Page 1

Manual

6-in Wheel

1/3 Horsepower (maximum developed)

1/6 Horsepower (continuous duty)

3450 R.P.M. (no load speed)

Model No.

152.211240

DER

WARNING

JS

CAUTION:

FOR YOUR OWN SAFETY; Read

and follow all of the Safety and

Operating Instructions before

Operating this Bench Grinder

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Part NooOR91510

VER. 2.07

Customer Helpline

1-800-897-7709

Please have your Model No,

and Serial No_available,

Espafiolpg. 17

Page 2

SECTION PAGE

Product Specifications ................................................................................................................................................... 2

Safety Instructions ......................................................................................................................................................... 3

Grounding Instructions ................................................................................................................................................... 4

Specific Safety instructions for Bench Grinders ........................................................................................................ 5

Accessories and Attachments ........................................................................................................................................ 6

Carton Contents ............................................................................................................................................................. 6

Know Your Bench Grinder .............................................................................................................................................. 7

Assembly Instructions ................................................................................................................................................... 8

Operating the Bench Grinder ....................................................................................................................................... 10

Maintenance .................................................................................................................................................................. 12

Troubleshooting Guide ................................................................................................................................................ 16

Parts List ....................................................................................................................................................................... 13

Service Information ...................................................................................................................................... Back Cover

FULL ONE YEAR VVARRANTY

If this product fails due to a defect in material or workmanship within one year from the date of purchase, RETURN

IT TO THE NEAREST SEARS STORE OR CRAFTSMAN OUTLET, and it will be replaced, free of charge..

This warranty gives you specific legal rights, and you may also have other rights, which vary, from state to state.

Sears, Roebuck and Co., Dept.. 817 WA, Hoffman Estates, IL 60179

Motor

Maximum HP developed

Continuous Duty HP

Volts

Hertz

RPM

Grinding Wheel Size

Grinding Wheel Grit

Lamp

Tool Rests

Eye Shield Assemblies

Spark Arrestors

'I/3

1/6

120

60

3450 RoPM.

(no toad speed)

6" x 3/4" x 1/2"

60, 36

120V, 40 watt or less Track

Light Bulb, Type R20,

medium base or equivalent

(not included)

Left and Right, Cast Iron

Clear Lexan Left and Right

Left and Right

To avoid electrical shock to yourself and damage to the

Bench Grinder, use proper circuit protection.

The Bench Grinder is factory wired for t20V, 60 Hz,

operation. Connect to a 120V, 15 amp branch circuit

and use a 15 amp time delay fuse or circuit breaker..

The electrical circuit cannot have any wire size less

than #14. To avoid shock or fire, replace power cord

immediately if it is damaged in any way..

Page 3

GENERAL SAFETY INSTRUCTIONS

Operating a Bench Grinder can be dangerous if safety

and common sense are ignored. The operator must be

familiar with the operation of the tool Read this manual

to understand this Bench Grinder.. DO NOT operate this

Bench Grinder if you do not fully understand the limita-

tions of this tool DO NOT modify this Bench Grinder in

any way°

BEFORE USING THE BENCH GRINDER

To avoid serious injury and damage to the tool, read

and follow all of the Safety and Operating instructions

before operating the Bench Grinder..

1.. Some dust created by using power tools contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Some examples of these chemicals are:

o Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

masonry products.

o Arsenic and chromium from chemically treated

lumber..

Your risk from these exposures varies, depending

on how often you do this type of work_ To reduce

your exposure to these chemicals: work in a well-

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic particles°

2.. READ the entire Owner's Manual.. LEARN how to

use the tool for its intended applications.

3,. GROUND ALL TOOLS. If the toot is supplied with

a 3-prong plug, it must be plugged into a 3-contact

electrical receptacle,. The 3rd prong is used to

ground the tool and provide protection against acci-

dental electric shock.. DO NOT remove the 3rd

prong.. See Grounding Instructions on page 4.

4., AVOID A DANGEROUS WORKING ENVIRON-

MENT. DO NOT use electrical tools in a damp

environment or expose them to rain..

5. DO NOT use electrical tools in the presence of

flammable liquids or gases..

6, ALWAYS keep the work area clean, welt lit, and

organized.. DO NOT work in an environment with

floor surfaces that are slippery from debris, grease,

and wax..

7_ KEEP VISITORS AND CHILDREN AWAY. DO NOT

permit people to be in the immediate work area,

especially when the electrical tool is operating_

DO NOT FORCE THE TOOL to perform an opera-

tion for which it was not designed. Itwill do a safer

and higher quality job by only performing operations

for which the tool was intended.

9_

WEAR PROPER CLOTHING. DO NOT wear loose

clothing, gloves, neckties, or jewelry', These items

can get caught in the machine during operations

and pul! the operator into the moving parts,. The

user must wear a protective cover on their hair, if

the hair is long, to prevent itfrom contacting any

moving parts°

10.

ALWAYS WEAR EYE PROTECTION, Any power

tool can throw debris intothe eyes during opera-

tions, which could cause severe and permanent

eye damager ALWAYS wear Safety Goggfes (that

complywith ANSI standard Z87..1) when operating

power tools,.Safety Goggles are available at Sears

Retail Stores

1t.

WEAR A DUST MASK TO PREVENT INHALING

DANGEROUS DUST OR PARTICLES,

!2o

ALWAYS UNPLUG THE TOOL FROM THE ELEC-

TRICAL RECEPTACLE when making adjustments,

changing parts or performing any maintenance._

13.

KEEP PROTECTIVE GUARDS IN PLACE AND IN

WORKING ORDER.

14

AVOID ACCIDENTAL STARTING, Make sure

that the power switch is in the "OFF" position

before piugging in the power cord to the electrical

receptacle.

15.

REMOVE ALL MAINTENANCE TOOLS from the

immediate area prior to turning "ON" the Bench

Gdnder_

16. USE ONLY RECOMMENDED ACCESSORIES,

Use of incorrect or improper accessories could

cause serious injuryto the operator and cause

damage to the tool. If in doubt, check the instruction

manual that comes with that particular accessory°

17. NEVER LEAVE A RUNNING TOOL UNATTENDED°

Turn the power switch to the "OFF" position, DO

NOT leave the too!unti_ it has come to a complete

stop°

18, DO NOT STAND ON A TOOL. Serious injurycould

result ifthe tool tips over or you accidentally contact

the tool..

19_

DO NOT store anything above or near the tool

where anyone might try to stand on the tool to

reach it..

Page 4

20 MAINTAINYOURBALANCE.DONOTextend

yourselfoverthetool.WearoilresistantpJbber-

soledshoes.Keepfloorclearofddebris,grease,

andwax

21.MAINTAIN TOOLS WITH CARE. Always keep tools

clean and in good working order Keep all blades

and tool bits sharp°

22° EACH AND EVERY TIME, CHECK FOR DAM_

AGED PARTS PRIOR TO USING THE TOOL.

Carefully check all guards to see that they operate

properly, are not damaged, and perform their

intended functions, Check for alignment, binding or

breaking of moving parts, A guard or other part that

is damaged should be immediately repaired or

replaced.

23. CHILDPROOF THE WORKSHOP AREA by remov-

ing switch keys, unplugging tools from the electrical

receptacles, and using padlocks.

24 DO NOT OPERATE TOOL IF UNDER THE IN-

FLUENCE OF DRUGS OR ALCOHOL.

25, SECURE ALL WORK. Use clamps or jigs to secure

the workpiece. This is safer than attempting to hold

the workpiece with your hands.

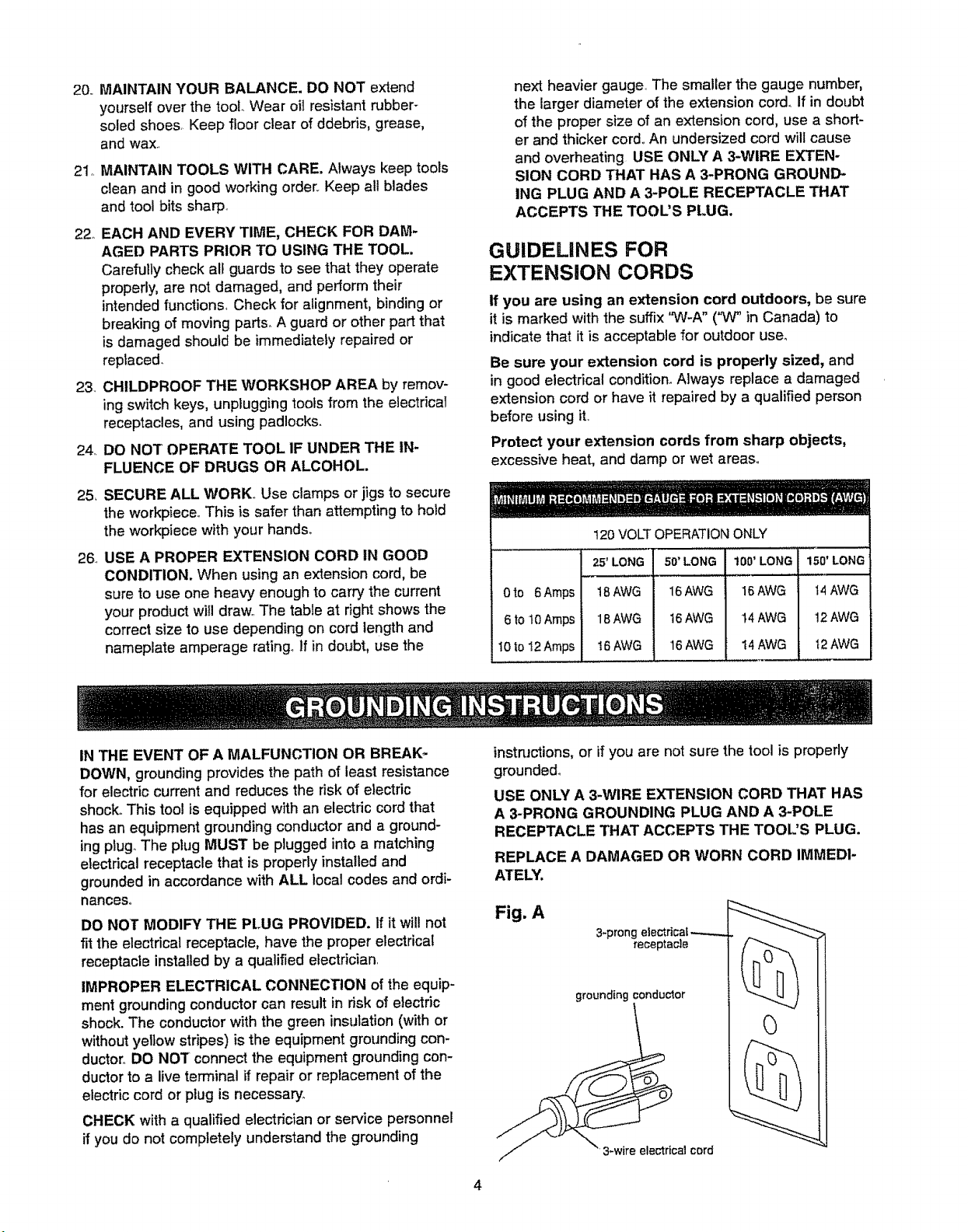

26 USE A PROPER EXTENSION CORD IN GOOD

CONDITION. When using an extension cord, be

sure to use one hearty enough to carry the current

your product will draw. The table at right shows the

correct size to use depending on cord length and

nameplate amperage rating_ If in doubt, use the

next heavier gauge The smaller the gauge number,

the larger diameter of the extension cord. If in doubt

of the proper size of an extension cord, use a short-

er and thicker cord, An undersized cord will cause

and overheating USE ONLY A 3-WIRE EXTENo

SlON CORD THAT HAS A 3-PRONG GROUND-

ING PLUG AND A 3-POLE RECEPTACLE THAT

ACCEPTS THE TOOUS PLUG.

GUIDELINES FOR

EXTENSION CORDS

If you are using an extension cord outdoors, be sure

it is marked with the suffix "W-A" ('_V'_in Canada) 1o

indicate that it is acceptable for outdoor user

Be sure your extension cord is properly sized, and

in good electrical condition_Always replace a damaged

extension cord or have it repaired by a qualified person

before using it.

Protect your extension cords from sharp objects,

excessive heat, and damp or wet areas,

120VOLTOPERATIONONLY

150'LONG

14AWG

12AWG

t2AWG

0 to 6Arnps

6to I0 Arnps

I0 to 12 Amps

25' LONG

18AWG

18AWG

t6AWG

50' LONG 100' LONG

16AWG 16AWG

16AWG 14AWG

16AWG 14AWG

IN THE EVENT OF A MALFUNCTION OR BREAK-

DOWN, groundingprovidesthe path of least resistance

for electric current and reduces the riskof electric

shock. This tool is equipped with an electric cord that

has an equipment groundingconductor and a ground-

ing plug.The plug MUST be plugged into a matching

electrical receptacle that is properlyinstalled and

grounded in accordance with ALL local codes and ordi-

nances°

DO NOT MODIFY THE PLUG PROVIDED. If it will not

fit the electrical receptacle, have the proper electrical

receptacle installed by a qualified electrician

IMPROPER ELECTRICAL CONNECTION of the equip-

ment grounding conductor can result in risk of electric

shock. The conductor with the green insulation (with or

without yellow stripes) isthe equipment grounding con-

ductor. DO NOT connect the equipment grounding con-

ductor to a live terminal if repair or replacement of the

electric cord or plug is necessary_

CHECK with a qualified electrician or service personnel

ifyou do not completely understand the grounding

instnJctions, or if you are not sure the tool is properly

grounded.

