Page 1

IIIIIIIII I

2-170701

I [11 II ........

I II II - --_

Sears

k ............. . ......

owners

manual

MODEL NO.

161.210400

l

.;_(/ )-

CRRFTSHRN

Caution:

Read Rules For

Safe Operation

and Complete

Operating Test

Procedures

Carefully

ENGINE ANALYZER

FOR 12& 24 VOLT SYSTEMS

. OPERATING INSTRUCTIONS

• SAFETY RULES

•TUNE- UP PROCEDURES

• REPAIR PARTS

............ •........ . .....

PRINTED iN U.S.A.

,, ,,,, , ,, ,,,,,, , ,I .......... ' I I II Illl 11 IIIIIII IIII 11

SEARS, ROEBUCK AND CO. U.S.A.

CHICAGO, ILLINOIS 6068.4 ......

2-17070_

Page 2

TOT Numld

TEST lll!lii(l

T[S? _UHO_X

!£ST llli_l

?_ST liilli_l

TEst m, ilIl

TEST _U_ER

tEPt.ACfi,I_

R(ILAc[,MENI

34€-*Lo_ v_XAG[ OnOPT(STS ................................ST

_I_--E|SStOII COtI_O. $#;1_ TIE.los ..................... S2

HF-_ illIIlllNGS ........................................ t8

lii--l[Ai Wlli!lOi lffN'OtTil IIlD ............................!!

_4B--ELEC?NICALiIRIN_ltARNE$S ............................. _9

e,',_T_LIST .................................................$t

Page 3

IMPORTANT

The information in thls manual will serve as a generaJ gulde for engine

tune-up and charging systemtests and adlustments.

CONSULT THE VEHICLE SERVICE MANUAL FOR SPECIFIC TUNE..UP

INFORMATION AND TEST PROCEDURES. ALWAYS FOLLOW THE

MANUFACTURER°S SPECIFICATIONS AND TEST PROCEDURES FOR

ADJUSTING DWELL ANGLEe IDLE SPEED AND CHARGING SYSTEM

OUTPUT, ESPECIALLY VEHICLES WITH MODERN ELECTRONIC

IGNITION AND EMISSION CONTROLS. DO NOT ATTEMPT TO

SERVICE VEHICLE WITHOUT MANUFACTURER'S INSTRUCTIONS.

The following Is a list of publishers who have service manuals available for your

specific vehicle at a nominal cost. Write to them for availability and prices, specifying

the make, style, and model year of your vehicle.

A. E. A. Tune-Up Charts

Automotive Electric Assn.

130i W. 22nd St., Suite 202

Executive Plaza Building

Oak Brook, Illinois 6052%

Chilton_s Auto Repair Manual

Chllton Company

56th and Chestnut Streets

Philadelphia, Pennsylvania 19139

GM Diagnosis and Repair Manual

GM DR Manual Headquarters

P. O. Box 1185

Southfield, Michigan 48075

Motor's Auto Repair Manual

250 W. 55th Street

New York, N. Y. 10019

National Service Data Book

National Automotive Service, Inc.

Div. Glenn Mitchell Manuals, Inc.

Box 10465

San Diego, Ca]ifornia 92110

Chrysler Corporation

Service Publications Dept.

26001 Lawrence Ave.

Center Line, Michigan 48015

Helm Incorporated

P. O. Box 07150

Detroit, Michigan 48207

FULL 1 YEAR WARRANTY

IF, WITHIN 1 YEAR FROM THE DATE OF PURCHASE, THIS AUTOMOTIVE TEST

INSTRUMENT FALLS DUE TO A DEFECT iN MATERIAL OR WORKMANSHIP,

RETURN tT TO THE NEAREST SEARS STORE THROUGHOUT THE UNITED STATES÷

AND SEARS WILL REPAIR OR REPLACE iT, FREE OF CHARGE.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

SEARS, ROEBUCK AND CO,

DEPARTMENT 898/731A

SEARS TOWER

CHICAGO, IL 60684

Page 4

Wage

RULESFOR SAFE AUTOMOTIVE TESTING

READ CAREFULLY

Read this Owner's Manual and these

Rules for Safe Automotive Testing core-

fully. Fa_iure to Follow instructions

and safety _ies could result tn serious

bodily _nlury and/or damage to the

Instrument.

2_

Beforestarting the englne_ set the park.,

Ing brake and place gear selector In

NEUTRAL an standard transmissionsor

PARKon automatic transmission.

3_

The carbon monoxide in exhaust gas is

highly toxic. To avoid asphyxiation,

alway_ operate vehlcle In a well..

ventilated area. if vehicle Is In an en-

closed arean exhaust should be routed

dtrectly to the outside via leakproof ex-

haust hose.

e

Whenoperating any test instrument from

on auxiliary battery+ connect a jumper

wlre between the negative terminal of

the aux_llary battery and chards ground

on the vehicle under testfor negative

groundsysten_h Forpositive ground

systems+connect the jumperwire to the

positive terminal of the auxll _ary battery

and chosdsground an the vehicle.

Whenworking in a garage or other en-

closedarea, auxii la_ battery should be

located at least 18 Inches above the floor

to minimize the potsibllity of spork_

;gniHng gasolinevaporsand causlng an

explosion.

comportment€ontaining charging bat..

terles shouldbe well ventilated to

prevent accumulaHon of explosive

gases. To avoid spark_, do ru_tdisturb

the battery charger connectlonswhile

battery is charglngs and always turn

charger off before dlsconnecti_'gthe

battery clips. When removing or re-

connecting battery cables, make sure

Ignition switch and all acce.orles are

turned off.

v

Never add acid to a battery once the

battery has beenplaced In service.

Doing so m_y result in dangerous

spatteringof electrolyte o

9_

Keep hanch, halr_ necktie, loose

clothing and test leadswell away from

fan blade, fan belt_ power steering

belt, air conditioner belt and other

movingengine parts_as serious injury

could result from entanglement.

10.

Do not touch hot exhaust manifold,

radiator or hlgh-voitage spark plug

and coil ter_nlnals. Spark voltages ore

nat normal ll) lethal but an tnvotuntmy

lerk of the handsor armscaused by

electrical shockm_ result in Injury,

II.

Never took dlre:tly Into carburetor

throat while engine iscranking or

running. A sudden backfire can cause

serious burns.

,

An automobile battery Is €apable or pm-

duc|ng very hlgh currents. Therefore,

exercise reasonable care when working

near the battery to avoid electrical con-

nectionsthroughtools, wristwatch, etc.

B

Avoid contact with battery electrolyte.

It can eat holes In clathlng, burn skin

and cause permanent damage to eyes.

Always wear q_iash proof safety goggles

when working around the battery, if

battery electrolyte is splashed in the

eyes or on skln, immediately flush the

affected area for 15 minutes with large

quantities of clean water. In case of

eye €ontact0 seek medical a_d,

e

The gasesgeneratedby a chargtng bat-.

tory are highly explosive. Do not

smokeor permit flame or spark to occur

near o battery at any tlme+ particular-

ly when it Is charglng. Any roomor

i2.

To avoid the possibility of a flash fire,

do not smoke or permit flame or spark

to occur rear carburetor_ fuel line+

fuel filter, fuel pumpor other poten-

tial sourcesof spilled gasoline or

go$ol|ne vapors.

13.

Never remove radiator cop while the

engine is hot. Hot €oolant escaplng

under pressure can cause serious burnt.

14.

The jack suppliedwith the vehicle

shou|dbe usedon|y for changing wheels.

Never crawl under car or run engine

while vehicle lson iack.

15.

When making electrical test connec-

tions to the vehicle, do not usethe

carburetor or other fuel systemcompo-

nentsas a groundconnectlon_ as a

spark could lgnffe the gasoline vapors

and cause a fire or an explosion.

Page 5

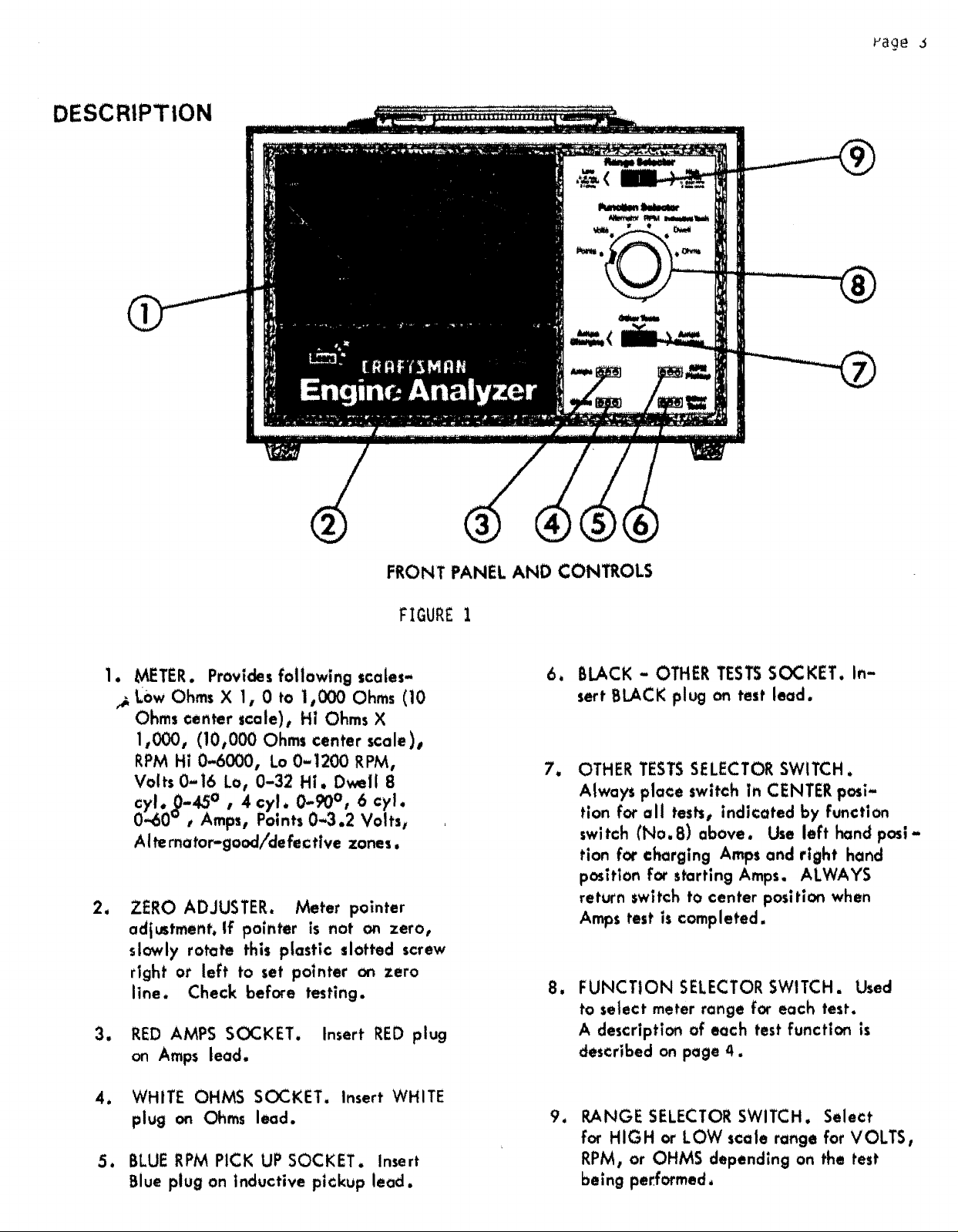

DESCRIPTION

_ge J

I •

METER. Provides following scales-

Low Ohms X 1, 0 to 1,000 Ohms (10

Ohms center scale), HI Ohms X

1,000, (10,000 Ohms center scale)t

RPM Hi 0-6000, Lo 0-1200 RPM,

Volts 0-i6 Lo, 0-32 Hi. Dwell 8

cyl. _)-45 a , 4 cy!. 0-90 °, 6 cyl.

0-60 , Amps, Parers 0-3.2 Volts1

AIte rnator-good/defective zones.

e

ZERO ADJUSTER. Meter painter

adjustment, if pointer is not on zero,

slowly rotate this plastic slotted screw

right or left to set pointer on zero

line. Check before testing.

.

RED AMPS SOCKET. Insert RED plug

on Amps lead.

FRONT PANEL AND CONTROLS

FIGURE I

6. BLACK - OTHER TESTSSOCKET. In-

sert BLACK plug on test lead.

OTHER TESTS SELECTOR SWITCH.

•

Always place switch In CENTER posi-

tion for all tests, indlcoted by functlon

switch (No.B) above. Use left hand posl-

tlon for charging Amps and right hand

positton for starting Amps. ALWAYS

return switch to center posltlon when

Amp$ test is completed.

. FUNCTION SELECTOR SWITCH. Used

to select meter range for each test.

A description of each test function is

described on page 4.

WHITE OHMS SOCKET. Insert WHITE

4_

plug on Ohms lead.

BLUE RPM PICK UP SOCKET. Insert

e

Blue plug on inductive pickup lead.

. RANGE SELECTOR SWITCH. Select

for HIGH or LOW scale range for VOLTS,

RPM, or OHMS depending on the test

being performed.

Page 6

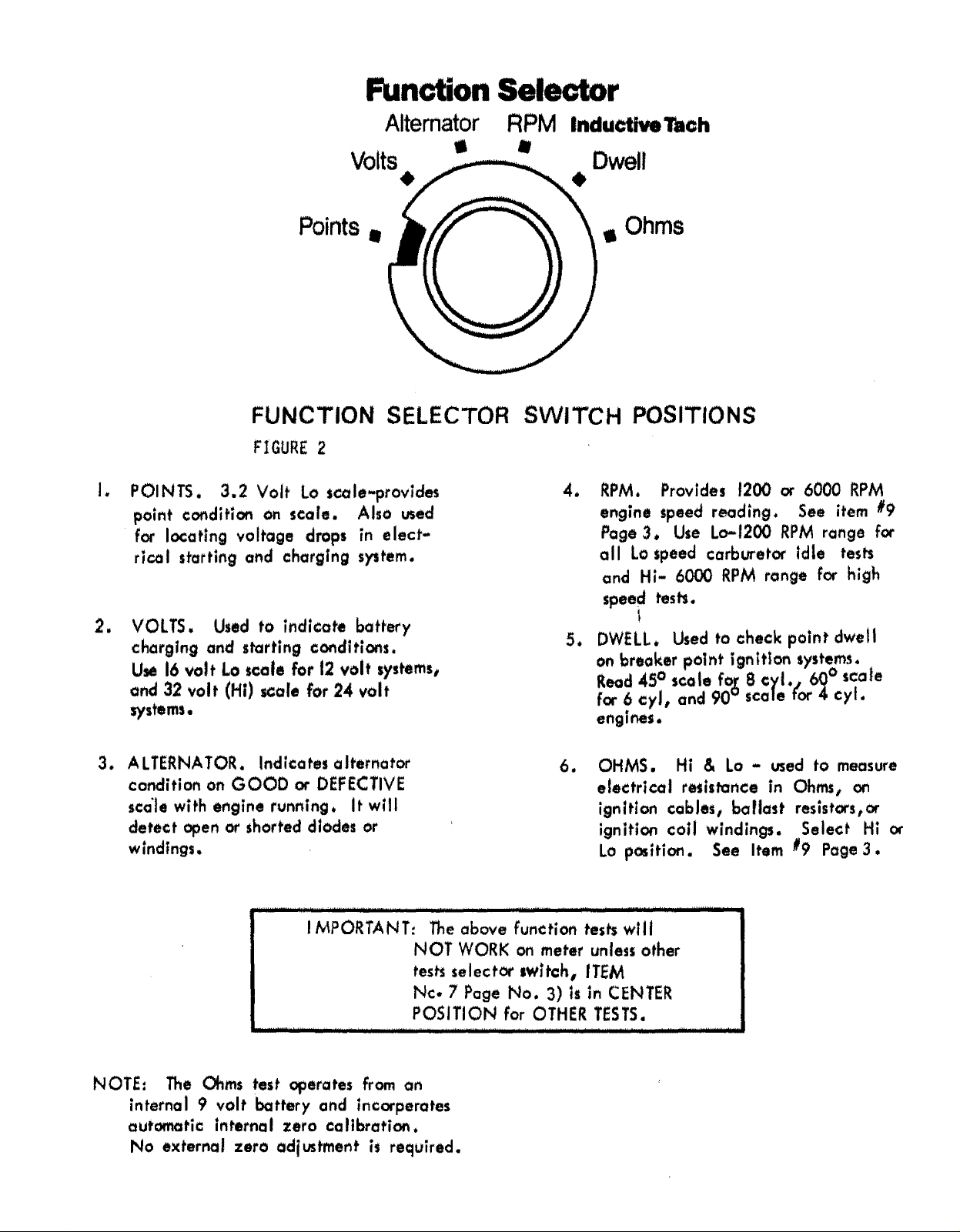

Function Selector

Alternator RPM InducttveTach

m m D

Volts__, well

Points m _ Ohms

FUNCTION SELECTOR SWITCH POSITIONS

FIGURE 2

POINTS. 3.2 Volt Lo scale-provldes

point condition on scale. Also used

for locating voltage drops in elect..

rlcal starting and charging system.

m

VOLTS. Used to Indicate battery

charging and starting cor_ditlons.

