Craftsman 143999011 Owner’s Manual

SEARS

operator's

manual

MODEL NO. 143.999011

SOLID STATE IGNITION

[ y, -!:-,_y:

_,q_'_l'_

. d

Li3 ........

___j._c=..__

ENGIN

OCT2o "°L..... !_Q

CAUT!ON:_

Read RULES.fo_

Safe OPERATION

and INSTRUCTIONS

Carefully

California Proposition 65 WARNING: The engine exhaust from this product contains chemicals I

known to the State of California to cause cancer, birth defects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

• Operating

• Maintenance

• Repair Parts

I

Printed in U.S.A. 3-1-99 181-1199-11

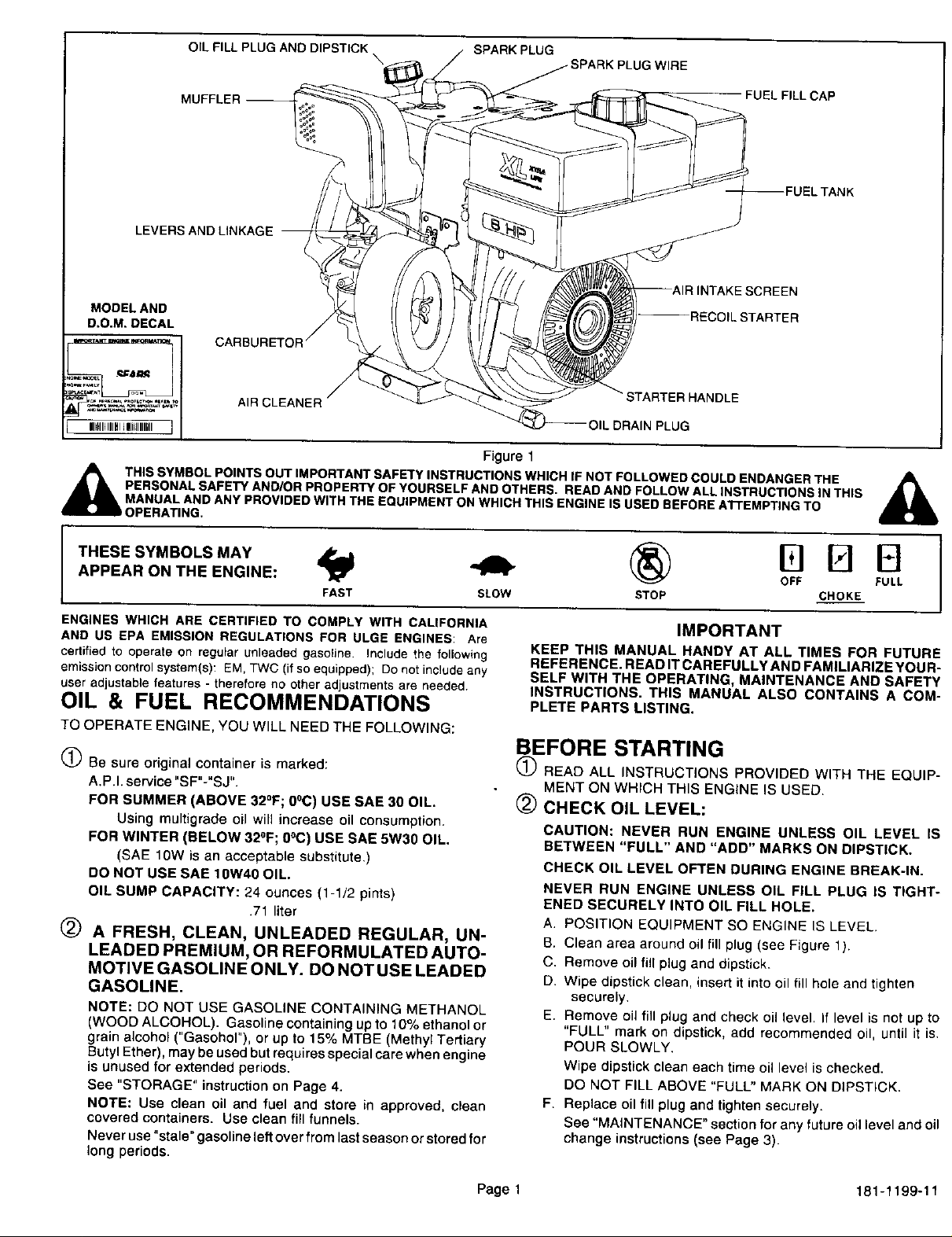

LEVERS AND LINKAGE

MODEL AND

D.O.M. DECAL

OIL FILL PLUG AND DIPSTICK SPARK PLUG

\ WIRE

FUEL FILL CAP

]REEN

AIR CLEANER

Figure 1

,_ THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD ENDANGER THE

PERSONALSAFETY AND/OR PROPERTY OF YOURSELFAND OTHERS. READ AND FOLLOWALL INSTRUCTIONS IN THIS

MANUALAND ANY PROVIDED WITH THE EQUIPMENT ON WHICH THIS ENGINE IS USED BEFORE AI-rEMPTING TO

OPERATING,

STARTER HANDLE

PLUG

E! FI FI

APPEAR ON THE ENGINE:

FAST SLOW STOP

ENGINES WHICH ARE CERTIFIED TO COMPLY WITH CALIFORNIA

AND US EPA EMfSSfON REGDLAT|ONS FOR ULGE ENGINES: Are

certifiedto operate on regular unleaded gasoline Include the following

emission control system(s): EM, TWC (if so equipped); Do not include any

user adiustable features - therefore no other adjustmentsare needed.

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

(_) Be sure original container is marked:

A.P.I. service "SF"-"SJ".

FOR SUMMER (ABOVE 32°F; 0°C) USE SAE 30 OIL.

Using multigrade oil will increase oil consumption.

FOR WINTER (BELOW 32°F; 0°C) USE SAE 5W30 OIL.

(SAE 10W is an acceptable substitute.)

DO NOT USE SAE 10W40 OIL.

OIL SUMP CAPACITY: 24 ounces (1-1/2 pints)

.71 liter