USE ONLY A 3-WIRE EXTENSION CORD THAT HAS

A 3-PRONG GROUNDING PLUG AND A 3-POLE

RECEPTACLE THAT ACCEPTS THE TOOL'S PLUG.

REPLACE A DAMAGED OR WORN CORD IMMEDI-

ATELY.

Fig. A

3-prong electdca_.--..-._

receptacle

grounding conductor

at cord

4

Page 5

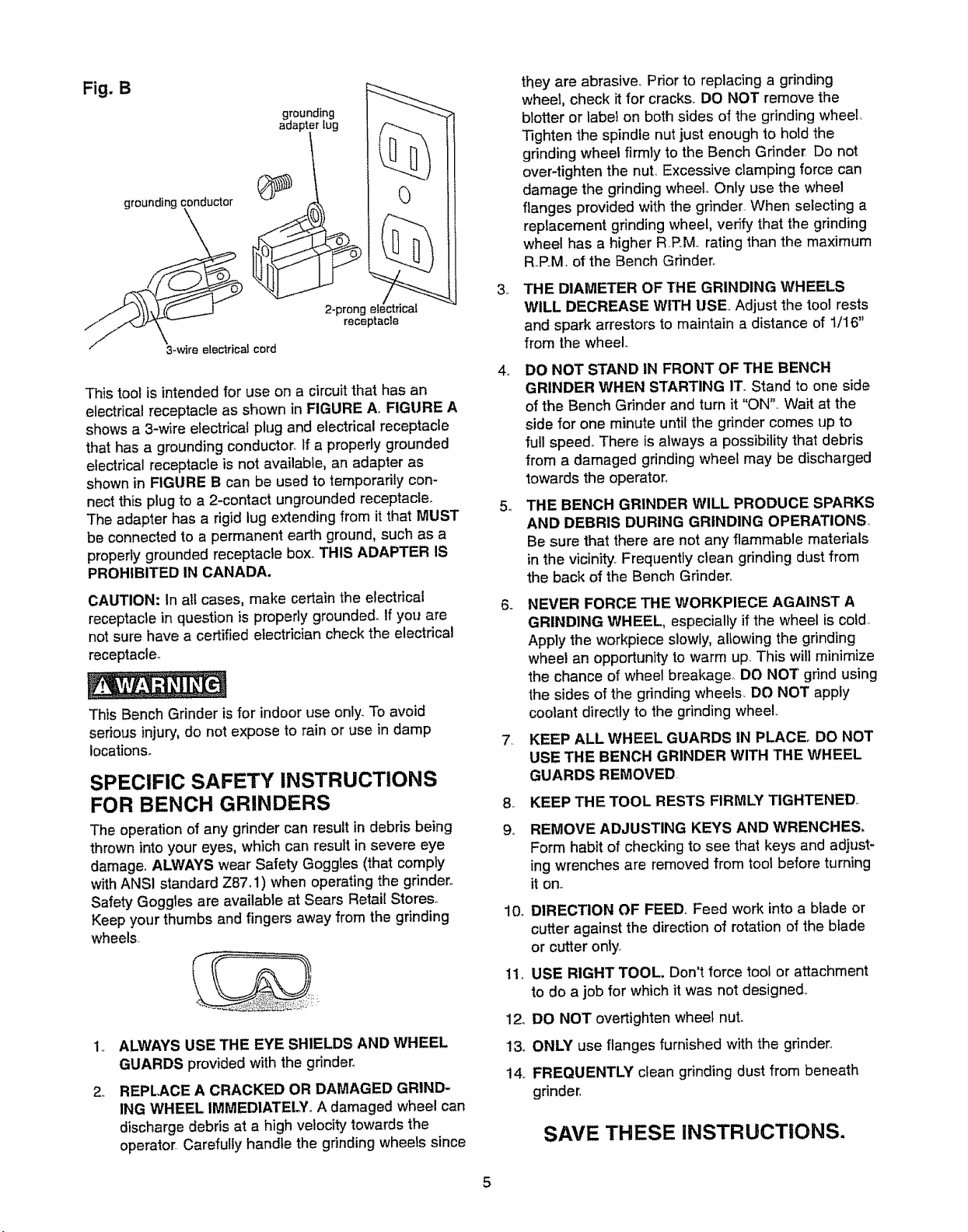

Fig. B

grounding

lug

grounding conductor

2-prong electrical

receptacle

This tool is intended for use on a circuit that has an

electrical receptacle as shown in FIGURE AmFIGURE A

shows a 3-wire electrical plug and electrical receptacle

that has a grounding conductor,, if a properly grounded

electrical receptacle is not available, an adapter as

shown in FIGURE B can be used to temporarily con-

nect this plug to a 2-contact ungrounded receptacle.

The adapter has a rigid lug extending from it that MUST

be connected to a permanent earth ground, such as a

properly grounded receptacle box,, THIS ADAPTER IS

PROHIBITED IN CANADA.

CAUTION: In all cases, make certain the electrical

receptacle in question is properly grounded° If you are

not sure have a certified electrician check the electrical

receptacle_

This Bench Grinder is for indooruse only. To avoid

serious injury, do not expose to rain or use in damp

locations=

SPECIFIC SAFETY INSTRUCTIONS

FOR BENCH GRINDERS

The operation of any grinder can result in debrisbeing

thrown intoyour eyes, which can result in severe eye

damage. ALWAYS wear Safety Goggles (that comply

with ANSI standard Z87.1) when operating the gdnder.

Safety Goggles are available at Sears Retail Stores.

Keep your thumbs and fingers away from the grinding

wheels,

ALWAYS USE THE EYE SHIELDS AND WHEEL

GUARDS provided with the grinder°

REPLACE A CRACKED OR DAMAGED GRIND-

.,

ING WHEEL IMMEDIATELY A damaged wheel can

discharge debris at a high velocity towards the

operator Carefully handle the grinding wheels since

they are abrasives, Prior to replacing a grinding

wheel, check it for cracks,, DO NOT remove the

blotter or label on both sides of the grinding wheel_

Tighten the spindle nut just enough to hold the

grinding wheel firmly to the Bench Grinder Do not

over-tighten the nut, Excessive clamping force can

damage the grinding wheel,, Only use the wheel

flanges provided with the grinder, When selecting a

replacement grinding wheel, verify that the grinding

wheel has a higher R,PM,, rating than the maximum

R_P.M,ofthe Bench Grinder°

THE DIAMETER OF THE GRINDING WHEELS

3_

WILL DECREASE WITH USE Adjust the tool rests

and spark arrestors to maintain a distance of 1/16"

from the wheel

4,, DO NOT STAND IN FRONT OF THE BENCH

GRINDER WHEN STARTING ITo Stand to one side

of the Bench Grinder and turn it "ON"., Wait at the

side for one minute until the grinder comes up to

full speed. There is always a possibility that debris

from a damaged grinding wheel may be discharged

towards the operator_

5 THE BENCH GRINDER WILL PRODUCE SPARKS

AND DEBRIS DURING GRINDING OPERATIONS

Be sure that there are not any flammable materials

in the vicinity. Frequently clean grinding dust from

the back of the Bench Grinder.

NEVER FORCE THE WORKPIECE AGAINST A

.,

GRINDING WHEEL, especially if the wheel is cold

Apply the workpiece slowly, allowing the grinding

wheel an opportunityto warm up This will minimize

the chance of wheel breakage_ DO NOT grind using

the sides of the grinding wheets_ DO NOT apply

coolant directly to the grinding wheel,,

KEEP ALL WHEEL GUARDS IN PLACE, DO NOT

7_

USE THE BENCH GRINDER WITH THE WHEEL

GUARDS REMOVED

KEEP THE TOOL RESTS FIRMLY TIGHTENED

am

REMOVE ADJUSTING KEYS AND WRENCHES.

9o

Form habit of checking to see that keys and adjust-

ing wrenches are removed from tool before turning

it on,,

10o DIRECTION OF FEED,, Feed work into a blade or

cutter against the direction of rotation of the blade

or cutter only,

1t,, USE RIGHT TOOL. Don't force tool or attachment

to do a job for which it was not designed,,

12o DO NOT overtighten wheel nut.

13,, ONLY use flanges furnished with the grinder_,

14, FREQUENTLY clean grinding dust from beneath

grinder,

SAVE THESE INSTRUCTIONS.

5

Page 6

AVAILABLE ACCESSORIES

Visit your Sears Hardware Department or see the

Sears Power and Hand Tool Catalog for the following

accessories_

ITEM

Replacement grinding wheels

Wire and Buffing wheels

Spacers

Universal stand

STOCK NUMBER

See catalog or store

See catalog or store

See catalog or store

See catalog or store

Sears may recommend other accessories not listed in

this manual.,

See your nearest Sears Hardware Department or Sears

Power and Hand Tool Catalog for other accessories,,

Do not use any accessory unless you have completely

read the Owner's Manual for that accessory.,

Use only accessories recommended for this Bench

Grinder_ Using other accessories may cause serious

injury and cause damage to the Bench Grinder.

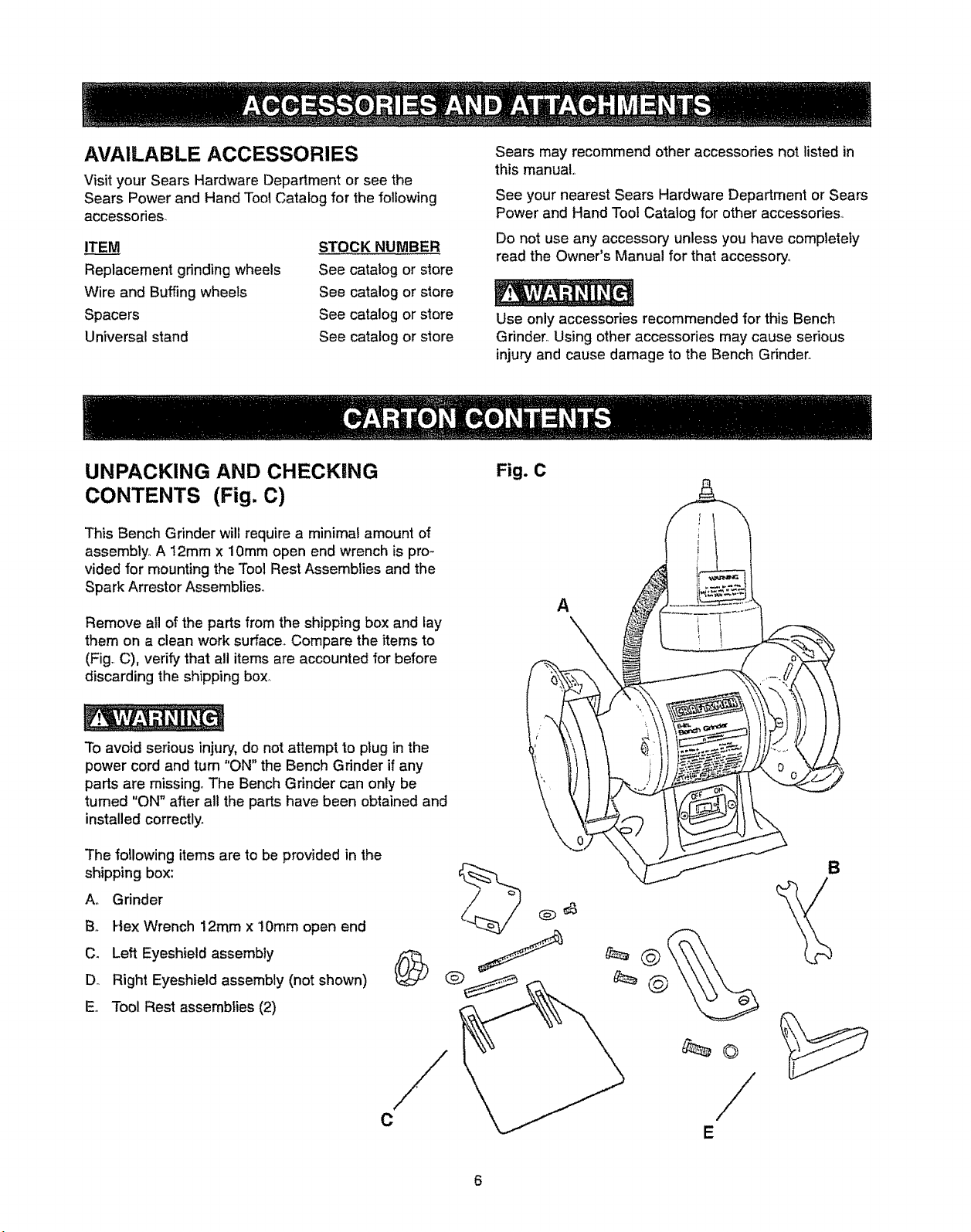

UNPACKING AND CHECKING

CONTENTS (Fig. C)

This Bench Grinder will require a minimal amount of

assembly° A 12mm x 10mm open end wrench is pro-

vided for mounting the Tool Rest Assemblies and the

Spark Arrestor Assemblies°

Remove ail of the parts from the shipping box and lay

them on a clean work surface,, Compare the items to

(Fig,,C), verify that all items are accounted for before

discarding the shipping box,.

