Craftsman 152241180 Owner’s Manual

Owner's Manual

CRItFTSMAN°

8-in. Wheel

215Horsepower (maximum developed)

114Horsepower (continuous duty)

3450 R.P.M. (no load speed)

8-in.

BENCH GRINDER

Model No.

152.241180

C_US

Customer Helpline

CAUTION:

FOR YOUR OWN SAFETY; Read

and follow all of the Safety and

Operating Instructions before

Operating this Bench Grinder.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Part No. OR91301 EspaSol pg. 17

1-800-897-7709

Please have your Model No.

and Serial No. available.

SECTION PAGE

Warranty .......................................................... : ....................... 2

Product Specifications ................... . .................................................. 2

Safety Instructions ......................................................................... 3

Grounding Instructions ..................................................................... 4

Specific Safety Instructions for Bench Grinders ................................................. 5

Accessories and Attachments ....................... ......................................... 6

Carton Contents ........................................... . ............................... 6

Know Your Bench Grinder ................................................................... 7

Assembly Instructions ............................. . ........................................ 8

Operating the Bench Grinder ................................................................ 11

Maintenance ............................................................................. 13

Troubleshooting Guide .................................................................... 13

Parts List ............................................................................... 14

Espafiol ........................................................ ......................... 17

Service Information ................................................................ Back Cover

FULL ONE YEAR WARRANTY

If this product fails due to a defect in material or workmanship within one year from the date of purchase, RETURN

IT TO THE NEAREST SEARS STORE OR CRAFTSMAN OUTLET, and it will be replaced, free of charge.

This warranty gives you specific legal rights, and you may also have other rights, which vary, from state to state.

Sears, Roebuck and Co., Dept 817 WA, Hoffman Estates, IL60179

Motor

Maximum HP developed

Continuous Duty HP

Volts

Hertz

RPM

Grinding Wheel Size

Grinding Wheel Grit

Lamp

Tool Rests

Eye Shield Assemblies

Spark Arrestors

Wheel dresser

2/5

1/4

120

60

3450 R.P.M.

(no load speed)

8" x 3/4" x 5/8"

60, 36

120V, 40 watt or less Track

Light Bulb, Type R20,

medium base or equivalent

(not included)

Left and Right

Clear Lexan Left and Right

Left and Right

Steel serrated wheels

To avoid electrical shock to yourself and damage to the

Bench Grinder, use proper circuit protection.

The Bench Grinder is factory wired for 120V, 60 Hz,

operation. Connect to a 120V, 15 amp branch circuit

and use a 15 amp time delay fuse or circuit breaker.

The electrical circuit cannot have any Wire size less

than #14. To avoid shock or fire, replace power cord

immediately if it is damaged in any way.

GENERAL SAFETY INSTRUCTIONS

Operating a Bench Grinder can be dangerous ifsafety

and common sense are ignored. The operator must be

familiar with the operation of the tool. Read this manual

to understand this Bench Grinder. DO NOT operate this

Bench Grinder if you do not fully understand the limita-

tions of this tool. DO NOT modify this Bench Grinder in

any way.

BEFORE USING THE BENCH GRINDER

To avoid serious injury and damage to the tool, read

and follow all of the Safety and Operating Instructions

before operating the Bench Grinder.

1. READ the entire Owner's Manual. LEARN how to

use the tool for its intended applications.

.

GROUND ALL TOOLS. If the tool is supplied with a

3-prong plug, it must be plugged into a 3-contact

electrical receptacle. The 3rd prong is used to

ground the tool and provide protection against

accidental electric shock. DO NOT remove the 3rd

prong. See Grounding Instructions on page 4.

.

AVOID A DANGEROUS WORKING ENVIRON-

MENT. DO NOT Use electrical tools in a damp

environment or expose them to rain.

.

DO NOT use electrical tools in the presence of

flammable liquids or gasses

,

ALWAYS keep the work area clean, well lit, and

organized. DO NOT work in an environment with

floor surfaces that are slippery from debris, grease,

and wax.