(_) A FRESH, CLEAN, UNLEADED REGULAR, UN-

LEADED PREMIUM, OR REFORMULATED AUTO-

MOTIVE GASOLINE ONLY. DO NOT USE LEADED

GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL

(WOOD ALCOHOL). Gasoline containing up to 10% ethanol or

grain alcohol ("Gasohol"), or up to 15% MTBE (Methyl Tertiary

Butyl Ether), may be used but requires special care when engine

is unused for extended periods.

See "STORAGE" instruction on Page 4.

NOTE: Use clean oil and fuel and store in approved, clean

covered containers. Use clean fill funnels.

Never use "stale" gasoline left over from last season orstored for

long periods.

IMPORTANT

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE

REFERENCE. READ IT CAREFULLY AND FAMILIARIZE YOUR-

SELF WITH THE OPERATING, MAINTENANCE AND SAFETY

INSTRUCTIONS. THIS MANUAL ALSO CONTAINS A COM-

PLETE PARTS LISTING.

BEFORE STARTING

1_ READ ALL INSTRUCTIONS PROVIDED WITH THE EQUIP-

MENT ON WHICH THIS ENGINE IS USED.

(_) CHECK OIL LEVEL:

CAUTION: NEVER RUN ENGINE UNLESS OIL LEVEL IS

BETWEEN "FULL" AND "ADO" MARKS ON DIPSTICK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

NEVER RUN ENGINE UNLESS OIL FILL PLUG IS TIGHT-

ENED SECURELY INTO OIL FILL HOLE.

A. POSITION EQUIPMENT SO ENGINE IS LEVEL.

B. Clean area around oil fill plug (see Figure 1).

C. Remove oil fill plug and dipstick.

D. Wipe dipstick clean, insert it into oil fill hole and tighten

securely.

E. Remove oil fill plug and check oil level. If level is not up to

"FULL" mark on dipstick, add recommended oil, until it is.

POUR SLOWLY.

Wipe dipstick clean each time oil level is checked.

DO NOT FILL ABOVE "FULL" MARK ON DIPSTICK.

F. Replace oil fill plug and tighten securely.

See "MAINTENANCE" section for any future oil level and oil

change instructions (see Page 3).

