Craftsman 143998003 Owner’s Manual

S£/ J:kS

operator's

manual

MODEL NO. 143.998003

SOLID STATE IGNITION

NGIN

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

d_lb California Proposition 65 WARNING: the engine exhaust from this product contains chemicals

Printedin U.S.A. 5/1199 181-1202-11

known to the State of Caliibrnia to cause cancer, birth defects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IT, 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

• Operating

• Maintenance

• Repair Parts

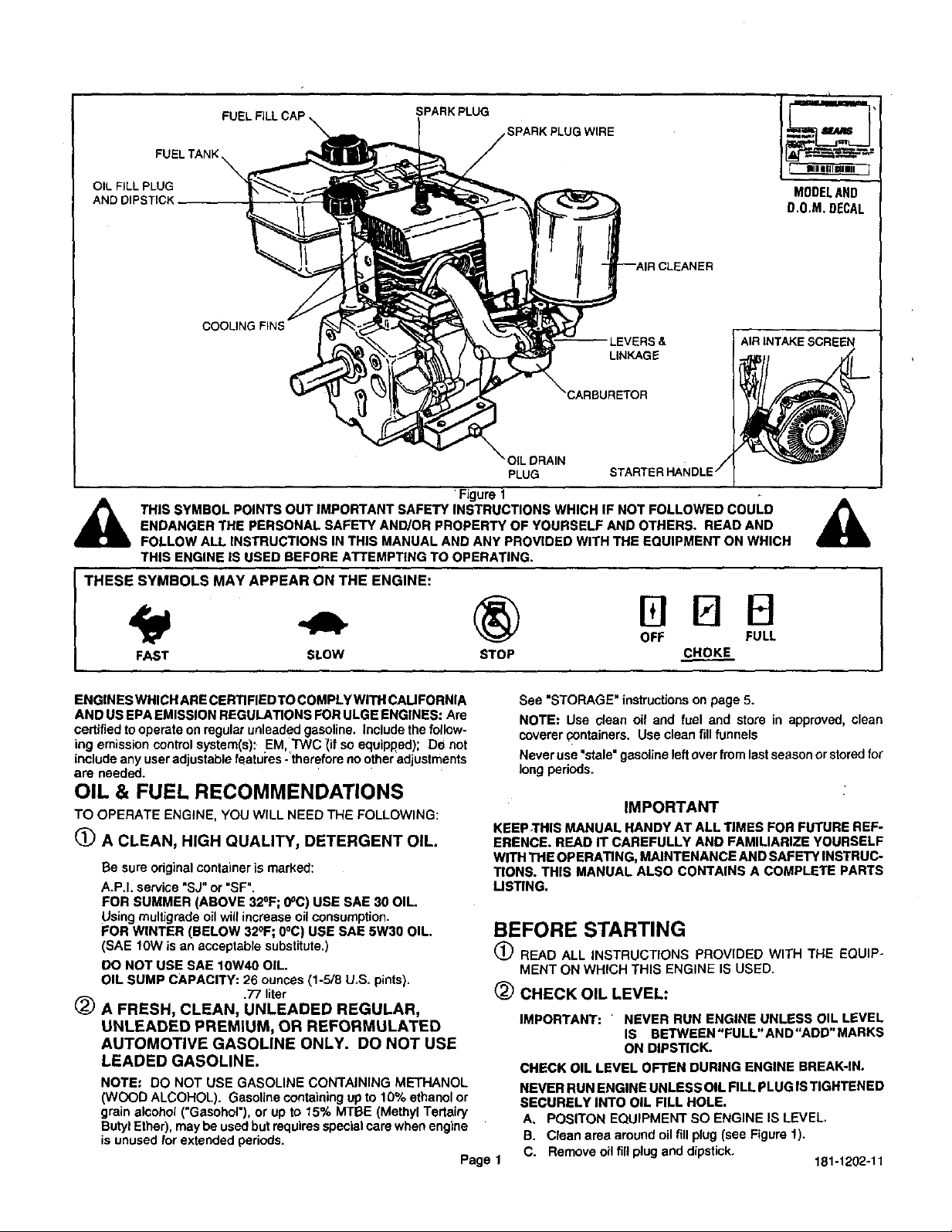

SPARK PLUG

SPARK PLUG WIRE

OIL FILL PLUG

AND DIPSTICK

COOLING FINS

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD

ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS, READ AND

FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED WITH THE EQUIPMENT ON WHICH

THIS ENGINE IS USED BEFORE ATTEMPTING TO OPERATING.