KEEP VISITORS AND CHILDREN AWAY. DO NOT

.

permit people to be in the immediate work area,

especially when the electrical tool is operating.

.

DO NOT FORCE THE TOOL to perform an opera-

tion for which it was not designed for. It will do a

safer and higher quality job by only performing

operations for which the tool was intended.

.

WEAR PROPER CLOTHING. DO NOT wear loose

clothing, gloves, neckties, or jewelry. These items

can get caught in the machine during operations

and pull the operator into the moving parts. The

user must wear a protective cover on their hair, if

the hair is long, to prevent it from contacting any

moving parts.

.

ALWAYS WEAR EYE PROTECTION. Any power tool

can throw debris into the eyes during oper-ations,

which could cause severe and permanent eye dam-

age. ALWAYS Wear Safety Goggles (that comply

with ANSI standard Z87.1) when operating power

tools. Safety Goggles are available at Sears Retail

Stores.

10. WEAR A DUST MASK TO PREVENT INHALING

DANGEROUS DUST OR PARTICLES.

11. ALWAYS UNPLUG THE T(3OL FROM THE ELEC-

TRICAL RECEPTACLE when making adjustments,

changing parts or performing any maintenance.

12. KEEP PROTECTIVE GUARDS IN PLACE AND IN

WORKING ORDER.

13. AVOID ACCIDENTAL STARTING. Make sure that

the power switch is in the "OFF" position before plug-

ging in the power cord to the electrical receptacle.

14. REMOVE ALL MAINTENANCE TOOLS from the

immediate area prior to turning "ON" the Bench

Grinder.

15.

USE ONLY RECOMMENDED ACCESSORIES. Use

of incorrect or improper accessories could cause seri-

ous injury to the operator and cause damage to the

tool. If in doubt, check the instruction manual that

comes with that particular accessory.

16.

NEVER LEAVE A RUNNING TOOL UNATTENDED.

Turn the power switch tothe "OFF" position. DO NOT

leave the tool until it has come to a complete stop.

17.

DO NOT STAND ON A TOOL. Serious injury could

result if the tool tips over or you accidentally contact

the tool.

18.

DO NOT store anything above or near the tool where

anyone might try to stand on the tool to reach it.

19.

MAINTAIN YOUR BALANCE. DO NOT extend your-

self over the tool. Wear oil resistant rubber-soled

shoes. Keep floor clear of debris, grease,

and wax.

20.

MAINTAIN TOOLS WITH CARE. Always keep tools

clean and in good working order. Keep all blades and

toot bits sharp.

SAVE THESE INSTRUCTIONS.

3

21.

EACHANDEVERYTIME,CHECKFORDAMAGED

PARTSPRIORTO USINGTHETOOL.Carefully

checkallguardstoseethattheyoperateproperly,

arenotdamaged,andperformtheirintendedfunc-

tions.Checkfor alignment,bindingor breakingof

movingparts.Aguardorotherpartthatisdamaged

shouldbeimmediatelyrepairedor replaced.

22.

CHILDPROOFTHEWORKSHOPAREAbyremov-

ingswitchkeys,unpluggingtoolsfromtheelectrical

receptacles,andusingpadlocks.

23.

DO NOT OPERATE TOOL IF UNDER THE INFLU-

ENCE OF DRUGS OR ALCOHOL.

24.

SECURE ALL WORK. When it is possible, use

clamps or jigs to secure the workpiece. This is safer

than attempting to hold the workpiece with your

hands.

25.

