Craftsman 161216300 Owner’s Manual

Ie J Y2

owners

manual

MODEL NO.

161.216300

Caution:

ReadRules For

Safe Operation

and Complete

Operating Test

Procedures

Carefully

INE ANALYZ

FOR 12 VOLT SYSTEMS

OPERATING INSTRUCTIONS

SAFETY RULES

TUNE-UP PROCEDURES

REPAIR PARTS

IIIII

J_

IIIII .I I III illll U III!IIII

L IllIII . .I II I ,JJ..... II IJLJIIJIII I III1[ . l Ill . . I

III II

SEARS, ROEBUCK AND CO. U.S.A.

I IIIIIII IIIIII I

PRINTED IN U.S.A,

I iilliiII III II IIIIIIIIIIIIIIIIIIIIII

CH!CAGO, ILLINOIS 60684

. II IJ IIIII[ I . I IIIIIIIIIIIIIIIIIWHIIIIIIIIIII II

2-168302

RULES FOR SAFE AUTOMOTIVE TESTING

WARNING -- READ CAREFULLY

Read this OperaUon Manual and these Rules for Safe

Automotive Testing carefully. Failure to follow instructions

and safety rules could result in sedous bodily injury and/or

damage to the Instrument.

1.

Before starting the engine, set the parking brake and place the

gear selector in NEUTRAL on standard transmissions and

PARK on automatic transmiasionl,

2. The carbon monoxide m exhaustgas is highly tOxiC To avoid

asphyxiation, always operate vehicle in • well-ventilated ares,

If vehicle ss tn an enclose_l area, exhaust should be routed

directly to the outside vie leak-proof exhaust hose.

3 An automobile battery is capabfe of producing very high

currents Therefore, exercise reasonable care when working

near the battery to avoid electrical connections through tools,

wristwatch, etc

4 Avoid contact with battery electrolyte Electrolyte can burn

holes m clothing, burn skin and cause permanent damage to

eyes Always wear splash-proof safety goggles when work=ng

around the battery tf battery electrolyte rs splashed m the eyes

or on skin. immediately flush the affected area Ior 15 minutes

with targe quanhhes of clean water; m case of eye contact, seek

medical atd immediately

5. The gases generated by a charging battery are highly explo-

sive Do not smoke or permit flame or spark Io occur near a

battery at any hme, particularly when _t=scharging. Any room

or compartment containing charging batteries should be

well ventilated to prevent accumulation of exploswe gases To

avoid sparks, do not disturb the baltery charger connections

while battery is charging, and always turn charger off before

disconnecting the battery chps When removing or recon-

necting battery cables, make sure =gnition switch and all

accessories are turned off A techmque used by many

mechanics _s to carefully blow across the top of the baltery

to remove any hydrogen gas accumulation before connechng

or disconnecting battery clips

6. Never add acid to a battery once the battery has been placed =n

service; doing so may result _n dangerous spattering of

electrolyte.

7. Keep hands, hair, neckbe, loose clothing and test leads well

away from fan blades, fan belt, power steering belt, air con-

drtioner belt and other moving engine parts as serious injury

Could result from entanglement.

8. Oo not tuch hot exhaust mamfotd, redactor or high-voltage

spark plug and Cod terminals Spark voltages are not normally

lethal, but an involuntary lark of the hands or arms caused by

electrical shock may result =n,nJury.

9 Never look directly into carburetor throat whde engine _s

cranking or running A sudden backfire can cause serious

burns.

10 To avoid the possibility of a flash fire, do not smoke or permit

flame or spark to occur near carburetor, fuel hne, fuel filter,

fuel pump or other potential sources of spdled gasoline or

gasottne vapors

1! Naver remove radlator cap while the engme ts hot, Hot coolant

escaping under pressure can cause serious burns.

12 The jack supphed with the vehicle should be used onty for

changing wheels. Never crawl under car or run engine while

vehicle is on jack.