Use 16volt Lo scale for t2 volt systems_

and 32 volt (HI) r_ale for 24 volt

systems•

. ALTERNATOR. Indlcates alternator

condition on GOOD or DEFECTIVE

sca'te wlth englne running. It w(ll

detect open or shorted diodes or

windings.

.................................................. i i i iiillll illrlll[ i iii ii ...................................................

IMPORTANT: The above function tests will

4. RPM. Provides i200 or 6000 RPM

engine speed reading. See item #9

Page 3. Use Lo-i200 RPM range fat

all Lo speed carburetor idle tests

and Hi- 6000 RPM range for high

speed tests.

5. DWELL. Used to check point dwell

on breaker polnt ignitton systems.

Read 45 ° scale fo[ 8 cvi.o 60 ° scale

for 6 cyl, and 90" scale for 4 cyt.

engines.

OHMS. HI & Lo - used to measure

.

electrical resistance in Ohms, on

ignition cables, ballast resistOrSeor

ignition coil windings. Select HI or

Lo position. See Item 19 Page 3.

NOT WORK on meter unless other

tests selector sw(tch4, ITEM

Nc. 7 Page No. 3) Is in CENTER

POSITION for OTHER TESTS.

NOTE: The Ohms test operates from an

internal 9 volt battery and ;ncorperates

automatic Internal zero calibration.

No external zero adjustment ;s required.

Page 7

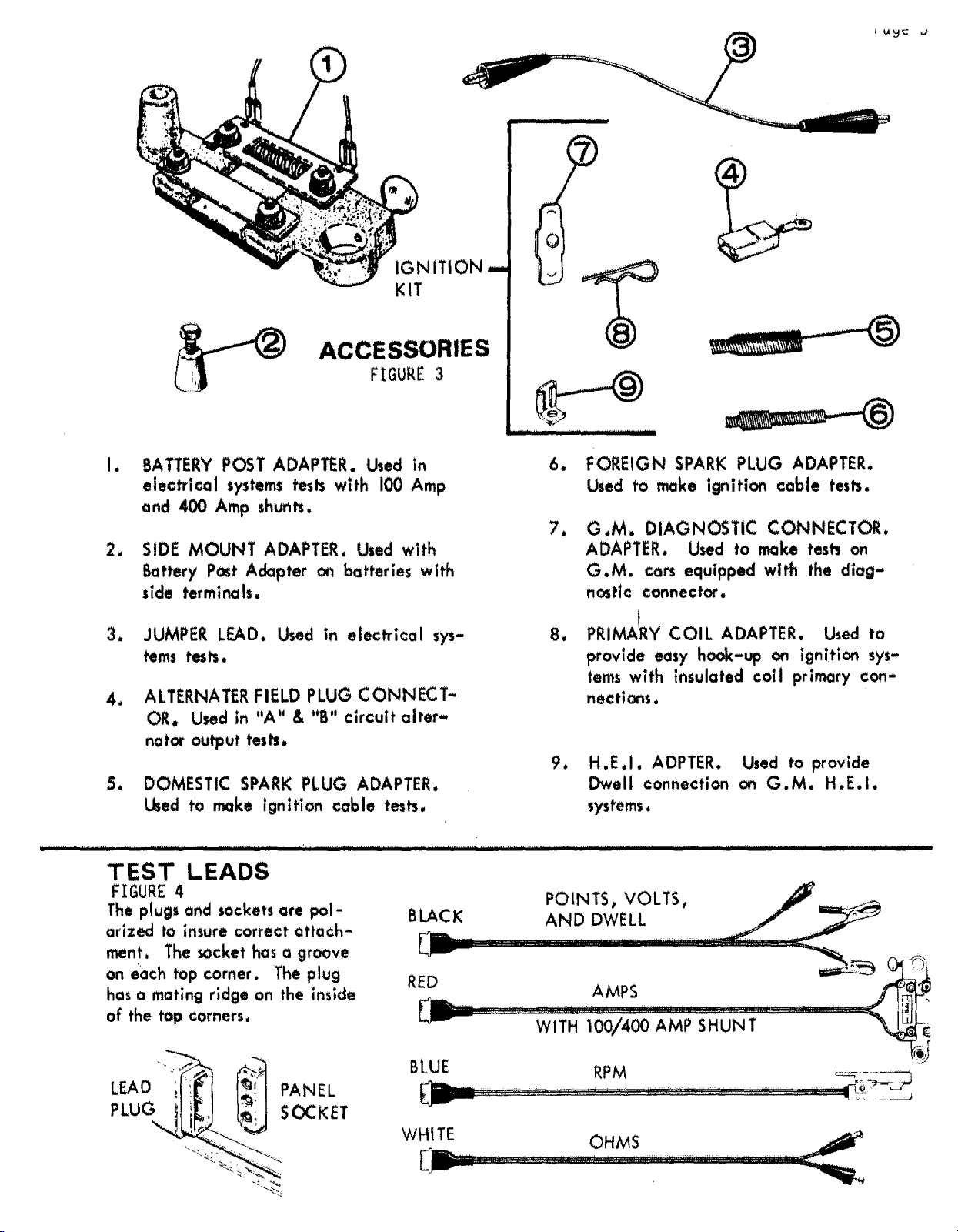

IGNITION J

KIT

ACCESSORIES

FIGURE 3

I.

BATTERY POST ADAPTER. Used in

electrical systems tests with i00 Amp

4t FOREIGN SPARK PLUG ADAPTER.

Used to make ignition cable tests.

and 400 Amp shunts.

G.M. DIAGNOSTIC CONNECTOR.

2_

SIDE MOUNT ADAPTER. Used with

Battery Post Adapter on batteries with

side terminals.

.

JUMPER LEAD. Used in electrical sys-

tems tests.

ALTERNATER FIELD PLUG CONNECT-

d

ADAPTER. Used to make tests on

G.M. cars equipped with the diag-

nostic connector.

PRIMA!RY COIL ADAPTER. Used to

.

provide easy hook-up on ignLtion sys-

tems with insulated call primary con-

necHons.

OR. Used in "A" & "B" circuit alter-.

nator output tests.

9_

H.E.i. ADPTER. Used to provide

5_

DOMESTIC SPARK PLUG ADAPTER.

Used to make ignition cable tests.

................................................ ' .......................... _'_ ..................... Itrtrnlnrlrllllllrlrlll .................................................................................................

Dwell connection on G.M.H.E.I.

systems.

TEST LEADS

FIGURE 4

The plugs and socketsare pol-

arized to insure correct attach-

ment. The socket has a groove

on each top corner. The plug

has a mating ridge on the inside

of the top corners.

BLACK

RED

POINTS, VOLTS, j _m,._

AND DWELL ..................._.,_,,_ _,_

AMPS ....

r* _"b'_WITH '-'_':::':'100/400.......AMP"' _'SHUNT'" _-- I_€;

LEAD _ PANEL

PLUG k_ SOCKET

BLUE

_m,.. OHMS

WHITE

RPM

Page 8

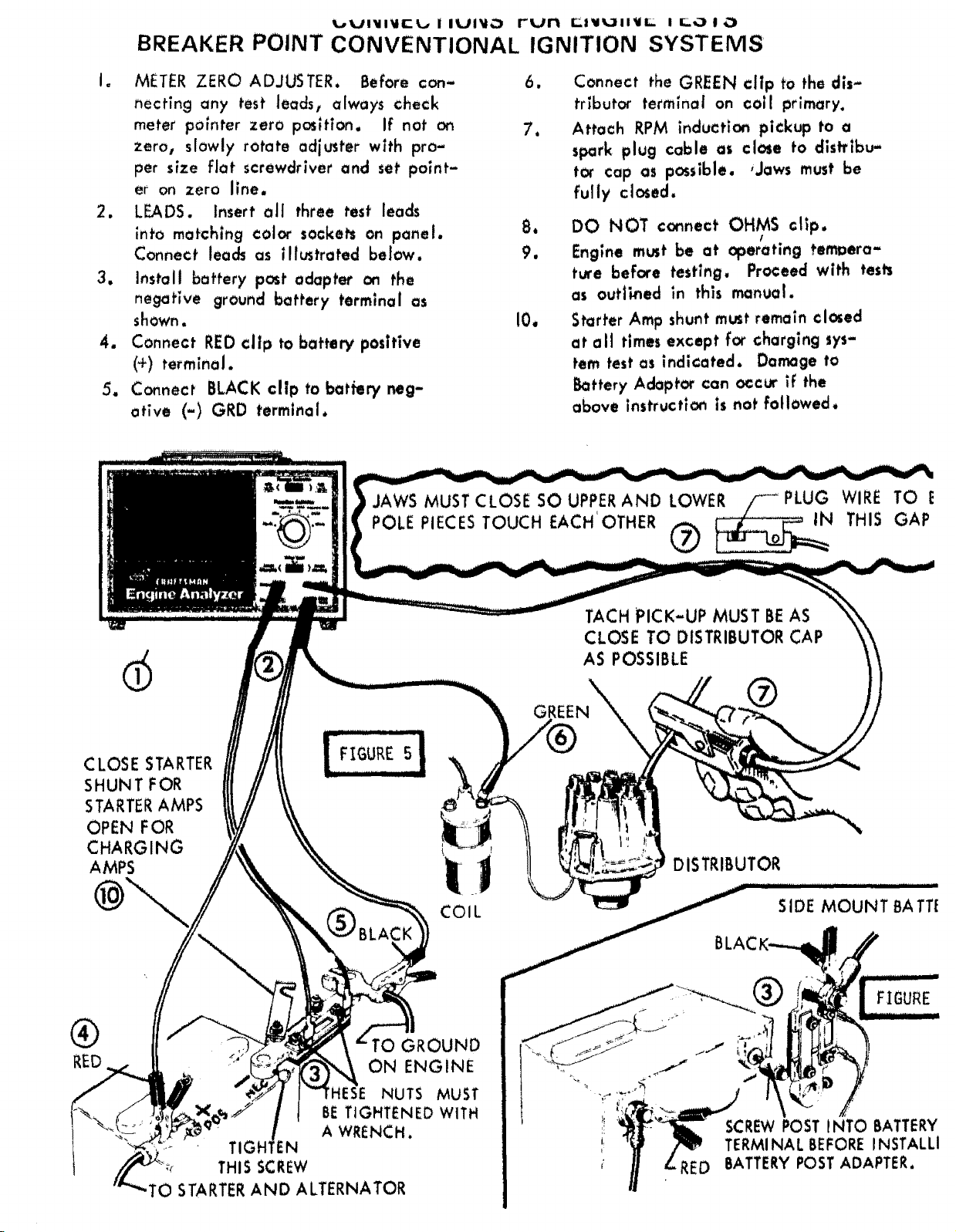

v_,a_,.,/l_ll_lr'1_,. I IUI_I_'.'_ run r-t_l_C.lll_iL I r..,.._ t O

BREAKER POINT CONVENTIONAL IGNITION SYSTEMS

I,, METER ZERO ADJUSTER. Before con-

necting any test leads, always check

meter po_nter zero position, if not on

zero, slowly rotate adjuster with pro-

per size flat screwdriver and set point-

er on zero line.

2. LEADS. insert all three test leads

into matching color sockets on panel.

Connect leads as illustrated below.

3. Install battery post adapter on the

negative ground battery terminal as

shown.

4, Connect RED clip to battery positive

(+) termlnal,

5. Connect BLACK clip to battery neg-

atlve (-) GRD terminal,

JAWS MUSTCLOSE SO UPPERAND LOWER yPLUG

PoLEP,ECESTOUt. ACH'o'r.ER®

6_

9.

10.

Connect the GREEN clip to the dis,.

tr_butor termlnai on call primary.

,

Attach RPM induction pickup to a

spark plug cable as close to dlstrtbu-

tar cap as possible. ,Jaws must be

fuliy closed.

,

DO NOT cc_nect OHMS clip.

Engine must be at operating tempera-

ture before testing, Proceed with tests

as outt_ed in this manual.

Starter Amp shunt must remain closed

at all times except for charging sys-

tem test as indicated. Damage to

Battery Adaptor can occur if the

above instruction is not followed,

I

WIRE TO E

THIS GAP

CLOSE STARTER

SHUNT FOR

STARTERAMPS

OPEN FOR

CHARGING

AMPS

®

RED

TACH PICK-UP MUST BE AS

CLOSE TO DISTRIBUTOR CAP

AS POSSIBLE

tEEN

FIGURE

TO GROUND

ON ENGINE

iSE NUTS MUST

_-_ BETIGHTENED WITH

A WRENCH.

TI EN

THIS SCREW

I'O STARTER AND ALTERNATOR

SCREW POST INTO BATTERY

TERMINAL BEFORE INSTALLI

BATTERY POST ADAPTER,

RED

Page 9

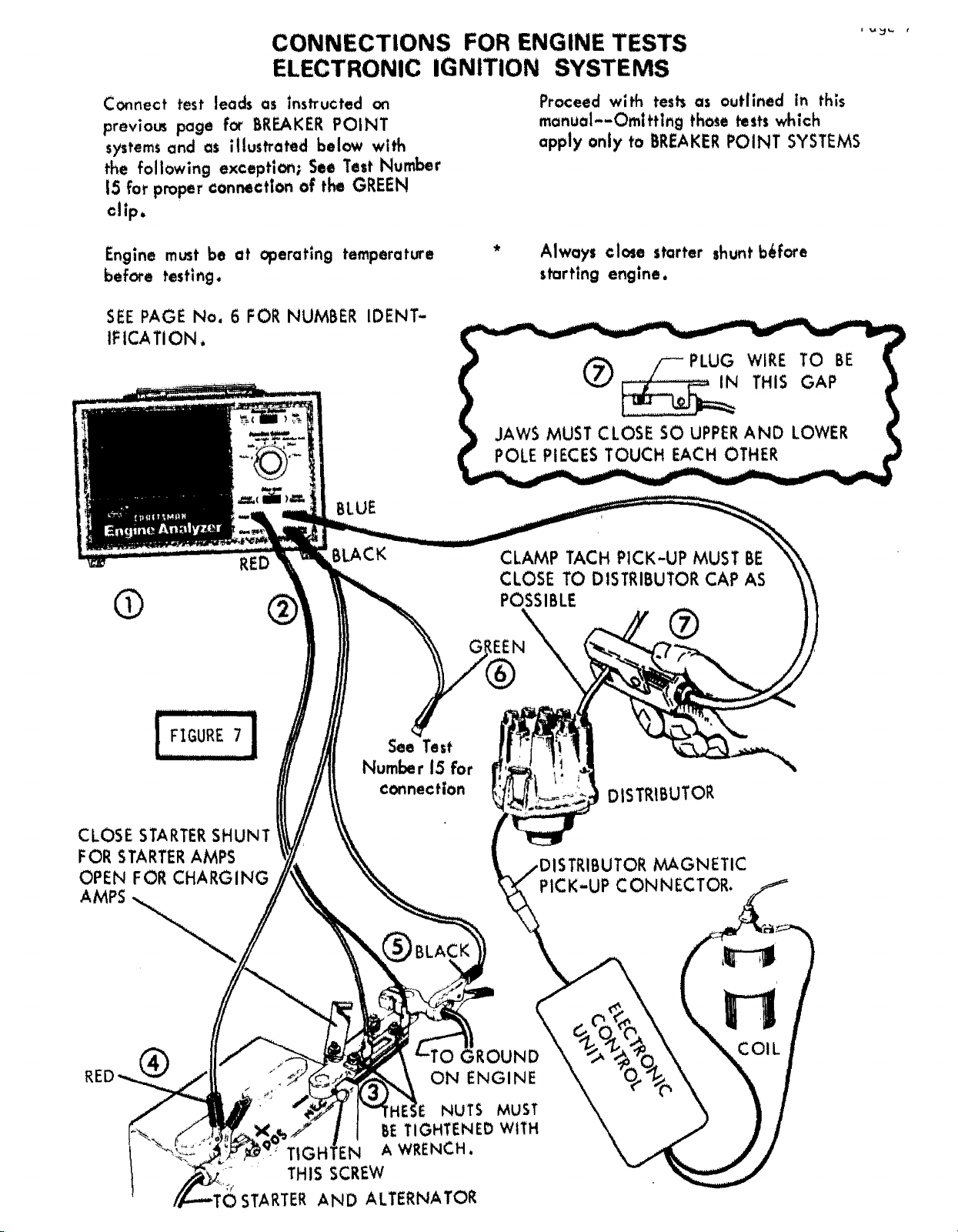

CONNECTIONS FOR ENGINE TESTS

ELECTRONIC IGNITION SYSTEMS

Connect test leads as instructed on

previous page for BREAKER POINT

systemsand as illustrated below with

the following exception; See Test Number

15 far proper connection of the GREEN

clip.

