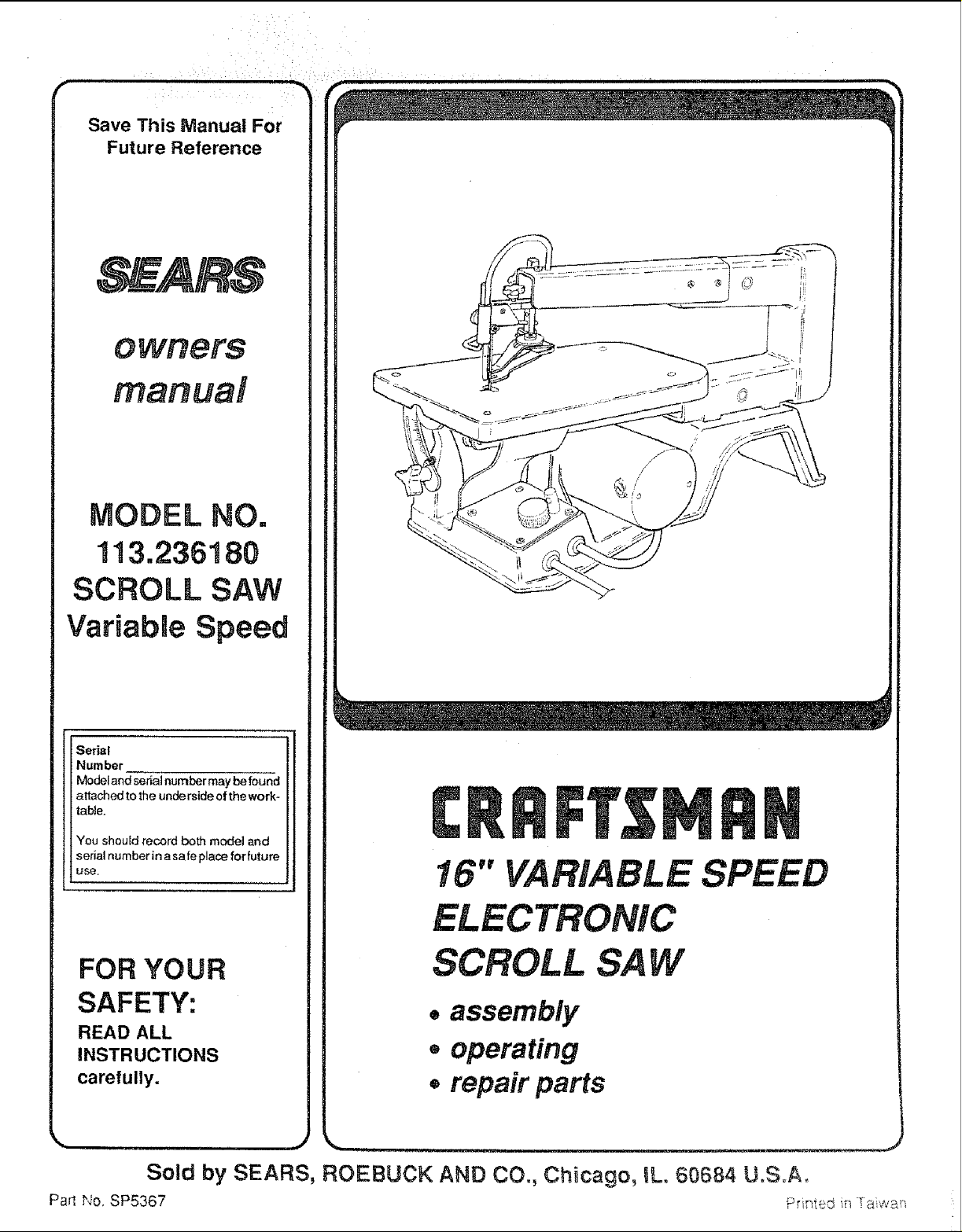

Craftsman 113236180 Owner’s Manual

Future Reference

MODEL NO.

1!3.23($180

SCROLL SAW

Variable Speed

Serial

Number

Model and ser;al number may be found

attached to the underside of the work-

table.

