Craftsman 113236400 Owner’s Manual

/_ Save This Manual _-'_

For Future Reference

MODEL NO.

113.236400

SCROLL SAW

Variable Speed

With Stand

Serial

Number

Model and serial numbers

may be found attached at rear

of saw.

You should record both model

and serial number in a safe

ptace for future use.

FOR YOUR

SAFETY

READ ALL

iNSTRUCTIONS

CAREFULLY

...)

®

CONTRACTOR SERIES

20" VARIABLE SPEED

SCROLL SAW

- assembly

,,operating

8

* repa=r parts

I

J

J

Pa_ No. SP5498

Sears, Roebuck and Co. Hoffman Estates, iL 60179 U.S.A.

Pnnted in Taiwan

TOOLS

within one year from the date of

THE UNITED STATES, and

free of charge.

'commercial or rental purposes, warranty will apply for ninety days from

.:the:date of purchase, .

-_This warranty applies only while this product is in the United States.

you specific legal rights and you may also have other rights which vary from state

Sears, Roebuck and Co., D817 WA Hoffman Estates, IL. 60179

safety instructions for scroll saw

-Safety is a combination of Common sense, staying a|ed WHEN INSTALLING OR MOVING THE SAW

"and knowing how your scroll saw works. Read this man-

ualto understand this saw.

Safety Signal Words

DANGER: means if the safety information is not followed

someone will be seriously injured or killed.

WARNING: means if the safety information is not followed

-someone could be seriously injured or killed.

CAUTION: means ifthe safety information is not followed

someone may be injured.

BEFORE USINGTHE SAW

[ WARNING: TO avoid mistakes that could cause I

t setious permanent injury, do not plug the saw in

] until the following steps are completed.

., Assembly and alignment. (See pages 7 - 14).

-. Leamtlie_:use_ and:function of the speed control ON-

OFE ik'iiob_;beVe|:_10Ckkdbb,=bladeholders, blade sup- NEVER STAND ON TOOL. Serious injury could occur it

p0rt; h0ia:a0wn,blade:tension -knob, and blade the tool tipsor you accidentally hit the cutting tool. Do not

guard,(Seepages i4_-1i5) ,;-; ......... i_ _ _- - '_..

- Review ahdUhderstandatt,S_,fety_irist_cti0'ns!ar_d opei ;_

ating:procedures in:this hladuai.-: _ ::- :.:_ :i:,:

• Review 0f the maintenance :instrQctioi_s for this saw.

(Seep,_ge_9):• :::' " : : :_

Read the warning label below, found on the base of the

saw.

AVOID DANGEROUS ENVIRONMENT. Use the saw in

a dry, indoor place, protected from rain. Keep work area

wel! lighted.

To avoid injury from unexpected saw movement:

• T_m saw off and unplug cord before moving the saw.

• Always get help before moving the saw. The saw with

stand, weighs 135 pounds. You could strain your back

or the saw could fall on you.

• Put the saw on a firm level surface where there is

plenty of room for handling and properly supporting the

workpiece.

o Support the saw so the table is level and the saw does

not rock.

!

• Boll the stand to the floor if it tends to slip, walk, or slide

during operations like cutting long heavy boards, or

when using an auxiliary table.

store anything above or near the tool where anyone

might stand on the tool to reach them.

To avoid injury or death from electrical shock:

, GROUND THE SAW. This saw has an approved 3 con-

ductor cord and a 3-prong grounding type plug. Use

........... grounded outlets rated 120 volts. 15

amperes (amps). The green conductor in the cord is the

grounding wire. To avoid electrocution, NEVER con-

nect the green wire to a live terminal.

• Make sure your fingers do not touch the plug's metal

prongs when plugging or unplugging the saw,

_' i _ i_ _ ..... _i..... :

Before Each Use:

Inspect your saw.

DISCONNECT THE SAW. To avoid injury from acciden-

tal starting, unplug the saw, turn the switch "OFF" and

lock the switch before changing the setup or removing

covers, guards or blade.

CHECK FOR DAMAGED PARTS. Check for:

• Alignment of moving pads.

• Binding of moving parts.

° Broken parts.

° Stable mounting and

- Any other conditions that may affect the way the saw

works.

if any part is missing, bent or broken in any way, or any

electrical part doesn't work properly, turn off and unplug

the saw, REPLACE damaged, missing or failed parts

before using the saw again, Keep Guards In Place and

in working order.

MAINTAIN TOOLS WITH CARE. Keep the saw clean for

best and safest performance. Follow instructions under

"Maintenance",

REMOVE ADJUSTING KEYS AND WRENCHES from

toot before turning it on.

To avoid injury from jams, slips or thrown pieces:

- Choose the right size and style blade for the material

and the type of cutting you ptan todo.

° USE ONLY RECOMMENDED ACCESSORIES. (See

page 20). Consult this owners manual for recom-

mended accessories. Fot]ow the instructionsthat come

with the accessories. The. use of improper accessories

may cause risk of injury to person.

- Make sure the blade teeth point downward, toward the

table.

• Make sure the b_adetension isproperly adjusted,

=Make sure the bevel lock knob is tight and no parts

have excessive play.

• To avoid accidental blade contact, minimize blade

breakage and provide maximum blade support, always

adjust the blade hold-down and blade guard to just

clear the workpiece,

• KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents. Floor must not be slippery.

To avoid burns or other fire damage, never use the saw

near flammable liquids,vapors or gases.