To avoid serious injury, do not attempt to plug in the

power cord and turn "ON" the Bench Grinder if any

parts are missing. The Bench Grinder can only be

turned "ON" after all the parts have been obtained and

installed correctly.

The following items are to be provided in the

shipping box:

Am Grinder

Fig. C

A

B

B,. Hex Wrench 12ram x 'I0mm open end

C. Left Eyeshield assembly

Do Right Eyeshield assembly (not shown)

Eo Tool Rest assemblies (2)

C

Page 7

11B

10

7

15

16

5

6

8

3

11A

/

9

12

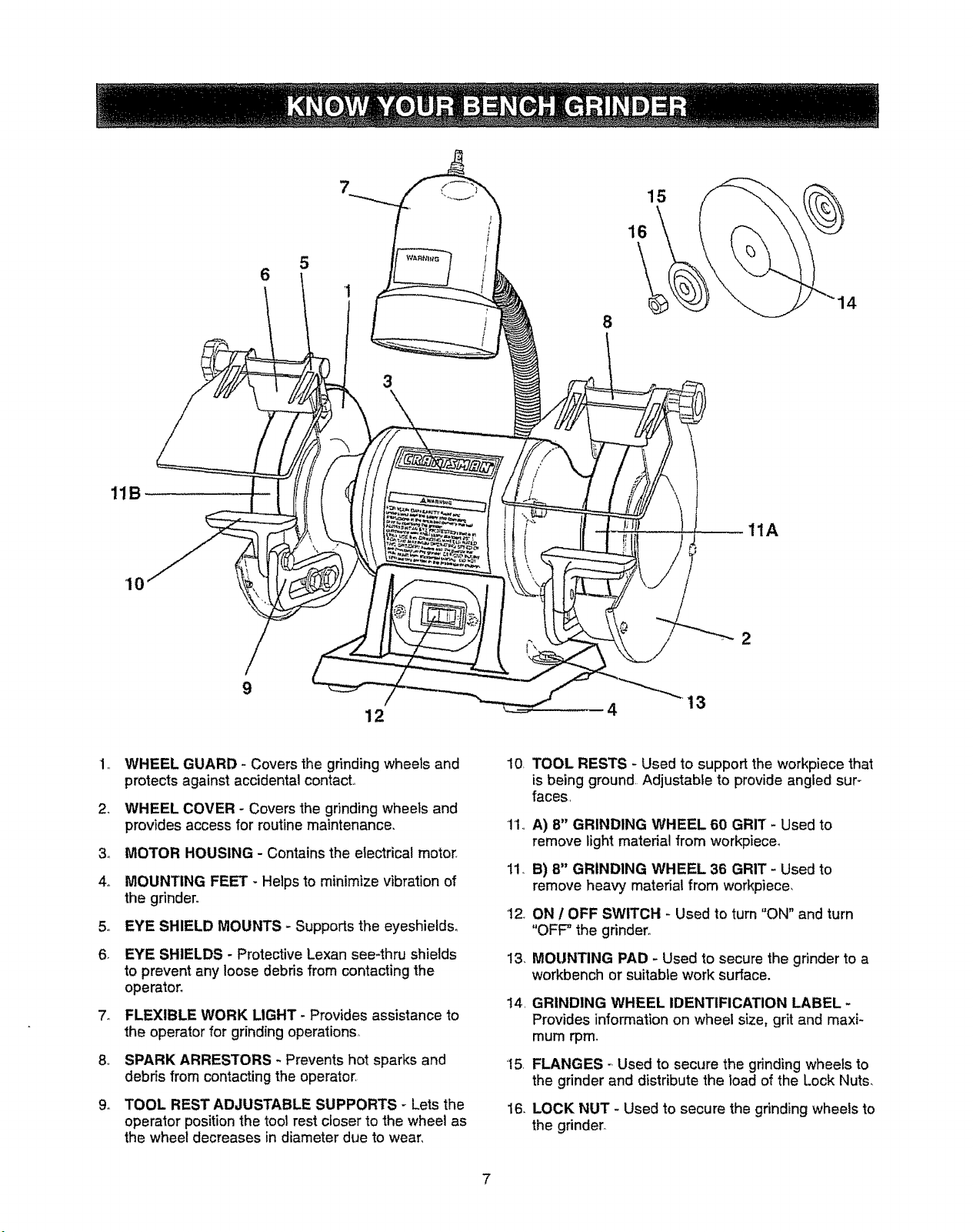

1 WHEEL GUARD - Covers the grinding wheels and

protectsagainst accidental contact

2, WHEEL COVER - Covers the grinding wheels and

provides access for routine maintenance.

3o MOTOR HOUSING - Contains the electrical motor

4_ IVIOUNTING FEET - Helps to minimize vibration of

the grinder°

5o EYE SHIELD MOUNTS - Supports the eyeshieldso

6. EYE SHIELDS - Protective Lexan see-thru shields

to prevent any loose debris from contacting the

operator.

7o FLEXIBLE WORK LIGHT - Provides assistance to

the operator for grinding operations°

8. SPARK ARRESTORS - Prevents hot sparks and

debris from contacting the operator.

9. TOOL REST ADJUSTABLE SUPPORTS - Lets the

operator position the tool rest closer to the wheel as

the wheel decreases in diameter due to wear_

4

10

TOOL RESTS - Used to support the workpiece that

is being ground Adjustable to provide angled sur-

faces

11. A) 8" GRINDING WHEEL 60 GRIT - Used to

remove light material from workpieceo

11_B) 8" GRINDING WHEEL 36 GRIT - Used to

remove heavy material from workpiece,

12. ON / OFF SWITCH - Used to turn "ON" and turn

"OFF" the grinder.

13, MOUNTING PAD - Used to secure the grinder to a

workbench or suitabte work surface.

GRINDING WHEEL IDENTIFICATION LABEL -

14

Provides informationon wheel size, grit and maxi-

mum rpm.

15

FLANGES - Used to secure the grinding wheels to

the grinder and distribute the load of the Lock Nuts_

16,

LOCK NUT - Used to secure the grinding wheels to

the grinder.

t3

Page 8

A12mmx10mmopenendwrenchisprovidedfor

mountingtheToolRestAssembliesandtheSpark

ArrestorAssemblies,.

1, DONOTassembletheBenchGrinderunti!youare

surethetoolISNOTpluggedin.

2, DONOTassembletheBenchGrinderuntilyouare

surethepowerswitchisinthe"OFF"position,

3., DONOTassembletheBenchGrinderuntilyouare

surethegrindingwheelsarefirmlytightenedtothe

BenchGrinder,,

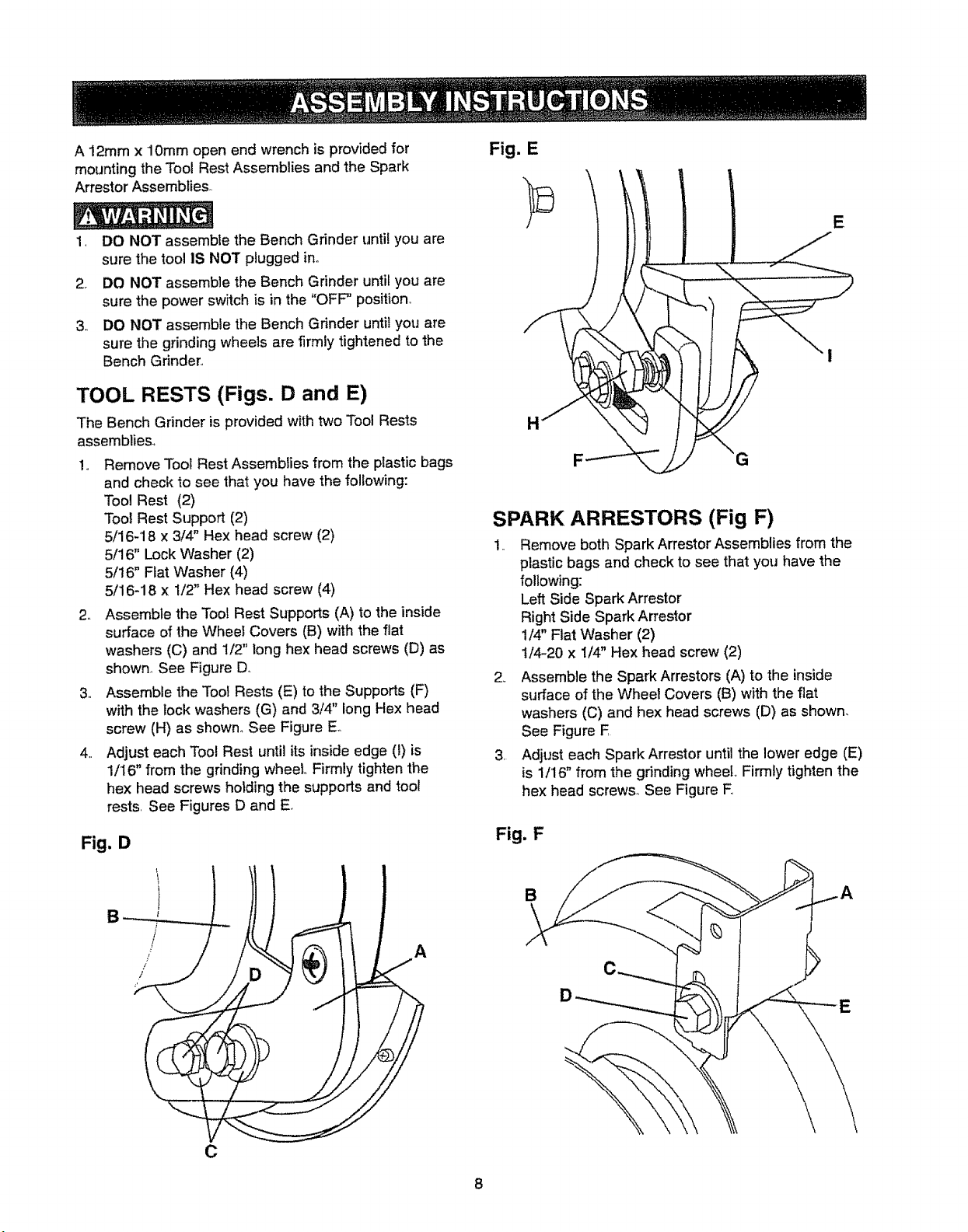

TOOL RESTS (Figs. D and E)

The Bench Grinder is provided with two Tool Rests

assemblies,,

1,, Remove Tool Rest Assemblies from the plastic bags

and check to see that you have the following:

Tool Rest (2)

Tool Rest Support (2)

5/16-18 x 3/4" Hex head screw (2)

5/16" Lock Washer (2)

5/16" Flat Washer (4)

5/16-18 x 1/2" Hex head screw (4)

2,. Assemble the Tool Rest Supports (A) to the inside

surface of the Wheel Covers (B) with the flat

washers (C) and 1/2" long hex head screws (D) as

shown° See Figure D,.

3., Assemble the Tool Rests (E) to the Supports (F)

with the lock washers (G) and 3/4" long Hex head

screw (H) as shown. See Figure Eo

4,, Adjust each Tool Rest until its inside edge (1)is

1/16" from the grinding wheel Firmly tighten the

hex head screws holding the supports and tool

rests, See Figures D and E

Fig. E

SPARK ARRESTORS (Fig F)

1 Remove both Spark Arrestor Assemblies from the

plasticbags and check to see that you have the

following:

Left Side Spark Arrestor

Right Side Spark Arrestor

1/4" Flat Washer (2)

t/4-20 x I/4" Hex head screw (2)

2,, Assemble the Spark Arrestors (A) to the inside

surface of the Wheel Covers (B) with the flat

washers (C) and hex head screws (D) as shown.

