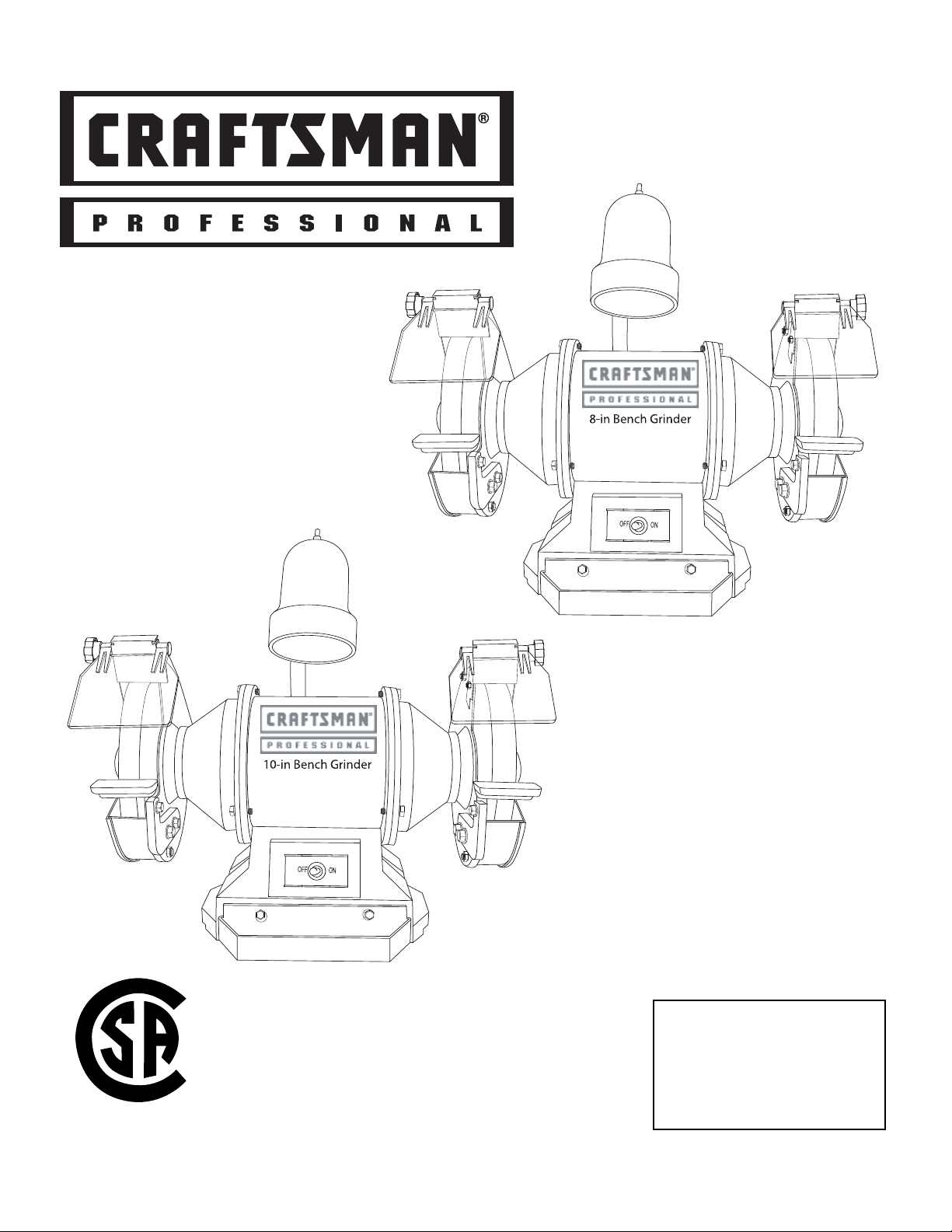

Page 1

Owner’s Manual

8-in. Wheel

3/4 Horsepower (continuous duty)

3450 R.P.M. (no load speed)

8-in. BENCH

GRINDER

Model No.

152.220180

CAUTION:

®

CUS

FOR YOUR OWN SAFETY; Read and follow

all of the Safety and Operating Instructions

before Operating this Bench Grinder

10-in. Wheel

1 Horsepower (continuous duty)

1725 R.P.M. (no load speed)

10-in. BENCH

GRINDER

Model No.

152.220600

Customer Helpline

1-800-897-7709

Please have your Model No.

and Serial No. available.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Part No. OR94750

Español pg. 19

Page 2

TABLE OF CONTENTS

ECTION PAGE

S

arranty ..........................................................................................................................................................................2

W

roduct Specifications...................................................................................................................................................2

P

afety Instructions .........................................................................................................................................................3

S

rounding Instructions..................................................................................................................................................5

G

pecific Safety Instructions for Bench Grinders ........................................................................................................6

S

Accessories and Attachments ......................................................................................................................................6

Carton Contents..............................................................................................................................................................7

Know Your Bench Grinder.............................................................................................................................................8

Assembly Instructions ...................................................................................................................................................9

Operating the Bench Grinder ......................................................................................................................................11

Maintenance..................................................................................................................................................................13

Troubleshooting Guide ................................................................................................................................................13

Parts List .......................................................................................................................................................................14

Español..........................................................................................................................................................................19

WARRANTY

FULL ONE YEAR WARRANTY

If this product fails due to a defect in material or workmanship within one year from the date of purchase, return it

to the nearest Sears Service Center for repair, free of charge.

This warranty gives you specific legal rights, and you may also have other rights, which vary, from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

PRODUCT SPECIFICATIONS

8-in. Bench Grinder

Motor

Continuous duty HP 3/4

Volts 120

Hertz 60

RPM

Grinding

Grinding Wheel Grit 60, 120

Shaft diameter 5/8" diameter

Arbor Bushing 1" diameter x 1" face by

Lamp 120V, 40 watt Type A or

Tool Rests Left and Right

Drill bit sharpening plate

Eye Shield Assemblies Clear Lexan Left and Right

Spark

Quench tray Yes

Wheel Dresser Yes

Wheel

Arrestors

Size 8" diameter x 1" face x

3450 R.P.M. (no load speed)

1" bore

5/8" bore

smaller bulb-Medium Base

(bulb not included)

Right only

Left and Right

10-in. Bench Grinder

Motor

Continuous duty HP 1

Volts 120

Hertz 60

RPM

Grinding

Grinding Wheel Grit 60, 120

Shaft diameter 3/4" diameter

Arbor Bushing 1-1/4" diameter x 1" face by

Lamp 120V, 40 watt Type A or

Tool Rests Left and Right

Drill bit sharpening plate

Eye Shield Assemblies Clear Lexan Left and Right

Spark

Quench tray Yes

Wheel dresser Yes

2

Wheel

Arrestors

Size 10" diameter x 1" face x

1725 R.P.M. (no load speed)

1-1/4" bore

3/4" bore

smaller bulb-Medium Base

(bulb not included)

Right only

Left and Right

Page 3

!

WARNING

o avoid electrical shock to yourself and damage to the

T

Bench Grinder, use proper circuit protection.