13. When mak=ng electrical test connect=ons to the vehicle, do nol

usa the carburetor or other fuel system components as a

ground connection, as a spark could _gn=te the gasoline vapors

and cause a fire or an explosion

14 Do not let test cables rest or tall on or near hot or mowng

engine parts,

15 Use cauhon when d=sconnectmg rgmhon cables Pull cables

carefully at the boot w_th the pr'oper tool

THIS MANUAL PRESENTS COMPLETE HOOKUP INSTRUCTIONS FOR THE SEARS 161.2163 ENGINE ANALYZER. IT ALSO

DESCRIBES MANY OF THE TESTS THAT THIS INSTRUMENT IS CAPABLE OF PERFORMING AS WELL AS WHEN THEY

SHOULD BE USED BASED ON VEHICLE PERFORMANCE, TUNE-UP OR TROUBLE ENCOUNTERED. CONSULT YOUR

VEHICLE SERVICE MANUAL FOR SPECIFIC TUNE-UP INFORMATION AND TEST PROCEDURES. FOLLOW THE

MANUFACTURER'S SPECIFICATIONS AND TEST PROCEDURES FOR ADJUSTING DWELL ANGLE AND IDLE SPEED,

ESPECIALLY ON VEHICLES WITH MODERN ELECTRONIC IGNITION AND EMISSION CONTROLS. DO NOT ATTEMPT TO

SERVICE A VEHICLE WITHOUT THE MANUFACTURER'S INSTRUCTIONS AND SPECIFICATIONS,

VEHICLE MANUAL, SOURCES FOR SERVICE INFORMATION.

The following is a tiStof publishers who have service manuals for your specific vehicle at nominal cost.

Write to them for availability and prices, specifying the make, style, and model year of your vehrcle.

Amedcan Molora Corporallon

Myr=ad

8835 General Drive

Plymouth Township

M_ch_gan 48170

Ch ry$1er Corporation

Dyment D_Stnbution Service

Service Publication

20026 Progress Drive

Strongevdle, Ohio 44136

Fgcd Publication Department

Hblm Incorporated

Post Office Box 07150

Detroit, Michigan 48207

IMPORTANT

Buick

Tuar Company

Post Office Box 354

Fhnt, M_chigan 48501

Oldsmobile

Lansing L=thographers

Post Office Box 23188

Lansing. Michigan 48909

Cadillac, Chevrolet, Pontiac

Helm incorporated

Post Office Box 07130

Detroit, Michigan 48207

OTHER SOURCES - Nonfactory

Domestic and Impod Cart

Chdton Book Company

ChHton Way

Radnor, PA 19089

Cordura Publications

M_tchell Manuals, Inc.