See Figure F

3, Adjust each Spark Arrestor until the lower edge (E)

is 1/16" from the grinding wheel. Firmly tighten the

hex head screws_ See Figure E

Fig. D

Fig. F

B

Page 9

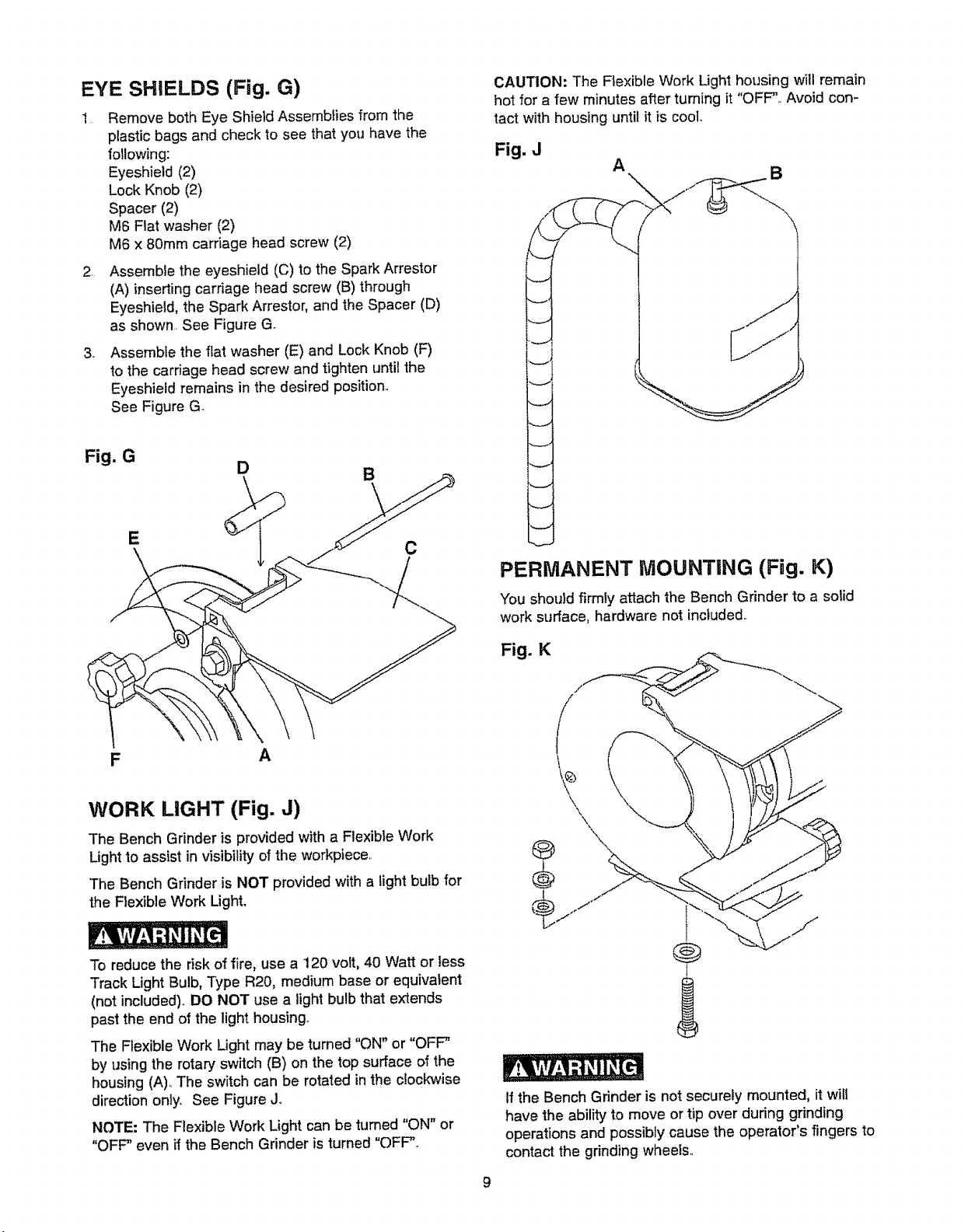

EYE SHIELDS (Fig. G)

1 Remove both Eye Shield Assemblies from the

plastic bags and check to see that you have the

following:

Eyeshield (2)

Lock Knob (2)

Spacer (2)

M6 Flat washer (2)

M6 x 80ram carriage head screw (2)

2. Assemble the eyeshield (C) to the Spark Arrestor

(A) inserting carriage head screw (B) through

Eyeshield, the Spark Arrestor, and the Spacer (D)

as shown. See Figure G.

3_

Assemble the flat washer (E) and Lock Knob (F)

to the carriage head screw and tighten until the

Eyeshieid remains in the desired position..

See Figure G.

Fig. G

D B

CAUTION: The Flexible Work Lighthousing will remain

hot for a few minutes after turning it "OFF".. Avoid con-

tact with housing until it is cool.

Fig, J

A

\ ,B

E

C

A

WORK LIGHT (Fig. J)

The Bench Grinder is provided with a Flexible Work

Light to assist in visibilityof the workpiece..

'The Bench Grinder is NOT provided with a tightbulb for

the Flexible Work Light.

To reduce the risk of fire, use a 120 volt, 40 Watt or tess

Track Light Bulb, Type R20, medium base or equivalent

(not included). DO NOT use a light bulb that extends

past the end of the light housing.

PERMANENT MOUNTING (Fig. K)

You should firmly attach the Bench Grinder to a sotid

work s[Jrface, hardware not inc_udedo

Fig. K

\f

\

\

®

®

The Ftexible Work Light may be turned "ON" or "OFF"

by using the rotary switch (B) on the top surface of the

housing (A).,The switch can be rotated in the clockwise

direction only. See Figure J,.

NOTE: The Flexible Work Light can be tumed "ON" or

"OFF" even if the Bench Grinder is turned "OFF"°

If the Bench Grinder is not securely mounted, it will

have the ability to move or tip over during grinding

operations and possibly cause the operator's fingers to

contact the grinding wheels..

9

Page 10

(

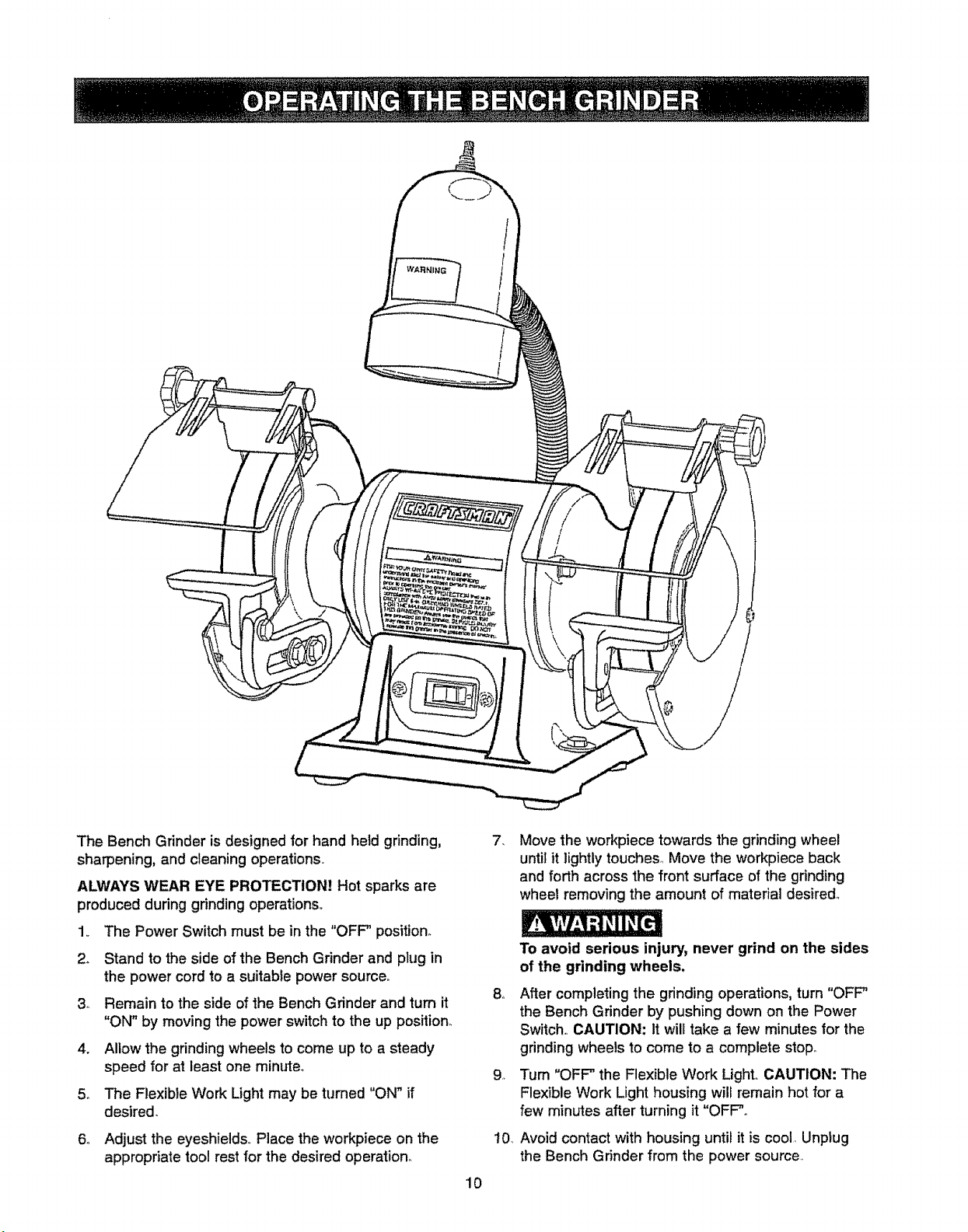

The Bench Grinder is designed for hand held grinding,

sharpening, and cleaning operations.,

ALWAYS WEAR EYE PROTECTION! Hot sparks are

produced during grinding operations,.

1,. The Power Switch must be in the "OFF" position.

2. Stand to the side of the Bench Grinder and plug in

the power cord to a suitable power source..

3_ Remain to the side of the Bench Grinder and turn it

"ON" by moving the power switch to the up position_

4. Allow the grinding wheels to come up to a steady

speed for at least one minute°

5.. The Flexible Work Light may be turned "ON" if

desired.

6o Adjust the eyeshields.. Place the workpiece on the

appropriate tool rest for the desired operation_

10

7_

Move the workpiece towards the grinding wheel

until it lightly touches1 Move the workpiece back

and forth across the front surface of the grinding

wheel removing the amount of material desired_

To avoid serious injury, never grind on the sides

of the grinding wheels.

8_

After completing the gdnding operations, turn "OFF"

the Bench Grinder by pushing down on the Power

Switch,. CAUTION: Itwill take a few minutes for the

grinding wheels to come to a complete stop_

Tum "OFF" the Flexible Work LighL CAUTION: The

Flexible Work Light housing will remain hot for a

few minutes after turning it "OFF".

10

Avoid contact with housing until itis cool Unplug

the Bench Grinder from the power source

Page 11

CHANGING THE GRiNDiNG WHEEL (Fig. N)

Fig. N

G

M

K

L

\

H

Due to normal wear, both wheels will need to be

replaced occasionally. See Figure N

1o Turn the power switch "OFF" and unplug the power

cord from itspower source

2.. Rotate the eyeshields to the "UP" position for

access to the toot rests°

3, Remove the screws (G) holding the Wheel Covers

(H) to the Bench Grinder+.

4.+ Remove the Wheei Covers°

5+ Place a small wooden wedge between the Abrasive

wheel and Tool Rest to prevent the wheels from

rotating.

.,

Remove the right side grinding wheel by turning the

locknut in the counterclockwise direction with a

wrench (not included).. The left side wheel can be

removed by turning the !ocknut (K) in the clockwise

direction..

7+ Remove the Outer Wheel Flange (L) and then

remove the abrasive wheel (I) from the arbor shaft

(M)..

,,

CAUTION: The new abrasive wheel to be put onto

the Bench Grinder must be have a higher R_PoMo

rating than the Bench Grinder° The abrasive wheel

must have a 6" diameter with a 1/2" bore diameter

for the arbor shaft+The label on the side of the

abrasive wheels must stay on, DO NOT remove

this label..

9+ Replace the abrasive wheel, outer wheel flange,

and the locknut in reverse order from removal+

CAUTION: DO NOT OVER-TIGHTEN the lock nut as

this may damage the abrasive wheel and cause serious

injury to the operator_

1+1

Page 12

CAUTION: REPLACE the abrasive wheels if there is

amy damage at all FAILURE to reptace a damaged

Turnthepowerswitch"OFF"andunplugthepower

cordfromitspowersourcepriortoanymaintenance,,

wheel can cause serious injuryto the operator,

CAUTION: DO NOT USE FLAMMABLE MATERIALS

to clean the Bench Grinder, A ctean dry rag or brush is

LUBRICATION

all that is needed to remove dust and debris buildup,,

The Bench Grinder has sealed lubricatedbearings in

the motor housing that do not require any additional

lubrication from the operator,,

Repairs to the Bench Grinder should be performed by

trained personnel only Contact your nearest Sears

CLEANING

With the Bench Grinder unplugged, rotate the abrasive

wheels slowly and inspect for any damage or trapped

shavings,,

Canada Inc, outlet for authorized service° Unauthorized

repairs or replacement with non-factorj parts could

cause serious injury to the operator and damage to the

Bench Gfinde[,

TO PREVENT INJURY TO YOURSELF or damage to the Bench Grinder, turn the switch to the "OFF" position and

unplug the power cord from the electrical receptacle before making any adjustments°

PROBLEM LIKELY CAUSE(S) SOLUTION

Motor does 1oMachine not plugged in 1,,Plug power cord into electrical receptacle

not run 2,, Power switch in "OFF" position 2 Lift switch to "ON" position

3. Power cord is faulty 3_ Return to Sears Service Center

4.,Fuse or circuit breaker are open 4. Overloaded electrical circuit

5. Damaged motor 5. Return to Sears Service Center

,, ,,,,,,,,,.....

