Craftsman 149236222 Owner’s Manual

S_/A/RS

owners

manual

MODELNO.

149.236222

SERIAL

OR CODE

NUMBER:

Model and code number may be

found on the back of the base

You should record both model and

code number and re_.ain in a safe

place for fulure use

CALIFORNIA OWNERS: a unique

serial code number is slamped on

the underside of !he machine

CAUTION:

Read All Instructions

Carefully Before Start.

ing Assembly and Use.

Save This Manual For

FutureReference,

S_FAIRS/ CRAFT$IvtRN_

41_-I C

JOINTER-- PLANER

=assembly

, operating

• repair parts

SEARS, ROEBUCK AND CO. DepL 6981731A, Sears Tower, Chicago, IL 60684

Part No 4502.250-00 7f90

FULL ONE.YEAR WARRANTY ON CRRFTSMRN ,JOINTER -- PLANER

If within one year from the date of purchase, this Craftsman Jointer -- Planer fails due to a defect

in material or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS STORE OR SERVICE

CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights and you may also have other rights which vary from

state to state°

Sears, Roebuck and Co. Dept. 698173tA, Sears Tower, Chicago, IL 60684..

GENERAL SAFETY RULES FOR POWER TOOLS

1. KNOW YOUR POWER TOOL

For your own safety, read the owner's manual carefully

Learn its application and limitations as well as the specific

hazards peculiar to this tool

2 GROUNDING INSTRUCTIONS

A All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding pro°

vtdes a path of ]east resistance for electric current to reduce

the risk of electric shock This Iool is equipped with an

electric cord having an equipment.grounding conductor and

a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet instafled by a qualified electrician

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock The conductor wilh

insulation having an outer surface that is green with or with-

out yeltow stripes is the equipment-grounding conductor If

repair or replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conducto_ to a live

terminal

Check with a qualified electrician or serviceman if the

grounding instruclions are not complelely understood, or if

in doubt as to whether the too] is properly grounded

The use of any Extension Cord will cause some loss of power

To keep this Io a minimum and to prevent overheating and

motor burn-out, use the table below to determine the MINI..

