Page 1

sEßm

owners

manual

MODEL NO.

149.236321

SERIAL

OR CODE

NUMBER:

Model and code number may be

found on the back of the base.

You should record both mode! and

code number and retain in a safe

place for future use.

CALIFORNIA OWNERS: a uniQue

serial code number is stamped on

the underside of the machine.

CAUTION:

Read All Instructions

Carefully Before Start

ing Assembly and Use.

Save This Manual For

Future Reference.

Bmm/tRnmMnH ®

5Ve-INCH

JOINTER — PLANER

• assembly

• operating

• repair parts

SEARS, ROEBUCK AND CO., Dept. D/817WA, Hoffman Estates, IL 60195

Part No. 4551-252-00

7/90

Page 2

FULL ONE-YEAR WARRANTY ON CRAFTSMAN. JOINTER — PLANER

if within one year from the date of purchase, this Craftsman Jointer — Planer fails due to a defect

in material or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS STORE OR SERVICE

CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights and you may also have other rights which vary from

state to state.

Sears, Roebuck and Co., Dept. D/817WA, Hoffman Estates, IL 60195

A

1. KNOW YOUR POWER TOOL

For your own safety, read the owner's manual carefully.

Learn its application and limitations as well as the specific

hazards peculiar to this tool.

2. GROUNDING INSTRUCTIONS

A. All grounded, cord-connected tools;

In the event of a malfunction or breakdown, grounding pro

vides a path of least resistance for electric current to reduce

the risk of electric shock. This tool is equipped with an

electric cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. The conductor with

Insulation having an outer surface that is green with or with

out yellow stripes is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor to a live

terminal.

GENERAL SAFETY RULES FOR POWER TOOLS

A

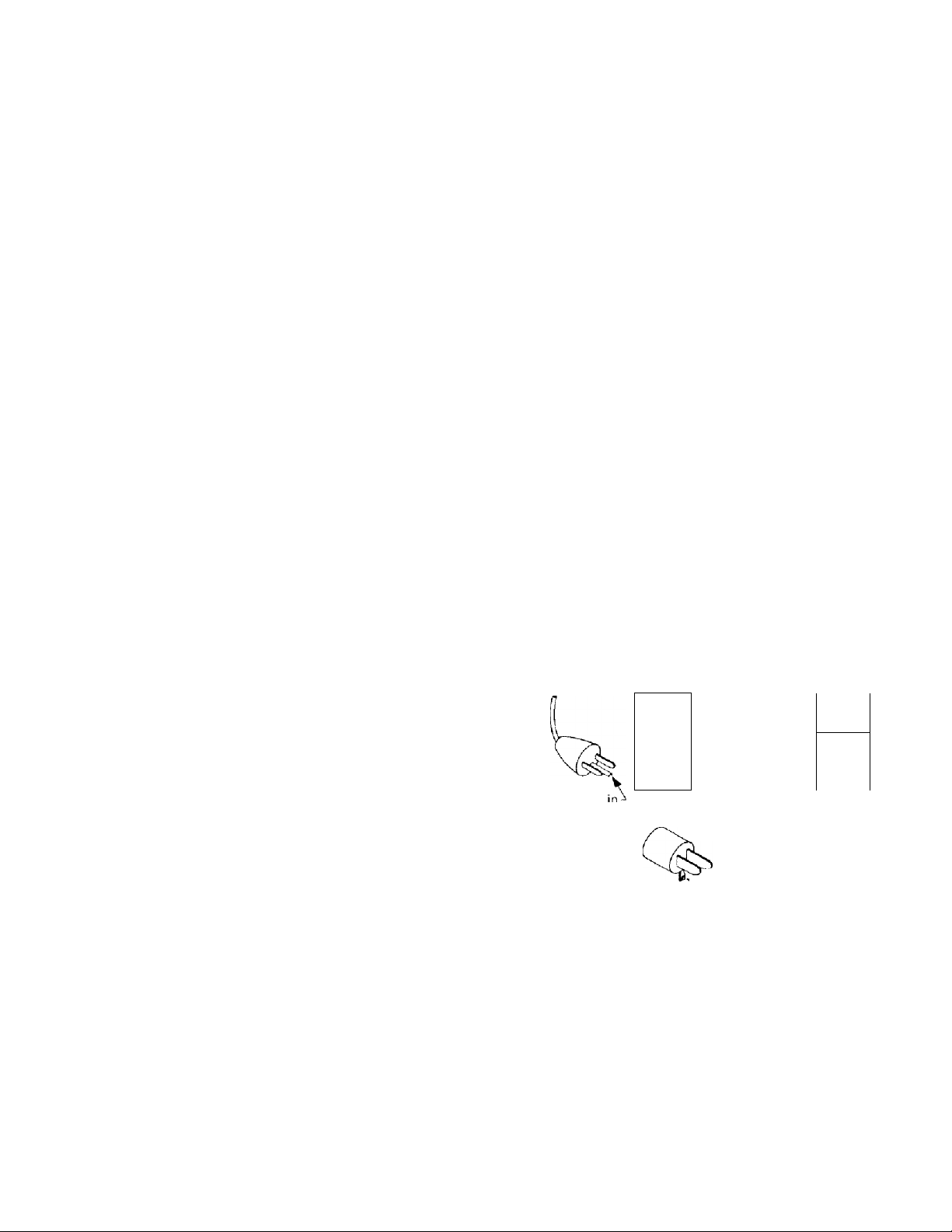

B. Grounded, cord-connected tools intended for use on a

supply circuit having a nominal rating less than 150 volts:

This tool is intended for use on a circuit that has an outlet

that looks like the one illustrated in Sketch A In Figure 1. The

tool has a grounding plug that looks like the plug illustrated

in Sketch A in Figure 1. A temporary adapter, which looks like

the adapter illustrated in Sketches B and C, may be used to

connect this plug to a 2-pole receptacle as shown in Sketch

B if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet

can be installed by a qualified electrician. The green-colored

rigid ear, lug, etc. extending from the adapter must be con

nected to a permanent ground such as a properly grounded

outlet box.

Grounding P

©

•

(A)

Adapter

Meta! Screw -—__

Cover of Grounded

-Ч—-Outlet Box

---------------

■ / /

(TT]

►-

B)

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if

in doubt as to whether the tool is properly grounded.

The use of any Extension Cord will cause some loss of power.

To keep this to a minimum and to prevent overheating and

motor burn out, use the table below to determine ihe MINI

MUM wire size (A.W.G.) Extension Cord.

Use only 3-wire extension cords that have 3-prong grounding

plugs, and 3-pole receptacles that accept the tool's plug.

Extension Cord Length

25 Feet

50 Feet

100 Feet

Extension Cords suitable for use with your Jointer-Planer are

available at your nearest Sears Catalog Order or Retail Store.

Repair or replace damaged or worn cord immediately.

Wire Size, A.W.G.