I THESE SYM4 BOLS MAY APPEAR ON THE ENGINE:

FAST SLOW

LINKAGE

OIL DRAIN

PLUG

'Figure t

liBEl

OFF FULL

STOP CHOKE

MODELAND

D.O.M. DECAL

AIR INTAKE SCREEN

ENGINES WHICH ARE CERTIFIED TO COMPLY WITH CAUFORNIA

AND US EPA EMISSION REGULATIONS FOR ULGE ENGINES: Are

certified to operate on regularunleadedgasoline. Includethefo{Iow-

ing emission controlsystem(s): EM TWC {if so equipped); De not

{ncludeany user adjustablefeatures - thereforeno0theradjustments

are needed.

OIL & FUEL RECOMMENDATIONS

TO OPERATEENGINE.YOUWILL NEEDTHEFOLLOWING:

(_) A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sure originalcontainer is marked:

A.P.I. service "SJ" or "SF",

FOR SUMMER (ABOVE 32°F; 0°C) USE SAE 30 OIL.

Using multigrade oil wiUincrease oilconsumption.

FOR WINTER (BELOW 32°F; 0°C) USE SAE 5W30 OIL.

(SAE 10W is an acceptable substitute.)

DO NOT USE SAE 10W40 OIL.

OIL SUMP CAPACITY: 26 ounces (1-5/8 U.S. pints).

.77 liter

(_ A FRESH, CLEAN, UNLEADED REGULAR,

UNLEADED PREMIUM, OR REFORMULATED

AUTOMOTIVE GASOLINE ONLY. DO NOT USE

LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL

(WOOD ALCOHOL). Gasoline containing up to 10% ethanol or

grain alcohol ('Gasohol"), or up to 15% MTBE (Methyl Tertairy

ButylEther), may beused but requiresspecialcare when engine

is unused for extended periods.

See "STORAGE" instructions on page 5.

NOTE: Use (::leanoil and fuel and store in approved, clean

coverer containers. Use clean fill funnels

Never use "stale" gasoline leftover from last seasonor stored for

long periods.

IMPORTANT

KEEPTHIS MANUAL HANDY AT ALL TIMES FOR FUTURE REF-

ERENCE. READ IT CAREFULLY AND FAMILIARIZE YOURSELF

WITH THE OPERATING, MAINTENANCE AND SAFETY INSTRUC-

TIONS. THIS MANUAL ALSO CONTAINS A COMPLETE PARTS

LISTING.

BEFORE STARTING

READ ALL INSTRUCTIONS PROVIDED WITH THE EQUIP-

MENT ON WHICH THIS ENGINE IS USED.

(_ CHECK OIL LEVEL:

IMPORTANT: NEVER RUN ENGINE UNLESS OIL LEVEL

IS BIETWEEN"FULL" AN D"ADD" MARKS

ON DIPSTICK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

NEVER RUN ENGINE UNLESS OIL FILL PLUG IS TIGHTENED

SECURELY INTO OIL FILL HOLE.

A, POSITON EQUIPMENT SO ENGINE IS LEVEL,

B. Clean area around oil fill plug (see Figure 1).

Page 1

C. Remove oil fill plug and dipstick,

181-1202-11

BEFORE STARTING (Continued)

D. Wipe dipstickclean, insert it into oil rill hole and tighten

securely.

E. Remove oil fill plug and check oil level. If level is notup to

"FULL" mark on dipstick,add recommended oil, until it is.

POUR SLOWLY.

Wipe dipstickclean each time oil level is checked.

DO NOT FILL ABOVE "FULL"MARK ON DIPSTICK.

F. Replace oil fill plugand tighten_je_urely.

See "MAINTENANCE" section for any future oil level and oil

change instructions(see Page 2).

(_ FILL FUEL TANK

with gasoline as specified in the preceding"OIL & FUEL

RECOMMENDATIONS" item2.

NEVER MIXOIL WITH GASOLINE

Never use"stale" gasolineleftoverfrom last season orstoredfor

longperiods.

_IL EVER FILL FUEL TANK INDOORS. NEVER FILL FUELTAN K ]

WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE

WHEN FILLILNG FUEL TANK.