Engine must be at operating temperature

before testing.

SEE PAGE No. 6 FOR NUMBER IDENT-

IFICATION.

i

BLUE

Proceed with tests as outlined in this

manual--Oral fling those tests which

apply only to BREAKERPOINT SYSTEMS

Always close starter shunt b6fore

starting engine.

_PLUG WIRE TO BE

®

JAWS MUST CLOSE SO UPPERAND LOWER

POLE PIECES TOUCH EACH OTHER

RED

CLOSESTARTE_SHUNT

FORSTARTERAMPS

OPENFORCHARGING

AMPS_.__

_LACK

See Test

Numbe r 1.5for

connection

CLAMP TACH PICK-UP MUST BE

CLOSE TO DISTRIBUTOR CAP AS

POSSIBLE

®

IEEN

DISTRIBUTOR

STRIBUTOR MAGNETIC

_ICK-UP CONNECTOR.

)BLACK

®

GROUND

ON ENGINE

NUTS MUST

BETIGHTENED WITH

EN A WRENCH.

THIS SCREW

STARTER AND ALTERNATOR

Page 10

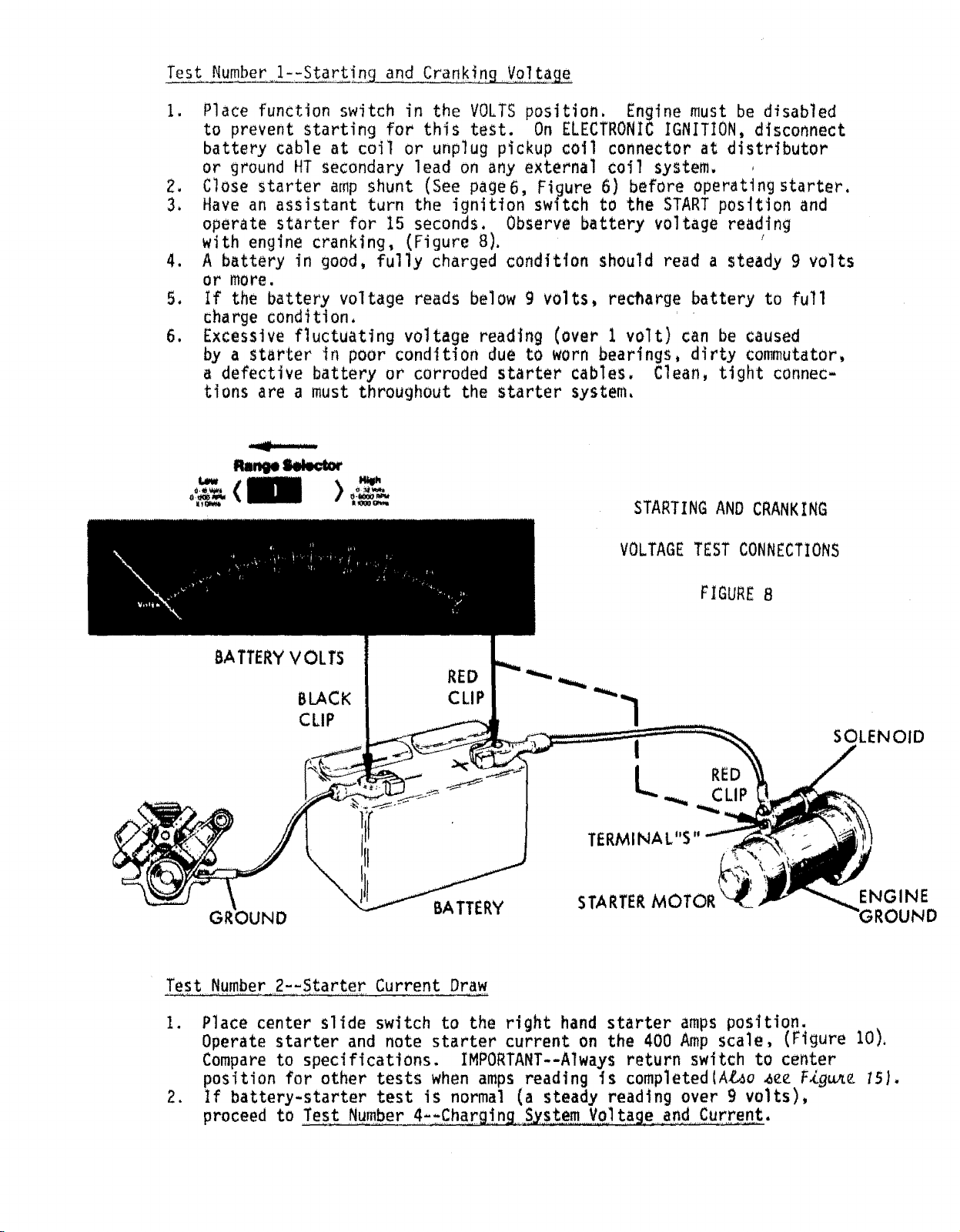

Test Number 1--Startin_ and Crank ing_Vg.!tage,

I. Place function switch in the VOLTS position. Engine must be disabled

to prevent Starting for this test. On ELECTRONIC IGNITION, disconnect

battery cable at coil or unplug pickup coil connector at distributor

or ground HT secondary lead on any external coil system. ,

2. Close starter amp shunt (See page 6, Figure 6) before operating starter.

3. Have an assistant turn the ignition switch to the START position and

operate starter for 15 seconds. Observe battery voltage reading

with engine cranking, (Figure 8).

4. A battery in good, fully charged condition should read a steady 9 volts

or more.

5. If the battery voltage reads below g volts, recharge battery to full

charge condition.

6. Excessive fluctuating voltage reading (over i volt) can be caused

by a starter in poor condition due to worn bearings, dirty commutator,

a defective battery or corroded starter cables, Clean, tight connec-

tions are a must throughout the starter system.

STARTING AND CRANKING

BA TTERY V OLTS

RED

BLACK

CLIP

CLIP

GR BATTERY STARTERMOTOR ENGI NE

Test Number_2-,Starter Current Draw

VOLTAGE TEST CONNECTIONS

FIGURE B

SOLENOID

L

TERMINAL"S"

)UND

I. Place center slide switch to the right hand starter amps position.

Operate starter and note starter current on the 400 Amp scale, (Figure 10),

Compare to specifications. IMPORTANT--Always return switch to center

position for other tests when amps reading is compieted{AZ_o _¢e F_gu_e 15J.

2. If battery-starter test is normal (a steady reading over 9 volts),

proceed to Test Number 4_Cha_gingS_stemVg]tage and Current.

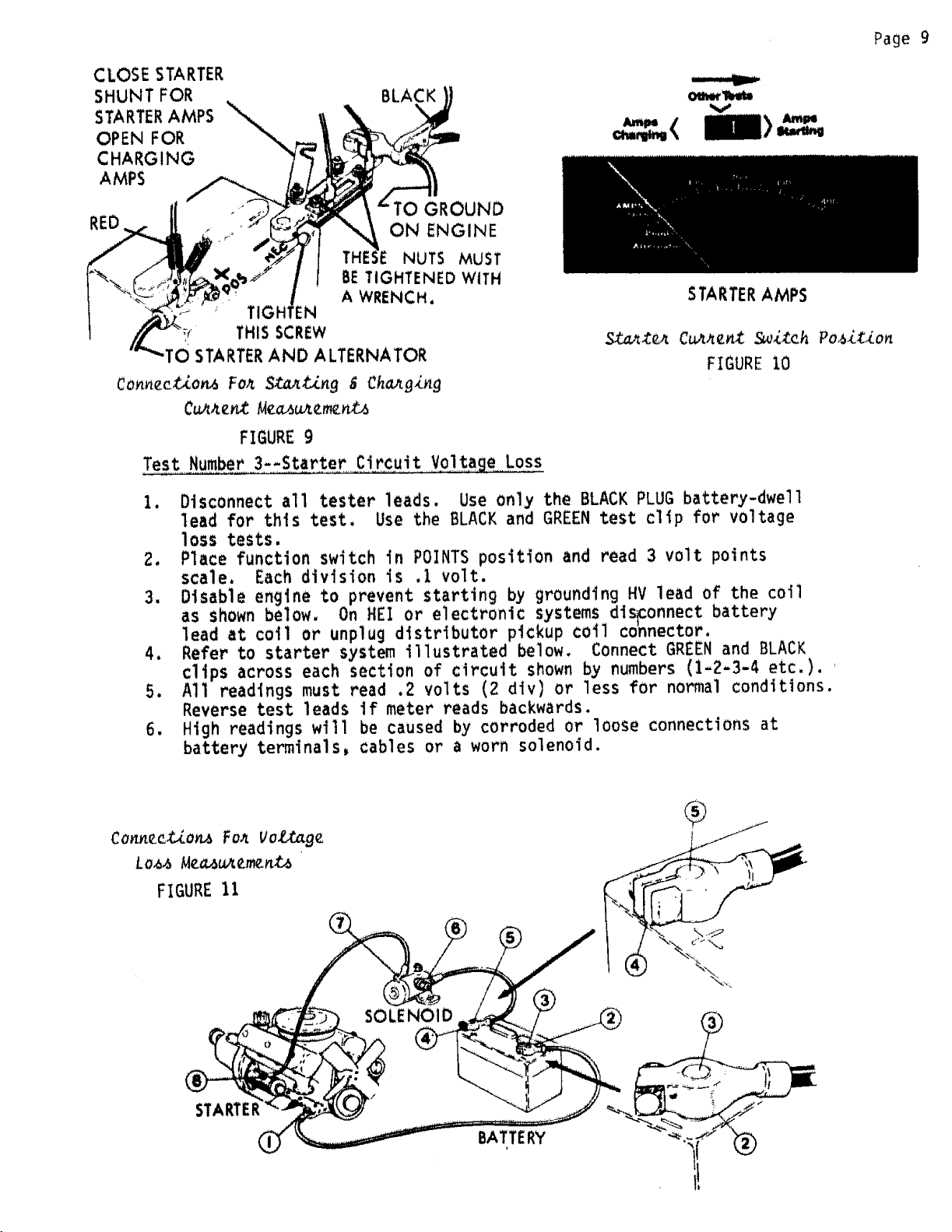

Page 11

CLOSE STARTER

SHUNT FOR

STARTER AMPS

OPEN FOR

CHARGING

AMPS

BLACK

Page 9

v

RED

BETIGHTENED WITH

A WRENCH.

TIGH!

v THIS SCREW

STARTERAND ALTERNATOR

Conn_c_on_ For S_J_uzt_.ng il C,ho_rg_ng

CuArent Measurements

FIGURE g

Test Number 3--Starter Circuit Voltage_..Loss

I. Disconnect all tester leads. Use only the BLACK PLUG battery-dwell

lead for this test. Use the BLACK and GREEN test clip for voltage

loss tests.

2. Place function switch in POINTS position and read 3 volt points

scale. Each division is .I volt.

3. Disable engine to prevent starting by grounding HV iead of the coil

as shown below. On HEI or electronic systems disconnect battery

lead at coil or unplug distributor pickup coil connector.

4. Refer to starter system illustrated below. Connect GREEN and BLACK

clips across each section of circuit shown by numbers (i-2-3-4 etc.).

5. All readings must read .2 volts (2 div) or less for normal conditions.

Reverse test leads if meter reads backwards.

6. High readings will be caused by corroded or loose connections at

battery terminals, cables or a worn solenoid.

TO GROUND

ON ENGINE

NUTS MUST

STARTERAMPS

S_t_ C_r{nt .,c_it_h Po_Z_Zon

FIGURE 10

Connect_Lon,s For Vo.&_ge

Lo_S M_asu_r_ments

FIGURE 11

STARTER

®

®

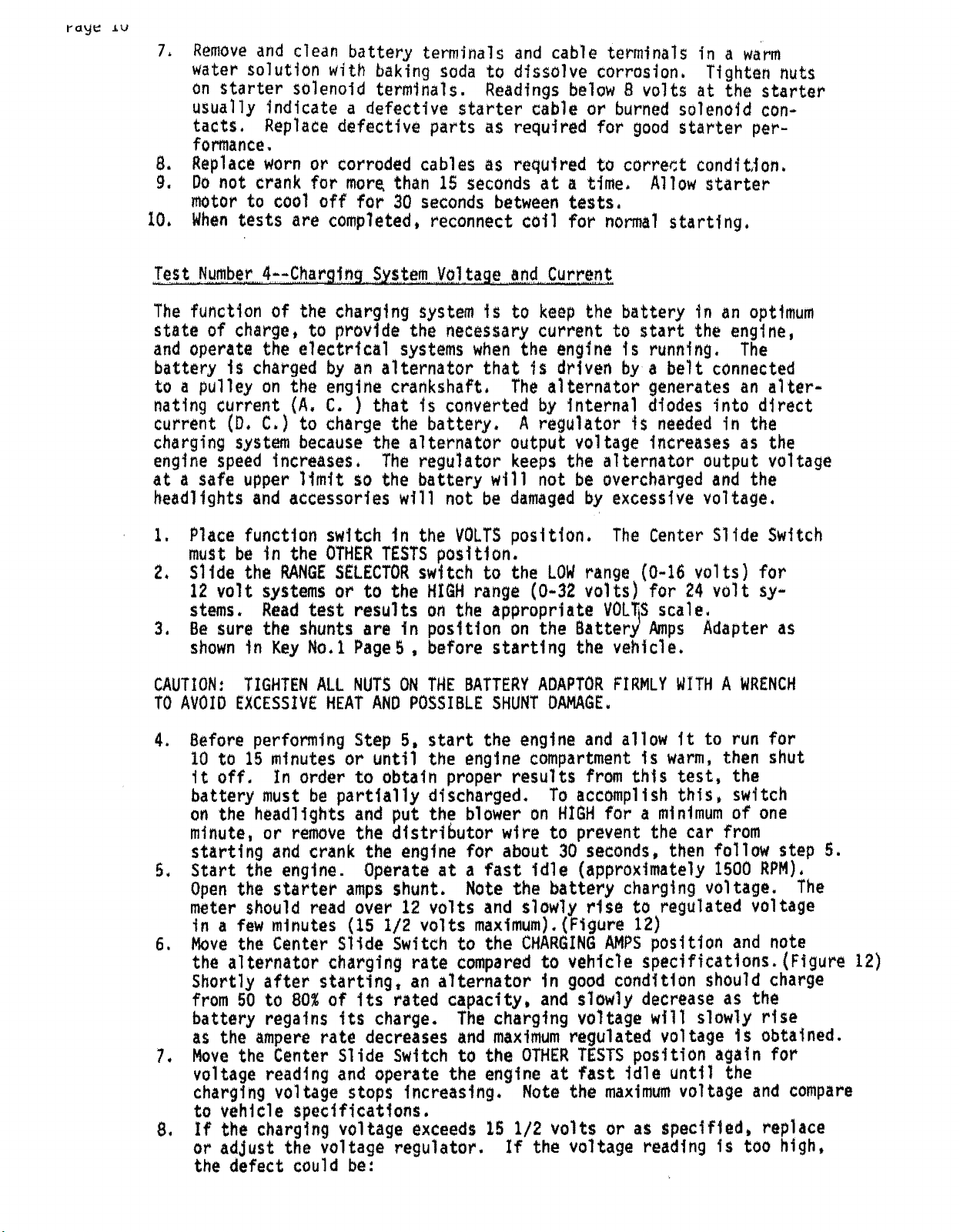

Page 12

va_ iu

7, Remove and clean battery terminals and cable terminals in a warm

water solution with baking soda to dissolve corrosion, Tighten nuts

on starter solenoid terminals. Readings below B volts at the starter

usually indicate a defective starter cable or burned solenoid con-

tacts. Replace defective parts as required for good starter per-

formance.