16

16

14

Grounding

(C)

Means

Figure 1 — Wiring Methods

3. KEEP GUARDS IN PLACE

in working orderand in proper adjustment and alignment.

4. REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning on tool.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents.

6. DON’T USE IN DANGEROUS ENVIRONMENT

Don’t use power tools in damp or wet locations, or expose

them to rain. Keep work area well illuminated.

Page 3

7. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from work area.

8. MAKE WORKSHOP KID PROOF

with padlocks, master switches, or by removing starter keys.

9. DON’T FORCE TOOL

It will do the job better and be safer at the rate for which it

was designed.

10. USE RIGHTTOOL

Don't force tool or attachment to do a job for which It was nol

designed.

11. WEAR PROPER APPAREL

No loose clothing, gloves, neckties, rings, bracelets, or

jewelry to get caught in moving parts. Nonslip footwear is

recommended. Wear protective hair covering to contain long

hair.

12. ALWAYS USE SAFETY GLASSES

Also use face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact resistant lenses. They

are NOT safety glasses.

13. SECURE WORK

Use clamps or a vise to hold work when practical. It's safer

than using your hand and frees both hands to operate tool.

14. DON'T OVERREACH

Keep your proper footing and balance al all times.

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended accessories.

Use of improper accessories may be hazardous.

19. NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped or if the cutting

tool is uninlentionally contacted.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is

damaged should be carefully checked to ensure that it will

operate properly and perform its Intended function - check

for alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

21. DIRECTION OF FEED

Feed work into a blade or cutter against the direction of

rotation of the blade or cutter only.

22. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don't leave tool until it comes to a complete

stop,

23. WEAR EAR PROTECTION

When operating for prolonged period of time,-use of ear pro

tection is recommended.

15. MAINTAIN TOOLS IN TOP CONDITION

Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

16. DISCONNECTTOOLS FROM POWER SOURCE ,

before servicing and when changing accessories such as

blades, bits, cutters, or when mounting and re-mounting

motor.

17. AVOID ACCIDENTAL STARTING

Make sure switch is in ‘‘OFF” posilion before plugging in

cord.

TABLE OF CONTENTS

GENERAL SAFETY RULES FOR POWER TOOLS.........................2, 3

UNPACKING AND CHECKING CONTENTS

SAFETY RULES FOR JOINTER-PLANER.

ASSEMBLY. .....................................................................................5-7

Depth of Cut Hand Knob

Chip Deflector.

Cutter Guard Assembly................................................................. 5

Fence................................................................................................6

Fence Extension

Checking Cutter Blades..................................................................7

INSTALLING THE JOINTER-PLANER................................................8

CONTROLS AND ADJUSTMENTS..................................................8, 9

Depth of Cut Hand Knob

Check Depth of Cut.........................................................................9

Fence Adjustment...........................................................................9

Cutter Guard

Guard Stop.......................................................................................9

ON/OFF Switch.................................................................................9

................................................................................5

................................................................................

................................................................

..........................................................................

................................................................

......................................

...

.....................................

6, 7

.9

The operation of any power too! can result in foreign objects

being thrown into the eyes, which can resul! in severe eye

damage. Always wear safety goggles complying with ANSI Z87.1

(shown on Package) before commencing power tool operation.

Safety Goggles are available at Sears retail or catalog stores.

BASIC JOINTER-PLANER OPERATION....................................10-12

4

5

5

8

Selling the Guard Stop.................................................................10

Feeding the Workpiece

Using Holddown/Push Blocks....................................................11

Beveling, Chamfering.......................................................... 11, 12

Using a Wet/Dry Vac.................................................................. 12

MAINTENANCE

Timing Belt Replacement

Cutter Guard Return Spring........................................................12

Blade Replacement and Adjustment..........................................13

General Maintenance...................................................................13

REPAIR PARTS.............................................................................14, 15

TROUBLE SHOOTING......................................................................16

How to Order Replacement Parts.

.........................................................................12, 13

............................................................

............................................................

.............................................

10, 11

12

16

Page 4

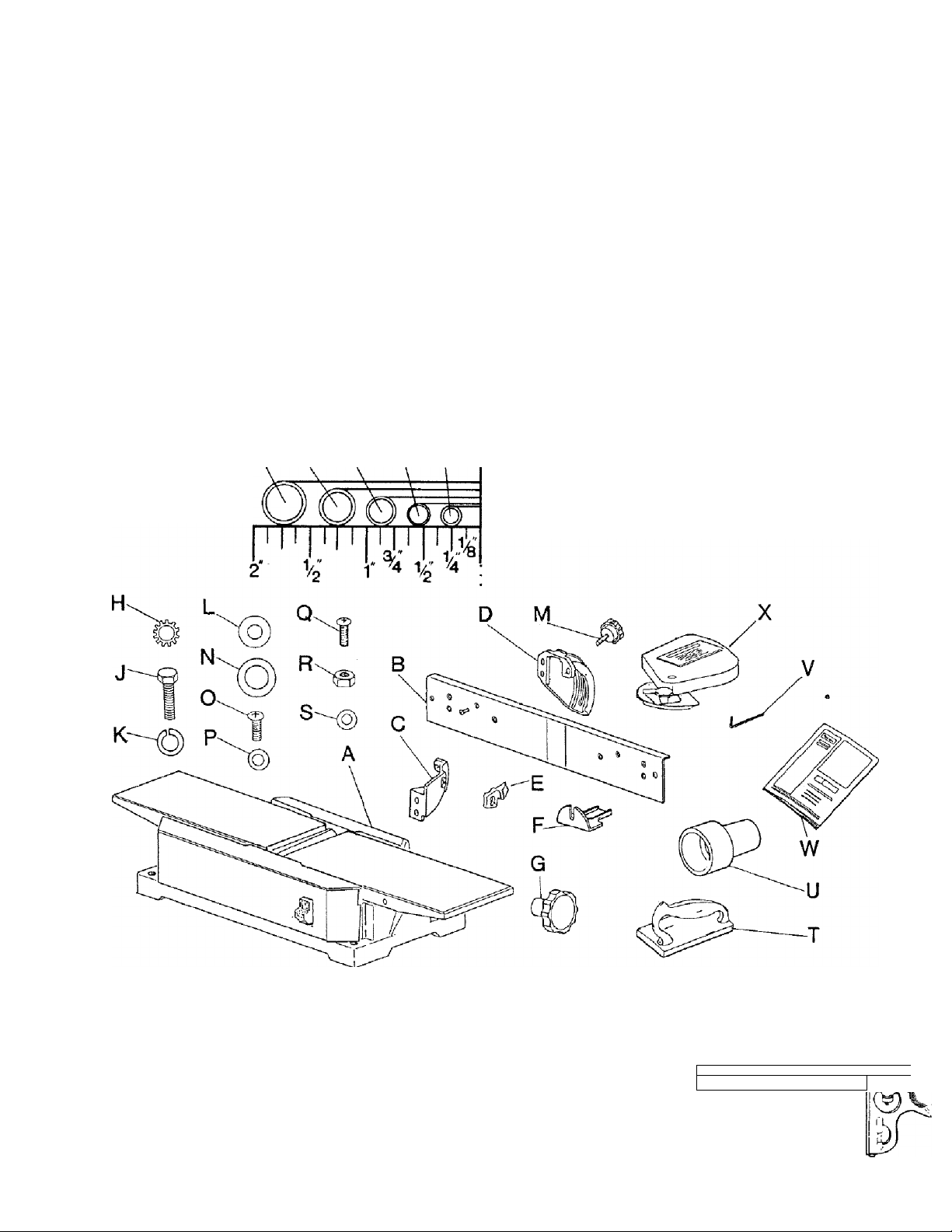

UNPACKING AND CHECKING CONTENTS

Model 149,236321 Jointer-Planer Is shipped complete in one

carton.