OFF FULL

CHOKE

A

q

Page 1 181-1199-11

BEFORE STARTING (Continued)

_) FILL FUEL TANK with gasoline as specified in the preced-

ing "OIL & FUEL RECOMMENDATIONS item 2.

NEVER MIX OIL WITH GASOLINE

Never use "stale" gasoline left over from last season or stored for

long periods.

,_NEVER FILL FUEL TANK INDOORS. NEVER FILL FUEL

TANK WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE

W___N__ILLING FUEL TANK,

ANk NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2"

BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE

FOR FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM O

ENGINE AND EQUIPMENT BEFORE STARTING ENGINE.

FUEL SYSTEM MUST BE LEAKPROOF AND MEET ALL

_1 ANY LIQUEFIED PETROLEUM (LPG) OR NATURAL GAS 1

APPLICABLE CODES AND REGULAT ONS.

(_ CHECK THE FOLLOWING:

_1_ BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH 1

CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHES /

DISENGAGED. (FOLLOW EQUIPMENT MANUFACTUR- /

ER'S INSTRUCTIONS.) THIS SHOULD PLACE ANY /

SAFETY SWITCHES IN SAFE STARTING POSITION. J

B. Be sure spark plug wire is attached to spark plug (see Figure

1).

C, Be sure stop switch (see Figure 1) next to spark plug is not

contacting spark plug.

D. Be sure any ignition switch on engine or equipment is in ON,

BUN or START position.