PLAN AHEAD TO PROTECT YOUR EYES,

HANDS, FACE AND EARS:

KNOW YOUR SAW, Read and understand the owners

manual and labels affixed to the too!. Learn its application

and limitations as well as the specific potential hazards

peculiar to this tool.

To avoid injury from accidental sontact with moving parts,

don't do layout, assembly, or setup work on the saw while

any parts are moving.

AVOID ACCIDENTAL STARTING. Make sure switch is

"OFF" before plugging saw into a power outlet.

Plan Your Work.

• USE THE RIGHT TOOL. Don_ force too! or attachment

to do a job it was not designed to do.

• UsethiS scroll s#,w to cut onlywo0d, wo0diike products,

plastics and nonferrous:metals .... .

CAUTION: This :Saw:i_ NOT designed for cutting

ferrous metals like it0n 0r steel When cutting non-

ferrous metals (brass, copper and aluminum, etC.),

metal shavings can react with wood dust and start

a fire. To avoid this:

• Disconnect any type of dust collecting hose from

the saw.

• Remove al| traces of wood dust from on and

around the saw.

• Remove all metal shavings from on or around the

saw before sawing wood again.

Dress for safety

Any power saw can throw foreign objects into the eyes.

This can cause permanent eye damage. Wear safety

goggles (not glasses) that comply with ANSI Z87.1

(Shown on package). Everyday eyeglasses have only

impact resistant lenses. They are not safety glasses.

Safety goggles are available at Sears Retail Stores.

Glasses or goggles not in compliance with ANSI Z87.1

could seriously hurt you when they break.

• Do not wear loose cJothJng, gloves, neckties or jewelry

(rings, wristwatches). They can :get caught and draw

you into moving pads.

• Wear nons}ip footwear,

° Tie back lor_ghair.

• Roll tong sleeves above the elbow.

° Noise levels vary widely, To avoid possible hearing

damage, wear ear plugs or muffs when using saw for

hours at a time.

• For dusty operations, wear a dust mask along with the

safety goggles.

Inspect _'our Workpiece.

Make sure there are no nails or foreign objects in the par_

of the workpiece to be cut.

Use extra caution with large, very small or awkward

workpieces:

• Never use this toot to finish pieces too smelt to hotd by

hand.

, Use extra supports (tables, saw horses, blocks, etc.) for

ar_yworkpieces large enough to tip when not held down

to the table top.

-Never use artother person as a substitute for a table

extension, or as additional support for a workpiece or to

help teed, support or puff the workpiece

safetyinstructions for scroll saw

When c[itt _g:irreg;u|adY-shaped workpieces plan your Before starting Your cut watch the saw while it runs. If it

work sO it Will dot pii_ch the blade. A piece:of, molding, makes an unfamiliar noise or vibrates a lot, stop immedi-

-f0i; examp'le must lay flat orbe held bya f_ture Or jig ately Turn the saw off. Unplug the saw. Do not restart

that Willnot let:ittW st, rock oi slip whilebeihg cut, until lindingand correcting the problem.

, P_e_:sUpport round:materiai such as dowel rods, or KEEP CHILDREN AWAY. Keep al_ visitors a safe dis-

tul_ing__ey_have _ tendency to roll during a cut, _using tance from: the :saw. Make sure bystanders are clear o!

the bl_e to bite. To avoid this, always use a "V" block. : the Saw and workpiece.

-Cut onlyone workpiece at a time.

, Clear, everything except the workpiece and related

- Support devices off the table before turning the saw on.

Plan the way you will hold the workpiece from start

to finish.

Do not hand hold pieces so small that your fingers will go

under the work hold down. Use jigs or fixtures to hold the

work and keep your hands away from the blade.

Avoid awkward operations and hand positions where a sud-

den slip could cause fingers or hand to move intothe blade.

Don't Overreach. Keep good footing and balance.

Keep your face and body to one side oI sawb{ade, out of

line-with a possible thrown piece:

SECURE WORK. Use clamps to hold work when practi-

cal. It!s often safer than using your hand, and frees both

hands to operate the too!.

Avoid awkward operations and hand positions where a sud-

den slip could cause fingers or hand to move into the blade.

DON'T OVERREACH. Keep good footing and balance.

Keep your face and body to one side of the blade, out of

line with a possible thrown piece if the blade should break.

WHENEVER SAW IS RUNNING

DON'T FORCE TOOL. It wil!do the job better and safer at its

designed rate. Feed the workpiece into the saw blade only

fast enough to let it cutwithout bogging down or binding.

Before freeing any jammed material:

* Push switch "OFF".

......... all moving parts to stop.

o Unplug the saw.

When backing up the workpiece, the blade may bind

in the kerr (cut). This is usually caused by sawdust

clogging up the kerr. If this happens:

- Turn switch "OFF".

, Wait for allmoving parts to stop.

° Unplug the saw

oRemove the blade from the blade holders.

- Remove workpiece with blade from the table, Remove

blade from workpiece.

Before removing loose pieces from the table, turn

saw off and wait for all moving parts to stop.

BEFORE LEAVING THE SAW

Wait for all moving parts to stop.

MAKE WORKSHOP CHILD PROOF. Unplug the saw.