8. Replace worn or corroded cables as required to correct condition.

g. Do not crank for mor_ than 15 seconds at a time, Allow starter

motor to cool off for 30 seconds between tests,

10. When tests are completed, reconnect coil for normal starting.

The function of the charging system is to keep the battery In an optimum

state of charge, to provide the necessary current to start the engine,

and operate the electrical systems when the engine is running. The

battery is charged by an alternator that is driven bye belt connected

to a pulley on the engine crankshaft. The alternator generates an alter-

nating current (A, C. ) that is converted by internal diodes Into direct

current (D. C,) to charge the battery, A regulator is needed in the

charging system because the alternator output voltage increases as the

engine speed increases, The regulator keeps the alternator output voltage

at a safe upper limit so the battery will not be overcharged and the

headlights and accessories will not be damaged by excessive voltage.

I. Place function switch in the VOLTS position. The Center Slide Switch

must be in the OTHER TESTS position.

2. Slide the RANGE SELECTOR switch to the LOW range(O-16 volts) for

12 volt systems or to the HIGH range (0-32 volts) for 24 volt sy-

stems. Read test results on the appropriate VOL_S scale.

3. Be sure the shunts are in position on the Battery Amps Adapter as

shown in Key No.I Page 5, before starting the vehicle.

CAUTION: TIGHTEN ALL NUTS ON THE BATTERY ADAPTOR FIRMLY WITH A WRENCH

TO AVOID EXCESSIVE HEAT AND POSSIBLE SHUNT DAMAGE.

4. Before performing Step 5, start the engine and allow it to run for

10 to 15 minutes or until the engine compartment is warm, then shut

it off. In order to obtain proper results from this test, the

battery must be partially discharged. To accomplish this, switch

on the headlights and put the blower on HIGH for a minimum of one

minute, or remove the distributor wire to prevent the car from

starting and crank the engine for about 30 seconds, then follow step 5,

5, Start the engine. Operate at a fast idle (approximately 1500 RPM).

Open the starter amps shunt. Note the battery charging voltage. The

meter should read over 12 volts and slowly rise to regulated voltage

in a few minutes (15 I/2 volts maximum).(Figure 12)

6. Move the Center Slide Switch to the CHARGING AMPS position and note

the alternator charging rate compared to vehicle specifications.(Figure 12)

Shortly after starting, an alternator in good condition should charge

from 50 to 80% of its rated capacity, and slowly decrease as the

battery regains its charge. The charging voltage will slowly rise

as the ampere rate decreases and maximum regulated voltage Is obtained.

7. Move the Center Slide Switch tO the OTHER TESTS position again for

voltage reading and operate the engine at fast idle until the

charging voltage stops increasing. Note the maximum voltage and compare

to vehicle specifications.

8. If the charging voltage exceeds IB I/2 volts or as specified, replace

or adjust the voltage regulator. If the voltage reading is too high,

the defect could be:

Page 13

Page 11

DEFECT

A. High resistance in the ground

circuit

B. Regulator set too high

Clean and tighten all ground

connections

Adjust to the proper setting

ACTION

(If adjustment is possible)

Most late model vehicles use

a regulator which is of solid

state design and cannot be

adjusted. These must be re-

placed when they are defective,

C. Defective regulator

Replace Regulator

if the voltage reading is too low, the problem is either in the alternator,

regulator, or the battery.

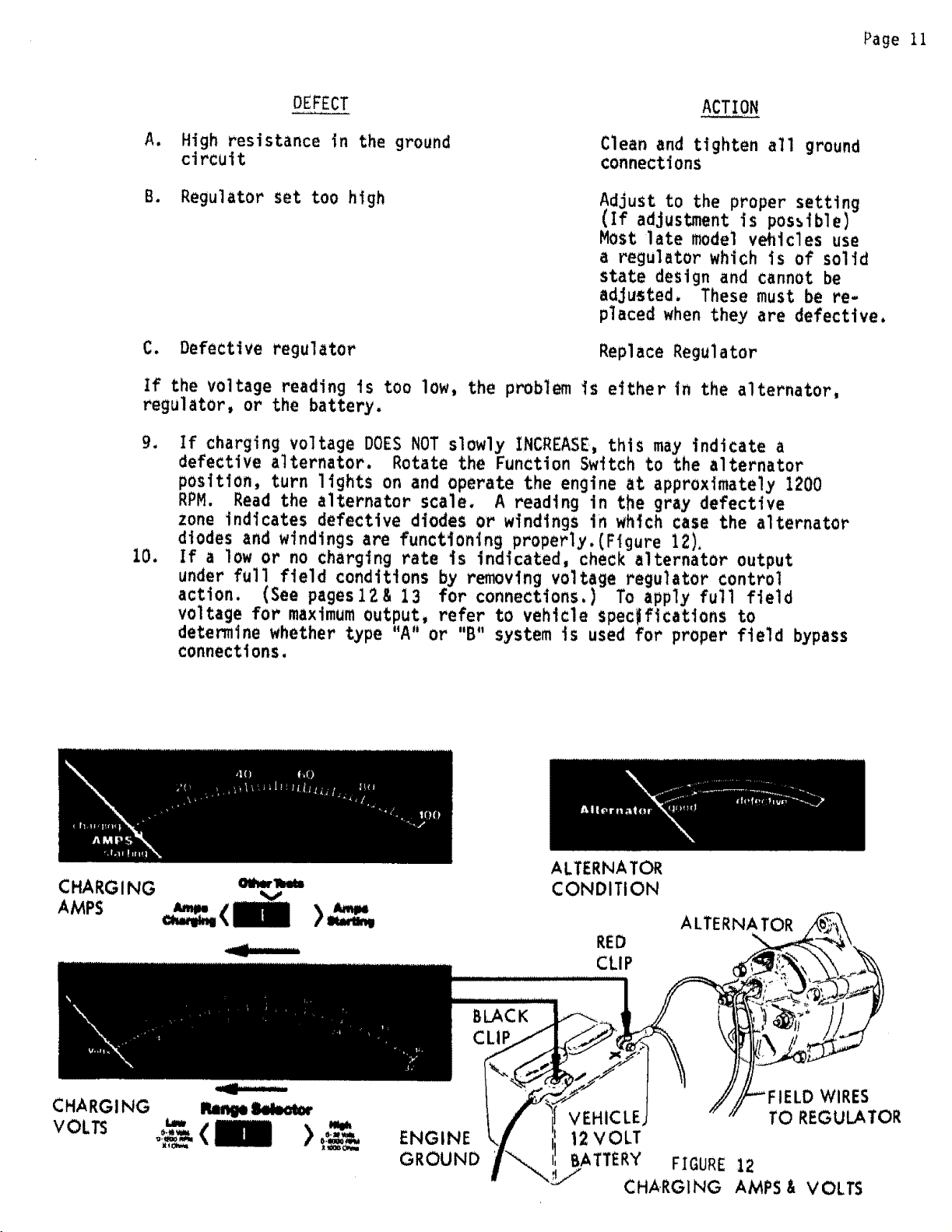

9. If charging voltage DOES NOT slowly INCREASE, this may indicate a

defective alternator. Rotate the Function Switch to the alternator

position, turn lights on and operate the engine at approximately 1200

RPM. Read the aiternator scale. A reading in the gray defective

zone indicates defective diodes or windings in which case the alternator

diodes and windings are functloningproperly.(Figure 12).

10. If a low or no charging rate is indlcated, check alternator output

under full field conditions by removing voltage regulator control

action. (See pages12& 13 for connections.) To apply full field

voltage for maximum output, refer to vehicle specifications to

determine whether type "A" or "B" system is used for proper field bypass

connections.

CHARGING

AMPS

CHARGING

V OLTS

ALTERNA TOR

om,w_,m CONDITION

V

RED

CLIP

BLACK

VEHICLE TO REGULATOR

ENGINE

GROUND

12 VOLT

BATTERY FIGURE 12

"J_'/ CHARGING AMPS & VOLTS

ALTERNATOR

WIRES

Page 14

Page12

IIATTERY _ft AOAPTI[R CONN-

tCtlONS ItOlt ALTERNATOR Tilt

CHARGING ot_,r_

V

AM ,s gill

FIGURE 13

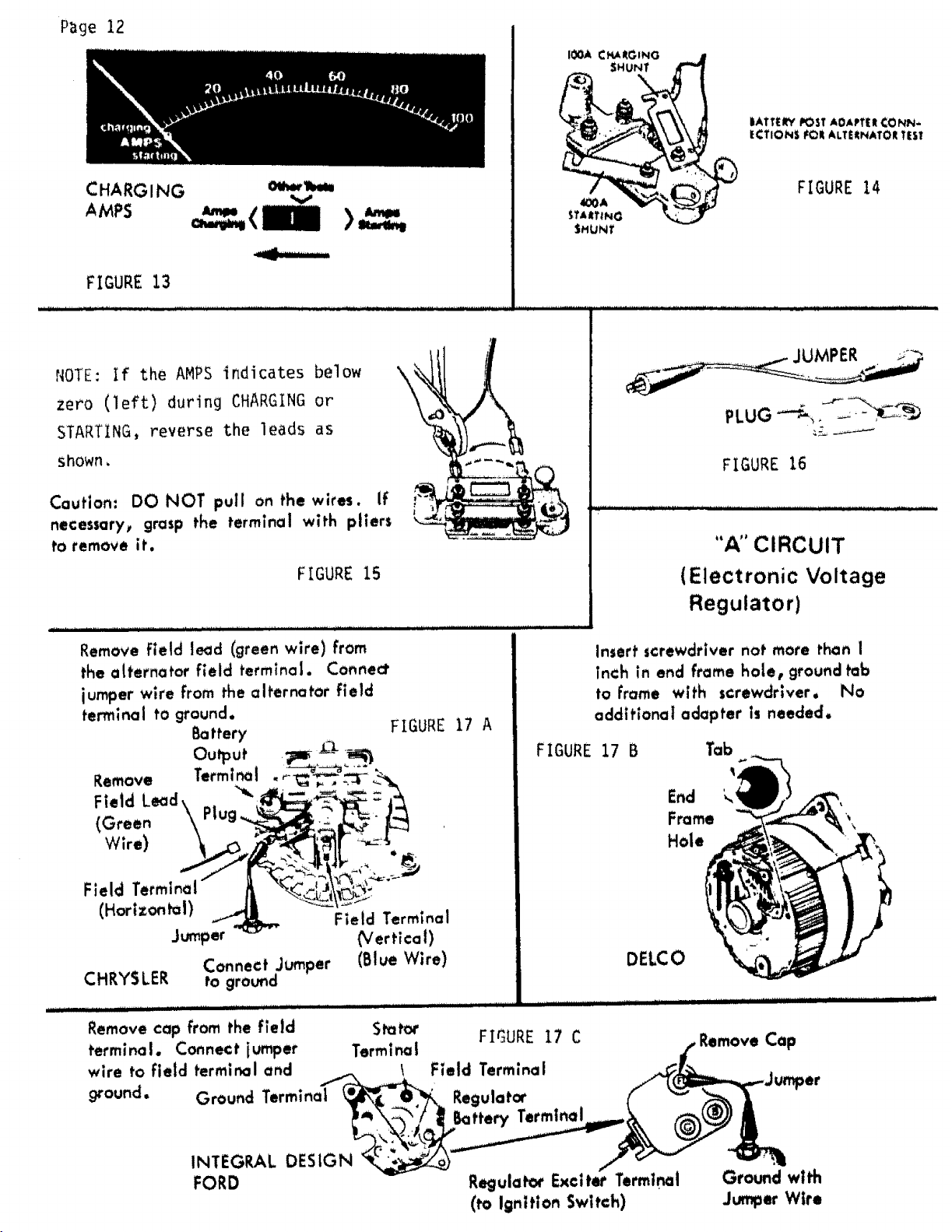

NOTE: If the AMPS indicates below

zero (left) during CHARGING or

STARTING, reverse the leads as

shown,

Caution: DO NOT pull on the wires, if

necessary_ grasp the terminal with pliers

tO remove it,

FIGURE 15

FIGURE 14

FIGURE 16

"A" CIRCUIT

(Electronic Voltage

Regulator)

Remove field lead (green wire) from

the alternator field terminal. Connect

iumper wire from the alternator field

terminal to ground.

Battery

Output

Remove

Field Lead

(Green

Wire)

Field Terminal

(Horizonhal)

CHRYSLER to ground

JJL ...... _.....................

Remove cap from the field Stator

terminal. Connect jumper Terminal

wlre to field terminal and !

ground. Ground Terminal

Terminal

Plug

Jumper

Connect Jumper

FIGURE i7 A

Field Terminal

(Vertical)

(Blue Wire)

FIGURE 17 C

Field Term;hal

Regulat_

Terminal

Insert screwdriver not more than I

inch in end frame hole, ground tab

to frame with screwdr;ver. No

additional adapter is needed.

FIGURE 17 B

Hole

DELCO

Tab

End

Frame

Remove Cap

\

INTEGRAL DESIGN

FORD Regulator Exclte' Terminal

(to Ignition Switch)

Ground with

Jumper Wire

Page 15

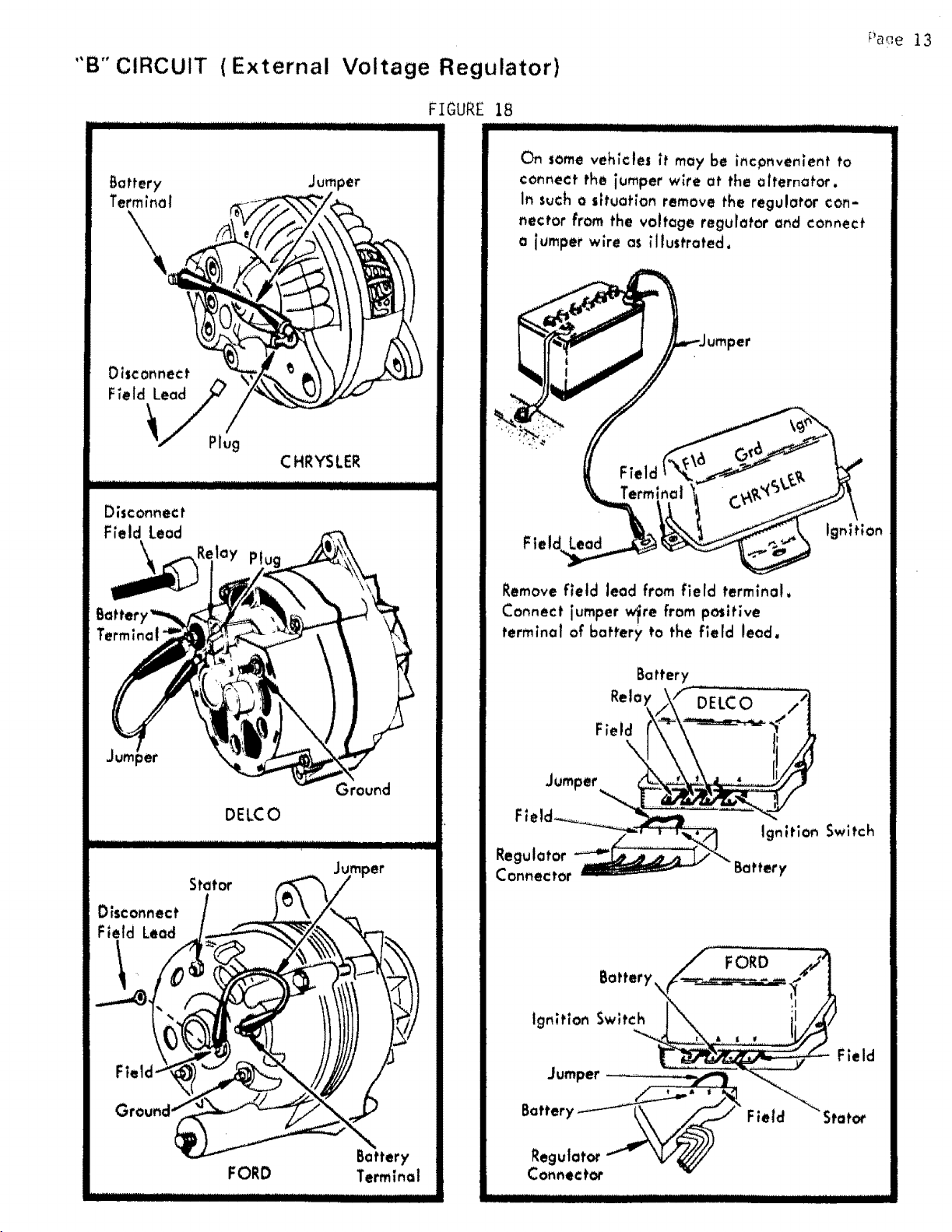

"B" CIRCUIT ( External Voltage Regulator)

i'_e 13

.................................................... II II]llllllnll I IIIIIIIIII II ................. r

Battery Jumper

Term _nol

Plug

CHRYSLER

bisconnect

F_eld Lead

FIGURE 18

On some vehicles if may be inc_onvenlent to

connect the iumper wlre at the alternator.