Motor does not

have full power

Motor stalls or

runs slow

Fuse blows or

circuit breaker

trips

1.,Incorrect line voltage

2. Damaged motor

I., Motor is overloaded

2. Poor air circulation around motor

1.,Motor is overloaded

2oIncorrect line voltage

3. Capacitor has failed

t., Motor overloaded

2,,Overloaded electdcal circuit

3. Wrong fuse or circuit breaker

4. Undersized or excessive length of

extension cord, see manual

5,,Grinding wheels are blocked

1oHave a qualified electrician check line for proper voltag

2_ Retum to Sears Service Center

I. Reduce pressure on workpiece

2_ Remove any blockage around motor

1.,Reduce pressure on workpiece

2o Have a qualifiedelectrician check line for proper volta_

3oRetum to Sears Service Center

1o Reduce pressure on workpiece

2_,Reduce the amount of items on circuit

3o Replace with correct fuse or circuit breaker

4,, Use correct size

5,,Unplug machine and remove obstruction

12

Page 13

6-IN. BENCH GRINDER PARTS LIST MODEL NO. 152.211240

When servicing, use onty CRAFTSMAN replacement parts, Use of any other parts may create a HAZARD or cause

product damage.

Any attempt to repair or replace electrical parts on this Dust Collector may create a HAZARD unless repair is done by

a qualified service technician, Repair service is available at your nearest Sears Service Center.

Always order by PART NUMBER, not by key number,.

Key No. PART No. Description Qty. Key No. PART No, D_scriptfon

OR91510 Owner's Manual (Not Illustrated) 1 46 OR91512

t

OR90055 CARRIAGE HD SCR M6 x 8Dram

2

OR90152 EYESHIELD

3

STD851006 FLAT WASHER M6

4

OR90001 KNOB M6

5

OR90002 SPACER

6

OR90003 SPARK ARRESTOR (RIGHT)

7

STD551012 FLAT WASHER 1t4"

8

OR90t50 HEX HD SDR t14-20 x 1/4"

STD511002 SCR #!O-24 x 1/4"

9

10

ORVJO004 COVER

11

OR90030 HF..X NUT ti2-12

12

0R90005 FLANGE

13

OR90067 6" GRINDING WHEEL 60 GRIT

t4

OR90006 WHEEL GUARD (RIGHT)

15

0R90007 ROTATION LABEL

16

20

21

22

23

31

33

36

40

41

42

43

44

45

I7

18

30

37

38

39

STD511003

OR9152;3

OR9t512

STD55t13t

STD523t07

ST055103t

ST0523I 05

0R91520

ORD180

OR915tl

OR90O01

STD851oo6

OR90t52

OR90055

OR90002

OR90025

OR90t 50

STD551012

ST0523t 07

ST055!131

SCR #t0-24 x 3/8" 3

TOOL REST SUPPORT (COLOR; BLACK') 1

TOOL REST (COLOR: BLACK) 1

LOCK WASHER ,5116" 1

HEX HD SCREW 5t16_18 X 3/4" 1

FLAT WASHER 5/16" 2

HEX HD SCR 5/16-18 x 1/2" 2

MOTOR ASS'Y 1

(See KEY NO's t00-110 for individual parts)

NAMEPLATE 1

SPEC PLATE t

KNOB M6

FLAT WASHER M6

EYESHIELD

CARRIAGE HD SCR M6 x 8Dram

SPACER

SPARK ARRESTOR (LEFT)

HEX HD SCR 114_20 x 1t4"

FLAT WASHER 1/4"

HEX HD SCREW 5/16-18 X 3/4"

LOCK WASHER 5!16'

1

1

!

t

1

t

1

1

3

t

1

2

1

1

1

1

1

1

t

1

1

t

1

47 OR91523

4B STD523105

49 STD551031

50 OR90007

51 OR90028

52 ST051!003

53 OR90186

54 OR90BOS

55 OR90029

56 OR90004

57 STD511002

58 OR90069

59 STD511003

60 OR90053

62 OR90166

63 STD51t003

64 OR90031

65 OR9t513

68 OR90183

69 0R90184

70 OR90!69

71 STD51t003

72 ST0511003

76 STD55t125

77 STD622507

78 OR91514

81 OR902t0

82 OR9t317

84 0R90045

85 ST0551010

86 STD511005

93 OR90050

95 OR90185

TOOL REST (COLOR: BLACK) 1

TOOL REST SUPPORT (COLOR: BLACK) 1

HEX HD SCR 5/t6-18 x 1/2" 2

FLAT WASHER 5/I6" 2

ROTATION LABEL 1

WHEEL GUARD (LEFT) t

SCR 010-24 x 3/8" 3

6" GRINDING WHEEL 36 GRiT 1

(AVAILABLE AT MOST RETAIL STORES)

FLANGE 2

LEFT HAND HEX NUT 1/2-12 1

COVER 1

SCR 010-24 X 1/4" 3

POWER CORD 1

SCR 010-24 x 3/8" 1

(AVAILABLE AT MOST RETAIL STORES)

EXT TOOTH WASHER #10 1

STRAIN RELIEF (6N_4)

SCR i110-24 x 3/8"

CORD MOUNrTING PLATE

BASE

SWiTCH PLATE

SWITCH

CAPACITOR CLAMP

SCR f_10"24 x 3/8"

SCR 4110-24 x 318"

LOCK WASHER t/4"

SCR 1t4-20 X 3/4"

CAPACFFOR(10ui,250v)

LIGHT ASSEMBLY (COLOR: BLACK)

WARNING LABEL

PAD

FLAT WASHER #10

SCR #10-24 x 1/2"

10ram x 12ram OPEN END WRENCH

COVER PLATE

Qty.

1

2

1

1

1

1

1

1

2

2

2

1

1

1

4

4

4

1

1

13

Page 14

6-IN. BENCH GRINDER MODEL NO. 152.211240

\

ruo'J

u')

,_or_

u'_ it)

t4

Page 15

÷ NOYE$ ÷

15

Page 16

16

Page 17

ManuaU del Proprietario

Rueda de 6 puig.

113 caballo de fuerza (mdximo desarrollado)

1/6 cabalio de fuerza (servicio continuo)

3450 R.P.IVl. (velocidad sin carga)

No. de Modelo

152.211240

WARN|NG

®

US

PRECAUCION:

PARA SU SEGURIDAD PERSONAL;

Lea y obedezca todas las

tnstruccionesde Seguridad y

Funcionamientoantes de accionar

esta Rectificadora de Banco.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

No. de Pieza OR91510

17

[Jnea de Ayuda al Cliente

1-800-897-7709

Sirvase tener listo su

Noode Modelo y No. de Serie

VER. 2.07

Page 18

SECC!ON PAGINA

Garantfa ....................................................................................................................................................................................................... 18

Especificaciones del Producto .................................................................................................................................................................. 18

lnstrucciones de Seguridad ............................................................................................................................................................................19

Instrucciones de Conexi6n a Tierra ..............................................................................................................................................................20

Instrucciones de Seguridad Especfficas para tas Rectificadoras de Banco .....................................................................................2i

Accesorios y Conexiones ......................................................................................................................................................................... 22

Contenido de la Caja ..................................................................................................................................................................................... 22

Conozca su Rectificadora de Banco ...................................................................................................................................................................23

instrucciones de Montaje ........................................................................................................................................................................... 24

Accionando la Rectificadora de Banco ........................................................................................................................................................26

Mantenimiento .......................................................................................................................................................................................................28

Gufa de Localizaci_n de Aver_as.................................................................................................................................................................. 28

Listado de Piezas .................................................................................................................................... '............................................... 29

lnformaciSn de servico ............................................................................................................................................... Portada posterior

GARANTIA COMPLETA DE UN AI_tO

Si este producto queda averiado debido a defectos materiales o de elaboraci6n dentro de un aSo a partir de ta fecha de

compra, DEVUELVALO A SU TIENDA SEARS O CRAFTSMAN MAS CERCANA y se la reemplazaremos libre de costo.

Esta garantfa le otorga derechos legales especfficos, y tambi6n podrdtener otros derechos que pueden variar de un estado

al otroo

Sears, Roebuck and Co, Depto 817 WA, Hoffman Estates, IL 60179

Motor

OF m_.ximo desarrotlado 1/3

HP Servicio ContJnuo 1/6

Vottios !20

Hertzios 60

RPM 3450 R.PMo

(velocidad sin carga)

Dimensiones de la 6 x 3/4 x 1/2 pulg.

Rueda Rectificadora

Grano de la Rueda 60, 36

Rectificadora

Ldmpara Bombitla para luz de card!,

Portaherramientas

Ensambtados de Escudos

Oculares

Amortiguador de Chispa_

Protectores de Chispas

120 v, 40 vatios o menor,

tipo R20, base mediana o

su equivalente (no incluida)

lzquierdo y derecho,

hierro moldeado

Izquierdo y derecho de Lexan

transparente

Izquierdo y derecho

Izquierdo y derecho

Utilice la protecci6n de circuitos debida para evitar el riesgo

personal de los choques el_ctricos y e! daSo al la

Rectificadora de Baneoo

La Rectificadora de Banco viene cableada de f_brica para el

funcionamiento a 120 V, 60 Hz. Con6ctete a un circuito

dedvado de 120 V, t5 amp y utilice un fusible de retardaci6n

de tiempo o disyuntor de circuitos de 15 amp. El tamaSo de

hilo del circuito el_ctrico no puede ser menor que #14 Para

evitar el riesgo de choques o de incendios, reponga el cordon

de potencia inmediatamente si queda daSada en cualquier

manera

18

Page 19

INSTRUCCIONES GENERALES

DE SEGURIDAD

E{ funcionamiento de una Rectificadora de Banco puede

resuftar peligroso si se hace caso orniso de la seguridad y del

sentido cornL_n_El operario debe estar farniliadzado con el

funcionamiento de la herramienta, Lea este manual para

entender su Rectificadora de Banco,.NO OPERE esta

Rectificadora de Banco si no entiende a cabalidad las limi_

taciones de dicha herrarnienta. NO realice modificaciones de

cuaiquier tipo a esta Rectificadora de Banco.

ANTES DE UTILIZAR

LA RECTIFICADORA DE BANCO

Para evitar tas heridas graves y el daSo a ta herramienta, lea

y obedezca todas tas tnstrucciones de Seguddad y Operaci6n

antes de operar la Rectificadora de Banco,

1o Parte del polvo que se crea usando las herramientas

el6ctricas contiene productos qufmicos queet estado de

California reconoce como causantes de c_ncer, defectos

de nacimiento, o daSos en el sisterna reproductivo,

Algunos ejernptos de estos productos qufmicos son:

=Et plomo de pinturas con base de plomo

oEl Silic6n cdstalino de ladrilios0 cernento, y de otros

productosde albaSiler_a

. E] ars6nico y el cromo de la madera de construcci6n

qu_micamente tratada

El riesgo de estas exposiciones varfa, dependiendo de

cuantas veces se realiza este tipo de trabajo. Para

reducir tu exposici6n a estos productos qufrnicos, trabaje

en un &rea bien ventilada, y trabaje con el equipo

aprobado de seguridad, tal como rn&scaras diseSadas

para el polvo.

2. LEA a consciencia el Manual del Propietario,,

APRENDA c6mo hacer uso de esta herramienta para

sus aplicaciones diseSadas,

3., CONECTE TODAS LAS HERRAMIENTAS A TIERRAo

Si ta herramienta se suministra con un enchufe de 3

machos, se le debe enchufar a un tornacorrientes que

disponga de 3 contactos et_ctricos_ Ei tercer macho se

utiliza para conectar la herramienta a tierra y ofrecer pro-

tecci6n contra los choques el_ctricos accidentaleso NO

quite el tercer macho. Vea las lnstrucciones de Conexi6n

a Tierra en la p_gina 20.,

4, EVITE UN ENTORNO LABORAL PEUGROSO° NO

utiiice las herramientas e!6ctdcas en un entorno hSmedo,

ni tampoco las exponga a ituviao

5,, NO utilice herramientas el_c_ricas si hay gases o Ifquidos

inflamables presentes,,

6,, MANTENGA SIEMPRE su zona de trabajo lirnpia, bien

alumbrada y organizada NO TRABAJE en Un entorno

con superficies de piso resbalosas a consecuencia de los

escornbros, la grasa y la cera,,

7. MANTENGA ALEJADOS A LOS NII_IOS Y VtSITANTES_

NO perrnita que haya personas en la zona inrnediatade

trabajo, particularmente cuando la herramienta el_ctrica

se encuentre en funcionamiento.