MUM wire size (A.WG) Extension Cord

Use only 3-wire extension cords that have 3-prong grounding

plugs, and 3-pole receptacles that accept the tool's plug

Extension Cord Length Wire Size, A WG

25 Feet 16

50 Feet 16

100 Feet 14

Extension Cords suitable tor use with your Joinler-Ptaner are

available at your nearest Sears Calalog Order or Retail Store

Repair or replace damaged or worn cord immediately

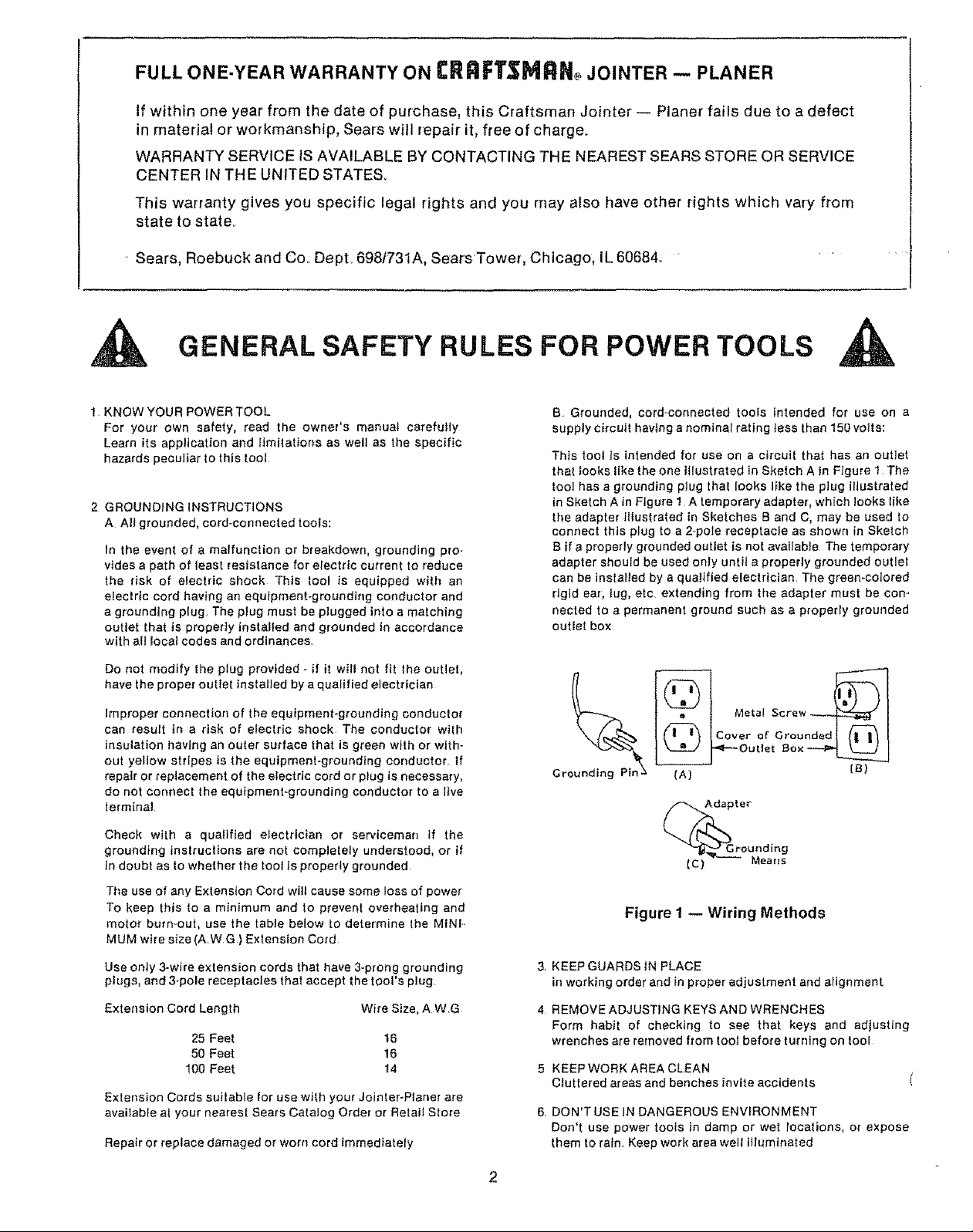

B Grounded, cord.connected tools intended for use on a

supply circuit having a nominal rating Jess than 150 votts:

This tool is intended for use on a circuit that has an outJet

that looks like the one illustrated in Sketch A in Figure 1. The

too] has a grounding plug that looks like the plug illustrated

in Sketch A in Figure ! A temporary adapter, which looks like

the adapter illustrated in Sketches B and C, may be used to

connect this plug to a 2-pole receptacle as shown in Sketch

B if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlel

can be tnstatted by a qualified electrician. The green_colored

rigid ear, lug, ete extending from the adapter must be con..

nected to a permanent ground such as a properly grounded

outlet box

Adapter

(C) Mea_ls

Figure I -- Wiring Methods

_L

KEEP GUARDS IN PLACE

in working order and in proper adjustment and alignment.

4

REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning on lool

5

KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents

6

DON'TUSE IN DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet feeations, or expose

them to ratn_ Keep work area well illuminated

7 KEEP CHILDREN AWAY

All visttors should be kept a safe distance from work area

8. MAKE WORKSHOP KID PROOF

with padlocks, master switches, or by removing starter keys

9. DON'T FORCE TOOL

It will do the job better and be safer at the rate for which it

was designed.

10. USE RIGHT TOOL

Don't force tool or attachment to do a job for which it was nol

designed.

11: WEAR PROPER APPAREL

No loose clothing, gloves, neckties, rings, bracelets, or

jewelry to get caught in rnoving parts. Nonslip footwear Is

recommended Wear protective hair covering to contain long

hair

12. ALWAYS USE SAFETY GLASSES

Also use face or dust mask if cutting operation is dusty

Everyday eyeglasses only have impact resistant lenses They

are NOT safety glasses

!3 SECURE WORK

Use clamps or a vise to hold work when practical It's safer

than using your hand and frees both hands to operate toot

14 DON'T OVERREACH

Keep your proper footing and balance at all times

15 MAINTAIN TOOLS IN TOP CONDITION

Keep tools sharp and clean for best and safest performance

Follow instructions for lubricating and changing accessories

16 DISCONNECT TOOLS FROM POWER SOURCE

before servicing and when changing accessories such as

blades, bits, cutters, or when mounting and re.mounting

motor.