Separate all parts from packing materials and check each one

with the illustration and the list of loose parts to make certain

ail items are accounted for, before discarding any packing

material.

If any parts are missing, do not attempt to assemble the

jointer-planer, plug in the power cord or turn the switch on

until the missing parts are obtained and are installed correctly.

Wipe all parts thoroughly with a clean, dry cloth,

Apply a coat of clear automobile paste wax to the tables.

WARNING: FOR YOUR OWN SAFETY, NEVER CON

NECT TO POWER SOURCE UNTIL ALL ASSEMBLY

A

STEPS ARE COMPLETE. AND YOU HAVE READ AND

UNDERSTAND THE SAFETY AND OPERATIONAL INSTRUC

TIONS.

BOLT FINDER

Use to identify fastener

size. Hold head of screw

against folded edge. In

side diameter of sized

circle is for nut, outside

diameter Is for screw.

3/8 5/16' 1/4 1^10 *8

TABLE OF LOOSE PARTS

ITEM DESCRIPTION

NO.

A

Jointer-Planer................................................................ 1

B

Fence

c

D

E

F

G

H

J

K

L

M

N

O

P

Q

R

S

T

u

V

W

X

...............................................................................

Fence Bracket..................................................................2

Fence Segment................................................................2

Tilt Indicator Assembly...................................................2

Chip Deflector

Hand Knob......................................................................1

316" Lockwasber..............................................................1

1/4 "-20 X 3/4" Hex Cap Screw

1/4 Split Lockwasher

1/4 Flat Washer................................................................4

Fence Lock Knobs

9/32" ID X 17/32" ODx 1/8" Thick Washer

S10-24 X 1/2 Machine Screw

#10 Fiat Washer...............................................................2

#8-32 X 1/2" Flat Head Machine Screw..........................6

#8-32 Hex Nut...................................................................6

#8 Flat Washer.................................................................6

Push Block.......................................................................2

2-1/2" to 1-1/4" Vac. Hose Adapter.................................i

5/32" Hex Key (Allen Wrench)

Owner's Manual

Cutter Guard Assemply

.................................................................

.....................................

......................................................

..........................................................2

.......................................

......................................

...........................................................

..............................................

Supplied in loose parts bag

......................

QTY.

1

1

4

4

2

2

1

1

1

14mm or9/16" Wrench

10mm Wrench

8mm or 5/16" Wrench

TOOLS REQUIRED

Medium Slotted Screwdriver

#2 Phillips Screwdriver

—T -'T-x T r T- . r ^ ^ ^ ^

— - r t .

Combination Square

t-x-zLcn

Page 5

A SAFETY RULES FOR JOINTER—PLANER A

Safety is a combination of operator common sense and alertness at all times when the Jointer—Planer is being

used. Study these rules and general safety rules before operating and retain them for future use.

1. WEAR EYE PROTECTION.

2. NEVER MAKE JOINTING OR PLANING CUT DEEPER THAN

1/8 INCH —PER PASS,

3. FEED WORKPIECE AGAINST ROTATION OF CUTTER.

4. KEEP FINGERS AWAY FROM REVOLVING CUTTER - use

fixtures when necessary.

5. NEVER PERFORM JOINTING OR PLANING OPERATION

WITH CUTTER HEAD GUARD REMOVED.

6. NEVER FORCE CUTTING ACTION. Stalling or partial stalling

of motor can cause major damage. Allow motor to reach full

speed before cutting.

7. NEVER - Attempt to perform an abnormal or little used

operation without study and the use of adequate hold down

/push blocks, jigs, fixtures, stops, etc.

8. NEVER - Attempt to cut small pieces.

WARNING: DO NOT AT ANY TIME LET BRAKE FLUIDS, GASOLINE, PENETRATING OILS, ETC.

A

COME IN CONTACT WITH PLASTIC PARTS. THEY CONTAIN CHEMICALS THAT CAN DAMAGE

AND/OR DESTROY PLASTICS.

9. ALWAYS • Use hold down/push blocks for Jointing material

narrower than 3 inches, or planing material thinner than 3

inches.

10. ALWAYS - Keep cutler sharp.

11. NEVER ■ Use in an explosive atmosphere. Normal sparking of

motor may ignite fumes.

12. OUTDOOR EXTENSION CORD USE ■ When tool is used

outdoors, use only extension cords suitable for use outdoors.

Outdoor approved cords are marked with the suffix W-A, for

example - SJTW-A or SJOW-A.

13. ALWAYS use identical replacement parts when servicing.

14. This tool is intended for RESIDENTIAL USE ONLY.

WARNING: DO NOT ALLOW FAMILIARITY (GAINED FROM

FREQUENT USE OF YOUR JOINTER—PLANER) TO BECOME

COMMONPLACE. ALWAYS REMEMBER THAT A CARELESS

FRACTION OF A SECOND IS SUFFICIENT TO INFLICT SEVERE

INJURY.