The Bench Grinder is factory wired for 120V, 60 Hz,

peration. Connect to a 120V, 15 amp branch circuit

o

SAFETY INSTRUCTIONS

GENERAL SAFETY INSTRUCTIONS

Operating a Bench Grinder can be dangerous if safety

and common sense are ignored. The operator must be

familiar with the operation of the tool. Read this manual

to understand this Bench Grinder.

Bench Grinder if you do not fully understand the limitations of this tool.

any way.

DO NOT modify this Bench Grinder in

BEFORE USING THE BENCH GRINDER

!

WARNING

To avoid serious injury and damage to the tool, read

and follow all of the Safety and Operating Instructions

before operating the Bench Grinder.

DO NOT operate this

nd use a 15 amp time delay fuse or circuit breaker.

a

The electrical circuit cannot have any wire size less

than #14. To avoid shock or fire, replace power cord

immediately if it is damaged in any way.

8. WEAR PROPER CLOTHING. DO NOT wear loose

clothing, gloves, neckties, or jewelry. These items

can get caught in the machine during operations

and pull the operator into the moving parts. The

user must wear a protective cover on their hair, if

the hair is long, to prevent it from contacting any

moving parts.

ALWAYS WEAR EYE PROTECTION. Any power

9.

tool can throw debris into the eyes during operations, which could cause severe and permanent

eye damage.

comply with ANSI standard Z87.1) when operating

power tools. Safety Goggles are available at Sears

Retail Stores.

ALWAYS wear Safety Goggles (that

1. READ the entire Owner’s Manual. LEARN how to

use the tool for its intended applications.

2. GROUND ALL TOOLS. If the tool is supplied with a

3-prong plug, it must be plugged into a 3-contact

electrical receptacle. The 3rd prong is used to

ground the tool and provide protection against

accidental electric shock. DO NOT remove the 3rd

prong. See Grounding Instructions on page 5.

3. AVOID A DANGEROUS WORKING ENVIRON-

MENT. DO NOT use electrical tools in a damp

environment or expose them to rain.

4. DO NOT use electrical tools in the presence of

flammable liquids or gasses.

5. ALWAYS keep the work area clean, well lit, and

organized. DO NOT work in an environment with

floor surfaces that are slippery from debris, grease,

and wax.

6. KEEP VISITORS AND CHILDREN AWAY. DO NOT

permit people to be in the immediate work area,

especially when the electrical tool is operating.

OOL

T

FORCE

7. DO

NOT

tion for which it was not designed. It will do a safer

and higher quality job by only performing operations

for which the tool was intended.

THE

to perform an opera

-

10. WEAR A DUST MASK TO PREVENT INHALING

DANGEROUS DUST OR PARTICLES.

11. ALWAYS UNPLUG THE TOOL FROM THE ELECTRICAL RECEPTACLE when making adjustments,

changing parts or performing any maintenance.

12. KEEP PROTECTIVE GUARDS IN PLACE AND IN

WORKING ORDER.

13.

AVOID ACCIDENTAL STARTING. Make sure that

the power switch is in the “OFF” position before

plugging in the power cord to the electrical

receptacle.

REMOVE ALL MAINTENANCE TOOLS from the

14.

immediate area prior to turning “ON” the Bench

Grinder.

15. USE ONLY

Use of incorrect or improper accessories could

cause serious injury to the operator and cause

damage to the tool. If in doubt, check the instruction

manual that comes with that particular accessory.

16. NEVER LEAVE A RUNNING TOOL UNATTENDED.

Turn the power switch to the “OFF” position. DO

NOT leave the tool until it has come to a complete

stop.

RECOMMENDED

ACCESSORIES

.

3

Page 4

SAFETY INSTRUCTIONS (cont.)

7.

1

O NOT STAND ON A TOOL.Serious injury could

D

result if the tool tips over or you accidentally contact

the tool.

18. DO NOT store anything above or near the tool

here anyone might try to stand on the tool to

w

reach it.

MAINTAIN YOUR BALANCE. DO NOT extend

19.

yourself over the tool. Wear oil resistant rubbersoled

shoes. Keep floor clear of debris, grease, and wax.

MAINTAIN TOOLS WITH CARE. Always keep tools

20.

clean and in good working order. Keep all blades

and tool bits sharp.

EACH AND EVERY TIME, CHECK FOR DAMAGED

21.

PARTS PRIOR TO USING THE TOOL. Carefully

check all guards to see that they operate properly,

are not damaged, and perform their intended functions. Check for alignment, binding or breaking of

moving parts. A guard or other part that is damaged

should be immediately repaired or replaced.

CHILDPROOF THE WORKSHOP AREA by remov-

22.

ing switch keys, unplugging tools from the electrical

receptacles, and using padlocks.

ALIFORNIA PROPOSITION 65

26.C

SOME DUST CREATED BY POWER SANDING,

SAWING, GRINDING, DRILLING AND OTHER

CONSTRUCTION ACTIVITIES

nown to cause cancer, birth defects or other repro-

k

ductive harm.

contains chemicals

GUIDELINES FOR

EXTENSION CORDS

If you are using an extension cord outdoors, be sure

it is marked with the suffix “W-A” (“W” in Canada) to

indicate that it is acceptable for outdoor use.

Be sure your extension cord is properly sized, and

in good electrical condition. Always replace a damaged

extension cord or have it repaired by a qualified person

before using it.

Protect your extension cords from sharp objects,

excessive heat, and damp or wet areas.

23. DO NOT OPERATE TOOL IF UNDER THE INFLU-

ENCE OF DRUGS OR ALCOHOL.

24. SECURE ALL WORK. When it is possible, use

clamps or jigs to secure the workpiece. This is

safer than attempting to hold the workpiece with

your hands.