17..AVOID ACCIDENTAL STARTING

Make sure switch is in *'OFF" position before plugging in

cord

18

USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended accessories.

Use of improper accessories may be hazardous

19.

NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped or if the cutting

1ool is unintentionally contacted

20 CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is

damaged should be carefully checked to ensure that ii will

operate properly and perform its intended function - check

for alignment of moving parts, btnding of moving parts,

breakage of parts, mounting, and any other conditions that

• may affect its-operation A guard or other part that.is damaged

should be properly repaired or replaced.

21..DIRECTION OF FEED

Feed work into a blade or cutter against the direction of

rotation of the blade or cutter only

22 NEVER LEAVE TOOL RUNNING UNATTENDED TURN

POWER OFF. Don't leave tool until it comes to a complete

stop

23. WEAR EAR PROTECTION

When operating for prolonged period of time, use of ear pro-

tection is recommended

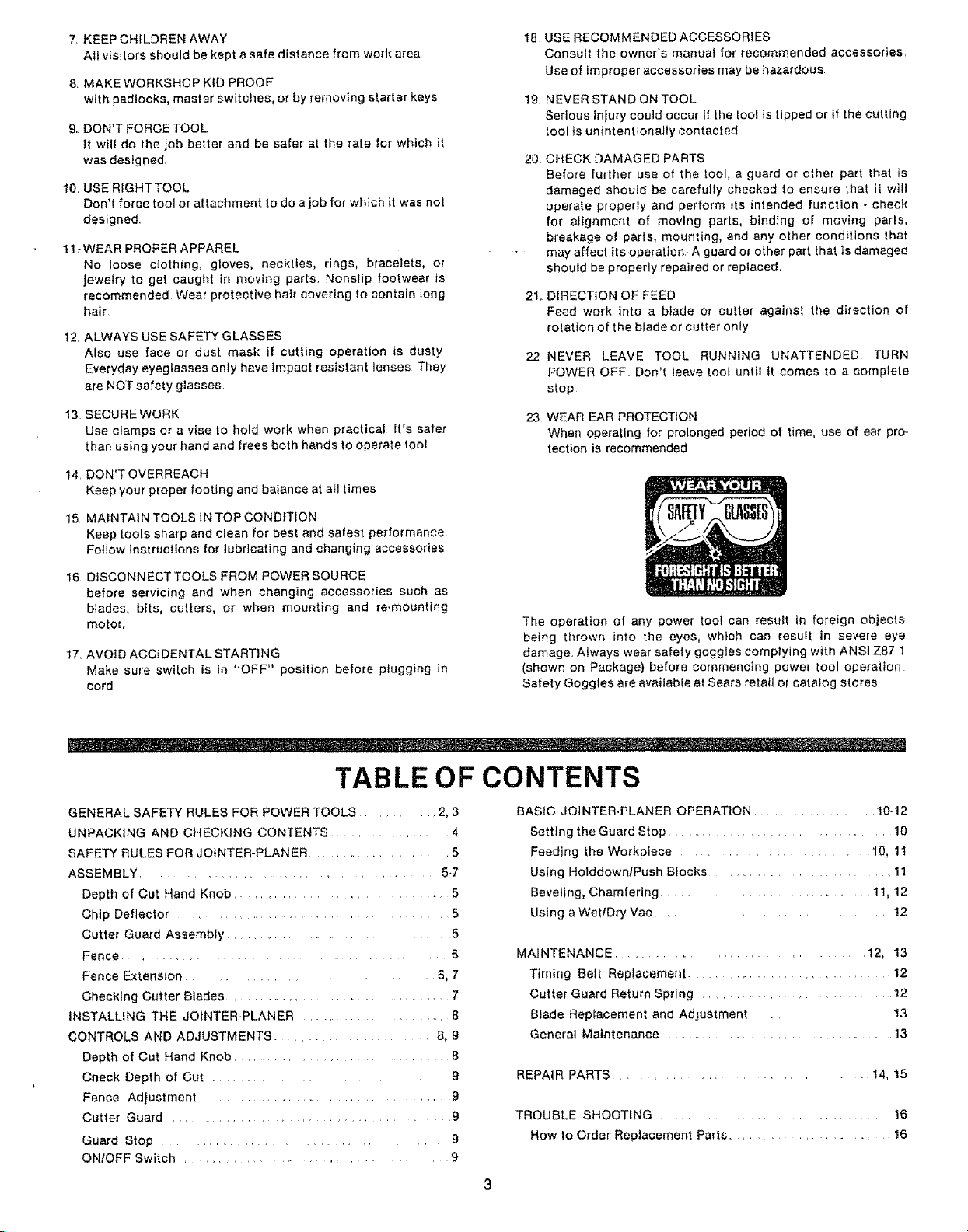

The operation of any power tool can result in foreign objects

being thrown into the eyes, which can result in severe eye

damage. A_ways wear safety goggles complying with ANSI Z87 1

(shown on Package) before commencing power tool operation.

Safety Goggtes are available at Sears retail or catalog stores.