Imsuch a iftuaHon remove the regulator con-

nector from the voltage regulator and €onnect

a iumper wire as illustrated.

ignition

Te _1

DELCO

Stator _"_\ /

Di,conoe=t/ __./7,_

Remove field lead from field terminal.

Connect iumper w_re from positive

terminal of battery to the field lead.

Jumper

Battery,

Ignition Switch

F;et

Gr°umd__B_attery

FORD Term;hal

........................................................................ 1111111111111111111111111111111111"

Jumper

Batter

Regulator

Commector

Field

Field Stator

Page 16

ru_E _

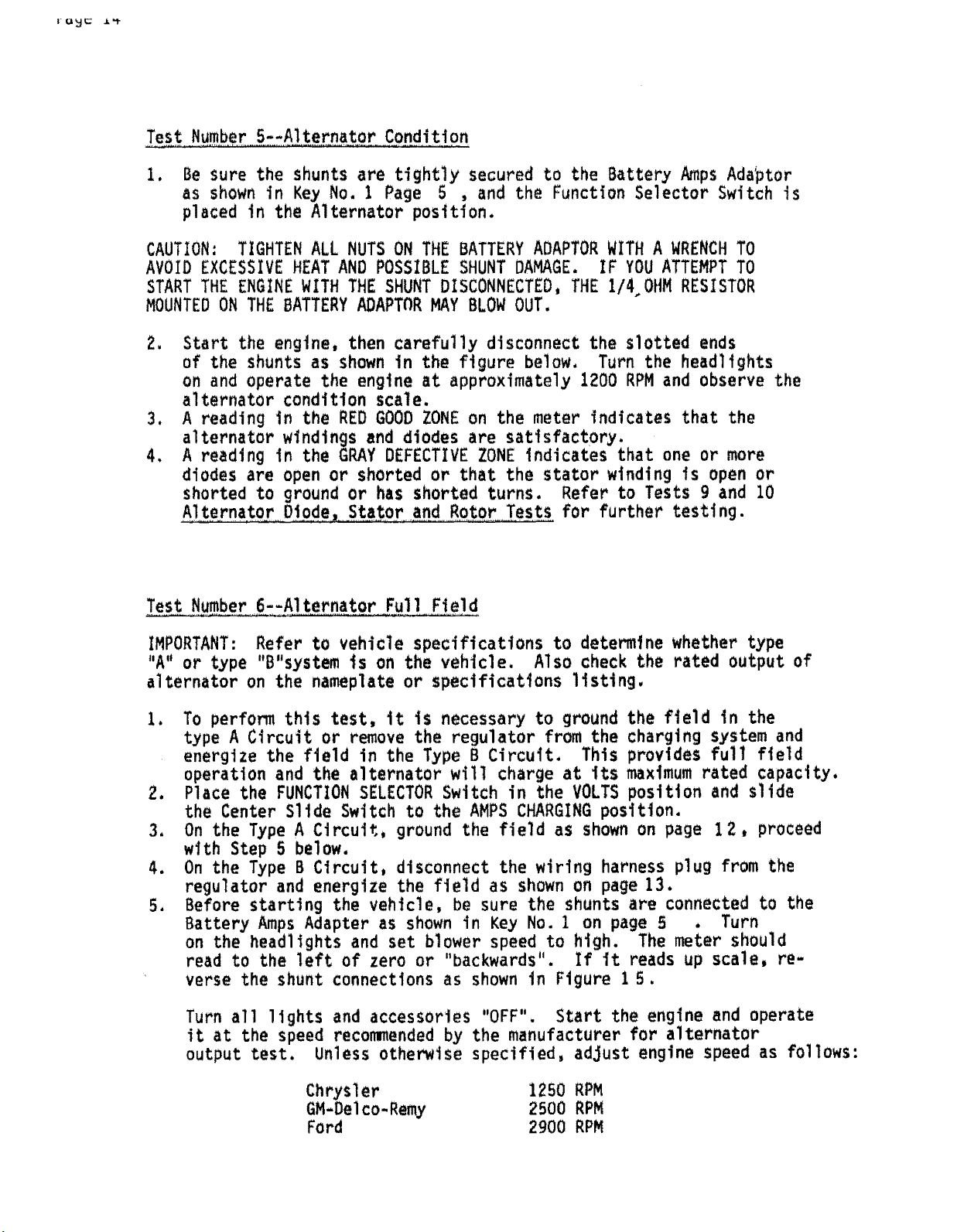

I. Be sure the shunts are tightly secured to the Battery Amps Adaptor

as shown in Key No. I Page 5 , and the Function Selector Switch is

placed in the Alternator position.

CAUTION: TIGHTEN ALL NUTS ON THE BATTERY ADAPTOR WITH A WRENCH TO

AVOID EXCESSIVE HEAT AND POSSIBLE SHUNT DAMAGE. IF YOU ATTEMPT TO

START THE ENGINE WITH THE SHUNT DISCONNECTED, THE 1/40HM RESISTOR

MOUNTED ON THE BATTERY ADAPTOR MAY BLOW OUT.

2. Start the engine, then carefully disconnect the slotted ends

of the shunts as shown in the figure below. Turn the headlights

on and operate the engine at approximately 1200 RPM and observe the

alternator condition scale.

3. A reading in the RED GOOD ZONE on the meter indicates that the

alternator windings and diodes are satisfactory.

4. A reading in the GRAY DEFECTIVE ZONE indicates that one or more

diodes are open or shorted or that the stator winding is open or

shorted to ground or has shorted turns. Refer to Tests 9 and 10

Alternator Diode, Statorand Rotor Tests for further testing.

IMPORTANT: Refer to vehicle specifications to determine whether type

"A" or type "B"system is on the vehicle, Also check the rated output of

alternator on the nameplate or specifications listing,

1. To perform this test, it is necessary to ground the field in the

type A Circuit or remove the regulator from the charging system and

energize the field in the Type B Circuit. This provides full field

operation and the alternator will charge at its maximum rated capacity,

2. Place the FUNCTION SELECTOR Switch in the VOLTS position and slide

the Center Slide Switch to the AMPS CHARGING position.

3, On the Type A Circuit, ground the field as shown on page 12, proceed

with Step 5 below.

4. On the Type B Circuit, disconnect the wiring harness plug from the

regulator and energize the field as shown on page 13.

5. Before starting the vehicle, be sure the shunts are connected to the

Battery Amps Adapter as shown in Key No. I on page 5 • Turn

on the headlights and set blower speed to high. The meter should

read to the left of zero or "backwards". If it reads up scale, re-

verse the shunt connections as shown in Figure 1 5.

Turn all lights and accessories "OFF". Start the engine and operate

it at the speed recommended by the manufacturer for alternator

output test. Unless otherwise specified, adjust engine speed as follows:

Chrysler 1250 RPM

GM-Delco-Remy 2500 RPM

Ford 2900 RPM

Page 17

With the engine running, carefully open the starter shunt as shown

in Key 10 on page 6 . Observe the current (amps) reading on the

0-100 Amps scale, reduce engine speed to curb idle and compare meter

reading with the manufacturer's specifications.

ALTERNATOR FULL FIELD

NOTE: To determine the actual output current, add 5 amperes to the meter

reading obtained during the output test. This is the approximate current

used by the ignition system, dash instruments and alternator field toll

combined which does not reach the battery to be measured during

this test. If the meter reading is at or higher than specified, the

alternator output is satisfactory. If the meter reading Is less than

specified, a loose or worn alternator drive belt, a faulty field or

battery wire to the alternator, or a poorly grounded or defective alternator

is indicated. If the meter reading is to the left of zero, a broken

field wire or a defective alternator is indicated. (Meter reading is the

battery discharge current used by the ignition system and dash instruments.)

Page 15

6. When test is completed, shut off the engine, disconnect jumper lead,

remove the shunt, and reconnect wiring harness plug, connector or

field wire to the regulator for normal operation,

Repeat Test Number 4:±Charging System Vp]tage and Current

If the voltage reading is within the range as specified by the vehicle

service manual, (typically between i3.8 and 15.2 volts on 12 volt systems,

and 27.6 and 30.4 on 24 volt systems) the regulator is satisfactory.

If the voltage reading is out of specifications but satisfactory

operation was obtained on the CHARGING SYSTEM VOLTAGE AND CURRENT and

ALTERNATOR CONDITION tests, the voltage regulator should be adjusted

(if possible) or replaced.

Test Number B--Battery

Repeat Test Number4-,ChargingSystemvo]tage and Current

After the VOLTAGE REGULATOR--TEST 7 is completed, the regulator should

be functioning satisfactorily, leaving the battery as the only untested

component remaining in the CHARGING SYSTEM. To test battery condition,

attach the shunt to the BATTERY POST ADAPTER (Key I Page 5 ), start

the engine, and operate it at approximately 1200 RPM. If the voltage

reading is less than 13.8 volts, check the water level in the battery and

fill to the proper level, if necessary. Charge the battery and repeat

this test. if the voltage reading is still low, the battery is defective

and should be replaced.

Page 18

Page 16

Test Number 9--Ohms Test

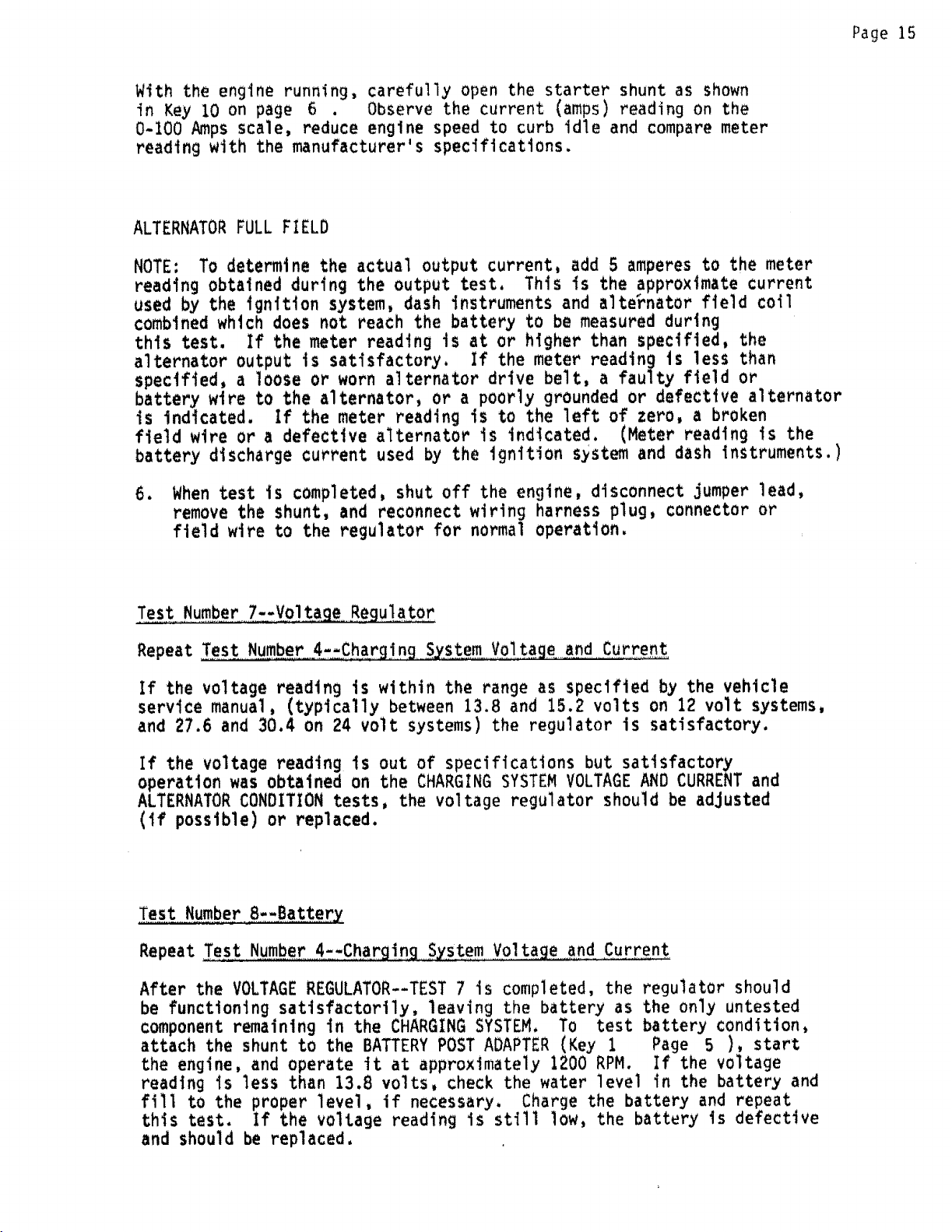

1. The ohmmeter test is powered by an internal 9 volt battery. No

zero calibration is required by the operator. Place Function

Selector Switch in the Ohms position and select either the Hi

or Lo range to match the component under test. (X i or X lOOd)

2. CONNECTIONS: Insert the white Plug Ohms Lead into the corresponding

tester socket as illustrated below.

3. OPERATION: The meter will read full scale at INF. with cllps,open,

and when the clips are connected together will read zero on the

left. (See Paragraph #6.) To measure resistance, connect the clips

to the component to be tested and read the prope_ Ohms scale. (X 1 or

x 1ooo)

4. IMPORTANT CAUTION: ALWAYS disconnect ALL L£ADS from any electrical

part to be tested on the vehicle. Failure to observe this caution may

result in damage to the tester.

5. Refer to manufacturer's specifications for normalresistance value

of any part being tested, ignition cables, ballast resistor, coil

windings, etc.

WHITE PLUG

FIGURE 19

I i

SECONDARY

OHMS

OHMMETER BATTERY

The 9 volt battery ts located in the rear com-

partment,

Observe correctt polarity when installing

battery.

IMPORTANT: 9 VOLT BATTERY ( SEARS#

64i7) IS NOT SUPPLIED WiTH THIS ANA-

LYZER.--OHMS CIRCUIT WILL NOT WORK

WITHOUT BATTERY.

OHMS TESTS ON VARIOL

VEHICLE COMPONENTS

PRIMARY

OHMS

1

FUSE

OHMMETERCONNECTIONS

RED

BLACK

BA LLAST RESISTOR

COIL

Page 19

6. BATTERY REPLACEMENT. When the g volt battery is low, the meter will

not read full scale with the clips open. Replace the battery to

obtain accurate OHMS measurement.

7. IMPORTANT: When the tester is not in use or when Ohms tests are

completed ALWAYS turn the Function Selector Switch OUT of the

Ohms position to prevent battery discharge.

