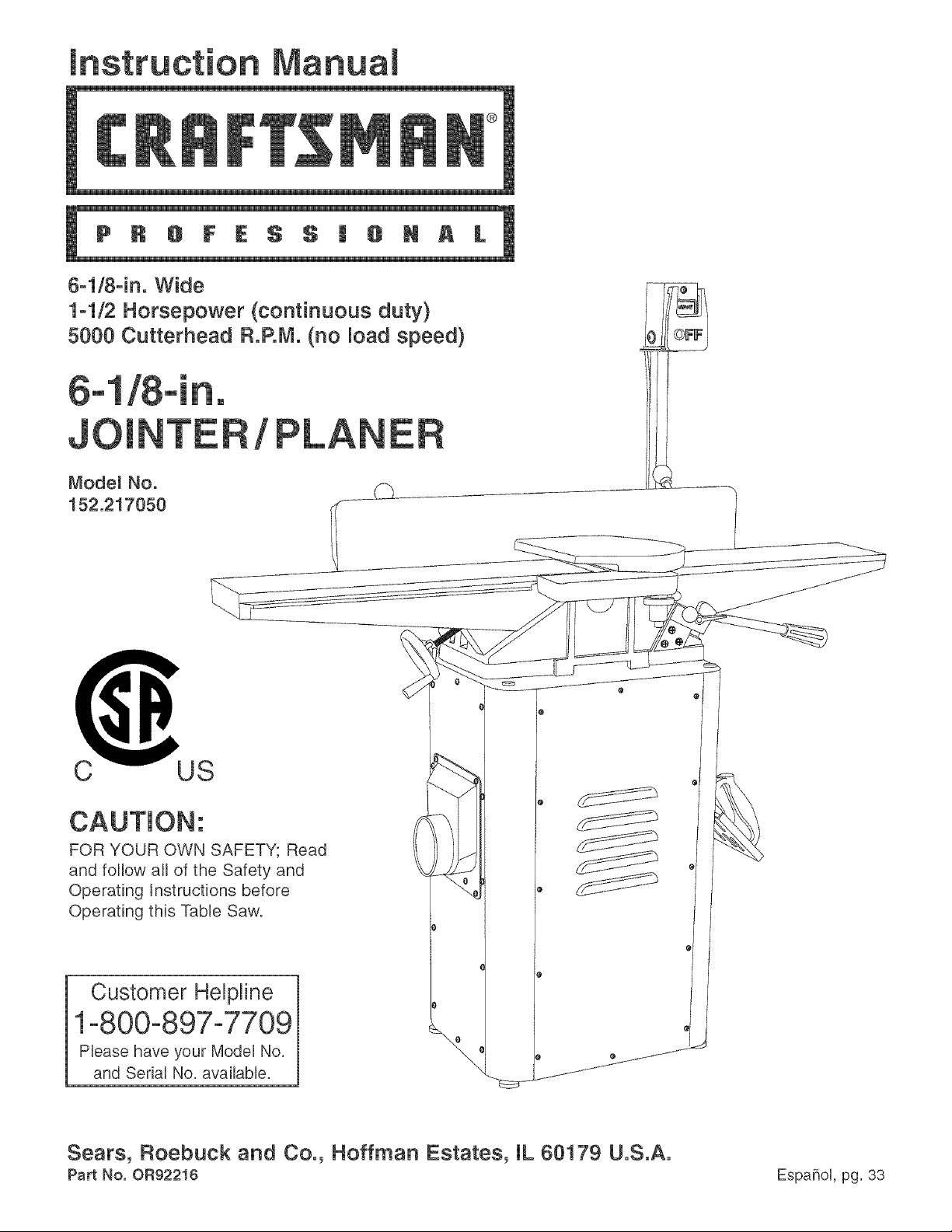

Craftsman 152217050 Owner’s Manual

truction anu

6-1/8-in. Wide

1-1/2 Horsepower (continuous duty)

5000 Cutterhead R.P.M. (no load speed)

/

Mode_ No.

152.217050

®

C S

FOR YOUR OWN SAFETY; Read

and foUlow all of the Safety and

Operating Instructions before

Operating this Table Saw.

Customer Helpline

1-800-897-7709

PRease have your Model No.

and SedaR No. availabUe.

Sears, Roebuck and Co., Hoffman Estates, JL 60179 U.S.A.

Part No. 0R92216

EspaSoU,pg, 33

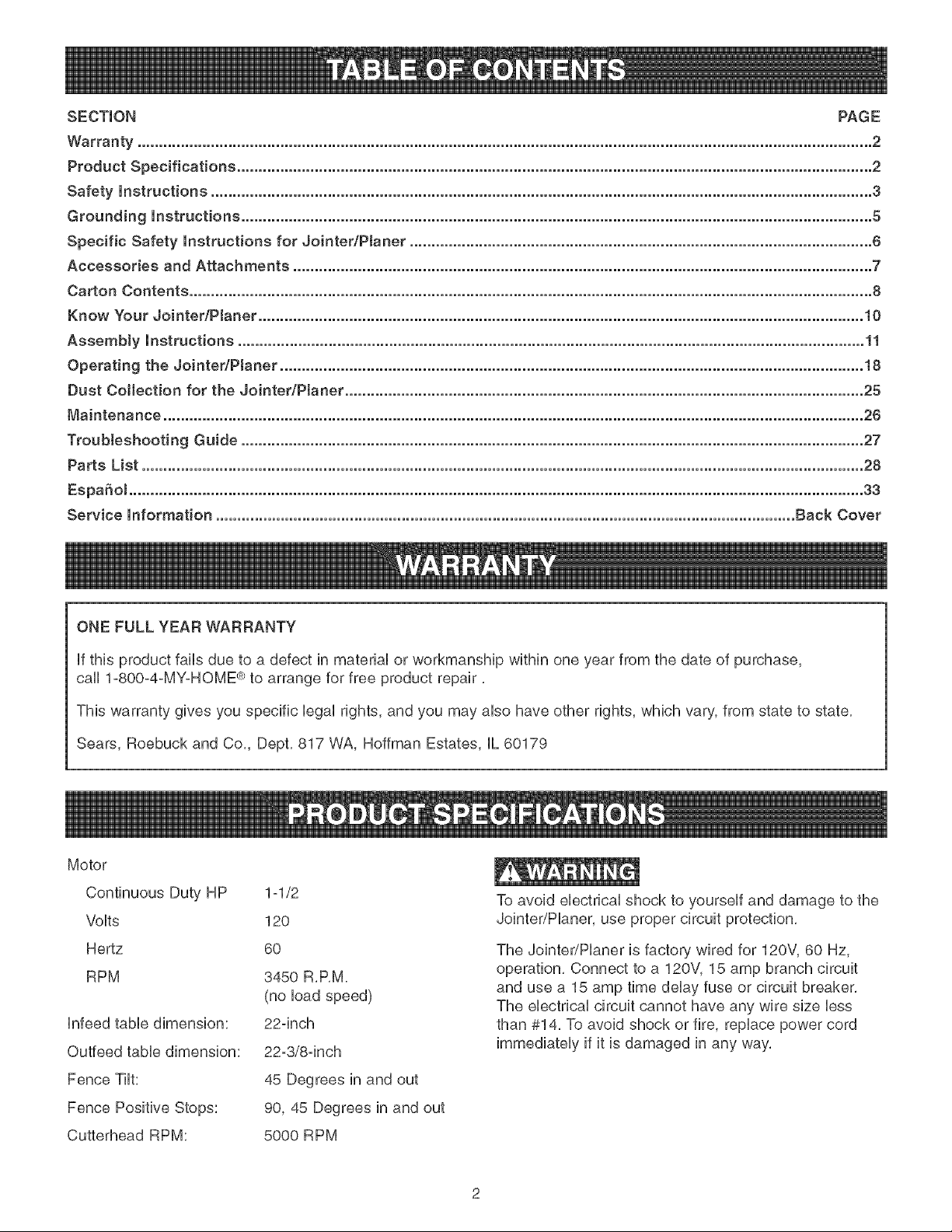

SECTION PAGE

Warranty..........................................................................................................................................................................2

ProductSpecifications...................................................................................................................................................2

Safetyinstructions.........................................................................................................................................................3

Groundinginstructions..................................................................................................................................................5

SpecificSafetyinstructionsfor Jointer/Ptaner...........................................................................................................6

AccessoriesandAttachments......................................................................................................................................7

CartonContents..............................................................................................................................................................8

KnowYourJointer/PJaner............................................................................................................................................10

Assemblyinstructions.................................................................................................................................................11

OperatingtheJointedPtaner.......................................................................................................................................18

DustCollectionfortheJointedPtaner........................................................................................................................25

Maintenance..................................................................................................................................................................26

TroubleshootingGuide................................................................................................................................................27

PartsList.......................................................................................................................................................................28

EspaSoJ..........................................................................................................................................................................33

Service information ...................................................................................................................................... Back Cover

ONE FULL YEAR WARRANTY

if this product fails due to a defect in material or workmanship within one year from the date of purchase,

call 1-800-4-MYoHOME C_)to arrange for free product repair,

This warranty gives you specific legal rights, and you may also have other rights, which vary, from state to state,

Sears, Roebuck and Co,, Dept, 817 WA, Hoffman Estates, IL 60179

Motor

Continuous Duty HP

Volts

Hertz

RPM

Infeed table dimension:

Outfeed table dimension:

1-1/2

120

6O

3450 R,P,M

(no load speed)

22-inch

22-3/8-inch

To avoid electrical shock to yourself and damage to the

Jointer/Planer, use proper circuit protection,

The Jointer/Planer is factory wired for 120V, 60 Hz,

operation, Connect to a 120V, 15 amp branch circuit

and use a 15 amp time delay fuse or circuit breaker,

The electrical circuit cannot have any wire size less

than #14, To avoid shock or fire, replace power cord

immediately if it is damaged in any way,

Fence Tilt:

Fence Positive Stops:

Cutterhead RPM:

45 Degrees in and out

90, 45 Degrees in and out

5000 RPM

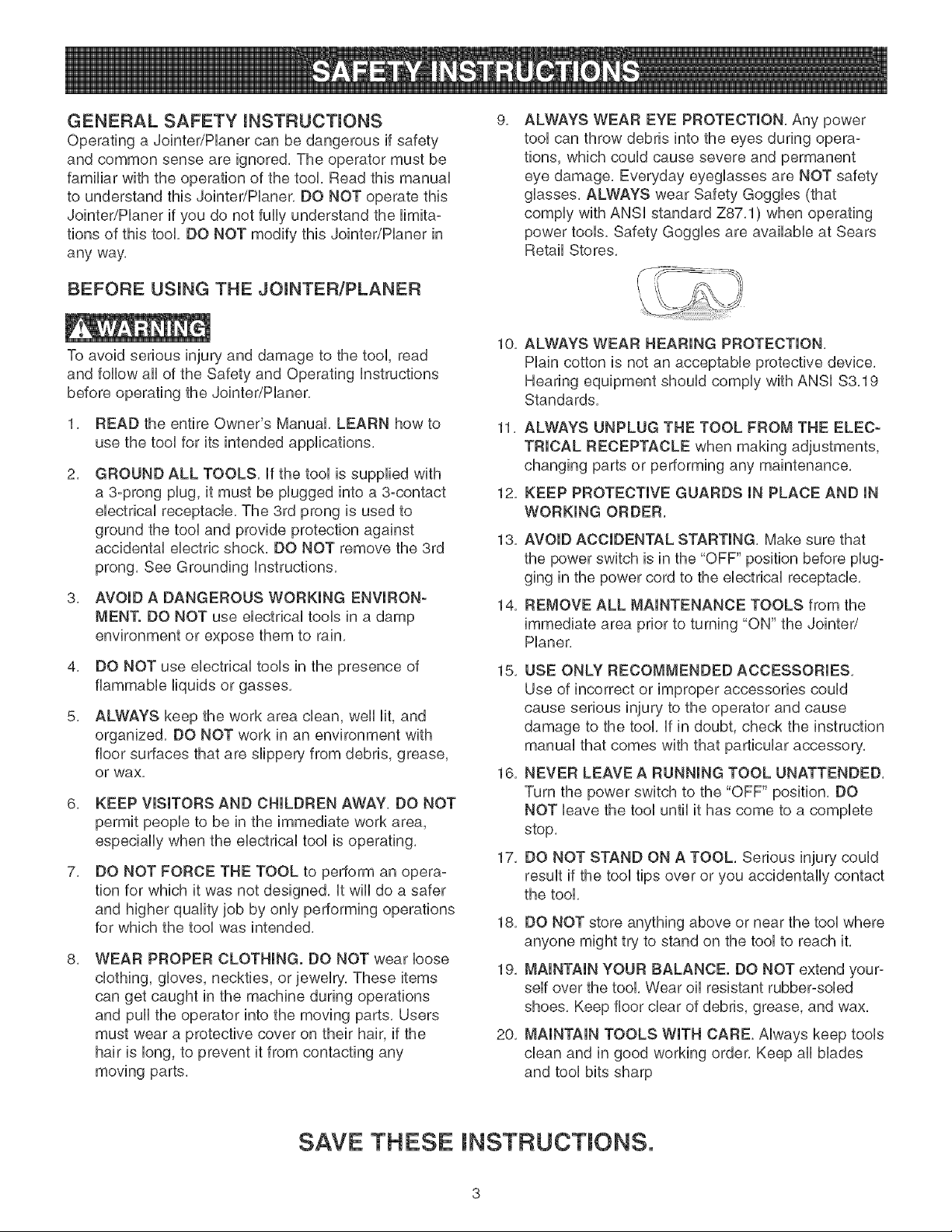

GENERAL SAFETY INSTRUCTmONS

Operating a Jointer/Haner can be dangerous if safety

and common sense are ignored, The operator must be

familiar with the operation of the tool Read this manuaU

to understand this Jointer/Haner, DO NOT operate this

Jointer/Haner if you do not fully understand the Hmita-

tions of this tool DO NOT modify this Jointer/Haner in

any way,

BEFORE USUNG THE JOINTER/PLANER

To avoid serious injury and damage to the tool, read

and follow all of the Safety and Operating Instructions

before operating the Jointer/Haner,

READ the entire Owner's Manual, LEARN how to

use the tool for its intended applications,

2,

GROUND ALL TOOLS, If the tool is supplied with

a 3-prong plug, it must be plugged into a 3-contact

electrical receptacle, The 3rd prong is used to

ground the tool and provide protection against

accidental electric shock, DO NOT remove the 3rd

prong, See Grounding Instructions,

3,

AVOID A DANGEROUS WORKING ENVIRON-

MENT. DO NOT use electrical tools in a damp

environment or expose them to rain,

4,

DO NOT use electrical tools in the presence of

flammable liquids or sasses,

5,

ALWAYS keep the work area clean, well lit, and

organized, DO NOT work in an environment with

floor surfaces that are slippery from debris, grease,

or wax,

6,

KEEP VISITORS AND CHILDREN AWAY, DO NOT

permit people to be in the immediate work area,

especially when the electrical tool is operating,

7,

DO NOT FORCE THE TOOL to perform an opera°

tion for which it was not designed, It will do a safer

and higher quality job by only performing operations

for which the tool was intended,

8, WEAR PROPER CLOTHING. DO NOT wear loose

clothing, gloves, neckties, or jewelry, These items

can get caught in the machine during operations

and pull the operator into the moving parts, Users

must wear a protective cover on their hair, if the

hair is long, to prevent it from contacting any

moving parts,

9,

ALWAYS WEAR EYE PROTECTION, Any power

tooUcan throw debris into the eyes during opera-

tions, which couUdcause severe and permanent

eye damage, Everyday eyegUasses are NOT safety

gUasses,ALWAYS wear Safety Goggbs (that

compUy with ANSi standard Z87,1) when operating

power toob, Safety Goggbs are avaHabb at Sears

Retail Stores,

10,

ALWAYS WEAR HEARING PROTECTION,

Plain cotton is not an acceptable protective device,

Hearing equipment should comply with ANSI $3,19

Standards,

11,

ALWAYS UNPLUG THE TOOL FROM THE ELEC-

TRICAL RECEPTACLE when making adjustments,

changing parts or performing any maintenance,

12,

KEEP PROTECTIVE GUARDS IN PLACE AND IN

WORKING ORDER,

13,

AVOID ACCIDENTAL STARTING, Make sure that

the power switch is in the "OFF" position before plugo

gins in the power cord to the electrical receptacle,

14,

REMOVE ALL MAINTENANCE TOOLS from the

immediate area prior to turning "ON" the Jointed

Planer,

15, USE ONLY RECOMMENDED ACCESSORIES,

Use of incorrect or improper accessories could

cause serious injury to the operator and cause

damage to the tool, If in doubt, check the instruction

manual that comes with that particular accessory,

16, NEVER LEAVE A RUNNING TOOL UNATTENDED,

Turn the power switch to the "OFF" position, DO

NOT leave the tool until it has come to a complete

stop,

17, DO NOT STAND ON A TOOL, Serious injury could

result if the tool tips over or you accidentally contact

the tool,

18, DO NOT store anything above or near the tool where

anyone might try to stand on the tool to reach it,

19, MAINTAIN YOUR BALANCE. DO NOT extend your°

self over the tool, Wear oil resistant rubber-soled

shoes, Keep floor clear of debris, grease, and wax,

20, MAINTAIN TOOLS WITH CARE, Always keep tools

clean and in good working order, Keep all blades

and tool bits sharp

SAVE THESE INSTRUCTIONS.

21.

EACH AND EVERY TmME,CHECK FOR DAM-

AGED PARTS PRmORTO USmNGTHE TOOL.

Carefully check aHguards to see that they operate

properUy,are not damaged, and perform their

intended functions. Check for alignment, binding or

breaking of moving parts. A guard or other part that

is damaged shouUd be immediateUy repaired or

repUaced.

22. CHILDPROOF THE WORKSHOP AREA by remov-

ing switch keys, unplugging tools from the electrical

receptacles, and using padlocks.

23, DO NOT OPERATE TOOLS IF UNDER THE

INFLUENCE OF DRUGS OR ALCOHOL.

24. SECURE ALL WORK. When it is possible, use

clamps or jigs to secure the workpiece. This is safer

than attempting to hold the workpiece with your

hands.

25, STAY ALERT, WATCH WHAT YOU ARE DOING,

AND USE COMMON SENSE WHEN OPERATING

A POWER TOOL. DO NOT USE A TOOL WHILE

TIRED OR UNDER THE INFLUENCE OF DRUGS,

ALCOHOL, OR MEDmCATmON,A moment of inat-

tention while operating power tooUsmay resuUtin

serious personaU injury.

26, ALWAYS WEAR A DUST MASK TO PREVENT

INHALING DANGEROUS DUST OR AIRBORNE

PARTICLES, including wood dust, crystalline sHba

dust and asbestos dust, Direct particles away from

face and body, Always operate tool in well ventilat-

ed area and provide for proper dust removal, Use

dust collection system wherever possible, Exposure

to the dust may cause serious and permanent res-

piratory or other injury, including silicosis (a serious

lung disease), cancer, and death, Avoid breathing

the dust, and avoid prolonged contact with dust,

Allowing dust to get into your mouth or eyes, or lay

on your skin may promote absorption of harmful

material, Always use properly fitting NIOSH/OSHA

approved respiratory protection appropriate for the

dust exposure, and wash exposed areas with soap

and water,

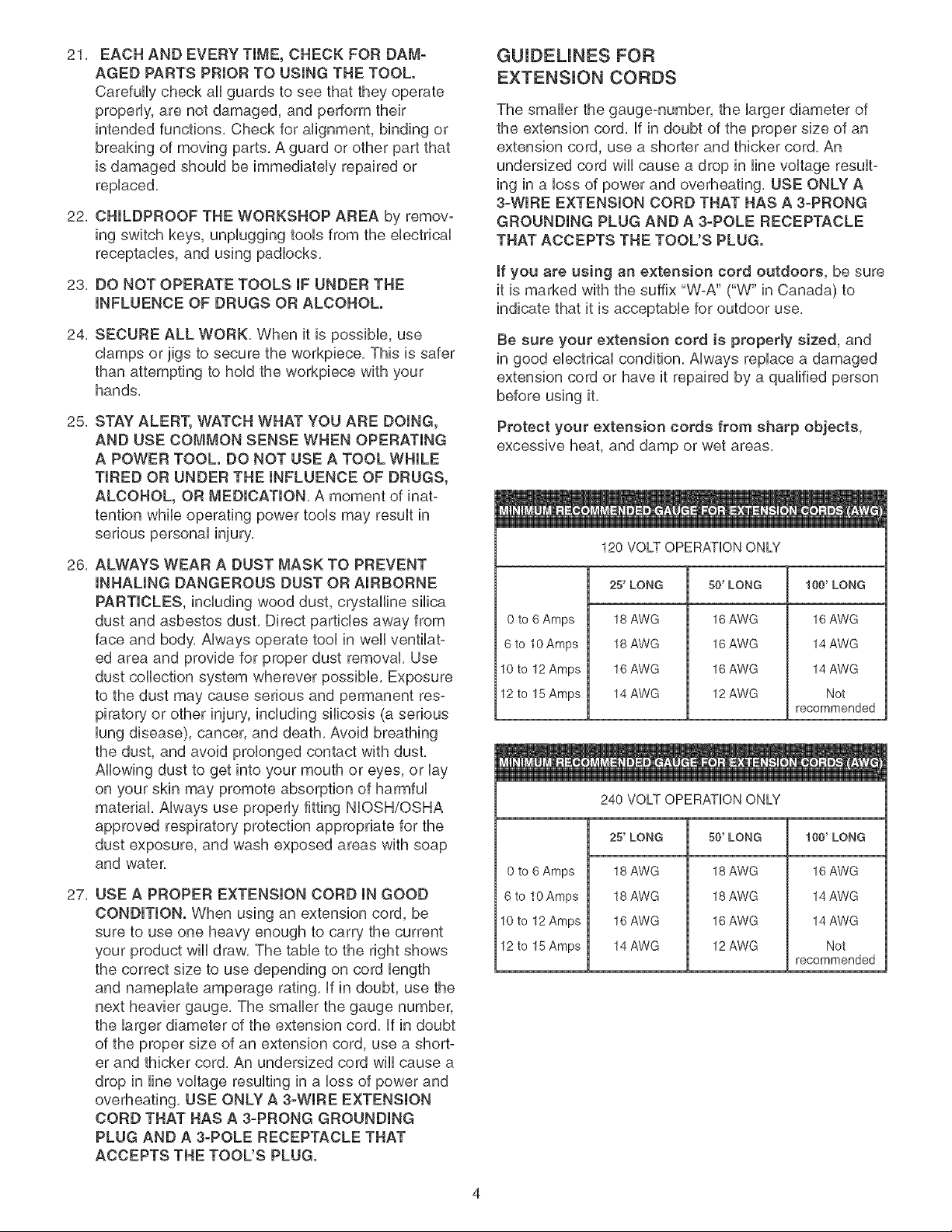

27, USE A PROPER EXTENSION CORD IN GOOD

CONDITION. When using an extension cord, be

sure to use one heavy enough to carry the current

your product will draw, The table to the right shows

the correct size to use depending on cord length

and nameplate amperage rating, if in doubt, use the

next heavier gauge. The smaller the gauge number,

the larger diameter of the extension cord. if in doubt

of the proper size of an extension cord, use a short°

er and thicker cord. An undersized cord will cause a

drop in line voltage resulting in a loss of power and

overheating, USE ONLY A 3_WIRE EXTENSION

CORD THAT HAS A 3-PRONG GROUNDING

PLUG AND A 3-POLE RECEPTACLE THAT

ACCEPTS THE TOOL'S PLUG.

GUIDEUNES FOR

EXTENSUON CORDS

The smaller the gauge-number, the larger diameter of

the extension cord, if in doubt of the proper size of an

extension cord, use a shorter and thicker cord, An

undersized cord wiii cause a drop in line voltage result-

ing in a loss of power and overheating, USE ONLY A

3-WIRE EXTENSION CORD THAT HAS A 3-PRONG

GROUNDING PLUG AND A 3-POLE RECEPTACLE

THAT ACCEPTS THE TOOL'S PLUG.

If you are using an extension cord outdoors, be sure

it is marked with the suffix "W-A" CW" in Canada) to

indicate that it is acceptable for outdoor use.

Be sure your extension cord is property sized, and

in good electrical condition. Always replace a damaged

extension cord or have it repaired by a qualified person

before using it.

Protect your extension cords from sharp objects,

excessive heat, and damp or wet areas,

120 VOLT OPERATION ONLY

25'LONG 50' LONG 100' LONG

0 to 6 Amps

6 to 10 Amps

10to 12 Amps

12 to 15 Amps

0 to 6 Amps

6 to 10 Amps

10to 12 Amps

12 to 15 Amps

18 AWG

18 AWG

16 AWG

14 AWG

240 VOLT OPERATION ONLY

25' LONG

18 AWG

18 AWG

16 AWG

14 AWG

16 AWG

16 AWG

16 AWG

12 AWG

50' LONG

18 AWG

18 AWG

16 AWG

12 AWG

16 AWG

14 AWG

14 AWG

Not

recommended

100' LONG

16 AWG

14 AWG

14 AWG

Not

recommended

THiS TOOL MUST BE GROUNDED WHILE iN USE

TO PROTECT THE OPERATOR FROM ELECTRIC

SHOCK.

iN THE EVENT OF A MALFUNCTION OR BREAK-

DOWN, grounding provides the path of bast resistance

for eUectriccurrent and reduces the risk of eUectric

shock, This tooUis equipped with an eUectric cord that

has an equipment-grounding conductor and a ground-

ing pDg, The pUugMUST be pDgged into a matching

eUectrbaUreceptacle that is properUy installed and

grounded in accordance with ALL bcaU codes and ordi-

nances,

DO NOT MODIFY THE PLUG PROVIDED. ff it wHUnot

fit the eUectrbaUreceptacb, have the proper eUectrbaU

receptacle installed by a qualified electrician,

IMPROPER ELECTRICAL CONNECTION of the equip-

ment-grounding conductor can result in risk of electric

shock, The conductor with the green insulation (with or

without yellow stripes) is the equipment-grounding

conductor, DO NOT connect the equipment-grounding

conductor to a live terminal if repair or replacement of

the electric cord or plug is necessary,

USE ONLY A 3-WIRE EXTENSION CORD THAT HAS

A 3-PRONG GROUNDING PLUG AND A 3-POLE

RECEPTACLE THAT ACCEPTS THE TOOL'S PLUG.