8. NO FUERGE LA HERRAMIENTA a realizar operaciones

para las cuales no fue diseSada. Realizar_ una labor m&s

segura y de major calidad si sete utiliza para realizar

operaciones para las cuales fue disefadaso

94

UTlUCE VESTIMENTA APROPIADA. NO vista ropa

holgada, guantes, corbatas ni artfculos de joyeria,, Estos

artfcutos pueden quedar atrapados en la m&quina

durante las operaciones y tirar del operafio, atray6ndolo

hacia tas piezas en movimiento° El usuario debe llevar

una cubierta protectiva sobre el cabeklo, si tiene cabe!lera

larga, para impedir el contacto con cuatquier pieza en

rnovimientoo

"I0,.

UTILICE PROTECCION OCULAR SIEMPRE. Cua[quier

herrarnienta rnecdnica puede expulsar escornbros hacia

fos ojos durante las operaciones, resuttando en daSo

ocular grave y permanente, Los anteojos cotidianos NO

son gafas de seguddad., Haga uso SlEMPRE de Gafas

de Seguridad (que cumplan con la norrnativa Z87.1 de

ANSI) cuando vaya a utilizar herramientas mec&nicas.,

Las Galas de Seguddad est,_n disponibles en las tiendas

Sears de ventas al detal,,

1"{,,

UTtLICE PROTECCION AUDITiVA SIEMPRE,, Ef algo-

d6n corriente no representa un dispositivoprotector

aceptable,, La protecci6nauditiva debe cumplir con la

normativa $3.19 de ANSL

12o

SIEMPRE DESENCHUFE LA HERRAMIENTA DEL

TOMACORRIENTES cuando vaya a realizar ajustes,

cambiar plazas o reaiizar cualquier clase de rnanteni-

rniento.

1 3._

MANTENGA LOS ESCUDOS DE PROTECCION EN SU

SITIO Y EN BUEN ESTADO DE FUNCIONAMIENTOr,

t4,

EVITE EL ARRANQUE ACCIDENTAL. Aseg_rese de

qua el interruptor de potencia se encuentre en Eaposici6n

de "APAGADO" antes de enchufar el cord6n de potencia

en el tomacorrienteso

15_

QUITE TODAS LAS HERRAMIENTAS DE MANTENF

MIENTO de la zona inmediata antes de encender la

rectificadora de banco.

16, SOLO UTILICE ACCESORIOS DE RECOMENDADOS,

Et uso de accesorios incorrectos o inapropriados puede

ocasfonar heddas graves al operario y ocasionar dafio a

la herramienta. Si tiene dudas, consulte e[ manual de

instrucciones que se adjunta conel accesofio especffico,

17,, JAMAS DEJE UNA HERRAMIENTA EN FUNCIONA-

MIENTO SIN ATENDERo Conmute el interruptor de

energt'a a la posici6n de apagado,, NO abandone la

herramienta hasta que _sta se haya detenido por

completo,

18o NO SE PARE SOBRE LA HERRAMIENTA, Pueden

producirse heridas graves si la herramienta se vueLca

o si usted hace contacto con Faherrarnienta acciden-

talmente_

19,, NO ALMACENE nada por encima ni cerca de la m_.quina

en donde alguien pueda intentar pararse en la herra-

rnienta para alcanzarlo,

20, MANTENGA SU EQUILIBR10. NO se extienda sobre [a

herramienta. Haga uso de zapatos con suela de caucho

resistente al aceite,. Mantenga el piso libre de escombros,

grasa, o cera.

21_ MANTENGA SUS HERRAMIENTAS CUIDADOSA-

MENTE. Mantenga sus herramientas iirnpias yen buen

estado, Mantenga afifadas todas la hojas y brocas

19

Page 20

22 REVISE Si HAY PIEZAS DAI_IADAS ANTES DE CADA

use DE LA HERRAMIENTA. Revise redes los protec-

totes cuidadosamente para eomprobar que funcionan

correctamente y que no est_n daSados, y q[Je realizan

sus funciones diseSadas correctamenteo Revise el alinea-

miento, fa fijaci6n ota ruptura de las piezas on movimien-

to. Cualquier protector u otra pieza que se encuentre

daSada debe repararse o reemplazarse inmediatamente..

23. HAGA SU TALLER A PRUEBA DE NII_IOS quitando las

|laves de1 interrupter, desenchufando las herramientas de

ios tomacorrientes y mediante el use de candados

24. NO OPERE LA HERRAMIENTA BAJO LA INFLUENCIA

DE LAS DROGAS O DEL ALCOHOL.

25, AFIANCE TODO EL MATERIAL. UtiLice abrazaderas o

plantillas para asegurar el materia!., Esto ofrece mayor

seguridad que intentar sujetar ef material con sus propias

manos,

26, UTILICE UNA EXTENSION ELECTRICA CORRECTA Y

EN BUEN ESTADO,, Cuando vaya a hacer use de una

extensi6n el_etrica, aseg_rese de utifizar una que sea _o

suficientemente fuerte come para transportar la corriente

a ser utilizada per su herramienta. La siguiente tab_apre-

senta tas dimensiones correctas a uti[izarse de acuerdo

con tasdimensiones de la extensi6n y ta clasificaciSn de

amperaje en la placa de notaciones. Si tiene dudas,

utitice la siguiente extensiSn de mayor calibre.. Mientras

menor sea el n0mero de calibre, mayor serd el didmetro

de la extensi6n etdctrica. Si tiene dudas sobre las dimen-

siones correctas de una extensi6n et_.ctrica, utitice un

cord6n m,_s corto y m&s grueso. Una extensi6n de

dimensiones insuficientes producir& una cafda en el

vo)taje de Ifnea, resultando en una p_rdida de potencia y

el sobrecaientamiento. SOLO UTILICE UNA EXTEN-

SION ELECTRICA DE 3 HILOS QUE DISPONGA DE UN

ENCHUFE DE CONEXION A TIERRA DE 3 MACHOS, Y

UN RECEPTACULO DE 3 POLOS QUE ACEPTE EL

ENCNUFE DE LA MAQUINA.

DIRECTRICES PARA LAS

EXTENSlONES ELECTRICAS

St est.1 haciendo use de una extensidn eldctrica a la

intemperie, est_ seguro de que la extensi6n se encuentre

marcada con°W-A" ("V¢'en el CanadA), lo que indica que su

use a ia intempefie es aceptable_

Estd seguro de! dimensionamiento correcto de su exten-

si6n et6ctrica, y que se encuentre en buen estado ei_ctrico.

Repare siempre una extensi6n el6ctrica daSada, o procure

que una persona experta la repare antes del use,,

Proteja sus extensiones et_ctricas contra los objetos

filosos, et taler on exceso y los tugares mojades o hOmedos_

FUNCIONAMIENTO A 120 VOLTIOS SOLAMENTE

0to 6AmpeSos!

6toI0 Amperios

10to12Amperios

P,ES loopIES

DE LARGO DE LARGO

I

18AWG

18AWG

16AWG

50 PIES

DE LARGO

16 AWG

16AWG

t6 AWG

16 AWG

I4 AWG

14 AWG

' PSES

DE LARGO

14AWG

t2 AWG

12AWG

EN EL CASe DE UN MALFUNCIONAMIENTO O AVERIA, |a

conexi6n a tierra ofrece el trecho de menor resistencia para _a

corriente el_ctrica y reduce el riesgo de los cheques e]_ctri-

cos. Esta herramienta viene equipada con un cord6n ef6ctrico

que dispone de un conductor de conexi6n a tierra para el

equipo asf come un enchufe de conexiSn a tierra.. El enchufe

DEBE estar enchufado a un tomacordentes adaptado que

haya side correctamente instalado y conectado a tierra de

acuerdo con TODOS los c6digos y ordenanzas municipales..

NO MODIFIQUE EL ENCHUFE SUMINISTRADOo Haga que

un electricista calificado instale el tomacorrientes apropiado si

e] enchufe no cabe en el tomacorfientes,,

LA CONEXION ELECTRICA INDEBIDA de_ conductor de

conexiSna tierra para el equipo puede resultar en el riesgo

de cheques ei6ctricos. El conductor con el aistamiento verde

(con o sin rayas amarillas) es el conductor do conexi6n a

tierra para el equipo., NO conecte el conductor de conexi6n a

tierra para el equipo a una terrninaci6n viva si resuita nece-

sario reparar o reemplazar el cord6n et6ctdco oe] enchufe,,

CONSULTE con un etectricis_ calificado o personal de servi-

cio si no entiende las instrucciones de conexi6n a t_erra com-

pletamente, o si no est_ seguro que la herra-mienta est_

debidamente conectada a tierra.

SOLO UT1LICE UNA EXTENSION ELECTRICA DE 3 HILOS

QUE DISPONGA DE UN ENCHUFE DE CONEXION A TIER-

RA DE 3 MACHOS, Y UN RECEPTACULO DE 3 POLOS

QUE ACEPTE EL ENCHUFE DE LA MAQUINA.

REPONGA CUALQUIER CORDON DA_IADO O GASTADO

INMEDIATAMENTE.

Fig. A

tomacorrientes para

conductor de conexi6n

3 machos

a tierra

Q

2O

Page 21

Fig. B

orejeta det adaptador

de cone×iSn a tierra

conductor de

conexi6n a tierra

tomacor_entes

para 2 machos

cord6n ei_ctrico de 3 hilos

Esta herramienta est_ diseSada para el uso en un circuito

que disponga de un tomacorrientes como el que se ifustra on

la FIGURA A. La FIGURA A muestra un enchufe ef_ctrico de

3 hi_osy un tomacorrientes el6ctrico con conductor de coo

nexi6n a tierra,, Si no se encuentra disponible un toma-

corrientes debidamente conectado a tierra, se puede hacer

uso de un adaptador, sedan Io i]ustrado en |a FIGURA B,

para conectar dicho enchufe provisionalmente a[ tomm

corrientes de 2 contactos que no est& conectado a tierra_ El

adaptador cuenta con una orejeta rigida que DEBE ser

conectada a una conexi6n a tierra permanente, tal como un

tomacordentes debidamente conectado a tierra,, ESTE ADAP-

TADOR ESTA PROHIBIDO EN EL CANADA,

PRECAUCION: En todos toscases, aseg_Jrese de que el

tomacorrientes on cuesti6n est_ debidamente conectado a

tierra. Si no est_ seguro, haga que un electdcista certificado

revise el tomacorrientes..

caci6n, revise por si existen gdetas. NO QUITE el

secante o la etiqueta en ambos lados de Is rueda de

rectificaci6n_ Apriete la tuerca del eje justo Io suficlente

como para sujetar la rueda de rectificaciSn firmemente a

fa Rectificadora de Banco,, No apriete la tuerca excesiva-

mente.. La fuerza abrazadora excesive puede dafiar la

rueda de rectificaci6no $61o utilice las pestaSas de rueda

proporcionadas con la rectificadora, Cuando vaya a

seleccionar una rueda de rectificaci6n do repuesto, com-

pruebe que [a rueda de rectificaciSn tiene una notaci6n

de R.,P.M,,m&s alta que las RP,M. m_.ximas de la

Rectificadora de Banco.,

3,

EL DIAMETRO DE LAS RUEDAS DE RECTIFtCACION

SE REDUCIRA CON EL USO. Ajuste los portaherramien-

tas y tos protectores do chispas para conservar una dis-

tancia de 1/16" de la rueda.,

4_

NO SE INCORPORE EN FRENTE DE LA RECTIR-

CADORA DE BANCO CUANDO VAYAA ENCENDER-

LA. Incorp6rese a un lado do la Rectfflcadora de Banco y

enci6ndala. Espere al lado por un minuto hasta que la

rectificadora alcance ptena velocidad,, Siempre existe la

posibilidad de que los escornbros de una rueda de rectifF

cac_6n daF1adapuedan descargarse hacia et operado,

5,

LA RECTIFICADORA DE BANCO PRODUCIRA CHIS-

PAS Y ESCOMBROS DURANTE LAS OPERACIONES

DE RECTIFICACION Asegurese que no existan materi-

ales inflamables en tas cercanfas,, Limpie el polvo resid-

ual de la rectificaci6n de la parte posterior de la

Rectificadora de Banco_

JAMAS FUERCE EL MATERIAL CONTRA LA RUEDA

DE RECTIFICACION, especiaLmente si fa rueda se

encuentra frfa. Aplique el matedai lentamente, permitien-

do que la rueda de rectificaciSn tonga la oportunidad de

caTentarse_Esto reducird la posibilidad de ruptura de ia

rueda., NO rectifique utifizando los lados de las ruedas de

rectificaci6n. NO aptique refrigerante directamente sobre

Ia _Jeda do rectificaciSn,

Esta rectificadora es para el uso en intefiores solamente, No

la exponga a la lluvia ni la utilice en tugares h0medos.,

INSTRUCCIONES DE SEGURIDAD

ESPECIFICAS PARA LAS

RECTIFiCADORAS DE BANCO

El funcionamtento de cualquier rectificadota puede resuitar en

la expuisi6n de chispas hacia sus ojos, Ioque puede resultar

en daSo grave a los ojoso UTILICE SIEMPRE Gafas de

Seguridad (que cumplan con la normative ANSt Z87,,t) al

operar la rectificadorao Las Galas de Seguridad est_n

disponibies en las Tiendas Sears de Ventas al DetaL Aparte

los pulgares y dedos de las ruedas de rectificaci6n.