You should record both model and

serial numberin a safeplace for future

use.

FOR YOUR

SAFETY:

READ ALL

INSTRUCTIONS

carefully.

16" VARIABLE

ELECTRONIC

SCROLL SA

• assembly

• operating

o repair parts

, .... _ _ ___=__ ....

Sotd by SEARS, ROEBUCK AND CO., Chicago, ILo 60584 U.S.A.

Par11'qo.SP5367

SAW

materialor workmanship,Searswillrepair

WARRANTY'SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE CENTER!DEPARTMENT

THROUGHOUT THE UN TED STATES

Thiswarranty applies onlywhile this product is used in the United States,

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

SEARS, ROEBUCKAND CO.,DEPT. 698/731A Sears Tower, Chicago, IL 60684

ill i , ii • •

eneral safety instructions for power tools

1=

KNOW YOUR POWER TOOL 10.

Read and understand the owner's manual and

labels affixed tothe tool. Learn itsapplication and

limitations as well as the specific potential haz-

ards peculiar to this tool. 11.

2. GROUND ALL TOOLS

ThiStOolis equipped withan approved 3-conduc-

tor cord and a 3-prong grounding type plug to fit

thepropergroundingtype receptacle. The green

conductor in the COrd is the grounding wire.

Never connect the green wire to a live terminal.

3. KEEP GUARDS IN PLACE

- in working order, and in adjustment and align-

ment.

4. REMOVEADJUSTING KEYS AN DWRENCHES

Form a habit of checking to see tha_ keys and

adjustingwrenches are removedfrom toolbefore

turning iton.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents.

Floormust notbeslipperydue tOwax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power toolsindamp Orwet locationsor

expose thereto rain. Keepworkareawell lighted.

Provide adequate surrounding wo*rkspace.

7. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from

work area.

8. MAKE WORKSHOP CHILD PROOF

- withpadlocks, master switches, or byremoving

starter keys.

9.

USE RIGHT TOOL

Don't force tool or attachment to do a job it was

not designed for.

WEAR PROPER APPAREL

DO not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches) to get caught in

moving parts. NONSLIP footwear is recom-

mended. Wear protective hair covering to con-

tain tong hair. Roll long sleeves above the elbow.

12.

USE SAFETY GOGGLES (Head Protection)

Wear safety goggles (must comply with ANSI

Z87.1) at all times. Everyday eyeglasses only

have impact resistant lenses, they are NOT safety

glasses'. Also, use face or dust mask if cutting

operation is dusty, and ear protectors (plugs or

muffS) during extended periods or operation,

13.

SECURE WORK

Useclamps or avise to hold work when practical.

It's safer than using your hands and frees both

hands to operate tool.

14.

DON'T OVERREACH

Keep proper tooting and balance at alttimes.

15.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing blades, bits, cutters, etc.

16.

DISCONNECT TOOLS

-before servicing; when changing accessories

such as blades, bits, cutter, etc.

AVOID ACCIDENTAL STARTING

17.

Make sure switch is in"OFF" position before 3lug-

ging in power cord.

i ,

2

h,i ,i,i i i i1,1 i

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories. Followthe instructionsthat accom-

pany the accessories. The use of improper

accessories may cause hazards.

ensure that itwilloperate properly and perform its

intended function. Check for alignment of mov-

ing parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that

may affect its operation. A guard or other part

i -iii i

that is damaged should be properly repaired or

19. NEVER STAND ON TOOL

replaced.

Serious injury could occur if the tool istipped or if

21.

the cutting tool is accidentally contacted.

DIRECTION OF FEED

Feed work into a blade or cutter against the

Donot store materials above or near thetool such

direction of rotation of the blade or cutter only.

that it is necessary to stand on the tool to reach

NEVER LEAVE TOOL RUNNING UNAT-

them.

22.

TENDED

20. CHECK DAMAGED PARTS

Befo re further use ofthetool, a guard orother part

Turn power off. Don't leave tool until it comes to

a complete stop.

that is damaged should be carefully checked to

additional safety instructions for scroll saw

Safety is a combination of operator common sense and B. Do not cut pieces of material too small to hold by

alertness at all times when the scroll saw is being used.