Lock the shop or on/off knob. Store the key away from

children and others not qualified to use lhe tool.

cause a severe injury,

• i! rl

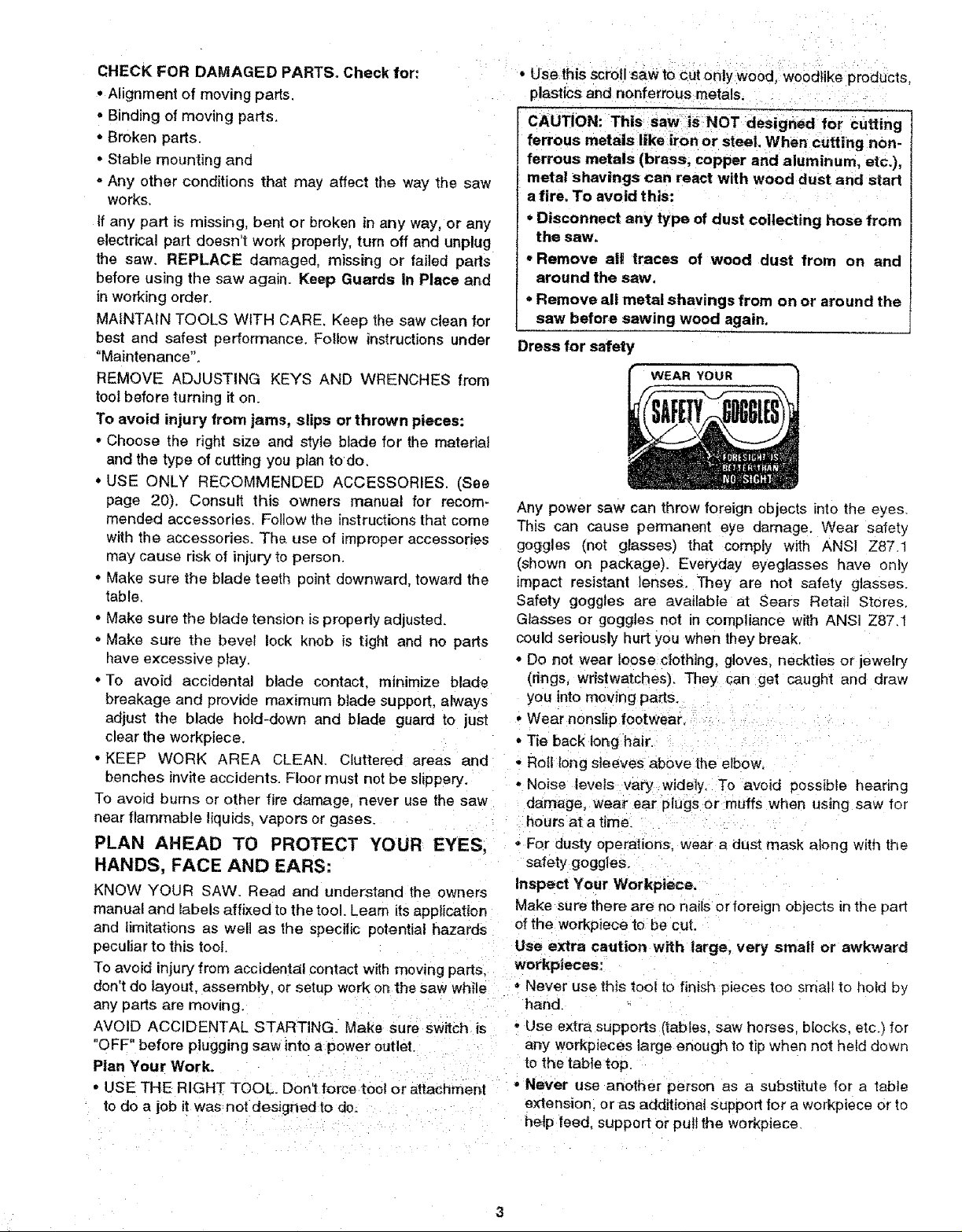

electrical connections

DANGER: To avoid electrocution:

1. Use only identical replacement parts when seP

vicing. Servicing should be performed by a

qualified service technician.

2. Do not use in rain or where floor is wet.

This tool is intended for indoor residential use

only.

t WARNING Do not permit fingers to touch the ter- I

I minals of plug when installing or removing the

I plug toot from the outlet, i

I If power cord is worn or cut, or damaged in any

I way, have it replaced immediately.

NOTE: The plug supplied on your too! may not fit intothe

outlet you are planning to use. Your local electrical Code

may require slightly different power cord plug.connec-

tions. It these differences exist refer to and make the

-proper adjustments per your local code before your tool

is pluggea in and turned on.