Io UTILICE StEMPRE LOS PROTECTORES OCULARES

Y DE RUEDA suminlstrados con ta rectificadora.

2_ REPONGA INMEDIATAMENTE CUALQUtER RUEDA

DE RECTIFICACION AGRIETADA O DA_ADA, Una

rueda de rectificaci6n da_ada puede descargar escom-

bros a alia velocidad en la direcci6n del operado,, Maneje

las ruedas de rectificaci6n con cuidado, ya que son

abrasantes,, Antes de reempiazar la rueda de rectifi-

MANTENGA TODAS LOS PROTECTORES DE RUEDA

EN SU SITIO, NO UTILICE LA RECTIFICADORA DE

BANCO CON LOS PROTECTORES DE RUEDA F(JERA

DE LUGAR.

8.

MANTENGA LOS PQRTAHERRAMtENTAS FIRME-

MENTE APRETADOS°

g,,

QUITE EL AJUSTE DE LLAVES Y DE LAS LLAVES.

Forme el h_bito de _acomprobaci6n para vet que las

Itaves y Ias ILavesdel ajuste estdn quitadas de la her-

ramfenta antes de girafla,,

t0o

DIRECCI6N DE LA ALIMENTACION. Atimente ei trabajo

en una l_mina o un cortador contra Ia rotaci6n de ia _mi-

na o un cortador sofamente_

11.

u'rILICE LA HERRAMIENTA DERECHA. No fuerce ia

herramienta o el accesofio para hacer untrabajo para el

cual no fue diseSado_

12. NO sobre apriete la tuerca de la rueda_

13. SOLAMENTE utilice _osrebordes equipados con Laamo-.

tadora.

14_

CON FRECUENCIA polvo que muele limpio debajo de la

amoladora

GUARDE ESTAS INSTRUCClONES,

21

Page 22

ACCESORIOS DISPONIBLES

V_site su Departamento de Ferreter_a de Sears o consuite el

Cat&logo de Herramientas Mec_nicas y de Mane para los

siguientes accesorios:

ARTICULO

Ruedas de rectificaci6n do

repuesto

Ruedas de alambre y pulido

Espaciadores

Estante universal

NUMERO DE EXISTENCIA

Ver cat&logo o tienda

Ver cat&logo o f3enda

Ver cata'logoo tienda

Ver cat&logo o tienda

Sears podr_ recomendar otros accesorios que no aparecen

listados on ese manual°

Consulte con su Departamento de Ferreterfa de Sears o con-

su?teel Cat, logo de Herramientas Mec_nicas y de Mane para

otros accesorios:

No utitice ninglJn accesorio a menos que haya lefdo el

manual del Propietado para dicho accesorio,

S6Io uUlicelos accesodos recomendados para esta

Rectificadora de Banco,, El use de otros accesorios podr&

ocasionar tesionamientos graves y dafiar la Rectificadora de

Banco,.

DESEMPAQUE Y VERIFICACION DE

CONTENIDOS (Fig. C)

Esta rectificadora de banco exigir& una cantidad mfnima de

ensamblaje,. Se suministra una Havede extreme abierto de

12 mmx 10 mm para montar fos Ensamblados de Porta-

herramientas y los Ensamblados de Protector de Chispas.

Quite todas las piezas de ta caja de envfo y col6quetas sobre

una supe_cie de trabajo limpia.,Compare los artfculos a la

Fig° C y verifique que redes los artfculos est_n contabitizados

antes de descartar la caja de envioo

Para evitar heridas graves, no intente enchufar el cordSn de

potencia y encienda la Rectificadora de Banco si fatta

cualquier pieza. La Rectificadora de Banco s61o podr& encen -

derse despu6s de que todas las plezas hayan side correcta-

mente obtenidas e instatadas,.

Los siguientes art[culosser_n proporcionados en la caja de

envio:

A.. RectJficadora

Be Uave de boca hexagonal, 12 mm x 10 mrn

C. Ensambiado del escudo ocular izquierdo

Fig. C

A

B

D. Ensamblado de?escudo ocular derecho

(no ilustrado)

Eo Ensamblados de portaherramientas (2)

/

C

22

E

Page 23

11B

10

15

16

5

6

4

8

3

_11A

/

9

12

1., PROTECTOR DE RUEDA - Cubre las ruedas de rectifi-

caci6n y protege contraet contacto accidental°

2o CUBIERTA DE RUEDA - Cubre las ruedas de rectifi-

caci6n y proporciona acceso para et mantenimiento

rutinario.,

CARCASA DEL MOTOR - Contiene e?motor el6ctfico.

4.

PIES DE MONTAJE - Ayudan a reducir ?avibraci6n de la

rectificadorao

5_

MONTAJES DEL ESCUDO OCULAR - Apoyan losescu_

dos ocuiares.,

6,,

ESCUDOS OCULARES - Escudos protectores de Lexan

transparente que impiden el contacto entre los escom-

bros sueltos y el operario.

7.

LUZ DE TRABAJO FLEXIBLE _ Proporciona ayuda al

operado en tas operaciones de rectificaci6n.

PROTECTORES DE CHISPAS - Impiden que las

chispas calientes y escombros entren en contacto con

el operafio.

9,,

SOPORTES AJUSTABLES DE PORTAHERRAMIEN-

TAS - Permiten que el operario posicione el portaher-

ramientas m,Sscerca a la rueda a la par que se reduce el

di_,metrode la rueda debido al desgaste,

4

PORTAHERRAMIENTAS - Utilizados para apoyar el

material que esta siendo rectificado. Ajustable para dar

cabida alas superficies anguladas.

11,

A) RUEDA RECTIFICADORA DE 8 PULG. CON

GRANO DE 60 - UtiEizadopara remover material ligero

de la pieza rectJflcadao

1!.

B) RUEDA RECTIFICADORA DE 8 PULG. CON

GRANO DE 36 - Utilizado para remover material pesado

de la pieza rectificada.

12,

INTERRUPTOR DE ENCEND1DO/APAGADO -UtiFizado

para encender y apagar la rectificadora_

13.

ALMOHADILLA DE MONTAJE - Utilizada para afianzar

la rectJficadoraa un banquillo de trabajo o superficie de

trabajo adecuada_

14. ETIQUETA DE IDENTIFICACION DE LA RUEDA DE

RECTIFtCACION - Proporciona informaci6n sobre eE

didmetro de meda, grano y rpm mdximaso

15, PESTA_AS - Utilizadas para asegurar las ruedas de rec-

tificaci6n a ia rectificadora y distribuir la carga de las

Tuercas de Cierre.

TUERCA DE CIERRE - Utilizada para asegurar las

ruedas de rectiflcaci6n a la rectificadora.

13

23

Page 24

Se proporciona una ltave de extremo abierto de 12 mmx 10

mrn para el montaje de los Ensamblados Portaherramientas y

los Ensamblados Protectores de Chispas,,

NO ensamble la Rectificadora de Rueda hasta que est6

seguro que la herramienta NO ESTE enchufadao

NO ensambte la Rectificadora de Banco hasta que est6

2_

seguro que el interruptor de energfa est8 en la posici6n

de APAGADO.,

NO ensamble la Rectificadora de Banco hasta que est6

3_

seguro de que las ruedas rectificadoras est6n firmemente

apretadas a la Rectiflcadora de Banco.

PORTAH ERRAM IENTAS

(Figuras D y E)

La Rectificadora de Banco viene equipada con dos ensambla-

dos de Portaherramientas..

1. Quite Ensamblados de Portaherramientas de las bofsas

de pt&sUcoy revise que tenga Io siguiente:

Portaherramientas (2)

Apoyo de Portaherramientas (2)

Tomillo de cabeza hexagonal. 5/16-18 x 3/4 pulg,, (2)

Arandela de cierre, 5/16 pulg. (2)

Arandela Plana de 5/16 pulg. (6)

Tomillo de Cabeza Hexagonal 5/16-18 x 1/2 pulg. (4)

2. Ensamble los Apoyos de Portaherramientas (A) a la

superficie interior de las Cubiertas de Rueda (B) con las

arandelas planas (C) y tomillos de cabeza hexagonal de

1/2 pulgo de largo (D) seg_n Io ilustrado.. Vet Fig,,Do

3., Monte los portaherramientas (E) a los soportes (F) con

las arandelas de cierre (G) y el tornilto de cabeza hexag-

onal de 3/4 pulg.,de largo (H) seg_n to ilustradoo

Consulte ta figura E,.

4,, Ajuste los portaherramientas hasta que sus bordes interi-

ores (I) est_n a 1t16 pulg,, de las ruedas de rectificaci6no

Apriete firmemente los tomiflos de cabeza hexagonal que

sostienen los soportes y los portaherramientas_, Vet

Figuras D y E.

Fig. D

Fig. E

H

PROTECTORES DE CHISPAS (Fig. F)

Quite ambos Ensambfados de Protectores de Chispas de

las botsas de pl_sticoy revise que tengan Io siguiente:

Protector de Chispas Izquierdo

Protector de Chispas Derecho

Arandela Piana de 1/4 putg. (2)

Tomilto de Cabeza Hexagonal de 1/4-20 x 1/4 pulgo (2)

24 Ensamble los Protectores de Chispas (A) a la superficie

interior de las Cubiertas de Rueda (B) con las arandelas

planas (C) y los tomillos de cabeza hexagonal (D) segL_n

Io itustrado,,Ver Fig, E

3,,

Ajuste los Protectores de Chispas hasta que sus bordes

infer_ores(E) est_n a 1/16 pulg. de las ruedas de recfJfi-

caciSnoApdete los tomillos de cabeza hexagonal firme-

menteo Ver Fig_E

Fig. F

24

B

Page 25

ESCUDOS OCULARES (Fig. G)

t., Quite ambos Ensamblados de Escudos Oculares de tas

bolsas de pf_stico y revise que contengan Io siguiente:

Escudo Ocular (2)

Perilla de Cierre (2)

Espaciador (2)

Arandela Plana M6 (2)

Tomillo de Carrocer[a M6 x 80 mm (2)

2. Ensambte el Escudo Ocular (C) al Protector de Chispas

(A) mediante la inserciSn del tornilfo de carrocerfa (B) al

escudo ocular, luego a trav_s de1Protector de Chispas

y luego a trav6s de! espaciador (D) segSn Io ilustrado..

Ver Fig. Go

3, Ensambte ta arandela plana (E) y la Pedlla de Cierre (F)

a! tornillo de carroceffa y apfi_tefo hasta que el Escudo

Ocular permanezca en ta posici6n deseada.. Ver Fig. G.

Fig, G

E

PRECALICION: El alojamiento de la Luz de Trabajo Flexible

permanecer& caliente per algunos minutes despu_s de haber-

la apagado.. Evite el contacto con dicho alojamiente hasta que

se enfrfe.

Fig. J

A

\ B

F A

LUZ DE TRABAJO (Fig. J)

La Rectificadora de Banco est_ equipada con una Luz de

Trabajo Flexible para ayudar en ta visibilidad del material.

La Rectificadora de Banco NO viene equipada con una

bombilta para ta Luz de Trabajo Flexible.

Para reducir el riesgo de incendio, utilice una bombilla para

luz de carril de 120 vottios, 40 varies or menor, tipo R20, base

mediana or su equivalente (no incluida). NO utilice una bom-

billa que se extienda m&s all_ del extreme de la pantaltao

La Luz de Trabajo Flexible puede encenderse o apagarse

mediante el use del interrupter rotativo (B) en la parte superi-

or del alojamiento (A). El interrupter puede girarse en el senti-

do de ias agujas del reloj exclusivamenteo Ver Fig,,J_

MONTAJE MOUNTING (Fig. K)

Debe conectar la Rectificadora de Banco firmemente a una

superficie de trabajo.. No se incluyela ferreter[a..