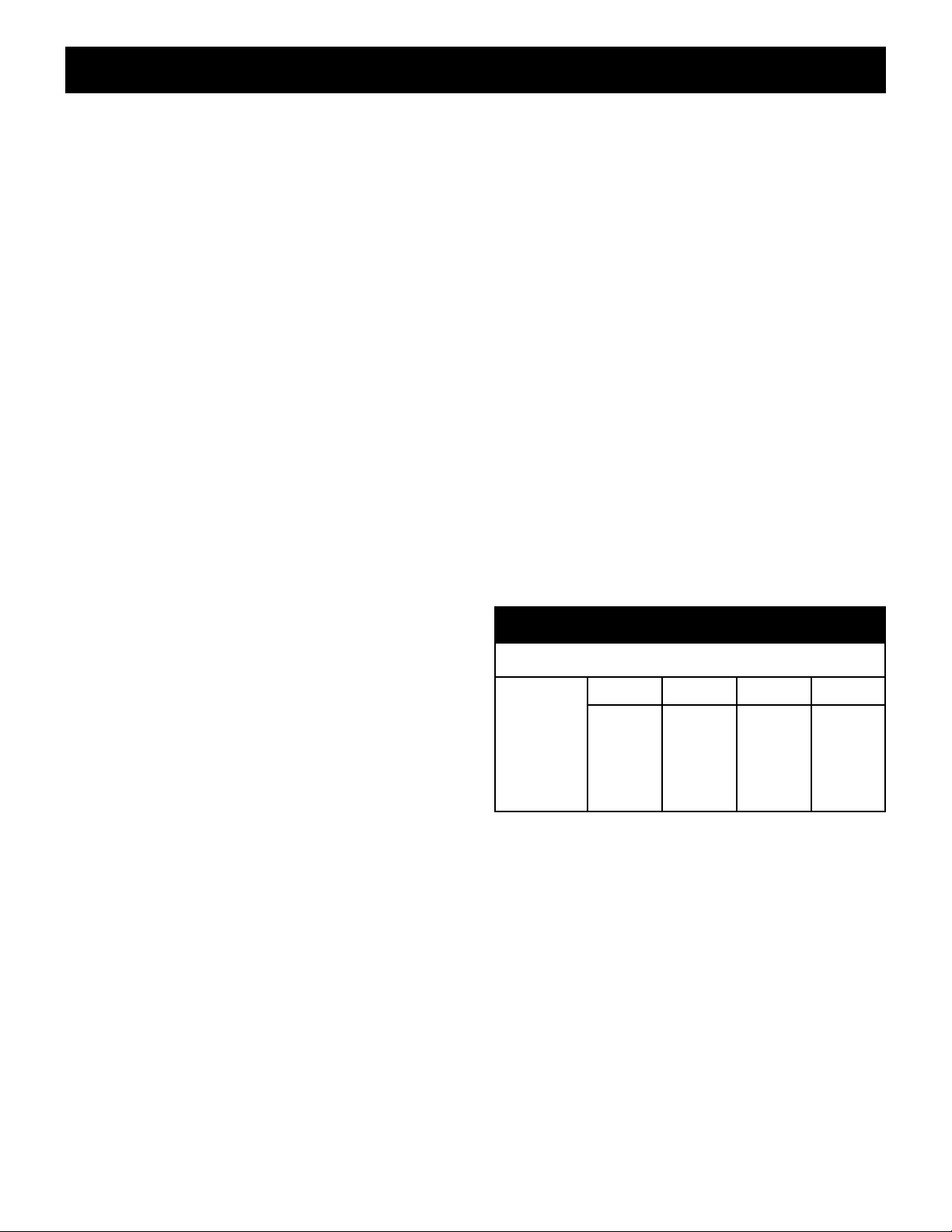

25. USE A PROPER EXTENSION CORD IN GOOD

CONDITION. When using an extension cord, be

sure to use one heavy enough to carry the current

your product will draw.

correct size to use depending on cord length and

nameplate amperage rating. If in doubt, use the

next heavier gauge. The smaller the gauge number,

the larger diameter of the extension cord. If in doubt

of the proper size of an extension cord, use a shorter and thicker cord. An undersized cord will cause a

drop in line voltage resulting in a loss of power and

overheating.

CORD THA

PLUG AND A 3-POLE RECEPTACLE THAT

ACCEPTS THE TOOL’S PLUG.

USE ONLY A 3-WIRE EXTENSION

T HAS A 3-PRONG GROUNDING

The table at right shows the

MINIMUM RECOMMENDED GAUGE FOR EXTENSION CORDS (AWG)

120 VOLT OPERATION ONLY

25’ LONG 50’ LONG 100’ LONG 150’ LONG

0 to 6 Amps 18 AWG 16 AWG 16 AWG 14 AWG

6 to 10 Amps 18 AWG 16 AWG 14 AWG 12 AWG

10 to 12 Amps 16 AWG 16 AWG 14 AWG 12 AWG

4

Page 5

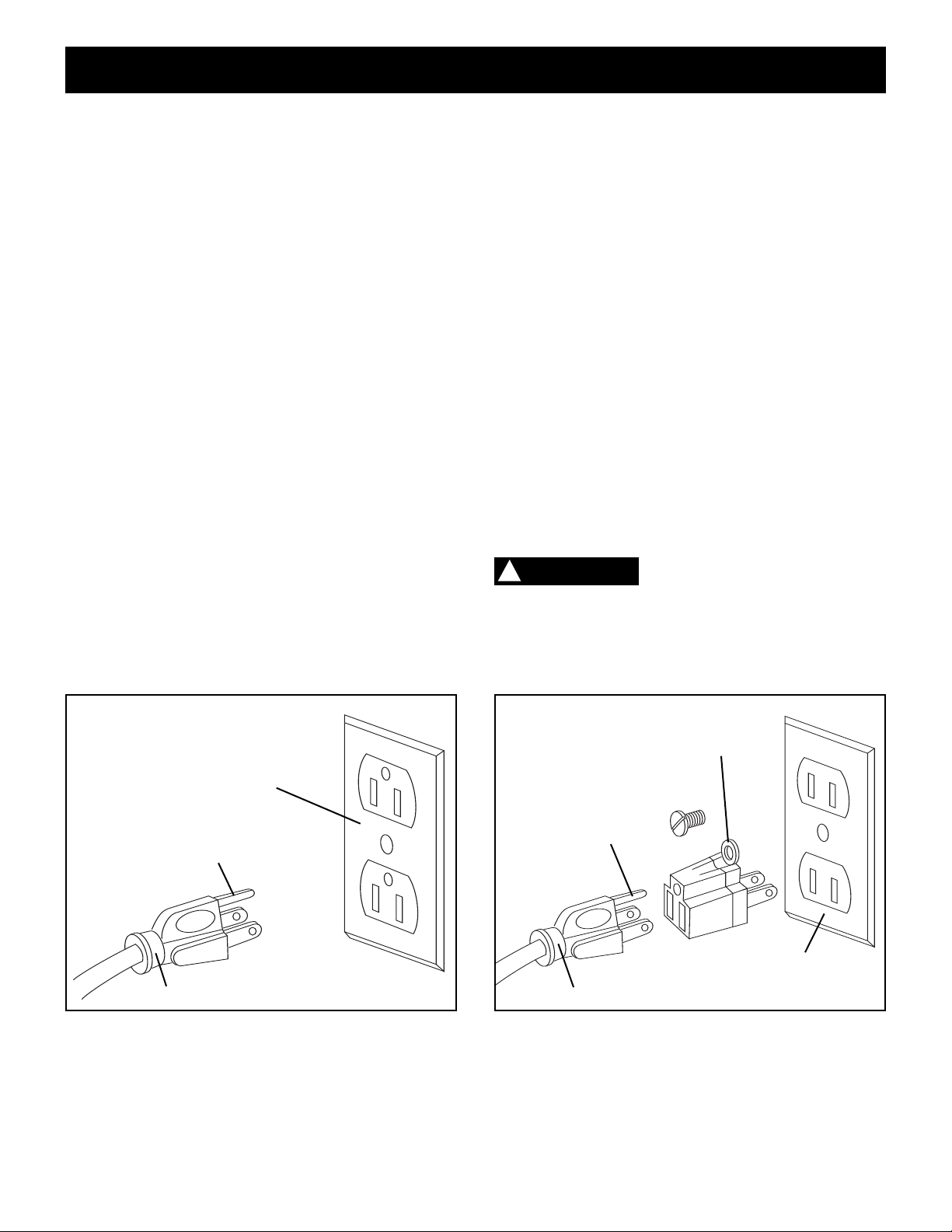

GROUNDING INSTRUCTIONS

N THE EVENT OF A MALFUNCTION OR BREAK-

I

DOWN, grounding provides the path of least resistance

for electric current and reduces the risk of electric

shock. This tool is equipped with an electric cord that

as an equipment grounding conductor and a ground-

h

ing plug. The plug MUST be plugged into a matching

electrical receptacle that is properly installed and grounded in accordance with

DO NOT MODIFY THE PLUG PROVIDED. If it will not

fit the electrical receptacle, have the proper electrical

receptacle installed by a qualified electrician.

