Craftsman 146669950 Owner’s Manual

2905A56

owner's manual

_/___/__ / CRAFTSMAN

WET SHARP

MACHINE

CAT. NO.

146,669950

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

• Introduction

• Operation

2905A56

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 US.A.

FULL ONE YEAR WARRANTY ON CRAFTSMAN WET SHARP MACHINE

If this Craftsman Wet Sharp Machine fails to give complete satisfaction within one year from the date of

purchase, RETURN IT TO THE NEAREST SEARS STORE THROUGHOUT THE UNITED STATES and

Sears will repair it, free of charge.

If the Wet Sharp Machine is used for commercial or rental purposes this warranty applies for only 90 days

from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state.

SEARS, ROEBUCK AND CO. DEPT. 698/731A SEARS TOWER CHICAGO, IL 60684

INTRODUCTION

DOUBLE INSULATION is a concept in safety, in

electric power tools, which eliminates the need for

the usual three wire grounded power cord and

grounded supply system. Wherever there is electric

current in the tool there are two complete sets of

insulation to protect the user. All exposed metal

parts are isolated from the internal metal motor

components with protecting insulation.

IMPORTANT -- Servicing of a tool with double

insulation requires extreme care and knowledge

of the system and should be performed only by a

qualified service technician. For service we sug-

gest you return the tool to your nearest Sears

Store for repair. Always use original factory re-

placement parts when servicing.

RULES FOR SAFE OPERATION

WARNING--DO NOT ATTEMPT TO OPERATE UNTIL YOU HAVE READ THOROUGHLY AND

UNDERSTAND COMPLETELY ALL INSTRUCTIONS, RULES, ETC. CONTAINED IN THIS MANUAL.

FAILURE TO COMPLY CAN RESULT IN ACCIDENTS INVOLVING FIRE, ELECTRIC SHOCK, OR

SERIOUS PERSONAL INJURY. SAVE OWNER'S MANUALAND REVIEW FREQUENTLY FOR CON-

TINUING SAFE OPERATION, AND INSTRUCTING POSSIBLE THIRD-PARTY USER.

READ ALL INSTRUCTIONS

1. KNOW YOUR POWER TOOL-- Read owner's manual carefully. Learn its applica-

tions and limitations as well as the specific potential hazards peculiar to this tool.

2. KEEP GUARDS IN PLACE and in working order.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. AVOID DANGEROUS ENVIRONMENT. Don't use power tool in damp or wet loca-

tions or expose to rain. Keep work area well lit.

5. KEEP CHILDREN AWAY. All visitors should be kept a safe distance from work area.

Do not let visitors contact tool or extension cord.

6. STORE IDLE TOOLS. When not in use, tools should be stored in dry, high or locked-

up place--out of reach of children.

7. DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. Don't force small tool or attachment to do the job of a heavy duty

tool. Don't use tool for purpose not intended--for example--Don't use a circular saw

for cutting tree limbs or logs.

9. WEAR PROPER APPAREL. No loose clothing or jewelry to get caught in moving

parts. Rubber gloves and footwear are recommended when working outdoors. Also,

wear protective hair covering to contain long hair.

10. USE SAFETY GLASSES with all tools. Everyday eyeglasses only have impact re-

sistant lenses, they are NOT safety glasses. Also face or dust mask if cutting

operation is dusty.

RULES FOR SAFE OPERA TION (Continued)

12. DON'T ABUSE CORD. Never carry tool by cord or yank it to disconnect from re-

ceptacle. Keep cord from heat, oil and sharp edges.

13. SECURE WORK. Use clamps or avise to hold work. It's safer than using your hand

and it frees both hands to operate tool.

14. DON'T OVERREACH. Keep proper footing and balance at all times.

15. MAINTAIN TOOLS WITH CARE. Keep tools sharp at all times, and clean for best

and safest performance. Follow instructions for lubricating and changing acces-

sories.

16. DISCONNECT TOOLS when not in use or before servicing.

17. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are removed from tool before turning it on.

18. AVOID ACClDENTALSTARTING. Don't carry plugged-in toolswith fingeron switch.

Be sure switch is off when plugging in.

19. NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal sparking of the motor

could ignite fumes.

20. INSPECT TOOL CORDS PERIODICALLY and if damaged, have repaired at your

nearest Sears Repair Center.

21. INSPECT EXTENSION CORDS PERIODICALLY and replace if damaged.

22. KEEP TOOLS DRY, CLEAN, AND FREE FROM OILAND GREASE. Always use a

clean cloth when cleaning. Never use brake fluid, gasoline, or any strong solvents to

clean yot_r tool.

23. STAY ALERT. Watch what you are doing and use common sense. Do not operate

tool when you are tired.

24. CHECK DAMAGED PARTS. Before further use of the tool, aguard or other part that

is damaged should be carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged should be properly repaired or

replaced by an authorized service center unless indicated elsewhere in this instruc-

tion manual.

25. DO NOT USE TOOL IF SWITCH DOESNOTTURN IT ON AND OFF. Have defective

switches replaced by authorized service center.

26. N EVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave

tool until it comes to a complete stop.

27. REPLACE CRACKED WHEEL IMMEDIATELY.

28. WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS.

29. THIS TOOL IS INTENDED FOR RESIDENTIAL USE ONLY.

30. MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing

starting keys.

31. ADJUST DISTANCE BETWEEN WHEEL & TOOL REST. Maintain 1/16" or less

clearance as the diameter of the wheel decreases with use.

32. SAVE THESE INSTRUCTIONS.

The operation of the Wet Sharp Machine can result in foreign objects being thrown

into the eyes, which can result in severe eye damage. Always wear safety glasses or

eye shields before commencing power tool operation. We recommend Wide Vision

Safety Mask for use over spectacles or standard safety glasses, available at Sears

Catalog Order or Retail Stores.