_1 EVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2" ]

BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE

FOR FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM

ENGINE AND EQUIPMENT BEFORE STARTING ENGINE, /

ANY LIQUIFIED PETROLEUM (LPG) OR NATURAL GAS FUEL I

SYSTEM MUST BE LEAKPROOF AND MEET ALL APPLICA-

BLE CODES AND REGULATIONS.

(_ CHECK THE FOLLOWING:

,_ A. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH]

CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHES

DISENGAGED. (FOLLOW EQUIPMENT MANUFACT- I

URER'S INSTRUCTIONS.) THIS SHOULD PLACE ANY

SAFETY SWITCHES IN SAFE STARTING POS TION.

B. Be surespark plugwire isattachedto sparkplug (see Figure

1).

C. Be sure anyignitionswitchon engine orequipmentis in ON,

RUN or START position.

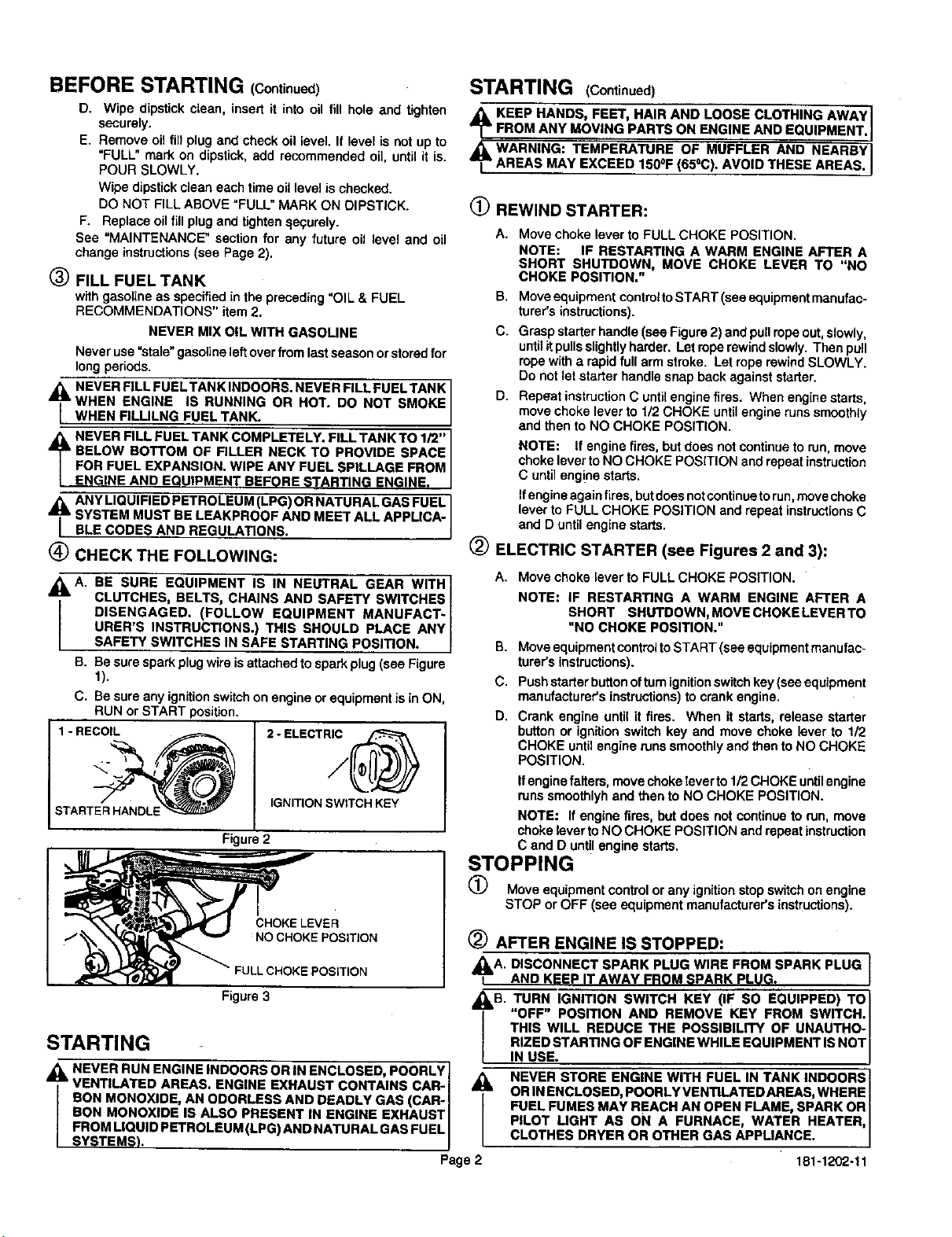

1- RECOIL 2 -ELECTRIC _

START IGNITIONSWITCHKEY

Figure2

CHOKE LEVER

NO CHOKE POSITION

_ITION

Figure 3

STARTING

NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY J

A

VENTILATED AREAS. ENGINE EXHAUST CONTAINS CAR- J

BON MONOXIDE, AN ODORLESS AND DEADLY GAS (CAR- I

BON MONOXIDE IS ALSO PRESENT IN ENGINE EXHAUST I

FROM LIQUID PETROLEUM (LPG) AND NATURAL GAS FUEL

SYSTEMS).

STARTING (Continued)

_11=KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY I

FROM ANY MOVING PARTS ON ENGINE AND EQUIPMENT.]

_1 WARNING: TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150°F (65°C). AVO D THESE AREAS.

REWIND STARTER:

A.

Movechoke leverto FULL CHOKE POSITION.

NOTE: IF RESTARTING A WARM ENGINE AFTER A

SHORT SHUTDOWN, MOVE CHOKE LEVER TO "NO

CHOKE POSITION."

B. Moveequipmentcontrelto START (seaequipmentmanufac-

turer'sinstructions).

C. Gresp starter handle (see Figure2) and pullrepe out,slowly,

untilitpullsslightlyharder. Letrope rewindslowly.Then pull

ropewith a rapid full arm stroke. Let rope rewindSLOWLY.

Do notlet starterhandle snap back againststarter.