WARNING: FOR YOUR OWN SAFETY, DO NOT

ATTEMPT TO OPERATE YOUR SCROLL SAW UN-

TIL IT IS COMPLETELY ASSEMBLED AND IN-

STALLED ACCORDING TO THE INSTRUCTIONS,..

AND UNTIL YOU READ AND UNDERSTAND THE

FOLLOWING. Page

1. General Safety Instructions for Power Tools ....2

2. Assembly .............................................................. 7

3. Basic Scroll Saw Operation .............................. 14

4. Maintenance ....................................................... 16

5. Stability of Machine.

Your scroll saw must be bolted securely to stand or

work bench, In addition, if there is any tendency for

the scroll saw to move during certain operations, bolt

your scroll saw stand or workbench to the floor.

6, Location

To avoid fire orexplosions, never use this tool where

flammable vapors or gases are in the air. To avoid

injuryfrom dropped unit, unplugsaw before moving it.

This scroll saw isintended for indoor use only.

7. Protection: Eyes, Hands, Face, Ears, Body

A. To avoid being pulled into the blade:

1. Roll long sleeves above elbows

2. Do not wear:

a. Gloves

b. Jewelry

c. Ties or other loose clothing

3. Tie back long hair

ii,Ju=u __ _____

hand outside the blade guard/hold down.

C, Avoid awkward hand positions where a sudden

slip could cause a hand to roove into the blade.

D. To avoid slips due to lifting of the work piece make

sure the blade teeth point downward toward the

table.

E. To avoid blade breakage always adjust blade

tension correctly.

F. To avoid losing control of the work piece or tool:

1. When cutting a large piece of material make

sure it is fully supported at table height.

2. Hold the work piece firmly against the table.

3. Do not feed the material too fast while cutting.

Only feed the material fast enough so that the

blade will cut.

4. Use caution when cutting off material which is

irregular in cross section and could pinch the

blade before the cut is completed. A piece of

molding, for example, must Iay flat on the table

and not be permitted to rock while being cut.

5. Use caution when cutting off round material

such as dowel rods, or tubing. They have a

tendency to roll while being cut causing the

btadeto bite. Use a V-blockto controlthe piece.

G. When backing the blade out of the workpiece, the

blade may bind in the kerr (cut).,. this is usually

caused by sawdust clogging up the keri, If this

happens: Turn off the scroll saw,., remove plug

from power source outlet,., wedge open the kerr

•.. back the blade out of the workpiece.

H. To avoid unsupervised work, use or accidents due

to inattention:

1, Never leave the scroll saw work area with the

power on, before the machine has come to a

complete stop.

2. Do not perform layout, assemb!y or set up work

on the tame while the cutting tool is in operation

or su

8, Should any part of this scrollsaw bt

fail in any way, or any

perform properly, shut off and remove

plug from power supply outlet. Replace damaged,

missing, and/or failed parts before resuming opera-

tion.

9. Think Safety.

Safety is a combination of operator common sense

and alertness wheneverthe scroll saw isin operation.

The operation of any power tool ca_ result in foreign

objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety goggles

complying with ANSI Z87.1 (shown on Package) before

commencing power tool operation. Safety goggles are

available at Sears retail or catalog stores.