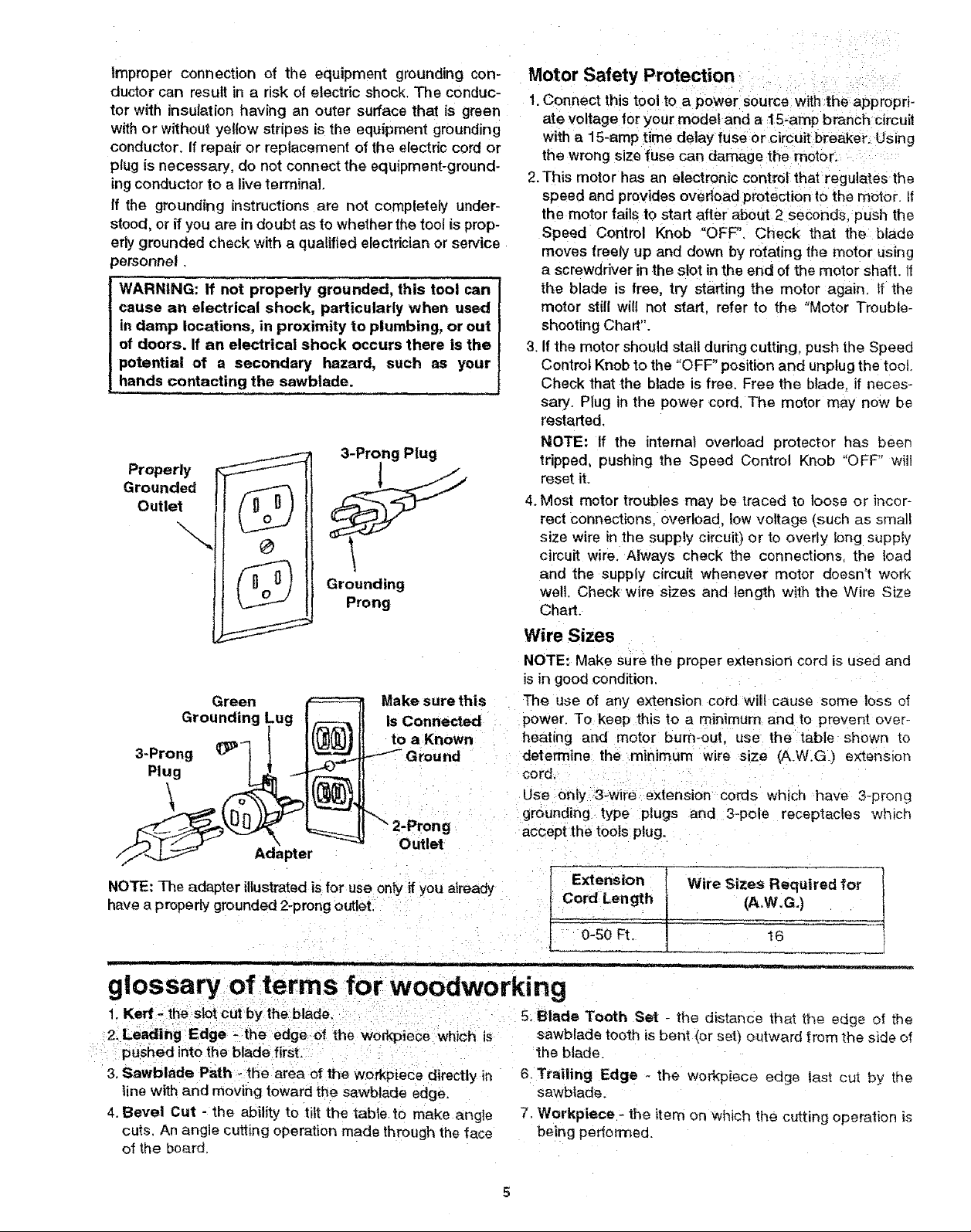

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electnc current to

reduce the risk of electric shock. This tool is equipped

with an electric cord having an equipment grounding con-

ductor and a grounding plug, as shown. The plug must

be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

Do not modify the plug provided. If it wil not tit lhe outlet.

have the proper outlet installed by a qualified electrician.

A temporary adapter may be used to connect this plug to

a 2-pole outlet as shown, if a properly grounded outlet is

I

not available. This temporary adapter should be used

only until a properly grounded outlet can be installed by a

qualified electrician. The green colored rigid ear. tug and

the like, extension from the adapter must be connected to

a permanent ground such as a properly grounded outlet

box.

Improper connection of the equipment grounding con-

ductor can result in a risk of electric shock. The conduc-

tor with insulation having an outer surface that is green

with or without yellow stripes is the equipment grounding

conductor. If repair or replacement of the electric cord or

plug is necessary, do not connect the equipment-ground-

ing conductor to a live terminal.

If the grounding instructions are not completely under-

stood, or if you are in doubt as to whether the tool is prop-

erly grounded check with a qualified electrician or service

)ersonnel,

WARNING: If not properly grounded, this tool can

cause an electrical shock, particularly when used

in damp locations, in proximity to plumbing, or out

of doors. If an electrical shock occurs there is the

potential of a secondary hazard, such as your

hands contacting the sawblade.

3-Prong Plug

Properly

Grounded

Outlet

\

\

O

Grounding

Prong

Motor Safety Protection • :

!. Connect this too! to a power source with the appropri-

ate voltage for your model and a 15-amp branch circu t

with a 15-amp time delay fuse or circuit breaker. Using

the wrong size fuse can damage the motor.

2.This motor has an electronic control that regulates the

speed and prov des overload protection to the motor, if

the motor fails to start after about 2 seconds push the

Speed Control Knob "OFF'. Check that the blade

moves freely up and down by rotating the motor using

a screwdriver in the slot in the end of the motor shaft. It

the blade is free, try starting the motor again, if the

motor still will not start, refer to the "Motor Trouble-

shooting Chart".

3. If the motor should stall during cutting, push the Speed

Control Knob to the "OFF" position and unplug the tool.

Check that the blade is free. Free the blade, if neces-

sary. Plug in the power cord The motor may now be

restarted.

NOTE: If the internat overload protector has been

tripped, pushing the Speed Control Knob "OFF" will

reset it.