REPLACE A DAMAGED OR WORN CORD IMMED-

iATELY.

FOR GROUNDED, CORD-CONNECTED MACHINES

INTENDED FOR USE ON A SUPPLY CIRCUIT HAVING

A NOMINAL RATING LESS THAN 150 VOLTS.

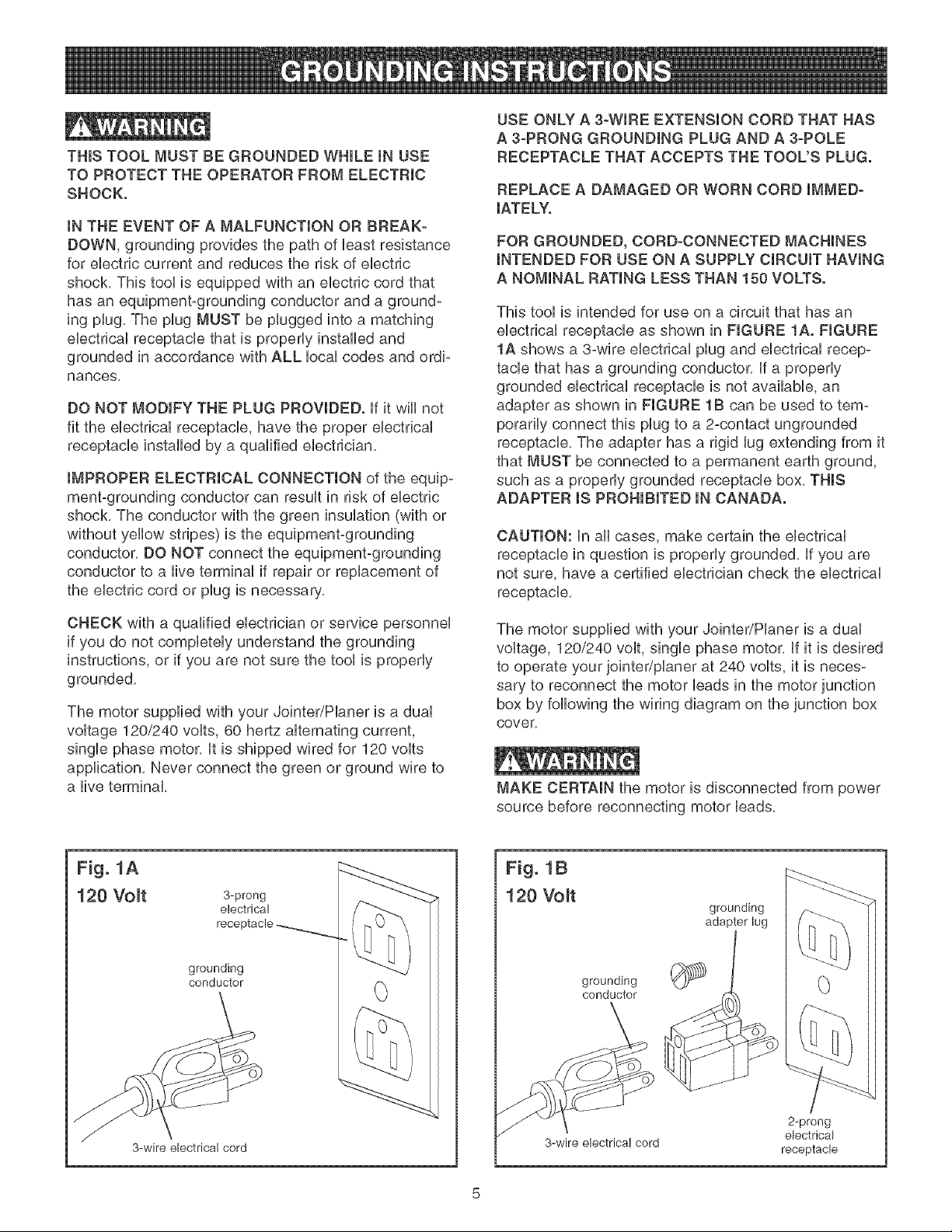

This tool is intended for use on a circuit that has an

electrical receptacle as shown in FIGURE 1A. FIGURE

1A shows a 3-wire electrical plug and electrical recep-

tacle that has a grounding conductor, if a properly

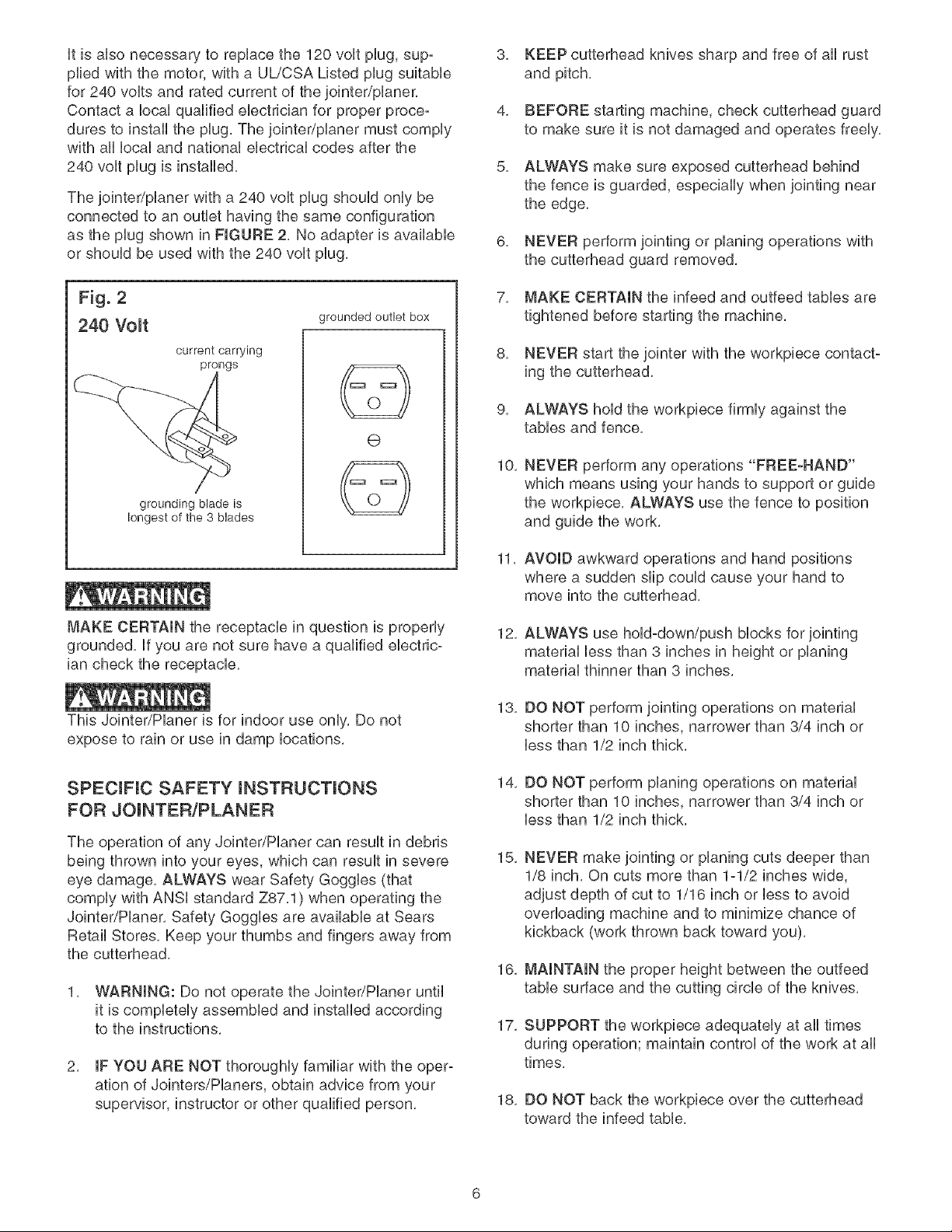

grounded electrical receptacle is not available, an

adapter as shown in FIGURE 1B can be used to tem-

porarily connect this plug to a 2-contact ungrounded

receptacle, The adapter has a rigid lug extending from it

that MUST be connected to a permanent earth ground,

such as a properly grounded receptacle box, THIS

ADAPTER IS PROHIBITED IN CANADA.

CAUTION: in all cases, make certain the electrical

receptacle in question is properly grounded, if you are

not sure, have a certified electrician check the electrical

receptacle,

CHECK with a qualified electrician or service personnel

if you do not completely understand the grounding

instructions, or if you are not sure the tool is properly

grounded,

The motor supplied with your Jointer/Planer is a dual

voltage 120/240 volts, 60 hertz alternating current,

single phase motor, it is shipped wired for 120 volts

application, Never connect the green or ground wire to

a live terminal,

Fig. 1A

120 Volt 3-prong

electrical

receptacle

grounding

conductor

The motor supplied with your Jointer/Planer is a dual

voltage, 120/240 volt, single phase motor, if it is desired

to operate your jointer/planer at 240 volts, it is neces-

sary to reconnect the motor leads in the motor junction

box by following the wiring diagram on the junction box

cover,

MAKE CERTAIN the motor is disconnected from power

source before reconnecting motor leads,

Fig. 1B

120 Voff

grounding

adapter lug

grounding

conductor

0

3-wire electrical cord

3-wire electrical cord

2-prong

electrical

receptacle

it is aUsonecessary to repUacethe 120 voUtpUug,sup-

plied with the motor, with a UL/CSA Listed pUugsuitabb

for 240 voUtsand rated current of the jointer/pUaner,

Contact a bcaU qualified eUectdcian for proper proce-

dures to install the pUug,The jointer/pUaner must compUy

with aHbcaUand nationaU eUectdcaUcodes after the

240 voUtpUugis installed,

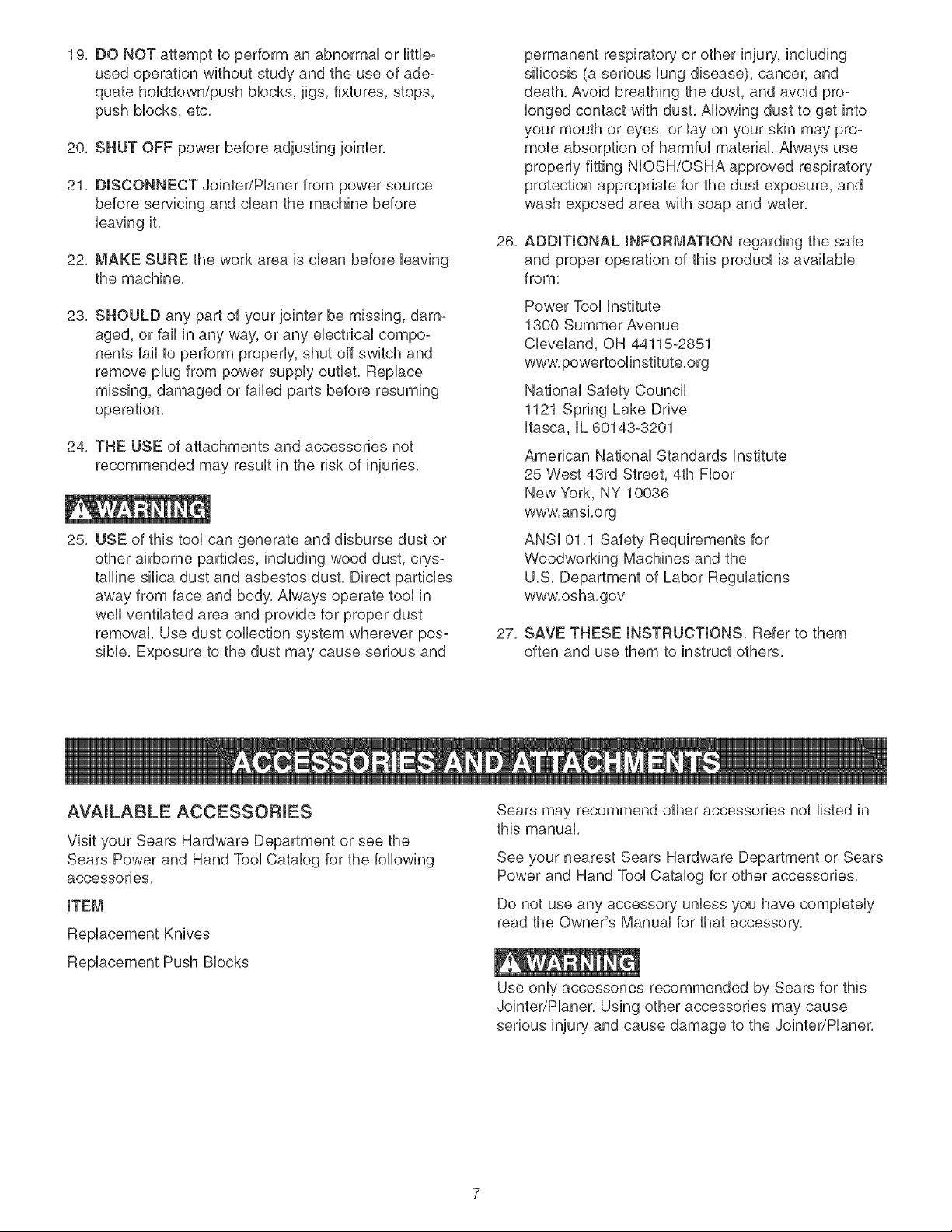

The jointer/planer with a 240 volt plug should only be

connected to an outlet having the same configuration

as the plug shown in FmGURE2, No adapter is available

or should be used with the 240 volt plug,

Fig. 2

240 Volt

current carMng

prongs

grounding blade is

longest of the 3 blades

grounded outlet box

6)