TABLE OF CONTENTS

GENERAL SAFETY RULES FOR POWER TOOLS 2, 3

UNPACKING AND CHECKING CONTENTS 4

SAFETY RULES FOR JOtNTER-PLANER 5

ASSEMBLY .. 5..7

Depth of Cut Hand Knob 5

Chip Deflector 5

Cutter Guard Assembly 5

Fence . _ 6

Fence Extension ....... 6, 7

Checking Cutter Blades 7

INSTALLING THE JOtNTER-PLANER 8

CONTROLS AND ADJUSTMENTS 8, 9

Depth of Cut Hand Knob 8

Check Depth of Cut ........... 9

Fence Adjustment 9

Cutter Guard 9

Guard Stop 9

ONfOFF Switch 9

BASIC JOtNTER-PLANER OPERATION .................. 10-12

Setting the Guard Stop ................................. 10

Feeding the Workplace .......................... 10, 11

Using HolddownfPush Blocks ......................... 11

Beveling, Chamfering ........................ 11, 12

Using a Wet/Dry Vac ................................... 12

MAINTENANCE ..................................... 12, 13

Timing Belt Replacement .................................. 12

Cutter Guard Return Spring .............................. 12

Blade Replacement and Adjustment ..................... 13

General Maintenance ...................................... 13

REPAIR PARTS ..................................... 14, 15

TROUBLE SHOOTING ................................... 16

How to Order Replacement Parts ........................... 16

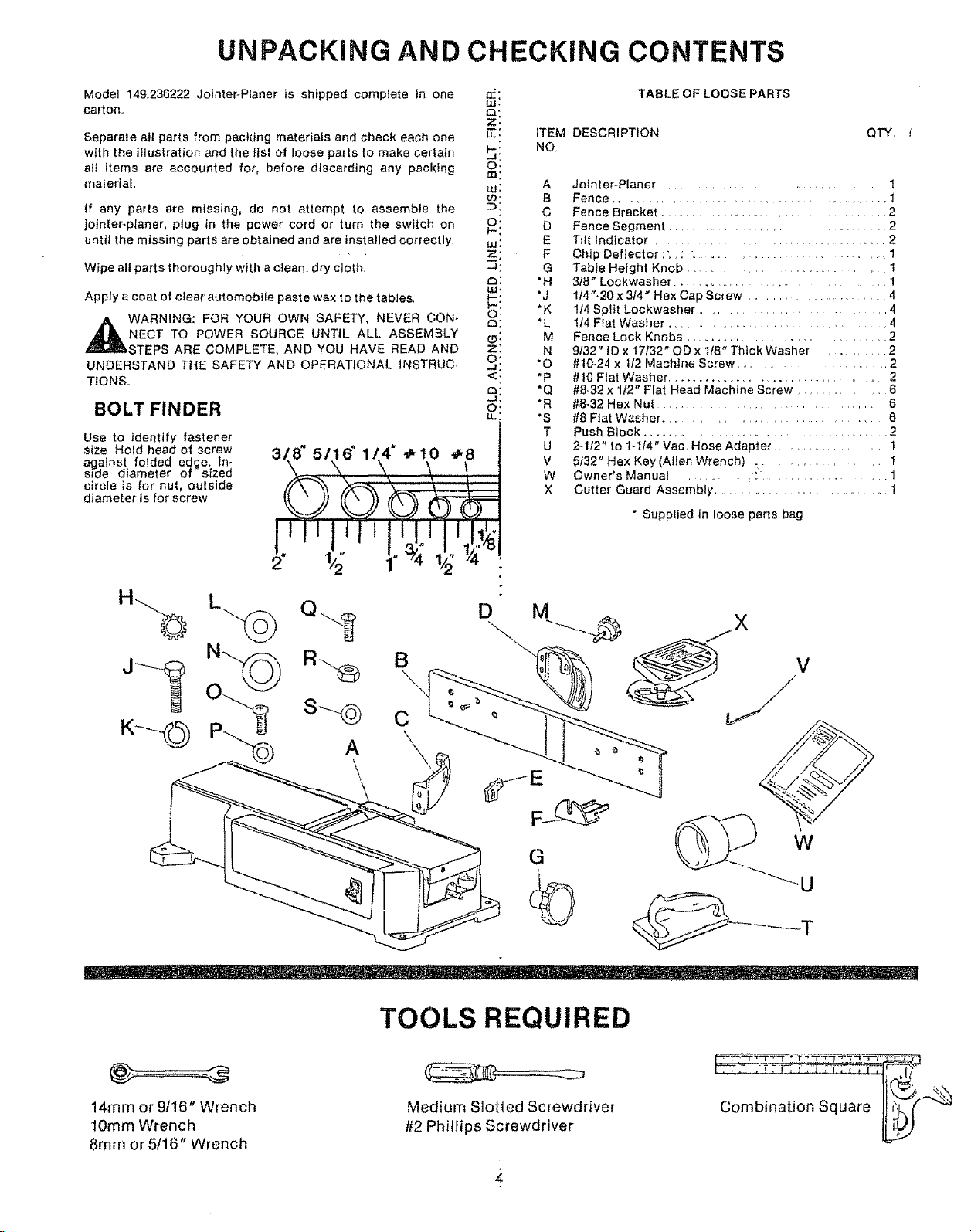

UNPACKING AND CHECKING CONTENTS

Model 149236222 Jolnter-Planer is shipped complete tn one

carton,

Separate all parts from packing materials and check each one

with the illustration and the tist of loose parts to make certatn

all items are accounted for, before discarding any packing

material

If any parts are missing, do not attempt to assemble the

jointer-planer, plug in the power cord or turn the switch on

until the missing parts are obtained and are installed correctly.

Wipe all parts thoroughly with a clean, dry etoth

Apply a coat of cleat automobile paste wax to the tables

WARNING: FOR YOUR OWN SAFETY, NEVER CON-

