Craftsman 113239390 Owner’s Manual

MODEL NO.

113.239201

SHAPER ONLY

113.239390

SHAPER WiTH STEEL

LEGS AND MOTOR

Serial

Number

Model and serial

number may be found

on the front of

the table.

You should record both

model and serial number

in a safe place for

future use.

CAUTaON:

Read GENERAL

and ADDITIONAL

SAFETY

iNSTRUCTIONS

carefully

WOOD SHAPER

• assembly

e operating

o repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No. 72036 Printed in USA.

....... _L,_l_J¸¸ .... I....... rr'l ......... - -II ..... i ¸ I li •

general safety

instructions

1. KNOW YOUR POWER TOOL

Read and understand the owner's manual and labels

affixed to the tool. Learn its application and

limitations as wetl as the specific potential hazards

peculiar to this tool,

2. GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor

cord and a 3-prong grounding type plug to fit the

proper grounding type receptacle. The green conductor

m the cord is the grounding wire. Never connect the

green wire to a live terminal,

3. KEEP GUARDS IN PLACE

in working order, and in proper adjustment and

alignment.

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from toot before turning tt on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

6, AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations or

expose them to rain. Keep work area well lighted,

Provide adequate sui'rOunding work space.

7. KEEP CHILDREN AWAY

All vtsltors should be kept a safe distance from work

area.

8. MAKE WORKSHOP KID-PROOF

with padlocks, master switches, or by removing

starter keys.

9. DON'T FORCE TOOL

tt wttl do the job better and safer at the rate for which

_t was designed.

10.

USE RIGHT TOOL

Don't force tool or attachment to do a job it was not

designed for.

11.

WEAR PROPER APPARE L

Do not wear loose clothing, gloves, neckties or iewefry

(rings, wrist watches) to get caught in moving parts.

Nonslip footwear is recommended, Wear protective

hair covering to contain long hair, Roll long sleeves

above the elbow,

USE SAFETY GOGGLES (Head Protection)

12.

Wear Safety goggles (must comply with ANSI Z87:1)

at all times, Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses. Also, use

face or dust mask if cutting operation iSdustY, and ear

for power tools

protectors (plugs or muffs) during extended periods of

operation,

13. SECURE WORK

Use clamps or a vise to hold work when practical. It's

safer than using your hand, frees both hands to operate

tool,

14. DON'T OVERREACH

Keep proper footing and batance at all times_

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance_ Follow instructions for lubricating and

changi ng accessories.

16. DISCONNECT TOOLS

before servicing; when changing accessories such as

blades, bits, cutters, etc.

t7. AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before plugging

In,

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessones Follow the {nstructions that accompany

the accessories. The use of improper accessories may

cause hazards,

NEVER STAND ON TOOL

19.

Serious injury could occur if the tool is tipped or if the

cutting tool is accidentaJly contacted,

Do no_ store materials above or near the tool such that

_I is necessary to stand on the tool to reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool, aguard or other part that

is damaged should be carefu!ly checked to ensure that it

will operate proper(y and perform its intended function.

Check for alignment of moving parts, binding of mowng

parts, breakage of parts, mounting, and any other

conditions that may .affect its operation. A guard or

other part that _s damaged should be properly repaired

or replaced.

21. DIRECTION OF FEED

Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only,

22. NEVER LEAVE TOOL RUNNING

UNATTENDED

: Turn power off. Don't leave tool until it comes to a

complete stop.

ADDiTiONAL SAFETY iNSTRUCTIONS

FOR WOOD SHAPER

CAUTION: Turn motor switch "OFF" and disconnect 19, NEVER perform freehand shaping - Use either the

Power Cord when changing Shaper cutters or making

adju st ments.

Safety is a combination of operator common sense and

alertness at all times when the Wood Shaper is being used,

WARNING: FOR YOUR OWN SAFETY, DO NOT

ATTEMPT TO OPERATE YOUR WOOD SHAPER UNTIL

IT IS COMPLETLY ASSEMBLED AND INSTALLED

ACCORDING TO THE INSTRUCTIONS... AND UNTIL

YOU HAVE READ AND UNDERSTAND THE

FOLLOWl NG: PAGE

1. General Safety Instructions for Power Tools ..... 2

2. Getting to Know your Wood Shaper ............ 12

3. Basic Wood Shaper Operation ................. 15

4. Maintenance .............................. 19

5. Stability of Machine

The Shaper must be bolted securely to a stand or work

bench, in addition, if there is any tendency for the

Shaper to tip over or move during certain operations, it

should be bolted to the floor.

6. Location

The Shaper should be positioned so neither the

operator nor a casual observer is forced to stand in line

with the workpiece when straight line shaping. This

Shaper is intended for indoor use only.

7. Protection: Eyes, Hands, Face, Ears, Body

Wear safety goggles that comply with ANSI Z87.1

1968. Wear ear plugs or muffs during extended periods

of operation. Do not wear gloves ... roll long sleeves

above the elbow.

8. Afways feed against rotation of the cutter. NEVER

"back up" the workpiece.

9. Do not take deep cuts or feed the stock too rapidly.

10. Be particularly careful in shaping wood that contains

cross grains or knots, as these may cause the hands to

be thrown into the cutter or cause kickbacks.

11. Before applying power, make sure the keyed washer is

installed immediately under the spindle nut and the

spindle nut is securely fastened, and all guards are in the

proper position. Make sure cutters are sharp.

12. Avoid awkward hand positions, where a sudden slip

could cause a hand to move into the cutter. Never reach

in back of or around the cutter with either hand to hold

down the workpiece.

13. Accumulations of stock or of finished work should not

be allowed on the table. Never clear table while cutter is

rotating.

14. Rubbish, shavings, stock, or other objects or material

should not be allowed on the floor where they may be a

tripping hazard.

15. Use working forms, patterns or holders wherever

possible, and keep them maintained. Care should be

taken that the work is securely fastened in these

fixtures. Stock is often of such size or shape that it

must be clamped in a holder before being shaped, The

inside jaws which clamp directly against the stock

should be lined with sand paper. Guards may also be

mounted on a holder to afford additional protection.

t6. When the fence is used, make sure it is securely fastened

and will not slip, and is properly adjusted.

t7. Do not wear gloves, neckties, loose sleeves, or ragged or

torn clothing of any kind. Wear safety goggles

complying with ANSI Z87.1-1968 to protect your eyes

from dust or flying particles.