3,

KEEP cutterhead knives sharp and free of all rust

and pitch,

4,

BEFORE starting machine, check cutterhead guard

to make sure it is not damaged and operates freely,

5,

ALWAYS make sure exposed cutterhead behind

the fence is guarded, especially when jointing near

the edge,

6,

NEVER perform jointing or planing operations with

the cutterhead guard removed,

7,

MAKE CERTAIN the infeed and outfeed tables are

tightened before starting the machine,

8,

NEVER start the jointer with the workpiece contact-

ing the cutterhead,

9,

ALWAYS hold the workpiece firmly against the

tables and fence,

10,

NEVER perform any operations "FREE-HAND"

which means using your hands to support or guide

the workpiece, ALWAYS use the fence to position

and guide the work,

MAKE CERTAIN the receptacle in question is properly

grounded, if you are not sure have a qualified electric-

ian check the receptacle,

This Jointer/Planer is for indoor use only, Do not

expose to rain or use in damp locations,

SPECIFIC SAFETY iNSTRUCTiONS

FOR JOINTER/PLANER

The operation of any Jointer/Planer can result in debris

being thrown into your eyes, which can result in severe

eye damage, ALWAYS wear Safety Goggles (that

comply with ANSi standard Z87,1 ) when operating the

Jointer/Planer, Safety Goggles are available at Sears

Retail Stores, Keep your thumbs and fingers away from

the cutterhead,

1, WARNING: Do not operate the Jointer/Planer until

it is completely assembled and installed according

to the instructions,

2, IF YOU ARE NOT thoroughly familiar with the oper-

ation of Jointers/Pianers, obtain advice from your

supervisor, instructor or other qualified person,

11,

AVOID awkward operations and hand positions

where a sudden slip could cause your hand to

move into the cutterhead,

12,

ALWAYS use hold-down/push blocks for jointing

material less than 3 inches in height or planing

material thinner than 3 inches,

13,

DO NOT perform jointing operations on material

shorter than 10 inches, narrower than 3/4 inch or

less than 1/2 inch thick,

14,

DO NOT perform planing operations on material

shorter than 10 inches, narrower than 3/4 inch or

less than 1/2 inch thick,

15,

NEVER make jointing or planing cuts deeper than

1/8 inch, On cuts more than 1-1/2 inches wide,

adjust depth of cut to 1/16 inch or less to avoid

overloading machine and to minimize chance of

kickback (work thrown back toward you),

16,

MAINTAIN the proper height between the outfeed

table surface and the cutting circle of the knives,

17,

SUPPORT the workpiece adequately at all times

during operation; maintain control of the work at all

times,

18,

DO NOT back the workpiece over the cutterhead

toward the infeed table,

19,DONOTattemptto performanabnormalorlittle-

usedoperationwithoutstudyandtheuseofade-

quateholddown/pushblocks,jigs,fixtures,stops,

pushblocks,etc,

20,SHUTOFFpowerbeforeadjustingjointer,

21,DISCONNECTJointer/Hanerfrompowersource

beforeservicinganddeanthemachinebefore

havingit,

22,MAKESUREtheworkareaiscleanbeforehaving

themachine,

permanentrespiratoryorotherinjury,including

silicosis(aseriouslungdisease),cancer,and

death.Avoidbreathingthedust,andavoidpro-

longedcontactwithdust.Allowingdustto getinto

yourmouthoreyes,orlayonyourskinmaypro-

moteabsorptionofharmfulmaterial.Alwaysuse

properlyfittingNIOSH/OSHAapprovedrespiratory

protectionappropriateforthedustexposure,and

washexposedareawithsoapandwater.

26.

ADDITIONALINFORMATIONregardingthesafe

andproperoperationofthisproductisavailable

from:

23,SHOULDanypartofyourjointerbemissing,dam-

aged,orfailinanyway,oranyebctdcalcompo-

nentsfailtoperformproperly,shutoffswitchand

removeplugfrompowersupplyoutbt,Replace

missing,damagedorfaibdpartsbeforeresuming

operation,

24.THEUSEofattachmentsandaccessoriesnot

recommendedmayresultintheriskofinjuries.

25,USEofthistoolcangenerateanddisbursedustor

otherairborneparticles,includingwooddust,crys-

tallinesilicadustandasbestosdust,Directparticles

awayfromfaceandbody,Alwaysoperatetoolin

wellventilatedareaandprovideforproperdust

removal,Usedustcollectionsystemwhereverpos-

sibb,Exposuretothedustmaycauseseriousand

PowerToolinstitute

1300SummerAvenue

Cleveland,OH44115-2851

www.powertoolinstitute.org

NationalSafetyCouncil

1121SpringLakeDrive

Itasca,IL60143-3201

AmericanNationalStandardsinstitute

25West43rdStreet,4thFloor

NewYork,NY10036

www.ansi.org

ANSi01.1SafetyRequirementsfor

WoodworkingMachinesandthe

U.S.DepartmentofLaborRegulations

www.osha.gov

27,SAVETHESEINSTRUCTIONS,Refertothem

oftenandusethemtoinstructothers,

AVAILABLE ACCESSORIES

Visit your Sears Hardware Department or see the

Sears Power and Hand Tool Catalog for the following

accessories.

ITEM

Replacement Push Blocks

Sears may recommend other accessories not listed in

this manual.

See your nearest Sears Hardware Department or Sears

Power and Hand Tool Catalog for other accessories.

Do not use any accessory unless you have completely

read the Owner's Manual for that accessory.

Use only accessories recommended by Sears for this

Jointer/Planer. Using other accessories may cause

serious injury and cause damage to the Jointer/Planer.