D. Repeat instructionC untilengine fires. When enginestarts,

move choke lever to 1/2 CHOKE until engine runs smoothly

and then to NO CHOKE POSITION.

NOTE: If engine fires, but does not continuetorun, move

choke leverto NO CHOKE POSITION and repeat instruction

C untileng!nestarts.

Ifangine again fires, butdoes notcontinuetorun,movechoke

lever to FULL CHOKE POSITION and repeat instructionsC

and D untilengine starts.

(_ ELECTRIC STARTER (see Figures 2 and 3):

A, Move choke lever to FULL CHOKE POSITION.

NOTE: IF RESTARTING A WARM ENGINE AFTER A

SHORT SHUTDOWN, MOVE CHOKE LEVER TO

"NO CHOKE POSITION,"

a.

MoveequipmentcontroltoSTART (see equipmentmanufac-

turer'sinstructions).

C.

Pushstarterbuttonofturnignitionswitchkey(see equipment

manufacturer'sinstructions)tocrank engine.

D,

Crank engine until it fires. When it starts, release starter

button or ignitionswitch key and move choke lever to 1/2

CHOKE until engine runssmoothlyand thento NO CHOKE

POSITION.

Ifengine falters, move chokelever to 1/2 CHOKE untilengine

runs smoothlyhand then to NO CHOKE POSITION.

NOTE: If engine fires, but does not continueto run, move

chokeleverto NO CHOKE POSITION and repeatinstruction

C and D untilengine starts.

STOPPING

I_ Move equipmentcontrolor any ignitionstopswitchon engine

STOP or OFF (see equipment manufacturer's instructions).

(_ AFTER ENGINE IS STOPPED:

_,IA. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG I

AND KEEP IT AWAY FROM SPARK PLUG. I

_klB. TURN IGNmON SWITCH KEY (IF SO EQUIPPED) TO I

"OFF" POSITION AND REMOVE KEY FROM SWITCH. I

THIS WILL REDUCE THE POSSIBILITY OF UNAUTHO- I

RIZED STARTING OF ENGINE WHILE EQUIPMENT IS NOT

N USE. J

_IL NEVER STORE ENGINE WITH FUEL IN TANK INDOORS I

OR INENCLOSED, POORLY VENTILATED AREAS, WHERE I

FUEL FUMES MAY REACH AN OPEN FLAME, SPARK OR J

PILOT LIGHT AS ON A FURNACE, WATER HEATER,

CLOTHES DRYER OR OTHER GAS APPLIANCE.