18. DO NOT perform layout, assembly, or set-up work on

the table while the cutting toot is rotating.

fence, or a starting pin in the table and a collar on the

spindle, or a pattern.

20. Do not place your fingers or hands near edge of

material being cut.

21. NEVER perform irregular shaping operations with the

cutter guard removed. Be positive it is installed and

adjusted per instructions.

22. NEVER perform internal shaping operations on this

Shaper.

23. Do not use your hands to remove objects or materials

from around cutters; use a brush.

24. Do not tamper with guards nor make them inoperative

in any way.

25. ALWAYS joint or plane edge on surface of workpiece

that will be in contact with fence and/or table.

26. NEVER attempt to shape warped or twisted or bowed

work pieces.

27. Before leaving the machine, make sure the motor switch

is "OFF" the power cord is disconnected from the

power source, and the cutter has stopped revofving.

28. Never operate the Shaper without a protective cover on

the unused shaft end of a double ended motor.

29. If any part of this Shaper should break, bend, or fai! in

any way or any electrical component fail to perform

properly, or if any is missing, shut off power switch,

remove power supply cord from power supply and

replace damaged missing and/or failed parts before

resuming operation.

WARNING: DO NOT ALLOW FAMILIARITY (GAINED

FROM FREQUENT USE OF YOUR WOOD SHAPER) TO

BECOME COMMONPLACE. ALWAYS REMEMBER

THAT A CARELESS FRACTION OF A SECOND IS

SUFFICIENT TO INFLICT SEVERE INJURY.

30. Note and follow Safety Instructions that appears on the

Shaper fence.

WAR NING

A KEYED WASHER MUST ALWAYS

BE USED UNDER THE SPINDLE NU'i"

31. Note and follow Safety instructions that appear on the

Shaper Switch assembly,

DANGER

FOR YOUR OWN SAFETY:

READ *&_D UNDE{_TANb OWNE_4 S

M_tNUAL BEFORE OPERATING _,_AC_4_NE

_ WEAR SAFE_'P¢ GOGGLES pen ANSI Z87 1

AT ALL TIM_S

2 BE POSIT_V_ K]_Y_D W_.$HER 1_ DIRECTLY

UND_.R SF'INDLE ,NUT AND SP_NDL_ _VLiT lS

T_G_TB_FORE TU_I_G S_A_E_ ON

3 ALWAYS _EED VVORKPI_CE AGAIN$1

ROTA:tON O_ CUT/,_ MOTOR ._t_D

CU'FTER ROTATE _N SAME _)t_CT_DN

4 AVOID AW?;WARD NAND POS_T_D_4$

5 K_P F;N_RS AWAY' I:ROM _VOLVtNG

CUTTER ,-- USE F_XTUR_S W_4E_

NECESSARY

_5 USE OV_R_4_AD GUARD WHEN AOJUS'€.

ABLE €_NC_ _$ NOT IN PLA_E

WARNING: THE 4-318" FLAT MOTOR PULLEY AND THE

2" SPINDLE PULLEY FURNISHED, WILL RUN THE CUT -

TER APPROXIMATELY 9000 R.P.M. WH EN USED WITH A

3450 MOTOR. NEVER SUBSTITUTE THESE PULLEYS

TO INCREASE THIS SPEED BECAUSE IT COULD BE

DANGEROUS.

Note and follow safety instructions that appear on the

motor.