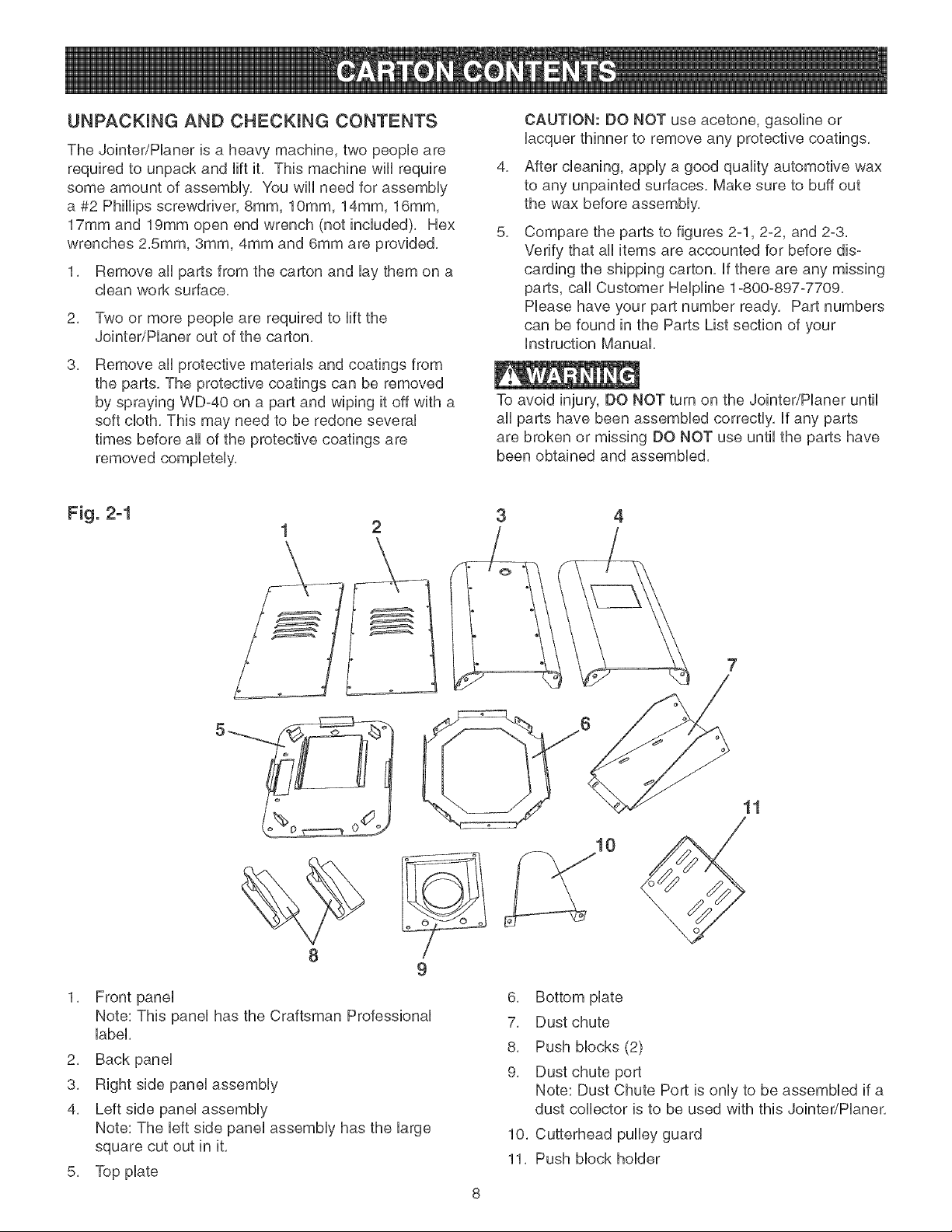

UNPACKUNG AND CHECKUNG CONTENTS

The Jointer/Haner is a heavy machine, two peopb are

required to unpack and lift it, This machine will require

some amount of assembly, You will need for assembly

a #2 Phillips screwdriver, 8mm, lOmm, 14mm, 16mm,

17mm and 19mm open end wrench (not included), Hex

wrenches 2,5mm, 3mm, 4mm and 6mm are provided,

1, Remove all parts from the carton and lay them on a

clean work surface,

2, Two or more people are required to lift the

Jointer/Planer out of the carton,

3,

Remove all protective materials and coatings from

the parts, The protective coatings can be removed

by spraying WD-40 on a part and wiping it off with a

soft cloth, This may need to be redone several

times before all of the protective coatings are

removed completely,

CAUTION: DO NOT use acetone, gasoline or

lacquer thinner to remove any protective coatings,

4,

After cleaning, apply a good quality automotive wax

to any unpainted surfaces, Make sure to buff out

the wax before assembly,

5,

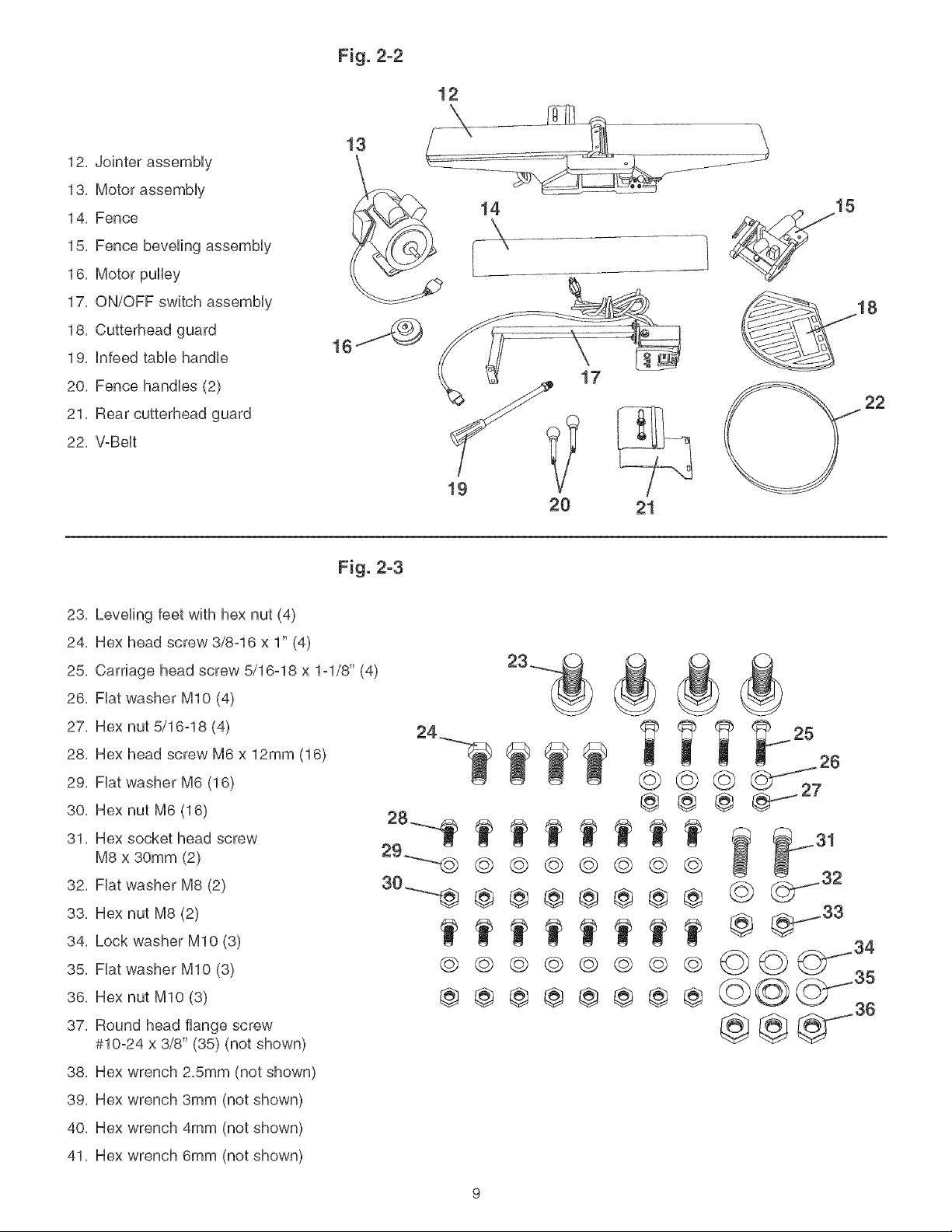

Compare the parts to figures 2-1,2°2, and 2-3,

Verify that all items are accounted for before dis-

carding the shipping carton, if there are any missing

parts, call Customer Helpline 1-800-897°7709,

Please have your part number ready, Part numbers

can be found in the Parts List section of your

instruction Manual,

To avoid injury, DO NOT turn on the Jointer/Planer until

all parts have been assembled correctly, if any parts

are broken or missing DO NOT use until the parts have

been obtained and assembled,

Fig. 2-1

2

3 4

11

10

1, Front panel

Note: This panel has the Craftsman Professional

label,

2, Back panel

3, Right side panel assembly

4, Left side panel assembly

Note: The left side panel assembly has the large

square cut out in it,

5, Top plate

9

6, Bottom plate

7, Dust chute

8, Push blocks (2)

9, Dust chute port

Note: Dust Chute Port is only to be assembled if a

dust collector is to be used with this Jointer/Planer,

10, Cutterhead pulley guard

11, Push block holder

12,Jointerassembly

13,Motorassembly

14,Fence

15,Fencebevelingassembly

16,Motorpulley

17,ON/OFFswitchassembly

18,Cutterheadguard

19,Infeedtablehandle

20,Fencehandles(2)

21,Rearcutterheadguard

22,V-Belt

Fig. 2-2

12

18

17

22

20 21

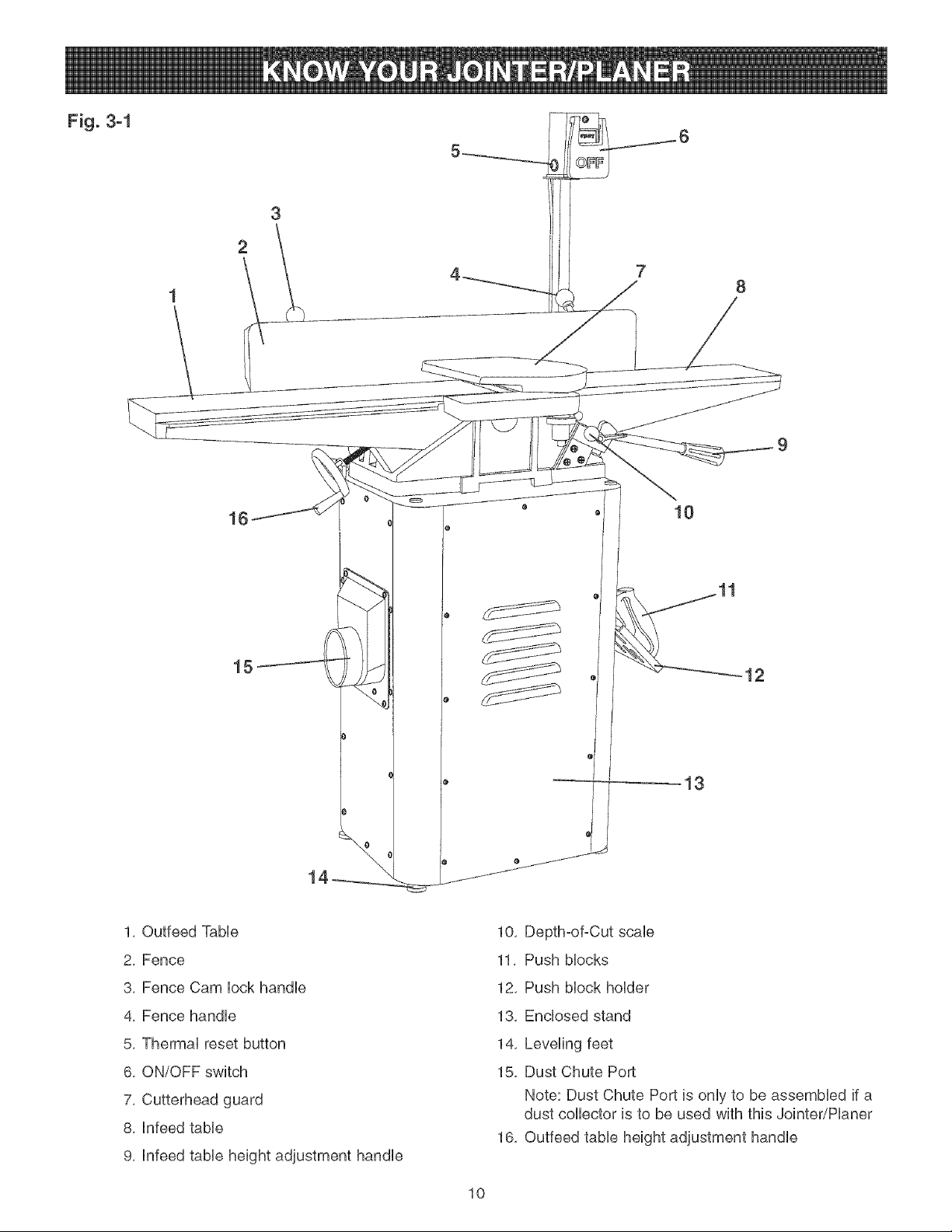

Fig. 2-3

23, Leveling feet with hex nut (4)

24, Hex head screw 3/8-16 x 1" (4)

25, Carriage head screw 5/16o18 x 1ol/8" (4)

26, Fiat washer MIO (4)

27, Hex nut 5/16°18 (4)

28, Hex head screw M6 x 12mm (16)

29, Fiat washer M6 (16)

30, Hex nut M6 (16)

31, Hex socket head screw

M8 x 30mm (2)

32, Fiat washer M8 (2)

33, Hex nut M8 (2)

34, Lock washer MIO (3)

35, Fiat washer MIO (3)

36, Hex nut MIO (3)

37, Round head flange screw

#10o24 x 3/8" (35) (not shown)

29----m@ @

© ©

@®

@@@@

@@@@

@@@@

@@@@

@@@

@@@

@ @

@ @ (_ 32

36

@@

38, Hex wrench 2,Smm (not shown)

39, Hex wrench 3mm (not shown)

40, Hex wrench 4mm (not shown)

41, Hex wrench 6mm (not shown)