Page 2

181-1202-11

MAINTENANCE

_ ARNING: TEMPERATUREOF MUFFLER AND NEARBYI

AREASMAY EXCEED150OF(65°C).AVOIDTHESEAREAS.

CHECK OIL LEVEL:

Check oillevel every five (5) operating hours or each time engine

is used. See "2CHECK OIL LEVEL" in "BEFORE STARTING" on

Page 1.

@ CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operatinghours thereafter, more often if operated in extremely

dusty or dirty conditions.

Change oil while engine isstill warm from recentrunning.

_IA. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG 1

AND KEEP IT AWAY FROM SPARK PLUG, |

B. Clean area around drain plug (see Figure1).

C. Positionequipmentso engineoildrain plugislowestpointon

engine,

D. Remove oil drain plug and oil fill plug to drain oil

E. Replace oil drain plugand tighten securely,

F. Fill oil sump with recommended oil. See "OIL & FUEL REC-

OMMENDATIONS" and =CHECK OIL LEVEL" on Page 1.

G. Replace oil fill plug and tighten securely.

H. Wipe up any spilled oil.

(_AIR CLEANER

IMPORTANT: NEVER RUN ENGINE WITHOUT COMPLETE

AiR CLEANER INSTALLED ON ENGINE.

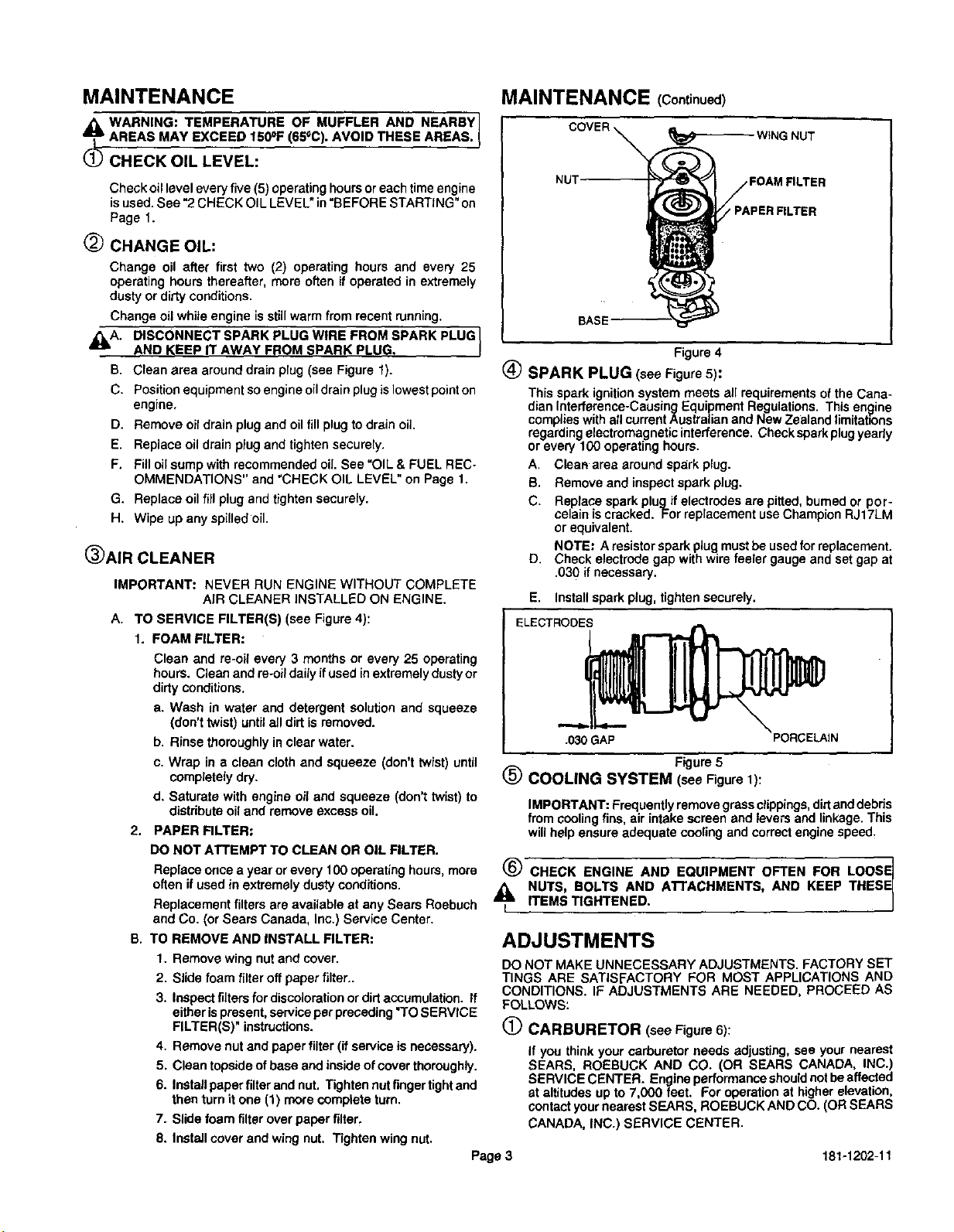

A. TO SERVICE FILTER(S) (see Figure 4):

1. FOAM FILTER:

Clean and re-oil every 3 months or every 25 operating

hours. Clean andre-oil daily if used in extremely dusty or

dirty conditions.

a, Wash in water and detergent solution and squeeze

(don't twist) until all dirt is removed.

b. Rinsethoroughly in clear water.

c. Wrap in a clean cloth and squeeze (don't twist) until

completely dry.

d. Saturate with engine oil and squeeze (don't twist) to

distributeoil and removeexcess oil.

2. PAPER FILTER:

DO NOT ATTEMPT TO CLEAN OR OIL FILTER.

Replace once a year or every t00 operating hours,more

oftenif usedin extremely dusty conditions.

Replacement filters are available at any Sears Roebuch

and Co. (or Sears Canada, Inc.) Service Center.

B. TO REMOVE AND INSTALL RLTER:

1. Remove wing nut and cover.

2. Slidefoam filteroffpaper filter..

3. Inspectfilters for discolorationor dirtaccumulation. If