IMPROPER ELECTRICAL CONNECTION of the equipment grounding conductor can result in risk of electric

shock. The conductor with the green insulation (with or

without yellow stripes) is the equipment grounding

conductor.

conductor to a live terminal if repair or replacement of

the electric cord or plug is necessary.

CHECK with a qualified electrician or service personnel

if you do not completely understand the grounding

instructions, or if you are not sure the tool is properly

grounded.

DO NOT connect the equipment grounding

ALL local codes and ordinances.

SE ONLY A 3-WIRE EXTENSION CORD THAT HAS

U

A 3-PRONG GROUNDING PLUG AND A 3-POLE

RECEPTACLE THAT ACCEPTS THE TOOL’S PLUG.

EPLACE A DAMAGED OR WORN CORD

R

IMMEDIATELY.

This tool is intended for use on a circuit that has an

electrical receptacle as shown in

shows a 3-wire electrical plug and electrical receptacle

that has a grounding conductor. If a properly grounded

electrical receptacle is not available, an adapter as

shown in

nect this plug to a 2-contact ungrounded receptacle.

The adapter has a rigid lug extending from it that

be connected to a permanent earth ground, such as a

properly grounded receptacle box. THIS ADAPTER IS

PROHIBITED IN CANADA.

CAUTION:

receptacle in question is properly grounded. If you are

not sure have a certified electrician check the electrical

receptacle.

!

This Bench Grinder is for indoor use only. Do not

expose to rain or use in damp locations.

FIGURE B can be used to temporarily con-

In all cases, make certain the electrical

WARNING

FIGURE A. FIGURE A

MUST

Fig. A

3-prong

electrical receptacle

grounding

conductor

3-wire electrical cord

Fig. B

grounding

conductor

3-wire electrical cord

grounding

adapter lug

2-prong

electrical

receptacle

5

Page 6

SPECIFIC SAFETY INSTRUCTIONS

FOR BENCH GRINDERS

The operation of any grinder can result in debris being

thrown into your eyes, which can result in severe eye

damage. ALWAYS wear Safety Goggles (that comply

with ANSI standard Z87.1) when operating the grinder.

afety Goggles are available at Sears Retail Stores.

S

Keep your thumbs and fingers away from the grinding

heels.

w

1. ALWAYS USE THE EYE SHIELDS AND WHEEL

GUARDS provided with the grinder.

2.

REPLACE A CRACKED OR DAMAGED GRINDING WHEEL IMMEDIATELY. A damaged wheel can

discharge debris at a high velocity towards the

operator. Carefully handle the grinding wheels since

they are abrasive. Prior to replacing a grinding

wheel, check it for cracks.

blotter or label on both sides of the grinding wheel.

Tighten the spindle nut just enough to hold the

grinding wheel firmly to the Bench Grinder. Do not

over-tighten the nut. Excessive clamping force can

damage the grinding wheel. Only use the wheel

flanges provided with the grinder. When selecting a

replacement grinding wheel, verify that the grinding

wheel has a higher R.P.M. rating than the maximum

R.P.M. of the Bench Grinder.

DO NOT remove the

3.

THE DIAMETER OF THE GRINDING WHEELS

ILL DECREASE WITH USE.Adjust the tool rests

W

and spark arrestors to maintain a distance of 1/16”

from the wheel.

4. DO NOT STAND IN FRONT OF THE BENCH

RINDER WHEN STARTING IT.Stand to one side

G

of the Bench Grinder and turn it “ON”. Wait at the

side for one minute until the grinder comes up to

full speed. There is always a possibility that debris

from a damaged grinding wheel may be discharged

towards the operator.

5. THE BENCH GRINDER WILL PRODUCE SPARKS

AND DEBRIS DURING GRINDING OPERATIONS

Be sure that there are not any flammable materials

in the vicinity. Frequently clean grinding dust from

the back of the Bench Grinder.

NEVER FORCE THE WORKPIECE AGAINST A

6.

GRINDING WHEEL, especially if the wheel is cold.

Apply the workpiece slowly, allowing the grinding

wheel an opportunity to warm up. This will minimize

the chance of wheel breakage. DO NOT grind using

the sides of the grinding wheels. DO NOT apply

coolant directly to the grinding wheel.

7. KEEP ALL WHEEL GUARDS IN PLACE. DO NOT

USE THE BENCH GRINDER WITH THE WHEEL

GUARDS REMOVED.

8. KEEP THE TOOL RESTS FIRMLY TIGHTENED.

9. ALWAYS USE THE SUPPLIED WHEEL DRESSER

TO RESURFACE THE FACE OF THE GRINDING

WHEEL.

.

ACCESSORIES AND ATTACHMENTS

AVAILABLE ACCESSORIES

Visit your Sears Hardware Department or see the

Sears Power and Hand Tool Catalog for the following

accessories.

ITEM STOCK NUMBER

Replacement grinding wheels See catalog or store

Wire and Buffing wheels See catalog or store

Spacers See catalog or store

Wheel dressers See catalog or store

Stand See catalog or store

Sears may recommend other accessories not listed in

this manual.

See your nearest Sears Hardware Department or Sears

Power and Hand

Do not use any accessory unless you have completely

read the Owner’s Manual for that accessory.

!

WARNING

Use only accessories recommended for this Bench

Grinder. Using other accessories may cause serious

injury and cause damage to the Bench Grinder

6

Tool Catalog for other accessories.

.

Page 7

CARTON CONTENTS

UNPACKING AND CHECKING

CONTENTS (Fig. C)

his Bench Grinder will require a minimal amount of

T

assembly. A 10mm and 13mm open end wrench is

provided for mounting the Tool Rest Assemblies and

the Spark Arrestor Assemblies.

Remove all of the parts from the shipping box and lay

them on a clean work surface. Compare the items to

Fig. C, verify that all items are accounted for before

discarding the shipping box.

!

WARNING

If any parts are missing, do not attempt to plug in the

power cord and turn “ON” the Bench Grinder. The

Fig. C

ench Grinder can only be turned “ON” after all the

B

parts have been obtained and installed correctly.

The following items are to be provided in the shipping

ox:

b

. Grinder

A

B. Quench tray

C. Wheel dresser

D. Eyeshield assembly

E. Left tool rest assembly (not shown)

F. Right tool rest assembly

G. Special Wrench

A

F

D

B

C

G

7

Page 8

KNOW YOUR BENCH GRINDER

6

5

10B

9

4

1

3

7

10A

2

8

11

14

13

1. WHEEL GUARD - Covers the grinding wheels and

protects against accidental contact.