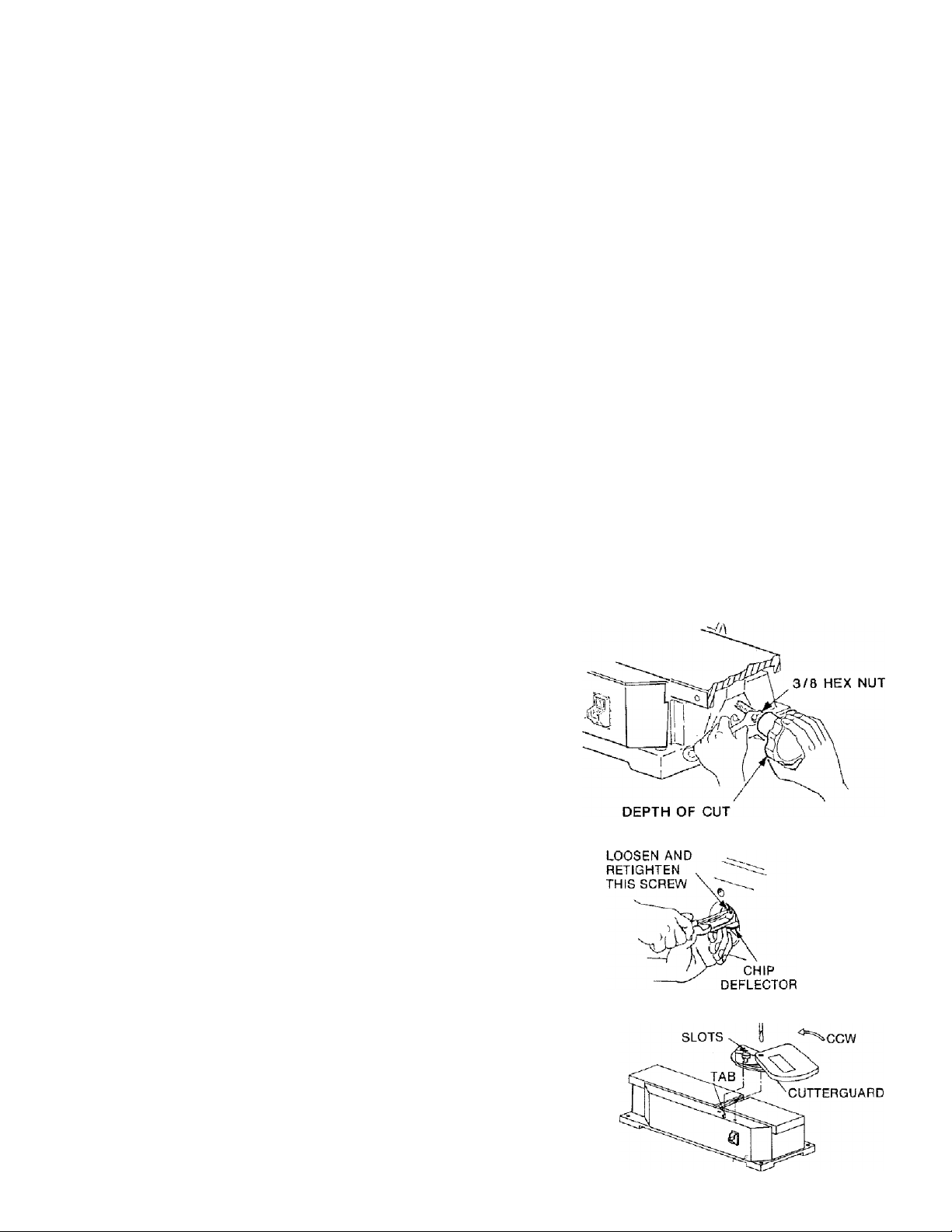

ASSEMBLY

DEPTH OF CUT HAND KNOB

1. Find one 3/8 lockwasher and the depth of cut hand knob from the

parts bag.

2. Turn the nut on the height adjustment screw until five full threads

extend beyond the nut.

3. Place lockwasher on height adjustment screw and thread hand knob

onto screw.

4. Back nut up against hub of hand knob. Tighten with 14mm or 9/16

wrench while holding hand knob.

CHIP DEFLECTOR

1. Loosen the screw in the center of vacuum port of chip discharge.

2. Install slot of chip deflector between the chip discharge and the flat

washer and retighten.

CAUTION: THE CHIP DEFLECTOR MUST BE IN PLACE FOR SAFE

OPERATION. FAILURE TO INSTALL THE CHIP DEFLECTOR MAY

RESULT IN PERSONAL INJURY.

A

CUTTER GUARD ASSEMBLY

Place the slot on the guard stop assembly over the tab on the front

cover as shown and align the shoulder bolt with the threaded hole.

2.

Rotate the cutter guard counterclockwise until the tab Is under the

cutter guard and tighten the shoulder bolt. Be sure the cutter guard

rotates freely after tightening the shoulder bolt.

CAUTION: THE CUTTER GUARD MUST BE IN PLACE FOR SAFE

OPERATION. FAILURE TO INSTALL THE CUTTER GUARD CAN

RESULT IN SERIOUS PERSONAL INJURY.

A

HAND KNOB

SHOULDER BOLT

Page 6

FENCE

1. From among the loose parts find the following:

(1) Fence

(2) Fence Brackets

(2) Fence Segments

(2) Tilt Indicators

(2) Lock Knobs

(4) 1/4-20 X 3/4" Hex Cap Screws

(4) 1/4 Lock Washers

(4) 9/32 ID X 9/16 00 x 1/16 Thick Washers

(2) 9/32 ID X 17/32 00 x 1/8 Thick Washers

(6) #8-32 X 1/2 Flat Head Machine Screws

(6) #8 Flat Washers

(6) #8-32 Hex Nuts

(2) #10-24 X 1/2 Pan Head Machine Screws

(2) #10 Flat Washers

1. Attach fence brackets to base using 1/4-20 x 3/4 hex cap screws,

9/32 lO X 1/16 thick washers and 1/4 lock washers, snug but do not

tighten.

2. Attach fence segments to fence with #8-32 flat head screws, #8 flat

washers and #8-32 hex nuts.

3. Place assembled fence on machine with fence brackets inside the

fence segments.

4. Position lock knobs with 9/32 ID x 17/32 OD x 1/8 thick washers thru

slots in fence segments and thread into fence brackets.

5. Place square against face of fence and table surface. Bring fence

square to tabie and tighten lock knobs.

6. THERE MUST BE 1/32" TO 1/16" gap between the lower edge of the

fence and jointer tables (with table set for 0" cut). To adjust, move

fence assembly by loosening the 1/4-20 x 3/4 hex cap screws attach

ing the fence brackets to the base. Retighten hex cap screws after

adjustment has been made.

LOCK KNOB

7. Recheck squareness of fence.

8. Install tilt indicators with #10-24 x 1/2 pan head machine screw and

#10 flat washers. Set 0° of indicators to 0° of segments and tighten

the screw.

9. The fence should now be adjusted and will accurately measure angles

to 45° Inboard and 45° outboard (see adjustments section).

FENCE EXTENSION

To aid in edge jointing of workpieces 4" and wider, you may extend the

fence height. The extension can be constructed of 1" (3/4" thick) stock

pine or hardwood.

Use #8 flat head wood screws of sufficient length to securely attach the

extension to the fence. Make sure that the head of the screws are below

the surface of the fence so as not to interfere with the workpiece.

For extra stability, additional countersunk holes have been provided near

the ends of the fence.

TILT INDICATOR SHOULD BE LINED UP WITH

THE FENCE SEGMENT AT THE O'MARK.

DO NOT OVER TIGHTEN

r1/4

Page 7

A= 11/16 Thick X 2'Wide X 10" Long

The 11/16 thickness can be obtained by pianing the board

on the Jointer-planer.