eitherispresent,serviceperpreceding"TO SERVICE

FILTER(S)" instructions.

4. Remove nut and paperfilter (if service is necessary).

5. Clean topside of base and inside of cover thoroughly.

6. Installpaper filter and nut. Tightennut fingertightand

then turn it one (1) more completeturn.

7. Slidefoam filter over paper filter,

8. Installcover and wing nut. Tighten wing nut.

MAINTENANCE (Continued)

_WING NUT

NUT

BASE--

Figure4

(_ SPARK PLUG (seeFigure5)=

This spark ignitionsystem meets al[ requirementsofthe Cana-

dianInterference-CausingEquipment Regulations. This engine

complieswithall currentAustralianand New Zealand limitatiOns

regardingelectromagneticinterference. Check sparkplugyeady

or every 100 operating hours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plugif electrodes are pitted,burnedor por-

celain is cracked. For replacementuse ChampionRJ17LM

or equivalent.

NOTE: A resistorspark plug mustbe usedfor replacement.

D. Check electrode gap with wire feeler gauge and setgap at

.030 if necessary.

E. Install spark plug,tightensecurely.

ELECTRODES

.030 GAP

(_ COOLING SYSTEM (seeFigure1):

IMPORTANT: Frequentlyremovegrassclippings,dirtand debris

fromcooling fins, air intake screen and levers and linkage. This

willhelp ensure adequate cooling and correctengine speed.

(_)'CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOSE]

_1= NUTS, BOLTS AND AI"FACHMENTS, AND KEEP THESE_

I ITEMS TIGHTENED.

ADJUSTMENTS

DO NOT MAKE UNNECESSARY ADJUSTMENTS. FACTORY SET

TINGS ARE SATISFACTORY FOR MOST APPLICATIONS AND

CONDITIONS. IF ADJUSTMENTS ARE NEEDED, PROCEED AS

FOLLOWS:

(_ CARBURETOR (see Figure6):

If you think your carburetor needs adjusting, see your nearest

SEARS, ROEBUCK AND CO. (OR SEARS CANADA, INC.)

SERVICE CENTER. Engine performanceshouldnotbe affected

at altitudesup to7,000 feet. For operation at higher elevation,

contactyour nearest SEARS, ROEBUCK AND CO. (OR SEARS

CANADA, INC.) SERVICE CENTER.

Page 3

Figure5

18t-1202-11

Loading...

Loading...