4. Most motor troubles may be traced to loose or incor-

rect connections, overload, low voltage (such as small

size wire in the supply circuit) or to overly long supply

circuit wire. Always check the connections the toad

and the supply circuit whenever motor doesn't work

well. Check wire sizes and length with the Wire Size

Chart.

Wire Sizes

NOTE: Make sure the proper extension cord is used and

is in good condition,

Green

Grounding

3-Prong _"

Plug

\

Adapter

NOTE: The adapter illustratedisfor use only ifyou already Cord Length t (A.W,G.)

have a properly grounded 2oprong outlet. __

Make sure this

is Connected

to a Known

2-Prong

Outlet

The use of any extension cord wi!l cause some loss ot

power. To keep this to a minimum and to prevent over-

heating and motor bum-out, use the table shown to

determine the minimum wire size (A.W.G_) extenston

cord.

Use 0nly 3_wire extension cords which have 3-prong

grounding type plugs and 3-pole receptacles which

accept the tools plug.

!

Extension ! Wire Sizes Required for

0-50 Ft. _[ 16

glossary of erms for woodworking

!. Kerr - the Slotcut by the blade, i . 5. Blade Tooth Set - the distance that the edge ot the

2. Leading Edge - the edge of the workpiece which =s

pushed into the blade first.

3. Sawblade Path -the area of the workpiece directly in

line with and moving toward the sawblade edge.

4. Bevel Cut - the ability to tilt the table to make angle

cuts, An angle cutting operation made through the face

of the board

t m

sawblade tooth is bent {or set) outward from the side of

the blade_

6. Trailing Edge - the workpiece edge test cut by the

sawblade.

7. Workpiece- the item on which the cutting operation is

being pedormed.