2. WHEEL COVER - Covers the grinding wheels and

provides access for routine maintenance.

3. MOTOR HOUSING - Contains the electrical motor.

4. EYESHIELD MOUNTS - Supports the eyeshields.

5. EYESHIELDS - Protective Lexan see-thru shields

to prevent any loose debris from contacting the

ARK

.

WORK

ARREST

RESTS

LIGHT

ORS

Used to support the workpiece

-

WHEEL

- Provides assistance to

Prevents hot sparks and

-

120 GRIT

- Used to remove

.

operator

6. FLEXIBLE

the operator for grinding operations.

7. SP

debris from contacting the operator.

8. TOOL REST ADJUSTABLE SUPPORTS - Lets the

operator position the tool rest closer to the wheel as

the wheel decreases in diameter due to wear

OOL

9. T

that is being ground. Adjustable to provide angled

surfaces.

10. A) GRINDING

light material from workpiece.

10. B) GRINDING WHEEL 60 GRIT - Used to remove

heavy material from workpiece.

11. ON / OFF SWITCH - Used to turn “ON” and turn

“OFF” the grinder.

12. WHEEL DRESSER - Used to clean and smooth

surface of the 8" Grinding Wheel (not shown).

13. QUENCH TRAY - Used to cool workpiece after

grinding.

AD

14. MOUNTING

workbench or suitable work surface.

15. GRINDING WHEEL IDENTIFICATION LABEL -

Provides information on wheel size, grit and maximum RPM. Must be left on to distribute the load of

tightening the Lock Nuts (not shown).

16. ARBOR BUSHING - Used when wheels have an

oversized wheel bore (not shown).

17. FLANGES - Used to secure the grinding wheels to

the grinder and distribute the load of the Lock Nuts

(not shown).

18. LOCK

the grinder (not shown).

P

- Used to secure the grinder to a

NUT

- Used to secure the grinding wheels to

8

Page 9

ASSEMBLY INSTRUCTIONS

10mm and 13mm open-end wrench (included) is

A

required for assembly of the Tool Rest Assemblies and

the Spark Arrestor Assemblies.

!

WARNING

• DO NOT assemble the Bench Grinder until you are

sure the tool IS NOT plugged in.

• DO NOT assemble the Bench Grinder until you are

sure the power switch is in the “OFF” position.

• DO NOT assemble the Bench Grinder until you are

sure the grinding wheels are firmly tightened to the

Bench Grinder.

Fig. E

E

H

F

TOOL RESTS (Figs. D and E)

The Bench Grinder is provided with two dif

Rest assemblies.

The Right Side Tool Rest is also flat, but has an accessory plate for sharpening drill bits.

1. Remove both Tool Rest Assemblies from the plastic

bags and check to see that you have the following:

Left Side Tool Rest

Left Side Tool Rest Support

Right Side Tool Rest

Right Side Tool Rest Support Drill Bit Sharpening

Plate M8 Flat Washer (qty. 6)

M8 x 12mm Hex head screw (qty. 4)

Adjustment Knob (qty. 2)

2. Assemble the Tool Rest Supports (A) to the inside

surface of the Wheel Covers (B) with the flat washers (C) and hex head screws (D) as shown. See

Fig. D.

3. Assemble the Tool Rests (E) to the Supports (F)

with the flat washers (G) and Adjustment Knobs (H)

as shown. See Fig. E.

The Left Side Tool Rest is entirely flat.

Fig. D

ferent Tool

G

4. Adjust the Tool Rests until they are 1/16” from the

grinding wheels. Firmly tighten the hex head screws

holding the supports.

SPARK ARRESTORS (Fig. F)

1. Remove both Spark Arrestor Assemblies from the

plastic bags and check to see that you have the

following:

Left Side Spark Arrestor

Right Side Spark Arrestor

M6 Flat Washer (2)

M6 X 6mm Hex head screw (2)

2. Assemble the Spark Arrestors (A) to the inside surface of the Wheel Covers (B) with the flat washers

(C) and hex head screws (D) as shown. See Fig. F.

3. Adjust the Spark Arrestors until they are 1/16" from

the grinding wheels. Firmly tighten the hex head

screws.

B

D

C

Fig. F

B

A

C

D

A

9

Page 10

EYE SHIELDS (Fig. G)

WORK LIGHT (Fig. H)

1. Remove both Eye Shield Assemblies from the plasic bags and check to see that you have the follow-

t

ing. Eyeshield (qty. 2) Lock Knob (qty. 2) Spacer

qty. 2) M6 Flat washer (qty. 2) M6 x 80mm carriage

(

head screw (qty. 2)

2. Assemble the Eyeshield (C) to the Spark Arrestor

(A) by inserting the carriage head screw (B) through

Eyeshield (C), Spark Arrestor (A), and the spacer

(D) as shown.

3. Assemble the flat washer (E) and Lock Knob (F) to

the carriage head screw and tighten until the

Eyeshield remains in the desired position.

Fig. G

D

B

E

C

The Bench Grinder is provided with a Flexible Work

Light to assist in visibility of the workpiece.

The Bench Grinder is NOT provided with a light bulb for

he Flexible Work Light.

t

!

WARNING

To reduce the risk of fire, use a 120V, 40 watt Type A or

smaller bulb, medium base. DO NOT use a light bulb

that extends past the end of the light housing.

The Flexible Work Light (A) may be turned “ON” or

“OFF” by using the rotary switch (B) on the top surface

of the housing. The switch can be rotated in the clockwise direction only.

NOTE: The Flexible Work Light can be turned “ON” or

“OFF” even if the Bench Grinder is turned “OFF”.

CAUTION: The Flexible Work Light housing will remain

hot for a few minutes after turning it “OFF”. Avoid contact with housing until it is cool.

Fig. H

B

F

A

QUENCH TRAY

1. The Quench Tray is provided to cool the workpiece

during and after grinding operations.

2. Attach the Quench Tray to base of the Bench

Grinder as shown.

3. Tighten the two screws.

4. Partially fill the Quench Tray with water. DO NOT

overfill! DO NOT use any other liquid in the Quench

Tray other than water.

A

PERMANENT MOUNTING

ou should firmly attach the Bench

Y

surface or heavy-duty stand (hardware not included).

Grinder to a solid work

5. Place the workpiece into the water after performing

the grinding operation to cool it.

6. DO NOT put any water directly onto the grinding

wheels.

!

WARNING

If the Bench Grinder is not securely mounted, it will

have the ability to move or tip over during grinding

operations and possibly cause the operator

contact the grinding wheels.

10

s fingers to

’

Page 11

OPERATING THE BENCH GRINDER

USING THE WHEEL DRESSER (Fig. J)

The Bench Grinder is designed for hand held grinding,

harpening, and cleaning operations.

s

LWAYS WEAR EYE PROTECTION!Hot sparks are

A

produced during grinding operations.

1. The Power Switch must be in the “OFF” position.

2. Stand to the side of the Bench Grinder and plug in

the power cord to the correct power source.