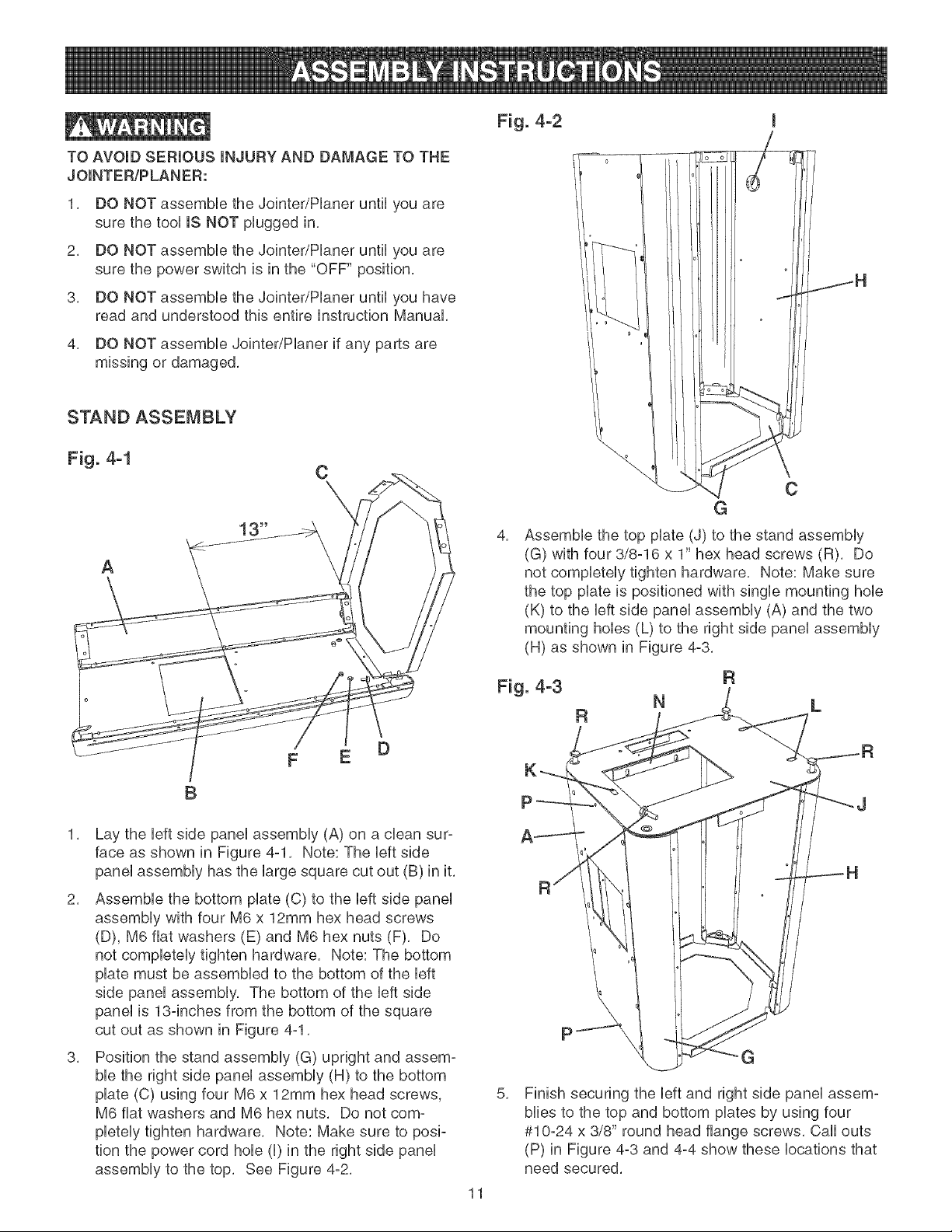

Fig. 3-1

_6

5_

3

2

7

10

1, Outfeed TaMe

2, Fence

3, Fence Cam HockhandHe

4, Fence handHe

5, ThermaH reset button

6, ON/OFF switch

7, Cutterhead guard

8, Hnfeed tame

9, Hnfeed tame height adjustment handHe

12

13

10, Depth-of-Cut scaHe

11, Push Mocks

12, Push Mock hoHder

13, EncHosed stand

14, Leveling feet

15, Dust Chute Port

Note: Dust Chute Port is onHyto be assembHed if a

dust coHHectoris to be used with this Jointer/PHaner

16, Outfeed tame height adjustment handHe

10

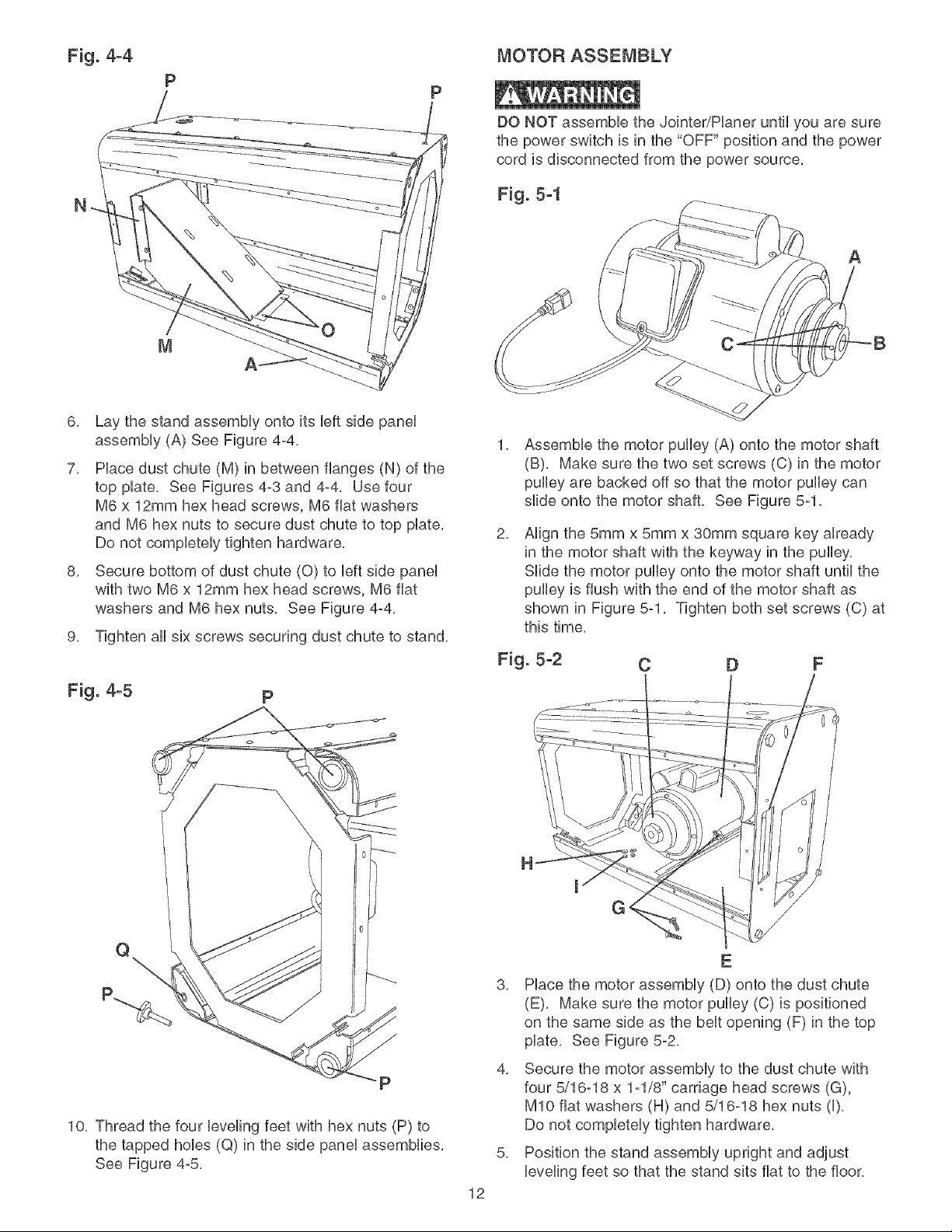

TO AVOmDSERmOUSmNJURYAND DAMAGE TO THE

JOmNTER/PLANEFt:

1, DO NOT assemble the Jointer/Planer until you are

sure the tool mSNOT plugged in,

2, DO NOT assemble the Jointer/Planer until you are

sure the power switch is in the "OFF" position,

3, DO NOT assemble the Jointer/Planer until you have

read and understood this entire instruction Manual,

4, DO NOT assemble Jointer/Planer if any parts are

missing or damaged,

C

13"

A

Fig. 4-2 I

C

G

4,

Assemble the top plate (J) to the stand assembly

(G) with four 3/8-16 x 1" hex head screws (R), Do

not completely tighten hardware, Note: Make sure

the top plate is positioned with single mounting hob

(K) to the left side panel assembly (A) and the two

mounting hobs (L) to the right side panel assembly

(H) as shown in Figure 4-3,

B

1, Lay the left side panel assembly (A) on a clean sur-

face as shown in Figure 4-1, Note: The left side

panel assembly has the large square cut out (B) in it,

2, Assemble the bottom plate (C) to the left side panel

assembly with four M6 x 12mm hex head screws

(D), M6 fiat washers (E) and M6 hex nuts (F), Do

not completely tighten hardware, Note: The bottom

plate must be assembled to the bottom of the left

side panel assembly, The bottom of the left side

panel is 13-inches from the bottom of the square

cut out as shown in Figure 4-1,

3, Position the stand assembly (G) upright and assem-

ble the right side panel assembly (H) to the bottom

plate (C) using four M6 x 12mm hex head screws,

M6 fiat washers and M6 hex nuts, Do not com-

pletely tighten hardware, Note: Make sure to posi-

tion the power cord hob (I) in the right side panel

assembly to the top, See Figure 4-2,

11

N

5,

Finish securing the left and right side panel assem-

bibs to the top and bottom plates by using four

#10-24 x 3/8" round head flange screws, Call outs

(P) in Figure 4-3 and 4-4 show these locations that

need secured,

Fig. 4-4 MOTOR ASSEMBLY

P

DO NOT assemMe the Jointer/Haner until you are sure

the power switch is in the "OFF" position and the power

cord is disconnected from the power source,

N

6, Lay the stand assemMy onto its Ueftside paneU

assemMy (A) See Figure 4-4,

7, Hace dust chute (M) in between flanges (N) of the

top pUate, See Figures 4-3 and 4-4, Use four

M6 x 12mm hex head screws, M6 fiat washers

and M6 hex nuts to secure dust chute to top pUate,

Do not compUeteUytighten hardware,

8, Secure bottom of dust chute (0) to Ueftside paneU

with two M6 x 12mm hex head screws, M6 fiat

washers and M6 hex nuts, See Figure 4-4,

1,

Assemble the motor pulley (A) onto the motor shaft

(B), Make sure the two set screws (C) in the motor

pulley are backed off so that the motor pulley can

slide onto the motor shaft, See Figure 5-1,

2,

AHgn the 5mm x 5mm x 30mm square key aUready

in the motor shaft with the keyway in the pufley,

SHde the motor pufley onto the motor shaft until the

pufley is flush with the end of the motor shaft as

shown in Figure 5-1, Tighten both set screws (C) at

this time,

9, Tighten aft six screws securing dust chute to stand,

Fig. 5-2 C D

A

Fig. 4-5 p

X\

10, Thread the four leveling feet with hex nuts (P) to

the tapped holes (Q) in the side panel assemblies,

See Figure 4-5,

12

H

E

3,

Place the motor assembly (D) onto the dust chute

(E), Make sure the motor pulley (C) is positioned

on the same side as the belt opening (F) in the top

plate, See Figure 5-2,

4,

Secure the motor assembly to the dust chute with

four 5/16-18 x 1-1/8" carriage head screws (G),

MIO flat washers (H) and 5/16-18 hex nuts (I),

Do not completely tighten hardware,

5,

Position the stand assembly upright and adjust

leveling feet so that the stand sits flat to the floor,

Fig. 5-3

L

1,

Position the Jointer/Haner (A) onto the stand (B) so

that the three studs under the jointer's base a(ign

with the three sbts in the top plate of the stand,

K

See Figure 6-1,

2,

Secure the jointer to the stand with three MIO fiat

washers, MIO bck washers and MIO hex nuts,

Note: Two of the studs in the jointer base can be

accessed inside of the stand, The third stud can

only be accessed through the dust chute opening in

the side panel Securely tighten aU hardware,

(NFEED TABLE HANDLE ASSEMBLY

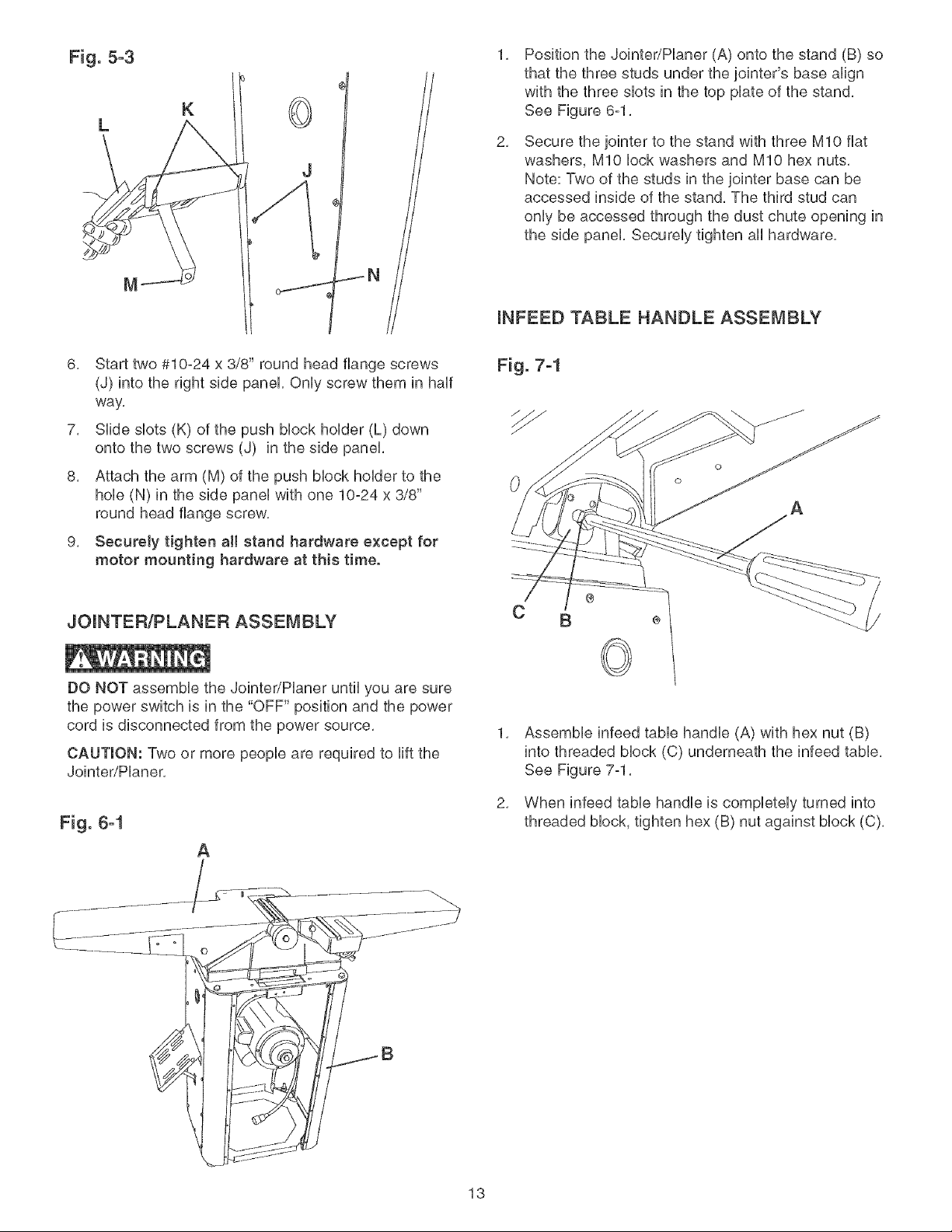

6, Start two #10-24 x 3/8" round head flange screws

(J) into the right side panel Only screw them in haft

way,

7, SHde sbts (K) of the push Mock holder (L) down

onto the two screws (J) in the side panel

8, Attach the arm (M) of the push Mock holder to the

hob (N) in the side pane( with one 10-24 x 3/8"

round head flange screw,

9, Securely tighten a)( stand hardware except for

motor mounting hardware at this time.