table of contents

Warranty Information .................................................. 2

Safety Instructions For Scroll Saws ........................... 3

Electrical Information.................................................. 4

Glossary of Terms for Woodworking .......................... 5

Unpacking & Checking Contents ............................... 6

Assen_ly and Alignment ............................................ 7

Assembling Stand .................................................. 7

Mounting Saw to Stand .......................................... 8

Installing Blade Box ............................................... 8

Setting the Table for Horizontal or Bevel Cutting,.. 9

Aligning Bevel Indicator ......................................... 9

Removing or Replacing Blades ........................... 11

Installing Plain End Blades .................................. 12

Installing Pin End Blades ..................................... 12

Adjusting Blade Guide ......................................... 13

Adjusting Hold-Down Foot ................................... 13

Adjusting Guide Post ........................................... 13

Adjusting Dust Blower .......................................... 13

Adjusting Blade Guard ......................................... 13

Quick Change Upper Blade Holder...................... 14

Getting to Know Your ScrollSaw ............................. 14

On-Off Knob ......................................................... 15

Choice of Blade and Speed ................................. 15

Basic Saw Operation ................................................ 16

Making Interior Scroll Cuts ................................... 19

Maintenance ........................................................... t9

Replacing Motor Brushes .................................... 19

Recommended Accessories .................................... 20

Troubleshooting ....................................................... 20

Wiring Diagram ........................................................ 20

Repair Parts ............................................................. 21

Service Information .................................................. 24

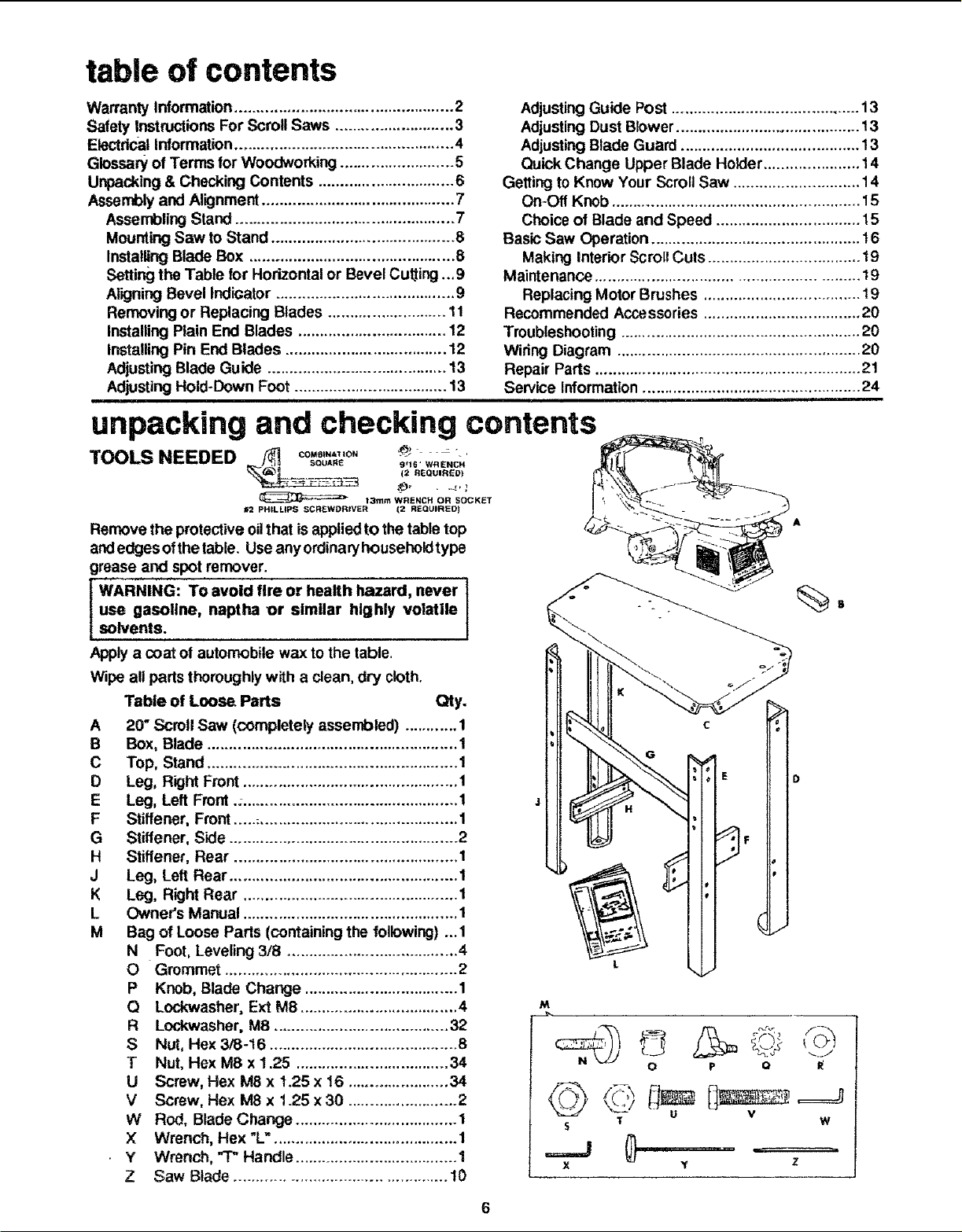

unpacking and checking contents

TOOLS NEEDED /_ CD.8,.._,o. '_ _ _ -,

#2 PHILLIPS SCREWDRIVER (2 REQUIRED)

Remove the protective oilthat is applied to the table top

andedgesof thetable. Use any ordinan/householdtype

grease and spot remover.

_QUARE 9116 ' WRENCH

(2 REQUIRED}

t3mm WRENCH OR 5DCKET

use gasoline, naptha or similar highly volatile

t WARNING: TO avoid fire or health hazard, never t

solvents.

Apply a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean, dry cloth.

Table of Loose Parts Qty.

A 20" Scroll Saw (completely assembled) ............ 1

B Box, Blade ......................................................... 1

C Top, Stand ......................................................... 1

D Leg, Right Front ................................................. 1

E Leg, Left Front ................................................... 1 ._

F Stiffener, Front ................................................... 1

G Stiffener, Side .................................................... 2

H Stiffener, Rear ................................................... 1

J Leg, Left Rear .................................................... 1

K Leg, Right Rear ................................................. 1

L Owner's Manual ................................................. 1

M Bag of Loose Pads (containing the following) ... 1

N Foot, Leveling 3/8 ....................................... 4

O Grommet ..................................................... 2

P Knob, Blade Change ................................... 1

Q Lockwasher, Ext M8 .................................... 4

R Lockwasher, M8 ........................................ 32

S Nut, Hex 3/8-16 ........................................... 8

T Nut, Hex M8 x t .25 ................................... 34

U Screw, Hex M8 x 1.25 x 16 ....................... 34

V Screw, Hex M8 x 1.25 x 30 ......................... 2

W Rod, Blade Change ..................................... 1

X Wrench, Hex "L". ......................................... 1

Y Wrench, "T" Handle ..................................... 1

Z Saw Blade ............................................... 10

I

M

S

.=__J

x

o p o I_

\_i/ u v

T W

Z

unpacking and checking contents

WARNING: For your own safety, never connect

plug to power source outlet until all assembly

steps are complete, and you have read and under-

stand the safety and operating instructions.

WARNING: This saw is heavy. To avoid back

Injury, or Injury from falling saw, get help when-

ever you have to Uft or move the saw.

Separate all parts from packaging materials and check

each item with illustration and "Table of Loose Parts".

Make certain all items are accounted for before discard-

ing any packaging material.

Ing, do not attempt to assemble the Scroll Saw,

I WARNING: To avoid injury, if any parts are miss-

plug in the power cord, or turn the switch 'ON'

until the missing parts are obtained and Installed

corre 'ti,y.,.............