B= 1/2" to 3/4" Thick X 3-1/2" Wide x 10" Long

This piece may also be made out of plywood.

,C= 3/4" Thick X 2-1/2" Wide x 19-1/2" Long

' The 2-1/2" width may be increased if desired.

OPTIONAL — For Extra Stability

D= 11/16" Thick X 2" Wide x 2" Long, 2 Pieces

E= 1/2" to 3/4" Thick X 3-1/2" Wide x 2" -»■ Long, 2 Pcs.

NOTE: Cut both 0 pieces from the same stock or thickness as

board A and cut both E pieces from the same stock or thickness

as board B.

CHECKING CUTTER BLADES

CAUTION: MAKE SURE THE SWITCH IS IN THE OFF POSITION

AND CORD IS UNPLUGGED BEFORE PROCEEDING WITH CHECK

ING CUTTER BLADES.

4

The blades in your Jointer-Planer have been adjusted at the factory to

assure proper operation. Shipping and handling, however, may cause

misalignment. For accurate cutting, the blades must be .003-In. higher

than the outfeed table (thickness of a piece of paper) when positioned at

the highest point.

1. Block the cutter guard open with a scrap piece of wood about 5-1/2"

long between the fence and cutter guard.

2. Locate the slot in the cutter head shaft through the small hole in the

backside of the machine directly above the vacuum port. Rotate the

cutter head with a screwdriver until one of the blades Is at its highest

position.

3. place a straight edge over the outfeed table and the blade. The

straight edge must touch evenly on the outfeed table at both ends of

the blade. Rotate the cutterhead slowly, and making sure the blade

lightly touches the straight edge. If the straight edge rises or blades

do not touch, follow the "REPLACING CUTTER BLADES" procedure

in the “MAINTENANCE” section.

CHIP DISCHARGE/VACUUM

Page 8

INSTALLING THE JOINTER—PLANER

If the Jointer-Planer is to be used in a permanent location, it

should be fastened securely to a firm supporting surface such

as a workbench. Holes should be drilled through supporting

surface of the workbench as illustrated. Each foot of the JointerPlaner should be bolted securely using 5/16" diameter machine

bolts, 5/16" hex nuts, and lock washers. Bolts should be of

sufficient length to accommodate foot of Jointer-Planer, washer,

hex nuts, and thickness of supporting surface. Tighten all four

bolts securely. If the Jointer-Planer is to be used in a portable

application, it is recommended that it be fastened to a rnounting

board. The board should be of sufficient size to avoid tipping of

Jointer-Planer while in use. Any good grade of plywood or chip

board with a 3/4" minimum thickness is recommended. Mount

Jointer-Planer to board using hole pattern as shown. Clamp

board securely to workbench or supporting surface.

Supporting surface where Jointer-Planer is mounted should be

examined carefully after mounting to insure that no movement

during use can result. If any "tipping" or "walking" is noted,

secure workbench or supporting surface before operating.

CONTROLS AND ADJUSTMENTS

CAUTION: MAKE SURE THE SWITCH IS OFF AND THE CORD IS UNPLUGGED BEFORE PER

A

FORMING ANY CHECKS OR ADJUSTMENTS.

1. DEPTH OF CUT HAND KNOB

Turning the hand knob clockwise raises the infeed table and

decreases the depth of cut. Turning it counter-clockwise

lowers the Infeed table and increases the depth of cut to the

maximum 1/8" depth per pass.

NOTE: When the table is lowered for the maximum 1/8"

depth cut, the hand knob will be relieved of tension and

will be loose. If this is disturbing, simply turn the hand knob

clockwise until it is again under tension. Turn the knob no

more than 1/2 turn after it is again under tension. This will

not change the depth of cut setting unless 1/2 turn is

exceeded.

Page 9

то CHECK DEPTH OF CUT

a. Place a straight edge on the outfeed table extending over the infeed

table.

b. Measure from the surface of the infeed table to the bottom of the

straight edge. This will be the depth of cut.

NOTE: This Jointer-Planer will nnake a maximum 1/8" deep cut. To reduce

THE DANGER of kickback and possible injury, the depth of cut should not

exceed 1/16" when cutting wood wider than 1-1/2".

CAUTION: MAKE SURE THE SWITCH IS OFF AND THE CORD IS

'

UNPLUGGED BEFORE PERFORMING THIS CHECK.

I

A

2. FENCE ADJUSTMENT

The fence can be adjusted to cut angles from 0° to 45°. Stop pins

allow automatic setting to 0°, 22Vz °, 30° or 45° in either the Inboard

or outboard direction.

TO ADJUST: Loosen fence lock knobs and lift the stop pins out and

turn to lock out. Move the fence to the desired angle. If It Is one of the

commonly used angles listed above, release the stop pins and they

will pop into place when the correct angle Is reached. Tighten the

fence lock knobs to lock the fence in place. For a less common angle

or to fine tune to an angle less than the 5° divisions on the fence seg

ment. Pull and lock out the stop pins and use the 0° to 5° scale on the

tilt indicator to set the exact angle desired.

1. FOR OUTBOARD TILT add the reading on the tilt indicator to the

reading on the fence segment,

2. FOR INBOARD TILT subtract the tilt Indicator reading from the

reading on the fence segment. Always tighten the lock knobs to

maintain the desired setting.

CUTTER GUARD

The cutter guard provides protection over the cutler head. It must

always be in place and functioning properly.

Check the guard to make sure it is functioning properly.

a.

Pass a 1/4" thick piece of wood over the cutter head between the

guard and fence. The guard must return automatically.

b.

Open the cutter guard all the way until it stops and release

it several times. It should always return to its original

position.

4.GUARD STOP

The Craftsman Jointer/Planer comes equipped with a cutter guard

stop assembly to improve safety and reduce risk of injury. Be sure to

read and understand all instructions in the ASSEMBLY and BASIC

JOINTER/PLANER OPERATION sections before operating this tool.

5. ON-OFF SWITCH

The operating positions of the ‘‘On-Off’’ switch are located on the

front of your Jointer-Planer. Push the switch up to turn your JointerPlaner “on" and down to turn your Jointer-Planer "off”. The switch

has a switch key which, when removed, allows the switch to be look

ed in the “off” position. To activate the locking feature push switch

to "off" position and pull switch key.

To turn Jointer-Planer "on” after it has been locked in the “off” posi

tion, the switch key must be replaced in the switch.

CAUTION: IF THE CUTTER GUARD FAILS TO OPERATE

PROPERLY, THE CUTTER GUARD RETURN SPRING

WILL NEED REPLACING. CONTACT YOUR NEAREST

A

SEARS STORE OR SERVICE CENTER FOR REPLACE

MENT SPRING AND INSTRUCTIONS BEFORE USING

THE JOINTER-PLANER.