CAUTION: Reversible motor - check rotationbefore using,

ii 'can: 'reSult: in foreign

which::can result in

ELECTRICA L:IREQU! REIV!ENTS

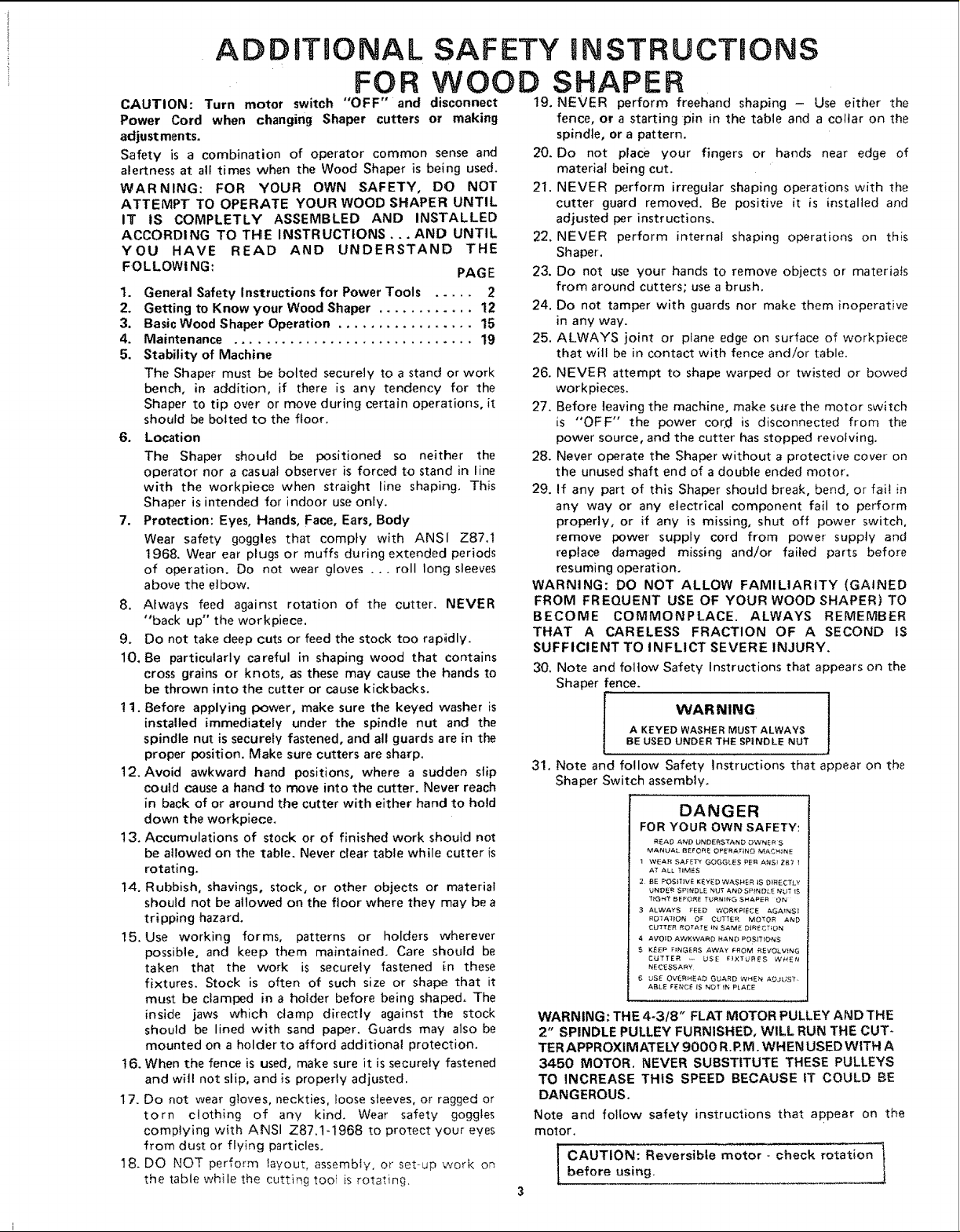

CONNECTING TO POWER SOURCE OUTLET

This machine must be grounded while in use to protect the

operator from efectr:ic shock.

Plug power cord into a 120V properly grounded type outlet

protected by a t5 amp dual element time delay or circuit

saver fuse or circuit breaker. If you are not sure that your

outlet is properly grounded, have it checked by a qualified

electrician.

WARNING: DO NOT PERMIT FINGERS TO TOUCH

THE TERMINALS OF PLUGS WHEN INSTALLING OR

REMOVING THE PLUG TO OR FROM THE OUTLET,

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK. PARTICULARLY WHEN

USED IN :DAMP LOCATIONS |N PROXIMITY TO

PLUMBING. IF A:N ELECTRICAL SHOCK OCCURS

THERE IS THE POTENTIAL OF A SECONDARY

HAZARD SUCH AS YOUR HANDS CONTACTING THE

CUTTER BLADE.

If power cord is worn or cut, or damaged in any way, have it

replaced immediately.

Yourshaper is wired for 120 volts and h_s a plug th at looks like

the one shown below.

3-PRONG

PLUG

PROPERLY

GROUNDED

OUTLET

@

GROU NDING

PRONG

l_his power tool is equipped with a 3_conductor cord and

grounding type plug listed by Underwriters" Laboratories. The

ground conductor has a green jacket and is attached to the

tool housingat one end and tothe ground prong in the attach-

ment plug at the other end.

Thisplug requires amating 3-conductor grounded type outlet

as shown above.

before cornmencing

Sears

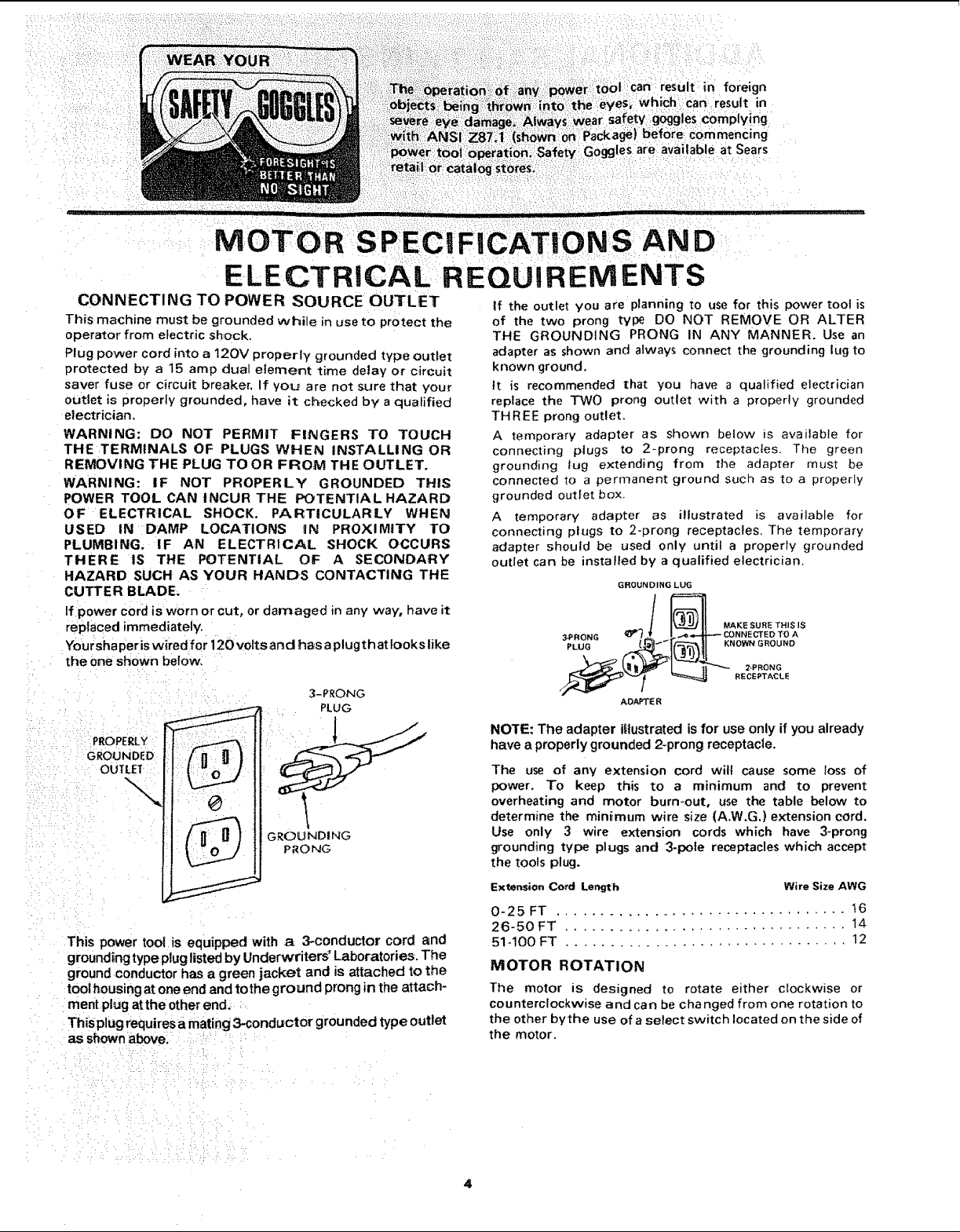

If the outlet you are planning to use for this power tool is

of the two prong type DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER. Use an

adapter as shown and always connect the grounding lug to

known ground.

tt is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet.