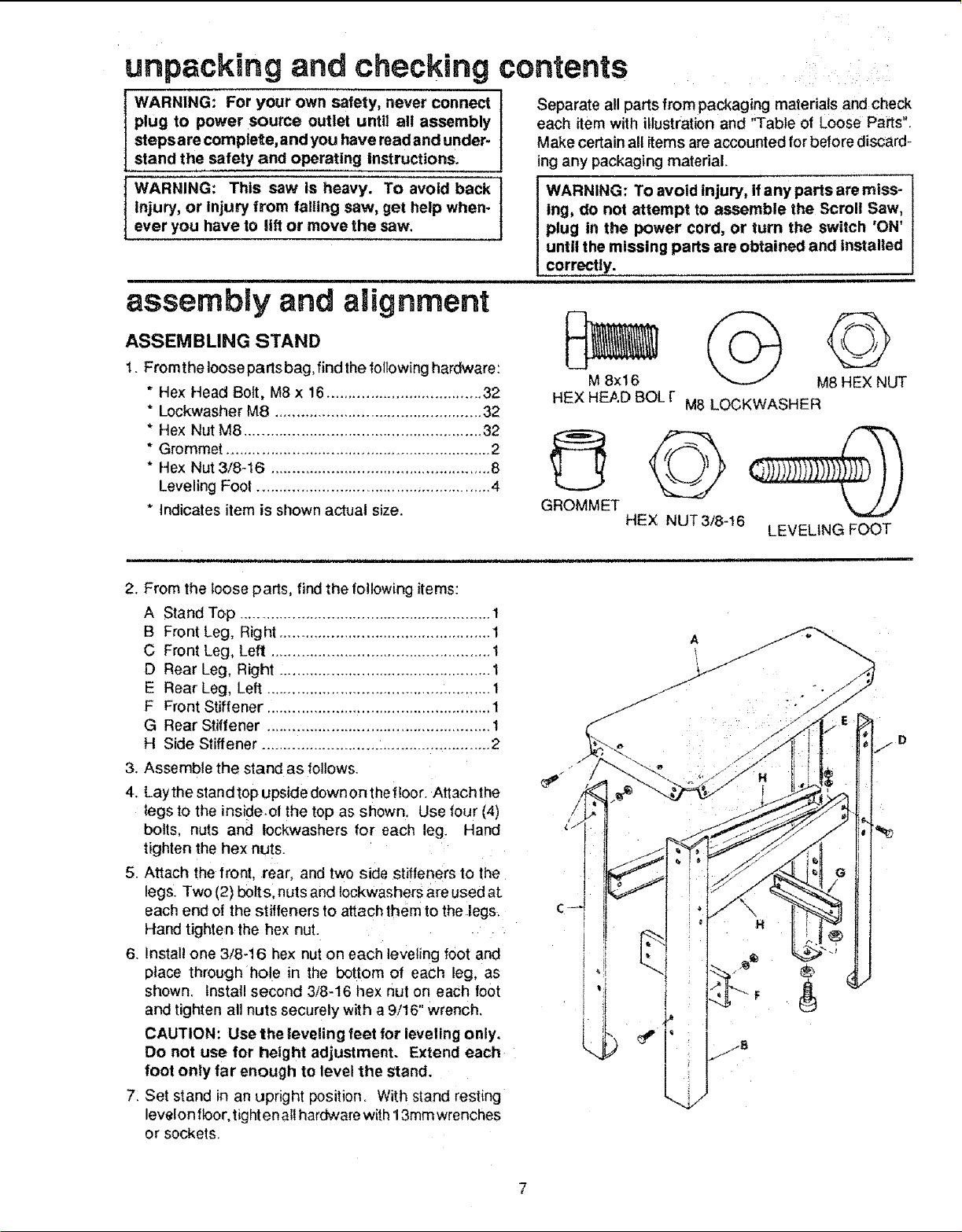

assembly and alignment.............................

ASSEMBLING STAND _

1. Fromthe loose parts bag, find thefollowing hardware: M 8x!6

* Hex Head Bolt, M8 x 16.................................... 32

* Lockwasher M8 ................................................ 32

* Hex Nut M8 ....................................................... 32

* Grommet ............................................................. 2

" Hex Nut 3/8-16 ................................................... 8

Leveling Foot ...................................................... 4

* Indicates item is shown actual size.

HEX HEAD BOL I- M8 LOCKWASHER

O

GROMMET

HEX NUT3/8-16 LEVEUNG FOOT

,ll

©

M8 HEX NUT

2. From the loose parts, find the following items:

A Stand Top .......................................................... 1

B Front Leg, Right ................................................. 1

C Front Leg, Left ................................................... 1

D Rear Leg, Right ................................................. 1

E Rear Leg, Left .................................................... 1

F Front Stiffener .................................................... 1

G Rear Stiffener .................................................... 1

H Side Stiffener ..................................................... 2

3. Assemble the stand as follows.

4. Laythe standtop upside downon the floor. Attachthe

legs to the inside.ol the top as shown. Use four (4)

bolts, nuts and Iockwashers for each leg. Hand

tighten the hex nuts.

5. Attach the front, rear, and two side stiffeners to the

legs. Two (2) bo_s, nuts and lockwashers are used at,

each end of the stiffeners to attach them to the legs.

Hand tighten the hex nut.

6. Install one 3/8-16 hex nut on each leveling foot and

place through hole in the bottom of each leg, as

shown. Install second 3/8,16 hex nut on each foot

and tighten all nuts securely with a 9/16" wrench.

CAUTION: Use the leveling feet for leveling only.

Do not use for height adjustment. Extend each

foot only far enough to level the Stand.

7: Set stand in an upright position, With stand resting

levelon floor, fightenal!hardwarewith13mm wrenches

or sockets.