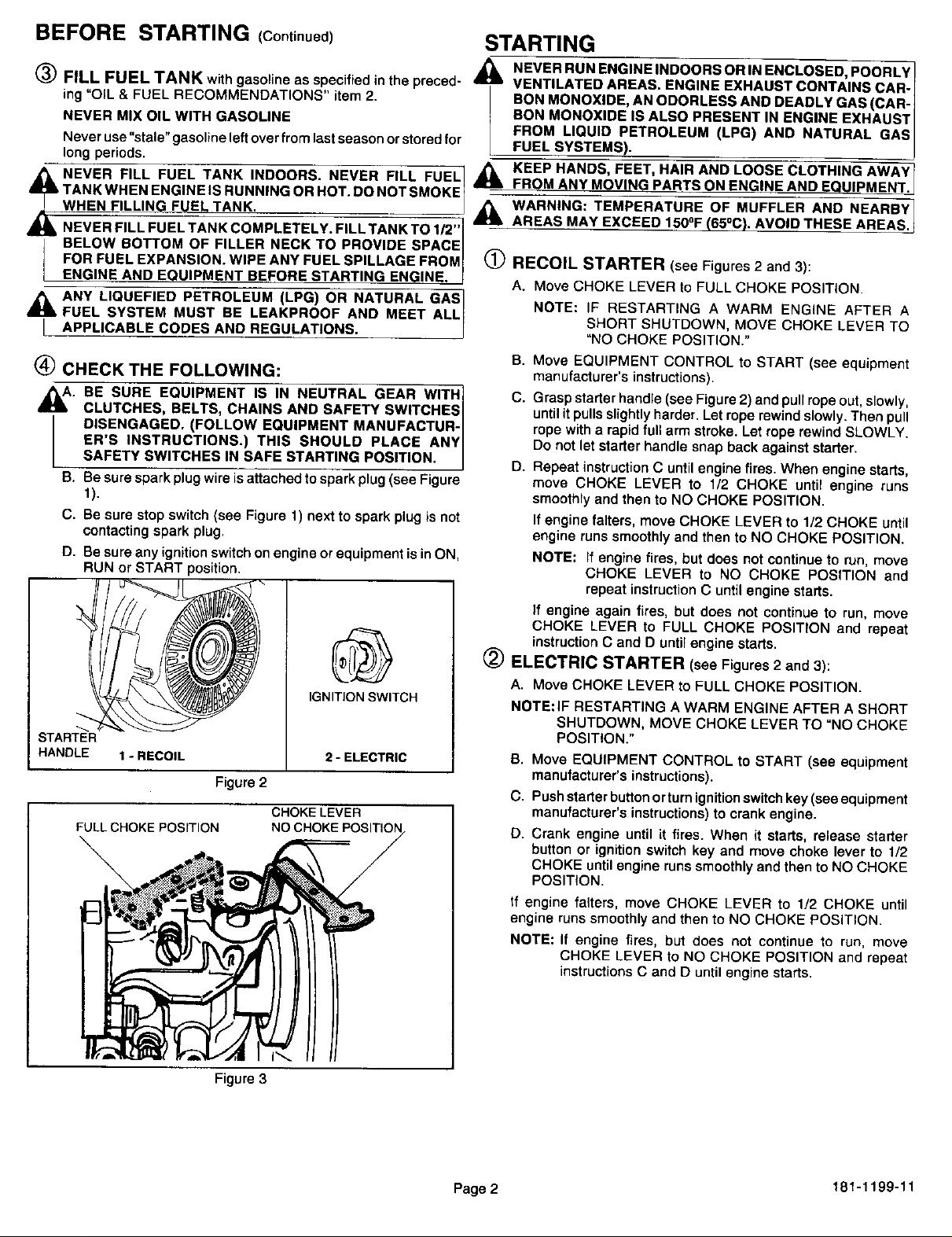

IGNITION SWITCH

STARTER

HANDLE

1 - RECOtL 2 - ELECTRIC

Figure 2

CHOKE LEVER

FULL CHOKE POSITION

NO CHOKE

\

STARTING

NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS. ENGINE EXHAUST CONTAINS CAR-

BON MONOXIDE, AN ODORLESS AND DEADLY GAS (CAR-

BON MONOXIDE IS ALSO PRESENT IN ENGINE EXHAUST

FROM LIQUID PETROLEUM (LPG) AND NATURAL GAS

|

FUEL SYSTEMS).

_KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY

FROM ANY MOVING PARTS _ONENGINE AND EQUIPMENT.

,_ WARNING: TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150°F (65°C). AVOID THESE AREAS.

RECOIL STARTER (see Figures 2 and 3):

A. Move CHOKE LEVER to FULL CHOKE POSITION.

NOTE: IF RESTARTING A WARM ENGINE AFTER A

SHORT SHUTDOWN, MOVE CHOKE LEVER TO

"NO CHOKE POSITION."

B. Move EQUIPMENT CONTROL to START (see equipment

manufacturer's instructions).

C. Grasp starter handle (see Figure 2) and pull rope out, slowly,

until it putts slightly harder. Let rope rewind slowly. Then pull

rope with e rapid full arm stroke. Let rope rewind SLOWLY.

Do not let starter handle snap back against starter.

D. Repeat instruction C until engine fires, When engine starts,

move CHOKE LEVER to 1/2 CHOKE until engine runs

smoothly and then to NO CHOKE POSITION.

If engine falters, move CHOKE LEVER to 1/2 CHOKE until

engine runs smoothly and then to NO CHOKE POSITION.

NOTE: If engine fires, but does not continue to run, move

If engine again fires, but does not continue to run, move

CHOKE LEVER to FULL CHOKE POSITION and repeat

instruction C and D until engine starts.

(_) ELECTRIC STARTER (see Figures 2 and 3):

A. Move CHOKE LEVER to FULL CHOKE POSITION.

NOTE:IF RESTARTING A WARM ENGINE AFTER A SHORT

B. Move EQUIPMENT CONTROL to START (see equipment

manufacturer's instructions).

C. Push starter button or turn ignition switch key (see equipment

manufacturer's instructions) to crank engine.

D. Crank engine until it fires. When it starts, release starter

button or ignition switch key and move choke lever to 1/2

CHOKE until engine runs smoothly and then to NO CHOKE

POSITION.

If engine falters, move CHOKE LEVER to 1/2 CHOKE until

engine runs smoothly and then to NO CHOKE POSITION.

NOTE: If engine fires, but does not continue to run, move

CHOKE LEVER to NO CHOKE POSITION and

repeat instruction C until engine starts.

SHUTDOWN, MOVE CHOKE LEVER TO =NO CHOKE

POSITION."

CHOKE LEVER to NO CHOKE POSITION and repeat

instructions C and D until engine starts.

Figure 3

Page 2 181-1199-11

STOPPING

(_) Move equipment control or any ignition stop switch on engine

to STOP or OFF (see equipment manufacturer's instructions).