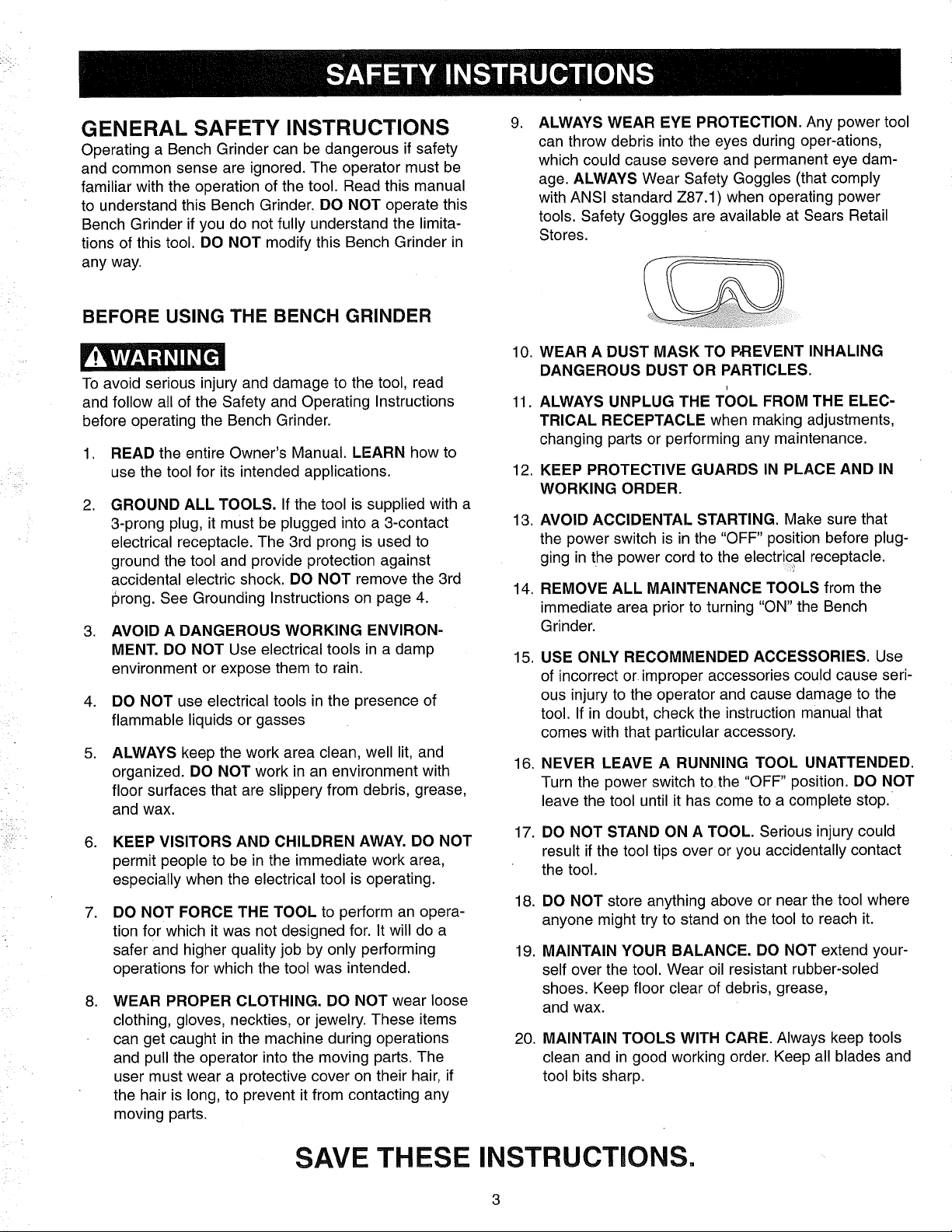

USE A PROPER EXTENSION CORD IN GOOD

CONDITION. When using an extension cord, be

sure to use one heavy enough to carry the current

your product will draw. The table at right shows the

correct size to use depending on cord length and

nameplate amperage rating. If in doubt, use the

next heavier gauge. The smaller the gauge number,

the larger diameter of the extension cord. If in doubt

of the proper size of an extension cord, use a short-

er and thicker cord. An undersized cord will cause

a drop in line voltage resulting in a loss of power

and overheating. USE ONLY A 3-WIRE EXTEN-

SION CORD THAT HAS A 3-PRONG GROUND-

ING PLUG AND A 3-POLE RECEPTACLE THAT

ACCEPTS THE TOOL'S PLUG.