WARNING: ALWAYS KEEP ALERT. DO NOT AL-

LOW FAMILIARITY (GAINED FROM FREQUENT USE

OF YOUR SCROLL SAW) TO CAUSE A CARELESS

MISTAKE. ALWAYS REMEMBER THAT A CARE-

LESS FRACTION OF A SECOND IS SUFFICIENTTO

INFLICT SEVERE INJURY,

f

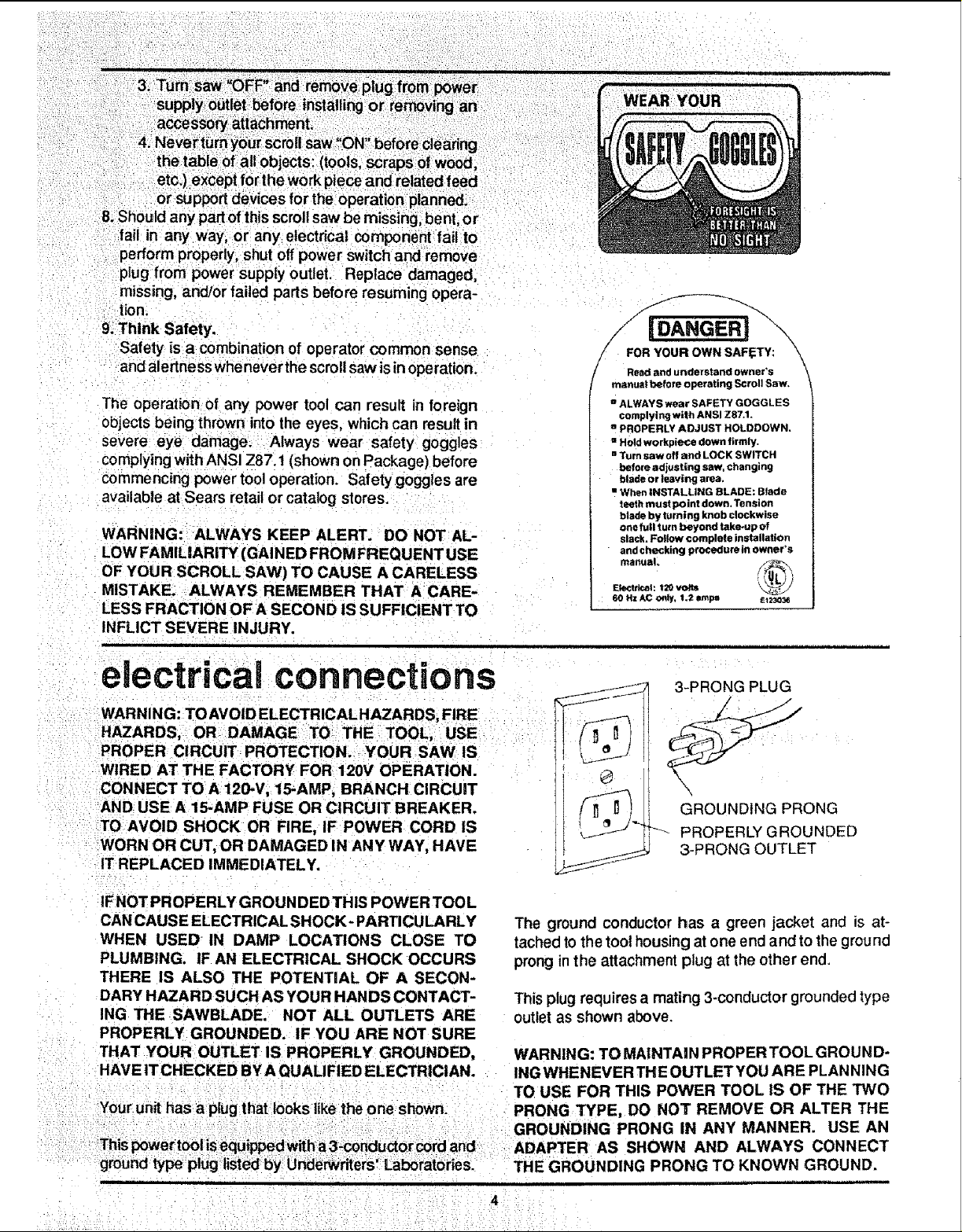

/ FOR YOUR OWN SAFETY: \

Read and understand owner's

manuat before operating SCroll Saw.

B ALWAYS wear SAFETY GOGGLES

complyingwith ANSI Z87,1.

o PROPERLY ADJUST HOLDDOWN,

= Hold workpiece down firmly,

o Turn sawoff and LOCK SWITCH

before adjusting saw, changing

bladeor leaving area.