3. Remain to the side of the Bench Grinder and turn it

“ON” by moving the power switch to the up position.

4. Allow the grinding wheels to come up to a steady

speed for at least one minute.

5. The Flexible Work Light may be turned “ON” if

desired.

6. Adjust the eyeshields. Place the workpiece on the

appropriate tool rest for the desired operation.

7. Move the workpiece towards the grinding wheel

until it lightly touches. Move the workpiece back

and forth across the front surface of the grinding

wheel removing the amount of material desired.

DO NOT EVER GRIND ON THE SIDES OF THE

GRINDING WHEELS.

8. The operator may place the hot end of the work-

piece into the water in the quench tray to cool it.

9. After completing the grinding operations, turn “OFF”

the Bench Grinder by pushing down on the Power

Switch. CAUTION: It will take a few minutes for the

grinding wheels to come to a complete stop.

Fig. J

C

A

The Wheel Dresser is to be used on the grinding

wheels. It will remove buildup of material on the grinding wheel, remove imperfections and make the corners

of the grinding wheel square. See Fig. J.

1. Loosen the correct side tool rest (A) and adjust it

until it is in the flat horizontal position as shown and

1/16” away from the grinding wheel.

2. Turn “ON” the Bench Grinder. Let the grinding

wheel come up to a steady speed for one minute.

3. After the grinding wheel has gotten to a steady

speed, place the Wheel Dresser (B) flat on the Tool

Rest with the serrated wheels facing the grinding

wheel.

Firmly hold on to the handle of the Wheel Dresser

4.

B

.

10. Turn “OFF” the Flexible Work Light.

Flexible Work Light housing will remain hot for a

few minutes after turning it “OFF”.

11. Avoid contact with housing until it is cool. Unplug

the Bench Grinder from the power source.

CAUTION: The

5. Move the Wheel Dresser forward until the serrated

wheels make light contact with the grinding wheel

(C). After contact has been made, slide the Wheel

Dresser side to side across the Tool Rest to dress

the grinding wheel until the edge of the grinding

wheel is square and the surface is clean.

After the operator has completed dressing the

6.

grinding wheel, turn “OFF” the Bench Grinder and

let the grinding wheel come to a complete stop.

7. Inspect the grinding wheel for any damage!

The grinding wheel may now be slightly smaller in

8.

diameter after dressing. Readjust the tool rests and

spark arrestors to maintain a 1/16” clearance to the

grinding wheel.

11

Page 12

CHANGING THE GRINDING WHEEL (Fig. K)

Fig. K

D

G

C

J

K

F

I

B

A

H

E

Due to normal wear, both wheels will need to be

replaced occasionally. See Fig. K.

1. Turn the power switch “OFF” and unplug the power

cord from its power source

2. Rotate the eyeshields to the “UP” position for

access to the tool rests.

3. Remove the three screws (A), flat washers (B),

external tooth lock washers (C) and nuts (D) holding the Outer Wheel Covers (E) to the Bench

Grinder

4. Remove the Outer Wheel Covers.

5. Place a small wooden wedge between the Abrasive

Wheel (F) and Tool Rest (G) to prevent the wheels

from rotating.

Remove the right side grinding wheel by turning the

6.

lock-nut (H) in the counterclockwise direction with

an open-end wrench (not included). The left side

wheel can be removed by turning the lock-nut in the

clockwise direction with an open-end wrench.

7. Remove the Outer Wheel Flange (I) and then

remove the abrasive wheel from the arbor shaft (J).

The

use, if the replacement wheel does not use this

bushing.

.

Arbor Bushing (K) should be saved, for future

CAUTION: The new abrasive wheel to be put on

8.

the Bench Grinder must have a higher R.P.M rating

than the Bench Grinder. The label on the side of the

abrasive wheels must stay on, DO NOT remove

this label.

9. Replace the abrasive wheel, outer wheel flange,

and the lock-nut in reverse order from removal.

CAUTION: DO NOT OVER-TIGHTEN the lock nut as

this may damage the abrasive wheels and cause serious injury to the operator

.

DUST PORT (Fig. N)

There is a dust port located on the inner side of each

Inner Wheel Guard. These dust ports allows the grinding dust to exit the wheel cavity.

If you choose to attach the dust ports to a dust collection system, make sure the dust collector is rated and

configured for your grinding operation.

12

Page 13

MAINTENANCE OF THE BENCH GRINDER

AUTION: REPLACEthe abrasive wheels if there is

!

WARNING

Turn the power switch “OFF” and unplug the power

cord from its power source prior to any maintenance.

LUBRICATION

The Bench Grinder has sealed lubricated bearings in

the motor housing that do not require any additional

lubrication from the operator.

CLEANING

With the Bench Grinder unplugged, rotate the abrasive

wheels slowly and inspect for any damage or trapped

shavings.

C

any damage at all. FAILURE to replace a damaged

wheel can cause serious injury to the operator.

CAUTION: DO NOT USE FLAMMABLE MATERIALS

o clean the Bench Grinder. A clean dry rag or brush is

t

all that is needed to remove dust and debris buildup.

!

WARNING

Repairs to the Bench Grinder should be performed by

trained personnel only. Contact your nearest Sears

Service Center for authorized service. Unauthorized

repairs or replacement with non-factory parts could

cause serious injury to the operator and damage to the

Bench Grinder.

TROUBLESHOOTING

TO PREVENT INJURY TO YOURSELF or damage to the Bench Grinder, turn the switch to the “OFF” position and

unplug the power cord from the electrical receptacle before making any adjustments.

PROBLEM LIKELY CAUSE(S)

Motor does 1. Machine not plugged in 1. Plug power cord into electrical receptacle

not run 2. Power switch in “OFF” position 2. Lift switch to “ON” position

3. Power cord is faulty 3. Return to Sears Service Center

4. Fuse or circuit breaker are open 4. Overloaded electrical circuit

5. Damaged motor 5. Return to Sears Service Center

Motor does not 1. Incorrect line voltage 1. Have a qualified electrician check line for proper voltage

have full power

2. Damaged motor 2. Return to Sears Service Center

Motor runs hot 1. Motor is overloaded

2. Poor air circulation around motor 2. Remove any blockage around motor

Motor stalls or 1. Motor is overloaded

runs slow

2. Incorrect line voltage 2. Have a qualified electrician check line for proper voltage

3. Capacitor has failed 3. Return to Sears Service Center

Fuse blows or 1. Motor overloaded 1. Reduce pressure on workpiece

circuit breaker 2. Overloaded electrical circuit 2. Reduce the amount of items on circuit

trips 3. Wrong fuse or circuit breaker 3. Replace with correct fuse or circuit breaker

4. Undersized or excessive length of

extension cord, see manual

5. Grinding wheels are blocked 5. Unplug machine and remove obstruction

SOLUTION

1. Reduce pressure on workpiece

1. Reduce pressure on workpiece

4. Use correct size

13

Page 14

PARTS

8-IN. PROFESSIONAL BENCH GRINDER PARTS LIST MODEL NO. 152.220180

!