Post Office Box 26260

San Diego, CA 92128

Motor's Auto Repair Manual

Hearst Company

250 W 55th Street

New Yo_k, N Y 10019

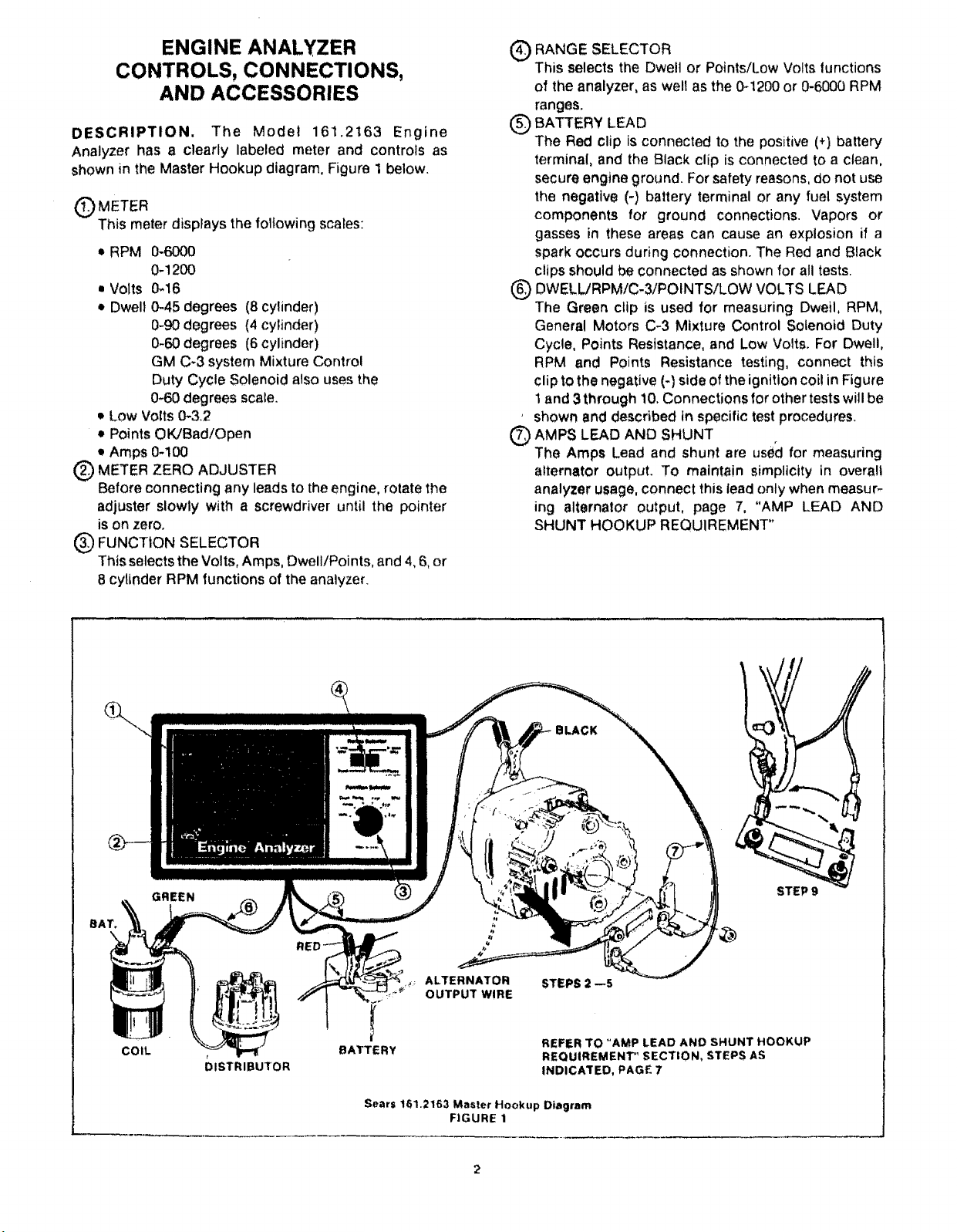

ENGINE ANALYZER

CONTROLS, CONNECTIONS,

AND ACCESSORIES

DESCRIPTION. The Model 161.2163 Engine

Analyzer has a clearly labeled meter and controls as

shown inthe Master Hookup diagram, Figure 1 below.

QMETER

This meter displays the following scares:

• RPM 0-6000

0.1200

= Volts 0-16

• Dwell 0-45 degrees (8 cylinder)

0-90 degrees (4 cylinder)

0-60 degrees (6 cylinder)

GM C_3 system Mixture Control

Duty Cycle Solenoid also uses the

0-60 degrees scale.

• Low Volts 0-3.2

• Points OK/Bad/Open

• Amps 0-!00

Q ETER ZERO ADJUSTER

Before connecting any leads to the engine, rotate the

adjuster slowly with a screwdriver until the pointer

is on zero,

@ FUNCT1ON SELECTOR

This selects the Volts, Amps, Dwell/Points, and 4, 6, or

8 cytinder RPM functions of the analyzer.

Q ANGE SELECTOR

This selects the Dwell or Points/Low Volts lunctions

of the analyzer, as well as the 0-1200 or 0-6000 RPM

ranges.

(_ BATTERY LEAD

The Red clip is connected to the positive (+) battery

terminal, and the Black clip is connected to a clean,

secure engine ground. For safety reasons, do not use

the negative (-) battery terminal or any fuel system

components for ground connections. Vapors or

gasses in these areas can cause an explosion if a

spark occurs during connection. The Red and Black

clips should be connected as shown for all tests.

(_ DWELLiRPM/C-3/POINTS/LOW VOLTS LEAD

The Green clip is used for measuring Dwetl, RPM,

General Motors C-3 Mixture Control Solenoid Duty

Cycle, Points Resfstance, and Low Volts. For Dwell,

RPM and Points Resistance testing, connect this

clip to the negative (-) side of the ignition coi! in Figure

i and 3 through 10, Connections for other tests will be

* shown and described in specific test procedures.

Q AMPS LEAD AND SHUNT

The Amps Lead and shunt are used for measuring

alternator output. To maintain simplicity in overall

analyzer usage, connect this lead only when measur-

ing alternator output, page 7, "AMP LEAD AND

SHUNT HOOKUP REQUIREMENT"