GUIDELINES FOR

EXTENSION CORDS

If you are using an extension cord outdoors, be sure

it is marked with the suffix "W-A" ("W" in Canada) to

indicate that it is acceptable for outdoor use.

Be sure your extension cord is properly sized, and

in good ele.ctr ca condition. Always replace a damaged

extension cord or have it repaired by a qualified person

before using it.

Protect your extension cords from sharp objects,

excessive heat, and damp or wet areas.

! _ fit " Of ! _l | *l O" " _ O_ 0"| _T!

120VOLTOPERATIONONLY

0 to 6 Amps

6 to 10 Amps

10 to 12 Amps

25' LONG

18 AWG

18 AWG

16 AWG

50' LONG

16 AWG

16 AWG

16 AWG

100' LONG

16AWG

14AWG

14AWG

150' LONG

14AWG

12AWG

12AWG

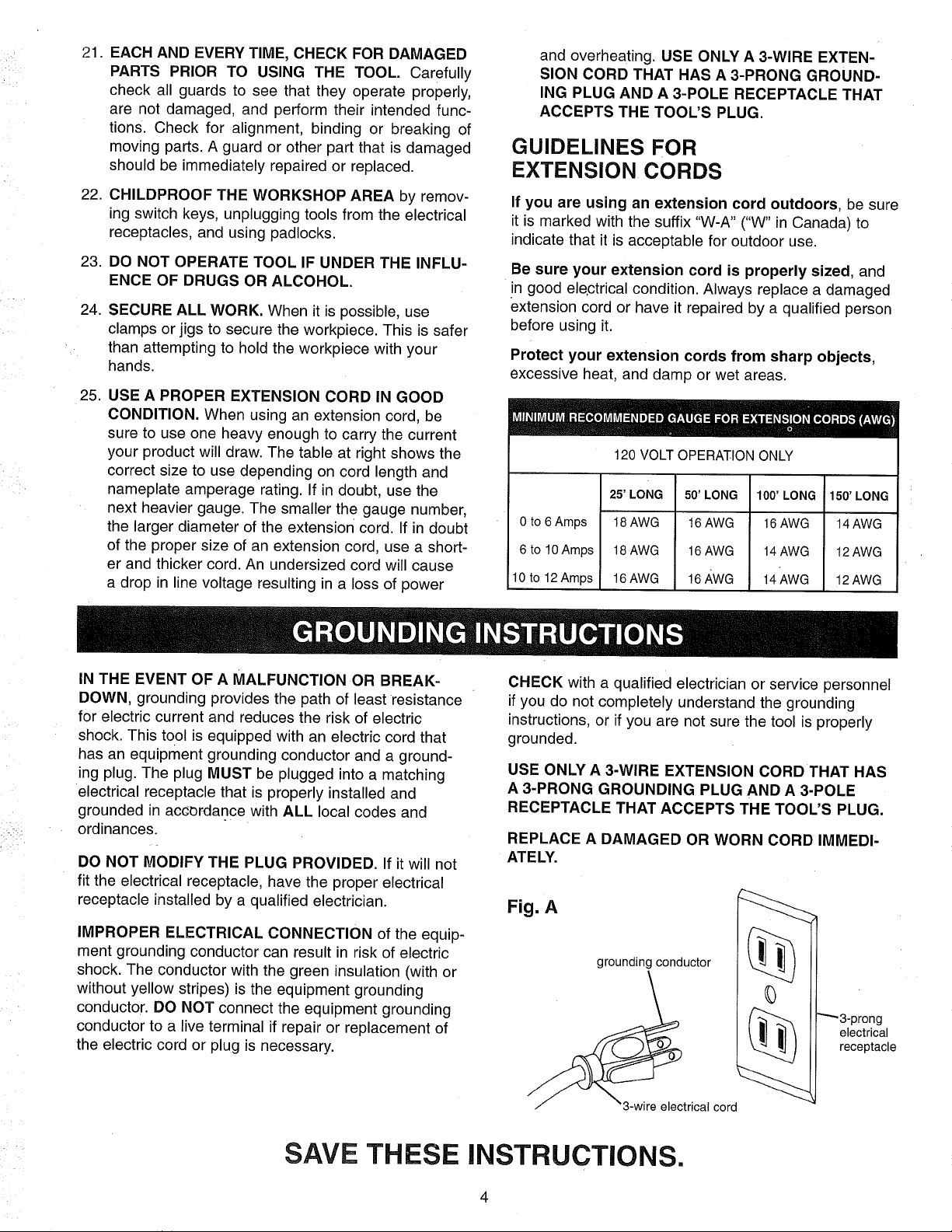

IN THE EVENT OF A MALFUNCTION OR BREAK-

DOWN, grounding provides the path of least resistance

for electric current and reduces the risk of electric

shock. This tool is equipped with an electric cord that

has an equipment grounding conductor and a ground-

ing plug. The plug MUST be plugged into a matching

electrical receptacle that is properly installed and

grounded in accordance with ALL local codes and

ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not

fit the electrical receptacle, have the proper electrical

receptacle installed by a qualified electrician.

IMPROPER ELECTRICAL CONNECTION of the equip-

ment grounding conductor can result in risk of electric

shock. The conductor with the green insulation (with or

without yellow stripes) is the equipment grounding

conductor. DO NOT connect the equipment grounding

conductor to a live terminal if repair or replacement of

the electric cord or plug is necessary.

CHECK with a qualified electrician or service personnel

if you do not completely understand the grounding

instructions, or if you are not sure the tool is properly

grounded.

USE ONLY A 3-WIRE EXTENSION CORD THAT HAS