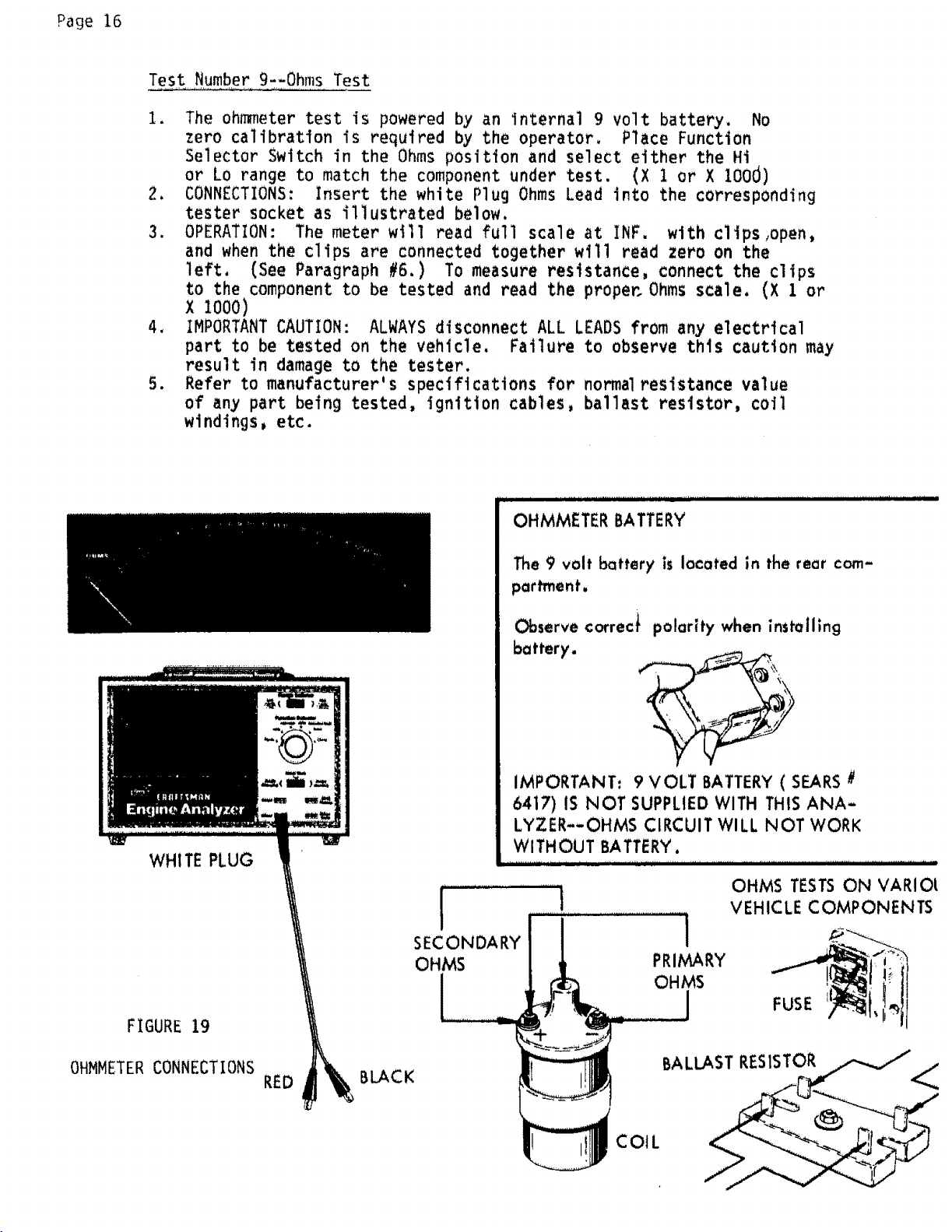

DIODE TESTS ON OHMS X 1000 POSITION

Alternator diodes in a disassembled alternator can be tested for "shorts"

or "opens" with the stator leads disconnected as illustrated. To

facilitate checking the diodes in the end frame and heat sink, place a short

length of wire or nail in the jaws of the RED and BLACK test clips as shown

in the illustration. Touch the RED lead to the diode case and the BLACK

lead to the diode lead as illustrated in Step A and note the meter reading,

Reverse the lead connections on the same diode and again note the reading

as in Step B. A good diode will have one low and one high reading, if

both readings are very low, or if both readings are very high, the diode is

defective and should be replaced.

Page 17

WHITE PLUG

Initial Connection

FIGURE 20

ALTERNATOR DIODE TESTS

LACK

RED

RED

STEP

Page 20

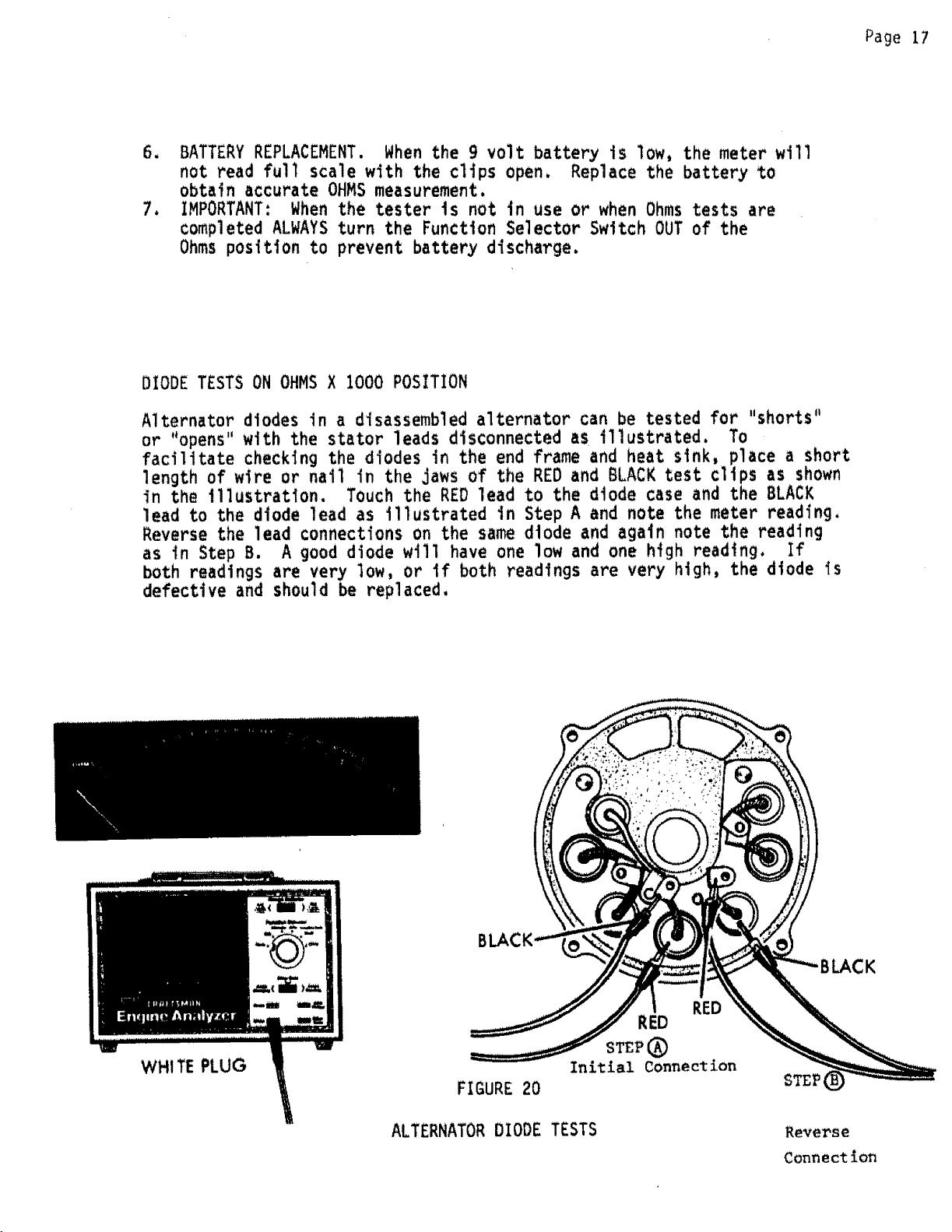

See steps 1-7 TestNumberg--OhmsTest for Ohmmeter use

ROTOR AND STATOR TESTS ON OHMS X 1000 POSITION

Rotor--

The alternator rotor may be tested for open or grounded field coils. To

check for opens, touch the test leads to each slip rJng. If the meter

reading is near zero, (left end) the winding is not open. If the meter

shows high reading (extreme right end of the scale), the winding is open

and the alternator should be repaired or replaced. To check for grounds,

touch the test leads from either sllp ring to the rotor shaft or to the

rotor poles. If the meter shows only a slight reading or none at all,

the field winding is not grounded. If the meter reading is near zero

(left end), the winding is grounded and the alternator should be re-

paired or replaced.

Stator--

The alternator stator windings may be checked for grounds or opens. Dis-

connect the three stator leads from the diodes before any test. To check

for opens, successively connect the tester leads between each pair of

stator leads. In each case, if the meter reading is near zero (left end),

the windings are not open. If the meter shows a high reading, the winding

is open and the alternator should be repaired or replaced. To check for

grounds, connect the tester leads to each stator lea_ and to the frame.

If the meter shows a full scale reading, the stator is not grounded, if

the meter is near zero (left end), the stator winding is grounded to the

frame and the alternator should be repaired or replaced.

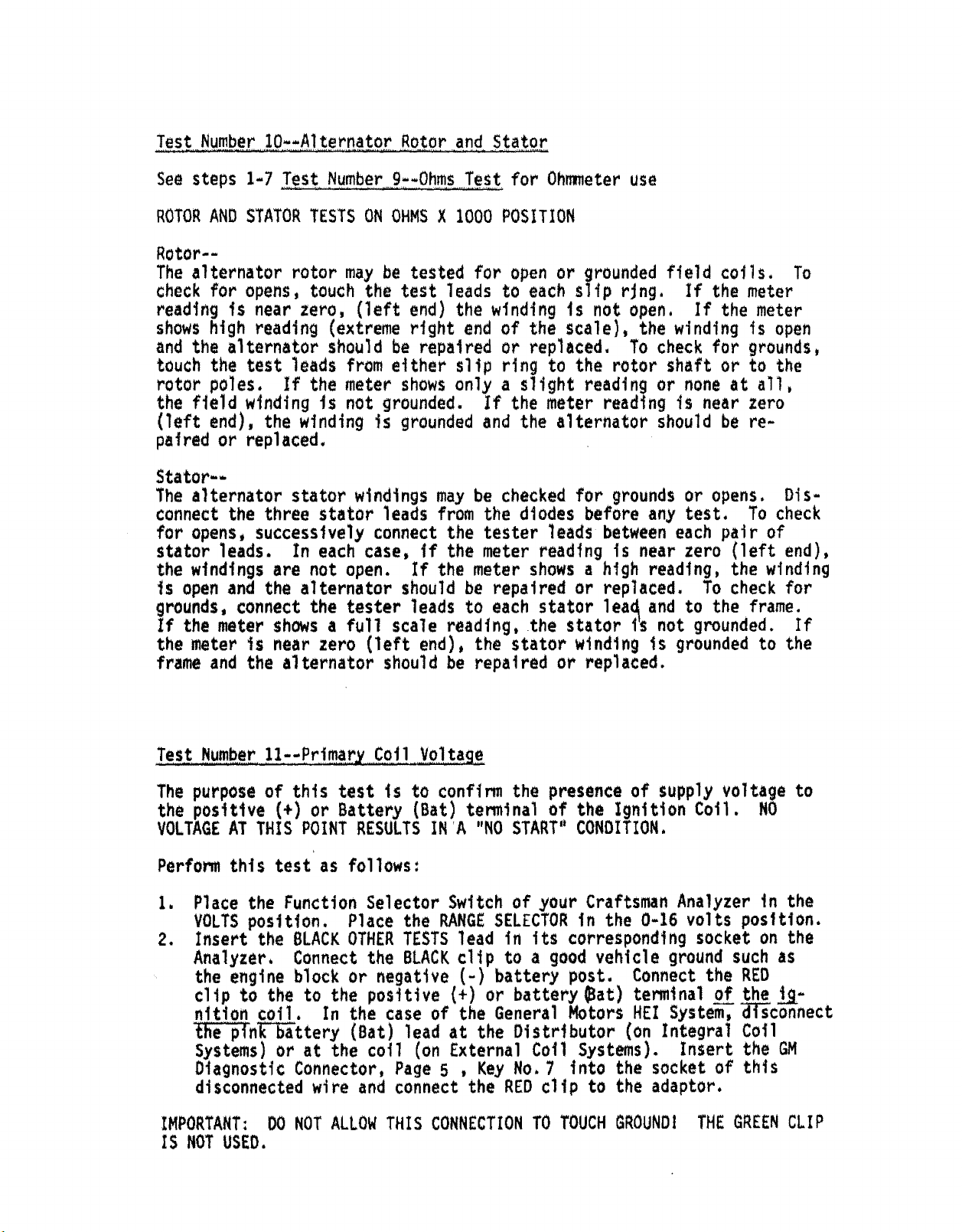

The purpose of this test is to confirm the presence of supply voltage to

the positive (+) or Battery (Bat) terminal of the Ignition Coil. NO

VOLTAGE AT THIS POINT RESULTS IN A "NO START" CONDITION,

Perform this test as follows:

lm

Place the Function Selector Switch of your Craftsman Analyzer in the

VOLTS position. Place the RANGE SELECTOR in the 0-16 volts position.

2.

Insert the BLACK OTHER TESTS lead in its corresponding socket on the

Analyzer. Connect the BLACK clip to a good vehicle ground such as

the engine block or negative (-) battery post. Connect the RED

clip to the to the positive (+) or battery_at) terminal of the i__R-

nition coil. In the case of the General Motors HEI Syste_,,disconnect

_-e_Tn_ttery (Bat) lead at the Distributor (on Integrai Coil

Systems) or at the coll (on External Coil Systems). Insert the GM

Diagnostic Connector, Page 5 , Key No, 7 into the socket of this

disconnected wire and connect the RED clip to the adaptor.

IMPORTANT: DO NOT ALLOW THIS CONNECTION TO TOUCH GROUNDI THE GREEN CLIP

IS NOT USED.

Page 21

3_

Turn the vehicle's Ignition Switch (key) to the "ON" or "RUN" position

only. Do not start the engine.

4.

Read the analyzer's voltmeter. Normal readings should be as follows:

Breaker Point Systems: At or slightly below battery voltage (12 volts)

if the points are open. Approximately 6 to 8 volts if the points are

closed, "Jog" the engine quickly to close the points if they are open.

The meter reading will be significantly lower with the points closed

as shown above.

If the Voltmeter stays at or very close to battery volts (12 volts)

with the points closed, a problem exists in one or more of the

following areas:

Ignition coll primary open, Pigtail from negative (-) or Distributor

(Dist) side of co11 to distributor open, points defective, or open

ground within the Distributor.

If the Voltmeter stays at.zero (no reading), a problem exists in the

supply circuit to the ignltion Coil i.e. ballast resistor open (when

equipped), ignition switch or related wiring open.

Page 1_

Electronic Ignitions: At or slightly below Battery Voltage (12 volts)

If the voltage is not as specified, see the proper diagnostic procedures

relating to your vehicle ignition type as shown later in this manual.

Your vehicle service manual is also a valuable toot in diagnosing

Electronic Ignition problems.

Page 22

Page 20

Test Number 12--Breaker Point Resistance

NOTE; This test does not apply to Electronic ignition systems.

NOTE: Remove the distributor cap before testing and inspect the contact

points. If they are blued, blackened, or noticeably pitted, they should

be replaced. Normal, used contact points are light gray In color.

i. Place the Function Selector Switch in the POINTS position. ,

Z. Disable engine to prevent starting by removing coil secondary lead

from distributor and connect to a good engine ground with Jumper lead

as illustrated below.

#

3. Have an assistant turn the ignition switch to the START position momentarily

to crank engine slowly a little at a time until the points are closed

as indicated by the lowest meter reading.

4. Points are in GOOD condition if the reading is .3 volts or less. Replace

points if the reading is out of the good zone, or over .3 volts.

5. If the reading still exceeds .3 volts, check the distributor ground

plate, (plate on which points are mounted), pigtail extension

to primary lead inside distributor or primary lead to coil for breaks,

or misaligned point contacts on points. Refer to your vehicle service

manual for other tests relating to the Breaker Point Circuit.

6. When new points are installed, always clean and lubricate cam,

check again for contact alignment, and resistance, Adjust to

correct Dwell before startlng--See Test Number I 3, Dwell Adjustment.

7. Correct the defect and repeat the test. When the points check OK,

turn the ignition switch OFF. Reinstall the high tension lead in

the center of the distributor cap.

FIGURE 21

SECONDARY COIL CONNECTIONS

TO PREVENT ENGINE STARTING

BLACK

CLIP

TO GROUND

ON ENGINE

GREEN

CLIP

DIST.

PRIMARY LEAD

GROUND

ON

ENGINE

Page 23

T.estNumber 13--Dwell Adjustment--Breaker Point S#s##m.s

1. Rotate the Function Selector Switch to the dwell position.

2. Consult your vehicle service manual to determine which vacuum hoses,

if any, should be disconnected and plugged prior to making dwell ad-

justment or test.