(_) Push stop switch (see Figure 1) located next to spark plug on

engine against spark plug and hold it in this position untilengine

is completely stopped.

AFTER ENGINE IS STOPPED:

,_k.A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG I

,_B. TURN IGNITION SWITCH KEY (IF SO EQUIPPED) TO I

AND KEEP IT AWAY FROM SPARK PLUG. J

"OFF" POSITION AND REMOVE KEY FROM SWITCH. I

RIZED STARTING OF ENGINE WHILE EQUIPMENT IS I

l THIS WILL REDUCE THE POSSIBILITY OF UNAUTHO- I

NOT IN USE. J

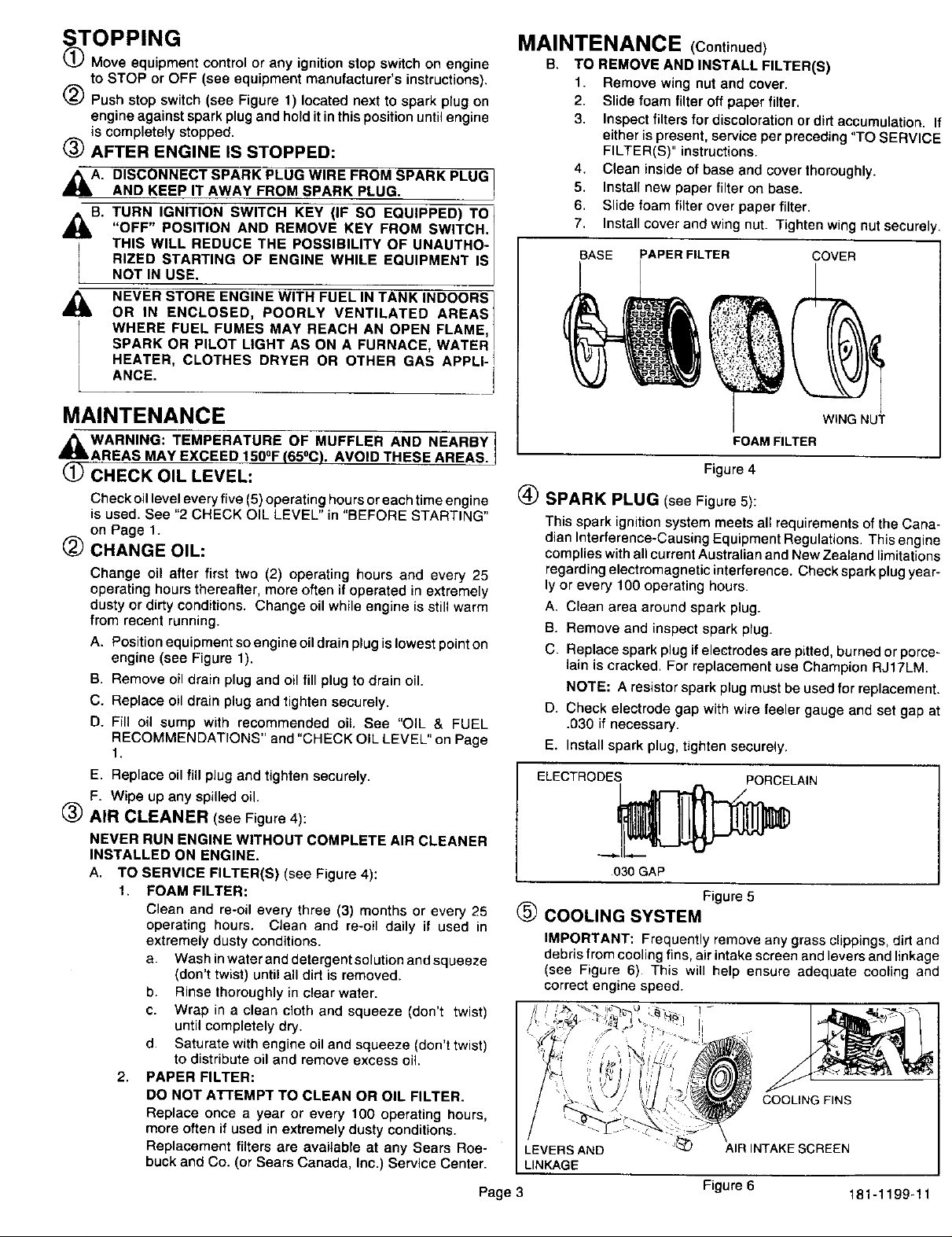

MAINTENANCE (Continued)