A 3-PRONG GROUNDING PLUG AND A 3-POLE

RECEPTACLE THAT ACCEPTS THE TOOL'S PLUG.

REPLACE A DAMAGED OR WORN CORD IMMEDI-

ATELY.

Fig. A

grounding conductor

electrical

receptacle

_trical cord

SAVE THESE

INSTRUCTIONS.

4

Fig. B

grounding

ada

grounding conductor

2-prong

electrical

3-wire electrical cord

This tool is intended for use on a circuit that has an

electrical receptacle as shown in FIGURE A. FIGURE A

shows a 3-wire electrical plug and electrical receptacle

that has a grounding conductor. If a properly grounded

electrical receptacle is not available, an adapter as

shown in FIGURE B can be used to temporarily con-

nect this plug to a 2-contact ungrounded receptacle.

The adapter has a rigid lug extending from it that MUST

be connected to a permanent earth ground, such as a

properly grounded receptacle box. THIS ADAPTER IS

PROHIBITED IN CANADA.

CAUTION: In all cases, make certain the electrical

receptacle in question is properly grounded. If you are

not sure have a certified electrician check the electrical

receptacle.

receptacle

1. ALWAYS USE THE EYE SHIELDS AND WHEEL

GUARDS provided with the grinder.

= REPLACE A CRACKED OR DAMAGED GRIND-

ING WHEEL IMMEDIATELY. A damaged wheel can

discharge debris at a high velocity towards the

operator. Carefully handle the grinding wheels since

they are abrasive. Prior to replacing a grinding

wheel, check it for cracks. DO NOT remove the

blotter or label on the both sides of the grinding

wheel. Tighten the Spindle nut just enough to hold

the grinding wheel firmly to the Bench Grinder. Do

not over-tighten the nut. Excessive clamping force

can damage the grinding wheel. Only use the wheel

flanges provided with the grinder. When selecting a

replacement grinding wheel, verify that the grinding

wheel has a higher R.EM. rating than the maximum

R.P.M. of the Bench Grinder.