®

aSSembiy+ an

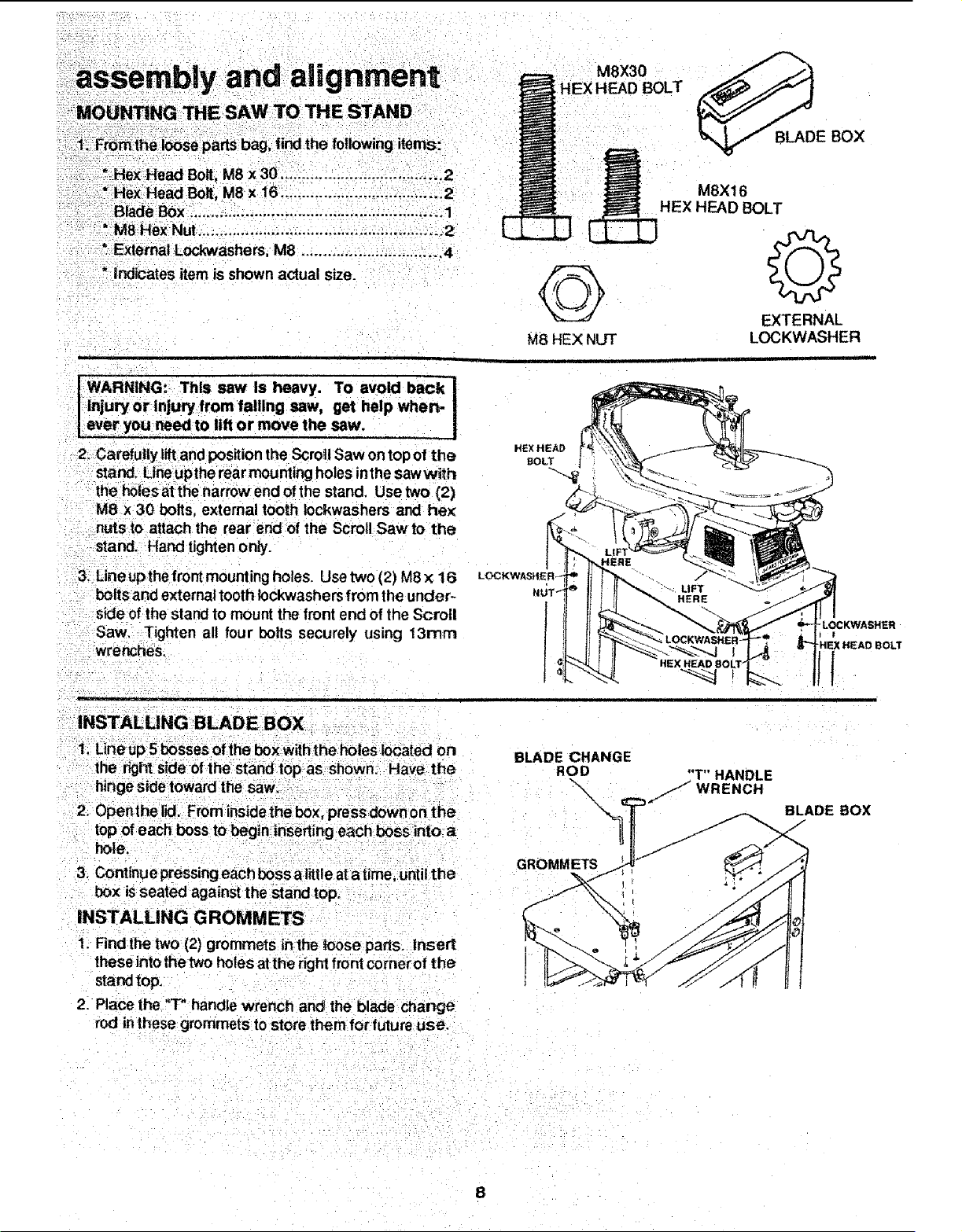

MOUNTING THE SAW TO THE STAND

...... •.... +

Y.+:i:i_:Fromihb loose parts bag, 1indthe following items:

: : *+Hex:Head Bolt:,M8 x30 .................. ...... 2

:_ * Hex Head Bolt, M8 x 16 ..................... :............ ,..2

d alignrnent

+++B_e Box+......,.........:............................i.......:+ol

• " M8 Rex Nut..... ,........... .........,+...+..,..+...+..+.-+..... 2

* External Lockwashers, M8 ............ _................... 4

* indicates item is shown actual size.

I Injury or Injury from falling saw, get help wherv

I WARNING: This saw Is heavy. To avoid back !

lever youneedto lift or move the saw,

2; Carefully Uftand positionthe Scroll Saw on top of the

stand. Lineupthe rear mountingholes inthe sawwith

tt_e_01esat the narrow end of the stand, Use two (2)

M8 x30 bolts, external tooth lockwashers and he>_

nuts to attach the rear end of the Scroll Saw to the

stand. -Hand tighten only.

HEX HEAD BOLT

©

M8 HEX NUT

HEXHEAD

BOLT

MSX30

M8X16

HEX HEAD BOLT

O

EXTERNAL

LOCKWASHER

3: Line up the front mount ing holes+ Use two (2) M8 x 16

boltsand external tooth Iockwashers from the under-

" sideof the stand to mount the front end of the Scroll

Saw, Tighten all four bolts securely using _3rnrn

wrenches.

:: , • : : .

, i i

;_+INSTALLING BLADE BOX + _+

+ i; Line up 5 boSSes0f=ihebox Withthe holes located on

the dght side ofthe stand topas stlown: :Have the

hinge Sidetoward the saw.. -+

2. Openthe lid. From inside the box, press down on the

top of each boss tobegin lilserting each boss into_ a

hole;

3, Continue pressing each boss alittle at a time, until the

box is seated against the stand top+ - -

INSTALLING GROMMETS

1. Find the two (2) grommets lnthe k)ose parts. Insert

theseintothe two holes at the right front comerof the

stand top+

2. Place the "T" handle wrench and theblade change

rod in these grommets to store them for future use.

BLADE CHANGE

ROD

\

\

GROMMETS

!

I

"T" HANDLE

/ WRENCH

BLADE BOX

Loading...

Loading...