B. TO REMOVE AND INSTALL FILTER(S)

1. Remove wing nut and cover.

2. Slide foam filter off paper filter.

3. Inspect filters for discoloration or dirt accumulation. It

either is present, service per preceding "TO SERVICE

FILTER(S)" instructions.

4. Clean inside of base and cover thoroughly.

5. Install new paper filter on base.

6. Slide foam filter over paper filter.

7. Install cover and wing nut. Tighten wing nut securely.

BASE PAPER FILTER COVER

,_ NEVER STORE ENGINE WITH FUEL IN TANK INDOORS I

OR IN ENCLOSED, POORLY VENTILATED AREAS]

WHERE FUEL FUMES MAY REACH AN OPEN FLAME, I

SPARK OR PILOT LIGHT AS ON A FURNACE, WATER I

HEATER, CLOTHES DRYER OR OTHER GAS APPLI-I

ANCE. I

MAINTENANCE

._WARNING: TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150°F (65°C). AVOID THESE AREAS.

1_ CHECK OIL LEVEL:

Check oil level every five (5) operating hours or each time engine

is used. See "2 CHECK OIL LEVEL" in "BEFORE STARTING"

on Page 1.

CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operating hours thereafter, more often if operated in extremely

dusty or dirty conditions. Change oil while engine is still warm

from recent running.

A. Position equipment so engine oil drain plug is lowest point on

engine (see Figure 1).

B. Remove oil drain plug and oil fill plug to drain oil.

C. Replace oil drain plug and tighten securely.

D. Fill oil sump with recommended oil. See "OIL & FUEL

RECOMMENDATIONS" and "CHECK OIL LEVEL" on Page

1.

E. Replace oil fill plug and tighten securely.

F. Wipe up any spilled oil.

(_) AIR CLEANER (see Figure 4):

NEVER RUN ENGINE WITHOUT COMPLETE AIR CLEANER

INSTALLED ON ENGINE.

A. TO SERVICE FILTER(S) (see Figure 4):

1. FOAM FILTER:

Clean and re-oil every three (3) months or every 25

operating hours. Clean and re-oil daily if used in

extremely dusty conditions.

a. Wash in water and detergent solution and squeeze

(don't twist) until all dirt is removed.

b. Rinse thoroughly in clear water.

c. Wrap in a clean cloth and squeeze (don't twist)

until completely dry.

d. Saturate with engine oil and squeeze (don't twist)

to distribute oil and remove excess oil.

2. PAPER FILTER:

DO NOT ATTEMPT TO CLEAN OR OIL FILTER.

Replace once a year or every 100 operating hours,

more often if used in extremely dusty conditions.

Replacement filters are available at any Sears Roe-

buck and Co. (or Sears Canada, Inc.) Service Center.

WING NUT

FOAM FILTER

Figure 4

®

SPARK PLUG (see Figure 5):

This spark ignition system meets all requirements of the Cana-

dian Interference-Causing Equipment Regulations. This engine

complies with all current Australian and New Zealand limitations

regarding electromagnetic interference. Check spark plug year-

ly or every 100 operating hours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plug if electrodes are pitted, burned or porce-

lain is cracked. For replacement use Champion RJ17LM

NOTE: A resistor spark plug must be used for replacement.

D. Check electrode gap with wire feeler gauge and set gap at

.030 if necessary.

E. Install spark plug, tighten securely.

ELECTRODES PORCELAIN

.030 GAP

Figure5

(_ COOLING SYSTEM

IMPORTANT: Frequently remove any grass clippings, dirt and

debris from cooling fins, air intake screen and levers and linkage

(see Figure 6). This will help ensure adequate cooling and

correct engine speed.

COOLING FINS

LEVERS AND

LINKAGE

AIR INTAKE SCREEN

Page 3 Figure 6 181-1199-11

Loading...

Loading...