WARNING: BE SURE SWITCH IS IN THE "OFF” POSITION

BEFORE PLUGGING JOINTER-PLANER INTO POWER SOURCE

FAILURE TO DO SO COULD RESULT IN ACCIDENTAL

STARTING CAUSING SERIOUS INJURY.

9

Page 10

BASIC JOINTER—PLANER OPERATION

For your safety do not exceed a 1/16" deep cut on a planing operation

for work pieces wider than 1-1/2". For work pieces less than 1-1/2",

a 1/8" cut can be taken at a slow feed rate.

This Jointer-Planer is designed with a special cutter head and inter

na! baffle that blows the sawdust and chips from the rear of the

machine. To keep this system operating properly, the motor speed

should be maintained. A feed rate that is too fast will slow the motor

down resulting in a poor cut and poor chip discharge. The type of

wood, wood grain, and moisture content of the wood all affect an

acceptable feed rate.

CAUTION; MAKE SURE ALL SIX BLADE LOCKING SCREWS

f-

ARE TIGHTENED SECURELY BEFORE ATTEMPTING TO

A

TURN THE MACHINE “ON” OR ATTEMPTING ANY OPERA

LTION.

Ì

SETTING THE GUARD STOP

CAUTION: MAKE SURE THE SWITCH IS IN THE OFF POSI

TION AND THE CORD UNPLUGGED BEFORE SETTING THE

GUARD STOP.

A

The guard stop assembly allows you to limit the cutter guard open

ing during operation and can be adjusted to prevent the cutter guard

from opening when the Jointer/Planer is not in use.

As a Safety Cover

When the Jointer/Planer is not in use, rotate the guard stop and

knob clockwise until it contacts the cutter guard and lock the knob.

During Operation

1. With the Jointer/Planer switch in the off position and the cord

unplugged place a workpiece of the size to be used on the

infeed table,

2. Loosen the guard slop knob and pass the workpiece between

the fence and the cutter guard and through the cutter area

until the cutter guard is rotated as far as this workpiece will

require.

For your own safety, ALWAYS use hold down/push blocks when

JOINTING wood that is NARROWER than 3 in. or when PLANING

WOOD THAT IS THINNER than 3 in.

Do not plane. Joint or bevel wood shorter than 12 in. Material this

short is more difficult to control while being cut. Smalt pieces of

wood can tip over on the tables or into the cutterhead and can be

kicked back toward you.

For best results, take light cuts. For average planing, jointing, or

beveling, a cut between 1/32 and 1/16 in. deep will produce the

best results.

Rotate the guard stop and knob clockwise until it contacts the

cutler guard and lock the knob. To prevent binding or pinching,

some clearance will be regutred between the guard stop and

the cutter guard.

4,

The guard stop is now set to cut workpiece of the same width

as the sample used in the set up.

Be sure to use this procedure whenever using the Jointer/

Planer and lock the cutter guard in the fully closed position

when not in use to prevent injury to anyone unfamiliar with this

tool. Failure to do so may result in serious injury.

FEEDING THE WORK PIECE

Hold the board firmly DOWN on both tables and AGAINST the fence

...keep fingers close together.

Feed the board at a continuous even rate of speed until the cut is

made along the entire length of the board. Any hesitation or stop

ping could cause a “step" to be cut on the edge of the board which

would cause the board to ride up on the outfeed table resulting in a

“crooksd” edge on the board.

wiTHTreawN

WOFKPECE

Start with the left hand in the forward position. As the RIGHT hand

passes over the cutterhead, remove the LEFT hand...CONTÌNUE

feeding while placing the LEFT hand behind the RIGHT, Continue

feeding in this manner "hand over hand,” until the entire length of

the board is cut. Pressure should be applied over the cutterhead

and outfeed table.

DO NOT FEED TOO FAST. A slow Steady rate of feed produces a

smooth accurate cut. Feeding too fast causes a “rippled” cut

makes it difficult to guide the workpiece accurately and could be

hazardous.

FEE) WORK PIECE .. f

AOAIHBT THE GRAIN

Always feed WITH THE GRAiN whenever possible. If the nature of

the work piece is such that it must be fed AGAINST THE GRAIN,

take very light cuts and feed slowly.

HAWPOVtt-HAMD

10

Page 11

WARNING: NEVER PLACE THE HEEL OF YOUR HAND AT

THE END OF THE WORK PIECE WHEN FINISHING A CUT.

THIS COULD RESULT IN YOUR HAND COMING IN CONTACT

A

WITH THE CUTTER CAUSING SERIOUS INJURY.

At the end of the cut, poaition your hand on TOP NEAR THE END

of the work piece and continue feeding the work piece until the

cutter guard has returned to its closed position.

WRONG

USING HOLD DOWN/PUSH BLOCKS

ALWAYS use the hold down/push blocks when JOINTING wood

that is NARROWER than 3 in. or PLANING wood that is THINNER

than 3 In.

Grasp the hold down/push blocks firmly with the fingers close to

gether and wrapped around the handle. Position them flat on top of

workpiece, and push the workpiece down against the table to pro

vide a quality cut and minimize the chance of a kickback.

Hold down pressure must be sufficient to prevent hold down/push

block from sliding or slipping on the surface of the workpiece when

advancing work piece over cutter head.

Use a hand-over-hand motion of the hold down/push blocks being

careful to maintain control of the workpiece at all times.

This means that once the work piece has passed the cutter head

onto outfeed table, one hold down/push block must always main

tain contact with the work piece with outfeed table.

When planing wood 3/4 in. thick and NARROWER than the hold

down/push block, tilt the hold down/push block so that if clears

the top of the cutter guard while feeding.

Never plane wood that Is thinner than 1/2 in...because it Is apt to

split or shatter and thus has a greater tendency to kickback.

CAUTION: IF THE HOLD DOWN/PUSH BLOCKS TEND TO

SLIP WHILE FEEDING, CLEAN RUBBER SURFACE IMMEDI

ATELY WITH SANDPAPER.

A

RIGHT

HAND-OVER HAND

BEVELING AND CHAMFERING

The fence on your jointer-planer Is adjustable from 45° Inboard to

45° outboard. Adjust the fence to desired angle and tighten lock

knobs,

BEVELING Is the cutting of an angle on the entire edge of a board.

Beveling may require several passes due to the depth of cut needed

to bevel entire edge of board.

BEVEL

CHAMFERING is removing only the corner of the edge of a board.

Normally a chamfer is made with one gut; therefore, a cut deeper

than 1/16" may be made.

11

Page 12

For beveling and chamfering operations, follow the same

procedure as for jointing and planing described on pages 10 and

11, Before performing these operations make sure the surface of

the work piece that contacts the fence is flat and smooth. Main

tain firm control of the work piece at all times holding it firmly

against fence surface and table surfaces.