A temporary adapter as shown below is available for

connecting plugs to 2=prong receptacles. The green

grounding tug extending from the adaptor must be

connected to a permanent ground such as to a properly

grounded outlet box.

A temporary adapter as illustrated is available for

connecting plugs to 2-prong receptacles, The temporary

adapter should be used only until a properly grounded

outlet can be installed by a qualified electrician.

GROUNDING LUG

3-PRONG

PLUG

ADAPTE R

MAKE SURE THISIS

KNOWN GROUND

2*PRONG

RECEPTACLE

NOTE: The adapter illustrated isfor use only if you already

have a properly grounded 2-prong receptacle.

The use of any extension cord will cause some loss of

power, To keep this to a minimum and to prevent

overheating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G,) extension cord.

Use only 3 wire extension cords which have 3-prong

grounding type plugs and 3-pote receptacles which accept

the tools plug.

Extension Cord Length

Wire Size AWG

0-25 FT ................................. 16

26-50 FT ............................... 14

51-100 FT ................................ 12

MOTOR ROTATION

The motor is designed to rotate either clockwise or

counterclockwise and can be changed from one rotation to

the other bythe use of a select switch located on the side of

the motor.

4

UNPACKING AND CH

CONTENTS

WARRANTY .... : ................................ 2

General Safety Instruction for Power Tools .......... 2

Additional Safety Instructions for Wood Shaper ...... 3

Motor Specifications and Electrical Requirements .... 4

UNPACKING AND CHECKING CONTENTS ....... 5

List of Loose Parts .............................. 5

ASSEMBLY ...................................... 6

Tools Needed ................................... 6

Installing Elevating Rod and Table Support ........ 7

Mounting Belt Guard and Motor to Motor Mount .. 7

Installing Motor Pulley ........................... 8

Mounting Motor Support Assembly to Shaper ..... 9

Mounting Switch Assembly ...................... 9

Assembling Steel Legs .......................... 9

Mounting Wood Shaper on Floor Stared .......... 10

Plugging in Motor .............................. 10

Installing Shaper Fence -- For Straight Edge

Shaping only ................................. 11

installing Shaper Cutter Guard --- For Curved

or Irregular Shaping only ..................... 11

GETTING TO KNOW YOUR: WOOD SHAPER .... 12

On-Off Switch ................................. 12

Elevating Control Lever ......................... 13

Spindle Lock Knob ............................. !3

Spindle ........................................ t3

Spacers ....................................... t 3

Keyed Washer ................................. 13

Fence Adjusting Knob .......................... 13

Fence Lock Knob ............................... t3

Fence Faces ................................... t3

Cutter Guard ................................... 13

Starting Pin .................................... 13

Removing and Installing Cutter .................. 13

ADJUSTMENTS ................................ 14

Shaper Fence .................................. !4

Fence Faces ................................... 14

BASIC SHAPING OPERATIONS ................. 15

Use of Cutter Spacers .......................... t5

Straight Edge Shaping .......................... 16

Shaping With Use of Miter Gauge and

Hold-Down Clamp (Optional Accessory) ........ 16

Irregular or curved Shaping ..................... 17

MAINTENANCE ................................. 19

LUBRICATION .................................. 19

Motor Maintenance and Lubrication ............. t9

RECOMMENDED ACCESSORIES ............... 19

TROUBLE SHOOTING ........................... 20

REPAIR PARTS ................................. 22

Motor Connections ............................. 27

O

ECKING CO NTENTS

Model 113.239390 Wood Shaper is shipped complete in

one carton and includes st:eel legs and motor.

Model 113.239201 Wood Shaper is shipped complete in

one carton but DOES NOT INCLUDE Steel Legs or Motor.

Separate al! parts from p_oking materials and check each

one with the illustration and the tist of Loose Parts to make

certain all items are accounted for, before discarding any

packing material.

If any parts are missing, do not attempt to assemble the

Shaper, plug in the pov_er cord or turn the switch on until

the missing parts are obtair_ed and are installed correctly.

Remove the protective oil that is applied to the table top

and edges of the t_ble. Use any ordinary household type

grease and spot remover.

CAUTION: Never use g,asoline, naptha or similar highly

volatile solvents.

Apply a coat of automobilJe wax to the table.

Wipe aH parts thoroughly with a clean, dry cloth,

WARNING: FOR yOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET UNTIL

ALL ASSEMBLY STEPS ARE COMPLETE, AND YOU

HAVE READ AND UNDERSTAND THE SAFETY AND

OPERATIONAL INSTR UCT_ONS.