NECT TO POWER SOURCE UNTIL ALL ASSEMBLY

STEPS ARE COMPLETE, AND YOU HAVE READ AND

UNDERSTAND THE SAFETY AND OPERATIONAL INSTRUC-

TIONS.

BOLT FINDER

Use to identify fastener

size Hold head of screw

against folded edge. tn:

s_de diameter or s_zea

circle is for nut, outside

diameter is for screw

318' 5116" 1/?

lilt

2" 4 1

÷t0 _8

\,

'J ,J

Ul,

D:

Z,

E: ITEM

b: NO,

O:

m:

LU: A

03. B

D: C

O: D

ua: E

z: F

-a: G

o: "H

a: *L

(9: M

Z: N

q! -o

_:. *p

2! "s

Ill ,,

TABLE OF LOOSE PARTS

DESCRIPTION QTY,

Jointer-Planer ................................. 1

Fence .............................................. 1

Fence Bracket ......................................... 2

Fence Segment ............................ 2

Tilt Indicator. ............................ 2

Chip Deflector ;: ,; .................... 1

Table Height Knob ................................... 1

3f8" Lockwasher ..................................... 1

1t4"-20 x 3t4" Hex Cap Screw .......................... 4

.K

1f4 Split Lockwasher ....................... 4

1t4 Fiat Washer .......................... 4

Fence Lock Knobs ............................ 2

9132" ID x 17f32" OD x 1t8" Thick Washer .......... 2

#10..24 x 112Machine Screw ........................ 2

#10 Flat Washer ...................................... 2

#8-32 x 112" Flat Head Machine Screw ............... 6

"a

*R

#8-32 Hex Nut .............................. 6

#8 Flat Washer ................................ 6

T

Push Block ............................................ 2

U

2-112" to 1..1f4" Vac Hose Adapter .................... 1

V

5t32" Hex Key (Allen Wrench) . ................ 1

W

Owner's Manual ...................................... 1

X

Cutter Guard Assembly ...................... 1

• Supplied in loose parts bag

14mm or 9116" Wrench

10mm Wrench

8mm or 5116" Wrench

TOOLS REQUIRED

Medium Slotted Screwdriver

#2 Phillips Screwdriver

, !, ! ,_, _, I, I , _q:_,tt"