THE DIAMETER OF THE GRINDING WHEELS

.

WILL DECREASE WITH USE. Adjust the tool rests

and spark arrestors to maintain a distance of 1/16"

from the wheel.

DO NOT STAND IN FRONT OF THE BENCH

,

GRINDER WHEN STARTING IT. Stand to one side

of the Bench Grinder and turn it "ON". Wait at the

side for one minute until the grinder comes up to

full speed. There is always a possibility that debris

from a damaged grinding wheel may be discharged

towards the operator.

This Bench Grinder is for indoor use only. To avoid

serious injury, do not expose to rain or use in damp

locations.

SPECIFIC SAFETY INSTRUCTIONS

FOR BENCH GRINDERS

The operation of any grinder can result in debris being

thrown into your eyes, which can result in severe eye

damage. ALWAYS wear Safety Goggles (that comply

with ANSI standard Z87.1) when operating the grinder.

Safety Goggles are available at Sears Retail Stores.

Keep your thumbs and fingers away from the grinding

wheels.

,. THE BENCH GRINDER WILL PRODUCE

SPARKS AND DEBRIS DURING GRINDING

OPERATIONS. Be sure that there are not any flam-

mable materials in the vicinity. Frequently clean

grinding dust from the back of the Bench Grinder.

, NEVER FORCE THE WORKPIECE AGAINST A

GRINDING WHEEL, especially if the wheel is cold.

Apply the workpiece slowly, allowing the grinding

wheel an opportunity to warm up. This wilt minimize

the chance of wheel breakage. DO NOT grind using

the sides of the grinding wheels. DO NOT apply

coolant directly to the grinding wheel.

7. KEEP ALL WHEEL GUARDS IN PLACE. DO NOT

USE THE BENCH GRINDER WITH THE WHEEL

GUARDS REMOVED.

8. KEEP THE TOOL RESTS FIRMLY TIGHTENED.

9. ALWAYS USE THE SUPPLIED WHEEL DRESSER

TO RESURFACE THE FACE OF THE GRINDING

WHEEL.

SAVE THESE iNSTRUCTiONS.

AVAILABLE ACCESSORIES

Visit your Sears Hardware Department or see the Sears

Power and Hand Tool Catalog for the following

accessories.

Sears may recommend other accessories not listed in

this manual.

See your nearest Sears Hardware Department or Sears

Power and Hand Tool Catalog for other accessories.

ITEM

Replacement grinding wheels

Wire and Buffing wheels

Spacers

Wheel dressers

Universal stand

STOCK NUMBER

See catalog or store

See catalog or store

See catalog or store

See catalog or store

See catalog or store

Do not use any accessory unless you have completely

read the Owner's Manual for that accessory.

Use only accessories recommended for this Bench

Grinder. Using other accessories may cause serious

injury and cause damage to the Bench Grinder.