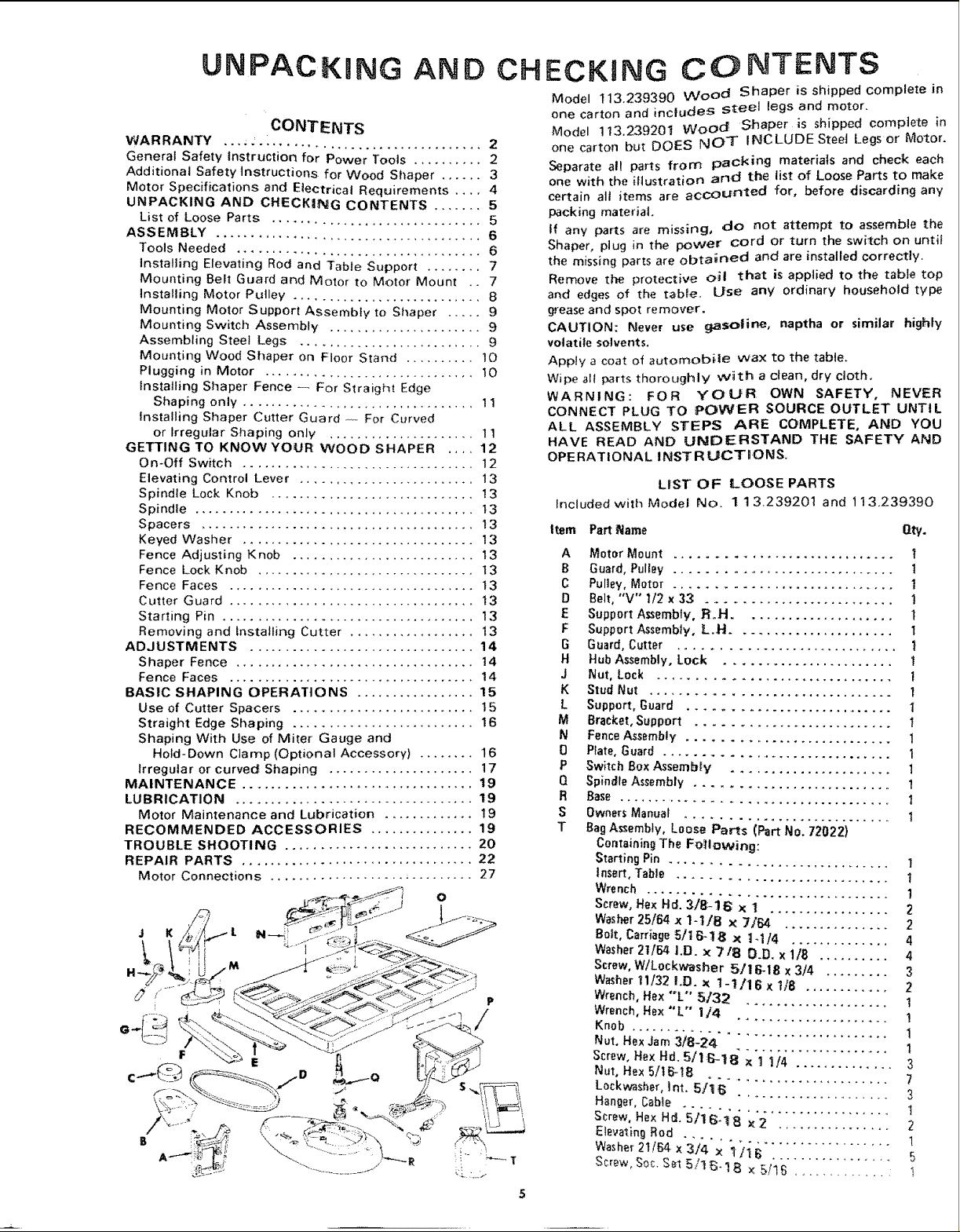

LIST OF LOOSE PARTS

Included with Model No. 113.23920t and 113,239390

Item Part Name Qt_/.

A

Motor Mount .............................

B

Guard, Pulley ............................. t

C

Pulley, Motor ............................. 1

D

Belt, "V" 1/2 x 33: ........................... 1

E

Support A_sembfy, _H ..................... 1

F

Support Assembly, L.H ...................... 1

G

Guard, Cutter ............................. t

H

Hub Assembly, Lock ....................... t

J

Nut, Lock ............................... 1

K

Stud Nut .................................. 1

L

Support, Guard ............................ 1

M

Bracket, Support ........................... I

N

Fence Assembly ............................ 1

O

Plate, Guard ................................ I

P

Switch Box Assembly ...................... 1

Q

Spin_fe Assembly .......................... 1

R

Base

S

Owners Manual

T

Bag Assembly, Loose Parts (Part No. 72022)

Containing The Fo_llowing:

Starting Pin 1

Insert, Table

Wre rich 1

Screw, Hex Hd. 3/8-16; x 1 2

Bolt, Carriage 5/t6-18 × t-1/4 .............. 4

Washer 21164 i.D. x 71B O.D. x 1/8 .......... 4

Screw, W/L0ckv_asher 5716-18 x 3/4 ......... 3

Washer 11/32 I.D. x 1 -!/16 x 1,/8 ............ 2

Wrench, Hex "L °' 5132

Wrench, Hex *'L'" I/4

Knob

............................ I

............................ I

=====================2

...... * ............. 1

Nut, He× 5/16-t8

L0ckwasher, Int. 5I:t _;................ 7

Han_er, Cable - ..................... 3

Screw0 H ex H_1."5"1:I_: lj'_ 1"2 .............. 1

Elevating Rod ................ 2

3

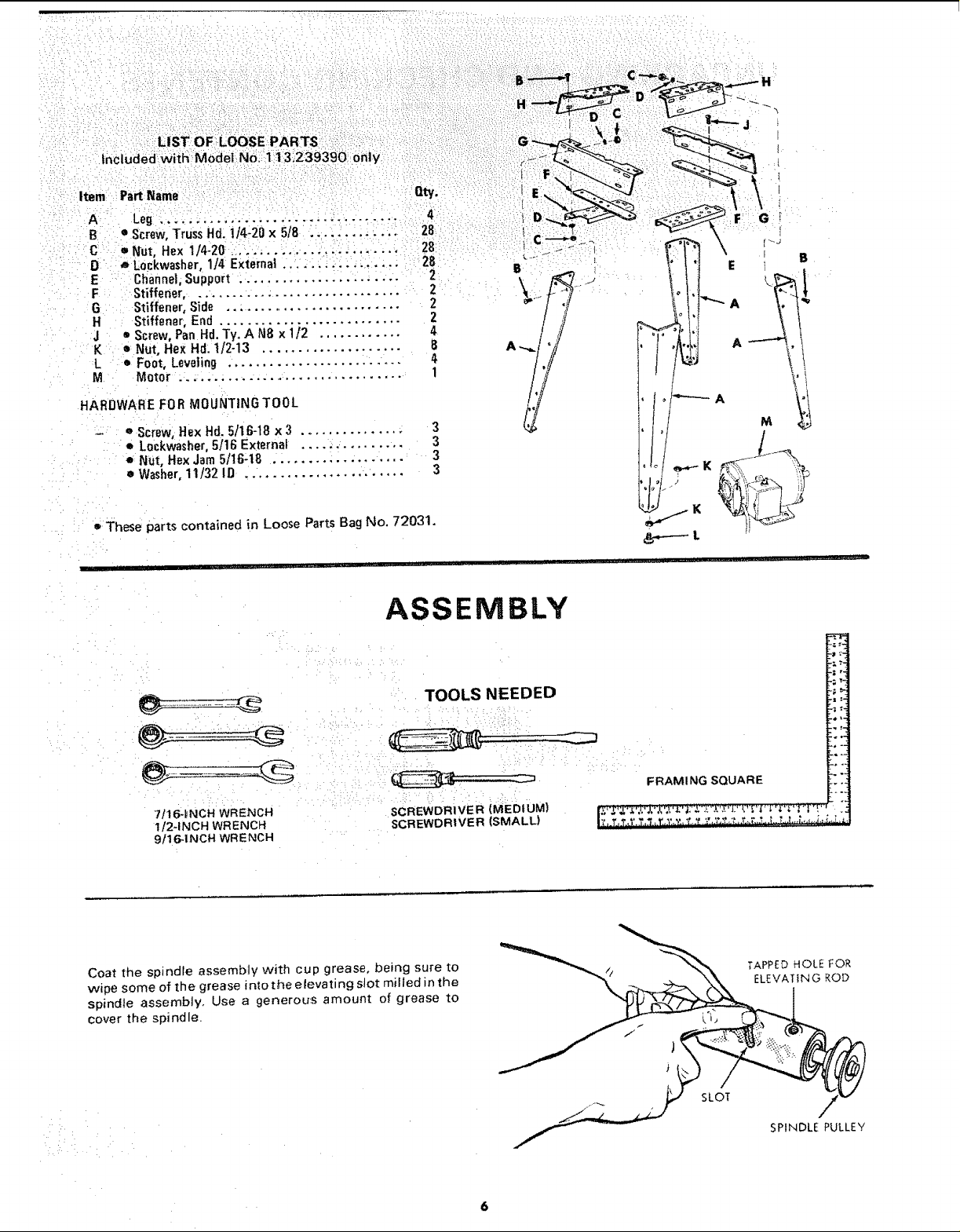

tnclude

Item PartName

A Leg

B

C

D

E

F

G

H

J

K

L

M

liARDWARE FOR MOUNTING TOOL

• These parts contained in Loose Parts Bag No, 72031.

.i ¸¸ . H • : ;.:

•S++e+,"ii&+_+.+;+i+++++'_+;+: i:i:i:i;::ii ++

eNut, Hex 1]4-20 ._+++..... ....:.;: ........ 2B -

o L0ckwasher, 114 External ................... 2B

Channel,Support ....................... 2

Stiffener.............................. 2

Stiffener, Side .......................... 2

Stiffener; End .......................... 2

• Screw,Pan lid. Ty. A N8 x 1/2 ............ 4

• Nut, FlexHd. t/2-13 .................... B

• Foot, Leveling ......................... 4

Motor ................................ 1

" Screw,liex lid. 5/16-18 x 3 ............... 3

• Lockwasher,5116External ............... 3

• Nut, Hex Jam 5/16-1B ................... 3

• Washer,ti/32 ID ....................... 3

0_.

, i,," _ ..

B

':' " H

+ s

"; [

1

f N

ASSEMBLY

7tI6++NCH WRENCH

1/2-INCH WRENCH

9116-1NCH WRENCH

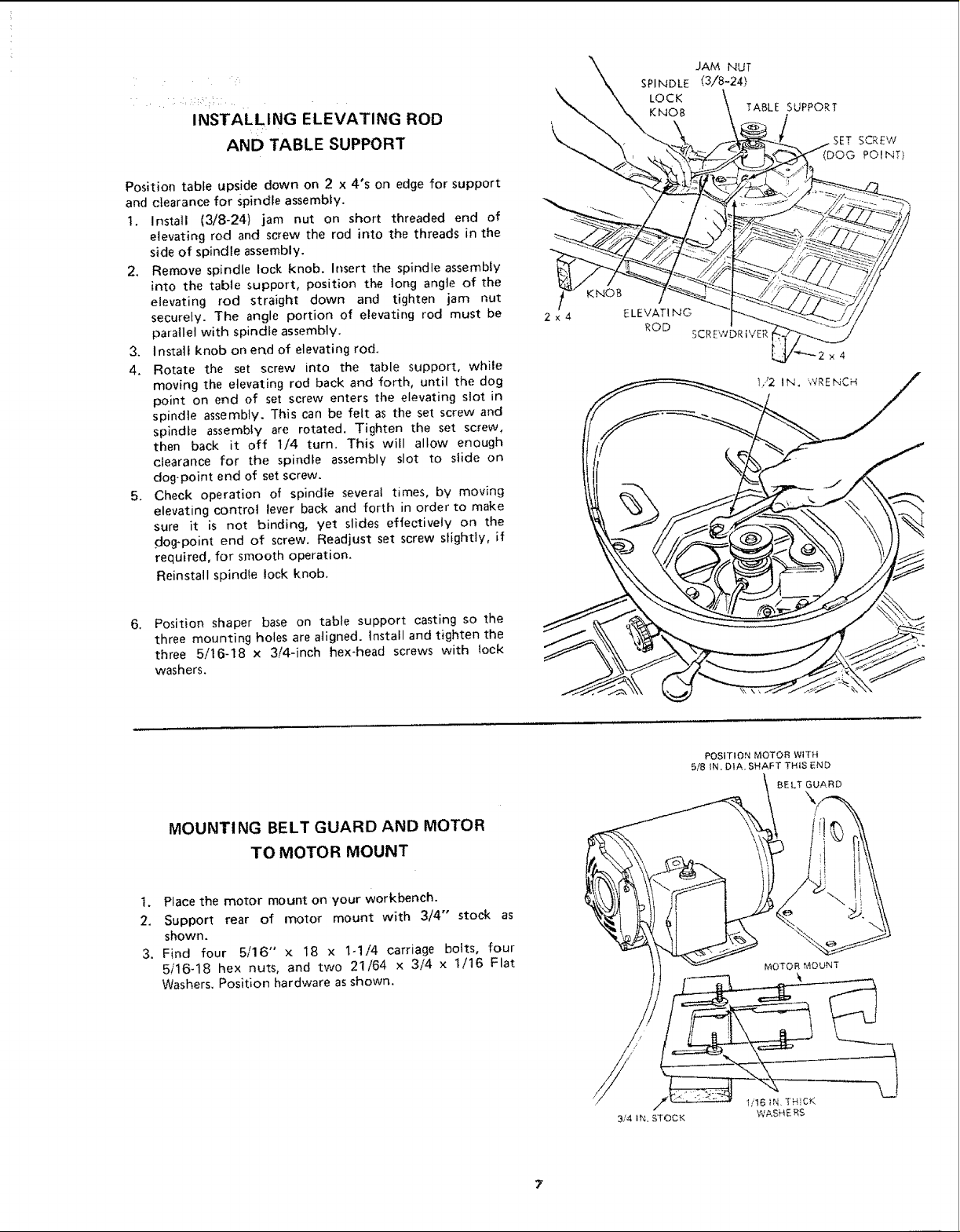

Coat the spindle assembly with cup grease, being sure to

wipe some of the grease into tf+e elevating stot miffed in the

spindle assembJy, Use a generous amount of grease to

cover the spindle.