JO(NTER/PLANER ASSEMBLY

DO NOT assemble the Jointer/Haner until you are sure

the power switch is in the "OFF" position and the power

cord is disconnected from the power source,

CAUTION: Two or more people are required to lift the

Jointer/Haner,

Fig. 6-1

A

Fig. 7-1

@

C B ÷

©

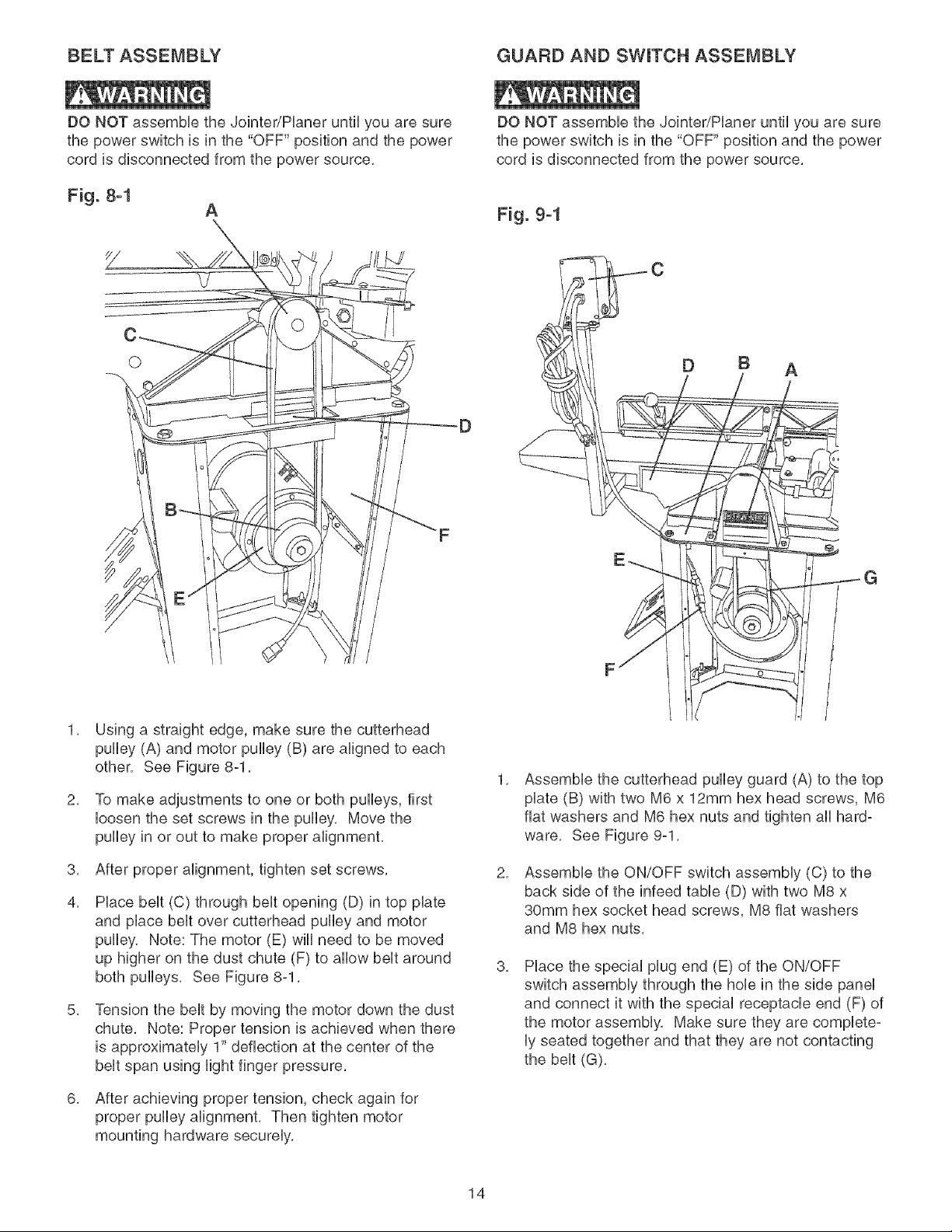

1,

Assemble infeed table handle (A) with hex nut (B)

into threaded block (C) underneath the infeed table,

See Figure 7-1,

2,

When infeed table handle is completely turned into

threaded block, tighten hex (B) nut against block (C),

13

BELT ASSEMBLY GUARD AND SWITCH ASSEMBLY

DO NOT assembb the Jointer/Haner until you are sure

the power switch is in the "OFF" position and the power

cord is disconnected from the power source,

Fig. 8-1

A

O

DO NOT assembb the Jointer/Haner until you are sure

the power switch is in the "OFF" position and the power

cord is disconnected from the power source,

Fig. 9-1

D B A

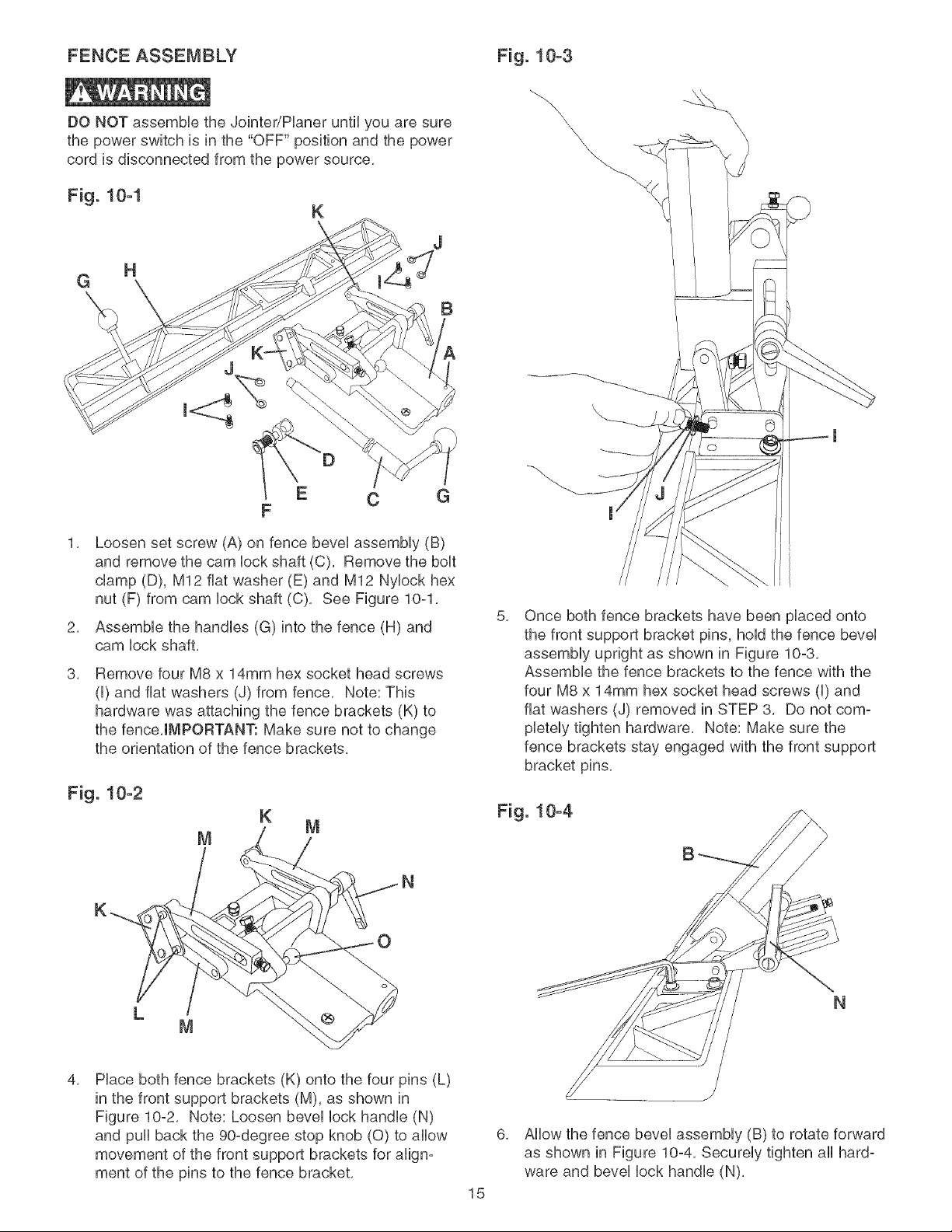

Using a straight edge, make sure the cutterhead

pulby (A) and motor pulby (B) are aligned to each

other, See Figure 8-1,

2,

To make adjustments to one or both pulbys, first

loosen the set screws in the pulby, Move the

pulby in or out to make proper alignment,

8,

After proper alignment, tighten set screws,

4,

Hace belt (C) through belt opening (D) in top plate

and place belt over cutterhead pulby and motor

pulby, Note: The motor (E) will need to be moved

up higher on the dust chute (F) to allow belt around

both pulleys, See Figure 8-1,

8,

Tension the belt by moving the motor down the dust

chute, Note: Proper tension is achieved when there

is approximately 1" deflection at the center of the

belt span using light finger pressure,

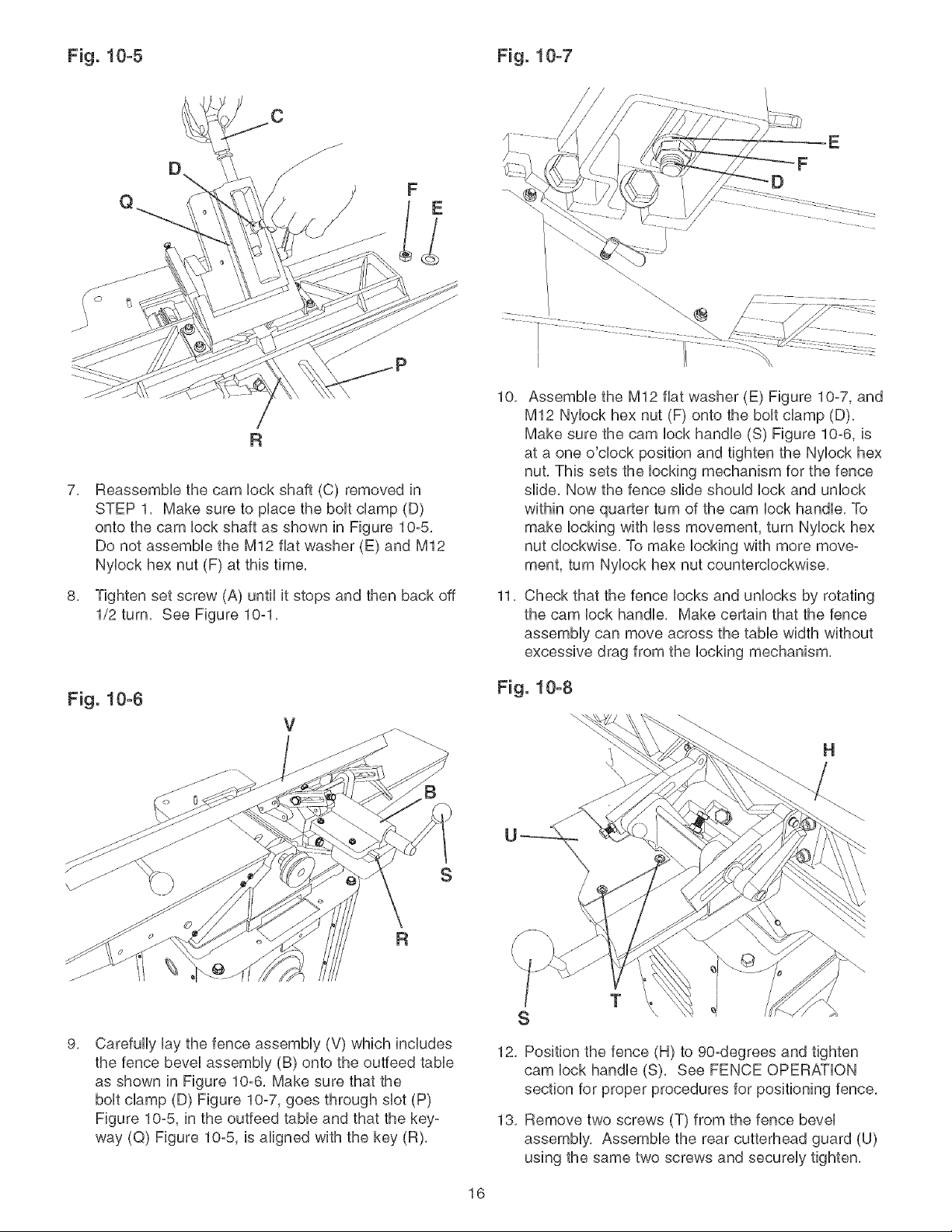

1,

Assemble the cutterhead pulley guard (A) to the top

plate (B) with two M6 x 12mm hex head screws, M6

fiat washers and M6 hex nuts and tighten all hard°

ware, See Figure 9-1,

2,

Assemble the ON/OFF switch assembly (C) to the

back side of the infeed table (D) with two M8 x

30mm hex socket head screws, M8 fiat washers

and M8 hex nuts,

8,

Place the special plug end (E) of the ON/OFF

switch assembly through the hob in the side panel

and connect it with the special receptacle end (F) of

the motor assembly, Make sure they are complete-

ly seated together and that they are not contacting

the belt (G),

G

6,

After achieving proper tension, check again for

proper pulley alignment, Then tighten motor

mounting hardware securely,

14

FENCE ASSEMBLY

DO NOT assemble the Jointer/Haner until you are sure

the power switch is in the "OFF" position and the power

cord is disconnected from the power source,

\

Fig. 10-1

K

G

H

E C G

F

Loosen set screw (A) on fence bevel assembly (B)

and remove the cam lock shaft (C), Remove the bolt

damp (D), M12 fiat washer (E) and M12 Nylock hex

nut (F) from cam lock shaft (C), See Figure 10-1,

2,

Assemble the handles (G) into the fence (H) and

cam lock shaft,

3,

Remove four M8 x 14mm hex socket head screws

(I) and fiat washers (J) from fence, Note: This

hardware was attaching the fence brackets (K) to

the fence,IMPORTANT: Make sure not to change

the orientation of the fence brackets,

J

B

5,

Once both fence brackets have been placed onto

the front support bracket pins, hold the fence bevel

assembly upright as shown in Figure 10-3,

Assemble the fence brackets to the fence with the

four M8 x 14mm hex socket head screws (I) and

fiat washers (J) removed in STEP 3, Do not com-

pletely tighten hardware, Note: Make sure the

fence brackets stay engaged with the front support

bracket pins,

Fig. 10-2

K

4,

Hace both fence brackets (K) onto the four pins (L)

in the front support brackets (M), as shown in

Figure 10-2, Note: Loosen bevel lock handle (N)

and pull back the 90-degree stop knob (0) to allow

movement of the front support brackets for align-

ment of the pins to the fence bracket,

Fig. 10-4

N

N

6,

Allow the fence bevel assembly (B) to rotate forward

as shown in Figure 10-4, Securely tighten all hard-

ware and bevel lock handle (N),

15

Fig. 10-5 Fig. 10-7

10,

Assemble the M12 fiat washer (E) Figure 10-7, and

M12 Nylock hex nut (F) onto the bolt clamp (D),

Make sure the cam lock handle (S) Figure 10-6, is

at a one o'clock position and tighten the Nyloek hex

nut, This sets the locking mechanism for the fence

7,

Reassembb the cam lock shaft (C) removed in

STEP 1, Make sure to place the bolt clamp (D)

onto the cam lock shaft as shown in Figure 10-5,

Do not assembb the M12 fiat washer (E) and M12

Nylock hex nut (F) at this time,

slide, Now the fence slide should lock and unlock

within one quarter turn of the cam lock handle, To

make locking with less movement, turn Nylock hex

nut clockwise, To make locking with more move-

ment, turn Nylock hex nut counterclockwise,

E

5,

Tighten set screw (A) until it stops and then back off

1/2 turn, See Figure 10-1,

Fig. 10-6

9,

Carefully lay the fence assembly (V) which includes

the fence bevel assembly (B) onto the outfeed table

as shown in Figure 10-6, Make sure that the

bolt clamp (D) Figure 10-7, goes through slot (P)