Combination Square

SAFETY RULES FOR JOINTER--PLANER

Safety is a combination of operator common senso and alertness at all times when the Jointer--Planer is being

used. Study these rules and general safety rules before operating and retain them for future use.

1, WEAR EYE PROTECTION

2 NEVER MAKE JOINTiNG OR PLANING CUT DEEPER THAN

1t8 iNCH -- PER PASS

3 FEED WORKPIECE AGAINST ROTATION OF CUTTER

4 KEEP FINGERS AWAY FROM REVOLVING CUTTER -- use

fixtures when necessary

5, NEVER PERFORM JOINTING OR PLANING OPERATION

WITH CUTTER HEAD GUARD REMOVED

6 NEVER FORCE CUTTING ACTION Stalttng or partial stalling

of motor can cause major damage. Allow motor to reach full

speed before cutting,

7. NEVER - Attempt to perform an abnormal or lJttte used

operation without study and the use of adequate hold down

/push blocks, jigs, fixtures, stops, etc

8 NEVER- Attempt to cut small pieces.

WARNING: DO NOT AT ANY TIME LET BRAKE FLUIDS, GASOLINE, PENETRATING OILS, ETC

COME tN CONTACT

WITH PLASTIC PARTS. THEY CONTAIN CHEMICALS THAT CAN DAMAGE

AND/OR DESTROY PLASTICS.