• When INSTALLING BLADE: Blade

teeth must point down, Tension

blade by turning knob clockwise

one full turn beyond take-up of

alack. Fol!ow ©omplnte installation

and checking procedure in owner's

60 Hz AC oaty, 1.2 empm EI_'_

electrical connections

WARNING: TO AVOID ELECTRICAL HAZARDS, FIRE

HAZARDS, OR DAMAGE TO THE TOOL, USE

PROPER CIRCUIT PROTECTION. YOUR SAW IS

WIRED AT THE FACTORY FOR 120V OPERATION.

CON NECT TO A 120-V, 15-AMP, BRANCH CIRCUIT

AND USE A 15-AMP FUSE OR CIRCUIT BREAKER.

TO AVOID SHOCK OR FIRE, IF POWER CORD IS

WORN OR CUT, OR DAMAGED IN ANY WAY, HAVE

IT REPLACED IMMEDIATELY.

IFNOT PROPERLY GROUNDED THIS POWER TOOL

CAN CAUSE ELECTRICAL SHOCK- PARTICULARLY

WHEN USED IN DAMP LOCATIONS CLOSE TO

PLUMBING, IF AN ELECTRICAL SHOCK OCCURS

THERE IS ALSO THE POTENTIAL OF A SECON-

DARY HAZARD SUCH AS YOUR HANDS CONTACT-

ING THE SAWBLADE. NOT ALL OUTLETS ARE

PROPERLY GROUNDED. IF YOU ARE NOT SURE

THAT YOUR OUTLET IS PROPERLY GROUNDED,

HAVE ITCHECKED BYA QUALIFIED ELECTRICIAN.

'(our unit has aptug that looks like the one shown.

, ii

3-PRONG PLUG

\

GROUNDING PRONG

PROPERLY GROUNDED

3-PRONG OUTLET

The ground conductor has a green jacket and is at-

tached to the tool housing at one end and to the ground

prong in the attachment plug at the other end.

Thisplug requires a mating 3-conductor grounded type

outlet as shown above.

WARNING: TO MAINTAIN PROPERTOOLGROU hiD-

INGWHENEVERTHE OUTLETYOU ARE PLANNING

TO USE FOR THIS POWER TOOL IS OF THE TWO

PRONG TYPE, DO NOT REMOVE OR ALTER THE

GROUNDING PRONG IN ANY MANNER. USE AN

ADAPTER AS SHOWN AND ALWAYS CONNECT

THE GROUNDING PRONG TO KNOWN GROUND.

4

_._.___.._._l_ __ iml! nl lU nl ii __ i iii nll IIH'I_-- _.' _.-_-J _HJlJ i ,,,,,,,r