3. Run the engine at specified idle speed and note dwell reading on proper

4-6 or 8-cylinder scale to correspond to the engine under test.

4. Compare results to vehicle specifications_ adjust _o correct dwell

if required.

READ PROPERSCALE TO SUIT

NUMBER OF ENGINE CYLINDERS

Page 21

BLACK

RED J CLIP

CLIP _J

GREEN

CLIP

DIST.

BAT,+

COIL _

DISTRIBUTOR

FIGURE 22

DWELL ADJUSTMENT CONNECTIONS

On engines that have a sliding window in the distributor cap, adjust dwell

as follows:

I. Operate engine at specified idle.

2. Raise the window and insert a I/8" Allen wrench into the adjustment screw.

3. Turn the adjustment screw until the correct dwell is indicated on the

dwell scale.

Page 24

Page Z2

NOTE:

Disconnect omd plug the vacuum advance

llne from the disfr;butor. If the vehicle

is equipped with an advance-retard sole-

t_o;d, disconnecf the wire at the carburetor

end,

WINDOW

1/8" ALLEN

WRENCH

ADJUSTMENT

SCREW

GM TYPE

PLUG END OF VACUUM LINE

FIGURE 23 FIGURE 24

On engines with non-window distributors, adjust the dweil as follows:

Locking

I. Stop the engine and remove €o11 wire from the center tower of distributor

cap. Connect the jumper wire between coll wire and engine ground to

prevent arcing while cranking the engine,

2. Remove the distributor cap and rotor.

3. Connect a remote starter switch to the vehicle or have an assistant

crank the engine for you with the ignition switch.

4. Turn the ignition switch on and with the engine_cranking, observe the

reading on the dwell scale.

5. To adjust dwell, loosen LOCKING screw slightly and adjust point gap by

turning ADJUSTMENT screw (Figure 25) or by inserting a screwdriver in

slotted hole (Figure 26 ) and turning the tool slightly left or right to

obtain the specified point dwell reading. Tighten locking screw and

recheck dwell while cranking engine. Repeat procedure if necessary.

6. Reassemble distributor and recheck dwell reading with engine operating

at specified idle.

..................................... II1[[I III I[111['1[11

Slotted Hole

Breaker Po(nf

P - Lock|ng Screw

Ga_

FIGURE 25

TYPICAL

INTERNAL

TYPE FIGURE 26

BREAKER

ADJUS TMENTS

Page 25

NOTE; It is important to recheck the ignition timing every time the dwell is

adjusted. A one degree change in dwell causes a one degree change in timing.

THIS TEST DOES NOT APPLY TO ELECTRONIC OR TRANSISTOR IGNITION SYSTEMS EXCEPT

DELCO HEI AND THOSE TYPES USING CONVENTIONAL CONTACT POINTS. ON HE1

SYSTEMS, THE DWELL ANGLE WILL BE LOW AT iDLE SPEED AND WILL INCREASE STEADILY

AS ENGINE SPEED INCREASES. IF IT DOES NOT, THE ENGINEMAY MISFIRE DURING

ACCELERATION AND AT HIGH SPEEDS. TO CORRECT THIS CONDITION, REPLAC_ THE

ELECTRONIC MODULE IN THE DISTRIBUTOR,

There is a direct relationship between dwell and timing. However, it is

only a one way relationship. If you change the dwell angle of the breaker

points, you will automatically change the timing of the ignition. Changing

the timing, however, has no effect on the dwell angle. FOR THIS REASON IT

IS IMPORTANT TO RE-CHECK THE TIMING WHEVEVER THE DWELL ANGLE HAS BEEN ADJUSTED.

When the dwell angle is increased, the timing is retarded. Conversely, when

the dwell angle is decreased, the timing is advanced. In fact, there is a

one-to-one ratio between dwell and timing. For every one degree change in

dwell, there is a corresponding one degree change in timing. This can

sometimes be used to make minor changes in timing. If, for example, it is

desired to advance the timing two degrees, it canbe done by reducing the

dwell angle two degrees. This assumes that the dwell angle will not be

changed out of its specified range.

Page 23

Due to normal wear of the rubbing bloc_ the normal tendency Is for the

dwell angle to increase. This, of course, causes the _iming to become retarded

and results in a loss of power and econorRy, if the engine has been properly

tuned initially, restoring the dwell angle to its original setting will

restore the timing to its original setting.

I/

_o 49._ _ /

// 'w°°

W;de Gap

Small Gap

TYPICAL DWELL

8 CYL, ENGINE

SMALL DWELL ANGLE

CAUSES POOR HIGH SPEED

PERFORMANCE

FIGURE 27

LARGE DWELL ANGLE

CAUSES POINTS TO BURN

Page 26

T_estNumbeF !4-_DwelI Variation Test

Repeat Test Number 13, Steps i-4

NOTE: This test does not apply to transistorized ignition systems (except

those types using conventional contact points).

I. Rotate the Function Selector Switch to the DWELL position.

2. Disconnect and plug vacuum advance hose(s) as described in DWELL

Angle Test 13 on page 21 and 2_

3. Operate engine at curb idle. ,,,lie observing DWELL scale for any

change in reading, increase engine speed to approximately 1500 RPM

and then return to idle.

4. Reconnect vacuum advance hose(s).

15 2O 25 3O

I0 35

5 40

0 ,45

8(

FIGURE 28

DWELL VARIATION

Variation on 4, 6, and 8=cylinder engines should not exceed 3 degrees.

if it does, check for:

a. wear in distributor shaft

b. wear in distributor shaft bushing

c. wear in breaker plate

NOTE: Manufacturer's specifications for some engines call for the

distributor vacuum advance hose to remain connected during the Dwell

Variation Test. In this case, a maximum dwell variation of 6 degrees is

allowed unless otherwise specified by the manufacturer.

Page 27

Test Number IS--Dwell Anqle--Electronic!gn!t!qnSystems

(Electronic Solid State or Transistor Ignition Systems)

General--

Due to the vast array of electronic ignition and engine control systems

being used on late model cars, it is essential that specific service

information for the vehicle under test be obtained. Although Dwell

Angle is not adjustable on electronic systems, the reading obtained is

important and should be within the manufacturer's speclfled limits. If

it is not, consult the manufacturer's shop manuals for diagnostic procedures,

Preparation for tests--

Before beginning tests, always check the zero adjustment of the instrument

as outlined under Description--Zero Adjuster, above. Attach the test leads

to the instrument and proceed to the section in this manual describing,

CONNECTIONS FOR TESTING the appropriate vehicle.

CONNECTIONS FOR TESTING

Ford--

On Ford cars with 1974 electronic ignition systems, use the Ford adapter

pin as shown in Figure29, below. Connect the GREEN clip from the Craftsman

Engine Analyzer to the adapter pin. Connect the RED cllp to the positive

battery terminal and the BLACK clip to a clean and secure ground such as

the engine block.

TO IGN. TO DIST.

SWITCH

FORD

ADAPTER

FIGURE 29

On Ford cars with insulated

call term(neis, lift the dls-

trlbutor terminal and slide the

Ford Adapter €lip in place as

shown, then push the terminal

dawn on it. Remove when the

tests are finished.

DWELL CONNECTION TO

1974 FORD ELECTRONIC

IGNITION SYSTEM

Page 28

vage Zb

On 1975 and later Ford electronic ignition systems, connect the GREEN

cllp from the Craftsman Engine Analyzer to the wire terminal on the TACH

side of the coll as shown in FIGURE 3_ below.

Connect the RED clip to the positive battery terminal and the BLACK cllp

to a clean and secure ground such as the engine block,

GREEN

DWELL CONNECTION TO

i975 AND LATER FORD

ELECTRONIC IGNITION

SYSTEMS

FIGURE 30

On General Motors cars equipped with an ENGINE ELECTRICAL DIAGNOSTIC

CONNECTOR (usually located under the hood near the left front fender

wheel well), open the hinged cover and insert the spade terminal adapter

in socket number 6, as shown in Figure31, below. Connect the GREEN clip

from the Craftsman Engine Analyzer to the spade teHminal adapter Just

installed, Connect the RED cllp to the posltive battery terminal and the

BLACK cllp to a clean and secure ground such as the engine block.

NOTE: Experience has shown that this is the easiest way to make a dwell

connection to GM vehicles. Only if your vehicle does not have an ENGINE

ELECTRICAL DIAGNOSTIC CONNECTOR should you use one of the two (2) connection

procedures to follow.

CAUTION: Do not confuse the ENGINE ELECTRICAL DIAGNOSTIC CONNECTOR with

the HEATER/AIR CONDITIONING DIAGNOSTIC CONNECTOR located on the passenger

side of the vehicle near the air conditioning system.

DWELL CONNECTION TO

GENERAL MOTORS CARS

WITH DELCO HEI AND

ELECTRICAL

DIAGNOSTIC

CONNECTOR

TERMINAL

DIAGNOSTIC CONNECTOR,

FIGURE 31

ELECTRICAL

DIAGNOSTIC

CONNECTOR

Page 29

General Motors--

On General Motors cars with 4-cylinder and in-line 6-cylinder engines

and separate ignition coil, connect the GREEN clip from the Craftsman

Engine Analyzer to the open TACH terminal as shown in FIGURE 32, below.

Connect the RED clip to the positive battery terminal and the BLACK

clip to a clean and secure ground, such as the engine block.

DWELL CONNECTION

TO GENERAL MOTORS

CARS WITH SEPAPJ_TE

IGNITION COIL

CONNECT GREEN CLIP

TO THIS TERMINAL

FIGURE 32

Page 27

On the General Motors integral ignition coil, V-8 and V-6 HEI systems,

slide the adapter onto the TACH terminal as shown in Flgure 33 below.

Connect the GREEN clip from the Craftsman Engine Analyzer to the adapter

just installed. Connect the RED cllp to the positive battery termlnal

and the BLACK clip to a clean and secure ground such as the engine block.

DWELL CONNECTION

TO GENERAL MOTORS

CARS WITH DELCO

HEi IGNITION SYSTEMS

FIGURE 33

ADA

Page 30

Page 28

Ford / Chrysler / American Motors

i. Connect the test leads from the Craftsman Engine Analyzer as shown

in Figure 29or 30 as appropriate to the vehicle under test. Keep

the leads clear of fan, belts, and pulleys.

2. Set the Function Selector Switch to the DWELL position.

3. Start the engine and let it warm to curb Id]e speed (check manufacturer's

recommendations).

4. Read the appropriate 4, 6, or 8 cylinder DWELL scale, depending

upon the engine type.

5. The DWELL reading obtained should meet the manufacturer's specification

for that engine. If it does not, consult the manufacturer's shop

manuals for diagnostic procedures.

General Motors

I. Connect the test leads from the Craftsman Engine Analyzer as shown

in Figure 31_32, or33 as appropriate to the vehicle under test. Keep

the leads clear of fan, belts, and pulleys.

2. Continue with steps g through 5 as described under Ford / Chrysler /

American Motors, above.

3. On HEI systems, the indicated DWELL Angle wlll normally be low at

idle speed and wil_ increase steadily as engine speed increases. If

it does not, consult the manufacturer's shop manuals for diagnostic

procedures.

Page 31

, use _

TestNumberi6--initia] ignition Timing

This test should be made following any dwell adjustments as the point

setting controls the basic ignition timing. On electronic ignition

systems refer to the vehicle service manual for special instruction_. Spark

timing controls are used to advance or retard timing. Follow manufacturer's

service procedures to check & adjust timing properly.

I. Connect a timing light to the battery and #i spark plug cable as_illustrated

below, in Fiqure 38.

2. Rotate the Function Selector Switch to the RPM position and set the RPM

range selector to the Lo-1200 RPM position for idle speeds and the Hi-6000

RPM for the high speed tests.

3. Locate the timing mark on the fly wheel and degree indicator plate.

Clean both surfaces and apply a white chalkmark on the fly wheel mark

for good vlsibility.(Figure 35)

4. Consult your vehicie service manual or tune-up decal under the hood

to determine which, if any vacuum hoses must be removed for proper

timing adjustment. Make sure to follow all timing instructions

pertaining to your vehicle. The above illustration shows the vacuum

advance hose disconnected and plugged.(Figure 37)

5. Close starter shunt, start the engine and operate at specified engine

speed. Refer to vehicle tune up specifications label under the hood

for proper RPM.

6. Operate timing light and aim it at the timing mark. Note the position of the

fly wheel mark in relation to the degree indicator. Compare to specified

initial timing. If not within specifications, readjust distributor as

required,

7. TIMING ADJUSTMENT. To change timing, loosen the d_stributor hold down

screw or bolt and rotate the distributor body as shown in Figures

36 and 37. until proper timing is indicated.

Test Number 17--TimingAdyanceSystems

NOTE: The following centrifugal and vacuum advance tests are general

ones and may not apply to many of.the more modern vehicles. Many of today's

vehicles have complex emission and ignition control systems which may alter

or prevent spark advance from taking place under various conditions. It

is therefore very important to consult your vehicle service manual for

the proper procedures to check and/or repair advance systems.

Ao Mechanical

CENTRIFUGAL ADVANCE. With the distributor vacuum hose disconnected and

plugged, operate the engine at specified idle speed and note position

of timing mark. INCREASE engine RPM slowly and observe movement of timing

mark. The mark should move steadily and without jerking in the opposite

direction tO fly wheel rotation, up to approximately 1800 RPM. Decrease

speed and mark should return smoothly to its original position.

VACUUM ADVANCE TEST. Operate the engine at 1500 RPM and connect the vacuum

advance hose to the distributor vacuum control and observe movement of

the timing mark. The mark should move opposite to fly wheel rotation

and may appear beyond the range of the degree indicator with a normal

operating vacuum control.

Page 32

BATTERY POST ADAPTER CONN-

ECTIONS FOR STARTING ENGINE

FIGURE 34

.............................. '................... II1[I fl[ [[[[ [[[[I I J[lll rr i rrrlll

Hold down

screw or bolt

FIGURE 37

ROTATION

ROTATION'\II 1[Ii_"__/

FIGURE 35

.......... ,....................................................... 11111111 hill I[IH[ I1 ifll[i[lllll

Rotor Rotor

Rotation Rotation

Vehicle

Battery

Tester

PlckuI

SEEPAGES 6 AND 7 FOR

PROPERHOOK-UP FOR

RPM

NO.I

SPARK

PLUG

Advance

Retard Advance

FIGURE 38

FIGURE 36

Page 33

RECONNECT FOR VACUUM

ADVANCE TEST

FIGURE 39

rage _

Bu Electronic

Many of today's modern vehicles use sophisticated computer controlled

spark advance systems. Your Craftsman Analyzer, a top quality timing

light such as the Sears 213400 Timing Light or 219400 Advance Timing

Light, and the vehicle service manual are essentialitools for accurately

checking these complex advance systems.

IMPORTANT: DO NOT ATTEMPT TO SERVICE THESE ELECTRONIC ENGINE SYSTEMS

WITHOUT THE VEHICLE SERIVCE MANUAL.

Some of the Systems currently in use are:

Chrysler Corporation

Ford Motor Company:

General Motors:

ELB (Electronic Lean Burn) introduced

in 1976, Re-named ESA (Electronic

Spark Advance) in 1979.

EEC I, EEC II, EEC 111, (Electronic

Engine Control) introduced in 1977.

ESS (Electronic Spark Selection)

introduced in 1977.

EST (Electronic Spark Timing)

ESC (Electronic Spark Control)

C-4 (Computer Controlled Catalytic

Converter)

C-3 (Computer Conmland Control)

Page 34

Page 3Z

Test Number IB--Carburetor Adjustmentr-M_xture (Atr_Fue!_Ratia_

I. Rotate the Function Selector Switch to the RPM position. Slide the

Range switch to the L0-1200 RPM position for idle speed tests.

2. EMISSION CONTROL SYSTEMS, Carburetors on late-model vehicles usually

have sealing caps on idle mixture screws which prohibit or restrict

carburetor adjustment. These are factory calibration seals. Refer

to vehicle manufacturer's service manual for mixture screw adjustment

procedures.

3. IDLE MIXTURE ADJUSTMENT. It is adviseable whenever possible to use

the mixture adjustment procedure as outlined in the manufacturer's

service manual. The following procedure should work well, however,

on those vehicles without emission control systems. Turn the idle

mixture screw in (lean) until the idle RPM starts to decrease and the

engine begins to idle roughly. When this point is reached slowly back

the idle mixture screw out (rich) until the maximum steady RPM is obtained.