3

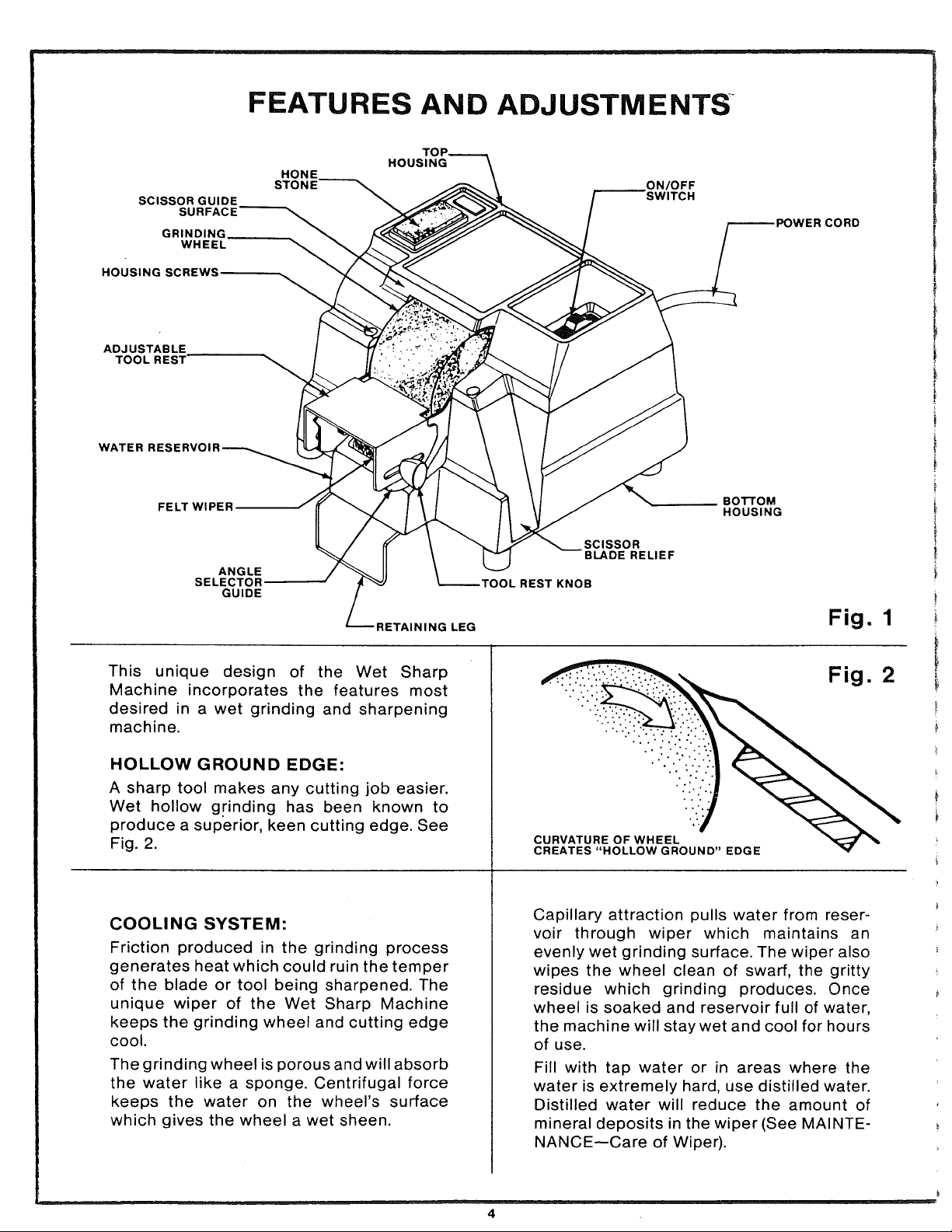

SCISSOR GUIDE

GRINDING

WHEEL

HOUSING SCREWS

ADJUSTABLE

TOOL REST

WATER RESE

FEATURES AND ADJUSTMENTS

HOUSING

STC ON/OFF

_WER CORD

FELT WIPER

ANGLE

SELECTOR

GUIDE

RETAINING LEG

This unique design of the Wet Sharp

Machine incorporates the features most

desired in a wet grinding and sharpening

machine.

HOLLOW GROUND EDGE:

A sharp tool makes any cutting job easier.

Wet hollow grinding has been known to

produce a superior, keen cutting edge. See

Fig. 2.

COOLING SYSTEM:

Friction produced in the grinding process

generates heat which could ruin the temper

of the blade or tool being sharpened. The

unique wiper of the Wet Sharp Machine

keeps the grinding wheel and cutting edge

cool.

The grinding wheel is porous and will absorb

the water like a sponge. Centrifugal force

keeps the water on the wheel's surface

which gives the wheel a wet sheen.

tOOL REST KNOB

CURVATURE OF WHEEL

CREATES "HOLLOW GROUND" EDGE

Capillary attraction pulls water from reser-

voir through wiper which maintains an

evenly wet grinding surface. The wiper also

wipes the wheel clean of swarf, the gritty

residue which grinding produces. Once

wheel is soaked and reservoir full of water,

the machine will stay wet and cool for hours

of use.

Fill with tap water or in areas where the

water is extremely hard, use distilled water.

Distilled water will reduce the amount of

mineral deposits in the wiper (See MAINTE-

NANCE-Care of Wiper).

SCISSOR

BLADE RELIEF

BOTTOM

HOUSING

Fig. 1

Fig. 2

4

Loading...

Loading...