TAPPED HOLE FOR

ELEVATING ROD

SLOT

- i ¸

?

SPINDLE PULLEY

INSTALLING ELEVATING ROD

AND TABLE SUPPORT

Position table upside down on 2 x 4's on edge for support

and clearance for Spindle assembly.

1. Install (3/8-24) jam nut on short threaded end of

elevating rod and screw the rod into the threads in the

side of spindle assembly.

2. Remove spindle lock knob. Insert the spindle assembly

into the table support, position the long angle of the

elevating rod straight down and tighten jam nut

securely. The angle portion of elevating rod must be

parallel with spindle assembly.

3. Install knob on end of elevating rod.

4. Rotate the set screw into the table support, while

moving the elevating rod back and forth, until the dog

point on end of set screw enters the elevating slot in

spindie assembly. This can be felt as the set screw and

spindle assembly are rotated. Tighten the set screw,

then back it off 1/4 turn. This will allow enough

clearance for the spindle assembly slot to slide on

dog-point end of set screw.

5. Check operation of spindle several times, by moving

elevating control lever back and forth in order to make

sure it is not binding, yet slides effectively on the

dog-point end of screw. Readjust set screw slightly, if

required, for smooth operation.

Reinstall spindle lock knob.

, Position shaper base on table support casting so the

three mounting holes are aligned. Install and tighten the

three 5/!6-18 × 3/4-inch hex-head screws with lock

washers.

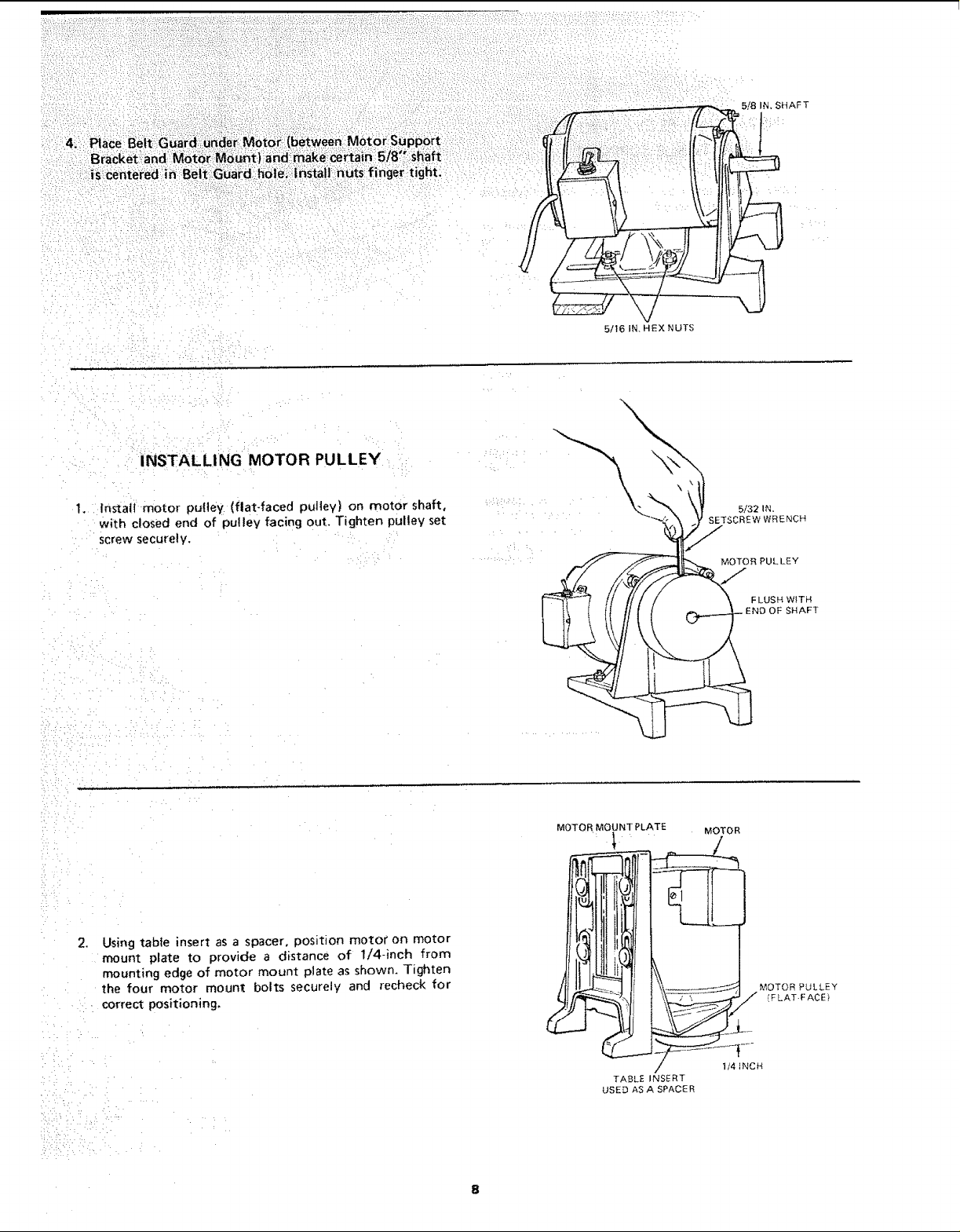

MOUNTING BELT GUARD AND MOTOR

TO MOTOR MOUNT

1. Place the motor mount on your workbench.

2. Support rear of motor mount with 3/4" stock as

shown.

3. Find four 5/16" x 18 x 1-1/4 carriage bolts, four

5/16-18 hex nuts, and two 21/64 x 3/4 x t/16 Flat

Washers. Position hardware as shown.

POSITION MOTOR WITH

51"8IN. DIA, SHAFT TI41S END

BELT GUARD

MOTOR MOUNT

3/4 IN, STOOl<

t/16 IN.THiCK

WASHERS

INSTALLING MOTOR PULLEY

5/16INHEXNUTS

1. Install motor pulley (flat-faced pulley) on motor shaft,

with closed end of pulley facing out. Tighten pulley set

screw securel y.

2.

Using table insert as a spacer, position motor on motor

mount plate to provide a distance of 1/4-inch from

mounting edge of motor mount plate as shown. Tighten

the four motor mount bolts securely and recheck for

correct positioning.