WARNING

When servicing, use only CRAFTSMAN replacement parts. Use of any other parts may create a HAZARD or cause

product damage.

!

WARNING

Any attempt to repair or replace electrical parts on this Bench Grinder may create a

by a qualified service technician. Repair service is available at your nearest Sears Service Center.

Always order by PART NUMBER, not by key number.

HAZARD unless repair is done

EY PART

K

O. NO. DESCRIPTION QTY.

N

1 OR90055 M6x80mm CARRIAGE HD SCREW 1

2 OR90152 EYESHIELD 1

OR90059 M6mm FLAT WASHER 1

3

OR90001 M6mm KNOB 1

4

OR90002 SPACER 1

5

6 OR90488 SPARK ARRESTOR-L.H 1

OR90059 M6mm FLAT WASHER 1

7

OR90530 M6x10mm HEX HD SCREW 1

8

OR90001 M6mm KNOB 1

9

10 OR90059 M6mm FLAT WASHER 1

11 OR90152 EYESHIELD 1

12 OR90055 M6x80mm CARRIAGE HD SCREW 1

13 OR90002 SPACER 1

14 OR90489 SPARK ARRESTOR-R.H 1

15 OR90530 M6x10mm HEX HD SCREW 1

16 OR90059 M6mm FLAT WASHER 1

17 OR90567 PAN HD SCREW M6x60mm 3

18 OR90059 M6mm FLAT WASHER 3

19 OR94751 OUTER WHEEL GUARD-RH 1

20 OR94170 HEX NUT M14 1

21 OR90519 WHEEL FLANGE 1

22 OR71420 GRINDING WHEEL,120 GRIT-

23 OR90525 WHEEL BUSHING 1

24 OR90519 WHEEL FLANGE 1

25 OR90501 PAN HD SCREW M6x16mm 4

26 OR90502 M6mm LOCK WASHER 4

27 OR94752 INNER WHEEL GUARD ASSEMBLY-RIGHT, INCL: 1

28 OR90526 ROTATION LABEL 1

29 OR90059 M6mm FLAT WASHER 3

30 OR90235 HEX NUT M6 3

31 OR90502 M6mm LOCK WASHER 3

33 OR94753 MOTOR ASSEMBLY, INCL: REF 34 & REF 36 1

34 OR94754 NAME PLATE LABEL 1

36 OR94755 SPEC LABEL 1

38 OR90502 M6mm LOCK WASHER 3

39 OR90235 HEX NUT M6 3

40 OR90059 M6mm FLAT WASHER 3

41 OR94756 INNER WHEEL GUARD ASSEMBLY-LEFT, INCL: 1

42 OR90526 ROTATION LABEL 1

43 OR90502 M6mm LOCK WASHER 4

OR91826

44

OR90519

45

OR90551

46

OR90525

47

OR90519

48

OR90498

49

OR94757

50

OR90059

51

OR90567

52

8" DIA x 1" WIDE x 1" BORE 1

AN HD SCREW M6x16mm

P

FLANGE

WHEEL

GRINDING WHEEL, 60 GRIT

x 1" WIDE x 1" BORE

8" DIA

BUSHING

WHEEL

FLANGE

WHEEL

HEX NUT

OUTER WHEEL

M6mm FLA

P

M14-LEFT

GUARD-LH

ASHER

W

T

AN HD SCREW M6x60mm

-

HAND

EY PART

K

O. NO. DESCRIPTION QTY.

N

53 OR94747 LEFT TOOL REST ASSY, CONST OF:

4 OR90203 LEFT TOOL REST SUPPORT 1

5

5 OR90204 LEFT TOOL REST 1

5

6A OR90625 5/16 FLAT WASHER 1

5

56B OR90155 KNOB 5/16 - 18 1

56C OR90311 M8 FLAT WASHER 2

56D OR90248 M8 LOCK WASHER 2

6E OR93917 M8 x 20mm HEX HEAD SCREW 2

5

7 OR94748 RIGHT TOOL REST ASSY, CONST OF :

5

58 OR90191 RIGHT TOOL REST SUPPORT 1

59 OR90192 RIGHT TOOL REST 1

60A OR90155 KNOB 5/16 - 18 1

60B OR90625 5/16 FLAT WASHER 1

60C OR93917 M8 x 20mm HEX HEAD SCREW 2

60D OR90248 M8 LOCK WASHER 2

60E OR90311 M8 FLAT WASHER 2

63 OR71428 LIGHT ASSY, INCL: 1

64 OR90544 LIGHT WARNING LABEL 1

66 OR90227 M10mm LOCK WASHER 1

67 OR90228 M10x1mm HEX NUT 1

68 OR90507 PAN HD SCREW M5x8mm 2

69 OR90362 M5 EXT TOOTH WASHER 2

70 OR71429 CORD CLAMP 1

71 OR71430 CLAMP PLATE 1

72 OR94758 BASE 1

73 OR71432

74 OR90248 M8mm LOCK WASHER

OR90504

75

76 OR71433

77 OR71434 CAP

OR71435 END CAP 2

78

OR90362

79

80 OR90507 P

OR90362 M5 EXT T

82

OR90863

83

OR71436

84

OR71437

85

OR90333

86

OR71438

87

OR90505

4

1

1

1

1

1

1

3

3

88

OR90362

89

OR71439

90

OR71424

91

OR90362

92

OR90507

93

OR71440

94

OR90507

95

OR90050

96

OR90510

97

OR94750

98

REF 54 TO REF 56E 1

EF 58 TO

R

CORDSET

HEX HD SCREW M8x18mm 2

CLAMP

M5 EXT

AN HD SCREW M5x6mm

AN HD SCREW M5x12mm

P

AD

P

BASE PLA

M6x10mm HEX HD SCREW

W

AN HD SCREW M5x12mm

P

M5 EXT

SWITCH

SWITCH PLA

M5 EXT

AN HD SCREW M5x8mm

P

DIAMOND WHEEL

AN HD SCREW M5x8mm

P

10mm x 12mm OPEN END WRENCH (NOT

BEARING (NOT

OWNERS MANUAL

REF 60E 1

F) 1

°

OR(150

ACIT

OOTH WASHER

T

ASHER

OOTH W

TE

Y

TRA

TER

A

ASHER

OOTH W

T

TE

ASHER

OOTH W

T

DRESSER

SHOWN)

SHOWN)

(NOT

SHOWN)

1

2

1

1

1

2

4

4

1

2

1

2

4

1

1

2

2

1

2

1

2

1

14

Page 15

8-IN. PROFESSIONAL BENCH GRINDER PARTS LIST MODEL NO. 152.220180

15

Page 16

PARTS

10-IN. PROFESSIONAL BENCH GRINDER PARTS LIST MODEL NO. 152.220600

!

WARNING

When servicing, use only CRAFTSMAN replacement parts. Use of any other parts may create a HAZARD or cause

product damage.

!

WARNING

Any attempt to repair or replace electrical parts on this Bench Grinder may create a

by a qualified service technician. Repair service is available at your nearest Sears Service Center.

Always order by PART NUMBER, not by key number.