COIL

GREEN

DISTRIBUTOR

ALTERNATOR

OUTPUT W!RE

BATTERY

Sears 161.2163 Master Hookup Diagram

FIGURE 1

STEP 9

STEPS 2 --S

REFER TO "AMP LEAD AND SHUNT HOOKUP

REQUIREMENT" SECTION, STEPS AS

INDICATED, PAGE 7

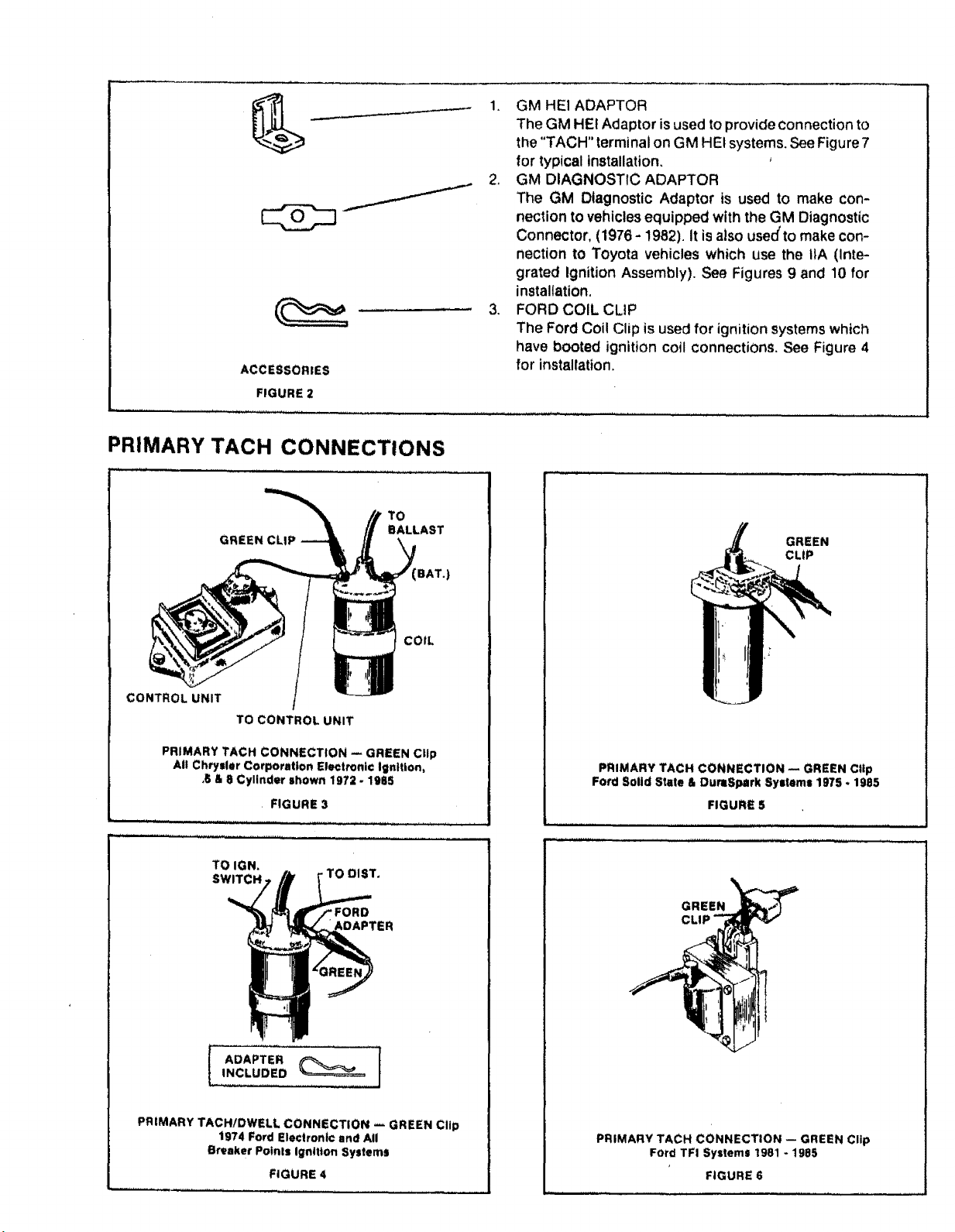

ACCESSORIES

FIGURE 2

PRIMARY TACH CONNECTIONS

TO

GREEN CLIP

BALLAST

1+ GM HEI ADAPTOR

The GM HEt Adaptor isused to provideConnection to

the "TACH" terminal on GM HEt systems. See Figure 7

for typical installation.

2+ GM DIAGNOSTIC ADAPTOR

The GM Diagnostic Adaptor is used to make con-

nection tovehicles equipped with the GM Diagnostic

Connector, (1976 - 1982). It isalso used'to makecon-

nection to Toyota vehicles which use the tlA (Inte-

grated Ignition Assembly). See Figures 9 and 10 for

installatiOn.

3. FORD COIL CLIP

The Ford Coil Clip is usedfor ignition systemswhich

have booted ignition coil connectiOnS.See Figure 4

for installation,

GREEN

CLIP

BAT.)

CONTROL UNIT

TO CONTROL UNIT

PRIMARY TACH CONNECTION -- GREEN Clip

At! Chrysler Corporation Electronic ignition,

,6 & 8 Cylinder shown 1972 - 1985

+ FIGURE 3

............................. ,,,,r,,

TO IGN.

SWITCH .TO DIST,

INCLUDED

ADAPTER ]

COIL

PRIMARY TACH CONNECTION -- GREEN Clip

Ford Solid State & DuraSpark Systems 1975 • 1985

FIGURE $

GREEN___

PRIMARY TACH/DWELL CONNECTION _ GREEN Clip

1974 Ford Electronic and All

Breaker Potnls Ignition Systems

FIGURE 4

PRIMARY TACH CONNECTION -- GREEN Clip

FOrd TFI Systems 1981 - 1985

FIGURE 6

Loading...

Loading...