SETSCREW WRENCH

f

/"

_IOTOR MOiNT PLATE MOTOR

5132 IN,

MOTOR PUL LEY

FLUSH W{TH

MOTOR £ULLEY

SHAFT

/ 1/4 INCH

TABLE INSE RT

USED AS A SPACER

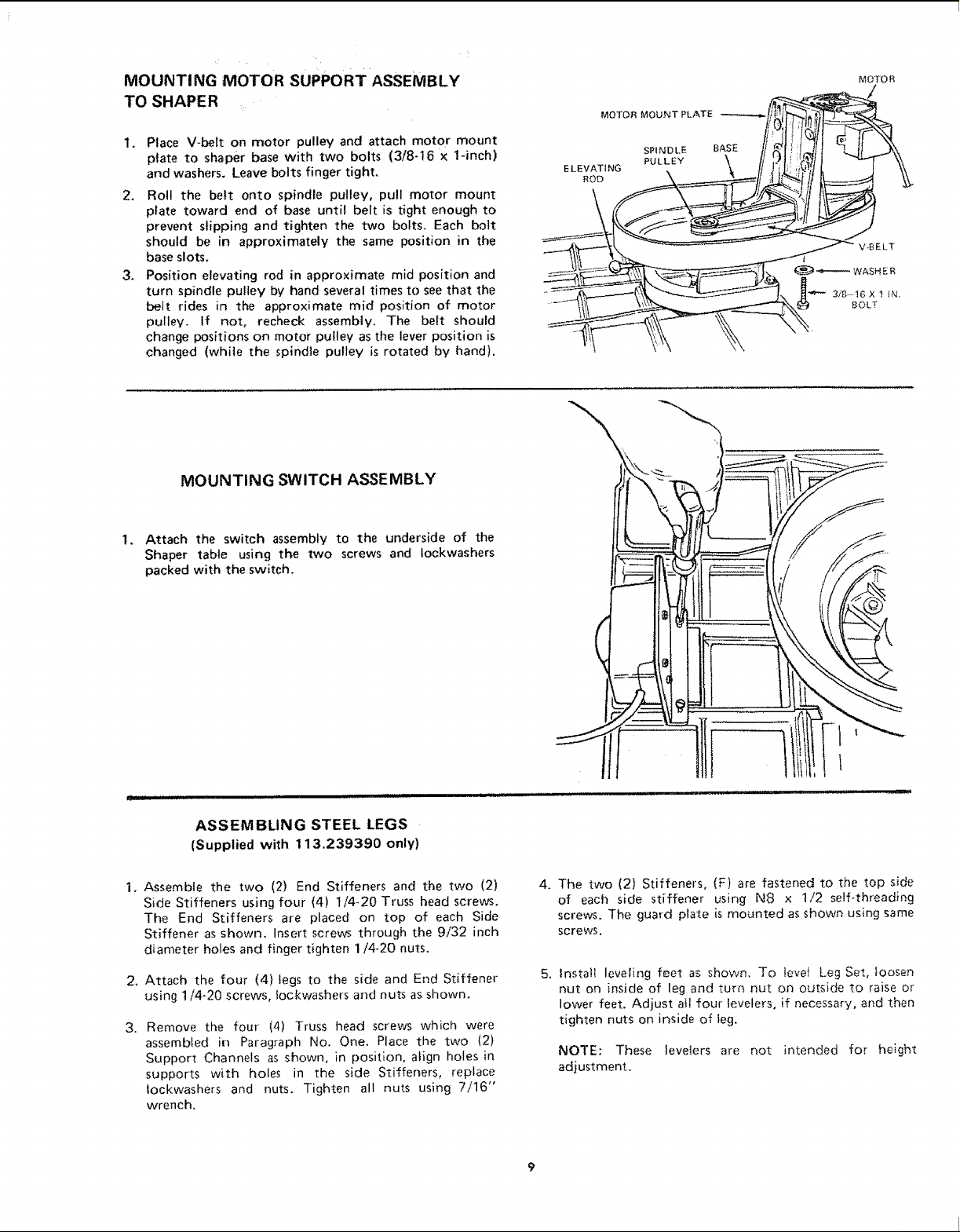

MOUNTING MOTOR SUPPORT ASSEMBLY

TO SHAPER

MOTO R

MOTOR MOUNT PLATE

1. Place V-belt on motor pulley and attach motor mount

plate to shaper base with two bolts (3/8-16 x 1-inch)

and washers. Leave bolts finger tight.

2. Roll the belt onto spindle pulley, pull motor mount

plate toward end of base until belt is tight enough to

prevent slipping and tighten the two bolts. Each bolt

should be in approximately the same position in the

base slots.

3o Position elevating rod in approximate mid position and

turn spindle pulley by hand several times to see that the

belt rides in the approximate mid position of motor

pulley. If not, recheck assembly. The belt should

change positions on motor pulley as the lever position is

changed (while the spindle pulley is rotated by hand).

MOUNTING SWITCH ASSEMBLY

Attach the switch assembly to the underside of the

Shaper table using the two screws and Iockwashers

packed with the switch.

ELEVATING

ROD

SPINDLE BASE

PULLEY

ASSEMBLING STEEL LEGS

(Supplied with 113,239390 only)

1.

Assemble the two (2) End Stiffeners and the two (2)

Side Stiffeners using four (4) 1/4_20 Truss head screws.

The End Stiffeners are placed on top of each Side

Stiffener as shown. Insert screws through the 9/32 inch

diameter holes and finger tighten 1/4-20 nuts.

2.

Attach the four (4) legs to the side and End Stiffener

using 1/4-20 screws, _ockwashers and nuts as shown.

3,

Remove the four (4) Truss head screws which were

assembled in Paragraph No. One. Place the two (2)

Support Channels as shown, in position, align holes in

supports with holes in the side Stiffeners, replace

tockwashers and nuts. Tighten all nuts using 7/16"

wrench,

4. The two (2) Stiffeners, (F) are fastened to the top side

of each side stiffener using N8 x t/2 self-threading

screws. The guard plate is mounted as shown using same

screws.

5. Install leveling feet as shown. To ieve! Leg Set, ]oosen

nut on inside of leg and turn nut on outside to raise or

lower feet. Adjust a_l four levelers, if necessary, and then

tighten nuts on inside of leg.

NOTE: These levelers are not intended for height

adjustment.

Loading...

Loading...