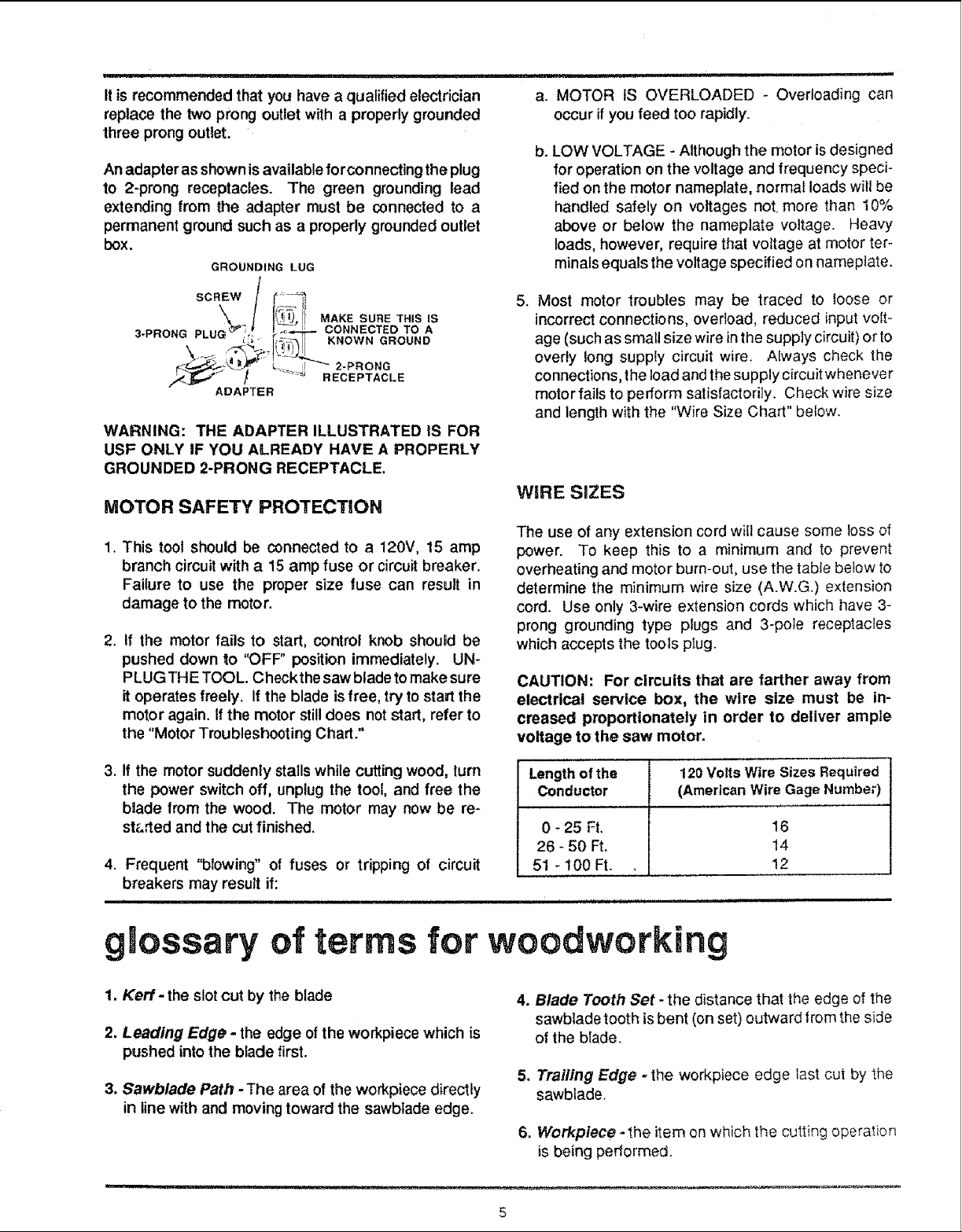

It is recommended that you have a qualified electrician a. MOTOR IS OVERLOADED - Overloading can

replace the two prong outlet with a properly grounded

occur if you feed too rapidly.

three prong outlet.

b_

LOW VOLTAGE - Although the motor isdesigned

An adapter as shown is available forconnecting the plug

to 2-prong receptacles. The green grounding lead

extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet

box.

GROUNDING LUG

for operation on the voltage and frequency speci-

fied on the motor nameplate, normal loads will be

handled safely on voltages not. more than I0%

above or below the nameplate voltage. Heavy

loads, however, require that voltage at motor ter-

minals equals the voltage specified on nameplate.

scREw/ I I

._ _,.,.,.. .... _; i f_ CONNECTED TO A

_-_n_,_ fLU',= ,_" [,_;-,_,1 KNOWN GROUND

WARNING: THE ADAPTER ILLUSTRATED IS FOR

USF ONLY IF YOU ALREADY HAVE A PROPERLY

GROUNDED 2-PRONG RECEPTACLE,

MOTOR SAFETY PROTECTION

1. This tool should be connected to a 120V, t5 amp

branch circuit with a 15 amp fuse or circuitbreaker.

Failure to use the proper size fuse can result in

damage to the motor.

2. If the motor fails to start, control knob should be

pushed down to "OFF" position immediately. UN-

PLUG THE TOOL. Check the saw blade to make sure

it operates freely. If the blade is free, try to start the

motor again. If the motor still does not start, refer to

the "Motor Troubleshooting Chart."

