escape izquierdo

de presiOn,1/4pulg.

de alum.

3/8 pulg. de alum.

juego es para solamente

una rueda)

Ref.#

nente

67 Perno, SHC M8 x 1.25 4

x 25 mm (ZDC Placa)

68 Arandela de freno M8 4

69 Arandela, plana M8 4

70 E101802 Protector, 16/3 AWG 1

ST

NOTAS

25

Page 27

Your Home

For repair - in your home - of aft major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME °" (1-800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts & Repair Center.

1-800-488-1222

Call anytime, day or night (U.S.A. only)

www,sears,corn

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Parapedir serviciode reparaci6n

a domicilio,ypara ordenarpiezas:

1-888-SU-HOGA RSM

(1-888-784-6427)

(R)Registered Trademark/ Trademark/ Service Mark of Sears, Roebuck and Co.

(R)Marca Registrada/ TMMarca de Fabrica/ ". Marca de Servicio de Sears, Roebuck and Co.

McMarque de commerce/MD Marque depos6e de Sears, Roebuck and Co. © Sears, Roebuck and Co.

TM SM

SM

Au Canada pourservice en frangais:

1-800-LE-FO YER Mc

(1-800-553-6937)

www.sears.ca

Loading...

Loading...