9 ALWAYS - Use hold downfpush blocks for jointing material

narrower than 3 inches, or planing material thinner than 3

inches

10 ALWAYS., Keep cutter sharp

11 NEVER- Use in an explosive atmosphere Normal sparking of

motor may ignite fumes

12 OUTDOOR EXTENSION CORD USE. When toot is used

outdoors, use only extension cords suitable for use outdoors

Outdoor approved cords are marked with the suffix W-A, for

example- SJTW,-A or SJOW-A

13. ALWAYS use identical replacement parts when servicing

14 This tool is intended for RESIDENTIAL USE ONLY,

WARNING: DO NOT ALLOW FAMILIARITY (GAINED FROM

FREQUENT USE OF YOUR JOfNTER--PLANER) TO BECOME

COMMONPLACE ALWAYS REMEMBER THAT A CARELESS

FRACTION OF A SECOND IS SUFFICIENT TO INFLICT SEVERE

INJURY,

ASSEMBLY

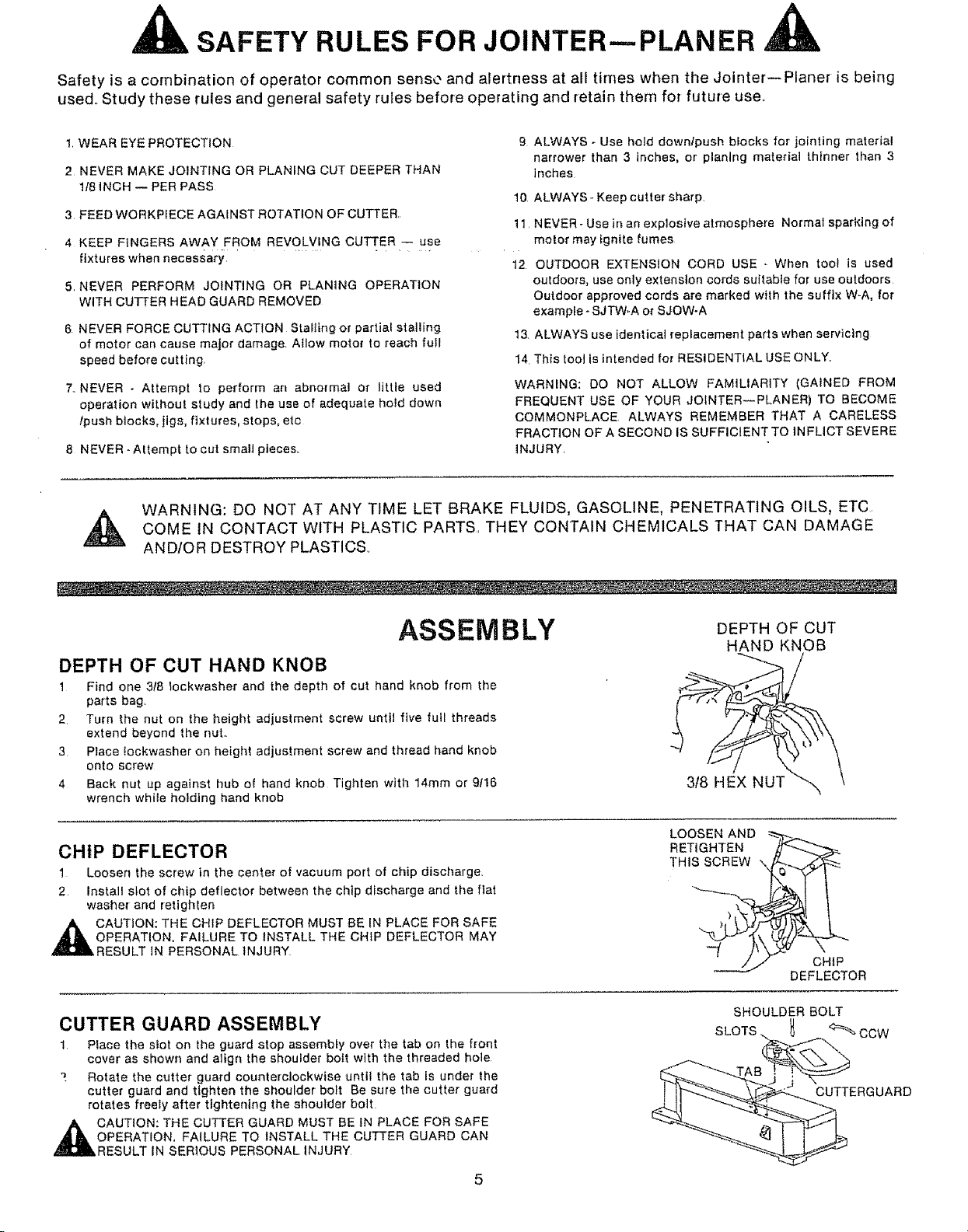

DEPTH OF CUT HAND KNOB

1 Find one 3f8 tockwasher and the depth of cut hand knob from the

parts bag.

2 Turn the nut on the height adjustment screw until five full threads

extend beyond the nut.,

3 Place !ockwasher on height adjustment screw and thread hand knob

onto screw

4 Back nut up against hub of hand knob Tighten with 14mm or 9/16

wrench while hotdtng hand knob

CHIP DEFLECTOR

1 Loosen the screw in the center of vacuum port of chip discharge,

2 Install slot of chip deflector between the chip discharge and the fiat

washer and retighten

,_ CAUTION: THE CHIP DEFLECTOR MUST BE IN PLACE FOR SAFE

OPERATION. FAILURE TO INSTALL THE CHIP DEFLECTOR MAY

RESULT iN PERSONAL INJURY

CUTTER GUARD ASSEMBLY

1 Place the slot on the guard stop assembty over the tab on the front

cover as shown and a]ign the shoulder boff with the threaded hole

7 Rotate the cutter guard counterclockwise until the tab is under the

cutter guard and tighten the shoulder bolt Be sure the cutter guard

rotates freely after tightening the shoulder bolt

DEPTH OF CUT

HAND KNOB

3/8 HEX NUT

LOOSEN AND

RETIGHTEN

THiS SCREW \

CH1P

DEFLECTOR

SHOULDER BOLT

SLOTS CCW

CUTTERGUARD

OPERATION, FAILURE TO INSTALL THE CUTTER GUARD CAN

,_CAUTION: THE CUTTER GUARD MUST BE tN PLACE FOR SAFE

RESULT IN SERIOUS PERSONAL INJURY

Loading...

Loading...