When making any mixture adjustment only turn the mixture screw i/8

of a turn at a time. Between adjustments allow about 30 seconds for

the engine speed to stabilize.(Figuro 40)

4. MULTI-BARREL CARBURETORS, Repeat procedure described in Test Number

3 on EACH mixture screw until the smoothest maximum RPM is obtained.

Turn each screw i/8 of a turn at a time to prevent engine stalling.

If the final idle RPM is now higher than specified, readjust mixture

screws again until no further increase is possible.(Figure 4))

5. NOTE: On vehicles with emission control systems, air injection pumps

and positive crankcase ventilation, refer to vehicle tune-up decal in

the engine compartment for idle adjustment procedures.

IMPORTANT! Air/Fuel mixture adjustment is one of the more critical adjust-

ments on the engine, Fuel economy and Emission Control can be diminished

through incorrect settings or adjustment, Carefully follow the vehicle

manufacturer's instructions when adjusting carburetor idle mixture.

Curb Idle Speed

Adjustment

TYPICAL,SINGLE

AND MULTIPLE BARREL

CARBURETORS

Idle

Mixture

Screw

FIGURE 40 FIGURE 41

Anti-Dieseling Solenoid

Idle

_ixture

Screws

Page 35

T_},t Number_!9--CarburetorAdjustment--Curb idle Speed

Rotate the Function Selector Switch to the RPM position. Slide the

Range Switch to the L0-1200 RPM position for idle speed tests.

2.

IDLE SPEED ADJUSTMENT. Engine must be at normal operating temperature

before setting curb idle. Refer to vehicle specifications for idle

RPM range. Check for variations in curb idle with air conditioner on,

and any other specified idle range requirements.

Curb idle speed can be affected by other engine adjustments such as

timing, air/fuel ratio, and emission control operation. Carefully follow

manufacturer's instructions when adjusting curb Idle. Be certain to

recheck it after making any other engine adjustments.

Pege 33

Aw

Anti-Dleseling Solenoid Adjustment

The purpose of this device is to prevent engine run-on (dieseling) after

the key is turned off. Basic operation of this solenoid is as follows:

When the ignition key is in the run position, voltage is applied to the

solenoid, energizing it and causing it to move the idle position of

the throttle. Curb Idle is adjusted with the solenoid energized. When

the key is turned off the solenoid retracts and allows the throttle-

plates to close or return to a base idle, hence, sh_tting off the fuelialr

supply to the engine. By using the RPM, VOLTS, and OHMMETER sections

of your Craftsman Analyzer and specific tests described in your vehicle

service manual, you will be able to diagnose faults and properly adjust

the antl-dleseling solenoid.

8_

Air-Conditionlng Solenoid Adjustment

The purpose of the Air Conditioning solenoid is to maintain proper engine

idle speed with the vehicle's air conditioner running. It is

energized by the same circuit as the Air-Conditioning clutch and

when energized "kicks" the throttle enough to bring the idle to

its intended curb idle speed, By using the RPM, VOLTS, and OHMMETER

sections of your Craftsman Analyzer and specific tests described in

your vehicle service manual, you will be able to diagnose faults

and properly adjust the air-conditioning solenoid.

Page 36

Page 34

Test Number 21 and 22-_Fast !dle and Automatic Choke Adjustment

The purpose of the fast idle function is to maintain proper engine

speed during cold engine and warm-up operation. Additional throttle

opening is needed with the automatic choke butterfly valve in a closed

or partially closed position to keep the engine running smoothly and

prevent stalling. The choking action provides a richer fuel-air mixture

during cold engine operation to compensate for poor fuel_atomization. The

increased idle speed warms up the engine quickly which enhances fuel-air

atomization and mixing.

The fast idle adjustment screw seats on a cam which is thermostatically

controlled through the choke linkage. As the engine warms, the choke opens,

the fast Idle cam drops to progressively lower steps and the fast idle

speed gradually approaches curb-idle. On a fully-warmed engine, the fast

idle cam releases the fast idle adjustment screw completely. Engine

Idle speed is then controlled by the curb idle adjustment screw.

Fast idle adjustment procedures differ among the various automobiles.

Consult your specific vehicle service manual for proper procedures. It

may be necessary to bypass one or more spark timing or emissions system

controls, either vacuum or electric, while adjusting the fast idle.

Many late model vehicles use a full electric or an electrically

assisted choke. It contains a small electric heater which activates a

bimetallic coil spring or belleviile washer to reduce the choke time

under certain conditions. This heater may be controlled by a temperature

switch located either in the choke housing or elsewhereion the engine.

The Ohmmeter Function can be used to confirm switch continuity, heater

element resistance and related wiring. The Voltmeter function is used to

confirm the presence of voltage to and within the choke system as directed

by your vehicle service manual. Use the RPM function to set fast Idle

per manufacturer's instructions.

Page 37

Test Number 23--Ignition Coil

Refer to Test Number 9--OhmsTest (sections I-7) for Ohmmeter use.

IGNITION COIL PRIMARY RESISTANCE TEST

I. Set the Range Slide Switch to the OHMS X I position.

2. Remove the primary wires from both coil terminals.

3. Connect the RED and BLACK test leads to primary coil terminals, as

illustrated in Figure 42.

4. Observe reading on the Low Ohms scale, then re-connect primary wires.

D=._ 35

BLACK

FIGURE 42

PRIMARY RESISTANCE

TEST CONNECTIONS

Ao

The reading should meet the vehicle manufacturer's specifications

Generally, the coil primary winding resistance should be between I and

2 ohms. Check your vehicle service manual for the exact value.

B4

if the reading is substantially above or below the manufacturer's

specifications, the ignition coil is defective and should be replaced.

Page 38

COILSECONDARYRESISTANCEONOHMSX 1000 POSITION

FIGURE43

I. Remove the high tension lead from the coil tower, Be sure the ignition

switch is OFF.

2, Connect one of the OHMMETER test leads to either coil screw terminal.

(On late model Ford cars, use the Ford Adapter as illustrated on page 25.)

Connect the other lead to a spark plug adapter and insert in the coil

tower as shown,

3. Read the Ohms X 1000 scale on the meter and compare the reading with

the manufacturer's specification in the next column.

TEST RESULTS

The resistance of most coils for standard ignition systems are given in

the table below,

_NUFACTUREB SECONDARYRES!STA_4CE_(OHM_S)

American Motors

Chrysler g,Bo0 to 11,500

6,500 to 9,500

Ford 7,500 to 9,000

G. M. Delco Remy 5,500 to g,500

If the reading is higher or lower than the manufacturer's specification,

the coil should be replaced.

Page 39

Test Number 24--Ignition Cables

Refer to Test Number 9--OhmsTest (sections 1-7) for Ohmmeter use.

IGNITION CABLE TEST

Standard ignition cable is NOT solid wire. It is a graphite impregnated

fibre conductor with a built-in resistance of 1000 to 50,000 ohms,

depending upon the length of the cable and the type of _ngine. This

resistance is necessary to suppress spark interference with radio,

television, and other communication reception. It also contributes to

longer distributor cap and spark plug electrode life. If the resistance

value of the cable is significantly increased by stretching or breaking the

internal graphite impregnated conductor, the engine will misfire and its

overall performance will deteriorate.

I. Remove the cables from the engine. When removing the wire from the

spark plug, grasp the spark plug boot and twist and pull wire

with a firm, steady force. DO NOT yank on the cable to remove it.

2. Use the X 1000 position on the RANGE SELECTOR of the Craftsman

Analyzer.

3. Connect the RED and BLACK Ohn=netertest leads to the ends of the cable

as shown below, and use an adaptor spring at the SPARK PLUG END of the

cable as shown.(Figure 44_

4. Gently flex the ignition cable while testing, if the OHMMETER reading

wanders excessively or rises to infinity (,o) thelcable is defective

and should be replaced.

5. Consult your vehicle service manual for the proper resistance range

per inch or foot of cable. Replace those wires which are out of

tolerance.

rdge Jl

ADAPTER SPRING,

BLACK

SPARK PLUG END

DISTRIBUTOR END

'RED

IGNITION CABLE

TEST CONNECTIONS

FIGURE 44

Page 40

Page38

Te__..t.Numbe.r....25._.Ba.]].ast, ..Res.!sto r

Refer to Test Number 9--Ohms Test (sections 1-7) for Ohmmeter use.

The purpose of the ballast resistor (when equipped) is to limit the

current available to the ignition coil when the vehicle is running.

Failure of this resistor results in a dead engine. If the engine trys to

start when cranking, but the instant you release the key,it stops, then

you may have an "open" ballast resistor. You can feel and hear the engine

cranking speed increase because the ignition system is trying to take over.

With the ignition key off, locate the ballast resistor and remove the

wires that are connected to it. (The ballast resistor is usually a

white ceramic block with brass terminals and is generally located on the

fire wall. If you have difficulty locating it, consult your vehicle service

manual.)

NOTE: Many Chrysler Corporation Electronic Ignition systems use a dual

ballast resistor, One side of this resistor functions exactly as indicated

above. The other side is the auxiliary ballast resistor and it should read

approximately 5 ohms.(Figure 45)

PROCEDURE

The OHMS scale is used to test the ballast resistor. To test the ballast

resistor, disconnect all leads at their terminals to pr@vent possible damage

to the analyzer or to prevent inadverdent measurement of other circuits

connected to it.

CONNECTIONS:

Ii

Insert the white plug OHMS lead into the corresponding tester socket,

2.

Connect the RED and BLACK clips to the ballast resistor as shown. Some

ballast resistors are dual units--such as on some Chrysler automobiles,

while others are single units--or resistor wires. Some ignition

systems utilize the ballast resistor in the coil primary (see ignition coil

test).

TEST PROCEDURE:

i. The Ohmmeter will read full scale at the extreme right hand side,

INFINITY ( Oo ), with the BLACK and RED clips disconnected.

When the clips are connected together, the meter pointer will

read zero on the left (short circuit or zero ohms).

2. To measure the ballast resistor, connect the RED and BLACK clips as

shown in Fi_ure 45 . Set the Function Selector Switch to the OHMS

position.

3. Set the Range Selector Switch to the LOW scale. Typical readings should

be between 0.5 and 7.5 ohms.

IMPORTANT: Consult your vehicle service manual for the exact OHMS value

for your car. The value read should be very close to the specified value

as large differences can cause damaged points or electronic ignition module

(when too low).

Page 41

4. If the meter reads _ , (right hand side of the scale) the

ballast resistor is open and must be replaced.

CHRYSLER _,REGULAR

BALLAST --

.5 TO .6

,_ OHMS

BLACK

Hage ._J

OHMS "--I

BALLAST RESISTOR TEST CONNECTIONS

FIGURE 45

Test Number 26--lqnition Switch

The ignition switch performs many duties beyond starting the vehicle. With

the guidance of your vehicle service manual, your Craftsman Voltmeter and/or

Ohmmeter can confirm operation of the ignition switch,

Some of the ignition switch functions are as follows:

i. Activate starter relay (start position)

2. Bypass ignition ballast resistor (start position)

3, Confirm tell-tale cluster lights (start position)

4. Activate ignition

5. Activate accessories

If you have difficulty with any of the above circuits, the ignition switch

is a possible source of trouble. Consult your vehicle service manual for

exact diagnostic procedures.

Page 42

Page 40

ELECTRONIC IGNITION SYSTEMS

The following ten pages are devoted to the four basic Electronic Ignition

Systems as used by American Motors, Chrysler Corporation, Ford Motor Company,

and General Motors,

The diagrams and charts will step you through point-to-point testing of the

various components within each system. You will use the VOLTS, OHMS and

POINTS-LOW VOLTS positions of your analyzer. It would be advlseable before

beginning these tests to review the use of the VOLTS, OHMS, and POINTS

positions of your analyzer as shown earlier in this manual.

American Motors 1975-76

American Motors 1977 & Up See Ford Motor Co.

Chrysler Corporation

Ford Motor Company

General Motors (integral Coil)

General Motors (External Coil)

Test Number 27--Amerlcan Motors Electronic igni_tl.pn..._.Sys.tem

Te.st_Number 28--Chrysler Electronic Ignition System

Test Number 2g--Ford Electronic igD_ItlonSy_s.tem

Test Number 30--Delco HEI ignition

Test.Number 31--DelcQHE(..Ign!.t!on_.System_H!.tbSeparateCoil

Page 43

GENERAL MOTORS HIGH ENERGY IGNITION-- DISABLING PROCEDURES

When performing Charging System teals on General Motors vehicles equipped with

High Energy Ignition (HEt), the engine can be prevented from starling as follows:

........ i II .,r r, ,, , .,,i,rbl Ir I, , ,, J,im.,.I,,,, ,,,, ,,,,,,,,,

SYSTEMS WITH COIL IN DISTRIBUTOR CAP

Disconnect primary wire from the BAT

terminal on the distributor cap,

CAUTION: The tachometer terminal must

NEVER be connected to ground at the

distributor cap, as damage to the

distributor module can result.

SYSTEMS WITH SEPARATE COIL

Remove high,tension coll wire from colt

secondary terminal, Connect Jumper Wire

between coil secondary terminal and a

good ground on the engine.

_r _'_--_ ' _,_"€_,. PRIMARY

Page 41

....................................................... LI]_ IL IILILI[_II LJLI l .......... _I I IILIIIIIILIi .........................................................

HEI WITH ELECTRICAL

DIAGNOSTIC CONNECTOR

Insert the GM Diagnostic Connector

Terminal in terminal No, 6 of Electrical

Diagnostic Connector, Connect jumper wire

between this terminal and a good ground,

CAUTION: The tachometer terminal must

NEVER be conneoted to ground at the

distributor cap, as damage to the

distributor module can result.

ELECTRICAL

G

DIAGNOSTIC

CONNECTOR

TERMINAL

ENGINE

GROUND

JUMPER'

WIRE

L

DIAGNOSTIC

CONNECTOR

Page 44

Page 42

,Tes_tNumber 27

POS,-,,_

COIL -

TERMINAL

HIGH TENSION

ITPUT TERMINAL

ELECTRONIC

MODt LE

IGNITION

SWITCH

NEG4 POS

COIL

12 VOLT

BATTERY

COIL

TERMINAL

GROUND

BLACK

DISTRIBUTOR

CONNECTOR

GROUND

DISTRIBUTOR

DISTRIBUTOR

FIGURE 46

SENSOR UNIT

AMERICAN MOTORS ELECTRONIC IGNITION SYSTEM

Page 45

Page 43

Number 27

Continued

AMERICAN MOTORS ELECTRONIC IGNITION COMPONENTS

S[LECTOR C LIP

TESt KNOB CONNECTIONS firST PROCEDURE

POSITION RED j BLACK AND RESULTS

A Battery State 16 VOLTS

of Charge

B fgnltio_ Switch 16 VOLTS

....Termlnal

C Call Primo_y

and Electronic 16 VOLTS

Module

................................... : _.-o= ........................... . ............... = :

OHMS 3

D Colt Pdmory X [ Coll

Reslst_nce Pro, (÷)

2

Battery

Pos.(+)

3

Coil

Poi,(*)

4

Call

Ne0.(-)

Terminal

Terminal

J

Batte,y

Neg.(-)

flattery

Neg,(_)

flattery

Neg. (-)

Coil

Neg. (-)

Terminal

_,s¸ - =±- , ,,111 .......................... :........................................

1

!

I

4

Remove Coil High Tension W_re from the distributor and

ground _t. Crank Engine. Meter should read above 9.0

rafts, If not_ charge battery and repeat test. Replace

H|gh Tension Wire lt_ dlstr_butor.

Wffh Ignition Switch on, meter should read _t least |0

vain, tf not_ inspect the sw_tch fm lame connections

and faulty €onfiders, Replace switch ifdefective,

Unplug dlstHbutot connector. With Ignition Switch on,

meter should read between 5 o_d 8 volts, If OK proceed

tO Test F, if less thor_ 5 Volt: or more than 8 vohst pro-

ceed wt_ ?elf O,

WIth distributor connector unplugged and call negotlve

lead dIsconnected, meter should read between .7and

2.5 €;_mswith Ign;t;o_ Switch ofF. if not, _eploce €o;t,

E Coil Secondary OHMS Coil

Retlstdnce x IOO0

F Distt{butor Semor

Unit ContinuHy

OHMS 8