USING A WET-DRY VAC

Your Jointer-Planer has a rear chip exhaust which fits all

Craftsman Wet-Dry Vacs with a 2-1f2 inch hose. A 2-1/2 in. to

1-1/4 in. hose adapter is suppiied with the machine for 1-1/4 in.

hose connections. Attaching a Craftsman Wet-Dry Vac will keep

your work area cleaner. Craftsman Wet-Dry Vacs are available at

Sears Catalog and Retail Stores.

Use hold down/push blocks for wood under 3 in. wide. Position

them so you have control of the work piece at all times and so

they do not contact the guard or the cutler head.

WARNING: DO NOT REMOVE CHIP DEFLECTOR EVEN

IF VACUUM HOSE REMAINS PERMANENTLY ATTACH

A

ED TO MACHINE. NEVER LEAVE HOSE ON MACHINE

DURING OPERATION IF A VAC IS NOT USED DURING OPERA

TION OR THE HOSE AND MACHINE WILL CLOG WITH CHIPS.

MAINTENANCE

TIMING BELT REPLACEMENT

1. Unplug your Jointer-Planer and pul switch in OFF position.

DANGER: FAILURE TO UNPLUG YOUR JOINTER-

A

2. Remove access cover plate by loosening two pan head screws

3. Remove old timing belt by turning belt and maintaining out

4. Replace with new timing belt by turning bell and maintaining

PLANER COULD RESULT IN ACCIDENTAL STARTING

CAUSING SERIOUS INJURY.

under the machine and one located under the cutter guard,

being careful not to damage or disconnect the switch wiring.

DO NOT remove cutter guard or guard spring from access

cover.

ward pressure.

inward pressure. NOTE: Make sure full width of belt is on

both pulleys.

CHIP EXHAUST

VACUUM PORT

CUTTER GUARD RETURN SPRING

do not LUBRICATE THE PIVOT POINT OF THE CUTTER

жЖсиАпо.

Oil and lubricating products may contain chemicals that can

damage and/or destroy the cutter guard or other plastic parts.

CAUTION: IF THE CUTTER GUARD FAILS TO OPERATE

PROPERLY (SEE "CONTROLS AND ADJUSTMENTS”

A

SECTION), THE CUTTER GUARD RETURN SPRING WILL

NEED REPLACING, CONTACT YOUR NEAREST SEARS STORE

OR SERVICE CENTER FOR REPLACEMENT SPRING AND IN

STRUCTIONS BEFORE USING THE JOINTER—PLANER.

12

Page 13

BLADE REPLACEMENT AND ADJUSTMENT

NOTE: To rotate the cutterhead or to hold it steady, use a

screwdriver in the slot in the cutter shaft through the small hole

n the rear of the machine just above the vacuum port.

1. Unplug your Jointer-Planer and put switch in off position.

DANGER; Failure to unplug your Jointer-Planer could result

in accidental starting causing serious injury.

2. Block the cutter guard open.

3. Using the 5/32" hex key {Allen wrench), remove the three (3)

blade lock screws securing blade and blade clamp.

4. Lift blade and blade clamp from cutter head.

5. Clean any sawdust from cutterhead and any parts you have

removed.

6. Place blade clamp against the replacement blade and replace

in cutterhead with the (3) blade lock screws, NOTE: Relighten

blade lock screws so that the blade is held by friction but still

allows for blade movement.

7. Place a straight edge across the outfeed table and across the

cutterhead opening.

8. Rotate the cutterhead until the blade contacts the straight

edge (rotate backwards to prevent damage to the cutting

edge). A properly adjusted blade will lightly tick (touch) the

straight edge. •

9. BLADE TOO HIGH: If the Straight edge is lifted by the blade,

it must be lowered. Tap the blade lightly with a scrap piece of

wood to lower it.

10. BLADE TOO LOW: If the blade does not touch the straight

edge, it should be raised. Pry the lower edge of the blade with

a screwdriver against the edge of the outfeed table. Always

protect the edge of the table with a scrap of wood or piece of

cardboard.

11. Tighten blade lock screws.

CUTTER HEAD

BLADE

BLADE

BLADE CLAMP

LOCK SCREW

NOTE: Check blade height at both ends of blade. After the first

one is adjusted, repeat for second blade.

CHIP DISCHARGE/VACUUM

12. Recheck blade adjustment, making sure blade is still level

with outfeed table.

13. Recheck screws to be sure they are secure.

DANGER: FAILURE TO TIGHTEN BLADE LOCK

SCREWS COULD RESULT IN SERIOUS INJURY.

A

GENERAL MAINTENANCE

Keep your Jointer-Planer clean and adjusted properly for

maximum performance and longevity of the machine. Do not

allow pitch to accumulate on the tables, fence, cutter guard, or

blades. Clean them frequently with Sears Gum and Pitch

Remover stock number 49191.

WARNING: DO NOT AT ANY TIME LET BRAKE FLUIDS,

GASOLINE, PENETRATING OILS, ETC. COME IN CON

A

TACT WITH PLASTIC PARTS. THEY CONTAIN CHEM

ICALS THAT CAN DAMAGE AND/OR DESTROY PLASTICS.

DO NOT allow anything to obstruct the chip discharge outlet or

disturb the air flow produced by the cutter head.

If the chip discharge of your Jointer-Planer clogs with chips,

turn the switch OFF and UNPLUG the unit to avoid accidental

starting. Dislodge the chips and debris with a pencil or small

wood dowel, When resuming operation with the same work piece,

feed at a slower rate to avoid re-clogging. Use of a Wet-Dry Vac

will virtually eliminate the chances of clogging.

13

Page 14

CRAFTSMAN 5-1/8 INCH JOINTER-PLANER MODEL No. 149.236321

J3

m

Page 15

CRAFTSMAN 5-1/8 INCH JOINTi_.<-PLANER MODEL No. 149.236321

PARTS LIST

REF.

PART NO. DESCRIPTION QTY.

NO.