HAZARD unless repair is done

EY PART

K

O. NO. DESCRIPTION QTY.

N

1 OR90055 M6x80mm CARRIAGE HD SCREW 1

2 OR90152 EYESHIELD 1

OR90059 M6mm FLAT WASHER 1

3

OR90001 M6mm KNOB 1

4

OR90002 SPACER 1

5

6 OR90488 SPARK ARRESTOR-L.H 1

OR90059 M6mm FLAT WASHER 1

7

OR90333 M6x12mm HEX HD SCREW 1

8

OR90001 M6mm KNOB 1

9

10 OR90059 M6mm FLAT WASHER 1

11 OR90152 EYESHIELD 1

12 OR90055 M6x80mm CARRIAGE HD SCREW 1

13 OR90002 SPACER 1

14 OR90489 SPARK ARRESTOR-R.H 1

15 OR90333 M6x12mm HEX HD SCREW 1

16 OR90059 M6mm FLAT WASHER 1

17 OR90567 PAN HD SCREW M6x60mm 3

18 OR90059 M6mm FLAT WASHER 3

19 OR94740 OUTER WHEEL GUARD-RH 1

20 OR90499 HEX NUT M16 1

21 OR71446 WHEEL FLANGE 1

22 OR71447 GRINDING WHEEL, 120 GRIT-

23 OR71448 WHEEL BUSHING 1

24 OR71446 WHEEL FLANGE 1

25 OR90501 PAN HD SCREW M6x16mm 4

26 OR90502 M6mm LOCK WASHER 4

27 OR94741 INNER WHEEL GUARD ASSEMBLY-RIGHT, INCL:

OR90526

28

29 OR90059

30 OR90235 HEX NUT

OR90502 M6mm LOCK WASHER 3

31

OR94742

33

34 OR94743 NAME PLA

OR94744 SPEC LABEL 1

36

OR90502

38

OR90235

39

OR90059

40

OR94745

41

42 OR90526 ROTATION LABEL 1

43 OR90502 M6mm LOCK WASHER 4

44 OR91826 PAN HD SCREW M6x16mm 4

45 OR71446 WHEEL FLANGE 1

46 OR90520 GRINDING WHEEL, 60 GRIT-

47 OR71448 WHEEL BUSHING 1

48 OR71446 WHEEL FLANGE 1

49 OR90500 HEX NUT M16-LEFT HAND 1

50 OR94746 OUTER WHEEL GUARD-LH 1

51 OR90059 M6mm FLAT WASHER 3

52 OR90567 PAN HD SCREW M6x60mm 3

10" DIA x 1" WIDE x 1-1/4" BORE 1

REF 28 1

TION LABEL 1

ROTA

M6mm FLA

OR ASSEMBLY

MOT

M6mm LOCK W

HEX NUT

M6mm FLA

INNER WHEEL

REF 42 1

10" DIA

ASHER 3

W

T

M6

, INCL: REF 34 & REF 36

TE LABEL

ASHER

M6

ASHER

W

T

x 1" WIDE x 1-1/4" BORE 1

GUARD

ASSEMBL

-LEFT

Y

, INCL:

3

1

1

3

3

3

EY PART

K

O. NO. DESCRIPTION QTY.

N

53 OR94747 LEFT TOOL REST ASSY, CONST OF:

4 OR90203 LEFT TOOL REST SUPPORT 1

5

5 OR90204 LEFT TOOL REST 1

5

6A OR90625 5/16 FLAT WASHER 1

5

56B OR90155 KNOB 5/16 - 18 1

56C OR90311 M8 FLAT WASHER 2

56D OR90248 M8 LOCK WASHER 2

6E OR93917 M8 x 20mm HEX HEAD SCREW 2

5

7 OR94748 RIGHT TOOL REST ASSY, CONST OF :

5

58 OR90191 RIGHT TOOL REST SUPPORT 1

59 OR90192 RIGHT TOOL REST 1

60A OR90155 KNOB 5/16 - 18 1

60B OR90625 5/16 FLAT WASHER 1

60C OR93917 M8 x 20mm HEX HEAD SCREW 2

60D OR90248 M8 LOCK WASHER 2

60E OR90311 M8 FLAT WASHER 2

63 OR71428 LIGHT ASSY, INCL: 1

64 OR90544 LIGHT WARNING LABEL 1

66 OR90227 M10mm LOCK WASHER 1

67 OR90228 M10x1mm HEX NUT 1

68 OR90507 PAN HD SCREW M5x8mm 2

69 OR90362 M5 EXT TOOTH WASHER 2

70 OR71429 CORD CLAMP 1

71 OR71430 CLAMP PLATE 1

72 OR94749 BASE 1

73 OR71454

74 OR90248 M8mm LOCK WASHER

OR90504

75

76 OR71455

77 OR71456 CAP

OR71450 END CAP 2

78

OR90362

79

80 OR90507 P

OR90362 M5 EXT T

82

OR90863

83

OR71436

84

OR71437

85

OR90333

86

OR71438

87

OR90505

88

OR90362

89

OR71439

90

OR71424

91

OR90362

92

OR90507

93

OR71440

94

OR90507

95

OR90050

96

OR90510

97

OR94750

98

REF 54 TO REF 56E 1

EF 58 TO

R

POWER CORD

HEX HD SCREW M8x18mm 2

CLAMP

M5 EXT

AN HD SCREW M5x6mm

AN HD SCREW M5x12mm

P

AD

P

BASE PLA

M6x10mm HEX HD SCREW

W

AN HD SCREW M5x12mm

P

M5 EXT

SWITCH

SWITCH PLA

M5 EXT

AN HD SCREW M5x8mm

P

DIAMOND WHEEL

AN HD SCREW M5x8mm

P

10mm x 12mm OPEN END WRENCH (NOT

BEARING (NOT

OWNERS MANUAL

REF 60E 1

F) 1

°

OR(100

ACIT

OOTH WASHER

T

ASHER

OOTH W

TE

Y

TRA

TER

A

ASHER

OOTH W

T

TE

ASHER

OOTH W

T

DRESSER

SHOWN)

SHOWN)

(NOT

SHOWN)

1

2

1

1

1

2

4

4

1

2

1

2

4

1

1

2

2

1

2

1

2

1

16

Page 17

10-IN. PROFESSIONAL BENCH GRINDER PARTS LIST MODEL NO. 152.220600

17

Page 18

18

Page 19

® Registered Trademark /TM Trademark /SM Service Mark of Sears Brands, LLC

® Marca Registrada /

TM

Marca de Fábrica /SM Marca de Servicio de Sears Brands, LLC

MC

Marque de commerce /MD Marque déposée de Sears Brands, LLC © Sears Brands, LLC

Get it fixed, at your home or ours!

Your Home

For repair – in your home –ofall major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME

®

(1-800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts & Repair Center.

1-800-488-1222

Call anytime, day or night (U.S.A. only)

www.sears.com

To purchase a protection agreement (U.S.A.)

or maintenance agreement (Canada) on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparación

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR

®

(1-888-784-6427)

Au Canada pour service en français:

1-800-LE-FOYER

MC

(1-800-533-6937)

www.sears.ca

Loading...

Loading...