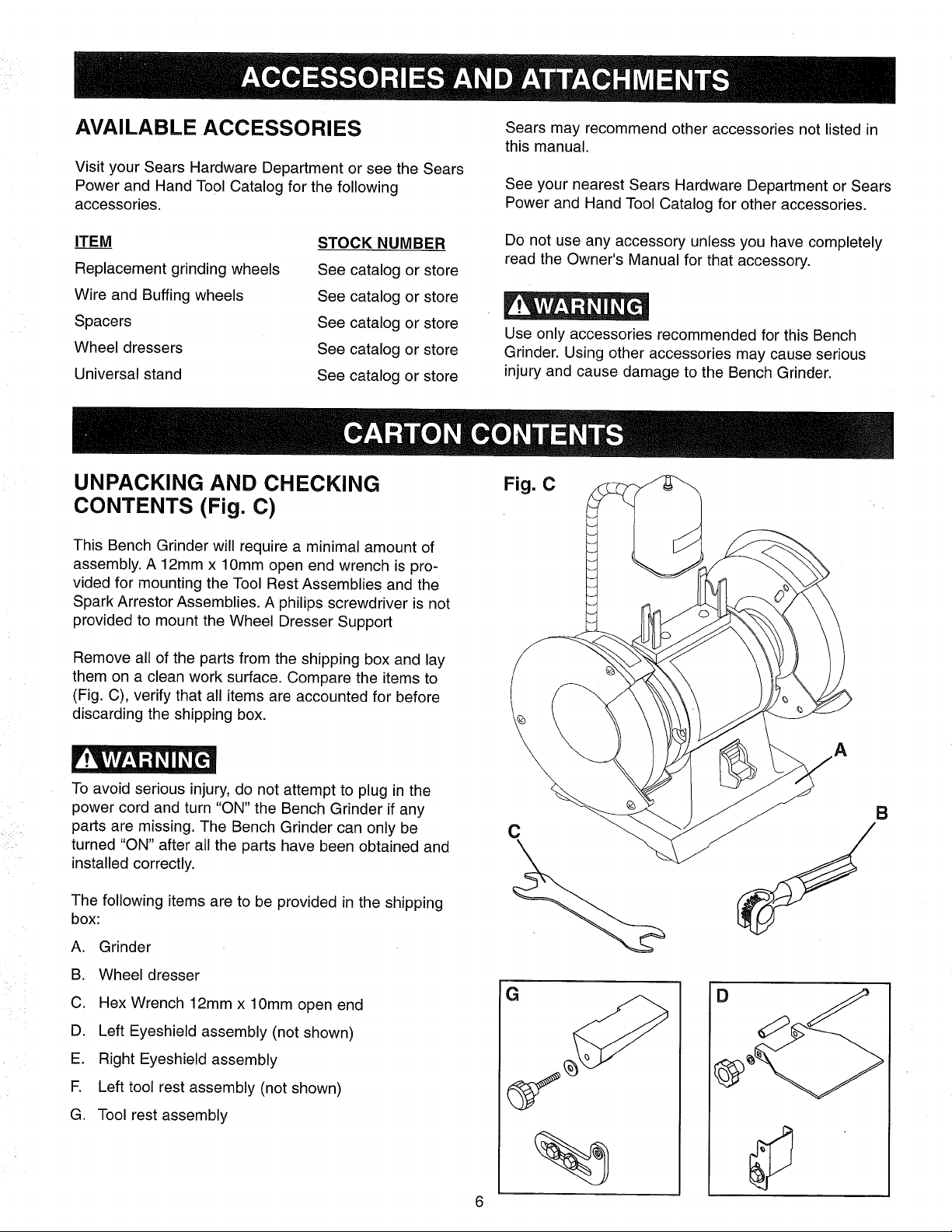

UNPACKING AND CHECKING Fig. C

CONTENTS (Fig. C)

This Bench Grinder will require a minimal amount of

assembly. A 12mm x 10mm open end wrench is pro-

vided for mounting the Tool Rest Assemblies and the

Spark Arrestor Assemblies. A philips screwdriver is not

provided to mount the Wheel Dresser Support

Remove all of the parts from the shipping box and lay

them on a clean work surface. Compare the items to

(Fig. C), verify that all items are accounted for before

discarding the shipping box.

To avoid serious injury, do not attempt to plug in the

power cord and turn "ON" the Bench Grinder if any

parts are missing. The Bench Grinder can only be

turned "ON" after all the parts have been obtained and

installed correctly.

The following items are to be provided in the shipping

box:

A. Grinder

B. Wheel dresser

C. Hex Wrench 12mm x 10mm open end

D. Left Eyeshield assembly (not shown)

E. Right Eyeshield assembly

F. Left tool rest assembly (not shown)

G. Tool rest assembly

A

B

C

G

D

6

Loading...

Loading...