Fig. K

\

\

®

I

@

I

AVISO" La Luz de Trabajo Rexible podr_ encenderse o apa-

garse aunque la Rectificadora de Banco se encuentre apaga-

da._

Si la Rectificadora de Bar]co no se encuentra montada con

seguridad, tendr& la capacidad de moverse o votcarse

durante las operaciones de rectificaci6n y posiblemente hacer

que los dedos del operario entrenen contacto con las ruedas

de rectificaciSno

25

Page 26

/

La Rectificadora de Banco est_ disefiada para las opera-

ciones manuales de rectificaci6n, afitado y limpieza_

iUTILICE PROTECCION OCULAR SIEMPRE! Se producen

chispas calientes durante las operaciones de rectificacf6no

1. El interruptorde energfa debe estar en la posici6n de

"APAGADO",,

2 Incorpbrese at lado de la Rectificadora de Banco y

enchufe el cord6n de energfa a un tomacorrientes

apropiado.

3_ Permanezca al lado de la Rectificadora de Banco y

enci_nclala moviendo el interruptorde potencia a ta

posiciOn de arriba.

4o Permita que las ruedas de rectificaci6n alcaneen una

velocidad uniforme durante al menos un minuto.,

5.. La Luz de Trabajo Flexible puede encenderse si se

desea,,

6. Ajuste tos escudos oculares. Coloque el material sobre el

portaherramientas adecuado para elfuncionamiento

deseadoo

26

Mueva el material hacia la raeda rectificadora hasta

7_

tocarla ligeramente,, Mueva el material conaccibn de

vaiv6n a Io largo de ta superficie de ta rueda de rectifi-

caciSn, quitando la cantidad de material deseado_

Para evitar lesiones graves, jamds rectifique en los

lados de la rueda de rectificacidn.

8.

Despu6s de haber completado las operaciones de rectifi-

caci6n, apague la Rectificadora de Banco presionando el

Interruptor de Potencia hacia abajo,, PRIECAUCION: Se

requerir&n algunos minutos para que las ruedas de recti-

ficaciOn se detengan por completo,,

94

Apague la Luz de Trabajo Flexible. PRECAUCION: El

alojamiento de la Luz de Trabajo Flexible permanecerd

caliente pot algunos minutos despuds de habeda apaga-

do,

10_

Evite el contacto con e! alojamiento hasta que se haya

enfriado. Desenchufe la Rectificadora de Banco de la

fuente de energia.

Page 27

CAtUIBIANDO LA RUEDA DE RECT FiCACION (Fig. N)

Fig. N

G

K

M

H

Debido a! desgaste normal, ambas ruedas tendr_n qua ser

reemptazadas ocasionalmente. Ver Fig., N,

to Apague el interruptorde energfa y desenchufe el eord6n

de energ[a de su fuente de potenciao

2. Gire los escudos oculares a la posici6n vertical para

obtener acceso a los portaherramientas,,

3,, Quite los tomii!os(G) que sujetan et Protector de Ruedas

(H) s Is Rectificadora de Banco,

4o Quite los Protectores de Rueda,,

5_ Coloque una pequeSs cuSa de madera entre la Rueda

Abrasante y 81Portaherramientas para impedir la

rotaciSn de las ruedaso

64 Quite la rueda de reetificaci6ndel lado derecho haciendo

girar tatuerca de cierre en el sentido contrado alas agu-

jas del reloj utitizando para ello una Ilave (no inctuida)., La

rueda del lado izquierdo puede quitarse haciendo girar la

tuerca de cierre (K) en el sentido de tas agujas de1reloj.,

7. Quite ia PestaSa de la Rueda Exterior (L) y luego quite la

rueda abrasante (I) deeeje det _.rbol (M).,

8,, PRECAUCION: La nueva rueda abrasante a ser cofo-

cada sobre la Rectificadora de Banco debe tener una

notaci6n de R_P.M mf_s atta que la Rectificadora de

Baneo. La rueda abrasante debe tener un di_metro de

6 pulg., con un di&metro de &nima de 1/2 pufg_ para el eje

del _rbol. La etiqueta en et costado de tas ruedas abras-

antes debe permanecer adheddao NO quite esta etiquetao

9,. Reponga la rueda abrasante, la pestafia de Is rueda

extema y la tuerca de cierre en el sentido inverso de su

desmontaje_

PRECAUCION: NO APRIETE EXCESIVAMENTE Is tuerca

de cierre, ya que esto puede daSar tas ruedas abrasantes y

ocasionar heridss graves at operario,_

27

Page 28

PRECAUCION: REPONGA las ruedas abrasantes si existe

cua_quier dafio,, EL DEJAR de reemplazar una rueda dafiada

Apague el interruptor de energfa y desenchufe e! cordon de

energfa de su fuente de potencia antes de realizar cuatquier

mantenimiento_

LUBRICAC|ON

La Rectificadora de Banco tiene cojinetes de lubricaciOn sella-

dos en la carcasa del motor que no requieren fubricaciOn

adicional por parte del operario.

LIMPIEZA

Con fa Reotif_cadora de Banco desenchufada, gire las ruedas

abrasantes lentamente e inspeccione por si existe cualquier

da5o o virutas atrapadas.

PARA IMPEDIR LAS HERIDAS PERSONALES o el da5o a la Rectificadora de Banco, gire el interruptor a la posieiOn de

"APAGADO" y desenchufe el cordon de energfa del tomacorrientes antes de realizar cualquier ajuste,

PROBLEMA CAUSA PROBABLE SOLUCION

,, ,,,,,, , ,,, , ,,,,__,_L ....... • _ ,....

Motor no 1.,M_quina desenchufada 1. Enchufe el cord6n al tomacorrientes

funciona 2, Interruptor de energfa en posiciOn 2. Levante el intemJptora la posiciOn de encendido

de apagado

Cord6n de energfa defectuoso 3,

4.

Fusible o disyuntor abierto 4o

5o

Motor dafado 5.,

puede ocasionar lesionamiento grave al operario.

PRECAUCION: NO UTILICE MATERIALES INFLAMABLES

para limpiar la Rectificadora de BancooTodo 1oque se necesi-

ta para quitar la acumulaciOnde poivo y escombros es una

patio seco y limpioo un eepitloo

Las reparaciones a la Rectificadora de Banco deben ser real-

izados pot personal capacitado solamente,, Commun_quese

con su Centro de Servicio de Sears m&s cercano para recibir

servicio autorizado, Las reparaciones desautorizadas o el

reemplazo con piezas que no sean de f_brica podr_n dar

lugar a lesionamiento grave af operario y daOar ia

Rectificadora de Banco,

DevuOlvato al Centro de Servicio de Sears

Circuito elOctrico sobrecargado

DevuOlvalo al Centro de Servioio de Sears

Motor no tiene

ptena potencia

b

Motor marcha

caiiente

Motor se cala

Eo marcha

lentamente

Se funde el

fusible o se

dispara el

disyuntor de

circuttos

1. Tensi6n incorrecta de lfnea

2.,Motor dafiado

1,,Motor sobrecargado

2oMala circulaciOn de aire alrededor

del motor

1oMotor sobrecargado

2. TensiOn incorrecta de Ifnea

3. Fa!la del capacitador

t. Motor sobrecargado

2. Circuito elOctrico sobrecargado

3. Fusible o disyuntor equivocados

4o Mal tamafio o Iongitud excesiva de la

extension elOctrica, ver manual

5. Ruedas de rectificaciOn bloqueadas

1. Haga que un electricista experto revise la Ifnea

para determinar la tension correcta

2,.Devu_tvato af Centro de Servicio de Sears

1, Reduzca la presi6n sobre e! material

2_Quite cualquier obstrucciOn en tomo at motor

1. Reduzca la presiOn sobre et mateda_

2. Haga que un etectricista experto revise la Ifnea para

determinar tatension correcta

3oDevuOlvalo al Centro de Servicio de Sears

1. Reduzca la presiOn sobre el material

2.,Reduzca tacantidad de art[culos en el mismo circuito

3o Reponga con el fusible o disyuntor correcto

4. Utilice el tama5o correcto

5. Desenchufe la m&quina y quite la obstrucciOn

28

Page 29

LISTADO DE PIEZAS PARA LA RECTtFICADORA DE BANCO DE 6 PULG,

NO, DE MODELO 152.2'11240

Cuando vaya a rendir servicio, s61outilice piezas de repuesto CRAFTSMAN.. El uso de cua[quier otro tipo de pieza puede con-

stituir un PELIGRO u ocasionar daSo at producto,

Cualquier intento de reparar o reempiazar tas piezas el6ctricas en esta Rectificadora de Banco puede representar un PELIGRO a

menos que tab reparaciones hayan sido reatizadas por un t6cnico de servicio experto. El ser¢icio de reparaciones se encuentra

disponibte en su Centro de Servicio Sears m6s cercano..

Haga su pedido por NUMERO DE PIEZA siempre, en vez de por nt]mero de clave.

No, No, No, No,

Clave dePF/A D_cHpcl6n Cantldad ClavedeP[EZA

OR915t0 Manu;a_del Propteta_io(no ilust_ad) 1 46 OR91512

OR90055 TORNILLO DE CARROCERIA M5 x 80 mm

1

2

OR90I 52 ESCUDOOCULAR

3

STD8510D6 ARANDELAPLANAM6

4

ORgDoDI PERtLLA M5

OR,30002 ESPACIADOR

5

6

7

8

9

10

ti

12

13

14

15

t5

17

18

2O

21

22

23

3O

31

33

38

3'/

38

39

40

41

42

43

44

45

OR9D003

STD551012

OR90150

STD511062

OR90004

OR90O3o

OR900o5

OR9O057

ORg0005

OR£OD07

STD5110[:,3

OR_1523

OR91512

STD55t131

STD523107

STD551031

STD523105

OR91520

OR90t80

OR91511

ORgD00t

STD85t008

OR90152

OR90055

ORg0D02

ORgD025

ORg015O

STD551012

STD523107

STD55t131

SUPRESOR DE CHtSPAS(DERECHO)

ARANDELA PLANA, 1/4 pulg

TORNILLO DE CABF-.ZAHEXAGONAL. 1/4-2[}x 1/4 pulg

TORNILLO #10,24 X _/4 pulg

CUB1ERTA

TUERCA HEXAGONAL. 1/2-12

PESTAt_A

RUEDA DE RECTtFICAC{_)NDE 5 PULG, CON

GRANO DE 60 (D_SPONtBLEEN LA MAYORIA

DE LASTiENDAS DETALLISTAS)

PROTECTOR DE RUEDA (DERECHO)

ETIQUETADE ROTACI()N

TORNILLO #10-24 X 3/8 pul9 3

SOPORTE DEL PORTAHERRAMIENTAS (COLOR: NEGRO) !

PORTAHERRAMtENTAS (COLOR: NEGRO) 1

ARANDELA DE C1ERRE,5/15 PULG 1

TORNtLLODE CABF--.ZAHEXAGONAL, 5116-18x 3/4 pulg 1

ARANDELA PLANA, 5116pulg. 2

TORNILLO DE CABEZA HEXAGONAL, 5t16,,18x "!/2 pulg 2

ENSAMBLADO DEL MOTOR _l

(Cons,jltar NUMEROS DE CLAVEt00,110

paralos nOmerosde ptezaindMdua_ea)

PLACA DE NOMCRE 1

PLACA DE NOTACtONES 1

PER1LLAM6

ARANDELA PLANA M6

ESCUDO OCULAR

TORNILLO DE CARROCER{AM6 X 80 mm

ESPACIADOR

SUPRESOR DE CHISPAS (IZQU_ERDO) 1

TORN[LLO DE CABEZAHEXAGONAL, t/4_20x 1/4 puig 1

ARANDELA PLANA, i/4 pulg 1

TORNILLO DE CABEZA HEXAGONAL, 5t16-t8 x 3!4 pufg 1

ARANDELA PLANA.5/16 pulgo

1

1

1

1

t

1

l

1

3

t

1

2

!

t

1

l

t

1

47 OR91523

48 STD523105

4_ STD55!031

50 OR90007

51 ORgO{)2B

52 STD51t003

53 OR9_3185

54

OR90005

ORgOD29

55

56

OR90004

57

STD51t002

58

OR90059

59

STD511003

6O

OR90053

62

OR90165

63

STD511003

64

OR9003t

65

OR91513

58

OR90183

69

0R£{_184

7O

OR90169

71

5TD511003

STD511003

72

76

STD581125

77

STD622507

78

OR91514

8I

OR90210

OR91317

82

84

OR90045

85

STD55t010

85

5TD5t1005

83

ORgO050

95

OR90185

Descripddn Canttd_.,d

PORTAHERRAMIEN-rAS (COLOR; NEGRO) 1

SOPORTE DE PORTAHERRAMIENTAS(COLOR: NEGRO) 1

TORNILLO DE CABEZA HEXAGONAL. 5/16-18 x 1/2 putg 2

ARANDELA PLANA, 5f16 pulg 2

ETIQUETADE ROTACK_N 1

PROTECTOR DE RUEDA (IZOUIERDD) 1

TORNILLO ft10,24 x 3/8 pulg 3

RUEDA DE RECTtFtCAC]ON DE 6 PULG..CON I