1

4550-001-70 Base

2 4550-011-70

Infeed Table

3 2292-075-90 Rocker Link Hinge

4

1791-001-00

5

1727-001-00 *1/4-20 X 1-1/4 Socket Set Screw

6 STD541025

7

4550-050-70 Hand Knob

11/32 ID X 9/32 OD x 1/32 Washer 4

1/4-20 Hex Nut

8 STD551237 3/8 External Tooth Lock Washer

9 STD541237

10 4550-051-70

11

2232-059-00 Table Spring

12

2292-046-00 8mm Shaft “E” Clip

13

4550-090-90 Cutterhead Assembly, Includes Ref 14-18

3/8 Hex Jam Nut

Table Screw

14 2292-027-00 1/4-20 X 1/2 Socket Button Head Screw 6

15 4550-093-70 Blade Clamp 2

16

4550-092-70 Blade

17 4550-091-70 Cutt6rh©3d 1

18 STD502505 1/4-20 X 1/2 Socket Set Screw 2

19 4550-044-90

CA

20 STD551210 #10 External Tooth Lock Washer 7

21

STD511003 #10-24 X 3/8 Pan Head Mach Screw 7

22

STD503105 5/16-18 X 1/2 Socket Set Screw

23

1714-002-00 1/4-20 X 3/4 10mm Hex Head Screw 4

24

STD610805 #8 X 3/8 Type B Pan Head Screws

Chip Chute/Baffle Assembly

25 STD510805 #8-32 X 1/2 Pan Head Mach Screw 4

26 STD551208 #8 External Tooth Lock Washer

27 4550-220-90

Motor Assembly, Includes Ref Nos 28-31

28 4550-046-70 Motor Housing

29 4550-221-00 Motor (Northland (#73523) 1

30 STD501002

31 2292-021-00

32

STD522505

33 2292-064-00

34 2292-069-00

#10-24 X 5/16 Socket Set Screw

Motor Pulley

1/4-20 X 1/2 Hex Flange Screw

Motor Bracket

3/16 Cable Clamp, Heyco #3303

35 2292-032-00 XL120 X 3/8 Wide x 12 Timing Belt 1

36 2292-029-00

37 4550-094-70

38 4550-041-70

Machine Pulley

Cutterhead Shaft

Front Cover

39 2292-067-00 DPST Switch (Includes Ref No 40) 1

40 2292-068-00 Switch Key (Order for Key Only) 1

41 STD511007 #10-24 x 3/4 Pan Head Mach Screw 6

42 STD551010

#10 Flat Washer 5

1 REF.

NO.

1

1

4

43 4550-120-70

44 2292-036-00 Guard Spacer

45

46 2292-034-00

2

2

1

1

1

1

1

4

1

47

48 2292-050-00 1/4-20 X 1/2 Shoulder Bolt Slotted

49 4550-012-70 Outfeed Table

50 2292-016-00

51 STD315205

52 2292-048-00

53 STD551025

54 STD551125

55 STD522507 1/4-20 X 3/4 Hex Head Cap Screw

56 STD581018

PART NO. DESCRIPTION

Guard Return Spring

4550-039-70 Cutterguard

Danger Plate (Order for Label Only)

2292-051-00

.260 ID X .440 OD Wave Washer

Fence Bracket

10mm X 30mm Ball Bearing, Double Seals

10mm Shaft Retaining Ring 1

1/4 Flat Washer

1/4 Split Lock Washer

3/16 Shaft “E” Clip

57 4550-121-70 Detent Spring

2

1

4550-162-70 Stop Pin 2

58

4550-161-70 Tilt Indicator

59

60

4550-020-70

61 1699-010-00

62

4550-163-70

Fence

*#8-32 X 1/2 Flat Head Mach Screw 6

Fence Segment

QTY.

1

1

1

1

1

1

1

2

2

4

4

4

2

2

2

1

2

63 1791-002-00 9/32 ID X 17/32 OD x 1/8 Washer 2

4

1

4

1

1

2

1

3

1

2

1

1

1

64 2292-019-00 1/4-20 X 1 Lock Knob 2

65 STD551008

66 STD541008 #8-32 Hex Nut 6

67

4550-040-70

68 2292-013-00

69 2288-000-00

70 2292-044-00

#8 Flat Washer

Rear Cover

Chip Deflector 1

5/32 Hex Key (Allen Wrench) 1

2-1/2 Male, 1-1/4 Female Vacuum Adapter 1

71 2292-047-00 Push Blocks (Order No. 2299)

72 2292-066-00

6MO" Long 18/3SJT Cord 1

73 2292-010-00 Strain Relief Bushing (Heyco #1214)

74

STD511005

#10-24 X 1/2 Pan Head Mach Screw 2

75 1699-013-00 #8 X 1/4 Thread Forming Screw

76 4550-036-70 Knob, Guard Stop 1

77 4550-037-70 Guard Stop

78 STD551031 5/16 Fiat Washer

79 4550-038-70 Guard Stop Bracket

80 STD532507 1/4-20 X 3/4 Carriage Bolt 1

4550-250-00 Sears Craftsman Label (Not Illustrated)

-

4551-252-00 Owners Manual (Not Illustrated)

-

2292-057-00

Parts Bag (Not Illustrated)

2105-039-00 Plastic Cable Tie (Not Illustrated)

6

1

2

1

1

1

1

1

1

1

1

1

■'Standard Hardware Item - May Be Purchased Locally-

Page 16

TROUBLE SHOOTING CHART

TROUBLE

Wood strikes outfeed

table after passing over

cutterhead

Ripples on planed surface.

Planed surface not straight.

Excessive gouging at end of cut.1. Blades set too high above outfeed table.

90" and 45" cuts inaccurate

Cutter guard does not

function properly.

Chip discharge clogs

1. Blades improperly adjusted below

surface of outfeed table.

2. Infeed table out of adjustment

1. One blade set higher than other.

2. Dull blades.

3. Board not held firmly against fence or

outfeed table

1. Infeed table loose or out of adjustment. 1, Adjust infeed table, see Maintenance

2. Blades set too low.

1. Fence and tilt indicators not adjusted

properly.

■1. Return spring broken, or spring

has been weakened.

1, Obstruction reducing air flow. ,

2. Cutter head speed too slow.

3, Wood has high moisture content.

PROBABLE CAUSE REMEDY

1. Re adjust blades.

2. Contact your nearest Sears store

or service center.

1. Re-adjust blades

2. Re-sharpen or replace.

3. Hold board firmly against fence and

outfeed table.

section.

2, Re-adjust blades.

1. Reset blades,

1. Re-adjust fence, see Assembly

section,

1. Replace spring immediately. Contact

your nearest Sears store or service

center.

1. Remove obstruction.

2. Decrease feed speed.

3. Decrease feed speed.

f

Cutter slows down

during operation

owners

manual

Service

MODEL NO.

149.236321

How To Order

Repair Parts

1, Work feed speed loo fast.

2. Attempting to remove too much material

S£4/i^a/CRflFTSMflN»

SVs-INCH JOINTER-PLANER

Now that you have purchased your Jointer-Planer, should a need ever exist for

repair parts or service, simply contact any Sears Service Center and most Sears,

Roebuck and Co. stores. Be sure to provide all pertinent facts when you call or

visit.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING INFORMATION:

•PART NUMBER • PART DESCRIPTION

• MODEL NUMBER:

149.236321

All parts listed may be ordered from any Sears Service Center and most Sears ¿tores.

If the parts you need are not stocked locally, your order will be electronically

transmitted to a Sears Repair Parts Distribution Center for handling.

1. Decrease feed speed.

2. Decrease depth of cut, make ,

• NAME OF ITEM: 5-1/8 INCH

JOINTER—PLANER

two or more cuts. 1

1

SEARS, ROEBUCK AND CO., Dept. D/817WA, Hoffman Estates, IL 60195

Printed in U.S.A.

Loading...

Loading...