Figure 10-5, in the outfeed table and that the key-

way (Q) Figure 10-5, is aligned with the key (R),

11,

Check that the fence locks and unlocks by rotating

the cam lock handle, Make certain that the fence

assembly can move across the table width without

excessive drag from the locking mechanism,

Fig. 10-8

H

I

T

S

12, Position the fence (H) to 90-degrees and tighten

cam lock handle (S). See FENCE OPERATION

section for proper procedures for positioning fence,

13, Remove two screws (T) from the fence bevel

assembly, Assemble the rear cutterhead guard (U)

using the same two screws and securely tighten,

16

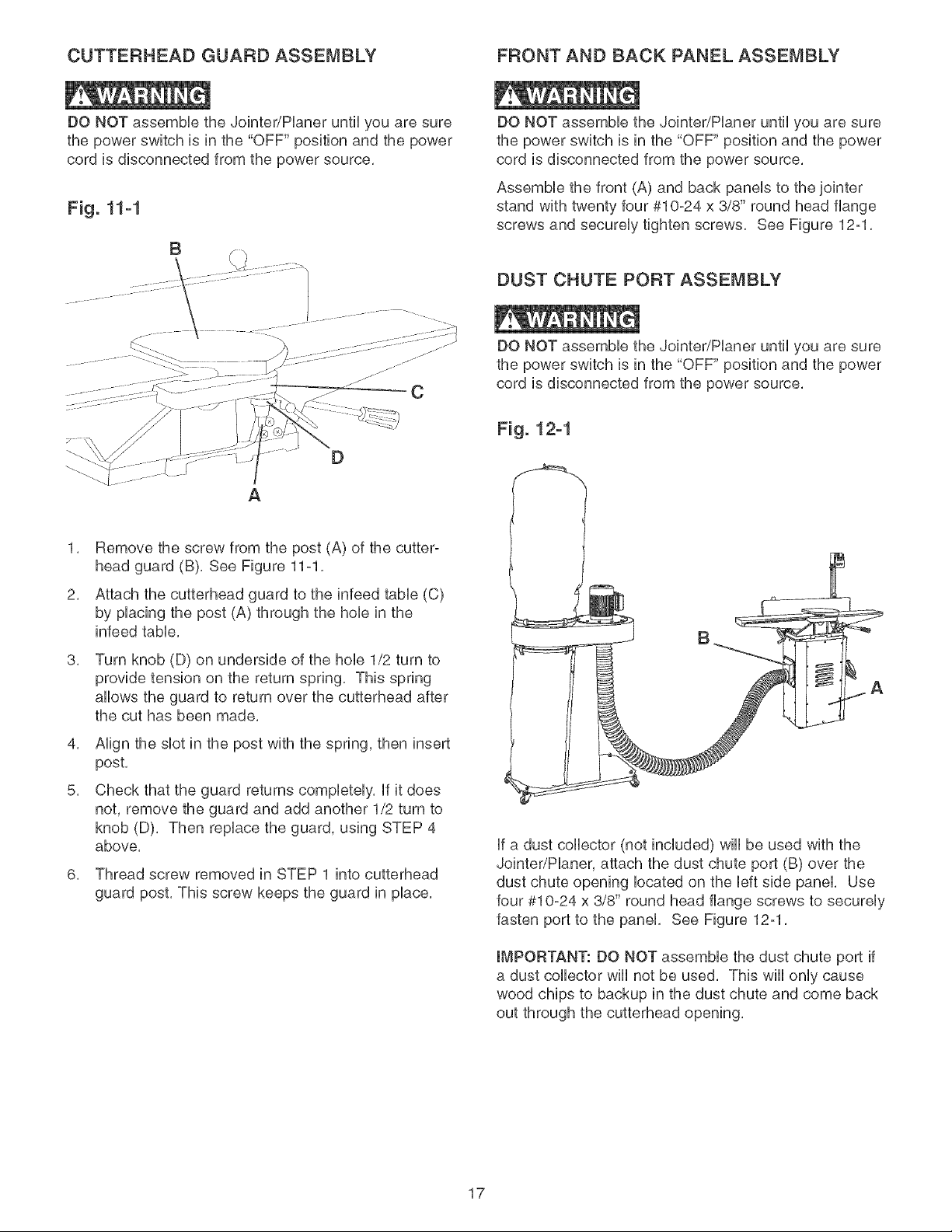

CUTTERHEAD GUARD ASSEMBLY FRONT AND BACK PANEL ASSEMBLY

DO NOT assembie the Jointer/Pianer until you are sure

the power switch is in the "OFF" position and the power

cord is disconnected from the power source,

Fig. 11-1

B

C

A

1, Remove the screw from the post (A) of the cutter-

head guard (B), See Figure 11-1,

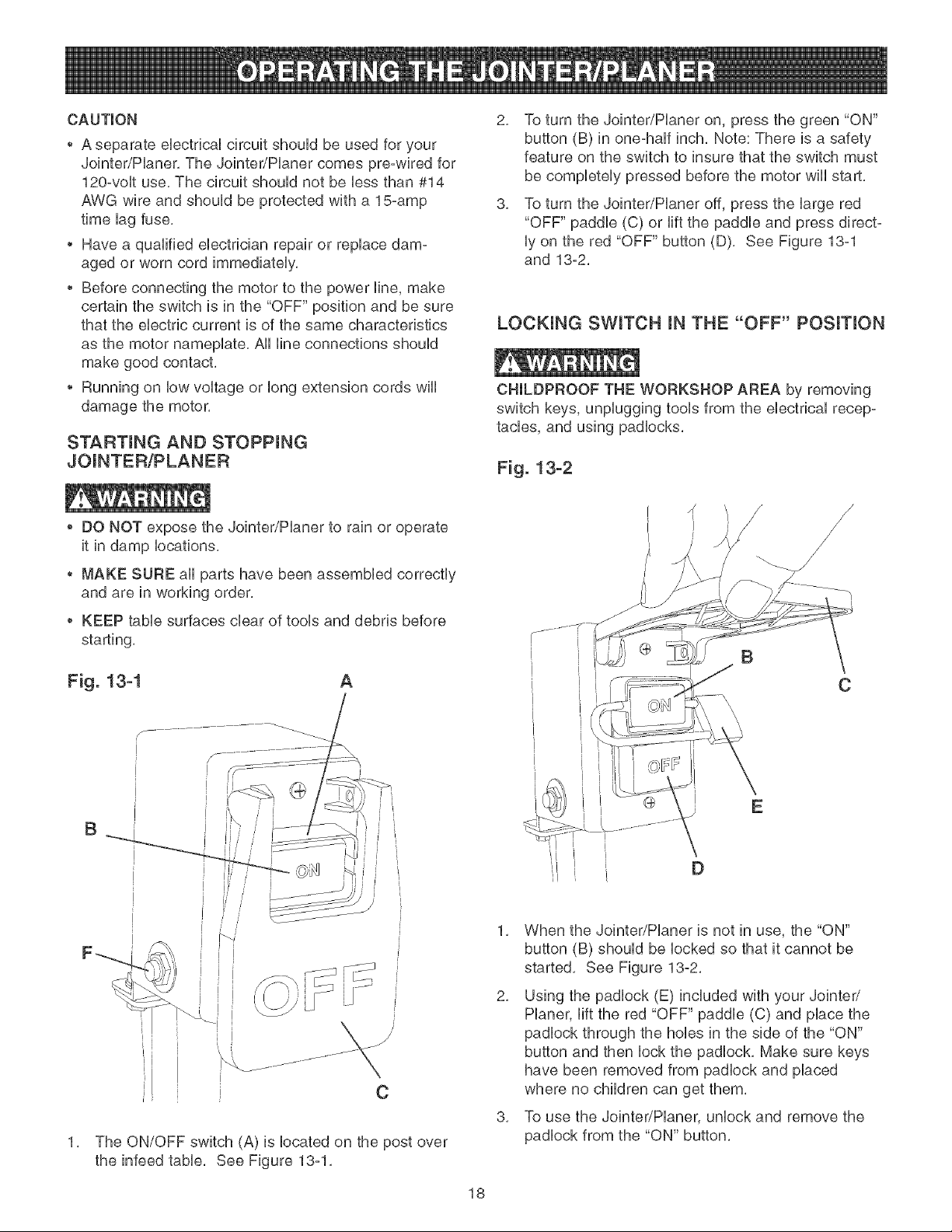

DO NOT assembie the Jointer/Pianer until you are sure

the power switch is in the "OFF" position and the power

cord is disconnected from the power source,

Assembie the front (A) and back paneis to the jointer

stand with twenty four #10-24 x 3/8" round head flange

screws and secureiy tighten screws, See Figure 12-1,

DUST CHUTE PORT ASSEMBLY

DO NOT assembie the Jointer/Pianer until you are sure

the power switch is in the "OFF" position and the power

cord is disconnected from the power source,

Fig. 12-1

2, Attach the cutterhead guard to the infeed tame (C)

by piacing the post (A) through the hob in the

infeed tame,

3,

Turn knob (D) on underside of the hob 1/2 turn to

provide tension on the return spring, This spring

allows the guard to return over the cutterhead after

the cut has been made,

4, Align the slot in the post with the spring, then insert

post,

5, Check that the guard returns completely, if it does

not, remove the guard and add another 1/2 turn to

knob (D), Then replace the guard, using STEP 4

above,

6, Thread screw removed in STEP 1 into cutterhead

guard post, This screw keeps the guard in place,

B

if a dust collector (not included) wiii be used with the

Jointer/Planer, attach the dust chute port (B) over the

dust chute opening located on the left side panel, Use

four #10-24 x 3/8" round head flange screws to securely

fasten port to the panel, See Figure 12-1,

IMPORTANT: DO NOT assemble the dust chute port if

a dust collector wiii not be used, This wiii only cause

wood chips to backup in the dust chute and come back

out through the cutterhead opening,

17

CAUTION

• AseparateeUectdcaUcircuitshouUdbeusedforyour

Jointer/Haner.TheJointer/Hanercomespre-wiredfor

120-voUtuse.ThecircuitshouUdnotbeUessthan#14

AWGwireandshouUdbeprotectedwitha15-amp

timeUagfuse.

HaveaquaUifiedeUectdcianrepairorrepUacedam-

agedorworncordimmediateUy.

BeforeconnectingthemotortothepowerHne,make

certaintheswitchisinthe"OFF"positionandbesure

thattheeUectriccurrentisofthesamecharacteristics

asthemotornamepUate.AHHneconnectionsshouUd

makegoodcontact.

RunningonUowvoUtageorUongextensioncordswHU

damagethemotor.

STARTING AND STOPPING

,, DO NOT expose the Jointer/Haner to rain or operate

it in damp locations,

2. To turn the Jointer/Haner on, press the green "ON"

button (B) in one-half inch. Note: There is a safety

feature on the switch to insure that the switch must

be completely pressed before the motor will start.

3. To turn the Jointer/Haner off, press the large red

"OFF" paddle (C) or lift the paddle and press direct°

ly on the red "OFF" button (D). See Figure 13-1

and 13-2.

LOCKING SWITCH IN THE "OFF" PosmoN

CHILDPROOF THE WORKSHOP AREA by removing

switch keys, unplugging tools from the electrical recep-

tacles, and using padlocks.

Fig. 13-2

MAKE SURE all parts have been assembled correctly

and are in working order,

,, KEEP table surfaces clear of tools and debris before

starting,

Fig. 13-1 A

B

r

C

1. The ON/OFF switch (A) is located on the post over

the infeed table. See Figure 13-1.

C

E

D

1. When the Jointer/Planer is not in use, the "ON"

button (B) should be locked so that it cannot be

started. See Figure 13o2.

2. Using the padlock (E) included with your Jointeri

Planer, lift the red "OFF" paddle (C) and place the

padlock through the holes in the side of the "ON"

button and then lock the padlock. Make sure keys

have been removed from padlock and placed

where no children can get them.

3. To use the Jointer/Planer, unlock and remove the

padlock from the "ON" button.

18

Loading...

Loading...