\ I { ,iF AKE o.ETN,S,s

\ t_"* - I!H]}

! RECEP AC.E

ADAPTER

5. Most motor troubles may be traced to loose or

incorrect connections, overload, reduced input volt-

age (such as small size wire inthe supply circuit) or to

ovedy long supply circuit wire. Always check the

connections, the load andthe supply circuit whenever

motor fails to perform satisfactorily. Check wire size

and lengthwith the "Wire Size Chart" betow.

WiRE SIZES

The use of any extension cord will cause some toss of

power. To keep this to a minimum and to prevent

overheating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G.) extension

cord. Use only 3-wire extension cords which have 3-

prong grounding type plugs and 3-poIe receptacles

which accepts the tools plug.

CAUTION: For circuits that are farther away from

electrical service box, the wire size must be in-

creased proportionately in order to deliver ample

voltage to the saw motor.

3. If the motor suddenly stallswhile cutting wood, turn

the power switch off, unplug the tool, and free the

Lengthof the 120 Volts Wire Sizes Required

Conductor (American Wire Gage Numbe0

blade from the wood. The motor may now be re-

st&rtedand the cut finished.

0 - 25 Ft. 16

26 - 50 Ft. 14

4. Frequent "blowing" of fuses or tripping of circuit

51 - 100 Ft. 12

breakers may result if:

i i

i, UUllUl, ii I,,,,,H i i,i ,nn

glossary of terms for woodworking

1. Kerr- the slot cut by the blade

2, Leading Edge - the edge of the workpiece which is

pushed into the blade first.

3. Sawblade Path -The area of the workpiece directly

in line with and moving toward the sawblade edge.

4. Blade Tooth Set -the distance that the edge of the

sawbtade tooth is bent (on set) outward from the side

of the blade.

5. Trailing Edge -the workpiece edge last cut by the

sawblade.

6. Workplece -the item on which the culting operation

is being performed.

contents -.,

Warranty information .....;:.......:.._.......:........ .i," ,"_12

General Safety Instructions for Power Tools ........2

Additlonal Safety Instruction for Scrol| Saws ....... 3

Electrical Information ...,..,..,.., ........... ;.i...... .......... 4

Glossary of Terms for Woodworking .... . ..... .........5

Unpacking &Checking Contents ;........... .i............. 6

Assembly . o . , . :

Setting the Table for Horizontal or

Bevel Cutting _..................... _,..,...................... 7

Aligning the Bevel Indicator ........................ 8

Mountlr_g the Scroll Saw .................................... ....9

Removing and Installing Blades ........................... 10

Recommended Accessories ................................. 16

Troubleshooting ..................................................... 17

Wiring Diagram ....................................................... 17

Repair Parts ............................................................ 18

Service lnformaUon ................................................ 20

unpack n

" 4

and checking contents

TOOLS NEEDED

(_ COMBINATION

MEDIUM PHILLIPS SCREWDRIVER

WARNING: FOR YOUR OWN SAFETY, NEVER

!

AND YOU HAVE READ AND UNDERSTAND THE L__

SAFETY AND OPERATIONAL INSTRUCTIONS.

Separate all parts from packaging mater als and check

each item with illustration and "Table of Loose Parts."

Make certain all items are accounted for before discard_

ing any packaging material.

COMBINATION SQUARE MUST BE TRUE

DRAW LIGHT

LINE ON BOARD

ALONG THIS

SHOULD BE NO GAP OR OVERLAp HERE WHEN

SQUARE IS FLIPPED OVER IN DOTTED POSITION

STRAIGHT EDGE OF

BOARD 3/4*INCH THICK

THIS EDGE MUST BE

PERFECTLY STRAIGHT

/

/

CAUTION: To avoid Injury, if any parts are missing,

donot attempt to assemble the Scroll Saw, plug in

the power cord, or turn the switch on until the

missing parts are obtained and installed correctly.

Table of Loose Parts Qty.

1,16" Scroll Saw (Completely assembled ) ........... 1

2. Owner"s Manual ................................................ 1

3. Parts Bag containing: ......................................... 1

t Blade, 2 Hex "L" Wrenches, and 1 U-Shaped Bar

NOTE: Hardware to mount this scroll sawto abench or

leg set isNOT supplied. See mounting instnJctions for

3

Loading...

Loading...